Page 1

INSTALLATIONGUIDE

FLIR

ORYX®

Version 1.0

Revised 10/27/2017

Copyright © 2017 FLIR Integrated Imaging Solutions Inc.

Allrights reserved.

Page 2

FCC Compliance

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesirable operation.

Korean EMCCertification

The KCC symbol indicates that this product complies with Korea’s Electrical Communication Basic Law regarding

EMC testing for electromagnetic interference (EMI) and susceptibility (EMS).

Hardware Warranty

The warranty for the Oryx camera is 3 years. For detailed information on how to repair or replace your camera,

please see the terms and conditions on our website.

Export Control

The ECCN for this product is EAR099.

WEEE

The symbol indicates that this product may not be treated as household waste. Please ensure this

product is properly disposed as inappropriate waste handling of this product may cause potential

hazards to the environment and human health. For more detailed information about recycling of this

product, please contact us.

Trademarks

Names and marks appearing on the products herein are either registered trademarks or trademarks of FLIR

Systems, Inc. and/or its subsidiaries.

Licensing

To view the licenses of open source packages used in this product please see What open source packages does

firmware use?

Copyright © 2017 FLIR Integrated Imaging Solutions Inc.

Allrights reserved.

Page 3

Table of Contents

1 Oryx Installation Guide 1

2 Handling Precautions and Camera Care 2

3 Oryx Installation 3

3.1 Preparing for Installation 3

3.2 Installing Your Interface Card and Software 4

3.3 Installing Your Oryx 5

3.4 Powering Your Oryx 6

4 Tools to Control the Oryx 7

4.1 Using the Spinnaker® Software Development Kit 7

4.1.1 SpinView Camera Evaluation Application 7

4.1.2 Custom Applications Built with the Spinnaker API 7

4.2 Using GenICam Applications 8

5 Configuring Oryx Setup 9

5.1 Configuring Camera Driver 9

5.2 Configuring the IP Address 11

5.3 Allocating Bandwidth 11

5.3.1 Determining Bandwidth Requirements 11

5.4 Configuring Other Ethernet Settings 12

5.4.1 Stream Channel Destination Address 12

5.4.2 Heartbeat 13

5.5 Camera Firmware 14

5.5.1 Determining Firmware Version 14

5.5.2 Upgrading Camera Firmware 14

6 Oryx Physical Interface 15

6.1 Oryx Physical Description 15

6.2 Oryx Dimensions 16

6.3 Interface Connector 16

6.3.1 Ethernet Connector 16

6.3.2 Interface Cables 16

6.3.3 Interface Card 17

6.3.4 General Purpose Input/Output (GPIO) 17

6.4 Mounting 19

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide i

Page 4

6.5 Case Temperature and Heat Dissipation 19

6.6 Lens Mounting 20

6.6.1 Back Flange Distance 20

6.7 Non-Volatile Flash Memory 21

6.8 Dust Protection 21

6.9 Infrared Cut-Off Filters 22

7 Input/Output Control 23

7.1 General Purpose Input/Output (GPIO) 23

7.2 GPIO Electrical Characteristics 25

7.2.1 Output Timing Characteristics 28

7.2.2 Input Timing Characteristics 29

8 Troubleshooting 30

8.1 Support 30

8.2 Status Indicator LED 31

8.2.1 Network Status LEDs 31

Contacting Us 32

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide ii

Page 5

1 Oryx Installation Guide

Welcome to the Oryx camera. We offer a number of resources to assist you with the Oryx.

n Release Notes—information about the current firmware release including feature additions or changes,

bug fixes, and known issues.

n Specifications—information about the camera model as it performs with the current firmware.

n Getting Started—quick start guide for installing the camera and software.

n Installation Guide—information about installing the camera and SDK, the physical interface and

mechanical properties, troubleshooting and how to get help. This document is available as a PDF for

download or as a webpage included in the firmware release package.

n Technical Reference—information about the features supported by the camera model with the current

firmware, including: image format control, acquisition control, sequencing, binning/decimation, and others.

This document is available as a PDF for download or as a webpage included in the firmware release

package.

1 Oryx Installation Guide

n Firmware—programming inserted into the programmable ROM of the camera that can be updated in-field.

New firmware packages are available for download and include both the firmware file and documentation.

n Spinnaker SDK—software development kit that provides GenICam-compliant controls to create

applications for the camera. Spinnaker is available for download. Each installation includes API

documentation for C, C++, and C#.

Our website provides additional information in our Knowledge Base and Technical Application Note library. As

well, the Downloads site is the portal to access documentation and firmware updates.

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 1

Page 6

2 Handling Precautions and Camera Care

2 Handling Precautions and Camera Care

Warning! Do not open the camera housing. Doing so voids the

Hardware Warranty described in the Terms and Conditions on

our website.

Your FLIR digital camera is a precisely manufactured device and should be handled with care. Here are some tips

on how to care for the device.

n Avoid electrostatic charging.

n When handling the camera unit, avoid touching the lenses. Fingerprints will affect the quality of the image

produced by the device.

n To clean the lenses, use a standard camera lens cleaning kit or a clean dry cotton cloth. Do not apply

excessive force.

n Extended exposure to bright sunlight, rain, dusty environments, etc. may cause problems with the

electronics and the optics of the system.

n Avoid excessive shaking, dropping or any kind of mishandling of the device.

Related Knowledge Base Articles

Title Article

Cleaning the imaging surface of your

camera

Knowledge Base Article

10243

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 2

Page 7

3 Oryx Installation

3.1 Preparing for Installation

What system configuration is recommended?

3 Oryx Installation

Recommended

System

Configuration

Operating

System

Windows7,

Windows8, or

Windows10

(32- or 64-bit)

CPU RAM Ports

Intel i5

8 GB

(dual

channel

memory)

FLIRACC-01-1101—

NBASE-T Ethernet

PCI Express 2.0 x4,

1 port, Tehuti TN4010

Software to run /

compile example code

Microsoft Visual Studio 2010,

Visual Studio 2013, or

Visual Studio 2015

Do you have all the parts you need?

To install your camera you will need the following components:

n Ethernet cable (see Interface Cables)

n GPIOcable (see General Purpose Input/Output (GPIO))

n C-mount Lens (see Lens Mounting )

n Interface card (see Interface Card)

FLIR sells a number of the additional parts required for installation. To purchase, visit our Accessories page.

Do you have a downloads account?

Our downloads page has many resources to help you operate your camera effectively, including:

n Spinnaker SDKsoftware, including drivers (required for installation)

n Firmware updates and release notes

n Dimensional drawings and CADmodels

n Documentation

To access the software and firmware downloads you must have a downloads account.

1. Go to the FLIR website.

2. In the upper right corner, click Register.

3. Complete the form, then click Register.

After you submit your registration, you will receive an email with instructions on how to activate your account.

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 3

Page 8

3.2 Installing Your Interface Card and Software

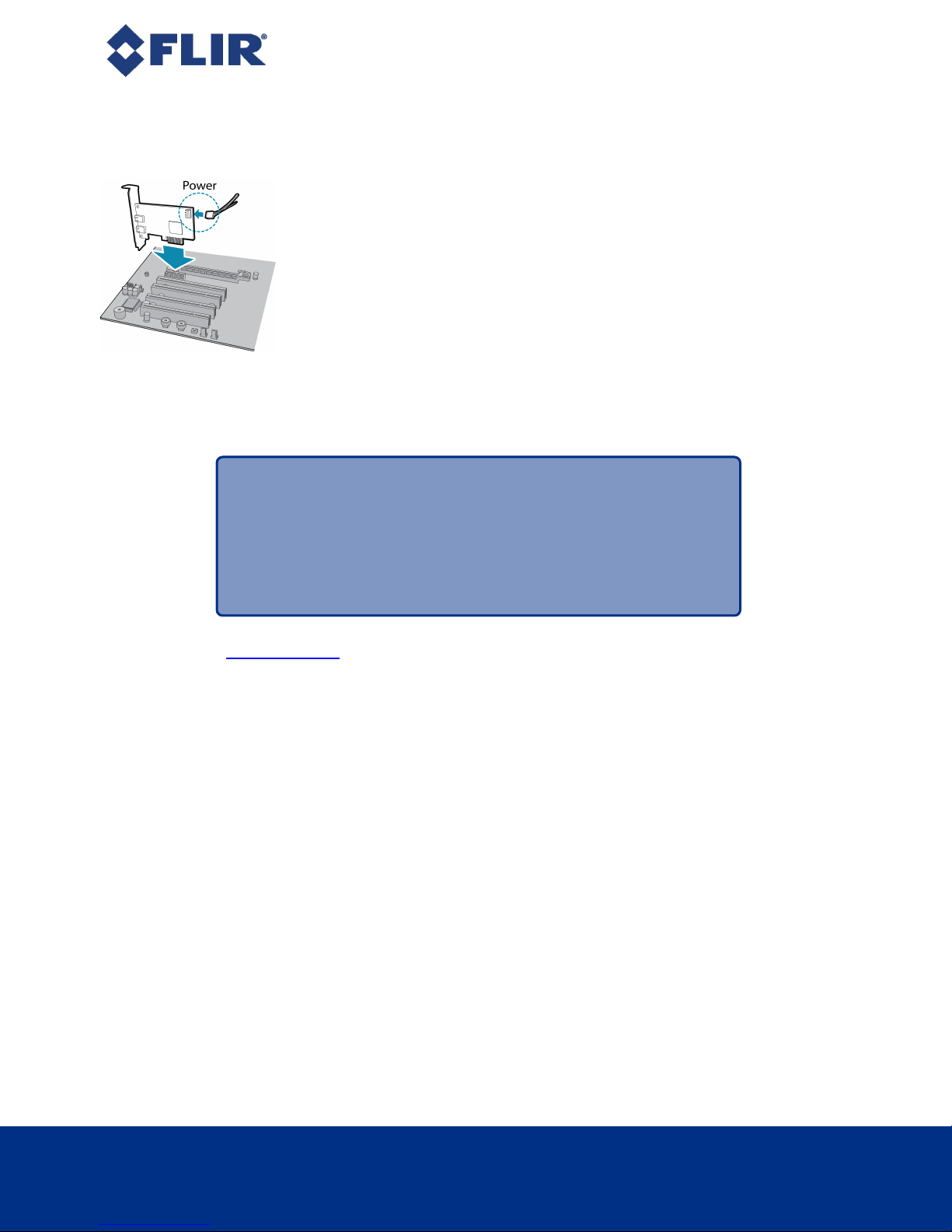

1. Install your Interface Card

Ensure the card is installed per the manufacturer's instructions.

Connect the internal IDE or SATApower connector on the card to the computer power

supply.

Alternatively, use your PC's built-in host controller, if equipped.

Open the Windows Device Manager. Ensure the card is properly installed. Ethernet cards appear under Network

Adapters. An exclamation point (!) next to the card indicates the driver has not yet been installed.

2. Install the Spinnaker® Software

Note: For existing users who already have Spinnaker installed,

we recommend ensuring you have the latest version for optimal

performance of your camera. If you do not need to install

Spinnaker, use SpinView to install and enable drivers for your

card.

3 Oryx Installation

a. Login to the Downloads page.

b. Select your Product Family, Camera Model and Operating System from the drop-down lists.

c. Click on the Software search results to expand the list.

d. Click the appropriate link to begin the download and installation.

After the download is complete, the Spinnaker setup wizard begins. If the wizard does not start automatically,

double-click the .exe file to open it. Follow the steps in each setup dialog.

3. For Ethernet cards: Enable jumbo frames

a. In Start->All Programs-> Point Grey Spinnaker SDK->SpinView, right click on the Network Adapter

and select Adapter Configuration, then select IP Configuration.

b. Click Open Network Connections.

c. Click Change Settings.

d. Click on the Advanced tab and from the Settings list select Jumbo Packet.

e. Set the Value to 9014 Bytes and click OK.

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 4

Page 9

3.3 Installing Your Oryx

1. Attach a Lens

Unscrew the dust cap from the lens holder to install a lens.

2. Connect the interface Card and Cable to the Camera

Plug the interface cable into the host controller card and the camera. The cable jack

screws can be used for a secure connection.

When the camera is first connected, the operating system automatically installs the camera driver. Camera

drivers are available with the Spinnaker SDK installation.

3. Plug in the GPIO connector

GPIOis used for power, trigger, and strobe.

4. Configure IPSettings

By default, a dynamic IPaddress is assigned to the camera according to the DHCP protocol. If DHCP addressing

fails, a link-local address is assigned. If necessary, change the IPaddress of the camera to be on the same subnet

as the NIC.

3 Oryx Installation

5. Confirm Successful Installation

Run the SpinView application: Start->All Programs-> Point Grey Spinnaker->SpinView

The SpinView application can be used to test the camera's image acquisition capabilities.

Changes to your camera's installation configuration can be made using the SpinView application.

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 5

Page 10

3.4 Powering Your Oryx

Power is provided externally through the GPIO interface: 12 - 24 V. Power consumption is 15W maximum, 11 W

nominal.

The camera does not transmit images for the first 100 ms after power-up. The auto-exposure and auto-white

balance algorithms do not run while the camera is powered down. It may therefore take several images to get a

satisfactory image.

When the camera is power cycled (power disengaged then re-engaged), the camera reverts to its default factory

settings, or if applicable, a saved user set.

3 Oryx Installation

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 6

Page 11

4 Tools to Control the Oryx

4 Tools to Control the Oryx

The Oryx's features can be accessed using various controls, including:

n Spinnaker SDK including API examples

n SpinView camera evaluation application, included in the Spinnaker SDK installation

n Third-party GenICam applications

4.1 Using the Spinnaker®Software Development Kit

You can monitor or control features of the camera through Spinnaker API examples provided in the Spinnaker SDK,

or through the SpinView camera evaluation application. A Programmer's Guide and API Reference is included in

the installation.

4.1.1 SpinView Camera Evaluation Application

The SpinView application is a generic, easy-to-use streaming image viewer included with the Spinnaker SDK that

can be used to test many of the capabilities of your camera. It allows you to view a live video stream from the

camera, save individual images, adjust the various attributes, frame rates, features and settings of the camera. It

includes tools for updating firmware, managing drivers, IP addressing, and activity logging.

4.1.2 Custom Applications Built with the Spinnaker API

The Spinnaker SDK includes a full Application Programming Interface that allows you to create custom

applications to control your camera. Included with the SDK are a number of source code examples to help you get

started.

Spinnaker API examples are provided for C, C++, C#, and VB.NET languages. These examples are precompiled

for your convenience.

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 7

Page 12

4.2 Using GenICam Applications

GigE Vision is an interface standard that allows for fast image transfer over Ethernet networks. All cameras

supporting GigE Vision interact the same way with software also supporting GigE Vision.

For more information on the standard, visit visiononline.org.

The standard defines required elements for camera identification, control, and output. It uses GenICam, a

programming interface for camera attribute control. GenICam allows camera vendors to define features and

attributes in an XML file stored inside the camera. The file is parsed by the host application when the camera is

initially discovered. One of the key benefits of GenICam is the ability for camera vendors to introduce new

camera-specific features without needing to update the host application.

Each camera attribute, such as exposure time, is controlled by a specific GenICam feature. The camera includes

an XML device description file for interfacing with third-party GenICam-compliant APIs.

For more information on GenICam, visit emva.org.

Getting Started with Third-Party Applications Resources

Title Article

Getting Started with OpenCV

4 Tools to Control the Oryx

Technical Application Note

10861

Getting Started with MATLAB

Getting Started with MVTec HALCON

Getting Started with Cognex VisionPro

Getting Started with Adaptive Vision

Getting Started with Matrox Imaging Library

Getting Started with Matrox Design Assistant

Getting Started with NI-MAX and LabVIEW

Getting Started with NI Vision Builder for Automatic Inspection

Technical Application Note

10898

Technical Application Note

10793

Technical Application Note

10794

Technical Application Note

10865

Technical Application Note

10790

Technical Application Note

10862

Technical Application Note

10791

Technical Application Note

10875

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 8

Page 13

5 Configuring Oryx Setup

After successful installation of your camera and interface card, you can make changes to the setup. Use the tools

described below to change the IP Address or the driver for your interface card.

For information on updating your camera's firmware post installation, see Camera Firmware.

5.1 Configuring Camera Driver

For the Oryx camera, ensure that PGRLWF driver version 2.7.3.92 or above is installed.

The PGRLWF driver should already be installed automatically using the Spinnaker SDK installer when the Camera

Evaluation option is selected. Or in the case of Application Development option, the driver is installed if you select

the GigE Driver checkbox.

Alternatively, you can manually install the driver. The PGRLWF files are located in:

C:\Program Files\Point Grey Research\Spinnaker\driver64

To verify your driver:

5 Configuring Oryx Setup

1. Launch SpinView:

Start-->All Programs-->Point Grey-->Spinnaker SDK-->SpinView

2. Select the camera.

3. In the Feature tree search box, enter "driver". The Device Driver Version feature is highlighted.

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 9

Page 14

5 Configuring Oryx Setup

4. If you need to update the driver, right-click on the device and select Filter Driver Configuration.

5. In the Filter Driver Configuration window, ensure the driver is installed and enabled. Click Refresh if making

changes.

Note: If the filter driver is not installed, a caution icon appears

next to the device. Right-click on the device and select

GigEFilter driver is not installed-->Install filter driver to resolve.

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 10

Page 15

5.2 Configuring the IP Address

When a new GigE camera is first powered and initialized, a dynamic IP address is assigned to the camera

according to the DHCP protocol. If DHCP addressing fails, a link-local address is assigned. You can configure the

IP address using the GenICam Features Transport Layer Control.

Alternatively, SpinView is a tool included with the Spinnaker SDK that allows you to set the internet protocol (IP)

configuration for any GigE interface cards or FLIR GigE Vision cameras connected to your system. Using

SpinView, you can:

n Set the IP address for the current connection.

n Program a persistent IP address for the camera.

n Configure the default IP addressing behavior of the camera on startup using a persistent IP, DHCP or LLA.

n Enable Jumbo Frames on the GigE NIC.

Both your camera and host adapter must have an IP address on the same subnet. This can be assigned in three

ways:

n Persistent—The camera has a fixed IP address that does not change. Generally the address is within a

closed network range of 192.168.X.X.

5 Configuring Oryx Setup

n Dynamic (DHCP)—The camera is set to automatically obtain an IP address. This means that the IP

address may change (within a range) every time the camera or computer is restarted. It may take up to one

minute for the IP address to resolve and the camera to enumerate.

n Default (LLA)—The camera uses an IP address from the link-local address block 169.254.x.x.

The camera assigns its current IP address in the following sequence:

1. Persistent—Uses the defined IP address. If not available, then;

2. DHCP—Attempts to find a dynamic IP address. If not available, then;

3. LLA—Uses an LLA IP address.

SpinView can automatically force an IP address refresh. This detects the IP address of the Network Interface card

and automatically sets the camera’s IP address relative to the card.

To open SpinView:

Start Menu > All Programs > Point Grey Spinnaker SDK > SpinView

5.3 Allocating Bandwidth

The User Datagram Protocol (UDP) used by the GigE Vision standard provides no guaranteed transmission or

fixed timing mechanism. Therefore, bandwidth must be managed by the Device Throughput Limit, based on

desired resolution and frame rate.

5.3.1 Determining Bandwidth Requirements

The maximum bandwidth available is 1.25 GB. This includes image data, control data and image resends, which

occur when frames are being dropped. Each image and each packet has a certain amount of overhead that will

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 11

Page 16

5 Configuring Oryx Setup

use some bandwidth. Therefore, when calculating your bandwidth requirements, you should not attempt to use

the full maximum of 1.25 GB. The default bandwidth is 850 MB.

Note: If the packet size and packet delay combination exceeds

the available bandwidth, frames will be dropped.

To calculate your bandwidth requirements:

Determine your required resolution, frame rate, and pixel format (bytes per pixel)

(Height x Width x Frame Rate x Bytes per Pixel)/1000000 = Bandwidth in MB

For example, for an image that is 4K resolution, 60 FPS, Mono8:

3840 (H) x 2160 (W) x 60 (FPS) x 1 (BPP) = ~497 MB

Once you have calculated your required bandwidth, you can allocate an amount to each camera by adjusting the

packet size and packet delay. Allocating a specific amount to each camera helps to avoid dropped packets due to

a data burst. You would do this in a set up with multiple cameras, or in a situation where the system bandwidth

might be limited or shared due to hardware architecture.

Bandwidth Requirements for Multiple Cameras

Multiple cameras can be set up in two ways: 1) Each camera is connected directly to a single Ethernet port; or, 2)

multiple cameras are connected to a single port through an Ethernet switch.

If using the first method, each camera has the full bandwidth allocation available to it. If using the second method,

the combination of all cameras on a switch cannot exceed the available bandwidth.

Related Knowledge Base Articles

Title Article

Setting Up Multiple GigECameras

Technical Application Note 10351

5.4 Configuring Other Ethernet Settings

5.4.1 Stream Channel Destination Address

The stream channel destination address (SCDA) register is used to specify the streaming destination IP address.

The default SCDA is the IPaddress of the network or computer to which the camera is connected. It can be set

within a range so that the camera sends data as a multicast. As long as switches in the path between the sender

and receivers support and are configured for multicasting, multiple receivers can listen to the data stream from the

camera.

Multicast addresses are between 224.0.0.0 and 239.255.255.255.

Note: For more information on multicast address assignments,

see http://tools.ietf.org/html/rfc3171

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 12

Page 17

To control SCDA use:

n GenICam—GevSCDA in the Transport Layer Control

5.4.2 Heartbeat

The heartbeat is a mandatory GigE Vision feature to monitor the connection between an application and the

camera. The application must continually reset the heartbeat timer, or the camera assumes an error has occurred

and shuts down the connection.

In general, the Spinnaker API manages the heartbeat at a low level; however the following two features are

controllable: Heartbeat Timeout and Heartbeat Disable.

Heartbeat Timeout

Heartbeat timeout is the time, in milliseconds, that the camera waits before closing the connection. Heartbeat

timeout can be set between 500 ms and 10 seconds. The default setting is 3000 ms (3 seconds). If there is no

communication between the camera and the application for longer than the timeout value, the connection is shut

down.

To control Heartbeat Timeout use:

n GenICam—Under Transport Layer Control, GevHeartbeatTimeout.

5 Configuring Oryx Setup

n Spinnaker API—The Spinnaker SDK supports configuring heartbeat timeout.

Heartbeat Disable

The heartbeat is enabled by default.

To disable Heartbeat use:

n GenICam—Under Transport Layer Control GevGVCPHeartbeatDisable.

n Spinnaker API—The Spinnaker SDK supports disabling heartbeat.

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 13

Page 18

5.5 Camera Firmware

Firmware is programming that is inserted into the programmable read-only memory (programmable ROM) of

most FLIR cameras. Firmware is created and tested like software. When ready, it can be distributed like other

software and installed in the programmable read-only memory by the user.

The latest firmware versions often include significant bug fixes and feature enhancements. To determine the

changes made in a specific firmware version, consult the Release Notes.

Firmware is identified by a version number, a build date, and a description.

5.5.1 Determining Firmware Version

To determine the firmware version number of your camera:

n Query the GenICam Device Control feature DeviceFirmwareVersion.

5.5.2 Upgrading Camera Firmware

Camera firmware can be upgraded or downgraded to later or earlier versions using SpinView, part of the Spinnaker

SDK available from the Downloads page.

5 Configuring Oryx Setup

Before upgrading firmware:

n Install the Spinnaker SDK, available from the Downloads page.

n Download the firmware file from the Downloads page.

To upgrade the firmware:

1.

Start Menu-->All Programs-->Point Grey Spinnaker SDK-->SpinView

2. From the Device list, right click the camera and select Update Device Firmware.

If you get a Device is Active warning, close the Display pane or click the Disconnect button and right click

the camera again.

3. Browse to select the firmware file and click Open.

4. Click Yes to continue.

Warning! Do not disconnect the camera during the firmware

update process.

Related Knowledge Base Articles

Title Article

FLIR software and firmware version numbering scheme/standards

Knowledge Base Article 10310

Determining the firmware version used by my camera

Should I upgrade my camera firmware or software?

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

Knowledge Base Article 10312

Knowledge Base Article 10216

FLIROryx®Installation Guide 14

Page 19

6 Oryx Physical Interface

6.1 Oryx Physical Description

6 Oryx Physical Interface

1. Lens holder (C-mount)

See Lens Mounting

2. Glass/IR filter system

See Dust Protection and Infrared Cut- Off

Filters

3. M4.OXO.7 mounting holes (x16)

SeeMounting

4. General purpose I/O connector

See General Purpose Input/Output (GPIO)

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

5. Status LED

See Status Indicator LED

6. Interface connector

See Interface Connector

7. Camera label

Contains camera information such as model

name, serial number and required

compliance.

8. 1/4-20 mounting hole

SeeMounting

FLIROryx®Installation Guide 15

Page 20

6.2 Oryx Dimensions

Note: To obtain 3D models, go to our Downloads page or

contact Support.

6 Oryx Physical Interface

6.3 Interface Connector

6.3.1 Ethernet Connector

The 8-pin RJ- 45 Ethernet jack is equipped with two (2) M2 screwholes for secure connection. Pin assignments

conform to the Ethernet standard.

6.3.2 Interface Cables

To purchase a recommended cable from FLIR, visit the Products Accessories page.

Category 5e cables up to 40 meters in length can be used with 10 GigE. For cable lengths greater than 40 meters,

Category 6a cables should be used. FLIR sells Category 5e cables.

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

Oryx Dimensional Drawing

FLIROryx®Installation Guide 16

Page 21

Note: For optimal ESD protection, we recommend using a

shielded Ethernet cable or connecting the camera housing to

chassis ground (earth).

6.3.3 Interface Card

The camera must connect to an interface card. This is sometimes called a host adapter, a bus controller, or a

network interface card (NIC).

A 10G BASE-T NIC is recommended for streaming images on the Ethernet network between the camera and host

system.

FLIR sells a compatible card (PN: ACC-01-1101) available from our Products Accessories page.

6.3.4 General Purpose Input/Output (GPIO)

The camera has an 12-pin GPIO connector on the back of the case; refer to the diagram below for wire colorcoding.

6 Oryx Physical Interface

Color Pin Line Function Description

Black

White

Red

Green

Orange

Blue

White with black

stripes

Red with black

stripes

Green with black

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

1 N/A GND DCcamera power ground

2 N/A POWER DCcamera power

Line

3

1

Line

4

4

Line

5

0

Line

6

3

Line

7

2

Line

8

5

9 N/A GND DC camera power ground

GPIO_OPT_OUT1 Opto-isolated output (GPO1)

GPIO_OPT_OUT2 Opto-isolated output (GPO2)

GPIO_OPT_IN1 Opto-isolated input (GPI1)

GPIO_OPT_IN2 Opto-isolated input (GPI2)

GPIO_TTL_IO3 TTL input/output 3

GPIO_TTL_IO4 TTL input/output 4

FLIROryx®Installation Guide 17

Page 22

Color Pin Line Function Description

stripes

6 Oryx Physical Interface

Orange with

black stripes

Blue with black

stripes

Black with white

stripes

10 N/A POWER DC camera power

Line

11

3.3 VOUTPUT

6

12 N/A OPTO_GND

+3.3 V output, current 120 mA (nominal) - firmware

enabled

Ground for opto-isolated I/O, not connected to camera

ground

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 18

Page 23

6.4 Mounting

The case is equipped with the following mounting holes:

n Four (4) M4.0 x 0.7 mounting holes on each side of the case

n One (1) 1/4-20 UNC mounting hole on the bottom of the case

6.5 Case Temperature and Heat Dissipation

You must provide sufficient heat dissipation to control the internal operating temperature of the camera.

The camera is equipped with an on-board temperature sensor. It allows you to obtain the temperature of the

camera board-level components. The sensor measures the ambient temperature within the case.

As a result of packing the camera electronics into a small space, the outer case of the camera

can become hot to the touch when running. This is expected behavior and will not damage the

camera electronics.

To reduce heat, use a cooling fan to set up a positive air flow around the camera, taking into consideration the

following precautions:

6 Oryx Physical Interface

n Mount the camera on a heat sink, such as a camera mounting bracket, made out of a heat-conductive

material like aluminum.

n Make sure the flow of heat from the camera case to the bracket is not blocked by a non-conductive

material like plastic.

n Make sure the camera has enough open space around it to facilitate the free flow of air.

To access temperature information:

n Query the GenICam Device Control feature DeviceTemperature.

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 19

Page 24

6.6 Lens Mounting

Lenses are not included with individual cameras.

Related Knowledge Base Articles

Title Article

Selecting a lens for your

camera

The lens mount is compatible with C-mount lenses. Correct focus cannot be achieved using a CS-mount lens on a

C-mount camera.

6.6.1 Back Flange Distance

The Back Flange Distance (BFD) is offset due to the presence of both a 1 mm infrared cutoff (IRC) filter and a 0.5

mm sensor package window. These two pieces of glass fit between the lens and the sensor image plane. The IRC

filter is installed on color cameras. In monochrome cameras, it is a transparent piece of glass. The sensor

package window is installed by the sensor manufacturer. Both components cause refraction, which requires

some offset in flange back distance to correct.

The resulting C-mount BFDis 17.99 mm.

6 Oryx Physical Interface

Knowledge Base Article 10694

For more information about the IRC filter, see Infrared Cut-Off Filters.

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 20

Page 25

6.7 Non-Volatile Flash Memory

The camera has 4 MB non-volatile memory for users to store data.

Related Knowledge Base Articles

Title Article

Storing data in on-camera flash memory

6.8 Dust Protection

The camera housing is designed to prevent dust from falling directly onto the sensor's protective glass surface.

This is achieved by placing a piece of clear glass (monochrome camera models) or an IR cut-off filter (color

models) that sits above the surface of the sensor's glass. A removable plastic retainer keeps this glass/filter

system in place. By increasing the distance between the imaging surface and the location of the potential dust

particles, the likelihood of interference from the dust (assuming non-collimated light) and the possibility of damage

to the sensor during cleaning is reduced.

6 Oryx Physical Interface

Knowledge

Base

Article

10370

Warning! Cameras are sealed when they are shipped. To avoid

contamination, seals should not be broken until cameras are

ready for assembly on site.

Warning! Use caution when removing the protective glass or

filter. Damage to any component of the optical path voids the

Hardware Warranty. Removing the protective glass or filter alters

the optical path of the camera, and may result in problems

obtaining proper focus with your lens.

Related Knowledge Base Articles

Title Article

Removing the IR filter from a color camera

Selecting a lens for your camera

Knowledge

Base

Article

10080

Technical

Application

Note

10694

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 21

Page 26

6.9 Infrared Cut-Off Filters

FLIR color camera models are equipped with an additional infrared (IR) cut- off filter. This filter can reduce

sensitivity in the near infrared spectrum and help prevent smearing. The properties of this filter are illustrated in the

results below.

IR filter transmittance graph

6 Oryx Physical Interface

Transmission Wavelength

T=50%

T>80%

T>85%

T average 1%

T<3%

680 nm ±10 nm

400 nm - 420 nm

420 nm - 650 nm

750 nm - 1100 nm

750 nm - 1100 nm

In monochrome models, the IR filter is replaced with a transparent piece of glass.

The following are the properties of the IR filter/protective glass:

Type

Material

Dimensions

Thickness

Anti-reflective

Schott B270

15.5 ±0.08 x 18 ±0.08

mm

1 ±0.07 mm

For more information, see Dust Protection.

Related Knowledge Base Articles

Title Article

Removing the IR filter from a color camera

Knowledge Base Article 10080

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 22

Page 27

7 Input/Output Control

7.1 General Purpose Input/Output (GPIO)

The camera has an 12-pin GPIO connector on the back of the case; refer to the diagram below for wire colorcoding.

GPIO pin assignments (as shown looking at rear of camera)

7 Input/Output Control

Color Pin Line Function Description

Black

White

Red

Green

Orange

Blue

White with black

stripes

Red with black

stripes

Green with black

stripes

Orange with

black stripes

1 N/A GND DCcamera power ground

2 N/A POWER DCcamera power

Line

3

4

5

6

7

8

9 N/A GND DC camera power ground

10 N/A POWER DC camera power

GPIO_OPT_OUT1 Opto-isolated output (GPO1)

1

Line

GPIO_OPT_OUT2 Opto-isolated output (GPO2)

4

Line

Line

Line

Line

GPIO_OPT_IN1 Opto-isolated input (GPI1)

0

GPIO_OPT_IN2 Opto-isolated input (GPI2)

3

GPIO_TTL_IO3 TTL input/output 3

2

GPIO_TTL_IO4 TTL input/output 4

5

Blue with black

stripes

Black with white

stripes

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

Line

11

6

12 N/A OPTO_GND

3.3 VOUTPUT

FLIROryx®Installation Guide 23

+3.3 V output, current 120 mA (nominal) - firmware

enabled

Ground for opto-isolated I/O, not connected to camera

ground

Page 28

For details on GPIO circuits, see GPIO Electrical Characteristics.

7 Input/Output Control

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 24

Page 29

7.2 GPIO Electrical Characteristics

Both the opto-isolated input and output have over current protection.

The output is open collector and thus requires a pull-up resistor to operate. The rise time and bias current will be

determined by the resistor value chosen. If the camera is generating an output signal that approaches the rise time

plus the fall time of the opto-isolated circuit, care must be taken to optimize the pull-up resistor chosen to minimize

the rise time while still remaining within the current limits of the output circuit.

The opto-isolated specifications listed below are applicable when power to the camera is provided through the

interface and not through the GPIO.

Warning! To avoid damage, connect the OPTO_GND pin first

before applying voltage to the GPIO line.

Warning! Prolonged use of the camera outside of the Operating

Range described below may lead to unexpected behavior and

should be avoided.

7 Input/Output Control

Operating Range

Description Minimum Maximum

Non-opto-isolated Voltage 0 V 24 V

Opto-isolated Input Voltage 0 V 30 V

Opto-isolated Output Voltage 0 V 24 V

Non-opto-isolated Sinking Current 25 mA

Opto-isolated Output Current 25 mA

3.3 V Output Curr ent 200 mA

Absolute Maximum Ratings

Description Minimum Maximum

Non-opto-isolated Voltage -24 V 42 V

Opto-isolated Input Voltage -70 V 40 V

Opto-isolated Output Voltage -24 V 24 V

External Voltage Resistor Combinations at 90 FPS

External

Voltage

3.3 V 200 Ω 1.44 V 3.29 V 8.2 mA

5.0 V 1.0 kΩ 0.88 V 4.94 V 3.8 mA

External

Resistor

OPTO_OUT

Low Voltage

OPTO_OUT

High Voltage

Output Current

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 25

Page 30

7 Input/Output Control

External

Voltage

12 V 2.0 kΩ 1.1 V 11.93 V 5.1 mA

12 V 2.4 kΩ 0.98 V 11.93 V 4.2 mA

24 V 4.7 kΩ 0.75 V 23.75 V 4.5 mA

30 V 4.7 kΩ 0.88 V 29.81 V 5.7 mA

Values are for reference only

External

Resistor

OPTO_OUT

Low Voltage

OPTO_OUT

High Voltage

Output Current

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

Opto-isolated input circuit

Opto-isolated output circuit

FLIROryx®Installation Guide 26

Page 31

7 Input/Output Control

Input/Output circuit

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 27

Page 32

7.2.1 Output Timing Characteristics

Note: Timing specifications are preliminary and subject to

change.

7 Input/Output Control

Output Timing Characteristics

Opto-isolated Output Performance at (measured at Vcc = 5 V, Rext = 1 kΩ)

Parameter Symbol Opto-isolated at 1 FPS Opto-isolated at 90 FPS

Output Low Voltage V

Output High Voltage V

Output Threshold High Voltage V

Output Threshold Low Voltage V

Cycle Rise Time t

Cycle Fall Time t

Opto Current 3.8 mA 3.8 mA

Opto Isolator Delay(High to Low) 2.92 µs 2.92 µs

Opto Isolator Delay(Low to High) 24.2 µs 24.2 µs

L

H

THH

THL

R

F

0.84 V 0.83 V

4.98 V 4.98 V

4.56 V 4.56 V

1.25 V 1.24 V

7.9 µs 7.8 µs

2.1 µs 1.44 µs

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 28

Page 33

7.2.2 Input Timing Characteristics

Note: Timing specifications are preliminary and subject to

change.

7 Input/Output Control

Input Timing Characteristics (Vcc = 5 V pk-pk)

Parameter Symbol Opto-isolated at 5 FPS

Input Low Voltage V

Input High Voltage V

Propagation Delay Low to High t

Propagation Delay High to Low t

Minimum PositivePulse Width t

Minimum Negative Pulse Width t

MPPW

MNPW

IL

IH

PDLH

PDHL

≤0.825 V

≥2.325 V

7.7 µs

16.2 µs

0.772 ms

32.56 ms

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 29

Page 34

8 Troubleshooting

8.1 Support

FLIR endeavors to provide the highest level of technical support possible to you. Most support resources can be

accessed through our Product Support page.

Creating a Customer Login Account

The first step in accessing our technical support resources is to obtain a Customer Login Account. This requires a

valid name and e-mail address. To apply for a Customer Login Account go to our website, and from the upper right

corner, click Register. Complete the form and then click Register. After you submit your registration, you will

receive an email with instructions on how to activate your account.

Knowledge Base

Our Knowledge Base contains answers to some of the most common support questions. It is constantly updated,

expanded, and refined to ensure that our customers have access to the latest information.

Learning Center

8 Troubleshooting

Our Learning Center contains links to many resources including videos, case studies, popular topics, application

notes, and information on sensor technology.

Product Downloads

With a Customer Login Account you can access the latest software and firmware for their cameras from our

Product Downloads page. We encourage you to keep your software and firmware up-to-date by downloading and

installing the latest versions.

Contacting Technical Support

Before contacting Technical Support, have you:

1. Read the product documentation?

2. Searched the Knowledge Base?

3. Downloaded and installed the latest version of software and/or firmware?

If you have done all the above and still can’t find an answer to your question, contact our Technical Support team.

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 30

Page 35

8.2 Status Indicator LED

LED GigE

No Light

8 Troubleshooting

No power

or LED is in inactive state

or LED is in error status state with no error

Blinking Green (1 blink)

Blinking Green (2 blinks)

Blinking Green (3 blinks)

Solid Green

Rapid Flashing Green

Flashing Green and Red

8.2.1 Network Status LEDs

No Light

Left and Right Bright Green

Left Dim and Right Bright Green

Left and/or Right Blinking Green

Persistent IPAddress

DHCPIPAddress

Link-Local Address (LLA)

Acquisition Started

Firmware update in progress

General Error

No network connection

10 GigE connection

1 GigE connection

Data transfer in progress

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 31

Page 36

Contacting Us

For any questions, concerns or comments please contact us via the following methods:

Contacting Us

Email

Knowledge Base

Downloads

Contact Information

General questions

Technical support (existing customers only)

Find answers to commonly asked questions in our

Knowledge Base

Download the latest documents and software

Contact Us on our website

10/27/2017

©2017 FLIR Integrated

Imaging Solutions Inc.

Allrights reserved.

FLIROryx®Installation Guide 32

Loading...

Loading...