Fisher Paykel CG305DNGX1N, CG365DLPX1N, CG305DLPX1N, CG244DNGX1N, CG244DLPX1N Installation Manual

Page 1

GAS COOKTOP

CG244D, CG05D & CG65D models

INSTALLATION GUIDE

US CA

590486G 08.17

Page 2

1 SAFETY AND WARNINGS

!

WARNING!

Electrical Shock Hazard

Disconnect product from the mains power supply before servicing. This

appliance is equipped with a three-prong grounding plug for your

protection against shock hazard and should be plugged directly into a

properly grounded power outlet. Do not under any circumstances cut or

remove the grounding prong from this plug.

Failure to follow this advice may result in electrical shock or death.

!

WARNING!

Cut Hazard

Take care - panel edges are sharp.

Failure to use caution could result in injury or cuts.

IMPORTANT SAFETY INSTRUCTIONS

●

This appliance shall be installed in accordance with the installation requirements of the

local gas authority or the appropriate installation code or in the absence of local codes

with the latest National Fuel Gas Code NFPA 54/ANSI Z223.1 or CAN/CSA B149.1,2

(Canada). Local building and electrical codes must be adhered to.

●

Electrical installation must be in accordance with the National Electrical Code, ANSI/

NFPA70 - latest edition or CSA C22.1 (Canada) and/or local codes.

●

Installation in manufactured (mobile) home: installation must conform with the

Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280 [formerly

the Federal Standard for Mobile Home Construction and Safety, Title 24, HUD (Part

280)] or, when such standard is not applicable, the Standard for Manufactured Home

Installations, ANSI/NFPA 225, or with local codes where applicable.

●

Installation in Recreational Park Trailers: installation must conform with state or other

codes or, in the absence of such codes, with the Standard for Recreational Park Trailers,

ANSI A119.5.

●

Do not remove permanently affixed labels, warnings, or plates from the product. This

may void the warranty.

●

Flexible appliance connectors shall meet the requirements of ANSI Z21.24 and State

Boards. They shall not exceed 35 1/2 inches (900 mm) in length. In order to avoid hazard,

these appliances must be installed according to these instructions.

●

This appliance must be installed by an authorized person (Warning: this appliance must

be installed by a licensed plumber or gas fitter when within the Commonwealth of

Massachusetts).

●

Please make this information available to the person installing the appliance as it could

reduce your installation costs.

●

Please leave these instructions with the appliance. Inform the customer to retain for

future reference and for the local inspectors’ use.

●

Failure to install the appliance correctly could invalidate any warranty or liability claims.

●

Leak testing of the appliance shall be conducted according to the manufacturer’s

instructions.

Only genuine replacement parts may be used for servicing the appliance. These are

available from your nearest Fisher & Paykel Service Center.

Before you install the appliance, please make sure that

●

the local distribution conditions (nature of gas and pressure) and the adjustment of the

appliance are compatible. For adjustment conditions for this appliance, see ‘Gas rate

summary’ under step 3.

●

a suitable isolating switch is incorporated in the fixed wiring in an acceptable position.

●

the appliance is connected to a power outlet that is electrically grounded in accordance

with local codes or in the absence of local codes, with the National Electric Code ANSI/

NFPA 70 or CSA C22.2 (Canada).

●

there is a power outlet (110-120V 60Hz) within reach of the appliance cable (35 1/2” (900

mm) from the center rear of the appliance). This must be accessible after installation. The

mains power supply cable should not touch any metal parts.

●

the countertop is square and level and no structural members interfere with space

requirements

●

the countertop is made of heat-resistant material.

●

you take note of the following recommended non-combustible materials: 1/4” (6 mm) flame

retardant millboard covered with not less than No. 28 MSG sheet steel, 1/32” (0.4 mm)

stainless steel, 1/32” (0.6 mm) aluminum or 1/32” (0.5 mm) copper.

●

the gas shut-off valve is accessible after installation.

●

if the power supply cable is damaged, it is replaced only by the special cable: Part no.

531954 FLEX TERMINAL BLOCK ASSY US, obtainable from authorized Fisher & Paykel

Service Agents.

IMPORTANT!

SAVE THESE INSTRUCTIONS

The models shown in this installation guide may not be available in all markets and are subject to change at any time. For current details about model and specification availability in your country, please go to our

website www.fisherpaykel.com or contact your local Fisher & Paykel dealer.

1

Page 3

2 PARTS SUPPLIED

Wok stand (1)

SEMI-RAPID SEMI-RAPID

MINI WOK AUX

Small pan support

(1)

(CG305D & CG365D

models only)

SEMI-RAPID SEMI-RAPID

RAPID

CG305D & CG365DCG244D

Fibre washers (1)

DUAL WOK

Elbow 1/2“ NPT

external thread (1)

3 GAS RATE SUMMARY

AUX

Clamping

Regulator (1)

Foam tape (1)

brackets (4)

and screws (4)

High Altitude Installations - CG30D & CG365D models

For installations above 3000’ conversion kits are required:

3,000-6,000’ 534695 KIT HI ALT NG

534697 KIT HI ALT LP

6000’+ 534696 KIT HI ALT NG

534698 KIT HI ALT LP

High Altitude Installations - CG244D models

For installations above 3000’ conversion kits are required:

3,000-6,000’ 535432 KIT HI ALT 3000-6000 NG GOS244

535434 KIT HI ALT 3000-6000 LG GOS244

6000’+ 535433 KIT HI ALT 6000+ NG GOS244

535435 KIT HI ALT 6000+ LG GOS244

Contact your authorized dealer, customer care or refer to the website

listed at the back of this document.

US CA

INJECTOR ORIFICE (MM)

NG 4” H2O (0.15 psi)

LP 11” H2O (0.39 psi)

CG244D 0.9 3500 0.55 3500 1.40 8500 0.75 6700 na na na na 1.55 11100 0.94 11100 na na na na

CG305D 0.9 3500 0.55 3500 1.40 8500 0.75 6700 1.65 11500 0.98 11500 na na na na

CG365D 0.9 3500 0.55 3500 1.40 8500 0.75 6700 1.65 11500 0.98 11500 na na na na

NOMINAL RATING (BTU/HR)

NG LP NG LP NG LP NG LP NG LP

INJECTOR ORIFICE (MM)

AUX SEMI-RAPID RAPID MINI WOK DUAL WOK

NOMINAL RATING (BTU/HR)

INJECTOR ORIFICE (MM)

NOMINAL RATING (BTU/HR)

INJECTOR ORIFICE (MM)

NOMINAL RATING (BTU/HR)

INJECTOR ORIFICE (MM)

NOMINAL RATING (BTU/HR)

INJECTOR ORIFICE (MM)

NOMINAL RATING (BTU/HR)

INJECTOR ORIFICE (MM)

NOMINAL RATING (BTU/HR)

INJECTOR ORIFICE (MM)

NOMINAL RATING (BTU/HR)

INJECTOR ORIFICE (MM)

1.50

1.50

0.70

1.50

1.50

0.70

NOMINAL RATING (BTU/HR)

19000

19000

0.83

0.83

0.50

0.83

0.83

0.50

INJECTOR ORIFICE (MM)

19000

19000

NOMINAL RATING (BTU/HR)

2

Page 4

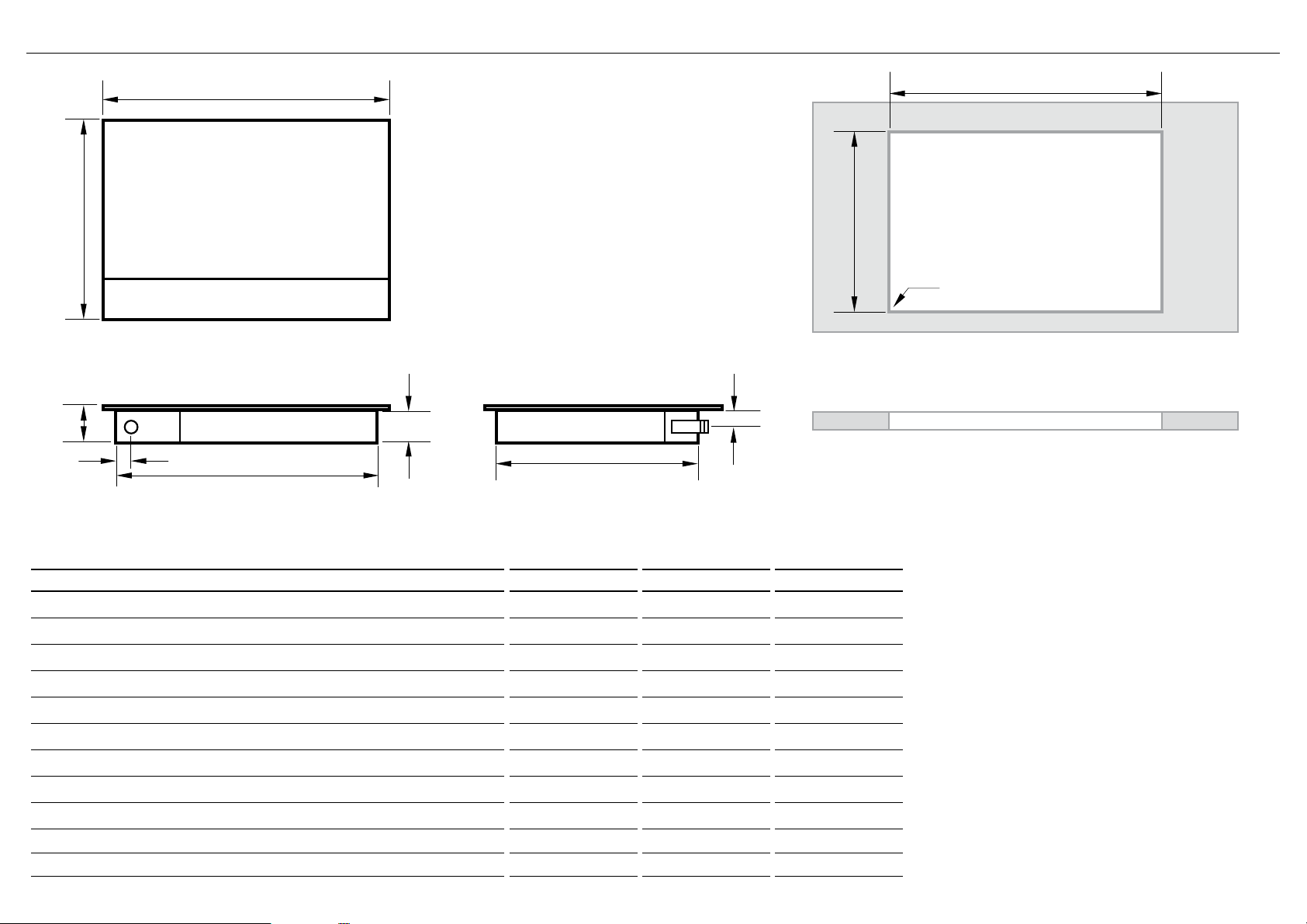

4 PRODUCT & CABINETRY DIMENSIONS

A

K

D

B

E

C

G

F

J

H

I

TOP

Note: Gas inlet connection is located in the

rear right corner.

REAR

PRODUCT DIMENSIONS inches (mm) inches (mm) inches (mm)

Overall height of product (excluding burners, dials and pan supports) 2 1/2” (64) 2 1/2” (64) 2 1/2” (64)

A

Overall width of product

B

Overall depth of product

C

Height of chassis (below top of counter)

D

Width of chassis

E

Depth of chassis

F

Overall width of cutout

G

Overall depth of cutout

H

Corner radius of cutout

I

Distance from top of counter to center of gas inlet on product

J

Distance from edge of chassis to gas inlet on product

K

3

SIDE

CG244D CG305D CG365D

23 5/8” (600) 29 1/2” (749)

20 7/8” (530) 20 7/8” (530)

2 5/16” (59) 2 5/16” (59)

21 7/8” (555) 27 1/2” (698)

19 1/8” (486) 19 5/16” (490)

22 1/16” (560) 27 3/4” (705)

19 5/16” (490) 19 1/2” (495)

max. 3/8” (10) max. 3/8” (10)

1 1/4” (32)

13/16” (21)

1 1/4” (32) 1 1/4” (32)

13/16” (21) 13/16” (21)

35 1/2” (900)

20 7/8” (530)

33 11/16” (856)

34 1/16” (865)

19 5/16” (490)

max. 3/8” (10)

TOP

FRONT

2 5/16” (59)

19 1/8” (486)

Page 5

5 CLEARANCE DIMENSIONS

F

E

H

G

C

I

A

CLEARANCE DIMENSIONS inches (mm) inches (mm) inches (mm)

Minimum clearance from left edge of product to nearest vertical surface 12” (294) 12” (294) 12” (294)

A

Minimum clearance from right edge of product to nearest vertical surface 12” (294) 12” (294) 12” (294)

B

Minimum clearance from rear edge of product to:

C

nearest combustible surface

nearest non-combustible surface*

Minimum clearance from front edge of counter to front edge of product 1 1/4” (32) 1 1/4” (32) 1 1/4” (32)

D

Minimum clearance from cooking surface to combustible surface centered above the cooking surface 30” (762) 30” (762) 30” (762)

E

Maximum overall depth of overhead cabinetry 13” (330) 13” (330) 13” (330)

F

Minimum distance between overhead cabinets installed to either side of product 24” (588) 30” (762) 36” (915)

G

Minimum vertical distance between counter and cabinet extending above the counter 18” (457) 18” (457) 18” (457)

H

Minimum clearance below top of countertop to:

I

nearest combustible surface

F&P oven or nearest non-combustible surface

Maximum distance from the center of the product to the nearest grounded power outlet.

J

The power supply cable must not touch any hot metal surfaces.

* Recommended non-combustible materials are: 1/4” (6 mm) flame retardant millboard covered with not less than No. 28 MSG sheet steel, 0.015” (0.4 mm) stainless steel,

0.024” (0.6 mm) aluminum or 0.020” (0.5 mm) copper.

ISO

D

B

J

FRONT

CG244D CG305D CG365D

3” (74)

1 1/2” (38)

2 3/4” (70)

2 9/16” (65)

35 1/2” (900) 35 1/2” (900) 35 1/2” (900)

7” (178)

1 1/2” (38)

2 3/4” (70)

2 9/16” (65)

7” (178)

1 1/2” (38)

2 3/4” (70)

2 9/16” (65)

4

Page 6

6 DISCARD PACKAGING

Model may vary from illustrations shown

7 FIT THE ELBOW AND WASHER

Recycle responsibly

8 APPLY ADHESIVE FOAM TAPE AROUND EDGE

Foam Tape

1 Turn the cooktop upside down and

Adhesive side

Ensure edge of tape

lines up with outer

edge of cooktop

place it on a soft surface.

2 Spread the seal around the edges,

with the adhesive side facing down

to form a continuous seal around the

cooktop.

3 Using a sharp cutter or trimmer

knife, trim the excess sealing material

around the edge of the cooktop. Take

care not to damage the countertop.

Floating nut Fibre washer

Elbow (1/2 “ NPT external thread)

9 LOWER GENTLY INTO THE CUTOUT

5

Page 7

on

x 4

!0 FIT CLAMPING BRACKETS BASED ON THE COUNTERTOP THICKNESS & SECURE TO COUNTERTOP

view from below

x 4

”- ¾” ¾”- 1 ”

(16-20mm) (20-30mm)

1

”- 1½”

(30-40mm)

½” +

1

(40mm+)

!1 GAS CONNECTION

●

Make sure the connection point will be accessible with the cooktop installed.

●

To enable the gas supply to be readily shut off by the customer, make sure the connection is fitted with an isolating valve

close to the cooktop.

●

The appliance must be isolated from the gas supply piping system by closing its individual shut-off valve during any pressure testing of the

gas supply piping system at test pressures at or less than 1/2 p.s.i. (3.5 kPa).

●

Maximum inlet gas supply pressure 20” W.C. (5 kPa). Minimum gas supply pressure for regulator testing 5” W.C. Natural Gas / 12” W.C LP

gas.

●

A manual shut-off valve must be installed in an accessible location in the gas line external to the appliance for the purpose of turning on or

shutting off gas to the appliance. (In Massachusetts, such shut-off devices should be approved by the Board of State Examiners of Plumbers

& Gas Fitters).

●

Gas connection to the product must use the nipple supplied with a 1/2” NPT external thread. The supplied gas pressure regulator must be

installed where it will be accessible for adjustment. The metal flexible hose used must be new, CSA or UL-approved, and must have a 1/2”

NPT external thread on one end and a 1/2” NPT one on the other

If connecting the gas with a flexible hose

●

Ensure the hose is long enough to allow for removal of cooktop for servicing.

●

Make sure the connector is located as shown in step 5 CLEARANCE DIMENSIONS.

●

The hose assembly must be with an Rp 1/2” (ISO 7-1) female thread connection.

●

The hose assembly must be as short as practicable and comply with the relevant requirements.

●

The hose must not be kinked, subjected to abrasion or permanently deformed.

●

The hose must not be near or in contact with any hot surfaces (e.g. base of metal hotlplate, flue, or chassis of undercounter oven etc.)

Repeat on all the other sides

6

Page 8

!2 CONNECT TO THE GAS SUPPLY

This appliance is factory set for use with Natural Gas at 4” W.C.P. or LP

Gas at 11” W.C.P. Check the label on the underside of the appliance.

Gas regulator

●

For use with a gas pressure regulator as shown.

Pressure

Regulator

shows

Direction of

Gas Flow

!3 LEAK TESTING

●

Leak testing of the appliance shall be conducted according to the manufacturer’s instructions.

●

The appliance and its individual shut-off valve must be disconnected from the gas supply piping system during

any pressure testing of that system in excess of 1/2 psi (3.5kPa).

●

The appliance must be isolated from the gas supply piping system by closing its individual manual shut-off valve

during any pressure testing of the gas supply piping system at test pressures at or less than 1/2 psi (3.5 kPa).

●

Maximum inlet gas supply pressure 20” W.C. (5 kPa)

●

Minimum gas supply pressure for regulator testing 5” W.C. Natural Gas, 12” W.C. LP Gas.

To Cooktop

Regulator

Solid or Flexible

Connector

Shut-Off

Valve

Pipe Stub from

House supply

Cooktop

ON

ON

GAS

GAS

After installing the gas supply and making all connections, check thoroughly for possible leaks:

1 Turn all control dials on unit to “OFF” position.

2 Open the valve on the gas supply.

3 Using a leak detection fluid (eg Rocol leak detection spray), check each gas connection one at a time by spraying

or brushing the solution over the connection. The presence of bubbles will indicate a leak.

4 If necessary, tighten the fitting and recheck for leaks.

5 Turn on burner valve and light each burner.

6 Check for a clear blue flame without yellow tipping. If burners show any abnormalities, check that they are

located properly and in line with the injector orifice.

7

Page 9

!4 AFFIX DUPLICATE DATA LABEL SOMEWHERE

INSTALLATION INSTRUCTIONS

ACCESSIBLE & PLUG COOKTOP IN

Duplicate data label

!6 LEAK TESTING

!5 FIT PAN SUPPORTS

Ensure the pan supports are located securely

and in the correct orientation (refer to User guide)

●

To check that the ignition system operates correctly, light each burner by itself, then all burners in combination.

●

Check for a well-defined blue flame without any yellow tipping.

●

If any abnormality is evident, check that the components of the burner assembly are located properly

●

If proper operation cannot be obtained, contact Customer Care or your nearest F&P Authorized Service Center.

●

The cooktop must not be used by the customer until proper operation has been achieved.

Lifting off

Yellow tip

Good flame

8

Page 10

!7 FINAL CHECKLIST

TO BE COMPLETED BY THE INSTALLER

Have you installed the clamping brackets?

Have you verified that the type of model (factory-set for NG or LP) matches the type of gas at the site of installation?

Have you sealed all connections with gas tape?

Have you used the fibre washer supplied?

Have you leak-tested all connections?

Is the cooktop set to the correct working pressure?

Have you affixed the supplied duplicate data plate label on an adjacent

surface accessible to the customer?

Is the cooktop grounded?

Check that the power supply cord is NOT touching the cooktop.

OPERATION:

Do all burners ignite both individually and in combination?

Are the flames consistent and appropriately sized?

Have you demonstrated the basic operation to the customer?

Complete and keep for safe reference:

Model

Serial No.

Purchase Date

Purchaser

Dealer Address

Installer’s Name

Installer’s Signature

Installation Company

Installation Date

9

Copyright © Fisher & Paykel Appliances 2016. All rights reserved.

The product specifications in this booklet apply to the specific products

and models described at the date of issue. Under our policy of continuous

product improvement, these specifications may change at any time. You

should therefore check with your Dealer to ensure this booklet correctly

describes the product currently available.

Page 11

101112

Page 12

Page 13

Page 14

SURFACE DE CUISSON AU GAZ

Modèles

CG244D, CG05D et CG65D

INSTRUCTIONS D’INSTALLATION

US CA

590486G 08.17

Page 15

1 CONSIGNES DE SÉCURITÉ ET MISES EN GARDE

!

MISE EN GARDE!

Risque de choc électrique

Débranchez l’appareil de l’alimentation électrique avant toute réparation.

Cet appareil est équipé d’une fiche à trois broches avec mise à la terre pour

protéger des chocs électriques. Branchez-la directement dans une prise

électrique avec mise à la terre adéquate. Vous ne devez en aucune circonstance

couper ou retirer la broche de mise à la terre de cette fiche.

Le non-respect de cette consigne peut entraîner un choc électrique ou la mort.

!

MISE EN GARDE!

Risque de coupure

Attention, les bords du panneau sont tranchants.

Des blessures ou des coupures peuvent se produire si vous ne faites pas

preuve de prudence.

CONSIGNES DE SÉCURITÉ IMPORTANTES!

●

Cet appareil devra être installé conformément aux exigences des réglementations

locales relatives augaz ou des codes d’installation appropriés, ou en l’absence de codes

locaux, de la norme NFPA 54/ANSI Z223.1 ou CAN/CSA B149.1,2 de la dernière édition

du National Fuel Gas Code du Canada. Les codes locaux du bâtiment et de l’électricité

doivent être respectés.

●

Toute installation électrique doit être conforme à la norme ANSI/NFPA70 de la dernière

édition du Codenational de l’électricité ou à la norme CSA C22.1 (Canada) et/ou aux

codes locaux.

●

Installation dans une maison préfabriquée (mobile): l’installation doit être effectuée

conformément à la norme Manufactured Home Construction and Safety Standard,

Titre24 CFR, Partie3280 [anciennement Federal Standard for Mobile Home Construction

and Safety, Titre24, HUD (Partie280)] ou, lorsqu’une telle norme est inapplicable, à

la norme Standard for Manufactured Home Installations, ANSI/NFPA 225, ou aux codes

locaux en vigueur.

●

Installation dans une caravane de parc: l’installation doit être effectuée conformément

aux codes de l’État et autres codes, ou en l’absence de tels codes, à la norme Standard

for Recreational Park Trailers, ANSI A119.5.

●

Ne retirez pas les étiquettes, mises en garde ou plaques signalétiques apposées sur

l’appareil. Cela pourrait entraîner l’annulation de la garantie.

●

Les raccords flexibles de l’appareil doivent être conformes à la norme ANSI Z21.24 et

aux règlements de commissions d’État. Leur longueur ne doit pas dépasser 351/2po

(900mm). Installez ces appareils conformément aux instructions afin d’éviter tout

danger.

●

●

Cet appareil doit être installé par un technicien autorisé (mise en garde: dans les limites

de l’ÉtatduMassachusetts, cet appareil doit être installé par un monteur d’installation au

gaz ou plombierautorisé).

●

Remettez ces instructions à la personne qui installera l’appareil. Cela pourrait réduire vos

coûts d’installation.

●

Laissez ces instructions avec l’appareil. Demandez au client de les conserver pour toute

référence ultérieure ou vérification des inspecteurs locaux.

●

Le fait de ne pas installer l’appareil de façon adéquate pourrait entraîner l’annulation de

toute garantieou réclamation.

●

La vérification des fuites doit être effectuée conformément aux instructions du fabricant.

●

Utilisez uniquement des pièces de remplacement authentiques pour effectuer l’entretien

ou lesréparations de l’appareil. Vous pouvez vous les procurer auprès d’un Centre de

service Fisher& Paykel de votre région.

Avant d’installer l’appareil, assurez-vous que:

●

les conditions de distribution locales (nature du gaz et pression) et le réglage de l’appareil

sont compatibles. Pour connaître les conditions de réglage de cet appareil, voir ‘Tableau de

débit des gaz’ àl’étape3.

●

le câblage fixe comporte un interrupteur de sectionnement approprié, installé dans une

position convenable.

●

l’appareil est branché à une prise électrique mise à la terre en conformité avec les codes

locaux ou, enl’absence de tels codes, avec la norme ANSI/NFPA70 ou CSA C22.2 du Code

national de l’électricité(Canada).

●

une prise électrique (110-120V 60Hz) se trouve à proximité du câble de l’appareil

(351/2po (900mm) à partir de la partie centrale à l’arrière de l’appareil). Cette prise doit

demeurer accessible après l’installation. Le câble d’alimentation ne doit toucher aucune

pièce métallique.

●

le comptoir est au niveau et bien droit, et aucune pièce de charpente ne nuit aux exigences

dedégagement.

●

le comptoir est fait d’un matériau résistant à la chaleur.

●

vous prenez note de ces matériaux incombustibles recommandés: panneau de celloderme

ignifuge de 1/4po (6mm) couvert d’une tôle d’acier n°28 MSG (minimum), d’acier

inoxydable de 1/32po (0,4mm),

●

d’aluminium de 1/32po (0,6mm) ou de cuivre de 1/32po (0,5mm).

●

le robinet d’arrêt du gaz est accessible après l’installation.

●

si le câble d’alimentation est endommagé, il doit être remplacé uniquement par un câble

spécial: Pièce n°531954 FLEX TERMINAL BLOCK ASSY US, disponible auprès des agents

de service autorisés deFisher&Paykel.

IMPORTANT!

CONSERVEZ CES INSTRUCTIONS

Les modèles illustrés dans ce document pourraient ne pas être offerts par tous les détaillants et sont sujets à modifications sans préavis. Pour les plus récentes informations sur la disponibilité des modèles et des

caractéristiques dans votre pays, veuillez visiter notre site Web local à l’adresse indiquée à la fin de ce document, ou contacter votre détaillant Fisher&Paykel local.

1

Page 16

2 PIÈCES FOURNIES

Support de wok (1)

Petite pièce d’appui (1)

Rondelle en fibre (1)

(Modèles CG305 et

CG365 seulement.)

3 TABLEAU DE DÉBIT DES GAZ

SEMI-RAPIDE SEMI-RAPIDE SEMI-RAPIDE SEMI-RAPIDE

DOUBLE POUR

WOK

MINI WOK AUXILIAIRE

RAPIDE

CG305D et CG365DCG244D

AUXILIAIRE

Coude avec filetage

NPT externe de

1/2po (12,5mm) (1)

Installations en haute altitude - Modèles CG30D & CG365D

Pour les installations au-dessus de 3000pi, des ensembles deconversion sont requis:

3000-6000pi 534695– ENSEMBLE HAUTE ALTITUDE POUR GN

534697– ENSEMBLE HAUTE ALTITUDE POUR GPL

6000pi+ 534696– ENSEMBLE HAUTE ALTITUDE POUR GN

534698– ENSEMBLE HAUTE ALTITUDE POUR GPL

Installations en haute altitude - Modèles CG244D

Pour les installations au-dessus de 3000pi, des ensembles deconversion sont requis:

3000-6000pi 535432 KIT HI ALT 3000-6000 NG GOS244

535434 KIT HI ALT 3000-6000 LG GOS244

6000pi+ 535433 KIT HI ALT 6000+ NG GOS244

535435 KIT HI ALT 6000+ LG GOS244

Communiquez avec votre détaillant autorisé ou l’assistance à laclientèle, ou consultez notre

site Web, à l’adresse indiquée à l’arrière de ce document.

Supports de

retenue (4)

et vis (4)

Régulateur (1)

Isolant adhésif (1)

US CA

ORIFICE D’INJECTION (MM)

VALEUR NOMINALE

(BTU/HEURE)

ORIFICE D’INJECTION (MM)

VALEUR NOMINALE

(BTU/HEURE)

GN 4po (102mm) H2O

(0,15psi)

GPL 11po (279mm) H2O

(0,39psi)

CG244D

CG305D

CG365D 0.9 3500 0.55 3500 1.40 8500 0.75 6700 1.65 11500 0.98 11500 na na na na

0.9 3500 0.55 3500 1.40 8500 0.75 6700 na na na na 1.55 11100 0.94 11100 na na na na

0.9 3500 0.55 3500 1.40 8500 0.75 6700 1.65 11500 0.98 11500 na na na na

AUXILIAIRE SEMI-RAPIDE RAPIDE MINI WOK DOUBLE POUR WOK

GN GPL GN GPL GN GPL GN GPL GN GPL

ORIFICE D’INJECTION (MM)

VALEUR NOMINALE

(BTU/HEURE)

ORIFICE D’INJECTION (MM)

VALEUR NOMINALE

(BTU/HEURE)

ORIFICE D’INJECTION (MM)

VALEUR NOMINALE

(BTU/HEURE)

ORIFICE D’INJECTION (MM)

VALEUR NOMINALE

(BTU/HEURE)

ORIFICE D’INJECTION (MM)

VALEUR NOMINALE

(BTU/HEURE)

ORIFICE D’INJECTION (MM)

VALEUR NOMINALE

(BTU/HEURE)

ORIFICE D’INJECTION (MM)

VALEUR NOMINALE

(BTU/HEURE)

ORIFICE D’INJECTION (MM)

1.50

1.50

0.70

1.50

1.50

0.70

19000

19000

0.83

0.83

0.50

0.83

0.83

0.50

VALEUR NOMINALE

19000

19000

(BTU/HEURE)

2

Page 17

4 PRODUCT & CABINETRY DIMENSIONS

A

K

D

B

E

C

G

F

J

H

I

3

DESSUS

Remarque: Le raccord d’admission de gaz

est situé dans le coin arrière droit.

ARRIÈRE

Dimensions du produit et des armoires

Hauteur hors tout du produit (excluant les brûleurs, les boutons et les pièces d’appui)

A

Largeur hors tout du produit

B

Profondeur hors tout du produit

C

Hauteur du châssis (sous la surface du comptoir)

D

Largeur du châssis

E

Profondeur du châssis

F

Largeur hors tout de l’ouverture

G

Profondeur hors tout de l’ouverture

H

Rayon du coin de l’ouverture

I

Distance entre la surface du comptoir et le centre de l’admission de gaz du produit

J

Distance entre le rebord du châssis et l’admission de gaz du produit

K

CÔTÉ

DESSUS

DEVANT

pouces (mm)

CG244D CG305D CG365D

2 1/2 po (64) 2 1/2 po (64) 2 1/2 po (64)

23 5/8 po (600) 29 1/2 po (749) 35 1/2 po (900)

20 7/8 po (530) 20 7/8 po (530) 20 7/8 po (530)

2 5/16 po (59) 2 5/16 po (59) 2 5/16 po (59)

21 7/8 po (555) 27 1/2 po (698) 33 11/16 po (856)

19 1/8 po (486) 19 5/16 po (490) 19 1/8 po (486)

22 1/16 po (560) 27 3/4 po (705) 34 1/16 po (865)

19 5/16 po (490) 19 1/2 po (495) 19 5/16 po (490)

max. 3/8 po (10) max. 3/8 po (10) max. 3/8 po (10)

1 1/4 po (32) 1 1/4 po (32) 1 1/4 po (32)

13/16 po (21) 13/16 po (21) 13/16 po (21)

Page 18

5 DIMENSIONS DE DÉGAGEMENT

F

G

E

A

C

I

D

H

J

B

ISO

DEVANT

CG244D CG305D CG365D

Dimensions de dégagement pouces (mm) pouces (mm) pouces (mm)

Dégagement minimal entre le côté gauche du produit et la surface verticale la plus proche

A

Dégagement minimal entre le côté droit du produit et la surface verticale la plus proche

B

Dégagement minimal entre l’arrière du produit et:

C

La surface combustible la plus proche

La surface incombustible la plus proche*

Dégagement minimal entre le devant du comptoir et le devant du produit

D

Dégagement minimal entre la surface de cuisson et une surface combustible centrée au-dessus de la surface de cuisson

E

Profondeur hors tout maximale des armoires suspendues

F

Distance minimale entre les armoires suspendues installées des deux côtés du produit

G

Distance verticale minimale entre le comptoir et une armoire au-dessus du comptoir

H

Dégagement minimal entre le dessous du comptoir et:

I

La surface combustible la plus proche

Une cuisinière f&p ou la surface incombustible la plus proche

Distance maximale entre la partie centrale du produit et la prise électrique avec mise à la terre la plus proche.

J

Le câble d’alimentation ne doit toucher aucune surface métallique chaude.

* Recommended non-combustible materials are: 1/4” (6 mm) flame retardant millboard covered with not less than No. 28 MSG sheet steel, 0.015” (0.4 mm) stainless steel,

0.024” (0.6 mm) aluminum or 0.020” (0.5 mm) copper.

12” (294) 12” (294) 12” (294)

12” (294) 12” (294) 12” (294)

3” (74)

1 1/2” (38)

1 1/4” (32) 1 1/4” (32) 1 1/4” (32)

30” (762) 30” (762) 30” (762)

13” (330) 13” (330) 13” (330)

24” (588) 30” (762) 36” (915)

18” (457) 18” (457) 18” (457)

2 3/4” (70)

2 9/16” (65)

35 1/2” (900) 35 1/2” (900) 35 1/2” (900)

7” (178)

1 1/2” (38)

2 3/4” (70)

2 9/16” (65)

7” (178)

1 1/2” (38)

2 3/4” (70)

2 9/16” (65)

4

Page 19

6 METTEZ L’EMBALLAGE AU REBUT

Le modèle peut être différent des

illustrations présentées

7 INSTALLEZ LE COUDE ET LA RONDELLE

Recyclez de façon responsable

8 APPLIQUEZ L’ISOLANT ADHÉSIF AUTOUR DUREBORD

Isolant adhésif

1 Retournez la surface de cuisson à

l’envers sur unesurface douce.

Côté adhésif

Assurez-vous que

le rebord de l’isolant s’aligne

avec le rebord extérieur de

la surface de cuisson

5

2 Appliquez le joint autour des rebords

en plaçant le côté adhésif vers le bas,

pour obtenir un joint continu autour de

la surface de cuisson.

3 Utilisez un outil de coupe tranchant

ou des ciseaux pour couper l’excédent

de matériel de scellement autour du

rebord de la surface de cuisson. Veillez

à ne pas endommager le comptoir.

Écrou flottant

Rondelle en fibre

Coude (avec filetage NPT externe

de 1/2po (12,5mm))

9 DÉPOSEZ L’APPAREIL DOUCEMENT DANS L’OUVERTURE

Page 20

!0 INSTALLEZ LES SUPPORTS DE RETENUE EN LES AJUSTANT À L’ÉPAISSEUR DU COMPTOIR ET FIXEZ L’APPAREIL AU COMPTOIR

on

x 4

view from below

vue du dessous

⁄ po - ¾ po ¾ po - 1 ⁄ po

(16 - 20 mm) (20 - 30 mm)

1 ⁄ po -

1 ½ po

(30 - 40 mm)

1 ½ po +

(40 mm+)

!1 RACCORDEMENT DU GAZ

●

Assurez-vous que le point de raccordement demeure accessible après l’installation de lasurface de cuisson.

●

Pour que le client soit en mesure de couper facilement l’alimentation en gaz, assurez-vousque le raccordement soit muni d’un robinet d’isolement situé

à proximité de la surface de cuisson.

●

Fermez le robinet d’arrêt individuel de l’appareil pour l’isoler de la tuyauterie d’alimentation engaz pendant toute vérification de pression de la tuyauterie

d’alimentation alors que lapression d’essai est égale ou inférieure à 1/2psi(3,5kPa).

●

Pression d’admission maximale de l’alimentation en gaz: 20po (508mm) de colonne d’eau (5kPa). Pression minimale de l’alimentation en gaz pour la

vérification du régulateur de gaz: 5po (127 mm) de colonne d’eau pour le gaz naturel, 12po (305mm) de colonne d’eau pour legaz de pétrole liquéfié.

●

Vous devez installer un robinet d’arrêt manuel dans un endroit accessible de la canalisation externe de l’appareil pour pouvoir ouvrir ou couper

l’alimentation en gaz à l’appareil (au Massachusetts, de tels dispositifs doivent être approuvés par le Board of State Examiners ofPlumbers & Gas Fitters).

●

Le raccordement en gaz à ce produit doit utiliser le coude fourni avec filetage NPT externe de 3/8po (9,5mm). Le régulateur de pression du gaz fourni

doit être installé dans un endroit accessible permettant de le régler. Le tuyau en métal flexible utilisé doit être à l’état neuf, homologué CSA ou UL, et

muni de filetage NPT externe de 3/8po (9,5mm) à l’une des extrémités, et de filetage NPT de 1/2po (12,7mm) à l’autre extrémité.

Pour le raccordement du gaz à l’aide d’un tuyau flexible

●

Assurez-vous que le tuyau soit suffisamment long pour permettre le retrait de la surface decuisson pour l’entretien.

●

Assurez-vous que le connecteur soit positionné de la manière indiquée à l’étape5 «DIMENSIONS DE DÉGAGEMENT».

●

L’assemblage du tuyau doit être effectué à l’aide d’un raccord à filetage femelle de type Rp 1/2po (ISO7-1).

●

L’assemblage du tuyau doit être aussi court que possible et conforme aux exigencesapplicables.

●

Le tuyau ne doit pas être entortillé, soumis à l’abrasion ou déformé de manière permanente.

●

Le tuyau ne doit pas être installé à proximité ou placé en contact avec des surfaces chaudes (p.ex. la base de la plaque chauffante métallique, le conduit

de fumée ou le châssis d’une cuisinière sous le comptoir).

x 4

Répétez sur tous les autres côtés

6

Page 21

!2 RACCORDEZ À L’ALIMENTATION EN GAZ

Cet appareil est réglé en usine pour utiliser une pression de gaz naturel de

4po (102mm) de colonne d’eau ou une pression de gaz de pétrole liquéfié

de 11po (279mm) de colonne d’eau.

Vérifiez l’étiquette apposée sous l’appareil.

Régulateur de gaz

●

Pour l’utilisation avec un régulateur de pression de gaz, tel qu’illustré.

Le régulateur

de pression

indique le sens

de circulation

du gaz

!3 VÉRIFICATION DES FUITES

●

La vérification des fuites doit être effectuée conformément aux instructions du fabricant.

●

L’appareil et son robinet d’arrêt individuel doivent être débranchés de la tuyauterie d’alimentation en gaz lorsque la

vérification de pression donne une valeur supérieure à 1/2psi (3,5kPa).

●

Fermez manuellement le robinet d’arrêt individuel de l’appareil pour l’isoler de la tuyauterie d’alimentation en gaz

pendant toute vérification de pression de la tuyauterie d’alimentation alors que la pression d’essai est égale ou

inférieure à 1/2psi (3,5kPa).

●

Pression d’admission maximale de l’alimentation en gaz: 20po (508mm) de colonne d’eau (5kPa)

●

Pression minimale de l’alimentation en gaz pour la vérification du régulateur de gaz: 5po (127mm) de colonne d’eau

pour le gaz naturel, 12po (305mm) de colonne d’eau pour le gaz depétrole liquéfié.

Surface de cuisson

Vers la surface de cuisson

Régulateur

Connecteur

solide ou flexible

Robinet

d’arrêt

Tuyau de

l’alimentation de la

maison

GAZ

OUVERT

Une fois l’installation de l’alimentation en gaz et tous les raccordements effectués,

vérifiez soigneusement l’installation pour déceler toute fuite:

1 Tournez tous les boutons de réglage de l’appareil à la position «OFF».

2 Ouvrez le robinet de l’alimentation en gaz.

3 À l’aide d’un fluide de détection de fuite (p.ex. un vaporisateur de détection de fuite Rocol), vérifiez tous les raccords

de gaz un à un en vaporisant ou appliquant la solution sur le raccord. Laprésence de bulles indique une fuite.

4 Si nécessaire, serrez le raccord et vérifiez de nouveau s’il y a des fuites.

5 Ouvrez la valve de brûleur et allumez chaque brûleur.

6 Vérifiez si l’appareil produit une flamme bleu clair sans pointe jaune. Si les brûleurs fonctionnent anormalement,

vérifiez s’ils sont installés adéquatement, en ligne droite avec l’orifice d’injection.

7

Page 22

!4 APPOSEZ LE DOUBLE DE L’ÉTIQUETTE SIGNALÉTIQUE À UN

INSTALLATION INSTRUCTIONS

ENDROIT ACCESSIBLE ET BRANCHEZ LA SURFACE DE CUISSON

Double de l’étiquette

signalétique

!6 FAITES UN ESSAI

!5 INSTALLEZ LES PIÈCES D’APPUI

Assurez-vous que les pièces d’appui soient positionnées correctement et dans

le bon sens (reportez-vous au Guide de l’utilisateur).

●

Pour vous assurer que le système d’allumage fonctionne correctement, allumez chaque brûleur individuellement, puis tous les brûleurs simultanément.

●

Vérifiez si l’appareil produit une flamme bleu clair bien définie, sans pointe jaune.

●

Si vous constatez un fonctionnement anormal, vérifiez si les composantes de l’assemblage de brûleur sont installées correctement.

●

S’il est impossible d’obtenir un fonctionnement adéquat, communiquez avec le service à la clientèle ou un centre de service F&P autorisé de votre région.

●

Le client ne doit pas utiliser la surface de cuisson avant qu’elle ne fonctionne correctement.

pointe jauneéloignement

amme

adéquate

8

Page 23

!7 LISTE DE VÉRIFICATION FINALE

À ÊTRE REMPLIE PAR L’INSTALLATEUR

Avez-vous installé les supports de retenue?

Avez-vous vérifié si le type de modèle (réglé en usine pour le gaz naturel (GN) ou le gaz de pétrole liquéfié (GPL))

correspond au type de gaz disponible sur le site d’installation?

Avez-vous utilisé la rondelle en fibre fournie?

Avez-vous vérifié tous les raccords pour déceler d’éventuelles fuites?

La surface de cuisson est-elle réglée à la pression adéquate?

Avez-vous apposé le double de l’étiquette signalétique fourni sur une

surface adjacente accessible au client?

La surface de cuisson est-elle mise à la terre?

Assurez-vous que le câble d’alimentation électrique ne touche PAS à

la surface de cuisson.

FONCTIONNEMENT:

Est-ce que tous les brûleurs peuvent s’allumer individuellement et simultanément?

Les flammes sont-elles uniformes et de la bonne taille?

Avez-vous expliqué le fonctionnement de base au client?

Compléter et conserver pour référence sûre:

Modèle

N ° De Série

Purchase Date

Date D’achat

Adresse Du Revendeur

Nom De L’installateur

Signature De L’installateur

Société D’installation

Date D’installation

9

Page 24

10

Loading...

Loading...