Page 1

Installation instructions

and User guide

Gas cooktops

CG122 & CG244 models

Instructions d’installation

et Guide d’utilisation

Table de cuisson au gaz

Modèles CG122 et CG244

Instructivo de instalación

y Guía del usuario

Parrilla con quemadores a gas

Modelos CG122 y CG244

US CA

Page 2

WARNING!

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

NEVER use this appliance as a space heater

to heat or warm the room. Doing so may

result in carbon monoxide poisoning and

overheating of the appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch.

Do not use any phone in your building.

Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

Page 3

DATA PLATE

PLAQUE SIGNALÉTIQUE

PLACA DE DATOS

1

US CA

CONVERSION LABEL

ÉTIQUETTE DE CONVERSION

ETIQUETA DE CONVERSIÓN

Page 4

Page 5

Contents

3

US CA

Safety and warnings

Installation instructions

Introduction

Using your cooktop

Care and cleaning

Troubleshooting

Warranty and service

4

10

22

23

26

30

31

Important!

SAVE THESE INSTRUCTIONS

The models shown in this document may not be available in all markets and are

subject to change at any time. For current details about model and specification

availability in your country, please go to our website www.fisherpaykel.com or

contact your local Fisher & Paykel dealer.

Page 6

US CA

4

Safety and warnings

Installation

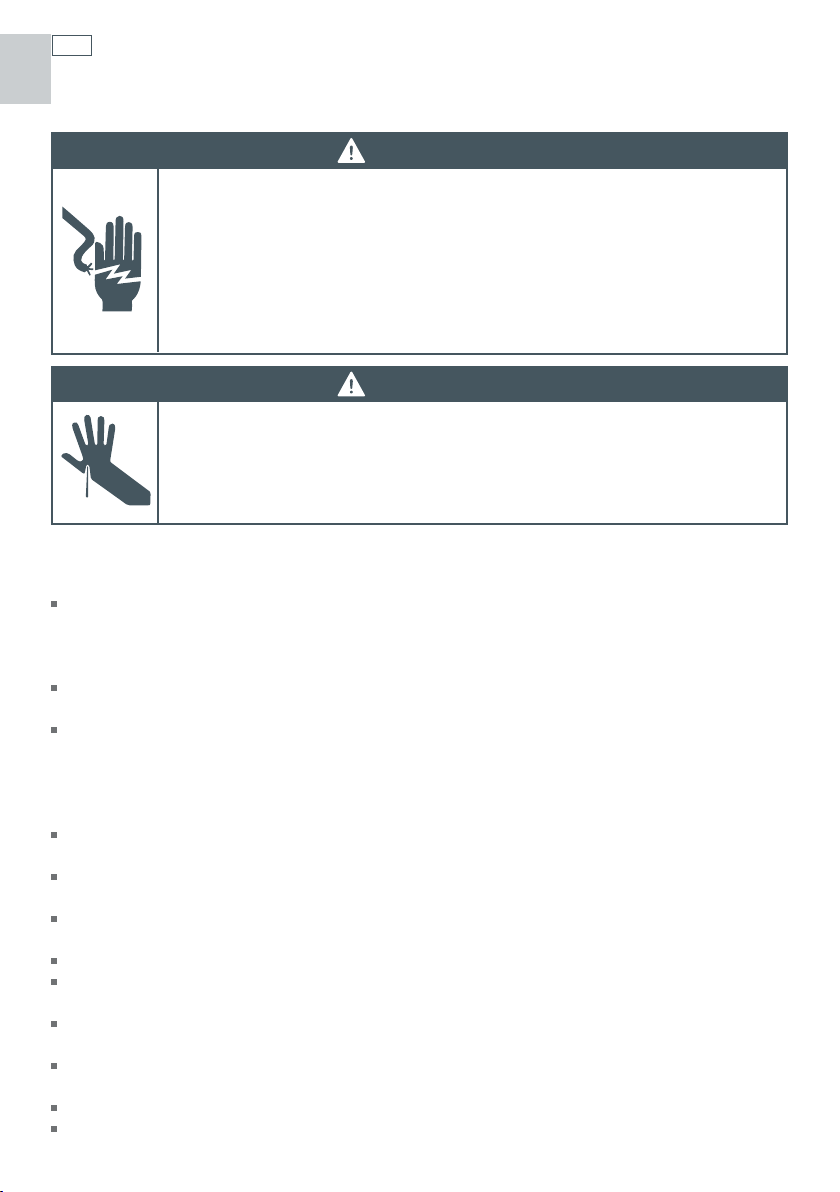

WARNING!

Electrical Shock Hazard

Disconnect product from the mains power supply before servicing. This

appliance is equipped with a three-prong grounding plug for your protection

against shock hazard and should be plugged directly into a properly

grounded power outlet. Do not under any circumstances cut or remove the

grounding prong from this plug.

Failure to follow this advice may result in electrical shock or death.

WARNING!

Cut Hazard

Take care - panel edges are sharp.

Failure to use caution could result in injury or cuts.

Important safety precautions!

This appliance shall be installed in accordance with the installation requirements of the local

gas authority or the appropriate installation code or in the absence of local codes with the latest

National Fuel Gas Code ANSI Z223.1 or CAN/CSA B149.1,2 (Canada). Local building and electrical

codes must be adhered to.

Electrical installation must be in accordance with the National Electrical Code, ANSI/NFPA70 latest edition or CSA C22.1 (Canada) and/or local codes.

Installation in manufactured (mobile) home: installation must conform with the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280 [formerly the Federal Standard

for Mobile Home Construction and Safety, Title 24, HUD (Part 280)] or, when such standard is

not applicable, the Standard for Manufactured Home Installations, ANSI/NCSBCS A225.1, or with

local codes where applicable.

Installation in Recreational Park Trailers: installation must conform with state or other codes or,

in the absence of such codes, with the Standard for Recreational Park Trailers, ANSI A119.5.

Do not remove permanently affixed labels, warnings, or plates from the product. This may void

the warranty.

Flexible appliance connectors shall meet the requirements of ANSI Z21.24 and State Boards. They

shall not exceed 36 inches in length.

In order to avoid hazard, these appliances must be installed according to these instructions.

This appliance must be installed by an authorized person (Warning: this appliance must be

installed by a licensed plumber or gas fitter when within the Commonwealth of Massachusetts).

Please make this information available to the person installing the appliance as it could reduce

your installation costs.

Please leave these instructions with the appliance. Inform the customer to retain for future

reference and for the local inspectors’ use.

Failure to install the appliance correctly could invalidate any warranty or liability claims.

Only genuine replacement parts may be used for servicing the appliance. These are available

from your nearest Fisher & Paykel Service Center.

Page 7

Safety and warnings

Before you install the appliance, please make sure that

the local distribution conditions (nature of gas and pressure) and the adjustment of the

appliance are compatible. For adjustment conditions for this appliance, see ‘Connecting the

cooktop to the gas supply’ and ‘Gas rate summary’.

a suitable isolating switch is incorporated in the fixed wiring in an acceptable position.

the appliance is connected to a power outlet that is electrically grounded in accordance with

local codes or in the absence of local codes, with the National Electric Code ANSI/NFPA 70 or CSA

C22.2 (Canada).

there is a power outlet (120V 60Hz) within reach of the appliance cable (for CG122 models, a

grounded power outlet should be located within 36”/914 mm of the right rear corner of the

cutout; for CG244 models, a grounded power outlet should be located within 36”/914 mm of the

center rear side of the cutout). This must be accessible after installation. The mains power supply

cable should not touch any metal parts.

the countertop is square and level and no structural members interfere with space requirements.

the countertop is made of heat-resistant material.

the gas shut-off valve is accessible after installation.

When you install the appliance

Gas supply connection

This appliance is factory set for use with Natural Gas at 4” of water column pressure. It can also

be used on LP/Propane Gas at 11” of water column pressure after conversion. Manifold pressure

should be checked with a manometer.

Incoming line pressure upstream from the gas pressure regulator must be 1” W.C.P higher than

the manifold pressure in order to check the regulator.

The gas pressure regulator supplied with this cooktop can withstand a maximum input pressure

of ½ p.s.i. (14” W.C.P). If the line pressure is in excess of that amount, a step-down regulator will

be required.

A manual shut-off valve must be installed in an accessible location in the gas line external to the

appliance for the purpose of turning on or shutting off gas to the appliance. (In Massachusetts,

such shut-off devices should be approved by the Board of State Examiners of Plumbers & Gas

Fitters).

Gas connection to the product must use the components supplied, see ‘Installing the gas

pressure regulator’ and ‘Gas connection specifications’.

Ensure the washers (supplied) are correctly positioned, see ‘Installing the gas pressure regulator’

and ‘Gas connection specifications’. Failure to do so will cause a gas leak.

Leak testing

Leak testing of the appliance shall be conducted according to the manufacturer’s instructions.

The appliance, its individual shutoff valve and the gas pressure regulator must be disconnected

from the gas supply piping system during any pressure testing of that system in excess of ½ p.s.i

(3.5 kPa).

The appliance must be isolated from the gas supply piping system by closing its individual

shutoff valve during any pressure testing of the gas supply piping system at test pressures at or

less than ½ p.s.i. (3.5 kPa).

Minimum gas supply pressure for regulator testing 5” W.C. Natural Gas, 12” LP Gas.

After installing the gas supply or converting to a different gas type and making all connections,

check thoroughly for possible leaks.

5

US CA

Page 8

US CA

6

Safety and warnings

Operation and maintenance

Your safety is important to us. Please read this information before using your appliance.

WARNING!

Explosion Hazard

Do not use water on grease fires. A violent steam explosion may result.

Smother fire or flame or use dry chemical or foam type extinguisher.

Do not use the appliance to heat unopened food containers, such as cans.

This will cause the container to burst and could result in injury.

Failure to do so may result in death or electrical shock.

Poisoning Hazard

Clean the appliance with caution. If a wet sponge or cloth is used to wipe

spills on a hot cooking area, be careful to avoid steam burn. Some cleaners

can produce noxious fumes if applied to a hot surface.

Failure to do so may result in poisoning or death.

WARNING!

Page 9

Safety and warnings

WARNING!

Electrical Shock Hazard

Locate the wall power outlet and disconnect the appliance from the power

supply and turn off the gas supply at the shut-off valve before servicing this

appliance.

This appliance is equipped with a three-prong grounding plug for your

protection against shock hazard and should be plugged directly into a

properly grounded power outlet. Do not under any circumstances cut or

remove the grounding prong from this plug.

Failure to do so may result in electrical shock.

Hot Surface Hazard

Do not touch burners or areas near burners. Burners may be hot even

though they are dark in color. Burners and areas near burners may become

hot enough to cause burns. To avoid risk of burns and/or fire, keep loose

clothing, potholders or any other flammable materials well clear of the

burner flame. Do not touch or let clothing, potholders or other flammable

materials contact burners or areas near burners until they have had sufficient

time to cool. Among these areas are the burners and grates.

Always use a dry potholder when removing cookware from the appliance.

Do not use wet or damp potholders as these can cause steam burns. Do not

use towels or similar cloths for removing cookware.

Do not leave children alone or unattended near the appliance. Never allow

children to stand, sit or play near, on or with the appliance.

Be careful when reaching for items stored in cabinets over the appliance.

Flammable materials could be ignited if brought in contact with flame or hot

surfaces and may cause severe burns.

Failure to do so could result in burns and scalds.

WARNING!

7

US CA

Page 10

US CA

8

Safety and warnings

Important safety precautions!

Have your appliance installed and properly grounded by a qualified installer in accordance with

the installation instructions.

Ensure that a manual gas shut-off valve is installed in a location accessible after installation.

Be sure to have the installer show you how to turn off the gas and electrical supply.

Use this appliance only for its intended purpose as described in this user guide.

Wear proper apparel. Loose fitting or hanging garments should never be worn while using the

appliance.

Turn the pot handles to the side or the back of the appliance away from the reach of children.

Handles should not be positioned over adjacent burners.

Always check that you have turned the burners off when you have finished cooking.

Never leave the appliance unattended when in use. Boilover causes smoking and greasy

spillovers that may ignite.

Before using the appliance, ensure that all burners have been assembled correctly.

Do not operate a burner without all burner parts in place.

Always keep flammable wall coverings, curtains or drapes a safe distance from your appliance.

For safety reasons, the burner flame size should be adjusted so it does not extend beyond the

edge of the cookware.

Use cookware of the appropriate size and construction for the type of cooking. This appliance

is equipped with burners of different sizes. Cookware must be matched to the size of the burner.

Select utensils with flat bottoms large enough to cover the burner flames. The use of undersize

utensils will expose a portion of the burner flames to direct contact and may result in ignition of

clothing. Proper relationship of utensil to burner will also improve efficiency.

Do not stand on this gas appliance.

For safety reasons, do not store items of interest to children above or at the back of the appliance

- children climbing on the appliance to reach items could be seriously injured.

When deep-frying in fat, be sure the pan is large enough not to cause an overflow from bubbling

of the fat. Do not deep-fry foods with a high moisture content or food covered with frost.

Do not let cooking grease or other flammable materials accumulate near the appliance.

Do not repair or replace any part of the appliance unless specifically recommended in this user

guide. All other servicing should be referred to a qualified technician.

Glazed cooking utensils - only certain types of glass, glass/ceramic earthenware, or other glazed

utensils are suitable for cooktop service without breaking due to sudden change in temperature.

Page 11

Safety and warnings

Important safety precautions!

If/When the appliance is converted for use with Natural Gas or LP/Propane Gas, make sure that

you save the injectors removed from the appliance for future use. To convert to a different gas

type, contact your service agent/gas fitter.

Do not obstruct the flow of combustion and ventilation air to the appliance.

The Governor of California is required to publish a list of substances known to the state of

California to cause cancer or reproductive harm and requires businesses to warn customers of

potential exposures to such substances.

WARNING!: Gas appliances contain or produce substances which can cause death or serious

illness and which are known to the State of California to cause cancer, birth defects or other

reproductive harm. To reduce the risk from substances in fuel or from fuel combustion, make

sure this appliance is installed, operated, and maintained according to the manufacturer’s

instructions.

9

US CA

Page 12

US CA

10

Installation instructions

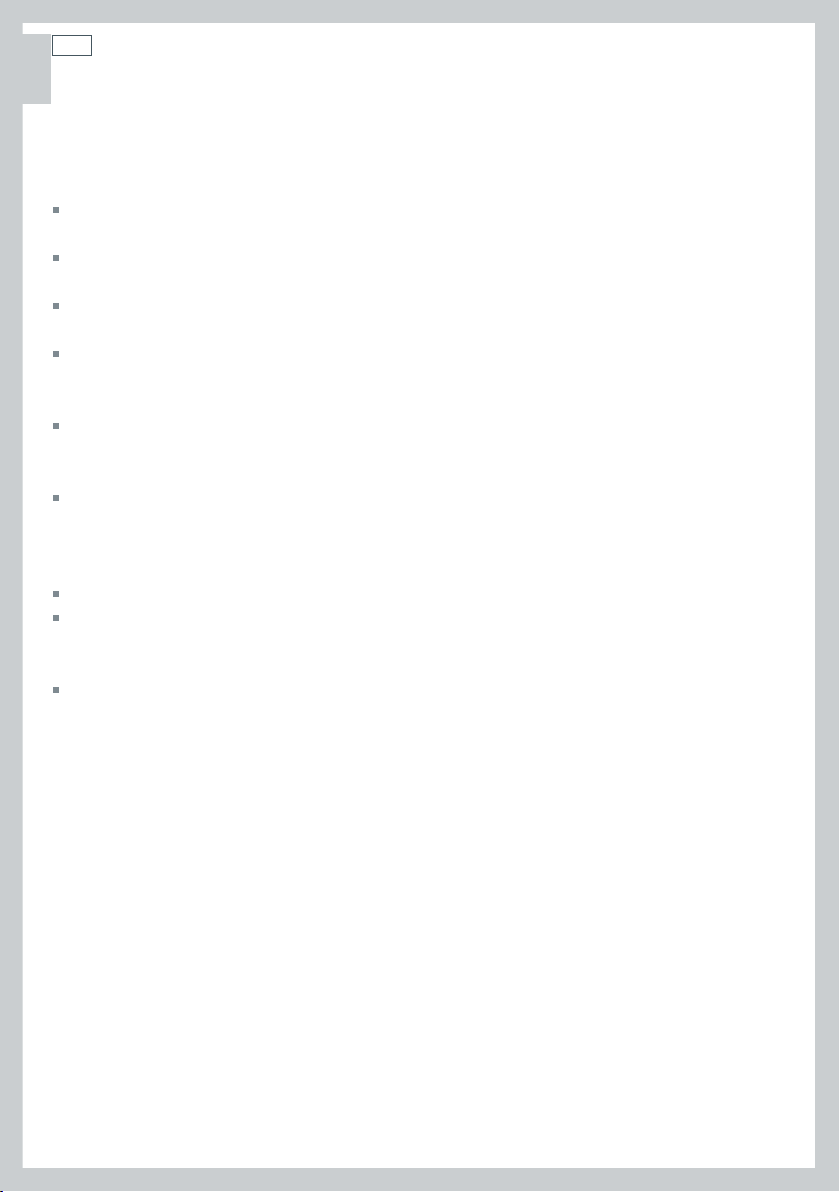

Dimensions and clearances - CG122 models

The installation shall comply with the dimensions and clearances in Fig. 1, bearing in mind the

following requirements:

The cooktop may be installed directly into existing cabinetry. The minimum required depth of

the countertop is 24” (610 mm).

When centring the cooktop in the cutout, make sure that the distance between the edge of the

cutout and the edge of the countertop is 2” 23/64 (60 mm) both in the front and the back.

When the cooktop is installed in the cutout, the distance between the edge of the cooktop and

the edge of the countertop must be 1” 31/32 (50 mm) both in the front and the back.

If the hole for the gas pipe is made in the wall, it must be located at least 11” 51/64 (300 mm)

below the underside of the countertop. If the hole for the gas pipe is made in the cabinet floor,

it must be located at least 3” 1/8 (79.2 mm) away from the wall.

The power supply cable supplied is 48” (1220 mm) long and has a three-prong grounded plug. It

must be plugged into a grounded power outlet, located within 36” (914.4 mm) of the right rear

corner of the cutout.

The cooktop MUST NOT be installed directly adjacent to side walls, tall cabinets, tall appliances

or other such vertical combustible surfaces. There MUST be a minimum side clearance of 4” (102

mm) from the edge of the cutout to such vertical combustible surfaces EITHER ON THE LEFT OR

THE RIGHT of the cutout. One side (left or right) MUST ALWAYS be kept clear.

The maximum overall depth of overhead cabinetry above the cooktop is 13” (330 mm).

The cabinet directly above the cooktop (minimum width 11” 13/32 (290 mm)) must be centred

with the cooktop and be at least 30” (762 mm) above the countertop. Other overhead cabinets

must be at least 18” (457 mm) above the countertop.

If an undercounter cabinet has a drawer, a 4” (102 mm) clearance from the top of the countertop

to the top of the drawer (or other obstruction) is required. The depth of the drawer may need to

be modified to avoid interfering with the gas pressure regulator.

Page 13

Installation instructions

11

US CA

11” 21/64

(288 mm)

20” 1/16

(510 mm)

max 13”

(330 mm)

24”

(610 mm)

(50 mm)

1” 31/32

20” 1/16

(510 mm)

(50 mm)

1” 31/32

(60 mm)

2” 23/64

19” 9/32

(490 mm)

(CUT-OUT)

(60 mm)

2” 23/64

min 4”

(102 mm)

from cut-out

(CUT-OUT)

10” 5/8

(270 mm)

(CUT-OUT)

10” 5/8

(270 mm)

max 13”

(330 mm)

min 4”

(102 mm)

from cut-out

(60 mm)

2” 23/64

19” 9/32

(490 mm)

(CUT-OUT)

(60 mm)

2” 23/64

(50 mm)

1” 31/32

20” 1/16

(510 mm)

(50 mm)

1” 31/32

24”

(610 mm)

18”

(457 mm)

min

11” 13/32

(290 mm)

30”

(762 mm)

min 4”

(102 mm)

from cut-out

Fig. 1 Dimensions and clearances-CG122 models

min 4”

(102 mm)

from cut-out

min

11” 13/32

(290 mm)

30”

(762 mm)

18”

(457 mm)

Page 14

US CA

12

Installation instructions

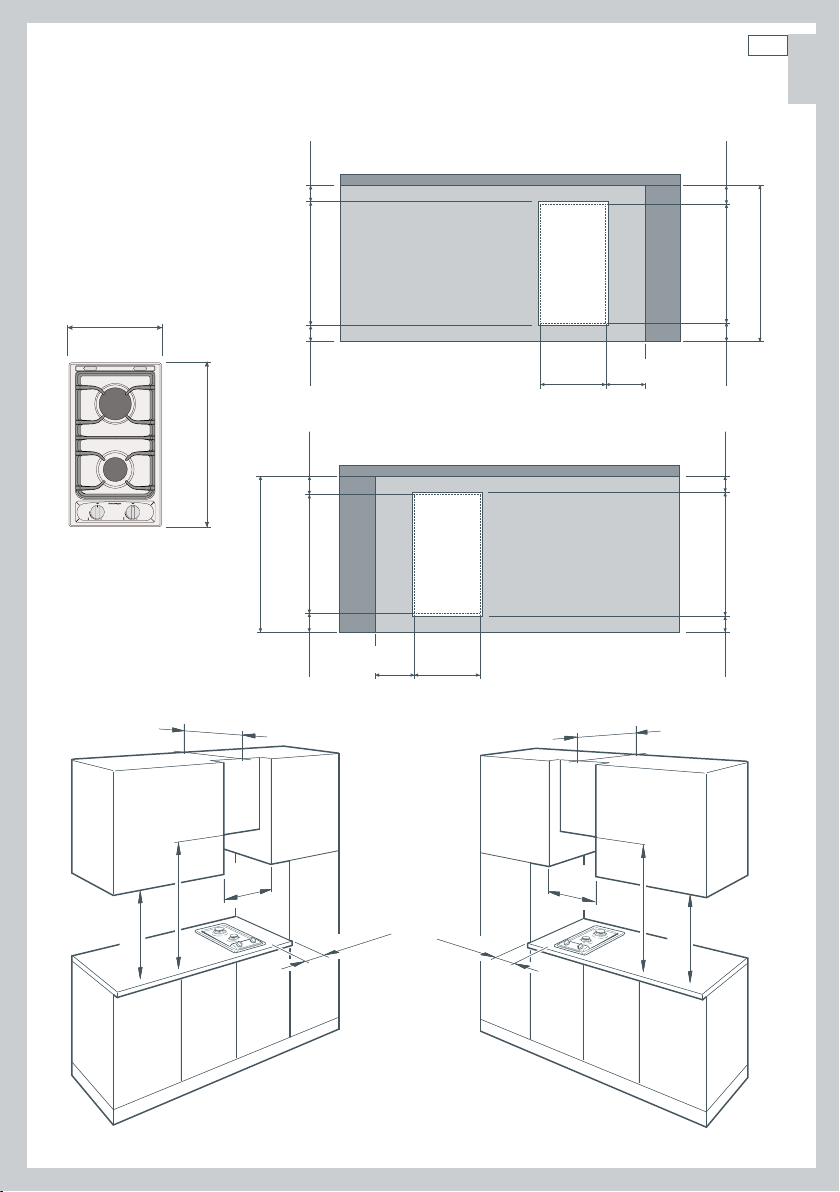

Dimensions and clearances - CG244 models

The installation shall comply with the dimensions and clearances in Fig. 2, bearing in mind the

following requirements:

The cooktop may be installed directly into existing cabinetry. The minimum required depth of

the countertop is 24” (610 mm).

When centring the cooktop in the cutout, make sure that the distance between the edge of the

cutout and the edge of the countertop is 2” 9/16 (65 mm) both in the front and the back.

When the cooktop is installed in the cutout, the distance between the edge of the cooktop and

the edge of the countertop must be 2” 5/32 (55 mm) both in the front and the back.

If the hole for the gas pipe is made in the wall, it must be located at least 11” 51/64 (300 mm)

below the underside of the countertop. If the hole for the gas pipe is made in the cabinet floor,

it must be located at least 3” 5/16 (84.2 mm) away from the wall.

The power supply cable supplied is 48” (1220 mm) long and has a three-prong grounded plug. It

must be plugged into a grounded power outlet, located within 36” (914.4 mm) of the right rear

corner of the cutout.

The cooktop MUST NOT be installed directly adjacent to side walls, tall cabinets, tall appliances

or other such vertical combustible surfaces. There MUST be a minimum side clearance of 4” (102

mm) from the edge of the cutout to such vertical combustible surfaces ON THE RIGHT ONLY.

There MUST be a minimum side clearance of 20” (508 mm) from the edge of the cutout to such

vertical combustible surfaces ON THE LEFT ONLY. One side (left or right) MUST ALWAYS be kept

clear.

The maximum overall depth of overhead cabinetry above the cooktop is 13” (330 mm).

The cabinet directly above the cooktop (minimum width 22” 7/16 (570 mm)) must be centred

with the cooktop and be at least 30” (762 mm) above the countertop. Other overhead cabinets

must be at least 18” (457 mm) above the countertop.

If an undercounter cabinet has a drawer, a 4” (102 mm) clearance from the top of the countertop

to the top of the drawer (or other obstruction) is required. The depth of the drawer may need to

be modified to avoid interfering with the gas pressure regulator.

Page 15

Installation instructions

13

US CA

22” 53/64

(580 mm)

max 13”

(330 mm)

(500 mm)

19” 11/16

2” 5/32

(55 mm)

(500 mm)

19” 11/16

2” 5/32

(55 mm)

2” 5/32

(55 mm)

(500 mm)

19” 11/16

2” 5/32

(55 mm)

min 20"

(508 mm)

from cut-out

(CUT-OUT)

22” 1/64

(560 mm)

(CUT-OUT)

22” 1/64

(560 mm)

min 4"

(102 mm)

from cut-out

max 13”

(330 mm)

2” 9/16

(65 mm)

18” 7/8

(480 mm)

(CUT-OUT)

2” 9/16

(65 mm)

2” 9/16

(65 mm)

18” 7/8

(480 mm)

(CUT-OUT)

2” 9/16

(65 mm)

24”

24”

(610 mm)

(610 mm)

18”

(457 mm)

min

22” 7/16

(570 mm)

30”

(762 mm)

min 4”

(102 mm)

from cut-out

Fig. 2 Dimensions and clearances-CG244 models

min 20”

(508 mm)

f

r

om cut-out

30”

(762 mm)

min

22” 7/16

(570 mm)

18”

(457 mm)

Page 16

14

US CA

Installation instructions

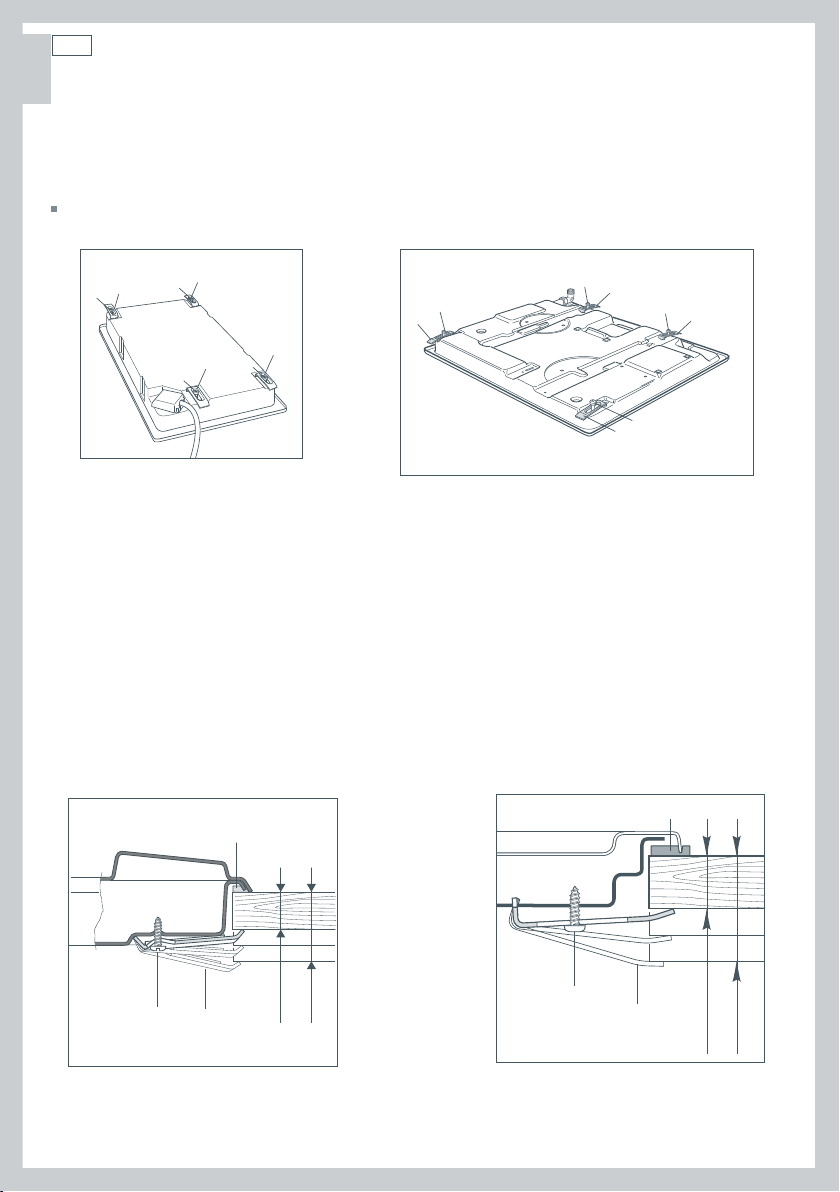

Fastening the installation brackets (Figs. 3-4)

Each cooktop is provided with an installation kit including brackets (“A”) and screws (“B”) for

fastening the cooktop to countertops from ⁄” (20 mm) to 1 ⁄” (40 mm) thick.

Turn the cooktop upside down, place it on a soft surface and fasten the brackets “A” to the

appropriate holes, without tightening the screws “B” for the moment (see Fig. 3 or 4).

A

B

A

B

A

B

Fig. 3 Location of installation brackets-CG122 models

A

B

B

A

Fig. 4 Location of installation brackets-CG244 models

B

A

B

A

B

A

Fastening the cooktop to the counter (Figs. 5-6)

1

Spread the sealing material “C” out along the edge of the cutout, making sure that the junctions

overlap at the corners.

2

Insert the cooktop into the cutout and position it correctly.

3

Adjust the position of the brackets “A” and tighten screws “B” to secure the cooktop

firmly in position. See Fig. 5 or 6.

4

Using a sharp cutter or trimmer knife, trim the excess sealing material around the edge of the

cooktop. Take care not to damage the countertop.

C

C

mm) min.

A

B

Fig. 5 Fastening the cooktop to the counter-CG122 models Fig. 6 Fastening the cooktop to the counter-CG244 models

(20

⁄”

mm) max.

(40

1⁄”

B

A

mm) min.

mm) max.

(20

(40

⁄”

1⁄”

Page 17

Installation instructions

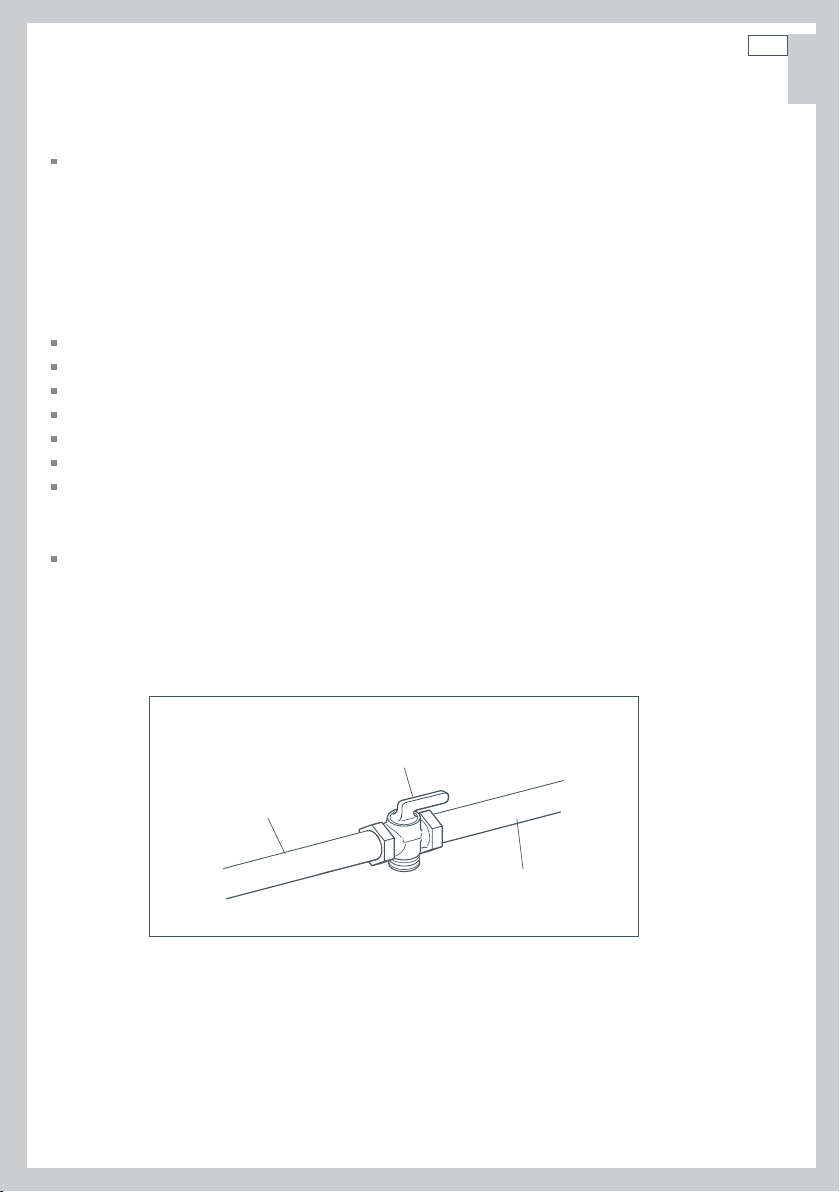

Connecting the cooktop to the gas supply

This appliance is factory-set to operate with Natural Gas, but is suitable for use with LP/Propane

gas after the appropriate conversion. For information on the gas types that may be used, check

the model/serial rating plate on the underside of the basepan. If that information conflicts

with the type of gas available in your area, check this with your local gas supplier. See section

‘Converting to a different gas type’ for conversion instructions.

When connecting the cooktop to the gas supply, ensure that:

all gas connections are made according to national and local codes.

the gas supply (service) line is the same size or greater than the inlet line of the appliance.

the sealing material on all pipe joints is able to resist the action of LP/Propane gas.

you use a new CSA or UL-approved gas supply line.

you securely tighten all gas connections.

if connecting the cooktop to LP/Propane gas, the gas pressure does not exceed 14” W.C.

the gas supply line is equipped with an approved shut-off valve. This valve should be located in

the same room as the cooktop and be within easy reach, so that gas to the appliance can be shut

off quickly in an emergency. Make sure access to this shut-off valve is not blocked.

you use the supplied gas pressure regulator only. All heavy-duty, commercial type cooking

equipment must have a gas pressure regulator on the incoming gas supply line for safe and

efficient operation, since gas pressure may fluctuate with local demand. The gas pressure

regulator supplied with this cooktop must be installed before any gas connections are made.

15

US CA

To cooktop

Shutoff valve

“open” position

Gas supply line

Fig. 7 Manual shut-off valve

Page 18

US CA

16

Installation instructions

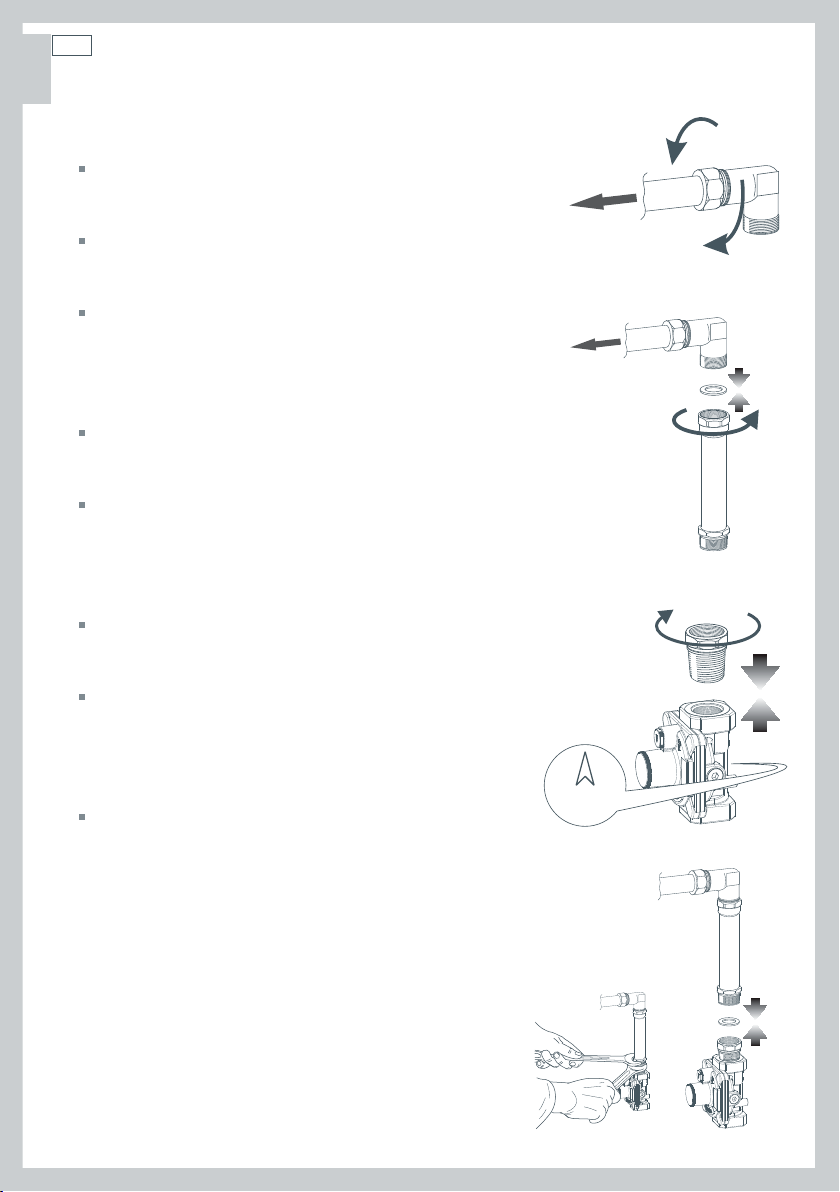

Installing the gas pressure regulator

1

Prepare the elbow connection:

2

Connect the extension pipe to the elbow:

3

Prepare the gas pressure regulator:

4

Connect the gas pressure regulator assembly to the

First use a wrench to loosen the manifold female

pipe fitting and then turn the elbow

connection in the required direction.

Once you have the spatial arrangement required,

use a wrench to re-tighten the elbow-

manifold female pipe fitting connection.

Note: when tightening the connection, make sure

you hold it firmly in position (eg by

using adjustable pliers or an adjustable wrench)

and take care not to damage the thread.

Mount the extension pipe to the elbow connection,

making sure you place the supplied

washer between them.

Note: when tightening the connection, make sure

you hold it firmly in position (eg by

using adjustable pliers or an adjustable wrench)

and take care not to damage the thread.

Mount the 3/8” NPT (conical) male connector to the

gas pressure regulator and tighten by

using a wrench.

Note: take care not to overtighten the connector, as

doing so may crack the gas pressure

regulator.

extension pipe:

Mount the gas pressure regulator assembly to the

extension pipe, making sure you place the supplied

washer between them (see Fig. 11).

Important!

Use two wrenches to tighten the connection.

UNLOCK

To cooktop

LOCK

Fig. 8 Preparing the elbow connection

To cooktop

LOCK

Fig. 9 Connecting the extension

pipe to the elbow

LOCK

Arrow

Fig. 10 Preparing the gas pressure regulator

Fig. 11 Connecting the gas pressure regulator assembly to the extension pipe

Page 19

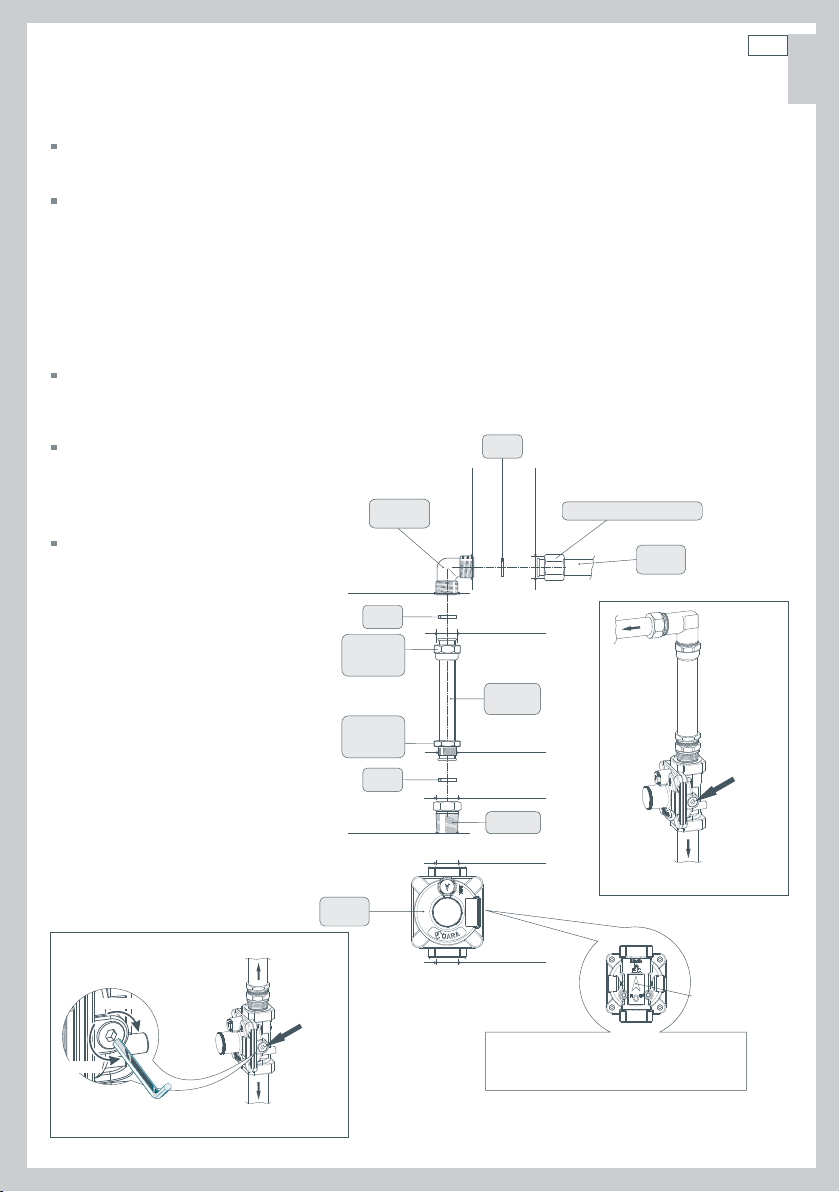

Installation instructions

Gas connection specifications

Refer to the ‘Safety and warnings’ section for additional gas connection specifications.

Flexible hose connections

If local codes permit, CSA design-certified, flexible metal appliance connector is recommended

for connecting this cooktop to the gas supply line. Do not kink or damage the flexible connector

when moving the cooktop. The gas pressure regulator has 3/8” NPT female pipe threads. You will

need to determine the fittings required, depending on the size of your gas supply line, flexible

metal connector and shut-off valve.

Rigid pipe connections

If rigid pipe is used as a gas supply line, a combination of pipe fittings must be used to obtain an

in-line connection to the cooktop. All strains must be removed from the supply and fuel lines so

the cooktop will be level and free of pressure from the piping.

Use joint compounds and

washers resistant to the action

of all gas types on all male

pipe threads.

Do not overtighten the gas

fitting when attaching it to

the gas pressure regulator,

as doing so may crack the

regulator.

To cooktop

1/2” G cylindrical

(ISO 228-1) male

Extension

Extension

pipe female

pipe female

pipe fitting

pipe fitting

Extension

pipe male

pipe fitting

3/8” NPT (conical)

male

Pressure

regulator

Elbow

connection

Washer

Washer

Washer

(ISO 228-1) male

1/2” G cylindrical

1/2” G cylindrical

(ISO 228-1) female

Extension

pipe

1/2” G cylindrical

(ISO 228-1) male

1/2” G cylindrical

(ISO 228-1) female

Connector

3/8” NPT

3/8” NPT

Manifold female pipe fitting

1/2” G cylindrical

(ISO 228-1) female

female

female

Cooktop

manifold

To cooktop

To mains

connection

17

Manifold

test point

pressure

1/8” NPT

US CA

Screw

Unscrew

To mains

connection

Fig. 12 Checking the manifold pressure

Manifold

test point

pressure

1/8” NPT

Arrow

WARNING: check that the gas pressure

regulator is correctly positioned.

The arrow on the back of the gas

regulator must be oriented toward the connector.

Fig. 13 Gas connection

Page 20

18

US CA

Installation instructions

Leak-testing the cooktop

After the final gas connection has been made, turn the manual gas valve on and test the cooktop

and all connections in the gas supply piping for leaks with a soapy water solution. During leaktesting, all the gas valves on the cooktop must be closed.

The presence of bubbles indicates a leak. If a leak is present, tighten or replace connections as

appropriate.

Important!

Do not use any naked flame to check for leaks.

Converting the cooktop to a different gas type

Important!

The conversion procedure must be carried out only by an authorized person.

This appliance is supplied with a set of injectors for the various types of gas.

Use the ‘Gas rate summary’ (following) to select the appropriate injector.

To convert from one gas type to another, you need to reset the gas pressure regulator, replace

the injectors, adjust the minimum burner setting, re-test for leaks and fill in/affix the gas

conversion labels.

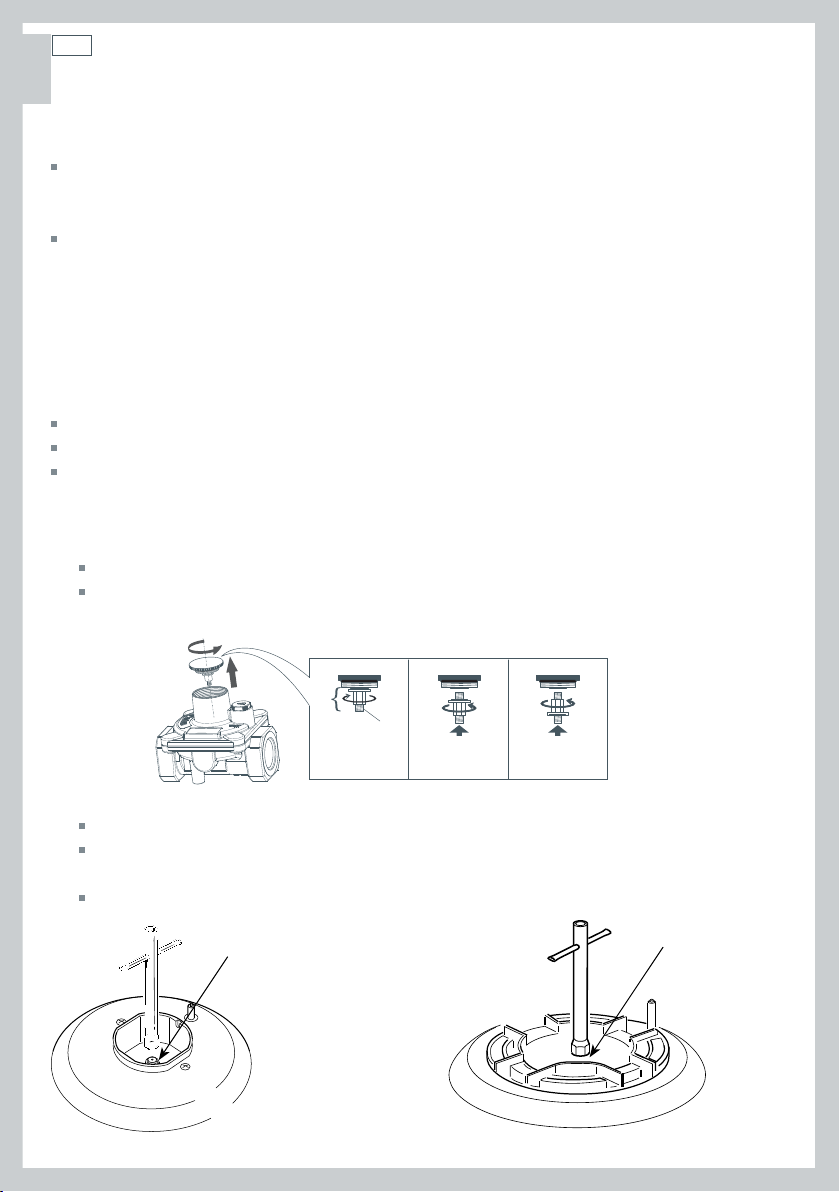

1

Reset the gas pressure regulator:

Unscrew the regulator cover and remove it.

Unscrew component “A”, reverse it and screw it back in according to the gas type you are

converting to (see Fig. 14 below).

1

2

A

NATURAL GAS

REGULATION

2

Replace the injectors:

Remove the grates, burners and the control knobs.

Using a wrench, replace the injectors with those suitable for the kind of gas you are

Fig. 14 Resetting the gas pressure regulator

converting the cooktop to. See the ‘Gas rate summary’ (following).

Note: the burners are designed so that regulation of primary air is not required.

Injector

Fig. 15 Auxiliary, rapid and semi-rapid burners

Fig. 16 Triple-ring wok burner (CG244 models only)

LP/PROPANE

REGULATION

Injector

Page 21

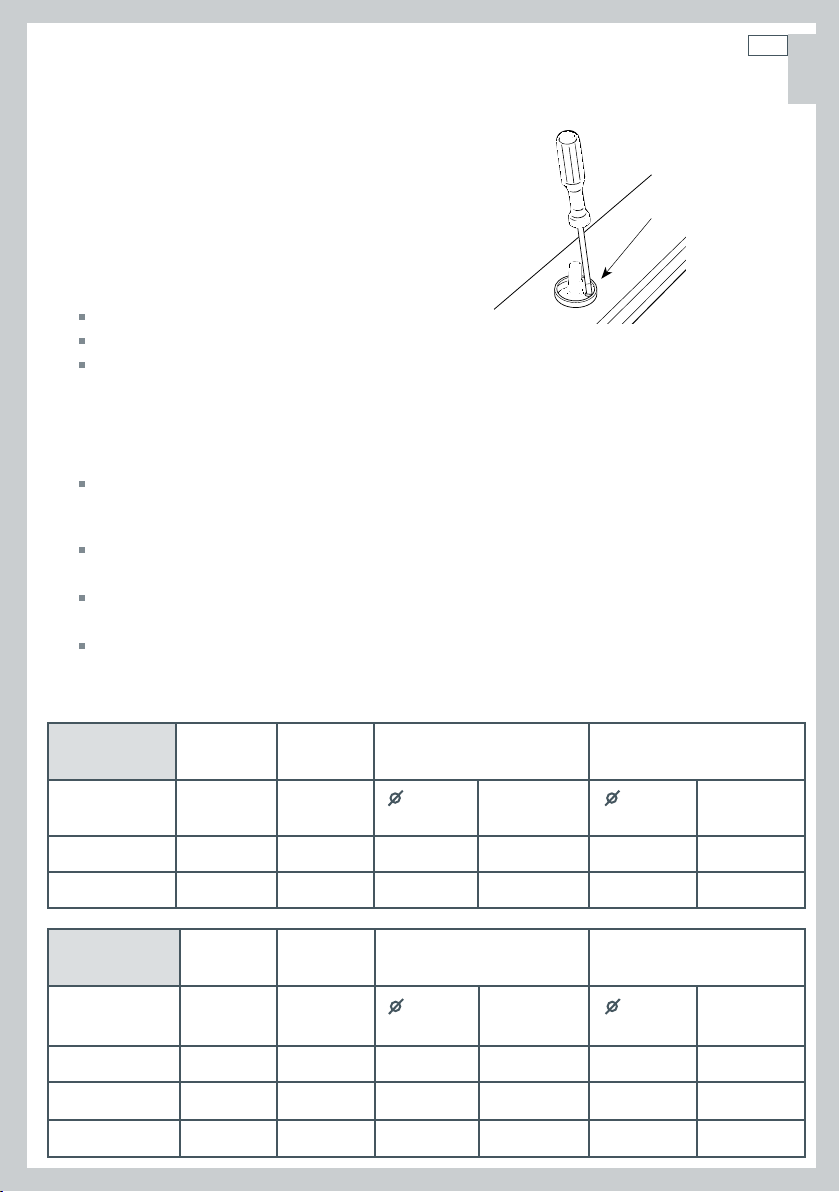

Installation instructions

3

Adjust the minimum burner setting:

When changing from one gas type to another, the

minimum valve output must also be correct,

considering that in this position the flame must be about

⁄” (4 mm) long and must remain lit even when the knob

is turned quickly from the maximum to the minimum

position.

The adjustment is performed with the burner lit, as

follows:

Turn the knob to the minimum position.

Remove the knob.

Turn the adjustment screw to the correct setting

with a screwdriver (Fig.17).

For LP/Propane gas, tighten the adjustment screw completely.

4

Re-test for leaks:

Repeat the steps under ‘Leak-testing the cooktop’.

5

Fill in/affix the gas conversion labels:

After completing the gas conversion, fill in the gas conversion labels (supplied with the

conversion kit).

Affix the adhesive/polyester label near the model/serial rating plate on the underside of

the basepan.

Affix the paper label into the appropriate frame at the front of this manual, under the

duplicate data (model/serial/rating) plate.

Gas rate summary

Fig. 17 Adjusting the minimum burner setting

Adjustment screw

19

US CA

CG122 models

Burners BTU/hr BTU/hr

Semi-rapid 6000 1500 72 34 118 adjustable

Rapid 10000 2000 94 44 155 adjustable

CG244 models

Burners BTU/hr BTU/hr

Auxiliary 3500 1000 55 27 90 adjustable

Semi-rapid 6000 1500 72 34 118 adjustable

Triple-ring wok 11500 5200 100 65 165 adjustable

Nominal

power

Nominal

power

Reduced

power

Reduced

power

LP/PROPANE

11” W.C.P.

injector

[1/100 mm]

LP/PROPANE

11” W.C.P.

injector

[1/100 mm]

By-pass

[1/100 mm]

By-pass

[1/100 mm]

NATURAL GAS

4” W.C.P.

injector

[1/100 mm]

NATURAL GAS

4” W.C.P.

injector

[1/100 mm]

By-pass

[1/100 mm]

By-pass

[1/100 mm]

Page 22

US CA

20

Installation instructions

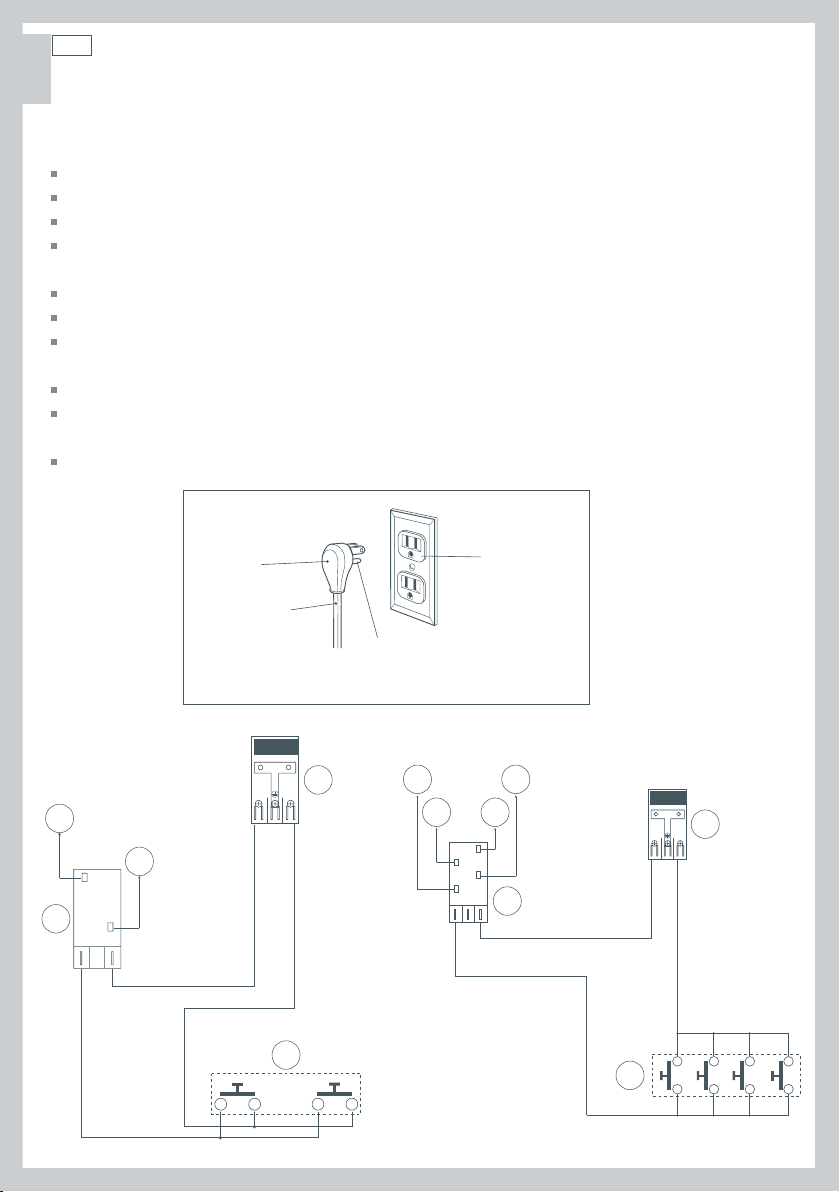

Electrical connection and requirements

Important!

Plug only into a grounded three-prong power outlet.

Do not remove the grounding prong.

Do not use an adapter.

If codes permit the use of a separate grounding wire, it is recommended that a qualified

electrician determine that the ground path is adequate.

Check with a qualified electrician if you are not sure whether the cooktop is properly grounded.

Do NOT ground to a gas pipe.

See ‘Safety and warnings’ for additional electrical requirements.

A 120-volt, 60-Hz, AC-only, 15 A, fused electrical supply is required.

A time-delay fuse or circuit breaker is recommended. It is recommended that a separate circuit

serving only this appliance be provided.

The power outlet must be checked by a qualified electrician to see if it is wired with correct

polarity.

Wiring digrams

CA

CA

A

3-prong

ground plug

supply cable

power

NL

PA

3-prong polarized

ground-type outlet

ground

prong

Fig. 18 Recommended grounding method

M

CA CA

CACA

M

NL

A

PA

Fig. 19 Wiring diagram - CG122 models Fig. 20 Wiring diagram - CG244 models

Page 23

Installation instructions

Final checklist

TO BE COMPLETED BY THE INSTALLER

Have you installed the fastening brackets?

Have you fastened the cooktop to the counter securely?

Have you used the supplied gas pressure regulator and washers?

Have you leak-tested all connections?

Is the regulator set for the correct gas type and pressure?

Are the injector sizes correct for the gas type?

Is the cooktop grounded?

Check that the power supply cable is NOT touching the cooktop.

OPERATION:

21

US CA

Do all burners ignitie individually and in combination?

Do the burners remain lit when turned down?

Are the flames consistent and appropriately sized?

Have you demonstrated the basic operation to the customer?

Installer’s name:

Installer’s signature:

Installation company:

Date of installation:

LEAVE THESE INSTRUCTIONS WITH THE CUSTOMER

Page 24

22

US CA

Introduction

About your new cooktop

Thank you for buying a Fisher & Paykel gas cooktop. Once it is installed and ready to use, you

will want to know everything about it to make sure you get excellent results right from the start.

This guide introduces you to all its special features. We recommend you read the whole guide

before using your new cooktop, for both safety and cooking success.

Before using your new cooktop

Before using your new cooktop, please:

Read this user guide, taking special note of the ‘Safety and warnings’ section.

Plug the cooktop into the power supply and turn it on so the electronic ignition will work.

2

2

1

3

43 7654

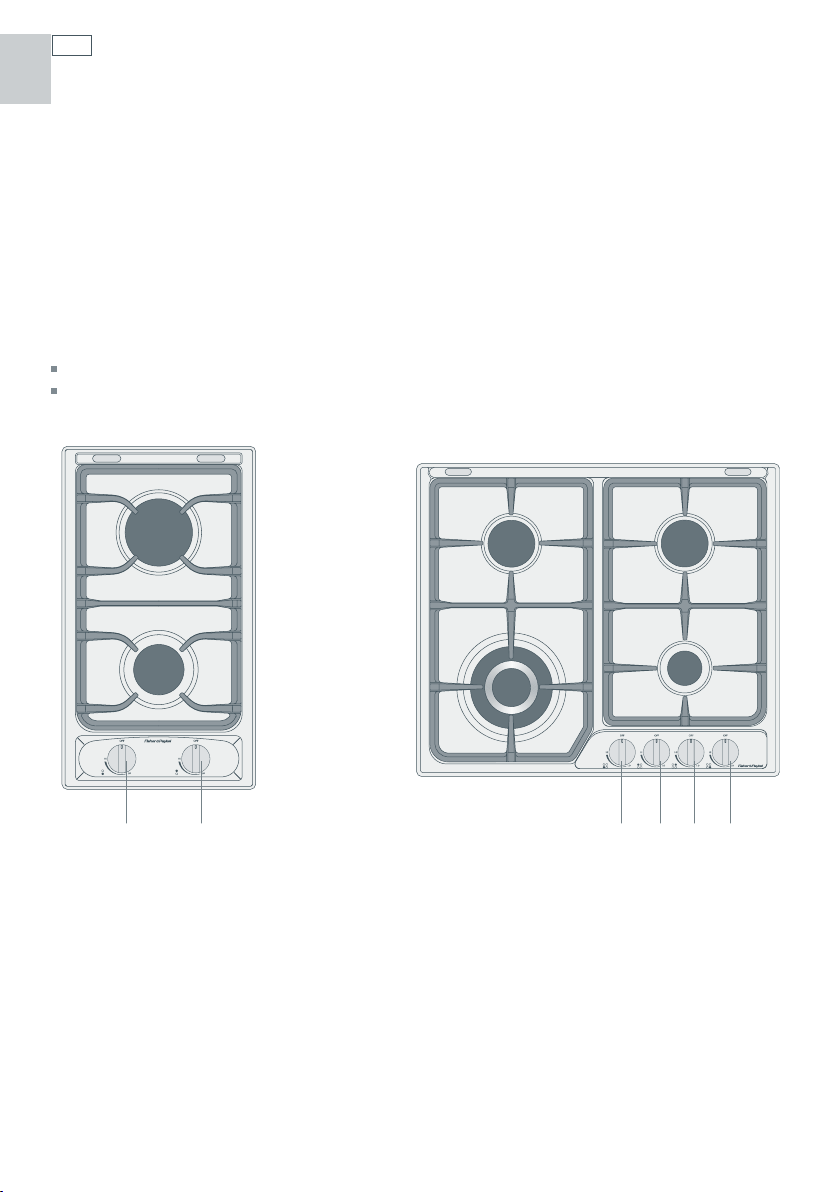

Fig.21 Cooktop layout - CG122 models Fig.22 Cooktop layout - CG244 models

1

Semi-rapid burner

2

Rapid burner

3

Rapid burner control knob

4

Semi-rapid burner control knob

1

Auxiliary burner

2

Semi-rapid burner

3

Triple-ring wok burner

4

Auxiliary burner control knob

5

Right semi-rapid burner control knob

6

Left semi-rapid burner control knob

7

Triple-ring wok burner control knob

2

1

Page 25

Using your cooktop

Gas burners

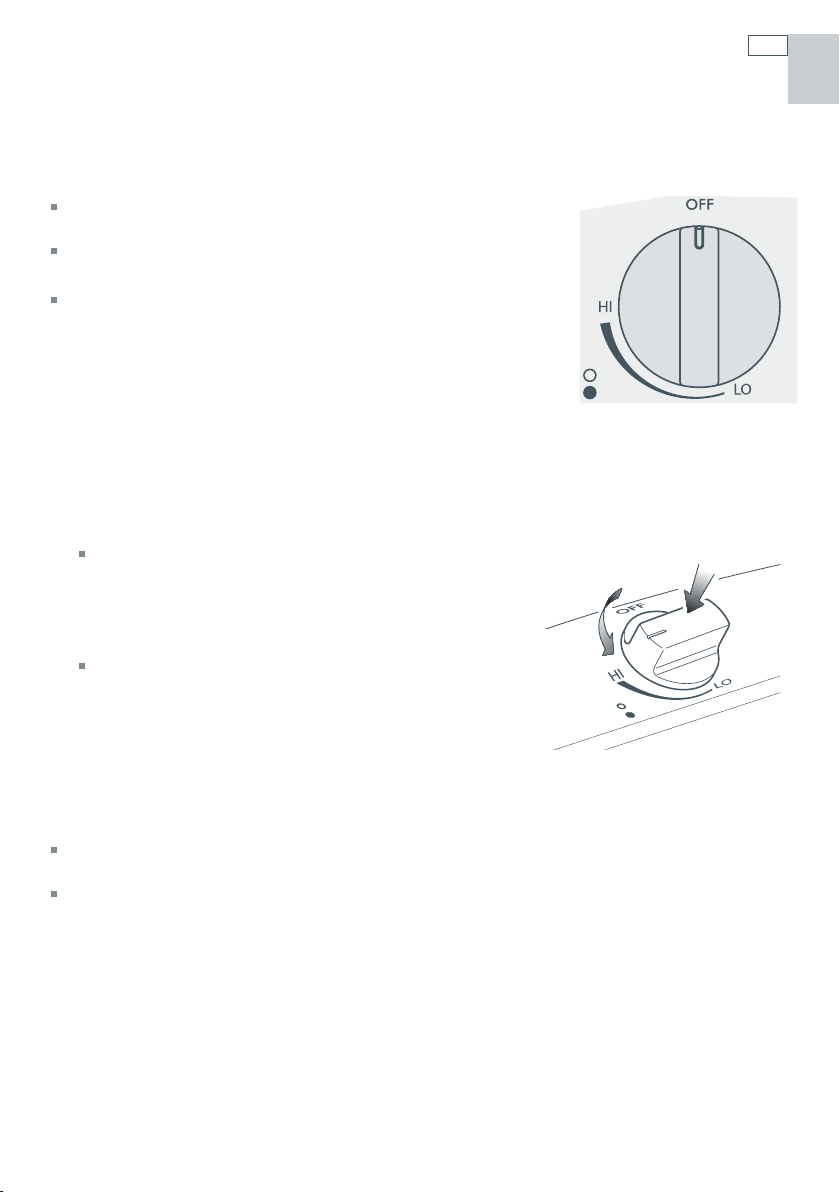

The knob (Fig. 23) controls the flow of gas through the safety valve.

OFF = closed valve

HI = maximum flow

LO = minimum flow

23

US CA

You can choose to cook at any heat between

HI

, but never between

HI

and

OFF

.

LO

and

Using the burners

Fig.23 Burner control knob

1

Choose the control knob for the burner you want to use.

2

Press the knob down gently and turn it counterclockwise

to the

HI

position. The ignitors on all the burners will

spark.

3

Adjust the flame anywhere between the

4

After use, always turn the knobs to the

Hold down the knob for approximately 10 seconds

after the burner has lit. Releasing the

knob too soon will extinguish the flame.

HI a

nd LO

positions. Do not adjust the flame between

Note: if the burner does not light within 15 seconds,

turn the control knob off and wait at

least one minute before trying again.

close the gas shut-off valve on the main gas supply line.

HI

OFF

position and

and

OFF

.

Flame failure safety feature

Your cooktop has a flame failure safety device; each burner is equipped with a flame failure

probe as well as the ignitor (see Fig. 25).

The flame failure probe cuts off the gas supply to the burner if the flame is blown out. If this

happens, turn off the burner and do not try to light it again for at least one minute (to allow the

gas to disperse).

(knobs may vary)

Fig.24 Pushing then

turning the control knob

(knobs may vary)

Page 26

24

US CA

Using your cooktop

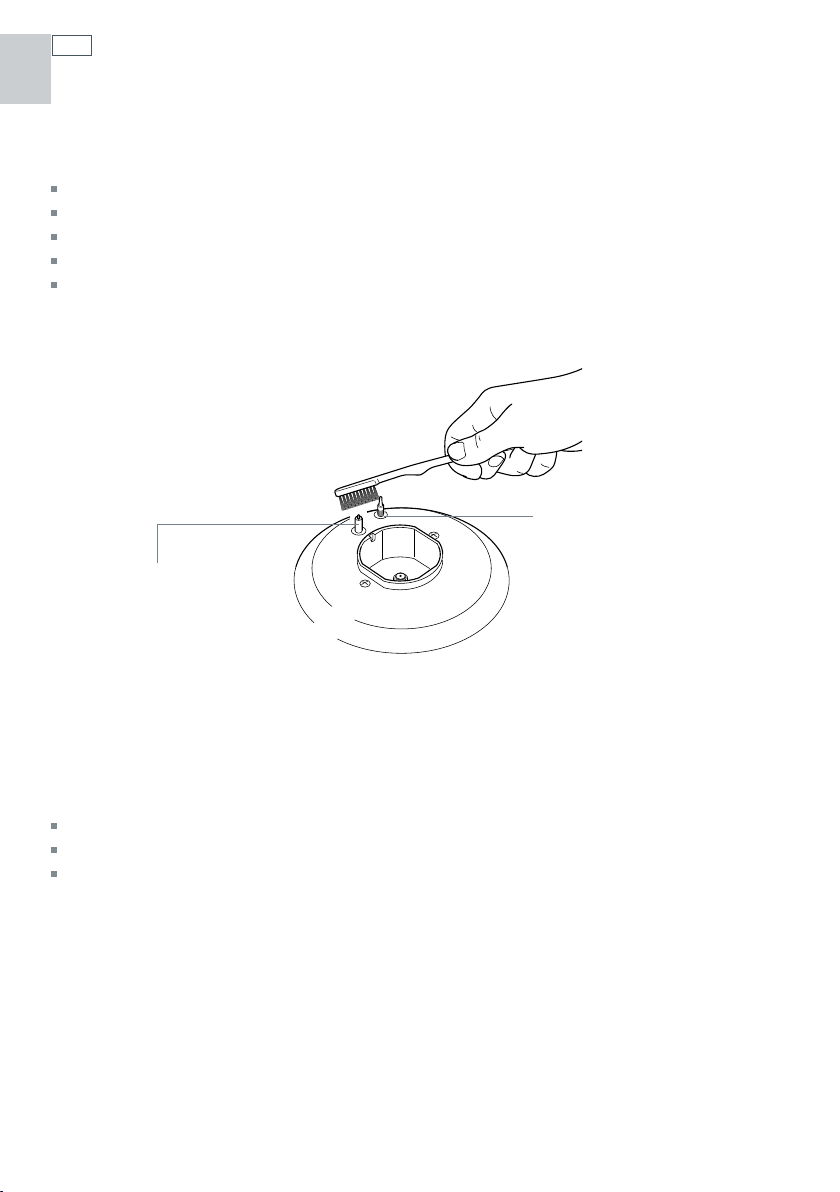

If a burner does not light

Check that:

the cooktop is plugged in and the electricity is switched on.

the gas is turned on.

the gas bottle is not empty (if you are using bottled gas).

you have held down the knob for at least 10 seconds.

the ignitors are sparking. If the ignitors are not sparking, they may be dirty or wet. Clean them

with a toothbrush and rubbing alcohol, as shown in Fig. 25.

Flame failure probe

Ignitor

Fig.25 Cleaning the ignitor and probe

If the flame is irregular

If the flame is yellow or irregular, check that the burner parts, including the burner cap, are:

clean and dry.

positioned correctly as shown in Figs. 28 and 31.

See also ‘Troubleshooting’.

Page 27

Using your cooktop

WRONG

CORRECT

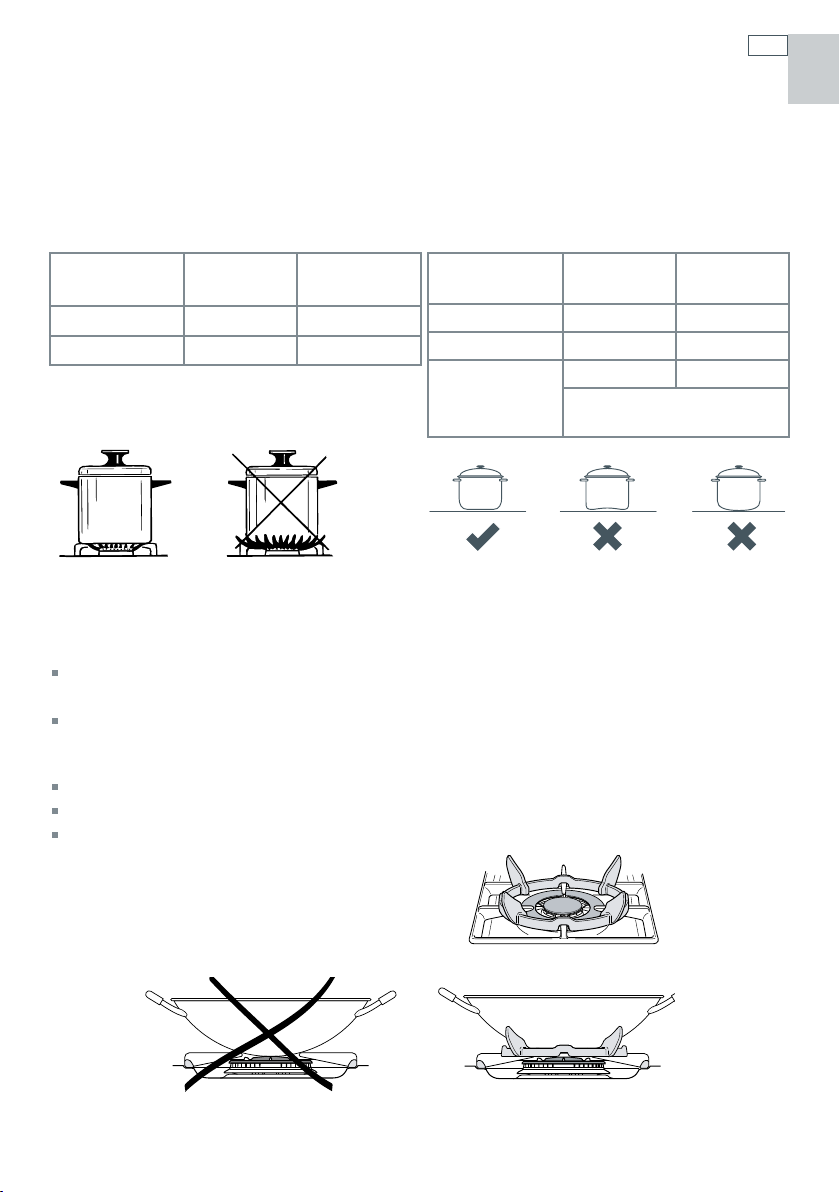

Matching cookware to burner

Use flat-bottomed pans, and make sure they match the size of the burner, as shown in the

following table. A small pan on a large burner is not efficient.

Diameters of pans which may be used on the cooktop

25

US CA

Burners-

CG122 models

Semi-rapid 4 ⁄”(12 cm) 9 ⁄”(24 cm)

Rapid 9 ⁄”(24 cm) 10 ¼ ”(26 cm)

Minimum Maximum

Do not use pans with concave

or convex bases

Fig. 26a Correct and incorrect matching

Burners-

CG244 models

Auxiliary 4 ⁄”(12 cm) 5 ½ ”(14 cm)

Semi-rapid 6 ⁄”(16 cm) 9 ⁄”(24 cm)

Triple-ring wok

Fig. 26b Efficient and inefficient saucepan bottoms

Minimum Maximum

10 ¼ ”(26 cm) 11 ⁄”(28 cm)

Maximum diameter for woks:

14 ⁄” (36 cm)

Wok stand for CG244 models

The wok stand is not supplied with your cooktop but purchased optionally. Contact your local

Fisher & Paykel dealer for details.

The wok stand fits over the triple-ring wok burner grates.

Important!

Using a wok without the stand may cause the wok to tip or the wok burner to operate incorrectly.

Do not use the stand for ordinary, flat-bottomed saucepans.

The wok stand MUST BE PLACED ONLY over the triple-ring wok burner grates.

WRONG

Fig. 27a Incorrect use of wok

CORRECT

Fig. 27b Correct use of wok on triple-ring wok burner

Page 28

US CA

26

Care and cleaning

General advice

Maintenance Period Description

Daily Clean gas cooktop as per following

instructions.

Monthly Remove all burner parts, and clean using a

non-abrasive detergent. Rinse in cold water,

dry thoroughly, and replace.

Clean the ignitor carefully, using a toothbrush

and rubbing alcohol.

Every 3-4 years Contact your local authorized gas Service

Agent to perform a thorough check on all gas

components on the gas cooktop.

Before cleaning, you must ensure that the gas is shut off and the cooktop is disconnected from

the power supply.

Clean the cooktop regularly – do not let stains become burnt on.

Allow the appliance to cool down before cleaning.

Avoid leaving acidic substances (lemon juice, vinegar etc.) on the surfaces.

The control knobs may be removed for cleaning but care should be taken not to damage the

seal.

Do not clean cooktop parts in a self-cleaning oven.

Do not use a steam cleaner to clean any part of your cooktop.

For stubborn stains, see the ‘Cleaning chart’.

Stainless steel parts

Stainless steel parts should be rinsed with water and dried with a microfiber or soft cloth.

Dry thoroughly to avoid leaving water marks. For extra shine on stainless steel, use a stainless

steel polish.

Clean brushed stainless steel in the direction of the grain.

For persistent dirt, use specific non-abrasive products available commercially or a little hot

vinegar.

Note: regular use could cause discoloring around the burners, because of the high flame

temperature.

Page 29

Care and cleaning

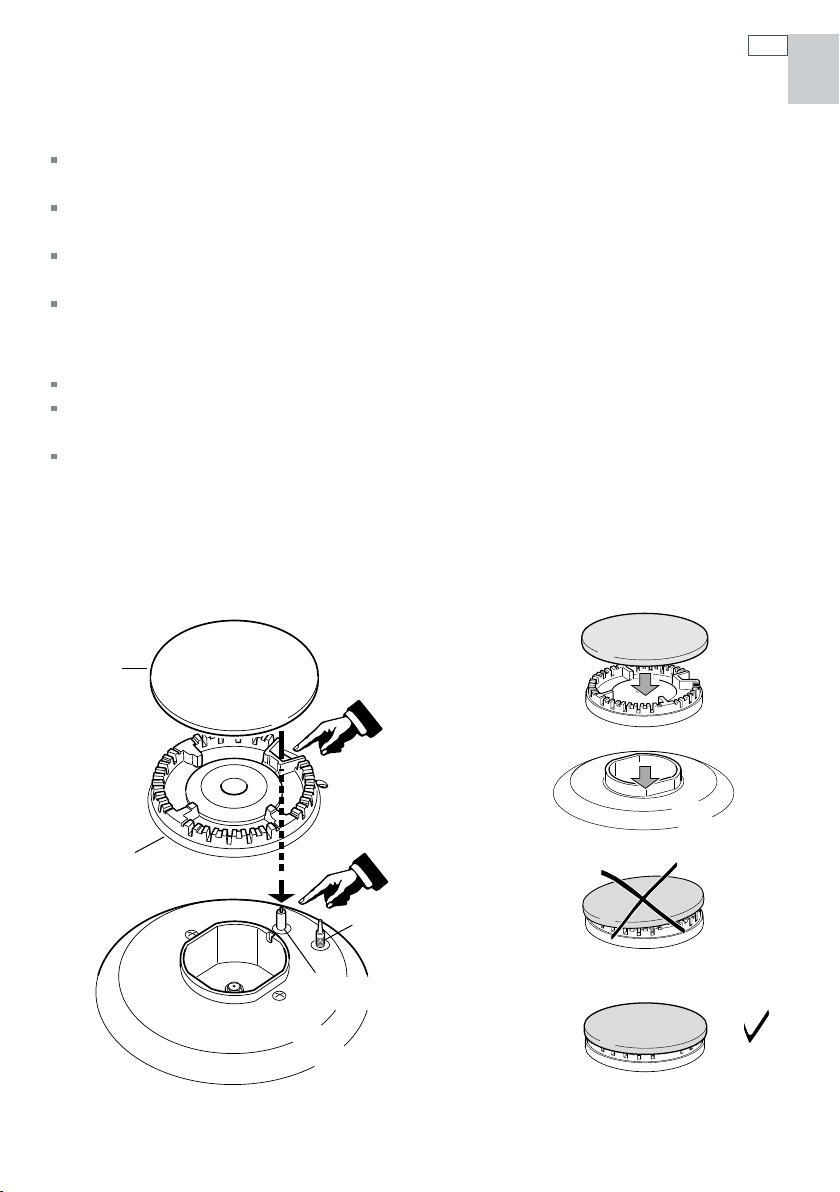

Burners and grates

You can remove and clean these parts with hot soapy water or other appropriate products - see

‘Cleaning chart’.

After cleaning, check that the burners and their flame spreaders are dry before replacing

correctly.

It is very important to check that the burner flame spreader and the cap have been correctly

positioned. Failure to do so can cause serious problems.

Note: to avoid damage to the electronic ignition, do not try to light a burner without all burner

parts correctly in place.

Replacing the burners

Check that the ignitor (Figs. 28 and 29) is always clean to ensure trouble-free sparking.

Check that the probe (Figs. 28 and 29) next to each burner is always clean to ensure correct

operation of the safety valves.

Both the ignitor and probe must be very carefully cleaned using a toothbrush and rubbing

alcohol (Fig.25).

27

US CA

Cap

Flame

spreader

Fig. 28a Correct line-up of auxiliary, rapid

and semi-rapid burner parts

Flame failure probe

Ignitor

Fig. 28b Replacing the auxiliary,

rapid and semi-rapid burner cap

Page 30

US CA

28

Care and cleaning

Replacing the triple-ring wok burner

Fit the burner spreader to the housing as shown by the arrow in Fig. 29. Make sure the burner is

not able to rotate (Fig. 30).

Probe

Ignitor

Fig. 29 Fitting the burner spreader to the housing -

triple-ring wok burner

Cap

Fig. 30 Correct positioning of cap and ring - triplering wok burner

Ring

Fig. 31 Incorrect and correct

positioning of cap and ring

- triple-ring wok burner

Page 31

Care and cleaning

Cleaning chart

Cooktop part Cleaning Important

Grates, burner caps Hot soapy water and nylon scourer.

Soak removeable parts in a solution

of biological clothes-washing

detergent.

Mild abrasive cream cleaners.

Fume-free or heavy-duty oven cleaners

(follow manufacturer’s instructions).

Burner parts

Control knobs

Hot soapy water.

To clear the holes use a stiff nylon

brush or wire eg straight-ended paper

clip.

Mild abrasive cream cleaners.

Hot soapy water and a soft cloth.

Always allow cooktop parts to

cool completely before cleaning

them.

Always apply minimal pressure

with abrasive cleaners.

Clean spills regularly before they

become burnt on.

Reassemble the burner parts

correctly.

29

US CA

Stainless steel base

Ignitors

Probe

Soak stains under a hot soapy cloth,

rinse and dry thoroughly.

Hard water spots can be removed with

household white vinegar.

Non-abrasive stainless steel cleaners.

Regular use of a stainless steel polish

will reduce fingerprints and other

marks.

Heavy soiling can be removed with

fume-free or heavy-duty oven cleaner

(follow manufacturer’s instructions).

Toothbrush and rubbing alcohol. A dirty or wet ignitor will

Toothbrush and rubbing alcohol..

Never use harsh/abrasive

cleaning agents as they will

damage the stainless steel

finish.

Chlorine or chlorine compounds

in some cleaners are corrosive to

stainless steel and may damage

the appearance of your cooktop.

Check the label on the cleaner

before using.

The graphics are silk-screen

printed and will not rub off.

prevent the burner lighting

efficiently.

A dirty probe may

prevent the safety valve from

working effectively.

Page 32

US CA

30

Troubleshooting

Troubleshooting chart

Problem Possible solutions

A burner does not light Check the cooktop is plugged in and the electricity is switched on.

My burner flames are

yellow or hard to start

One of my burners has an

uneven flame

The flame goes out at low

settings

My burners do not turn

down much (when running

on bottled gas or LP/

Propane)

The flame tips are very

yellow

There are objectionable

odors

The flame appears to lift

off the burner

There is an electricity

failure

Check the gas supply valve is turned on and the supply to the

house is working. You should hear the gas when you turn a burner

on.

Check the gas bottle is not empty.

The ignitors may be dirty. Clean them with a toothbrush and

rubbing alcohol.

The burner parts may not be located properly. Check the assembly

and make sure the burner cap is sitting flat.

The burner parts may not be located properly. Check the assembly

and make sure the burner cap is sitting flat.

If you use bottled gas, this may indicate you are getting near the

end of the bottle.

Check the burner parts are clean and dry.

The gas pressure may not be at the correct level. Check with your

service person or installer.

Your cooktop may not be set up for the gas you are using. Check

this with your service person or installer.

Check the burner parts are clean and dry. Check the assembly and

make sure the burner cap is sitting flat.

The gas supply pressure may be low. Check this with your service

person or installer.

The low setting may have been adjusted incorrectly. Check this

with your service person or installer.

If you use bottled gas, this may indicate you are getting near the

end of the bottle.

Your cooktop may not have been adjusted correctly. Check this

with your service person or installer.

Call your service person to service the cooktop.

Call your service person to service the cooktop.

Call your service person to service the cooktop.

If there is an electricity failure, you can still use your cooktop.

Light the burners by holding a match close to the side of the

burner and turning the control knob to the

the flame is burning evenly before adjusting.

HI position. Wait until

Page 33

Warranty and service

Before you call for service or assistance ...

Check the things you can do yourself. Refer to the installation instructions and your user guide

and check that:

1

Your product is correctly installed.

2

You are familiar with its normal operation.

If after checking these points you still need assistance, please refer to the Service & Warranty

book for warranty and after-sales service details or contact us through our website:

www.fisherpaykel.com

Contact details

A Service Summary is attached to the underside of the product.

For replacement parts or if further help is needed concerning this appliance call:

Toll Free 1 888 9 FNP USA (1 888 936 7872)

or write to:

Fisher & Paykel Appliances Inc.

5900 Skylab Road

Huntington Beach, CA 92647

USA

31

US CA

or contact us through our web site,

www.fisherpaykel.com

Product details

Fisher & Paykel Ltd

Model Serial no.

Date of purchase Purchaser

Dealer Suburb

Town Country

Page 34

MISE EN GARDE !

Si l'information que contient ce guide n'est pas

respectée à la lettre, il pourrait en résulter un

incendie ou une explosion et des dommages

matériels, des blessures ou la mort.

N'entreposez et n'utilisez ni essence ni

aucun autre type de liquide ou de vapeurs

inflammables à proximité de cet appareil ou

d'un autre électroménager.

N'utilisez JAMAIS cet électroménager

pour chauffer ou réchauffer une pièce. Un

empoisonnement au monoxyde de carbone et

une surchauffe de l'appareil pourraient en résulter.

QUE FAIRE SI VOUS DÉTECTEZ UNE

ODEUR DE GAZ

N'allumez aucun appareil électroménager.

Ne touchez aucun interrupteur électrique.

N'utilisez pas le téléphone de votre bâtiment.

Contactez immédiatement votre fournisseur de

gaz depuis le téléphone d'un voisin. Suivez les

consignes de votre fournisseur de gaz.

Si vous ne pouvez atteindre votre fournisseur

de gaz, contactez le service des incendies.

L'installation et l'entretien ou les réparations

doivent être effectués par un installateur qualifié,

un centre d'entretien ou le fournisseur de gaz.

Page 35

Table des matières

33

US CA

FR

Sécurité et mises en garde

Instructions d'installation

Présentation

Utilisation de votre table de cuisson

Entretien et nettoyage

Dépannage

Garantie et service

34

40

52

53

56

60

61

Important !

CONSERVEZ CES INSTRUCTIONS

Les modèles illustrés dans ce document peuvent ne pas être offerts dans tous les

marchés et sont sujets à changement sans préavis. Pour obtenir la plus récente

information sur les modèles et les spécifications offerts dans votre pays, veuillez

visiter notre site Web à l'adresse www.fisherpaykel.com ou communiquer avec le

détaillant Fisher & Paykel de votre région.

Page 36

US CA

FR

34

Sécurité et mises en garde

Installation

MISE EN GARDE !

Risque de choc électrique

Débranchez l'appareil de l'alimentation principale avant toute réparation.

Cet électroménager est doté d'une che de mise à la terre à trois broches

pour assurer votre protection contre les chocs électriques et doit être

branché directement dans une prise murale correctement mise à la terre. Ne

coupez en aucun cas la broche de mise à la terre de cette che et ne la retirez

d'aucune façon.

Ne pas suivre cet avis pourrait entraîner un choc électrique ou même la mort.

MISE EN GARDE !

Danger de coupure

Attention - les rebords des panneaux sont aigus.

Toute manipulation imprudente pourrait entraîner des blessures ou

des coupures.

Consignes de sécurité importantes

Cet appareil devra être installé conformément aux exigences des instances des produits de gaz

ou du code d'installation approprié ou, en l'absence de codes locaux, de la norme ANSI Z223.1 ou

CAN/CSA B149.1,2 du National Fuel Gas Code (Canada). Les codes du bâtiment et de l'électricité

doivent être respectés.

Toute installation électrique doit être conforme à la norme ANSI/NFPA70 - dernière édition ou à la

norme CSA C22.1 du Code national de l'électricité du Canada et/ou aux codes locaux.

Installation dans une maison mobile : l'installation doit être effectuée conformément à la norme

Manufactured Home Construction and Safety Standard, Titre 24 CFR, Partie 3280 [anciennement

Federal Standard for Mobile Home Construction and Safety, Titre 24, HUD (Partie 280)] ou,

lorsqu'une telle norme est inapplicable, à la norme ANSI/NCSBCS A225.1 de Manufactured Home

Installations ou aux codes locaux en vigueur.

Installation dans une caravane de parc : l'installation doit être effectuée conformément aux

codes d'état et autres codes ou, en l'absence de tels codes, à la norme ANSI A119.5 de Standard

for Recreational Park Trailers.

Ne retirez pas les étiquettes, mises en garde ou plaques signalétiques collés sur l'appareil. Cela

pourrait invalider la garantie.

Les raccords flexibles de l'appareil doivent être conformes à la norme ANSI Z21.24 et aux

organismes d'état. Leur longueur ne doit pas être supérieure à 36 po (914 mm).

Installez cet appareil conformément aux instructions afin d'éviter tout danger.

Cet électroménager doit être installé par un technicien autorisé (mise en garde : dans les limites

du Commonwealth du Massachusetts, cet électroménager doit être installé par un plombier

autorisé ou un monteur d'installation au gaz).

Remettez cette information à la personne qui installera l'appareil, cela pourrait réduire vos coûts

d'installation.

Veuillez conserver ces instructions avec l'électroménager. Informez le client de les conserver pour

référence future et pour l'usage des inspecteurs locaux.

Ne pas installer correctement cet appareil pourrait invalider toute garantie ou réclamation.

N'utilisez que les pièces de remplacement d'origine pour l'entretien ou les réparations à l'appareil.

Vous pouvez vous les procurer à votre centre de service Fisher & Paykel le plus près de chez vous.

Page 37

Sécurité et mises en garde

Avant d'installer l'appareil, assurez-vous que

les conditions de distribution locales (nature du gaz et pression) et le réglage de l'appareil

sont compatibles. Vous avez bien consulté la section « Connexion de la table de cuisson à

l'alimentation en gaz » et « Sommaire des débits gazeux » pour les conditions d'ajustement.

le câblage fixe comporte un interrupteur de sectionnement approprié et dans une position

acceptable.

l'appareil est branché à une prise électrique mise à la terre en conformité avec les codes locaux

ou, en l'absence de tels codes, avec la norme ANSI/NFPA 70 ou CSA C22.2 du Code national de

l'électricité du Canada.

la prise de courant (120V 60Hz) se trouve à portée du fil de l'appareil (pour les modèles CG122,

une prise de courant doit se trouver à 914 mm (36 po) du coin arrière droit de la découpe ; pour

les modèles CG244, une prise de courant mise à la masse doit se trouver à 914 mm (36 po) du

côté arrière central de la découpe). Cette prise doit demeurer accessible une fois l'installation

complétée. Le câble de l'alimentation principale ne doit toucher aucune pièce métallique.

le plan de travail est de niveau et bien droit et qu'aucune membrure structurale ne nuit aux

exigences d'espacement.

le plan de travail est fait d'un matériau résistant à la chaleur.

la soupape de coupure du gaz est accessible une fois l'installation complétée.

Lors de l'installation de l'électroménager

Connexion à l'alimentation en gaz

Cet appareil est réglé en usine pour un usage avec gaz naturel à une pression de colonne d'eau

de 4 po (101 mm). Il peut également être utilisé avec gaz propane / PL à une pression de colonne

d'eau de 11 po (279 mm) après conversion. La pression du collecteur doit être vérifiée à l'aide

d'un manomètre.

La pression de canalisation entrante en amont du régulateur de pression de gaz doit être de 1 po

(25 mm) WCP supérieure à la pression du collecteur pour pouvoir vérifier le régulateur.

Le régulateur de pression de gaz fourni avec cette table de cuisson supporte une pression

maximale d'entrée de ½ psi. (14 po WCP). Si la pression de canalisation est supérieure à ce

chiffre, vous devrez utiliser un régulateur de diminution.

Vous devez installer une soupape manuelle de coupure du gaz dans un endroit accessible de

la canalisation externe de l'appareil pour pouvoir déclencher ou couper l'alimentation de gaz

à l'appareil. (Au Massachusetts, de tels dispositifs doivent être approuvés par le Board of State

Examiners of Plumbers & Gas Fitters).

La connexion de gaz au produit doit employer les composants fournis, consultez « Installation du

régulateur de pression du gaz » et « Spécifications relatives à la connexion de gaz ».

Assurez-vous que les rondelles (fournies) sont correctement placées, consultez « Installation du

régulateur de pression du gaz » et « Spécifications relatives à la connexion de gaz ». Ne pas vous

conformer à cette étape causera une fuite de gaz.

Vérification des fuites

La vérification des fuites doit être effectuée conformément aux instructions du fabricant.

L'appareil, sa soupape de coupure individuelle et le régulateur de pression du gaz doivent être

débranchés de la tuyauterie de l'alimentation en gaz durant toute vérification de pression du

système supérieure à ½ psi (3,5 kPa).

Fermez la soupape individuelle de coupure de l'appareil pour l'isoler de la tuyauterie

d'alimentation en gaz durant tout essai de pression de la tuyauterie d'alimentation si la pression

d'essai est inférieure à ½ psi (3,5 kPa).

Pression minimale d'alimentation en gaz pour vérification du régulateur gaz naturel WC 5 po

(127 mm), gaz PL 12 po (304 mm).

Une fois l'installation de l'alimentation en gaz ou la conversion à un type de gaz différent

terminée et toutes les connexions effectuées, vérifiez soigneusement pour déceler toute fuite.

35

US CA

FR

Page 38

US CA

FR

36

Sécurité et mises en garde

Utilisation et entretien

Votre sécurité est importante. Veuillez lire cette information avant d'utiliser votre électroménager.

MISE EN GARDE !

Risque d'explosion

N'utilisez jamais d'eau sur les incendies de graisse. Une violente explosion de

vapeur pourrait en résulter. Étouffez le feu ou les flammes ou employez un

extincteur de type chimique ou à mousse.

N'utilisez jamais l'appareil pour faire chauffer un récipient non ouvert, par

exemple une boîte de conserve. Cela ferait éclater le récipient, causant ainsi

de graves blessures.

Ne pas vous conformer à cet avis pourrait entraîner des blessures, voire la mort.

Risque d'empoisonnement

Nettoyez l'appareil avec soin. Si vous utilisez une éponge ou un chiffon pour

essuyer les débordements sur une surface de cuisson brûlante, attention aux

brûlures par la vapeur ! Certains produits nettoyants produisent des vapeurs

nocives si on les applique sur une surface brûlante.

Ne pas vous conformer à cet avis pourrait avoir pour résultat un

empoisonnement, voire la mort.

MISE EN GARDE !

Page 39

Sécurité et mises en garde

MISE EN GARDE !

Risque de choc électrique

Repérez la prise murale et débranchez l'appareil de l'alimentation électrique,

puis coupez l'alimentation en gaz au niveau de la soupape de coupure avant

d'entretenir cet électroménager.

Cet électroménager est doté d'une fiche de mise à la terre à trois broches

pour assurer votre protection contre les chocs électriques et doit être

branché directement dans une prise murale correctement mise à la terre.

Ne coupez en aucun cas la broche de mise à la terre de cette fiche et ne la

retirez d'aucune façon.

Ne pas vous conformer à cet avis pourrait avoir pour résultat un choc électrique.

Risque de surface brûlante

Ne touchez pas les brûleurs ou les zones les avoisinant. Les brûleurs

pourraient être brûlants même s'ils présentent une couleur foncée. Les

brûleurs et les zones qui les entourent peuvent devenir suffisamment

chauds pour provoquer des brûlures. Pour éviter tout risque de brûlure et/

ou d'incendie, conservez tout vêtement ample, poignées ou autre matières

inflammables loin de la flamme du brûleur. Ne touchez pas les brûleurs ou

les zones les avoisinant et ne laissez rien les toucher jusqu'à ce qu'ils soient

suffisamment refroidis. On retrouve dans cette zone les brûleurs et les grilles.

Utilisez toujours une poignée sèche lorsque vous retirez un ustensile de

cuisson de sur le feu. N'utilisez jamais une poignée mouillée ou humide car la

vapeur qu'elle dégage pourrait causer des brûlures. N'utilisez ni serviette ni

chiffon pour retirer un ustensile de cuisson de sur le feu.

Ne laissez pas les enfants seuls ou sans surveillance jouer autour de l'appareil.

Ne laissez jamais les enfants jouer ou s'asseoir sur l'appareil.

Soyez prudent lorsque vous retirez des articles des armoires surplombant

l'électroménager. Les matières inflammables pourraient s'enflammer si elles

touchent la flamme ou les surfaces brûlantes et causer de graves brûlures.

Ne pas vous conformer à cet avis pourrait causer des brûlures ou échaudures.

MISE EN GARDE !

37

US CA

FR

Page 40

US CA

FR

38

Sécurité et mises en garde

Consignes de sécurité importantes

L'installation et la mise à la terre de votre appareil doivent être effectuées par un installateur

qualifié conformément aux instructions d'installation.

Assurez-vous que la soupape de coupure du gaz est installée dans un endroit accessible une fois

l'installation terminée.

Demandez à l'installateur de vous montrer comment couper l'alimentation en gaz et en

électricité.

Utilisez cet appareil uniquement aux fins pour lesquelles il a été conçu, comme le stipule le

présent guide de l'utilisateur.

Portez des vêtements appropriés. Ne portez pas de vêtements amples ou pendants lorsque vous

utilisez cet électroménager.

Tournez les poignées des casseroles vers l'arrière de l'appareil, loin de portée des enfants. Les

poignées ne doivent pas surplomber les brûleurs adjacents.

Vérifiez toujours que vous avez bien éteint les brûleurs une fois la cuisson terminée.

Ne laissez jamais l'appareil sans surveillance lorsqu'il est utilisé. Un bouillonnement important

causera des débordements graisseux qui pourraient s'enflammer.

Avant d'utiliser l'appareil, vérifiez que tous les brûleurs sont correctement assemblés.

N'utilisez jamais un brûleur sans que toutes ses pièces ne soient en place.

Veillez à ce que les rideaux, recouvrements ou draperies soient toujours à distance sécuritaire de

votre appareil.

Pour des raisons de sécurité, la taille de la flamme du brûleur doit être ajustée de façon à ne pas

se déployer au-delà du rebord d'un ustensile de cuisson.

Employez une batterie de cuisine de dimensions et de modèle appropriées au type de cuisson

désiré. Cet appareil est doté de brûleurs de différentes tailles. Les ustensiles de cuisson doivent

correspondre à la taille du brûleur choisi. Sélectionnez ceux dont le fond est assez grand pour

couvrir les flammes du brûleur. L'emploi d'ustensiles sous-dimensionnés exposera une portion des

flammes du brûleur à un contact direct et pourrait faire enflammer les vêtements. Une relation

ustensile à brûleur adéquate améliorera l'efficacité.

Ne vous tenez jamais debout sur cet électroménager au gaz.

Pour des raisons de sécurité, n'entreposez jamais des articles qui pourraient intéresser les enfants

au-dessus ou à l'arrière de l'appareil - un enfant qui grimperait sur l'appareil pour atteindre de

tels articles pourrait être gravement blessé.

Pour faire frire dans la graisse, assurez-vous que la poêle est assez grande pour que la graisse

n'en déborde pas en bouillonnant. Ne faites jamais frire d'aliments dont le contenu en humidité

est élevé ou recouverts de givre.

Ne laissez pas la graisse de cuisson ni aucune autre matière inflammable s'accumuler à proximité

de l'appareil.

Ne réparez et ne remplacez aucune des pièces de l'électroménager à moins que ce guide

d'utilisation ne le recommande spécifiquement. Tout autre entretien doit être confié à un

technicien qualifié.

Ustensiles de cuisson vitrifiés - seuls certains types de verre, de poterie de verre/céramique ou

autres ustensiles vitrifiés peuvent être utilisés sur cette table de cuisson sans que les changements

de température soudains ne les fassent éclater.

Page 41

Sécurité et mises en garde

Consignes de sécurité importantes

Si l'appareil a été converti pour usage avec gaz naturel ou propane/PL, veillez à conserver les

injecteurs qui en ont été retirés pour usage futur. Pour convertir à un type de gaz différent,

contactez votre agent de service/monteur d'installation au gaz.

N'obstruez pas le débit d'air de combustion et de ventilation à l'appareil.

Le Gouverneur de la Californie est tenu de publier une liste de substances dont l’État sait qu’ils

accroissent les risques de cancer ou d’infertilité; les entreprises sont tenues d’aviser leur clientèle

des risques associés à de telles substances.

AVERTISSEMENT!: Les appareils au gaz contiennent ou produisent des substances qui peuvent

entraîner la mort ou des maladies graves, et dont l’État de la Californie reconnaît qu’ils

augmentent les risques de cancer, d’anomalies congénitales ou autres risques au système

reproductif. Pour réduire les risques causés par les substances contenues dans le carburant ou par

la combustion du carburant, s’assurer d’installer, d’entretenir et d’utiliser cet appareil selon les

consignes du fabricant.

39

US CA

FR

Page 42

US CA

FR

40

Instructions d'installation

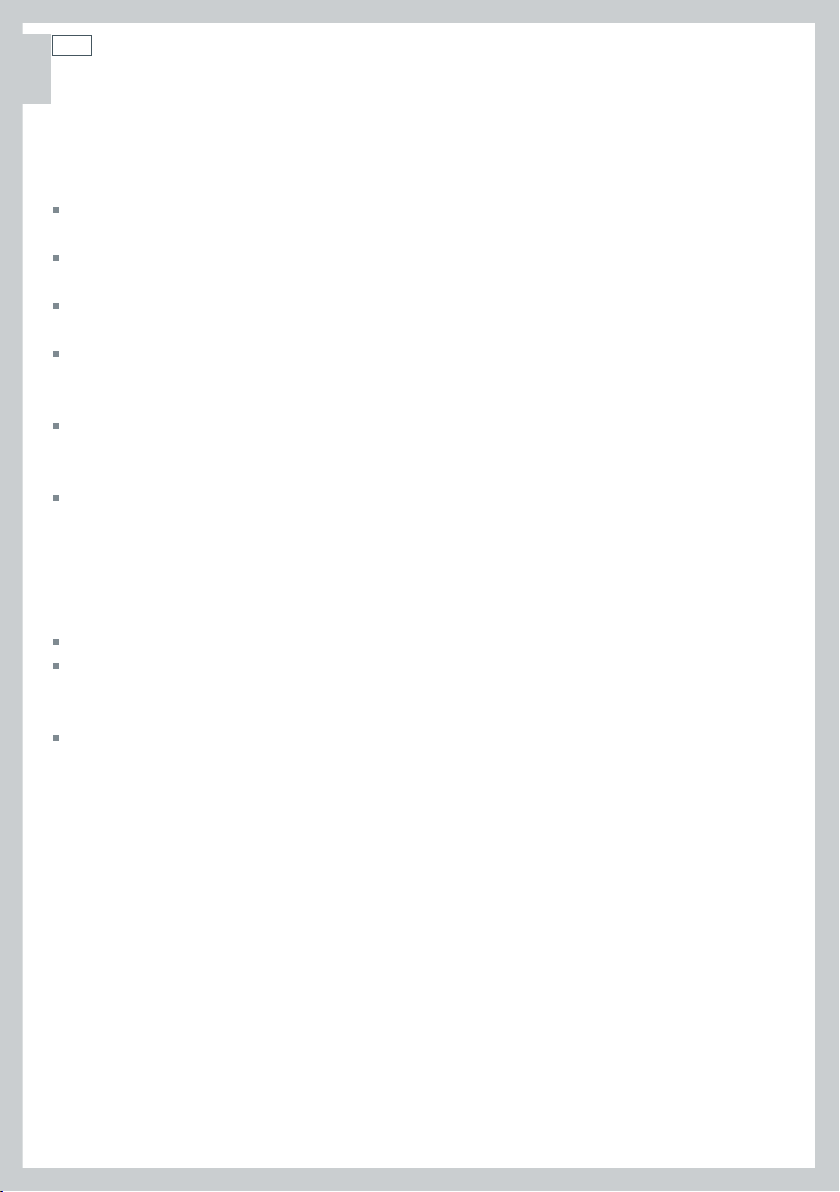

Dimensions et dégagement - modèles CG122

L'installation doit être conforme aux dimensions et dégagements mentionnés à la figure 1, en

gardant à l'esprit les exigences suivantes :

La table de cuisson peut être posée directement dans une armoire existante. Le plan de travail

doit présenter une profondeur minimale de 24 po (610 mm).

Lorsque vous centrez la table de cuisson dans la découpe, veillez à ce que la distance entre le

rebord de la découpe et le plan de travail soit de 2 po 23/64 (60 mm) à l'avant et à l'arrière.

Une fois la table de cuisson installée dans la découpe, la distance entre le rebord de la découpe

et le plan de travail doit être de 1 po 31/32 (50 mm) à l'avant et à l'arrière.

Si le trou du tuyau de gaz est percé dans le mur, il doit se trouver à au moins 11 po 51/64 (300

mm) sous la partie inférieure du plan de travail. Si le trou du tuyau de gaz est percé dans le

plancher de l'armoire de rangement, il doit se trouver à au moins 3 po 1/8 (79,2 mm) du mur.

Le câble d'alimentation électrique fourni mesure 48 po (1 220 mm) et est doté d'une fiche à trois

broches mise à la terre. Il doit être branché dans une prise murale mise à la terre, à une distance

inférieure à 36 po (914,4 mm) du côté arrière droit de la découpe.

La table de cuisson NE DOIT PAS jouxter les murs latéraux, les armoires élevées, les appareils

électroménagers hauts ou toute autre surface combustible verticale. Le dégagement latéral

minimal DOIT être de 4 po (102 mm) depuis le rebord de la découpe jusqu'à de telles surfaces

verticales combustibles DU CÔTÉ GAUCHE OU DU CÔTÉ DROIT de la découpe. L'un des côtés

(que ce soit le gauche ou le droit) DOIT TOUJOURS être libre.

La profondeur globale maximale des armoires de rangement suspendues au-dessus de la table

de cuisson est de 13 po (330 mm).

Le cabinet suspendu directement au-dessus de la table de cuisson (largeur minimale

11 13/32 po (290 mm) doit être centré avec la plaque et se trouver à au moins 30 po (762 mm)

au-dessus du plan de travail. Les autres cabinets suspendus doivent se trouver à au moins 18 po

(457 mm) au-dessus du plan de travail.

Si l'une des armoires situés sous le comptoir possède un tiroir, vous devez prévoir un

dégagement de 4 po (102 mm) du dessus de la table de travail jusqu'au haut du tiroir (ou de

toute autre obstruction). Il faudra peut-être modifier la profondeur du tiroir pour éviter toute

interférence avec le régulateur de pression du gaz.

Page 43

Instructions d'installation

41

US CA

FR

11 po 21/64

(288 mm)

(510 mm)

20 po 1/16

max 13 po

(330 mm)

24 po

(610 mm)

(50 mm)

1 po 31/32

(510 mm)

20 po 1/16

(50 mm)

1 po 31/32

(60 mm)

2 po 23/64

(490 mm)

19 po 9/32

(DÉCOUPE)

(60 mm)

2 po 23/64

min 4 po

(102 mm)

depuis la découpe

(DÉCOUPE)

10 po 5/8

(270 mm)

(DÉCOUPE)

10 po 5/8

(270 mm)

min 4 po

(102 mm)

depuis la découpe

max 13 po

(330 mm)

(60 mm)

2 po 23/64

(490 mm)

19 po 9/32

(DÉCOUPE)

(60 mm)

2 po 23/64

(50 mm)

1 po 31/32

(510 mm)

20 po 1/16

(50 mm)

1 po 31/32

24 po

(610 mm)

18 po

(457 mm)

min

11 po 13/32

(290 mm)

30 po

(762 mm)

min 4 po

(102 mm)

depuis la découpe

(102 mm)

depuis la découpe

Fig. 1 Dimensions et dégagement - modèles CG122

min 4 po

min

11 po 13/32

(290 mm)

30 po

(762 mm)

18 po

(457 mm)

Page 44

US CA

FR

42

Instructions d'installation

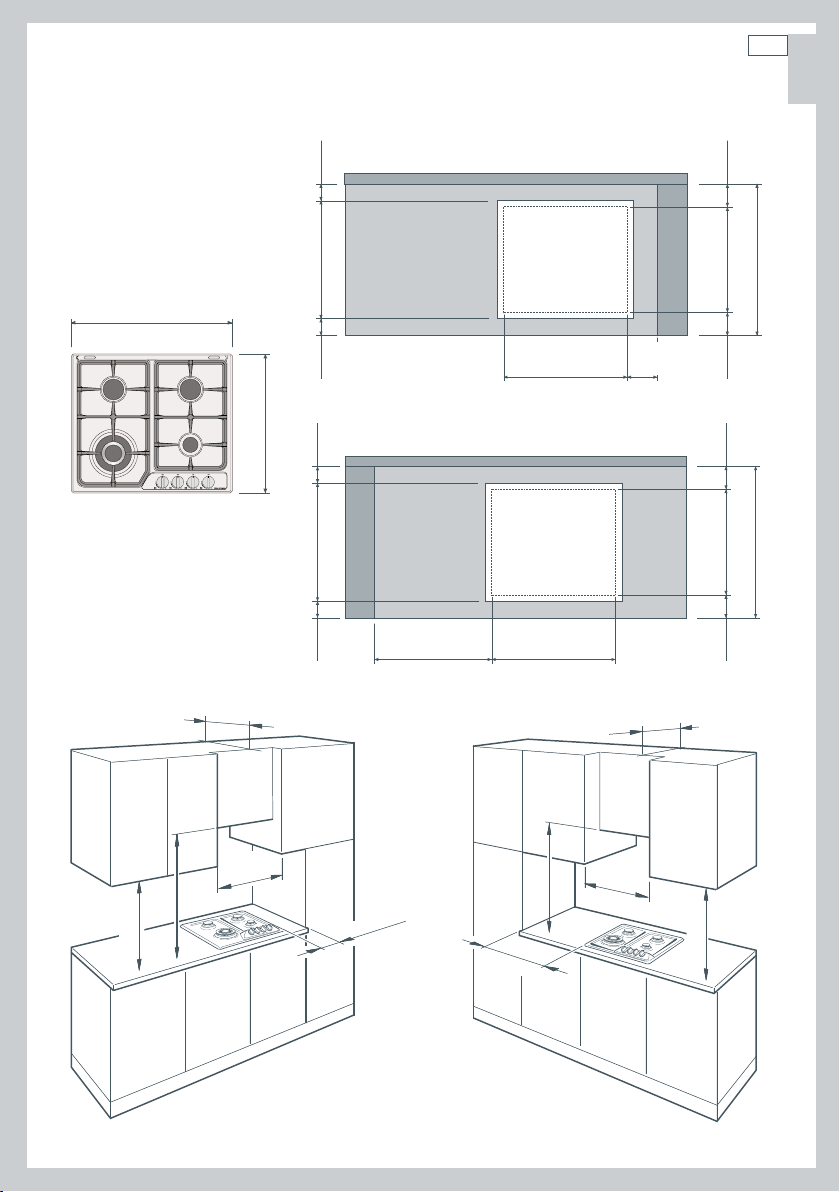

Dimensions et dégagement - modèles CG244

L'installation doit être conforme aux dimensions et dégagements mentionnés à la figure 2, en

gardant à l'esprit les exigences suivantes :

La table de cuisson peut être posée directement dans une armoire existante. Le plan de travail

doit présenter une profondeur minimale de 24 po (610 mm).

Lorsque vous centrez la table de cuisson dans la découpe, veillez à ce que la distance entre le

rebord de la découpe et le plan de travail soit de 2 po 9/16 (65 mm) à l'avant et à l'arrière.

Une fois la table de cuisson installée dans la découpe, la distance entre le rebord de la découpe

et le plan de travail doit être de 2 po 5/32 (55 mm) à l'avant et à l'arrière.

Si le trou du tuyau de gaz est percé dans le mur, il doit se trouver à au moins 11 po 51/64 (300

mm) sous la partie inférieure du plan de travail. Si le trou du tuyau de gaz est percé dans le

plancher de l'armoire de rangement, il doit se trouver à au moins 3 po 5/16 (84,2 mm) du mur.

Le câble d'alimentation électrique fourni mesure 48 po (1 220 mm) et est doté d'une fiche à trois

broches mise à la terre. Il doit être branché dans une prise murale mise à la terre, à une distance

inférieure à 36 po (914,4 mm) du côté arrière droit de la découpe.

La table de cuisson NE DOIT PAS jouxter les murs latéraux, les armoires élevées, les appareils

électroménagers hauts ou toute autre surface combustible verticale. Le dégagement latéral

minimal DOIT être de 4 po (102 mm) depuis le rebord de la découpe jusqu'à de telles surfaces

verticales combustibles DU CÔTÉ DROIT SEULEMENT. Le dégagement latéral minimal DOIT

être de 20 po (508 mm) depuis le rebord de la découpe jusqu'à de telles surfaces verticales

combustibles DU CÔTÉ GAUCHE SEULEMENT. L'un des côtés (que ce soit le gauche ou le droit)

DOIT TOUJOURS être libre.

La profondeur globale maximale des armoires de rangement suspendues au-dessus de la table

de cuisson est de 13 po (330 mm).

L'armoire suspendue directement au-dessus de la table de cuisson (largeur minimale 22 po 7/16

(570 mm)) doit être centrée avec la table et se trouver à au moins 30 po (762 mm) au-dessus du

plan de travail. Les autres cabinets suspendus doivent se trouver à au moins 18 po (457 mm)

au-dessus du plan de travail.

Si l'une des armoires situés sous le comptoir possède un tiroir, vous devez prévoir un

dégagement de 4 po (102 mm) du dessus de la table de travail jusqu'au haut du tiroir (ou de

toute autre obstruction). Il faudra peut-être modifier la profondeur du tiroir pour éviter toute

interférence avec le régulateur de pression du gaz.

Page 45

Instructions d'installation

43

US CA

FR

22 po 53/64

(580 mm)

max 13 po

(330 mm)

(500 mm)

19 po 11/16

(55 mm)

2 po 5/32

(500 mm)

19 po 11/16

(55 mm)

2 po 5/32

(55 mm)

2 po 5/32

(500 mm)

19 po 11/16

(55 mm)

2 po 5/32

min 20 po

(508 mm)

depuis la découpe

(DÉCOUPE)

22 po 1/64

(560 mm)

(DÉCOUPE)

22 po 1/64

(560 mm)

min 4 po

(102 mm)

depuis la découpe

max 13 po

(330 mm)

(65 mm)

2 po 9/16

(480 mm)

18 po 7/8

(DÉCOUPE)

(65 mm)

2 po 9/16

(65 mm)

2 po 9/16

(480 mm)

18 po 7/8

(DÉCOUPE)

(65 mm)

2 po 9/16

24 po

24 po

(610 mm)

(610 mm)

18 po

(457 mm)

min

22 po 7/16

(570 mm)

30 po

(762 mm)

min 4 po

(102 mm)

depuis la découpe

Fig. 2 Dimensions et dégagement - modèles CG244

30 po

min 20 po

(508 mm)

depuis la découpe

(762 mm)

min

22 po 7/16

(570 mm)

18 po

(457 mm)

Page 46

44

US CA

Instructions d'installation

FR

Fixer les supports d'installation (Fig. 3-4)

Chaque table de cuisson possède une trousse d'installation incluant les supports ("A") et les vis

("B") destinés à fixer la table de cuisson à un plan de travail d'une épaisseur de ⁄ po (20 mm)

à 1 ⁄ po (40 mm).

Retournez la table de cuisson, placez-la sur une surface lisse et serrez les supports « A » dans

les orifices appropriés, sans serrer les vis « B » tout de suite (voir Fig. 3 ou 4).

A

B

A

B

A

B

Fig. 3 Emplacement des supports d'installation -

modèles CG122

A

B

B

A

Fig. 4 Emplacement des supports d'installation -

modèles CG244

B

A

B

A

B

A

Fixer la table de cuisson au comptoir (Fig. 5-6)

1

Étendez le matériau de scellement « C » le long du rebord de la découpe en veillant à ce que les

jonctions se superposent dans les coins.

2

Insérez la table de cuisson dans la découpe et positionnez-la correctement.

3

Ajustez la position des supports « A » et serrez les vis « B » pour solidement

fixer la table de cuisson. Voir la Fig. 5 ou 6.

4

À l'aide d'un couteau aigu ou d'un ébarbeur, coupez l'excès de matériau de scellement autour du

rebord de la table de cuisson. Attention de ne pas endommager le plan de travail.

C

C

mm) min.

mm) max.

⁄ po

A

B

Fig. 5 Fixation de la table de cuisson au comptoir -

modèles CG122

(20

1⁄ po

(40

B

Fig. 6 Fixation de la table de cuisson au comptoir -

modèles CG244

A

mm) min.

⁄ po

(20

mm) max.

1⁄ po

(40

Page 47

Instructions d'installation

Brancher la table de cuisson à l'alimentation en gaz

Cet appareil électroménager est réglé en usine pour fonctionner au gaz naturel mais il est