Fisher & Paykel BGCV21248, BGRV21236, BGRV23030HC, BGCV21230, BGCV21236 Installation manual

...Page 1

INSTALLATION INSTRUCTIONS

Backguard for

Professional Ranges

BGRV2 models

US CA

www.dcsappliances.com

591091A 04.16

Page 2

1 SAFETY AND WARNINGS

!

WARNING!

Cut Hazard

Take care - panel edges are sharp.

Failure to use caution could result in injury or cuts.

IMPORTANT SAFETY INSTRUCTIONS!

●

Save these instructions for the local inspectors use.

●

To avoid hazard, follow these instructions carefully before installing or using this

product.

●

Please make this information available to the person installing the product - doing so

could reduce your installation costs.

●

If the installation requires alterations to the domestic electrical system, call a qualified

electrician. The electrician should also check that the socket cable section is suitable

for the electricity drawn by the range.

2 UNPACKING AND PARTS SUPPLIED

●

Service should only be done by authorized technicians. Technicians must disconnect the

power supply before servicing this appliance.

●

Installation must comply with your local building and electricity regulations.

●

Improper installation, adjustment alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly.

●

DO NOT obstruct the flow of combustion or ventilation air to the accompanying appliance.

Be sure a fresh air supply is available.

●

California Proposition 65 - The burning of gas cooking fuel generates some by-products which

are known by the State of California to cause cancer or reproductive harm. California law

requires businesses to warn customers of potential exposure to such substances. To minimize

exposure to these substances, always operate this unit according to the manufacturer’s

instructions and provide good ventilation to the room when cooking with gas.

●

Check local building codes for the proper method of installation. Local codes vary.

Installation, electrical connections, and grounding must comply with all applicable codes. In

the absence of local codes, the range should be installed in accordance with the latest edition

of National Fuel Gas Code ANSI Z223.1 and National Electrical Code ANSI / NFPA 70.

●

Do not place items of interest to children on racks or appliance. Children could be seriously

injured if they should climb onto or into the appliance to reach these items.

●

Do not place combustible material (paper, cloth, plastic, etc.) on the rack.

WALL MOUNT HIGH BACKGUARD

LOW SHELF Models

Low Shelf Rack & Handle Kit

30” & 36” Models (x2 Racks)

48” Models (x3 Racks)

Unpacking and handling

●

Inspect the backguard and racks to verify that there is no shipping

damage. If any damage is detected, call the shipper and initiate a

damage claim. DCS by Fisher & Paykel is not responsible for shipping

damage.

●

DO NOT discard any packing material (box, pallet, straps) until the

unit has been inspected.

●

Range Backguard

(model specific) (1)

WALL MOUNT HIGH BACKGUARD

HIGH SHELF Models

Remove the outer carton and any packing material and dispose

responsibly.

High Shelf Rack & Handle Kit

30” & 36” Models (x2 Racks)

48” Models (x3 Racks)

Angled Trim

IMPORTANT!

SAVE THESE INSTRUCTIONS

The models shown in this installation guide may not be available in all markets and are subject to change at any time. For current details about model and specification availability in your country, please go to our

website www.dcsappliances.com or contact your local DCS by Fisher & Paykel dealer.

2

Page 3

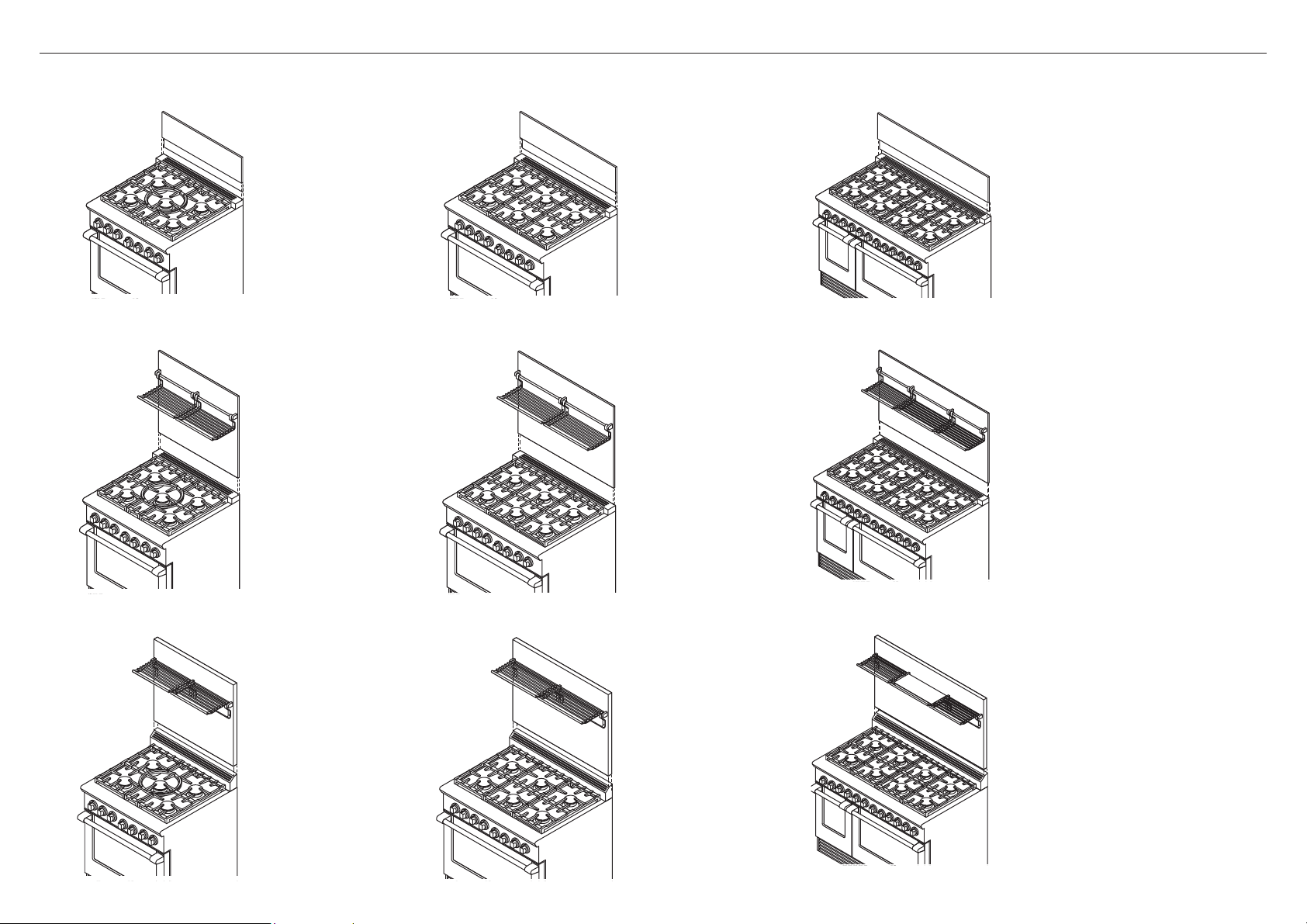

RANGE MOUNT LOW BACKGUARD

BGRV2-1230 BGRV2-1236 BGRV2-1248

WALL MOUNT HIGH BACKGUARD LOW SHELF

3 MODEL IDENTIFICATION

BGRV2-3030

WALL MOUNT HIGH BACKGUARD HIGH SHELF AND ANGLED VENT TRIM

BGRV2-3030H

BGRV2-3036

BGRV2-3036H

BGRV2-3048

BGRV2-3048H

3

Page 4

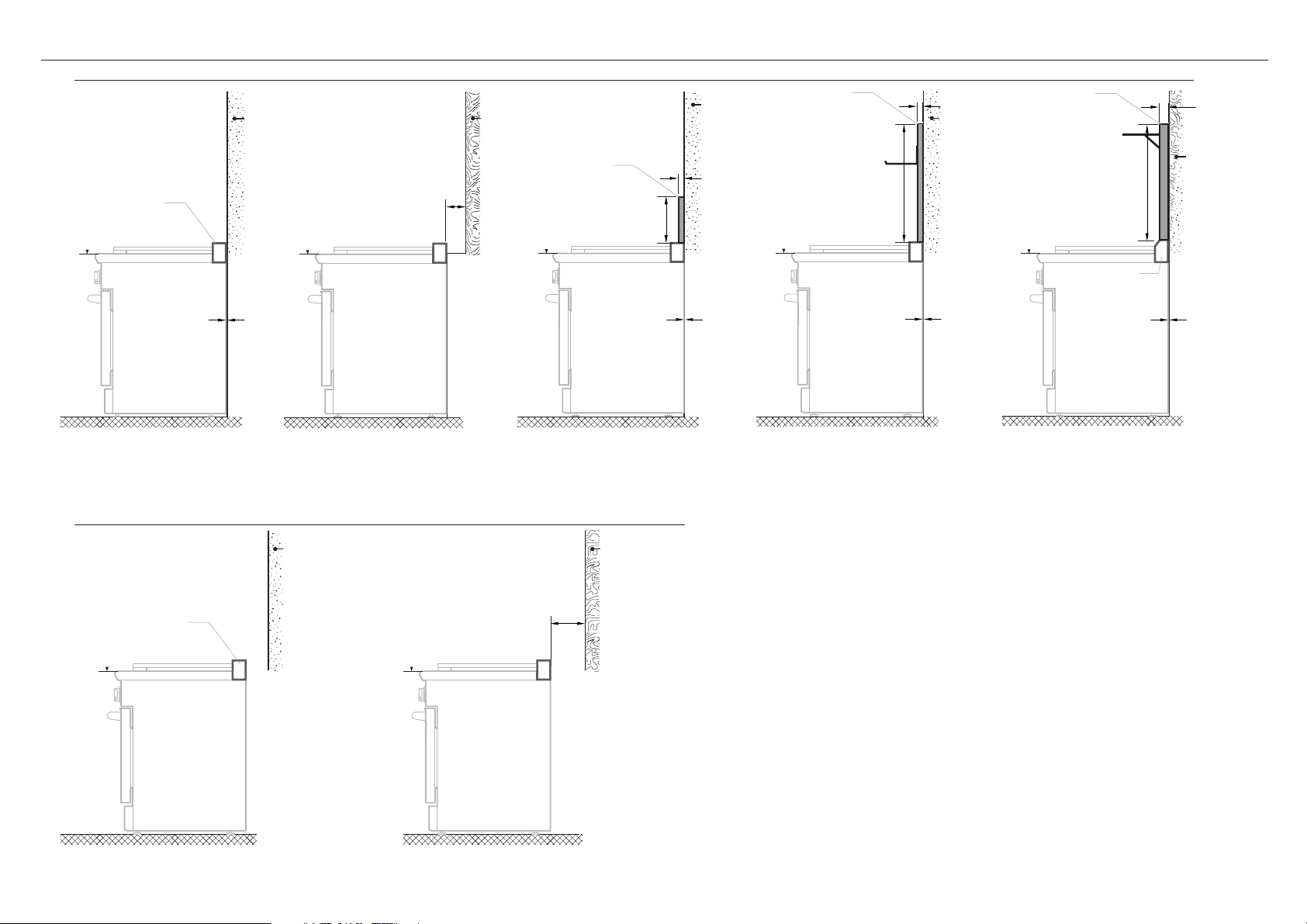

4 INSTALLATION SCENARIOS AND USE OF BACKGUARDS

WALL INSTALLATION

Vent Trim

cooking

surface

0” Clearance

scenario 1

NO BACKGUARD USED

Integral Flat Vent Trim or

Angled Flat Vent Trim (

(supplied with range)

ISLAND INSTALLATION

RGCV2-305 models only)

Non-combustible

surface*

(required)

cooking

surface

scenario 2

NO BACKGUARD USED

Integral Flat Vent Trim or

Angled Flat Vent Trim (

(supplied with range)

Min. 6” (152mm)

Clearance

RGCV2-305 models only)

Combustible

Surface

Range Mount

Low Backguard

cooking

surface

10 3/8”

(263mm)

1/2”

(13mm)

0” Clearance

scenario 3 scenario 4

RANGE MOUNT LOW BACKGUARD

(purchased separately)

Wall Mount

cooking

surface

High Backguard

Low Shelf

(720mm)

28 3/8”

Non-combustible

surface*

(required)

0” Clearance

WALL MOUNT HIGH BACKGUARD LOW SHELF

(purchased separately)

1/2”

(13mm)

Non-combustible

surface*

(required)

Wall Mount

High Backguard

High Shelf

26 1/2”

(673mm)

cooking

surface

Angled Vent Trim

(required)

0” Clearance

scenario 5

WALL MOUNT HIGH BACKGUARD

HIGH SHELF AND ANGLED VENT TRIM KIT

(purchased separately)

1 5/16”

(33mm)

Non-combustible

surface*

or

Combustible

surface

Non-Combustible

Surface*

Vent Trim

cooking

surface

scenario 6 scenario 7

NO BACKGUARD USED

Integral Flat Vent Trim or Angled Flat Vent Trim (RGCV2-305 models only)

(supplied with range)

4

Combustible

Surface

Min. 6” (152mm)

Clearance

cooking

surface

NO BACKGUARD USED

Integral Flat Vent Trim or Angled Flat Vent Trim (RGCV2-305 models only)

(supplied with range)

Page 5

4 INSTALLATION SCENARIOS AND USE OF BACKGUARDS

Important notes

●

All ranges come fitted standard with with either an Integral Flat Vent Trim or an Angled Vent Trim (RGCV2-305 models only)

●

There are three different backguards available for purchase:

●

Range Mount Low Backguard

●

Wall Mount High Backguard with Low Shelf

●

Wall Mount High Backguard with High Shelf, also supplied with an Angled Vent Trim.

●

For installations against non-combustible* surfaces only, you may install the range without a backguard or choose any of the three backguards.

●

For installations close to combustible surfaces (above the cooking surface), without a backguard, there must be a minimum 6” (152mm) clearance

(see Scenario 2 or 7 opposite)

●

For installations immediately against combustible surfaces (above the cooking surface), you must purchase and fit the Wall Mount High Backguard

High Shelf and Angled Vent Trim (see Scenario 5 opposite)

●

The cooking surface must sit flush or above the adjacent countertop level.

* Non-combustible surfaces:

as defined in ‘National Fuel Gas Code’ (ANSI Z223.1, Current Edition). Clearances from non-combustible materials

are not part of the ANSI Z21.1 scope and are not certified by UL. Clearances of less than 6” (152mm) must be

approved by the local codes and/or by the local authority having jurisdiction.

BACKGUARD MODEL NUMBERS

WALL

MOUNT HIGH

BACKGUARD

LOW SHELF

RANGE

RANGE

MOUNT LOW

BACKGUARD

30” models BGRV2-1230 BGRV2-3030 BGRV2-3030H 29 7/8” (759mm)

36” models BGRV2-1236 BGRV2-3036 BGRV2-3036H 35 7/8” (911mm)

48” models BGRV2-1248 BGRV2-3048 BGRV2-3048H 47 7/8” (1216mm)

WALL

MOUNT HIGH

BACKGUARD

HIGH SHELF

BACKGUARD

WIDTH

Note: For more information on Backguard installation, refer to the separate instructions provided with your backguard.

Backguard Installation Instructions can also be downloaded from our website, www.dcsappliances.com

5

Page 6

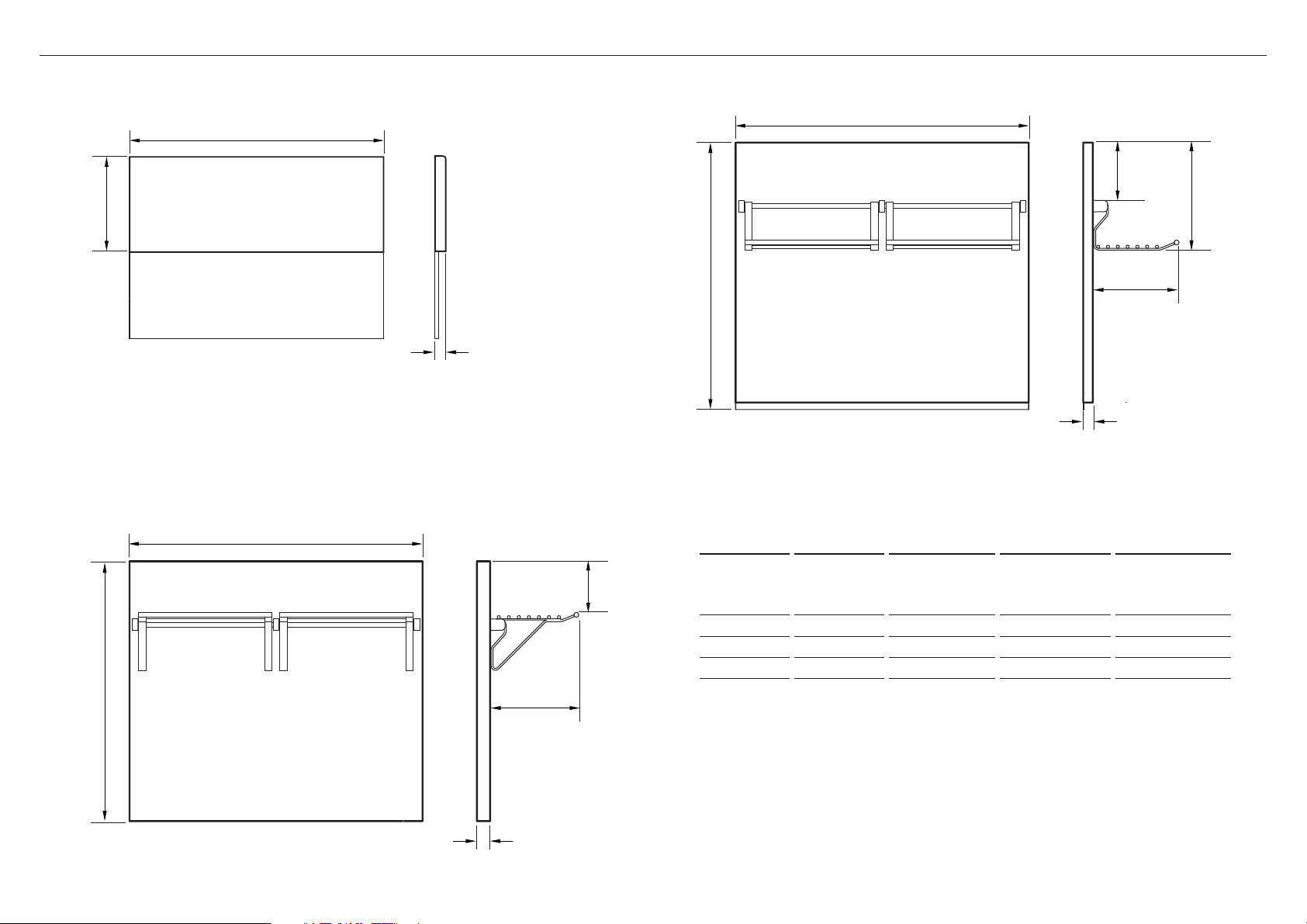

5 PRODUCT DIMENSIONS

29 1/8”

(740mm)

5 7/8”

(150mm)

8 13/16”

(224mm)

WIDTH

1/2”

(13mm)

10 15/16”

(278mm)

26 1/2”

(673mm)

WIDTH

1 5/16”

(33mm)

5 3/8”

(136mm)

9 1/16”

(230mm)

10 3/8”

(263mm)

WIDTH

1/2”

(13mm)

RANGE MOUNT LOW BACKGUARD

FRONT

PROFILE

WALL MOUNT HIGH BACKGUARD HIGH SHELF

WALL MOUNT HIGH BACKGUARD LOW SHELF

FRONT

PROFILE

6

FRONT

PROFILE

SUITABLE

RANGE

30” models BGRV2-1230 BGRV2-3030 BGRV2-3030H 29 7/8” (759mm)

36” models BGRV2-1236 BGRV2-3036 BGRV2-3036H 35 7/8” (911mm)

48” models BGRV2-1248 BGRV2-3048 BGRV2-3048H 47 7/8” (1216mm)

RANGE

MOUNT LOW

BACKGUARD

WALL

MOUNT HIGH

BACKGUARD

LOW SHELF

WALL

MOUNT HIGH

BACKGUARD

HIGH SHELF

BACKGUARD

WIDTH

Page 7

6-A RANGE MOUNT LOW BACKGUARD - ASSEMBLY

1

Attach low backguard to the rear of the range

1 Align the backguard with the range, so that it

rests on the vent trim.

2 Fasten the bottom of the backguard to the rear

of the range using all the screws provided, as

shown.

The two center screws come already attached to

the range for your convenience.

Finally position range

3 Push the range into position.

Follow the rest of the instructions shown in the

range installation instructions.

2

Center screw

These screws

come pre-attached to

rear of range

3

7

Page 8

6-B WALL MOUNT HIGH BACKGUARD WITH LOW SHELF - ASSEMBLY

1

VENT HOOD

BACKGUARD

RANGE

2

End

cap

3

Center

stanchion

#10 machine

Rod

screws

End

cap

1 Recommended installation order:

1] VENT HOOD

2] BACKGUARD

3] RANGE

Locate and Mark the two mounting screw locations

2 Use the diagram below depending on your

particular model.

Attach rod etc

3 Attach rod, end caps and center stanchion to

backguard with #10 machine screws supplied.

continued over...

B

C

Top of Vent Trim

Mounting screw locations

A

B

C

30” MODELS 36” MODELS 48” MODELS

inches (mm) inches (mm) inches (mm)

6 15/16” (176) 1 15/16” (50) 7 15/16” (202)

16” (406) 32” (813) 32” (813)

26 9/16” (675) 26 9/16” (675) 26 9/16” (675)

Mounting

Hole

location

Mounting

Hole

location

A

8

Page 9

4

Upper

mounting

screws

6-B WALL MOUNT HIGH BACKGUARD WITH LOW SHELF - ASSEMBLY

1/16”

(2mm)

6

5

Ensure backguard is

snug tight with the

bottom of the vent

hood and wall

Rear mounting slots

4 Use the marked holes to locate the upper

5 Place the backguard onto the screws by lining

6 Push backguard up and adjust until it sits flush

Ensure the backguard is tight on the wall and is

7 Once the backguard is in position, mark, drill and

8 Attach the racks to rod (racks may vary).

9 Push the range into position so that the

Follow the rest of the instructions shown in the

Mount Backguard to wall

mounting screw locations on the wall.

Pre-drill and install flange head screws (not

supplied), leaving 1/16” (1mm) between the

screw head and wall.

up the screw heads with the rear mounting slots.

with the bottom of the vent hood.

not loose. You may need to adjust the depth of

the mounting screws to achieve this.

install the lower mounting screws at the bottom

of the backguard.

Attach racks

Finally position range

backguard sits flush with the top of the range

vent trim.

range installation instructions.

8

Racks

Lower

mounting

screws

IMPORTANT!

The back section must be securely fastened to

the wall. Failure to do so could cause damage

or personal injury if the Backguard was to pull

free from wall when racks are loaded. The

maximum weight placed on each rack should

be 10lbs.

7

9

9

Page 10

6-C WALL MOUNT HIGH BACKGUARD WITH HIGH SHELF - REPLACE THE VENT TRIM

Flat Vent Trim

1

4

2

Remove the flat vent trim

1 If using the high backguard with high shelf, you must

install the angle trim (supplied) first.

First, remove the two screws at the back of the trim

as shown.

2 Carefully lift off the flat vent trim and also the pan

supports/griddle/grill frame etc.

IMPORTANT!

Be careful not to touch any exposed electrical

wiring or internals at this stage.

Install the angle vent trim

3 Paying particular attention to the metal tabs around

the opening of the range, carefully place the angle

trim down over the rear trim of the range.

4 The angle trim must fit properly over the spill guards

and hob edge.

5 Refit the two screws into the rear trim as shown.

10

3

5

Page 11

6-C WALL MOUNT HIGH BACKGUARD WITH HIGH SHELF - ASSEMBLY

End

cap

1

Ta b

Front section

3

Center

stanchion

Hole

Rod

End

cap

VENT HOOD

BACKGUARD

RANGE

Bend down

approx.

3/16” (5mm)

4

#10 machine

screws

Back section

Choose slots

Racks

6

2

30” MODELS = 16” (406mm)

36/48” MODELS = 32” (813mm)

7

1/4”

(6mm)

1 Recommended installation order:

1] VENT HOOD

2] BACKGUARD

3] RANGE

Locate and Mark the mounting screw locations for

backguard back section

2 After unpacking all backguard parts, position the

back section so that it’s 1/4” (6mm) and centered

above the Vent Trim attached to the range. Secure

back section to wall with the appropriate fasteners

(not supplied) to anchors or wood stud. The slots

in the back section may be used to adjust spacing

between range vent trim and backguard for a flush

fit.

Attach rod etc to front section

3 Attach rod, end caps and center stanchion to front

section of backguard with #10 machine screws

supplied.

Secure front section to back section

4 Bend wedge-shaped tabs down on top of the front

section approximately 3/16” (5mm).

5 Secure front section of backguard to back section

with #8 self-tapping sheet metal screws supplied.

When mounting the front section, ensure that these

tabs engage the mating holes in the top of the rear

section.

Attach racks

6 Attach the racks to rod (racks may vary).

Finally position range

7 Push the range into position so that the backguard

sits flush with the top of the range vent trim.

Follow the rest of the instructions shown in the range

installation instructions.

5

Front section

Ta b

Hole

#8

Selftapping

sheet metal

screws

Back section

IMPORTANT!

The back section must be securely fastened to

the wall. Failure to do so could cause damage or

personal injury if the Backguard was to pull free

from wall when racks are loaded. The maximum

weight placed on each rack should be 10lbs.

11

Page 12

7 FINAL CHECKLIST

TO BE COMPLETED BY THE INSTALLER

GENERAL

Correct and suitable placement of the appliance and backguard.

Specified clearances maintained to cabinet surfaces.

Specified clearances maintained to either combustible or non-combustible surfaces.

Backguard centered under hood and level - front to back, side to side and is securely fastened to the appliance

(Range Mount Low Backguard only) or to the wall.

All packaging material and tie straps removed.

Angle trim (Wall Mount High Backguard High Shelf only) is correctly placed over the rear trim of the trim and

fits properly over the spill guards and hob edge.

Ensure all racks are fitted and securely in place

Complete and keep for safe reference:

Model

Serial No.

Purchase Date

Purchaser

Dealer Address

Installer’s Name

Installer’s Signature

Installation Company

Installation Date

12

Copyright © Fisher & Paykel Appliances 2016. All rights reserved.

The product specifications in this booklet apply to the specific products

and models described at the date of issue. Under our policy of continuous

product improvement, these specifications may change at any time. You

should therefore check with your Dealer to ensure this booklet correctly

describes the product currently available.

Page 13

13

Page 14

INSTALLATION INSTRUCTIONS

Backguard for

Professional Cooktops

BGCV2 models

US CA

www.dcsappliances.com

591091A 04.16

Page 15

1 SAFETY AND WARNINGS

!

WARNING!

Cut Hazard

Take care - panel edges are sharp.

Failure to use caution could result in injury or cuts.

IMPORTANT SAFETY INSTRUCTIONS!

●

Save these instructions for the local inspectors use.

●

To avoid hazard, follow these instructions carefully before installing or using this

product.

●

Please make this information available to the person installing the product - doing so

could reduce your installation costs.

●

If the installation requires alterations to the domestic electrical system, call a qualified

electrician. The electrician should also check that the socket cable section is suitable

for the electricity drawn by the cooktop.

2 UNPACKING AND PARTS SUPPLIED

●

Service should only be done by authorized technicians. Technicians must disconnect the

power supply before servicing this appliance.

●

Installation must comply with your local building and electricity regulations.

●

Improper installation, adjustment alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly.

●

DO NOT obstruct the flow of combustion or ventilation air to the accompanying appliance.

Be sure a fresh air supply is available.

●

California Proposition 65 - The burning of gas cooking fuel generates some by-products which

are known by the State of California to cause cancer or reproductive harm. California law

requires businesses to warn customers of potential exposure to such substances. To minimize

exposure to these substances, always operate this unit according to the manufacturer’s

instructions and provide good ventilation to the room when cooking with gas.

●

Check local building codes for the proper method of installation. Local codes vary.

Installation, electrical connections, and grounding must comply with all applicable codes. In

the absence of local codes, the range should be installed in accordance with the latest edition

of National Fuel Gas Code ANSI Z223.1 and National Electrical Code ANSI / NFPA 70.

●

Do not place items of interest to children on racks or appliance. Children could be seriously

injured if they should climb onto or into the appliance to reach these items.

●

Do not place combustible material (paper, cloth, plastic, etc.) on the rack.

WALL MOUNT HIGH BACKGUARD

LOW SHELF Models

Low Shelf Rack & Handle Kit

30” & 36” Models (x2 Racks)

48” Models (x3 Racks)

Unpacking and handling

●

Inspect the backguard and racks to verify that there is no shipping

damage. If any damage is detected, call the shipper and initiate a

damage claim. DCS by Fisher & Paykel is not responsible for shipping

damage.

●

DO NOT discard any packing material (box, pallet, straps) until the

unit has been inspected.

●

Cooktop Backguard

(model specific) (1)

WALL MOUNT HIGH BACKGUARD

HIGH SHELF Models

High Shelf Rack & Handle Kit

Remove the outer carton and any packing material and dispose

responsibly.

30” & 36” Models (x2 Racks)

48” Models (x3 Racks)

IMPORTANT!

SAVE THESE INSTRUCTIONS

The models shown in this installation guide may not be available in all markets and are subject to change at any time. For current details about model and specification availability in your country, please go to our

website www.dcsappliances.com or contact your local DCS by Fisher & Paykel dealer.

2

Page 16

WALL MOUNT LOW BACKGUARD

BGCV2-1230 BGCV2-1236 BGCV2-1248

WALL MOUNT HIGH BACKGUARD LOW SHELF

3 MODEL IDENTIFICATION

BGCV2-3030

WALL MOUNT HIGH BACKGUARD HIGH SHELF

BGCV2-3030H

BGCV2-3036

BGCV2-3036H

BGCV2-3048

BGCV2-3048H

3

Page 17

WALL INSTALLATION

cooking

surface

Non-combustible

surface*

(required)

cooking

surface

4 COOKTOP INSTALLATION SCENARIOS AND USE OF BACKGUARDS

15/16”

(23mm)

Non-combustible

surface*

(required)

Min. 6” (152mm)

Clearance

Combustible

Surface

cooking

surface

Wall Mount

Low Backguard

12”

(305mm)

Non-combustible

surface*

(required)

15/16”

(23mm)

cooking

surface

Wall Mount

High Backguard

Low Shelf

(762mm)

30”

Wall Mount

High Backguard

High Shelf

cooking

surface

30”

(762mm)

15/16”

(23mm)

Non-combustible

surface*

or

Combustible

surface

Min. 0” Clearance

Cabinetry Cabinetry Cabinetry Cabinetry Cabinetry

scenario 1

NO BACKGUARD USED

ISLAND INSTALLATION

cooking

surface

scenario 2

NO BACKGUARD USED

Non-Combustible

Surface*

cooking

surface

scenario 3 scenario 4

WALL MOUNT LOW BACKGUARD

(purchased separately)

Combustible

Surface

Min. 6” (152mm)

Clearance

Min. 0” Clearance

Min. 0” Clearance

WALL MOUNT HIGH BACKGUARD LOW SHELF

(purchased separately)

0” Clearance

scenario 5

WALL MOUNT HIGH BACKGUARD HIGH SHELF

(purchased separately)

Cabinetry

scenario 6 scenario 7

NO BACKGUARD USED

4

Cabinetry

NO BACKGUARD USED

Page 18

4 COOKTOP INSTALLATION SCENARIOS AND USE OF BACKGUARDS

Important notes

●

There are three different backguards available for purchase:

●

Wall Mount Low Backguard

●

Wall Mount High Backguard with Low Shelf

●

Wall Mount High Backguard with High Shelf.

●

For installations against non-combustible* surfaces only, you may install the cooktop without a backguard or choose any of the three backguards.

●

For installations close to combustible surfaces (above the cooking surface), without a backguard, there must be a minimum 6” (152mm) clearance (see Scenario 2 or 7 opposite)

●

For installations immediately against combustible surfaces (above the cooking surface), you must purchase the Wall Mount High Backguard High Shelf (scenario 5 opposite).

●

The cooking surface must sit flush or above the adjacent countertop level.

* Non-combustible surfaces:

as defined in ‘National Fuel Gas Code’ (ANSI Z223.1, Current Edition). Clearances from non-combustible materials

are not part of the ANSI Z21.1 scope and are not certified by UL. Clearances of less than 6” (152mm) must be

approved by the local codes and/or by the local authority having jurisdiction.

BACKGUARD MODEL NUMBERS

COOKTOP

WALL

MOUNT LOW

BACKGUARD

WALL

MOUNT HIGH

BACKGUARD

LOW SHELF

WALL

MOUNT HIGH

BACKGUARD

HIGH SHELF

BACKGUARD

WIDTH

30” models BGCV2-1230 BGCV2-3030 BGCV2-3030H 29 7/8” (759mm)

36” models BGCV2-1236 BGCV2-3036 BGCV2-3036H 35 7/8” (911mm)

48” models BGCV2-1248 BGCV2-3048 BGCV2-3048H 47 7/8” (1216mm)

Note: Backguard Installation Instructions can also be downloaded from our website, www.dcsappliances.com

5

Page 19

5 PRODUCT DIMENSIONS

30”

(762mm)

5 7/8”

(150mm)

8 13/16”

(224mm)

WIDTH

15/16”

(23mm)

10 15/16”

(278mm)

30”

(762mm)

WIDTH

15/16”

(23mm)

5 3/8”

(136mm)

9 1/16”

(230mm)

12"

(305mm)

WIDTH

15/16"

(23mm)

WALL MOUNT LOW BACKGUARD

FRONT

WALL MOUNT HIGH BACKGUARD HIGH SHELF

WALL MOUNT HIGH BACKGUARD LOW SHELF

PROFILE

FRONT

PROFILE

6

FRONT

PROFILE

SUITABLE

RANGE

30” models BGCV2-1230 BGCV2-3030 BGCV2-3030H 29 7/8” (759mm)

36” models BGCV2-1236 BGCV2-3036 BGCV2-3036H 35 7/8” (911mm)

48” models BGCV2-1248 BGCV2-3048 BGCV2-3048H 47 7/8” (1216mm)

WALL

MOUNT LOW

BACKGUARD

WALL

MOUNT HIGH

BACKGUARD

LOW SHELF

WALL

MOUNT HIGH

BACKGUARD

HIGH SHELF

BACKGUARD

WIDTH

Page 20

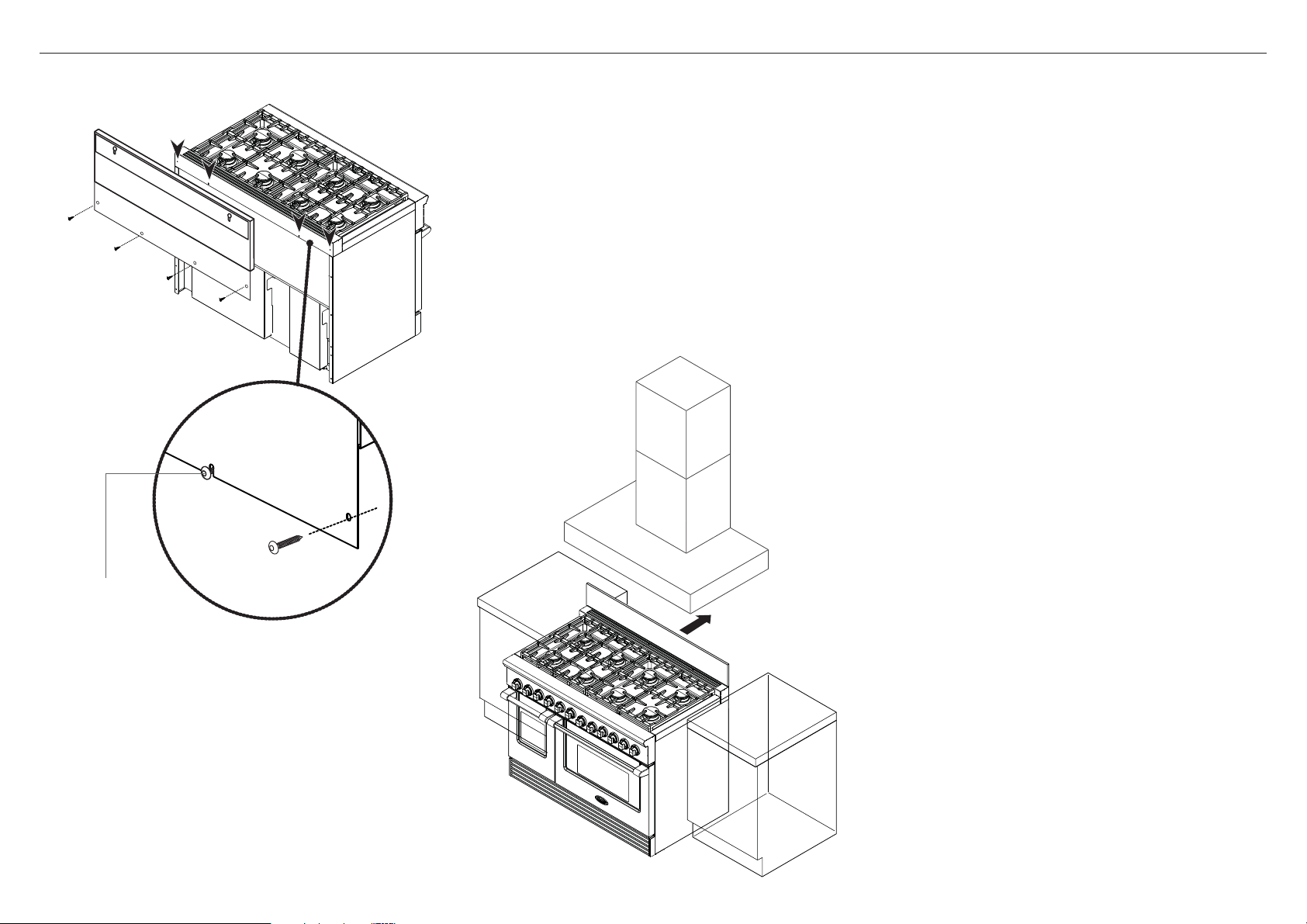

1

VENT HOOD

BACKGUARD

COOKTOP

6-A WALL MOUNT LOW BACKGUARD - ASSEMBLY

30” MODELS = 16” (406mm)

36/48” MODELS = 32” (813mm)

Use slots to

correctly position

Back section

2

Cooktop

Trim

1/4”

(6mm)

1 Recommended installation order:

1] VENT HOOD

2] BACKGUARD

3] COOKTOP

Locate and Mark the mounting screw locations for

back section

2 After unpacking all backguard parts, position the

back section so that it’s 1/4” (6mm) and centered

above the cooktop trim. Secure back section to wall

with the appropriate fasteners (not supplied) to

anchors or wood stud. The slots in the back section

may be used to adjust spacing between cooktop trim

and backguard for a flush fit.

Secure front section to back section

3 Secure front section of backguard to back section

with #8 self-tapping sheet metal screws supplied.

Finally position cooktop

7 Place the cooktop into position so that the backguard

sits flush with the top of the cooktop trim.

Follow the rest of the instructions shown in the

cooktop installation instructions.

Front section

Back section

34

#8

Selftapping

sheet metal

screws

IMPORTANT!

The back section must be securely fastened to

the wall. Failure to do so could cause damage or

personal injury if the Backguard was to pull free

from wall.

7

Page 21

6-B WALL MOUNT HIGH BACKGUARD WITH LOW SHELF/HIGH SHELF - ASSEMBLY

Use slots to

correctly position

1

End

cap

Ta b

Front section

3

Center

stanchion

Hole

Rod

VENT HOOD

BACKGUARD

COOKTOP

4

End

cap

Back section

Bend down

approx.

3/16” (5mm)

#10 machine

screws

6

Racks

2

30” MODELS = 16” (406mm)

36/48” MODELS = 32” (813mm)

Cooktop

Trim

7

1/4”

(6mm)

1 Recommended installation order:

1] VENT HOOD

2] BACKGUARD

3] COOKTOP

Locate and Mark the mounting screw locations for

back section

2 After unpacking all backguard parts, position the

back section so that it’s 1/4” (6mm) and centered

above the cooktop trim. Secure back section to wall

with the appropriate fasteners (not supplied) to

anchors or wood stud. The slots in the back section

may be used to adjust spacing between cooktop trim

and backguard for a flush fit.

Attach rod etc to front section

3 Attach rod, end caps and center stanchion to front

section of backguard with #10 machine screws

supplied.

Secure front section to back section

4 Bend wedge-shaped tabs down on top of the front

section approximately 3/16” (5mm).

5 Secure front section of backguard to back section

with #8 self-tapping sheet metal screws supplied.

When mounting the front section, ensure that these

tabs engage the mating holes in the top of the rear

section.

Attach racks

6 Attach the racks to rod (racks may vary).

Finally position cooktop

7 Place the cooktop into position so that the backguard

sits flush with the top of the cooktop trim.

Follow the rest of the instructions shown in the

cooktop installation instructions.

Hole

IMPORTANT!

The back section must be securely fastened to

the wall. Failure to do so could cause damage or

personal injury if the Backguard was to pull free

from wall when racks are loaded. The maximum

weight placed on each rack should be 10lbs.

5

Front section

Ta b

#8

Selftapping

sheet metal

screws

7

Back section

8

Page 22

7 FINAL CHECKLIST

TO BE COMPLETED BY THE INSTALLER

GENERAL

Correct and suitable placement of the appliance and backguard.

Specified clearances maintained to cabinet surfaces.

Specified clearances maintained to either combustible or non-combustible surfaces.

Backguard centered under hood and level - front to back, side to side and sits flush with the top of the cooktop trim.

All packaging material and tie straps removed.

Front section of backguard is securely attached to the back section.

Wedge-shaped tabs on top of front section (Wall Mount High Backguard only) are properly engaged with corresponding

holes in top of rear section.

Ensure all racks are fitted and securely in place

Complete and keep for safe reference:

Model

Serial No.

Purchase Date

Purchaser

Dealer Address

Installer’s Name

Installer’s Signature

Installation Company

Installation Date

Copyright © Fisher & Paykel Appliances 2016. All rights reserved.

The product specifications in this booklet apply to the specific products

and models described at the date of issue. Under our policy of continuous

product improvement, these specifications may change at any time. You

should therefore check with your Dealer to ensure this booklet correctly

describes the product currently available.

9

Page 23

10

Page 24

11

Loading...

Loading...