Page 1

TECHNICAL

MANUAL

RESPIRATORY

HUMIDIFIER

MR730

MR720

MR700

MR480

MODELS

Revision

Issued

Copyright © 1991

Auckland,

Fisher

23

Fisher & Paykel

&

HEALTHCARE

D

October

New

1995

Ltd,

Zealand

Healthcare

Paykel

Division

Page 2

Fisher & Paykel

and

reserve

Fisher &

Healthcare

Fisher & Paykel

P.O.

Auckland,

Telephone:

Facsimile:

Part

Number

Technical

Box

the

right

Paykel

Division.

14348,

New

+64-9-574

+64-9-574

185

Manual

MR730

MR720

MR700

MR480

Healthcare

Electronics

Panmure.

Zealand.

040 646

for

have a policy

to

alter

0100

0158

Respiratory

Dual

Servo

Dual

Servo

Dual

Servo

Single

of

continued

specifications

Limited.

Humidifier

(anaesthesia)

Servo

without

Issued

notice.

23/10/95

models:

product

improvement

Changes

GENERAL

and

version

to

Technical

Rewrite

3.0

software

Manual

Description

and

update

to

Since

of

Change

incorporate

Last

change

Version.

to

Rev H PCB

Page

Affected

various

Numbers

MR730/720/700/480

Technical

Manual # Revision D *

issued

October

1995

Page 3

CONTENTS

PAGE

1.0

1.1

1.1.1

1.12

1.1.3

12

13

14

1.5

2.0

2.1

2.1.1

2.1.2

2.2

221

222

2.2.3

2.24

23

2.3.1

2.3.2

24

2.5

2.6

2.6.1

2.62

2.6.3

2.7

2.7.1

2.7.2

MR700

Electrical

Standards

Series

Specifications

Models

Model

Common

MR730/720/700

MR480

and

Temperature

Temperature

Temperature

Operating

Adjustable

Airway

Chamber

Push

Mute

Chamber

Standby

Heater

Power

Version

Version

Heater

MR730/720

Warm

MR700/MR730

MR700/MR730

MR720

Standby

MR700/MR730

MR720

Controls

Temperature

Switches

Button

Button

Wire

Up

Seguences

1.0

2.0

Wire

Up

Mode

With

Mode

Standby

General

Electrical

Approvals

Control

Sensing..

Display

..

Controls

Control

Temp

On

in

(Heater

Button..

(MR700/720/730

Switch

Software

and

Version

Mode

Heater

and

and

Version

and

Mode

Specifications

..

Specifications

And

Modes

Control

Wire

On

(MR720,

(All

Wire

MR720(version

MR720(version

2.0/3.0

MR720

MR730

3.0

Software

models

Off

Mode

Software

(Version

(Version

except

(All

Mode

only)

and

1.0)

1.0)

2.0

and

essence

Models).

Only).

...

only).

MR480)..

MR480

in

Heater

in

Non

.

1.0)

Only.

3.0

software

..

Wire

Heater

Mode..

Wire

Mode

and

only)

.....................

1

1

1

„I

wel

1

2

πο

2

+3

…3

....3

3

„3

3

3

3

4

4

....4

4

4

s.m.

„5

5

MR480...

5

ο

5

„5

~

ci

rsrerresserserersererses

5

3.0

3.1

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

3.3

3.3.1

3.3.2

3.3.3

3.4

3.5

3.5.1

3.5.2

4.0

41

4.2

4.2.1

4.2.2

4.2.3

Alarms

Temperature

Alarms

In

Heater

Airway

Airway

and

Heater

Wire

temperature

temperature

Chamber

Chamber

Set

Low

Temperature

Heater

WireAlarm.........................

Airway

Airway

Audio

Safety

Temperature

Temperature

Temperature

Alarm

Protection

Microprocessor

Circuit

Introduction

Control

Operation

Board

Control

Input

Analog

Analog

to

Thermistors

Alarm

Alarm.

Heater

ee

Dog

U8

Wire

Alarm..

Alarm

and

U9

U10

b,d,e.

Indicators...

Probe

Alarm

Wire

Mode (MR700/720/730

Alarm........

High

Low

Temp

High

Alarm

Temp

Low

Alarm.

Waming.................

Alarms

in

Non

High

Low

(All

Models)...

Deviations...

Watch

..

Switches

Digital

Converter

Mode

.

only)..

(includes

MR480)..

e.

.6

6

6

6

6

7

7

7

7

8

8

8

.8

.8

.8

.8

…8

9

.9

.9

.9

.9

9

MR730/720/700/480

Technical

Manual

#

Revision D 3#-

Issued

October

1995

Page 4

CONTENTS

424

4.2.5

4.2.6

4.2.7

4.2.8

4.2.9

43

4.3.1

4.3.2

44

5.0

5.1

5.2

53

54

6.0

6.1

6.2

6.2.1

6.2.2

6.2.3

63

6.3.1

6.3.2

6.3.3

64

6.4.1

642

Processor

Power

Power

41

Heater

Watch

Power

Revision

Revision H PCBs.......

Probe

Temperature

Calibration

Introduction

Equipment

Calibration

Calibration

Performance

Control

Line

Interrupt

Line

Interrupt

°C

Comparator

Plate

Overtemperature..

Dog...

Board......

D/F

.....

...

Required.

Procedure

Procedure

Check

Introduction

Performance Check

Equipment

Static

Dynamic

Performance

Equipment

Static

Dynamic

Dual

Probe

Equipment

Test

Required

Test

Sequence

Test

Check

Required

Test

Procedure

Test

Temperature

Required

Procedure

U3

(Revisions

(Revision H PCB)

PCBs

versus

Thermistor

coroa

for

Models

for

Models

MR730/720/700

..

(MR73

Sequence

(MR480)....

.........

(MR480).

Procedure

Test.

..

....

D/F

PCBs).

Resistance..

ces

with

Revision D PCBs

with

Revision F PCBs

ee

(MR730/720/700

(MR480).

00)

esses

veses

or

earlier

or later...

conse

13

13

13

13

„14

SS

.

15

15

15

16

19

7.0

71

72

7.2.1

722

73

74

7.5

7.6

8.0

8.1

82

83

84

8.5

8.6

8.7

8.8

8.9

8.9.1

8.9.2

Servicing

Introduction

Printed

Control

Power

Replacement

Heater

Fault

Screw

Schematics,

MR700

Component

Component

Component

Link

Circuit

Circuit

Circuit

Circuit

Circuit

Circuit

Electrical

Contro!

Power

Information

Circuit

Board

PCB

PCB

of

Revision D Power & Control

Plate

Location

Torque

Settings.

Part

Series

Circuit

Layout - Revision H PCB

Layout - Revision F PCB..

Layout - Revision D PCB

Pad

Locations

Diagrams - Revision H PCB

Diagrams - Revision H PCB.Power

Diagrams - Revision F PCB

Diagrams - Revision F PCB

Diagrams - Revision D PCB

Diagrams - Revision D PCB

Partslist.................

Board

Components:

Board

Components:

Removal

Lists

Layout

for

Programming

..

PCB

and

Mechanical

Block

Diagram

.....

Control

Control

Control

Power

Control

Power

esere

(Revision H PCB)

(Revision H PCB)...

PCB.

PCB

PCB..

PCB.

PCB

PCB

Assemblies...

Drawings

Options - Revision H PCB

...

.

a

20

Page 5

CONTENTS

PAGE

8.10

8.10.1

8.10.2

8.10.3

8.11

8.11

8.12

8.13

8.14

9.0

9.1

9.2

93

Appendix

Al

A2

A2.1

A22

A2.3

A3

A4

A5

A6

A6.1

A6.2

A6.3

46.4

A7

Mechanical

MR480

Parts

List

Mechanical

MR730/720/700

Heater

plate

Assembly

Exploded

Exploded

Exploded

PCB

Power

Product

Compatibility

Model

Serial

A.

Calibration

Engineering

Programming

Glossary

Error

MR700

Diagrams:

Diagrams:

Diagrams:Heater

Identification

PCB

Harness

Change

of

Software

Number

Number

Engineering

Engineering

Integral

Codes

Series

Serial

Status

Remote

Serial

Explanation

Explanation

conos

Mode...

sine

Menu

display

Functions:

Display

Control

of

Abbreviations

Humidifier

Data

Format

Information.

Standby

Data

Interface

Diagram

....

Revision F & H PCB

....

Parts

Mechanical

Parts.

Parts

(MR730/720/700/480)

MR480..............

MR730/720/700

plate

Assembly

.......................

Connection

History.....

and

Hardware

Diagram

.

..

functions:

Options

Serial

Connector.

Schematic

Non

.

Heater

Heater

Data

Diagrams

MR730/720/700/480

.

cerros

Versions..

00000

eeeeeeeen

eee

rn

Wire

Mode.

Wire

Mode

....

Interface

rire

.

(Inverted

eres

View

55

an

.

nn

Appendix

BI

B2

Appendix

C1

C2

B

Recommended

Recommended

C....

Troubleshooting

MR700

veve

Series

Maintenance

Maintenance

κο.

Fault

Guide

Flow

Schedule...................

Schedule

Checklist...

sous

For

The

Chart

MR700

For

No

Series

Go

Condition

Respiratory

Humidifiers.

ce

....63

.6S

MR730/720/700/480

Technical

Manual # Revision D #

issued

October

1995

Page 6

Page 7

page

1

1.0

1.1

1.1.1

MR700

This

respiratory

The

MR730/720

The

MR720

The

MR700

The

MR480

ELECTRICAL

MoDELs

Suppiy

Supply

Supply

SERIES

documentation

humidifiers.

has a lower

model

model

MR730/720/700

Voltage:

Frequency:

Current:

GENERAL

defines

models

is

is a non

SPECIFICATIONS

the

are

Heated

alarm

exclusively a Heated

Heated

-

SPECIFICATIONS

technical

limit

specifications

Wire

humidifiers

and

an

extended

Wire

Wire

humidifier.

230V

+25V

127V x 12V

115V

100V + 10V

50 - 60

Hz

1.0 A maximum

1.9 A maximum

2.0 A maximum

2.4 A maximum

of

the

with

the

warmup

humidifier.

at

230V

at

127V

at

115V

at

100V

MR730, MR720,

option

of

disabling

mode

for

use

in

MR700

the

and

Heater

Anaesthesia.

MR480

Wire.

1.1.2

1.1.3

1.2

Heater

Wire

Capacity:

MobeL

Supply

Supply

Supply

COMMON

Heater

Heater

STANDARDS

Classification

MR480

Voltage:

Frequency:

Current:

ELECTRICAL

Plate

Power:

Plate

Overheat

under

AND

60

230V

115V

100V

50 - 60

0.7 A maximum

1.4 À maximum

1.6 À maximum

SPECIFICATIONS

150

Protector:

APPROVALS

UL544,

JEC601-1,

Operates

CSA-C22.2

W

+25V

+10V

Hz

(ALL

MODELS)

W

at

118

No.125

AS3200.1,

at

230V

at

115V

at

100V

°C + 6

°C

BS5724:Part

1,

DIN

VDE

0750

Teil

1

MR730/720/700/480

Class

1

Type

B

Drip

Proof

Continuous

Not

to

be

used

Technical

Operation

in

the

presence

Manual

of

#

Revision D *

flammable

anaesthetics.

issued

October

1995

Page 8

page

2

1.3

1.4

1.5

TEMPERATURE

PID

(Proportional

heater

plate.

TEMPERATURE

Temperature

fast

response

chamber

measurement

temperature

outlet.

TEMPERATURE

Three

digit

14mm 7 segment

Range

5.0

to

80.0

Accuracy

25.0

to

CONTROL

Integral

SENSING

probes,

DISPLAY

degrees.

45.0

degrees + 0.3

Derivative)

using

control

standard

located

LED

(Light

Below

5.0

degrees

degree.

of

Heater

characteristic

at

the

patient

Emitting

displays

end

Diode)

Wire

(in

Heated

thermistors

of

the

delivery

display.

'Lo'.

Above

(YSI

80.0

Wire

mode

400

compatible)

tube

and

degrees

operation

at

the

displays

only)

and

mounted

in

humidifying

'Hî'.

」

Page 9

page

3

2.0

2.1

2.1.1

2.1.2

OPERATING

ADJUSTABLE

AIRWAY

Selects

scale

The

when

CHAMBER

The

difference

The

the

+2

Airway

adjustment.

Every

adjustment

replacing

TEMPERATURE

the

airway

marked

temperature

the

control

CONTROL

temperature

between

setting

chamber

°C

of

marked

display

humidifier

of

the

CONTROLS

CONTROLS

controlling

in

degrees

can

knob

of

the

the

the

Chamber

outlet

set

in

one

as

the

is

the

chamber

normal

CONTROL

temperature.

on

the

front

be

set

with a resolution

is

rotated

(HEATER

gas

WIRE

leaving

chamber

Control,

temperature.

degree

steps

control

also

knob

supplied

control

knob

with

AND

panel.

and

continues

ON

the

chamber

outlet

temperature

when

This

Chamber

and

can

is

rotated

with a fixed

by

preadjusting

the

fixed

knob.

MODES

The

range

of

0.1

to

MODE

is

added

be

set

and

chamber

of

adjustment

°C.

The

set

temperature

be

flashed

for

five

ONLY)

regulated

and

to

the

Control

with a resolution

continues

the

by

the

the

airway

setting

of

has a linear

to

be

control

existing

knob.

knob

temperature

the

flashed

is

from

seconds

Chamber

Temperature

range

of

0.5

°C.

for

This

prevents

to

the

desired

29

to

40

is

flashed

after the

Control

delivered

of

adjustment

The

value

five

seconds

°C

over a linear

on

the

display

last

adjustment.

knob,

it

to

the

Control,

determines

from

is

flashed

after

inadvertent

setting

and

sets

the

patient.

-5

to

on

the

last

then

the

2.2

2.2.1

2.2.2

PUSH

SWITCHES

MUTE

BUTTON

A

momentary

heater

wire

mode

A

secondary

engineering

On

every

CHAMBER

For

MR700

Operation

chamber

is

active.

This

For

MR700

Operation

chamber

is

active.

seconds

This

initial

TEMP

of

outlet

On

button

of

outlet

On

before

button

menu

is

is

push

will

disable

which

is

ten

minutes).

function

Series

this

release

used

Series

this

release

used

is

that

in

conjunction

(refer

Appendix

push

of

the

mute

BUTTON

Humidifiers

switch causes

temperature. A green

of

this

switch

in

conjunction

Humidifiers

switch

causes

temperature. A green

of

this

switch

blanking

momentarily

in

conjunction

an

audible

alarm

with

A2).

button a momentary

with

Version

the

airway

temperature

LED

adjacent

the

with

with

the

with

display

Version

airway

LED

the

display

and

reverts

the

mute

2.0

temperature

adjacent

continues

reverting

the

mute

for 3 minutes

the

Chamber

audio

1.0

Software:

display

to

the

switch

immediately

to

enter

the

and

Version

display

to

the

switch

te

show

to

show

to

enter

the

(except

Temp

beep

to

low

switch

indicates

momentarily

is

enabled

to

show

engineering

3.0

Software:

to

momentarily

is

enabled

the

chamber

the

airway

temperature.

engineering

temperature

enables

function

blank

to

indicate

the

airway

menu

(refer

blank

to

indicate

outlet

menu

(refer

alarm

in

entry

to

the

operation.

then

show

that

this

temperature.

Appendix

then

show

that

this

temperature

Appendix

non

the

function

A2).

the

function

for

2

A2).

2.2.3

STANDBY

This

amber

standby

To

beep

BUTTON

button

has

to

LED

starts

to

mode.

exit

Standby

mode

accompanies a change

MR730/720/700/480

(MR700/720/730

be

depressed

flash

press

for

(100/minute)

the

Standby

in

the

Technical

ONLY)

one

second

to

enter

the

button

can

then

button

for

1s,

Standby

mode

state.

Manual # Revision

or

exit

the

be

released

the

amber

D. 3 Issued

standby

and

LED

will

mode.

the

Humidifier

then

October

When

turn

the

off.

1995

adjacent

remains

An

audio

in

the

Page 10

page

4

2.2.4

2.3

2.3.1

HEATER

This

mode.

Pressing

wire

switching

POWER

VERSION

After

information

.

.

WIRE

is a latching,

The

adjacent

this

alarm

will

to

UP

1.0

switch

is

Watchdog

Display

Temperature

Chamber

9

Software

Maximum

9

Audio

SwiTCH

push

green

switch

will

commence

the

non

heater

SEQUENCES

SOFTWARE

on

the

humidifier

flashed

circuit

Test

Control

Control

Version

Heater

Beep

(MR720,

operated,

cause

MR730

switch

LED,

if

an

audible

if

switching

wire

mode

goes

on,

through

for 2 seconds.

test

Setting

setting

Number

Plate

Setting

ONLY)

which

selects

indicates

to

if a heater

If

All

Airway

eg

If

displayed

that

beep

and

the

heater

wire

the

following

successful

indicator

Temperature

'37.0'

heater

1.0

eg'110'

between

the

humidifier

the

LED

wire

mode

is

connected.

the

'SEE

LEDs

is

displayed

wire

mode

eg

'-1.0'.

the

heater

is

changes

with

no

sequence.

MANUAL'

are

illuminated

display

is

selected

Not

applicable

wire

mode

operating

to

indicate

heater

wire

Note

that

LED

and

then

the

for

and

in

the

heater

the

new

connected

each

displayed

lights

briefly.

'8.8.8.'

is

chamber

MR480

non-heater

wire

wire

mode.

state. A heater

or

if

displayed

control

on

the

setting

is

2.3.2

2.4

VERSION

After

displayed

.

ㆍ

.

9

.

9

2.0

switch

for 2 seconds,

Watchdog

Display

Model

Software

Temperature

Chamber

Maximum

Audio

HEATER

In

regulated

condensation.

adjusted

knob

the

WIRE

Heater

to

to

is

used

maintain

control

AND

on

the

Test

Number

Version

Beep

ON

Wire

To

for

this

circuit

Control

Heater

minimise

VERSION

3.0

humidifier

then

test

Number

Control

Setting

setting

Plate

MODE

On

Mode

the

desired

(ALL

rainout

at a fixed

purpose,

SOFTWARE

goes

through

the

display

Setting

MODELS

(heater

temperature

or

offset

from

see

2.1.2

is

momentarily

If

successful

All

the

eg

'730°

eg

'2.0'

eg

'37.0'

If

heater

is

displayed

ερ

110'

wire

switch

maximise

the

above.

the

following

the

indicator

Airway

EXCEPT

set

LEDs

Temperature

is

displayed

wire

mode

eg

MR480)

green

LED

and

humidity,

humidification,

airway

temperature.

sequence.

blanked.

'SEE

MANUAL'

are

illuminated

is

selected

'-1.0'.

Not

on)

the

within

the

Note

display

then

applicable

heater

close

chamber

The

front

that

each

LED

lights

and

'8.8.8.'

the

chamber

for

MR480

plate

and

limits

with a minimum

outlet

panel

information

briefly.

is

displayed

control

heater

wire

temperature

Chamber

Control

is

on

setting

are

of

can

be

2.5

MR730/720

In

the

non

Heater

temperature

heater

plate

backup

at

low

safety

flow

IN

HEATER

Wire

mode

is

maintained

to

deliver

mode,

rates

the

to

limit

(below 5 L/minute)

WIRE

of

the

by

heater

selected

temperature.

the

chamber

OFF

MODE

MR730/720

plate

control

outlet

is

enhanced

AND

MR480

(heater

The

temperature

only.

sensor

at

the

wire

The

sensor

at

to a maximum

sacrifice

switch

at

the

chamber

of

green

the

some

LED

off)

delivery

outlet

of

66

low

flow

the

delivery

hose

end

controls

is

employed

°C.

In

this

way

performance.

in

a

safety

the

Page 11

page

5

2.6

2.6.1

2.6.2

2.6.3

WARM

The

conditions

UP

Low

temperature

are

MODE

met:

MR700/MR730

the

airway

the

airway

software)

e

the

airway

MR700/MR730

the

airway

the

airway

the

airway

further

Note:-

switches

And a low

MR720

15

In

this

mode

on.

At

temperature

WITH

VERSION

minutes.

alarm

AND

MR720(VERSION

temperature

gets

temperature

temperature

AND

MR720(VERSION

temperature

temperature

temperature

the

this

audio

time

alarm

gets

the

2.0/3.0

is

disabled

within

does

not

increase

does

not

get

above

does

not

increase

increases

alarm

is

heater

plate

mute

is

for

SOFTWARE

during

1.0)

IN

0.8

degrees

within 2 ºC

1.0)

IN

30

°C

by 2 °C

not

enabled

circuit

10

minutes,

warm

up.

HEATER

of

by 2 °C

of

NON

HEATER

by 2 °C

within

for

switches

during

It

is

enabled

WIRE

MODE

the

temperature

within 4 minutes

the

set

point

within

WIRE

MODE

within

15

minutes

15

minutes

30

seconds

but

still

after

off.

which

the

as

soon

control

(2

minutes

.

ten

AND

has not

the

Airway

heater

as

any

setting.

for

minutes

MR480

reached

Temp

plate

is

of

the

following

version

of

switch

30

°C

Low

enabled.

3.0

after

LED

on.

a

2.7

2.7.1

2.7.2

If

the

above

mode

for

20

STANDBY

MODE

MR700/MR730

The

standby

be

emitted

In

the

nominal

Standby

warm

A

Remote

LED

MR720

The

warm

for

While

a) If

enter

the

b)

If

completion

conditions

once

standby

40.0

mode

up

mode

Standby

permanently

STANDBY

MR720

up

conditions

version

unit

3.0

in

standby

the

airway

warm

re-enters

the

airway

and

up

of

warm

up

conditions

minutes

mode

for

version

AND

MR720

can

be

successful

mode

all

Low

°C

and

the

is

automatically

is

entered

request

on.

MODE

has a special

are

not

mode:

temperature

mode.

The

Standby

temperature

the

standby

if

these

are

are

2.0

(VERSION

entered

or

entered

or

Temperature

heater

wire

exited

(the

low

temperature

(see

Appendix

(VERSION

feature

where

met.

This

increases

unit

then

mode.

has

not

period,

not

initial

met,

not

initially

software

1.0)

exited

by

exited

standby

alarms

is

on a 15%

after

20

A6.3)

2.0

AND

it

will

standby

by 2 °C

rechecks

increased

warm-up

the

unit

alarms.

met

the

and

30

minutes

ONLY

depressing

mode

are

inhibited,

duty

minutes

alarms

remain

enables

3.0

SOFTWARE

go

into a standby

mode

time

at

any

time,

warm-up

exiting

by 2 °C

resumes.

MR720

for

the

standby

(refer

cycle.

(30

minutes

disabled - refer

the

standby

ONLY)

is

20

minutes

the

conditions

or

come

The

will

automatically

version

3.0

button

2.2.3)

the

heater

for

version

mode

mode

automaticaliy

for

MR720

will

and

within 2 °C

unit

then

rechecks

enter

the

standby

software

(refer

2.7).

for 1 second. A beep

plate

is

3.0

section

and

turns

version

exit

stand

if

these

of

the

warm-up

controlled

software)

2.6).

the

after

2.0

are

set

to

and

standby

turn

and

30

by

mode

not

met, then

temperature

exiting

will

a

the

amber

on

if

the

minutes

and

by

MR730/720/700/480

Technical

Manual # Revision D #

Issued

October

1995

Page 12

page

6

3.0

3.1

ALARMS

AND

TEMPERATURE

If

the

airway

temperature

Probe

alarm

will

flashing

Five

display,

(a)

(b)

(©)

(d)

Temperature

specific

as

shown

fault

--- . Temperature

---,

--.-

-

-.-.

INDICATORS

PROBE

be

types

below:

Low

Open

Open

Open

Very

Short

Very

Short

Very

ALARM

probe

enabled.

Probe

red

can

be

temperature

circuit

circuit

circuit

low

temperature

circuit

high

temperature

circuit

high

temperature

Indication

is

disconnected

LED

and

diagnosed

Probe

not

(~0

chamber

in

common

patient

airway

chamber

patient

airway

is

by

an

audio

and

plugged

°C)

outlet

lead

probe

(~0 °C)

outlet

(~100

probe

(~100

or

develops a low

a'-

- -'

message

alarm.

are

displayed

in.

probe

in

probe

probe

°C)

°C)

on

by

cable.

or

the

airway

the

sequence

high

resistance

the

Temperature

temperature

of

‘decimal

points’

display

plus

in

a

the

3.2

3.2.1

(e)

The

faults

does

not

A

Temperature

Once

the

ALARMS

HEATER

If

the

heater

alarm

LED

~

circuits

the

heater

An

open

On

MR720/730

2.9.4).

Note:

If

'F-2'

section

-.- - Short

(a

to

d)

above

immediately

Probe

alarm

condition

IN

HEATER

WIRE

ALARM

wire

is

disconnected

will

start

will

be

shutdown.

wire

fuse

is

circuit

heater

if

the

is

displayed

and

5).

in

probe

are

checked

cause

any

Alarm

immediately

has

been

WiRE

Mope

flashing

and

The

open

circuit).

wire

fuse

Heater

Wire

the

F2

cable

between

for

apparent

removed

(MR700/720/730

or

there

the

audio

display

is

indicated

is

connected

fuse

is

intact

will

patient

at a rate

of

operating

shuts

down

the

humidifier

is a fault

alarm

wili

continue

by

‘F-2'

but

then

check

airway

about

twice

anomaly

both

heater

will

with

the

heater

be

enabled.

to

indicate

appearing

switched

the

calibration

probe

per

is

checked

wire

enter

onLy)

wire

Both

the

temperature

on

the

off,

the

and

chamber

second.

The

twice a minute.

and

heater

warm

up

mode

circuit,

then

heater

wire

sensor

Airway

alarm

of

will

the

Temperature

sound

41°C

outlet

probe

final

fault

plate.

(refer

the

Heater

and

reading

(refer

overheat

(e)

section

Wire

heater

(unless

display.

section

(refer

which

2.6).

plate

3.2.2

AIRWAY

The

delivered

instantly

TEMPERATURE

red

Airway

to

disables

Temp

the

patient

both

HIGH

High

LED

is

2°C

heater

ALARM

will

flash

higher

than

circuits.

and

an

audible

the

Temperature

alarm

will

Control

sound

if

the

gas

setting. A high

temperature

temperature

alarm

being

Page 13

page

7

3.2.3

3.2.4

AIRWAY

The

red

Airway

delivered

Notes:

If

Airway

heater

wire

heat

for a further

This

alarm

CHAMBER

This

alarm

1)

The

chamber

Temperature

2)

The

temperature

This

alarm

start

flashing.

the

high

temperature

TEMPERATURE

Temp

to

the

patient

Temperature

circuits

is

TEMP

will

temperature

will

100

disabled

HIGH

activate

of

set

temperature

Control

temperature

causes

by

10

the

The

audio alarm

of

condition

LOW

ALARM

Low

LED

is

2°C lower

Low

alarm

switch

seconds,

during

ALARM

if:

gas

leaving

for

setting

the

gas

°C

or

more.

heater

circuits

will

flash

(4°C

condition

off.

Pressing

the

Airway

warm-up,

the

more

and

the

leaving

to

(which

is

cleared.

and

an

audible

for

MR720

persists

the

Temperature

see

section

mute

2.6.1.

model)

for

button

humidification

than

20

minutes.

Chamber

the

switch

can

Control

humidification

off

and

be

muted)

is

alarm

than

more

than

will

Low

LED

chamber

(The

chamber

setting).

chamber

the

Chamber

also

enabled.

will

sound

the

Temperature

100

silence

will

outlet

is

set

outlet

Temp

This

if

the

seconds

the

Audio

continue

more

than 4 °C

temperature

exceeds

High

alarm

gas

temperature

Control

the

heater

alarm

to

flash..

is

the

chamber

amber

LED

remains

setting.

plate

and

resume

higher

the

sum

indicator

active

being

and

than

of

set

until

the

the

to

3.2.5

3.2.6

CHAMBER

This

alarm

For

Chamber

The

temperature

chamber

OR

For

Chamber

The

temperature

minutes.

THEN:

The

Chamber

muted)

mute

SET

Version

This

LED

is

button

LOW

alarm

will

adjusted

Temp

Low

will

activate

Set

Temperature < 35°C

of

set

temperature

Set

Temperature > 35°C

of

Temp

enabled.

will

silence

WARNING

1.0

and

Version

will

activate

immediately

above

31.0

ALARM

gas

leaving

gas

leaving

Low

This

be

°C.

if:

for

more

alarm

alarm

the

Audio

2.0

Software

if

the

enabled

There

the

humidification

than

20

the

humidification

amber

LED

remains

active

alarm.

chamber

is

and

remain

no

audible

set

chamber

minutes.

chamber

will

begin

to

until

the

low

temperature

on,

until

is

such time

alarm.

outlet

is

less

outlet

is

less

flash

and

the

temperature

below

31.0

as

the

than

than

audio

condition

°C.

In

this

chamber

4°C

31°C

alarm

is

case

set

lower

than

for

more

(which

can

cleared.

the Set

temperature

the

than

20

be

Pushing

Low

amber

is

the

Version

This

3.0

alarm

Software

will

34.0°C.

In

these

cases

set

airway

or

chamber

MR730/720/700/480

activate

the

Set

Low

if

either

the

amber

LED

temperature

Technical

is

chamber

will

immediately

adjusted

Manual

set

temperature

above

34.0

#

Revision

or

be

enabled

°C.

D #

Temperature

and

remain

There

is

no

Issued

control

on,

audible

October

setting

until

alarm.

1995

is

such

below

time

as

the

Page 14

page

8

3.3

3.3.1

3.3.2

3.3.3

3.4

TEMPERATURE

HEATER

This

(Heater

begins

AIRWAY

The

delivered

AIRWAY

The

delivered

Notes:

The

Pushing

the

This

AUDIO

WIRE

indicates

Wire On

and

the

TEMPERATURE

red

Airway

to

the

TEMPERATURE

red

Airway

to

the

audio

alarm

the

mute

Airway

alarm

Temp

is

ALARM

disabled

ALARMS

ALARM

that a heater

LED

heater

Temp

patient

Temp

patient

is

not

button

Low

wire

is

off). In

plate

is

HIGH

High

is

41°C

LOW

Low

is

29.5

enabled

disables

LED

during

IN

NON

has

this

switched

ALARM

LED

will

or

higher.

ALARM

LED

will

°C

or

for

30

the

will

continue

warm-up,

HEATER

been

connected

case

the

off.

flash

Power

flash

less.

seconds

audio

to

see

WIRE

Heater

and

an

to

and

an

after

alarm

and

flash.

section

MODE

when

Wire

audible

the

heater

audible

the

low

restores

2.6.2.

(INCLUDES

the

non

heater

alarm

LED

alarm

will

sound

plate

is

immediately

alarm

will

sound

temperature

power

to

wire

will

LED

the

MR480)

mode

be

flashing,

if

the

gas

shut

if

the

gas

begins

heater

plate

has

been

selected

the

audio

temperature

off.

temperature

flashing.

for

ten

minutes,

alarm

being

being

3.5

3.5.1

A

choice

of

the

ISO

draft

control

A

a

until

audio

SAFETY

TEMPERATURE

‘An

of a Low

however

There

Firstly,

monitors

at

Secondly, a bimetallic

exceeds

by

Heater

heater

link

momentary

low

temperature

the

alarm

alarm

PROTECTION

over

temperature

Temperature

remains

are

two

an

the

41.0

degrees.

118

gaining

plate

plate

(L1),

refer

depression

alarm

condition

to

be

re-enabled.

DEVIATIONS

on

independent

over

temperature

airway

°C + 6

°C

access

to

temperature

limits

of

alarm condition

until

thermistor

the

50,

standard

Appendix

of

the

mute

in

no

heater

clears.

alarm,

(ALL

the

backup

Any

MODELS)

pressing

fault

protection

sensor.

thermostat

and

opens

under

surface

is

limited

80

and

90

audio

A3.

button

wire

new

causes

has

over

fixed

the

mains

to

°C

110

alarm

or a gliding

will

mode,

alarm

an

immediate

Mute

causes

cleared.

temperature

circuit

independent

This

backup

to

the

heater

active

of

the

heater

°C

max

can

be

selected.

silence

the

see

3.3.3.

condition

heating

protection

protection

plate

supply.

plate

and

during

normal

(Refer

tone

can

audio

alarm

The

relevant

occurring

shut

down

to

recommence,

circuits.

of

the

microprocessor

is

preset

operates

On

if

cooling,

manually

operation

Appendix

be

selected

within a mute

of

both

to

the

this

by

for

about 3 minutes

LED

indicators

heater

the

Low

disconnect

heater

plate

protector

depressing

(80

°C

A3.)

the

programming

remain

delay

circuits.

Temperature

control

continuously

the

temperature

can

the

red reset

for

MR720).

(except

will

cause

In

heating

only

be

button.

for

flashing

the

the

case

LED

circuits

reset

Optional

3.5.2

MICROPROCESSOR

A

control

detected a hardware

additional

LED

The

on.

watch

loop

in

the

hardware

dog

circuit

WATCH

DOG

operating

reset

circuit

disables

is

tested

the

software

attempts

heating

at

turn

on

continuously

to

re-initialise

circuit,

by

deliberately

monitors

blanks

for

the

microprocessor.

the

display and

halting

the

correct

operation.

turns

the

processor

If

this

is

Humidifier

and

forcing

Should a fault

not

successful

Fault

be

red

initialisation.

Page 15

page

9

4.0

41

4.2

4.21

CIRCUIT

INTRODUCTION

This

in

Sections

CONTROL

The

one

for

the

software

CONTROL

Three

dual

1. . A

OPERATION

section

temperature

describes

8.6

BOARD

basic

MR730/720/700/480

version.

THERMISTORS

standard

thermistor

temperature

humidifier

2. A second

humidifying

control

3. A third

J3-1,3).

the

thermistor

This

briefly

the

to

8.8.

control

thermistor

board,

with

range

characteristic

probe

is

mounted

(connector

front

panel.

thermistors

sensor,

in a probe

J4-1,3).

mounted

chamber

chamber

prevents

(connector

outlet

is

permanently

excessive

operation

various

discreet

of

humidifiers.

control

another

thermistor

at

the

This

temperature

in a probe

J4-2,3).

temperature.

mounted

heater

of

each

of

hardware

Each

all

temperature

monitors

end

of

the

measures

In

heater

in

intimate contact

plate

temperatures

the

circuit

sections.

changes, provides

model

however

functions.

the

heater

delivery

is

indicated

the

wire

hose

chamber

mode

during a warm

Refer

is

controlled

Two

plate

temperature.

to

measure

by

the

digital

temperature

this

thermistor

with

the

heater

up

to

the

circuit

the

controlling

by a unique

thermistors

delivered

display

at

the

top

is

used

plate

cycle.

on

to

(HP)

diagrams

functions

are

used

airway

the

of

the

monitor

(connector

in

a

and

4.2.2

4.2.3

INPUT

ANALOG

SWITCHES

The 1 by 8 analog

reference

potentiometer

across

From

chamber

ANALOG

The

suppression.

pass

voltage

with

discharged

gain

Under

ramps

referenced

level

the

potentials.

VR3,

resistors

the 3 by 2 analog

temperature

outlet

TO

DIGITAL

R18,

temperatures

probe

The

operational

amplifier

transients

R35

connected

state.

of

about

0.5

processor

up

of

UI0d

speed

control

(0.1-5ms).

via

R41

the

up

capacitor

U8

AND

switch

(U8)

selects

Selected

and

R17

CONVERTER

selected output

sequentially

offset

potentiometer

and

R16,

switch

(U9)

from

inputs

are

filtered

of

with a gain

appearing

(through

With

giving a resting

to

output

VR5

(PB6)

This

the

of

C24,

at

its

an

and

when

rising

output

the

comparator

is

fed

input.

analog

R34

level

ramp

voltage

US

under

and

from

under

the

dual

U10

B,D,E

the

analog

of

11.

The

switch

connected

of

the

switch

voltage

level

to

the

RST

processor

are

potentials

VR2.

(7):

the

processor

probe

temperature

by

the

C30, C31,

switch

This

stage

integrating

in

U9)

to

about

-2.5

section

is

fed

of

U10d.

stage

U10e

6.5

interrupt

control

(PB0-3)

giving;

(4-6):

calibration

heater

plate

control

(PB4-6)

R28,

network

is

filtered

stage

U10b

across

the

the

non-inverting

to

-3

volts

of

U9

across

via

R36

to

When

switches

input

various

(0-3):

the

temperatures

(HP)

thermistor.

the

airway

sensor

U8,

R26,

U9

with

are

C19,

is

fed

C23

rests

for

integrating

input

at

the

output

C22

is

the

comparator

the

ramp

voltage

high.

This

of

U3.

input signals

position

of

temperature

also

read.

C20

network

to

pin

to

give

most

of

capacitor

of

U10b

pin

1.

opened

stage

exceeds

fast

rising

and

of

the

temperature

9,

34.5

and

and

for

EMI

10

of

U10d, a low

protection

the

C22

the

the

U10e

edge,

from

time

(50-60ms)

holding

stage

has a ‘static’

output

of

where

the

threshold

assisted

60

°C

the

any

it

ina

U10b

it

is

by

set

4.2.4

PROCESSOR

After

selecting

pause

linear

will

cause a RST6.5

MR730/720/700/480

to

allow

ramp

CONTROL

output

one

U10d

and

U3

of

the

10

to

settle.

the

14

interrupt

Technical

input

At

this

bit

counter

to

occur.

signals

point

in

The

Manual

through

the

switch

U4

is

processor

№

the

switch

across

started.

on

responding

Revision

network

the

Within a time

D. # issued

of

integrator

to

U8,

U9

U10b

period

the

interrupt,

October

there

is

of

100ns

is a

50-60ms

opened

to

first

stops

1995

initiating

Sms

the

a

ramp

Page 16

the

counter,

network

equated

during

calibration

then

U8,

to

the

calibration

performed,

U9

input

closes

can

now

signal.

to

give

the

switch

be

stepped

In

the

desired

and

the digital

this

across

to

the

way

all

ramp

display

page

the

integrator

next

10

input

rate.

updated.

10

input.

channels

Thus

readying

The

14

all

points

it

for

bit

counter

are

continuously

are

scanned

the

next

can

once

now

cycle.

The

be

read

scanned.

every

input

switch

and

its

value

VRS

is

set

500-600ms,

self

4.2.5

4.2.6

4.2.7

POWER

A

R56

software

enabling a zero

frequency

Power

The

ground

any

frequency

triac

common

41

Operational

inverting

inverting

ensure

(OVHT)

switching

both

A

resistor

clamped

LINE

sample

of

and

O1,

determines

thus

LINE

zero

crossing

referenced

unwanted

facilitating

switching.

error

°C

COMPARATOR

input

input

that

the

is

fed via the

transistors

heaters

watch

dog

R31

off

INTERRUPT

the

buffered

INTERRUPT

amplifier

to

failure,

to

in

power

supply

by

the

supply

crossing

eliminating

is

derived

when

noise

from

the

The

ADC

from

this

source.

U10c

pin 5 is

goes

output

connected

to

an

pin 7 of

isolating

Q10

be

shut

down.

which

the

inverting

the

event

(REVISIONS

frequency

Schmitt

detector

any

D/F

trigger

frequency

for

triac

common

is

USf

facilitating

switching.

error

(REVISION H PCB)

from

the

10Vac

the

diodes

D13 - D16

the

zero

crossing

generation

is

also

is a protection

adjustable

and

is a high

input

of a processor

phase

directly

U10c

diode

Q12.

of

of a real

synchronised

circuit

(via

divider

is

low

resistor

In

this

output

U10c.

crash.

PCBs)

derived

circuit.

above

way, a patient

from

from

and

fed

to

the

The

from

this

secondary.

are

not

The

time

clock

with

to

sense

connector

network

an

R32,

input

networks

USg,

This

also

ensures

the

the

generation

ADC

source.

Resistor

conducting.

operating

and

excessive

J4-1)

temperature

D19,

airway

is

communicated

power

RST7.5

is

also

R61.ensures

software

also

enabling a zero

the

line

to

the

VR4,

R33.

R55

and

temperature

that

both

transformer

interrupt

of a real

Network

of

time clock and

phase

synchronised

Ri,

that

determines

frequency

delivery

patient

VRA

of

41

D20,

thus

temperature

airway

is

set

°C.

R61

greater

via

isolating

heater

control

22Vac

secondary

U3.

The

operating

the

secondary

R69,

and

the

supply

crossing

eliminating

rise.

thermistor.

during

calibration

This

low

to

clamp

the

than

diode

circuits

via

also

with

the

is

C2

removes

detector

any

The non

The

output

bases

41°C

causes

D11

and

are

line

for

to

of

4.2.8

4.2.9

HEATER

Thermistor

plate

cools

maximum

Also

electronic

primary

mechanical

heater

WATCH

During

the

wave,

13

through

input

nature

initialise,

deliberately

the

and

PLATE

HP

limit

(default

below

heater

mounted

control

and

plate

DOG

operation

state

of

output

buffered

of

USg

is

R3

forces

of

the

it

fails

processor

also

tums

OVERTEMPERATURE

senses

the

heater

110

°C)

during

this

limiting

plate

on

thus

causes

cut

out

module.

by

held

giving a high

re-initialisation

fault.

in a safe

halting

has

off

temperature.

temperatures

the

heater

system

complete

must

be

the

processor

port

PB7

USb,

is

hard

up.

The

purpose

program

failed

the

the

display

plate

fail.

manually

of

fed

Should

output

of

mode.

execution

high

plate

temperature.

normal

Under

can

is a mechanical

This

mechanical

shut

down

reset

is

continually

U4

every

to

the

charge

this

square

from

pin

the

processor

of

this

is

The

watch

and waiting

output

of

I.C.

U7

to

blank

operation,

certain

be

selected.

118

cut

of

the

by

means

monitored

16.6

or

20ms

pump

wave

12,

which

which

to

ensure

dog

circuit

U5g

also

the

Should

the

power

operating

(See

Appendix

°C

cut

out

is

connected

humidifier

of

the

reset

for

(power

circuitry

may

that

for

digital

C16,

be

interrupted

drives

the

or

may

if

the

is

tested

initialisation

turns

on

display.

heater

plate

to

the

heater

plate

conditions,

A3:

out

which

will

in

series

should a serious

button

located

correct

function.

line

frequency

D4,

DS

for

trap

interrupt input

not

be

processor

every

time

via the

Q3

which

and

any

successful

should

lights

exceed

the

is

discontinued

for

increased

Programming

give

protection

with

the

fault

on

the

This

is

interrupt).

C15

which

reason,

depending

fail,

the

humidifier

watch

the

'see

C15

of

and

dog.

maximum

safety,

Control

should

power

transformer

develop.

underside

done

by

This

ensures

will

discharge

U3.

This

is

unable

is

tumed

To

indicate

manual’

heater

until

it

lower

Options.)

the

The

of

the

changing

square

that

pin

high

trap

on

the

to

re-

on

that

LED10

by

Page 17

page

11

43

4.3.1

4.3.2

POWER

Revision

A

circuit

stabilized

The

the

UA

The

signal,

connected

Wire.

Тнас

Q12,

Transistors

BOARD

D/F

PCBs

bridge

rectifier

is

protected

by

Q8,

Heater

Wire

optoisolator

on

the

control

resistor

with

ОП

and

R52

processor

or

open

(mounted

HPC.

Q5

and

U11

REVISION H PCBS

A

bridge

rectifier

circuit

is

protected

stabilized

by

O8,

(D13-D16)

by a 1

Amp

is

derived

(HHC)

is

which

from

controlled

in

board.

connected

to

interpretation,

circuit

and

on

the

heatsink)

Q6

are a RS232

(D13-D16)

by a 1

is

derived

supplies

Amp

from

supplies

turn

the

fuse

the

is

anode

power

(Fi)

voltage

by

driven

provides

also

the

integrity

is

level

power

fuse

(F1)

the

voltage

to

the 5 volt

mounted

on

doubling

triac

Q9

which

by

Q10.

of

Q9

provides a signal

the

information

of

fuse

controlled

driver

mounted

by

for the

to

the 5 volt

on

doubling

regulator

the

circuit

network

is

mounted

O10

is

Q7

board.

D17, D18.

controlled

through

to

determine

F2, the 4 Amp

optoisolator

serial

regulator

the

circuit

network

U12,

data

interface.

Q7

board.

D17,

mounted

The 5 volt

on

the

directly

(HHS)

fuse

which

mounted

The 5 volt

D18.

on

the

negative

heat

sink.

from

an

to

USd

if

the

Heater

supplying

in

turn

on

the

power

negative

heat

sink.

supply

Q9

is

switched

output

and

U4.

Wire

is

to

the

is

controlled

heat

sink.

supply

This

port

This

Heater

by

This

by

of

The

Heater

the

optoisolator,

U4

on

balance

Heater

D21,

triac

not

connected

cycle.

interpretation,

also

Q11

output

with

Transistors Q5

Wire

the

control

the

heater

wire

sensing

R66

and

off

and a heater

The

output

the

integrity

controls

port

(HPC)

C33

form a snubber

R67.

then

provides

power

(HHC)

U11,

board

of

and

wire

is

R51

the

of

fuse

to

on

Q6

is

controlled

which

in

turn

(HHC).

with

accomplished

and

wire

Resistor

respect

R52

connected

optoisolator

the

optoisolator

the

information

F2, the 4 Amp

the

heater

plate

U4

on

the

control

for

the

triac

are a RS232

by

is

driven

to

ground.

through

limit

then

will

feeds

and

and

level

triac

Q9

by

R9,

C6

the

the

current

the

optoisolator

be

turned

U4

to

determine

fuse

supplying

is

under

board.

the

optoisolator.

driver

which

is

mounted

Q10.

Q10

form a snubber

optoisolator

through

will

on

and

off

on

the

control

if

the

power

control

Resistors

for

the

R64,

serial

on

the

is

controlled

on

the

U13

and

associated

the

LED

when

remain

in

board.

Heater

to

of

optoisolator

R57

data

off.

synchronisation

This

Wire

is

the

Heater

limit

interface.

heat

sink.

directly

triac.

Capacitors

the

triac

Otherwise

with

signal,

connected

Wire.

U12

and

the

gate

O9

is

from

an

output

C8,

components

is

on

or

if a heater

the

secondary

with

processor

or

open

transistor

current

to

switched

port

C32

R51,

off.

With

wire

circuit

Q12

via

the

triac

by

of

R52,

the

is

and

an

and

MR730/720/700/480

Technical

Manual

Revision D #

Issued

October

1995

Page 18

page

12

44

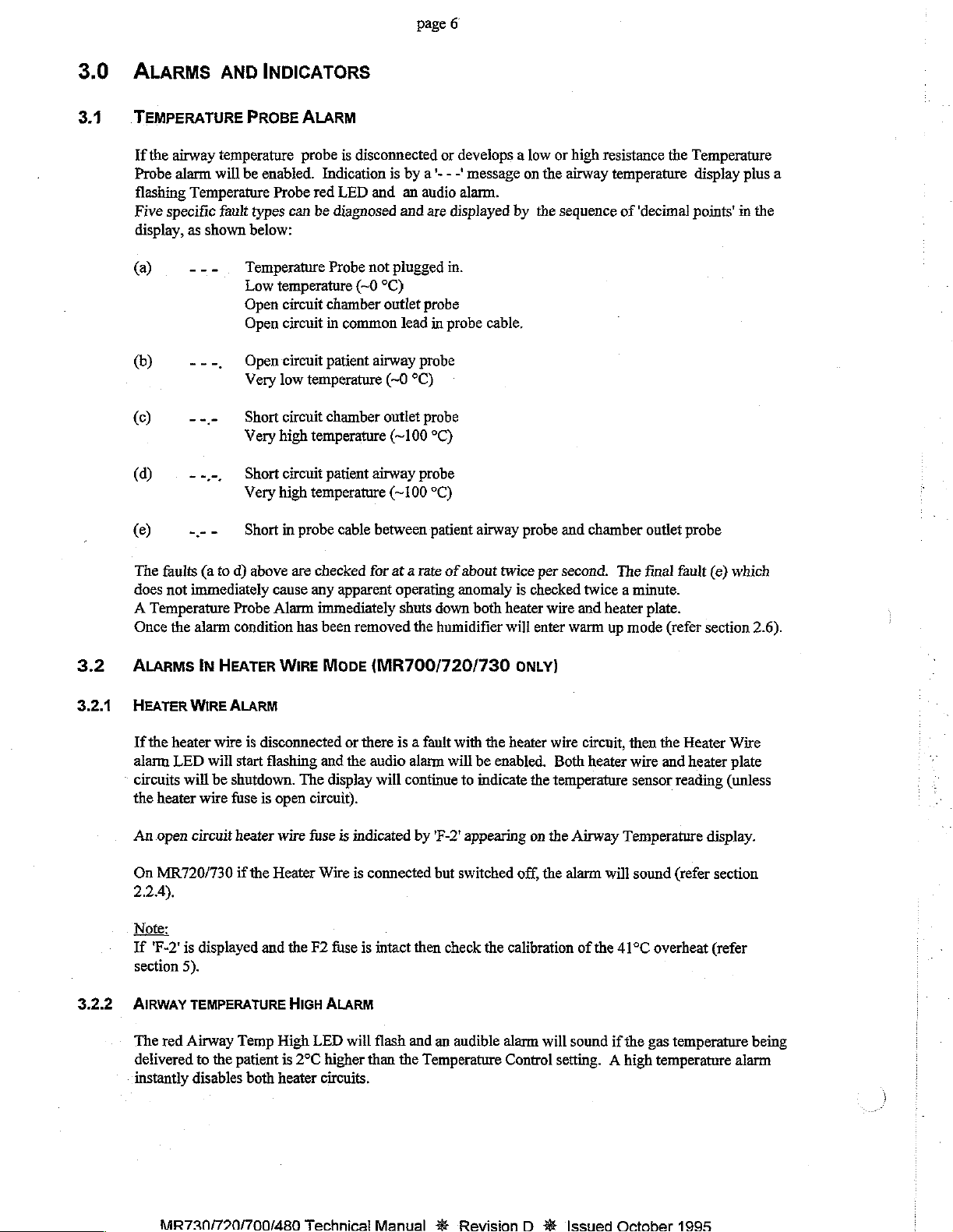

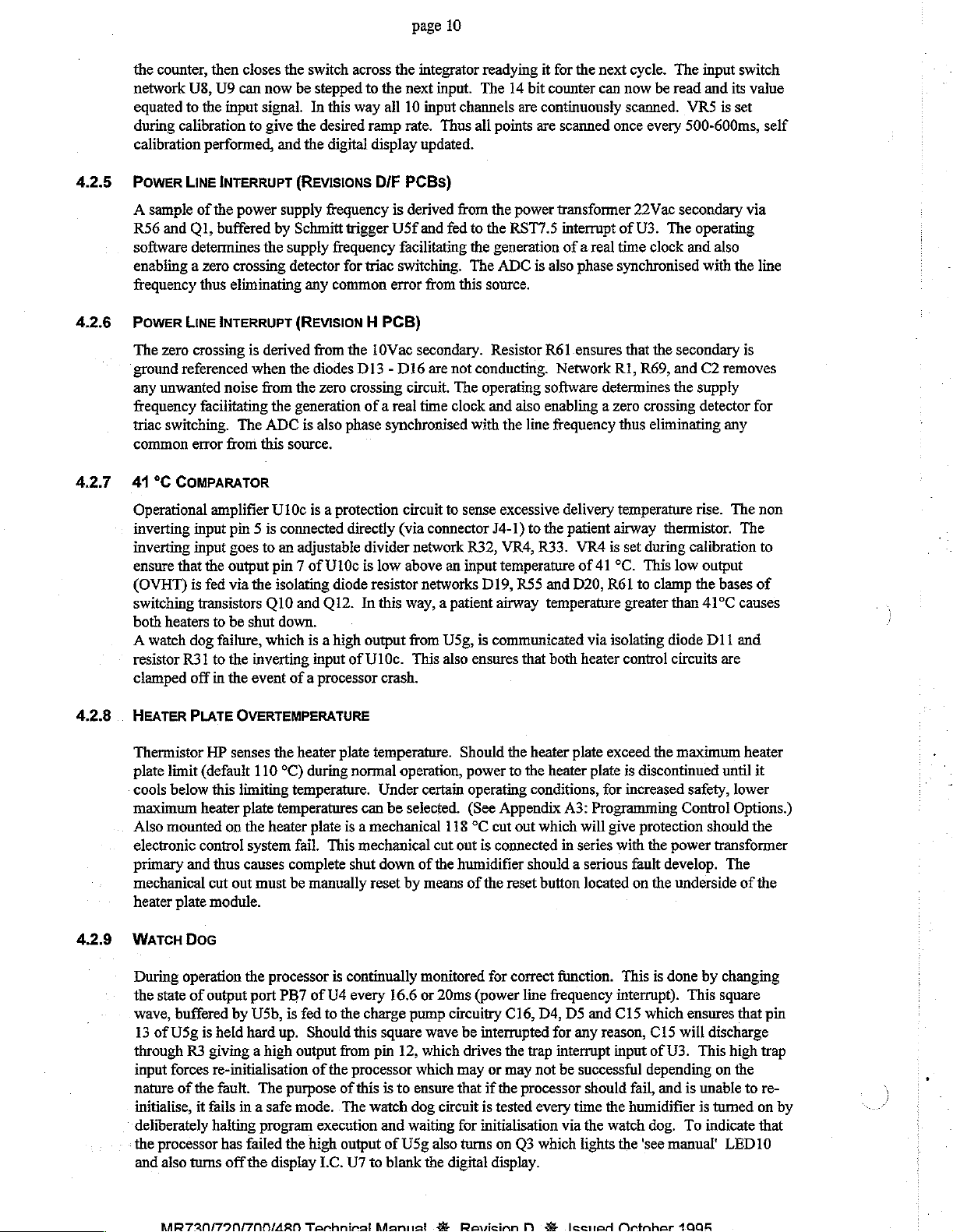

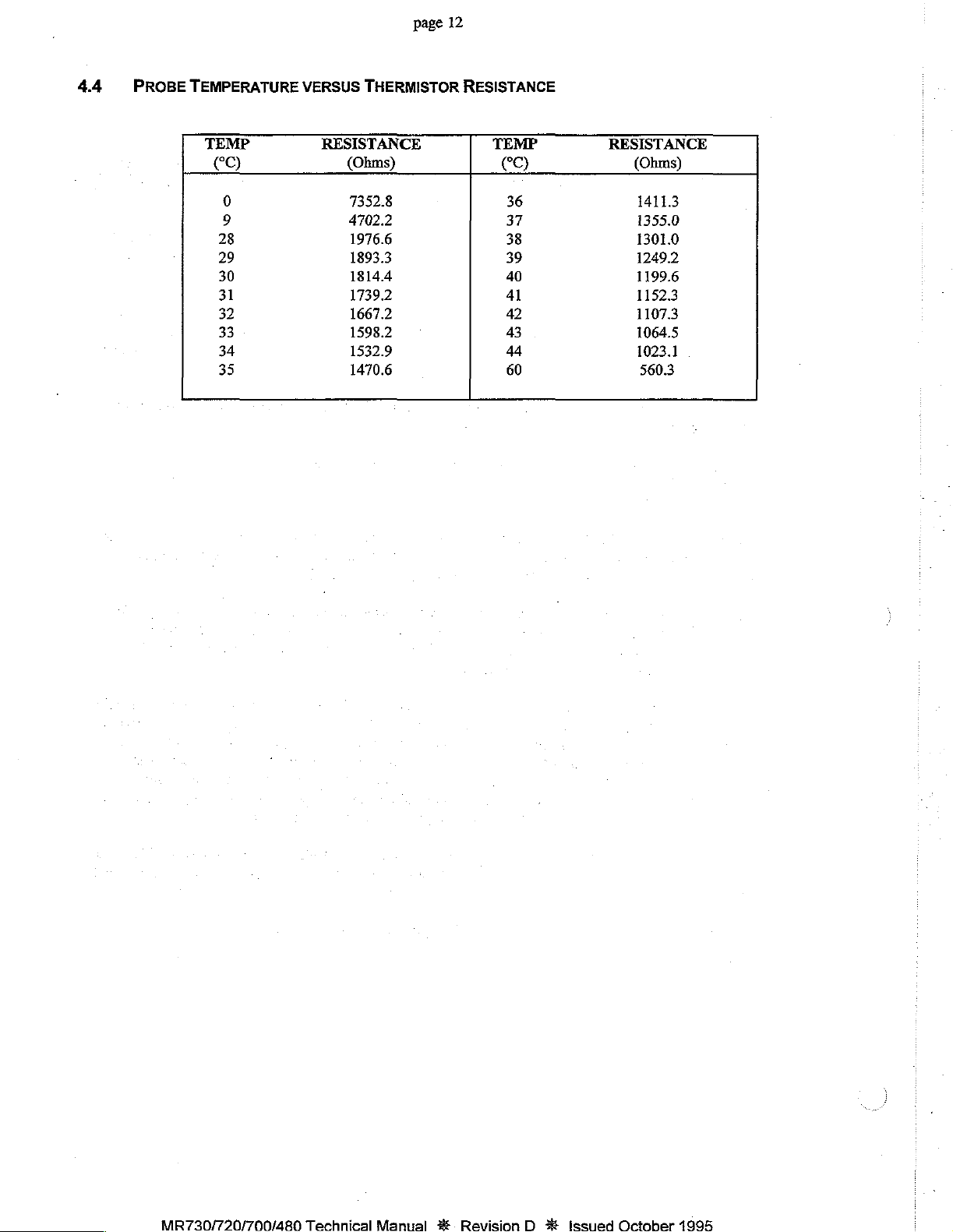

PROBE

TEMPERATURE

TEMP

CO

0

9

28

29

30

31

32

33

34

35

VERSUS

RESISTANCE

THERMISTOR

(Ohms)

7352.8

4702.2

1976.6

1893.3

1814.4

1739.2

1667.2

1598.2

1532.9

1470.6

RESISTANCE

TEMP

CC)

36

37

38

39

40

41

42

43

44

60

RESISTANCE

(Ohms)

14113

1355.0

1301.0

1249.2

1199.6

1152.3

1107.3

1064.5

1023.1

560.3

Page 19

page

13

5.0

5.1

5.2

CALIBRATION

INTRODUCTION

Calibration

calibration,

Note:

Calibration

There

the A to D converter.

This

error

any

repair

with

Calibration

calibration

EQUIPMENT

1)

should

be

performed

perform a performance

For

instructions

is

facilitated

are

only

two

adjustments

calibration

messages

the A to D converter

procedure

in

the

that

may

have

should

be

performed

display)

checked

after

REQUIRED

41

°C

calibration

probe,

after

check

on

disassembly

by

entering a special

VR4

may

be

carried

or

if

any

altered

the

potential

would

require a calibration

and

performed

the

unit

has

available

any

of

the

and

VR5,

of

warmed

in

MR700

as

out

the

servicing

involving

outlined

unit,

refer

Calibration

the

41

if

the

unit

circuit

boards

of

the

+5

after

the

up.

series

the

in

section

to

6.0.

Section

mode.

°C

comparator

is

thought

have

or

-5

volt

check.

unit

has

been

calibration

printed

7.0

Servicing

See

Appendix

stage

to

be

been

replaced

rails

or

running

kit

(F

circuit

boards.

Information.

Al.

and

the

out

of

calibration

or

component

for

at

dz P part

After

setting

of

(E0x-E7x

repaired.

change

least

half

no.

900MR548).

the

span

of

In

particular

associated

an

hour;

ie

5.3

Models

2)

3)

CALIBRATION

(See

1)

2)

3)

Before

Heater

For

MR480

with a 100mm

product

With

models

Wire

switch

Plug

in

Gain

access

humidifier

4)

With

model

the

control

5)

With

the

6)

Using

the

7)

Adjust

off

VR4

Serial

Wire

module.

only - jumper

length

PROCEDURE

change

MR730/720/700

is

on

the

41

°C

to

the

front

MR480

board.

Chamber

Chamber

VR4

slowly

and

recheck

Number

92XXAAA05495

connector

of

cable

and a 22K

FOR

history - section

ensure

(Heater

calibration

Wire On

adjustment

probe.

potentiometers

panel.

only

connect

Temp

button

Temp

button

so

the

display

that

VR4

is

cable,

MODELS

9.0

for

that a Heater

LED

the

jumper

held

down

step

through

just

changes

not

rotated

(Revision D PCB

which

consists

resistor.

WITH

REVISION D PCBS

serial

number

should

be

VR4

cable

turn

on

to

number