Page 1

FORM NO.80324

November I. 1996

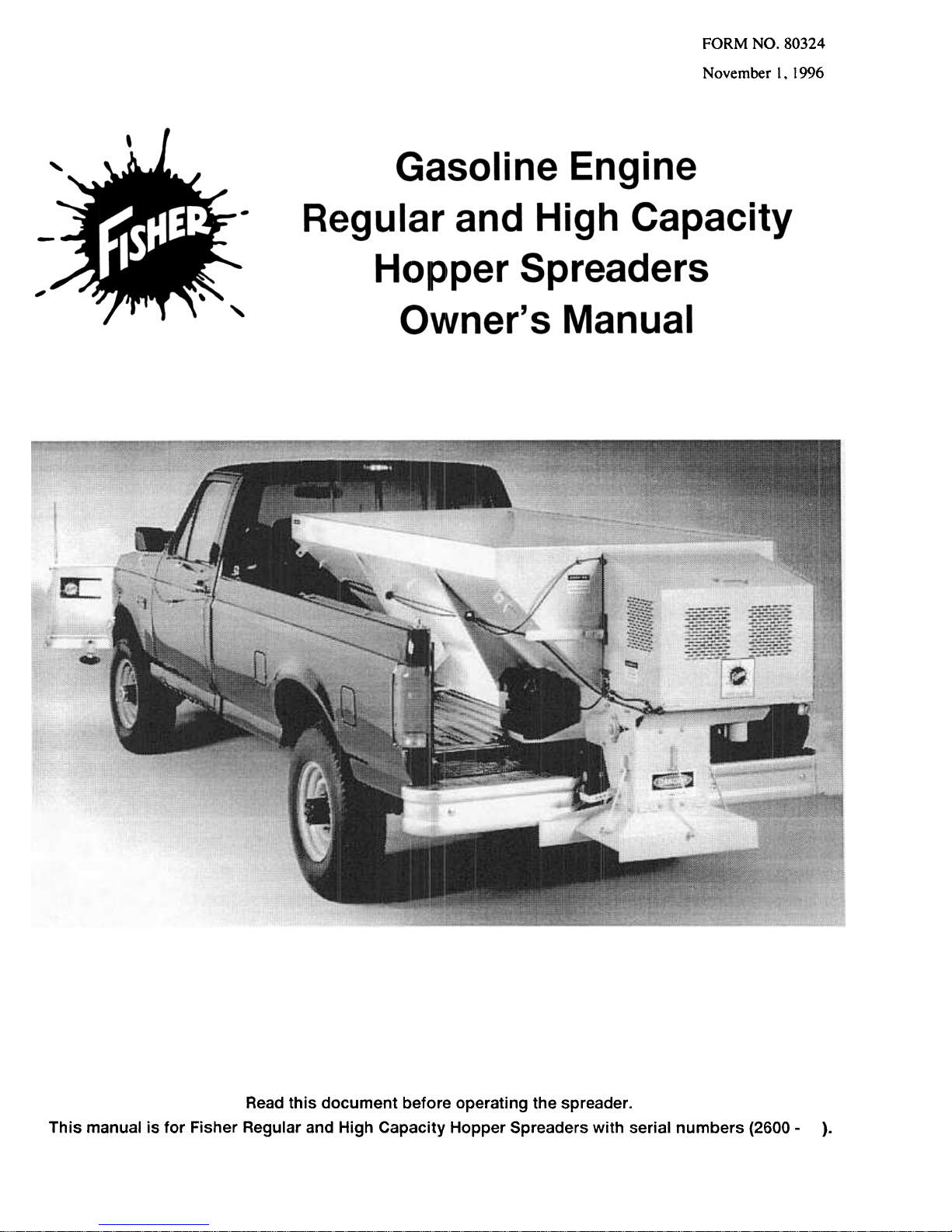

Read this document before operating the spreader .

This manual is for Fisher Regular and High Capacity Hopper Spreaders with serial numbers (2600 -

).

Page 2

Page 3

PREFACE

substitute items as they could affect the

perfonnance and warranty of this product.

Before using your FISHER spreader, make sure

your vehicle is equipped with all vehicle

manufacturer's and Fisher's recommended

options for spreading. Read this manual and all

spreader labels before using the spreader.

Welcome to the growing family of FISHER@

spreader owners.

This manual provides safety, operation,

maintenance, repair parts, and accessories

information for your new FISHER spreader. To

keep your spreader operating safely and

efficiently, insist that all operators and

maintenance personnel read and understand this

manual.

When service is necessary , your local Fisher

dealer/distributor knows your spreader best and is

interested in your complete satisfaction. Contact

your dealer or distributor if you require assistance,

Always obtain original Fisher service parts from

your Fisher dealer/distributor. Never accept any

Before using your spreader, read this manual

carefully and follow its recommendations.

Fisher Engineering reserves the right under its product improvement procedures to change construction or design details and

furnish equipment when so altered without reference to illustrations or specifications used herein. Fisher Engineering and the

vehicle manufacturer may require and/or recommend optional equipment for hopper spreaders. Do not exceed the gross

vehicle weight rating or the gross axle weight rating with a spreader. Fisher Engineering offers a one-year limited warranty

for all hopper spreaders. See separately printed pages for this important information. FISHER@ is a registered trademark of

Douglas Dynamics, L.L.C.

Form No.80324

November 1, 1996

Page 4

Page 5

T ABLE OF CONTENTS

PREFACE

TABLE OF CONTENTS

1

I

I

I

2

4

4

4

5

SAFETY Safety Definitions. Safety Precautions. Battery Safety. Spreader Labels. GENERAL INFORMA TION ...

TorqueChart Material Weights Detennining Vehicle Payload .

7

.7

.7

.7

.7

8

8

Gear Case. 20

Gear Case Assembly. 2 I

Housing Pre-assembly 21

Cover Pre-assembly 21

Output Shaft Pre-assembly 21

Input Shaft Pre-assembly 21

Assembly of Pre-assembled Parts. ..21

Gear Case Disassembly. 22

Feed Gate -Regular Capacity. 22

Feed Gate -High Capacity. 23

Labels -Regular and High Capacity ...23

CabControl 24

Clamp Loops. 24

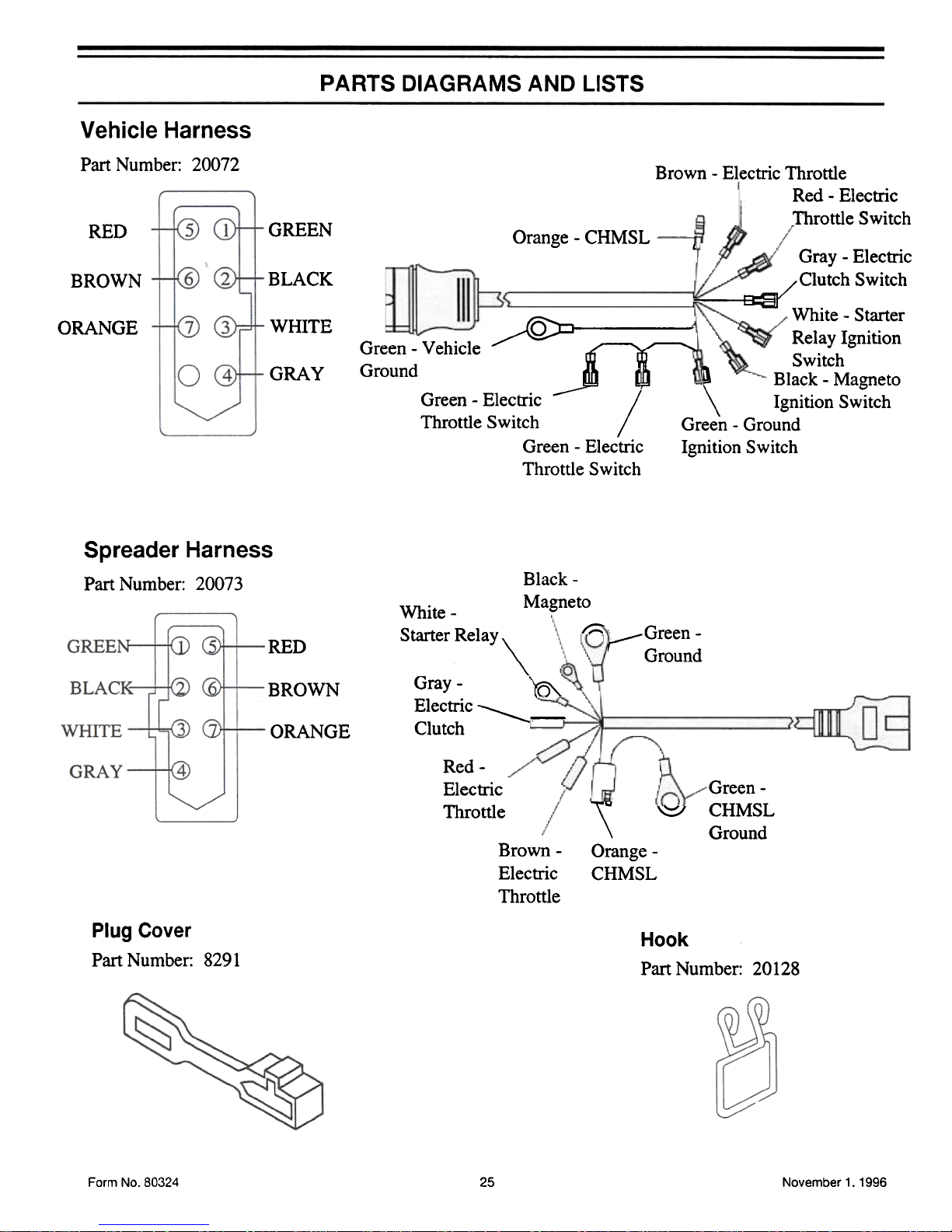

Vehicle Harness. 25

Spreader Harness. 25

PlugCover 25

Hook. 25

Electric Throttle. 26

Removal Instructions. 26

Installation Instructions. 26

OPERATION. Cab Control Identification

Engine Operation. ...

Starting the Engine .

Stopping the Engine .

Clutch Operation. ...

Baffle Adjustment. ...

...10

...10

...10

...10

...11

...11

MAINTENANCE. General. Grease Chains. Electric Clutch. Engine Service and Repair. ..

ABBREVIATION KEY.

11

12

12

13

14

ACCESSORIES. 27

Center High-Mounted Stoplight

(CHMSL)Kit 27

Installation Instructions. ...27

Inverted Vee Assembly Regular Capacity Mild Steel. 28

Installation Instructions. 28

Inverted Vee Assembly Regular Capacity Stainless Steel. 29

Installation Instructions. ...29

Inverted Vee Assembly HighCapacity 30

Installation Instructions. 30

.16

PARTS DIAGRAMS AND LISTS. .

Chute Assembly -Regular Capacity

Chute Assembly -High Capacity .

Conveyor Drive and Idler -

Regular Capacity Conveyor Drive and Idler -

High Capacity. Engine Drive with Clutch -

Regular and High Capacity. ...

.18

Form No.80324

November 1, 1996

Page 6

Page 7

SAFETY

Safety Definitions

C AUTION: Indicates a situation that, if not

avoided, could result in damage to product

or property.

.Stop the spreader before leaving the

vehicle to unclog, adjust, oil, or clean the

spreader

.Before servicing the spreader, wait for all

movement to stop.

.Keep hands, feet, and clothing away from

power-driven parts and the conveyor chain.

.Do not climb on or allow others to climb

on the spreader at any time while operating.

.While operating the spreader, use auxiliary

warning lights except when prohibited by

law.

N OTE: Identifies tips, helpful hints, and

maintenance information the reader should

know.

Safety Precautions

Observe the following safety procedures before

and during the use of the spreader. By following

these rules and applying common sense, possible

injury and potential damage to the product may

be avoided.

I CAUTION: I

.Do not operate a spreader in need of

maintenance.

.Before operating the spreader, reassemble

any parts or hardware that were removed.

.Before operating the spreader, remove

materials such as cleaning rags, brushes,

and hand tools from the spreader .

Battery Safety

.Before working with the spreader, secure

all loose fitting clothing and unrestrained

hair.

.Before starting the spreader, check that all

personnel and equipment are clear of the

spreader and the spray area-

.Before operating the spreader, check that

all safety guards are in place.

.A void exposing battery to a spark or flame.

.Always charge battery in a well ventilated

area.

.A void contact with battery acid. It can

cause serious personal injury and damage

to the equipment.

.Always disconnect battery before

removing or replacing any electrical

components.

.Never lay anything on a battery .This

could result in electrical shock or bums, or

damage to the vehicle or equipment.

'm No, 80324

November 1, 1996

Page 8

SAFETY

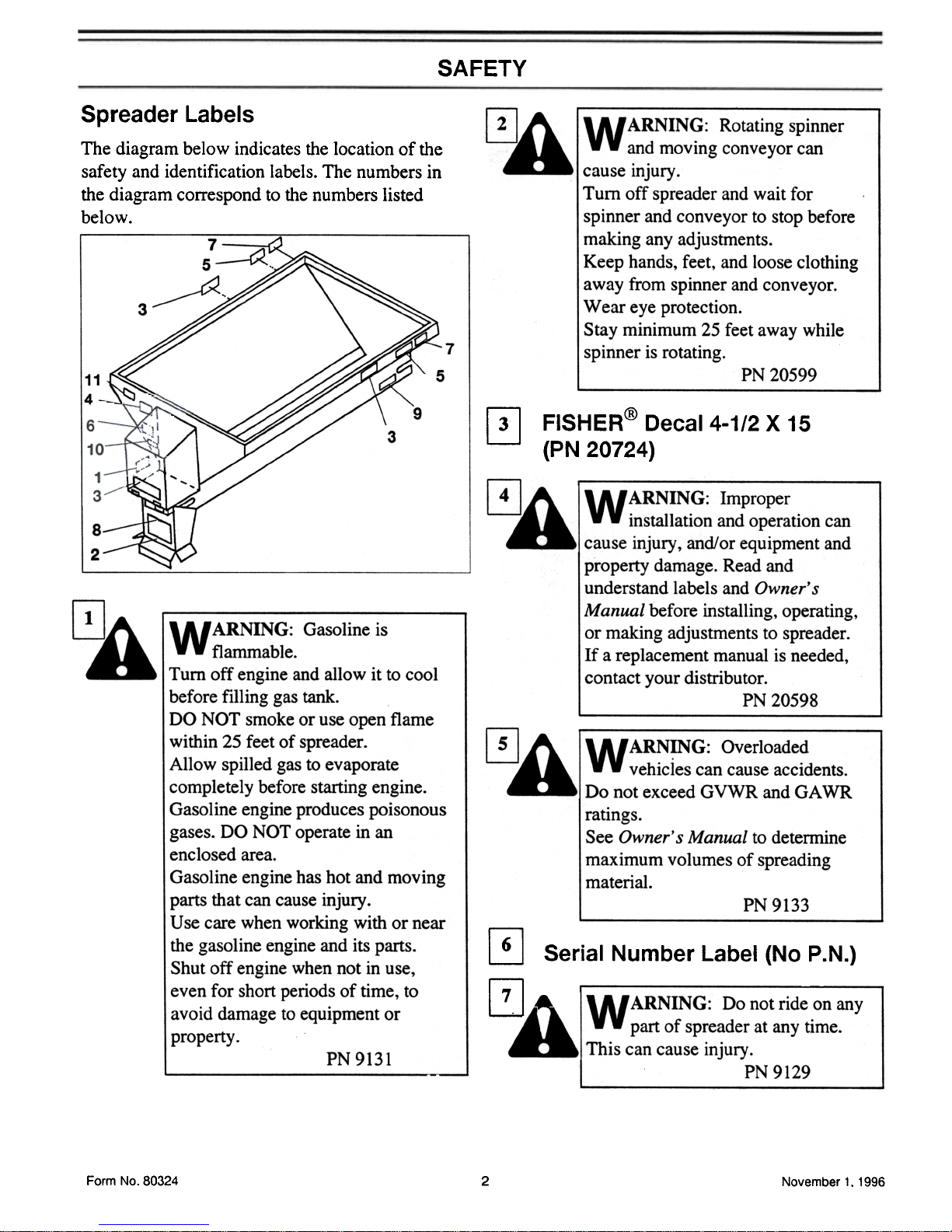

Spreader Labels

The diagram below indicates the location of the

safety and identification labels. The numbers in

the diagram correspond to the numbers listed

below.

3~

7

, 5

11

,

9

0

FISHER@ Deca14-1/2 X 15

(PN 20724)

/~

3

8

0 Serial Number Label (No p .N.)

0A

Form No.80324 2

November 1.1996

7~

5-

Page 9

SAFETY

~

Form No.80324

3

November 1, 1996

Page 10

GENERAL INFORMA TION

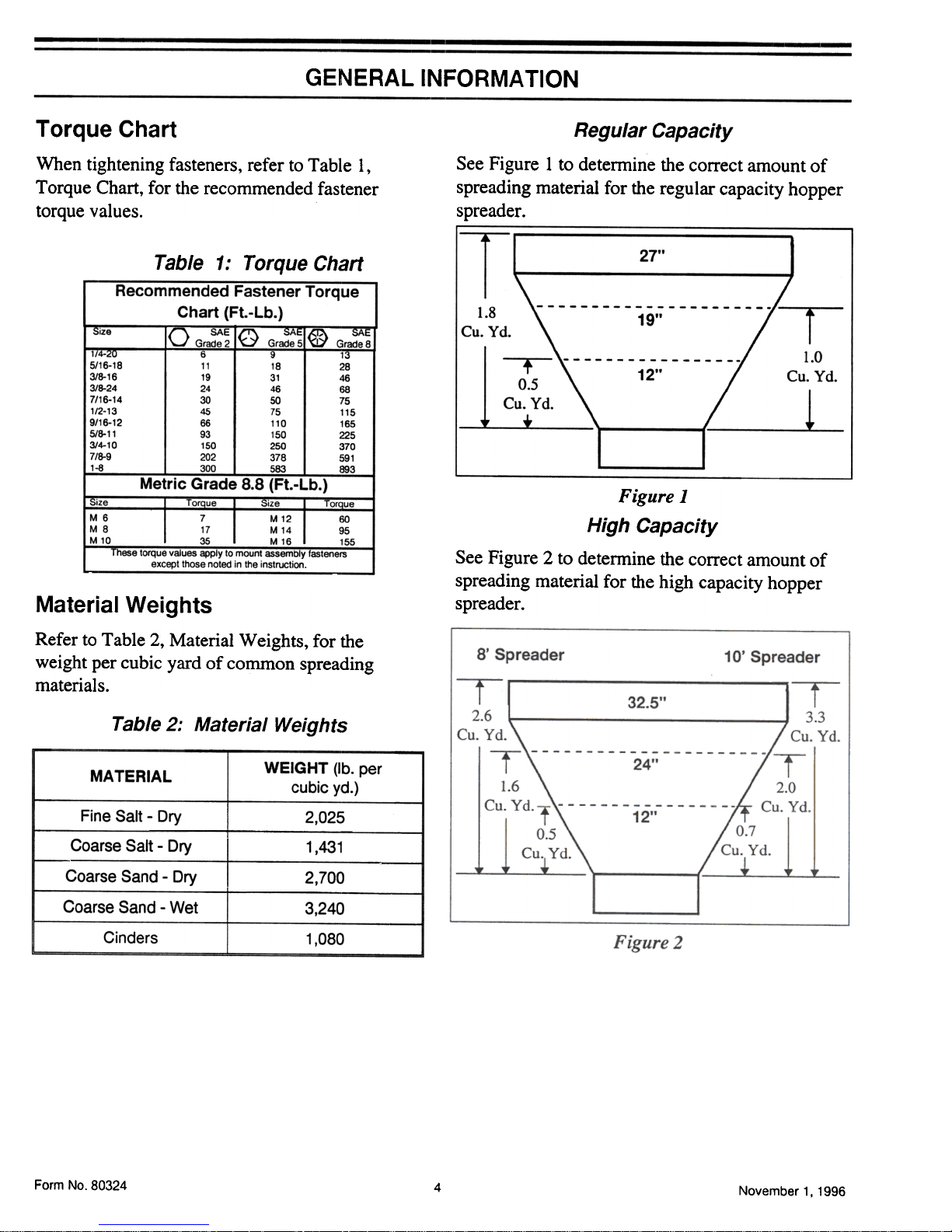

Torque Chart

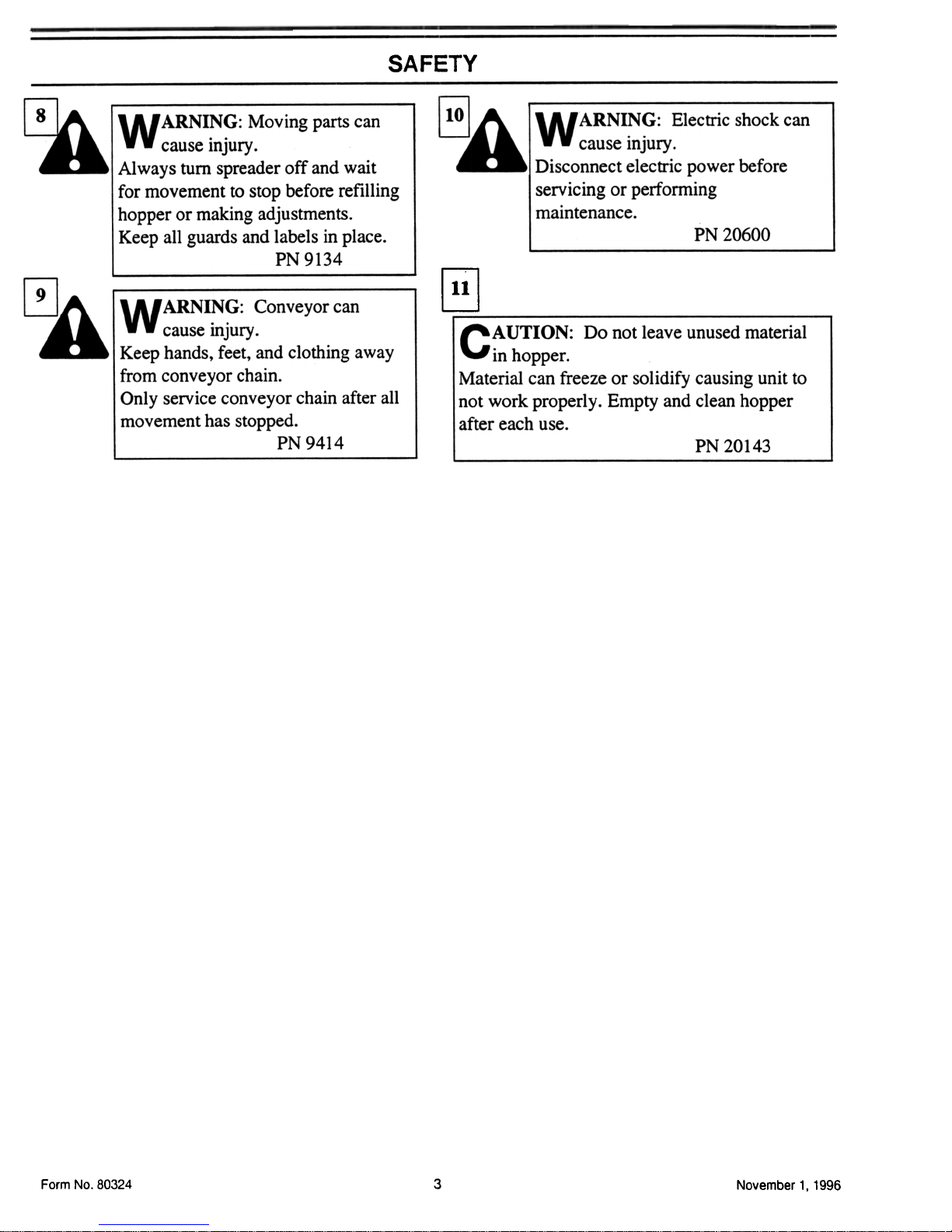

Regular Capacity

When tightening fasteners, refer to Table I,

Torque Chart, for the recommended fastener

torque values.

See Figure 1 to determine the correct amount of

spreading material for the regular capacity hopper

spreader .

Table 1: Torque Chart

Figure 1

High Capacity

See Figure 2 to detennine the correct amount of

spreading material for the high capacity hopper

spreader.

Material Weights

Refer to Table 2, Material Weights, for the

weight per cubic yard of common spreading

materials.

Table 2: Material Weights

WEIGHT (Ib. per

cubic yd.)

MATERIAL

Fine Salt -Dry

2.025

Coarse Sand -Wet

3,240

1,080

Cinders

Form No.80324

4

November 1, 1996

Page 11

GENERAL INFORMA TION

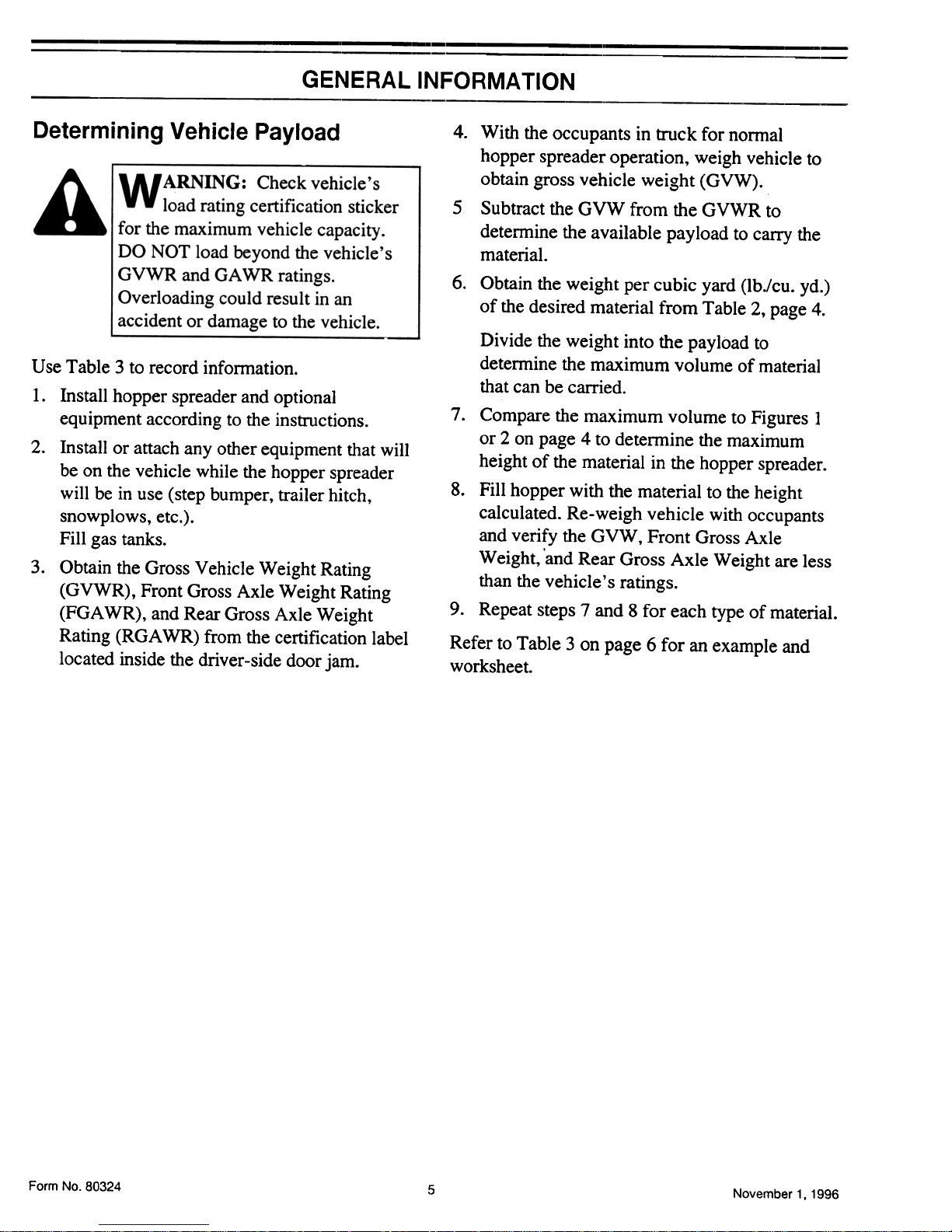

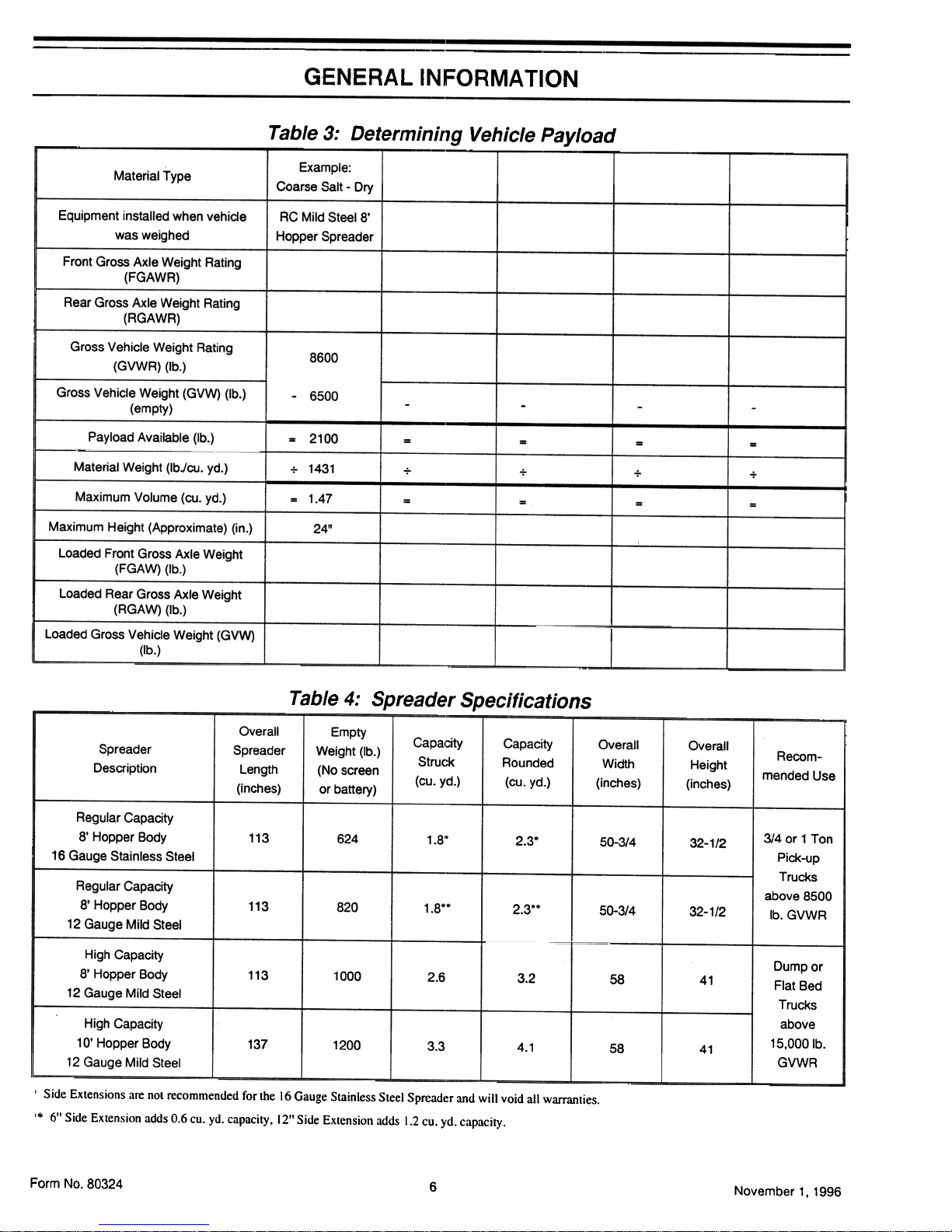

Determining Vehicle Payload

4.

5

6.

With the occupants in truck for nonnal

hopper spreader operation, weigh vehicle to

obtain gross vehicle weight (GVW).

Subtract the GVW from the GVWR to

detennine the available payload to carry the

material.

Obtain the weight per cubic yard (lb./cu. yd.)

of the desired material from Table 2, page 4.

Use Table 3 to record information.

I. Install hopper spreader and optional

equipment according to the instructions.

2. Install or attach any other equipment that will

be on the vehicle while the hopper spreader

will be in use (step bumper, trailer hitch,

snowplows, etc.).

Fill gas tanks.

3. Obtain the Gross Vehicle Weight Rating

(GVWR), Front Gross Axle Weight Rating

(FGA WR), and Rear Gross Axle Weight

Rating (RGA WR) from the certification label

located inside the driver-side door jam.

Divide the weight into the payload to

detemline the maximum volume of material

that can be carried.

7. Compare the maximum volume to Figures I

or 2 on page 4 to determine the maximum

height of the material in the hopper spreader.

8. Fill hopper with the material to the height

calculated. Re-weigh vehicle with occupants

and verify the GVW, Front Gross Axle

Weight, 'and Rear Gross Axle Weight are less

than the vehicle's ratings.

9. Repeat steps 7 and 8 for each type of material.

Refer to Table 3 on page 6 for an example and

worksheet.

Form No.80324

5

November 1,1996

Page 12

GENERAL INFORMA TION

Table 3: Determining Vehicle Payload

Example:

Coarse Salt -Dry

Material Type

Equipment installed when vehicle

was weighed

RC Mild Steel 8'

Hopper Spreader

Front Gross Axle Weight Rating

(FGAWR)

Rear Gross Axle Weight Rating

(RGAWR)

Gross Vehicle Weight Rating

(GVWR) (lb.)

8600

Gross Vehicle Weight (GVW) (lb.)

(empty)

-6500

Payload Available (lb.)

= 2100

Material Weight (lbJcu. yd.)

+ 1431

= 1.47

24"

Maximum Volume (cu. yd.)

Maximum Height (Approximate) (in.)

~

Loaded Front Gross Axle Weight

(FGAW) (lb.)

Loaded Rear Gross Axle Weight

(RGAW) (lb.)

Loaded Gross Vehicle Weight (GVW)

(lb.)

Table 4: Spreader Specifications

Overall

Spreader

Length

(inches)

Empty

Weight (lb.)

(No screen

or battery)

Capacity

Struck

(cu. yd.)

Capacity

Rounded

(cu. yd.)

Overall

Width

(inches)

Overall

Height

(inches)

Spreader

Description

Recom-

mended Use

Regular Capacity

8' Hopper Body

16 Gauge Stainless Steel

113

624

314 or 1 Ton

Pick-up

Trucks

above 8500

Ib. GVWR

1.8.

2.3*

50-3/4

32-1/2

Regular Capacity

8' Hopper Body

12 Gauge Mild Steel

113

820

1.8**

2.3**

50-3/4

32-1/2

High Capacity

8' Hopper Body

12 Gauge Mild Steel

Dump or

Flat Bed

Trucks

above

15,000 Ib

GVWR

113

1000

2.6

3.2

58

41

High Capacity

10' Hopper Body

12 Gauge Mild Steel

137

1200

3.3

4.1

58

41

, Side Extensions are not recommended for the 16 Gauge Stainless Steel Spreader and will void all warranties.

,* 6" Side Extension adds 0.6 cu. yd. capacity, 12" Side Extension adds 1.2 cu. yd. capacity.

Form No.80324

6

November 1,1996

Page 13

OPERA TION

Cab Control Identification

8

When the engine starts, release the ignition

switch.

N OTE: If the engine does not start after 10

seconds of cranking, turn both vehicle and

spreader ignition switches to OFF and see the

Briggs & Stratton Owner's Manual that is

shipped with the spreader.

Figure 3

9. After the engine starts, move the throttle

switch to IDLE and hold for 1/2 -1 second to

release the choke.

10. To control the engine speed:

.Increase: hold the throttle switch at

CHOKFlFAST .

.Decrease: hold the throttle switch at IDLE.

N OTE: Maximum engine speed is obtained

just prior to choking the engine.

N OTE: The conveyor and spinner will

operate when the clutch switch is in the ON

or BLAST position.

Engine Operation

Refer to Figure 3 as a reference for starting and

stopping the engine.

Starting the Engine

Stopping the Engine

1. Move the throttle to illLE and hold for two

seconds.

2. Turn the spreader ignition switch to OFF.

N OTE: Read and understand the engine

manufacturer's Owner's Manual before

starting the engine.

Turn the vehicle ignition switch to ON.

2. Verify the clutch switch is OFF.

4.

5.

Turn the spreader ignition switch (labeled

"Engine" on the cab control) to ON.

Move the throttle switch to IDLE and hold

for two seconds; release.

Turn the spreader ignition switch to ST ART .

While the engine is cranking, move the

throttle switch to CHOKE/FAST .

When the engine starts to fire, release the

throttle switch.

Form No.80324

7

November1,1996

Page 14

OPERA TION

Clutch Operation

Baffle Adjustment

.Start the engine.

2. Adjust the speed to slightly above idle.

3. Move the clutch switch to ON.

Spread pattern and the amount of material

dispensed depends on engine RPM, gate position,

and baffle settings.

.Decreasing RPM and/or gate-opening will

decrease the amount of material coming to

the spinner .

.Increasing RPM and/or gate-opening will

increase the amount of material coming to

the spinner.

See Figure 4, and Figures 5 and 6 on the next

page.

4. Increase the engine speed to the desired RPM.

Figure 4

Driver-side Internal

Baffie & Control -

\

\

.\

/

/

,

/ ,

/

,

~

,

Driver-side

External Bame

Rear External

Dame

Form No.80324

8

November 1, 1996

Page 15

OPERA TION

These figures are as viewed from the top of the

spinner looking down.

Figure 5

Figure 6

Form No.80324

9

November 1, 1996

Page 16

MAINTENANCE

General

At the end of the season, oil or paint all

bare surfaces after washing and before

storing the unit.

Grease

.Maintain spinner shaft-to-gear case roller

chain tension. Correct chain tension allows

5/16" deflection midway between the

sprockets. See Figure 7.

To increase chain tension: loosen the

bearing mounting hardware and pull the

spinner shaft away from the gear case.

Make sure the spinner shaft is vertical and

the sprockets are lined up before

re-tightening the fasteners. Oil this chain

after each use, and at the end of the season.

Figure 7

.Maintain engine-to-electric clutch roller

chain tension. Correct tension allows 5/16"

deflection midway between sprockets. See

Figure 8.

.Use dielectric grease on all electrical

connections at the beginning and end of

each season, and as required during the

season.

.After every lO hours of operation, grease

the idler bearings on the idler shaft,

flanged bearings on the drive shaft and the

input shaft above the gear case, and the

spinner shaft bearings.

.After every 50 hours of operation, grease

the input shaft bearing on the gear case and

verify the oil level of the gear case is level

with the fill hole.

.Change gear case oil once a year. Drain oil

by removing the side cover of the gear

case. Refill with SAE 90 weight gear oil.

Oil level should be even with the fill hole.

Chains

At the beginning of each season, and once

a month during the season, verify the drive

sprocket set screws are tight.

Figure 8

To increase chain tension: loosen the four

engine mount-to-engine base bolts and pull

the engine away from the electric clutch.

Re-tighten bolts. Oil this chain after each

use, and at the end of the season.

Form No.80324

10

November 1 , 1996

Page 17

MAINTENANCE

Electric Clutch

Periodically check the conveyor chain

tension.

To check the tension, measure in 201'-24"

from the rear edge of the sills. Push up on

the chain with your hand. The conveyor

chain should lift 1"-3" off the conveyor

chain guide or cross angles. See Figure 9.

To minimize problems and extend the life of the

electric clutch, do the following:

.At the end of each snow season, remove

and clean the clutch.

.After cleaning the clutch, coat both

mating surfaces of the clutch with oil or

light grease.

.Remove oil and grease prior to using the

clutch again.

Engine Service and Repair

Maintain the spreader engine according to the

Briggs & Stratton Engine Owner's Manual that

is shipped with the spreader. Engine warranty is

covered by Briggs & Stratton and is described in

the back of the manual.

If service or repair is needed, contact an

authorized Briggs & Stratton Service Center. To

serve you promptly, the Service Center will need

the model, type, and code number for your

engine.

Your nearest service center is listed in the

"Yellow Pages" under "Engines, Gasoline" or

"Gasoline Engines."

Figure 9

.Use the (2) 5/8" x 6" take-up bolts at the

front of the spreader to adjust the conveyor

chain tension. Turn both sides equal

amounts to ensure the tension is equally

distributed across both sides of the

conveyor chain.

.Always empty the spreader when it is not

in use to prevent a frozen conveyor chain.

ABBREVIA TION KEY

AR

ASSY

CB

CHMSL

CNP

CS

DIA

ELEC

EX

FL

G

HC

HP

HSG

HX

ID

LO

LK

MS

MS

NP1F

NYIS

PH

PN

PT

RC

SAE

SBH

SOTS

SFLS

SO

SP

SQ

SS

STD

STS

T

1FTS

TV

zYC

ZP

As Required

Assembly

Carriage Bolt

Center High-Mounted Stoplight

Cone Point

Cap Screw

Diameter

Electric

External

Flat

Grade

High Capacity

Horsepower

Housing

Self-Drilling Tap Screw

Serrated Flange Lock Screw

Socket Head

Spring

Square

Set Screw

Standard

Stainless Steel

Tooth/Teeth

Thread Forming Tapping Screw

Type

Zinc Yellow Chromate

Zinc Plated

Hex (Head)

Inside Diameter

Long

Lock

Machine Screw (fastener descriptions)

Mild Steel (non-fastener descriptions)

National Pipe Thread (Fluid)

Nylon Insert

Cross Recessed (Phillips Head)

Pan

Prevailing Torque

Regular Capacity

Society of Automotive Engineers

Socket Button Head

Form No.80324

11

November 1. 1996

Page 18

PARTS DIAGRAMS AND LISTS

"' 25

-8

24 "

10

17, 18 (2 REa), 19, 20

23,

""'

2

,

6---

4 ~

/~- ,

,3

17, 18 (2 REO), 19, 20

,/

6/

5

I

/

,

9

/

/

~

12

/

5

/13

/

/

ITEM PARTNO.

1 9189

1 9031

1 9194

1 9032

2 .9298

2 .20092

2 .9299

2 .20093

3 ..9195

4 ..9201

5 ..91004

6 ..9261

7 ..20599

QTY. DESCRIYnON ITEM PARTNO.

1 CHUTEASSY 141'RCMS 17 .90111

1 CHUTE ASSY 14'1 RC STS 17 .91014

1 CHUTEASSY26"RCMS 18 .90315

1 CHUTE ASSY 26'1 RC STS 18 .91006

1 CHUTEHSGASSY 14"RCMS 19 .90361

1 CHUTE HSG ASSY 14" RC STS 19 .91007

1 CHUTE HSG ASSY 26" RC MS 20 .90334

1 CHUTE HSG ASSY 26" RC STS 20 .91008

3 CONTROL ROD 10" 21 90315

2 ADJUSTMENT PIN 21 91006

3 1/8X3/4 COTTER PIN ZP 22 90361

5 3/32X2-1/4HAIRPIN COTTER ZP 22 91007

1 LABEL -INFORMATION 23 90334

(WARNING) 23 91008

1 SPINNER SHAFr RC ZYC (14" CHT) 24 90103

1 SPINNER SHAFr RC ZYC (26" CHT) 24 91015

1 SPINNERDISKRCMS 25 9188

1 SPINNER DISK RC STS * .20353

2 3/4" PILLOW BLOCK BEARING

1 SPROCKET, #40X24TX3/4" ID

1 1/16X1/2 COTTER PIN

1 1/4 X 1-1/2 CLEVIS SHEAR PIN

1 MACHINE KEY, 3/16" SQ X 1" LG

QTY. DESCRIP'nON

4 3/8-16X1-1/2 HX CS G5 ZP

4 3/8-16X1-1/2 HX CS STS

8 3/8 PLAIN WASHER TY A STD ZP

8 3/8 PLAIN WASHER TY A STD STS

4 3/8 SP LK WASHER ZP

4 3/8 SP LK WASHER STS

4 3/8-16 HX NUT ZP

4 3/8-16HXNUTSTS

4 3/8 PLAIN W ASHER TY A STD ZP

4 3/8 PLAIN WASHER TY A STD STS

4 3/8 SP LK WASHER ZP

4 3/8 SP LK WASHER STS

4 3/8-16 HX NUT ZP

4 3/8-16 HX NUT STS

4 3/8-16X1 HX CS G5 ZP

4 3/8-16X1 HX CS STS

1 #40 ROLLER CHAIN, 38" LONG

1 #40 ROLLER CHAIN MASTER LINK

8

8

9

9

10

.9191

.9192

.9196

.20095

.9193

.9187

.91022

.9265

.9197

12

13

14

Form No.80324

12

November 1. 1996

Items with a single part 11

~number or description are ' .0 0..",

common to regular capacity

mild steel and 16-gauge stainless steel 14- .0

14" and 26" chute assemblies. 0-/

Page 19

PARTS DIAGRAMS AND LISTS

Chute Assembly -High Capacity

~~~

O /8 26

10

/ r--. 17, 18 (2 REa), 19, 20

11

-

,

25

14

22

,

"

"

~

23,

"

0

-21

24 "

"""'

--?

,

.~ ~ 18, 19, 20

./

-2

7

6

b+--3

6-

17, 18 (2 REQ), 19, 20

~

6-

5

/1

.9

/

12

/

/

5

13

LJ

/

,j/

ITEM PART NO.

20 .90334

21 .20326

22 90315

23 90361

24 90334

25 90103

26 20325

* .20353

ITEM PART NO.

1 9107

2 .20318

3 ..9195

4 ..9201

5 ..91004

6 ..9261

7 ..20599

QTY. DESCRIFI10N

6 3/8-16HXNUTZP

1 ACCESSPANEL

4 3/8 PLAIN W ASHER TY A STD ZP

4 3/8 SP LK WASHER ZP

4 3/8-16HXNUTZP

4 3/8-16Xl HX CS G5 ZP

1 #40 ROLLER CHAIN, 42" LONG

1 #40 ROLLER CHAIN MAS1ER LINK

QTY. DESCRIPI10N

1 CHUTE ASSY 31 " HC MS

1 CHUTE HSG ASSY 31 " HC MS

3 CONTROL ROD 10"

2 ADJUSTMENT PIN

3 1/8 X 3/4 COTTER PIN ZP

S 3/32X2-1/4HAIRPIN COTTER ZP

1 LABEL -INFORMATION

(W ARNIN G )

1 SPINNER SHAFf HC ZYC

(31" CHT)

1 SPINNER DISK HC MS

2 1 " PILLOW BLOCK BEARING

1 SPROCKET, #40 X 24T X 1 " ID

1 1/16X1/2 COTTER PIN ZP

1 1/4" X 2" CLEVIS PIN ZP

1 MACHINE KEY 1/4" SQ X 1 " LG

4 3/8-16/1-1/2 HX CS GS ZP

10 3/8 PLAIN WASHER TY A STD ZP

6 3/8 SP LK W ASHER ZP

8 20320

9

10

11

12

13

14

17

18

19

20321

20322

20323

91022

20351

20324

90111

90315

90361

*Not Shown

Abbreviation Key found on page 11.

Indented parts are included in the assembly under which

they are listed.

Quantities shown are included with the assembly.

13

November 1, 1996

Form No.80324

Page 20

PARTS DIAGRAMS AND LISTS

Conveyor Drive and Idler -Regular Capacity

N OTE: Assemble chain link and pin to

chain bar as shown.

'm No.80324

14

November 1. 1996

Page 21

PARTS DIAGRAMS AND LISTS

Conveyor Drive and Idler -Regular Capacity

Items with a single part number or description are common

to regular capacity, mild steel and 16-gauge stainless steel

spreaders.

ITEM PART NO. QTY. DESCRIPTION

I 20085 1 ENGINE BASE RC MS

I 20094 I ENGINE BASE RC STS

4 9171 1 GEAR CASE

5 9169 1 DRIVE SHAFf COUPLING

6 9167 1 WIPER BELT RC

10 9172 2 STRAP, RUBBER HOLD DOWN

11 9184 1 illLER SHAFf RC ZYC

12 9164 I DRIVE SHAFf RC ZYC

13 9182 2 ROD END RC

14 9183 2 illLER SPROCKET 6T

16 9163 2 DRIVE SPROCKET 6T

17 9174 1 SPROCKET#40XI6TX1.0" ill

18 9177 I CONVEYOR CHAIN 8' RC

(12"-123 LINK)

AR CONVEYOR CHAIN BAR RC

AR CONVEYOR CHAIN LINK

AR CONVEYOR CHAIN PIN

AR 3/32Xl/2 COTTER PIN ZP

2 1/4-20 x 1/2 SO SS CNP

2 5/16-18X3/4 SQ SS STS

2 1-1/8" 2 BOLT FLANGE BEARING

1 1" 2 BOL T FLANGE BEARING

5 1/4-20X3/4 HX CS G2 ZP

5 1/4-20X3/4 HX CS STS

2 5/16-18Xl-l/2 HX CS G5 ZP

2 5/16-18X1-1/2 HX CS STS

5 1/4 PLAIN WASHER TY A STD

ZP

5 1/4 PLAIN WASHER TY A STD

STS

4 3/8-16X1-1/4 SBH CS STS

4 3/8-16Xl HX CS G5 ZP

4 3/8-16X1 HX CS STS

ITEM PART NO.

32 90608

32 91016

33 20150

33 20151

35 90980

36 90359

36 91017

37 90981

38 90361

38 91007

39 90364

39 91018

40 90315

40 91006

42 90330

42 91019

43 90332

43 90988

44 90334

44 91008

45 90343

45 91020

47 91021

48 91022

49 20189

50 67147

51 9166

52 20188

* 9333

* 9334

53 67092

54 91330

19 .9181

20 .9178

21 .9179

22 .91010

23 9447

24 91011

25 9162

26 9176

27 90461

27 91012

28 90054

28 90977

29 90311

QTY. DESCRIYnON

4 1/2-13X1 HX CS G5 ZP

4 1/2-13X1 HX CS STS

2 5/8-11X6"TAKE UP BOLTZYC

2 5/8-11X6'1 TAKE UP BOLT STS

2 5/16 PLAIN WASHER TY A STD

STS

5 1/4 SP LK WASHER ZP

5 1/4 SP LK WASHER STS

2 5/16 SP LK W ASHER STS

8 3/8 SP LK W ASHER ZP

8 3/8 SP LK W ASHER STS

4 1/2 SP LK W ASHER ZYC

4 1/2 SP LK WASHER STS

4 3/8 PLAIN WASHER TY A STD ZP

4 3/8 PLAIN WASHER TY A STD STS

5 1/4-20 HX NUT ZP

5 1/4-20 HX NUT STS

2 5/16-18 HX NUT ZP

2 5/16-18 HX NUT STS

8 3/8-16HXNUTZP

8 3/8-16 HX NUT STS

2 5/8-11 HX NUT ZYC

2 5/8-11 HX NUT STS

2 1/8X1 COTTER PIN

2 1/16X1/2 COTTER PIN ZP

2 3/16X1-1/4!1 ZYC CLEVIS PIN

2 3/8X2 CLEVIS PIN G5 ZYC

3 MACHINEKEY,1/4!1SQX1-1/2LG

2 GREASE FITTING -STRAIGHT

4 TIE-DOWN CHAIN 36!1 LONG

4 LINK -CHAIN TIE DOWN

4 #10-24 X 1/2 SBH CS STS

4 #10-24 PT HX LKNUT NYIS STS

29

91013

30

31

31

67093

90103

91015

* Not Shown

Abbreviation Key is found on page 11.

Indented parts are included in the assembly under which

they are listed. Quantities shown are included with the as-

sembly.

Form No.80324

15

November 1, 1996

Page 22

PARTS DIAGRAMS AND LISTS

Conveyor Drive and Idler -High Capacity

Form No.80324

16

November 1, 1996

Page 23

PARTS DIAGRAMS AND LISTS

ITEM PART NO.

32 90608

33 20338

35 90980

QTY. DESCRIPTION

4 1/2-13X1 HX CS G5 ZP

2 5/8-11 X 9"TAKE UPBOLTZYC

2 5/16 PLAIN WASHER TY A STD

STS

7 1/4 SP LK WASHER ZP

2 5/16 SP LK WASHER STS

12 3/8 SP LK WASHER ZP

4 1/2 SP LK W ASHER ZYC

4 3/8 PLAIN WASHER TY A STD ZP

7 1/4-20 HX NUT ZP

2 5/16-18HXNUTZP

12 3/8-16HXNUTZP

2 5/8-11 HX NUT ZYC

2 1/8X1 COTrER PIN

2 1/16X1/2 COTrER PIN ZP

2 3/16X1-1/4 ZYC CLEVIS PIN

2 3/8X2 CLEVIS PIN G5 ZYC

3 MACHINEKEY,1/4"SQX1-1/2LG

2 GREASE FITnNG -STRAIGHT

4 TIE-DOWN CHAIN 36" LONG

4 LINK -CHAIN TIE DOWN

4 #10-24 X 1/2 SBH CS STS

4 #10-24PTHXLKNUTNYIS STS

ITEM PART NO.

I 20327

4 9171

5 9169

6 20328

10 9172

II 20329

12 20330

13 20331

14 20332

16 20333

17 9174

18 20334

36

37

38

39

40

42

43

44

45

47

48

49

50

51

52

*

*

53

54

90359

90981

90361

90364

90315

90330

90332

90334

90343

91021

91022

20189

67147

9166

20188

9333

9334

67092

91330

18 20335

QTY. DESCRIPTION

1 ENGINE BASE HC MS

1 GEAR CASE

1 DRIVE SHAFr COUPLING

1 WIPER BELT HC

2 STRAP, RUBBER HOLD DOWN

1 illLER SHAFr HC ZYC

1 DRIVE SHAFr HC ZYC

2 ROD END HC

2 illLER SPROCKET 8T

2 DRIVE SPROCKET 8T

1 SPROCKET, #40 X 16TX 1.0" ill

1 CONVEYOR CHAIN 8' HC

(16"-123 LINK)

1 CONVEYOR CHAIN 10' HC

(16"-153 LINK)

AR CONVEYOR CHAIN BAR HC

AR CONVEYOR CHAIN LINK

AR CONVEYOR CHAIN PIN

AR 3/32X 1/2 COTTER PIN ZP

2 1/4-20 X 1/2 SO SS CNP

2 5/16-18X3/4 SQ SS STS

2 1-1/8"4 BOLT FLANGE BEARING

1 1" 2 BOL T FLANGE BEARING

7 1/4-20X3/4HX CS G2 ZP

2 5/16-18Xl-1/2 HX CS G5 ZP

7 1/4 PLAIN WASHER TY A STD

ZP

8 3/8-16Xl-1/4 SBH CS STS

4 3/8-16X1 HX CS G5 ZP

19 .20336

20 .9178

21 .9179

22 .91010

23 9447

24 91011

25 20337

26 9176

27 90461

28 90054

29 90311

* Not Shown

Abbreviation Key is found on page 11.

Indented parts are included in the assembly under which

they are listed. Quantities shown are included with the as-

sembly.

30 67093

31 90103

Form No.80324

17

November 1,1996

Page 24

PARTS DIAGRAMS AND LISTS

Form No.80324

18

November 1, 1996

Page 25

PARTS DIAGRAMS AND LISTS

Engine Drive with Clutch -Regular and High Capacity

ITEM PART NO.

1 9106

2 20084

2 20339

3 9208

3 20096

3 20340

* 9229

5 9207

6 9000

QTY. DESCRIPTION ITEM PART NO.

I 8.5 H.P. ENGINE 26 91023

I ENGINE MOUNT RC 28 91160

I ENGINE MOUNT HC 29 91031

I CHAIN GUARD RC MS 29 67083

I CHAIN GUARD RC STS 30 90359

I CHAIN GUARD HC MS 30 91017

I BATTERY CASE W/STRAP 31 90360

I ELECTRIC CLUTCH 32 90361

I TUBULAREXHAUST 32 91007

EXTENSION 33 90980

I RELAY-HOPPERSPREADER

I RUBBER GROMMET, I" 34

2 LOCKING COLLAR, I" 35

I SPROCKET, #40 X 12TX 1.0'1 35

I SPROCKET, CLUTCH (#40 X 52 T) 36

I AL TERNA TOR WIRE WITH 36

PLUG 37

I #40 ROLLER CHAIN, 39" LONG (RC) 37

I #40 ROLLER CHAIN, 47" LONG (HC) 38

I BATTERY CABLE -38

BLACK 53"LG

I CABLE-STARTER

I RED BATTERY CABLE (POS)

I CLUTCH GROUND WIRE

I ENGINE COVER RC MS

I ENGINE COVER RC STS

I ENGINE COVER HC MS

7 1/4-20X3/4 HX CS G2 ZP

7 1/4-20X3/4 HX CS STS

8 5/16-18X3/4HX CS STS

4 5/16-18XI-I/2 HX CS G5 ZP

4 3/8-16XI CB G5 ZP

7

8

9

II

13

14

20136

9221

9206

9209

9202

20194

90987

90330

91019

90332

90988

90334

91008

90315

91006

15

15

16

9220

20341

67239

17

18

19

21

21

21

22

22

23

24

26

9227

9226

67241

9281

20097

20342

90461

91012

90974

90054

90965

42

43

44

*

9166

67092

91330

20353

QTY. DESCRIPTION

4 3/8-16Xl CB STS

4 #8-18X3/8 SFLS 1FrS TY AB ZP

3 1/4 EX TOOTH LK WASHER ZP

3 1/4 EX TOOTH LK WASHER STS

3 1/4 SP LK WASHER ZP

3 1/4 SP LK WASHER STS

7 5/16SPLKWASHERSTS

4 3/8 SP LK WASHER ZP

4 3/8 SP LK WASHER STS

10 5/16PLAINWASHERTYA

sm STS

5 5/16-18 PT HX LK NUT NYIS STS

7 1/4-20 HX NUT ZP

7 1/4-20 HX NUT STS

4 5/16-18HXNUTZP

4 5/16-18 HX NUT STS

4 3/8-16 HX NUT ZP

4 3/8-16 HX NUT STS

4 3/8 PLAIN WASHER TY A sm ZP

4 3/8 PLAIN WASHER TY A sm

STS

2 KEY, .25 SQ X 1-1/2"LG

4 #10-24XI/2 SBH CS STS

4 #10-24 PT HX LKNUT NYIS STS

I #40 ROLLER CHAIN MASTER LINK

* Not Shown

Items with a single part number or description are common

to regular capacity (mild steel and 16-gauge stainless steel)

and high capacity spreaders.

Form No.80324

19

November 1,1996

Page 26

PARTS DIAGRAMS AND LISTS

Gear Case

Form No.80324

20

November 1, 1996

Page 27

PARTS DIAGRAMS AND LISTS

Gear Case

ITEM PART NO.

1 9171

2 .67245

3 .67246

4 .67247

5 .67265

6 .67266

7 .67249

8 .67248

9 .67250

10 .67251

11 .67252

12 .67253

13 .67254

14 .67255

15 .67256

16 .67257

QTY. DESCRIPTION

1 GEAR CASE

1 GEAR CASE HOUSING

1 GEAR (BRONZE)

1 WORM GEAR

1 INPUTS HAFf

1 OUTPUT SHAFf

2 BEARING CONE

2 BEARING CONE

4 BEARING CUP

1 SEAL

1 CAP

1 SEAL

2 SNAP RING

1 COVER

4 CAPSCREW

1 GASKET

ITEM PART NO.

17 .67258

18 .67259

19 .67260

QTY. DESCRIPTION

AR SHIM (0.020" 1HK)

I SNAP RING

I WOODRUFF KEY

(# 18 -HARDENED)

I WOODRUFF KEY

("A" -HARDENED)

I 1/8 VENT PLUG

I ZERK FITnNG

I SET SCREW

I PLUG 3/8 NPTF SQ

20

.67261

21

22

23

24

.67262

.67263

.67264

.7621

* Not Shown

Abbreviation Key is found on page II.

Indented parts are included in the assembly under which

they are listed. Quantities shown are included with the

assembly.

Gear Case Assembly

Input Shaft Pre-assembly

I. Install the snap ring in the snap ring groove.

2. Install the woodruff key into the keyway.

Housing Pre-assembly

1. Insert the snap ring into the output bore of the

housing.

2. Insert an output bearing cup into the housing

bore using a cup driver or a brass drift. Press

the cup tight against the snap ring.

3. Insert the snap ring into the input bore

opposite the grease zerk hole. Press an input

bearing cup tight against the snap ring.

4. Install and tighten the grease zerk into the

housing.

Cover Pre-assembly

1. Insert the snap ring into the output bore of the

cover.

2. Press an output bearing cup in tight against

the snap ring.

3. Install all vent and fill plugs into the cover.

3. Slide the wonn gear on tight to the snap ring

making sure the key does not fallout.

4. Slide the input shaft bearing cones tight

against the wonn gear and snap ring.

Assembly of Pre-assembled Parts

1. Insert the input shaft into the housing making

sure the shaft extends out the proper side.

2. Press an input bearing cup and a snap ring

into the input bore of the housing.

3. Adjust the bearings by tapping lightly on each

end of the shaft with a soft hammer. If

endplay exists, add shims under the snap ring

and repeat adjustment until the shaft spins

freely with no endplay.

Continued on next page.

Output Shaft Pre-assembly

Install the woodruff key into the keyway

Form No.80324

21

November 1, 1996

Page 28

PARTS DIAGRAMS AND LISTS

Insert an output bearing cone and the bronze

gear into the housing. Slide the output shaft

through the bronze gear and bearing cone,

taking care not to scratch the shaft.

Items with a single part number or description are

common to regular capacity, mild steel and

16-gauge stainless steel spreaders.

N OTE: The end of the output shaft should

extend 1.9411 beyond the machined mounting

surface on the back side of the housing.

Install and tighten the D43 set screw into the

bronze gear .Insert an output bearing cone on

the shaft until it is tight against the bronze

gear.

Install a gasket on the cover and insert it over

the end of the output shaft. Tighten the cover

down.

ITEM PART NO.

I 9231

I 20098

2 9232

2 20099

3 9233

3 20100

4 90965

4 91023

5 90986

5 90999

6

90315

6

91006

QTY. DESCRIPnON

1 WING NUT

1 WING NUT -STS

1 FEEDGATE~EVERRCMS

1 FEED GA TE LEVER RC STS

1 FEED GA TE RC MS

1 FEED GATE RC STS

1 3/8-16X1 CB G5 ZP

1 3/8-16X1 CB STS

1 3/8-16 PT HX JAM LKNUT NYIS ZP

1 3/8-16 PT HX JAM LKNUT NYIS

STS

2 3/8 PLAIN WASHER TY A STD

ZP

2 3/8 PLAIN W ASHER TY A STD

STS

1 FEED GA TE WIPER RC

1 FEED GA TE ANGLE RC MS

1 FEED GA TE ANGLE RC STS

4 1/4-20X3/4 FL MS ZP

4 1/4-20X3/4 FL MS STS

4 1/4-20 HX NUT ZP

4 1/4-20 HX NUT STS

4 1/4 SP LK WASHER ZP

4 1/4 SP LK W ASHER STS

Adjust the bearings by tapping lightly on each

end of the shaft with a soft hammer. If

endplay exists, add shims under the snap ring

and repeat adjustment until the shaft spins

freely with no endplay.

6. Grease the lips of the output and input shaft

seals and install the seals. Verify the seals are

seated flush (not cocked) in the housing. Use

a seal protector when installing any seals over

a keyway.

7. Install the caps in the input and output bores

using a sealant on both the cap outer diameter

and the bore inner diameter .

8. Remove the vent plug and pressurize the

housing with low pressure air (about 3 psi).

Brush a soap and water mix over the seals,

caps, and gaskets and check for leaks.

9. Install the gear case on spreader, grease input

shaft bearing, and fill unit with gear oil to a

level even with the fill hole.

7 9234

8 9235

8 20102

9 91030

9 91025

10 90330

10 91019

11 90359

11 91017

Gear Case Disassembly

To disassemble the gear case, reverse the Gear

Case Assembly. Take extreme caution when

removing the bearings. A light tap on the bearing

cups may be needed to remove the snap rings.

Form No.80324

22

November 1, 1996

Page 29

PARTS DIAGRAMS AND LISTS

Feed Gate -High Capacity

ITEM PART NO.

1 9231

2 20344

3 20345

4 90965

5 90986

6 90315

7 20346

8 20347

9 91030

10 90330

11 90359

QTY. DESCRIP'nON

I WING NUT

I FEED GATE LEVER HC MS

I FEED GATE HC MS

I 3/8-16XI CB G5 ZP

I 3/8-16 PT HX JAM LKNUT NYIS ZP

2 3/8 PLAIN W ASHER TY A sm ZP

I FEED GATE WIPER HC

I FEED GATE ANGLE HC MS

6 1/4-20X3/4FL MS ZP

6 1/4-20 HX NUTZP

6 1/4 SP LK WASHER ZP

ITEM PART NO.

1 9131

2 20599

3

4

20724

20598

5

9133

6

7 9129

8 9134

9 9414

10

II

20600

20143

QTY. DESCRIPTION

1 LABEL -W ARNING -Fire Hazard

1 LABEL -W ARNING -Rotating

Spinner

3 FISHER@ DECAL 4-1/2 X 15

1 LABEL -W ARNING -Read

Instruction Manual

2 LABEL -W ARNING -Overloaded

Vehicles

1 LABEL -SERIAL -Serial No.

2 LABEL -W ARNING -Do Not Ride

1 LABEL -W ARNING -Moving Parts

2 LABEL -W ARNING -Conveyor

Chain

1 LABEL -W ARNING -Electric Shock

1 LABEL -CAU11ON -Unused Material

Form No.80324

23

November 1, 1996

Page 30

PARTS DIAGRAMS AND LISTS

Cab Control

Front View

2

0

D

Electric Throttle

2/

ITEM PARTNO

1 20354

2 .9427

3 .9422

4 .67026

5 .20162

6 .9237

7 .67027

* .65368

8 .20088

9 .20089

10 .20090

11 .20086

12 90681

13 9472

14 9415

* 3042

* 8329

Clamp Loops

"

QTY. DESCRIPrION

1 CAB CONfROL (ELEC. THRO1TLE)

1 CONfROL PANEL -ELEC THRO1TLE

1 ELECTRIC THRO1TLE SWITCH

I FUSE HOLDER

I KEYED IGNITION SWITCH

1 CLUTCH SWITCH

1 FUSE CAP

1 KEY -HOPPER SPREADER

1 POWER WIRE -RED

I JUMPER WIRE -RED -4 TERMINAL

I JUMPER WIRE -RED -3 TERMINAL

I FUSE 3 AG -10 AMP

AR 1/4X3/4 HX SDTS ZP

AR CLAMP LOOP #10

AR CLAMP LOOP #6

AR RUBBER GROMMET 3/8" ID. Not shown

I DIELECTRIC GREASE TUBE

"

Form No.80324

24

November 1, 1996

""

\jiP 12 13, 14

U sed to secure spreader harness

and spreader cable to the spreader

and the cab control.

Page 31

PARTS DIAGRAMS AND LISTS

Vehicle Harness

Part Number: 20072

Brown -Electric Throttle

, Red -Electric

l Throttle Switch

GREEN

RED

Orange -CHMSL

,

Gray -Electric

~Clutch SwitchBLACK

BROWN

WHITE

Green -Vehicle ~

Ground ~ ~

Green -Electric

/Throttle Switch

Green -Electric

Throttle Switch

ORANGE

GRAY

,

White -Starter

Relay Ignition

Switch

~ Black- Magneto

\ Ignition Switch

Green -Ground

Ignition Switch

Spreader Harness

Black -

White -Magneto

Starter Relay

\

Part Number: 20073

/;;:::

r-- Green -

Ground

RED

Gray -I

Electric ~

Clutch

BROWN

~

D

ORANGE

Red -

Electric

Throttle

Green CHMSL

Ground

\

Orange CHMSL

~

Brown Electric

Throttle

Plug Cover

Part Number: 8291

Hook

Part Number: 20128

Form No.80324 25 November 1. 1996

Page 32

PARTS DIAGRAMS AND LISTS

CI~,..tri,.. Thrnttl~ 3--- Crank (shown against the

Electric Throttle Throttle Pin~3 ~ ~ Electric Throttle Bracket

~, according to step 4 of the

...

installatIon InstructIons

2 below.)

Engine Mount

9

>

ITEM PARTNO

6 90461

7 90311

8 90359

9 20359

QTY. DESCRIPTION

2 1/4-20X3/4 HX CS 05 ZP

2 1/4 PLAIN WASHER TY A STD ZP

2 1/4 SP LK W ASHER ZP

I NUT BAR

3. Fasten the electric throttle motor to the

bracket using the existing hardware.

4. U sing the electric throttle control, run the new

electric throttle motor until the crank is

against the bracket as shown in above

diagram.

5. Place the electric throttle arm on the crank as

shown in the above diagram.

6. Place the electric throttle assembly onto the

engine mount inserting the throttle pin into

the engine choke/throttle linkage plastic slider

(not shown).

7. Loosely bolt electric throttle assembly to the

engine mount with the existing hardware.

8. Keeping the electric throttle arm parallel to

and against the carburetor control bracket,

move the electric throttle bracket forward

putting the engine throttle into the full choke

position.

9. Tighten the fasteners according to the Torque

Chart on page 4.

10. Reconnect the battery cables.

ITEM PARTNO QTY. DESCRIPTION

I 20163 I ELECfRIC THROT11.E BRACKET

2 20134 I ELECfRIC THROT11.E MOTOR

3 20129 I ELECfRIC THROT11.E ARM

4 67091 3 #6-32X5/8 SBH CS STS

5 91027 3 #6-32 PT HX LK NUT NYIS STS

Removallnstructions

1. Disconnect the battery cables.

2. Carefully observe the existing installation.

Mark the electric throttle bracket position on

the engine mount.

3. Disconnect the brown and red spreader

harness wires from the electric throttle motor

leads.

4. Remove 1/4-20 fasteners that hold the electric

throttle bracket to the engine mount.

5. Remove #6-32 fasteners holding the electric

throttle motor to the bracket. Remove the

electric throttle motor.

Installation Instructions

1. Connect the brown and red spreader harness

wires (not shown) to the corresponding

colored electric throttle motor leads.

2. Using the electric throttle control, run the new

motor until the crank reaches the 12 o ' clock

position. (A 9-volt battery can be a substitute

for the control. )

1

Verify the crank is stopped in both directions

by the bracket, not the carburetor linkage.

Form No.80324

26

November 1, 1996

Page 33

A CCESSORI ES

Center High-Mounted Stoplight (CHMSL) Kit

1

rrEM PART NO.

5 ..90693

6 ..90694

* ..5793

* ..8329

* .3666

* .6456

* .13658

ITEM PARTNO. QTY. DESCRIP110N

10 9486 I STOPLAMP KIT

I. 9487 I STOPLIGHT ASSEMBL Y W/

GASKET

2 ..9488 I STOPLIGHT GASKET

* .9489 I VEmCLE HARNESS-STOPLIGHT

* .9493 I PARTS BAG ASSY

* ..9490 I PROTEcrOR PLUG

SAE2CONTAcr

Installation Instructions

QTY. DESCRIPTION

2 #6-32 X3/4 PH PN MS STS

2 #6-32 PT HX LK NlJf NYIS STS

1 BUTT SPLICE

1 DIELECTRIC GREASE TUBE

10 CABLE TIE

1 9-1-93 LITERATURE CHMSL

1 CHMSL INST ALLA TION

Indented parts are included in the

assembly under which they are listed.

Quantities shown are included with

the assembly.

* Not shown

Use the CHMSL manual supplied with the kit

for installation except for the following

situations:

.The CHMSL harness and the protective

plug (supplied with the CHMSL kit) are

NOT used. The CHMSL plugs into the

SAE two-pin connector included as part of

the spreader harness.

.The orange CHMSL feedwire from the cab

control is connected to the vehicle

CHMSL signal. See Cab Control and Wire

Harness Installation.

November 1,1996

27

Form No.80324

Page 34

ACCESSORIES

Inverted Vee Assembly -Regular Capacity Mild Steel

End Plate 15, 16, 17

2

15, 16, 17

/

'<

G

"""

Cross Channel

1

ITEM PART NO.

20 9138

1 .20164

2 .20165

3 .65994

QTY .DESCRIPTION

1 INVERTED VEE KIT RC MS

1 INVERTED VEE PLATE

1 INVERTED VEE SUPPORT

1 INVERTED VEE RC MS

ITEM PART NO. QTY. DESCRIPflON

15 .90103 10 3/8-16Xl HX CS 05 ZF

16 .90361 10 3/8 SF LK WASHER ZP

17 .90334 10 3/8-16HXNUTZP

Indented parts are included in the assembly under which they are listed.

4. Install item 2, inverted vee support, parallel to

the top of the hopper. U sing the two holes in

the end plates of the support as a guide, drill

two 7/16" holes through each side of the

spreader.

Installation Instructions

1. Center the inverted vee plate on the engine

side of the cross channel with the wide end of

the plate facing up.

2. U sing the two holes at the wide end of the

plate as a template, drill two 7/1611 diameter

holes through one leg of the cross channel

support. Assemble with two 3/8'1 x 111 hex

head cap screws, lock washers, and nuts.

N OTE: Fasten a 3/8" x 1 " hex head cap

screw, lock washer, and nut in each hole as it

is drilled. This will hold the support in place as

you drill your next hole.

3.

Assemble the inverted vee to the inverted vee

support and to the inverted vee plate

(installed in step I) with four 3/811 x 1'1 hex

head cap screws, lock washers, and nuts.

5. Adjust the height of the inverted vee for the

material being spread:

.Salt or dry sand -adjust the vee to the

lowest position.

.Salt/sand mix -adjust the vee to the middle

position.

.Wet sand -adjust the vee to the highest

position.

6. Tighten all fasteners according to the Torque

Chart on page 4.

Form No.80324

28

November 1, 1996

Page 35

ACCESSORIES

Inverted Vee Assembly -Regular Capacity Stainless Steel

Cross Channels

/

3,4, 5

/

/

/

I

/

/

~/

"'2

~

Indented parts are included in the assembly under which

they are listed.

3,

Tighten all fasteners according to the Torque

Chart on page 4.

ITEM PART NO. QTY. DESCRIPTION

I 20166 I INVER1ED VEE KIT RC MS

2 .65995 I INVER1ED VEE RC STS

3 .91015 4 3/8-16X1 HX CS STS

4 .91007 4 3/8 SP LK WASHER STS

5 .91008 4 3/8-16 HX NUT STS

Installation Instructions

1. Select the height for the inverted vee for the

material being spread:

.Salt and dry sand -adjust the vee to the

lowest position.

.Salt/sand mix -adjust the vee to the middle

position.

.Wet sand -adjust the vee to the highest

position.

2. Attach the inverted vee to the cross channels

with the provided fasteners.

Form No.80324

29

November 1, 1996

Page 36

ACCESSORIES

ITEM PART NO.

I 9347

I 9155

2 .20348

2 .20349

QTY .DESCRIPTION

I INVERTED VEE KIT 8' HC MS

I INVERTED VEE KIT 10' HC MS

I INVERTED VEE 8' HC MS

I INVERTED VEE 10' HC MS

ITEM PART NO.

4 .90103

5 .90361

6 .90334

7 .20165

QTY .DESCRIPTION

12 3/8-16X1 HX CS 05 ZP

12 3/8 SP LK WASHER ZP

12 3/8-16 HX NUf STS

2 INVERTED VEE SUPPORT

NOTE: Fasten a 3/811 x 1 II hex head cap

screw, lock washer, and nut in each hole as it

is drilled. This will hold the support in place as

you drill your next hole.

Installation Instructions

1. Assemble the inverted vee to the inverted vee

supports using four 3/8" x 1 I' hex head cap

screws, lock washers, and nuts.

2. Place the inverted vee/inverted vee support

assembly into the spreader as shown on the

above diagram. The end of the inverted vee

should be 8-10" away from the feed gate, and

the inverted vee supports should be parallel to

the top of the spreader.

3. Using the holes in the end plates of the

supports as guides, dri117/16" holes through

each side of the spreader.

4. Adjust the height of the inverted vee for the

material being spread.

.Salt or dry sand: adjust the vee to the

lowest position.

.Salt/sand mix: adjust the vee to the middle

position.

.Wet sand: ad just the vee to the highest

position.

5. Tighten all fasteners according to the Torque

Chart on page 4.

Form No.80324

30

November 1, 1996

Page 37

Page 38

FISHER ENGINEERING

12 WATER STREET

p .0. BOX 529

ROCKLAND,MAINE 04841

M A DIVISION OF DOUGLAS DYNAMICS, L.L.C.

Form No.80324

Printed in the U.S.A.

November 1. 1996

Loading...

Loading...