TECHNICAL

MANUAL

RESPIRATORY

HUMIDIFIER

HC500

Revision

March

C

1998

MODEL

Copyright © 1996

Fisher

Fisher & Paykel

Auckland,

Healthcare

New

Zealand

&.Paykel

HEALTHCARE

Ltd

National

Office:

Fisher & Paykel

P.O.

Box

14348,

Auckland,

Telephone:

Facsimile:

Part

Revision C March

Technical

Fisher & Paykel

Specifications

New

Number

Manual

185

Healthcare

Panmure

Zealand

+64-9-574

+64-9-574

041

077

1998

for

HC500

Healthcare

without

notice.

Lid

0100

0158

Respiratory

have a policy

Humidifier

of

continued

product

improvement

and

reserve

the

right

to

alter

Changes

Description

Performance

Maintenance

for

Revision

of

change

test

shortened

procedure

C

shortened

Section

4.0

App.

B

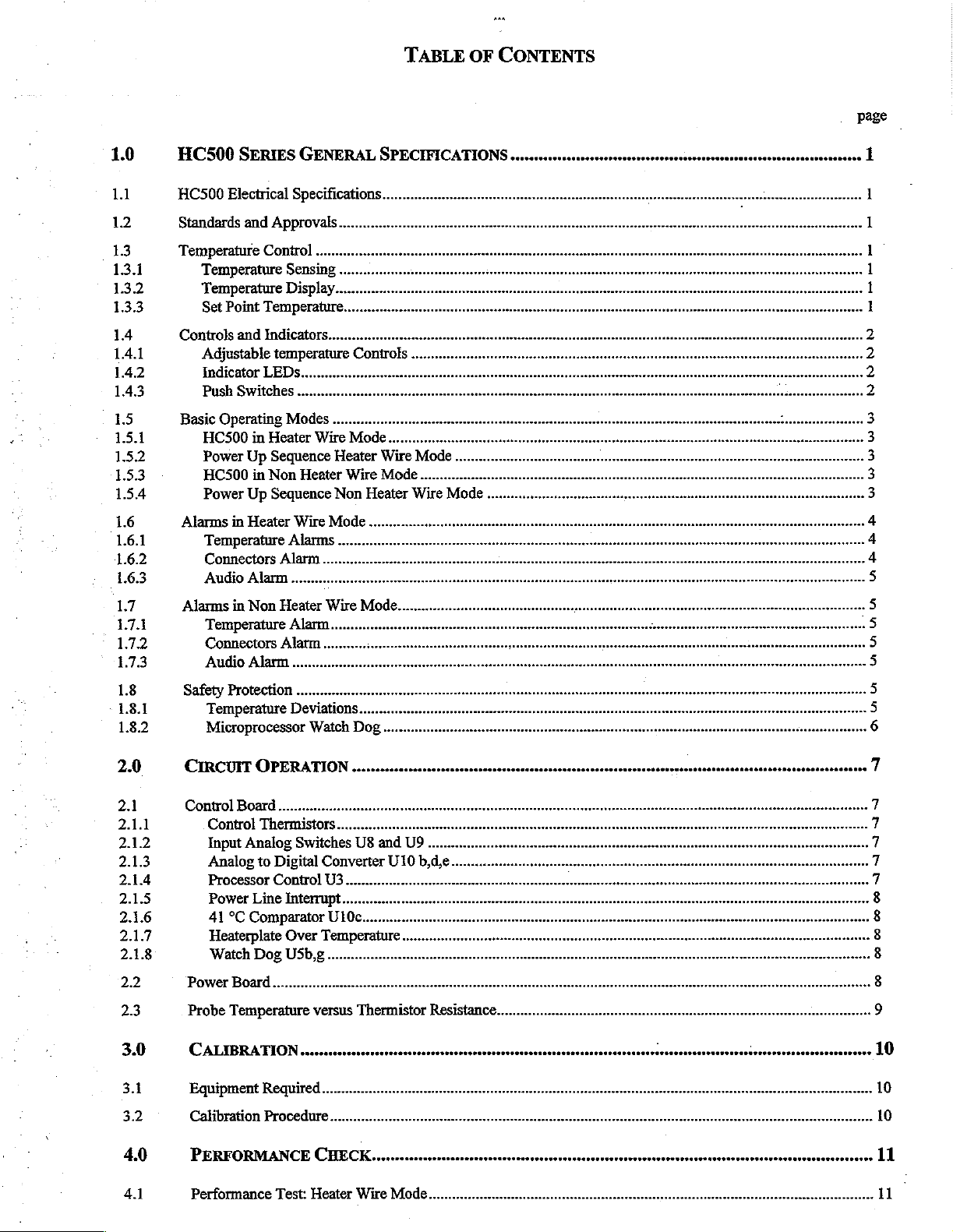

TABLE

OF

CONTENTS

page

1.0

11

12

13

13.1

1.3.2

1.3.3

14

14.1

1.4.2

1.4.3

15

1.5.1

1.5.2

1.5.3

1.5.4

1.6

1.6.1

1.6.2

1.6.3

17

1.7.1

1.72

1.7.3

HC500

HC500

Standards

SERIES

Electrical

and

Temperature

Temperature

Temperature

Set

Point

Controls

and

Adjustable

Indicator

Push

Switches

Basic

Operating

HC500

Power

HC500

Power

Alarms

in

Up

in

Up

in

Heater Wire

Temperature

Connectors

Audio

Alarm

Alarms

in

Non

Temperature

Connectors

Audio

Alarm

GENERAL

Specifications...

Approvals..................

Control

Sensing

Display.

Temperature..

Indicators

temperature

LEDs..

Modes

Heater

Seguence

Non

Sequence

Alarms

Alarm

Heater

Alarm

…

Wire

Heater

Mode

Wire

Alarm..

Controls

Mode.

Heater

Wire

Non

Heater

...

Mode...

SPECIFICATIONS

erre

iene

Wire

Mode

..

Wire

Mode

.

Mode.......

eee

re

nie

re

river

eee

are

see

iene

00000

zeeeee

receive

rece

1

1

re

nerina

neeeeeneenenenicnenzcnne

1

1.8

1.8.1

1.8.2

2.0

2.1

2.1.1

2.1.2

2.1.3

2.1.4

2.1.5

2.1.6

2.1.7

2.1.8

22

2.3

3.0

3.1

32

Safety

Protection

Temperature

Microprocessor

CIRCUIT

OPERATION

[SI

Control

Input

Analog

Processor

Power

41

Thermistors

Analog

to

Line

°C

Comparator

Heaterplate

Watch

Dog

Power

BOTd

Probe

Temperature

CALIBRATION

Equipment

Calibration

Required

Procedure..

Deviations.

Watch

Switches

Digital

Control

Converter

U3

Interrupt

Over

Temperature.

USb,g

siennes

versus

Dog...

U8

0106.

Thermistor

and

U10

U9

..

b,d,e

..

Resistance...

ss

AAA

. :

néé

„10

.

^

=

-124-2

E

00

00

00

8

9

10

10

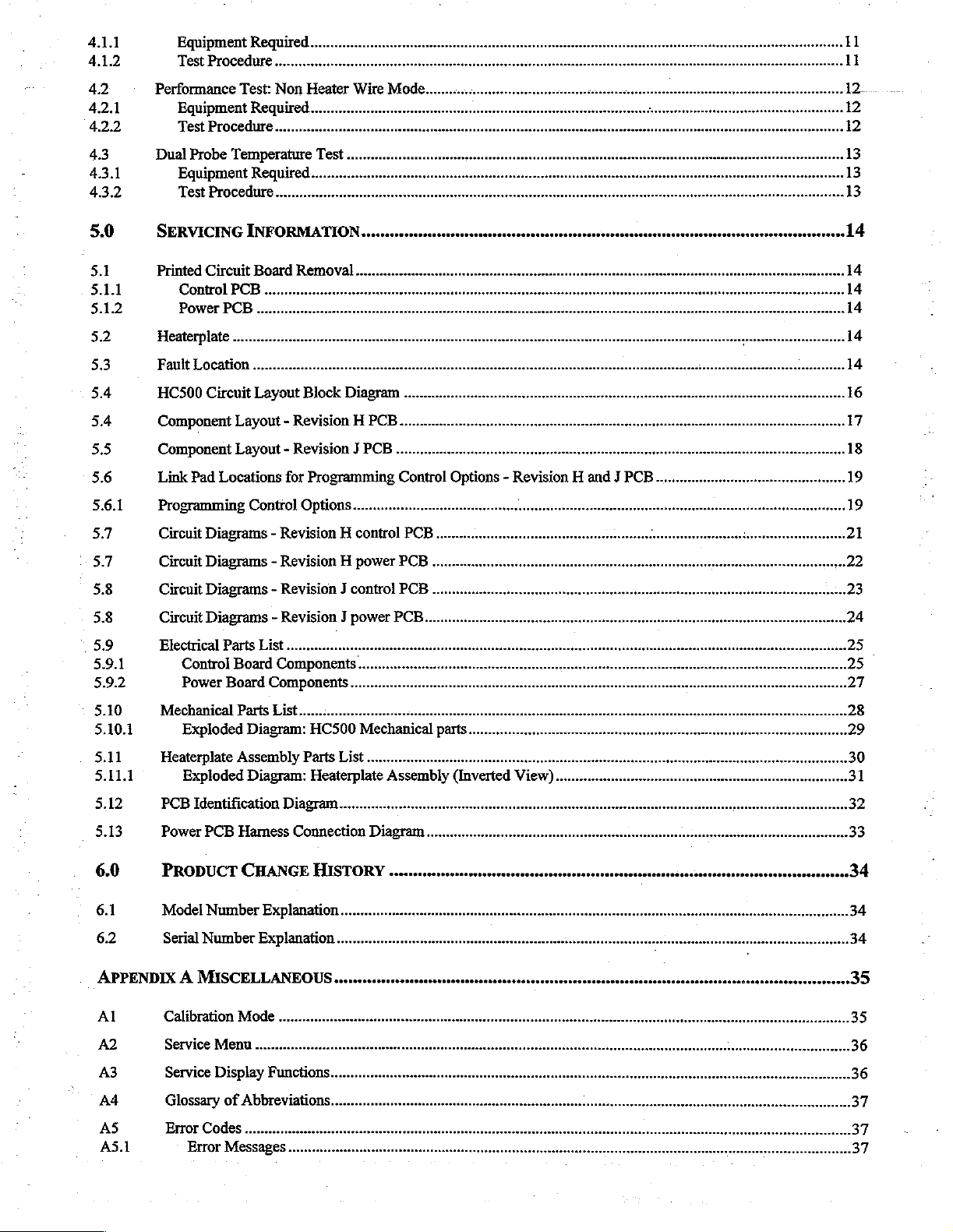

4.0

4.1

PERFORMANCE

Performance

Test:

CHECK.

Heater

Wire

Mode

κοκ

ονοσσν

ων

11

11

4.1.1

4.12

Equipment

Test

Procedure

Required...

4.2

4.2.1

422

43

43.1

432

5.0

5.1

5.1.1

512

3.2

5.3

54

5.4

5.5

5.6

5.6.1

5.7

Performance

Equipment

Test

Procedure

Dual

Probe

Temperature

Eguipment

Test

Procedure

SERVICING

Printed

Fault

HC500

Component

Component

Link

Programming

Circuit

Control

Power

PCB

PCB...

Location

Circuit

Layout - Revision H PCB

Layout - Revision J PCB

Pad

Locations

Circuit

Diagrams - Revision H control

Test:

Non

Heater Wire

Required...

Test.

Reguired

NUN

INFORMATION

Board

Removal

.

RR

E

Layout

Control

Block

for

Programming

OptionS

Mode

Diagram

eenennennenesnieenneses

uen

nee

..cocnacacononnorionacionocianonrnconerncinonon

Control

Options - Revision H and J PCB

PCB

canino

ornrncr

nie

reereeeien

ieri

noes

veve

sieve

arc

ran

roca

aaror

zi

rinzenezezioe

se

see nia

rieneore

nno

rivee

acres

14

sa

ReaReesAmENee

aora

ona

eeeerieneeonznninnee

zine

riva

reni

14

14

16

17

arinnennos

13

ee

19

19

nenenene

21

5.7

5.8

5.8

5.9

5.9.1

5.9.2

5.10

5.10.1

5.11

5.11.1

5.12

5.13

6.0

6.1

6.2

Circuit

Diagrams - Revision H power

Circuit

Сисий

Electrical

Diagrams - Revision J control

Главтапзз - Кеу

Parts

List

Control

Power

Mechanical

Exploded

Heaterplate

Exploded

РСВ

Power

PRODUCT

Model

Serial

Board

Board

Parts

Diagram:

Assembly

Diagram:

14епййсаноп

PCB

Harness

CHANGE

Number

Number

Explanation…...........

Explanation

Components..

ComponentS

List

ПЛаетаиа..........

Connection

Parts

APPENDIX A MISCELLANEOUS

PCB

PCB

dires

оп Т ро\’ег

РСВ..................

еее

ионигиииионииотиитититиииниаититининитиииизитнвиьнииииттитиитиоититурнии

veeererierzceneeeenenienseonieeneree

HC500

Mechanical

parts...

List

Heaterplate

HISTORY

Assembly

еле

Diagram

(Inverted

иионинитииоиоиоининиионинииценотивовютииюншииитирниититинизииншивиянититьлитииитьиииититтит

nent

View).

inner

rene

reeere

unir

recco

rieee

onere

re

ree reo

ennemies

penie

renne

renze

nera

eee

eeeeeezinnee

22

23

24

nere

nen

verenieoneeceeeiizienneee

32

33

34

34

34

35

Al

A2

A3

A4

A5

А5.1

Calibration

Service

Service

Glossary

Error

Error

Mode

Menu

Display

of

Abbreviations

Codes

Messages

ee

...

Functions

rennes

APPENDIX

B

MAINTENANCE

SCHEDULE

38

Bi

B2

B2.1

Recommended

Recommended

Electrical

APPENDIX C PROBLEMS

,

CI

cil Low

C.12

C.13

C.14

C.1.5

C.1.6

C.1.7

C.1.8

C.1.9

C.1.10

C.1.11

С.1.12

ο

Troubleshooting

Temperature...

High

Temperature...

Temperature

Excessive

Low

Humidity

Connectors

*Power-On"

‘see

manual’

Breathing

Error

Code

Chamber

No

Audible

HC500

Fault

Maintenance

Maintenance

Safety

Tests.

WITH

Guide

For

Fluctuating

Water

In

Circuit

Alarm

Indicator

Indicator

Circuit

Water

Flow

Leak..

Displayed

Leak

Sound

With

Chart

Schedule

Schedule

OPERATION

The

HC500

..

Off.

On....

Alarm

Indicator

For

No

Go

...cooconacacicnconnonenonacinmennarennoraroucronecncarinnararo

rr

onarorncoronras

orar

nor

nrn

rr

rasero

38

Checklist

Respiratory

Condition

Humidifier.

inner

40

asenceé

44

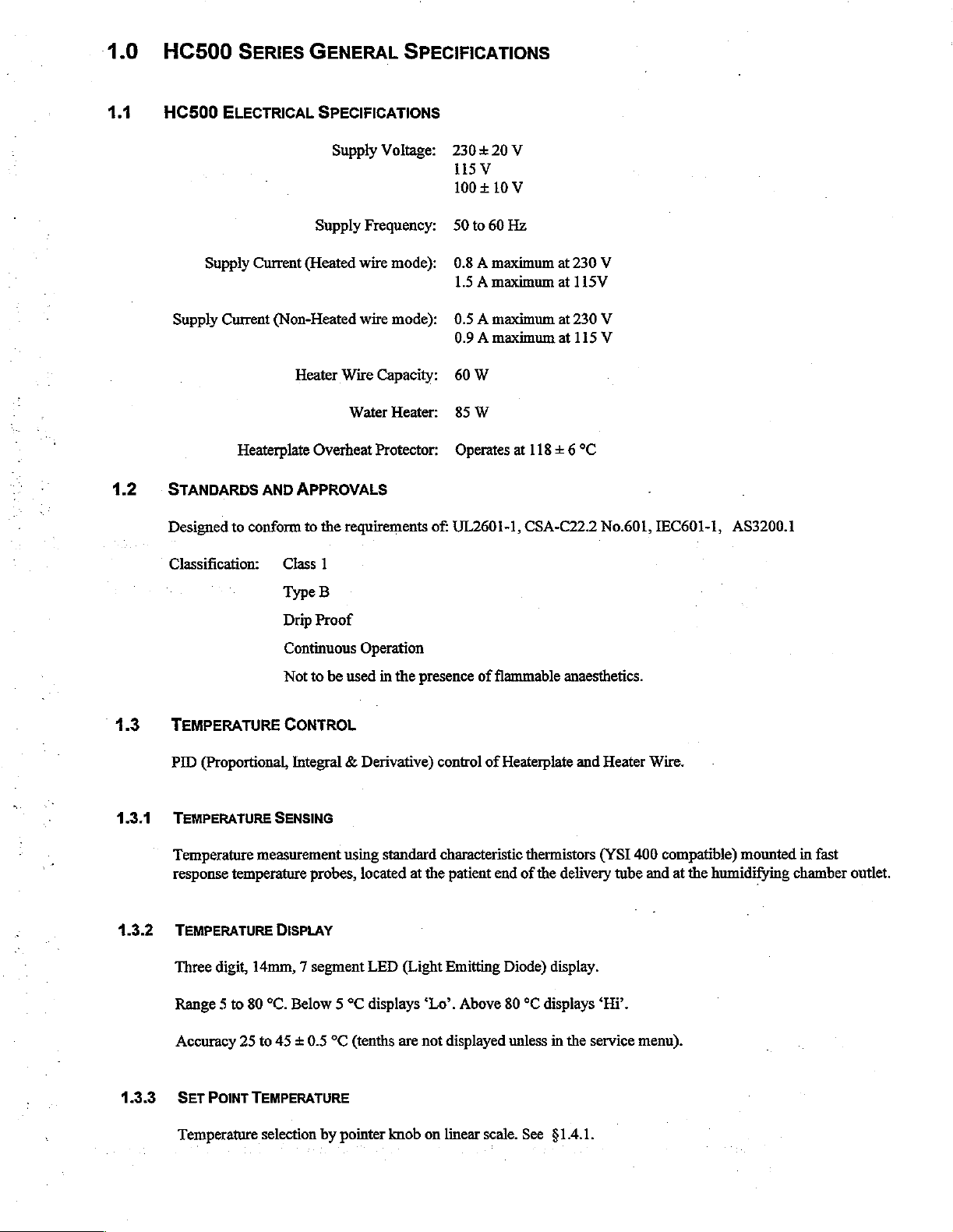

1.0

HC500

SERIES

GENERAL

SPECIFICATIONS

1.1

1.2

HC500

Supply

ELECTRICAL

Supply

Current

Current

Heaterplate

STANDARDS

Designed

to

conform

AND

Classification:

SPECIFICATIONS

Supply

Supply

(Heated

(Non-Heated

Heater

Wire

Overheat

APPROVALS

to

the

Class

1

Voltage:

Frequency:

wire

mode):

wire

mode):

Capacity:

Water

Heater:

Protector:

requirements

230+20V

115Y

100+10V

50

to

60

0.8 A maximum

1.5 A maximum

0.5 A maximum

0.9 A maximum

60

W

85

W

Operates

of:

UL2601-1,

Hz

at

118 + 6

CSA-C22.2

at

at

at

at

230

115V

230

115

°C

V

V

V

No.601,

IEC601-1,

AS3200.1

1.3

1.3.1

1.3.2

TEMPERATURE

PID

(Proportional,

TEMPERATURE

Temperature

response

TEMPERATURE

Three

Range 5 to

Accuracy

measurement

temperature

digit,

14mm, 7 segment

80

25

to

Type

B

Drip

Proof

Continuous

Not

to

be

used

Operation

in

CONTROL

Integral & Derivative)

SENSING

using

probes, located

DISPLAY

LED

°C.

Below 5 °C

45 + 0.5

°C

(tenths

displays

the

presence

control

standard

at

the

(Light

“Lo”.

are

not

of

flammable

of

Heaterplate

characteristic

patient

Emitting

Above

displayed

thermistors

end

of

the

Diode)

80

*C

unless

displays

anaesthetics.

and

Heater

(YSI

delivery

tube

display.

“Hi”.

in

the

service

Wire.

400

compatible)

and

at

menu).

mounted

the

humidifying

in

fast

chamber

outlet.

1.3.3

SET

POINT

TEMPERATURE

Temperature

selection

by

pointer

knob

on linear

scale.

See

§1.4.1.

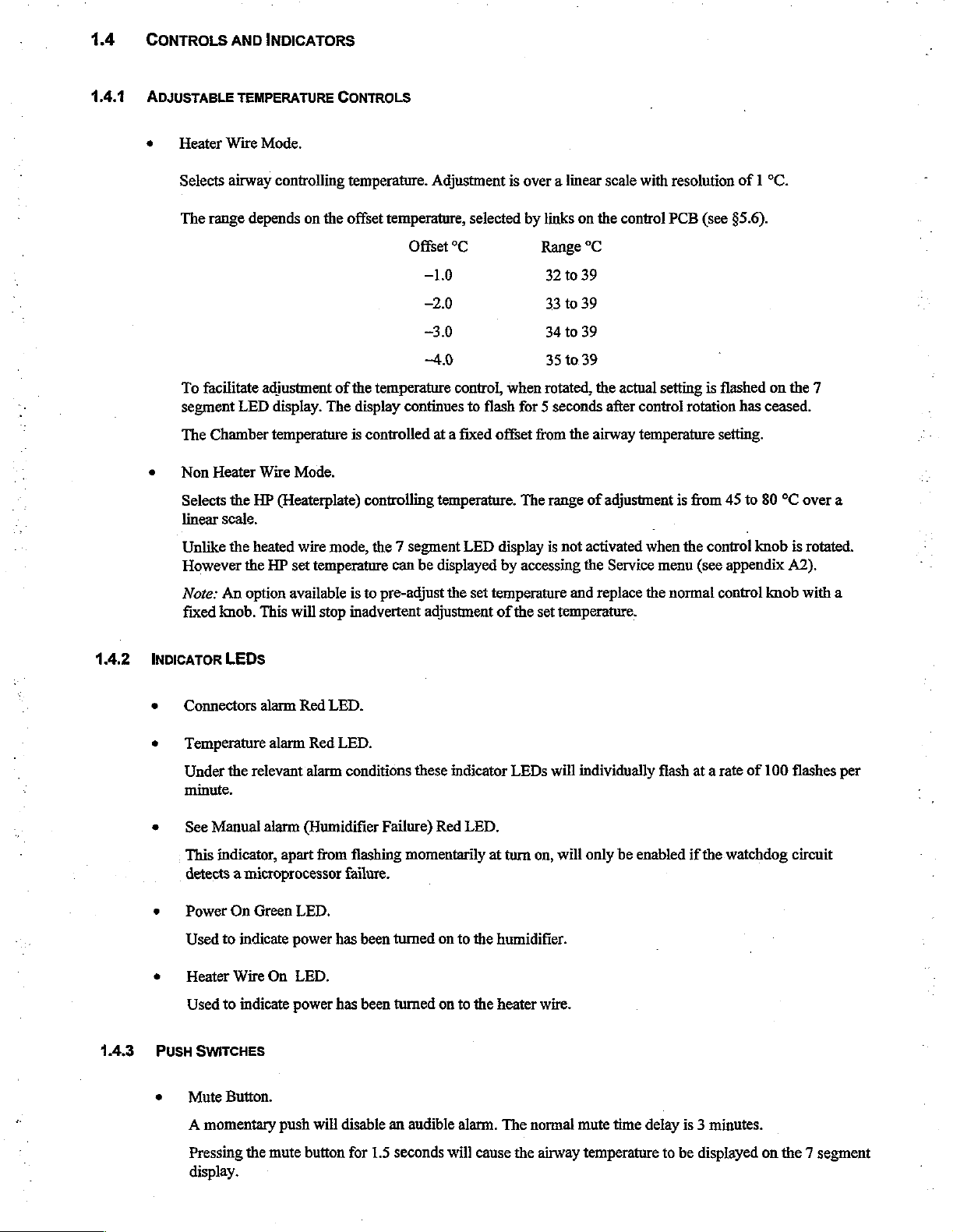

1.4

CONTROLS

AND

INDICATORS

1.4.1

ADJUSTABLE

Heater

Selects

The

range

To

facilitate

segment

The

Chamber

Non

Selects

linear

Unlike

However

TEMPERATURE CONTROLS

Wire

Mode.

airway

controlling

depends

adjustment

LED

display.

on

the

of

The

temperature

Heater

Wire

Mode.

the

HP

(Heaterplate)

scale.

the

heated

wire

mode,

the

HP

set

temperature

temperature.

offset

temperature,

Offset

-40

the

temperature

display

is

continues

controlled

controlling

the 7 segment

can

be

Adjustment

selected

°C

—1.0

—2.0

-3.0

control,

to

flash

at a fixed

temperature.

LED

displayed

is

over a linear

by

links

Range

32

33

34

35

when

rotated,

for 5 seconds

offset

from

The

range

display

by

is

accessing

on

the

°C

to

39

to

39

to

39

to

39

the

the

airway

of

not

activated

the

scale

with

control

actual

after

PCB

setting

control

temperature

adjustment

when

Service

menu

resolution

(see §5.6).

is

flashed

rotation

setting.

is

from

45

the

control

(see

appendix

of 1 °C.

on

has

ceased.

to

80

°C

knob

the

7

over

is

rotated.

A2).

a

142

Note:

An

option

fixed

knob.

This

INDICATOR

LEDs

Connectors

alarm

Temperature

the

Under

relevant

alarm

minute.

See

Manual

This

alarm

indicator,

apart

detects a microprocessor

Power

On

Green

Used

to

indicate

Heater

Wire

On

Used

to

indicate

available

will

Red

stop

LED.

Red

LED.

alarm

is

inadvertent

conditions

(Humidifier

from

flashing

failure.

LED.

power

has

LED.

power

has

to

pre-adjust

Failure)

momentarily

been

tumed

been

turned

the

set

adjustment

these

indicator

Red

LED.

on

to

the

on

to

the

temperature

of

the

set

temperature.

LEDs

will

at

turn

on,

will

humidifier.

heater

wire.

and

replace

the

individually

only

be

enabled

normal

flash

at a rate

if

control

the

watchdog

of

knob

100

with

a

flashes

per

circuit

1.4.3

PUSH

SWITCHES

Mute

Button.

A

momentary

Pressing

display.

the

push

mute

will

button

disable

for

1.5

an

audible

seconds

alarm.

will

The

cause

normal

the

airway

mute

time

temperature

delay

to

is 3

minutes.

be

displayed

on

the 7 segment

Using

the

mute

button

On

every

initial

e © Service Button.

This

is a

hidden

for

more

information.

+

Heater

Wire

Button.

This

toggles

either

will

light

the

operating

when

this

in

conjunction

push

of

the

mute

button

used

for

accessing

HC500

into

either a Heated

position a single

switch

is

latched.

with

the

Service

button, a momentary

the

service

Wire

or

Non

audio

beep

indicates

button

enables

audio

beep

and

calibration

Heated

successful

entry

to

indicates

function

menu.

Wire

mode.

latching.

The

the

Refer

When

'ON'

service

menu.

operation.

to

appendices

this

switch

LED

next

is

to

Ai

the

and

A2

latched

button

in

1.5

1.5.1

1.5.2

If a connector

attached

non

BASIC

HC500

The

HC500

both

ends

Heaterplate

when

heated

OPERATING

IN

HEATER

humidifier

of

the

and

with a minimum

The

control

fixed

Power

On

power

All

indicator

two

audible

knob

offset

below

Up

SEQUENCE

up

the

LEDs

seconds.

Then

beep.

alarm

immediately

switching

wire

mode.

MODES

WIRE

MODE

in

Heated

delivery

Heater

of

sets

microprocessor

hose,

Wire

are

condensation.

the

control

this

(the

offset

HEATER

(excluding

the

Temperature

to

non

heater

Wire

by

means

regulated

temperature

is

link

WIRE

watchdog

the

See

Control

follows

mode

the

operation

wire

mode

or

expecting

incorporates a temperature

of a dual

to

selectable,

temperature

maintain

at

the

airway

refer

the

desired

§5.6).

and

MODE

is

tested.

The

‘See

Manual

LED)

setting

is

are

illuminated

displayed

of

this

button,

one

sensing

temperature

the

chamber

Manual’

together

for a further

this

may

to

be

attached

controller,

probe

assembly.

and

outlet

LED

will

illuminate

with

one

second,

be

due

to a heater wire

when

switching

which

monitors

In

this

humidity,

temperature

“8.8”

on

the

within

briefly

followed

temperature

way

the

close

is

maintained

if

successful.

digital

display

by a single

being

from

limits,

the

at

for

at

a

1.5.3

1.5.4

HC500

In

sensor

at

maximum

:N

the

Non

at

the

humidification

lowered

The

control

mode

is

POWER

On power

All

indicator

audible

beep.

NON

HEATER

Heater

the

delivery

of

66

°C.

flow

performance.

knob

sets

80

°C.

UP

SEQUENCE

up

the

microprocessor

LEDs

WIRE

Wire

mode

end

(airway

chamber

In

this

the

control

NON

are

illuminated

MODE

the

HC500

outlet

way,

safety

temperature

HEATER

watchdog

delivery

end)

monitors

is

employed

at

low

WIRE

together

delivery

in a backup

flow

at

the

MODE

is

tested,

with

‘8.8’

temperature

rates

heaterplate,

the

on

is

maintained

temperature

safety

(below 5 litre/minute)

the

‘See

Manual’

the

digital

to

prevent

mode,

to

maximum

LED

display

by

Heaterplate

any

rise

limit

the

chamber

is

improved

heaterplate

will

illuminate

for

two

seconds,

control

above

at

41

outlet

the

expense

only.

°C.

temperature

briefly

if

followed

The

The

sensor

to

a

of

in

this

successful.

by a single

2.1.5

Power

A

buffered

to

frequency

switching.

this

LINE

sample

ground

source.

of

by

when

facilitating

The

INTERRUPT

the

power

Schmitt

the

trigger

diodes

ADC

supply

USf,

D13

the

generation

is

also

phase

frequency

and

fed

to

D16

are

of a real

synchronised

is

derived

to

the

RST7.5

not

conducting. The

time

with

from

interrupt

clock

the

the

power

and

also

line

frequency

transformer

of

U3.

Resistor

operating

software

enabling a zero

thus

eliminating

secondary

R68

pulls

determines

crossing

detector

any

via

R56

the

secondary

the

common

and

Q1,

winding

supply

for triac

error

from

2.1.6

2.1.7

41

°C

COMPARATOR

Operational

input

adjustable

low

above

D19,

pin

R55

amplifier

5 is

divider

an

and

temperature

A

watchdog

to

the

non

inverting

of a processor

HEATERPLATE

Thermistor

during

Under

HP

normal

certain

Programming

protection

transformer

mechanical

module.

should

primary

cut-out

connected

network

input

temperature

D20,

R61

greater

than

failure,

which

input

crash.

OVER

senses

operation,

operating

Control

the

and

must

U10c

U10c

is a

protection

directly

R33,

(via

VR4,

of

to

clamp

41

°C

causes

is a high

of

U10c.

TEMPERATURE

the

heaterplate

power

to

conditions

Options.)

electronic

thus

causes

be

manually

Also

control

circuit

connector

R32.

VR4

41

°C.

This

the

bases

of

both

heaters

output

from

This

also

temperature.

the

heaterplate

different

maximum

mounted

system

complete

reset

by

to

sense

J4-1)

is

set

low

output

switching

to

U5g,

ensures

Should

is

discontinued

on

the

fail.

This

shut

down

means

excessive

to

the

airway

during

calibration

(OVHT)

transistors

be

shut

down.

is

communicated

that

both heater

the

heaterplate

heaterplate

heaterplate

mechanical

of

the

humidifier

of

the

reset

delivery

temperature

thermistor.

to

ensure

is

fed

via

the

Q10

and

Q12.

via

isolating

control

circuits

exceed a preset

until

it

cools

temperatures

is a

mechanical

cut

out

is

should a serious

button

located

The

inverting

that

the

isolating

In

this

diode

are

below

this

can

be

selected.

thermal

connected

on

the

underside

rise.

The

input

output

diode

resistor

way,

an

D11

and

clamped

maximum

limiting

cut out

in

series

fault

non

inverting

goes

to

an

pin 7 of

UlOc

networks

airway

resistor

off

in

the

R31

event

temperature

temperature.

(See

§5.6,

which

will

give

with

the

power

develop.

of

The

the

heaterplate

is

2.1.8

WATCH

During

output

fed

this

which

or

should

humidifier

To

LED10,

POWER

A

protected

from

The

U12,

triac,

Doc

operation

port

to

the

charge

square

wave

drives

may

not

fail,

is

indicate

and

BOARD

bridge

rectifier

by a 1

the

voltage

heaterplate

which

and

with

U5B,G

the

PB7

of

U4

pump

be

the

trap

be

successful

and

is

unable

tumed

that

the

also

turns

(D13

Amp

doubling

is

switched

in

tum

C33,

processor

every

circuitry

interrupted

interrupt

is

16.6

C16,

for

input

depending

to

re-initialise,

on

by

deliberately

processor

fuse

off

to

has

the

display

D16)

(F1)

supplies

mounted

network

by a port

switches

form a snubber

triac

continually

or

20ms

D4,

monitored

(power

D5

and

any reason,

of

U3.

This

on

the

nature

it

fails

halting

failed,

the

high

I-C

U7

to

power

on

the

D17,

D18,

pin,

PC4,

Q11

(mounted

network

for

line

C15,

C15

will

high

trap

of

the

in a safe

program

output

blank

the digital

to

the 5 V

circuit

C25.

of

U4

on

on

the

both

the

for

correct

frequency

which

interrupt).

ensures

discharge

input

forces

fault.

The

mode.

The

execution

of

U5g

also

display.

regulator,

board.

The 5 V

the

control

heatsink).

triac

and

function.

through

that

This

This

square

pin

13

R3

giving a high

re-initialisation

purpose

and

Resistors

optoisolator.

of

watchdog

waiting

turns

on

Q7

mounted

negative

board

(HPC)

R57,

this

circuit

for

Q3

which

supply

R64

is

done

by

changing

wave

buffered

of

U5g

is

held

hard

output

of

the

processor

is

to

ensure

that

is

tested

every

initialisation

on

the

stabilised

and

controls

limit

lights

heat

sink.

the

via

the

humidifier

This

by

the

gate

the

state

by

USb

up.

Should

from

pin

12,

which

may

if

the

processor

time

the

the

watchdog.

fault

circuit

08,

is

derived

optoisolator

current

to

the

of

is

is

The

Heater

Wire

optoisolator

control

Heater

optoisolator’s

U13

then

the

HHS

circuit.

board

wire

during

to

U4.

signal

U11

(HHC).

sensing

LED

the

Resistor

circuit

(HHC)

which

in

R9

is

performed

by

R52

negative

R67

whether a heater wire

is

turn

is

and

C6

when

cycle

of

prevents

controlled

driven

are a snubber

by

optoisolator

triac

the

false

by

by

Q10.

Q9

is

on

22Vac

secondary.

triggering

is

connected

triac

Q9

Q10

is

network

U13

and

and

by

of

the

or

open

which

is

mounted

controlled

for

associated

R51

The

U13

circuit,

directly

the

heater

and

R52

output

of

phototransistor.

and

on

the

from

an

wire

triac.

components.

when

the

triac

the

optoisolator

The

whether

the

heat

sink.

output

Current

is

off.

Diode

(HHS)

software

heater

wire

Q9

is

port

of

is

limited

D21

connects

can

determine

fuse

switched

U4

on

the

through

protects

to

USd

F2

is

open

by

the

the

and

from

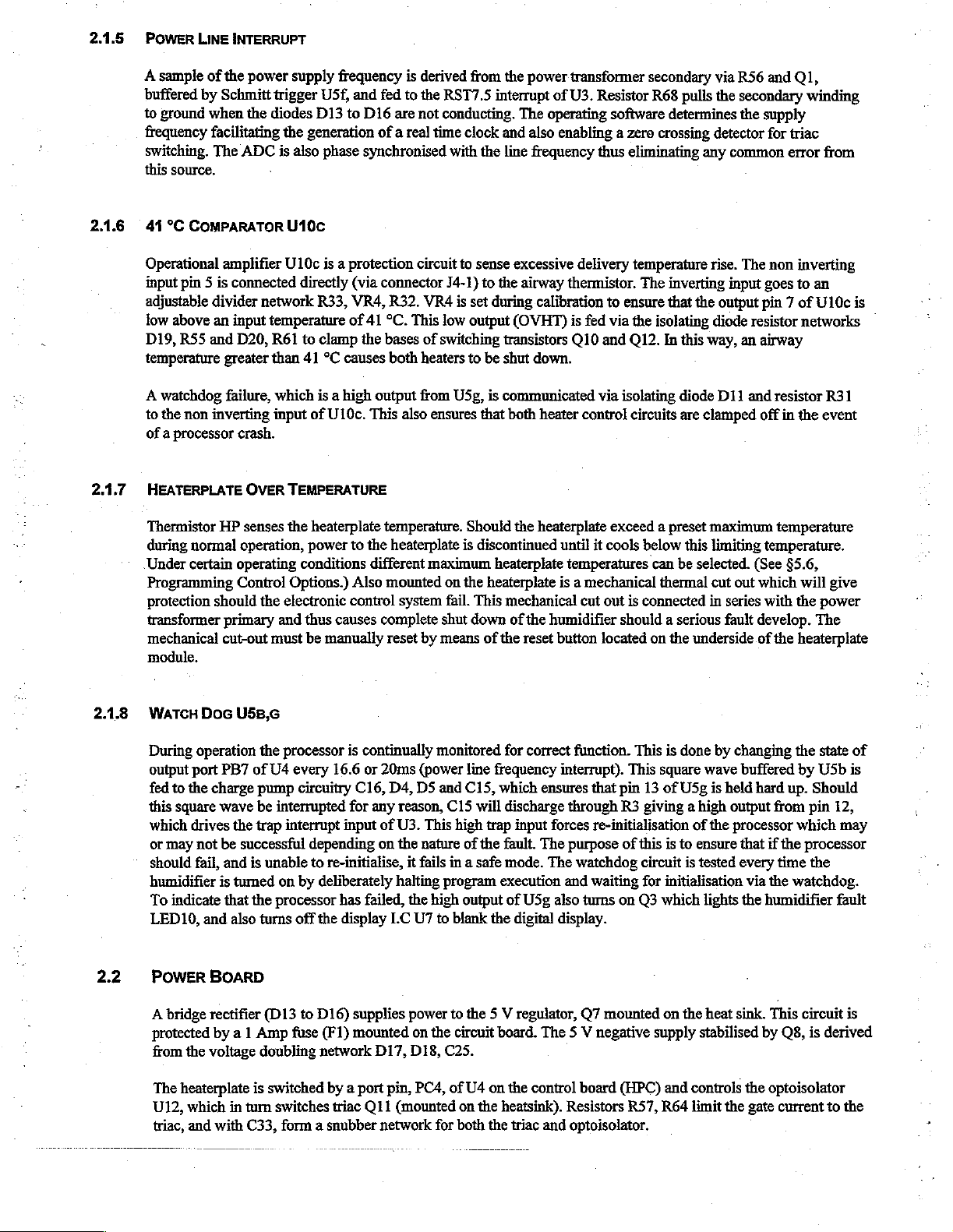

2.3

PROBE

TEMPERATURE

TEMP

(£0.5°C)

0

9

28

29

30

31

32

33

34

35

VERSUS

THERMISTOR

RESISTANCE

(Ohms)

73523

47022

1976.6

18933

18144

1739.2

1667.2

1598.2

1532.9

1470.6

RESISTANCE

TEMP

||

05°C)

36

37

38

39

40

41

44

42

43

60

RESISTANCE

(Ohms)

14113

1355.0

1301.0

712492

1199.6

11523

11073

1064.5

1023.1

5603

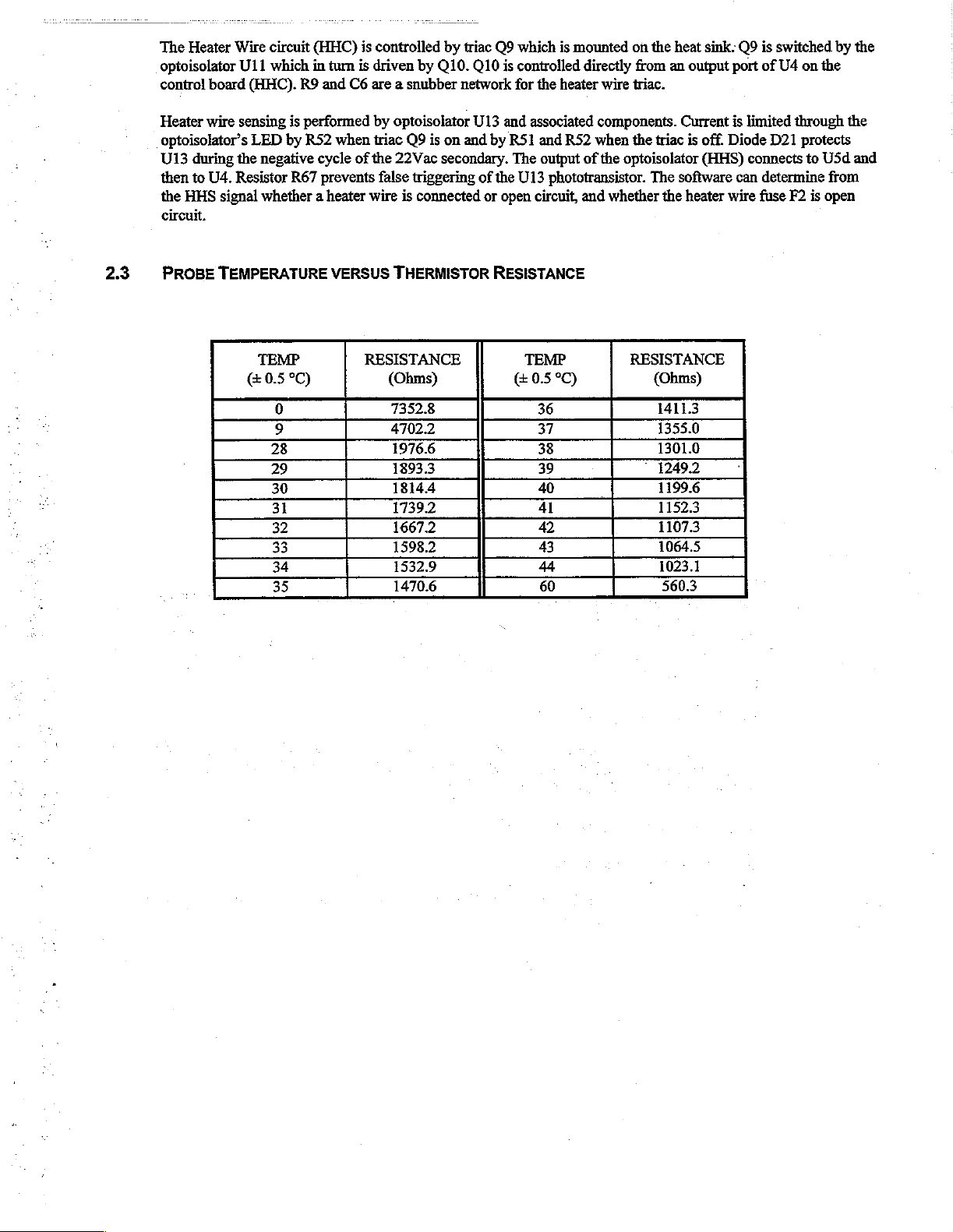

3.0

CALIBRATION

3.1

3.2

Calibration

adjustments

This

messages

may

would

Calibration

unit

EQuiPMENT

+

e

‧

is

facilitated

VR4

calibration

in

the

have

altered

require a calibration

should

has

warmed

REQUIRED

41

°C

calibration

Small

flat

Large

Pozidrive

CALIBRATION

Note:

For

instructions

by

and

VRS,

procedure

display)

the

potential

be

checked

or

up.

probe,

blade

screwdriver.

screwdriver.

PROCEDURE

on

disassembly

entering a special

the

41

°C

comparator

may

be

carried

if

any

of

of

the + 5 V rails

the

circuit

out

check.

and

performed

available

in

of

the

the

Calibration

stage

and

if

the

unit

is

boards

have

or

component

after the

F&P

unit,

unit has

calibration

refer

to

mode

(refer

setting

thought

been

change

been

kit

$5.0,

Servicing

appendix

the

span

to

be

out

replaced

associated

running

(F&P

part

Information.

A1).

There

are

of

the A to D converter.

of

calibration

or

repaired.

with

for

at

no.

900MR548).

(E0x

In

particular

the A to D converter

least

half

only

an

two

to

E7x

any

hour;

error

repair

ie

after

that

the

„=

Plug

2

Gain

humidifier

3

With

show

4

Using

5

Starting

too

the

6

Using

7

Remove

8

in

access

the

*-1-*

the

far

segments

the

Adjust

the

41

°C

calibration

to

the

adjustment

front

panel.

Service

button

Service

button

with a vertical

the

display

Service

the

VRS

becomes

of

the

all

button

41

°C

calibration

for a display

probe.

potentiometers

(SW3)

held

(SW3)

step

bar

display

all

horizontal

‘8’

display

(SW3)

step

probe.

reading

down

to

“-4-*

adjust

VR4

bars

are

of

equal

to

*-5-º

of zero.

VR4

and

turn on

the

so

the

([|.|j.||.

brightness.

(0)

(Note

VRS,

mains

display

through

this

display

by

removing

power

switch.

changes

8.8.8.

to

reading

to

an

==).

may

the

control

The

Temperature

all

“8”

The

correct

move

board

display.

If

point

by + 2.0

from

the

display

VR4

is

is

where

over

time.)

should

rotated

all

4.0

PERFORMANCE

These

test

procedures

dismantling

appendix

the

A2).

may

unit.

Performance

CHECK

be

used

to

check

is

monitored

the

operation

during

the

and

test

calibration

by

using

the

of

the

HC500

functions

humidifiers

of

the

Service

without

Menu

(refer

4.1

4.11

4.1.2

PERFORMANCE

The

heater

base

EQUIPMENT

Calibration

A Fisher

9

Dual

TEST

For

this

—

REQUIRED

temperature

Cup

(250 ml)

PROCEDURE

test

only

Plug

in a 34.5

Turn

the

TEST:

is

run

kit

& Paykel

HEATER

with

(Part

no

recommended

probe

of hot

water

the

HC500,

°C

test

temperature

WIRE

fixed

inputs

900MR548)

assembly

(>

41

test

probe

probe

and

control

knob

MODE

to

check

containing

reusable

(eg

900MR560).

°C).

and

heater

connect

fully

for

correct

heaterplate

34.5

°C

test

heater wire

wire

the

heater

anticlockwise

assembly

are

required.

wire

(minimum

probe

to

the

humidifier.

and heater

and

(eg

900MRS510

41

°C

calibration

wire

temperature).

control.

probe.

).

Turn

Check

i

ii

iii

(Note

iv

Push

Enter

ii

iii

iv

Run

on the

HC500

the

power

See

manual

All

LEDs

Display

if

the

5.6.1

for

Audio

the

heater

the

service

i

v

Heaterplate

for

at

least

mains

on

sequence:

light

and

digital

shows

set

set

temperature

how

to

reprogram

alarm

beeps.

wire

button

menu

Temp

Airway

Chamber

10

minutes

power

flashes

briefly.

display

temperature

shows

and

(refer

appendix

control

Offset:

temperature:

temperature:

maximum

without

switch.

illuminate

(either

32, 33,

35,

it

will

this.)

check

that

the

A3)

setting:

limit.

Record

interruption.

for 2 seconds.

or

34)

need

to

be reset

heater

wire

and check:

32

-1.0,

34.5 + 0.2

34.5 + 0.2

this:

for 2 seconds.

to

34

for

the

on

light

comes

or

33

or

34 + 0.1°C

-2.0,

or

-3.0

°C

°C

purposes

on.:

(SET)

°C

(OFF)

(Air)

of

this

(Ch)

(HPL)

test,

see

section

After

ten

i

Heater

ii

Heaterplate

minutes

wire

:

cold

(feel).

cold.

(<

60

°C).

Turn

10

Enter

i

11

Run

12

After

i

ii

13

Disconnect

14

Press

15

Reconnect

16

Disconnect

17

Reconnect

18

Place

the

temperature

the

service

Temp

control

for

at

least 10

ten

minutes:

Check

in

the

heaterplate

Heater

Wire

the

the

MUTE

the

heater

the

the

temperature

the

airway

control

menu

(refer

setting:

minutes

Service

maximum

hot

heater

button

temperature

probe

without

menu

noted

(feel).

wire

and

and

wire

and

probe

probe

end

sensor

knob

fully

appendix

interruption.

that

above

check

check

that

check

and

and

into a cup

clockwise.

A3)

and

the

heaterplate

(6v).

Note

that

the

Connectors

the

audio

that

the

Connectors

check

again

check

that

of

check:

39

°C

temperature

the

default

alarm

is

for

the

the

Connectors

hot

water

(hP)

setting

light

flashes,

silenced.

LED

stops

Connectors

alarm

(>

41

°C).

(SET)

is

approximately

is

100

°C.

and

the

audio alarm

flashing.

and

audio

stops.

the

alarms.

same

as

the

commences.

4.2

4.2.1

19

Check

that

show

the

Note:

The

since

they

20

Remove

below

41

21

Go

straight

PERFORMANCE

This

test

checks

EQUIPMENT

Calibration

A Fisher & Paykel

Fisher & Paykel

the

Temperature

current

HC500

are

due

the

temperature

°C

check

to

the

TEST:

that

the

REQUIRED

kit

(Part

light

airway

temperature

may

indicate

to

the

that

the

non

heater

NON

heaterplate

no

900MR548)

dual

humidification

spurious

rapid

change

probe

from

Temperature

wire

HEATER

is

temperature

flashes

and

above

‘EP4’

in

temperature.

the

cup and

light

mode

test.

WIRE

controlled

containing

probe

assembly,

chamber

(eg

the

41

°C.

or

goes

MODE

to

the

HC335)

HC500

similar

watch

off

correct

34.5

°C

audio

alarm

messages

the

temperature

and

the

Airway

temperature,

test

probe

eg

900MR560.

filled

to

the

begins.

on

the

fall.

display

selected

and

41

maximum

The

temperature

display.

When

These

the

goes

by

the

°C

calibration

water

level.

display

can

be

temperature

blank.

“Temp

Control’

probe

should

ignored

drops

knob.

4.2.2

Cup

TEST

PROCEDURE

(Ensure

1

Fill

2

Plug

3

Turn

(250

that

the

in

the

ml)

of

the

heater

chamber

the

34.5

Temp

hot

water

wire

is

to

the

maximum

°C

test

Control

(>

turned

probe.

knob

41

°C).

off

i.e.-

water

fully

clockwise.

heater

ON

level

and

Enter

LED

slide

it

the

is

off)

onto

the

Service

heaterplate.

Menu

and

check:

4

This

i

Temperature

Run

for a further

is

the

end

of

the

Control

30

setting:

minutes,

performance

then

check

check,

80.0

again

record

the

+0.2

the

test

°С

heaterplate

results

(ЗЕТ)

on

the

temperature,

maintenance

it

should

chart , see

now

appendix

read

80 + 1

B2.

°C.

4.3

431

4.3.2

DUAL

PROBE

This

test

is

recommended

as

to

the

accuracy

both

probes

(chamber

verification

manner,

depending

thermometer

EQUIPMENT

‧

e

e

‧

TEST

of

any

probes

on

REQUIRED

Dual

Temperature

Mercury

Cup

(250

Heater

wire

PROCEDURE

reading

TEMPERATURE

to

be

performed

of

the

temperature

and

airway)

temperature,

exhibiting a temperature

the

accuracy

filled

ml)

of

if

using

if

of

would

also

probe

glass

thermometer.

warm

water ( 20

HC500

so

desired.

the

be

to

be

TEST

probe. This

firstly

to

In

mercury

suspect.

tested.

to

in

heater

on

temperature

test

one

another,

the

first

difference

in

the

glass

40

°C).

wire

mode.

probes

allows

the

and

secondly

case,

assuming

of

more

thermometer

at

least

every

operator

than

to

to a glass

that

both

0.7

°C

any

probes

six

months,

compare

thermometer

probes

would

be

not

agreeing

or

the

temperature

have

not

suspect.

within + 1.5

if

there

for

absolute

failed

in a similar

In

the

is

any

doubt

readings

second

°C

of

case,

of

the

1 . Plug

connected.

2

Turn

3

Insert

40°C.

with a rubber

4

Place

5

Enter

alternate

points

6

Check

not

7

Check

the

dual

on

the

both

temperature

As

temperature

the

thermometer

the

Service

between

showing).

the

temperature

exceed

that

probe

HC500

band

menu

the

0.7 °C.

the

chamber

into

the

mains

power.

sensor

gradients

during

this

in

the

(refer

airway

difference

and

HC500

probes

can

test.

water

appendix

and

chamber

airway

Humidifier.

into a container

be

quite

large

alongside

between

probes

the

A2)

and

temperatures

chamber

read

If in

Heater

filled

it

is

recommended

probes

select

and

within

Wire

mode,

with

water

and

allow a minute

‘CP’

(compare

(chamber

temperature

airway probes

1.5

°C

of

the

ensure a heater wire

at a temperature

that

the

two

probes

for the

temperatures

probes)

mercury

option.

as

indicated

thermometer.

is

displayed

by

between

be

held

The

display

with

the

display.

assembly

20

and

together

to

stabilise.

will

all

decimal

It

should

is

5.0

SERVICING

This

section

two

separate

be

replaced

INFORMATION

provides

circuit

by a new

information

boards,

board. See

the

for

power

§3

regarding

servicing

board

the

and

calibration

HC500

control

Humidifier.

board.

In

the

after

repair.

The

electronic

event

of a board

circuitry

developing a fault,

is

contained

it

on

may

5.1

5.1.1

5.1.2

PRINTED

CIRCUIT

CONTROL PCB

The

front

panel

from

the

rear

connectors

down

release

When

POWER

Separate

Power

The

edge

lifted

harness

and

the

three

the

the

latches

PCB

the

PCB

power

of

the

slightly

connectors

cut the

(i

board.

case

and

board

board

cable

and

heaterplate

of

the

humidifier

and

J2)

plastic

This

release,

front

Control

and

and

to

clear

which

tie

BOARD

REMOVAL

assembly

body.

disconnected

retaining

is

from

heat

moving

the

holding

latches

facilitated

the

board

the

humidifier

PCB

(J1

sink

assembly

the

lower

retaining

can

now

the

The

from

protruding

if a slight

will

and

J2).

board

be

detached.

mains

cord

is

separated

front

panel

the

rear

upward

pop

up

leaving

body

Cut

the

can

now

forward

guides

in

place.

from

assembly

of

the

through

finger

the

and

disconnect

cable

tie

be

removed

slightly

and

moved

Before

removing

the

humidifier

can

control

the

board.

board

pressure

push-on

holding

by

to

disengage

further

now

be

If

the

can

be

is

maintained

control

the

two

ribbon

the

heaterplate and

flexing

from

forward

the

PCB,

body

moved

front

moved

knob

the

case

the

to

unscrew

by

removing

aside

panel

in

on

behind

cable

sides

case.

gain

access

the 4 fixing

and

the

is

now

the

appropriate

either

edge

in

the

connectors

chassis

The

the

away

board

to

mains

wires

from

the

cord

screws

two

ribbon

positioned

direction

of

the

board.

front

panel.

joining

the

together.

the

chamber

should

now

various

wiring

connections

cable

face

to

be

5.2

5.3

HEATERPLATE

To

reset

the

over

(through a smali

To

replace

μα

2

3

4

5

6

When

heaterplate

FAULT

the

heaterplate:

Separate

Unclip

Unplug

Unscrewthe

Unplug

assembly

Detach

the

the

the

the

the

replacing

spring

LOCATION

is

temperature

hole

under

the

case

front

from

Power

PCB

from

heaterplate

earth

ribbon

now

heaterplate

the

heaterplate,

loading).

wires

screw

cables

separate

from

protector,

separate

heaterplate

the

humidifier

the

case

from

the

on

the

chassis

from

the

Power

from

the

the

case

ensure

that

in

body

Power

case

front

the

for

PCB

body.

the

the

case

front

body.

(see

$5.1.2).

PCB

the

heaterplate

to

by

removing

three

springs

front

from

panel

case

(connectors

earth

the

Control

the

three

are

in

the

case

body,

assembly).

J3

and

17).

wire.

PCB

(connectors

screws

place

on

the

then

push

J1

and

which

secure

heaterplate

the

reset

32).

The

it

to

the

fixing

button

front

case

legs

case

front.

(check

the

If

neither

transformer

checked

the

by

digital

display

primary,

depressing

check

the

nor any

that

the

red

reset

of

the

front

mechanical

button

(see

panel

LEDs

overheat

§5.2).

are

on

protector

and

on

the

no

power

heaterplate

appears

has

not

to

be

cut

reaching

out.

This

the

may

be

Determine

display

humidifier

presence

ms

clock

fault

if

is

blank,

fault

of a 33

is

elsewhere.

all

power

supplies

check

the

LED

indicator

to

40

ms

period

present a fault

in

are

operational

watchdog

and

isolate

square

the

watchdog

output

the

wave

circuitry

and

(pin

heater

at

PB7

all

fuses

12

U5g).

circuits,

(pin 1 USb).

is

indicated

are intact.

A high

output

but not

If

but

If

the

power

here

will

necessarily

the

watchdog

if

port

PB7

is

supplies

blank

stop

the

output

not

changing

are

OK

the

display,

processor.

is

high

and

state

but

the

tum

on

Check

the

33

there

the

for the

to

40

is

a

54

HC500

CIRCUIT

ul

084

LAYOUT

109911198

qunoo

pees

SHA

|

BLOCK

ХПИ

16400

Авар

046

«

=

(dus

Fume

LE

ОЛ

|

Moro

ejes

ses

dues

10183006

DIAGRAM

uogeusosu!

Áejdsip

了

ΝΟΙΜΘΛΟ

Jejunos

=

=

(e)

озеру!

sazı

x=

8

J0sseooldojol

山

99

99

191

198

=

JIMMGIBSU

epou

vonna

On

2

一

一

让

|

(ol

Wodd3sosseooid)

90Id

IOUO9

e

81198

。

dvdl

4

4

sup

.

BOT

qnd

XNW

ouez

BujSsoso

NI

님

Bopyopem

sou

1

wi

ae

UniOA

mere

pan

ay

mm

本

o

Bep

by

seul

lolluoo

=

16189U

и

N

JOjeJeduioo

NS

euuayeay

ор

0

OYAZE

ejerdiajeeu

22

ooo

sles

o

quiod

Bop

PUA

Ly

jnolp

ohuoo

9JIAU9jBSU

nolo

lonuoo

aleldisleay

jauuedi

시

0009

nono

©

69096

vo

È

9

Bep

“vo

09

TEA

dual

125

>

Y

dgdUdBlO

"sy

1.

D

©

©

5.4

COMPONENT

LAYOUT - REVISION H PCB

=

>

iy

È

|=

0

|

5

N

г

o

<

©

~

+

2

gee

に

κο

3

é

med."

=

ZA

。

ノ

4/77

mors

see

s

ερ

μάς

KDM)

S

F

Genre,

s

A

ale

5

seas:

a

5

O

Selle

E

“peo

ee

22924;

3

Z,

Len

+

39Υ110Λλ

“E

яя

ses)

E

>

ΗΟΙΗ

ΝΟΗΠΥΟ

©

ン

ee

ee:

~

e

s

o

lea

‘less

ele

È

è

02

IN

ge 33

3,

Fe

Elam

C

SE

008

U

©

8

B

8

호

U

O

3

see,

cds

.

Rice

Elles!

GIVE

È

*

..

tld

(o)

оо

Е

CO

aft

see

μή

ae

후

fica

し

ze

Sİ

ee

:

2.

e

5.5

COMPONENT

LAYOUT - REVISION J PCB

e

|

a

è

|

>

T

ii

~

oo

S

©

o

M)

z

Zem

U

SH

el

ae

=,

©

E

He

UF

i

Het

Е

EPA

ewe

5.6

LINK

PAD

LOCATIONS

FOR

PROGRAMMING

CONTROL

OPTIONS - REVISION H AND J PCB

Link

Pads ® >

Control

(viewed

soldered

Board

from

side)

MİN

e

Si

SE,

k

se

pre

o

Location

E

leje

el

+

...

Pads

for

Programming

of

Link

Control Options

5.6.1

PROGRAMMING

The

following

x = don't

=

0 = no

LI

1

1 1

0

0 0

x x

x

x x

x

x x

x

The

offset.

care.

link.

link.

12

0

1

x

x

x

factory

default

CONTROL

options

5

K

X

κ

KRK

の

ビー

メー

AA

A

settings

can

pe

mx

Mx

MM

HM

OPTIONS

be

enabled

re a E

κ

K

K

K

K

K

r

r

© ©

are

for

by

a

ὃν

KM

에

에

ON

NONO

DO

mi

the

joining

50

80

90

100

ISO

Gliding

—1.0

—2.0

~3.0

—4.0

100

*C

the

pads

°C

maximum

°C

maximum

°C

maximum

°C

maximum

draft

standard

tone

°C

temperature

°C

temperature

°C

temperature

°C

temperature

maximum

on

the

control

temperature

temperature

temperature

temperature

audio

alarm.

audio

alarm.

offset.(32

offset.(33

offset

offset.(35

heaterplate,

PCB

as

shown

Heaterplate.

Heaterplate.

Heaterplate.

Heaterplate

to

39

°C

to

39

°C

(factory

ISO

setting).(34

to

39

°C

audio

(factory

range)

range)

range)

alarm

in

$5.6.

settng).

to

39

and —3.0

°C

range)

°C

temperature

I T I I I

sese

in

Me

E)

o

ven

we

LI

JJMAV

em

3HV9HLTV3H

R

H3HSIJ

ET

a

"NGIuJ30

»

OBRAS

E

1

z

133HS

11

NOISIAIG

SaINOSI9313

uva

33HS

は

ua

com

ино

=

피

“nt

обо

и

e

и

smuo

бло

«а

al

300 100

soul

ЗИ

Mo

oo

=

no;

da

40

238NON

616

040

9NMKYSG

5y0

saves

costa

VETO

ue

emas,

va

a

ae

배게:

©

Y

mare

E

=

σα

TOULNOI

I

H

NOISIAZY

=

-

SNYSDVIC

I

LINOUID

219

wi

EHS

Tt

OL

EN

om

Drea

Cain

aon

ми

235),

arme

OO

CENTER)

SRI

E

AB»

üne

vas

sean

sa

terem

am

Jo

waoe

reni

vedono

sens

で

LZE

NO

O3NWLNOD

—

404

TOBINDO

e

CUTE

TA

TENENTE

E

E

0

FT

==

=

5

a

OU

WERE

门

s

Β

e

-

e

57

to

su

CIRCUIT

DIAGRAMS

-

REVISION

H

POWER

PCB

CE

TONA

A

ENİ

ANA

SUS

FISHER

HEALTHCARE

&

PAYKEL

DIVISION

f=

z

b

mue

em,

[ec]

RA

POWER

P.C.B.

sage

Dia

vicia

πιο

|

ou:

te

em

VET

E

mom

Ys

se

AME

be

qo

mu

ef

|

a

em

ea

ΕΞ]

aroma

seres

3

LT

At

ο

зу

па

№

Steaua

E

serou

pra

j

=

“as

tono

xa

tr

2

A

İron

parer

dia,

>

‘боты

De]

CE

©

———O

шт

=

AL

pm

ovino

suoi

o

=>

ama

—

b

5

A

Yar

D

qe

re)

ima

i

se

3-1

ен

vam

・

ve

LE

rt

matt

str

fe

>

van

ones

MAYA

erin

a

©

en.

τσ

δν

%

YIHSIJ

017

NOISIAIO

9040810373

=

“reto

3UVOHLIVIH

73440

“o

Datura

03454

sE

Sa

FE

|

aus

[in

=

es

Fano

D/K

S

VY

IT

Soa

TE

E

yere

‘oe

“SHOES

DESİ

mame

E

Od

TOXLNOD

f

NOISIASY

-

SIAVHDVIO

LINIUIO

gs

©

1938

1

Ur

oL

sm

9

anziana

m

mo

1009

asa

애

no

sho

une

"Z

133HS

NO

dANNILNOO

=

694

TOVINOO

51013309

E

E

Н

EE

a

EE

Е

ES

de

pl

NA

EREC

ETO

AO

OV

IE

RER

E

το

42

SHEET

1

H

5.8

ro su

CIRCUIT

DIAGRAMS

-

REVISION

J

POWER

PCB

A

ER

τς

TEE

AR

PE

ri

MM

sou

043

040

319

SHEET

ος

SER

2

2

dE

aos

POWER

PCB,

προς

Çam

ESER

(HEALTHCARE

&

PAYKEL

DIVISION

dro

"7

or

ка

зат

а

a

|

Pa

2990

ELL

rom

mur

—]

i

4

233

μη

o

mm

i

||

:

veal)

si

sare

oca

ay

5

m

ο

mem

orna

sea

О

ο

(

‘LT

Άνω

위시

5011

0

i

i

i

ae

Tusa

deb

we

-o

b

nos

or

mì

>

:

i

se

#5

a

gi

ane

tos

>

STAR

sa

ni

PORT

ον

μα

i

pom

i

i

e

EE)

18.

Aero

25-2

y

pa

seen

re

soa

;

:

.

5.9

ELECTRICAL

The

electrical

diagrams

Note:

The

.

Control

PARTS

LIST

components

and

Power

listed

below

PCB

are

referenced

Assemblies

listed

below

in

accordance

are

with

parts

for

the

component

layout

revision H and J PCBs.

and

the

circuit

5.9.1

CONTROL

C1,

C3,

D1,

D2, D3, D4,

D6,

BOARD

COMPONENTS

Reference

C4, C5,

cio,

C9,

ci

C2

C12,C13

C14,

C15,

C16

C17

C18,C19,C20

C22,C23

C21,

C24

D5,

D7, D8,

D0,

D11,

D9,

D12

Description

PCB

Upgrade

operating

PCB

Eprom

Cap.

Cap.Mylar

Cap.

Cap.

Cap.

Cap.

Cap.

Cap.

Diode

manual

Assembly

Programmed

Ceramic

100nmF

Ceramic

Elec.

10

Ceramic 1 nF

Ceramic

Mylar

10

Ceramic

1N4l48

kit-Control

and

HC500

100

nF

22

pF

pF

25

22

nF

nF

50

470

pF

..ononocconnnoranionsonnecnernrncs

swing

Control

HC500

50

50

Ve

50

V...

V.

50

V

50

V..

50

(Contains

tag)

Version

V.

V.

V.....

PCB,

1.0..

front

merce

fascia,

Part

Number

043040919

043041056

362040084

312040153

316040085

..

312040130

..

311040663

«

312040107

..

312040116

316040084

..

312040118

361040155

DSPI,

DSP2,

NA,

LED1,LED2

LED6, LED8,

QE,

Q2,

Q3,

R1,

R2,

R3,

R14,

R26,

R28,

R36,

R39, R41,

R10, R33,

R19,

DSP3

RA

LED10

Q4,

Q13

RS,

R6,

R31,

R43

R4 Resistor

R7,R13

R8_

R65,R70

RII

RI2

815

R16

R17

及

18

R24,R69

R20

Display

14

LED

LED

Transistor

Resistor

pin

ribbon

green

red...

LED

current

inner

BC547B

10k

DIL

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

4k7

27k

22k

180R

6k8

9k09

560R

1k5

4k7

2k2

412R

(HDSP5301

connector

orLLA6760).............

socket...

rein

0.25 W 3%.

Resistor

einen

pack

0.25 W 5%...

0.25 W 5%...

0.25 W 5%...

0.25 W 5%.

0.25 W 5%

0.25 W 1%

0.25 W 0.5%

0.25 W 0.5%

0.25 W 0.5%

0.25 W 5%

0.25 W 0.5%

7/27k

Metal

Metal

Metal

Metal

Metal

een

ns

999860001

341040357

361040329

neon

onen

onen

361040327

vonné

361040159

325040284

3W...occocionameseonssicmenes

8

Film.

Film.

Film....

Film.

Film...

seerne

325046010

...

325040287

…

325040319

…

325040318

...

325040309

....

325040335

....

325040145

«

325040135

es

....

325040137

....

325040138

....

325040282

325040152

R21,

R22,

R25,

R23,

R35,

R32,

R37,

SW3,

R27,

R29

R40

R30

R63

R34

R38

R42

SW4

SWS

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Push

Heater

820R

220k

22R

2k7

switch...

Wire

0.25 W 0.5%

100k

0.25 W 1%

0.25 W 1%

15k

0.25 W 5%

180k

0.25 W 1%

0.25 W 1%

0.25 W 5%

switch...

Metal

Metal

Metal

Metal

Metal

Film...

Film

.... ....

Film

.....

Film

Film...

325040136

325040139

ve.

325040134

....

325040317

...

325040125

..

325040133

999012720

349040094

…

349040099

SPKI

uz

U3

U4

US

U6,

US

U7

U9

U10

Audio

Transducer

IC

Octal

Latch

IC

Micro-Processor

IC

Ram

VO

IC

Hex

inverter

IC 8 Channel

IC

Display

IC

3x2

Channel

IC

Quad

Operation

10kPreset

5kPotentiometer...........

10k

Preset

Multiturn......

50k

Preset

rennes

Crystal644

Spacer

Service

Spacer,

Heater

CB-12KP........................

74LS373

8085

A-Z.

Timer

81C55

74HC14

Mux.

Driver

Mux.

MHZ

Button

Wire

CD4051B.

MM5451N

CD4053B....

Amplifier

PCB

Switch

TL074.

....

....

ue

oeeoeeaeoesen

ne

426040015

once

999610004

ve

999630012

...

363040415

.…

363040232

…

363040125

....

363040126

.

999610003

…

363040124

327041561

„

327041562

327041565

327041563

ner

999820001

693040701

693040522

5.9.2

POWER

BOARD

COMPONENTS

D13,

C6,

D14,

019,

06,

Reference

C8,

C32

C7,

C33

C25,

C27

C26

C28,

C29

030,

031

D15,D16,

217,

018

020,

D21

Fi

F2

F3,

F4

F3,

F4

Q10,

Q12

Q5

Q7

Q8

09,011

Description

PCB

Assembly

Cap.

MKT.

Cap.

Poly

Cap.

Elec.

Cap.

Elec.

Cap.

Elec.

Cap.

Ceramic

Diode

IN4002................riirrirnne

Diode

1N4148...,...sssesssssssnesssesssesessnesscnesnsssesenreneesesstsnsesenenanene

Fuse

fast

acting 1 Amp

Fuse

fast

acting 4 Amp

Fuse

fast

acting

Fuse

fast

acting 2 Amp

Transistor

Transistor

IC 5 Volt

IC 5 Volt

Triac

Q4004L3

Power.

100

nF

100

nF

250

470

pF

25

1000

uF

10

pF

25

22

nF

1.5

BC547B

BC557B

Positive

Negative

Regulator

or

BTA

100

V...

V...

V..

25

V.....

V

50

Vi...

(20 * 5

(20

x 5

Amp

(20

(20

x 5

..

..

7805.

Regulator

08-600

mm)...

mm)

x 5

mm)

mm)

79105.

cirie ieri

rss

for

230

for

115

Part

Number

.

043040637

..

311040028

…

316040073

....

999234710

…

999231020

...

311040663

.

312040116

nienecreecenreneecszeceniene

V.

V......................

361040163

361040155

999830001

...

999830017

…

999830008

999830009

...

361040159

.

361040156

.

999600003

.

363040146

.

999550011

911,

R44, R46,

R54,

R48,

R58,

R60,

R45,

R55,

912

013

R50,

R64,

R66

R61

R47

R49

R53,

R59

R56

R57

R51,

R52

R64

R67

R68

R9

IC

Optocoupler

IC

Optocoupler

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Fuse

18R

10k

2k7

22k

120R

270R

12k

180R

3k3

220R

1M

100K

clips.........

MOC3022

CNY

0.25 W 5%...

0.25 W 5%

0.25 W 5%...

0.25 W 3%...

0.25 W 5%..

0.25 W 5%..

0.25 W 5%

0.25 W 5%..

0.25

W5%

0.25 W 5%..

0.25 W 5%

0.25 W 5%.....................

a.e

MOC30230r

I7-Bonococinnanacnonoroconeorenencinocarnonoonconiearicisacos

nn

итнизивьитьииоливиинивотунивошонипопивонолиия

K3022PG

ner

rm

...................

kasser

errar

367060001

363040045

325040366

325040284

999012720

νκτοωνε

325040318

..

325046034

..

325040294

・

325040289

.

325040309

…

325040303

..

325040296

.

325052305

325040139

999840001

5.10

MECHANICAL

Refer

to

the

PARTS

exploded

LIST

diagram ( $5.10.1).

Reference

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

Description

1

Heaterplate

Heaterplate

Heaterplate

Chamber

Chamber

Chamber

Chamber

Spring

Guard

BW

Gasket

La

PCB

Où

O

3

00

Assembly

PCB

Assembly

Case

Front

Probe

Case

Door

Switch

PCB

Assembly

Case

Foot..........

Case

Door

Mains

Mains

Mains

Mains

Mains

Mains

Mains

Mains

Screw

Case

Воду

Washer

Nut

M6

Bracket

Screw

Screw

Nut

M4

Bracket

Screw

Transformer

Transformer

Transformer

Tape

28

Screw

29

Clamp

30

Clamp

Insulator

31

Washer

32

Screw

33

Lug

Earth.....

Screw

34

Washer

35

Harness

36

Socket

37

Probe

38

Assembly

Assembly

Assembly

Clamp

Clamp

Clamp

Clamp

Mounting

Chamber

85 W 100

85 W 115

85 W 230

Kit

Blank ( includes

Kit

French

Kit

German

Kit

English

Kit..

Clamp...........

Kit

Socket

HC500

HC500

Specify:

Cap.

Control..

Control

‘Case