Page 1

Instruction Manual

D101453X012

HIGH-SEAL Live-Loaded Packing

HIGH‐SEAL ULF Live‐Loaded Packing System

July 2017

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 2.................................

Spring Selection 3.............................

Installation 3..................................

Parts Ordering 6................................

Retrofit Parts 7.................................

Parts List 8....................................

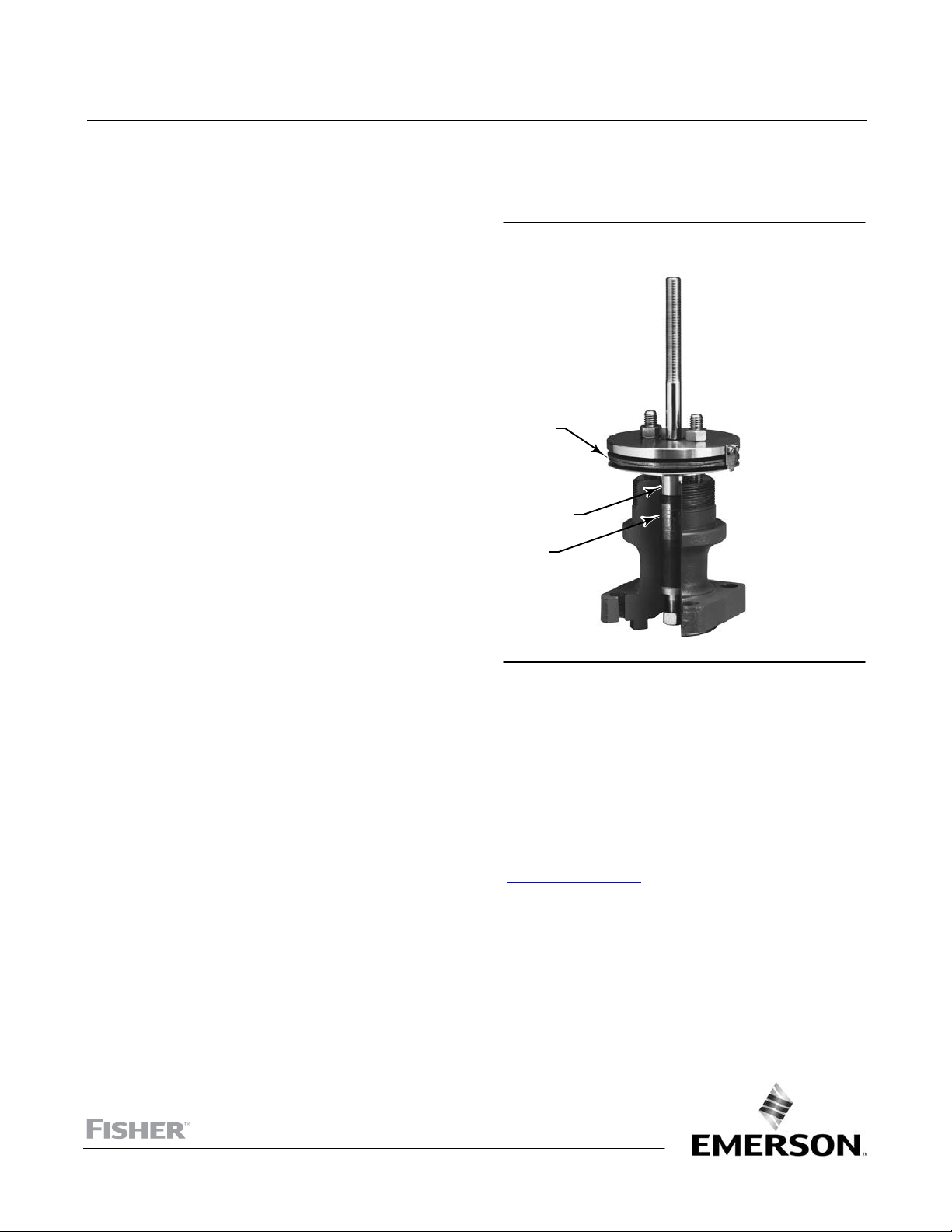

Figure 1. HIGH‐SEAL ULF Live‐Loaded Packing

System

SPRING

PACKING

FOLLOWER

PACKING

RINGS

W5784

Introduction

Scope of Manual

This instruction manual includes installation, maintenance, and parts information for HIGH‐SEAL ULF live‐loaded

packing systems (see figure 1). These systems are available for sliding‐stem valves with 9.5, 12.7, 19.1, 25.4, 31.8 and

50.8 mm (3/8, 1/2, 3/4, 1, 1‐1/4, and 2‐inch) stem diameters. Refer to separate manuals for instructions covering

valves and actuators. For rotary valve applications, contact your Emerson sales office

to your rotary valve instruction manual.

Do not install, operate, or maintain HIGH‐SEAL ULF live‐loaded packing systems without being fully trained and

qualified in valve, actuator, and accessory installation, operation, and maintenance. To avoid personal injury or

property damage, it is important to carefully read, understand, and follow all the contents of this manual, including all

www.Fisher.com

or Local Business Partner or refer

Page 2

HIGH-SEAL Live-Loaded Packing

July 2017

Instruction Manual

D101453X012

safety cautions and warnings. If you have any questions about these instructions, contact your Emerson sales office or

Local Business Partner before proceeding.

Description

HIGH‐SEAL ULF live‐loaded packing systems combine the excellent sealing performance of the ENVIRO‐SEAL Graphite

ULF packing set with the high‐performance of the HIGH‐SEAL spring pack. The long‐travel HIGH‐SEAL Belleville springs

accurately compensate for any packing consolidation or wear, keeping the packing stress nearly constant over the life

of the packing set.

The HIGH‐SEAL load scales ensure accurate initial packing adjustment and provide positive visual indication of the

packing stress at any time. It is recommended that new packing sets be adjusted to the MAX level.

HIGH‐SEAL ULF packing systems are intended for more‐severe applications with pressure limits up to 290 bar (4200

psig), except for 9.5 mm (3/8 inch) stem size, which is restricted to 110 bar (1600 psig). If your application exceeds

these limits, consult your Emerson sales office or Local Business Partner. For ratings on packing systems, refer to

59.1:062 Packing Selection Guidelines For Sliding Stem Valves (D101986X012

pressure/temperature limits of the valve. If the piping and valve are insulated, do not allow insulation to extend above

the yoke boss surface, covering the HIGH‐SEAL ULF packing arrangement. Keep the HIGH‐SEAL ULF packing

arrangement exposed to ambient air conditions.

). However, do not exceed the

Table 1. Packing Friction with HIGH‐SEAL Graphite ULF Packing

VALVE STEM DIAMETER

mm Inches

Newtons

9.5

12.7

15.9

19.1

25.4

31.8

50.8

9.5

12.7

15.9

19.1

25.4

31.8

50.8

3/8

1/2

5/8

3/4

1

1‐1/4

2

Pounds (Force)

3/8

1/2

5/8

3/4

1

1‐1/4

2

HIGH‐SEAL GRAPHITE ULF PACKING

935

1250

1680

2350

3740

4800

6000

210

230

380

530

840

1100

1350

The flange, Belleville springs, stud bolts and nuts, packing follower, and packing arrangement are an integral part of

the HIGH‐SEAL ULF system (see figure 6). For maximum packing life and to operate within the friction specified in table

1, do not interchange any other packing parts with the parts in the HIGH‐SEAL ULF system.

WARNING

HIGH‐SEAL ULF live‐loaded packing systems are intended for a specific range of pressure, temperature and other service

conditions. The valves for which these packing systems are available are also intended for a specific range of pressure,

temperature and other service conditions. Do not expose the packing system or the valve to service conditions or variables

other than those for which the packing system and valve are intended. If you are not sure what these conditions are,

contact your Emerson sales office or Local Business Partner. Provide the product serial number (shown on the nameplate)

and all other pertinent information. Applying different conditions could result in parts damage, malfunction of the valve or

loss of control of the process, and could also result in personal injury or property damage.

2

Page 3

Instruction Manual

D101453X012

HIGH-SEAL Live-Loaded Packing

July 2017

Spring Selection

The Belleville springs for HIGH‐SEAL ULF systems are rated by stem size (see table 1). Available materials for the

Belleville springs are S17700 (17‐7 PH stainless steel) and N07718.

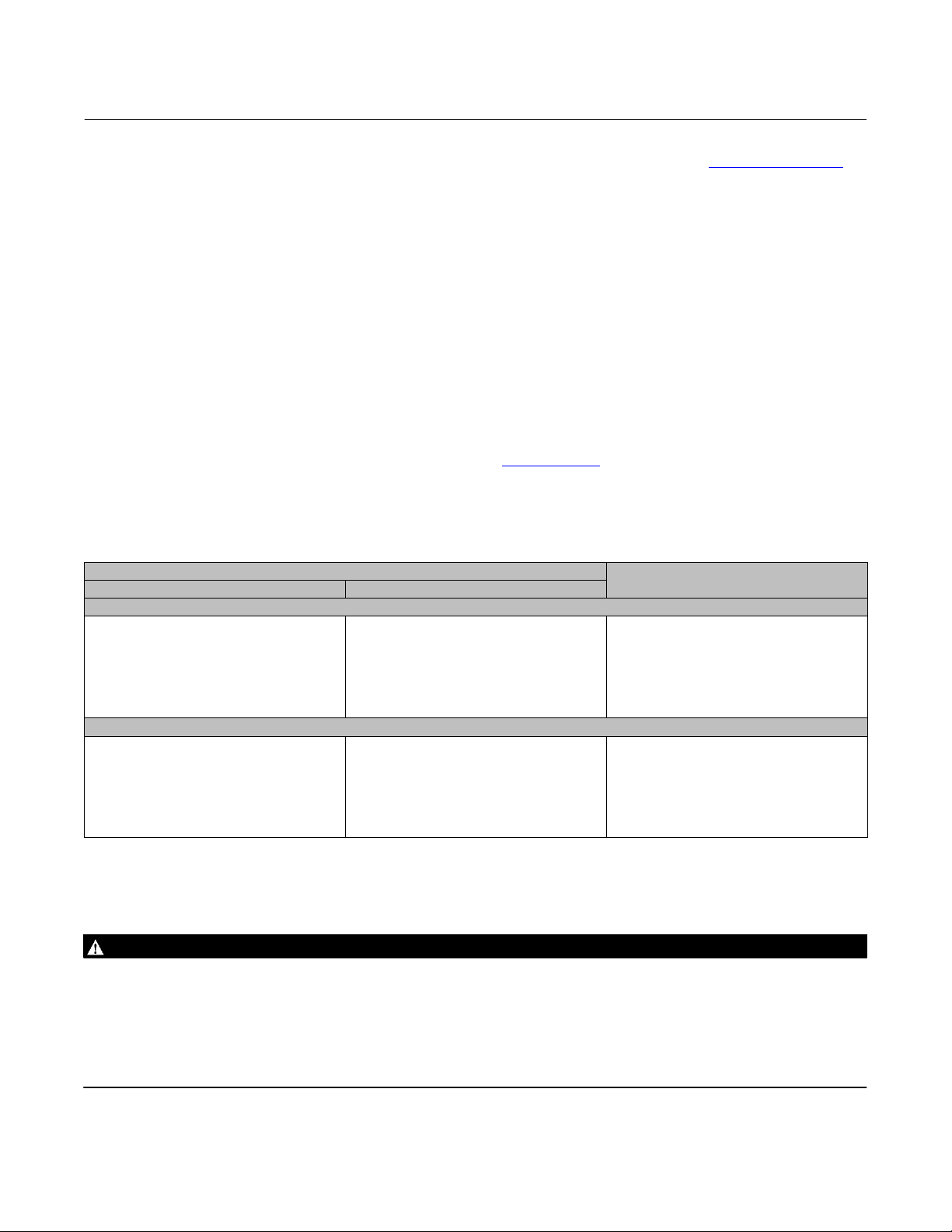

It is important to match the appropriate load scale (see figure 2) to the stem size of the valve. Stem size is stamped on

the load scale.

Figure 2. Typical Load Scale

STEM SIZE

MAXIMUM SPRING LOAD

MINIMUM SPRING LOAD

ZERO SPRING LOAD

(PACKING NUTS FINGER‐TIGHT)

A4990‐2

Installation

HIGH‐SEAL ULF packing systems are designed for quality performance over extended periods. This longevity allows

packing maintenance to be performed as it should be, at regularly scheduled plant outages or turn‐arounds.

WARNING

Avoid personal injury from sudden release of process pressure. Before performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

3

Page 4

HIGH-SEAL Live-Loaded Packing

July 2017

Instruction Manual

D101453X012

If the valve is in service, isolate the control valve from the line pressure, release pressure from both sides of the valve

body, and drain the process media from both sides of the valve. If using a power actuator, also shut off all pressure

lines to the power actuator and release all pressure from the actuator. Use lock‐out procedures to be sure that the

above measures stay in effect while you work on the equipment. Refer to instructions in the appropriate valve and

actuator instruction manuals.

If you are installing the HIGH‐SEAL ULF packing system in a valve that is still connected to an actuator, it will be

necessary to disconnect the valve from the actuator to provide sufficient space to install the packing assembly. Refer

to appropriate valve and actuator instruction manuals. Remove old packing parts from the packing box by using the

valve instruction manual procedures.

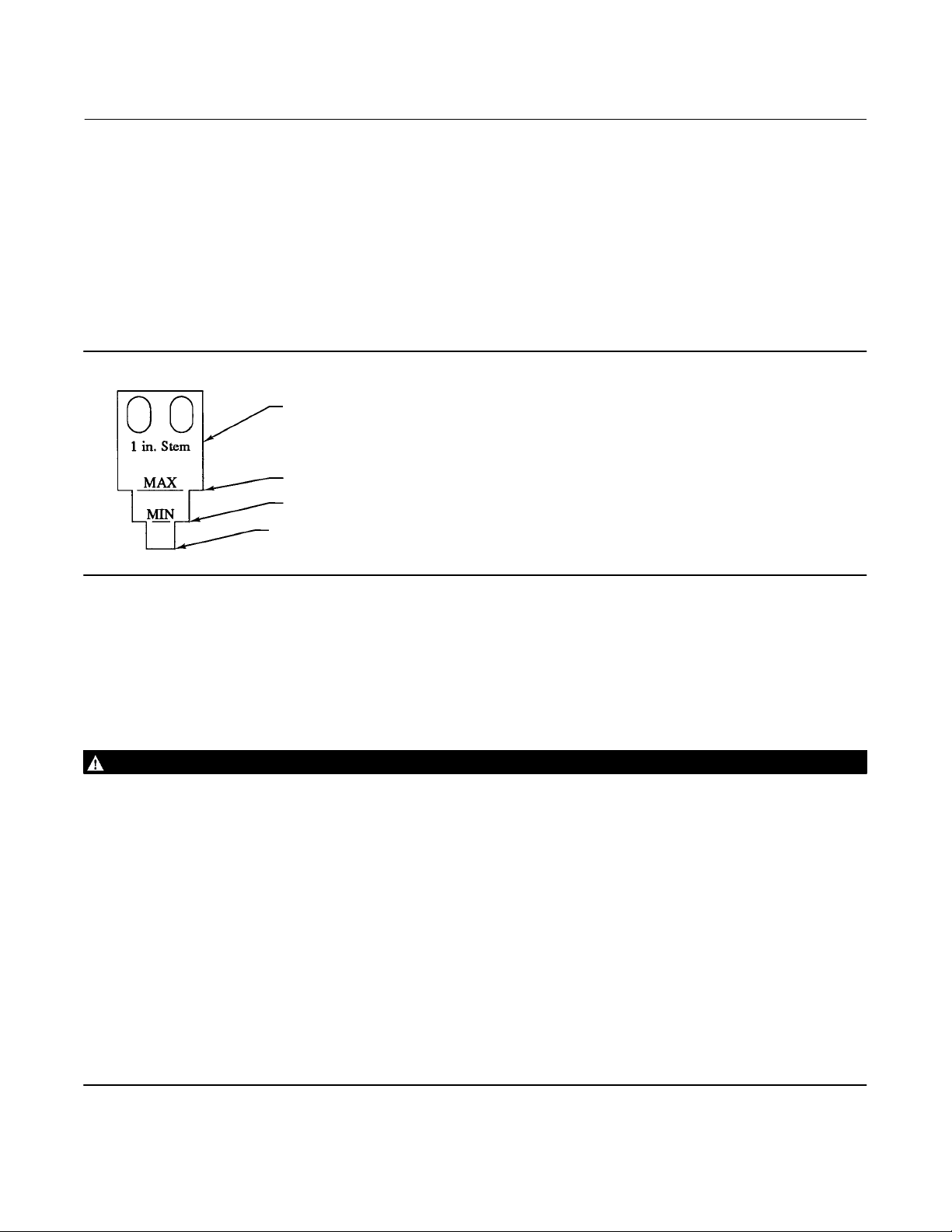

Figure 3. HIGH‐SEAL ULF Packing Assembly Showing the Load Properly Adjusted for Decompressed Springs

FLANGE

BELLEVILLE SPRINGS NOT COMPRESSED

INDICATOR DISK

INDICATOR DISK ALIGNED WITH BOTTOM OF LOAD SCALE

A4991‐2

THESE TWO SURFACES MUST REMAIN PARALLEL AS YOU ALTERNATELY AND EVENLY TIGHTEN THE PACKING NUTS.

The valve stem condition is critical to packing sealing performance and life. As‐new surface finish (0.1 μm [4 μin]R

a

max) is recommended for best performance. Refer to the appropriate valve instruction manual for instructions on

replacing the valve stem.

Check the condition of the packing bore after you have removed the packing. An easy method for cleaning debris and

minor imperfections from the bore is to use a brake cylinder hone attached to an electric drill. This method will do a

good job of cleaning the packing bore without changing the dimension of the bore.

Inspect the packing bore size and surface finish. If the packing bore is worn, pitted, damaged, or oversized more than

0.010 inch, replace the valve bonnet or have your Emerson Automation Solutions Service Center repair it.

Key number locations are shown in figure 6.

1. If a retrofit kit is being installed in place of the original packing, remove existing packing studs from the valve, and

replace them with the longer studs (key 200).

2. Install the packing arrangement into the valve packing box.

Note

Be sure to install the packing rings in the sequence shown in figure 6. Identify parts by color or by the number stamped on the part.

4

Page 5

Instruction Manual

D101453X012

HIGH-SEAL Live-Loaded Packing

July 2017

D For valves with 9.5 mm (3/8 inch) valve stems, do not install the packing follower (key 203) at this time. (Note: the

yoke boss will not slide over the packing follower. The packing follower must be installed while lowering the

actuator yoke onto the valve.)

D For valves with 12.5 mm (1/2 inch) or larger stem diameters, install the packing follower (key 203).

3. Refer to the appropriate valve and actuator instruction manuals when connecting the valve to the actuator. While

lowering the actuator yoke onto the valve, install the packing follower [for a 9.5 mm (3/8 inch) valve stem size],

indicator disk, springs, and flange (keys 203, 206, 202, and 201).

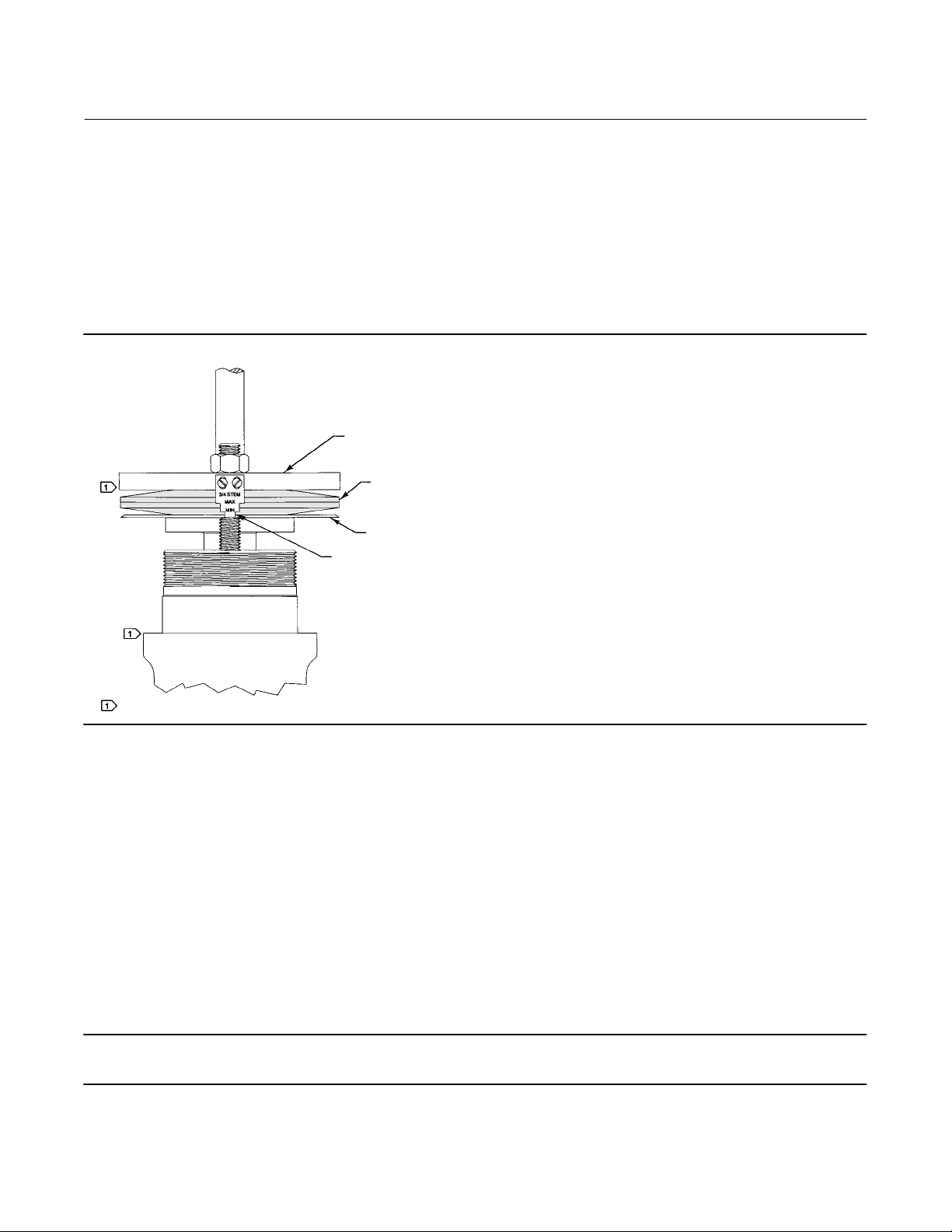

Figure 4. Load Scale Indicating Minimum Spring Compression

BELLEVILLE SPRINGS WITH MINIMUM COMPRESSION

INDICATOR DISK

INDICATOR DISK ALIGNED WITH MINIMUM COMPRESSION LINE ON LOAD SCALE

A4992‐2

THESE TWO SURFACES MUST REMAIN PARALLEL AS YOU ALTERNATELY AND EVENLY TIGHTEN THE PACKING NUTS.

Figure 5. Load Scale Indicating Maximum Spring Compression

BELLEVILLE SPRINGS WITH MAXIMUM COMPRESSION

INDICATOR DISK

INDICATOR DISK ALIGNED WITH MAXIMUM COMPRESSION LINE ON LOAD SCALE

A4993‐3

THESE TWO SURFACES MUST REMAIN PARALLEL AS YOU ALTERNATELY AND EVENLY TIGHTEN THE PACKING NUTS.

5

Page 6

HIGH-SEAL Live-Loaded Packing

July 2017

4. Place the packing follower against the packing as shown in figure 6.

5. Place the indicator disk (key 206) and the first Belleville spring (key 202) while guiding them onto the packing

follower (key 203). Make certain the cone‐shaped side of the Belleville spring is towards the indicator disk as shown

in figure 3.

6. Place the second Belleville spring (key 202) with the coned‐shaped side toward the flange (key 201); see figure 3.

Position the flange on top of the spring, making sure the second spring fits into its guide in the flange.

Instruction Manual

D101453X012

CAUTION

Keep the packing follower and flange centered on the valve stem. If any metal part makes contact with the stem, it can

cause damage to the stem surface. Vertical scratches or nicks on the stem surface can cause excessive leakage from the

packing.

7. Lubricate the packing nuts with anti‐seize lubricant and tighten them hand‐tight.

8. The load scale (figure 2) is used to indicate compression on the Belleville springs. Position the load scale (key 205)

by slightly loosening the mounting screws (key 204). Align the bottom edge of the load scale with the indicator disk

and retighten the screws. Figure 3 illustrates the load scale properly adjusted before the nuts have been tightened

and with the Belleville springs not compressed.

9. Tighten the packing nuts while observing the two load scales (key 205) to make sure the flange (key 201) is

tightened evenly. Figure 4 indicates minimum spring compression with the indicator disk aligned with the

minimum compression line on the load scale. Be sure to keep the follower centered on the stem while tightening

the nuts. Tighten the nuts alternately and evenly, keeping the flange parallel with the valve (see figures 4 and 5),

until the indicator disk aligns with the maximum compression line on the load scales, as shown in figure 5.

10. The packing is now properly loaded and the packing nuts do not need to be retightened unless the indicator

begins to approach the minimum compression line (see figure 4). After the valve has been in service for awhile,

visually check the load scale to determine loading. Under normal conditions, the packing nuts should not require

retightening for the life of the packing.

Parts Ordering

Each valve assembly is assigned a serial number that can be found on the valve. This same number also appears on the

actuator nameplate when the valve is shipped from the factory as part of a control valve assembly. Refer to the serial

number when contacting your Emerson sales office

replacement parts, refer to the serial number and to the 11‐character part number for each part required from the

following parts list.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Automation Solutions should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

6

or Local Business Partner for technical assistance. When ordering

Page 7

Instruction Manual

D101453X012

HIGH-SEAL Live-Loaded Packing

July 2017

Retrofit Parts

Retrofit parts meet requirements to convert existing Fisher A, CAV4, E, EH, HP, YD, and YS valves to the HIGH‐SEAL ULF

packing box construction.

WARNING

Stems and packing box constructions that do not meet Emerson Automation Solutions stem finish specifications,

dimensional tolerances, and design specifications may adversely alter the performance of this packing retrofit, resulting in

personal injury or property damage.

HIGH‐SEAL Retrofit Kits

STEM SIZE DIAMETER,

mm (Inch)

9.5 (3/8) 54 (2‐1/8) RPACKXRT312 RPACKXRT322

12.7 (1/2) 71 (2‐13/16) RPACKXRT332 RPACKXRT342

19.1 (3/4) 90 (3‐9/16) RPACKXRT352 RPACKXRT362

25.4 (1) 127 (5) RPACKXRT372 RPACKXRT382

31.8 (1‐1/4) 127 (5, 5H) RPACKXRT392 RPACKXRT402

50.8 (2) 177.8 (7) Consult your Emerson sales office or Local Business Partner

1. The 50.8 mm (2‐inch) stem will typically require a longer actuator yoke to clear the HIGH‐SEAL packing studs (key 200).

YOKE BOSS DIAMETER,

mm (Inch)

S17700 Springs N07718 Springs

RETROFIT KITS

(1)

Parts Included in Retrofit Kits

KEY NUMBER DESCRIPTION

200 Packing Stud 2 3

201 Packing Flange 1 1

202 Belleville Spring 2 2

203 Packing Follower 1 1

204 Screw 4 6

205 Load Scale 2 3

206 Indicator Disk 1 1

207 Bushing 1 1

208 Bushing 1 1

209 Packing Ring 2 2

210 Packing Ring 2 2

211 Packing Box Ring 1 1

212 Packing Nut 2 3

214 Packing Washer 3 3

219 Washer (not required on 9.5 mm [3/8 inch] stem) 2 3

QUANTITY

For 9.5, 12.7, 19.2, 25.4, &

31.8 mm Stems

(3/8, 1/2, 3/4, 1, & 1‐1/4 Inch

Stems)

For 50.8 mm Stems

(2‐Inch Stems)

ULF

7

Page 8

HIGH-SEAL Live-Loaded Packing

July 2017

Parts List

Instruction Manual

D101453X012

Key Description Part Number

Note

Part numbers are shown for recommended spares only. For part

numbers not shown, contact your Emerson sales office

Partner.

Key Description Part Number

200 Stud

201 Flange

202 Spring See Spring Identification and Dimensions table

203 Packing Follower

or Local Business

204 Screw

205 Load Scale

206 Indicator Disk

207* Bushing See following table

208* Bushing See following table

209* Packing Ring See following table

210* Packing Ring See following table

211* Packing Box Ring See following table

212 Nut

213 Anti‐seize lubricant

(not furnished with unit) (not shown)

214* Packing Washer See following table

219 Washer

8

Page 9

Instruction Manual

D101453X012

Figure 6. HIGH‐SEAL Graphite ULF Packing Assembly

HIGH-SEAL Live-Loaded Packing

July 2017

39B4153‐A

1. FIND NUMBER 219 NOT REQUIRED WITH 3/8 INCH STEM

9

Page 10

HIGH-SEAL Live-Loaded Packing

July 2017

Instruction Manual

D101453X012

For 9.5, 12.7 and 19.1 mm (3/8, 1/2 and 3/4 Inch) Stems with ULF Packing

PART NUMBER

9.5 mm

KEY

QTY DESCRIPTION MATERIAL

NO.

207* 1 Bushing Carbon 12B5780X012 12B5782X012 12B5784X012

208* 1 Bushing Carbon 19B2882X012 19B2883X012 19B2889X012

209* 2 Packing ring Carbon/graphite composite 12B5798X012 12B5799X012 12B5800X012

210* 2 Packing ring (packing ribbon) Graphite/zinc 14B7519X012 14B7498X012 14B7520X012

211* 1 Packing box ring S31600 12B5774X012 12B5775X012 12B5776X012

214* 3 Packing washer PTFE 12B6936X012 12B6937X012 12B6938X012

*Recommended spare part.

(3/8 inch)

Stem,

54 mm

(2‐1/8 inch)

Yoke Boss

12.7 mm

(1/2 inch)

Stem,

71 mm

(2‐13/16 Inch)

Yoke Boss

19.1 mm

(3/4 Inch)

Stem,

90 mm

(3‐9/16 Inch)

Yoke Boss

Spring Identification and Dimensions

SPRING DIMENSIONS

Valve Stem

SPRING

Inside Dia 47.6 1.875 60.3 2.375 74.6 2.938 96.8 3.813 103.2 4.063 138 5.438

Outside Dia 98.4 3.875 111.1 4.375 146.1 5.75 206.4 8.125 206.4 8.125 225 8.875

Thickness 2.4 0.094 4.0 0.156 5.2 0.203 6.7 0.266 7.1 0.281 8.3 0.328

Diameter

mm Inches mm Inches mm Inches mm Inches mm Inches mm Inches

9.5 3/8 12.7 1/2 19.1 3/4 25.4 1 31.8 1‐1/4 50.8 2

Valve Stem

Diameter

Valve Stem

Diameter

Valve Stem

Diameter

Valve Stem

Diameter

Valve Stem

Diameter

For 25.4, 38.1, and 50.8 mm (1, 1‐1/4 and 2‐inch) Stems with ULF Packing

QTY

For 25.4 &

KEY

38.1 mm

NO.

(1 & 1‐1/4

Inch)

Stems

207* 1 1 Bushing (black w/white color code) Carbon 12B5786X012 12B5788X012 12B5790X012

208* 1 1 Bushing (black) Carbon 19B2891X012 19B4141X012 19B4143X012

209* 2 2 Packing ring

210* 2 2 Packing ring (packing ribbon) Graphite/zinc 14B7521X012 14B7522X012 17B3077X012

211* 1 1 Packing box ring S31600 12B5777X012 12B5778X012 12B5779X012

214* 3 3 Packing washer PTFE 12B6939X012 12B6940X012 19B4144X012

*Recommended spare part.

For 50.8

mm

(2 Inch)

Stems

DESCRIPTION MATERIAL

Carbon/graphite

composite

25.4 mm

(1‐inch)

Stem,

127 mm

(5‐Inch)

Yoke Boss

12B5801X012 12B5802X012 12B5803X012

PART NUMBER

31.8 mm

(1‐1/4 Inch)

Stem,

127 mm

(5‐Inch)

Yoke Boss

50.8 mm

(2‐Inch)

Stem,

178 mm

(7‐Inch)

Yoke Boss

10

Page 11

Instruction Manual

D101453X012

HIGH-SEAL Live-Loaded Packing

July 2017

11

Page 12

HIGH-SEAL Live-Loaded Packing

July 2017

Instruction Manual

D101453X012

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

12

E 1989, 2017 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...