Page 1

sto

abcock

ControlWave

Redundancy

Setup Guide

Bri

D5123 – December, 2005

l B

Page 2

The information in this document is subject to change without notice. Every effort has been

made to supply complete and accurate information. However, Bristol Babcock assumes no

responsibility for any errors that may appear in this document.

Bristol Babcock does not guarantee the accuracy, sufficiency or suitability of the software

delivered herewith. The Customer shall inspect and test such software and other materials to

his/her satisfaction before using them with important data.

There are no warranties, expressed or implied, including those of merchantability and fitness for

a particular purpose, concerning the software and other materials delivered herewith.

Bristol is a registered trademark of Bristol Babcock. Other trademarks or copyrighted products

mentioned in this document are for information only, and belong to their respective companies,

or trademark holders.

Copyright (c) 2005, Bristol Babcock, 1100 Buckingham St., Watertown, CT 06795. No part of

this manual may be reproduced in any form without the express written permission of Bristol

Babcock.

Page 3

IMPORTANT! READ INSTRUCTIONS BEFORE STARTING!

Be sure that these instructions are carefully read and understood before any

operation is attempted. Improper use of this device in some applications may result

in damage or injury. The user is urged to keep this book filed in a convenient

location for future reference.

These instructions may not cover all details or variations in equipment or cover

every possible situation to be met in connection with installation, operation or

maintenance. Should problems arise that are not covered sufficiently in the text, the

purchaser is advised to contact Bristol Babcock for further information.

EQUIPMENT APPLICATION WARNING

The customer should note that a failure of this instrument or system, for

whatever reason, may leave an operating process without protection. Depending

upon the application, this could result in possible damage to property or injury to

persons. It is suggested that the purchaser review the need for additional backup

equipment or provide alternate means of protection such as alarm devices, output

limiting, fail-safe valves, relief valves, emergency shutoffs, emergency switches, etc.

If additional information is required, the purchaser is advised to contact Bristol Babcock.

RETURNED EQUIPMENT WARNING

When returning any equipment to Bristol Babcock for repairs or evaluation,

please note the following: The party sending such materials is responsible to ensure

that the materials returned to Bristol Babcock are clean to safe levels, as such levels

are defined and/or determined by applicable federal, state and/or local law

regulations or codes. Such party agrees to indemnify Bristol Babcock and save

Bristol Babcock harmless from any liability or damage which Bristol Babcock may

incur or suffer due to such party's failure to so act.

ELECTRICAL GROUNDING

Metal enclosures and exposed metal parts of electrical instruments must be

grounded in accordance with OSHA rules and regulations pertaining to "Design

Safety Standards for Electrical Systems," 29 CFR, Part 1910, Subpart S, dated: April

16, 1981 (OSHA rulings are in agreement with the National Electrical Code).

The grounding requirement is also applicable to mechanical or pneumatic

instruments that include electrically-operated devices such as lights, switches, relays,

alarms, or chart drives.

Page 4

Thank you for choosing ControlWave!

We hope you will find ControlWave to be the best solution for your process automation needs.

From the start, Bristol Babcock designed this unit to merge the simplicity and modularity of a

programmable logic controller, with the full communication and programming capabilities of a

remote process controller. The result - the ControlWave-series of Process Automation

Controllers, are true PLC/RTU hybrids, incorporating the best features of both types of devices.

ControlWave features a low-power, modular design, which supports all five IEC 61131-3

programming languages: ladder logic (LD), sequential flow chart (SFC), function block diagram

(FBD), structured text (ST), and instruction list (IL). A full suite of PC-based configuration

wizards and programming tools is provided, as well as a rich library of Bristol Babcock function

blocks that may be used for various process control applications.

Before You Begin

This guide is intended to help you get redundancy 'up-and-running' with a minimal amount of

effort. It does NOT, however, tell you everything you need to know about setting up and

configuring ControlWave hardware and software. We have included references throughout this

book to other places in the documentation set, where you can get more details on a particular

subject.

Throughout your configuration activities, please be aware of the following items:

Shock Hazard! Always follow accepted safety guidelines. As with all electronic devices,

improper installation, grounding, or usage can cause an electrical shock. If you have any doubts

about how to install, ground, and use this product safely, please consult a qualified electrician.

Electrostatic Discharge (ESD) - Sensitive electronic devices such as this can be damaged by

electrostatic discharge. Please follow accepted ESD guidelines.

If You Need Help…

If you're having problems setting up and configuring your ControlWave, please call our

ControlWave Application Support team at (860) 945-2394 or (860) 945-2286 for assistance.

Help is available Monday through Friday 8:00 AM to 4:30 PM Eastern Time, excluding

holidays, and scheduled factory shutdowns.

4

Page 5

Table of Contents

The Concept of Redundancy........................................................................................................... 9

Redundancy Options Available ..............................................................................................10

Control Redundancy - CPU and Power Supply.............................................................. 10

Local I/O Redundancy.................................................................................................... 13

I/O Expansion Rack Redundancy................................................................................... 14

Setting up Redundancy Hardware ................................................................................................ 17

Major Types of ControlWave Redundancy Hardware ........................................................... 17

ControlWave Redundant Controller............................................................................... 17

Setting Up the ControlWave Redundant Controller......................................... 19

ControlWave Process Automation Controller................................................................ 24

ControlWave I/O Expansion Rack ................................................................................. 25

ControlWave I/O Switcher............................................................................................. 26

Overview of I/O Switcher Hardware Configuration ........................................ 27

Establishing Communications ...................................................................................................... 29

Establishing Communications Using LocalView .................................................................. 29

Establishing Communications Using NetView (ControlWave Already In a Network)......... 31

Setting Flash Parameters............................................................................................................... 32

Before you Begin ................................................................................................................... 33

Signing on to the ControlWave.............................................................................................. 33

Setting Up an Ethernet Port.................................................................................................... 33

Recommended Ranges for IP Addresses ............................................................................... 35

Setting Application Parameters for Redundancy................................................................... 36

Setting other Flash Parameters............................................................................................... 36

Saving the Flash Parameters to the Unit................................................................................ 37

Activating the newly saved parameters.................................................................................. 38

Saving the same parameters to the other unit:........................................................................ 38

Ethernet Connection Redundancy................................................................................................. 39

Testing the Redundant Setup (CPU and Power Supply) .............................................................. 40

Before Testing Redundancy................................................................................................... 40

Using the Sample Redundant Project or Creating Your Own Redundant Project................. 40

Testing the Redundant Setup.................................................................................................. 41

Notes on Redundant Operation..................................................................................................... 46

How do I force a fail-over to the Standby unit via program control?.................................... 46

Forcing I/O Expansion Rack Fail-over via Program Control ................................................ 49

How do I manually force a fail-over to the Standby unit?..................................................... 52

Manually failing over from "A" to "B".................................................................................. 52

Manually failing over from "B" to "A".................................................................................. 52

Return the A/B Enable Key Switch to Automatic Mode....................................................... 53

Specifying a New Primary Unit.............................................................................................. 53

Page 6

Codes Which Appear on the Standby Unit Display................................................................ 53

Redundancy Status Variables ....................................................................................................... 54

Troubleshooting Redundancy Problems....................................................................................... 59

6

Page 7

IMPORTANT:

This document is intended to describe the main steps necessary to configuring

ControlWave redundancy. It does NOT include everything you need to know about

configuring a ControlWave controller.

The following is assumed:

• The OpenBSI Network Edition and ControlWave Designer software kits have been

installed on your PC. If this is not the case, please see Chapter 2 of the Open BSI

Utilities Manual (document# D5081) for details on the installation procedure.

• Some familiarity with ControlWave software configuration.

7

Page 8

8

Page 9

The Concept of Redundancy

The Concept of Redundancy

Redundancy is a mechanism employed to prevent the loss of control over a process, and to

minimize the loss of data, which can occur, if any single part of a control system should fail.

Redundancy is recommended for plants or processes where a loss of control could result in

damage or injury.

All methods of ControlWave redundancy involve having a duplicate standby unit that is able to

take over in the event there is a failure in the primary unit. The process of transferring control

from the primary to the backup is referred to as fail-over. A fail-over condition typically falls

into one of two categories:

Hardware failures - These could occur from a variety of causes:

• loose cable

• improper configuration, e.g. board not seated properly

• power supply failure (no power for CPU)

• individual board or component breakdown

Software failures - Possible causes include:

• application program running in the CPU 'crashes', as indicated by an 'FF' code on the display

• all tasks are suspended for more than a user-configurable number of milliseconds

• a task watchdog occurs (this option can be user enabled/disabled)

• user-created logic for detection of a particular failure (e.g. local I/O) is activated, triggering a

switchover via a REDUN_SWITCH function block.

• user-created logic for detection of a particular failure in an I/O Expansion Rack, triggering a

switchover via the ERSTAT_x_FAILOVER_O system variable.

When redundancy is used, these sorts of failures trigger a watchdog relay, and cause a fail-over

from the on-line unit that failed to a standby backup unit. The standby unit has been configured

to be an exact duplicate of the on-line unit (except for the A/B switch setting and IP addresses)

so it can now assume full control over the process previously controlled by the failed unit, and

becomes the new on-line unit.

The redundant units that make up the primary and standby pair are referred to as the “A” unit,

and the “B” unit.

ControlWave redundancy only handles a single point of failure i.e. either the “A” set of

CPU/power supply/ or I/O can have a failure, or the “B” set of CPU / power supply or I/O can

have a failure. A failure of the “A” CPU, and the “B” power supply, however, would disable the

entire control system.

9

Page 10

The Concept of Redundancy

Redundancy Options Available

IMPORTANT

Throughout this manual, we will refer to the redundant units that make up the primary and

standby pair as the “A” unit, and the “B” unit. This term is used whether the units in

question refer to the “A” and “B” units in a ControlWave Redundant Controller, the “A”

and “B” ControlWave Process Automation Controllers, or “A” and “B” ControlWave I/O

Expansion Racks.

The ControlWave family of products offers three distinct types of redundancy. The choice of

which type(s) of redundancy you need is dictated by the needs of your particular application.

Your system may even include a mixture of the different types of redundancy.

Control Redundancy - CPU and Power Supply

Control Redundancy provides protection in the event a single failure occurs in either the

Central Processing Unit (CPU), or the Power Supply (PSSM) of a ControlWave controller.

ControlWave

Redundant

Controller

ControlWave I/O

Expansion Rack

(shared by both

Unit “A” and Unit “B”)

Unit “A”

CPU &

PSSM

W

I

RRTT

1

234

Unit “B”

CPU &

PSSM

W

I

RRTT

1

234

CCRS

10

Page 11

The Concept of Redundancy

Control redundancy is accomplished using the ControlWave Redundant Controller plus one or

more ControlWave I/O Expansion Racks. I/O Expansion Racks are required because the

ControlWave Redundant Controller does NOT support any local I/O boards.

Alternatively, Control redundancy can be accomplished using two separate ControlWave Process

Automation Controllers in conjunction with a ControlWave I/O Switcher. Because this particular

configuration also allows for Local I/O Redundancy, we will show a picture of it later, in the

‘Local I/O Redundancy’ section.

In either case, whenever the on-line ControlWave CPU receives a download of a new

ControlWave project file (boot project), that project is immediately transmitted to the Standby

ControlWave unit, and stored. This is known as a side-load, and typically occurs through an

Ethernet connection between the “A” and “B” units, which may either be specifically dedicated

for that purpose, or may also be used for Ethernet communications with other devices on the

network. Once the side-load occurs, the boot project is loaded into memory in the Standby but

kept in the 'Stopped' state.

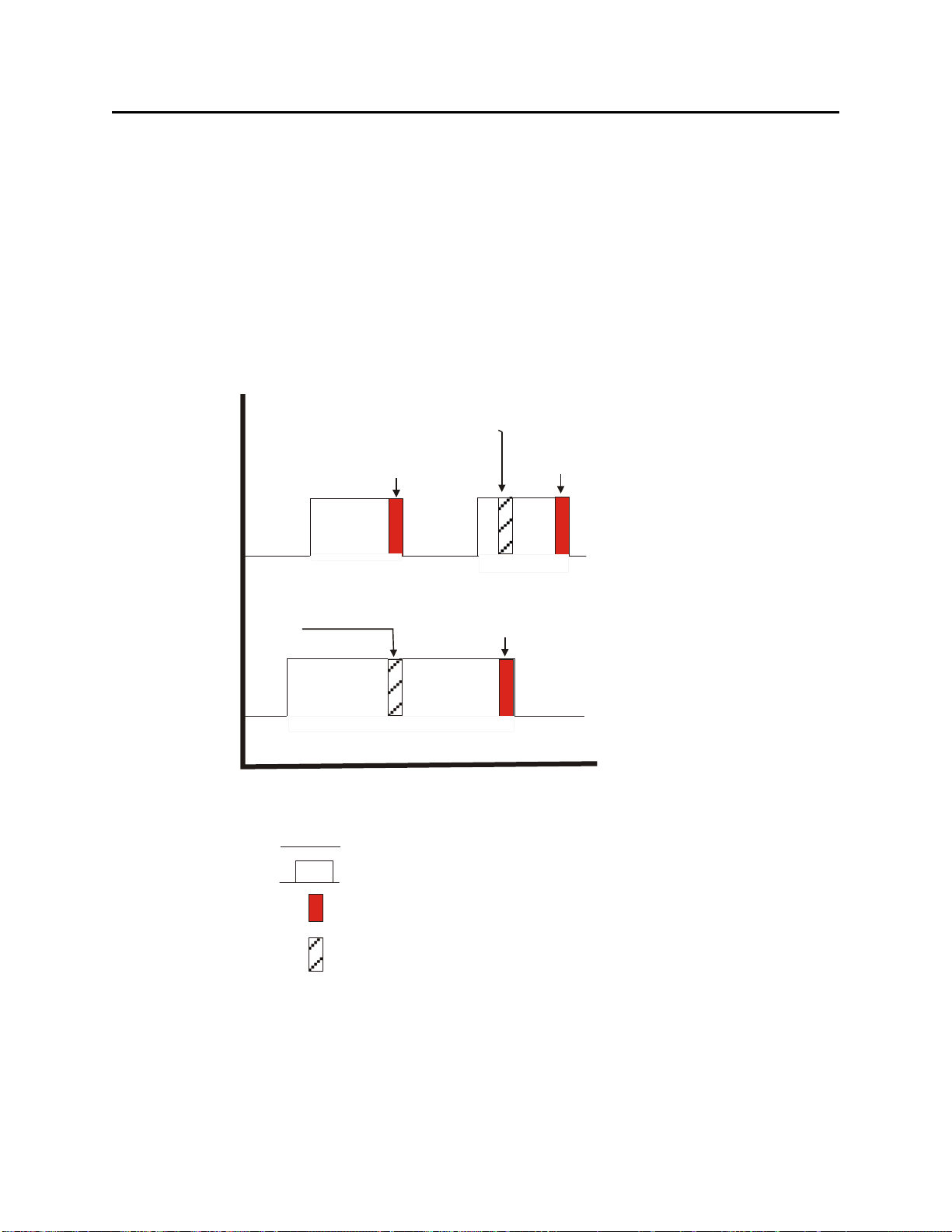

On-line unit receives

download of a new

ControlWave project

file (boot project)

Standby receives a

side-load of the new

On-line CPU

Unit A

boot project from the

On-line unit

Standby CPU

Unit B

The on-line ControlWave CPU is the only unit executing the project, communicating with I/O

boards and controlling the plant or process. The Standby CPU sits idle except for receiving

updates from the on-line unit.

The updates from the on-line unit to the standby unit occur at the end of each task execution

cycle, unless:

• there have been no changes to process I/O output variables -and-

• the minimum update time1 has not expired

1

The minimum update time is a configured value that may be used to limit the amount of traffic b etween the on-line

unit and the standby unit. Every time an update occurs the mini mu m u pd ate ti mer is res t art ed. Unless process I/O

output changes occur, any changes occurring during the time prior to expiration of the configured update timer will

not trigger an update to the standby unit. Instead, they will be held until expiration of the timer, and the end of a

task execution cycle. The timer value is set via the _RDN_MIN_UPD system variable.

11

Page 12

The Concept of Redundancy

Updates between the on-line unit, and the standby unit, may consist of multiple update messages,

followed by a ‘commit’ message. Until the commit message is received, the update messages are

not applied to the standby. This ensures that if the on-line unit fails before it sends the ‘commit’

message, that a partial update, e.g. incomplete data, is not used. Instead, the standby will discard

the incomplete update data, and start up using the last complete update that ended with a commit

message.

In general, data is only transferred from the on-line unit to the standby unit if it has changed.

Among the types of data transferred are:

• Any changed process I/O output variables

• All variables marked as RETAIN in the user's project

• Any data in the static memory area (begins at address 3.100000)

• Certain function block parameters that are retained

• Changes to certain port configuration information such as on-line baud rate changes, etc.

• Changes to user account definitions (usernames, passwords)

• Any newly generated alarms plus any changed alarm states from alarm function blocks

• Historical data (audit records, archive files)

On-line unit is curren t l y

running the project to

control the process

or plant, receiving data

via I/O boards, etc.

On-line CPU

Unit A

At the end of

each execution

cycle, changes

are copied to

the Standby, to

keep it up-to-date

Standby sits idle, except

for receiving updates from

the on-line unit.

Standby CPU

Unit B

If a failure occurs at the on-line unit, a watchdog relay is triggered, and control is switched to the

Standby CPU. The Standby CPU now becomes the new on-line unit.

12

Page 13

The Concept of Redundancy

p

o

p

izzle

s

NEW On-line CPU

Unit B

(formerly the Standby unit)

FAILED CPU

Unit A

Unit "A" suffers a component failure. Control is automatically

transferred to the "B" unit. The "B" unit becomes the NEW

on-line unit, and starts up its boot project.

The "B" unit is up-to-date to the point of the last COMPLETE

update received from "A" unit. (Typically, that would have

been the last execution cycle of the "A" unit, prior to its failure.)

Local I/O Redundancy

Local I/O redundancy provides protection in the event a single failure occurs in either the Central

Processing Unit (CPU), Power Supply, or I/O boards in one of two ControlWave Process

Automation Controllers serving together as a redundant pair.

This redundant configuration would require two (2) ControlWave Process Automation

Controllers, plus a ControlWave I/O Switcher.

ControlWave Process

Automation Controller

“Unit B”

ControlWave

I/O Switcher

ControlWave Process

Automation Controller

“Unit A”

Connections to

field inputs/outputs

13

Page 14

The Concept of Redundancy

With respect to failures of the CPU and power supply, everything would be handled exactly as

described previously in the ‘Control Redundancy - CPU and Power Supply’ section.

Detection of I/O failures, however, is handled differently. The ControlWave series controllers

cannot automatically detect an I/O failure based on data alone. The user must devise logic within

their ControlWave project to determine when a fail-over should occur, and then use a

REDUN_SWITCH function block, in their ControlWave project to trigger the actual fail-over.

When the fail-over occurs, I/O is automatically switched from the on-line unit to the backup

standby unit, which becomes the new on-line unit.

The logic for whether or not a given failure is sufficient reason to force a fail-over to the Standby

unit is based entirely on the user’s own criteria for what constitutes a serious failure. When

activated, this logic serves as a trigger to the REDUN_SWITCH function block, which forces the

fail-over.

Among the items which users might want to consider when making a determination of a local

I/O fail-over could be:

• Comparisons of data from the I/O board in question, with data collected independently from

some separate source.

• Board status codes that can indicate whether or not a board is present, or for analog boards,

whether a conversion operation failed. See the ‘I/O Mapping’ section of the ControlWave

Designer Programmer’s Handbook (document# D5125) for more information on these

codes.

• User-defined timeouts or out-of-range calculations.

• Current status of I/O boards in the standby unit, i.e. is the standby able to take over. This

information is accessible via system variables.

I/O Expansion Rack Redundancy

I/O Expansion Rack redundancy provides protection in the event a single failure occurs in either

of two ControlWave I/O Expansion Racks serving together as a redundant pair.

This redundant configuration would require two (2) ControlWave I/O Expansion Racks, a

ControlWave I/O Switcher, and a Host ControlWave unit, since the I/O Expansion Racks cannot

execute a ControlWave project, they just handle I/O operations.

Typically, the host ControlWave would be a ControlWave Redundant Controller.

14

Page 15

The Concept of Redundancy

s

Unit “A”

CPU &

PSSM

ControlWave Redundant

Controller provides Control

Redundancy , and also serves

as ‘Host’ to pair of redundant

I/O Expansion Racks.

This type of configuration allows Control Redundancy, via the dual CPUs and power supplies of

the ControlWave Redundant Controller, plus I/O redundancy via the dual ControlWave I/O

Expansion Racks, and ControlWave I/O Switcher.

Alternatively, the host could be a single ControlWave Process Automation Controller, in which

case this segment of the network would have NO CPU or power supply redundancy, but would

have I/O Expansion Rack Redundancy.

Unit “B”

CPU &

PSSM

W

W

I

I

RRTT

RRTT

1

1

234

234

CCRS

ControlWave I/O

Expansion Rack

“Unit B”

ControlWave

I/O Switcher

Connections to

field inputs/outputs

ControlWave I/O

Expansion Rack

“Unit A”

ControlWave I/O

ControlWave Process Automation

Controller serves as ‘Host’ to pair

of redundant I/O Expansion Racks.

There is NO CPU or power supply

redundancy in this configuration.

Expansion Rack

“Unit B”

ControlWave

I/O Switcher

Connections to

field inputs/output

ControlWave I/O

Expansion Rack

“Unit A”

Another possible configuration would be to use a pair of ControlWave Process Automation

Controllers, in conjunction with their own dedicated ControlWave I/O Switcher, as the host. In

general, this type of configuration would only be used in situations where a single ControlWave

Process Automation Controller does not have sufficient local I/O capacity for a given

application, and so additional I/O is needed, via I/O Expansion Racks. This system incorporates

Control Redundancy, plus Local I/O Redundancy, and I/O Expansion Rack Redundancy. In this

particular set up, because there are two separate ControlWave I/O Switchers, the “A” and “B”

units of each one are considered independent of each other, therefore, the control system could

still function even if, for example, the “A” I/O Expansion Rack failed, and the “B” Process

Automation Controller also failed, because the “B” I/O Expansion Rack could be used with the

“A” Process Automation Controller.

15

Page 16

The Concept of Redundancy

s

No matter which of these configurations you use, detection and handling of I/O failures in the

I/O Expansion Rack is handled by user-defined logic, in the host controller.

The I/O Expansion Racks cannot automatically detect an I/O failure based on data alone. The

user must devise logic within their ControlWave project to determine when a fail-over should

occur. See the ‘Local I/O Redundancy’ section for a list of possible I/O failure criteria.

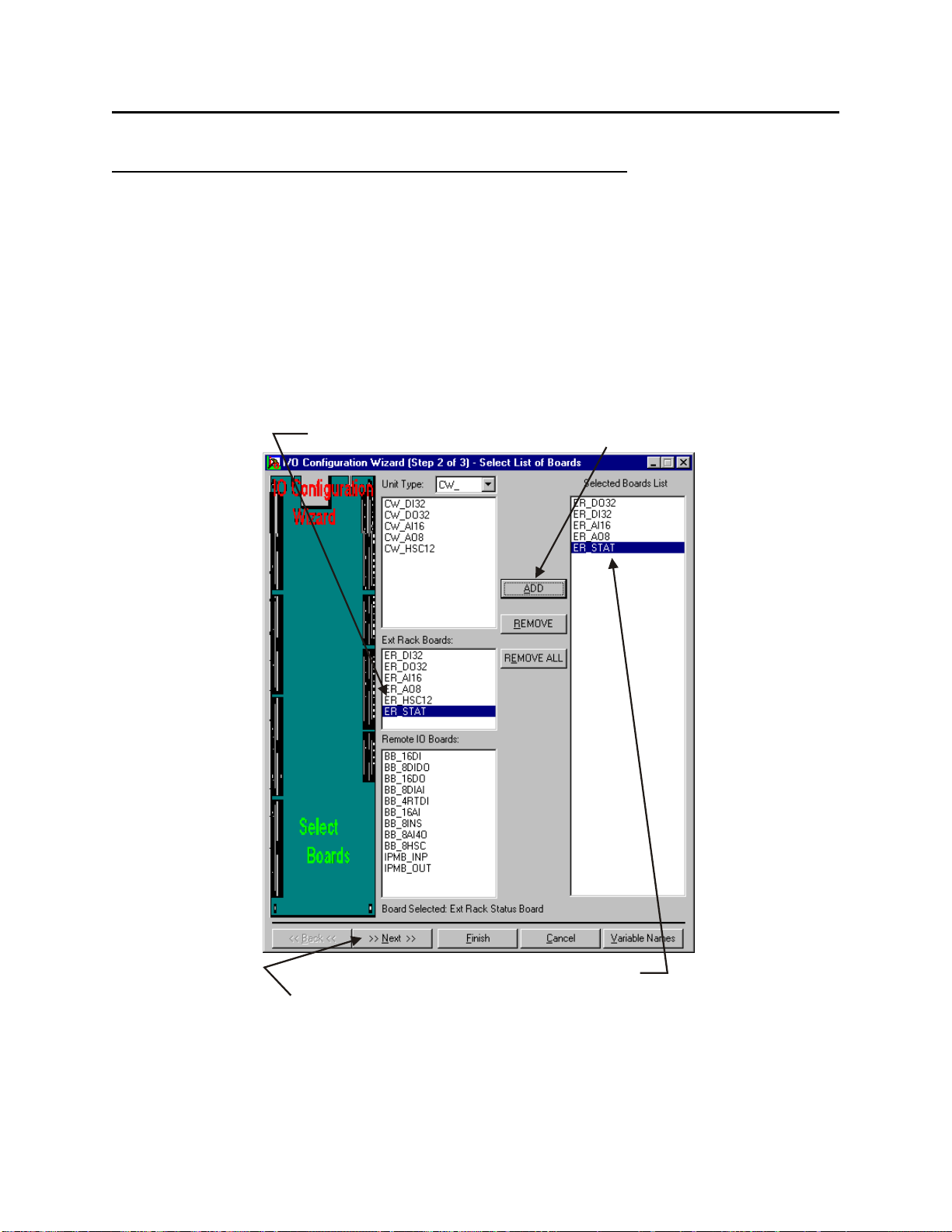

If the user determines that a fail-over is necessary, it must be triggered by a user write to the failover variable on the ER_STAT board. (NOTE: The ER_STAT board is not an actual physical

I/O board, but a virtual board that maintains data related to the I/O Expansion Rack.) When the

fail-over occurs, I/O is automatically switched from the on-line rack to the backup standby rack,

which becomes the new on-line unit.

The logic for whether or not a given failure is sufficient reason to force a fail-over to the Standby

unit is based entirely on the user’s own criteria for what constitutes a serious failure. When

activated, this logic serves as a trigger to the ER_STAT fail-over variable, which forces the failover.

NOTE: Non-I/O-related hardware failures which trigger the watchdog relay, for example, a

power failure at the on-line I/O Expansion Rack, will also force a fail-over to the standby unit.

ControlWave Process

Automation Controller

“Unit B”

ControlWave

I/O Switcher

Connections to

field inputs/outputs

for LOCAL I/O ONLY

ControlWave Process

Automation Controller

“Unit A”

ControlWave I/O

Expansion Rack

“Unit B”

ControlWave

I/O Switcher

Connections to

field inputs/output

ControlWave I/O

Expansion Rack

“Unit A”

16

Page 17

Setting up Redundancy Hardware

Setting up Redundancy Hardware

Major Types of ControlWave Redundancy Hardware

There are four (4) major pieces of ControlWave hardware that are useful in various redundant

ControlWave configurations. We will list each type here, and then provide a brief overview how

it works, and how it is set up, or provide references to where setup information is available.

Which types of hardware you use will depend upon which form(s) of redundancy you are

incorporating into your system: Control Redundancy, Local I/O Redundancy, or I/O Expansion

Rack Redundancy. The four types of redundancy hardware are:

• ControlWave Redundant Controller

• ControlWave Process Automation Controller

• ControlWave I/O Expansion Rack

• ControlWave I/O Switcher

ControlWave Redundant Controller

If you have a system which uses Control Redundancy ONLY, you will need a ControlWave

Redundant Controller (See ‘Control Redundancy - CPU and Power Supply’, earlier in this

manual.) The ControlWave Redundant Controller can also be used as the host controller, in a

system using I/O Expansion Rack Redundancy (See ‘I/O Expansion Rack Redundancy’, earlier

in this manual.)

The ControlWave Redundant Controller

consists of a single chassis holding a pair

of ControlWave central processing units

(CPUs) and power supplies, linked

together by a CPU and Communications

Redundancy Switch (CCRS) module.

The ControlWave Redundant Controller

has no local I/O; I/O resides in one or

more ControlWave I/O Expansion

Racks, and is shared between the two

CPUs. Only the on-line CPU

communicates with the I/O).

CPU and

power supply

“A”

CPU and

power supply

“B”

CCRS

17

Page 18

Setting up Redundancy Hardware

a

Redundant pair of ControlWave CPUs

They share the SAME node name in NetView

but each has a DIFFERENT IP address

ON-LINE

Unit "A"

IP address a.b.c.d

On-line unit is currently

in control of the process

or plant, communicating,

receiving data via I/O

boards, etc.

CCRS

The switch

allows the

automatic

fail-over from

one unit to

the other. It

also can be

used to 'force'

a manual

f

il-over.

STANDBY

Unit "B"

IP Address e.f.g.h

Standby sits idle

as a backup. It

waits to take

over should the

on-line unit fail.

18

Page 19

Setting up Redundancy Hardware

Setting Up the ControlWave Redundant Controller

This configuration involves unpacking the ControlWaveRED hardware, making proper ground

connections, connecting a communication cable to the PC workstation and setting switches. The

basic steps are outlined, below. For detailed information on a particular step, please consult the

referenced hardware manual.

1. Remove the unit from its carton and install it at its assigned work site. (see Section 2.3.1 of

CI-ControlWaveRED).

2. Install a ground wire between the Chassis Ground Lug and a known good Earth Ground (see

Section 2.3.1.1 of CI-ControlWaveRED).

3. Units are shipped from the factory with CPU switches set for redundant operation, and the

backup battery disabled. If the switch settings have been changed, please set them correctly

according to the following instructions.

Setting CPU Module DIP Switches on each CPU:

For Switch Bank SW1:

Switch

Number

SW1-1 ON This enables the Watchdog circuitry, which is required.

SW1-2 ON This unlocks soft switches, which is required.

SW1-3 ON This forces soft switches to be used, which is required.

SW1-4 See

SW1-5 ON This must be set to ON so that RETAIN memory can be

SW1-6 OFF This enables redundant operation, which is required.

SW1-7 See

SW1-8 ON This enables the boot project, which is required.

Must be

set to:

Notes

notes

Notes:

For firmware versions earlier than 4.2: Had to be set ON to

disable updump. For Version 4.2 or newer: Can be set either

ON (to disable updump), or OFF, to enable updump. Neither

switch position has an effect on the normal operation of the

unit, since updump mode is not activated unless the user

operates the RUN / REMOTE / LOCAL key switch, in a

particular sequence, to trigger the updump.

used.(Required)

This switch must be set either ON or OFF based on whether this

is the "A" CPU (which resides in Chassis slot 2) or the "B" CPU

(which resides in Chassis slot 4):

• SW1-7 must be ON if this is the "A" CPU (in Chassis slot 2)

• SW1-7 must be OFF if this is the "B" CPU (in Chassis slot

4)

19

Page 20

Setting up Redundancy Hardware

For Switch Bank SW3:

For Switch Bank SW3, all switches should be left in their default position of 'OFF' except for

SW3-4 which must be set to 'ON' to enable the backup battery. This is because units are

shipped from the factory with the backup battery disabled, to reduce the drain on the battery.

To enable the backup battery remove the “A” CPU Module from chassis slot 2, and set

switch SW3-4 to ON, then re-install it in chassis slot 2. Next, remove the “B” CPU Module

from chassis slot 4, and set switch SW3-4 to ON. Then re-install it in chassis slot 4. (see

Section 2.3.3. of CI- ControlWaveRED).

Reset

Switch

Comm.

Port 1 (J2)

Lithium

Battery

3.6V

950mA-hr

½ AA Cell

Comm.

Port 2 (J3)

Ethernet

Port 1 (J4)

Enlarged detail

of CPU switch

banks

(CAPITALIZED entry

indicates ON position)

Bootproject ENABLE / disable

Redundancy DISABLE / enable

static memory RETAIN / initialize

Updump DISABLE / enable

Soft switches USE / ignore

Soft switches write UNLOCK / lock

Watchdog circuit ENABLE/disable

UNIT A / unit B

Port 80

Display

Run/

Remote/

Local

Key Switch

SW1

SW1

SW3

SW3

Leave all SW3

CPU switches

in default 'OFF'

position, except

for #4.

ENABLE/disable battery backup

recovery mode ENABLE/disable

Unused

Unused

(CAPITALIZED entry

indicates ON position)

Most SW1 switches should be 'ON',

but SW1-6 MUST be ‘OFF’ to enable

redundancy, and SW1-7 must be set

'ON' if this is the "A" CPU, or

'OFF' if this is the "B" CPU.

20

Page 21

Setting up Redundancy Hardware

s

4. Install Watchdog Relay/MOSFET Switch wiring to each PSSM Module (see Section

2.3.4.1.3 of CI-ControlWaveRED).

+12Vdc Bulk Supply #1 Pos. Term.

+12Vdc Bulk Supply #1 Neg. Term.

Chassis Ground

+24Vdc Bulk Supply #1 Pos. Term.

+24Vdc Bulk Supply #1 Neg. Term.

Chassis Ground

5. Connect Bulk DC Power to each of the ControlWaveRED’s PSSM Modules, but don't apply

power at this time (see Section 2.3.4.1 through Section 2.3.4.1.2 of CI-ControlWaveRED).

6. Install the Bezels so that each one covers its associated PSSM and CPU Modules (see

Section 2.3.6 of CI-ControlWaveRED).

7. Connect the special serial communications cable between the four serial communications

ports on CPU Module A and Connector J5 on the front (left) of the CCRS Module. Then

connect the other special serial communications cable between the four serial communication

ports on CPU Module B and connector J6 on the front (right) of the CCRS Module.

Typical Configuration

+VIN

1

+VINF

Shared +12Vdc Power Supply

-VIN

-VINF

CHASSIS

5

+VIN

1

+VINF

Shared +24Vdc Power Supply

-VIN

-VINF

CHASSIS

5

21

Page 22

Setting up Redundancy Hardware

A / B Enabled switch

Run / Remote/ Local

switch

CPU & Power supplyACPU & Power Supply

B

&

= Serial Comm. Port Designation

CPU & Communications

Redundancy Switch (CCRS) Module

12

COM1 COM2

1

6

J1 J2

9

5

COM3 COM4

49

50

J3 J4

J5 J6

1

J7

= Ethernet Comm. Port Designation

8. Connect COMM Port 2 of the CPU & Communications Redundant Switch Module (CCRS)

to one of the communication ports on your PC or laptop. (For more information on

communication ports see Section 2.3.3.2 of CI-ControlWaveRED).

2

• Plug one end of an RS-232 null modem cable

into one of your PC communication ports.

• Plug the other end of the RS-232 null modem cable into Serial Communication Port 2

(COM2) of the ControlWaveRED's CCRS Module.

10. Set the CCRS Module's A/B Enabled key switch to the "A" position.3

11. Set the RUN/REMOTE/LOCAL switch on both CPU A and CPU B to 'LOCAL'.

2

For a wiring diagram of an RS-232 null modem cable, see Figure 2-8 in the CI-ControlWave manual.

3

We have chosen 'A' for purposes of this example, however, you could have chosen 'B', and substituted 'B' in

subsequent steps which mentioned 'A'.

22

Page 23

Setting up Redundancy Hardware

12.Connect an Ethernet cable between one of the Ethernet Ports on CPU Module A and an

Ethernet Hub. Connect another Ethernet cable between the same Ethernet hub and the

Ethernet Port on CPU Module B with the same designation, i.e. Ethernet Port 1 (E1),

Ethernet Port 2 (E2) or Ethernet Port 3 (E3). Alternatively, you can omit the hub, and

connect a Point-to-Point 10Base-T Ethernet cable directly between the two ports.4

13. Apply power to the ControlWaveRED by setting the power s witch on the “A” unit to the '1'

position. (The power switch is located behind the bezel door). When the power up sequence

is completed, the status display should either be blank, or show “00”. “00” appears if there is

no project loaded; if it is blank, it means a project is already loaded and running. For a full

description of possible running status codes, see Table 2-9 in the CI-ControlWaveRED

manual.5

At this point, you can proceed to connect devices to any unused serial and Ethernet ports(s) as

required by your particular application.

4

For more information on the Point-to-Point 10Base-T Ethernet cable, see Figure 2-13 in the CI-

ControlWaveRED manual.

5

Table 2-9 in CI-ControlWaveRED shows the normal status codes you are most likely to see. Table 3-3 of the same

manual covers Power On Self-Test (POST) status codes, most of which are not seen unless there is an error prior to

completion of the power up. One POST code you may encounter is "86" which indica tes that the unit has been set

for recovery mode (switch SW3-3 is ON) to allow a field upgrade of system firmware.

23

Page 24

Setting up Redundancy Hardware

ControlWave Process Automation Controller

The standard ControlWave Process Automation

Controller, when used in pairs of two (2), with

an I/O Switcher, is required in any system using

Local I/O Redundancy. (See ‘Local I/O

Redundancy’ earlier in this manual.) The

ControlWave Process Automation Controller

can also be used as the host controller, in a

system using I/O Expansion Rack Redundancy

(See ‘I/O Expansion Rack Redundancy’, earlier

in this manual.)

When used in Local I/O Redundancy, both ControlWave controllers will share the same node

name in NetView; only their IP addresses and the position of CPU switch SW1-7 will be

different. For instructions on how to set up the ControlWave Process Automation Controller,

please see the following manuals:

Manual # Manual Title Description

CI-ControlWave

D5084

The CPU switch settings are especially important when setting up the ControlWave Process

Automation Controller. For redundant operation you must set switch SW1-6 and SW1-7 as

shown in the table, below:

For these switches on the

ControlWave Process Automation

Controller:

SW1-6 This must be set OFF to allow redundant operation.

SW1-7 This switch must be set either ON or OFF based on

ControlWave Process

Automation Controller

ControlWave Quick Setup

Guide

ControlWave Process Automation Controller

Provides full instructions on setting up the

ControlWave controller hardware.

This document provides an overview of the

configuration process, with emphasis on

software setup.

Set as follows:

whether this is the "A" controller or the "B" controller

of this redundant pair.

• SW1-7 must be ON if this is the "A" controller

• SW1-7 must be OFF if this is the "B" controller.

24

Page 25

Setting up Redundancy Hardware

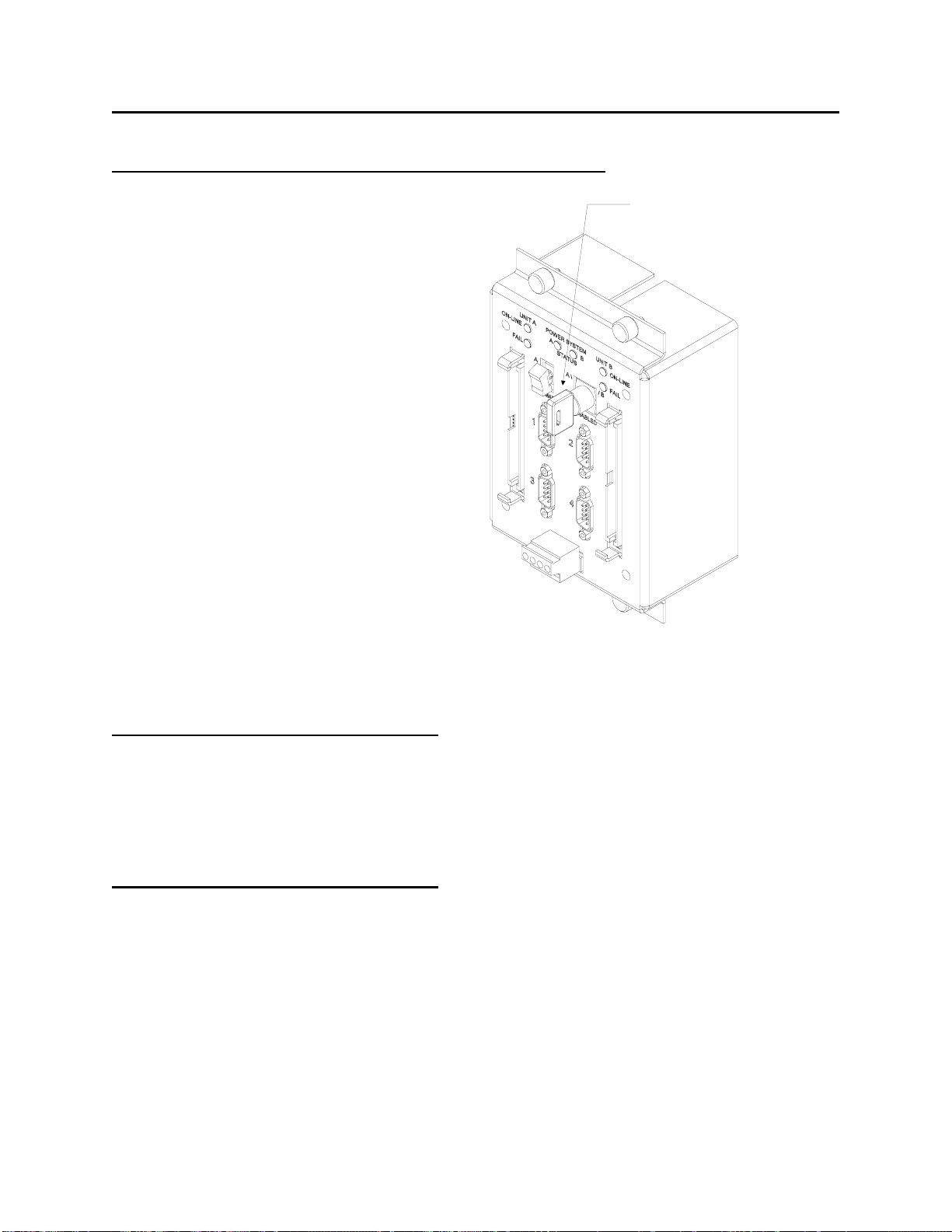

ControlWave I/O Expansion Rack

A ControlWave I/O Expansion Rack is

required whenever a ControlWave

Redundant Controller requires I/O, because

the ControlWave Redundant Controller has

no on-board local I/O. In addition, at least

two (2) I/O Expansion Racks are always

required in a system using I/O Expansion

Rack Redundancy. (See ‘I/O Expansion

Rack Redundancy’, earlier in this manual.)

For instructions on how to set up the ControlWave I/O Expansion Rack, please see the following

manuals:

Manual # Manual Title Description

CI-ControlWaveEXP

D5122

The CPU switch settings are especially important when setting up the ControlWave I/O

Expansion Rack. For redundant operation you must set switch SW1-6 and SW1-7 as shown in

the table, below:

For these switches on

the I/O Rack:

SW1-6 This must be set OFF to allow redundant operation.

SW1-7 This switch must be set either ON or OFF based on whether this is the

ControlWave I/O

Expansion Rack

ControlWave I/O

Expansion Rack Quick

Setup Guide

Set as follows:

"A" I/O rack or the "B" I/O rack of this redundant pair.

• SW1-7 must be ON if this is the "A" rack

• SW1-7 must be OFF if this is the "B" rack

ControlWave I/O Expansion Rack (distinguishable from

ControlWave Process Automation Controller by lack of a key

switch)

Provides full instructions on setting up the

ControlWave I/O Expansion Rack hardware.

This document provides an overview of the

configuration process, with emphasis on

software setup.

25

Page 26

Setting up Redundancy Hardware

6

ControlWave I/O Switcher

NOTE: The full name for this device is the ControlWave Redundant I/O and Communications

Switch Unit, and it is abbreviated as CWREDIO, but we will refer to it simply as the

‘ControlWave I/O Switcher’, or just the ‘I/O Switcher’.

The ControlWave I/O Switcher can be used with ControlWave I/O Expansion Racks to provide

I/O Expansion Rack Redundancy. When used in this way, a host (master) controller must exist,

which could be a ControlWave Process Automation Controller, or a ControlWave Redundant

Controller.

The ControlWave I/O Switcher can also be used together with two ControlWave Process

Automation controllers to provide Control Redundancy and Local I/O Redundancy.

Full instructions on setting up the I/O Switcher are included in the ControlWave Redundant I/O

and Communications Switch Unit manual CI-ControlWaveREDIO.

We will provide a brief overview of the major configuration steps, with references to where in

the hardware manual, you can find additional information.

2

Page 27

Setting up Redundancy Hardware

7

Overview of I/O Switcher Hardware Configuration

This involves unpacking the I/O Switcher hardware, mounting the chassis, configuring and

installing the various hardware modules, installing interconnect cables between each

ControlWave Process Automation Controller or each ControlWave I/O Expansion Rack and the

I/O Switcher, wiring I/O terminations, making proper ground connections, and wiring the

ControlWave Power Supply/Monitor Modules (PSMMs) to bulk power supplies.

In the discussion, below, the “A” and “B” ControlWave units refer to the redundant pair of

ControlWave Process Automation Controllers or ControlWave I/O Expansion Racks, which are

having I/O controlled via the ControlWave I/O Switcher.

To install and configure the ControlWave I/O Switcher follow steps 1 through 10 below:

1. Remove the Chassis from its carton and install it at its assigned work site (see Section 2.3.1 of

manual CI-ControlWaveREDIO).

2. Remove the power supply modules and the control module from their cartons and install them

into their designated slots (see Figure 2-6 of manual CI-ControlWaveREDIO). There are two

power supply modules (called PSSM), and one Redundancy Control Module (called IORCM).

3. Connect the Redundant ControlWave Communication Cables as follows:

Connect one end of Cable A to Comm. Ports 1 through 4 of the “A” ControlWave unit, and

the other end to Comm. Interface Connector J5 of the Redundancy Control Module (IORCM)

on the ControlWave I/O Switcher.

Connect one end of Cable B to Comm. Ports 1 through 4 of the “B” ControlWave unit and the

other end to Comm. Interface Connector J6 of the Redundancy Control Module (IORCM) on

the ControlWave I/O Switcher.

4. Connect network communications cables to the Redundancy Control Module (IORCM) as

follows (see Section 2.3.1.3 of manual CI-ControlWaveREDIO):

Comm. Port 1 = J1 - RS-232

Comm. Port 2 = J2 - RS-232

Comm. Port 3 = J3 - RS-232 or RS-485 (factory configured per order)

Comm. Port 4 = J4 - RS-232 or RS-485 (factory configured per order)

5. Remove the I/O Switch Modules (IORSM) from their cartons and install them into their user

assigned positions in the Chassis. There are from one to eight I/O Switch Modules, which

reside in slots 2 through 9 and mate with Backplane Connectors P4 through P11 respectively.

Install I/O wiring to each one (see Section 2.3.2 of manual CI-ControlWaveREDIO).

2

Page 28

Setting up Redundancy Hardware

6. Install a ground wire between the Chassis Ground Lug and a known good Earth Ground (see

Section 2.3.1.1 of manual CI-ControlWaveREDIO).

7. Install switchover control wires (not provided) between IORCM pluggable terminal block

connectors TB1 and TB2 to connector TB1 on the PSSMs of both the “A” and “B”

ControlWave units (see Section 2.3.3.3 of manual CI-ControlWaveREDIO).

8. Remove the Power Supply Panel Cover and connect Bulk DC Power to the pluggable terminal

block connector TB1 on each of the two PSMMs (see Sections 2.3.3.1 & 2.3.3.2 of manual

CI-ControlWaveREDIO). Note: It is recommended that the pluggable terminal block (TB1)

associated with each PSMM not be connected until the entire system has been wired and

configured. When ready turn both PSMMs to their ON position via SW1 ( ‘I’ pressed) on each

PSMM.

9. Install the Power Supply Panel Cover removed in step 8. This item is screwed into place (see

Section 2.3.4 of manual CI-ControlWaveREDIO).

10.Configure each of the “A” and “B” ControlWave units associated with I/O Switcher and

apply power to them by setting the Power Switch on their PSSM Modules to the ‘I’ position.

Note: Both the “A” and “B” ControlWave units must be identical (except for IP addresses and

the position of CPU switch SW1-7) and must be equipped with Rev. B or higher CPU Boards

that are running with ControlWave firmware (Rev. 4.10 or higher).

28

Page 29

Establishing Communications

Fi

Establishing Communications

Communications between the PC and the ControlWave hardware (Controller, Redundant

Controller, or I/O Expansion Rack) can be established using either LocalView or NetView.

(LocalView is generally easier for first time users.)

For the ControlWave Controller, ControlWave Redundant Controller, or ControlWave I/O

Expansion Rack, you should plug the cable into the communication port in the associated

redundancy hardware, i.e. the port on the CCRS of the ControlWave Redundant Controller, or

the port on the IORCM of the ControlWave I/O Switcher.

For the Controlwave I/O Expansion Rack, if you are using RS485, the port you plug into must be

the one associated with COM1, and you must also enable diagnostics mode by setting switch

SW1-8 on the I/O Expansion Rack to ON. This will set COM1 on the rack to 9600 baud, 8 bits, 1

stop bit, no parity, allowing you to configure flash parameters.

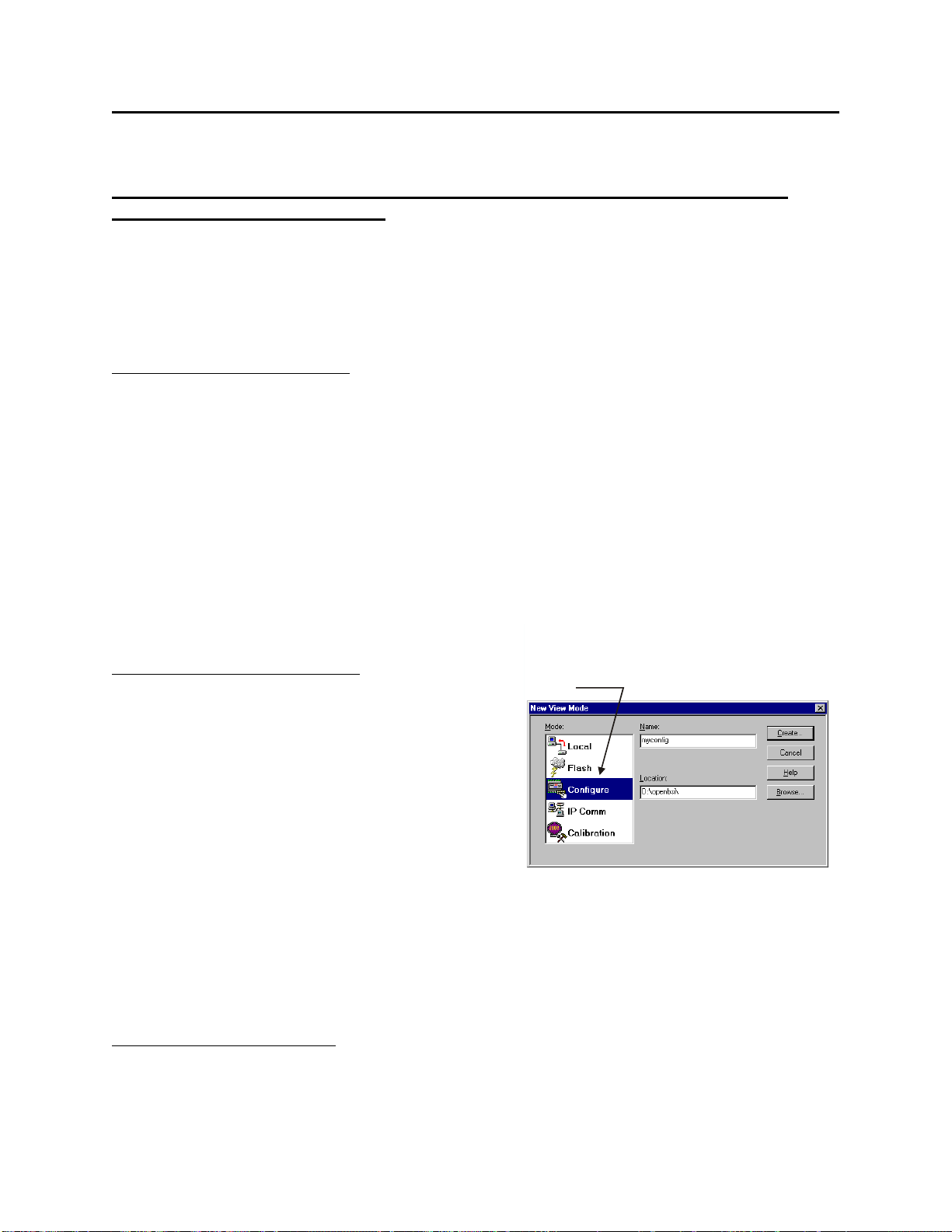

Establishing Communications Using LocalView

Step 1. Click as follows: StartÆProgramsÆOpenBSI ToolsÆLocalView

Step 2. Choose 'Local' for the mode, enter a

name for the LocalView file, and click on

[Create].

Step 3. Choose the communication port on the PC

workstation which you will use to

communicate with the ControlWave

unit. Then, specify the baud rate for

that port, and click on the [Next>] button.

rst, choose

'Local' as

the mode.

Choose the communication port on

workstation

Specify the baud rate for that port

Next, enter a

name for this

LocalView

file.

(NOT on the ControlWave)

Finally, click

on

[Create]

the PC

Finally, click on

29

[Next>]

Page 30

Establishing Communications

n

Step 4. First, turn off auto local address detection by answering "No" to the question. Then

specify '1' as the local address. For the RTU Type, choose ‘ControlWave’ if this is a

ControlWave Redundant Controller, or ControlWave Process Automation Controller. If

this is a ControlWave I/O Expansion Rack, choose ‘CWave_RIO’. Finally, click on

[Finish].

Turn off auto local

Choose

'ControlWave' or

‘CWave_RIO’

address detection

Use "1" as the

local address

Finally, click on

Step 5. At this point, LocalView will create a temporary network with a single ControlWave icon

called, generically, 'RTU'. Right-click on the icon, then choose RTUÆ RTU

Configuration Parameters from the pop-up menus.

[Finish]

Right-click on the ControlWave ico

Step 6. The Flash Configuration Utility will appear. See 'Setting Flash Parameters', later in th is

manual.

30

Page 31

Establishing Communications

Establishing Communications Using NetView (ControlWave Already In a Network)

IMPORTANT: This method assumes that the ControlWave unit has already been included in an

Open BSI network within the NetView program, and that it has been configured

to communicate over that network's communication line as described in the Open

BSI Utilities Manual (document# D5081).

Step 1. Click as follows: StartÆProgramsÆOpenBSI ToolsÆNetView

Step 2. Right-click on the ControlWave icon, in the NetView network tree, and choose

RTUÆRTU Configuration Parameters from the pop-up menus.

Right-click on the

ControlWave icon

Step 3. The Flash Configuration Utility will appear. See 'Setting Flash Parameters', later in th is

manual.

31

Page 32

Setting Flash Parameters

Setting Flash Parameters

The Flash Configuration Utility may be accessed either through NetView or LocalView. In either

case, it allows the user to specify all the major configuration parameters of the ControlWave

unit. As part of this manual, we will only discuss those parts of the Flash Configuration Utility

which are important for configuration of redundancy. A full discussion of the Flash

Configuration Utility is included in Chapter 5 of the Open BSI Utilities Manual (document#

D5081).

The various configuration settings are separated into different pages of the utility. You can

access them by clicking on the tab for a particular page. The pages associated specifically with

configuration of redundancy are:

• Ports - this includes all communication ports on the ControlWave units - up to four serial

ports (COM1 through COM4), and three Ethernet IP ports. In order to configure redundancy,

an Ethernet Port MUST be configured for each unit.

• Application Parameters – Most of these are 'tuning' parameters which govern how the

ControlWave executes its application (project), however, there are some directly related to

redundant operations.

32

Page 33

Setting Flash Parameters

Before you Begin

• For purposes of this explanation, we are going to configure unit ‘A’ first, therefore, the

‘A/B/Enable’ switch (located on the CCRS of the ControlWave Controller, or on the

Redundancy Control Module (IORCM) of the ControlWave I/O Switcher) should be set to

‘A’, and unit ‘A’ should be powered on. If the unit has a project already running in it, its

display should be blank; if not “00” should appear on the display.

• We are assuming, at this point, that you have successfully established communications with

the ControlWave using either LocalView or NetView.

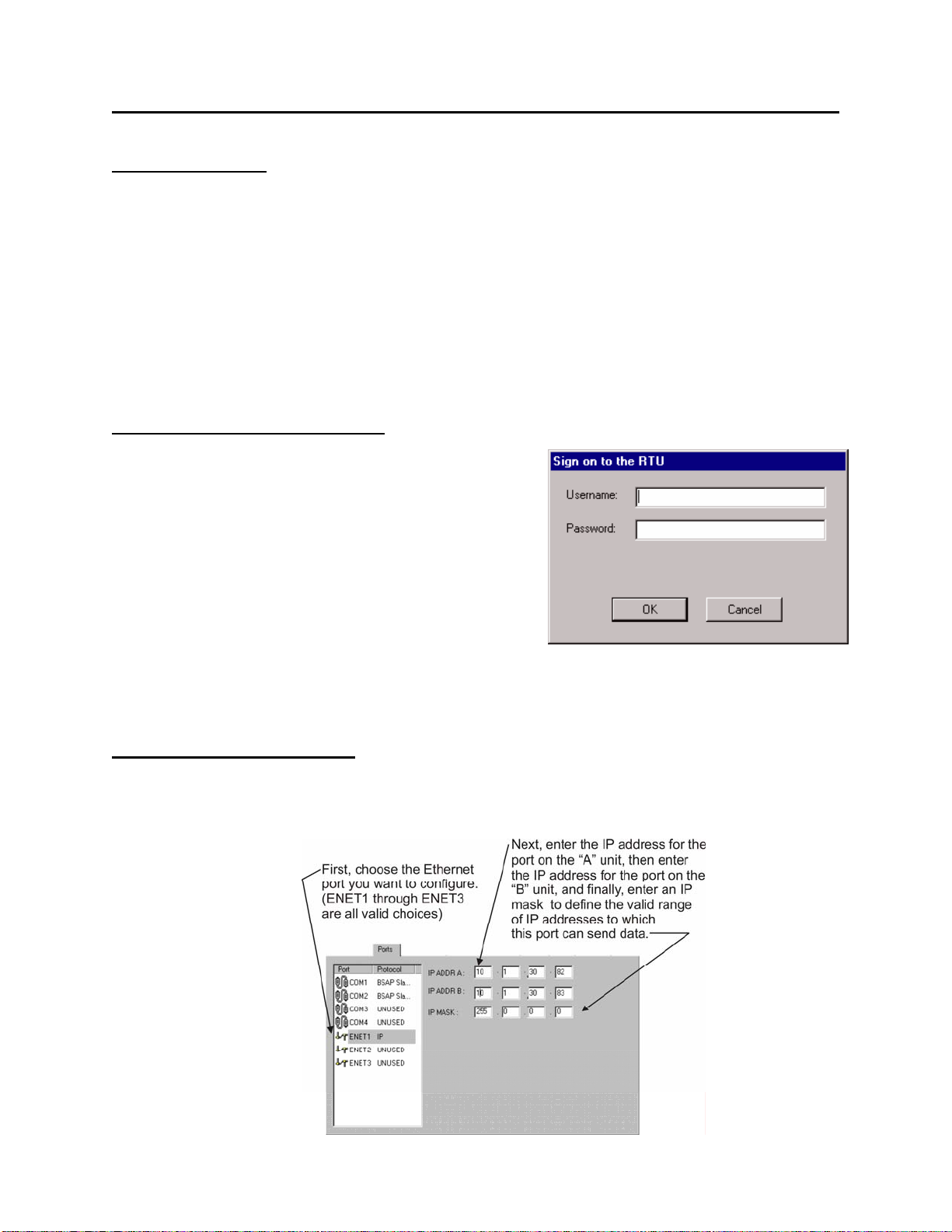

Signing on to the ControlWave

Click on the [Sign On] button, then enter a username

and password to sign on to the ControlWave. If this is

the first time you are signing on, and no user accounts

have been defined, use “SYSTEM” for the username,

and “666666” as the password.

NOTE: If you do NOT sign on, the first time you

attempt a read/write operation, you will be prevented

from doing so, and will be prompted to sign on then.

Once you have signed on, you can proceed to the ‘Ports’ page by clicking on the ‘Ports’ tab.

Setting Up an Ethernet Port

ControlWave redundant data is transferred via IP communications, therefore a ControlWave

CPU must have at least one Ethernet Port defined.

33

Page 34

Setting Flash Parameters

Step 1. Click on the 'Ports' tab, if you haven't already.

Step 2. Choose the Ethernet port you want to configure (ENET1, ENET2, or ENET3 are valid

choices.)

Step 3. Specify an "IP ADDR A" (the IP address for the chosen Ethernet Port on the “A” unit),

and “IP ADDR B” (the IP address for the corresponding Ethernet Port on the “B” unit),

and an "IP MASK" which defines the range of addresses reachable through this port. IP

addresses must be unique within your network. Conversely, IP masks are typically the

same for all devices in the same portion of a network. Together, the IP Address and IP

Mask define a range of addresses to which this port can send messages. (See

'Recommended Ranges for IP Addresses' later in this document.) Basically, a non-zero

value in any of the "IP MASK" fields indicates that the corresponding "IP ADDR A"

and “IP ADDR B” field is specifying a portion of the IP address which must be

identically matched with every destination IP address to which this port will send

messages. A zero value in any of the "IP MASK" fields means that this communication

port can send messages to addresses in which any integer from (0 to 255) is considered

valid for that corresponding portion of the destination IP address.

In newer ControlWave units, all Ethernet ports are pre-programmed at the factory

with initial IP addresses and masks, as follows:

Because each unit shipping from the factory will have these initially preprogrammed, you should only use these addresses for ‘bench’ testing and

configuration. These addresses must be changed before putting ControlWave units

on an actual network, since an address conflict would exist as soon as the second

ControlWave unit was placed online.

In the figure on the previous page, the "IP ADDR A" is 10.1.30.82, the “IP ADDR B”

is 10.1.30.83, and the "IP MASK" is 255.0.0.0. This means that this port can send to any

address in the format 10.x.y.z where x, y, and z, are any integer from 0 to 255. So,

10.43.127.76 and 10.84.35.93 would be valid destinations, but 24.1.1.1 would not

because the 255 in the "IP MASK" indicates that the corresponding portion of the "IP

ADDR A" and “IP ADDR B” MUST be 10.

ETH1 IP Address: 10.0.1.1 IP Mask: 255.255.255.0

ETH2 IP Address: 10.0.2.1 IP Mask: 255.255.255.0

ETH3 IP Address: 10.0.3.1 IP Mask: 255.255.255.0

IMPORTANT

34

Page 35

Setting Flash Parameters

There are other restrictions, for example, the non-zero mask entries must be all be in

contiguous fields, and must begin in the left-most portion of the address. More details on

these subjects are included in the Open BSI Utilities Manual (document# D5081).

NOTE: If you are using a direct Ethernet connection (no hub involved) between the two

units, you should configure IP addresses which are completely different from any other

Ethernet ports you have configured for the unit, and you should choose a mask which

limits the transmission to just between the two Ethernet ports used for redundant

operations, e.g. 255.255.255.248 will force “IP ADDR A” and “IP ADDR B” to match

exactly except for the last three bits of the address.

Step 4. At this point, you can proceed to configure additional ports (Ethernet, BSAP, etc.). When

finished defining ports, please click on the ‘Application Parameters’ tab, to go to the

Application Parameters page.

Recommended Ranges for IP Addresses

If you are intending to connect your Open BSI network directly to the global world-wide

Internet, you must obtain a range of IP addresses from your Internet service provider (ISP) or

from an Internet governing body such as the Internet Assigned Numbers Authority (IANA).

If you have no plans to connect your network to the global Internet, there is no restriction on

your choice of IP addresses, however, the Internet Engineering Task Force recommends, as per,

RFC 1918* that IP addresses for private networks should be assigned from the following ranges:

10.0.0.0 to 10.255.255.255

172.16.0.0 to 172.31.255.255

192.168.0.0 to 192.168.255.255

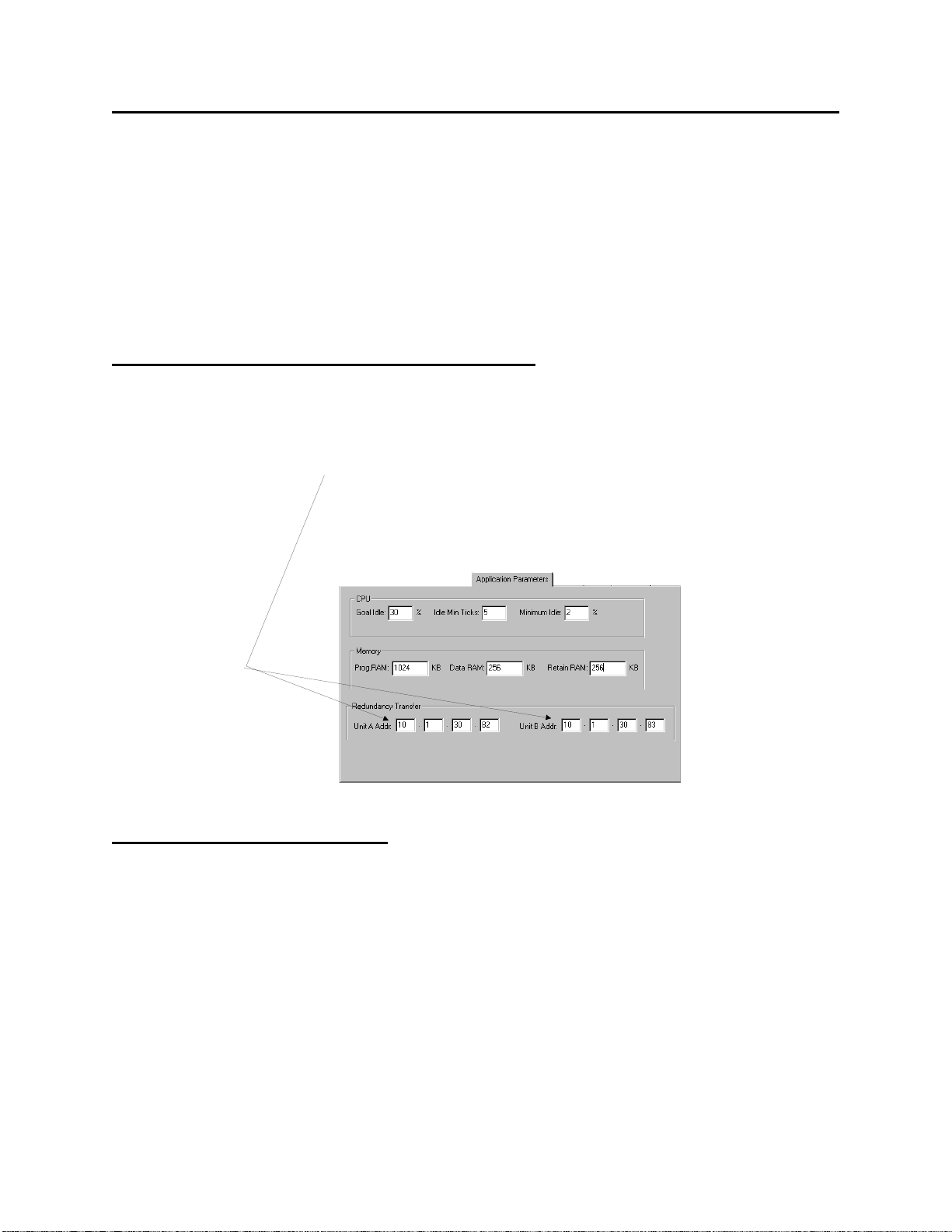

These particular ranges of Internet addresses have been set aside for private networks. Any

messages coming from these addresses can be recognized by most Internet Service Providers

(ISP) as coming from private networks, and so can be filtered out. This helps avoid addressing

conflicts should an accidental connection occur between a private network, and the global

Internet.

Devices (e.g. controllers, workstations) in Bristol Babcock networks always use fixed IP

addresses. This causes certain complexities if you choose to use Dynamic Host Configuration

Protocol (DHCP) in your network. Because DHCP assigns IP addresses dynamically, as they are

needed, you must examine your DHCP server to determine the addresses which have been

assigned for each Bristol controller or workstation, and then manually enter those addresses in

*

Rekhter, et al, Best Current Practice memo - "Address Allocation for Private Internets", Internet Engineering Task

Force, RFC 1918, February, 1996. Please see http://www.ietf.org for complete text of this memo.

35

Page 36

Setting Flash Parameters

6

NetView. You should then specify the longest possible lease time for the addresses, to help

prevent the loss of a given address through a device failure.

It is also strongly recommended that the DHCP server is configured such that the addresses

reserved for the Bristol controllers are permanently reserved (by tying them to the RTU MAC

addresses within the DHCP configuration or by having them in a totally different address range).

The same should be done when configuring RAS servers or other machines capable of providing

dynamic addressing information. Otherwise, you can easily have duplicate IP addresses on your

network.

Setting Application Parameters for Redundancy

Click on the ‘Application Parameters’ tab. Specify the IP addresses for unit "A" and unit "B".

These must correspond to the IP addresses you defined earlier for these units' respective Ethernet

ports.

Here you must enter the IP addresses

of both the “A” and “B” units in the

redundant pair. These addresses would

correspond to Ethernet ports configured

for each ControlWave. These addresses

MUST be different.

Setting other Flash Parameters

Additional Flash Parameters (user accounts, soft switches, audit/archive parameters, etc.) may

need to be defined, depending upon your particular user application. These should be done,

before proceeding.

If configuring I/O Expansion Racks, various timeouts must be defined, plus MODBUS users

must set certain parameters. See the ControlWave I/O Expansion Rack Quick Setup Guide

(document# D5122) for details.

For information on configuring parameters on other pages of the Flash Configuration utility,

please see the ControlWave Quick Setup Guide (document# D5084) and Chapter 5 of the Open

BSI Utilities Manual (document# D5081).

3

Page 37

Setting Flash Parameters

7

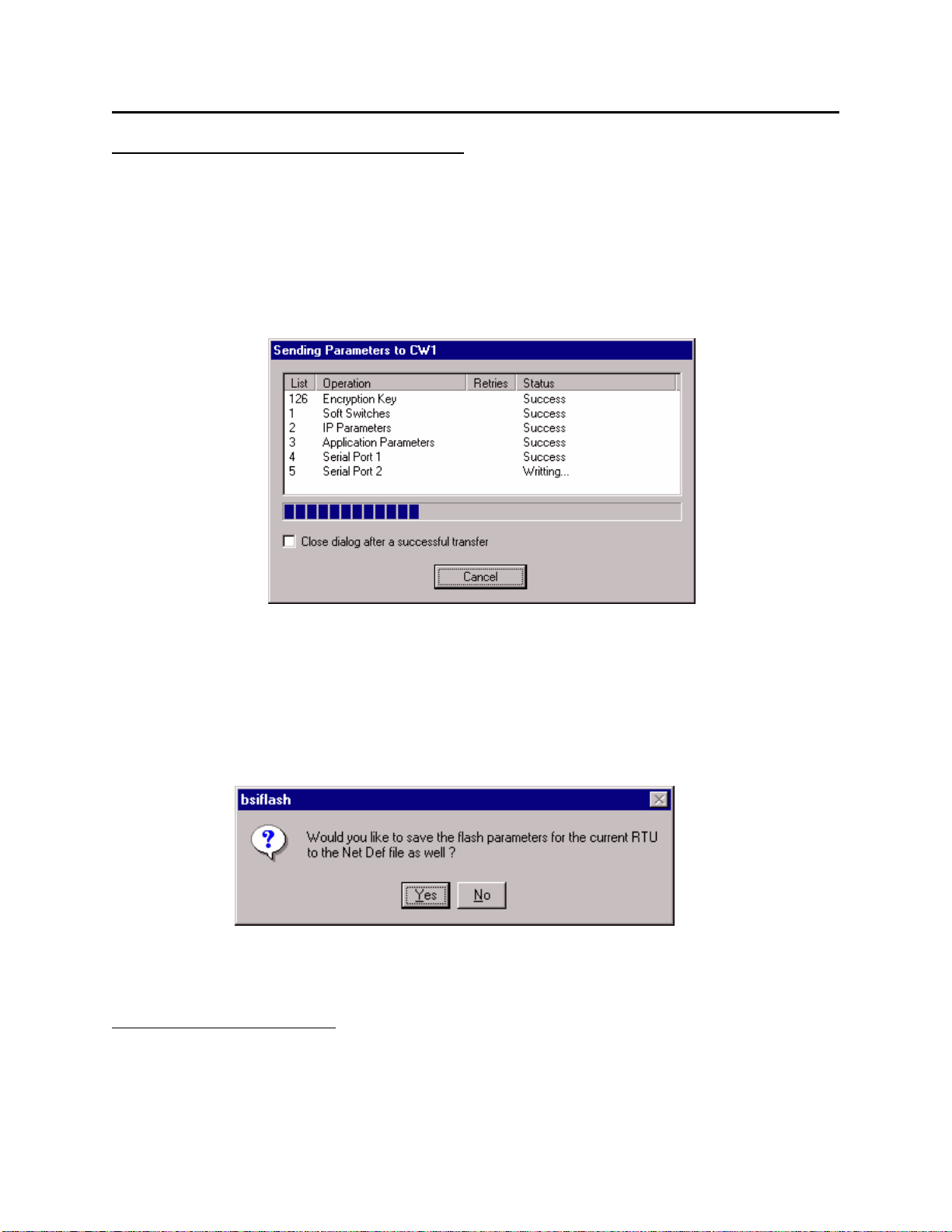

Saving the Flash Parameters to the Unit

When you’ve finished setting the Flash parameters, you must save them to the ControlWave unit,

in this case, unit A.

Click on the [Save to Rtu] button. This button saves ALL entries in the pages of the Flash

Configuration Utility to the ControlWave unit. NOTE: If you haven't signed on prior to clicking

on this button, you will be prompted to do so.

You will also be prompted whether or not to save these changes to the NETDEF file. Choosing

‘Yes’ in answer to this prompt avoids the need to re-enter the same configuration information in

NetView. This operation will only work when the Flash Configuration Utility is invoked from

within NetView or when LocalView is in Configure Mode; otherwise a permanent NETDEF file

is not available to write to6.

6

The reason other LocalView modes (e.g. 'Local' ) cannot perform these operations is that only 'Configure' mode

actually allows the user to specify a particular NETDEF file for modification (by checking the “Use an Existing

Configuration (.ndf) File” and then identifying the path and name of the NETDEF.) The other modes utilize a

temporary NETDEF which disappears on program exit.

3

Page 38

Setting Flash Parameters

Activating the newly saved parameters

After you have completed setting parameters on all the various pages of the Flash Configuration

Utility, you must save those entries to the ControlWave unit by clicking on the [Save to Rtu]

button. The new entries will be sent to the FLASH memory of the ControlWave unit.

For most of the parameters, the changes will NOT become active until you have reset the unit,

thereby forcing the parameters to be read by the system.

To reset the ‘A’ unit, power it OFF, and then back ON.

NOTE: If, after doing this, the new parameters still have not taken effect, make sure switch

SW1-3 was NOT incorrectly set to the OFF position. Switch SW1-3 must be ON (its

default position) for new FLASH parameters to be read.

Saving the same parameters to the other unit:

At this point, you have fully programmed the FLASH parameters for only one unit in the

redundant pair.

In order to act redundantly, the other unit must have an identical configuration. To do this, turn

the A/B Enable key switch on the CCRS or IORCM to ‘B’. Next, power on the other unit (in this

case ‘B’), and wait until its display shows either “00” (which indicates it has no project loaded),

or a blank screen (which indicates a project is loaded and running). NOTE: I/O Expansion Racks

don’t contain ControlWave projects, but their display will appear blank if they are operating

properly.

Click on [Save to Rtu] and the same parameters you saved on ‘A’ will be transferred to the ‘B’

unit. Turn OFF the power to unit ‘B’, then turn it back ON, and the new parameters will be

activated. You can now click on [Close] to exit the Flash Configuration Utility.

38

Page 39

Ethernet Connection Redundancy

Ethernet Connection Redundancy

In NetView, a single node (RTU) must be defined for the ControlWave Redundant Controller, or

pair of ControlWave Process Automation Controllers with an I/O Switcher.

This node will have two IP addresses "Primary Address" and "Secondary Address" which

correspond to IP addresses used to communicate with the controller. Typically, you would set

these to correspond to the ‘A’ and ‘B’ Ethernet Ports you defined for redundant transfer, but they

could be other Ethernet Ports you defined for the same node. You should also choose

"Symmetric Fallback"; this allows Open BSI to switchover to the alternate address if

communications are not possible on the current address. For more information on setting up

RTUs in NetView, see Chapter 6 of the Open BSI Utilities Manual (document# D5081).

Symmetric Fallback should be

chosen

39

Page 40

Testing the Redundant Setup (CPU and Power Supply)

C

ariables

Testing the Redundant Setup (CPU and Power Supply)

Before Testing Redundancy

Before attempting to test the redundant setup, it is recommended that you verify that each

ControlWave unit functions properly as a single stand-alone unit, by plugging in directly, and

attempting to communicate. Only when both ControlWave units have been successfully tested

operating in stand-alone mode, should redundancy testing begin.

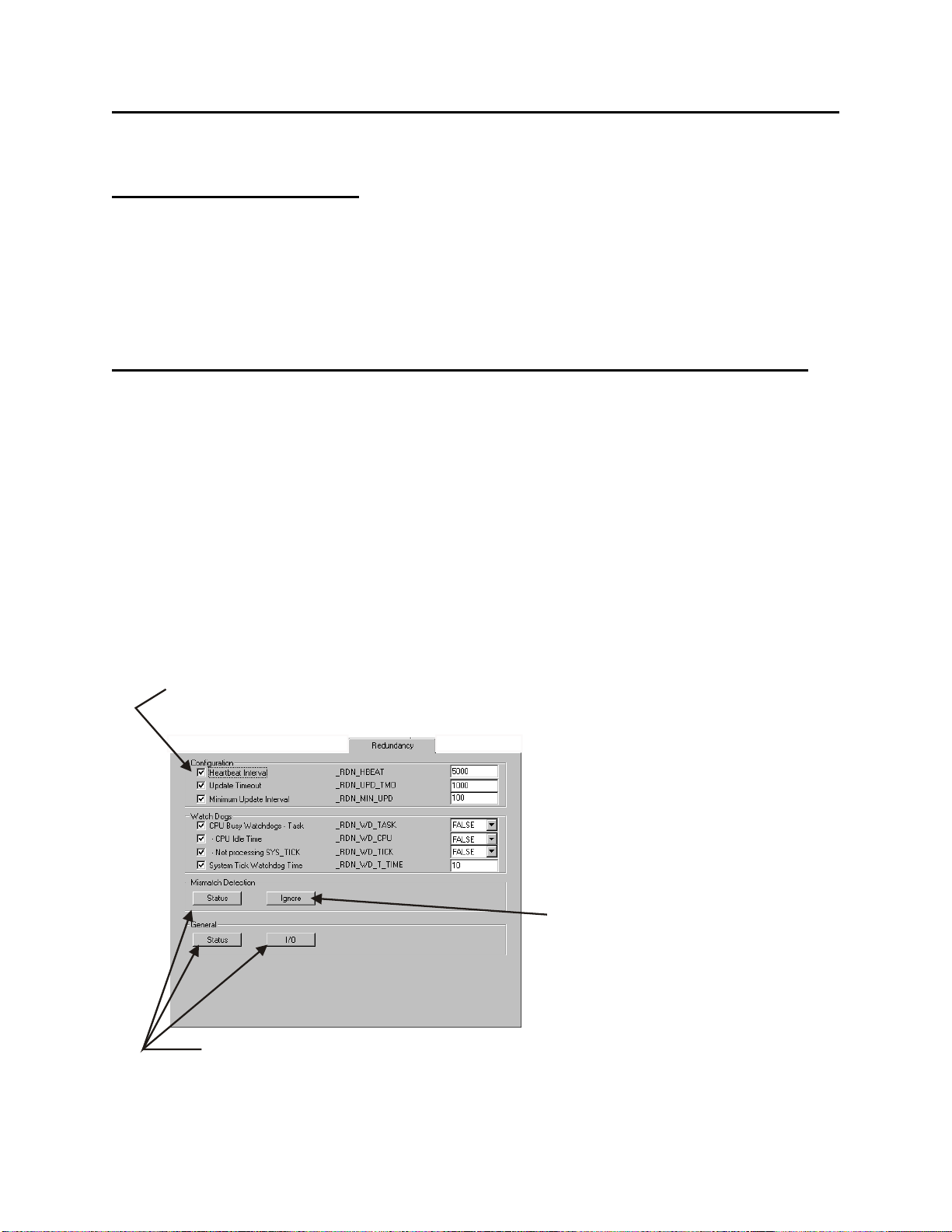

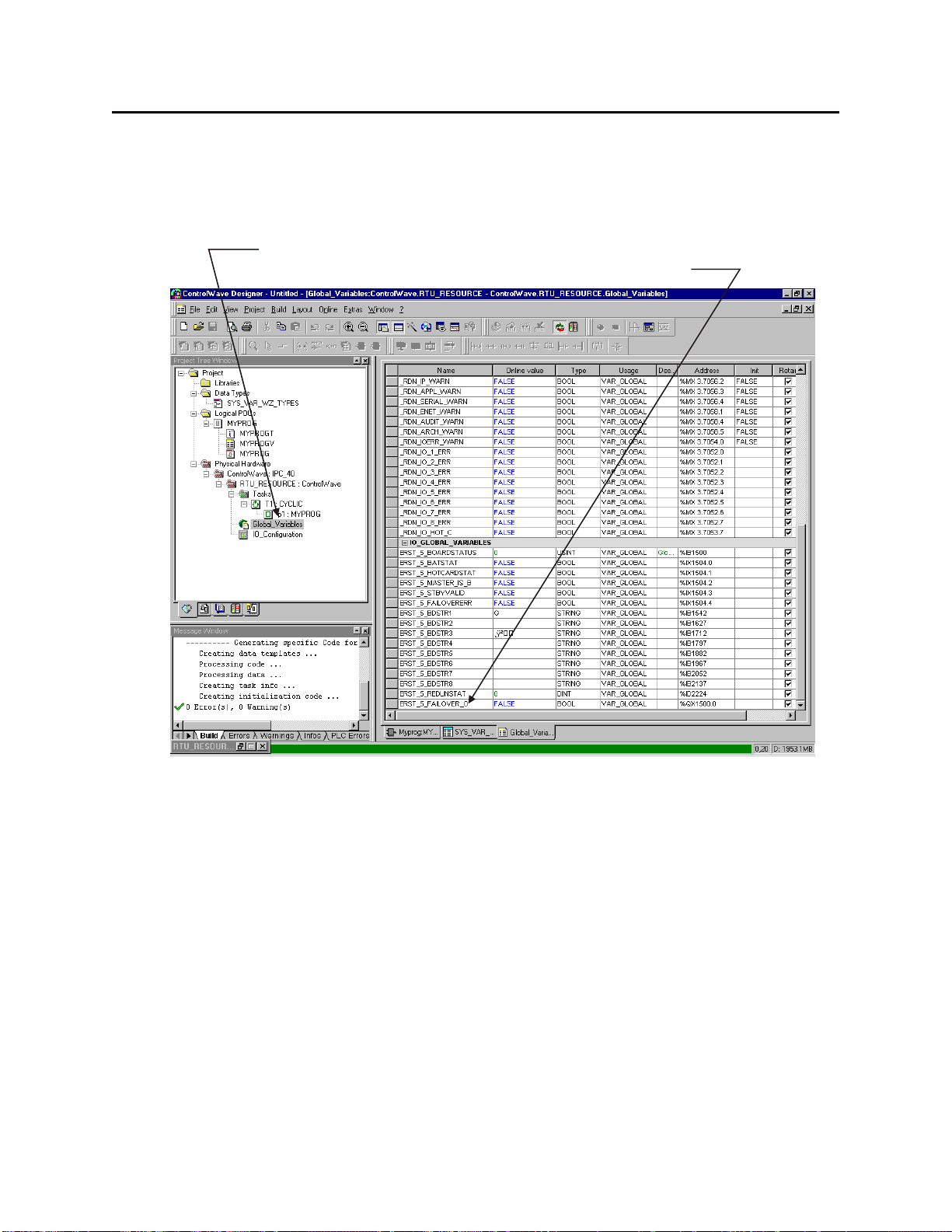

Using the Sample Redundant Project or Creating Your Own Redundant Project

RDNSAMPLE.ZWT is a zipped sample redundant project that is automatically installed in the

\OPENBSI\PROJECTS directory of your PC when you install the ControlWave Designer kit. It

is configured with redundancy status variables for monitoring the status of redundant operations.

NOTE: Any ControlWave project can serve as a redundant project, without changes, however, it

is recommended that the project be configured with redundancy status variables (such as in

RDNSAMPLE.ZWT) so that status and statistics regarding redundant operation can be viewed.

To add redundancy status variables to an existing project, call up the System Variable Wizard by

clicking on ViewÆSystem Variable Wizard, in ControlWave Designer, and check the

redundancy status variables on the ‘Redundancy’ page. See ‘Redundancy Status Variables’ later

in this manual for a description of each redundancy variable.

heck the boxes next to the various redundancy

variables to include them in your project.

This push button calls up a page

of redundancy variables which,

if selected, cause certain conditions

to be treated as ‘warnings’ instead

of ‘errors’ which would stop

redundancy from working.

These push buttons call up

additional pages of redundancy

v

.

40

Page 41

Testing the Redundant Setup (CPU and Power Supply)

Testing the Redundant Setup

NOTE: This test procedure does NOT address the subject of I/O Expansion Rack testing, since,

with the exception of power failure watchdog conditions, that is subject to user-defined criteria.

This test assumes the following:

• Unit “A” is already powered-on, and has been chosen as the primary unit using the Primary

switch on the CCRS or IORCM. (If you prefer to use “B”, substitute “A” for “B” and “B”

for “A” accordingly.)

• For this testing, your PC should be plugged into serial port COM2 of the CCRS or IORCM.

• The A/B Enable key switch is in the center position, i.e. automatic (not on ‘A’ or ‘B’).

The ControlWave Redundant Controller (or pair of ControlWave Controllers operating

redundantly) should NOT be connected to a running plant or process during this testing.

Safeguards must be taken prior to downloading to ensure that the controller is isolated

from the process and I/O is disconnected. Failure to take such precautions could result in

injury to persons or damage to property.

1. Power-ON the “B” unit, and wait for ‘BD’ to appear on the display.

2. Start ControlWave Designer, and open/unzip the project you want to use in the

ControlWave controller. (This could be the RDNSAMPLE project discussed earlier, or

another project you made yourself.)

3. Establish communications between

ControlWave Designer and the ControlWave

controller.

• Right-click on the RTU_RESOURCE in

the project tree, and choose "Settings"

from the menu. The Resource Settings

dialog box will appear.

• In the Resource Settings dialog box,

choose "DLL" for the 'Port'.

• Choose 'Serial' from the "DLL:" list box.

WARNING:

Right-click on the resource, and

choose from the menu.

"Settings"

41

Page 42

Testing the Redundant Setup (CPU and Power Supply)

d

• Specify the PC communication port (e.g. COM1), the baud rate, and the timeout in

milliseconds. For this example, we are using COM1, 9600 baud, 2000 millisecond

timeout.

Choose

"DLL"

Choose

"Serial"

Click on

[Ok]

when finishe

Specify the COM port, baud rate, and timeout (in msec)

• Click on [OK].

• Click on the 'Project Control Dialog' icon, and the RTU_RESOURCE dialog box will

appear.

Click on the ‘Project Control Dialog’ icon

42

Page 43

Testing the Redundant Setup (CPU and Power Supply)

t

4. Download the boot project into the ControlWave Redundant Controller (or ControlWave

Process Automation Controller belonging to a redundant pair).

• Click on [Download] in the RTU_RESOURCE

dialog box. The Download dialog box will appear.

• Now it is necessary to download the boot project into the controller. Since “A” is the

primary, the download will go to the “A” unit. In the Download dialog box, click on

[Download] in the ‘Bootproject’ section.

Click on to download the boot projec

[Download] .

Click on [Download]

43

Page 44

Testing the Redundant Setup (CPU and Power Supply)

C

• The download will not proceed if you

are not signed on. If you are not already

signed on, sign-on to the ControlWave,

by entering the username "SYSTEM"

and the password "666666" in response

to the Login prompt, then click on

[OK]. (NOTE: SYSTEM is a default

security account which is included in

the ControlWave when it ships from

the factory, so that you can access the

ControlWave during initial

configuration, before any other user

accounts have been defined.)

5. Activate the boot project, by clicking on the [Activate] button in the Download dialog

box. (If the Download dialog box is not visible, you can recall it by clicking on the

[Download] button in the RTU_RESOURCE dialog box.) As you activate the project,

the display on the “A” unit should show a ‘01’ code. Also, watch the display on the “B”

unit – it should momentarily show a ‘BC’ code as the side-load occurs, then a ‘BA’ code

when the side-load is complete. ‘BA’ (Backup Active) indicates that the “B” unit is

acting as the standby unit, and is ready to take over should the “A” unit fail.

lick here to activate the boot project.

44

Page 45

Testing the Redundant Setup (CPU and Power Supply)

6. At this point the “A” unit is loaded, but not yet running. Initiate

a cold start of the “A” unit by clicking on the [Cold] button in

the RTU_RESOURCE dialog box.

7. Now, enter Debug Mode in ControlWave Designer, by clicking on the debug

icon (shown at right)

8. Next, double-click on the Global_Variables worksheet in the tree, and locate the group

called SYS_VAR_WZ_DATA to view the system variables associated with redundancy.

In particular, look at the

variable called ‘_RDN_IS_B’,

and notice that it is FALSE.

9. Power-off the "A" unit, and

see if the "B" unit assumes

control as the new On-line

unit. (Momentarily, you will

see question marks for the

“Online value” of the

variables of the

SYS_VAR_WZ_DATA

group, then the screen will

refresh with data from the new

On-line unit.) The

‘_RDN_IS_B’ variable should

now show TRUE, verifying

that the “B” unit is now the

on-line unit.

45

Page 46

Notes on Redundant Operation

6

Notes on Redundant Operation

How do I force a fail-over to the Standby unit via program control?

IMPORTANT

If using Local I/O Redundancy, the only fail-overs (other than watchdog conditions) are

handled via the REDUN_SWITCH method, described, below. Users must define I/O failover criteria in their ControlWave project.

NOTE: To force a fail-over from one I/O Expansion Rack to another rack requires a

different method. See ‘Forcing I/O Expansion Rack Fail-over’.

If desired, the user can trigger a redundant fail-over from On-line unit to the Standby unit based

on conditions detected in the software.

To do this, users must incorporate the REDUN_SWITCH function into their project.

Excerpts from a POU using the REDUN_SWITCH function block in structured text (ST) are

shown below. Comments appear in italics:

IF (SWITCHNOW) We are putting this at the top of the POU. If SWITCHNOW is TRUE a failover occurs

right at the top. This ensures that failover doesn’t occur in the middle of the POU, which

would cause all changes within that execution cycle to be lost.

THEN

RDSTAT:=REDUN_SWITCH(SWITCHNOW);

SWITCHNOW:=FALSE;

;

ENDIF;

:

: the main body of the POU would appear here. Somewhere in here, a test to determine

: whether a failure has occurred requiring a switchover must be made. The condition causing the

failure can be anything the user chooses.

FAILURE:= some failure condition logic must be added here

:

:

IF (FAILURE) At the bottom of the POU, if the FAILURE condition, determined in the main body is

TRUE, then SWITCHNOW is set TRUE, so at the top of

the next execution cycle, the fail-over will occur.

THEN

SWITCHNOW:=TRUE;

ELSE

SWITCHNOW:=FALSE;

ENDIF

FAILURE:=FALSE;

In the structured text code, we use the REDUN_SWITCH function block, which takes the format

4

Page 47

Notes on Redundant Operation

7

S

statuscode:=REDUN_SWITCH(ibEnable)

Whenever the ibEnable variable is TRUE, a fail-over will be attempted immediately.

Some other things you should be aware of when using the REDUN_SWITCH function block:

• When using the REDUN_SWITCH function block, the condition that forces the fail-over, in

this case, the FAILURE variable, should be a local, non-retain variable. The reason for this is

that if the variable is retained, there is a possibility of repeated switchovers between A and B

since the same failure condition value would be transferred from the on-line to the standby,

causing the new on-line unit to try to fail back, and so on.

• As soon as the REDUN_SWITCH function block executes with a TRUE ibEnable variable,

the fail-over process begins immediately, no additional lines of code in the task are executed.

For this reason, we recommend that the REDUN_SWITCH function block always be placed

at the very beginning of the POU, to prevent a switchover in the middle of partial

calculations, which would have to be discarded (see next item).

The following items apply whether or NOT you are using REDUN_SWITCH in your

redundant system:

• Whenever an application-level task completes its

execution cycle, an update occurs. (In an update, all

changes to retain variables, I/O, historical data, etc.

On-Line Unit

RETAIN

VARIABLES

tandby Unit

RETAIN

VARIABLES

are sent to the standby unit, to keep it up-to-date.) If

a fail-over occurs somewhere during the task’s

I/O

I/O

execution, changes resulting from that particular

task execution will NOT be sent to the backup.

(Partial updates can occur, however, if there is an

overlap in the execution cycles of more than one

task. As soon as the first of the overlapping tasks

completes execution, an update of ALL changes to

retain memory, historical data, I/O, etc. will be sent

to the standby unit, even for items which were

partially updated by the task which did not finish

HISTORICAL

DATA

At the completion of

the execution cycle of

ANY task, all changes

for these items are sent

from the online unit to

the standby unit; whether

or not they have to do with

that particular task.

HISTORICAL

DATA

yet.)

For this reason, although you can have multiple program POUs in your project, we