User’s Guide

pp

s

Click here to return to the Table of Contents

D5132

October, 2008

ristol ControlWave Pump Controller A

Bristol ControlWave Pump Controller

Application User’s Guide

lication

Remote Automa tio n Solution

www.EmersonProcess.com/Remote

BLANK PAGE

Click here to return to the Table of Contents

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

Contents

Chapter 1 – Introduction 1-1

1.1 Scope of this Manual.................................................................................................................1-1

1.2 Overview ...................................................................................................................................1-2

Chapter 2 – Installation 2-1

2.1 Before You Begin......................................................................................................................2-1

2.2 Downloading the Application from the Web Site.......................................................................2-2

2.3 Installing the Application ...........................................................................................................2-2

2.4 Updating an Existing Controller with the Pump Controller Application.....................................2-9

2.4.1 Loading the Flash Configuration Profile (FCP) File....................................................2-10

2.4.2 Downloading the ControlWave Project.......................................................................2-13

Chapter 3 – Configuration 3-1

3.1 Starting the Configuration Wizard.............................................................................................3-3

3.2 Pump Configuration ..................................................................................................................3-4

3.2.1 Configure Pumps ..........................................................................................................3-5

3.3 Variable Frequency Drive (VFD) Configuration ........................................................................3-6

3.3.1 Configure VFD ..............................................................................................................3-7

3.3.2 Configure Fixed Speed Pump Control..........................................................................3-8

3.4 Single Loop Controller (SLC) Configuration..............................................................................3-9

3.4.1 Configure the SLC.......................................................................................................3-10

3.5 Station Flow.............................................................................................................................3-11

3.5.1 Configure Flow Input...................................................................................................3-13

3.5.2 Configure Estimated Flow Input..................................................................................3-14

3.5.3 Configure Flow Totalization.........................................................................................3-15

3.6 Alarm Limit Configuration........................................................................................................3-17

3.7 Discharge Pressure Measurement and Control......................................................................3-19

3.7.1 Configure Discharge Pressure Input...........................................................................3-20

3.7.2 Configure Discharge Pressure Control.......................................................................3-21

3.7.3 Configure Discharge Pressure Override Control ........................................................3-22

3.8 Suction Pressure Measurement and Control..........................................................................3-24

3.8.1 Configure Suction Pressure Input...............................................................................3-25

3.8.2 Configure Suction Pressure Override.........................................................................3-26

3.9 Local Tank Level Measurement and Control..........................................................................3-28

3.9.1 Configure Level Input..................................................................................................3-29

3.9.2 Configure Level Control ..............................................................................................3-31

3.9.3 Configure Level Override............................................................................................3-32

3.10 Remote Tank Level Measurement and Control......................................................................3-34

3.10.1 Configure Level Input..................................................................................................3-35

3.10.2 Configure Level Control ..............................................................................................3-36

3.10.3 Configure Level Override............................................................................................3-37

3.11 Well Drawdown Level Measurement and Control...................................................................3-40

3.11.1 Configure Well Drawdown Level Input........................................................................3-41

3.11.2 Configure Well Drawdown Level Override..................................................................3-42

3.12 Time Control............................................................................................................................3-44

3.12.1 Configure Timeclock Control.......................................................................................3-45

3.12.2 Configure Restricted Time of Use Override................................................................3-47

3.13 Station Control.........................................................................................................................3-49

3.14 Chlorine Residual....................................................................................................................3-51

Issued Oct-08 Contents iii

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3.14.1 Configure CL2 Residual Monitor Input........................................................................3-52

3.15 Configure pH Monitor..............................................................................................................3-53

3.15.1 Configure pH Monitor Input.........................................................................................3-54

3.16 Chemical Feed Pump..............................................................................................................3-55

3.17 Rain Gauge.............................................................................................................................3-56

3.17.1 Configure Rain Gauge Input.......................................................................................3-57

3.18 I/O Configuration.....................................................................................................................3-58

3.18.1 Configure All I/O..........................................................................................................3-59

3.18.2 Configure CL2 Probe..................................................................................................3-64

3.18.3 Configure pH Probe ....................................................................................................3-65

3.19 Recipe.....................................................................................................................................3-66

3.19.1 Creating a Recipe .......................................................................................................3-67

3.19.2 Changing the Floating Point Format of Values...........................................................3-68

3.19.3 Saving the Recipe.......................................................................................................3-69

3.19.4 Recalling a Saved Recipe, and Sending Its Values to the Pump Controller..............3-69

3.20 Saving the Configuration.........................................................................................................3-70

Chapter 4 – Start Up 4-1

4.1 I/O Checkout.............................................................................................................................4-2

4.2 SLC Tuning...............................................................................................................................4-3

4.3 Pump Checkout.........................................................................................................................4-4

4.3.1 Permissive and Interlock Details...................................................................................4-7

Chapter 5 – Operation 5-1

5.1 Fixed Speed (FS) Pump Control Settings.................................................................................5-2

Chapter 6 – Logs 6-1

6.1 View Archives............................................................................................................................6-2

6.2 View Audit Trail.........................................................................................................................6-6

6.2.1 Data Storage.................................................................................................................6-7

6.2.2 Search Criteria..............................................................................................................6-8

6.3 Collection ..................................................................................................................................6-9

iv Contents Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

Chapter 1 – Introduction

This manual explains how to install and configure the ControlWave

Pump Controller application. This application may be used with either

ControlWave MICRO or ControlWave Express controllers.

Chapter 1 details the structure of the manual, and discusses the basic

features of the ControlWave Pump Controller application.

In This Chapter

1.1 Scope of this Manual.......................................................................1-1

1.2 Overview..........................................................................................1-2

1.1 Scope of this Manual

This manual is divided up into the following chapters:

Chapter 1

Introduction

Chapter 2

Installation

Chapter 3

Configuration

Chapter 4

Start Up

Chapter 5

Operation

Chapter 6

Logs

Describes the organization of the manual, and the

basic features of the ControlWave Pump Controller

application.

Describes how to install the ControlWave Pump

Controller pages on your PC.

Describes how to use the configuration menus of the

application to configure the ControlWave Pump

Controller.

Describes how to use the startup menus of the

ControlWave Pump Controller application.

Describes how to use the operation menus of the

ControlWave Pump Controller application.

Describes how to retrieve historical data (archive

files, audit trail data) from the ControlWave Pump

Controller.

Other relevant documentation you may need to refer to:

For help on this: Refer to these document(s):

Installing the controller hardware,

wiring I/O, connecting

communication cables to the PC, etc.

Depending upon the type of controller

model you purchased, either

CI-ControlWave MICRO -or-

Using portions of the TechView

software related to calibration or online editing.

Issued Oct-08 Introduction 1-1

CI-ControlWaveExpress

TechView User’s Guide (D5131)

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

1.2 Overview

The Emerson ControlWave Pump Controller is a pre-programmed

application that may be configured by the user to perform a variety of

pump station control actions.

These actions include starting and stopping up to 3 fixed speed pumps

based on:

a local or remote tank level indication,

tank floats,

local discharge and suction pressure,

well drawdown level and

time of day.

In addition, the fixed speed pumps may be operated to supplement a

single variable frequency drive (VFD) pump.

The VFD may be operated to maintain either flow or discharge pressure

setpoints.

The ControlWave Pump Controller monitors other typical parameters at

a pump station, including chlorine residual, pH, and intrusion alarms.

The ControlWave Pump Controller generates alarms when any of these

parameters exceed operator specified alarm limits, and maintains

historical information (minimum, maximum, and averages or totals) on

an hourly and daily basis.

There is no programming required to use the ControlWave Pump

Controller. The user configures the controller using OpenBSI

TechView, which presents operator menus for performing

configuration, monitoring, and operating the pump station. Initial

configuration can be done using the Configuration Wizard, which

presents the user with a series of questions to be answered. After

configuring the initial site, configuring additional sites can be performed

by copying a previous configuration into the new ControlWave Pump

Controller.

1-2 Introduction Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

The ControlWave Pump Controller is available in the following

configurations:

Platform I/O Boards Configuration

ControlWave MICRO 2 Mixed I/O Boards CWM_2M

ControlWave MICRO 1 Mixed I/O Board

CWM_1M_1D

1 Mixed DI/O Board

ControlWave MICRO 1 Mixed DI/O Board

CWM_1D_1A

1 Mixed AI/O Board

ControlWave Express

PAC

1 I/O Expansion

Board

MPMP_1_0_D

Each of these configurations comes standard with two (2) RS-232 ports

and one (1) RS-485 port. An Ethernet port can be added as an option to

each.

A Keypad/Display is available as an option with each of these units.

The available I/O for each configuration is shown below:

Configuration DI DO DI/O AI AO HSC CNT/DI

CWM_2M 0 0 12 8 2 4 0

CWM_1M_1D 12 4 6 4 1 2 0

CWM_1D_1A 12 4 0 6 2 0 0

ExpressPAC 4 2 2 3 1 2 2

Issued Oct-08 Introduction 1-3

Click here to return to the Table of Contents

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

Chapter 2 – Installation

Chapter 2 discusses some preliminary activities which must be

performed before you start, and then covers the process of loading the

ControlWave Pump Controller application pages onto your PC.

In This Chapter

2.1 Before You Begin.............................................................................2-1

2.2 Downloading the Application from the Web Site .............................2-2

2.3 Installing the Application..................................................................2-2

2.1 Before You Begin

Verify that the latest version of OpenBSI or BSIConfig is installed on

your PC. To confirm that the software is installed, click on Start Æ

Programs and look for a program group called OpenBSI or BSIConfig

Issued Oct-08 Installation 2-1

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

Verify that the ControlWave Pump Controller is wired to the field

devices and power is applied to the unit.

2.2 Downloading the Application from the Web Site

In your Internet browser, go to the Remote Automation Solutions web

site, at the following address:

http://www.bristolbabcock.com/services/members/application_files/ap_

controlwave_std_programs.htm

Download the file PUMP_APP.EXE, and save it on your desktop

2.3 Installing the Application

STEP 1

Double-click on the MPMP_1_0.EXE icon (saved as an icon on your

desktop in the previous step.).

STEP 2

Click on Unzip to extract the required files to the C drive. The program

will automatically install the required files in the

C:\OpenBSI\WebWaterApp folder. If this folder does not exist, it will

be created. Close the WinZip Self Extractor.

2-2 Installation Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

STEP 3

Two Icons will now be available from the Desktop – mH2OIP.tvs is

used to connect to the ControlWave Pump Controller via Ethernet and

mH2OSerial.tvs is used to connect to the ControlWave Pump Controller

via a serial RS-232 connection.

If you have purchased a ControlWave Pump Controller, or have already

re-configured your ControlWave Micro or ControlWave Express as a

ControlWave Pump Controller, proceed to STEP 4.

To reconfigure a previously purchased ControlWave Micro or

ControlWave Express as a ControlWave Micro Pump Controller,

proceed to the instructions in Sections 2.4.1 and 2.4.2 then return to

STEP 4.

STEP 4

To connect to a ControlWave via a serial RS-232 connection, connect a

null modem serial cable (P/N 392843-01-3) between a serial port on

your PC and COM1 (the C1 port) on the ControlWave Micro or

ControlWave Express. If you don’t have a null modem serial cable, you

can build one according to the instructions in the controller’s hardware

manual. After the connection is made, proceed to STEP 5A

If you wish to connect to the ControlWave Pump Controller using

Ethernet, and if the desired IP Address of the Controller has already

been set in the Controller, make an Ethernet connection between the PC

and the Controller. This can be done by connecting a null modem

Ethernet cable directly between the Ethernet Port on the Controller and

the Ethernet Card on your PC, or connecting an Ethernet patch cable

between the Controller and an Ethernet Switch and a second patch cable

between the Ethernet Switch and the PC. Please proceed to STEP 5B

.

Issued Oct-08 Installation 2-3

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

If the IP Address in the Controller has not been set, follow the

instructions in Section 2.4.1 and then return to STEP 5B.

STEP 5A

Start TechView by double clicking on the mH2OSerial.tvs shortcut on

the Desktop.

Ignore the question regarding the number of runs.

By default, the TechView session assumes the Local Address of the unit

is 1. If you have previously changed the Local Address of the

ControlWave Pump Controller, select the correct address from the drop

down menu.

By default, the TechView session uses COM1 from your PC. If the

communications port being used on your PC is a port other than COM1,

change it by using the drop down menu.

By default, the TechView session communicates at a baud rate of

115200. It is strongly recommended that you use this speed to

communicate with the ControlWave Pump Controller via TechView. If

it was necessary to change the baud rate of the ControlWave Pump

Controller, select the proper baud rate from the drop down menu.

Click on OK.

2-4 Installation Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

You will be prompted for a Username and Password. By default, the

Username is SYSTEM and the Password is 666666. Enter the

Username and Password and click on Signon.

Proceed to STEP 6

STEP 5B

Start TechView by double clicking on the mH2OIP.tvs shortcut on the

Desktop.

Enter the IP Address of the

Pump Controller.

Click on OK.

You will be prompted for a

Username and Password. By

default, the Username is

SYSTEM and the Password is

666666. Enter the Username

and Password and click on

Signon.

Proceed to STEP 6

Issued Oct-08 Installation 2-5

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

STEP 6

If TechView is successfully connected to the ControlWave Pump

Controller, you should see the screen below. To start configuring the

ControlWave Pump Controller, proceed to STEP 7.

If TechView is unable to connect to the ControlWave Pump Controller,

you will see the ‘Node currently off-line’ message. Verify that your

communication configuration parameters are correct (address, port, etc.)

are correct, and that cables are connected properly.

2-6 Installation Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

STEP 7

If you see the screen below, you have successfully connected to the

ControlWave Pump Controller with TechView.

Along the right hand side of the screen are some icons.

NOTE: This option is not applicable to this application.

Clicking on the On-Line Edits icon allow certain limited edits to be

made to lists and archive files. For details on on-line edits, please

see the TechView User’s Guide (document# D5131).

Clicking on the Station icon allows you to call up the menus for

configuring the ControlWave Pump Controller application.

Click on the Station icon.

Station icon

Issued Oct-08 Installation 2-7

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

By clicking on the System Information button, the following screen will

be displayed.

This page is a summary of System Information. A comparison of the

CPU Type, Firmware Revision, and I/O cards is made between the

actual and required. If everything is OK, the screen will appear as

above. If there is a mismatch detected, some items will be highlighted,

as shown in the screen below:

2-8 Installation Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

Before proceeding, any I/O card mismatches must be resolved.

WARNING

If you fail to resolve IO Card mismatches the ControlWave

Pump Controller will not operate properly.

If you have a mismatched PROM version, verify that the actual PROM

version is older than the desired PROM version (for instance, PROM

version V04:60:00 is older than V04:72:00; PROM version V04:80:00

is newer than V04:72:00).

Using an older PROM Version or Web Page Version may cause some

of the features of the ControlWave Pump Controller program to

function improperly.

If you do have an older PROM version, you may upgrade by

downloading the latest firmware from our web site:

www.bristolbabcock.com/services/members/application_files/Contract/f

lashware/controlwave_flashware.htm

In order to be able to download the latest firmware, you must be a

Software Support Plan member. If you are unsure if you are a Software

Support Plan member, please contact your local sales representative.

Close this page by clicking on the . button.

2.4 Updating an Existing Controller with the Pump Controller Application

If you have an existing ControlWave MICRO, or ControlWave Express,

already installed in the field, with the required I/O, and want to update it

to run the pump controller application, you will need to:

Load the Flash Configuration Profile (FCP) file for the Pump

Controller application.

Download the appropriate ControlWave project into the unit.

Issued Oct-08 Installation 2-9

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

2.4.1 Loading the Flash Configuration Profile (FCP) File

1. In TechView, click on Operations Æ Access Flash Parameters

-or- click on the ‘Access Flash’ icon, to start the Flash

Configuration Utility.

Access Flash icon

2. In the Flash Configuration Utility, click on the [Read Profile from

File] button.

2-10 Installation Issued Oct-08

Click on the [Read Profile

From File] button

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3. Choose the FCP file for the water application, located in the

\OpenBSI\WebWaterApp\Config folder, and click on [Open].

Choose the FCP file, then click on

[Open].

Issued Oct-08 Installation 2-11

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

4. The FCP file for the ControlWave Pump Controller application will

be opened. If you need to set the proper IP address for the controller,

click on the ‘Ports’ tab, and enter the address in the “IP ADDR A:”

field.

Enter the IP address here

5. When you have completed any necessary edits, click on the [Save to

Rtu] button.

6. When prompted to confirm that you want to proceed, click [Yes].

The FCP file will be copied into the ControlWave for you.

When finished, click on [Save to Rtu]

Click [Yes]

2-12 Installation Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

2.4.2 Downloading the ControlWave Project

1. Right-click on the ‘RTU’ icon in TechView, and choose

“Downloader” from the pop-up menu.

2. Click on the [Browse Bootfile] button, and navigate to the

\MPMP_V_vv subfolder of the Downloads directory, where V is the

major file version, and vv is the minor file version. NOTE: In these

examples, the version shown is 1_0D, however; your version will

be different.

Click on the [Browse Bootfile] button,

and navigate to the \MPMP_V_vv

folder.

Issued Oct-08 Installation 2-13

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3. From that folder, you need to select the resource sub-folder which

contains the project file (*.PRO) you need to download. (See

Section 1.2 for details on the different resources.)

4. Once you have selected the project which has the correct

configuration for your hardware, click on it, then click on [Open].

2-14 Installation Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

5. In the Downloader, enter a valid username/password combination

for the controller, then click on [Begin]. The project (.PRO file) will

be downloaded into the ControlWave unit.

Enter a valid “Username”/”Password”

combination, then click on [Begin].

Issued Oct-08 Installation 2-15

Click here to return to the Table of Contents

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

Chapter 3 – Configuration

This chapter covers the steps necessary to configure the ControlWave

Pump Controller application.

In This Chapter

3.1 Starting the Configuration Wizard....................................................3-3

3.2 Pump Configuration.........................................................................3-4

3.2.1 Configure Pumps..................................................................3-5

3.3 Variable Frequency Drive (VFD) Configuration...............................3-6

3.3.1 Configure VFD......................................................................3-7

3.3.2 Configure Fixed Speed Pump Control .................................3-8

3.4 SLC Configuration ...........................................................................3-9

3.4.1 Configure the SLC..............................................................3-10

3.5 Station Flow ...................................................................................3-11

3.5.1 Configure Flow Input ..........................................................3-13

3.5.2 Configure Estimated Flow Input.........................................3-14

3.5.3 Configure Flow Totalization................................................3-15

3.6 Alarm Limit Configuration ..............................................................3-17

3.7 Discharge Pressure Measurement and Control ............................3-19

3.7.1 Configure Discharge Pressure Input..................................3-20

3.7.2 Configure Discharge Pressure Control ..............................3-21

3.7.3 Configure Discharge Pressure Override Control................3-22

3.8 Suction Pressure Measurement and Control.................................3-24

3.8.1 Configure Suction Pressure Input ......................................3-25

3.8.2 Configure Suction Pressure Override ................................3-26

3.9 Local Tank Level Measurement and Control.................................3-28

3.9.1 Configure Level Input .........................................................3-29

3.9.2 Configure Level Control......................................................3-31

3.9.3 Configure Level Override ...................................................3-32

3.10 Remote Tank Level Measurement and Control.............................3-34

3.10.1 Configure Level Input .........................................................3-35

3.10.2 Configure Level Control......................................................3-36

3.10.3 Configure Level Override ...................................................3-37

3.11 Well Drawdown Level Measurement and Control .........................3-40

3.11.1 Configure Well Drawdown Level Input...............................3-41

3.11.2 Configure Well Drawdown Level Override .........................3-42

3.12 Time Control ..................................................................................3-44

3.12.1 Configure Timeclock Control..............................................3-45

3.12.2 Configure Restricted Time of Use Override .......................3-47

3.13 Station Control...............................................................................3-49

3.14 Chlorine Residual ..........................................................................3-51

3.14.1 Configure CL2 Residual Monitor Input...............................3-52

3.15 Configure pH Monitor.....................................................................3-53

3.15.1 Configure pH Monitor Input................................................3-54

3.16 Chemical Feed Pump ....................................................................3-55

3.17 Rain Gauge....................................................................................3-56

3.17.1 Configure Rain Gauge Input...............................................3-57

3.18 I/O Configuration............................................................................3-58

3.18.1 Configure All I/O.................................................................3-59

3.18.2 Configure CL2 Probe..........................................................3-64

3.18.3 Configure pH Probe............................................................3-65

3.19 Recipe............................................................................................3-66

3.19.1 Creating a Recipe...............................................................3-67

Issued Oct-08 Configuration 3-1

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3.19.2 Changing the Floating Point Format of Values ..................3-68

3.19.3 Saving the Recipe ..............................................................3-69

3.19.4 Recalling a Saved Recipe, and Sending Its Values to the Pump

Controller............................................................................3-69

3.20 Saving the Configuration ...............................................................3-70

To configure the ControlWave Pump Controller, click on the Configure

tab and then click on the Station Configuration Wizard button.

The System Information screen was discussed earlier in Section 2.3.

First, click on the ‘Configure’ tab,

then click on the Station

Configuration Wizard button.

This will open the Configuration Wizard screens.

3-2 Configuration Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3.1 Starting the Configuration Wizard

The Station Configuration Wizard asks you questions to assist you in

configuring the ControlWave Pump Controller.

WARNING

While configuring the ControlWave Pump Controller, the user

will be able to change I/O assignments, modify start and stop

setpoints, and adjust alarm limits, etc. It is up to the user to

make sure that all equipment is made safe. Before putting the

controller in the configuration mode, it is recommended that any

associated processes be closed down or placed under manual

control. This precaution will prevent any processes from

accidentally running out of control while configuration is being

done.

To start the Configuration Wizard, click

on the [Start?] button. Clicking on the

Start button does two things:

It saves the current configuration in a temporary file on the

ControlWave Pump Controller. This configuration may be restored

at any time (See Section 3.20).

It also allows the user to enter the Configuration Wizard screens. If

the screen does not say Configuring, the user is not permitted to go

forward in the configuration process.

Issued Oct-08 Configuration 3-3

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

There are two ways to navigate through the Configuration Wizard:

Click on the NEXT button at the bottom of each page to sequentially

move through the configuration, -or-

Use the ‘Select a Device’ drop down menu, to choose a particular

item to configure, and then click on Configure. (This option is

accessible from all of the main configuration pages, and allows the

user to quickly navigate the system to make changes to a particular

item.)

3.2 Pump Configuration

The first screen allows the user to choose how many fixed speed pumps

are included in the system. Selection of and configuration of the

variable speed drive (VFD) will be done in a separate step.

3-4 Configuration Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

To select the number of

pumps to be included,

right click on the data

entry field (the white

field with the black text),

and left click on Change

Signal Value.

This will bring up a drop

down menu. You may

choose none, 1, 2, or 3

Pumps, and then click on

OK.

Once the number of pumps has been selected, the user may configure

the pumps by clicking on the CONFIGURE PUMPS button.

3.2.1 Configure Pumps

From this screen, the user may provide a unique descriptor for each

pump, and set other parameters for the pump controls.

Issued Oct-08 Configuration 3-5

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

Field Description

MODE

START DELAY

(Seconds)

RESPONSE

DELAY

(Seconds)

MINIMUM

RUNTIME

(Seconds)

MAXIMUM

STARTS/HOUR,

MAXIMUM

STARTS/DAY

The user may select between 2 WIRE or 3 WIRE. 2 WIRE

control is used when there is a single maintained contact for

starting the pump. 3 WIRE control is used when there is

one momentary start contact and one momentary stop

contact for starting and stopping the pump.

The amount of time, in seconds, that the program will wait

after receiving a start command before it turns on the start

DO.

The amount of time, in seconds, that the program will wait

for a positive indication that the pump has started or stopped

after a start or stop DO is turned on.

The amount of time, in seconds, that the pump will run after

being started, even if a stop command is issued. The pump

will be stopped immediately if the pump interlock conditions

are not met.

This represents the maximum starts per hour or day that will

be allowed for the pump. After the maximum starts are

attempted in a period, any additional start attempts will be

ignored.

To return to the previous screen, click on BACK.

3.3 Variable Frequency Drive (VFD) Configuration

3-6 Configuration Issued Oct-08

Clicking on CONFIGURE VFD will bring up a page similar to the page

Click here to return to the Table of Contents

for configuring the pumps. (See 3.3.1)

The VFD speed may be used to control the operation of the fixed speed

pumps. Typically, a fixed speed pump would be started if the VFD

speed reached some high limit, and then the fixed speed pump would be

stopped if the VFD speed reached some low limit. If this option is

required click on CONFIGURE FIXED SPEED PUMP CONTROL.

(See 3.3.2)

3.3.1 Configure VFD

ControlWave Pump Controller Application User’s Guide (D5132)

The only difference between this page and the pump configuration page

is that the analog output used to control the VFD is configured on this

page.

Field Description

MODE

The user may select between 2 WIRE or 3 WIRE. 2 WIRE

control is used when there is a single maintained contact for

starting the VFD. 3 WIRE control is used when there is one

momentary start contact and one momentary stop contact

for starting and stopping the VFD.

START DELAY

(Seconds)

Issued Oct-08 Configuration 3-7

The amount of time, in seconds, that the program will wait

after receiving a start command before it turns on the start

DO.

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

RESPONSE

DELAY

(Seconds)

MINIMUM

RUNTIME

(Seconds)

MAXIMUM

STARTS/HOUR,

MAXIMUM

STARTS/DAY

OUTPUT ZERO

OUTPUT SPAN

OUTPUT UNITS

The amount of time, in seconds, that the program will wait

for a positive indication that the VFD has started or stopped

after a start or stop DO is turned on.

The amount of time, in seconds, that the VFD will run after

being started, even if a stop command is issued. The VFD

will be stopped immediately if the pump interlock conditions

are not met.

This represents the maximum starts per hour or day that will

be allowed for the VFD. After the maximum starts are

attempted in a period, any additional start attempts will be

ignored.

This is the speed command sent to the VFD when the

output is 4 mA or 1 Volt.

The difference between the value of the speed command at

4 mA (or 1 volt) and its value at 20 mA (5 volts).

instance, if the ZERO is 5.0 Hz and the SPAN is 85.0 Hz,

the SPAN is 80.0.

This is the engineering units of the speed command.

To return to the VFD screen, click on BACK.

For

3.3.2 Configure Fixed Speed Pump Control

3-8 Configuration Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

Depending on the number of fixed speed pumps configured, the user

may assign up to three start setpoints and three stop setpoints, to control

the operation of the fixed speed pumps.

Field Description

START

SETPOINT

STOP

SETPOINT

START

COMMAND

STOP

COMMAND

If the actual VFD speed exceeds this value, the START

COMMAND will be activated to start the associated fixed

speed pump.

If the actual VFD speed falls below this value, the STOP

COMMAND will be activated to stop the associated fixed

speed pump.

The START command is activated (and displays ‘START’ in

this field) when the actual VFD speed exceeds the START

SETPOINT. Otherwise, this field displays ‘OFF’.

The STOP command is activated (and displays ‘STOP’ in this

field) when the actual VFD speed falls below the STOP

SETPOINT. Otherwise, this field displays ‘OFF’.

3.4 Single Loop Controller (SLC) Configuration

If there is a VFD being used, then the Single Loop Controller (SLC)

function must be included to provide PID control to the VFD.

To configure the Single Loop Controller click on CONFIGURE THE

SLC. (See 3.4.1).

Issued Oct-08 Configuration 3-9

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3.4.1 Configure the SLC

Field Description

PV1/PV2

SOURCE

The source of each process variable may be selected from this

list: Discharge Pressure, Suction Pressure, Local Level,

Remote Level, Drawdown Level, Chlorine Residual, a Fixed

Value, or Zero (0.0)

PV1/PV2

ZERO

3-10 Configuration Issued Oct-08

The value of the process variable (PV1 or PV2) at 4 mA or 1

volt.

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

PV1/PV2

SPAN

PV1/PV2

UNITS

PV1/PV2

DESCRIPTION

MV

DESTINATION

MV ZERO

MV SPAN

MV

DESCRIPTION

The difference between the value of the process variable (PV1

or PV2) at 4 mA (or 1 volt) and its value at 20 mA (5 volts).

instance, if the ZERO is 0.0 GPM and the flow rate at 20 mA is

150.0 GPM, the SPAN is 150.0. If the ZERO is 15.0 GPM and

the flow rate at 20 mA is 150.0 GPM, the SPAN is 135.0.

The engineering units of the process variable (PV1 or PV2).

A textual description of the process variable (PV1 or PV2)

The destination of the manipulated variable (MV) is currently

the VFD1 speed.

The value of the manipulated variable (MV) at 4 mA or 1 volt.

The difference between the value of the manipulated variable

(MV) at 4 mA (or 1 volt) and its value at 20 mA (5 volts). For

instance, if the ZERO is 0.0 GPM and the flow rate at 20 mA is

150.0 GPM, the SPAN is 150.0. If the ZERO is 15.0 GPM and

the flow rate at 20 mA is 150.0 GPM, the SPAN is 135.0.

A textual description of the manipulated variable (MV).

For

3.5 Station Flow

Tuning of the Single Loop Controller PID loops is done via the Startup

or Operate pages.

To configure alarm limits, click on ALARM LIMITS. (See Section 3.6

for details.)

When finished, click on BACK.

The ControlWave Pump Controller will perform flow measurement in a

variety of ways:

If there is an analog flow transmitter available, the flow rate

measurement and flow totalization will be performed via an analog

input to the ControlWave Pump Controller.

If there is a pulse type flow meter (turbine meter, ultrasonic meter,

propeller meter) the flow rate measurement and flow totalization

will be performed via a high speed counter input to the ControlWave

Pump Controller.

Issued Oct-08 Configuration 3-11

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

There are some flow meters that offer an analog variable for flow

rate and a pulse signal for flow totalization. In this case, both an

analog input and a high speed counter input would be used on the

ControlWave Pump Controller.

Finally, there are some systems where there is no flow measurement

device at all, but flow can be estimated based on the run status of the

pumps.

To configure the Flow Rate Input from an analog transmitter, click on

CONFIGURE FLOW INPUT and see Section 3.5.1.

To configure Estimated Flow, Click on ESTIMATE FLOW? button,

then click on CONFIGURE ESTIMATED FLOW INPUT and see

Section 3.5.2.

To configure flow totalization, click on CONFIGURE FLOW

TOTALIZATION and see Section 3.5.3.

3-12 Configuration Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

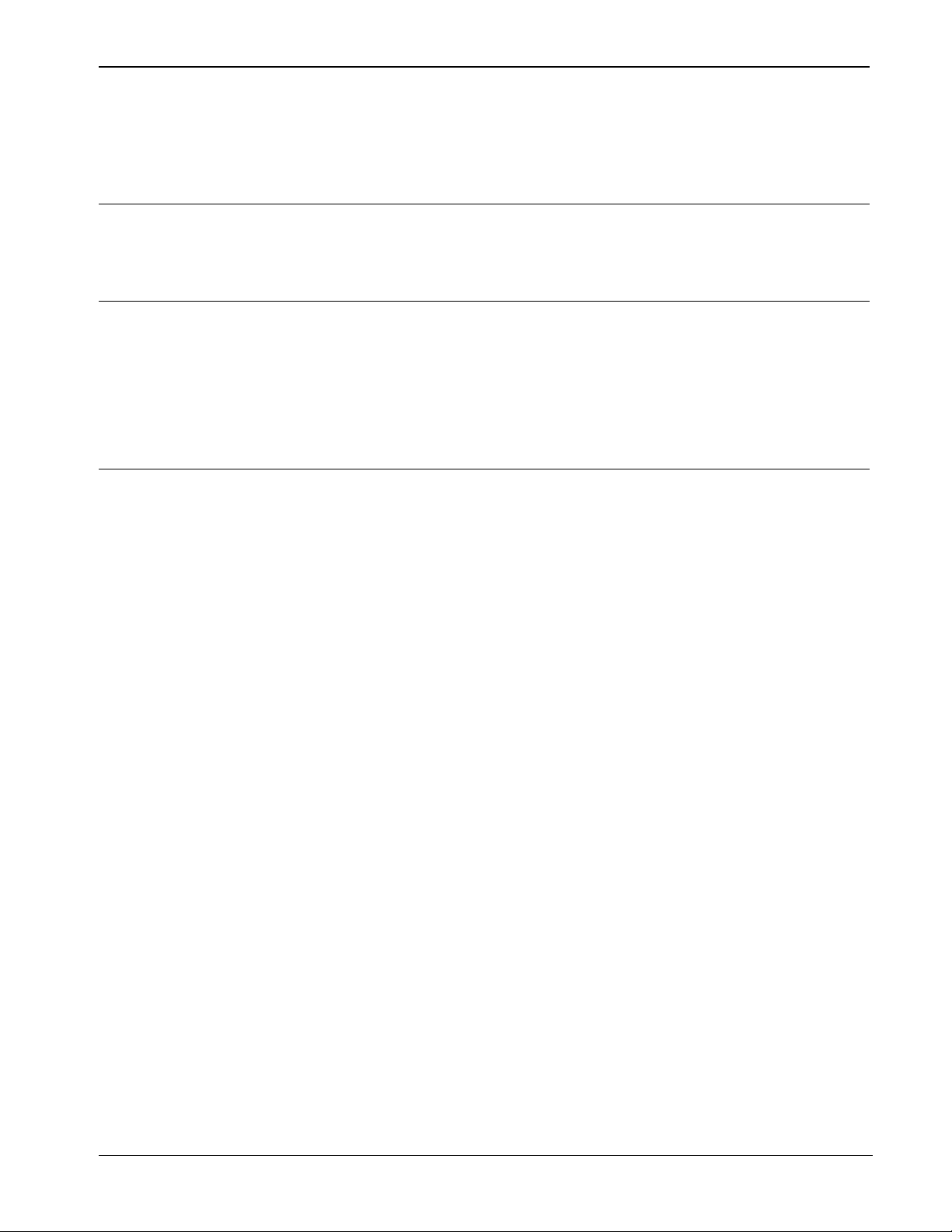

3.5.1 Configure Flow Input

Field Description

ZERO

SPAN

UNITS

DESCRIPTOR

The value of the flow rate variable at 4 mA or 1 volt.

The difference between the value of the flow rate variable at 4

mA (or 1 volt) and its value at 20 mA (5 volts).

the ZERO is 0.0 GPM and the flow rate at 20 mA is 150.0

GPM, the SPAN is 150.0. If the ZERO is 15.0 GPM and the

flow rate at 20 mA is 150.0 GPM, the SPAN is 135.0.

The engineering units of the flow rate variable.

A textual description of the flow rate variable. This descriptor

will be used throughout the rest of the menus to represent flow.

For instance, if

To configure alarm limits, click on ALARM LIMITS. (See Section 3.6

for details.)

When finished, click on BACK.

Issued Oct-08 Configuration 3-13

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3.5.2 Configure Estimated Flow Input

Field Description

VALUE

PUMP1,

PUMP2,

PUMP3

UNITS

DESCRIPTOR

This is the live value of the estimated flow.

This is the estimated value of flow when each pump is running.

If more than one pump is running, the estimated flow will be the

sum of the estimated flow for each pump that is running.

This is the engineering units for flow.

This is a textual description of the flow transmitter.

3-14 Configuration Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3.5.3 Configure Flow Totalization

Flow totalization can be performed one of two ways, by integrating the

flow rate received via the analog input, or by accumulating pulses from

a flow meter that represent a fixed volume of flow per pulse.

When totalization is performed using the analog input, the flow rate

(Gallons per minute, gallons per hour, million gallons per day, etc.) is

integrated to calculate the total volume (Gallons, Million Gallons, etc.)

delivered over a period of time.

In order to perform this integration, a totalizer span value must be

entered. This totalizer span is used to adjust the available flow rate

units to the desired flow total units.

For example, if the flow rate is in Gallons per Minute (GPM) and the

desired flow total units are Million Gallons (MGals) the totalizer span is

0.00000001667, as shown by the calculation below:

Issued Oct-08 Configuration 3-15

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

TOTALIZER SPAN = (Gal/Minute) * (Minute/60 seconds) * (Seconds/Sample) * (MGals/1,000,000) GAL

TOTALIZER SPAN = 1/(60*1,000,000)

TOTALIZER SPAN = 0.00000001667

When totalization is performed using a pulse input, each pulse

represents a fixed volume (Gallons, cubic feet, etc.) that has passed

through the meter. In this case totalizing the volume requires that each

pulse gets multiplied by a factor (commonly called a K Factor by the

meter manufacturer). The K Factor must be entered as volume per pulse

(for instance, 100 gallons/pulse).

However, some manufactures list their K Factor as pulses per volume

(for instance, 11.7 pulses/gallon). In this case, the K Factor entered in

the Pump Controller must be the reciprocal of the manufacturers K

Factor.

In this example, our K Factor would be 1 Gallon/11.7 Pulses, or

0.08547 Gallons/Pulse.

In addition, the user may opt to adjust the totalized units using the K

Factor. If the K Factor represents 1 gallon per pulse, but the user

wanted to see total volume in Millions of Gallons (MGAL), the K

Factor would be entered as 0.000001 (1/1,000,000).

3-16 Configuration Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

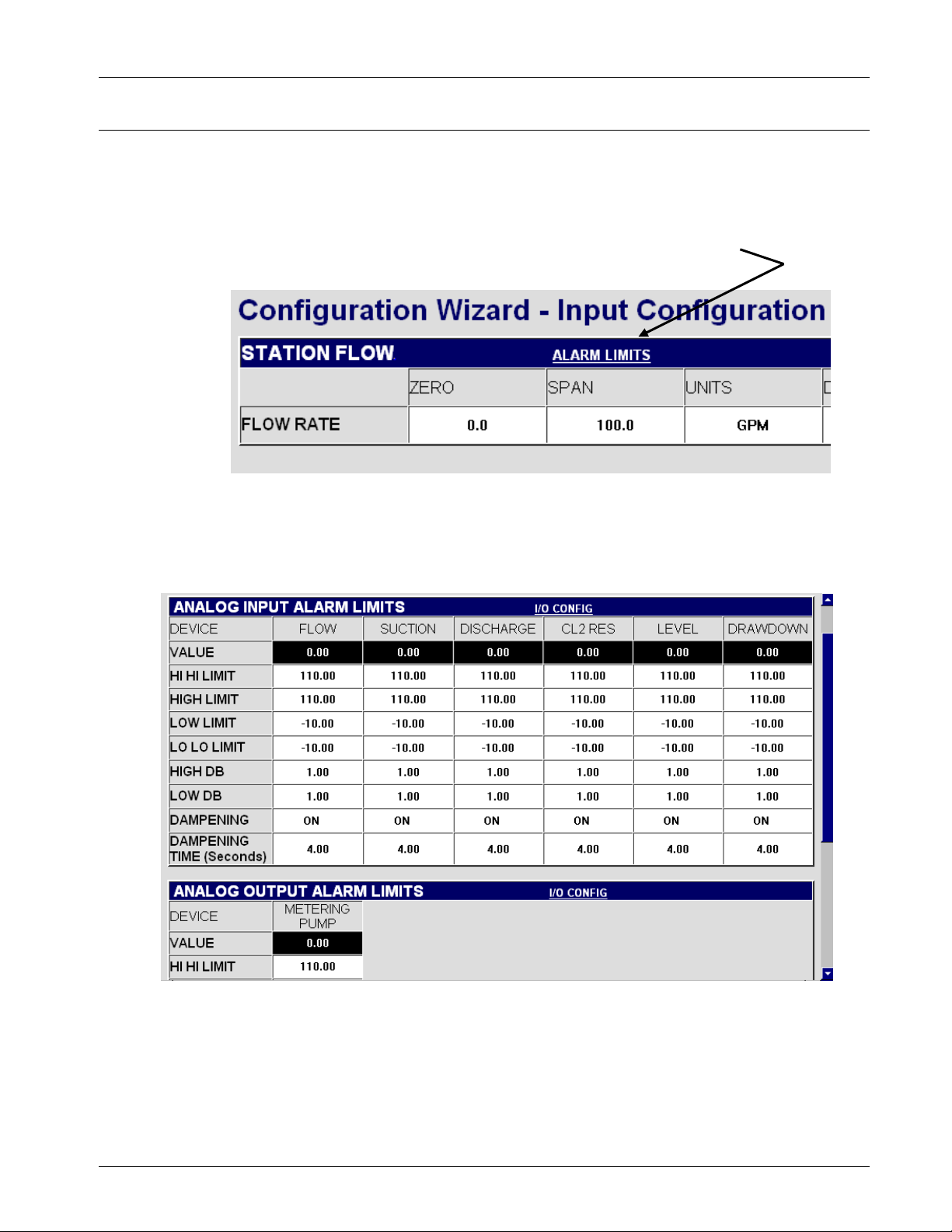

3.6 Alarm Limit Configuration

Selecting Alarm Limits from any analog configuration menu allows for

configuration of the alarm limits for any and all analog input

parameters.

Click here to configure alarm limits

Alarm limits can be configured during the individual analog input

configurations or after all inputs are configured.

Issued Oct-08 Configuration 3-17

ControlWave Pump Controller Application User’s Guide (D5132)

A

Click here to return to the Table of Contents

Alarm limits are provided for High, HI HI, Low, Low – Low. Each limit

has an independent High and Low Deadband and dampening filter.

Field Description

VALUE

HI HI LIMIT

HIGH LIMIT

LOW LIMIT

LO LO LIMIT

HIGH DB

The current value of this variable.

A high-high alarm message is generated when the variable’s

value exceeds this value. The high-high alarm condition

remains in effect until the value of the variable falls below the

HI HI LIMIT, minus the HIGH DB value.

A high alarm message is generated when the variable’s value

exceeds this value. The high alarm condition remains in effect

until the value of the variable falls below the HIGH LIMIIT,

minus the HIGH DB value.

A low alarm message is generated when the variable’s value

falls below this value. The low alarm condition remains in effect

until the value of the variable rises above the LOW LIMIT, plus

the LOW DB value.

A low-low alarm message is generated when the variable’s

value falls below this value. The low-low alarm condition

remains in effect until the value of the variable rises above the

LO LO LIMIT, plus the LOW DB value.

A value used to define a range below the HI HI LIMIT, or HIGH

LIMIT, within which the alarm condition for that limit still exists,

even though the value of the variable is below the limit. This

range helps reduce the number of multiple alarm and return-to

normal messages being generated if the value of the variable

is fluctuating near the alarm limit.

LOW DB

DAMPENING

DAMPENING

TIME

(seconds)

3-18 Configuration Issued Oct-08

value used to define a range above the HI HI LIMIT, or HIGH

LIMIT, within which the alarm condition for that limit still exists,

even though the value of the variable is above the limit. This

range helps reduce the number of multiple alarm and return-to

normal messages being generated if the value of the variable

is fluctuating near the alarm limit.

When ON, enables the dampening feature. When OFF, the

dampening feature is disabled. The dampening feature delays

the speed of the response of the output to a given change of

the input.

rapid or oscillatory change of the measured variable.

The period of time (in seconds) during which the indicated

value changes only 63% of the difference between the ’present

measured variable’ and the ’present indicated value’ in one

damping time period. It would take 5 times the Dampening

Time for the ’present indicated pressure’ to equal the ’present

measured pressure’ (if a change in the ’present measured

pressure’ didn’t occur). An increase in the Dampening Time

results in an increased smoothing of the indicated value.

It is used to slow down the output response to a

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3.7 Discharge Pressure Measurement and Control

The ControlWave Pump Controller will perform discharge pressure

measurement.

In addition, the discharge pressure may be used for primary control of

the pumps, or override control of the pumps.

To configure the Discharge Pressure Input from an analog transmitter,

click on CONFIGURE DISCHARGE PRESSURE INPUT and see

Section 3.7.1

To configure the discharge pressure for primary pump control, click on

CONFIGURE DISCHARGE PRESSURE CONTROL and see Section

3.7.2

To configure the discharge pressure for override pump control, click on

CONFIGURE DISCHARGE PRESSURE OVERRIDE and see Section

3.7.3

Issued Oct-08 Configuration 3-19

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3.7.1 Configure Discharge Pressure Input

Field Description

ZERO

SPAN

UNITS

DESCRIPTOR

The value of the discharge pressure value when the analog

input is at 4 mA or 1 volt.

Enter the SPAN value. The SPAN represents the difference

between the discharge pressure value when the analog input is

20 mA or 5 Volts and when the analog input is at 4 mA or 1

Volt. For instance, if the ZERO is 0.0 PSI and the discharge

pressure at 20 mA is 300.0 PSI, the SPAN is 300.0. If the

ZERO is 25.0 PSI and the discharge pressure at 20 mA is

300.0 GPM, the SPAN is 275.0.

The engineering units of the discharge pressure input.

A textual description of the discharge pressure input. This

descriptor will be used throughout the rest of the menus to

represent discharge pressure.

To configure alarm limits, click on ALARM LIMITS. (See Section 3.6

for details.)

When finished, click on BACK.

3-20 Configuration Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3.7.2 Configure Discharge Pressure Control

Field Description

PUMPS

AVAILABLE

DISCHARGE

(or other

name)

LEAD / LAG1 /

LAG2 START

SETPOINT

LEAD / LAG1 /

LAG2 STOP

SETPOINT

LEAD / LAG1 /

LAG2 START

COMMAND

LEAD / LAG1 /

LAG2 STOP

COMMAND

This represents the number of pumps available for control.

This is the DESCRIPTOR assigned to the Discharge Pressure

Input. The field to the right is the live Discharge Pressure

reading.

When the live pressure value drops below this setpoint, the

appropriate pump START COMMAND will be set to START.

When the live pressure value rises above this setpoint, the

appropriate pump STOP COMMAND will be set to STOP.

When the live pressure value drops below the START

SETPOINT, the corresponding START COMMAND is set to

START, to start the pump. Otherwise, it is set to OFF.

When the live pressure value rises above the STOP

SETPOINT, the corresponding STOP COMMAND is set to

STOP, to stop the pump. Otherwise, it is set to OFF.

To configure alarm limits, click on ALARM LIMITS. (See Section 3.6

for details.)

When finished, click on BACK.

Issued Oct-08 Configuration 3-21

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3.7.3 Configure Discharge Pressure Override Control

Override Control provides start and stop overrides that would take

precedence over primary control. Override Control is used to either

start a single pump or stop all pumps.

From here, either or both START OVERRIDE control and STOP

OVERRIDE control can be enabled and configured.

Field Description

START

OVERRIDE

ENABLE/DISABL

START

OVERRIDE

Right-click in this field, and choose either ‘ENABLE’ or

‘DISABL’ from the drop-down menu.

When enabled, a pump can be started based on whether

the discharge pressure value either exceeds (ONHIGH) or

falls below (ONLOW) the START OVERRIDE SETPOINT.

This start command takes precedence over the primary

pump control scheme.

When disabled, the pump is only under primary control.

Right-click in this field, and choose either ‘ONLOW’ or

‘ONHIGH’ from the drop-down menu.

ONLOW / ONHIGH

3-22 Configuration Issued Oct-08

When START OVERRIDE is enabled, ‘ONLOW’ causes

the START OVERRIDE command to be activated when

the discharge pressure value falls below the START

OVERRIDE SETPOINT.

When START OVERRIDE is enabled, ‘ONHIGH’ causes

the START OVERRIDE command to be activated when

the discharge pressure value rises above the START

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

OVERRIDE SETPOINT.

When START OVERRIDE is disabled, this field is ignored.

START

OVERRIDE

SETPOINT

START

OVERRIDE

COMMAND

STOP OVERRIDE

ENABLE/DISABLE

STOP OVERRIDE

ONLOW / ONHIGH

When START OVERRIDE is enabled, this is the trigger

value for the discharge pressure at which a pump will be

started.

When START OVERRIDE is disabled, this field is ignored.

Displays ‘START’ when the START OVERRIDE condition

exists or ‘OFF’ when the START OVERRIDE condition

does not exist.

Right-click in this field, and choose either ‘ENABLE’ or

‘DISABL’ from the drop-down menu.

When enabled, a pump can be stopped based on whether

the discharge pressure value either exceeds (ONHIGH) or

falls below (ONLOW) the STOP OVERRIDE SETPOINT.

This stop command takes precedence over the primary

pump control scheme.

When disabled, the pump is only under primary control.

Right-click in this field, and choose either ‘ONLOW’ or

‘ONHIGH’ from the drop-down menu.

When STOP OVERRIDE is enabled, ‘ONLOW’ causes the

STOP OVERRIDE command to be activated when the

discharge pressure value falls below the STOP

OVERRIDE SETPOINT.

STOP OVERRIDE

SETPOINT

STOP OVERRIDE

COMMAND

STOP OVERRIDE

WILL BE PERMIS /

INTLCK

When STOP OVERRIDE is enabled, ‘ONHIGH’ causes the

STOP OVERRIDE command to be activated when the

discharge pressure value rises above the STOP

OVERRIDE SETPOINT.

When STOP OVERRIDE is disabled, this field is ignored.

When STOP OVERRIDE is enabled, this is the trigger

value for the discharge pressure at which a pump will be

stopped.

When STOP OVERRIDE is disabled, this field is ignored.

Displays ‘STOP’ when the STOP OVERRIDE condition

exists or ‘OFF’ when the STOP OVERRIDE condition does

not exist.

The user can choose whether the STOP OVERRIDE is a

PERMISSIVE OVERRIDE (PERMIS) or an

INTERLOCKED OVERRIDE (INTLCK).

A PERMISSIVE STOP OVERRIDE may be overridden by

a START OVERRIDE, but will not be overridden by a start

command issued by any of the primary controls. An

INTERLOCKED STOP OVERRIDE will not be overridden

by any start command, whether issued by a primary

control or an override control.

When finished, click on BACK.

Issued Oct-08 Configuration 3-23

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3.8 Suction Pressure Measurement and Control

The ControlWave Pump Controller will perform suction pressure

measurement.

In addition, the suction pressure may be used for override control of the

pumps.

To configure the Suction Pressure Input from an analog transmitter,

click on CONFIGURE SUCTION PRESSURE INPUT and see Section

3.8.1.

To configure the suction pressure for override pump control, click on

CONFIGURE SUCTION PRESSURE OVERRIDE and see Section

3.8.2.

3-24 Configuration Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3.8.1 Configure Suction Pressure Input

Field Description

ZERO

SPAN

UNITS

DESCRIPTOR

The value of the suction pressure value when the analog input

is at 4 mA or 1 volt.

Enter the SPAN value. The SPAN represents the difference

between the suction pressure value when the analog input is

20 mA or 5 Volts and when the analog input is at 4 mA or 1

Volt. For instance, if the ZERO is 0.0 PSI and the suction

pressure at 20 mA is 300.0 PSI, the SPAN is 300.0. If the

ZERO is 25.0 PSI and the suction pressure at 20 mA is 300.0

GPM, the SPAN is 275.0.

The engineering units of the suction pressure input.

A textual description of the suction pressure input. This

descriptor will be used throughout the rest of the menus to

represent suction pressure.

To configure alarm limits, click on ALARM LIMITS. (See Section 3.6

for details.)

When finished, click on BACK.

Issued Oct-08 Configuration 3-25

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3.8.2 Configure Suction Pressure Override

Override Control provides start and stop overrides that would take

precedence over primary control. Override Control is used to either

start a single pump or stop all pumps.

From here, either or both START OVERRIDE control and STOP

OVERRIDE control can be enabled and configured.

Field Description

START

OVERRIDE

ENABLE/DISABL

Typically, START OVERRIDE would not be used with

suction pressure, however, it is supported if required.

Right-click in this field, and choose either ‘ENABLE’ or

‘DISABL’ from the drop-down menu.

When enabled, a pump can be started based on whether

the suction pressure value either exceeds (ONHIGH) or

falls below (ONLOW) the START OVERRIDE SETPOINT.

This start command takes precedence over the primary

pump control scheme.

START

OVERRIDE

ONLOW / ONHIGH

3-26 Configuration Issued Oct-08

When disabled, the pump is only under primary control.

Right-click in this field, and choose either ‘ONLOW’ or

‘ONHIGH’ from the drop-down menu.

When START OVERRIDE is enabled, ‘ONLOW’ causes

the START OVERRIDE command to be activated when

the suction pressure value falls below the START

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

OVERRIDE SETPOINT.

When START OVERRIDE is enabled, ‘ONHIGH’ causes

the START OVERRIDE command to be activated when

the suction pressure value rises above the START

OVERRIDE SETPOINT.

When START OVERRIDE is disabled, this field is ignored.

START

OVERRIDE

SETPOINT

START

OVERRIDE

COMMAND

STOP OVERRIDE

ENABLE/DISABLE

STOP OVERRIDE

ONLOW / ONHIGH

When START OVERRIDE is enabled, this is the trigger

value for the suction pressure at which a pump will be

started.

When START OVERRIDE is disabled, this field is ignored.

Displays ‘START’ when the START OVERRIDE condition

exists or ‘OFF’ when the START OVERRIDE condition

does not exist.

Right-click in this field, and choose either ‘ENABLE’ or

‘DISABL’ from the drop-down menu.

When enabled, a pump can be stopped based on whether

the suction pressure value either exceeds (ONHIGH) or

falls below (ONLOW) the STOP OVERRIDE SETPOINT.

This stop command takes precedence over the primary

pump control scheme.

When disabled, the pump is only under primary control.

It is very common to use low suction pressure for STOP

OVERRIDE.

Right-click in this field, and choose either ‘ONLOW’ or

‘ONHIGH’ from the drop-down menu.

When STOP OVERRIDE is enabled, ‘ONLOW’ causes the

STOP OVERRIDE command to be activated when the

suction pressure value falls below the STOP OVERRIDE

SETPOINT.

When STOP OVERRIDE is enabled, ‘ONHIGH’ causes the

STOP OVERRIDE command to be activated when the

suction pressure value rises above the STOP OVERRIDE

SETPOINT.

When STOP OVERRIDE is disabled, this field is ignored.

STOP OVERRIDE

SETPOINT

STOP OVERRIDE

COMMAND

STOP OVERRIDE

WILL BE PERMIS /

INTLCK

Issued Oct-08 Configuration 3-27

When STOP OVERRIDE is enabled, this is the trigger

value for the suction pressure at which a pump will be

stopped.

When STOP OVERRIDE is disabled, this field is ignored.

Displays ‘STOP’ when the STOP OVERRIDE condition

exists or ‘OFF’ when the STOP OVERRIDE condition does

not exist.

The user can choose whether the STOP OVERRIDE is a

PERMISSIVE OVERRIDE (PERMIS) or an

INTERLOCKED OVERRIDE (INTLCK).

A PERMISSIVE STOP OVERRIDE may be overridden by

a START OVERRIDE, but will not be overridden by a start

command issued by any of the primary controls. An

INTERLOCKED STOP OVERRIDE will not be overridden

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

by any start command, whether issued by a primary

control or an override control.

When finished, click on BACK.

3.9 Local Tank Level Measurement and Control

The ControlWave Pump Controller will perform local tank level

measurement.

The local tank level can be used for primary and override control.

In addition, float switches can be used to perform pump control, either

as primary or backup control to the tank level transmitter. If using float

switches in the local tank, select whether the floats are used for PUMP

UP or PUMP DOWN control.

To configure the local tank level input from an analog transmitter, click

on CONFIGURE LEVEL INPUT and see Section 3.9.1

3-28 Configuration Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

To configure the local tank level for primary pump control, first select

whether operating the pumps will fill the tank (PUMP UP control) or

operating the pumps will empty the tank (PUMP DOWN control).

After selecting PUMP UP or PUMP DOWN control, click on

CONFIGURE LEVEL CONTROL and see Section 3.9.2.

To configure the local tank level for override pump control, click on

CONFIGURE LEVEL OVERRIDE and see Section 3.9.3.

3.9.1 Configure Level Input

Field Description

LEVEL ZERO

LEVEL SPAN

Enter the ZERO value. This represents the level value

when the analog input is at 4 mA or 1 Volt).

Enter the SPAN value. The SPAN represents the

difference between the level value when the analog input

is 20 mA or 5 Volts and when the analog input is at 4 mA

or 1 Volt. For instance, if the ZERO is 0.0 FEET and the

level at 20 mA is 35.0 FEET, the SPAN is 35.0. If the

ZERO is 35.0 FEET and the level at 20 mA is 45.0 FEET,

the SPAN is 10.0.

LEVEL UNITS

Issued Oct-08 Configuration 3-29

Enter the engineering units indicating level.

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

LEVEL

DESCRIPTOR

Enter a descriptor for the local level transmitter. This

descriptor will be used throughout the rest of the menus to

represent local level.

In addition to the level, it is possible in some cases to calculate the

volume in the tank. This is only possible when there is a linear

relationship between level and volume. In other words, if 1 foot of tank

level always equals the same number of gallons in the tank, then volume

can be calculated. However, if the tank is non-linear (for instance, a tank

shaped like a sphere or a cylinder lying horizontally) volume

measurement is not possible.

VOLUME ZERO

VOLUME SPAN

Enter the ZERO value. This represents the volume value

when the level value is at zero.

Enter the SPAN value. The SPAN represents the

difference between the volume value when the level input

is at 20 mA or 5 Volts and when the level input is at 4 mA

or 1 Volt. For instance, if the ZERO is 0.0 GALLONS and

the volume when the level input at 20 mA is 300,000

GALLONS, the SPAN is 300,000.0. If the ZERO is

10,000.0 GALLONS and the volume when the level input

is at 20 mA is 50,000 GALLONS, the SPAN is 40,000.0.

VOLUME UNITS

VOLUME

DESCRIPTOR

Enter the engineering units indicating volume.

The volume descriptor will be generated automatically by

appending the word ‘VOLUME’ to the LEVEL

DESCRIPTOR. This descriptor will be used throughout

the rest of the menus to represent volume of the local tank.

To configure alarm limits, click on ALARM LIMITS. (See Section 3.6

for details.)

When finished, click on BACK.

3-30 Configuration Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

3.9.2 Configure Level Control

Field Description

PUMPS

AVAILABLE

Descriptor

Level Reading

LEAD, LAG1/2

START SETPOINT

&

START

COMMAND

The number of pumps available for control.

This is the descriptor for the Local Level Input. By default,

this shows ‘CLEARWELL’.

The live, local level reading.

Setting the START SETPOINTS depends on whether

PUMP UP control or PUMP DOWN control was selected.

When PUMP UP control is selected, if the live tank level

drops below the START SETPOINT, the appropriate pump

START COMMAND will be set to START.

LEAD, LAG1/2

STOP SETPOINT

&

STOP COMMAND

Issued Oct-08 Configuration 3-31

When PUMP DOWN control is selected, if the live tank

level rises above the START SETPOINT, the appropriate

pump START COMMAND will be set to START.

Setting the STOP SETPOINTS depends on whether

PUMP UP control or PUMP DOWN control was selected.

When PUMP UP control is selected, if the live tank level

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

rises above the STOP SETPOINT, the appropriate pump

STOP COMMAND will be set to STOP.

When PUMP DOWN control is selected, if the live tank

level falls below the STOP SETPOINT, the appropriate

pump STOP COMMAND will be set to STOP.

When finished, click on BACK.

3.9.3 Configure Level Override

Override Control provides start and stop overrides that would take

precedence over primary control. Override Control is used to either

start a single pump or stop all pumps.

From here, either or both START OVERRIDE control and STOP

OVERRIDE control can be enabled and configured.

Field Description

START

OVERRIDE

3-32 Configuration Issued Oct-08

Right-click in this field, and choose either ‘ENABLE’ or

‘DISABL’ from the drop-down menu.

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

ENABLE/DISABL

START

OVERRIDE

ONLOW / ONHIGH

START

OVERRIDE

SETPOINT

When enabled, a pump can be started based on whether

the local tank level value either exceeds (ONHIGH) or falls

below (ONLOW) the START OVERRIDE SETPOINT. This

start command takes precedence over the primary pump

control scheme.

When disabled, the pump is only under primary control.

Right-click in this field, and choose either ‘ONLOW’ or

‘ONHIGH’ from the drop-down menu.

When START OVERRIDE is enabled, ‘ONLOW’ causes

the START OVERRIDE command to be activated when

the local tank level value falls below the START

OVERRIDE SETPOINT.

When START OVERRIDE is enabled, ‘ONHIGH’ causes

the START OVERRIDE command to be activated when

the local tank level value rises above the START

OVERRIDE SETPOINT.

When START OVERRIDE is disabled, this field is ignored.

When START OVERRIDE is enabled, this is the trigger

value for the local tank level at which a pump will be

started.

When START OVERRIDE is disabled, this field is ignored.

START

OVERRIDE

COMMAND

STOP OVERRIDE

ENABLE/DISABLE

STOP OVERRIDE

ONLOW / ONHIGH

Displays ‘START’ when the START OVERRIDE condition

exists or ‘OFF’ when the START OVERRIDE condition

does not exist.

Right-click in this field, and choose either ‘ENABLE’ or

‘DISABL’ from the drop-down menu.

When enabled, a pump can be stopped based on whether

the local tank level value either exceeds (ONHIGH) or falls

below (ONLOW) the STOP OVERRIDE SETPOINT. This

stop command takes precedence over the primary pump

control scheme.

When disabled, the pump is only under primary control.

Right-click in this field, and choose either ‘ONLOW’ or

‘ONHIGH’ from the drop-down menu.

When STOP OVERRIDE is enabled, ‘ONLOW’ causes the

STOP OVERRIDE command to be activated when the

local tank level value falls below the STOP OVERRIDE

SETPOINT.

When STOP OVERRIDE is enabled, ‘ONHIGH’ causes the

STOP OVERRIDE command to be activated when the

local tank level value rises above the STOP OVERRIDE

SETPOINT.

STOP OVERRIDE

SETPOINT

Issued Oct-08 Configuration 3-33

When STOP OVERRIDE is disabled, this field is ignored.

When STOP OVERRIDE is enabled, this is the trigger

value for the local tank level at which a pump will be

stopped.

When STOP OVERRIDE is disabled, this field is ignored.

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

STOP OVERRIDE

COMMAND

STOP OVERRIDE

WILL BE PERMIS /

INTLCK

Displays ‘STOP’ when the STOP OVERRIDE condition

exists or ‘OFF’ when the STOP OVERRIDE condition does

not exist.

The user can choose whether the STOP OVERRIDE is a

PERMISSIVE OVERRIDE (PERMIS) or an

INTERLOCKED OVERRIDE (INTLCK).

A PERMISSIVE STOP OVERRIDE may be overridden by

a START OVERRIDE, but will not be overridden by a start

command issued by any of the primary controls. An

INTERLOCKED STOP OVERRIDE will not be overridden

by any start command, whether issued by a primary

control or an override control.

When finished, click on BACK.

3.10 Remote Tank Level Measurement and Control

The ControlWave Pump Controller will perform remote tank level

measurement.

The remote tank level is identical to the local tank level indication, with

the following exceptions:

There are no provisions for float control when using a remote tank

level.

There are no volume calculations provided for the remote tank level.

3-34 Configuration Issued Oct-08

ControlWave Pump Controller Application User’s Guide (D5132)

Click here to return to the Table of Contents

To configure the remote tank level input, click on CONFIGURE

LEVEL INPUT and refer to Section 3.10.1.

To configure the remote tank level for primary pump control, first select

whether operating the pumps will fill the tank (PUMP UP control) or

operating the pumps will empty the tank (PUMP DOWN control).

After selecting PUMP UP or PUMP DOWN control, click on

CONFIGURE LEVEL CONTROL and refer to Section 3.10.2.

To configure the level override, click on CONFIGURE LEVEL

OVERRIDE and refer to Section 3.10.3.

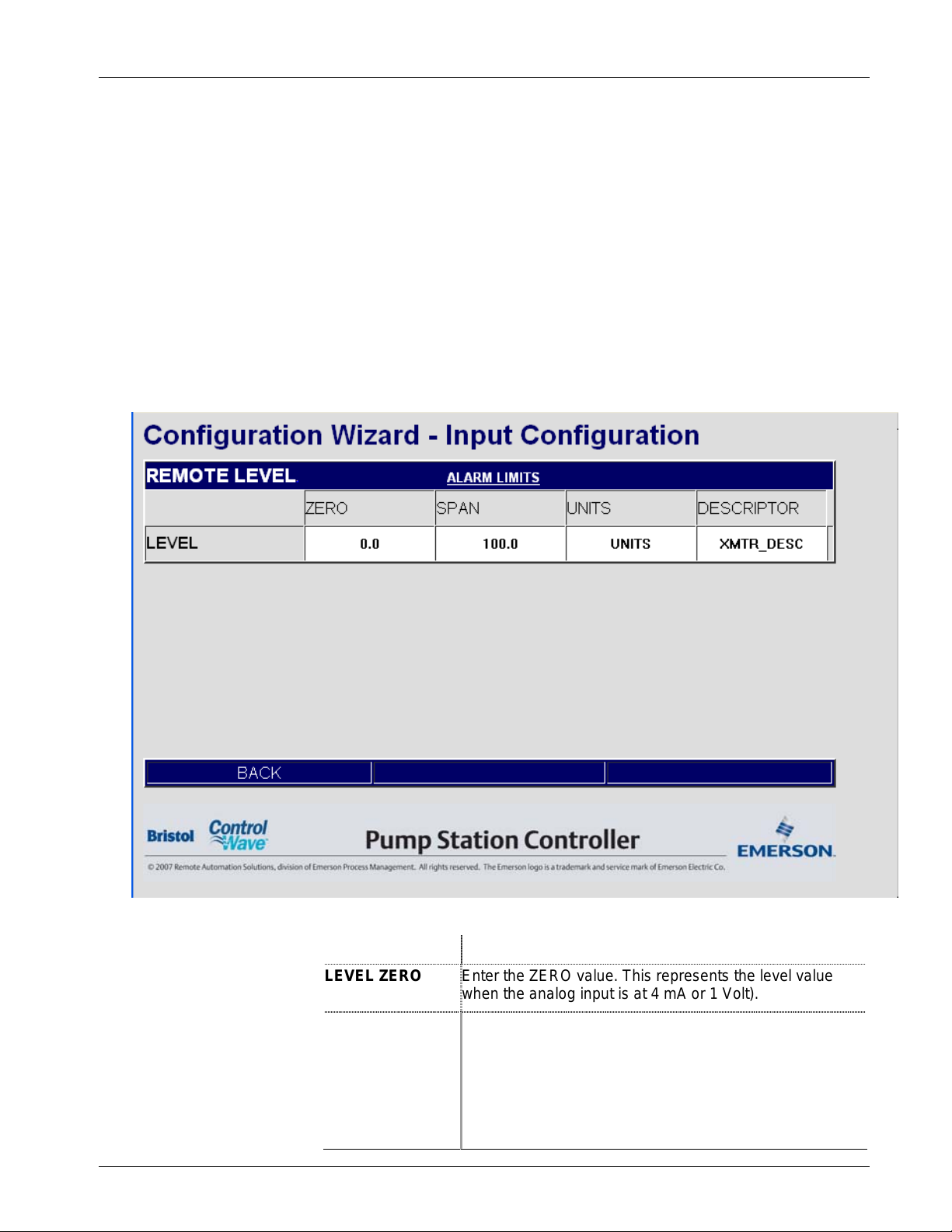

3.10.1 Configure Level Input

Field Description

LEVEL ZERO

Enter the ZERO value. This represents the level value