Page 1

Instruction Manual

D103407X012

Fisher™ 1052PSV Size 60 Rotary Actuator

1052PSV Actuator

March 2021

Contents

Introduction 1.................................

Scope of Manual 1.............................

Specifications 2...............................

Description 2.................................

Educational Services 2.........................

Principle of Operation 3.........................

Installation 4..................................

Lifting Guidelines 5............................

Conduit Connection 6..........................

Valve Flow Direction 6.........................

Actuator Mounting 7..........................

Precise Valve/Actuator Closed Position

and Turnbuckle Adjustment 8.................

Actuator Spring Adjustment 10..................

Initial Setting 10...........................

Stroking Range 10.........................

Accessory Mounting 11........................

Maintenance 14................................

Disassembly 15...............................

Assembly 17..................................

Troubleshooting 20.............................

Adjustable Travel Stops 20.......................

Parts Ordering 21...............................

Spare Parts 21.................................

Parts List and Special Tools 23....................

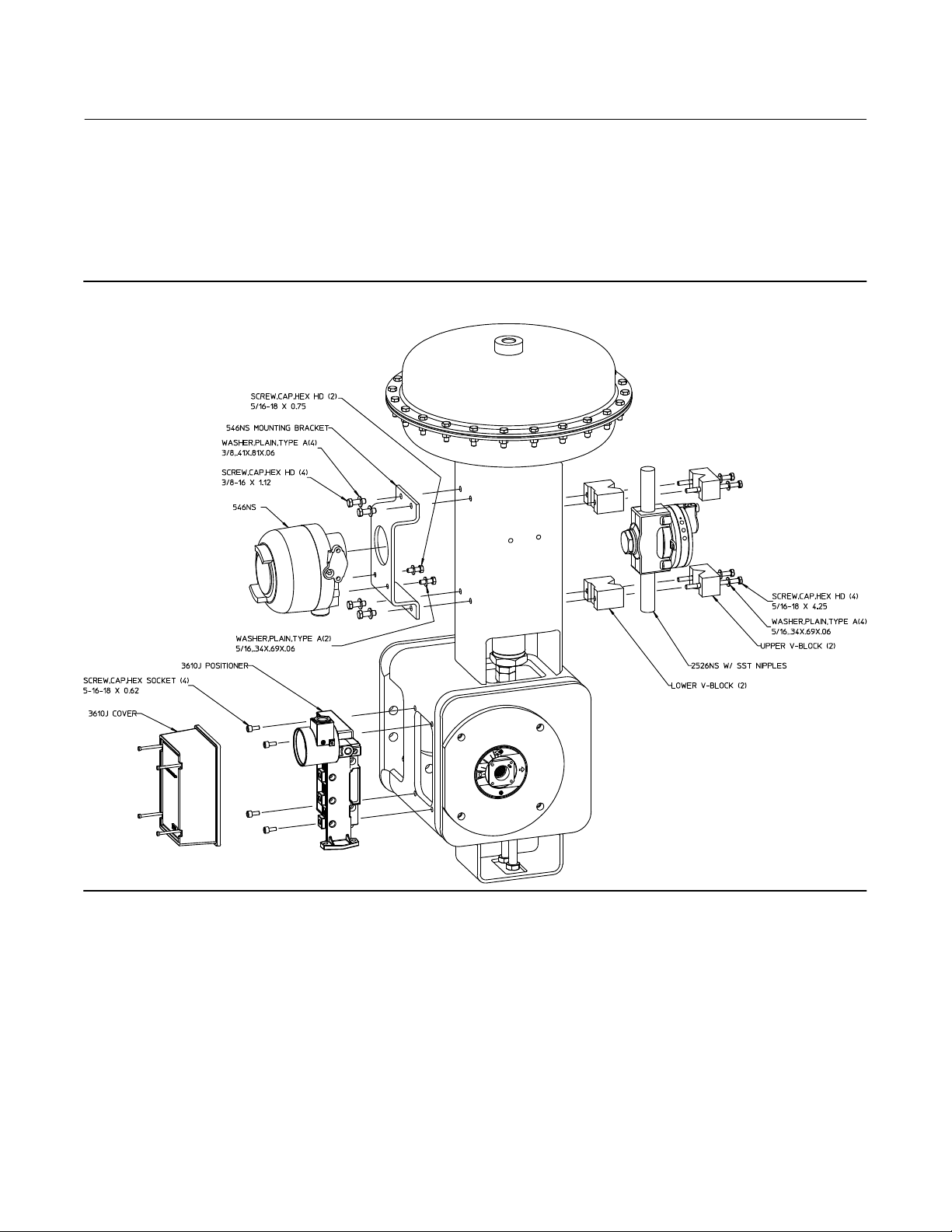

Figure 1. Fisher SS-84PSV4 Valve

with 1052PSV Actuator and 3610J Positioner

X0001-1

Introduction

Scope of Manual

This instruction manual includes installation, adjustment, maintenance, and parts ordering information for the Fisher

1052PSV (Size 60) pneumatic spring-and-diaphragm rotary actuator (see figure 1).

The seismically qualified actuator design is based on the standard Fisher 1052 size 60 actuator. The 1052PSV size 60

actuator incorporates the tilting diaphragm rod, turnbuckle adjusting feature, upper diaphragm casing assembly, and

SS-129 dual springs mounted within a fabricated box construction. The actuator box is designed for standard 3610J

positioner mounting. Adjustable valve open position is provided by limiting lever rotation with adjustable travel limit

bolts in the bottom of the fabricated actuator box.

To ensure proper assembly, the Vee-Ballt, valve drive shaft, and actuator lever connections are a missing-tooth spline

design, allowing one-way only assembly.

Instructions for the control valve, positioner, and other accessories are covered in separate instruction manuals.

www.Fisher.com

Page 2

1052PSV Actuator

March 2021

Table 1. Fisher 1052PSV Actuator Specifications

Instruction Manual

D103407X012

Operation

Direct Acting: Increasing loading pressure extends

Material Temperature Capabilities

EPDM Diaphragm: -40 to 107_C (-40 to 225_F)

the diaphragm rod out of the spring barrel

Service: For on‐off or throttling service with or

without a positioner

Travel Indication

Graduated disk and pointer combination located on

Actuator Sizes

Size 60

Maximum Diaphragm Sizing Pressure

2.7 bar (39 psig)

Maximum Diaphragm Casing Pressure

3.4 bar (50 psig)

Nominal Valve Shaft Rotation

80 degrees rotation (standard) travel stop

Valve Shaft Diameters

(1)

(3)

actuator end of valve shaft, with valve ball position

indicator

Pressure Conduit Connections

Standard: 3/4 NPT internal thread

Mounting Positions

RH mount, PDTO, Vee-Ball rotates CCW to close,

spring-fail closed

Approximate Weights

136 kg (300 lb)

31.8 mm (1‐1/4 inches)

Additional Specifications

Stroking Time

Opening requirement is 1 to 5 seconds

1. Use this value to determine the maximum torque output allowed.

2. The pressure/temperature limits in this manual and any applicable standard or code limitation for valve should not be exceeded.

3. This maximum casing pressure is not to be used for normal operating pressure. Its purpose is to allow for typical regulator supply settings and/or relief valve tolerances.

For casing pressure ranges and for material

identification of the parts, see the Parts List

(2)

Do not install, operate, or maintain a 1052PSV actuator without being fully trained and qualified in valve,

actuator, and accessory installation, operation, and maintenance. To avoid personal injury or property

damage, it is important to carefully read, understand, and follow all the contents of this manual,

including all safety cautions and warnings. If you have any questions about these instructions, contact

your Emerson sales office

before proceeding.

Description

The 1052PSV diaphragm rotary actuator is a pneumatic spring‐return actuator for use with the SS-84PSV4 rotary‐shaft

control valve. The 1052PSV actuator can be used for on‐off service, or it can be used for throttling service when

equipped with or without a valve positioner. The 1052PSV actuator spring is adjustable (see figure 2).

Educational Services

For information on available courses for Fisher 1052PSV actuators, as well as a variety of other products, contact:

Emerson Automation Solutions

Educational Services - Registration

Phone: 1-641-754-3771 or 1-800-338-8158

E-mail: education@emerson.com

emerson.com/fishervalvetraining

2

Page 3

Instruction Manual

D103407X012

1052PSV Actuator

March 2021

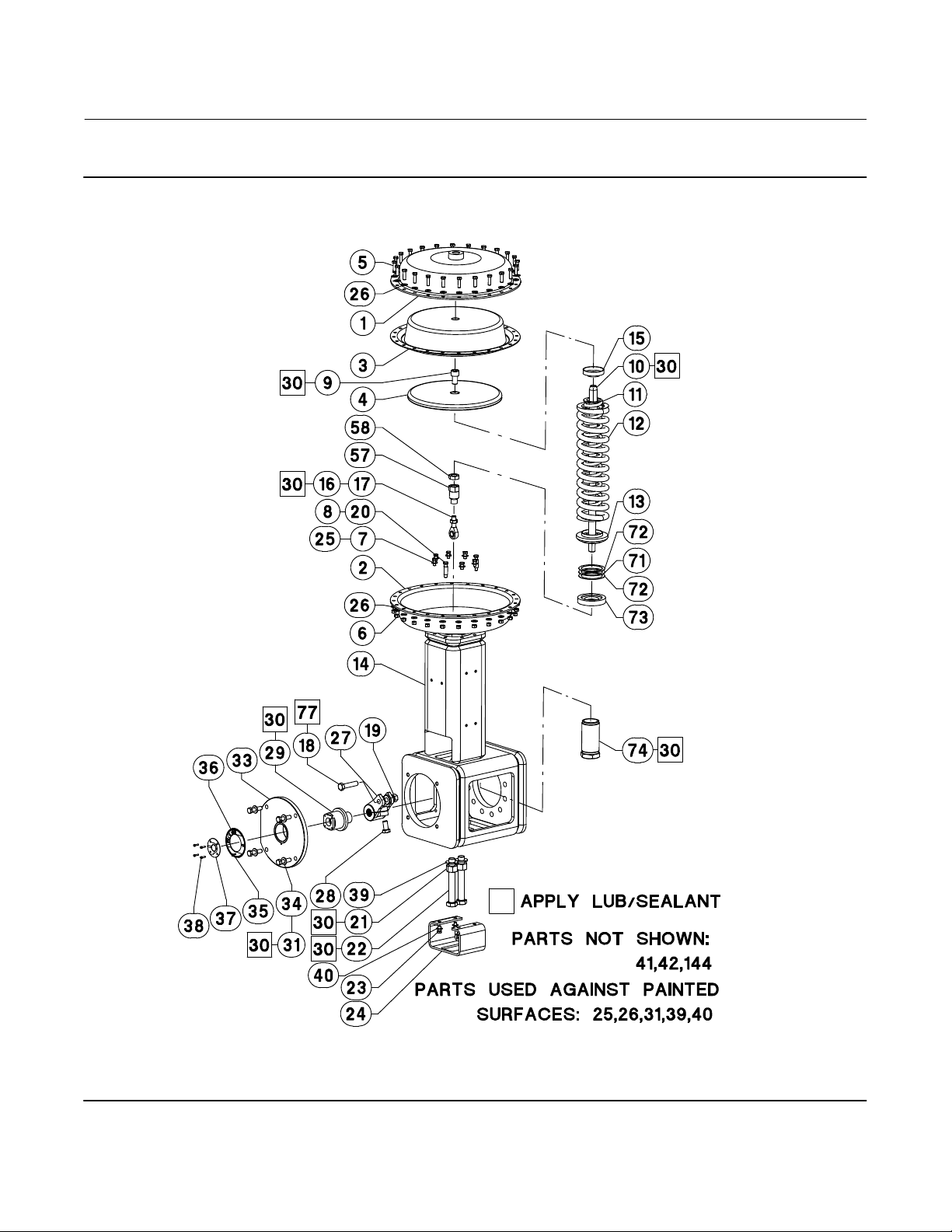

Figure 2. Fisher 1052PSV Actuator Adjustable Spring Seat

DIAPHRAGM ROD,

KEY 10

LOWER SPRING SEAT,

KEY 13

NEEDLE THRUST BEARING AND RACE,

KEY 71, 72

THRUST COLLAR,

KEY 73

SPRING ADJUSTOR,

KEY 74

Table 2. Recommended Bolting Torques

Description, Key Number Size Wrench Size NSm lbfSft

Diaphragm Casing, 5 3/8‐24 9/16 27 20

Casing to Actuator Box, 7, 8 3/8‐16 9/16 41 30

Diaphragm Plate to Rod, 9 3/4‐16 5/8 Allen 102 75

Rod end bearing locknut, 16 5/8‐18 15/16 61 45

Rod end bearing to lever, 18 5/8‐11 15/16 163 120

Lever Clamp, 28 5/8‐11 15/16 163 120

Cover, 34 1/2‐13 3/4 81 68

Turnbuckle locknut, 58 7/8‐14‐LH 1-5/16 163 120

Travel stop hex nut, 21 7/8-9 1-7/16 163 120

Protective Bracket to Actuator Box, 23 3/816 9/16 41 30

Accessory Mountings

Positioner – Sckt Hd Cap Screw 5/1618 5/16 23 17

546 to Bracket – Hex Hd Cap Screw 5/1618 1/2 23 17

546 Bracket to Actuator box – Hex Hd Cap Screw 3/816 9/16 41 30

2625 Vblocks to Actuator Box – Hex Hd Cap Screw 5/1618 1/2 23 17

67CFSR to Actuator Box – Hex Hd Cap Screw 5/1618 1/2 23 17

GO Switch™ Mounting

Go Switch Bracket – Hex Nut 5/1618 1/2 23 17

Go Switch to Bracket – Hex Nut 5/818 15/16 47 35

Target Magnet to Trip Arm Bracket – Hex Nut 7/1620 11/16 47 35

Trip Arm Bracket to Hub – Socket Hd Cap Screw 832 9/64 3.4 2.5 (30 lbfin)

Principle of Operation

The diaphragm rod moves down as loading pressure is increased on top of the diaphragm. As the loading pressure is

decreased, the spring forces the diaphragm rod upward.

The spring and diaphragm have been selected to meet the requirements of the application and, in service, the

actuator should produce full travel of the valve with the diaphragm pressure as indicated on the nameplate.

3

Page 4

1052PSV Actuator

March 2021

Instruction Manual

D103407X012

Consult the separate positioner instruction manual for actuator principle of operation with positioner.

Specifications

Specifications are shown in table 1. Specifications for actuator operation, as it originally comes from the factory, are

stamped on the nameplate attached to the actuator.

Installation

When an actuator and valve body are shipped together, the actuator is normally mounted on the valve. Follow the

valve body instructions when installing the control valve in the pipeline, and then perform the procedures presented in

the Loading Connection section. If the actuator is shipped separately or if it is necessary to mount the actuator on the

valve, perform the procedures presented in the Actuator Mounting section.

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury. Be aware of pinching parts during installation, maintenance, and adjustments of valve/actuator components.

To avoid personal injury or property damage resulting from the sudden release of pressure, do not install the valve

assembly where service conditions could exceed the limits given on the valve and actuator nameplates. Use

pressure‐relieving devices as required by accepted industry, local, state, or federal codes, and good engineering practices.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

Figure 3. Mounting Styles and Positions for the Fisher 1052PSV Actuator

POSITION 1

4

2

43A6505‐A

A1584‐3

FISHER SS-84PSV4 VALVE: RIGHT-HAND MOUNTING, PDTO ACTION, CCW BALL/PLUG ROTATION TO CLOSE

3

1

NOTE: POSITION 1 IS STANDARD

1

FLOW

CAUTION

To avoid parts damage, do not use an operating pressure that exceeds the Maximum Diaphragm Casing Pressure (table 1).

Use pressure‐limiting or pressure‐relieving devices to prevent the diaphragm casing pressure from exceeding its limit.

To avoid parts damage, do not stroke the actuator while cover (key 33) is off.

4

Page 5

Instruction Manual

D103407X012

1052PSV Actuator

March 2021

Lifting Guidelines

CAUTION

Care must be taken when lifting the valve/actuator assembly to ensure the accessories and tubing are not damaged in the

process. The entire assembly with accessories weighs approximately 340 kg (750 lb). Make sure to use appropriate lifting

straps/eyebolts/hoists capable of lifting this weight.

Figure 4. Lifting Guidelines

VALVE/ACTUATOR ASSEMBLY VALVE ONLY ACTUATOR ONLY

W100061

W100062

W100063

Lifting Valve/Actuator Assembly

To lift the assembly, insert 3/4-10 eyebolts into the two tapped holes on the top of the valve body. These two tapped

holes will carry most of the weight, but the assembly must be balanced using a strap on the 1052PSV casing as shown

in figure 4. The ends of the strap will be positioned underneath two L-shaped flanges or through eyebolts. Figure 4

shows L-shaped flanges attached to the casings. An alternative casing lift method is to use 3/8 inch eyebolts

positioned 180 degrees apart. Use protective pads between the strap and the casing to help prevent damage to the

painted surface. Torque the 3/8-24 cap screws or eyebolts and nuts to 20 lbf•-ft. The assembly can now be lifted using

a hoist capable of leveling these lifting points.

Lifting Valve Only

To lift the valve, insert 3/4-10 eyebolts into the two tapped holes on the top of the valve body. These two tapped holes

will carry most of the weight, but the assembly must be balanced using a strap underneath the valve bottom flange

(key 5 in the SS-84PSV4 instruction manual, D103416X012

using a hoist capable of leveling the 3 lifting points.

), as shown in figure 4. The assembly can now be lifted

5

Page 6

1052PSV Actuator

March 2021

Instruction Manual

D103407X012

Lifting Actuator Only

The actuator with accessories shall be lifted by the casing flange as shown in figure 4. Figure 4 shows L-shaped flanges

attached to the casings. An alternative casing lift method is to use 3/8 inch eyebolts positioned 180 degrees apart. Use

protective pads between the strap and the casing to help prevent damage to the painted surface. Torque the 3/8-24

cap screws or eyebolts and nuts to 20 lbf•ft. A single hoist lift point on the strap will balance and lift the actuator in a

level manner.

Conduit Connection

Diagnostic test fittings are Swagelok tee fittings with 1/4 inch Swagelok QC-series quick connects and appropriate

body protectors installed. Refer to the Bill of Material drawing for locations of diagnostic fittings.

The supply regulator for this assembly requires a 3/4 NPT pipe connection. Use a 3/4 NPT pipe run from the outlet of

the supply regulator to the actuator assembly.

Figure 5. Lever Operating Clearance

See appropriate accessory instruction manuals for additional conduit connections.

Valve Flow Direction

Valve construction can change the flow direction for a control valve assembly. It is important to observe the flow

direction in all valve applications before installing the valve in the pipeline (see figure 3). Refer to the appropriate valve

bulletin or instruction manual.

Note

Observe all warnings and cautions provided in the appropriate valve instruction manual Installation section.

6

Page 7

Instruction Manual

D103407X012

1052PSV Actuator

March 2021

Actuator Mounting

Use the following steps in this and the loading connection, turnbuckle adjustment, precise adjustment, and spring

adjustment section to connect a valve and an actuator. Key numbers are shown in figure 13.

WARNING

To avoid personal injury, perform the steps in the WARNING at the beginning of the Maintenance section to isolate the

control valve and actuator.

1. Unscrew cap screws (key 34), and remove the cover (key 33).

2. Proper installation of this actuator is right-hand mounted, actuator stem positioned vertically with the valve in a

horizontal pipeline.

3. Mount the actuator on the valve body and secure it with the washers and valve mounting screws. The torque for the

5/8 inch studs and nuts is 163 NSm (120 lbfSft).

CAUTION

Exceeding any torque requirement may impair the safe operation of this actuator by causing broken or damaged parts.

Refer to table 2 for the bolting torque requirements.

4. Screw the left‐hand threaded locknut (key 58) onto the diaphragm rod (key 10) as far as possible.

5. Screw the turnbuckle (key 57) as far as it will go onto the actuator rod.

6. Screw the locknut (key 16) as far as it will go onto the rod end bearing (key 17). Thread this assembly completely

into the turnbuckle (key 57).

7. If the lever (key 27) is attached to the rod end bearing, remove the cap screw and hex nut (keys 18 and 19).

8. If the 1052PSV spring adjustment has been changed, complete the Initial Setting portion of the 1052PSV Spring

Adjustment section before proceeding.

9. Slide the lever into place (see figure 5). Clamp with the cap screw (key 28).

10. Rotate the lever (key 27) to align with the rod end bearing (key 17). This connection can be aided by moving the

actuator off its up travel stop with a regulated air source and adjusting the turnbuckle (key 57) slightly.

11. Apply sealant (key 77) or equivalent thread‐locking compound to the threads of the cap screw (key 18).

12. Connect the lever (key 27) and the rod end bearing (key 17) with the cap screw and hex nut (keys 18 and 19).

Tighten the cap screw to the recommended bolt torque shown in table 2.

13. Note the valve position and direction of rotation. Position the travel indicator (key 37) according to the valve

position just noted.

CAUTION

To avoid parts damage, do not stroke the actuator while the cover (key 33) is off.

14. Replace the cover (key 33), and secure with washers (key 31) and cap screws (key 34).

7

Page 8

1052PSV Actuator

March 2021

Figure 6. Precise Valve/Actuator Closed Position Adjustment

Instruction Manual

D103407X012

WARNING

Be aware of pinching parts during installation, maintenance, and adjustments of valve/actuator components. To avoid

injury, keep hands and tools clear of actuator access windows when operating or adjusting the actuator.

Precise Valve/Actuator Closed Position and Turnbuckle Adjustment

Correct turnbuckle adjustment ensures that the valve is correctly closed when the actuator is against its travel stops.

Key numbers are shown in figure 13.

A regulated air supply with appropriate gauge will be required to stroke the actuator. The following wrench sizes will

be used to adjust the turnbuckle: 1-5/16 inch wrench for the turnbuckle (key 57), 15/16 inch wrench for the lower

locknut (key 16), and 1-5/16 inch wrench for the left-hand upper locknut (key 58).

Note

For the most accurate adjustment of the actuator, do not remove the cover (key 33) during this procedure.

1. Loosen the lower locknut (key 16).

2. Make sure the actuator box assembly (key 14) is clear of any tools or other instruments that could obstruct the

actuator stroke path. Pressure the diaphragm casing enough to stroke the actuator down so that the left‐hand

threaded upper locknut (key 58) is accessible through the access opening. Loosen the locknut.

8

Page 9

Instruction Manual

D103407X012

1052PSV Actuator

March 2021

3. Release all pressure from the actuator by venting the casing to atmosphere, making sure the diaphragm is against

its up travel stop. Check the valve position using a digital protractor, to align the horizontal edge of the hub (key 29)

to a flat surface on the top of the valve body (key 1 of the valve assembly). Refer to figure 6.

4. If the two surfaces are not within 0.3 degrees, adjust the turnbuckle (key 57) with a 1-5/16 inch wrench and

recheck. Continue this procedure until the valve is in the closed position when the actuator is resting on its up travel

stop.

Figure 7. Accessory Mounting - Fisher 546NS, 2625NS, and 3610J

5. Stroke the actuator to midtravel to gain better access to the turnbuckle and locknuts for tightening. Tighten the

7/814LH locknut (key 58) to 163 NSm (120 lbfSft) with a 1-5/16 inch wrench and then tighten the 5/818 locknut

(key 16) to 61 NSm (45 lbfSft) with a 15/16 inch wrench.

6. Install the travel indicator scale (key 35) and secure with self-tapping screws (key 36). Refer to figure 10 for proper

orientation.

9

Page 10

1052PSV Actuator

March 2021

Instruction Manual

D103407X012

CAUTION

The bolt pattern on the travel indicator scale (key 35) is symmetric, meaning the component could be installed in multiple

orientations. Ensure the travel indicator scale is mounted correctly as shown in figure 10, otherwise there will be false valve

position indication.

WARNING

Be aware of pinching parts during installation, maintenance, and adjustments of valve/actuator components. To avoid

injury, keep hands and tools clear of actuator access windows when operating or adjusting the actuator.

Actuator Spring Adjustment

Initial Setting

The 1052PSV nameplate specifies an initial spring setting. Initial setting is the casing pressure at which the diaphragm

and diaphragm rod begin to move away from the up travel stop with the actuator disconnected from the valve. (With

the actuator connected to the valve and pressure applied to the valve, a higher pressure will be required to start

actuator travel).

The initial setting was selected (based upon the service conditions specified when the actuator was ordered) so that,

when the actuator and valve are in service, the valve will seat properly and full travel will be obtained within a

diaphragm casing range of 0 to 2.7 bar (0 to 39 psig).

If the actuator has been disassembled or if the spring adjustment was changed, and it is desired to match the initial

setting stated on the nameplate, make sure the rod end bearing (key 17, figure 13) has been disconnected from the

lever (key 27, figure 13). Adjust the spring so that the diaphragm rod just starts to travel at the spring set pressure

specified on the nameplate.

Be sure the rod end bearing does not hit the lever as the diaphragm and diaphragm rod move away from the up travel

stop. To adjust the spring, use the special 2-1/2 inch wrench. Rotate the spring adjustor to move it toward the casing

to increase initial setting or away from the casing to decrease initial setting (keys 1 and 2, figure 13).

1. A regulated air supply with an appropriate gauge will be required to supply air pressure on top of the diaphragm to

stroke the actuator.

2. Rotate the spring adjustor (key 74), with the special 2-1/2 inch hex wrench, GE45169, so that the diaphragm rod

(key 10) just starts to travel at the spring set pressure specified on the nameplate (0.34 bar [7.0 psig] typical).

Note

Perform this setting with the actuator disconnected from the valve. The spring adjustor will need to compress the springs

and 12) approximately 1-7/8 inch for a 0.34 bar (7.0 psig) initial spring set.

(keys 11

Stroking Range

The initial spring setting listed on the nameplate has been determined to be the optimum setting, and it is not

recommended to make spring adjustments that will cause this value to change or be exceeded. For

10

Page 11

Instruction Manual

D103407X012

push‐down‐to‐open valve action, the initial spring setting is the maximum allowable to provide the maximum spring

closing force.

The following steps will set the stroking range or valve rotation to 80 degrees. There are two travel stop spacers

located in the casing in case the adjustable stops are not set properly.

1052PSV Actuator

March 2021

CAUTION

Any increase of this setting can over‐stress the spring at full travel and may shorten the fatigue life of the spring.

1. Apply sufficient supply pressure on top of the diaphragm to stroke the valve to 80 degrees (+/- 2 degrees).

2. Apply nuclear grade anti-seize lubricant (key 30) to the two 7/89 x 6.50 cap screws (key 22) and the two 7/89 hex

nuts (key 21), threading the nut as far as possible onto the cap screw.

3. Now thread the cap screws and nuts (keys 22 and 21), including washers (key 39), into the actuator box until each

cap screw just touches the lever (key 27) without torquing. Using a 1-7/16 inch wrench, tighten the nuts (key 21) to

163 NSm (120 lbfSft).

Figure 8. Bolting Sequence

Accessory Mounting

The following instructions describe how to install a 67CFSR regulator, 546NS I/P transducer, 2625NS volume booster,

3610J valve positioner, and Topworxt GOt proximity switches. For removal of each accessory, follow the steps in

reverse.

Fisher 2625NS Mounting -- Bolt the 2625NS and SST nipples to the actuator box with the vblock assemblies. Apply

thread locking adhesive, medium strength, (key 77) to the 5/1618 x 4.25 cap screws and tighten to 23 NSm (17 lbfSft)

with a 1/2 inch wrench. Washers are included when v-blocks are painted.

Fisher 546 Mounting -- Attach the 546 I/P to the 546 mounting bracket with 5/1618 x 0.75 cap screws and washers.

Apply thread locking adhesive, medium strength, (key 77) to the 5/1618 cap screws and tighten to 23 NSm (17 lbfSft)

11

Page 12

1052PSV Actuator

March 2021

Instruction Manual

D103407X012

with a 1/2 inch wrench. Now apply thread locking adhesive, medium strength, (key 77) to the 3/816 x 1.12 cap screws

and attach the 546 mounting bracket to the actuator box (key 14), including washers, tightening to 41 NSm (30 lbfSft)

with a 9/16 inch wrench. Washers are included when brackets are painted.

Fisher 3610J Mounting -- Attach the 3610J positioner to the actuator box with 5/1618 x 0.62 cap screws as shown in

figure 7. Apply thread locking adhesive, medium strength, (key 77) to the 5/1618 cap screws and tighten to 23 NSm

(17 lbfSft) with a 1/2 inch wrench.

Fisher 67CFSR Mounting -- Install two 67CFSR regulators to opposite sides of the 7 inch upper tube of the actuator box

(key 14). Apply thread locking adhesive, medium strength, (key 77) to the 5/1618 x 3.50 cap screws and tighten to 23

NSm (17 lbfSft) with a 1/2 inch wrench.

1. Position the actuator box assembly (key 14) over the valve shaft, and secure it to the valve with the valve mounting

cap screws.

2. Tighten the bolted joints on this valve/actuator assembly using the criss-cross pattern shown in figure 8. Tighten

each bolt evenly and in the sequence shown in figure 8. Tighten the valve mounting cap screws to 163 NSm (120

lbfSft).

Figure 9. Accessory Mounting - Fisher 67CFSR and GO Switch

12

Page 13

Instruction Manual

D103407X012

1052PSV Actuator

March 2021

WARNING

Be aware of pinching parts during installation, maintenance, and adjustments of valve/actuator components. To avoid

injury, keep hands and tools clear of actuator access windows when operating or adjusting the actuator.

Loading Connection

Follow these steps if the tubing and fittings have been loosened or removed from the accessories.

1. Connect the loading pressure piping to the pressure connection in the top of the diaphragm casing. Run 3/8 inch

tubing between the 1/4 NPT pressure connection and the instrument. Run 1/2 inch tubing between the volume

booster and the upper casing.

2. Keep the length of pipe or tubing as short as possible to avoid transmission lag in the control signal. If an accessory

(such as a volume booster or a valve positioner) is used, be sure that the accessory is properly connected to the

actuator. If a valve positioner is part of the assembly, the pressure connection to the actuator will normally be made

at the factory.

3. When the control valve is completely installed and connected to the instrument, check for correct action

(air‐to‐open) to match the controlling instrument. For successful operation, the actuator stem and valve shaft must

move freely in response to the loading pressure change on the diaphragm.

Figure 10. Indicator Orientation Shown When Valve/Actuator are in the Closed Position

PROPER ORIENTATION OF

TRAVEL INDICATOR (KEY 37),

SHOWN WITH ARROW

POINTING TOWARD COVER

(KEY 33) FLAT.

WARNING

PROPER ORIENTATION OF TRAVEL

INDICATOR SCALE (KEY 35), SHOWN

WITH FLOW ARROW POINTING

AWAY FROM COVER (KEY 33) FLAT.

Be aware of pinching parts during installation, maintenance, and adjustments of valve/actuator components. To avoid

injury, keep hands and tools clear of actuator access windows when operating or adjusting the actuator.

13

Page 14

1052PSV Actuator

March 2021

Instruction Manual

D103407X012

GO Switch Mounting

1. Coat two 1/2-13 x 2.00 cap screws (key 34) with nuclear grade anti-seize lubricant and bolt the GO Switch

mounting bracket and actuator cover (key 33) to the actuator box (key 14) as shown in figure 9. Torque to 92 NSm

(68 lbfSft).

2. Apply thread locking adhesive, medium strength, (key 77) to the four 5/1618 x 1.00 cap screws and bolt the two

angle GO Switch brackets to the mounting bracket. Torque the 5/1618 cap screws and nuts to 23 NSm (17 lbfSft).

3. Apply thread locking adhesive, medium strength, (key 77) to the four 8-32 x 0.88 socket head cap screws (key 38).

Install the slotted, open trip arm and closed trip arm brackets, with travel indicator scale (key 37), to the hub

(key29) as shown in figures 9 and 10. Install the 8-32 x 0.88 socket head cap screws (key 38) finger tight.

CAUTION

The bolt patterns on the travel indicator and travel indicator scale (keys 37 and 35) are symmetric, meaning the

components could be installed in multiple orientations. Ensure the travel indicator and travel indicator scale are mounted

correctly as shown in figure 10, otherwise there will be false valve position indication.

4. Install one GO Switch and hex nut on each GO Switch bracket and one target magnet with a hex nut on each trip

arm bracket.

5. Adjust the valve to the desired full open rotation, typically 40 to 80 degrees.

6. With the valve in the desired open position, establish a 0.100 inch gap between the GO Switch and target magnet;

this is accomplished by adjusting the open trip arm bracket rotationally and by changing the thread engagement of

the switch and magnet. Torque the 8-32 x 0.88 inch socket head cap screws (key 38) to 3.4 N•m (2.5 lbf•ft

[30 lbf•in]) using a 9/64 inch socket wrench.

7. Apply thread locking adhesive, medium strength, (key 77) to the target magnet 7/16-20 threads and torque to

47 N•m (35 lbf•ft). Apply thread locking adhesive, medium strength, (key 77) to the GO Switch 5/8-18 threads and

torque to 47 N•m (35 lbf•ft).

8. Return the valve back to the closed position and verify the gap between the closed position GO Switch and target

magnet is 0.100 inch.

Maintenance

Actuator parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of

inspection and replacement depends upon the severity of service conditions. Key numbers are shown in figure 13 for

the 1052PSV actuator.

WARNING

Avoid personal injury or property damage from sudden release of process pressure or uncontrolled movement of parts.

Before performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury. Be aware of pinching parts during maintenance operations.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve. Drain the process media from both sides of the valve.

14

Page 15

Instruction Manual

D103407X012

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

D Be aware of pinching parts during installation, maintenance, and adjustments of valve/actuator components. To avoid

injury, keep hands and tools clear of actuator access windows when operating or adjusting the actuator.

1052PSV Actuator

March 2021

CAUTION

To avoid parts damage, do not stroke the actuator while cover (key 33) is off.

Disassembly

The following procedure describes how to completely disassemble the actuator. When inspecting and replacing parts,

perform only those steps necessary to accomplish the repair.

Do not, under ordinary circumstances, remove the cap screws (keys 7 and 8) at this time.

CAUTION

Cap screw (key 18) must be disengaged from the lever (key 27) before removing the diaphragm casing (key 1). Failure to do

so will allow the spring precompression to rotate the valve beyond its fully open or closed position. This could cause

damage to the valve components and/or seal.

1. Perform the steps in the WARNING at the beginning of the Maintenance section to isolate the control valve and

actuator.

2. Remove the tubing or piping from the top of the actuator.

3. Remove the positioner, if used. If necessary, refer to the positioner instruction manual for removal instructions.

4. Unscrew the cap screws (key 34), and remove the washers (key 31), cover (key 33), and any accessories attached to

this end of the actuator.

5. Remove the travel indicator (key 37) from the hub (key 29). Slide the hub (key 29) from the cover.

6. Inspect, and if necessary, replace the cover bushing (key 31). Remove the travel indicator scale (key 35) by

removing the self‐tapping screws (key 36). Press the bushing out of the cover (key 33).

7. Remove the cap screw and hex nut (keys 18 and 19).

8. Make note of the lever/valve shaft orientation, and then loosen the cap screw (key 28).

15

Page 16

1052PSV Actuator

March 2021

Figure 11. Lower Casing Travel Stop Orientation

Instruction Manual

D103407X012

TRAVEL

STOP

BODY

TRAVEL

STOP

CAUTION

When removing the actuator from the valve, do not use a hammer or similar tool to drive the lever (key 27) off the valve

shaft. Driving the lever could damage internal valve parts. On some valve types, driving the lever off the shaft could move

the valve disk or ball and bearings away from the centered position, causing subsequent damage to valve parts as the valve

is operated.

A wheel puller may be used to remove the lever. It is okay to tap the wheel puller screw lightly to loosen the lever, but

hitting the screw with excessive force could also damage valve parts or disrupt the centered position of the valve disk and

bearings.

WARNING

To avoid personal injury from pre‐compressed spring force suddenly thrusting the upper diaphragm casing (key 1) away

from the actuator, relieve 1052PSV spring compression before proceeding further.

9. To relieve spring compression, use the special 2-1/2 inch wrench to rotate the spring adjustor (key 74), and move it

away from the actuator casings. Continue rotating the spring adjustor until spring compression is completely

removed.

10. Unscrew and remove the cap screws, washers, and hex nuts (keys 5, 26, and 6), and then remove the upper

diaphragm casing and the diaphragm (key 3).

11. To remove the diaphragm plate (key 4), remove the rod end bearing (key 17), the lower locknut (key 16),

turnbuckle (key 57), and the left hand threaded upper locknut (key 58) from the diaphragm rod (key 10).

12. Pull the diaphragm plate (key 4) and attached parts out of the actuator. Then remove the cap screw (key 9) to

separate the diaphragm plate and the diaphragm rod.

13. Remove the actuator springs (keys 11 and 12) from the actuator. Then remove the lower spring seat (key 13),

thrust bearing and bearing races (keys 71 and 72), and thrust collar (key 73).

14. If replacing the spring adjustor (key 74), rotate it away from the casing (keys 1 and 2) until disengaged.

16

Page 17

Instruction Manual

D103407X012

1052PSV Actuator

March 2021

15. Unbolt the actuator box assembly (key 14) from the valve.

Assembly

This procedure assumes that the actuator was completely disassembled. If the actuator was not completely

disassembled, start these instructions at the appropriate step.

Key numbers are shown in figure 13.

1. Refer to figure 5 for the orientation of the actuator box assembly (key 14).

WARNING

Exceeding any torque requirement may impair the safe operation of the actuator and lead to possible personal injury or

property damage.

2. Place the lower diaphragm casing (key 2) on top of the actuator box (key 14) 7 inch square tube. Install six hex head

cap screws (key 7) with washers (key 25) in holes identified with a number 7 in figure 11. Using a 9/16 inch hex

wrench, tighten the cap screws to 41 NSm (30 lbfSft).

3. Install two travel stop spacers (key 20) onto the two hex head cap screws (key 8) and install into the holes

numbered 8/20 in figure 11. Using a 9/16 inch hex wrench, tighten the cap screws to 41 NSm (30 lbfSft).

4. Clean and then lubricate the threads of the spring adjustor (key 74) with nuclear grade anti-seize lubricant (key 30).

Install the spring adjustor in through the large window of the lower actuator tube (12 x 12 inch crosssection) and

up into the upper actuator tube (7 x 7 inch crosssection). Thread in until the top of the spring adjustor is

approximately 1/4 inch above the surface of spring plate.

5. Place the thrust collar (key 73) on top of the spring adjustor (key 74) by insertion into the window in the middle of

the upper actuator tube. Coat both sides of the needle thrust bearing (key 71) with nuclear grade anti-seize

lubricant (key 30), place between the two needle thrust bearing races (key 72), and install on top of the thrust collar

(key 73). Install the lower spring seat (key 13) on top of the needle bearing assembly (keys 71, 72, and 73) and down

into the counterbore of the thrust collar (key 73).

6. Install springs (keys 11 and 12) on top of the lower spring seat (key 13) through the center opening in the lower

diaphragm casing (key 2).

7. Place the upper spring seat (key 15) on top of the center spring (key 11).

8. Coat the tapered end of the diaphragm rod (key 10) and the threads of the socket head cap screw (key 9) with

nuclear grade anti-seize lubricant (key 30). Bolt the diaphragm plate (key 4) to the diaphragm rod tightening to 102

NSm (75 lbfSft) with a 5/8 inch hex Allen wrench.

Note

Use the turnbuckle (key 57) and locknut (key 58) clamped into clean vise jaw inserts for antirotation while tightening.

9. Lubricate the external threads on the diaphragm rod (key 10) with nuclear grade anti-seize lubricant.

10. Install the diaphragm plate/diaphragm rod assembly into the actuator box.

11. Screw the 7/814 lefthand threaded upper locknut (key 58) onto the diaphragm rod as far as possible without

torquing.

12. Screw the turnbuckle (key 57) as far as it will go onto the diaphragm rod without torquing.

13. Coat the threads of the rod end bearing (key 17) with nuclear grade anti-seize lubricant (key 30). Screw the 5/818

lower locknut (key 16) as far as it will go onto the rod end bearing (key 17) without torquing, to create a rod end

bearing assembly.

17

Page 18

1052PSV Actuator

March 2021

Instruction Manual

D103407X012

14. Thread the rod end bearing assembly completely into the turnbuckle (key 57) without torquing.

15. Install the diaphragm (key 3) onto the diaphragm plate (key 4) and line up the perimeter holes in the diaphragm

(key 3) and the lower diaphragm casing (key 2). Place the upper diaphragm casing (key 1) onto the lower

diaphragm casing (key 2). If necessary, rotate the spring adjustor (key 74) so that the upper diaphragm casing will

achieve solid contact with the diaphragm (key 3). Also ensure that the travel stop, in the upper diaphragm casing

(key 1), will not contact the diaphragm (key 3) when the casing cap screws and nuts (keys 5 and 6) are tightened.

16. Using a 9/16 inch wrench, secure the upper diaphragm casing (key 1) with cap screws (key 5), washers (key 26), and

hex nuts (key 6). Tighten the hex nuts (key 6) in the following manner.

a. The first four hex nuts tightened should be diametrically opposed and 90 degrees apart. Tighten these four hex

nuts to 13.6 NSm (10 lbfSft).

b. Tighten the remaining hex nuts in a clockwise, criss-cross pattern to 13.6 NSm (10 lbfSft).

c. Repeat this procedure by tightening four hex nuts, diametrically opposed and 90 degrees apart, to a torque of 27

NSm (20 lbfSft).

d. Tighten the remaining hex nuts in a clockwise, criss-cross pattern to a torque of 27 NSm (20 lbfSft).

e. After the last hex nut is tightened to 27 NSm (20 lbfSft), all of the hex nuts should be tightened again to 27 NSm

(20 lbfSft) in a circular pattern around the bolt circle.

17. Perform the initial spring setting per the 1052PSV Spring Adjustment section.

18. Refer to the Actuator Mounting section if the actuator is not already mounted.

19. Install the lever (key 27) on the valve drive shaft as shown in figure 12. Note: The splined connection is a missing

tooth design, ensuring a one-way assembly.

Figure 12. Lever Angle in Valve Closed Position

20. Viewing from the actuator end, rotate the lever counter-clockwise (CCW) to 45 degrees from horizontal as shown

in figure 12.

18

Page 19

Instruction Manual

D103407X012

1052PSV Actuator

March 2021

CAUTION

If the lever is rotated too far CCW, the trailing edge of the VeeBall can disengage the seal. To avoid damage to the ball and

seal, DO NOT rotate clockwise (CW) back into the seat. Continue to rotate CCW and repeat previous step 3.

21. During the remaining actuator assembly procedures, care should be taken to keep the VeeBall in the closed

position. Note: Final VeeBall centering will be accomplished in the section titled Precise Valve/Actuator Closed

Position Adjustment and Turnbuckle Tightening Instructions.

22. Coat the outside bearing surface of the hub (key 29), and the inside diameter of the bushing (key 31), with nuclear

grade anti-seize lubricant (key 30).

23. Install the hub (key 29) onto the valve drive shaft and place the actuator cover (key 33) over the hub.

24. Lubricate cap screws (key 34) with nuclear grade anti-seize lubricant (key 30) and bolt the actuator cover (key 33)

and the GO Switch mounting bracket to the actuator box (key 14) including washers (key 31). Using a 3/4 inch

wrench, tighten to 81 NSm (60 lbfSft). Refer to figure 6 for an illustration of the GO Switch mounting bracket.

25. With the hub against the cover, slide the lever (key 27) towards the hub (key 29) leaving a 3/32 inch gap between

them.

26. Clamp the lever (key 27) onto the valve drive shaft with the 5/811 x 1.25 cap screw (key 28). Using a 15/16 inch

wrench, tighten to 163 NSm (120 lbfSft).

27. Refer to the Precise Valve/Actuator Closed Position Adjustment section to connect the diaphragm rod to the valve

drive shaft.

28. Refer to the Stroking Range section to set the down travel stop position.

29. Bolt the protective bracket (key 24) to the actuator box using 3/816 x 0.75 cap screws (key 23) and washers (key

40, only when bracket is painted). Using a 9/16 inch wrench tighten to 41 NSm (30 lbfSft).

30. Install the travel indicator scale (key 35) and secure with self-tapping screws (key 36). Refer to figure 10 for proper

orientation.

31. Apply thread locking adhesive, medium strength, (key 77) to the four 8-32 x 0.88 socket head cap screws (key 38).

Install the slotted, open trip arm and closed trip arm brackets, with travel indicator scale (key 37), to the hub

(key29) as shown in figures 9 and 10. Install the 8-32 x 0.88 socket head cap screws (key 38) finger tight. Final

torque of the 8-32 socket head cap screws is described in the GO Switch Mounting Section of this manual, page 14.

CAUTION

The bolt patterns on the travel indicator and travel indicator scale (keys 37 and 35) are symmetric, meaning the

components could be installed in multiple orientations. Ensure the travel indicator and travel indicator scale are mounted

correctly as shown in figure 10, otherwise there will be false valve position indication.

32. Reference the accessory mounting section of this instruction manual to install accessories.

19

Page 20

1052PSV Actuator

March 2021

Troubleshooting

Table 1. Troubleshooting

Problem Possible Solution

Diaphragm Casing Leak

Actuator stoke is less

than full rated travel

Other Consult your Emerson sales office.

Verify proper tightening procedure and torque on casing cap screws.

Disassemble and inspect diaphragm for cracks or wear.

Verify the valve and actuator are in the closed position. Reference the Precise Valve/Actuator Closed Position Adjustment section

of this instruction manual.

Verify adjustable travel stops have been set properly. See Adjustable Travel Stops section of this instruction manual.

Check bench set for proper actuator spring load. See Spring Adjustment section of this instruction manual.

Adjustable Down Travel Stops

Note

When this valve is shipped, the manual travel stops are adjusted for 80 degrees rotation of the valve.

Instruction Manual

D103407X012

Adjustable down travel stops have been provided to limit the diaphragm rod travel away from the casing. This

adjustment will limit the amount of valve rotation from 40_ to 80_ open.

WARNING

To avoid personal injury, perform the steps in the WARNING at the beginning of the Maintenance section to isolate the

control valve and actuator.

Be aware of pinching parts during installation, maintenance, and adjustments of valve/actuator components. To avoid

injury, keep hands and tools clear of actuator access windows when operating or adjusting the actuator.

1. A regulated air supply with appropriate gauge will be required to stroke the actuator to the desired angle of

rotation.

2. The actuator should be fully assembled and connected to the valve before proceeding. If not, refer to the Assembly

section to assemble the actuator.

3. Zero the valve and actuator using the Precise Valve/Actuator Closed Position Adjustment and turnbuckle

adjustment instructions.

4. Apply pressure to the diaphragm casing while using a digital protractor to position the valve to the desired rotation.

Using the top of the valve body as a reference for 0 degrees, rotate the valve until the square on the hub (key 29) is

at the desired angle of rotation. Refer to figure 6.

5. Loosen both hex nuts (key 21) using a 1-5/16 inch wrench and rotate each nut away from the actuator box for

adjustment.

6. Thread cap screws (key 22) towards the lever (key 27) until each contacts the lever without torquing.

7. Apply nuclear grade anti-seize lubricant to the 7/8-9x6.50 cap screws (key 22), threading the nut as far as possible

onto the cap screw. Tighten the nuts (key 21) to 163 NSm (120 lbfSft) with a 15/16 inch wrench.

20

Page 21

Instruction Manual

D103407X012

1052PSV Actuator

March 2021

Parts Ordering

When corresponding with your Emerson sales office about this equipment, refer to the serial number found on the

actuator nameplate (key 41, figures 13). Also, specify the complete 11‐character part number from the following parts

list when ordering replacement parts. The Size 70 actuator is available only in Type 1052 actuators.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson should not, under any

circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the performance

of the valve, and could cause personal injury and property damage.

Spare Parts

The spare parts replacement interval is based in part on plant operation, operating conditions, normal maintenance

interval, process fluid, and other factors. Periodic inspection of the valve and actuator and diagnostics run on the

control valve assembly are recommended to identify the optimum replacement timing.

Table 2. Fisher 1052PSV Spare Parts

Drawing

Number

GE39223 GE39223X022 Hub, Key 29

2E8597 2E8597X0062

GE39188

GE39224

GE45169 GE45169X012

1. ME/n = construction/installation spares. P/n = preoperational spares. S/n = start-up spares. O/n = operational spares.

2. Dependant on good storage practices and conditions.

Replacement

Part Number

GE39188X022

Part

Description,

Key No.

Diaphragm,

size 60,

Key 3

Actuator

Cover/

Bushing

Assembly,

Key 33

Spring

Adjustor

Wrench

Qty Classification

Non-Safety

1

Related

Non-Safety

1

Related

Non-Safety

1

Related

Non-Safety

1

Related

Spare

Part

Code

O/n

O/n

O/n

O/n

(1)

Spare Part Requirement Rationale Shelf Life

Cycled parts will exhibit wear over time. Based on

experience and testing, Emerson recommends

replacing this component every 30 years.

Recommendation to purchase this spare part is

based on shelf life restrictions. The diaphragm is

a key component within the actuator

construction, required to ensure optimal

performance over time. Degradation of the

diaphragm could lead to inconsistencies with

valve operation. Emerson recommends replacing

this component every 6 years.

The bushing will see repeated cycles in contact

with a metal hub. It is the manufacturer's

recommendation to replace the cover/bushing

assembly when wear or diagnostic testing shows

degraded performance or after 30 years of

operation, whichever comes first.

The special wrench is not commercially available.

This wrench is required to adjust actuator spring

load.

N/A

EPDM

material

shelf life is

4 years

after

shipment

or 12 years

from cure

date.

N/A

N/A

Shelf Life

Rationale

Does not

exhibit a

tendency to

degrade over

time.

See FGS8A31

rev. P

(attached) for

information

regarding

elastomer shelf

life.

Does not

exhibit a

tendency to

degrade over

time.

Does not

exhibit a

tendency to

degrade over

time.

(2)

21

Page 22

1052PSV Actuator

March 2021

Figure 13. Fisher 1052PSV Actuator Assembly

Instruction Manual

D103407X012

22

GE39246-D

Page 23

Instruction Manual

D103407X012

Parts List

Key Description Qty Part Number

1 Upper Casing assy 1 11A2925X012

2 Lower Casing Diaphragm 1 2E847425062

3* Diaphragm, size 60 1 2E8597X0062

4 Diaphragm Plate assy 1 28A6022X012

5 Cap Screw, Hex Hd, 3/8-24X1.25 24 1A3683X0042

6 Hex Nut, 3/8-24 24 1A3465X0092

7 Cap Screw, Hex Hd, 3/8-16X0.75 6 1A3684X0082

8 Cap Screw, Hex Hd, 3/8-16X2.00 2 1A3445X0142

9 Cap Screw, Hex Socket, 3/4-16X1.25 1 1E7754X0032

10 Diaphragm Rod 1 GE39199X022

11 Spring, 2 3/4 X 15 3/4 right hand 1 14A9017X052

12 Spring, 3 1/16 X 16 5/8 left hand 1 14A9016X052

13 Lower Spring Seat 1 GE39198X012

14 Actuator Box assy (Mach) 1 GE39200X012

15 Upper Spring Seat 1 14A9025X012

16 Hex Jam Nut, 5/8-18 1 1A354035072

17 Rod Bearing, male end 1 1R4408X0082

18 Cap Screw, Hex Hd, 5/8-11 X2.75 1 1P9832X0022

19 Hex Nut 5/8-11 UNC-2B 1 1A343324122

20 Travel Stop Spacer 2 18B2658X052

21 Hex Nut, 7/8-9 2 1C1727K0012

22 Cap Screw, Hex Hd, 7/8-9X6.50 2 GE45339X012

23 Cap Screw, Hex Hd, 3/8-16X0.75 4 1A3684X0082

24 Protective Bracket 1 GE39230X012

25 Washer, Plain, 3/8 6 1B365428992

26 Washer, Plain, 3/8 48 1B365428992

27 Lever 1 GE39229X012

28 Cap Screw, Hex Hd, 5/8-11X1.25 1 12A9405X022

29* Hub 1 GE39223X022

30 Nuclear Grade Anti-Seize Lubricant 1 1M3801X0012

1052PSV Actuator

March 2021

Key Description Qty Part Number

31 Washer, Plain, 1/2 4 1A5189X0022

33* Actuator Cover/Bushing assy 1 GE39188X022

34 Cap Screw, Hex Hd, 1/2-13 X 2.00 4 1A3616X0042

35 Travel Indicator Scale 1 GE39243X012

36 Self Tapping Screw 6-32 X 0.31 2 1B5613X0032

37 Travel Indicator 1 GE39241X012

38 Cap Screw, Hex Socket, 8-32X 0.88 4 1H3284X0042

39 Washer, Plain, 7/8 2 1A519828992

40 Washer, Plain, 3/8 4 1B365428992

41 Rotary Actuator Nameplate 1 12B6401X012

42 Drive Screw 4 1A368228982

57 Turnbuckle, 7/8-14LH X 5/8-18 1 22A9624X032

58 Hex Jam Nut, 7/8-14 LH 1 1R4389X0012

71 Needle Thrust Bearing 1 1N888799012

72 Needle Thrust Bearing Race 2 1N888899012

73 Thrust Collar 1 GE39237X012

74 Spring Adjustor 1 GE39236X012

77 Thread Locking Compound

(Medium Strength) 1 1M3812X0012

144 Actuator Caution Tag 1 18B9855X012

Accessory Mounting Kits

Mounting Assy,1052PSV GO Switch 1 GE50812X012

Mounting Assy,1052PSV 546 1 GE42325X012

Mounting Assy,1052PSV 2625NS 1 GE42525X012

Special Tools

* Spring Adjustor Wrench 1 GE45169X012

*Recommended spare parts

23

Page 24

1052PSV Actuator

March 2021

Instruction Manual

D103407X012

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher, Vee-Ball, TopWorx, and GO Switch are marks owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric

Co. Emerson Automation Solutions, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the

property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

24

E 2009, 2021 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...