Page 1

Product Bulletin

EW Valve

D100023X012

51.1:EW

October 2020

Fisher™ EW Series (EWD/EWS/EWT)

Sliding-Stem Control Valves through NPS 12x8

Fisher EW Series easy-et valves (figures 1, 2, 3, and 4)

feature large internal cavities with expanded end

connections and a variety of unbalanced and balanced

plug designs. Sizes available from NPS 4x2

12x8. These combinations provide good fluid control

in economical, high-capacity valve bodies that keep

valve outlet velocities within practical limits.

These valves meet a variety of service requirements,

such as power plants where oversized piping is used to

limit fluid flow velocity. They also perform well in noise

abatement applications; for example, high-pressure

gas reducing stations where sonic velocities are often

encountered at the outlet of conventional valve

bodies.

(1)

through

The Fisher EW product line is available for a wide range

of applications, including sulfide and chloride

stress-cracking environments common to the oil and

gas production industries. To discuss available

constructions, contact your Emerson sales office

include the applicable codes and standards required

for these environments.

and

The easy-e Valve Family

EW Series valves are part of the versatile easy-e family

of Fisher industrial control valves. easy-e valves share

the following characteristics:

n Multiple trim material choices

n Trim temperature capability with metal seats

standard to 427_C (800_F)

n Interchangeable, restricted-capacity trims and

full-size trims to match variable process flow

demands

W2777-1

n Different cage/plug styles that provide particular

flow characteristics for highly-specialized

applications. The standard cage comes in three

different flow characteristics:

D quick-opening

D linear

D equal percentage

n Cavitrolt III cages are available to eliminate

cavitation damage and Whisper Trimt III cages are

available to help attenuate aerodynamic noise.

n 316 stainless steel packing box parts are standard

(including packing flange, studs, and nuts)

The temperature limits of EWT valves can be extended

above 232_C (450_F) by using PEEK

www.Fisher.com

Page 2

Product Bulletin

51.1:EW

October 2020

EW Valve

D100023X012

(PolyEtherEtherKetone) anti-extrusion rings in

combination with a spring-loaded PTFE seal. The PEEK

anti-extrusion rings expand to close off the clearance

gap between the plug and the cage where the PTFE

seal may extrude at high temperatures and pressures.

The temperature limits are extended to 316_C (600_F)

for non-oxidizing service and to 260_C (500_F) for

oxidizing service.

Note

Refer to Fisher Bulletin 51.1:EWN, EWN Series valves with

Whisper Trim III cages (D100024X012

information.

Note

Refer to Fisher Bulletin 80.3:010, WhisperFlot

Aerodynamic Noise Attenuation Trim (D102362X012

further information.

) for further

) for

Features

n Compliance with the Clean Air Act— ENVIRO-SEAL™

packing systems provide an improved stem seal to

help prevent the loss of valuable or hazardous

process fluid. The ENVIRO-SEAL packing systems

feature PTFE or Graphite ULF packing with

live-loading for reduced packing maintenance.

n Piping Economy—Expanded end connections of EW

Series valve bodies may reduce the need for line

swages while accommodating oversized piping

arrangements used to limit fluid flow velocities.

n Temperature Compensation—On designs with the

seat ring threaded into the valve body (figure 4), the

hung cage feature helps reduce gasketing problems

caused by thermal expansion and contraction of

long parts, such as the cage assembly.

n Standard Trim Parts across the easy-e product

line—Included are FGM gaskets, packing flange,

studs, and nuts.

n High-Temperature, Class IV or Class V

Shutoff—Optional multiple piston rings (figure 14)

for EWD and EWD-1 valve bodies permit Class IV

shutoff up to 593_C (1100_F).

Use of C-seal trim for EWD (see figure 5) permits

Class V shutoff up to 593_C (1100_F).

n Increased Pressure/Temperature Ratings—NPS 12x8

CL900 EW Series valve bodies with buttwelding end

connections are capable of increased ASME ratings

called Intermediate Standard Ratings. The extra

strength of the valve body allows these valves to be

used where pressures and temperatures exceed

Standard Class ratings in ASME B16.34.

See Bulletin 59.1:027, Increased Pressure/

Temperature Ratings for EH and EW Series Steel

Valves (D100076X012

) for further information.

n Noise Attenuation—In an EW Series valve, noise

produced by high flow rates and large pressure

drops can be reduced by up to 18 dbA with a

Whisper Trim I cage, by up to 30 dbA with a Whisper

Trim III cage, and by up to 40 dbA with a WhisperFlo

cage.

Table of Contents

Features 2.....................................

Specifications 3................................

C-seal Trim Description 6........................

ENVIRO-SEAL and HIGH-SEAL Packing Systems 6.....

Available Configurations 10......................

2

n Sour Service Capability— Unless otherwise noted,

references are to NACE MR0175-2002. Optional

materials are available to meet NACE MR0103 and

NACE MR0175 / ISO 15156. Material requirements

under these standards vary by edition and year of

issue; the specific standard must be specified.

Material Selection Guidelines 10..................

ANSI/FCI Class VI Shutoff Capabilities 12............

Fisher TSO (Tight Shutoff) Trim Capabilities 13......

Installation 13.................................

Dimensions 33.................................

Page 3

EW Valve

D100023X012

Specifications

Product Bulletin

51.1:EW

October 2020

Valve Body Configurations

See Available Configurations section

Valve Body Sizes

See table 2

End Connection Styles

Flanged:

ring-type joint flanges per ASME B16.5,

J CL150, 300, 600, and 900 raised-face or

J raised-face

per EN 1092-1/B

Buttwelding: Styles per ASME B16.25 schedules that

are consistent with ASME B16.34 are Schedule

or

J 80 for all CL300 and 600 valves, Schedule J 80

J XXS for NPS 8x6 CL900 valves, or Schedule

or

J 80, J 100, or J 120 for NPS 12x8 CL900 valves

Maximum Inlet Pressures and Temperatures

Consistent with applicable J CL300, J 600

J 900 pressure/temperature ratings per

(2)

J 40

(1)

, or

ASME B16.34 unless limited as follows:

Valves With All Except Cavitrol III or Whisper Trim III

Cages: Where limited by individual

pressure/temperature capabilities in figure 8 or 9 or

temperature capabilities in table 11, 12, 13, or 20.

Valves With Cavitrol III Cages: Where limited by

individual pressure/temperature capabilities in figure

12 or temperature capabilities in table 16 or 20

Valves With Whisper Trim III Cages: Where limited by

individual pressure/temperature capabilities in figure

15 or 16 or temperature capabilities in table 18 or 20

Maximum Pressure Drops

(1, 3)

Same as maximum inlet pressure for specific

construction defined above, except where further

limited as follows:

Valves With All Except Cavitrol III or Whisper Trim III

Cages: See figure 8 or 9

Valves With Cavitrol III Cages: See figure 12

Valves With Whisper Trim III Cages: 0.999 nP/P

1

maximum for levels A1 through D3

Construction Materials

Valve, Bonnet, and Bonnet Spacer If Used:

carbon steel,

moly steel,

J LCC carbon steel, J WC9 chrome

J CF8M (316 SST), J other materials

J WCC

upon request

Valve Plug, Cage, and Metal Seating Parts

Valves With All Except Cavitrol III or Whisper Trim III

Cages: See table 5 or 14

Valves With Cavitrol III Cages: See table 15

Valves With Whisper Trim III Cages: See table 17, 18, or

19

All Other Parts: See table 20

Material Temperature Capabilities

(1)

Valve Body/Trim Combinations

Valves With All Except Cavitrol III or Whisper Trim III

Cages: See figure 8 or 9 and table 11, 12, or 13

Valves With Cavitrol III Cages: See figure 12 and table

16

Valves With Whisper Trim III Cages: See figure 15 or 16

and table 18

All Other Parts: See table 20

Flow Characteristics

Standard Cages:

J equal percentage

J Quick-opening, J linear, or

Cavitrol and Whisper Trim Cages: Linear

Flow Directions

Valves with Standard Cages

EWD, EWD-1, EWT, and EWT-1: Normally down

EWS and EWS-1: Normally up

Valves with Cavitrol Cages: Always down

(6)

(5)

Valves with Whisper Trim III Cages: Always up

(5)

(6)

Flow Coefficients and Noise Level Prediction

Refer to Fisher Catalog 12

Shutoff Classifications Per ANSI/FCI 70-2 and IEC

60534-4

See tables 3 and 4

Port Diameters and Maximum Valve Plug Travels

See table 21

- continued -

3

Page 4

Product Bulletin

51.1:EW

October 2020

Specifications (continued)

EW Valve

D100023X012

Yoke Boss and Stem Diameters

See table 21

Optional Safety Instrumented System Classification

EWD, EWD-1, EWT, and EWT-1: SIL3 capable —

certified by exida Consulting LLC

Typical Bonnet Styles (see table 23)

J Plain, J style 1 cast extension, J style 2 cast

extension,

J ENVIRO-SEAL bellows seal bonnet

Options

J Lubricator, J lubricator/isolating valve, J drilled

and tapped connection in extension bonnet for

leak-off service,

J valve body drain plug,

J ENVIRO-SEAL bellows seal bonnet for positive stem

Packing Arrangements

J Standard PTFE, J Double PTFE, J Graphite,

J ENVIRO-SEAL PTFE, J ENVIRO-SEAL Duplex,

J ENVIRO-SEAL Graphite ULF, J HIGH-SEAL

sealing of hard-to-handle fluids at temperatures up to

566_C (1000_F),

J style 3 fabricated extension

bonnet made on order to a specific length for

cryogenic service,

J special seismic service bonnet,

J packings suitable for nuclear service, and J forged

bonnet for 5 in. (127 mm) yoke boss on NPS 8x6

Approximate Weights

CL900 valve,

(450_F) using PEEK anti-extrusion rings

J Class V shutoff for EWT above 232_C

J Class V

shutoff for EWD up to 593_C (1100_F) using C-seal

See table 22

1. The pressure/temperature limits in this bulletin and any applicable standard or code limitation should not be exceeded.

2. Certain bonnet bolting material selections may require a CL600 easy-e valve assembly to be derated. Contact your Emerson sales office

3. Only NPS 12x8 CL900 valve bodies with threaded (-1) seat rings can take full CL900 pressure drops; CL900 valve bodies with clamped (no dash number) seat rings are limited to CL600

pressure drops. Also, there are two different NPS 8x6 CL900 valve bodies, one for use only with Cavitrol III cages and the other for use with all other constructions. An NPS 8x6 CL900 valve body

with Cavitrol III cage can take full CL900 pressure drops. For information on other NPS 8x6 constructions that can take full CL900 pressure drops, contact your Emerson Automation Solutions

sales office. All other NPS 8x6 constructions are limited to CL600 pressure drops (1440 psid flowing drop) even though installed in a CL900 valve body.

4. Restriction based on excessive noise if max nP/P1 ratio for a given cage level is exceeded.

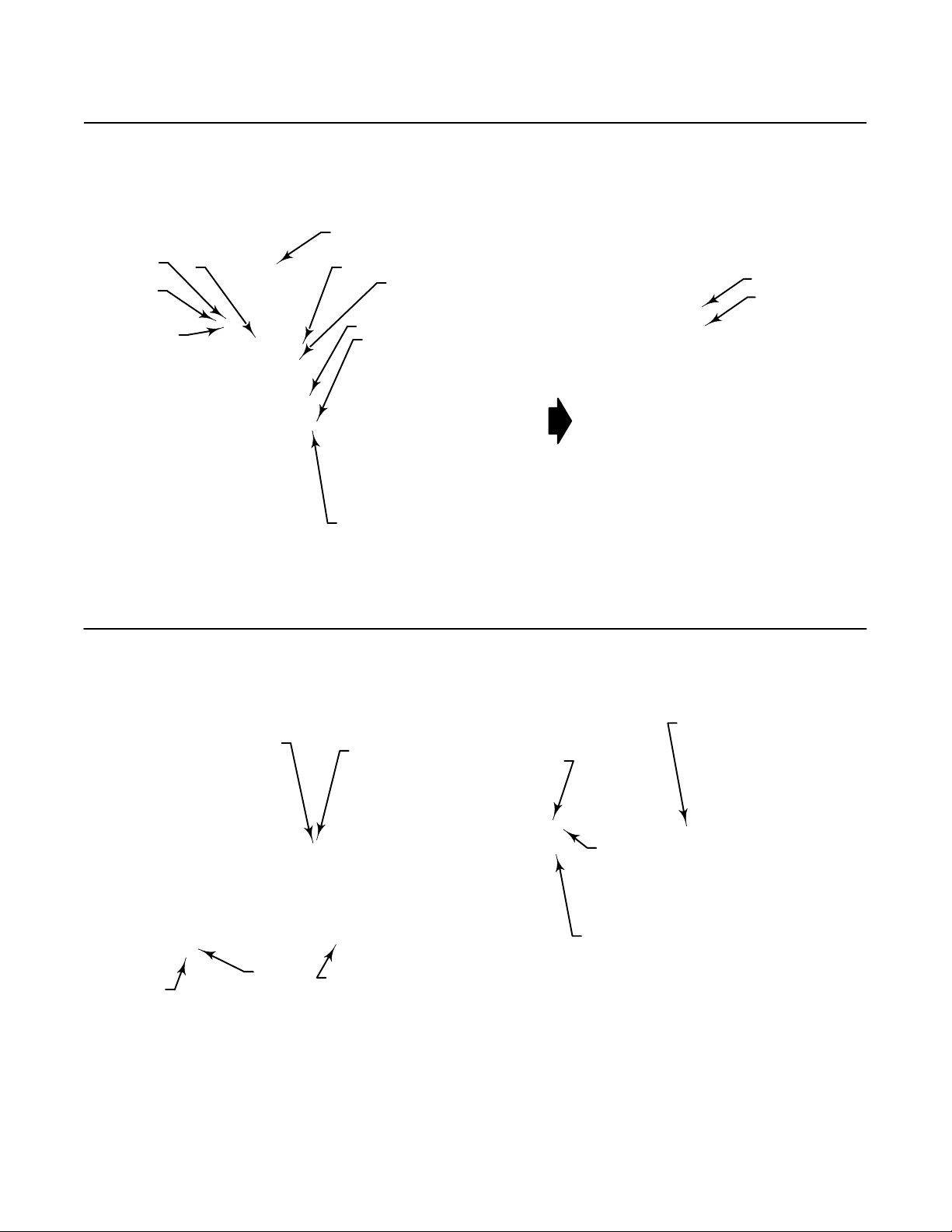

5. Down:in through cage and out through seat ring (direction shown in figure 1).

6. Up:in through seat ring and out through cage as shown in figure 13.

trim

for more information.

ENVIRO-SEAL Packing System Specifications

Applicable Stem Diameters

J 19.1 (3/4), J 25.4 (1), and J 31.8 (1-1/4)

diameter valve stems

Maximum Pressure/Temperature Limits

To Meet the EPA Fugitive Emission Standard of 100

(2)

PPM

(1)

For ENVIRO-SEAL PTFE and ENVIRO-SEAL Duplex packing

systems: full CL300 up to 232_C (450_F)

For ENVIRO-SEAL Graphite ULF packing system: 1500

psig (104 bar) at 316_C (600_F)

Construction Materials

PTFE Packing Systems:

Packing Ring and Lower Wiper: PTFE V-ring

(3)

V-ring

Graphite ULF Packing Systems: Graphite rings

Anti-Extrusion Washer: Filled PTFE (not required for

graphite packing)

Lantern Ring: S31600 (316 stainless steel) (not

required for graphite packing)

Packing Box Flange: S31600

Spring:

J 17-7PH stainless steel, J N06600, or

J S17700

Packing Follower: S31600 lined with carbon-filled

PTFE

Packing Box Studs: Strain-hardened 316 stainless

steel

Packing Box Nuts: 316 stainless steel SA194 Grade

8M

Male and Female Adaptor Rings: Carbon-filled PTFE

1. Refer to the valve specifications in this bulletin for pressure/temperature limits of valve parts. Do not exceed the pressure/temperature rating of the valve. Do not exceed any applicable code

or standard limitation.

2. The Environmental Protection Agency (EPA) has set a limit of 100 parts per million (ppm) for fugitive emissions from a valve in selected VOC (Volatile Organic Compound) services.

3. In vacuum service, it is not necessary to reverse the ENVIRO-SEAL PTFE packing rings.

4

Page 5

EW Valve

)

D100023X012

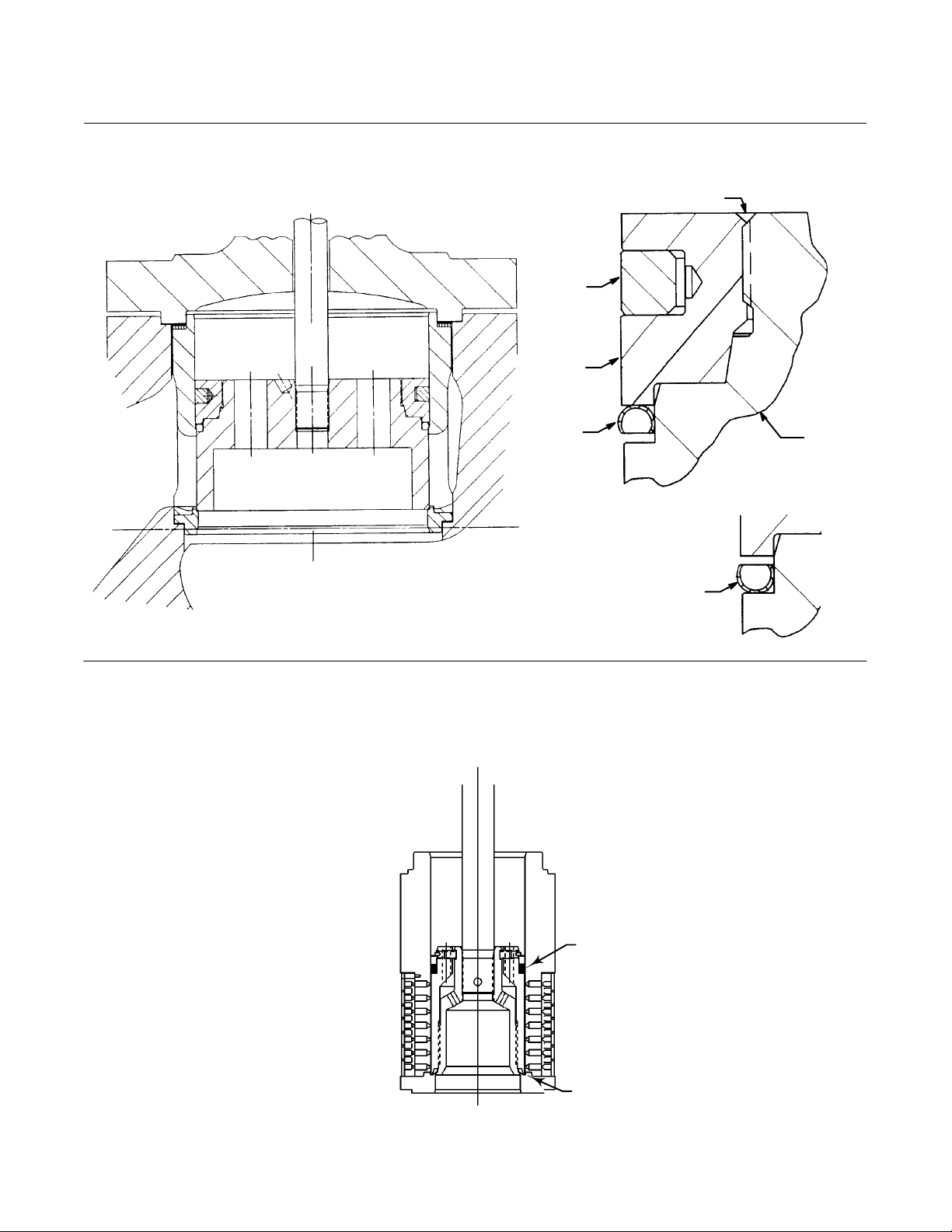

Figure 1. Fisher EWD Valve with Standard Cage

PTFE V-RING

BONNET

GASKET

PIN

SHIM

SPIRAL

WOUND

GASKET

W9035

TYPICAL OF CONSTRUCTIONS THROUGH NPS 12x6

PACKING

GRAPHITE PISTON

RING

CAGE

SEAT

RING

SEAT

RING

GASKET

VALVE

PLUG

Product Bulletin

51.1:EW

October 2020

LOAD RING

CAGE

RETAINER

W9036

NPS 12x8 CONSTRUCTION

NOTE:

The NPS 10x8 valve is similar in appearance to sizes through NPS 12x6. However, the NPS 10x8 uses the load ring shown for the NPS 12x8. It does not use the cage retainer.

Figure 2. Fisher EWT Trim Details

SOFT BACKUP

RING

SEAL

RING

RETAINING

RING

SEAL RING

(SHOWN POSITIONED

FOR USE WITH

STANDARD AND

CAVITROL CAGES)

METAL

BACKUP

RING

W2914−1 / IL

178 mm (7 INCH)

AND LARGER PORTS

METAL

DISC SEAT

W0992-3

PTFE

DISC

METAL DISC

RETAINER

STANDARD CONSTRUCTION

(SEAT PARTS ALSO TYPICAL OF

OPTIONAL EWS PTFE SEATING

W0995-2

137 mm (5.375 INCH)

AND SMALLER PORTS

SEAL RING

(SHOWN POSITIONED

FOR USE WITH

STANDARD AND

CAVITROL CAGES)

VALVE PLUG WITH OPTIONAL

PRESSURE-ASSISTED SEAL RING

5

Page 6

Product Bulletin

51.1:EW

October 2020

EW Valve

D100023X012

Figure 3. Fisher EWS Trim Details Showing Standard

Cage and Seating Construction

W0989-2

CLAMPED METAL

SEAT RING

C-seal Trim Description

C-seal trim (figure 5) is available for valves with port

diameters from 2.875 inches through 8 inches.

With C-seal trim, a balanced valve can achieve

high-temperature, Class V shutoff. Because the C-seal

plug seal is formed from metal (N07718 nickel alloy)

rather than an elastomer, a valve equipped with the

C-seal trim can be applied in processes with a fluid

temperature of up to 593_C (1100_F).

ENVIRO-SEAL and

HIGH-SEAL Packing

Systems

Fisher ENVIRO-SEAL and HIGH-SEAL packing systems

(figure 17) offer excellent sealing capabilities. These

systems easily install in your existing valves or can be

purchased with new valves. These systems help you

seal your process to conserve valuable process fluid

and to protect the environment against the emission

of hazardous or polluting fluids. The long-life and

reliability of these systems also reduce your

maintenance cost and downtime.

For applications requiring compliance with

environmental protection regulations, the unique

ENVIRO-SEAL packing system and, for hazardous

service, the ENVIRO-SEAL bellows seal bonnet (figure

18) are offered. The emission control packing system

or seal bonnet keeps emission concentrations below

the EPA 100 ppm requirement.

For an excellent stem seal in applications that are not

environmentally-sensitive, the HIGH-SEAL Graphite

ULF packing system is offered. The HIGH-SEAL packing

system provides excellent sealing at

pressure/temperature ratings beyond ENVIRO-SEAL

limits.

ENVIRO-SEAL packing systems, available with PTFE,

Graphite ULF, or Duplex packing, and the HIGH-SEAL

Graphite ULF packing system feature live-loading and

unique packing-ring arrangements for long-term,

consistent sealing performance.

6

Page 7

EW Valve

D100023X012

Figure 4. Fisher NPS 12x8 CL900 EWT-1 Valve

SEAL RING

(SHOWN

POSITIONED

FOR USE

WITH

STANDARD

CAGES)

Product Bulletin

51.1:EW

October 2020

W9037

THREADED

SEAT RING

7

Page 8

Product Bulletin

51.1:EW

October 2020

EW Valve

D100023X012

Figure 5. C-seal Trim

STAKE THREAD

PISTON

RING

RETAINER

C-SEAL

METAL

PLUG

(1)

SEAL

A6869

NOTES:

1. Reverse the orientation of the C-Seal plug seal proper shutoff when valve is used in a process with different fluid flow direction.

FLOW DOWN

C-SEAL

METAL

PLUG

(1)

SEAL

VALVE

PLUG

FLOW UP

Figure 6. Typical Balanced TSO Trim

8

A7096

VALVE PLUG

SEAL

PROTECTED SOFT SEAT

Page 9

Product Bulletin

(1)

(3)

(2,3)

(3)

(2)

EW Valve

D100023X012

Table 1. Metal Trim Part Materials for Compatibility with NACE MR0175-2002 (Sour Service) Specifications,

Environmental Restrictions Apply, Refer to Standard

Disk Seat and

Retainer for

Optional

PTFE-Seat

Construction

Valve Stem, Packing

Follower, Lantern Ring,

Packing Box Ring, and

Pin

S20910 (Valve Stem)

S31600 (All Other Parts)

Trim Designation Valve Plug Cage

316 SST with

85

S31600

electroless nickel

coating (ENC)

316 SST with

85C

S31600

electroless nickel

coating (ENC)

S31600 with seat

86

hard faced with

CoCr-A hardfacing

alloy

S31600 with seat

87

and guide hard

faced with CoCr-A

hardfacing alloy

S31600 with seat

87C

and guide hard

faced with CoCr-A

hardfacing alloy

1. NPS 10x8 and 12x8 valve body only.

2. 85C and 87C are trims for PTFE-seat constructions in EWS and EWT valves.

3. Not for use with Whisper Trim I with 5-3/8 inch and larger ports.

316 SST with

electroless nickel

coating (ENC)

316 SST with

electroless nickel

coating (ENC)

316 SST with

electroless nickel

coating (ENC)

Seat Ring

for Standard

Metal Seat

Construction

S31600 - - -

- - - S31600

R30006 (alloy 6) - - -

R30006 (alloy 6) - - -

- - - S31600

October 2020

51.1:EW

Load Ring

N05500

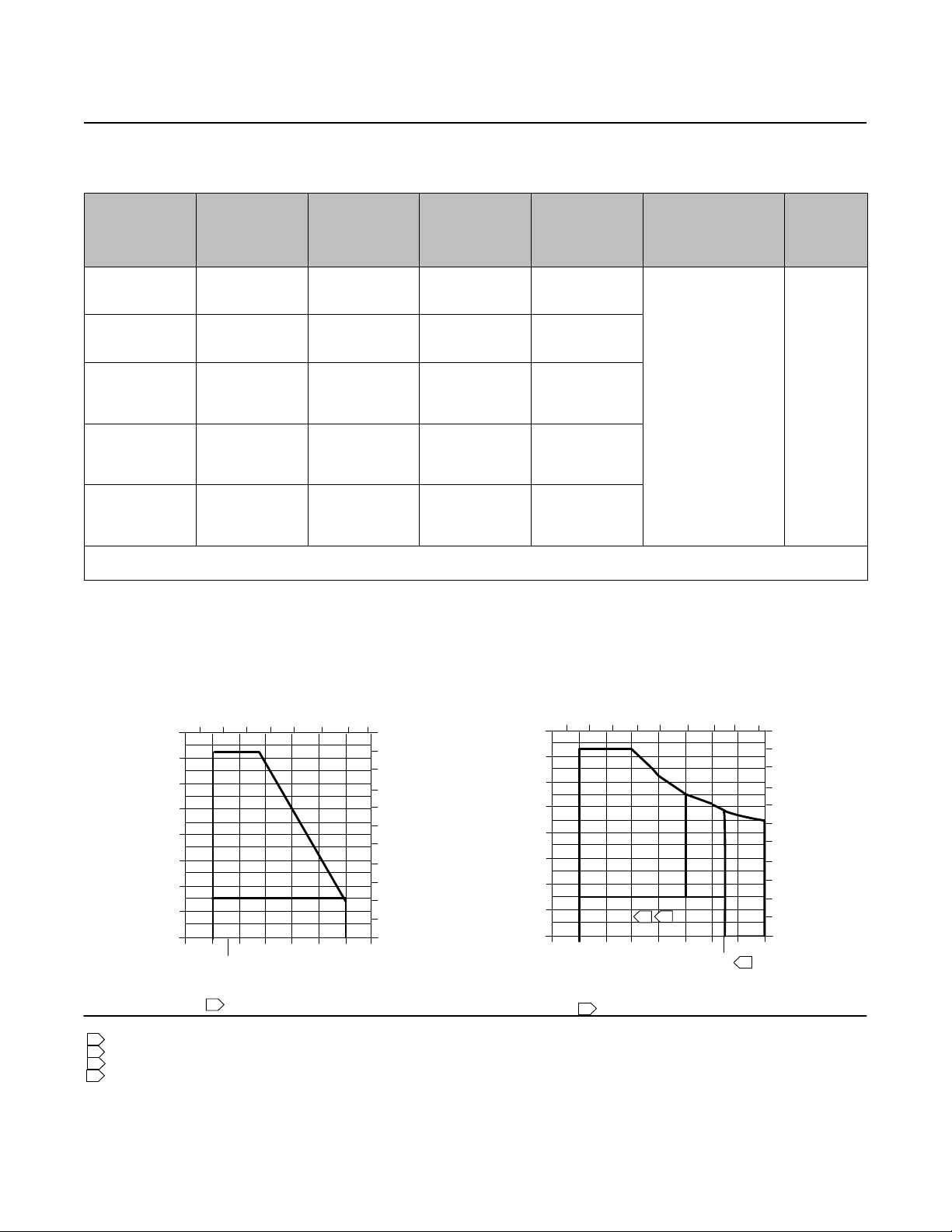

Figure 7. Typical Trim for NACE MR0175-2002 (Sour Service) (tables 11, 12, and 13 should be used along with these

graphs to determine specific limits based on valve size and trim selection)

FLUID TEMPERATURE, °C

−100 −50 0 50 100 150 200 250

1600

1400

1200

1000

800

600

400

PRESSURE DROP, PSI

200

0

−200 −100

A3115-3

NOTES:

1

Use trim 87 instead of trim 85 for non-lubricating fluids such as superheated steam or dry gasses between 149°C (300°F) and 316°C (600°F).

2

Do not exceed the maximum pressure and temperature for the class rating of the body material used, even through the trims shown may have higher capabilities.

3

Use trim 85 up to 99 BAR (1440 PSI) with clean dry gas. For process fluids other than clean dry gas, use trim 85 only up to 21 bar (300 PSI).

4

Trim 87 temperature limit can be extended above 232°C (450°F) If PEEK anti-extrusion rings and spring-loaded seal ring are used.

FOR STANDARD PTFE SEATING WITH ALL

87C

85C

0 100 200 300 400 500

−50

FLUID TEMPERATURE, °F

2

BODY MATERIALS

110

100

90

80

70

60

50

40

30

20

10

0

PRESSURE DROP, BAR

−100 −50 0 50 100 150 200 250

1600

1400

1200

1000

800

600

400

PRESSURE DROP, PSI

200

0

−200 −100 0 100 200 300 400 500 600

FOR OPTIONAL METAL SEATING WITH

FLUID TEMPERATURE, °C

86

3

1

85

FLUID TEMPERATURE, °F

2

CF8M MATERIAL

300

110

100

90

80

70

87

450

60

50

40

30

PRESSURE DROP, BAR

20

10

0

4

9

Page 10

Product Bulletin

(1)

(2)

(3)

51.1:EW

October 2020

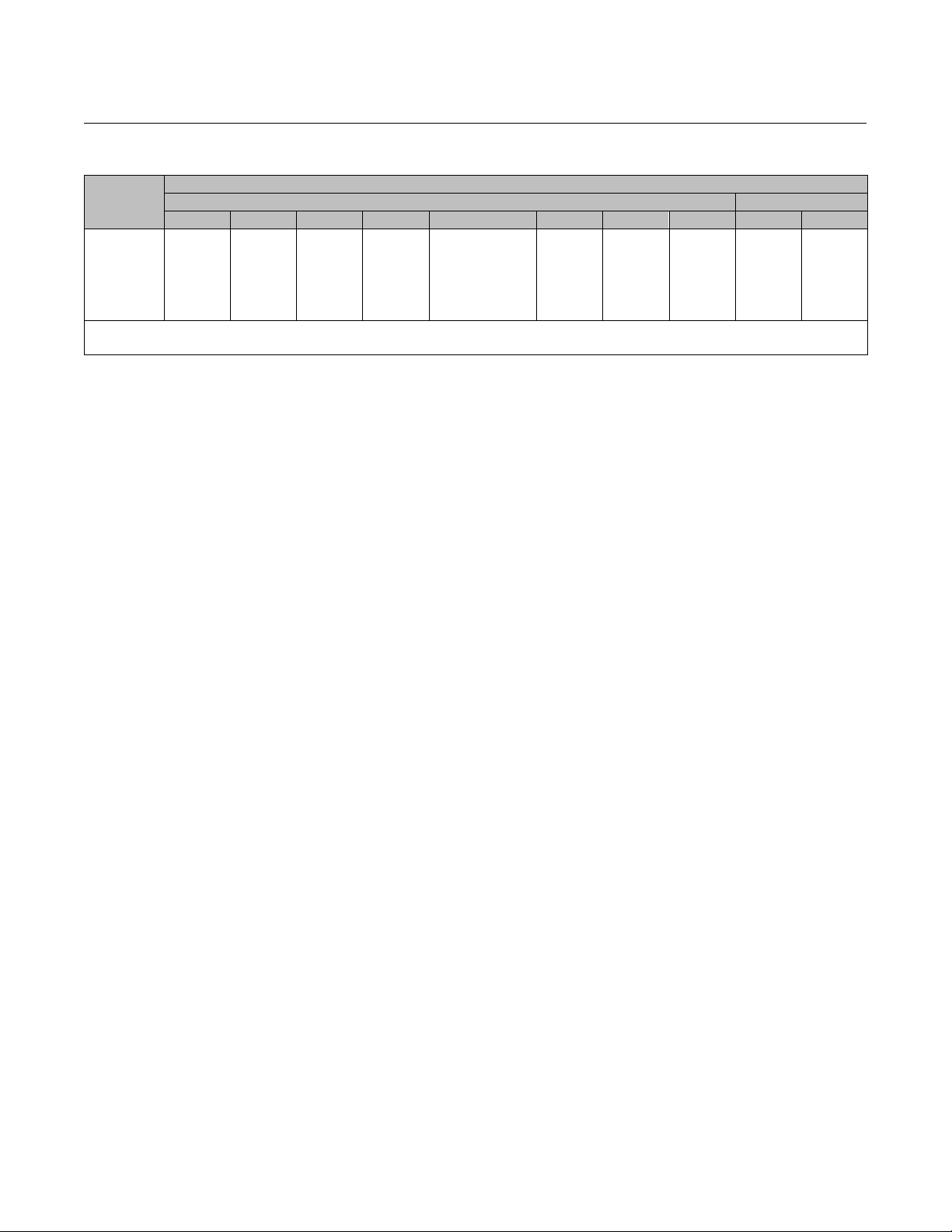

Table 2. Available Valve Constructions

VALVE

4x2 6x4 8x4 8x6 10x6

EWD

EWD-1

EWS

EWS-1

EWT

EWT-1

1. X indicates available construction.

2. Two-number valve size designates end connection size x effective trim size.

3. NPS 10x6 has a valve outlet area identical to the NPS 8x6.

- - -

- - -

- - -

x

x

x

- - -

- - -

- - -

x

x

x

x

- - x

- - x

- - -

D100023X012

VALVE SIZE

CL150, 300, or 600 CL900

x

- - x

- - x

- - -

x

- - x

- - x

- - -

, NPS

12x6 10x8 12x8 8x6 12x8

x

- - x

- - x

- - -

- - -

- - -

- - -

x

x

x

- - -

- - -

- - -

x

x

x

x

- - x

- - x

- - -

EW Valve

x

x

x

x

x

x

Available Configurations

All configurations covered in this bulletin use a

single-port, globe-style valve body with cage guiding

and push-down-to-close valve plug action. This valve

style is combined with different plug styles and either a

clamped seat ring (no dash number suffix) or a seat

ring threaded into the valve body (-1 suffix).

EWD: Balanced valve plug (figure 1) with clamped seat

ring and metal-to-metal seating for all general

applications over a wide range of pressure drops and

temperatures.

EWD-1: NPS 12x8 CL900 EWD valve body, with

threaded seat ring.

EWS: Unbalanced valve plug (figure 3) with clamped

seat ring and metal-to-metal or optional metal-to-PTFE

seating for all general applications requiring better

shutoff capabilities than can be obtained with the EWD

valve body.

EWS-1: NPS 12x8 CL900 EWS valve body, with

threaded seat ring and metal-to-metal seating.

Material Selection

Guidelines

Regardless of valve construction, select the valve

body/bonnet material from the specifications table,

keeping in mind that the valve service conditions

cannot exceed the ASME pressure/temperature

limitations for the selected valve body. Then, perform

steps 1 and 2 under the appropriate valve design

heading to complete the selection process.

EWD, EWS, or EWT Valve with all

except Cavitrol III or Whisper Trim III

Cages

1. Choose a trim combination for the service

conditions according to figure 7 and 8, while making

sure from tables 1 and 5 that this combination

provides the desired trim materials. Then, make sure

from table 11, 12, or 13 that the valve body/trim

temperature limits are not exceeded.

2. Finally, check in table 20 that packing and other

valve parts are available in materials that meet the

desired service conditions.

EWT: Balanced valve plug (figure 2) with metal-to-PTFE

seating (for stringent shutoff requirements) standard

in all EWT valves (except those with Cavitrol III cages).

Metal-to-metal seating for higher temperatures is

standard for all EWT valve bodies with Cavitrol III cages

and optional for these valves with other cages.

EWT-1: NPS 12x8 CL900 EWT valve body, with

threaded seat ring and with metal-to-metal seating

(figure 4).

10

EWD-1, EWS-1, or EWT-1 Valve with

Standard Cage

1. Choose a trim combination for the service

conditions according to figure 9, while making sure

from table 7 that this combination provides the

desired trim materials.

2. Finally, check in table 20 that packing and other

valve parts are available in materials that meet the

desired service conditions.

Page 11

Product Bulletin

(1)

(1)

(1)

EW Valve

D100023X012

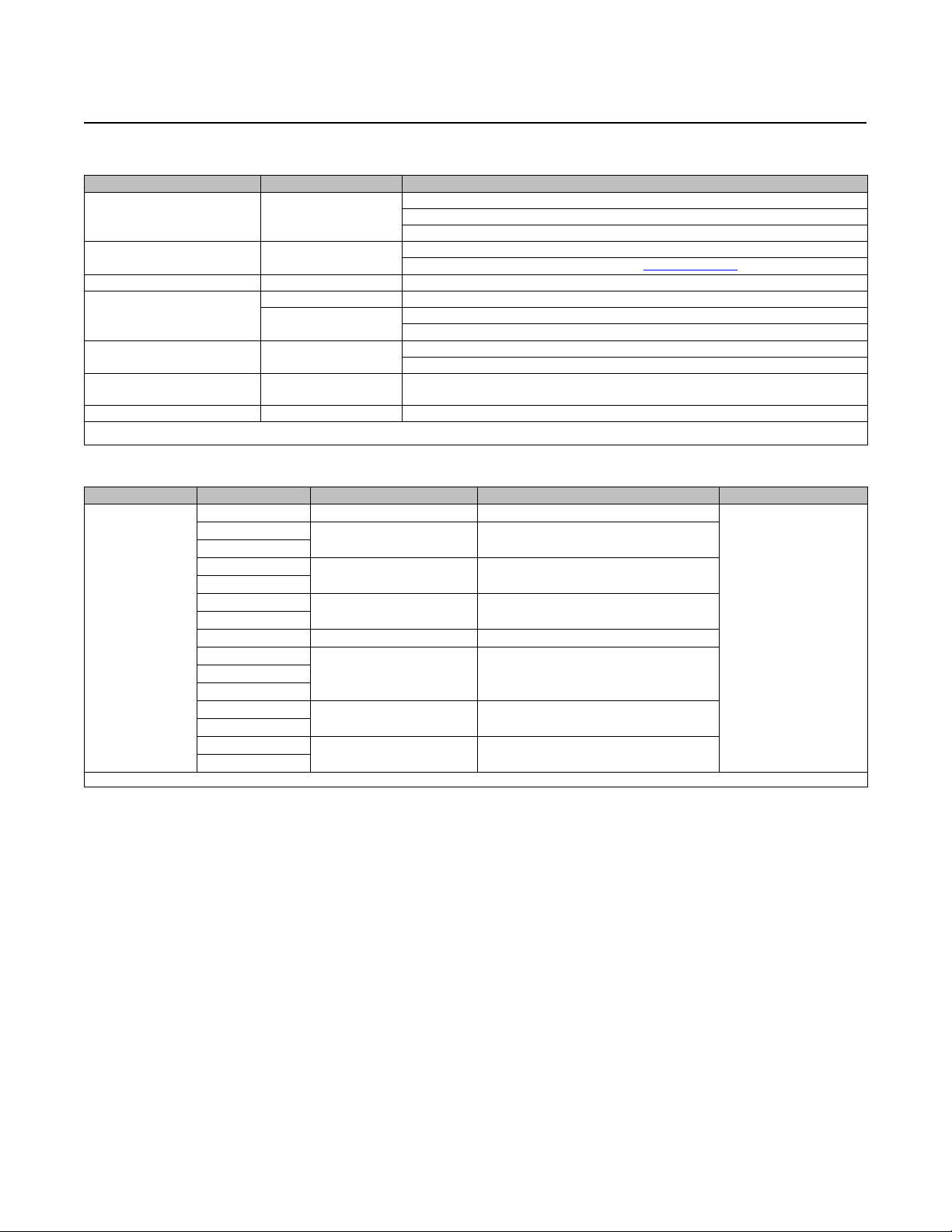

Table 3. Shutoff Classifications per ANSI/FCI 70-2 and IEC 60534-4

Valve Seating Shutoff Class

EWD or EWD-1 Metal

III (optional for NPS 6x4 through 12x8 valves)

IV (optional for NPS 6x4 through 12x8 valves with optional multiple graphite piston rings)

EWS or EWS-1 Metal

V (optional, consult your Emerson sales office)

EWS PTFE VI

EWT with all except

Cavitrol III cages

EWT with

1-stage Cavitrol III cage

EWT with 2-stage Cavitrol III cage

or 2- or 3-stage Cavitrol III cage

EWT-1 Metal IV

1. Class V shutoff for EWT requires spring-loaded seal ring, radius-seat plug, and wide-bevel seat ring. Not available with 8-inch port, quick-opening cage. Not available with S31600 (316 SST)

valve plug and seat ring (trims 4, 29, 85).

PTFE

Metal

Metal

Metal or PTFE V

Table 4. C-seal Shutoff Classification

Valve Valve Size, NPS Port Diameter, mm (Inches) Cage Style ANSI/FCI Leakage Class

6x4x2 1/2 73 (2.875) Eq. %, Linear, Whisper I, Cav III (2-Stage)

6x4

8x4

6x4

8x4

8x6

12x6

EWD (CL300, 600)

1. NPS 10x6 has a valve outlet area identical to the NPS 8x6.

10x6

8x6

10x6

12x6

10x8

12x8

10x8

12x8

111.1 (4.375)

87.3 (3.4375) Whisper III

136.5 (5.375) Cav III (2-Stage), Whisper III

136.5 (5.375) Whisper III

177.8 (7)

203.2 (8)

177.8 (7) Whisper III

Eq. %, Linear, Whisper I, Cav III (1-Stage),

Eq. %, Linear, Whisper I, Cav III (1-Stage),

Eq. %, Linear, Whisper I, Cav III (1-Stage),

II (standard)

IV (standard)

V (optional)

IV

V

IV (standard)

V (optional)

Whisper III

Class V to 593°C (1100°F)

[for port diameters from

73 through 203.2 mm

(2.875 though 8-inch) with

optional C-seal trim]

Whisper III

Whisper III

51.1:EW

October 2020

EWT Valve with Cavitrol III Cage

1. Choose a trim combination for the service

conditions according to figure 12, while making sure

from table 15 that this combination provides the

desired trim materials. Then, make sure from table 16

that the valve body/trim temperature limits are not

exceeded.

2. Finally, check in table 20 that packing and other

valve parts are available in materials that meet the

desired service conditions.

EWD, EWS, or EWT Valve with

Whisper Trim III Cage

1. Choose a trim combination for the service

conditions from table 17. Then, make sure from

table 18 that the valve body/trim temperature limits

are not exceeded.

2. Finally, check in table 20 that packing and other

valve parts are available in materials that meet the

desired service conditions.

11

Page 12

Product Bulletin

(1)

(11)

(10)

(2)(7)

(6)

(8)

(2)(8)

(9)

(6)

(6)

(2)(7)

(11)

51.1:EW

October 2020

EW Valve

D100023X012

Table 5. Fisher EWD, EWS, and EWT Metal Trim Part Combinations

Cavitrol III or Whisper Trim III Cages

TRIM DESIGNATIONS VALVE PLUG CAGE

1 (standard trim for all valves except

EWT and those in CF8M. Trim 57 is

standard for EWT. Trim 29 is standard

for all valves in CF8M)

3

and 3H

4

5

and 5H

6

27

28

29

(standard for all valves

in CF8M)

37 and 37H

57 (standard for all EWT valve bodies

in all materials except CF8M)

1. Nonferrous alloy combinations are also available. Consult your Emerson sales office for details.

2. Trims 3H, 5H, and 37H have clearances for high-temperature service.

3. Available only in linear, quick-opening, equal percentage, and Whisper Trim I cages.

4. Solid cast alloy 6 seat ring is used instead for NPS 4x2, 10x8, and 12x8 valve sizes.

5. CA15 is used for NPS 8x6 CL900 EWD and EWS.

6. Not for use with Whisper Trim I with 5-3/8 inch and larger ports.

7. With C-Seal trim, 3H, and 37H use solid cast Alloy 6 seat ring for NPS 8x4, 10x8, and 12x8 sizes.

8. Available only for NPS 8x6, 12x6, 10x8, 12x8 sizes Whisper Trim I cages.

9. Available only for NPS 10x8 and 12x8 Whisper Trim I cages.

10. For trim 3, upper temperature limited to 316_C (600_F) when used for Whisper Trim I cages.

11. For NPS 10 x 8 and 12 x 8 sizes with Whisper Trim I cages.

S41600 heat treated

17-4 SST HT

S31600 with seat and

guide hard faced

17-4 SST HT

R30006 or R30016

with CoCr-A

hardfacing alloy

S31600 17-4 SST HT S31600 S31600

(alloy 6)

(11)

(3)

S31600 with seat and

guide hard faced with

CoCr-A hardfacing

R31233

alloy

S31600 with seat and

guide hard faced with

CoCr-A hardfacing

S31603 CRPL

alloy

S31600 with seat and

guide hard faced

with CoCr-A

hardfacing alloy

S31600 with seat hard

faced

with CoCr-A

hardfacing alloy

S31600

S31600 with seat and

guide hard faced

with CoCr-A

hardfacing alloy

S41600 heat treated

17-4 SST HT

316 SST with

electroless

nickel coating

(ENC)

316 SST with

electroless

nickel coating

(ENC)

316 SST with

electroless

nickel coating (ENC)

17-4 SST HT

17-4 SST HT

(11)

Except for Valves with

Disk Seat, Retainer for PTFE

Seat Constructions

- - -

S31600 with seat hard faced

with CoCr-A hardfacing alloy

R30006 disk seat

and retainer

R30006 disk seat

and retainer

S31600 with seat hard faced

with CoCr-A hardfacing alloy

S31600 with seat hard faced

with CoCr-A hardfacing alloy

S31600 with seat hard faced

with CoCr-A hardfacing alloy

(9)

(9)

S31600 S31600

S31600 - - -

SEAT

Seat Ring for Metal Seat

Constructions

S41600 or CA15

CA6NM for EWD-1, EWS-1, EWT-1

with seat hard faced with CoCr-A

(4)

(5)

EWD, EWS

S31600

hardfacing alloy

S31600 with seat hard faced with

CoCr-A hardfacing alloy

R30006 (alloy 6)

(4)

(4)

(4)

S31600 with seat hard faced

with CoCr-A hardfacing alloy

S31600 with seat hard faced

with CoCr-A hardfacing alloy

S31600 with seat hard faced

with CoCr-A hardfacing alloy

(S41000) for

(4)

(4)

(4)

(4)

(4)

EWD-1, or EWT-1 Valve with

sure from table 19 that this combination provides the

desired trim materials.

Whisper Trim III Cage

2. Finally, check in table 20 that packing and other

1. Choose a trim combination for the service

conditions according to figure 15 or 16, while making

valve parts are available in materials that meet the

desired service conditions.

ANSI/FCI Class VI Shutoff Capabilities

EWS valves with metal seat constructions and EWT valves with soft seat and metal seat constructions can provide

ANSI/FCI Class VI shutoff capabilities. See tables 6 and 7.

12

Page 13

EW Valve

(1)

(1)

2

D100023X012

Table 6. Class VI Shutoff Availability

Valve Port Size, Inches Seat Minimum Seat Load

EWS 7 Metal 300 lbs/lineal inch

EWT 3.4375 7 Soft See Catalog 14

EWT 3.4375 7 Metal 300 lbs/lineal inch

Table 7. Class VI Trim Materials

VALVE CAGE VALVE PLUG SEAT RING SEAL RING

EWS 316 SST/ ENC

316 SST / ENC S31600 S31600/PTFE UHMWPE

316 SST / ENC S31600/CoCr-A seat S31600 UHMWPE R30003 -101 to 66 -150 to 150

EWT

1. UHMWPE (Ultra High Molecular Weight Polyethylene)

17-4 SST

(17-4PH SST)

17-4 SST S41600 S31600 UHMWPE R30003 -29 to 66 -20 to 150

S31600/CoCr-A

(alloy 6) seat

S41600 S31600/PTFE UHMWPE R30003 -29 to 66 -20 to 150

S31600 NA Not a limiting factor

R30003 -29 to 66 -20 to 150

Fisher TSO (Tight Shutoff) Trim Capabilities

Product Bulletin

51.1:EW

October 2020

TRIM TEMPERATURE LIMIT

_C _F

See figure 6 and tables 8, 9, and 10. For additional information contact your Emerson sales office.

Table 8. TSO (Tight Shutoff) Leakage Class

Leakage Class Maximum Leakage Test Medium Test Pressure Test Procedure

Valves with TSO trim are factory

TSO (Tight Shutoff)

1. Specify service Δ P when ordering.

tested to a more stringent Fisher test

requirement of no leakage at time of

shipment.

Water Service ΔP

ANSI/FCI Class V test procedure B

Table 9. TSO Shutoff Availability

VALVE CONSTRUCTION

EWT Std or Cavitrol III trim. Replaceable, protected soft seat

Table 10. Port Diameters, Valve Plug Travel, Yoke Boss Diameters for TSO (Tight Shutoff) Trim

MAX

VALVE TRIM

EWT NPS 6x4 Std 50.8 2 90 3-9/16 111 4.375 106 4.1875

EWT NPS 8x6

1. This column lists the percent reduction of published maximum CV of the trim listed in the TRIM column.

2. NPS 10x6 has a valve outlet area identical to the NPS 8x6.

and 10x6

(2)

TRAVEL

mm Inch mm Inch

50.8 2

Std

102 4 90 3-9/16 2%

YOKE BOSS SIZE PORT DIAMETER

Nominal Actual TSO

mm Inch mm Inch Inch

90

127

3-9/16

5

179 7 173 6.8125

CV REDUCTION AT 100%

3% (equal percent)

TRAVEL

4% (linear)

2%

(1)

UNBALANCE

AREA

0.154

0.30

Installation

Unless limited by seismic criteria, the valve body can

be installed in any position (as long as sufficient

support is provided if a fabricated extension bonnet is

used). However, the normal method is with the

actuator vertical above the valve, because non-vertical

positions may cause uneven trim wear and decreased

trim life.

Flow through the valve body must be in the direction

indicated by the flow direction arrow on the valve

body. Consider installing an upstream strainer,

especially if the valve body includes slotted or

multihole Whisper Trim or Cavitrol cages.

Dimensions are shown in figure 19.

13

Page 14

Product Bulletin

51.1:EW

October 2020

Figure 8. Typical Trim Used in Fisher EWD, EWS, or EWT Valves Except Those with Cavitrol III or Whisper Trim III Cages

(tables 11, 12, and 13 should be used along with these graphs to determine specific limits based on valve size and

trim selection)

EW Valve

D100023X012

A6334-2

NOTES:

1

Be especially careful to specify service temperature fi trim 3,4, or 37 is selected, as different thermal expansion rates require special plug clearances, also, use trim 37H

instead of trim 4 for non-lubricating fluids such as superheated steam or dry gasses between 149°C (300°F) AND 316°C (600°F).

Do not exceed the maximum pressure and temperature for the class rating of the body material used, even through the trims shown may have higher capabilities.

2

3

Use trim 27 instead of trim 29 for non-lubricating fluids such as superheated steam or dry gasses between 149°C (300°F) AND 316°C (600°F).

4

Trims 4 AND 29 may be used over 300 PSI only with clean, dry gas.

5

EWD, EWS, and EWT NPS 12x8 CL900 limited to CL600 pressure drops. See figure 9 and 10 EWD-1, EWS-1, and EWT-1 for full CL900 NPS 12x8

pressure drops.

14

Page 15

EW Valve

(1)

(4)

(4)

(4)

(4)

(4)

D100023X012

Product Bulletin

51.1:EW

October 2020

Table 11. Valve/Trim Temperature Capabilities

for CL300 or 600 Fisher EWD, EWS, and EWT Valves with 2-Inch (51

mm) or 3-Inch (76 mm) Travel (Except those with Cavitrol III or Whisper Trim III Cages) (figures 7 and 8 should be

used along with this table to determine specific limits based on valve size and trim selection)

VALVE/BONNET

MATERIAL

WCC steel

LCC steel

TRIM DESIGNATION

FROM TABLE 5

1

29, 85

5

5H

6

37

37H 210 427 410 800

57 -29 204 -20 400

1

29, 85

5

6

37

37H 210 343 410 650

57 -29 204 -20 400

VALVE SIZE,

NPS

4 x 2

6 x 4

8 x 4

8 x 6 or 10 x 6

12 x 8 or 10 x 8

8 x 6 or 10 x 6

12 x 8 or 10 x 8

8 x 6, 12 x 6, 10 x 8, or 12 x 8

4 x 2 through 12 x 8

8 x 6 or 10 x 6

10 x 8 or 12 x 8

8 x 6 or 10 x 6

10 x 8 or 12 x 8

8 x 6, 12 x 6, 10 x 8, or 12 x 8 -46 316 -46 600

4 x 2 through 12 x 8

-continued-

(3)

12 x 6

4 x 2

6 x 4

8 x 4

(3)

12 x 6

10 x 8 -29 316 -20 600

4 x 2

6 x 4

8 x 4

(3)

12 x 6

4 x 2

6 x 4

8 x 4

(3)

12 x 6

10 x 8 -46 316 -50 600

MATERIAL TEMPERATURE CAPABILITY

_C Min _C Max _F Min _F Max

-29

-29

-29

-29

-29

-29

-29

-29

-29

-29

-29

-29

-29 316 -20 600

316 427 600 800

-29 210 -20 410

-29

-29

-29

-29

-29

-29

-46

-46

-46

-46

-46

-46

-46 210 -50 410

399

343

329

316

260

427

316

221

218

204

174

316

343

343

329

329

260

343

316

218

218

204

163

316

-20

-20

-20

-20

-20

-20

-20

-20

-20

-20

-20

-20

-20

-20

-20

-20

-20

-20

-50

-50

-50

-50

-50

-50

750

650

625

600

500

800

600

430

425

400

345

600

650

650

625

625

500

650

600

425

425

400

325

600

15

Page 16

Product Bulletin

(1)

(5)

(5)

(4)

(4)

(4)

(4)

(4)

(1)

(4)

(1)

(4)

(4)

(1)

(4)

(1)

(2)

(2)

(2)

(2)

(2)

(2)

51.1:EW

October 2020

EW Valve

D100023X012

Table 11. Valve/Trim Temperature Capabilities

for CL300 or 600 Fisher EWD, EWS, and EWT Valves with 2-Inch (51

mm) or 3-Inch (76 mm) Travel (Except those with Cavitrol III or Whisper Trim III Cages) (figures 7 and 8 should be

used along with this table to determine specific limits based on valve size and trim selection) (continued)

VALVE/BONNET

MATERIAL

TRIM DESIGNATION

FROM TABLE 5

1

VALVE SIZE,

8 x 6 or 10 x 6

12 x 8 or 10 x 8

3

3H 427 566 800 1050

5

5H

4 x 2 through 12 x 8

8 x 6, 12 x 6, 10 x 8, or 12 x 8

6

WC9 chrome moly steel

27, 87

8 x 6 or 10 x 6

12 x 8 or 10 x 8

29, 85

8 x 6 or 10 x 6

12 x 8 or 10 x 8

37

37H 210 427 410 800

4 x 2 through 12 x 8

57 -29 204 -20 400

LCC steel

CF8M (316 SST)

5

6

27

28 -198

8 x 6, 12 x 6, 10 x 8, or 12 x 8 -198

4 x 2 through 12 x 8

29, 85 -198

1. For metal trim parts only.

2. May be used down to -254_C (-425_F) if manufacturing process includes Charpy Impact test.

3. NPS 10x6 has a valve outlet area identical to the NPS 8x6.

4. Available for Whisper Trim I cages.

5. For Trim 3, upper temperature to 316_C (600_F) when used for Whisper Trim I cages.

NPS

4 x 2

6 x 4

8 x 4

(3)

12 x 6

10 x 8 -29 316 -20 600

4 x 2

6 x 4

8 x 4

(3)

12 x 6

4 x 2

6 x 4

8 x 4

(3)

12 x 6

10 x 8 -198

MATERIAL TEMPERATURE CAPABILITY

_C Min _C Max _F Min _F Max

-29

-29

-29

-29

-29

-29

-29 427

399

343

329

316

260

427

-20

-20

-20

-20

-20

-20

750

650

625

600

500

800

-20 800

-29 316 -20 600

316 566 600 1050

-29

-29

-29

-29

-29

-29

-29

-29

-29

-29

-29

-29

343

221

218

204

163

343

316

221

218

204

163

316

-20

-20

-20

-20

-20

-20

-20

-20

-20

-20

-20

-20

650

430

425

400

325

650

600

430

425

400

325

600

-29 210 -20 410

-198

316

316

343 -325

149 -325

316 -325

-325

-325

600

600

650

300

600

16

Page 17

EW Valve

(1)

(3)

(3)

(3)

D100023X012

Product Bulletin

51.1:EW

October 2020

Table 12. 4-Inch (102 mm) Travel Whisper Trim I Fisher EWD and EWT Valve Body/Trim Temperature Capabilities

(CL150 - 600 and NPS 8 x 6, CL900) (figure 8 should be used along with this table to determine specific limits based

on valve size and trim selection)

MATERIAL TEMPERATURE

BODY/BONNET

MATERIAL

WCC steel

WC9 Chrome moly steel

1. For metal trim parts only.

2. Same material also used for bonnet spacer.

3. NPS 10x6 has a valve outlet area identical to the NPS 8x6.

(2)

LCC steel

TRIM DESIGNATION

FROM TABLE 5

37H

4 and 57

37H 210 343 410 650

VALVE SIZE, NPS

1

3

3H 316 427 600 800

5

5H 316 427 600 800

37 8 x 6 or 10 x 6

1 8 x 6 or 10 x 6

5

6 10 x 8 -46 316 -50 600

37 -29 210 -20 410

3

3H 316 566 600 1050

5

5H 316 566 600 1050

6 10 x 8 -29 316 -20 600

8 x 6 or 10 x 6

12 x 6 -29 285 -20 545

(3)

8 x 6 or 10 x 6

8 x 6, 12 x 6, 10 x 8

8 x 6 or 10 x 6

8 x 6, 12 x 6, 10 x 8

8 x 6 or 10 x 6

4 x 2 through 12 x 8

8 x 6, 12 x 6, 10 x 8

or 12 x 6

or 12 X 8

(3)

or 12 x 6

12 x 6 210 363 410 685

or 12 x 8

(3)

or 12 x 8

_C _F

Min Max Min Max

-29 329 -20 625

-29 316 -20 600

-29 316 -20 600

-29 204 -20 400

-29 210 -20 410

210 427 410 800

-29 329 -20 625

-46 316 -50 600

-46 204 -50 400

-29 316 -20 600

-29 316 -20 600

CAPABILITY

17

Page 18

Product Bulletin

(1)

(2)

(2)

(2)

(2)

51.1:EW

October 2020

EW Valve

D100023X012

Table 13. Fisher CL900 EWD, EWS, and EWT Valve Body/Trim Temperature Capabilities

along with this table to determine specific limits based on valve size and trim selection)

MATERIAL TEMPERATURE

BODY/BONNET

MATERIAL

WCC steel

LCC steel

WC9 chrome moly steel

316 SST (CF8M)

1. For metal trim parts only.

2. May be used down to -254_C (-425_F) if manufacturing process includes Charpy impact test.

TRIM DESIGNATION

FROM TABLE 5

VALVE

SIZE, NPS

_C _F

Min Max Min Max

1

29, 85

37

37H 210 427 410 800

57 -29 204 -20 400

1

4, 37 -46 210 -50 410

37H 210 371 410 700

57 -29 204 -20 400

29, 85 -46 204 -50 400

1

3

3H 427 566 800 1050

3

3H 427 566 800 1050

27, 87

29, 85

37

37H 210 427 410 800

57 -29 204 -20 400

27, 87

29, 85 -198

8 x 6

12 x 8

8 x 6 or 12 x 8

8 x 6 only

8 x 6

12 x 8

8 x 6

12 x 8

8 x 6

12 x 8

8 x 6

12 x 8

8 x 6 or 12 x 8

8 x 6 or 12 x 8

-29

-29

-29

-29

-29 210 -20 410

-29 329 -20 625

-29

-29

-29 427 -20 800

-29 427 -20 800

-29

-29

-29

-29

-29 210 -20 410

-198

(figure 8 should be used

CAPABILITY

316

427

204

316

316

427

204

343

204

316

343 -325

316 -325

-20

-20

-20

-20

-20

-20

-20

-20

-20

-20

600

800

400

600

600

800

400

650

400

600

650

600

18

Page 19

Product Bulletin

g

(2)

EW Valve

D100023X012

Figure 9. Typical Trim Used in Fisher EWD, EWS, and EWT NPS 8x6 CL900 Valves with Standard Cages and EWD-1,

EWS-1, and EWT-1 NPS 12x8 CL900 Valves with Standard Cages (see table 14)

FLUID TEMPERATURE, °C FLUID TEMPERATURE, °C

51.1:EW

October 2020

PRESSURE DROP, PSI

A6334-1

NOTE:

1

Do not exceed the maximum pressure and temperature for the class rating of the body material used, even through the trims shown may have higher capabilities.

FLUID TEMPERATURE, °F

WITH WCC STEEL BODY

1

PRESSURE DROP, BAR

PRESSURE DROP, PSI

FLUID TEMPERATURE, °F

WITH WC9 CHROME MOLY STEEL BODY

Figure 10. Typical Trim Used in NPS 8x6 CL900 Fisher

EWD, EWS, EWT and NPS 12x8 CL900 EWD-1,

EWS-1, and EWT-1 Valves with Standard Cages (see

table 14)

PRESSURE DROP, PSI

FLUID TEMPERATURE, °C

PRESSURE DROP, BAR

Table 14. NPS 8x6 CL900 Fisher EWD, EWS, EWT

and NPS 12x8 CL900 EWD-1, EWS-1, and EWT-1

Metal Trim Part Combinations Except for Valves with

Whisper Trim III Cages

Trim

Designation

1

27

37 and 37H

1. CA6NM is similar to 410 SST.

2. Trim 37H has clearances for high-temperature service.

Valve Plug Cage Seat Ring

S41600

(416 SST)

seat and guide

heat

treated

316 SST with

hard-faced

with CoCr-A

17-4 SST H900

316 SST with

electroless

nickel coating

(ENC)

S31600 with

seat and guide

hard-faced

17-4 SST H900

with CoCr-A

PRESSURE DROP, BAR

1

Heat-treated

CA6NM

316 SST with

seat

hard-faced

with CoCr-A

S31600 with

seat

hard-faced

with CoCr-A

(1)

A6334-1

NOTE:

1

Do not exceed the maximum pressure and temperature for the class

rating of the body material used, even through the trims shown may have

her capabilities.

hi

FLUID TEMPERATURE, °F

WITH CF8M (316 SST) BODY

1

19

Page 20

Product Bulletin

(1)

(2)

(1)

(2)

51.1:EW

October 2020

EW Valve

D100023X012

Figure 11. Detail of 2-Stage Cavitrol III Cage in CL300

or 600 Fisher EWT Valve

Figure 12. Typical Trim Used in Cavitrol III Cage

Constructions with Steel or Stainless Steel Valves

(see tables 15)

LIQUID TEMPERATURE, °C

CAGE

RETAINER/

BONNET

SPACER

PRESSURE DROP, PSI

W3331-1

A2732

NOTE:

Do not exceed the maximum pressure and temperature for the class rating of

the body material used, even through the trims shown may have higher capa

bilities.

Table 15. Cavitrol III

Trim

Designation

76 Heat-treated S42000 (420 SST) 17-4 SST H900 S31600 (316 SST)

1. Available only in EWT valve.

2. Not used in NPS 12x8 or 8x6 CL900 valves.

Metal Trim Part Combination

Valve Plug Cage Cage Retainer

LIQUID TEMPERATURE, °F

PRESSURE DROP, BAR

Seat Ring

S17400 with H900

heat-treat condition

Table 16. Cavitrol III Valve Body/Trim Temperature Capabilities

TRIM

DESIGNATION

FROM TABLE 15

76

S31600 (316 SST)

1. NPS 10x6 has a valve outlet area identical to the NPS 8x6.

2. This valve body/trim combination not available in CL900 valve.

3. This valve body/trim combination available in all NPS 12x8 rating classes.

20

VALVE BODY and BONNET

WCC carbon steel or WC9 chrome moly steel -29

LCC carbon steel -46 -50

NPS 4x2 valve

NPS 6x4 valve

NPS 8x4 valve

NPS 8x6 or 10x6

NPS 12x6 valve

NPS 12x8 valve

valve

(3)

MATERIAL TEMPERATURE

CAPABILITY

_C _F

Min Max Min Max

-20

-20

-20

-20

-20

-20

-20

These materials not

limiting factors

400

300

275

250

225

350

-29

-29

-29

-29

-29

-29

These materials not

limiting factors

204

149

135

121

107

177

Page 21

EW Valve

D100023X012

Product Bulletin

51.1:EW

October 2020

Figure 13. Fisher EWT Metal-Seat Valve with Whisper

Trim I Cage

BACKUP

RING

SEAL RING

CAGE

W9038

Figure 14. Fisher EWD Valve with Whisper Trim III

Cage (shown with optional drain plug)

OPTIONAL TRIPLE PISTON

RINGS USED TO OBTAIN

CLASS IV SHUTOFF (THIS

OPTIONAL SHUTOFF ALSO

AVAILABLE IN OTHER

EWD SIZES AND

CONSTRUCTIONS)

W9039

CAGE

RETAINER

BONNET

SPACER

BAFFLE

21

Page 22

Product Bulletin

(3)

(1)

(1)(3)

(1)

(1)(3)

(2)

(6)

(5)

(2)

(3)

(1)

(1)(3)

(2)

(2)

(7)

(6)

51.1:EW

October 2020

Table 17. Metal Trim Part Combinations for Fisher EWD, EWS, and EWT Valves with Whisper Trim III Cages

Baffle

Trim

Designation

Valve Plug Cage

Cage

Retainer

(for Level

D3 Cage

Only)

19.1 through 111.1, 177.8 and 203.2 mm (0.75 through 4.375, 7 and 8 Inch) Port Sizes

301G S41600 17-4 SST -- Steel S41600 -- S31600

301GC

312G

312GC

315G

315GC

318G

306

307G

307GH

S41600 17-4 SST -- Steel -- S31600 S31600

S31600/CoCr-A

Seat & Guide

S31600/CoCr-A

Seat & Guide

S31600/CoCr-A

Seat & Guide

S31600/CoCr-A

Seat & Guide

F22/CoCr-A Seat &

Guide

S31803/Ultimet

Seat & Guide

S31600/CoCr-A

Seat & Guide

S31600/CoCr-A

Seat & Guide

316/ENC

Electroless Nickel

-- S31600 R30006 -- S20910

Coated

316/ENC

Electroless Nickel

-- S31600 --

Coated

316 SST Chrome -- S31600 R30006 -- S20910

316 SST Chrome -- S31600 --

2.25 Cr-1 Mo

Nitrided

2205 Duplex

Plate

(7)

-- WC9 R30006 --

-- S31803 S31803/Ultimet -- S31803

17-4 SST -- Steel R30006 -- S31600

17-4 SST -- Steel R30006 -- S31600

136.5 mm (5.375 Inch) Port

301 S17400 416 SST WCC/ENC Steel S41600 -- S31600

301 A

301 C

304

312

312C

315

318

306

1. NACE compatible trims meets NACE MR0175 2002, MR0175/ISO15156, MR0103.

2. Not for use with EWT construction.

3. Not for use with EWD construction.

4. Trim 318G uses S41000 stem up to 538°C (1000°F) and S42200 stem above 538°C (1000°F).

5. For high temperature service.

6. 22 Cr- 5 Ni duplex stainless steel.

7. With C-seal construction use F22 alloy steel/CoCr-A/Nitrided cage material.

8. Trim 315 uses S31600 stem up to 427°C (800°F) and S20910 stem above 427°C (800°F).

9. For 8 inch port size, both disk seat and retainer use R30006.

S17400 416 SST WCC/Nitrided Steel S41600 -- S31600

S17400 416 SST WCC/ENC Steel -- S31600 S31600

S31600/CoCr-A

Seat & Guide

S31600/CoCr-A

Seat & Guide

S31600/CoCr-A

Seat & Guide

S31600/CoCr-A

Seat & Guide

S31600/CoCr-A

Seat & Guide

S31803/Ultimet

Seat & Guide

416 SST WCC/ENC Steel

316/ENC

Electroless Nickel

Coated

316/ENC

Electroless Nickel

Coated

316 SST/

Electrolyzed

Chrome Coat

2.25 Cr-1 Mo

Nitrided

2205 Duplex

Chrome Plate

316/ENC Electroless

Nickel Coated

316/ENC Electroless

Nickel Coated

S31600/

Electrolyzed

Chrome Coat

WC9 Nitrided

-- S31803 S31803/Ultimet -- S31803

S31600 R30006 -- S20910

S31600 --

S31600 S31600/CoCr-A --

WC9

Seat Ring for

Metal-

Seat

Construction

S31600/

CoCr-A Seat

S31600/

CoCr-A Seat

Disk Seat and

Retainer for

PTFE-Seat

Construction

R30006/

S31600

R30006/

S31600

R30006/

S31600

D100023X012

(9)

(9)

-- S31600

-- S20910

EW Valve

Stem

S20910

S20910

S41000/

(4)

S42200

S20910

S31600/

(8)

S20910

22

Page 23

Product Bulletin

EW Valve

D100023X012

Table 18. Valve/Trim Temperature Capabilities for Fisher EWD, EWS, and EWT Valves with Whisper Trim III Cages

VALVE/BONNET/

BONNET SPACER

MATERIAL

WCC or WC9

TRIM DESIGNATION

FROM TABLE 17

VALVE SIZE,

NPS

19.1 through 111.1, 177.8 and 203.2 mm (0.75 through 4.375, 7 and 8 Inch) Port Size

4 x 2

6 x 4

301G

301GC

312G

312GC

315G

315GC

8 x 4 -29 316 -20 625

8 x 6 or 10 x 6 -29 427 -20 800

10 x 8 -29 427 -20 800

12 x 8 -29 427 -20 800

4 x 2

6 x 4

8 x 4 -29 204 -20 400

8 x 6 or 10 x 6 -29 204 -20 400

10 x 8 -29 204 -20 400

12 x 8 -29 204 -20 400

4 x 2

6 x 4

8 x 4 -29 218 -20 425

8 x 6 or 10 x 6 -29 316 -20 600

10 x 8 -29 316 -20 600

12 x 8 -29 316 -20 600

4 x 2

6 x 4

8 x 4 -29 204 -20 400

8 x 6 or 10 x 6 -29 204 -20 400

10 x 8 -29 204 -20 400

12 x 8 -29 204 -20 400

4 x 2

6 x 4

8 x 4 -29 218 -20 425

8 x 6 or 10 x 6 -29 316 -20 600

10 x 8 -29 316 -20 600

12 x 8 -29 316 -20 600

4 x 2

6 x 4

8 x 4 -29 204 -20 400

8 x 6 or 10 x 6 -29 204 -20 400

10 x 8 -29 204 -20 400

12 x 8 -29 204 -20 400

4 x 2 -29 427 -20 800

6 x 4 -29 427 -20 800

318G (WCC only)

8 x 4 -29 427 -20 800

8 x 6 or 10 x 6 -29 427 -20 800

10 x 8 -29 427 -20 800

12 x 8 -29 427 -20 800

4 x 2

6 x 4

318G (WC9 only)

8 x 4

8 x 6 or 10 x 6 -29 593 -20 1100

10 x 8 -29 593 -20 1100

12 x 8 -29 593 -20 1100

-continued-

MATERIAL TEMPERATURE CAPABILITY

_C _F

Min Max Min Max

-29 399 -20 750

-29 316 -20 625

-29 204 -20 400

-29 204 -20 400

-29 316 -20 600

-29 218 -20 425

-29 204 -20 400

-29 204 -20 400

-29 316 -20 600

-29 218 -20 425

-29 204 -20 400

-29 204 -20 400

-29 593 -20 1100

-29 593 -20 1100

-29 593 -20 1100

51.1:EW

October 2020

23

Page 24

Product Bulletin

51.1:EW

October 2020

Table 18. Valve/Trim Temperature Capabilities for Fisher EWD, EWS, and EWT Valves with Whisper Trim III Cages

(continued)

VALVE/BONNET/

BONNET SPACER

MATERIAL

WCC or WC9

CF8M

TRIM DESIGNATION

FROM TABLE 17

VALVE SIZE,

NPS

19.1 through 111.1, 177.8 and 203.2 mm (0.75 through 4.375, 7 and 8 Inch) Port Size

4 x 2

6 x 4

306

307G

307GH 210 427 410 800

301G

301GC

312G

312GC

315G

315GC

306

8 x 4 -29 316 -20 600

8 x 6 or 10 x 6 -29 316 -20 600

10 x 8 -29 316 -20 600

12 x 8 -29 316 -20 600

4 x 2 through 12 x 8

4 x 2

6 x 4

8 x 4 -29 149 -20 300

8 x 6 or 10 x 6 -29 149 -20 300

10 x 8 -29 149 -20 300

12 x 8 -29 149 -20 300

4 x 2

6 x 4

8 x 4

8 x 6 or 10 x 6 -29 149 -20 300

10 x 8 -29 149 -20 300

12 x 8 -29 149 -20 300

4 x 2

6 x 4

8 x 4 -198 343 -325 650

8 x 6 or 10 x 6 -198 343 -325 650

10 x 8 -198 343 -325 650

12 x 8 -198 343 -325 650

4 x 2

6 x 4

8 x 4 -73 204 -100 400

8 x 6 or 10 x 6 -73 204 -100 400

10 x 8 -73 204 -100 400

12 x 8 -73 204 -100 400

4 x 2

6 x 4

8 x 4 -198 316 -325 600

8 x 6 or 10 x 6 -198 316 -325 600

10 x 8 -198 316 -325 600

12 x 8 -198 316 -325 600

4 x 2

6 x 4

8 x 4 -73 204 -100 400

8 x 6 or 10 x 6 -73 204 -100 400

10 x 8 -73 204 -100 400

12 x 8 -73 204 -100 400

4 x 2

6 x 4

8 x 4 -29 316 -20 600

8 x 6 or 10 x 6 -29 316 -20 600

10 x 8 -29 316 -20 600

12 x 8 -29 316 -20 600

-continued-

MATERIAL TEMPERATURE CAPABILITY

_C _F

-29 316 -20 600

-29 316 -20 600

-29 210 -20 410

-29 149 -20 300

-29 149 -20 300

-29 149 -20 300

-29 149 -20 300

-29 149 -20 300

-198 343 -325 650

-198 343 -325 650

-73 204 -100 400

-73 204 -100 400

-198 316 -325 600

-198 316 -325 600

-73 204 -100 400

-73 204 -100 400

-29 316 -20 600

-29 316 -20 600

EW Valve

D100023X012

24

Page 25

Product Bulletin

EW Valve

D100023X012

Table 18. Valve/Trim Temperature Capabilities for Fisher EWD, EWS, and EWT Valves with Whisper Trim III Cages

(continued)

VALVE/BONNET/

BONNET SPACER

MATERIAL

WCC or WC9

CF8M

TRIM DESIGNATION

FROM TABLE 17

301

301A

301C

304

312

312C

315

318 (WCC only)

318 (WC9 only)

306

301

301C

304

312

312C

315

306

VALVE SIZE,

NPS

136.5 mm (5.375 Inch) Port

8 x 6 or 10 x 6 -29 338 -20 640

12 x 6 -29 313 -20 595

8 x 6 or 10 x 6 -29 338 -20 640

12 x 6 -29 313 -20 595

8 x 6 or 10 x 6 -29 204 -20 400

12 x 6 -29 204 -20 400

8 x 6 or 10 x 6 -29 343 -20 650

12x6 -29 338 -20 640

8 x 6 or 10 x 6 -29 204 -20 400

12 x 6 -29 177 -20 350

8 x 6 or 10 x 6 -29 204 -20 400

12 x 6 -29 177 -20 350

8 x 6 or 10 x 6 -29 204 -20 400

12 x 6 -29 177 -20 350

8 x 6 or 10 x 6 -29 427 -20 800

12 x 6 -29 427 -20 800

8 x 6 or 10 x 6 -29 593 -20 1100

12 x 6 -29 593 -20 1100

8 x 6 or 10 x 6 -29 204 -20 400

12 x 6 -29 204 -20 400

8 x 6 or 10 x 6 -29 149 -20 300

12 x 6 -29 121 -20 250

8 x 6 or 10 x 6 -29 149 -20 300

12 x 6 -29 121 -20 250

8 x 6 or 10 x 6 -29 149 -20 300

12 x 6 -29 121 -20 250

8 x 6 or 10 x 6 -29 343 -20 650

12 x 6 -29 343 -20 650

8 x 6 or 10 x 6 -29 204 -20 400

12 x 6 -29 204 -20 400

8 x 6 or 10 x 6 -198 427 -325 800

12 x 6 -198 427 -325 800

8 x 6 or 10 x 6 -29 316 -20 600

12 x 6 -29 316 -20 600

MATERIAL TEMPERATURE CAPABILITY

_C _F

51.1:EW

October 2020

25

Page 26

Product Bulletin

(1)

51.1:EW

October 2020

Figure 15. Typical Trim Used in Fisher EWD-1 Valves with Whisper Trim III Cages (see table 19)

FLUID TEMPERATURE, °C

I, II

FLUID TEMPERATURE, °C

EW Valve

D100023X012

PRESSURE DROP, PSI

PRESSURE DROP, BAR

FLUID TEMPERATURE, °F

B1484-1

NOTE:

1

Do not exceed the maximum pressure and temperature for the class rating of the body material used, even through the trims shown may have higher capabilities..

2

May be used down to -101°C (-150°F) with level A, B, OR C cage, or with level D cage that has an 18-8 SST baffle.

WITH STEEL OR CHROME MOLY STEEL VALVE

PRESSURE DROP, PSI

WITH CF8M (316 SST) VALVE

IV

PRESSURE DROP, BAR

FLUID TEMPERATURE, °F

11

Table 19. Fisher EWD-1 and EWT-1 Metal Trim Part Combinations for Valves with Whisper Trim III Cages

Trim Designation Valve Plug Cage Seat Ring

I Heat-treated CA6NM

II

IV

1. CA6NM is similar to 410 SST.

S31600 (316 SST) with seat and

guide hard faced with CoCr-A

CF8M (316 SST) with seat and

guide hard faced with

CoCr-A

17-4 SST H1025

Heat-treated CA6NM

N06600 with seat

hard faced with CoCr-A

CF8M with seat

hard faced with CoCr-A

26

Page 27

EW Valve

D100023X012

Figure 16. Typical Trim Used in Fisher EWT-1 Valves with Whisper Trim III Cages (see table 19)

FLUID TEMPERATURE, °C

FLUID TEMPERATURE, °C

Product Bulletin

51.1:EW

October 2020

PRESSURE DROP, PSI

FLUID TEMPERATURE, °F

A2733-1

NOTE:

1

Do not exceed the maximum pressure and temperature for the class rating of the body material used, even through the trims shown may have higher capabilities.

2

May be used down to -101°C (-150°F) with level A, B, OR C cage, or with level D cage that has an 18-8 SST baffle.

WITH STEEL OR CHROME MOLY STEEL VALVE

PRESSURE DROP, BAR

1

PRESSURE DROP, PSI

FLUID TEMPERATURE, °F

WITH CF8M (316 SST) VALVE

1

PRESSURE DROP, BAR

27

Page 28

Product Bulletin

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(3)

(4)

(10)

(10)

(11)

(11)

(1)

(1)

(7)

(7)

(7)

(9)

(9)

(1)

(1)

(8)

(1)

(1)

51.1:EW

October 2020

Table 20. Materials and Temperature Limitations for Other Parts

PART MATERIAL

WCC or WC9 valve body

LCC valve body

WC9 valve body

Body-to-bonnet

bolting (see table 24

for NACE bolting

materials and

temperature limits)

CF8M (316 SST)

valve body

Studs Steel SA-193-B7, or steel SA-193-B7M for sour service

Nuts Steel SA-194-2H, or steel SA-194-2M for sour service

Studs Steel SA-193-B7

Nuts Steel SA-194-2H

Studs Steel SA-193-B16

Nuts Steel SA-194-7

Studs Steel SA-193-B7

Nuts Steel SA-194-2H

Studs Steel SA-193-B7M for sour service -46 427 -50 800

Nuts Steel SA-194-2HM for sour service -46 343 -50 650

Studs 304 SST SA-320-B8

Nuts 304 SST SA-194-8

Studs 316 SST SA-193-B8M (strain hardened)

Nuts 316 SST SA-194-8M

Studs 316 SST SA-193-B8M

Nuts 316 SST SA-194-8M

Disk (all soft-seat constructions) PTFE -73 204 -100 400

Std. for NPS 4x2 thru 12x6 Graphite (FMS 17F27)

EWD piston ring

Std. for NPS 10x8 and 12x8;

optional for NPS 4x2 thru 12x6

Graphite

FMS

17F39

Oxidizing service—all sizes -46

Nonoxidizing

service

NPS 12x8 CL900 and 12x8 CL600

and smaller

Fluorocarbon

Standard NPS 4x2 through 12x6 EWT valve plug seal

(except valve with Cavitrol III cage)

Backup ring

Ethylene-propylene

For use with hydrocarbons -34 71 -30 160

(5)

Nitrile

For use with other fluids -34 93 -30 200

Seal ring Carbon-filled PTFE -73 232 -100 450

Spring-loaded EWT or EWT-1 valve

(6)

plug seal

(standard for NPS 10x8 and

12x8 valve regardless of cage and all NPS 4x2 through

12x6 valves with Cavitrol III cage; optional in NPS 4x2

through 12x6 valves with other than Cavitrol III cages)

Backup ring S41600 (416 SST) -29 427 -20 800

Retaining ring S30200 (302 SST) -254 593 -425 1100

Seal ring PTFE with N10276 Spring -73 232

Anti-extrusion

rings

PEEK (PolyEtherEtherKetone) - - -

Valve plug stem and pin S31600 (316 SST) (S20910, NACE Std) -198

CB7CU-1 (17-4PH SST) -102 316 -150 600

Load ring (NPS 10x8 and 12x8 EWD, EWS, and EWT only)

N07718

N05500

Seat ring, bonnet and cage gaskets

Spiral wound gaskets N06600

FGM (standard) -198 593 -325 1100

PTFE-coated N04400 -73 149 -100 300

/laminated graphite FGM (standard) -198 593 -325 1100

PTFE V-ring -40 232 -40 450

Packing (temperatures shown are material temperature capabilities)

PTFE/composition -73 232 -100 450

Graphite ribbon/filament -198 538

Graphite ribbon for high-temperature oxidizing service 371 649 700 1200

Packing flange, studs and nuts when used with standard bonnet S31600 -198

Packing follower, and packing spring

or lantern ring S31600

Packing box ring when used with standard bonnet S31600

Extension bonnet bushing

1. May be used down to -254_C (-425_F) if manufacturing process includes Charpy impact test.

2. This minimum is due to thermal expansion differential between piston ring and cage at low temperatures.

3. For high-temperature air, hydrocarbons, and certain other chemicals and solvents, but cannot be used with ammonia, steam, or hot water.

4. Has excellent moisture resistance to hot water and steam and may be used with most fire-resistant hydraulic oils, but cannot be used with petroleum-based fluids and other hydrocarbons.

5. Cannot be used with fire-resistant hydraulic oils.

6. May be used to increase hot water service capability to 232_C (450_F).

7. This material may be used for cyclic temperatures or those above 232_C (450_F).

8. Spring is used only with single PTFE V-ring packing; lantern ring replaces spring in other packings.

9. Except 371_C (700_F) on oxidizing service.

10. If used with PEEK anti-extrusion rings, PTFE/carbon seal ring may be used in temperatures up to 316_C (600_F) for non-oxidizing service or up to 260_C (500_F) for oxidizing service.

11. These materials not limiting factors.

Trims 1 and 4 S41600 -29 427 -20 800

Other trims S31600 -198

MATERIAL TEMPERATURE CAPABILITY

_C Min

-29 427 -20 800

-46 371 -50 700

-29 593 -20 1100

-48 427 -55 800

-254 38 -425 100

(1)

-198

(1)

-198

-46

-46

-46

-18 204 0 400

-40 232 -40 450

-254 593 -425 1100

-240 260 -400 500

(1)

-198

EW Valve

D100023X012

_C

_F Min _F Max

Max

427 -325

649 -325

427 -50

482 -50

538 -50

593 -50

593 -325

593 -325

593 -325

593 -325

(1)

(1)

-100 450

- - -

-325 1000

(1)

800

1200

800

900

1000

1100

1100

1100

1100

1100

28

Page 29

EW Valve

(1,9)

(2)4(2)

(3)5(3)

(3)

(3)

(6)

(6)

(7)

(7)

D100023X012

Table 21. Port Diameters, Valve Plug Travel, and Stem and Yoke Boss Diameters

STEM AND YOKE BOSS DIAMETERS

Standard Optional

19.1 3/4 90.5 3 9/16

25.4

or

31.8

25.4

or

31.8

25.4

or

31.8

25.4

or

31.8

25.4

or

31.8

25.4

or

31.8

19.1 3/4 90.5 3 9/16

127 5

25.4 1

VALVE SIZE,

NPS

PORT

DIAMETER

MAX VALVE

PLUG TRAVEL

mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch

33.3 1.3125 31.8 1.25

4 x 2

58.7 2.3125 34.9 1.375

12.7 1/2 71.4 2 13/16 19.1 3/4 90.5 3 9/16

58.7 2.3125 28.6 1.125

111 4.375 50.8 2 12.7 1/2 71.4 2 13/16

6 x 4, 8 x 4

8 x 6, 10 x 6

or 12 x 6

8 x 6, 10 x 6

or 12 x 6

(8)

,

(8)

,

87.3 3.438

178 7 50.8 2

178 7

50.8 2 12.7 1/2 71.4 2 13/16 19.1 3/4 90.5 3 9/16

76.2 3 12.7 1/2 71.4 2 13/16

19.1 3/4 90.5 3 9/16

76.2 3 Cavitrol only

102

19.1 3/4 90.5 3 9/16 - - - Whisper Trim I

178 7 76.2 3

(8)

8 x 6, 10 x 6

12 x 6 137 5.375 165

10 x 8

178 7 102 4

137 5.375 127

6.5

203 8

76.2 3

152 6 Whisper Trim III only

19.1 3/4 90.5 3 9/16

19.1 3/4 90.5 3 9/16

178 7 152 6 Whisper Trim III only

203 8 76.2 3

(4)

CL300

or

CL600

(4)

203 8

178 7

152 6 Whisper Trim III only

12 x 8

203 8 76.2 3

CL900

197

7.75

171

6.75

1. Except for Cavitrol III cages, which are covered in separate documentation

2. Bonnet spacer required. This travel available only in CL300 or 600 EWD or EWT

3. Bonnet spacer required for EWD or EWT valve, but not EWS valve

4. Bonnet spacer required for EWD, EWS, and EWT valve.

5. H indicates heavy actuator‐to‐bonnet bolting is required

6. Port diameter for level A, B, or C cage.

7. Port diameter for level D cage

8. NPS 10x6 has a valve outlet area identical to the NPS 8x6.

9. Refer Fisher Bulletin 80.1:010 Whisper Trim III (D100191X012

152 6 31.8 1 1/4 127 5 - - - Whisper Trim III only

19.1 3/4 90.5 3 9/16

25.4 1

31.8 1 1/4 31.8 1 1/4

) for more information on Whisper Trim III.

Stem Yoke Boss Stem Yoke Boss

1 or

1 1/4

1 or

1 1/4

1 or

1 1/4

1 or

1 1/4

1 or

1 1/4

1 or

1 1/4

Product Bulletin

51.1:EW

October 2020

CAGE STYLE

Whisper Trim III only

Quick-opening, linear,

Eq.%, Whisper Trim I,

WhisperTrim III, or

127 5

127 5

Whisper Trim III only

Quick-opening, linear,

127 5

Eq.%, Whisper Trim I,

127 5 Whisper Trim III only

Quick-opening, linear,

127 5

Quick-opening, linear,

127 5

Quick-opening, linear,

(5)

127H

5H

(5)

Cavitrol

or Cavitrol

or Eq. %

or Eq. %

or Eq. %

(1)

(1)

(1)

29

Page 30

Product Bulletin

51.1:EW

October 2020

Figure 17. Typical ENVIRO-SEAL and HIGH-SEAL Packing Systems

PACKING

BOX

STUD

SPRING

FOLLOWER

PACKING

EW Valve

D100023X012

W8533-1

SPRINGS

ANTIEXTRUSION

RING

LANTERN

RING

W5803-3

TYPICAL HIGH-SEAL PACKING SYSTEM

WITH GRAPHITE ULF PACKING

TYPICAL ENVIRO-SEAL PACKING

SYSTEM WITH PTFE PACKING

PACKING

BOX

STUDS

PACKING

RING

VALVE

BONNET

W7018

TYPICAL ENVIRO-SEAL PACKING

SYSTEM WITH DUPLEX PACKING

PACKING

BOX

STUD

SPRINGS

FOLLOWER

PACKING

W8532-1

TYPICAL ENVIRO-SEAL PACKING SYSTEM

WITH GRAPHITE ULF PACKING

30

Page 31

EW Valve

(1)

D100023X012

Table 22. Approximate Weights

END CONNECTION

CL300 84 185 150 330 234 515 284 625 348 765 500 1102 567 1250 653 1440

CL600

CL900

1. NPS 10x6 has a valve outlet area identical to the NPS 8x6.

Flanged 100 220 195 430 272 600 308 680 431 950 721 1590 744 1640 857 1890

Buttwelding 61 135 122 270 177 390 272 600 380 839 526 1160 512 1130 658 1450

Flanged - - - 612 1350 - - - 1361 3000

Buttwelding - - - 454 1000 - - - 1293 2850

Figure 18. ENVIRO-SEAL Bellows Seal Bonnet

4 x 2 6 x 4 8 x 4 8 x 6 10 x 6

kg Lb kg Lb kg Lb kg Lb kg Lb kg Lb kg Lb kg Lb

Product Bulletin

51.1:EW

October 2020

VALVE SIZE, NPS

12 x 6 10 x 8 12 x 8

W5852-1

31

Page 32

Product Bulletin

51.1:EW

October 2020

Table 23. Bonnet Selection Guidelines

BONNET STYLE

(CL300, 600)

Plain Bonnet

J Standard for NPS 2, 4, and 6

nominal trim sizes

J Standard for NPS 10x8 and 12x8 valves

(in cast iron, WCC). Not

available in S31600

Style 1 Cast Extension Bonnet

J Optional for NPS 2, 4, and 6

nominal trim sizes

J Standard for NPS 10x8 and 12x8

valves (in S31600). Optional

in WCC; not available in cast iron

Style 2 Cast Extension Bonnet

J Optional for NPS 2, 4, and 6

nominal trim sizes

J Optional for NPS 10x8 and 12x8

valves (in WCC). Not available in cast

iron or S31600

ENVIRO-SEAL Bellows Seal Bonnet

J Optional for NPS 2, 4, 6, and 8 nominal

trim sizes. Maximum travel is 2 inches

1. For CL900 valve bodies, only the plain bonnet is available. Consult your Emerson sales office for assistance if application conditions indicate the need for an extension bonnet for a CL900

valve body.

2. These in-body process temperatures assume an outside, ambient temperature of 21_C (70_F) and no insulation on the bonnet. When using any packing at low process temperatures, a cast

extension bonnet may have to be used to prevent packing damage which could result from the formation of valve stem frost. Material selection for trim and other components will also be

limiting factors.

(1)

PACKING

PTFE V-ring -18 to 232 0 to 450

PTFE/composition -18 to 232 0 to 450

Graphite ribbon/filament -18 to maximum shown in table 20 0 to maximum shown in table 20

PTFE V-ring

PTFE/composition

Graphite ribbon/filament to maximum shown in table 20 to maximum shown in table 20

PTFE V-ring

PTFE/Composition

Graphite ribbon/filament to maximum shown in table 20 to maximum shown in table 20

PTFE

Graphite ULF

For exceptional stem sealing

capabilities. See Bulletin 59.1:070,

ENVIRO-SEAL Bellows Seal Bonnets,

pressure/temperature ratings.

_C _F

-46 to 427 -50 to 800

-101 to 427 -150 to 800

(D101641X012

IN-BODY PROCESS

TEMPERATURE LIMITS

capabilities. See Bulletin 59.1:070,

ENVIRO-SEAL Bellows Seal Bonnets,

) for

(2)

For exceptional stem sealing

(D101641X012

pressure/temperature ratings.

EW Valve

D100023X012

) for

Table 24. Bolting Materials and Temperature Limits for Bolting Compliance with NACE MR0175-2002, NACE