24003 Valve

D103329X012

Baumann™ 24003 3-Way Bronze or

Stainless Steel Control Valve

The Baumann 24003 3-way control valve is ideally

suited for control of flow and temperature where

mixing or diverting service is required. This 3-way valve

uses a rugged cast bronze or CF8M stainless steel body

with S31600 austenitic stainless steel trim for

extended service life.

Features

Product Bulletin

52.1:243WY

February 2021

n Compact and light weight design reduces installed

piping costs.

n Optional ENVIRO-SEALt packing system to meet

critical emission control requirements; suitable for

use in light duty chemical service (not for use in

corrosive service). This option is available in the

stainless steel version only.

n High quality S31600 austenitic stainless steel trim

materials.

n Dual plug and stem guiding provides increased

stability during plug travel.

n Multiple trim capacity reductions available to meet

changing process requirements.

n Fisher™ FIELDVUE™ digital valve controllers

available for remote calibration and diagnostics.

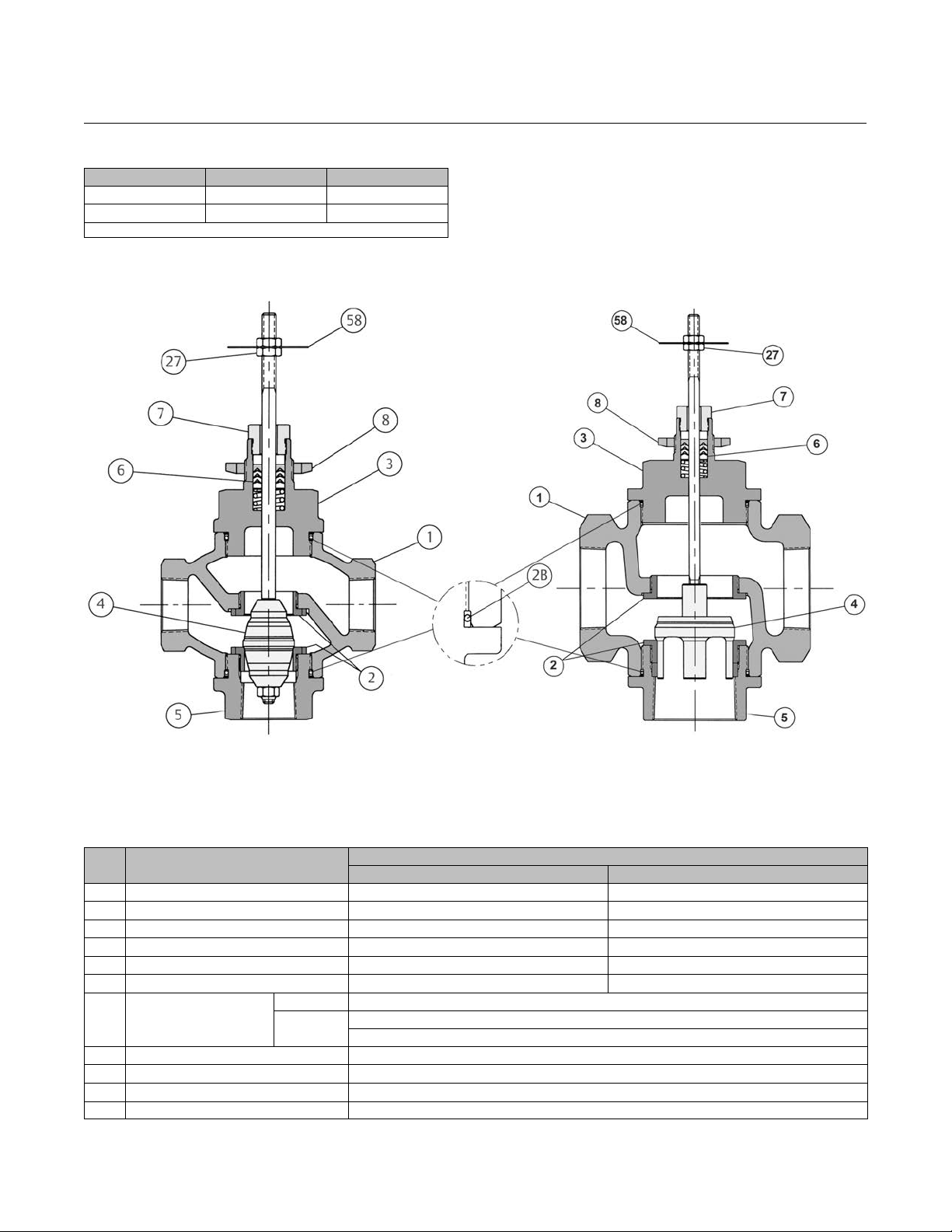

W9764-1

Stainless Steel 3-Way Valve with Baumann 32 Actuator

W9765-1

Bronze 3-Way Valve with Baumann 54 Actuator and

FIELDVUE DVC2000 Digital Valve Controller

www.Fisher.com

Product Bulletin

52.1:243WY

February 2021

24003 Valve

D103329X012

Table 1. Flow Direction

Service Inlet Outlet

Diverting C U and L

Mixing U and L C

1. C = Common port, U = Upper port, L = Lower port

(1)

Figure 1. Baumann 24003 Valve Body with Standard Bonnet and NPS 1 Integral Seat

O-RING USED IN

STAINLESS STEEL VALVE

ASSEMBLY ONLY

E1281

NPS 1/2 and 1

NPS 1-1/2 and 2

Table 2. Materials of Construction

KEY

NO.

1 Valve Body Bronze ASTM B62 ASTM A351 CF8M

2 Seat Rings ASTM A276 S31600 Condition A ASTM A276 S31600 Condition A

2B O-Ring N/A TFE/P (tetrafluoroethylene/propylene)

3 Bonnet Bronze ASTM B62 ASTM A351 CF8M

4 Plug & Stem Assembly ASTM A276 S31600 Condition A ASTM A276 S31600 Condition A

5 Bottom Port Bronze ASTM B62 ASTM A351 CF8M

6 Packing

7 Packing Follower ASTM A276 S31600 Condition A Stainless Steel

8 Drive Nut (Yoke) ASTM A194 S30400 Gr. 8

27 Locknuts Stainless Steel (18-8 SST)

58 Travel Indicator ASTM A240 S30400

DESCRIPTION

Bronze Stainless Steel

Standard PTFE (Polytetrafluoroethylene) / PTFE, 25% carbon filled

Optional

Molded Graphite Ribbon (Flexible Graphite)

ENVIRO-SEAL (Stainless Steel ONLY)

MATERIAL

2

24003 Valve

D103329X012

Product Bulletin

52.1:243WY

February 2021

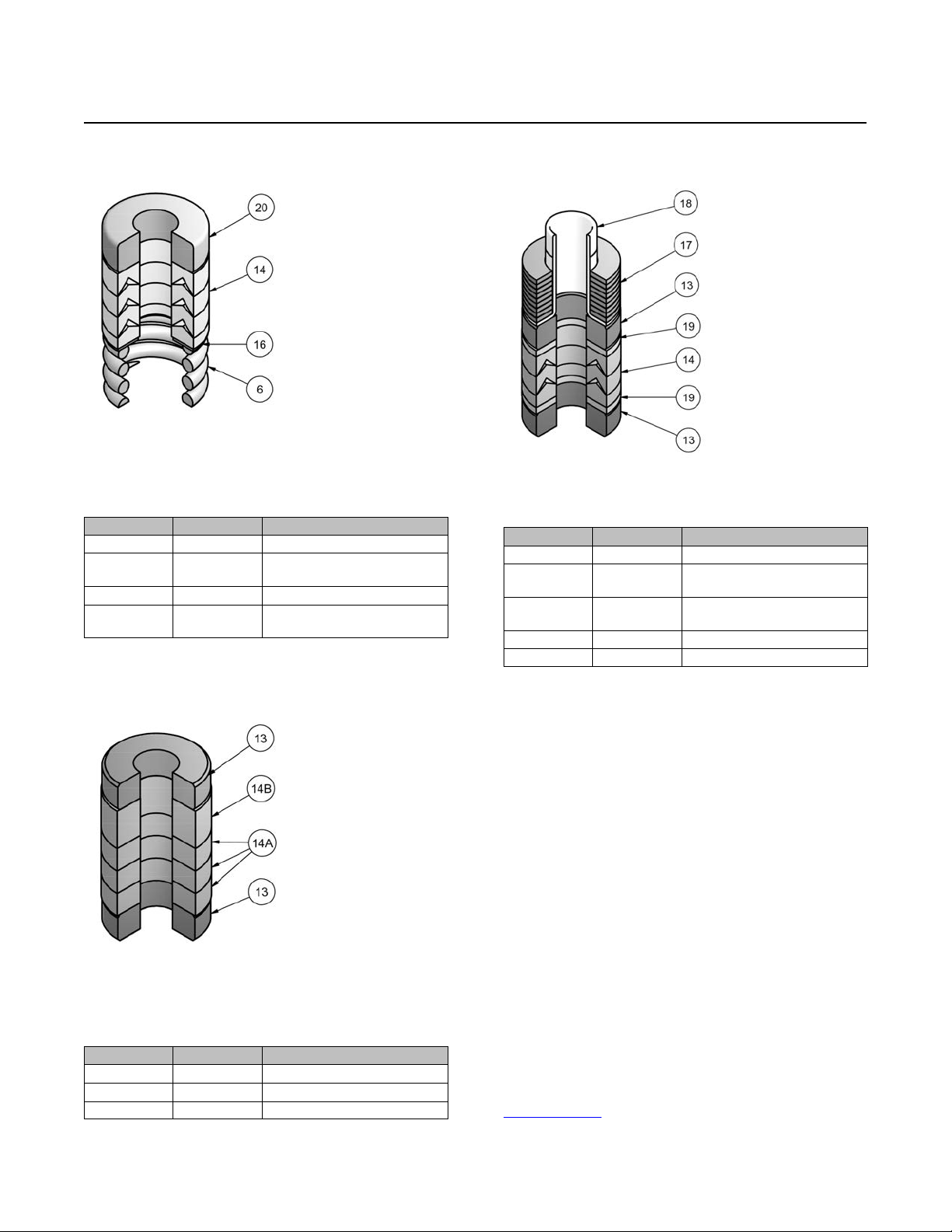

Figure 2. Standard Spring-Loaded PTFE V-Ring

Packing Kit

E1240

Table 3. Standard Spring-Loaded PTFE V-Ring

Packing Kit

Key Number Description Material

6 Spring ASTM A313 S30200

14 Packing Set

16 Washer ASTM A240 S31600

20 Spacer

PTFE (Polytetrafluoroethylene) /

PTFE, 25% carbon filled

J-2000

(filled-Polytetrafluoroethylene)

Figure 4. ENVIRO-SEAL Packing Kit (Optional for

Stainless Steel Only)

E1248

Table 5. ENVIRO-SEAL Packing Kit

(Optional for Stainless Steel Only)

Key Number Description Material

13 Bushing Carbon-Graphite

14 Packing Set

17

18 Bushing PEEK (polyetheretherketone)

19 Washer Modified PTFE

Belleville

Spring

PTFE (Polytetrafluoroethylene) /

PTFE, 25% carbon filled

N06600 Nickel Alloy (ASTM B637

N07718, 40 HRC max)

Figure 3. Molded Graphite (Flexible Graphite)

Packing Kit (Optional)

E1241

Table 4. Molded Graphite (Flexible Graphite)

Packing Kit (Optional)

Key Number Description Material

13 Bushings Carbon-Graphite

14A Packing Rings Graphite

14B Packing Ring Graphite

Special ENVIRO-SEAL

Packing Note

The ENVIRO-SEAL PTFE packing system is suitable for

100 ppm environmental applications on services up to

51.7 barg (750 psig) and process temperatures

ranging from -28 to 204_C (-20 to 400_F).

For non-environmental applications, this packing

system offers excellent performance at the same

temperature range up to the maximum valve working

pressure.

Temperature limits apply to packing arrangements

only. Complete valve assembly temperature limits may

differ, refer to appropriate pressure/temperature

ratings.

(Reference Fisher Packing Selection Guidelines for

Sliding-Stem Valves, Bulletin 59.1:062,

D101986X012

).

3

Product Bulletin

52.1:243WY

February 2021

Table 6. Technical Specifications

NOMINAL PIPE SIZE NPS 1/2, 1, 1-1/2, and 2

END CONNECTIONS Screwed NPT

SEAT PLUG SEALING Metal-to-Metal

CHARACTERISTIC Linear

SEAT LEAKAGE Class III

VALVE BODY MATERIAL Bronze Stainless Steel

PRESSURE RATING 400 psi @ 150_F / 250 psi @ 400_F 720 psi @ 150_F / 515 psi @ 400_F

TEMPERATURE LIMITS -20 to 400_F -20 to 400_F

Figure 5. Valve Body and Temperature Limits

Table 7. Max Cv Values at 100% Plug Opening

(Kv = 0.86 x Cv)

720 psi @ 150_F

CF8M VALVE BODY

ACCEPTABLE OPERATING LIMITS

400 psi @ 150_F

BRONZE VALVE BODY

ACCEPTABLE OPERATING

LIMITS

515 psi @ 400_F

250 psi @ 400_F

VALVE SIZE

NPS inches inches C

1/2

1

1-1/2 1.676 0.75 20

2 2.126 0.75 40

1. See Fisher Catalog 12 for a full range of flow and sizing information.

ORIFICE

DIAMETER

0.626 0.56 1, 2

0.876 0.56 4

0.876 0.56 4

1.126 0.56 10

PLUG TRAVEL

24003 Valve

D103329X012

(1)

RATED

VALUES

V

E1282

OPERATING TEMPERATURE _F

4

24003 Valve

D103329X012

Product Bulletin

52.1:243WY

February 2021

Figure 6. Mixing Service Flow Characteristics

FLOW INTO PORTS U AND L

PERCENTAGE OF MAXIMUM RATED Cv

E1283

% TRAVEL

Figure 7. Diverting Service Flow Characteristics

PERCENTAGE OF MAXIMUM RATED Cv

E1284

FLOW INTO PORT C

% TRAVEL

Table 8. Valve Body Dimensions and Weights: NPT Valve Bodies Only

VALVE SIZE

NPS A B C1 A B C1 Inches lbs

1/2 4.88 2.75 2.75 5.0 2.75 2.75 0.56 8

1 4.88 2.75 2.75 5.0 2.75 2.75 0.56 8

1-1/2 5.75 3.81 3.31 6.1 3.38 3.31 0.75 15

2 6.50 4.0 3.6 6.50 3.75 3.6 0.75 20

BRONZE, NPT STAINLESS STEEL, NPT (A)

VALVE BODY MATERIAL

TRAVEL WEIGHT

5

Product Bulletin

52.1:243WY

February 2021

Figure 8. Dimensional Drawing

229

(9.0)

24003 Valve

D103329X012

216

(48.5)

141

(5.5)

C

1

C

B

A

E1285

U

24000 3-WAY ATC/FAIL OPEN ACTUATOR

WITH HANDWHEEL

Note: Actuator removal requires 115 mm (4.5 inches) vertical clearance.

Table 9. Application Port

Service Inlet Outlet

Diverting C U and L

Mixing U and L C

1. C = Common port, U = Upper port, L = Lower port

(1)

mm

(inch)

6

24003 Valve

D103329X012

Figure 9. Mixing and Diverting Applications

Product Bulletin

52.1:243WY

February 2021

DIVERTING

VALVE

COOL

WATER

E1286

C

L

HEAT EXCHANGER

U

TEMPERED

WATER

U

HEATING WATER

MIXING VALVE

C

L

RETURN

Table 10. Model Numbering System

24 3

Valve Body Series Service Port “L” Fails 3-Way Valve Body Material

24 D Diverting 1 Closed 3 --- Bronze

M Mixing 2 Open S Stainless Steel

7

Product Bulletin

52.1:243WY

February 2021

24003 Valve

D103329X012

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Baumann, ENVIRO-SEAL, Fisher, and FIELDVUE are marks owned by one of the companies in the Emerson Automation Solutions business unit of Emerson

Electric Co. Emerson Automation Solutions, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are

the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2009, 2021 Fisher Controls International LLC. All rights reserved.

8

Loading...

Loading...