Page 1

PN 50049:E0 ECN 01-106

Universal Digital Alarm

Communicator/Transmitter

UDACT-F

Instruction Manual

Document 50049

01/22/2001 Rev:

E

Page 2

Fire Alarm System Limitations

While a fire alarm system may lower insurance

rates, it is not a substitute for fire insurance!

An automatic fire alarm system–typically made up of smoke

detectors, heat detectors, manual pull stations, audible warning devices, and a fire alarm control with remote notification

capability–can provide early warning of a developing fire.

Such a system, however, does not assure protection against

property damage or loss of life resulting from a fire.

The Manufacturer recommends that smoke and/or heat detectors be located throughout a protected premise following the

recommendations of the current edition of the National Fire

Protection Association Standard 72 (NFPA 72),

manufacturer's recommendations, State and local codes, and

the recommendations contained in the Guide for Proper Use

of System Smoke Detectors, which is made available at no

charge to all installing dealers. A study by the Federal Emergency Management Agency (an agency of the United States

government) indicated that smoke detectors may not go off in

as many as 35% of all fires. While fire alarm systems are designed to provide early warning against fire, they do not guarantee warning or protection against fire. A fire alarm system

may not provide timely or adequate warning, or simply may not

function, for a variety of reasons:

Smoke detectors may not sense fire where smoke cannot

reach the detectors such as in chimneys, in or behind walls, on

roofs, or on the other side of closed doors. Smoke detectors

also may not sense a fire on another level or floor of a building. A second-floor detector, for example, may not sense a

first-floor or basement fire.

Particles of combustion or "smoke" from a developing fire

may not reach the sensing chambers of smoke detectors because:

• Barriers such as closed or partially closed doors, walls, or

chimneys may inhibit particle or smoke flow.

• Smoke particles may become "cold," stratify, and not reach

the ceiling or upper walls where detectors are located.

• Smoke particles may be blown away from detectors by air

outlets.

• Smoke detectors may be drawn into air returns before

reaching the detector.

The amount of "smoke" present may be insufficient to alarm

smoke detectors. Smoke detectors are designed to alarm at

various levels of smoke density. If such density levels are not

created by a developing fire at the location of detectors, the

detectors will not go into alarm.

Smoke detectors, even when working properly, have sensing

limitations. Detectors that have photoelectronic sensing

chambers tend to detect smoldering fires better than flaming

fires, which have little visible smoke. Detectors that have ionizing-type sensing chambers tend to detect fast-flaming fires

better than smoldering fires. Because fires develop in different ways and are often unpredictable in their growth, neither

type of detector is necessarily best and a given type of detector may not provide adequate warning of a fire.

Smoke detectors cannot be expected to provide adequate

warning of fires caused by arson, children playing with

matches (especially in bedrooms), smoking in bed, and violent

explosions (caused by escaping gas, improper storage of

flammable materials, etc.).

Heat detectors do not sense particles of combustion and

alarm only when heat on their sensors increases at a predetermined rate or reaches a predetermined level. Rate-of-rise

heat detectors may be subject to reduced sensitivity over time.

For this reason, the rate-of-rise feature of each detector

should be tested at least once per year by a qualified fire protection specialist.

Heat detectors are designed to protect

property, not life.

IMPORTANT!

Smoke detectors must be installed in the

same room as the control panel and in rooms used by the system for the connection of alarm transmission wiring, communications, signaling, and/or power.

cated, a developing fire may damage the alarm system, crippling its ability to report a fire.

Audible warning devices such as bells may not alert people

if these devices are located on the other side of closed or

partly open doors or are located on another floor of a building.

Any warning device may fail to alert people with a disability or

those who have recently consumed drugs, alcohol or medication. Please note that:

• Strobes can, under certain circumstances, cause seizures

in people with conditions such as epilepsy.

• Studies have shown that certain people, even when they

hear a fire alarm signal, do not respond or comprehend the

meaning of the signal. It is the property owner's responsibility to conduct fire drills and other training exercise to make

people aware of fire alarm signals and instruct them on the

proper reaction to alarm signals.

• In rare instances, the sounding of a warning device can

cause temporary or permanent hearing loss.

A fire alarm system will not operate without any electrical

power. If AC power fails, the system will operate from standby

batteries only for a specified time and only if the batteries

have been properly maintained and replaced regularly.

Equipment used in the system may not be technically compatible with the control. It is essential to use only equipment

listed for service with your control panel.

Telephone lines needed to transmit alarm signals from a

premise to a central monitoring station may be out of service

or temporarily disabled. For added protection against telephone line failure, backup radio transmission systems are recommended.

The most common cause of fire alarm malfunction is inadequate maintenance. To keep the entire fire alarm system in

excellent working order, ongoing maintenance is required per

the manufacturer's recommendations, and UL and NFPA standards. At a minimum, the requirements of Chapter 7 of NFPA

72 shall be followed. Environments with large amounts of

dust, dirt or high air velocity require more frequent maintenance. A maintenance agreement should be arranged

through the local manufacturer's representative. Maintenance

should be scheduled monthly or as required by National and/

or local fire codes and should be performed by authorized professional fire alarm installers only. Adequate written records

of all inspections should be kept.

If detectors are not so lo-

LimWarLg.p65 01/10/2000

Page 3

Installation Precautions

Adherence to the following will aid in problem-free

installation with long-term reliability:

WARNING -

nected to the fire alarm control panel.

of power before servicing. Control unit and associated equipment may be damaged by removing and/or inserting cards,

modules, or interconnecting cables while the unit is energized.

Do not attempt to install, service, or operate this unit until this

manual is read and understood.

CAUTION -

Changes.

must be tested in accordance with NFPA 72 Chapter 7 after

any programming operation or change in site-specific software. Reacceptance testing is required after any change, addition or deletion of system components, or after any modification, repair or adjustment to system hardware or wiring.

All components, circuits, system operations, or software functions known to be affected by a change must be 100% tested.

In addition, to ensure that other operations are not inadvertently affected, at least 10% of initiating devices that are not

directly affected by the change, up to a maximum of 50 devices, must also be tested and proper system operation verified.

This system meets NFPA requirements for operation at

0-49° C/32-120° F

condensing) at 30° C/86° F. However, the useful life of the

system's standby batteries and the electronic components

may be adversely affected by extreme temperature ranges

and humidity. Therefore, it is recommended that this system

and all peripherals be installed in an environment with a nominal room temperature of 15-27° C/60-80° F.

Verify that wire sizes are adequate for all initiating and

indicating device loops. Most devices cannot tolerate more

than a 10% I.R. drop from the specified device voltage.

Several different sources of power can be con-

Disconnect all sources

System Reacceptance Test after Software

To ensure proper system operation, this product

and at a relative humidity of 85% RH (non-

Like all solid state electronic devices, this system may

operate erratically or can be damaged when subjected to lightning-induced transients. Although no system is completely

immune from lightning transients and interferences, proper

grounding will reduce susceptibility.

Overhead or outside

aerial wiring is not recommended, due to an increased susceptibility to nearby lightning strikes.

cal Services Department if any problems are anticipated or

encountered.

Disconnect AC power and batteries prior to removing or inserting circuit boards. Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing,

reaming, or punching of the enclosure. When possible, make

all cable entries from the sides or rear. Before making modifications, verify that they will not interfere with battery, transformer, and printed circuit board location.

Do not tighten screw terminals more than 9 in-lbs.

Over-tightening may damage threads, resulting in reduced

terminal contact pressure and difficulty with screw terminal

removal.

Though designed to last many years, system components

can fail at any time. This system contains static-sensitive

components. Always ground yourself with a proper wrist strap

before handling any circuits so that static charges are removed from the body. Use static-suppressive packaging

to protect electronic assemblies removed from the unit.

Follow the instructions in the installation, operating, and

programming manuals. These instructions must be followed

to avoid damage to the control panel and associated

equipment. FACP operation and reliability depend upon

proper installation by authorized personnel.

Consult with the Techni-

FCC Warning

WARNING: This equipment generates, uses, and can

radiate radio frequency energy and if not installed and

used in accordance with the instruction manual, may

cause interference to radio communications. It has

been tested and found to comply with the limits for class

A computing device pursuant to Subpart B of Part 15 of

FCC Rules, which is designed to provide reasonable

protection against such interference when operated in a

commercial environment. Operation of this equipment in

a residential area is likely to cause interference, in which

case the user will be required to correct the interference

at his own expense.

Canadian Requirements

This digital apparatus does not exceed the Class A

limits for radiation noise emissions from digital

apparatus set out in the Radio Interference Regulations

of the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits

radioelectriques depassant les limites applicables aux

appareils numeriques de la classe A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.

LimWarLg.p65 01/10/2000

Page 4

This digital communicator has been designed to comply with standards set forth by the following regulatory agencies:

• Underwriters Laboratories Standard UL 864

• NFPA 72 National Fire Alarm Code

• CAN/ULC - S527M Standard for Control Units for Fire Alarm Systems

Before proceeding, the installer should be familiar with the following documents.

NFPA Standards

This digital communicator complies with the following NFPA Standards:

NFPA 72 National Fire Alarm Code for Central Station Signaling Systems Protected Premises Unit

(Automatic, Manual and Waterflow), Local Fire Alarm Systems (Automatic, Manual, Waterflow

and Sprinkler Supervisory), Proprietary Fire Alarm Systems (Protected Premises Unit), Automatic

Fire Detectors, Installation, Maintenance and Use of Notification Appliances for Fire Alarm Systems and Inspection, Testing and Maintenance for Fire Alarm Systems.

FM Approved (with Ademco 685 Receiver)

Underwriters Laboratories Documents:

UL 38 Manually Actuated Signaling Boxes

UL 217 Smoke Detectors, Single and Multiple Station

UL 228 Door Closers–Holders for Fire Protective Signaling Systems

UL 268 Smoke Detectors for Fire Protective Signaling Systems

UL 268A Smoke Detectors for Duct Applications

UL 346 Waterflow Indicators for Fire Protective Signaling Systems

UL 464 Audible Signaling Appliances

UL 521 Heat Detectors for Fire Protective Signaling Systems

UL 864 Standard for Control Units for Fire Protective Signaling Systems

UL 1481 Power Supplies for Fire Protective Signaling Systems

UL 1638 Visual Signaling Appliances

UL 1971 Signaling Devices for Hearing Impaired

CAN/ULC - S524M Standard for Installation of Fire Alarm Systems

Other:

NEC Article 250 Grounding

NEC Article 300 Wiring Methods

NEC Article 760 Fire Protective Signaling Systems

Applicable Local and State Building Codes

C22.1, Canadian Electrical Code, Part I

C22.2 No. 0, General Requirements - Canadian Electrical Code, Part II

C22.2 No. 0.4, Bonding and Grounding of Electrical Equipment (Protective Grounding) - Canadian

C282, Emergency Electrical Power Supply for Buildings - Canadian

Requirements of the Local Authority Having Jurisdiction (LAHJ)

Fire•Lite Documents

Fire•Lite Device Compatibility Document Document #15384

4

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

Page 5

Table of Contents

CHAPTER 1: Product Description ......................................................................................................................... 7

1.1: Product Features..........................................................................................................................................7

FIGURE 1-1: UDACT-F Assembly ....................................................................................................8

1.2: Controls and Indicators ............................................................................................................................... 9

FIGURE 1-2: Controls and Indicators................................................................................................. 9

1.3: Compatible Panels....................................................................................................................................... 9

1.4: Digital Communicator................................................................................................................................. 9

1.5: Circuits ........................................................................................................................................................10

1.5.1: Power Requirements ......................................................................................................................... 10

1.5.2: Communications ............................................................................................................................... 10

1.5.3: Primary and Secondary Phone Lines ................................................................................................ 10

1.5.4: Communicator Fail Relay Driver...................................................................................................... 10

1.5.5: Earth Ground.....................................................................................................................................10

1.6: Specifications ..............................................................................................................................................10

1.7: Telephone Requirements and Warnings...................................................................................................... 11

1.7.1: Telephone Circuitry - PH1 & PH2 .................................................................................................... 11

1.7.2: Digital Communicator.......................................................................................................................11

1.7.3: Telephone Company Rights and Warnings: ......................................................................................11

1.7.4: For Canadian Applications................................................................................................................12

1.8: Modes and Special Functions......................................................................................................................13

1.8.1: Normal Mode ....................................................................................................................................13

1.8.2: Program Mode...................................................................................................................................13

1.8.3: Lamp Test Mode ...............................................................................................................................13

1.8.4: Troubleshoot Mode ...........................................................................................................................13

1.8.5: Type Mode.........................................................................................................................................13

1.8.6: Clear Function...................................................................................................................................13

1.8.7: Manual Test Function........................................................................................................................ 13

CHAPTER 2: Installation.........................................................................................................................................14

2.1: Mounting Options ......................................................................................................................................14

FIGURE 2-1: ABS-8RF....................................................................................................................... 14

2.2: Panel Mounting ........................................................................................................................................... 14

2.2.1: MS-9200............................................................................................................................................14

FIGURE 2-2: UDACT-F Mounting to MS-9200 ................................................................................14

FIGURE 2-3: External UDACT-F Mounting in ABS-8RF - MS-9200...............................................15

TABLE 2-1: Annunciator LED Assignments (MS-9200) ................................................................... 16

2.2.2: MS-9600............................................................................................................................................17

FIGURE 2-4: UDACT-F Wiring to MS-9600.....................................................................................17

TABLE 2-2: Annunciator LED Assignments (MS-9600) ................................................................... 18

2.2.3: Sensiscan 2000..................................................................................................................................19

FIGURE 2-5: UDACT-F Mounting in CHS-4 ....................................................................................19

FIGURE 2-6: EIA-485 Connection Sensiscan 2000............................................................................20

FIGURE 2-7: 24 VDC Power Connection to UDACT-F .................................................................... 21

TABLE 2-3: Sensiscan 2000 Annunciator LED Assignments ............................................................ 22

2.3: UL Power-limited Wiring Requirements..................................................................................................... 23

FIGURE 2-8: Typical Wiring Diagram for UL Power-limited Requirements ....................................23

2.4: Output Circuits ............................................................................................................................................ 24

2.4.1: Telephone Circuits ............................................................................................................................ 24

FIGURE 2-9: Wiring Phone Jacks....................................................................................................... 24

2.4.2: Relay Driver......................................................................................................................................25

FIGURE 2-10: Relay Driver Connections...........................................................................................25

FIGURE 2-11: Monitoring for UDACT-F Trouble.............................................................................26

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

5

Page 6

Table of Contents

CHAPTER 3: Programming Instructions ...............................................................................................................27

3.1: Entering Program Mode ..............................................................................................................................27

3.2: Switch (Key) Functions ...............................................................................................................................28

FIGURE 3-1: UDACT-F Keypad ........................................................................................................28

3.3: Programming Options .................................................................................................................................28

TABLE 3-1: Start and End Monitoring Address .................................................................................31

TABLE 3-2: Primary Number Event Codes - 3+1, 4+1 Express and 4+1 Standard ...........................34

TABLE 3-3: Primary Number Event Codes - 4+2 Standard and 4+2 Express....................................35

TABLE 3-4: Ademco Contact ID Primary Number ............................................................................36

TABLE 3-5: Secondary Number Event Codes - 3+1, 4+1 Express and 4+1 Standard .......................37

TABLE 3-6: Secondary Number Event Codes - 4+2 Standard and 4+2 Express................................38

TABLE 3-7: Ademco Contact ID Secondary Number ........................................................................39

CHAPTER 4: Operating Instructions ....................................................................................................................40

4.1: Normal Mode...............................................................................................................................................40

4.1.1: Keypad Functions ..............................................................................................................................40

4.1.2: Displays.............................................................................................................................................41

FIGURE 4-1: UDACT-F Phone Connectors and LEDs ......................................................................42

4.1.3: Normal Mode Operation ...................................................................................................................42

4.1.4: Key Report Descriptions ...................................................................................................................44

4.2: Type Mode ...................................................................................................................................................44

4.2.1: Disabling of Zones or Points.............................................................................................................45

4.2.2: Zone or Point Supervisory.................................................................................................................45

4.3: Troubleshoot Mode......................................................................................................................................46

FIGURE 4-2: Handset/Speaker Connection ........................................................................................46

4.4: Lamp Test Mode..........................................................................................................................................46

Appendix A: Reporting Formats ..........................................................................................................................47

TABLE A-1: Data Reporting Structure ..............................................................................................47

TABLE A-2: Letter Code Definitions for Table A-1 .........................................................................48

TABLE A-3: Ademco Contact ID Reporting Structure ......................................................................49

TABLE A-4: Addressable Module Reporting Structure .....................................................................50

TABLE A-5: Zone Reporting Structure ..............................................................................................50

Appendix B: Compatible Receivers .....................................................................................................................51

TABLE B-1: Compatible UL Listed Receivers ..................................................................................51

Appendix C: Programming Reference Sheets .....................................................................................................52

Appendix D: Point Assignments - MS-9200 ........................................................................................................56

Appendix E: Code Wheel Matching Point Assignments - MS-9200 .................................................................57

Appendix F: Point Assignments - MS-9600 .........................................................................................................58

F.1: Type Mode Programming ..........................................................................................................................58

F.1.1: For Zone Identification: ...................................................................................................................58

F.1.2: For Point Identification: ...................................................................................................................58

F.2: Event Code/Report Transmission ...............................................................................................................58

F.2.1: For Zone Reporting: .........................................................................................................................58

F.2.2: For Point Reporting: .........................................................................................................................58

F.3: Point Assignments ......................................................................................................................................59

Appendix G: Zone Assignments ...........................................................................................................................64

6

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

Page 7

Product Description

CHAPTER 1 Product Description

The Universal Digital Alarm Communicator/Transmitter (UDACT-F) may be used with the Fire•Lite MS-9200,

MS-9600 and Sensiscan 2000 FACPs (Fire Alarm Control Panels). The UDACT-F transmits system status to UL

listed Central Station Receivers via the public switched telephone network. The UDACT-F is compact in size and

may be mounted inside the host FACP or may mount externally in a separate enclosure. EIA-485 annunciator communications bus and 24 volt (nominal) connections are required. The UDACT-F is capable of reporting 198 points or

56 zones when used with the MS-9200, 636 points or 99 zones when used with the MS-9600 and 56 zones when used

with the Sensiscan 2000.

1.1 Product Features

• Dual telephone lines

• Dual telephone line voltage detect

• UL recognized “Dialer Runaway” prevention

• Compact in size: 6.75" (17.145 cm) x 4.25" (10.795 cm)

• Built-in programmer

• Built-in four character red 7-segment LED display

• Manual test report function

• Manual master transmission clear function

• Mounts either inside control panel or in separate ABS-8RF or UBS-1F enclosure

• Communicates vital system status including:

✓ Independent zone/point alarm

✓ Independent zone/point trouble

✓ Independent zone/point supervisory

✓ AC (mains) power loss - programmable

✓ Low battery and earth fault

✓ System off-normal

✓ 12 or 24 hour test signal

✓ Abnormal test signal per new UL requirements

✓ Annunciation of UDACT-F troubles, including loss of phone lines, communication failure with either

Central Station and total communication failure

• Troubleshoot Mode converts keypad to DTMF touchpad

• Individual LEDs for:

✓ Power

✓ EIA-485 loss

✓ Manual Test

✓ Kissoff

✓ Comm Fail

✓ Primary Line Seize

✓ Secondary Line Seize

• Open collector relay driver for Total Communication Failure or UDACT-F trouble

• Real Time Clock

• Extensive transient protection

• Simple EIA-485 interface to host panel

UBS-1F

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

7

Page 8

Product Features

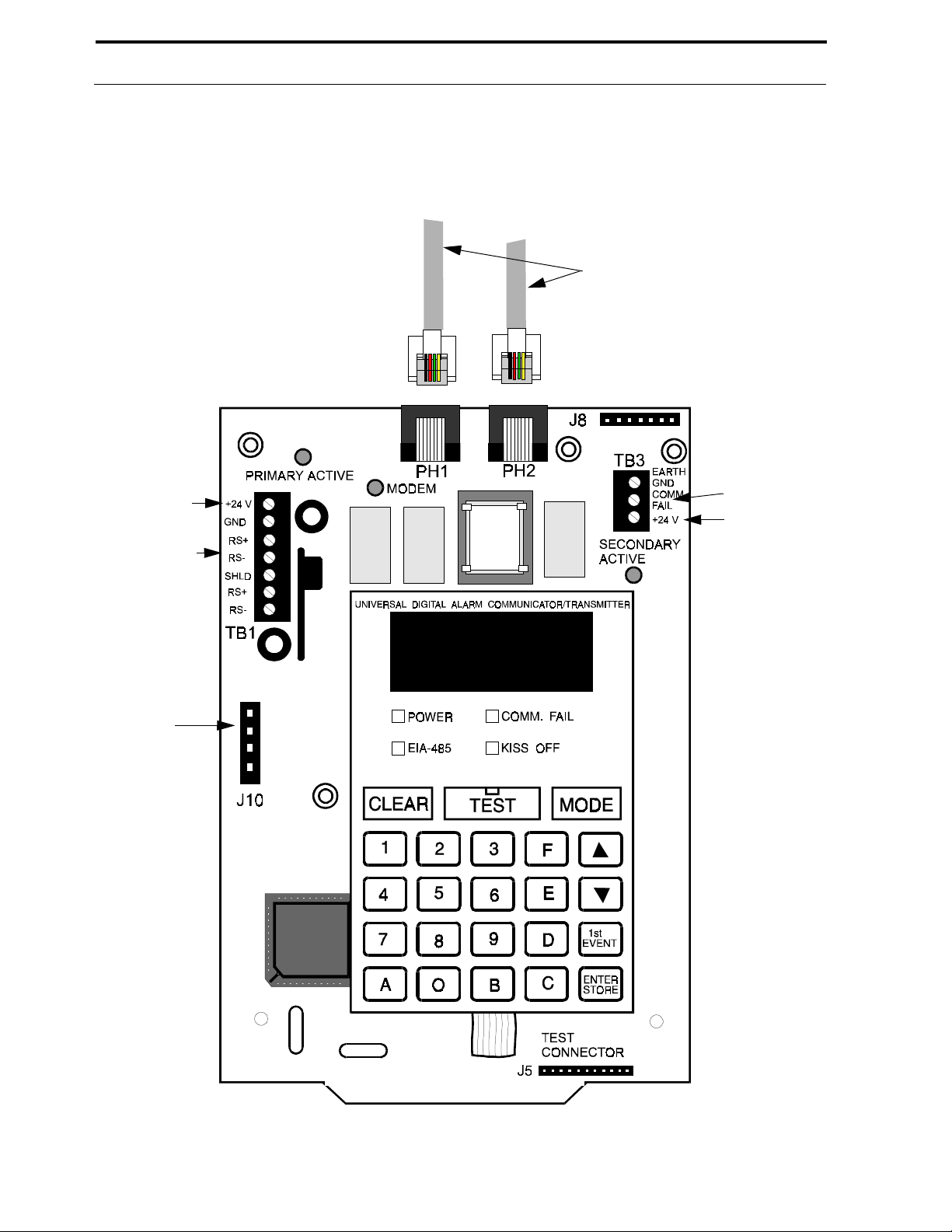

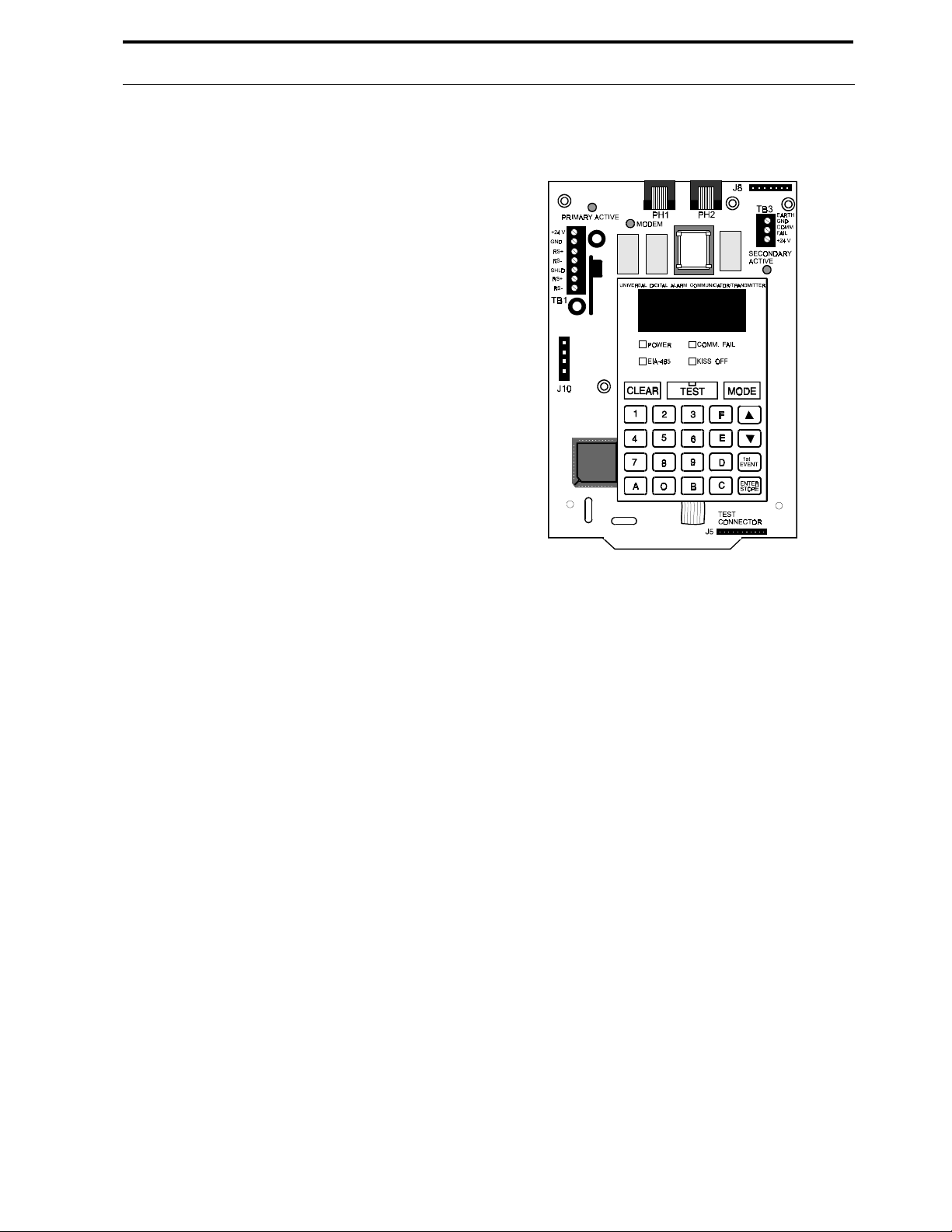

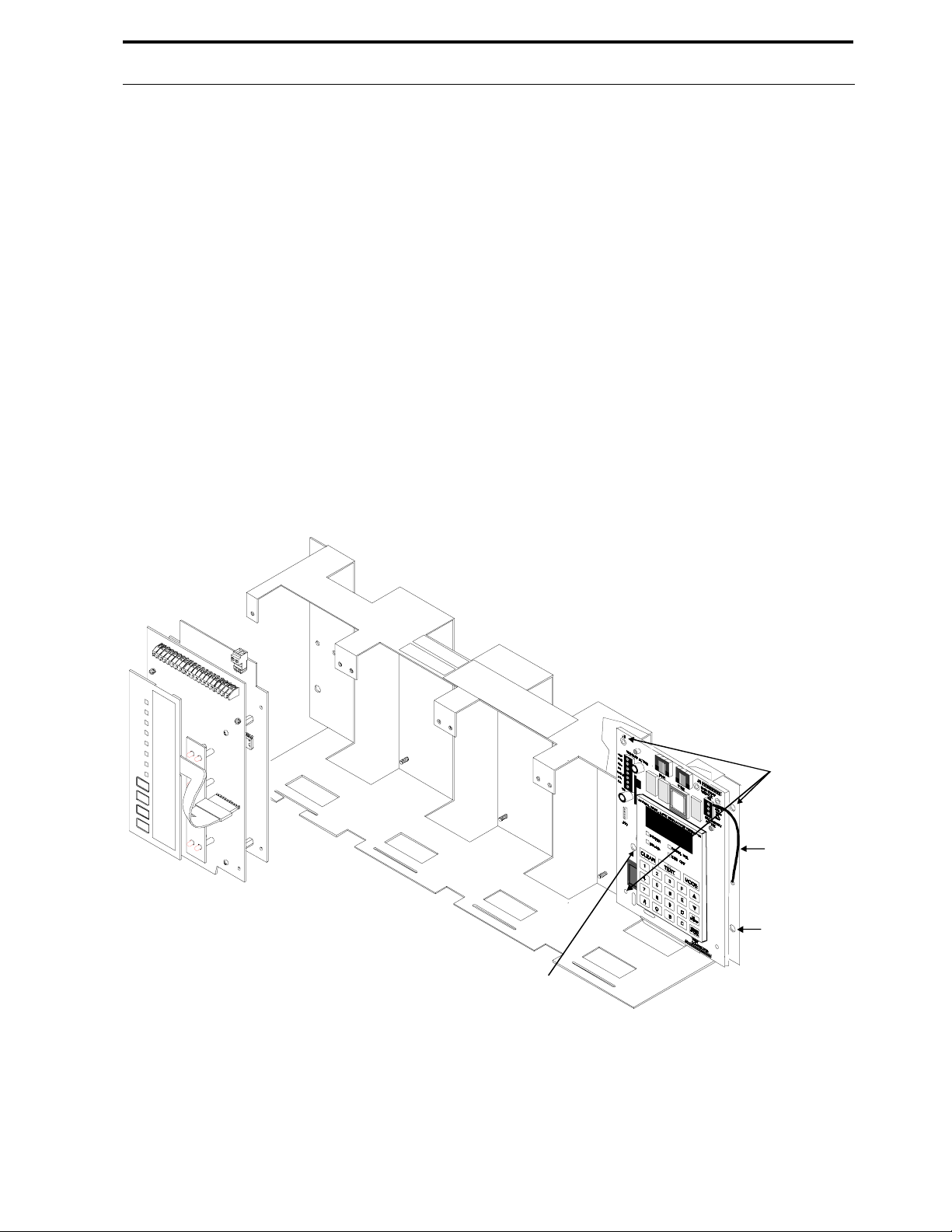

FIGURE 1-1:

24 VDC power in

(use power-limited

source)

EIA-485 connector

(use power-limited

source)

UDACT-F Assembly

Primary

Phone Line

Secondary

Phone Line

Modular Cables

P/N MCBL-7

(order separately)

Comm Fail Output

(power-limited)

24 VDC

(power-limited)

Connect to

J16 on MS-9200,

using supplied

ribbon cable

8

Document #50049 Rev.E0 1/22/01 P/N 50049:E0

Page 9

1.2 Controls and Indicators

Controls and Indicators

Front Panel Switches

CLEAR Digits 0 - 9

TEST A

MODE B

Up Arrow C

Down Arrow D

1st EVENT E

ENTER/STORE F

Displays

• EIA-485 - yellow LED

• COMM. FAIL - yellow LED

• KISS OFF - green LED

• POWER - green LED

• Four 7-Segment Displays - red

• Primary Phone Line Active - red LED

• Secondary Phone Line Active - red LED

• TEST - green LED

FIGURE 1-2:

Controls and Indicators

1.3 Compatible Panels

The UDACT-F has been designed to be compatible with the following Fire•Lite control panels:

• Sensiscan 2000

• MS-9200

• MS-9600

1.4 Digital Communicator

Two modular phone jacks allow easy connection to telephone lines. Modular jacks are labeled PH1 and PH2 for the

Primary and Secondary phone lines. Telephone line 'Primary and Secondary Active' red LEDs are provided as well as

a green 'Kissoff' LED. The integral digital communicator provides the following functions:

• Line Seizure - takes control of the phone lines disconnecting any premises phones

• Off/On Hook - perform on and off-hook status to the phone lines

• Listen for dial tone - 440 hertz tone typical in most networks

• Dialing the Central Station(s) number - default is Touch-Tone

• For tone burst or touchtone type formats: Discern proper 'Ack' and 'Kissoff' tone(s) - the frequency and time

duration of the tone(s) varies with the transmission format. The UDACT-F will adjust accordingly.

• Communicate in the following formats (refer to “Compatible Receivers” on page 51, for a list of compatible

receivers):

✓ 6 Tone Burst Types: 20 pps (3+1 Standard & Express, 4+1 Standard & Express, 4+2 Standard &

Express)

✓ 3 Touchtone Types: (4+1 Ademco Express, 4+2 Ademco Express, Ademco Contact ID)

®

, programmable to rotary

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

9

Page 10

Circuits

1.5 Circuits

The UDACT-F circuit board contains a CPU, other primary components and wiring interface connectors

1.5.1 Power Requirements

Operating voltage for the UDACT-F must be power-limited, filtered, nonresettable 21.2 to 28.2 volts. The 24 VDC

nominal operating power must be supplied by the control panel and is connected to TB1 of the UDACT-F.

Note: If the UDACT-F is installed in an MS-9200 FACP, power is provided directly through UDACT-F connector J10 which connects

via supplied ribbon cable to the MS-9200 main circuit board connector J16.

1.5.2 Communications

Communications between the UDACT-F and the host FACP is accomplished over a two-wire EIA-485 serial interface

which is power-limited and supervised by the control panel and the UDACT-F. The wiring connections are made to

the RS+, RS- and Shield terminals of TB1 on the UDACT-F.

The EIA-485 circuit cannot be T-tapped and must be wired in a continuous fashion from the control panel to the

UDACT-F and, if installed, an annunciator. The wire must be 12 AWG to 18 AWG (0.75 to 3.25 mm

2

) twisted,

shielded pair cable with a characteristic impedance of 120 ohms (+/- 20%). Limit the total wire resistance to 100

ohms on the EIA-485 circuit. Do not run cable adjacent to, or in the same conduit as, 120 VAC service, noisy electrical circuits that are powering mechanical bells or horns, audio circuits above 25 volts

, motor control circuits or

RMS

SCR power circuits.

Note: If the UDACT-F is installed in an MS-9200 FACP, the EIA-485 data line is supplied directly through UDACT-F connector J10

which connects via supplied ribbon cable to the MS-9200 main circuit board connector J16.

1.5.3 Primary and Secondary Phone Lines

Modular jacks are used to interface the primary and secondary phone lines to the public telephone network.

1.5.4 Communicator Fail Relay Driver

Relay driver output for Central Station communication failure is provided.

1.5.5 Earth Ground

Connect a separate earth ground wire to TB3 terminal 1 for transient protection. When mounted in the MS-9200 or

MS-9600, the UDACT-F receives an earth ground connection via the upper right corner mounting position.

1.6 Specifications

DC Power - TB1, Terminals 1 & 2

24 VDC (nominal) filtered, nonresettable and power-limited. Voltage range is 21.2 to 28.2 volts. DC power TB1 Terminals 1(+), 2(-) 40 mA in standby, 75 mA maximum while communicating (for MS-9200 installation, use connector

J10) and 100 mA with the open collector output engaged and communicating.

Data Communications - TB1, Terminals 3 - 7

EIA-485 serial interface, TB1 Terminal 3 = RS+, 4 = RS-, 5 = Shield, 6 = future use, 7 = future use. Power-limited

source must be used. (For MS-9200 installation, use connector J10).

10

Document #50049 Rev.E0 1/22/01 P/N 50049:E0

Page 11

Telephone Requirements and Warnings

Auxiliary Output - TB3, Terminals 2 & 3

TB3 Terminal 2 = Communicator Failure. Power-limited circuit. An open collector type output, normally high,

active low which sinks up to 40 mA. TB3 Terminal 3 = 21.2 to 28.2 volts, power-limited. Use UL listed relay P/N

MR-101/C or MR-201/C with this output.

Earth Ground - TB3, Terminal 1

TB3 Terminal 1 = Earth Ground connection. Connect this terminal to building earth ground using solid minimum 12

AWG (3.25 mm

2

) wire to provide lightning protection. This connection is not required when the UDACT-F is

mounted in an MS-9200 or MS-9600 since the upper right mounting hole provides an earth ground connection.

1.7 Telephone Requirements and Warnings

1.7.1 Telephone Circuitry - PH1 & PH2

Ringer Equivalence Number (REN) = 0.6B

AC Impedance 10.0 Mega Ohm

Complies with FCC Part 68

Mates with RJ31X Male Connector

Supervision Threshold: less than 4.0 volts for 2 minutes

The REN is used to determine the quantity of devices which may be connected to the telephone line. Excessive RENs

on the telephone line may result in the devices not ringing in response to an incoming call. In most, but not all areas,

the sum of the RENs should not exceed five (5.0). To be certain of the number of devices that may be connected to

the line, as determined by the total RENs, contact the telephone company to determine the maximum REN for the

calling area.

1.7.2 Digital Communicator

Before connecting the UDACT-F to the public switched telephone network, the installation of two RJ31X jacks is

necessary. The following information if provided if required by the local telephone company:

Manufacturer: Fire•Lite Alarms, Inc.

One Firelite Place

Northford, CT 06472

Product Model Number: UDACT-F

FCC Registration Number: 1W6USA-20723-AL-E

Ringer Equivalence Number: 0.6B

1.7.3 Telephone Company Rights and Warnings:

The telephone company, under certain circumstances, may temporarily discontinue services and/or make changes in

its facilities, services, equipment or procedures which may affect the operation of this digital communicator.

However, the telephone company is required to give advance notice of such changes or interruptions.

If the digital communicator causes harm to the telephone network, the telephone company reserves the right to

temporarily discontinue service. Advance notification will be provided except in cases when advance notice is not

practical. In such cases, notification will be provided as soon as possible. The opportunity will be given to correct

any problems and to file a complaint.

DO NOT CONNECT THIS PRODUCT TO COIN TELEPHONE, GROUND START OR PARTY LINE SERVICES.

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

11

Page 12

Telephone Requirements and Warnings

When the digital communicator activates, premise phones will be disconnected.

Two separate phone lines are required. Do not connect both telephone interfaces to the same telephone line.

The digital communicator must be connected to the public switched telephone network upstream of any private

telephone system at the protected premises.

An FCC compliant telephone cord must be used with this equipment. This equipment is designed to be connected to

the telephone network or premises wiring using a compatible RJ31X male modular plug which is Part 68 compliant.

1.7.4 For Canadian Applications

The following is excerpted from CP-01 Issue 5:

“NOTICE: The Industry Canada (IC) label identifies certified equipment. This certification means that the equipment

meets certain telecommunications network protective, operational and safety requirements as prescribed in the

appropriate Terminal Equipment Technical Requirements document(s). The Department does not guarantee the

equipment will operate to the user’s satisfaction.”

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the local

telecommunications company. The equipment must also be installed using an acceptable method of connection. The

customer should be aware that compliance with the above conditions may not prevent degradation of service in some

situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated by the

supplier. Any repairs or alterations made by the user to this equipment, or equipment malfunctions, may give the

telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power utility, telephone

lines and internal metallic water pipe system, if present, are connected together. This precaution may be particularly

important in rural areas.

CAUTION

Users should not attempt to make such connections themselves, but should contact the appropriate electric inspection

authority or electrician.

“The Ringer Equivalence Number

(REN) assigned to each terminal device provides an indication of the maximum

number of terminals allowed to be connected to a telephone interface. The termination of an interface may consist of

any combination of devices subject only to the requirement that the sum of the REN of all devices does not exceed 5.”

Representative: NOTIFIER/FIRE-LITE, CANADA

24 Viceroy Road

Concord, Ontario L4K2L9

IC Certificate Number: 2132 6030 A

Ringer Equivalence Number (REN): 0.6B

Load Number: 3

12

Document #50049 Rev.E0 1/22/01 P/N 50049:E0

Page 13

Modes and Special Functions

1.8 Modes and Special Functions

1.8.1 Normal Mode

Normal Mode is the standard mode of operation. In this mode, the UDACT-F monitors host FACP status as well as

monitoring telephone line voltage. The UDACT-F reports system status information to UL listed Central Stations.

Information transmitted includes general alarm, trouble and supervisory. It also transmits either the number of zones

or points activated or the specific point(s) activated. Specific system trouble conditions and specific UDACT-F troubles are also transmitted.

1.8.2 Program Mode

Program Mode is used to program the UDACT-F. While the UDACT-F is in the program mode, it cannot receive host

FACP status information. Refer to “Programming Instructions” on page 27, for complete programming instructions.

1.8.3 Lamp Test Mode

This mode turns on all segments of the four character display plus all LEDs on the UDACT-F.

1.8.4 Troubleshoot Mode

Troubleshoot Mode may be used for testing the telephone line wiring. Connection from the UDACT-F's modular

jacks, through RJ31X jacks and into the telephone network may be easily checked. In this mode, the keypad acts similar to a telephone touchpad.

1.8.5 Type Mode

Type Mode is used to define the specific type of device (point) used or function of a zone. This mode is also used to

disable the alarm report for any zone/point in the system. The feature which disables the zone/point alarm report

must be used for zones/points programmed into the host FACP as remote silence, reset, drill or acknowledge

switches.

1.8.6 Clear Function

When the clear function is activated, it causes the UDACT-F to immediately stop transmissions, hang-up from the

telephone network, clear out any messages that were waiting for transmission and reset.

1.8.7 Manual Test Function

The manual test function allows for a test report message to be sent to both Central Stations upon activation.

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

13

Page 14

Installation

CHAPTER 2 Installation

2.1 Mounting Options

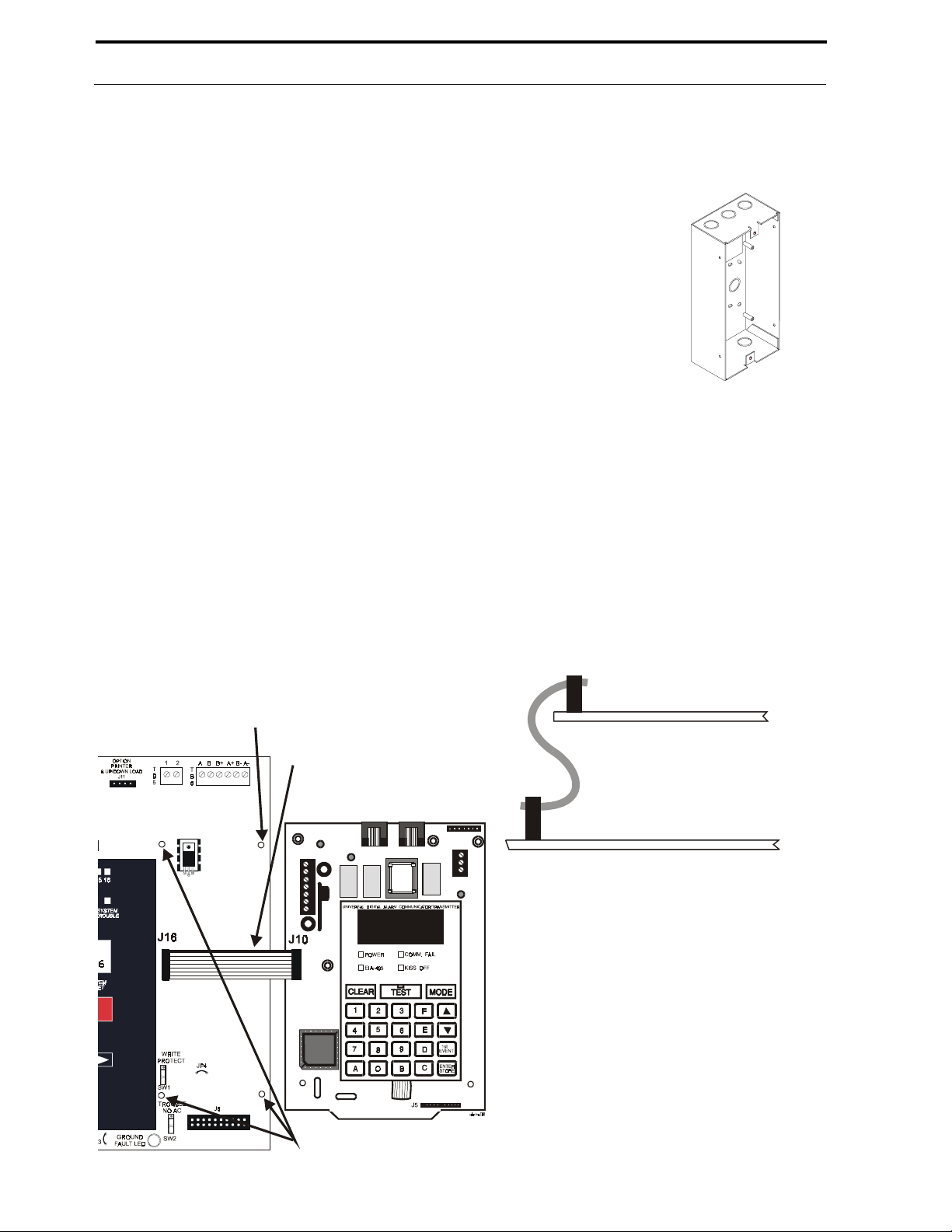

FIGURE 2-1:

ABS-8RF

The UDACT-F may be mounted in the control panel or mounted remotely in an

ABS-8RF or UBS-1F enclosure up to 6,000 feet (1,800 m) away from the control panel.

All power must be removed from the FACP before making any connections to prevent

circuit damage. The EIA-485 serial interface is connected between the control panel

and UDACT-F using twisted, shielded pair wire. Power should be wired from the control panel's 24 VDC (nominal) filtered, nonresettable output to TB1 on the UDACT-F

(except when mounted in the MS-9200).

2.2 Panel Mounting

2.2.1 MS-9200

The MS-9200 must have firmware with a Part Number of 73580 or higher installed to allow use of the UDACT-F.

Remove all power from the MS-9200 by disconnecting AC and batteries. Install the supplied standoffs (three nylon

and one aluminum standoff) in the appropriate holes located on the right side of the MS-9200 main circuit board as

illustrated in Figure 2-2. Using the ribbon cable supplied with the UDACT-F, connect J10 on the UDACT-F to J16 on

the MS-9200. Note that the colored edge of the ribbon cable must be oriented toward the top edge of the UDACT-F

as illustrated in Figure 2-2. Carefully seat the UDACT-F on the nylon standoffs and secure to the aluminum standoff

with the supplied screw.

The EIA-485 circuit and 24 VDC power are provided directly from connector J16 of the MS-9200. Note that a 120

ohm EOL resistor is not required on the UDACT-F EIA-485 terminals when it is installed inside the MS-9200 cabinet. The EOL resistor is required at the last device on the EIA-485 line, external to the MS-9200.

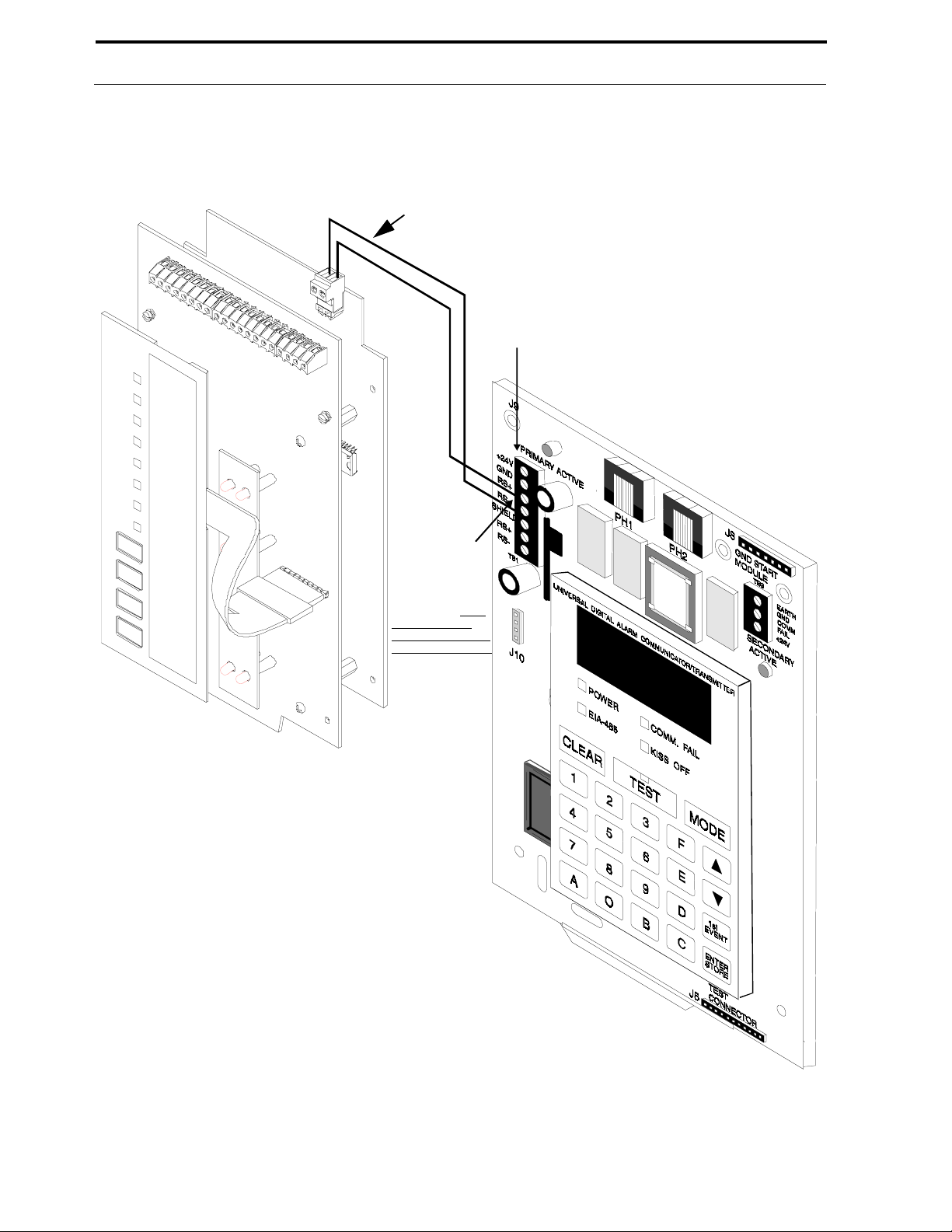

FIGURE 2-2:

Aluminum standoff

with nut, required for

transient protection

UDACT-F Mounting to MS-9200

Supplied ribbon cable attached

as illustrated to the right.

Note position of colored edge.

J10

UDACT-F

14

MS-9200

UDACT-F

J16

MS-9200

Nylon standoffs

Document #50049 Rev.E0 1/22/01 P/N 50049:E0

Page 15

Panel Mounting

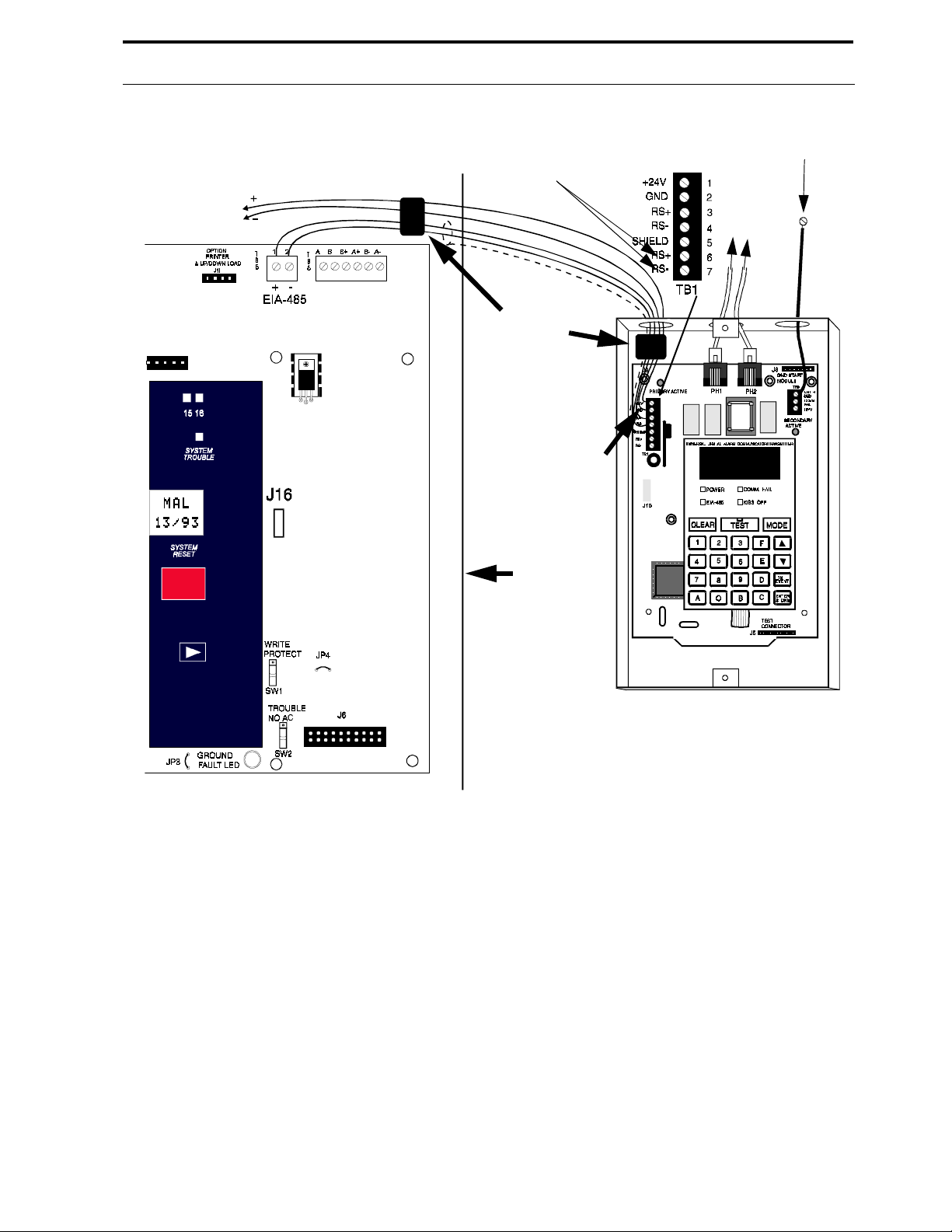

FIGURE 2-3:

Supervised and power-limited EIA-485 and power connections

Nonresettable

External UDACT-F Mounting in ABS-8RF - MS-9200

24 VDC

Power

DO NOT USE

THESE TERMINALS

Ferrite Cores

P/N FBD-1

Install 120 ohm EOL resistor

(P/N 71244) on TB1 Terminals

3 & 4, if last or only device on

EIA-485 line.

MS-9200 cabinet

Solid Earth

Ground

Connection

To Phone

Lines

(Supervised)

UDACT-F in ABS-8RF

(shown with cover removed)

MS-9200

Notes:

This arrangement allows use of the UDACT-F simultaneously with the RTM-8F module

1.

Ferrite cores are recommended for all applications

2.

Recommended wire is 12 AWG to 18 AWG (0.75 to 3.25 mm2) twisted wire

3.

Shielded wire is not required (unless mandated by local AHJ)

4.

If shield wire is used, connect only one end of the shield:

✓ shield may be connected to cabinet (earth ground) at fire alarm panel, or

✓ shield may be connected to TB1 Terminal 5 (shield) at UDACT-F as shown in Figure 2-3. Note that the

shield end that is not connected should be insulated to prevent accidental grounding. Do not connect

both ends of the shield under any circumstance, since a ground fault may result.

Conduit is recommended for external wire runs. Consult local building codes

5.

Connect Ground Strap (supplied with ABS-8RF enclosure) from Earth Ground terminal on the UDACT-F to a

6.

solid building earth ground. Conduit alone will not provide a reliable earth ground.

UDACT-F may be located up to 6,000 feet (1,800 m) away from the host control panel

7.

Refer to “Specifications” on page 10, for power requirements

8.

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

15

Page 16

Panel Mounting

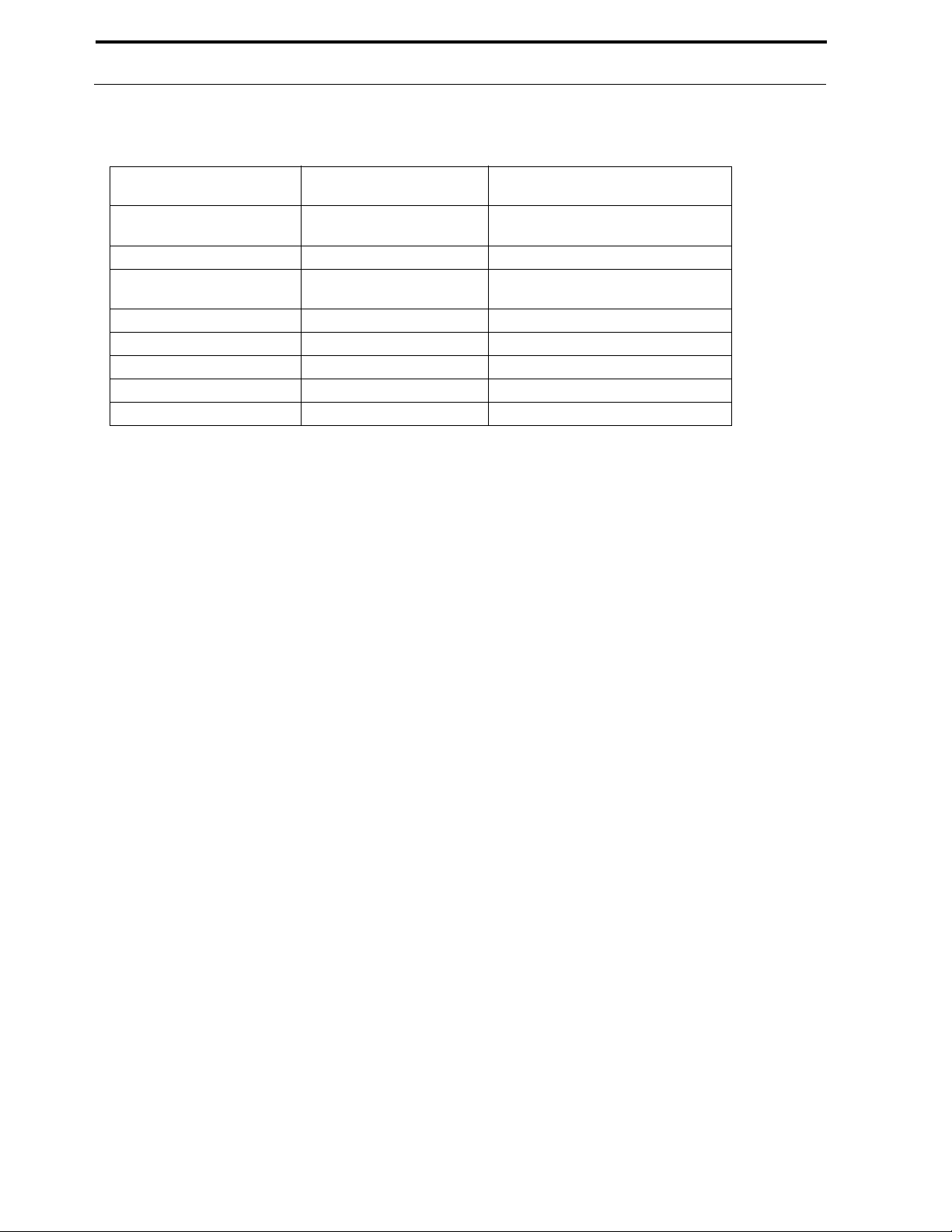

CAUTION: Connecting a UDACT-F to an MS-9200 which also has an ACM, AFM or LDM Series annunciator connected, will alter the assignments of the first eight yellow LEDs on the annunciator as follows:

TAB L E 2 - 1 : Annunciator LED Assignments (MS-9200)

Yellow Annunciator LED

1

2 Signals Silenced Signals Silenced

3Not Used

4 Not Used Supervisory

5 Supervisory Bell Trouble

6 Prealarm Prealarm/Maintenance Alert

7 AC Fail Low Battery

8 Panel Trouble AC Fail

Assignment

Without UDACT-F

System Trouble

(less AC loss)

Assignment

With UDACT-F

System Trouble

(less AC loss)

Program Mode

(panel off-normal)

16

Document #50049 Rev.E0 1/22/01 P/N 50049:E0

Page 17

Panel Mounting

2.2.2 MS-9600

The UDACT-F may be mounted to a BRKT-9600 bracket inside the FACP cabinet (see MS-9600 instruction manual)

or mounted remotely in a UBS-1F or ABS-8RF enclosure (see Figure 2-3) and wired according to the diagram below.

FIGURE 2-4:

24 VDC

Nonresettable

Power

TB3

CUT TO

DISABLE

LOCAL

CHARGER

UDACT-F Wiring to MS-9600

JP3

J10

4XTM OPT BD

TB4

CUT TO

MONITOR 4X TM

J11

ALARM TRBL SUPV

TB5

JP6

JP5

MS-9600 Control Panel

TB6

+ –

TB7

TXR

I

I

D

O

O

G

N

N

T

C

U

U

N

–

+

R

V

T

T

D

+

–

shield

TB8

J10

+24V

GND

RS+

RS–

SHIELD

RS+

RS–

1

2

3

4

5

6

7

J5

Notes for External Applications:

Ferrite cores are recommended for all applications

1.

Recommended wire is 12 AWG to 18 AWG (0.75 to 3.25 mm2) twisted wire

2.

Shielded wire is not required (unless mandated by local AHJ)

3.

If shield wire is used, connect only one end of the shield:

✓ shield may be connected to cabinet (earth ground) at fire alarm panel, or

✓ shield may be connected to TB1 Terminal 5 (shield) at UDACT-F as shown in Figure 2-3. Note that the

shield end that is not connected should be insulated to prevent accidental grounding. Do not connect

both ends of the shield under any circumstance, since a ground fault may result.

Conduit is recommended for external wire runs. Consult local building codes

4.

Connect Ground Strap (supplied with ABS-8RF enclosure) from Earth Ground terminal on the UDACT-F to a

5.

solid building earth ground. Conduit alone will not provide a reliable earth ground.

UDACT-F may be located up to 6,000 feet (1,800 m) away from the host control panel

6.

Refer to “Specifications” on page 10, for power requirements

7.

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

17

Page 18

Panel Mounting

Connecting a UDACT-F to an MS-9600 which also has an ACM, AFM or LDM Series annunciator connected, will

not

alter the assignments of the first eight yellow LEDs on the annunciator.

TAB L E 2 - 2 : Annunciator LED Assignments (MS-9600)

Yellow Annunciator LED

1

2 Signals Silenced

3

4 Supervisory

5 Bell Trouble

6 Prealarm/Maintenance Alert

7 Low Battery

8AC Fail

Assignment

With or Without UDACT-F

System Trouble

(less AC loss)

Program Mode

(panel off-normal)

18

Document #50049 Rev.E0 1/22/01 P/N 50049:E0

Page 19

Panel Mounting

2.2.3 Sensiscan 2000

Remove all power from the control panel by disconnecting AC and batteries. Install the three supplied nylon support

posts for the top and bottom left of the UDACT-F, one aluminum/nylon and one aluminum standoff in the CHS-4

chassis slot in which the UDACT-F is to be installed (refer to Figure 2-5). Position the UDACT-F on the standoffs

and secure on the aluminum standoff with a #6-32 screw. Alternatively, the UDACT-F may be mounted remotely

using an ABS-8RF or UBS-1F enclosure. Ferrite cores are recommended for this application. Refer to Figure 2-3,

“External UDACT-F Mounting in ABS-8RF - MS-9200,” on page 15, and the accompanying notes for wiring alternatives.

Connect the communication line between the EIA-485 terminal block on the CPU-2000 and TB1 Terminals 3 & 4 on

the UDACT-F, making certain to observe polarity. Refer to Figure 2-6, “EIA-485 Connection Sensiscan 2000,” on

page 20. Recommended wire is 12 AWG to 18 AWG (0.75 to 3.25 mm

nected to the EIA-485 line, install a 120 ohm EOL resistor across the UDACT-F TB1 Terminals 3 & 4.

Connect the supplied Ground Strap from the UDACT-F Earth Ground terminal on TB3 to the CHS-4 chassis. Connect 24 VDC filtered, nonresettable power to TB1 Terminals 1 & 2 on the UDACT-F. Refer to Figure 2-7, “24 VDC

Power Connection to UDACT-F,” on page 21.

2

) twisted pair. If no other devices are con-

FIGURE 2-5:

CPU-2000

UDACT-F Mounting in CHS-4

UDACT-F

nylon support

posts

ground strap

CHS-4

aluminum

standoff and

screw

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

nylon &

aluminum

standoff

19

Page 20

Panel Mounting

FIGURE 2-6:

EIA-485 Connection Sensiscan 2000

EIA-485 (super vised and power-limited)

+

Install 120 ohm EOL

resistor (P/N: 71244)

across Terminals 3

(RS+) & 4 (RS-) if

last or only device on

EIA-485 line. Note

that Terminals 6

(RS+) & 7 (RS-) are

not used at this time.

+

-

TB1

Terminal 3 RS+

Terminal 4 RS-

CPU-2000

UDACT-F

20

Document #50049 Rev.E0 1/22/01 P/N 50049:E0

Page 21

Panel Mounting

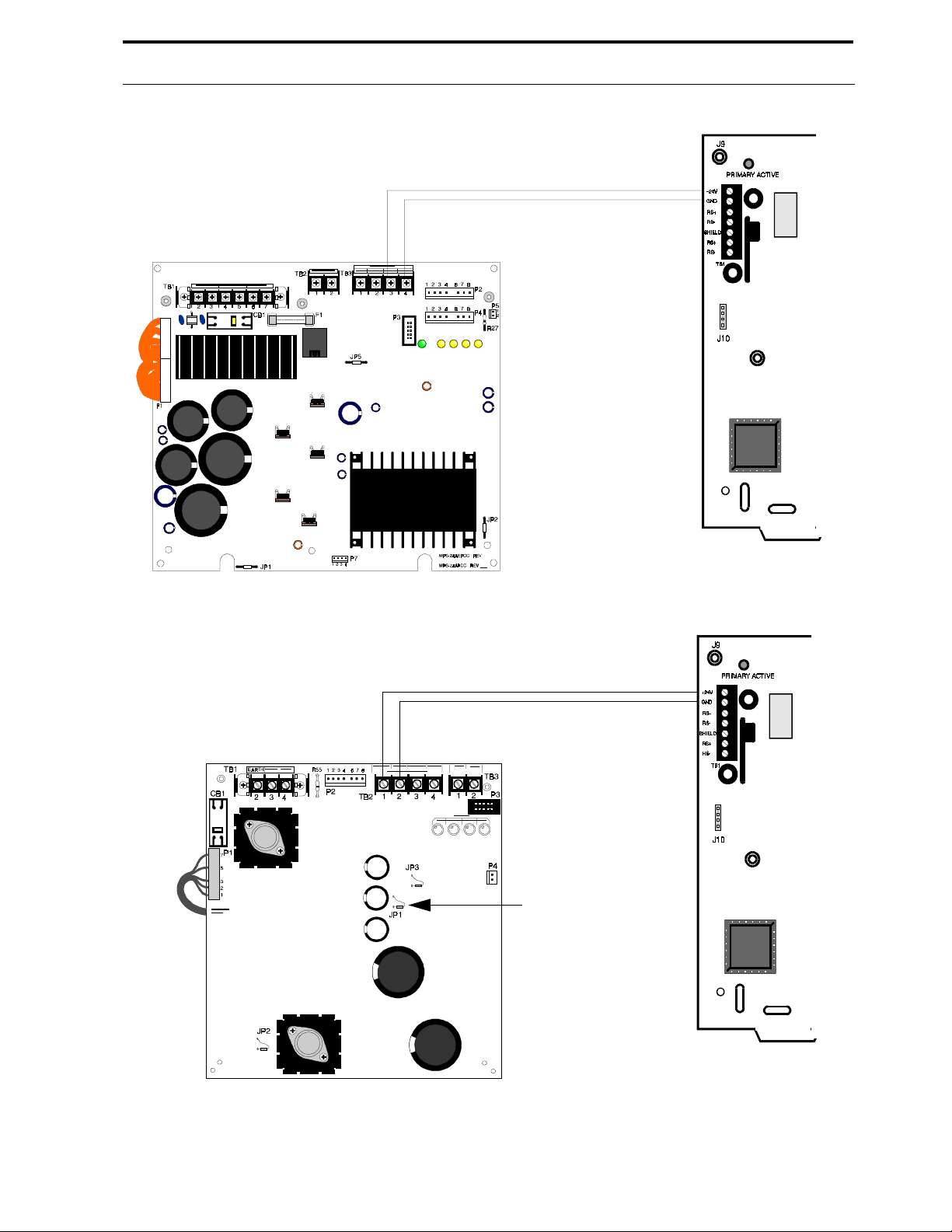

FIGURE 2-7:

24 VDC Power Connection to UDACT-F

Power (supervised and power-limited)

TB3-3 +

- TB3-4

TB1-1 +

TB1-2 -

UDACT-F

MPS-24AF

TB2-1 +

Power (supervised and power-limited)

- TB2-2

Cut jumper JP1 to make

output nonresettable for

use with UDACT-F

TB1-1 +

TB1-2 -

MPS-24BF

Power for the UDACT-F must be 24 VDC filtered, nonresettable

Note:

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

UDACT-F

21

Page 22

Panel Mounting

CAUTION: Connecting a UDACT-F to a Sensiscan 2000, which also has an AFM or LDM series annunciator

connected, will alter the assignments of the first eight yellow LEDs on the annunciator as follows:

TAB L E 2 - 3 : Sensiscan 2000 Annunciator LED Assignments

Yellow Annunciator

LED

1

2 Signals Silenced Signals Silenced

3 Not Used Not Used

4 Supervisory Supervisory

5 Indicating Circuit #1 Trouble Indicating Circuit #1 Trouble

6 Indicating Circuit #2 Trouble Indicating Circuit #2 Trouble

7 Municipal Tie Trouble Low Battery/Ground Fault

8 AC Fail AC Fail

LED Assignment

Without UDACT-F

System Trouble

(less AC loss)

LED Assignment

With UDACT-F

System Trouble

(less AC loss)

22

Document #50049 Rev.E0 1/22/01 P/N 50049:E0

Page 23

UL Power-limited Wiring Requirements

2.3 UL Power-limited Wiring Requirements

Power-limited and nonpower-limited circuit wiring must remain separated in the cabinet. All power-limited circuit

wiring must remain at least 0.25" away from any nonpower-limited circuit wiring. Furthermore, all power-limited

circuit wiring and nonpower-limited circuit wiring must enter and exit the cabinet through different knockouts and/or

conduits. A typical wiring diagram for the UDACT-F is shown below.

FIGURE 2-8:

Typical Wiring Diagram for UL Power-limited Requirements

Use power-limited source

Use power-limited source

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

23

Page 24

Output Circuits

2.4 Output Circuits

2.4.1 Telephone Circuits

Provision to connect to two independent telephone lines is available via two telephone jacks labeled PH1 (Primary)

and PH2 (Secondary). Telephone line control/command is possible via double line seizure as well as usage of an

RJ31X style interconnection. The RJ31X jacks must be ordered separately.

Note that it is critical that the UDACT-F be located as the first device on the incoming telephone circuit to properly

function.

FIGURE 2-9:

Wiring Phone Jacks

(Primary Lines)

Incoming Telco

Phone Lines

Green Wire

Tip

Red Wire

Ring

Primary Phone Line PH-1

To premises phones

Ring

Tip

Note: Shorting bars inside

RJ31X Jack removed during

male plug insertion

7 foot

cable

(MCBL-7)

order separately

Tip

Ring

Green Wire

Red Wire

(Secondary Lines)

Incoming Telco

Phone Lines

Ring

To premises phones

Tip

Secondary Phone Line PH-2

24

Male Plug Connectors

Modular Female Connectors

Document #50049 Rev.E0 1/22/01 P/N 50049:E0

Page 25

Output Circuits

2.4.2 Relay Driver

The UDACT-F's open collector output on TB3, Terminal 2, is provided for Communicator Failure and UDACT-F

trouble. It can be used to drive UL listed relay MR-101/C or MR-201/C. The output is rated for 40 mA. The normal

condition for the output is Off (deenergized).

Communicator Failure occurs when the maximum number of attempts to reach both Central Stations has taken place

or when both phone lines are disconnected. UDACT-F trouble conditions include loss of telephone line voltage to the

primary and/or secondary phone lines, communication failure to the primary or secondary Central Stations or total

communication failure.

Wiring from the UDACT-F terminal block TB3 to the relay must be in the same room no more than 20 feet (6 m) in

length and enclosed in conduit. Wiring from the relay output contacts must also remain in the same room as the

UDACT-F.

When the UDACT-F is programmed as 'Receive Only' (typically when annunciators are also used and are set for

'Receive/Transmit'), the relay output is used to provide a UDACT-F trouble input to the host control panel. For

MS-9200 and MS-9600 applications, use a monitor module to supervise the relay closure (refer to Figure 2-11). Program the adjective and noun fields for 'UDACT-F Trouble'. For Sensiscan 2000 applications, wire the relay output to

the annunciator trouble input circuit or use the relay to trigger zone trouble.

When the UDACT-F is programmed as 'Receive/Transmit', EIA-485 supervision and UDACT-F trouble status are

automatically handled by the host control panel.

FIGURE 2-10:

Relay Driver Connections

All wiring to relay must be in the

same room within 20 feet of the

UDACT-F and in conduit.

Relay Energized LED

DPDT Contacts

10 amps

@115 VAC

Connections must be in the

same room as the UDACT-F.

Relay Energized LED

DPDT Contacts

10 amps

@115 VAC

Note: The MR-101/C and MR-201/C include an enclosure.

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

25

Page 26

Output Circuits

FIGURE 2-11:

SLC Loop to Fire

Alarm Control Panel

Monitoring for UDACT-F Trouble

MMF-300 Series

Monitor Module

Wiring in

same room as

UDACT-F

All wiring to relay must be in the same room

within 20 feet of the UDACT-F and in conduit.

3.9K ohm EOL

resistor

(supplied)

Earth Grnd

Comm Fail

+24 VDC

UDACT-F

MR-101/C

(MR-201/C may also be used)

MMF-300 Series Monitor Module is used to supervise Normally Closed output of MR-101/C. On UDACT-F trouble and Comm. Fail, MR-101/

Note:

C relay contact will open, causing M300 to transmit trouble condition to the FACP.

26

Document #50049 Rev.E0 1/22/01 P/N 50049:E0

Page 27

Programming Instructions

CHAPTER 3 Programming Instructions

Programming of the UDACT-F is possible at any time including while the UDACT-F is communicating with a Central

Station. The UDACT-F has been designed for many different types of applications. After examining your specific

application, review the programming options and choose the entries best suited for your system.

The UDACT-F has a built-in programmer. All programming selections are stored in nonvolatile Electrically-Erasable

Programmable Read-Only Memory (EEPROM). This ensures that the UDACT-F will retain all entries made in

Programming Mode even if power is removed.

The user must

program the primary and secondary phone numbers, account numbers and 24 hour test report times for

each Central Station account and the current time. The UDACT-F comes with factory chosen options/features already

programmed. Other options/features may be programmed if desired. If all factory default settings are acceptable,

programming is complete.

3.1 Entering Program Mode

To enter the Program Mode, press the MODE key once (the display will go blank). The user then has ten seconds to

start entering the code 7764.

®

☛ 7764 spells PROG on a Touch-Tone

If an incorrect key is entered, reenter the proper 4-digit code before

the information is entered into the UDACT-F, the digits scroll across the display from right to left.

___7

__77

_776

7764

The user is allowed a pause of up to 10 seconds in between each key stroke while entering the code. After pressing

the [ENTER/STORE] key, the UDACT-F will be in Program Mode and display 00_F. The user is allowed up to ten

minutes of idle time at this point before starting the programming, otherwise, the UDACT-F will return to Normal

Mode. The user also has a maximum of 10 minutes between any key stroke. All entries made prior to the 10 minute

time-out are valid and stored.

phone

pressing the [ENTER/STORE] key. Note that as

Once in Programming Mode, the UDACT-F will:

• Ignore the Test and Clear keys

• Continue to communicate any events not previously acknowledge at the Central Station prior to entering

Programming Mode

Location 56 is factory set to '0' for UDACT-F communications disabled. This setting keeps the communicator off until

location 56 is changed to 1, 2, 3, 4, 5 or 6. Refer to program selection for address 56 in this section. Once location

56 is changed from 0 to 1, 2, 3, 4, 5 or 6 and a valid phone number is entered, transmission of the 'UDACT-F Off Normal' report will occur.

Throughout Programming Mode, the first three locations on the left of the display represent the memory address

which can range from 00 to 208 (alpha characters are not used). The last location (farthest right) represents the

contents of the memory address. The first address displayed is shown below:

00_F

(address)(data)

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

27

Page 28

Switch (Key) Functions

3.2 Switch (Key) Functions

The function of each switch (key) in Program Mode is illustrated in Figure 3-1.

FIGURE 3-1:

UDACT-F Keypad

No function in Program Mode

Address entry keys are 0 to 9

Data entry keys are 0 to 9 and A to F

3.3 Programming Options

Select operating mode

Increment memor y address

Decrement memory address

1st press = First memory address

2nd press = Enter any address

Save data, go to next address

Primary Phone Number (00-15)

The first sixteen addresses are factory set to 'F' (from 00_F to 15_F). Programming is typically done as follows:

✓ If the phone number to be entered is 484-7161, press 4

✓ The display will read 00_4

✓ Press the [ENTER/STORE} key to save the entry to memory and increment to the next address 01_F

✓ Enter the remaining numbers in their respective addresses as shown below:

48 4 7 16 1 FFF FFFFFF

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

Valid entries for both the primary and secondary phone numbers are 0 - F with the numeric digits as dialed numbers

and the alpha digits (A - F) representing the following functions:

A = * on a Touchtone phone keypad

B = # on a Touchtone phone keypad

C = look for secondary dial tone for up to two seconds, then dial anyway

D = three second pause

E = five second pause

F = end of phone number (F must be entered)

28

Document #50049 Rev.E0 1/22/01 P/N 50049:E0

Page 29

Programming Options

Primary Number Communication Format (16)

One location is needed to select the Communication Format to the primary phone number. Address 16 is used for this

purpose. The default (factory setting) for this address is 16_A, which is 4+2 Standard, 1800 Hz 'Carrier', 2300 Hz

'ack'. The user may enter 0, 1, 2, 4, 6, 8, C or E in place of the default, then press the [ENTER/STORE] key. Choose

from the list of formats below:

0: 4+1 Ademco Express Standard, DTMF, 1400/2300 ACK

1: 4+2 Ademco Express Standard, DTMF, 1400/2300 ACK

2: 3+1 Standard 1800 Hz Carrier, 2300 Hz ACK

3: Not used

4: 3+1 Standard 1900 Hz Carrier, 1400 Hz ACK

5: Not used

6: 4+1 Standard 1800 Hz Carrier, 2300 Hz ACK

7: Not used

8: 4+1 Standard 1900 Hz Carrier, 1400 Hz ACK

9: Not used

A: 4+2 Standard 1800 Hz Carrier, 2300 Hz ACK

B: Not used

C: 4+2 Standard 1900 Hz Carrier, 1400 Hz ACK

D: Not used

E: Ademco Contact ID

F: Not used

Note: Consult the Central Station for proper selection or consult the factory representatives. For any format chosen, the UDACT-F

automatically programs all of the event codes. Refer to Table 3-2 on page 34, Table 3-3 on page 35, Table 3-4 on page 36, Table 3-5

on page 37, Table 3-6 on page 38 and Table 3-7 on page 39.

Primary Number Account Code (17-20)

The Account Code if provided by the Central Station. Four locations at addresses 17 - 20 which default to all '0s'

must be changed to the supplied Account Code. Valid entries are 0 - 9 and A - F. The number of digits entered must

match the format selection. If programming '2' or '4' into address 16, enter the three digit code (location 20 is

ignored). If programming '0, 1, 6, 8, A, C or E' into address 16, enter the four digit code.

Primary Number 24 Hour Test Time (21-24)

Use military time when entering the 24 hour 'test' time. The 24 hour test report to phone number 1 takes up four locations (addresses 21 - 24). The default is 00:00 (12:00 midnight). The limits for each location are as follows:

21 = 0 to 2

22 = 0 to 9

23 = 0 to 5

24 = 0 to 9

Do not use 'A - F' as entries in these addresses.

Primary Number 24/12 Hour Test Time Interval (25)

The test report sent to the primary phone number may be sent every 12 or 24 hours. If the message is to be sent every

24 hours, leave the factory default entry of '0'. If a 12 hour test report time is needed, enter '1' for 12 hours.

Secondary Phone Number (26-41)

The sixteen addresses are factory set to 'F' (from 26_F to 41_F). Programming is typically done as follows:

✓ If the phone number to be entered is 484-7161, press 4

✓ The display will read 26_4

✓ Press the [ENTER/STORE] key to save the entry to memory and increment to the next address 27_F

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

29

Page 30

Programming Options

✓ Enter the remaining numbers in their respective addresses as shown below:

48 4 7 16 1 FFF FFFFFF

26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41

Valid entries for both the primary and secondary phone numbers are 0 - F with the numeric digits as dialed numbers

and the alpha digits (A - F) representing the following functions:

A = * on a Touchtone phone keypad

B = # on a Touchtone phone keypad

C = look for secondary dial tone for up to two seconds, then dial anyway

D = three second pause

E = five second pause

F = end of phone number (F must be entered)

Secondary Number Communication Format (42)

One location is needed to select the Communication Format to the secondary phone number. Address 42 is used for

this purpose. The default (factory setting) for this address is 42_A, which is 4+2 Standard, 1800 Hz 'Carrier', 2300

Hz 'ack'. The user may enter 0, 1, 2, 4, 6, 8, C or E in place of the default, then press the [ENTER/STORE] key.

Choose from the list of formats below:

0: 4+1 Ademco Express Standard, DTMF, 1400/2300 ACK

1: 4+2 Ademco Express Standard, DTMF, 1400/2300 ACK

2: 3+1 Standard 1800 Hz Carrier, 2300 Hz ACK

3: Not used

4: 3+1 Standard 1900 Hz Carrier, 1400 Hz ACK

5: Not used

6: 4+1 Standard 1800 Hz Carrier, 2300 Hz ACK

7: Not used

8: 4+1 Standard 1900 Hz Carrier, 1400 Hz ACK

9: Not used

A: 4+2 Standard 1800 Hz Carrier, 2300 Hz ACK

B: Not used

C: 4+2 Standard 1900 Hz Carrier, 1400 Hz ACK

D: Not used

E: Ademco Contact ID

F: Not used

Note: Consult the Central Station for proper selection or consult the factory representatives. For any format chosen, the UDACT-F

automatically programs all of the event codes. Refer to Table 3-2 on page 34, Table 3-3 on page 35, Table 3-4 on page 36, Table 3-5

on page 37, Table 3-6 on page 38 and Table 3-7 on page 39.

Secondary Number Account Code (43-46)

Four locations at addresses 43 - 46 default to all '0s'. Valid entries are 0 - 9 and A - F. The number of digits entered

must match the format selection. If programming '2' or '4' into address 42, enter three digits (location 46 is ignored).

If programming '0, 1, 6, 8, A, C or E' into address 42, enter four digits.

30

Document #50049 Rev.E0 1/22/01 P/N 50049:E0

Page 31

Programming Options

Secondary Number 24 Hour Test Time (47-50)

Use military time when entering the 24 hour 'test' time. The 24 hour test report to phone number 2 takes up four locations (addresses 47 - 50). The default is 00:00 (12:00 midnight). The limits for each location are as follows:

47 = 0 to 2

48 = 0 to 9

49 = 0 to 5

50 = 0 to 9

Do not use 'A - F' as entries in these addresses.

Secondary Number 24/12 Hour Test Time Interval (51)

The test report sent to the secondary phone number may be sent every 12 or 24 hours. If the message is to be sent

every 24 hours, leave the factory default entry of '0'. If a 12 hour test report time is needed, enter '1' for 12 hours.

Start Monitoring Address (52-53)

The entries in these addresses indicate the first group of zones or points to be monitored and reported to the Central

Station. The factory default entry is '01'. The only valid entry is '01' (S2000 or MS-9200) or ‘20’ (MS-9600). Refer

to Table 3-1 .

End Monitoring Address (54-55)

The entries in these addresses indicate the last group of zones or points to be monitored and reported to the Central

Station. The factory default entry is '01'. Valid entries are '01' and '04' (S2000 or MS-9200) or ‘20’ to ‘32’ (MS-

9600). Refer to Table 3-1 .

Note that the Start and End Monitoring Address programming locations are used to set the reporting range of the

UDACT-F.

TABLE 3-1:

MS-9200

MS-9600

S2000

1 = Report status of 56 software zones

2 = Report status of 99 software zones

3 = Report status of 56 zones

Note: For additional information on the starting and ending addresses, refer to the host FACP Technical Manual.

Start and End Monitoring Address

Zone Reporting (factory default) Point Reporting

START

Address 52-53

1

01

2

20

3

01

END

Address 54-55

01 MS-9200

32 MS-9600

START

Address 52-53

1

01

2

20

01 S2000 N/A N/A

1 = Report status of 198 points

2 = Report status of 636 points

END

Address 54-55

1

04

2

32

UDACT-F Communication Selection (56)

Leaving address 56 at '0' disables communications to the Central Station(s). Enter '1' for zone reporting receive only,

'2' for zone reporting receive/transmit, '3' for consecutive point reporting receive only, '4' for consecutive point reporting receive/transmit, '5' for code wheel matching point reporting receive only or '6' for code wheel matching point

reporting receive/transmit. Refer to “Type Mode” on page 44 and “Point Reporting” on page 50 for additional information on code wheel match reporting.

Note: Use receive only selections when using remote annunciators. Be certain to set one of the annunciators for receive/transmit for

EIA-485 communications bus supervision. Use the receive/transmit entries when annunciators are not installed or when the UDACTF receive/transmit function is to be used to supervise the EIA-485 communication bus. For additional information on the receive/

transmit function, refer to the specific annunciator technical manuals.

Document #50049 Rev. E0 01/22/01 P/N 50049:E0

31

Page 32

Programming Options

Backup Reporting (57)

Leaving address 57 at '0' means that reports will be transmitted to the secondary phone number only if attempts to

communicate to the primary phone number are unsuccessful. Programming a '1' causes all reports to be transmitted

to the secondary phone number.

Touchtone/Rotary Select (58)

A '0' programmed in this address by the factory triggers Touchtone dialing over both phone lines. Enter '1' for rotary

dialing.

Make/Break Ratio (59)

An entry must be made in this address only if address 58 is set to '1'. Address 59 is factory set to '0' which is a 67/33

ratio, but may be changed to '1' which is 62/38 ratio.

Address (60)

Leave factory default of '0'.

Address (61)

Leave factory default of '0'.

AC Loss Reporting Delay (62)

The factory default entry of '1' causes a 6 hour time delay for AC loss reporting. A '0' entry causes immediate reporting of AC loss. Valid entries are '0 to 9' and 'A to F' corresponding to the following reporting delay times:

1 = 6 hours 9 = 17 hours

2 = 7 hours A = 18 hours

3 = 8 hours B = 19 hours

4 = 9 hours C = 20 hours

5 = 10 hours D = 21 hours

6 = 11 hours E = 22 hours

7 = 15 hours F = 23 hours

8 = 16 hours

Host Panel ID (63)

Enter one of the following digits corresponding to the control panel in which the UDACT-F is installed. A correct

entry is essential for proper operation.

0 = MS-9200 5 = MS-9600

1 = Do not use 6 = Do not use

2 = Sensiscan 2000 7 = Do not use

3 = Do not use 8 = Do not use

4 = Do not use 9 = Do not use

Loop Number (64-65)

This address is used for Contact ID format only. The factory default setting is '00'. Refer to “Reporting Formats” on

page 47.

Sensor Number (66-68)

This address is used for Contact ID format only. The factory default setting is '000'. Refer to “Reporting Formats” on

page 47.

32

Document #50049 Rev.E0 1/22/01 P/N 50049:E0

Page 33

Programming Options

Programming Event Codes (69-208)

The type of reports and 'event codes' that are sent to the Central Station are referenced in Table 3-2 on page 34, Table

3-3 on page 35, Table 3-4 on page 36, Table 3-5 on page 37, Table 3-6 on page 38 and Table 3-7 on page 39. The

selections made for the Primary Central Station Number communication Format (address 16) and the Secondary Central Station Number Communication Format (address 42) automatically program addresses 69-208 with factory

default selections.

Any of the event codes may be changed. Consult the Central Station prior to altering the event codes. For the 3+1,

4+1 and 4+1 Express formats, entering an event code of '0' will cause the communicator to NOT transmit the report.

Enter '00' for 4+2 and 4+2 Express formats to NOT transmit the report. For Ademco Contact ID format, enter '000'.

Transmission of reports to either or both Central Station phone numbers may be disabled.

Note the special 'System Abnormal Test Report' event code. This report was added per UL DACT requirements. This

report is generated in place of the normal test report when an alarm and/or trouble condition exists at the time the test

report is due to be sent.

Programming the Real-Time Clock

Entering an address greater than 209 will cause a display of the current time. On initial power-up, the clock will start

running from the factory setting of 00:01 (military time). The far left digit will be flashing, indicating that this is the

first digit to be programmed.

Hours and Minutes

To set the hour, select a digit then press the [ENTER/STORE] key. The digit 2nd from the left will start flashing.

Select a digit then press the [ENTER/STORE] key. The hours setting is completed. With the digit 2nd from the