Page 1

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

FIAT DUCATO COURSE OUTLINE

SECOND PHASE

Training Academy

1/182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 2

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

Training Academy

DOCUMENTATION MODIFICATIONS / UPDATES

Date Referent File Name Description of modification

© 2006 - Fiat Auto S.p.A.

All rights reserved. No part of this publication may be reproduced or disclosed in any form

or by any means.

Processing the material below may not involve specific responsibilities for unintentional

errors or omissions.

The information given in this publication is continuously updated; Fiat Auto S.p.A.

disclaims all responsibilities for any errors, omissions, damage or loss that might result

from the use of outdated information.

This publication is issued for training purposes only.

Exhaustive, updated technical information for servicing purposes can be found in the

service manual and any other service information for the vehicle model concerned.

© 2006 Fiat Auto S.p.A. - All rights reserved

2/182

Page 3

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

CONTENTS

Training Academy

INDICE................................................................................................................................................................... 2

1. BRIEFING ........................................................................................................................................................ 2

2. DATI TECNICI................................................................................................................................................... 2

2.1 MOTORE......................................................................................................................................................... 2

2.1.1 Dati caratteristici ....................................................................................................................................... 2

2.2 FRIZIONE........................................................................................................................................................ 2

2.3 CAMBIO DI VELOCITA’................................................................................................................................. 2

2.4 DIFFERENZIALE............................................................................................................................................ 2

2.5 PIANO DI MANUTENZIONE PROGRAMMATA........................................................................................... 2

3. MOTORE.......................................................................................................................................................... 2

3.1 MOTORE 3.0................................................................................................................................................... 2

3.1.1 Caratteristiche ........................................................................................................................................... 2

3.1.2 Supporti motore.......................................................................................................................................... 2

3.1.3 Basamento e sottobasamento.................................................................................................................. 2

3.1.4 Testa cilindri ............................................................................................................................................... 2

3.1.5 Alberi della distribuzione.......................................................................................................................... 2

3.1.6 Albero motore........................................................................................................................................... 2

3.1.7 Volano......................................................................................................................................................... 2

3.1.8 Pistoni e bielle .......................................................................................................................................... 2

3.1.9 Comando della distribuzione................................................................................................................... 2

3.1.10 Impianto alimentazione aria................................................................................................................... 2

3.1.11 Impianto alimentazione combustibile .................................................................................................. 2

3.1.12 Impianto di scarico.................................................................................................................................. 2

3.1.13 Impianto EGR.......................................................................................................................................... 2

3.1.14 Impianto recupero vapori olio dal basamento .................................................................................... 2

3.1.15 Impianto lubrificazione motore.............................................................................................................. 2

3.1.16 Circuito raffreddamento motore.......................................................................................................... 2

3.2 GESTIONE ELETTRONICA MOTORE ......................................................................................................... 2

3.2.1 Controllo motore EDC 16 C 39................................................................................................................. 2

3.2.2 Pin out centralina controllo motore...................................................................................................... 2

3.2.3 Schema elettrico gestione motore.......................................................................................................... 2

3.2.4 Componenti dell’impianto di iniezione/accensione.............................................................................. 2

3.3 DIAGNOSI...................................................................................................................................................... 2

3.3.1 Sezione parametri...................................................................................................................................... 2

3.3..2 Sezione Errori........................................................................................................................................... 2

3/182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 4

Fiat Auto S.p.A.

3.3.3 Diagnosi attive visualizzabili con l’examiner......................................................................................... 2

FIAT DUCATO COURSE OUTLINE

Training Academy

3.3.4 Configurazioni visualizzabili con examiner.............................................................................................2

3.4 PROCEDURE.................................................................................................................................................2

3.4.1 Motore staccato- stacco testa/e cilindri e coppa olio per ispezione comprende posa su cavalletto e

rimozione............................................................................................................................................................2

3.4.2 Motore - Ricomposizione. Lavaggio e controllo parti smontate - Riattacco testa cilindri e coppa

olio - Non comprende interventi su testa cilindri e gruppo organi ausiliari................................................2

3.4.3 Attrezzi per la revisione motore.............................................................................................................. 2

4 TRASMISSIONE .............................................................................................................................................2

4.1 - CAMBIO DI VELOCITA E DIFFERENZIALE TIPO C 546 ( M40 )............................................................2

4.1.1 Caratteristiche costruttive.......................................................................................................................2

4.2 -PROCEDURE.................................................................................................................................................2

4.2.1 CAMBIO MECCANICO (6 VELOCITA') CON DIFFERENZIALE - SCOMPOSIZIONE E

RICOMPOSIZIONE - LAVAGGIO, VERIFICA PARTICOLARI - EV. SOST. SINCRONIZZATORI, COMANDI

INTERNI, RUOTISMI, ALBERI E CUSCINETTI................................................................................................. 2

4.2.2 Attrezzi per la revisione del cambio ........................................................................................................2

5. SOSPENSIONI pneumatiche autolivellanti posteriori..................................................................................2

6. CRONOTACHIGRAFO DIGITALE .................................................................................................................2

6.1. Diagnosi con Examiner................................................................................................................................ 2

7. TELECAMERA POSTERIORE........................................................................................................................2

© 2006 Fiat Auto S.p.A. - All rights reserved

4/182

Page 5

Fiat Auto S.p.A.

1. BRIEFING

After the sales launch in June 2006, the new Fiat Ducato range is complemented by new features for

improved versatility and efficiency.

The range of engine versions is complemented by the 157 bhp 3.0 Multijet engine combined with the new

M40 gearbox.

FIAT DUCATO COURSE OUTLINE

Training Academy

The new self-levelling rear air suspension offers great comfort and consistent chassis attitude under all

loading conditions (vehicle laden or unladen, load distributed evenly or unevenly). In addition, the rear

loading sill can be lowered to facilitate loading and unloading and the rear end can be raised to improve

ramp breakover angle and/or increase ground clearance when driving over an obstacle.

The new rear-view parking camera system with in-cab display provides better rear visibility when

manoeuvring.

5/182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 6

Fiat Auto S.p.A.

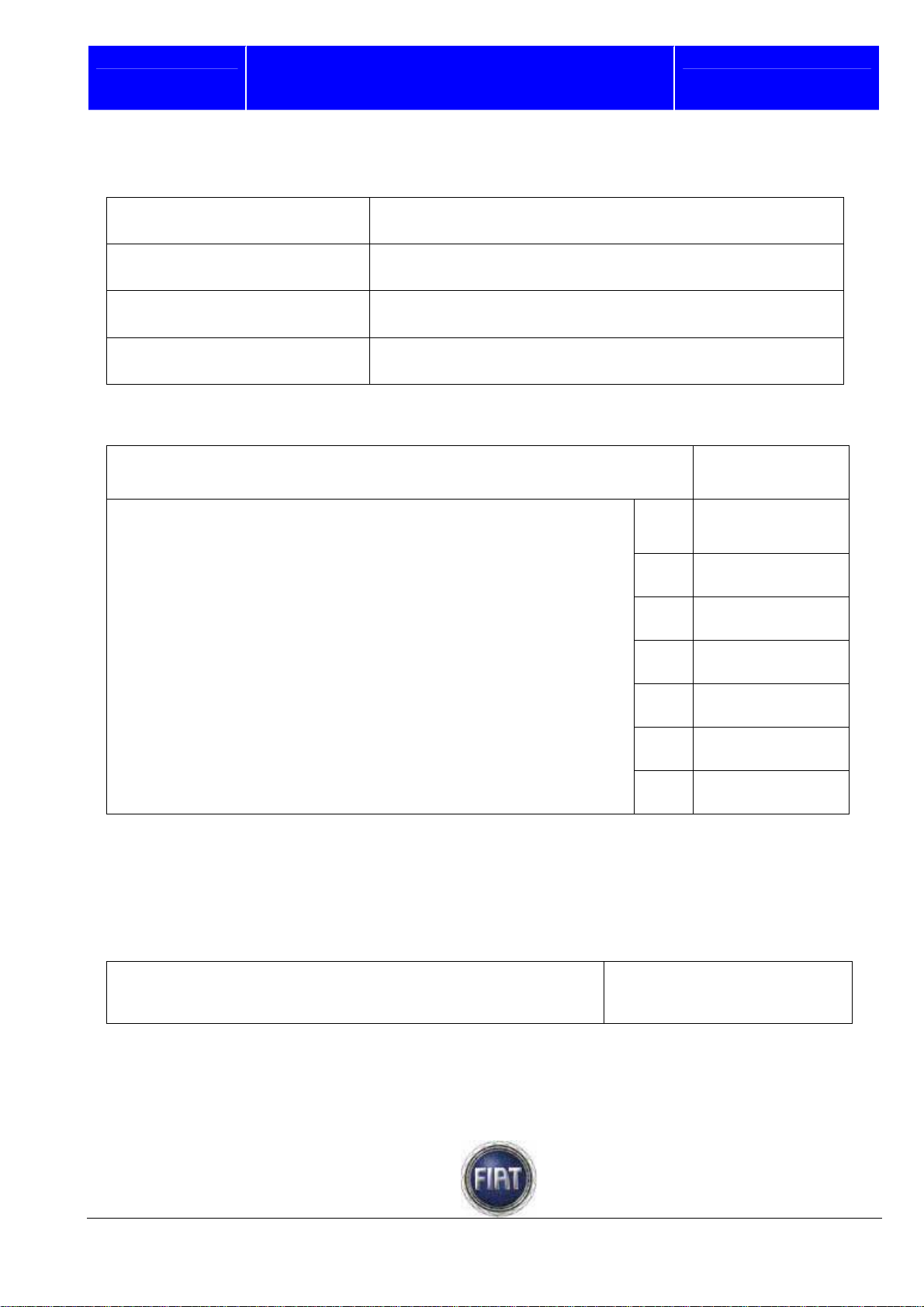

Lastly, the new Ducato can be equipped with a digital tachograph to monitor vehicle usage, a convenient

feature for companies that operate large fleets of vehicles

2. TECHNICAL DATA

2.1 ENGINE

2.1.1 Characteristic data

Type code

FIAT DUCATO COURSE OUTLINE

SofimF1CE048ID

Training Academy

Cycle

Number and arrangement of

cylinders

Piston diameter and stroke

(mm)

Total displacement

(cm3)

Compression ratio

Maximum power output

EEC(kW)

Maximum power output

EEC(bhp)

At

(rpm)

Maximum torque (EEC)

(Nm)

At

(rpm)

Diesel

4 in-line

95.8x104

2999

19:1

117

157

3500

400

1600

Fuel

Fuel system

© 2006 Fiat Auto S.p.A. - All rights reserved

Diesel fuel (ENS 590 Specification)

Multijet” Common Rail” direct injection

6/182

Page 7

Fiat Auto S.p.A.

2.2 CLUTCH

Type Dry single-plate, pressure plate with automatic play take-

Drive

FIAT DUCATO COURSE OUTLINE

up device

Push-type

Training Academy

Outer diameter of driven

plate (mm)

Inner diameter of driven

plate (mm)

2.3 GEARBOX

Type

Gear ratios

(*) Different versions

2.4 DIFFERENTIAL

Axle ratio

258±1

160±5

C546 (M40)

I

II

III

IV

V

VI

RM

3.950 - 4.222 - 4.563 (*)

4.167

2.350

1.462

1.047

0.955(*)

0.786

0.659(*)

0.652

0.552(*)

4.083

(*) Different versions

7/182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 8

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

2.5 SCHEDULED MAINTENANCE PLAN

Description

Training Academy

Check tyre condition / check for wear,

adjust tyre pressure (if needed).

Check operation of lighting system

(headlamps, indicators, emergency lights,

luggage compartment/passenger & driver

compartment lights; instrument panel

warning lights, etc.).

Check operation of windscreen wiper &

washer; adjust nozzles if necessary.

Check positioning/wear of windscreen

wipers

Check brake pads for wear; check front

and rear disk pad wear indicator for proper

operation (if fitted)

Visually inspect the conditions and

soundness of body outside, underbody

protection, rigid and flexible pipe lengths

(exhaust, fuel feed and brake pipes and

hoses), rubber parts (boots, sleeves,

bushes, etc.)

Visually inspect the accessory drive belts

45 90 135 180 225

+ + + + +

+ + + + +

+ + + + +

+ + + + +

+ + + + +

+ + + + +

+ +

Check the fluid levels (engine cooling,

brakes, windscreen washer, battery, etc.)

and top up, if necessary

Check the handbrake lever travel and

adjust as required

Check that the locks are clean and the

levers clean/lubricated

Measure exhaust emissions/smoke

Check operation of engine control systems

(via the diagnostic connector)

Replace the accessory drive belt

Change fuel filter

Change air filter cartridge

© 2006 Fiat Auto S.p.A. - All rights reserved

+ + + + +

+ + + + +

+ + + + +

+ + + + +

+ + + + +

+

+ + + + +

+ + + + +

8/182

Page 9

Fiat Auto S.p.A.

Change engine oil and engine oil filter

FIAT DUCATO COURSE OUTLINE

+ + + + +

Training Academy

Change brake fluid (or every 24 months)

Change pollen filter (or every 24 months)

Service must be performed every 30000 km if the vehicle is chiefly used in any of the following particularly

harsh conditions:

Towing trailer or caravan;

Dusty roads;

Frequent short trips (less than 7-8 km) with outside temperatures below freezing;

Engine frequently left idling or running long distances at low speed (door-to-door delivery for example),

or if not used for a long time;

City traffic.

+ +

+ + + + +

9/182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 10

Fiat Auto S.p.A.

3. ENGINE

3.1 3.0 ENGINE

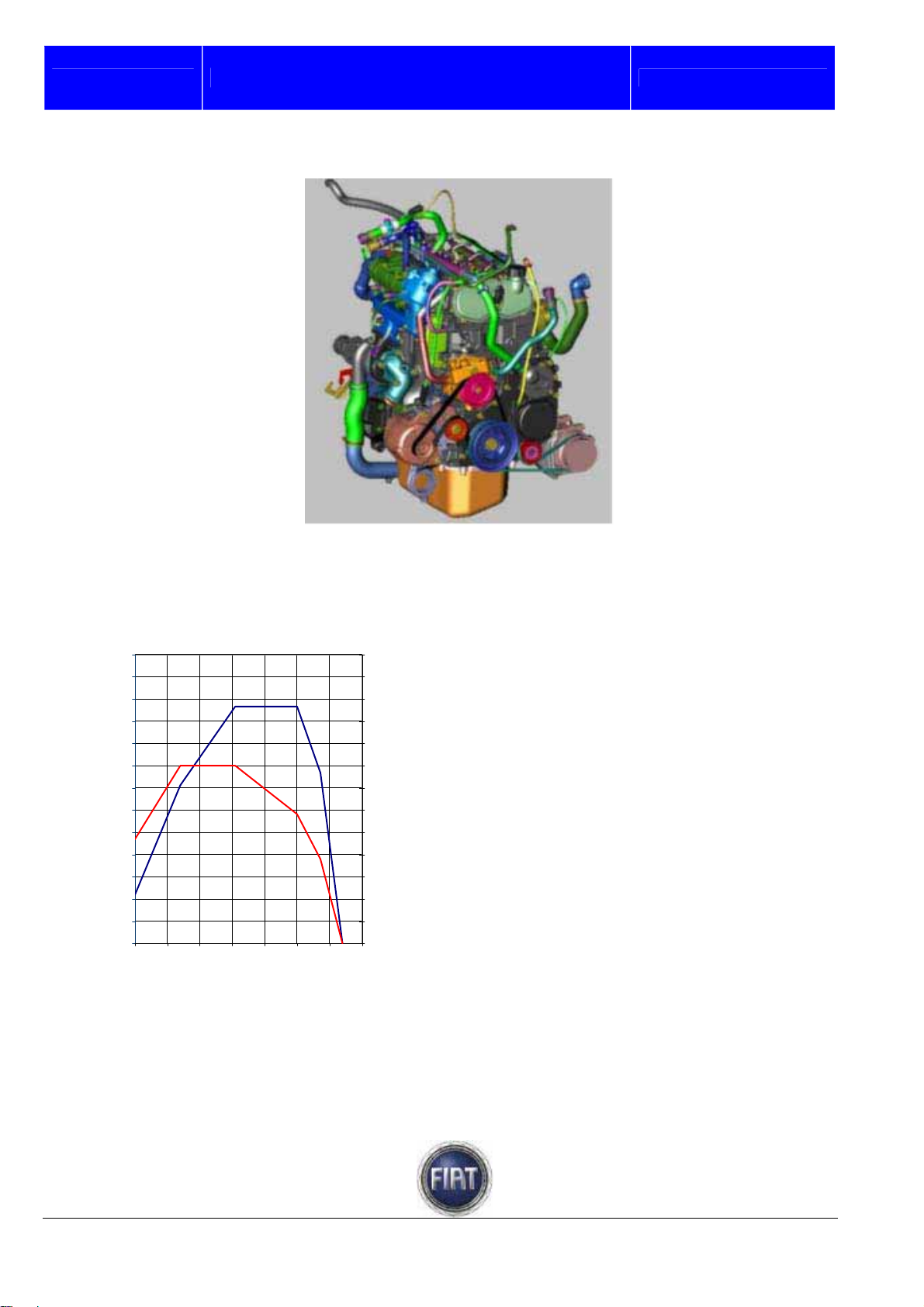

3.1.1 Features

The main features of the 3.0 Multijet engine

are as follows:

130

120

110

100

90

80

70

60

Power [kW]

50

40

30

20

10

0

1000 1500 2000 2500 3000 3500 4000 4500

FIAT DUCATO COURSE OUTLINE

F1C 107 kW [145 HP] - 400 Nm

WG

[rpm]

650

600

550

500

450

400

350

300

250

200

150

100

50

0

Training Academy

- turbocharged Diesel engine with fixed

geometry turbocharger;

- Euro 4 emissions compliant

- power output: 160 bhp;

- four cylinders in line;

- 2998 cc displacement;

- bore: 95.8 mm;

- stroke: 104 mm;

- compression ratio: 19:1

- firing order: 1 – 3 – 4 - 2

- double overhead camshaft, 16 valves;

- aluminium alloy cylinder head;

- camshaft bearing housings incorporated in

Torque [Nm]

upper head section;

- chain-driven timing system;

- rocker arms with hydraulic tappets;

- centrifugal water pump incorporated in

crankcase;

- engine control unit: Bosch EDC16C39;

- high-pressure pump: Bosch CP3.2 (no

transfer gear pump);

- nodular cast iron engine block;

- pressed sheet metal oil sump.

© 2006 Fiat Auto S.p.A. - All rights reserved

10/182

Page 11

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

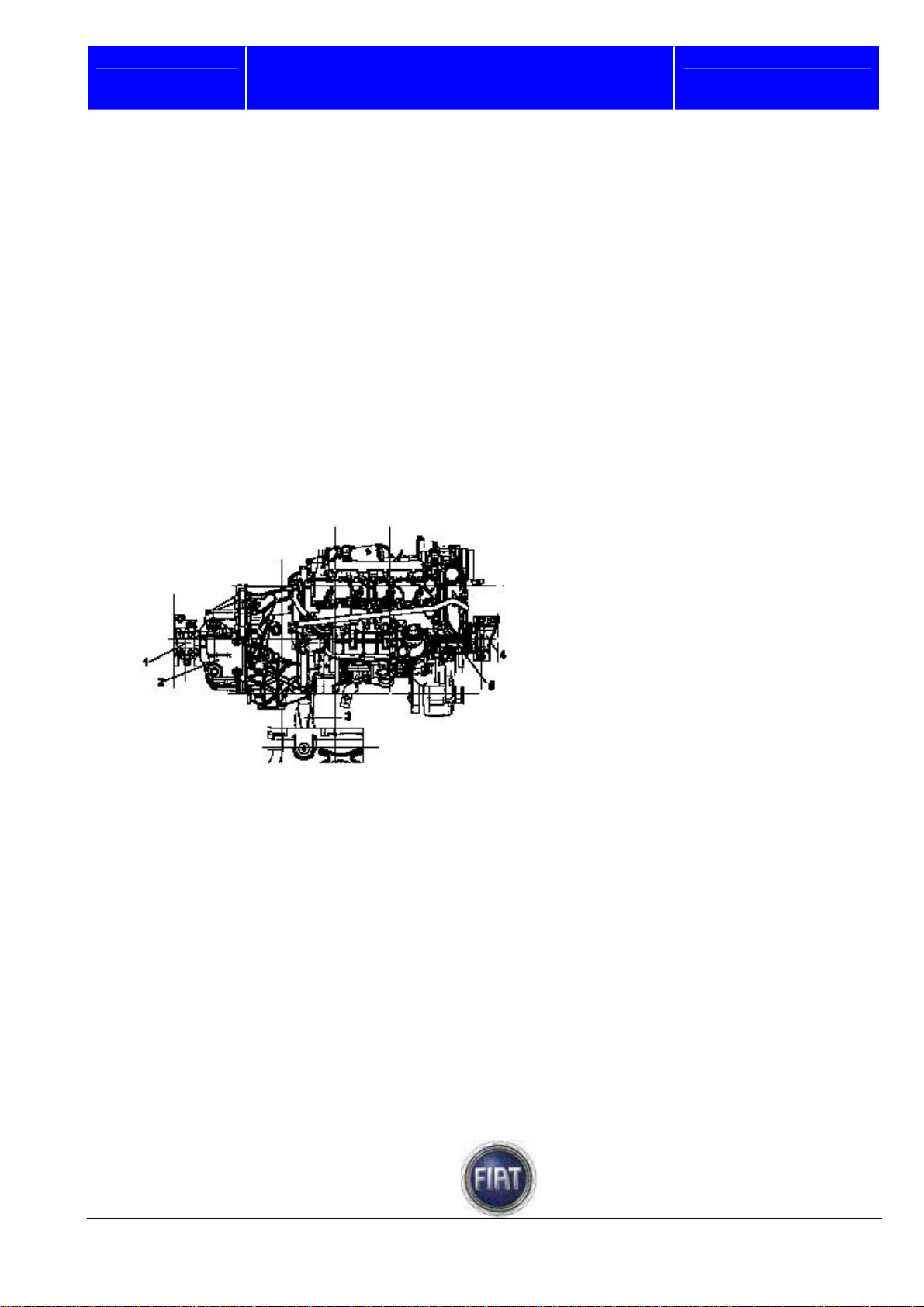

3.1.2 Engine mounts

GENERAL

The engine mounts connect engine and body.

They are designed to withstand engine weight and torque loads.

Engine mounts feature blocks made of metal and rubber that dampen engine vibration so as to

significantly reduce the amount of vibration transmitted to the body.

TYPE

The engine support system is a special baricentre system.

The engine is retained by two mounts (one on gearbox side and one on timing gear side) and a torque

linkage

.

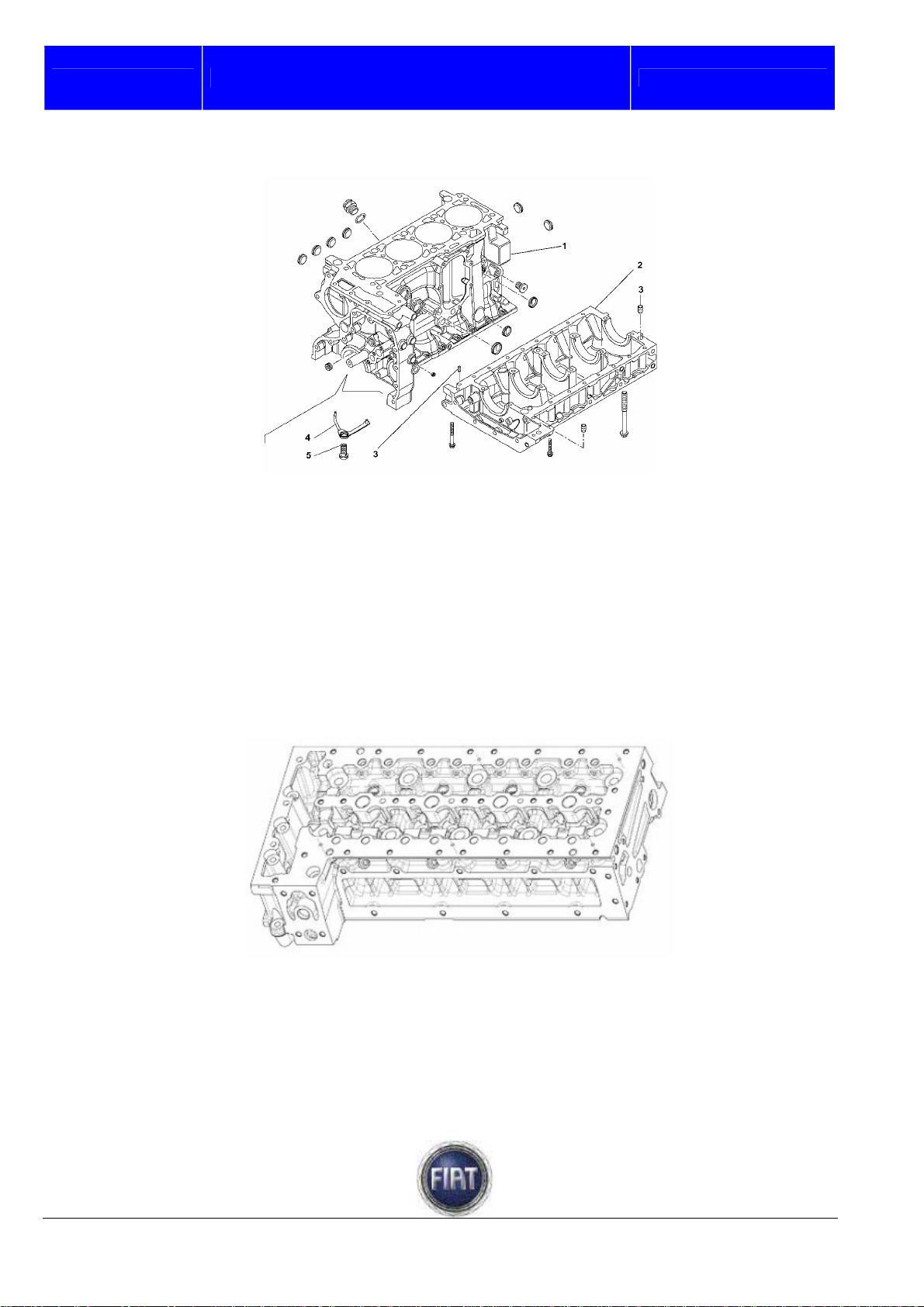

3.1.3 Crankcase and lower block

The crankcase is made of cast iron.

There are five main bearing housings.

Suitable coolant and oil galleries are provided in the crankcase walls.

Spray jets installed in crankcase bottom use engine oil to cool the pistons and lubricate the piston pins.

Crankcase and lower block are sealed with sealant.

Training Academy

1 – Flexible mount, gearbox side

2 – Mounting bracket, gearbox side

3 – Rear mounting bracket

4 – Flexible mount, timing gear side

5 – Mounting bracket, timing gear side

11/182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 12

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

1 - Crankcase

2 – Lower block

3 – Centring pin

4 – Piston cooling jet

5 – Jet connector

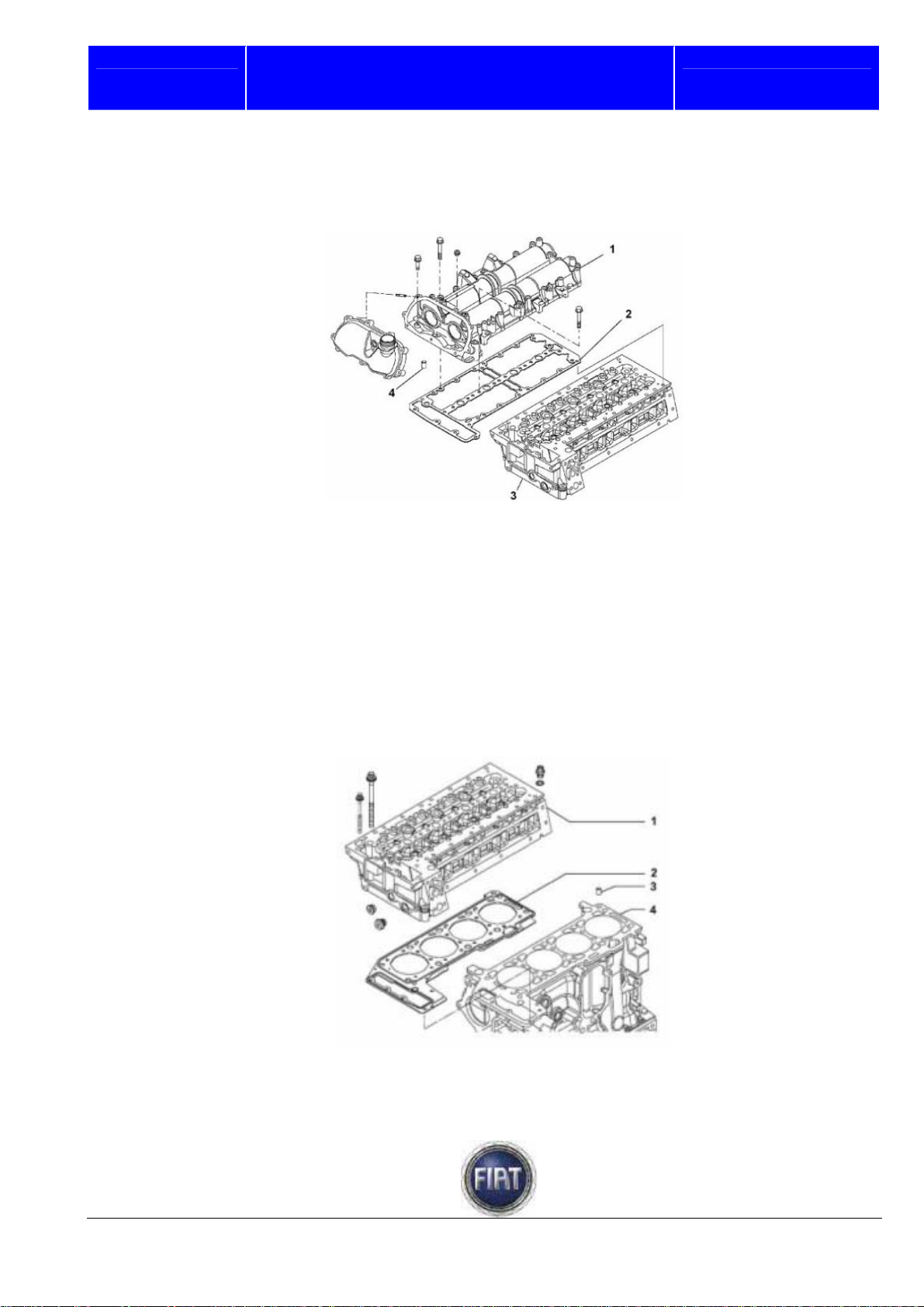

3.1.4 Cylinder head

The one-piece cylinder head is made from aluminium-silicon alloy.

Training Academy

Valve opening is controlled by two chain-driven hollow-section overhead camshafts; cams are fitted onto

the shafts; camshafts are installed in the upper head section.

The four valves per cylinder are located in their respective guides and operated by rocker arms actuated

by the cams of the camshafts; hydraulic tappets keep the rocker arms in contact with the valves.

© 2006 Fiat Auto S.p.A. - All rights reserved

12/182

Page 13

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

Training Academy

The valve guides are an interference fit in the seats in the cylinder head. The inner bore is bored to

specification after installation using a special boring tool.

Unlike cylinder heads with a prechamber, the whole combustion process occurs inside the combustion

chamber in the piston.

The cylinder head is made up of the following components:

- camshaft housing,

- hydraulic tappets, 1 – Upper head section

- rocker arms, 2 – Gasket

- camshafts, 3 – Cylinder head

- exhaust and intake valves, 4 – Centring bushes

- valve guides,

- valve seats.

1 – Cylinder head

2 – Gasket

3 – Centring bush

4 – Engine block

13/182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 14

Fiat auto S.p.A.

The head accommodates: intake ports; exhaust ports; valve passages; coolant galleries; oil galleries;

injector holes, glow plug holes, bolt holes for fastening to the engine block.

The head is installed on top of the cylinders; the aluminium alloy construction combines such advantages

as ligthweight, compression strength and high heat conduction.

Two centring bushes ensure correct location of the upper head section.

Head gasket

The gasket between cylinder head and crankcase is composed of three layers of stainless steel coated

with special heat-resistant rubber material.

While head gaskets of three different thicknesses are used at the factory, replacement gaskets come in

one standard thickness only. Factory gaskets are differentiated by notches as follows

- 1 notch : thickness class 1

- 2 notches: thickness class 2

- 3 notches: thickness class 3

FIAT DUCATO COURSE OUTLINE

Training Academy

1 – Head gasket

2 – Thickness class notches

3.1.5 Camshafts

The timing sensor detects the position of the intake camshaft drive gear to determine the current phase

of engine operation.

The timing sensor is located on the engine oil filler cover on the upper head section.

The camshafts are made from steel and feature a

hollow design

1 – Exhaust camshaft

2 – Intake camshaft

© 2006 Fiat Auto S.p.A. - All rights reserved

14 / 182

Page 15

Fiat Auto S.p.A.

Hydraulic tappets

1

. Tappet retaining spring

2. Hydraulic tappet

3. Rocker arm with spring

4. Cam

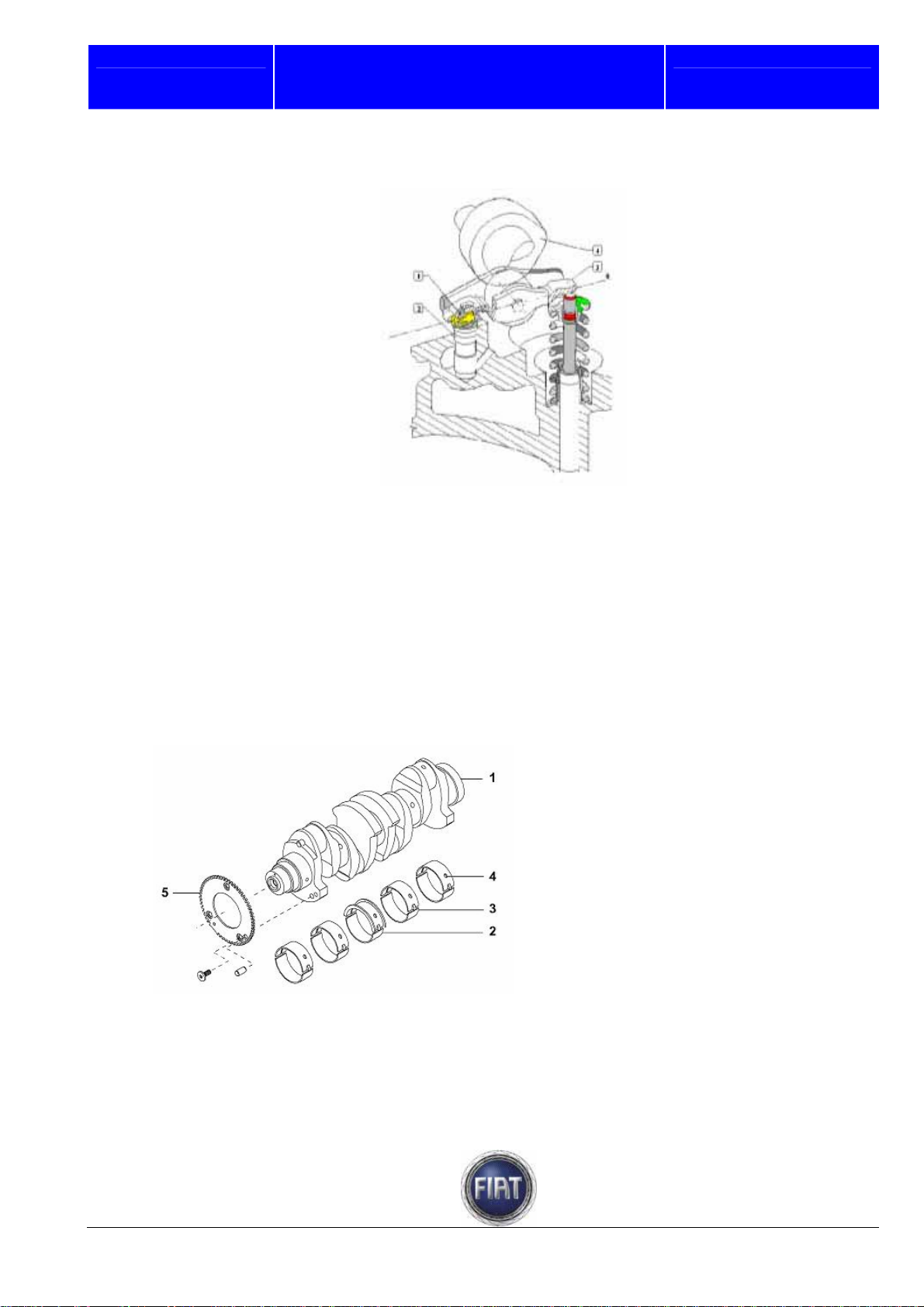

3.1.6 Crankshaft

The crankshaft is made of carbon steel and rests on five main bearing housings with plain bearings

in-between.

Crankshaft end float is determined by the half bearing housed at the central main bearing housing.

Eight counterweights set at 180° balance the rotating masses to provide perfect engine balance.

FIAT DUCATO COURSE OUTLINE

1 – Crankshaft

2 – Central main bearing (incorporates end

float adjustment)

3 – Main bearings

4 – Oilway hole

5. Phonic wheel

Training Academy

15 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 16

Fiat auto S.p.A.

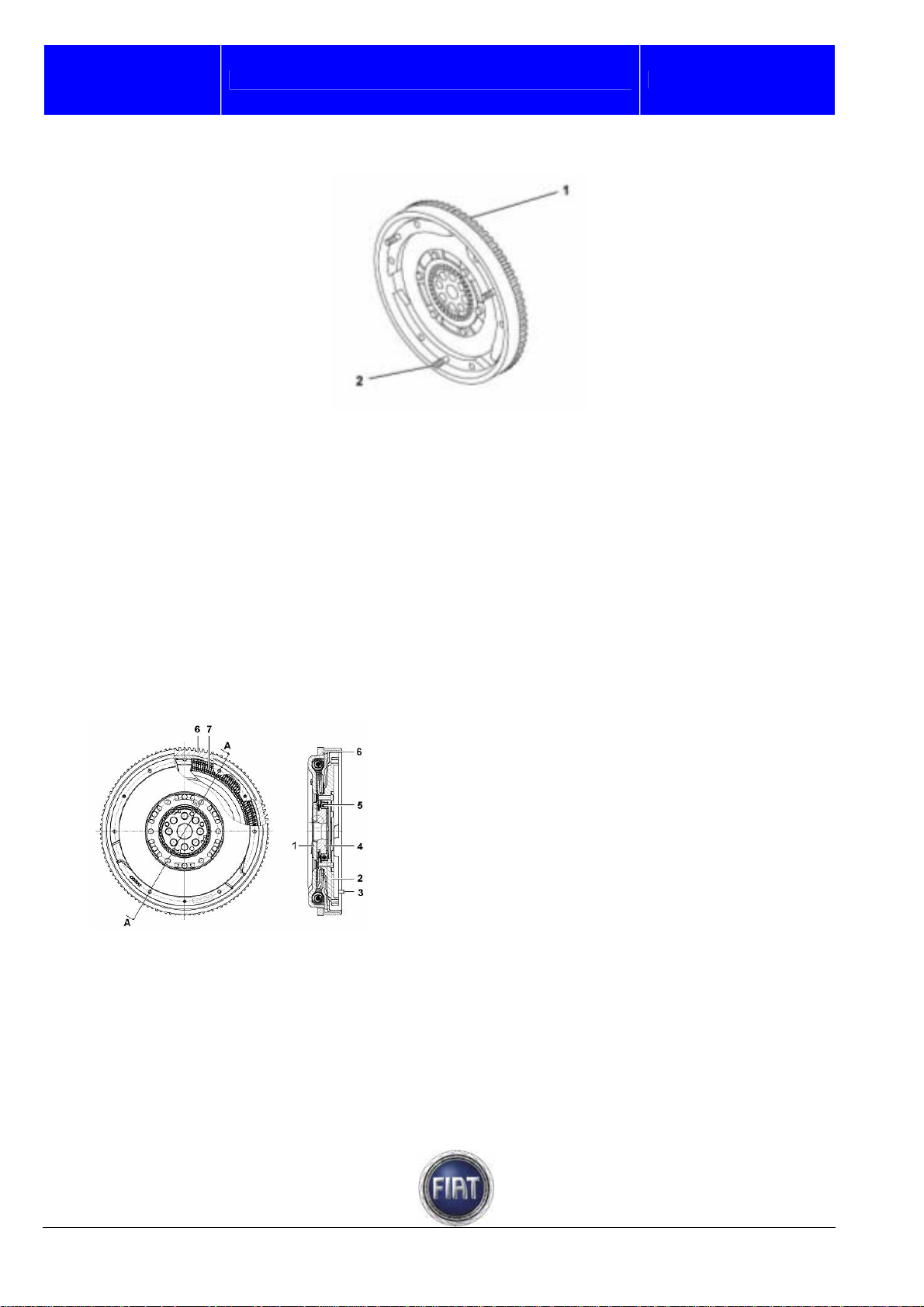

3.1.7 Flywheel

FIAT DUCATO COURSE OUTLINE

Training Academy

The dual-mass flywheel is secured to the crankshaft by 8 screws.

The flywheel has 3 centring pins for the clutch mechanism

The flywheel is an energy storage device that stores energy during the power stroke and gives up energy

during the combustion stroke to smooth out engine rotation.

Flywheel size is designed to enable engine idling and overcome friction developed during idling.The DVA

dual-mass flywheel (or clutch flywheel) consists of two separate masses for crankshaft and gearbox main

shaft with a torsional damping system in-between.

Resonance points, normally found in the 800 to 2200 rpm range with conventional flywheels, occur at lower

rpms, namely outside the operating range.

This flywheel design offers the following advantages over conventional flywheels:

- pulsing engine power is dampened resulting in less transmission noise;

- less overall noise translates into less in-cab noise.

The clutch disk (with springs) located between the dual-mass flywheel and the gearbox has lower inertia

to enable smoother gearshifts.

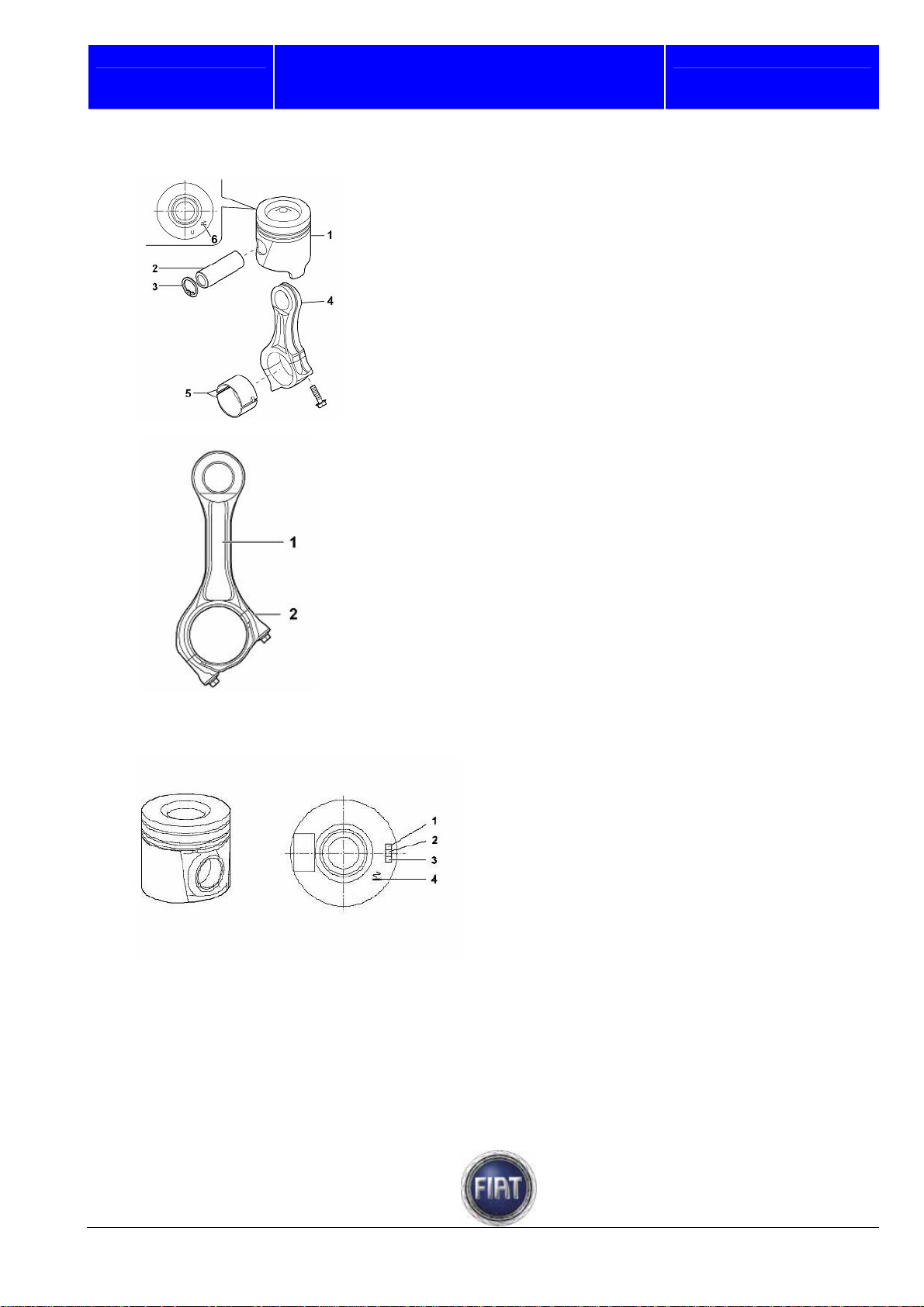

3.1.8 Pistons and connecting rods

CONSTRUCTION

The pistons are obtained from aluminium alloy castings; the connecting rods are forged from hardened

and tempered steel and split to obtain the con rod caps by the fracture splitting method.

The pistons have a recess for the combustion chamber.

The pistons and con rod small ends are joined by floating piston pins. Piston pins are restrained by two

circlips fitted in grooves in the piston pin sleeves.

1 – Mass integral with crankshaft.

2 – Mass integral with gearbox main shaft.

3 – Centring pin for clutch mechanism

4 – Hub

5 – Ball bearing

6 – Gearwheel

7 – Torsional damping system.

© 2006 Fiat Auto S.p.A. - All rights reserved

16 / 182

Page 17

Fiat Auto S.p.A.

To ensure correct piston position, the mark on the piston must be pointing to the timing gear side

FIAT DUCATO COURSE OUTLINE

1 – Piston

2 – Piston pin

3 – Circlips

4 – Connecting rod

5 – Con rod bearings

6 – Piston mark for correct installation

1 – Connecting rod

2 – Con rod cap

The aluminium alloy pistons are grouped

into two size classes and have a mark on

the crown to indicate correct mounting

position

Training Academy

1 – Engine type

2 – Piston class

3 – Supplier

4 – Mounting position of piston inside the

cylinder barrel

The piston is made up of two main components:- head, or area where the piston rings sit; its diameter is

slightly smaller than the cylinder bore to accommodate heat expansion; the piston crown features the

valve pockets and recessed combustion chambers,

17 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

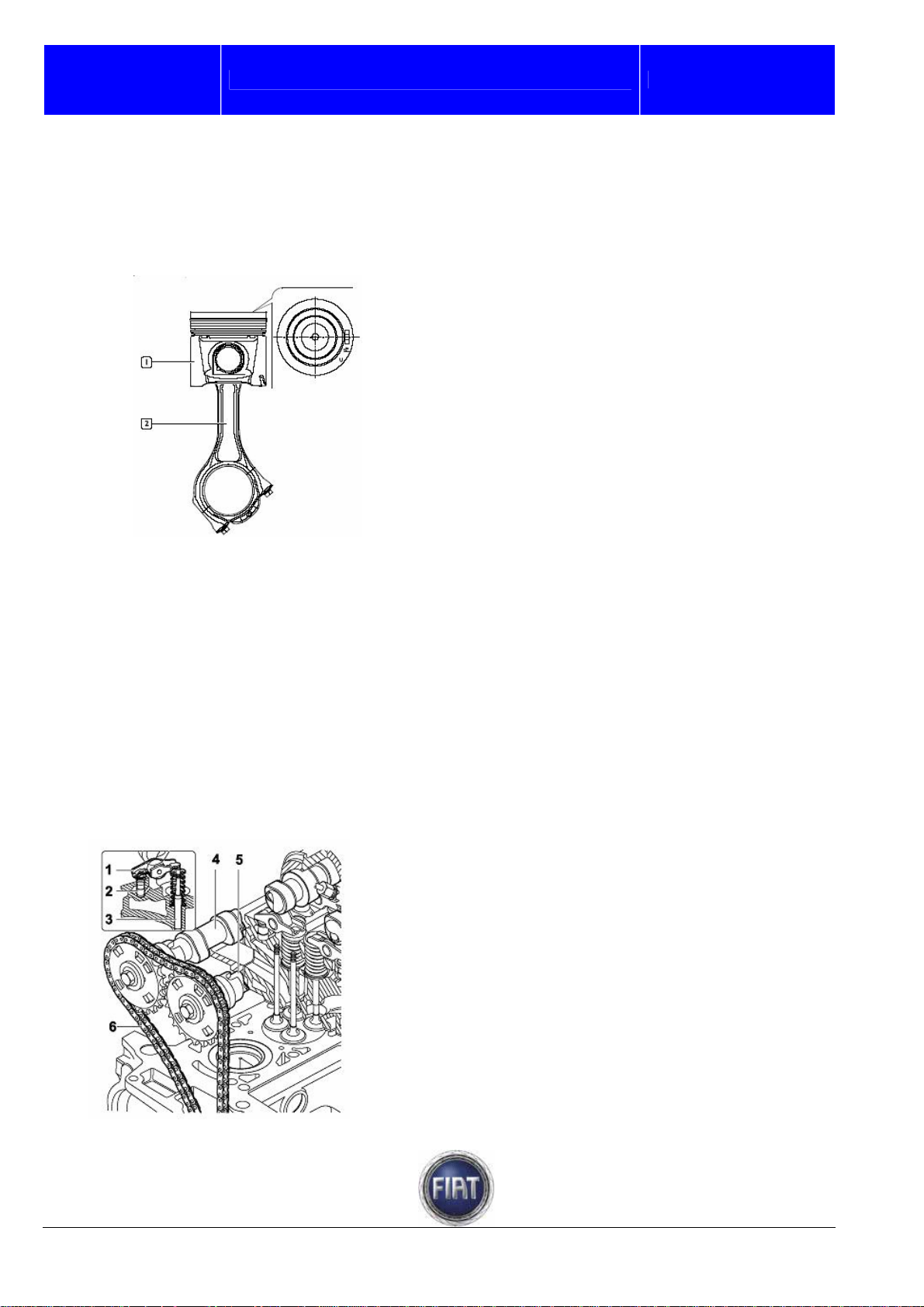

Page 18

Fiat auto S.p.A.

- the skirt, which acts as a guide for the con rod small end which withstands its axial thrust. The skirt

accommodates two sleeves for the piston pin and a groove matching the piston cooling jet in the

crankcase.

FIAT DUCATO COURSE OUTLINE

Piston (1) and connecting rod (2) with con

rod cap must be assembled with piston

mark, connecting rod and con rod

positioned as shown in the figure.

Training Academy

3.1.9 Camshaft drive

The timing system is a double overhead camshaft system with four valves per cylinder and hydraulic

tappets.

Drive is transmitted by two drive chains:

- a double 3/8” chain transmits drive from the crankshaft to the oil pump/vacuum pump and high pressure

pump shafts;

- a single chain transmits drive from the high pressure pump shaft to the camshafts.

The camshaft drive gears are interchangeable and feature slots for the sensor.

Each rocker arm is kept in contact with its valve by a cam and hydraulic tappet to eliminate the need for

periodic adjustments

.

1 – Rocker arm

2 – Hydraulic tappet

3 – Valve

4 – Exhaust camshaft

5 – Intake camshaft

6 – Cam chain

© 2006 Fiat Auto S.p.A. - All rights reserved

18 / 182

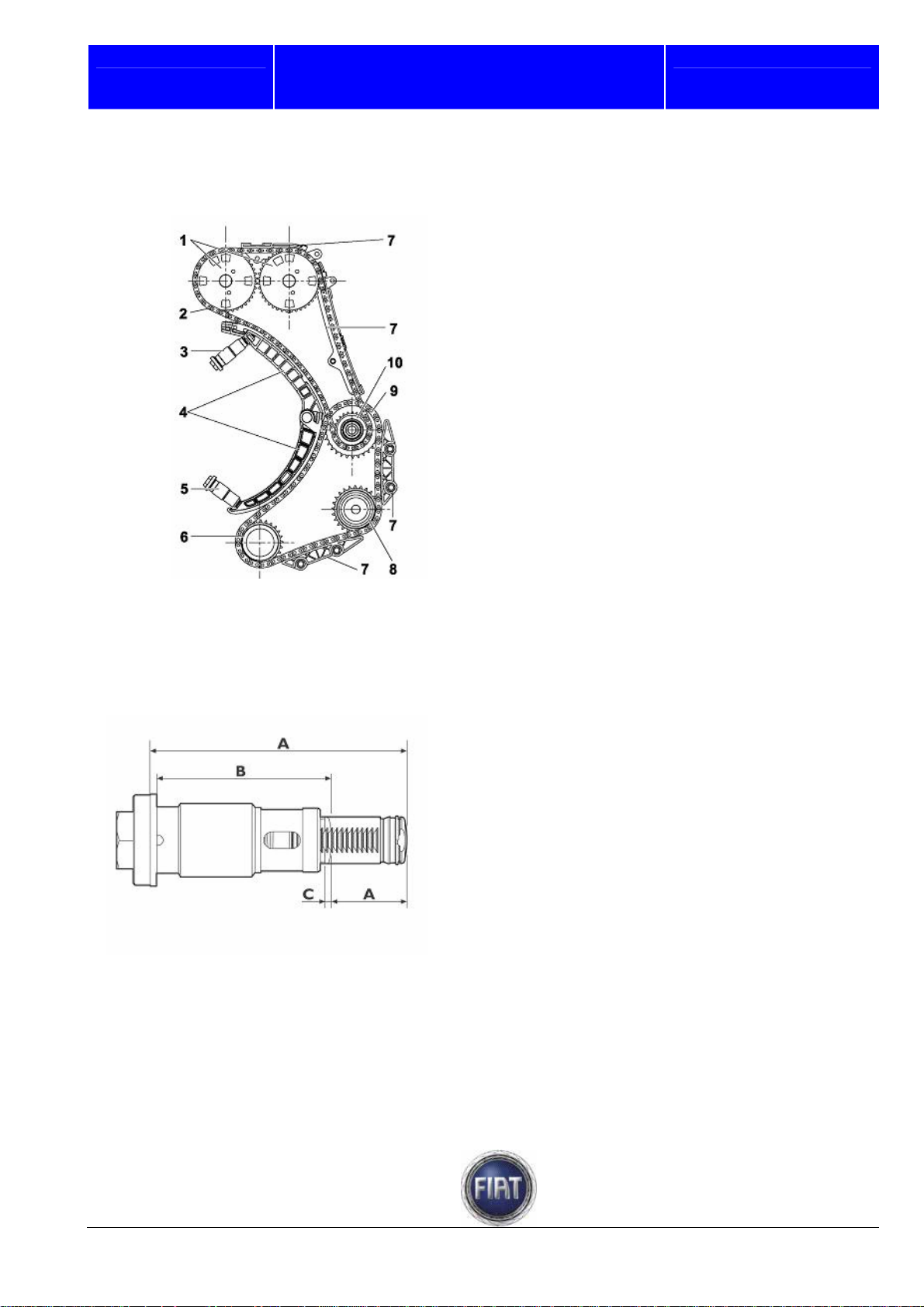

Page 19

Fiat Auto S.p.A.

The figure below shows how timing system and auxiliary drive system are operated

FIAT DUCATO COURSE OUTLINE

1 – Camshaft drive gears

2 – Single chain

3 – Hydraulic tensioner with backstop

4 – Chain tensioner mobile sliding shoes

5 – Hydraulic chain tensioner

6 – Drive gear on crankshaft

7 – Fixed sliding shoe

8 – Oil pump/vacuum pump and power

steering pump drive shaft gear

9 – Double chain

10 – High pressure pump drive shaft gear

Training Academy

Chain hydraulic tensioner

Timing chain tension is controlled by an automatic hydraulic tensioner with backstop that eliminates the

need for tension adjustments.

A = Fully extended: 76.9 ± 0.4 mm

B = With piston engaged: 53.6 mm

C = Minimum travel to disengage piston:

2.3 mm

D = Useful stroke: 24.5 mm

19 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

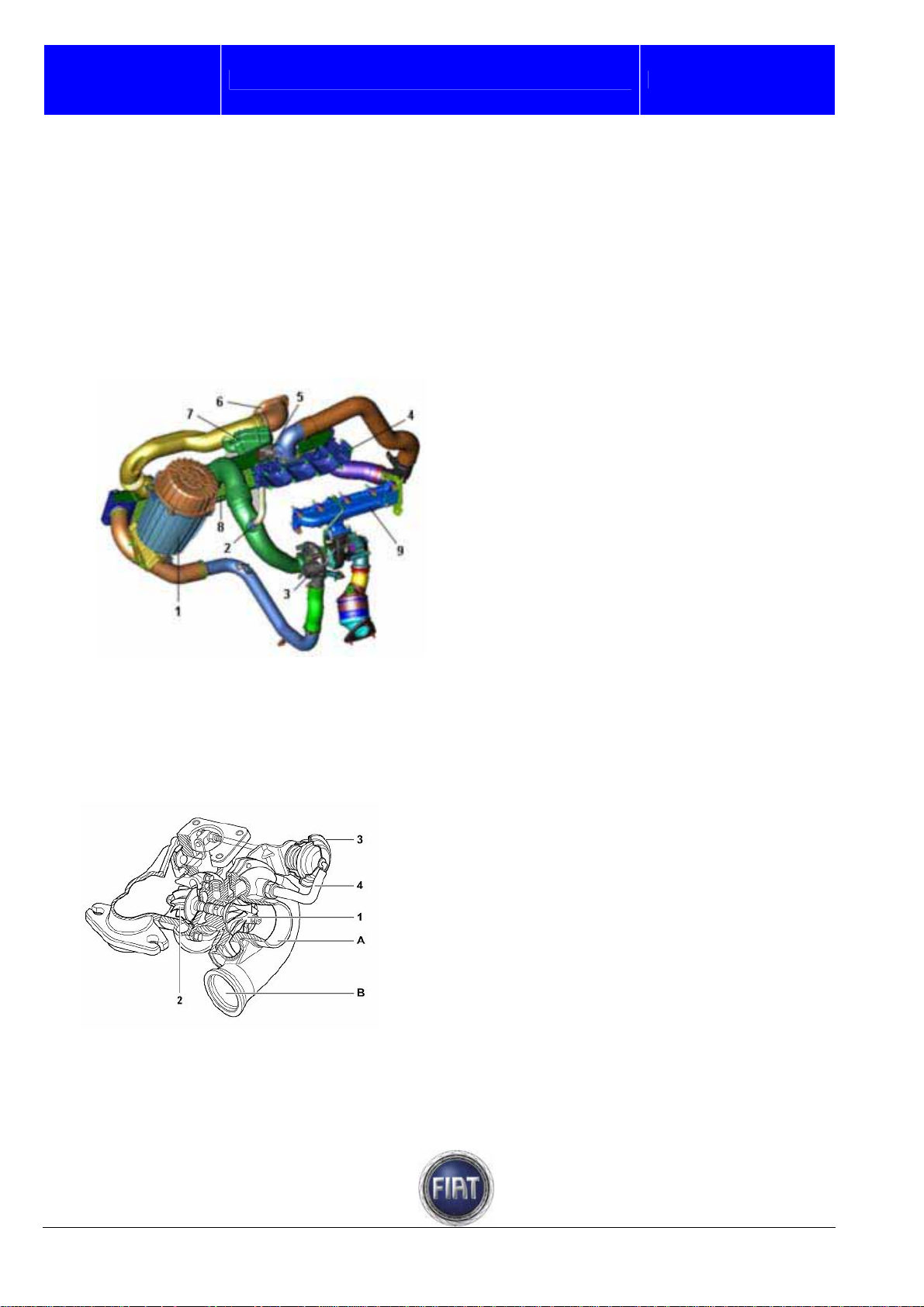

Page 20

Fiat auto S.p.A.

3.1.10 Air supply system

The intake air is filtered and conveyed to the exhaust gas turbocharger; before reaching the engine, the

compressed air is cooled in the air-air heat exchanger (Intercooler).

The following figure schematically illustrates the main elements comprising the air supply circuit.

FIAT DUCATO COURSE OUTLINE

1 – Air filter

2 – Oil vapour recovery fitting

3 – Turbocharger

4 – Intake manifold

5 – Throttle body actuator

6 – Air intake connector

7 – Resonator

8 – Intercooler heat exchanger

9 – Exhaust manifold

Training Academy

Turbocharger

The turbocharger is of the fixed geometry type with waste-gate valve

1 – Compressor

2 – Turbine

3 – Air-operated exhaust gas bypass actuator

4 – Pressure pipe to control WASTE – GATE

valve

A – Air enters compressor

B – Air exits compressor

© 2006 Fiat Auto S.p.A. - All rights reserved

20 / 182

Page 21

Fiat Auto S.p.A.

3.1.11 Fuel system

GENERAL

The fuel feed system is divided into a low pressure circuit and a high pressure circuit.

The low pressure circuit is composed of:

- tank

- submerged auxiliary motor pump;

- Diesel fuel filter;

- return manifold.

The high pressure circuit is composed of:

- pressure pump;

- distribution manifold.

Low pressure circuit

Fuel tank

The plastic fuel tank features a flexible filler neck and incorporates a seat for electric fuel pump and fuel

level meter.

FIAT DUCATO COURSE OUTLINE

Training Academy

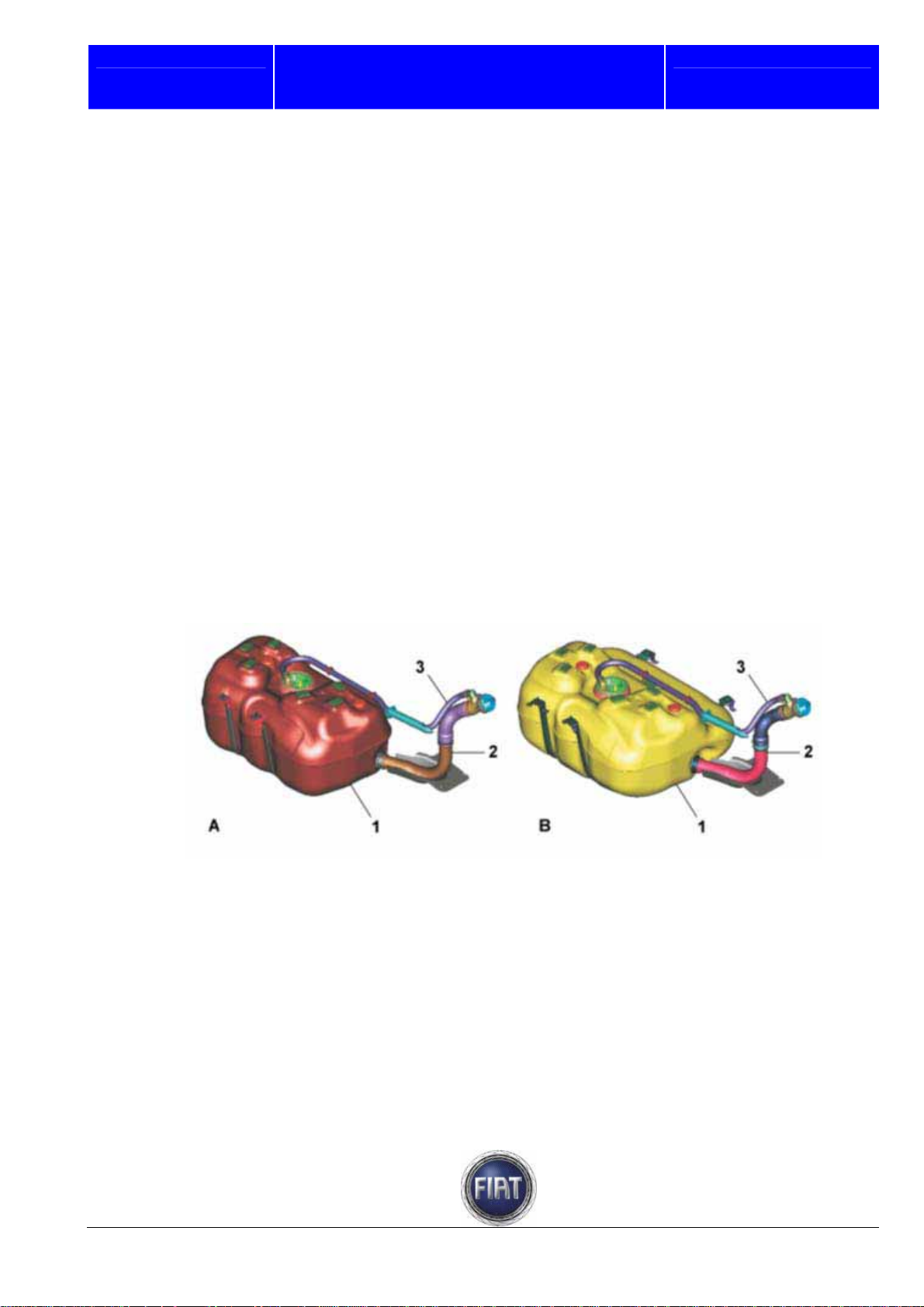

A – 90-litre tank

B – 125-litre tank

1 – Fuel tank

2 – Fuel filler neck

3 – Breather pipe

21 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 22

Fiat auto S.p.A.

FIAT DUCATO COURSE OUTLINE

Submerged pump assembly complete with level indicator control system

- electric fuel pump

- float level indicator

- diaphragm pressure regulator

- screen prefilter

Main components:

- fuel filter

Pump characteristic data:

- safety valve setting: 600 - 800 KPa,

- pump nominal delivery: 134 l/h (23°C),

- power supply: 12.5V.

Training Academy

A – Float level sensor

B – Delivery fitting

B – Return fitting

D – Electric connector

1 – Fuel level sensor power supply

2 – Fuel level sensor ground

3 – Fuel pump ground

4 – Fuel pump power supply

© 2006 Fiat Auto S.p.A. - All rights reserved

22 / 182

Page 23

Fiat Auto S.p.A.

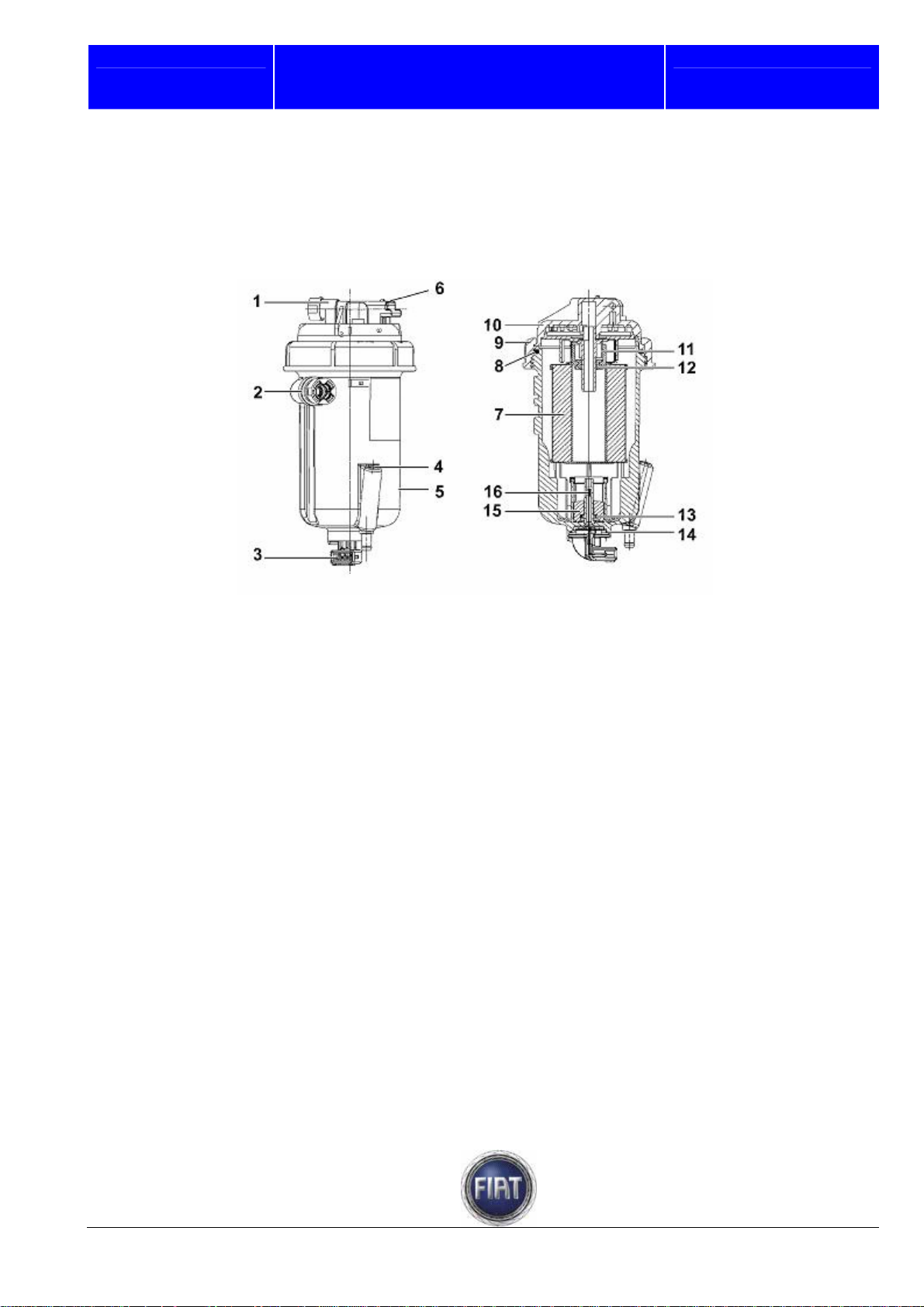

Fuel filter

The fuel filter is fitted in the engine compartment near the fireproof bulkhead.

The filter is made of a plastic shell that contains a depth partition cartridge made of synthetic material,

which ensures high efficiency, long service life and effective water separation.

1 – Fuel inlet

2 – Fuel outlet

3 – Eectric connector for water presence

sensor

4 – Water drain screw

5 – Filter body

6 – Fuel temperature sensor connector

7 – Filter cartridge (sealing O-ring supplied)

8 – Cover gasket

FIAT DUCATO COURSE OUTLINE

9 – Cover fixing ring nut

10 – Cover

11 – Spacer

12 – Rubber seal

13 – Ferromagnetic ring

14 – Gasket

15 – Float

16 – Water sensor

Training Academy

23 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 24

Fiat auto S.p.A.

FIAT DUCATO COURSE OUTLINE

Training Academy

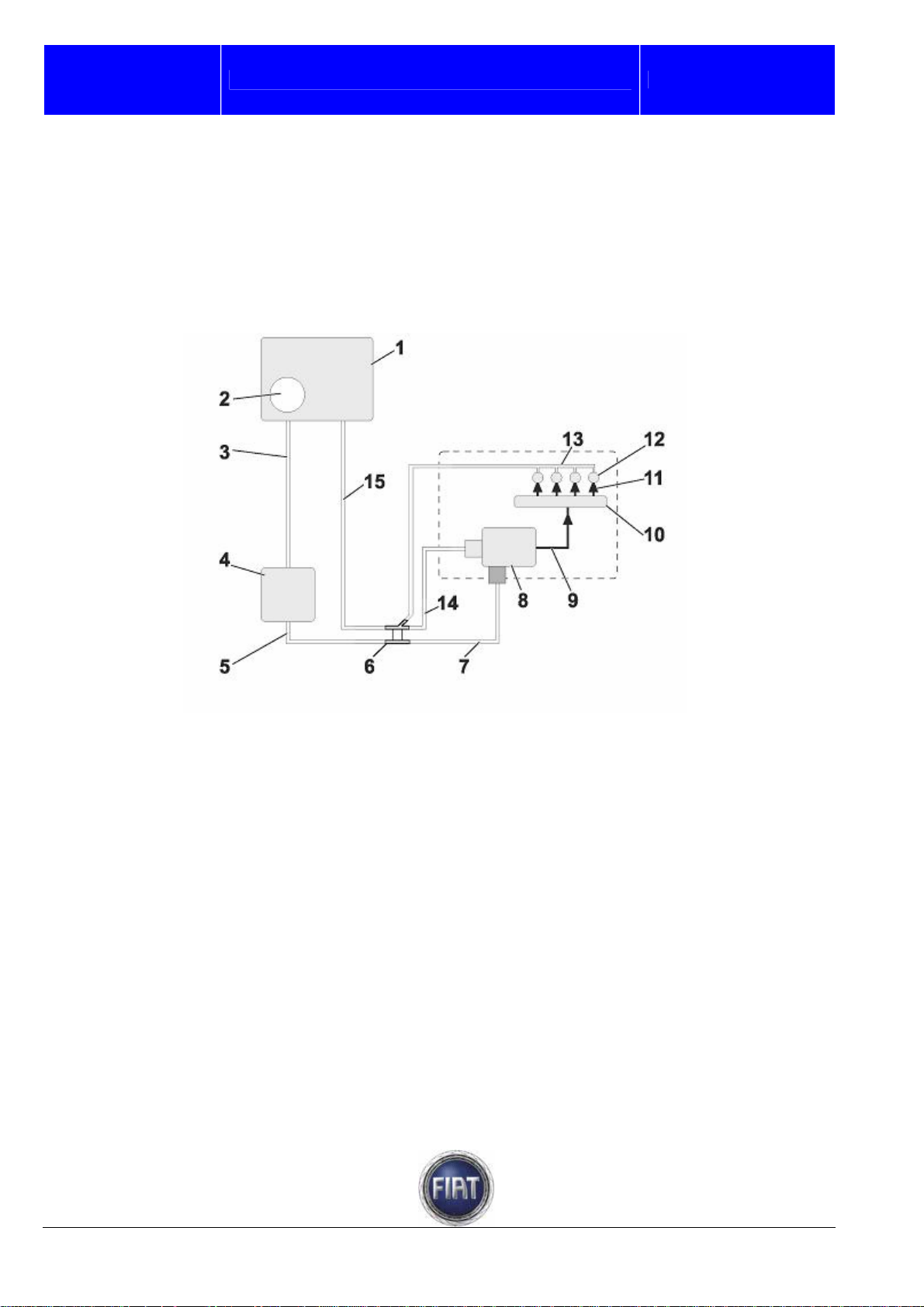

OPERATION

Diesel fuel is drawn from the tank by a 12 V electric pre-feed pump that provides adequate delivery to

lubricate and cool the Radialjet pump as well.

The Diesel fuel filter is installed between the electric pump and the Radialjet pump.

High-pressure hydraulic lines are steel pipes with 2 mm inner diameter and 6 mm outer diameter.

The fuel recirculated from pump and injectors is collected in a single pipe and delivered to the tank.

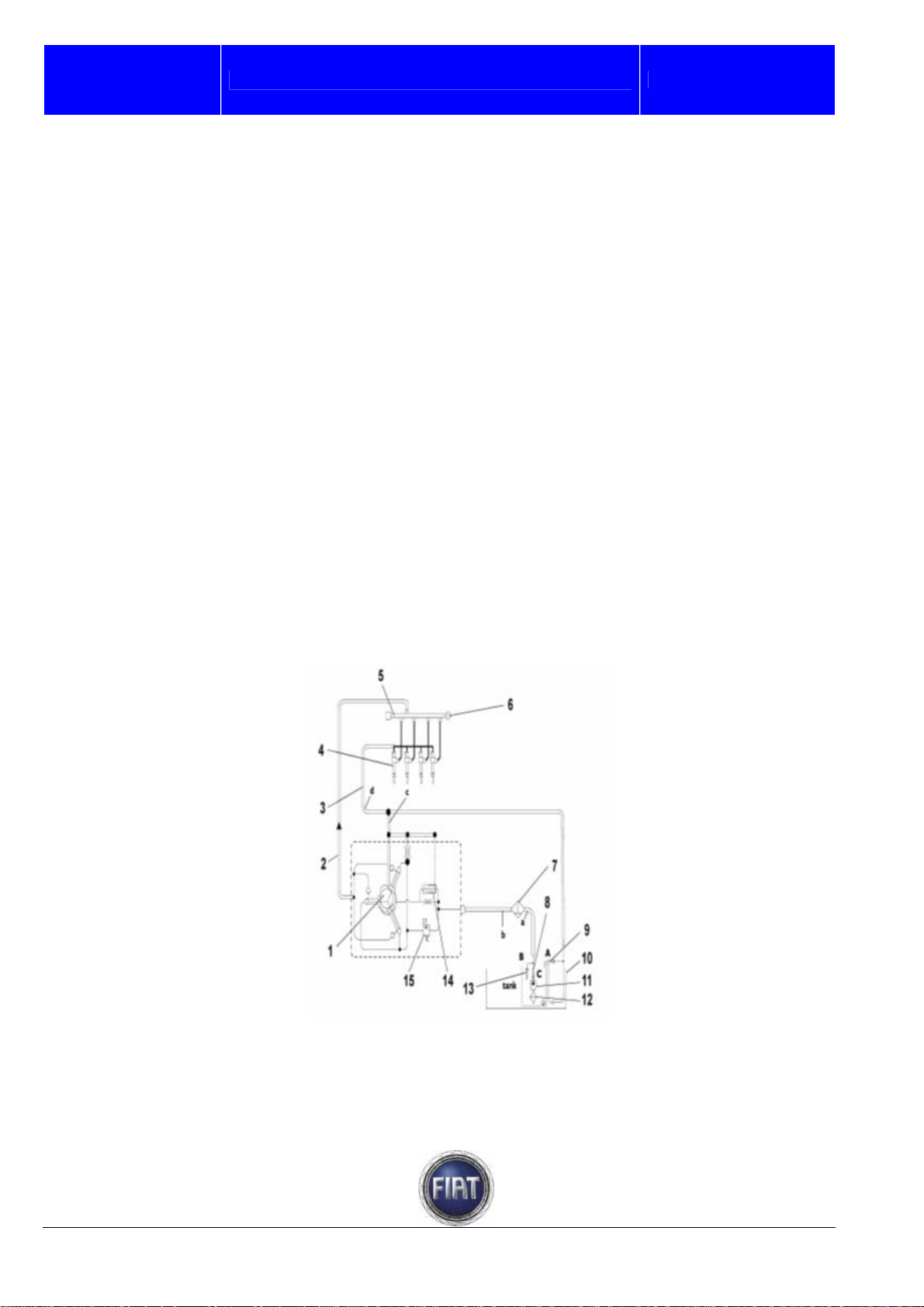

1 – Fuel tank

2 – Submerged pump assembly

3 – Pipe connecting tank with fuel filter

4 – Fuel filter

5 – Pipe connecting fuel filter with fuel pressure control valve

6 – Fuel pipe fitting

7 – Pipe connecting fuel pressure control valve with high pressure pump

© 2006 Fiat Auto S.p.A. - All rights reserved

24 / 182

Page 25

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

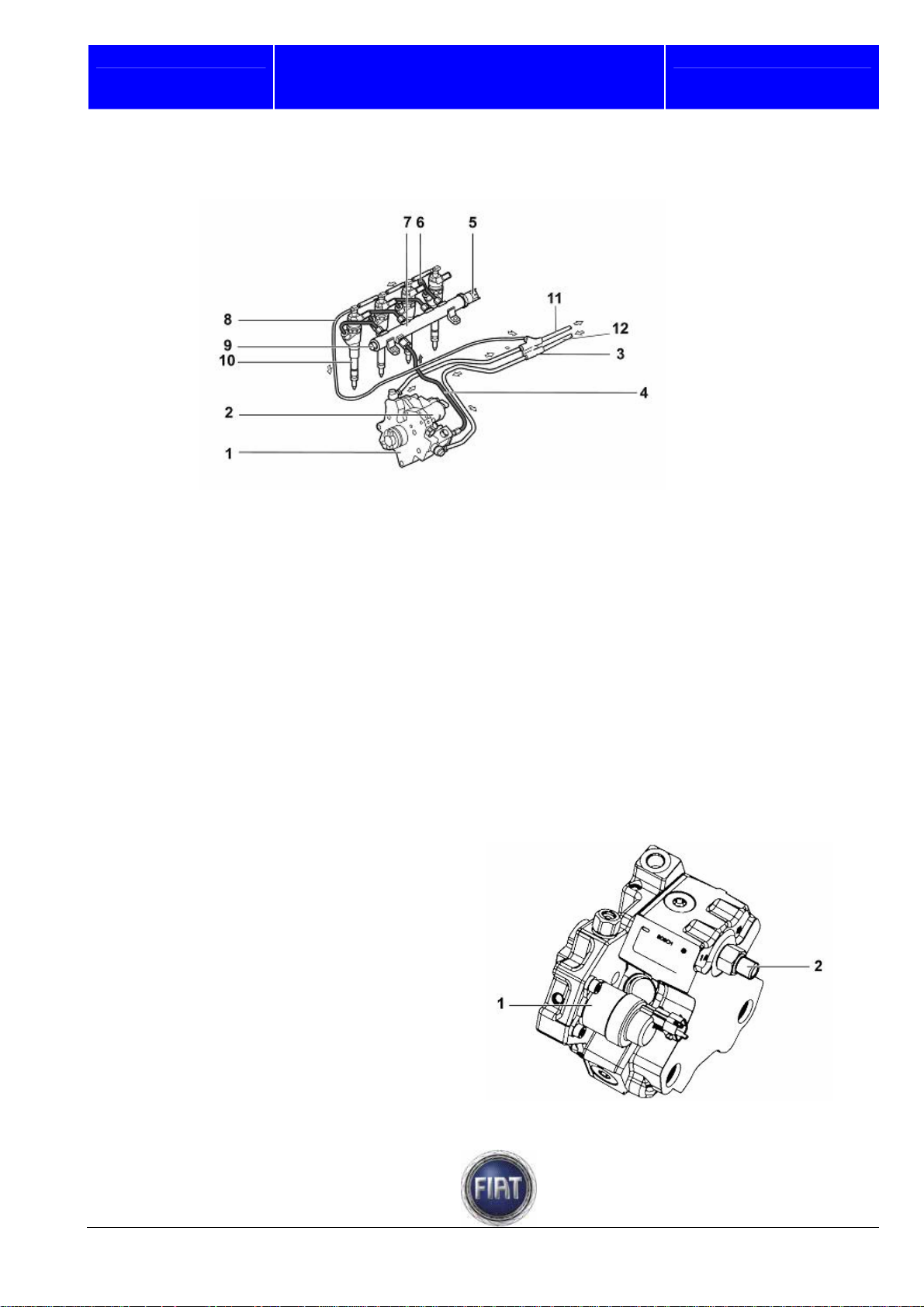

High pressure circuit

1 – Pressure pump

2 – Pressure regulator

3 – Fuel pipe fitting

4 – Pipe connecting high pressure pump with fuel manifold (Rail)

5 – Fuel pressure sensor

6 – Pipe connecting fuel manifold (Rail) with electro-injectors

7 – Fuel manifold (Rail)

8 – Return pipe from electro-injectors

9 – Plug

10 – Electro-injector

11 – Fuel pipe from filter

12 – Return to tank

High pressure pump

GENERAL’

The CP3.2 fuel pump of the Common Rail

system is called Radialjet pump because

pumping action is accomplished by three

pumping elements (pistons) arranged

radially in relation to the axis of rotation of

the pump shaft. The three pistons are

spaced 120° apart.

The quantity of fuel sent to the pumping

pistons is controlled by a pressure regulator

governed by the engine control unit

Training Academy

25 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 26

Fiat auto S.p.A.

FIAT DUCATO COURSE OUTLINE

Training Academy

RADIALJET PUMP CHARACTERISTICS

Pump pistons are operated by a rotating triangular cam integral with pump shaft. The rotating cam moves

a mechanical element (tappet) linking it to piston foot. Cam to tappet contact is ensured by a spring.

Each pumping unit has an intake valve and delivery ball valve. Fuel from the three delivery valves is

collected in a single point inside the pump and conveyed to a common manifold through a single duct. A

peculiar feature of this pump is that it is lubricated and cooled by the fuel circulating inside it or through

suitable ports.

Delivery pressure is controlled by a low-pressure solenoid valve installed at the pump inlet end so as to

compress just the amount of fuel needed to achieve required pressure according to ECU mapping.

The main features of the Radialjet pump are outlined below:

- type: Radialjet radial piston pump

- number of pistons: 3

- maximum operating pressure: 1600 bar

- feeding: Diesel fuel at 3.5 ÷ 5.0 bar

- lubrication: by Diesel fuel fed to pump

- cooling: by Diesel fuel fed to pump

Note: The high pressure pump cannot be serviced; do not remove or disturb the retaining screws.

OPERATION

The pump is driven by the crankshaft via a double chain and turns at the same speed as the engine. In

this injection system, valve timing and injection duration are controlled by the electroni c control system

and the pump simply maintains the fuel in the manifold at the required pressure.

The figure below shows the layout of pump hydraulic feeding system.

© 2006 Fiat Auto S.p.A. - All rights reserved

26 / 182

Page 27

Fiat Auto S.p.A.

(Relative) pressures in the circuit:

(a) 4.15 bar < p < 5.35 bar ; (b) 3.5 bar < p < 5.0 bar ; (c) p < 0.8 bar (d) 0.3 bar < p < 0.8 bar

1 – High pressure pump

2 – High pressure delivery pipe

3 – Return pipe from electro-injectors

4 – Electro-injectors

5 – Common Rail

6 – Fuel pressure sensor

7 – Filter with water separator

8 – Electric fuel pump check valve

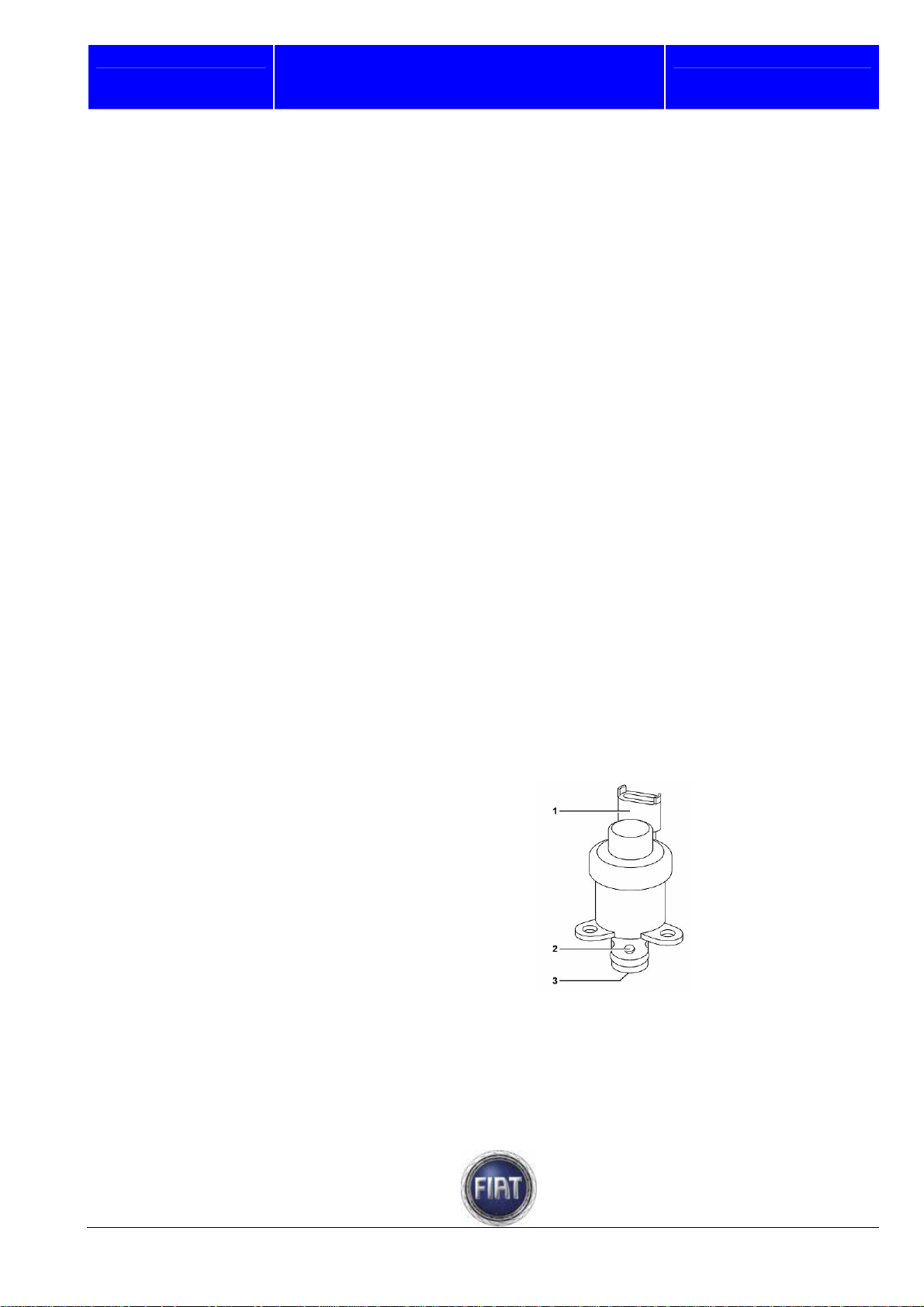

Fuel regulator

The fuel pressure regulator is installed in the low-pressure circuit of the CP3.2 pump.

The pressure regulator meters the amount of fuel delivered to the high-pressure circuit according to the

commands it receives directly from the engine control unit

The main components of the pressure regulator are listed below:

- connector,

- body,

- solenoid,

- preload spring,

- shutter cylinder.

The pressure regulator is normally open unless it is receiving any input signals; in this condition, the

pump will be delivering its maximum flow rate.

The engine control unit varies fuel delivery in the high-pressure circuit by partially closing or opening the

fuel pipe sections in the low pressure circuit via a PWM (Pulse Width Modulation) signal

1 – Connector

2 – Fuel outlet holes

3 – Fuel inlet hole

FIAT DUCATO COURSE OUTLINE

9 – Line pressure relief valve

10 – Tank

11 – Electric fuel pump

12 – Filter at electric fuel pump intake end

13 – Electric fuel pump overpressure valve

14 – Pressure relief valve

15 – Proportional pressure regulating

valve.

Training Academy

27 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 28

Fiat auto S.p.A.

FIAT DUCATO COURSE OUTLINE

Training Academy

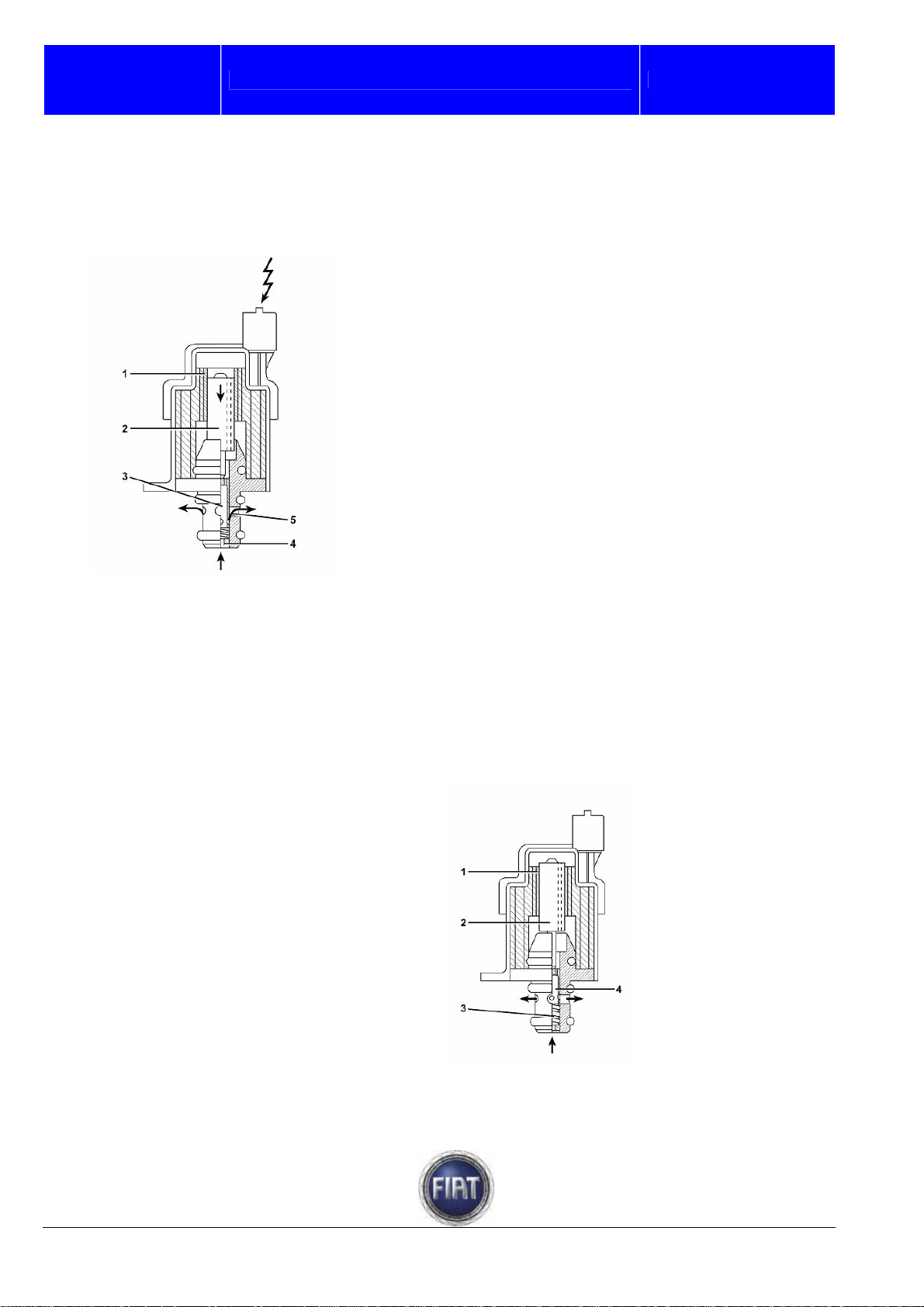

OPERATION

When the engine control unit governs the flow regulator (via PWM signal), the solenoid (1) is energised

and displaces the magnetic core (2).

The core causes the shutter cylinder (3) to move in an axial direction and fuel flow is restricted.

1 – Solenoid

2 – Magnetic core

3 – Shutter cylinder

4 – Fuel inlet

5 – Fuel outlet

When the solenoid (1) is de-energized, the magnetic core is pushed into its rest position by the preload

spring (3).

In this condition, the shutter cylinder (4) is in the position that provides a fully unrestricted fuel flow.

1 – Solenoid

2 – Magnetic core

3 – Preload spring

4 – Shutter cylinder

© 2006 Fiat Auto S.p.A. - All rights reserved

28 / 182

Page 29

Fiat Auto S.p.A.

Inertia switch

The inertia switch is located under the dashboard on passenger side. In the event of a collision, it cuts off

the fuel pump ground connection to shut off fuel delivery to the injection system.

It contains a ferromagnetic ball held in place in its tapered seat by a permanent magnet.

When vehicle deceleration exceeds a certain threshold due to a collision, the ball breaks free from its

seat and hits a switch, so that fuel pump relay ground is switched to the body computer.

This cuts off pump supply, releases the door locks and turns on the interior lighting.

The switch features a flexible cover to enable resetting.

NOTE: If you notice a burning smell or any leaks after an impact (including a minor collision), do no reset

the switch until you have located and repaired the trouble, or a fire may result. If there are no leaks and

the vehicle is capable of restarting, press the button to activate the fuel pump.

FIAT DUCATO COURSE OUTLINE

Training Academy

29 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 30

Fiat auto S.p.A.

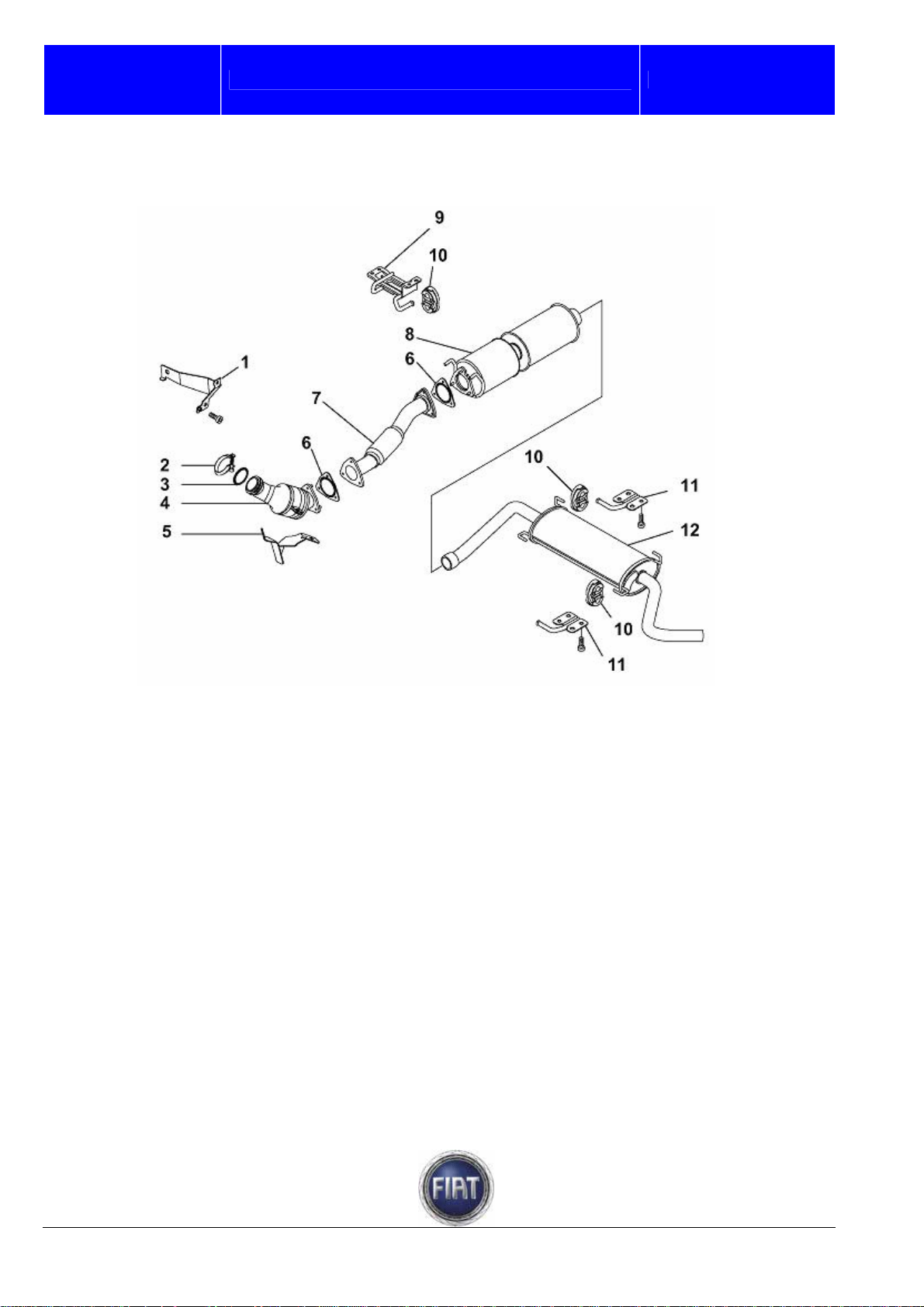

3.1.12 Exhaust system

The engine exhaust gases flow through the manifold to the three-way catalytic converter

1 – Pre-catalyst bracket

2 – Clamp

3 – Gasket

4 – Pre-catalyst

5 – Pre-catalyst bracket

6 – Gasket

FIAT DUCATO COURSE OUTLINE

7 – Exhaust pipe middle section

8 – Catalyst

9 – Catalyst bracket (on body)

10 – Flexible mounts

11 – Silencer bracket (on body)

12 – Silencer

Training Academy

© 2006 Fiat Auto S.p.A. - All rights reserved

30 / 182

Page 31

Fiat Auto S.p.A.

3.1.13 EGR system

GENERAL

This system recirculates part of the exhaust gases to the intake under certain particular operating

conditions.

This lowers peak temperature in the combustion chamber so as to reduce nitrogen oxide (NOx)

formation. The engine control unit recirculates a portion of the exhaust gases taken from the exhaust

manifold back to the engine intake.

To this end, the engine control unit processes the inputs from:

- atmospheric pressure sensor,

- water pressure sensor,

- engine rpm sensor,

- accelerator pedal potentiometer

and pilots both the vacuum control solenoid valve and the throttle valve via a PWM signal according to

the mapping stored in its memory.

Each time the engine control unit signals it to do so, the vacuum control solenoid valve opens a

connection between the servo brake vacuum circuit and the EGR circuit. This creates a certain amount of

vacuum in the EGR circuit according to the command signal. Vacuum operates the E.G.R. pneumatic

valve that retracts and lifts a shutter to open an exhaust gas passage to the intake.

This creates a connection between the exhaust and intake manifolds, so that part of the exhaust gases

flow into the intake manifold.

Exhaust gases are cooled while flowing through the heat exchanger and then conveyed into the throttle

valve chamber where they are mixed with the air from the intercooler and delivered to the intake manifold;

in the meantime, the engine control unit adjusts the amount of fuel injected into the cylinders depending

on the amount of exhaust gas recirculated.

When engine operating conditions are such that no gas recirculation is required (start-up, cold engine,

idle speed, load request, high altitude), the ECU sends no control signal to the vacuum control solenoid

valve. The solenoid valve closes the connection between the servo brake vacuum circuit and the E.G.R.

circuit and lets filtered air from the dedicated filter enter the E.G.R. circuit to restore atmospheric

pressure.

FIAT DUCATO COURSE OUTLINE

Training Academy

31 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 32

Fiat auto S.p.A.

FIAT DUCATO COURSE OUTLINE

a – Servo brake vacuum circuit

b – E.G.R. controlled vacuum circuit

1 – Engine control unit

2 – Throttle valve assembly

3 – Vacuum take-up point

4 – Water temperature sensor

E.G.R. valve

The E.G.R. valve is mounted at the end of the heat exchanger.

The valve is cooled by the engine coolant coming out of the heat exchanger to ensure improved efficiency

and long life.

The amount of recirculated exhaust gas is determined by a poppet valve operated by the vacuum let in by

a calibrated connector; vacuum is taken from the pipe connecting vacuum pump to servo brake.

The vacuum let in by the solenoid valve overcomes the pressure exerted by the spring (1) and raises a

diaphragm (2); the shutter (3) connected to it rises and lets burnt exhaust gases flow back into the intake

manifold

.

Training Academy

5 – Engine rpm sensor

6 – E.G.R. pneumatic valve

7 – Air flow meter

8 – Intake air filter

9 – EGR vacuum control valve

10 – Vacuum-operated servo brake

1 – Vacuum duct,

© 2006 Fiat Auto S.p.A. - All rights reserved

2 – Spring

3 – Diaphragm.

4 – Shutter.

32 / 182

Page 33

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

Training Academy

E.G.R. solenoid valve

The E.G.R. solenoid valve operates the E.G.R. valve to determine the amount of exhaust gases to be

delivered to the intake duct.

The duty-cycle-controlled solenoid valve determines the amount of servo brake pump vacuum to be

connected to the E.G.R. valve so as to recirculate a certain amount of exhaust gas.

The figure below shows the layout of the EGR circuit.

1 – Servo brake vacuum pump

2 – Engine control unit

3 – E.G.R. solenoid valve

4 – Filter for connection to the atmosphere

5 – E.G.R. valve on engine

A – Exhaust gas from exhaust manifold

B – Exhaust gas recirculated to the intake

manifold

The figure below shows a detail diagram of the E.G.R. solenoid valve

1 – Connection to the atmosphere

2 – Electrical connector

3 – Connection to vacuum source

3a – White identification dot

4 – Connection to E.G.R. valve

4a – Yellow identification dot

33 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 34

Fiat auto S.p.A.

FIAT DUCATO COURSE OUTLINE

Solenoid valve characteristic data

Pilot frequency: 140 ± 7Hz.

Minimum duty cycle value: 6%.

Maximum duty cycle value: 6%.

Maximum feed vacuum: 930 mbar.

Winding resistance: 5.5 ±5 Ohm at 20 ± 5°C

The following graph shows the solenoid valve characteristic curve

Training Academy

.

Heat exchanger

The heat exchanger installed between turbocharger and throttle valve assembly cools down exhaust gas

to reduce its volume.

Its body accommodates a set of corrugated pipes. The recirculated exhaust gas passing through the

pipes is cooled down by the engine coolant flowing inside the body.

© 2006 Fiat Auto S.p.A. - All rights reserved

34 / 182

Page 35

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

3.1.14 Crankcase oil vapour recovery system

General

A portion of combustion gases escapes past the end gaps of the piston rings into the sump; the oil fumes

in the sump become mixed with the exhaust gases.

From the chain compartment, this mixture is conveyed upwards, and oil is partly extracted by a device

located on top of the timing cover and conveyed into the air intake circuit. This device consists of a rotary

filter (3) splined to the shaft (1) of the high pressure/camshaft pump and a cover (2) that accommodates

two normally closed valves (4 and 5).

The diaphragm valve (4) controls the release of the partially filtered mixture to keep pressure inside the

chain compartment at ~ 10 ÷ 15 mbar. The umbrella valve (5) releases part of the remaining oil contained

in the mixture exiting the filter (3) into the chain compartment and oil condenses inside chamber (6).

Training Academy

A – Gas with an oil content greater than 10 g/h

B – Gas with an oil content ~ 0.2 g/h

C – Condensed oil returning to oil sump

35 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 36

Fiat auto S.p.A.

OPERATION

As the mixture passes through the rotary filter (3), oil particles are extracted by centrifugal force, hit the

cover walls, condense and are conveyed back into the lubrication circuit.

FIAT DUCATO COURSE OUTLINE

Training Academy

The filtered mixture is made to pass through the shaft holes (1) and the diaphragm valve (4) lets it flow

into the air conveyor upstream of the turbocharger. The valve (4) is opened or closed by the combined

action of the pressure acting on the diaphragm (4) and the vacuum underneath it. Any oil left in the

mixture exiting the rotary filter (3) condenses inside chamber (6) and is released into the chain

compartment by the umbrella valve (5) when the engine is stopped and the vacuum keeping the valve

closed is removed

© 2006 Fiat Auto S.p.A. - All rights reserved

36 / 182

Page 37

Fiat Auto S.p.A.

3.1.15 Engine lubrication system

GENERAL

The forced lubrication system consists of the following components:

- gear oil pump incorporated in the same assembly as the vacuum pump;

- pressure regulator incorporated in the oil pump;

- five-element heat exchanger;

- duel-filtration oil filter with incorporated safety valve.

OPERATION

Engine oil is drawn from the sump through the suction rose by the oil pump, pressurised and delivered to

the heat exchanger for cooling.

Oil flows through the oil filter and is conveyed to all lubrication points through galleries or pipes.

After the lubrication cycle, the oil drips back into the sump. The safety valve incorporated in the oil filter

cuts off the filter from the circuit when it becomes clogged.

In addition, the lubricating oil feeds the hydraulic tensioners of the auxiliary drive shafts and camshafts as

well as the hydraulic tappets.

FIAT DUCATO COURSE OUTLINE

Training Academy

A – Pressure regulator closed

B – Pressure regulator open

C – Oil pressure switch

D – Pressurised oil

E – Dripping oil

E – Coolant

37 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 38

Fiat auto S.p.A.

FIAT DUCATO COURSE OUTLINE

Oil pump/vacuum pump assembly

The oil pump/vacuum pump assembly is mounted on the crankcase on timing gear side.

The oil pump drive gear is driven by the crankshaft via a chain and transmits motion to the vacuum pump.

Note: this assembly cannot be serviced and must be replaced when faulty.

The figure below shows a cross-section view of the oil pump

1 – Oil pump

2 – Oil pressure regulator

3 – Vacuum pump

The oil pump is a gear pump; the vacuum

pump is a radial vane pump.

1 – Inlet duct for crankcase oil

2 – Oil intake duct

3 – Oil pressure regulator

4 – Oil delivery duct

5 – Vacuum pump air intake duct

6 – Vacuum pump oil intake duct

Oil pressure regulator

The oil pressure regulator is housed inside

the pump. The figure below shows its

components.

1 – Circlip

2 – Valve

3 – Spring

4 – Valve body.

Training Academy

© 2006 Fiat Auto S.p.A. - All rights reserved

38 / 182

Page 39

Fiat Auto S.p.A.

Oil pressure regulator valve closed

Oil pressure regulator valve open

Oil filter

FIAT DUCATO COURSE OUTLINE

When oil pressure in duct C drops below

4.4 bar, the valve (1) shuts holes D and E

and the pressurised oil is delivered to the

crankcase.

1 – Valve

2 – Spring

A – Sump oil intake duct

B – Oil delivery duct to crankcase

C – Oil return duct from crankcase

D – Oil drain hole

E – Oil drain hole

When pressure in duct C is 4.4 bar or

higher, it helps the valve (1)

overcome the spring (2); the valve lowers

and opens the drain holes D-E that connect

delivery duct A and intake duct B, so that

pressure drops.

As soon as pressure drops below 4.4 bar,

the spring (2) pushes the valve (1) back into

the closed position.

The oil filter is of the simple filtration type

with incorporated by-pass valve and opens

at a differential pressure of 2.5 ± 0.2 bar.

Training Academy

39 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 40

Fiat auto S.p.A.

Heat exchanger

The figure below shows the heat exchanger.

The amount of oil in the circuit and oil pressure are continually monitored by:

- oil pressure sensor,

- oil level sensor,

- engine oil level control unit.

Engine oil pressure sensor

The engine oil pressure sensor is located near the oil filter on the water-oil heat exchanger.

FIAT DUCATO COURSE OUTLINE

1 – Five-element heat exchanger

2 – Gasket

3 – Case

4 – Fitting

5 – Screw

6 – Oil filter mount

7 – Oil pressure switch

8 – Screw

9 – Heat exchanger case

10 – Gasket

Training Academy

1 – Engine oil pressure sensor

© 2006 Fiat Auto S.p.A. - All rights reserved

40 / 182

Page 41

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

The figure below shows the engine oil pressure sensor.

A – Detail of connector

1 – Connector

2 – Engine oil pressure sensor body

3 – Gasket

Engine oil level sensor

The engine oil level sensor is located near the alternator, on the crankcase exhaust side.

1 – Engine oil level sensor

The engine oil level sensor is a hot-wire

sensor.

The figure below shows the engine oil level sensor.

1 – Connector

2 – Engine oil level sensor body

3 – Gasket

Training Academy

41 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 42

Fiat auto S.p.A.

Engine oil level measurement

The system consists of an electronic control unit located near the engine control unit in the engine

compartment and a hot-wire sensor.

FIAT DUCATO COURSE OUTLINE

A – Engine oil level control unit

B – Detail of connector

1 – +12 Volt

2 – Output signal level

3 – Oil level sensor +

4 – Ground

5 – Ground signal

6 – Oil level sensor ground

Training Academy

Engine oil level is checked when the ignition key is turned to On to start the engine.

The system uses the heat dissipating properties of oil.

The current flowing through the hot wire causes its temperature and resistance to rise, while voltage

drops.

When the hot wire is submerged in oil, the oil will take up part of the heat; as a result, temperature,

resistance and voltage drop will be lower.

When the key is turned to On, the control unit feeds 210.5mA to the hot wire of the sensor. After a time

delay to allow for power supply to stabilise (t0 ÷ t1 = 150 mSec), the control unit takes a first voltage

reading (t1 ÷ t2 = 10 mSec ).

After another time delay (t0 ÷ t1 = 865 mSec), the control unit takes a second voltage reading and

compares it to the first reading.

At this point, one of the following may occur:

1) if the difference between the two readings is less than 125mV, it means that oil level is correct;

2) a difference greater than 445mV indicates minimum oil level;

3) if the second reading is greater than 3.5mV, it means that the sensor is interrupted;

4) if voltage is less than 1mV, it means that the sensor is shorted.

The oil control unit converts the reading into a PWM signal and sends it to the engine control unit. The

engine control unit sends the corresponding parameter over the C-CAN network to trigger the necessary

indications on the instrument panel.

PWM frequency : 125 ± 10Hz

Tolerance at ambient temperature PWM ± 3.5%

Oil level PWM signal represented by duty cycle TA

/ TP.

At the minimum level the PWM will be at 30%

(440mV) whereas at the max level it will be 90%

(125mV).

Between 10% and 15%, data acquisition is in

progress.

Between 3% and 7%, an error has occurred.

© 2006 Fiat Auto S.p.A. - All rights reserved

42 / 182

Page 43

Fiat Auto S.p.A.

3.1.16 Engine cooling circuit

The engine forced cooling system is a closed circuit and consists of the following components:

- expansion tank with an inlet and outlet valve incorporated in the plug to regulate circuit pressure;

- engine cooling module to dissipate the heat removed from the engine by the coolant;

- heat exchanger that cools lubricating oil;

- heat exchanger for exhaust gas (EGR) cooling;

- centrifugal water pump incorporated in crankcase;

- thermostat controlling coolant circulation

Diagram showing engine cooling system operation

FIAT DUCATO COURSE OUTLINE

Training Academy

1. Coolant pump

2. Coolant tank

3. Radiator

4. Thermostat

5. Oil/coolant heat exchanger

43 / 182

6. Exhaust gas/coolant heat

exchanger

7. Bleed screw

8. In-cab heater

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 44

Fiat auto S.p.A.

Engine coolant pump

The engine coolant pump is driven by the crankshaft via a poli-V belt; the pump delivers coolant to the

crankcase and - with greater pressure head - to the cylinder head.

The engine coolant pump is located on the crankcase on timing gear side.

When coolant temperature reaches or exceeds operating temperature, the thermostat trips and conveys

coolant to radiator and cooling fan.

Pressure in the circuit varies with temperature and is controlled by the inlet and outlet valves incorporated

in the expansion tank filler plug.

Supplemental engine coolant tank

The tank feeds coolant to the circuit and takes up excess coolant when it expands from heat as engine

temperature rises.

A calibrated valve in the sealed plug

- lets air exit the circuit; this is the air drawn from the pipe coming from the coolant outlet fitting on the

head; or

- lets air in when the engine has cooled down and vacuum is created in the circuit.

FIAT DUCATO COURSE OUTLINE

1 – Engine coolant pump

2 – Seal

3 – Pipe connecting pump to expansion

tank

1 – Expansion tank

2 – Engine coolant level sensor connector

3 – Fitting for coolant delivery to engine

cooling circuit

4 – Engine breather fitting

5 – Radiator breather fitting

6 – Expansion tank plug

Training Academy

© 2006 Fiat Auto S.p.A. - All rights reserved

44 / 182

Page 45

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

Expansion tank plug

The expansion tank plug maintains pressure in the cooling circuit within the specified range.

The plug accommodates two valves:

- one is set at 0.02÷0.07 kg/cm² and lets air at atmospheric pressure into the circuit to prevent vacuum

(inlet valve);

- the other valve is set at 1.4±0,1 kg/ cm² and releases exceeding pressure (outlet valve).

The outlet valve serves two purposes:

- it maintains a slight pressure in the circuit so as to increase coolant boiling point;

- it releases excess pressure to the atmosphere when coolant temperature rises.

The inlet valve lets air into the circuit when coolant cools down and shrinks in volume, creating vacuum in

the circuit.

Thermostat

The thermostat is housed inside the outlet manifold for the engine coolant exiting the head on the intake

side, and its purpose is to maintain ideal engine temperature:

Training Academy

1

– Threaded cover

2 – Cover

3 – Outlet valve spring

4 – Inlet valve

5 – Outlet valve

6 – Inlet valve spring

7 – Outlet valve

8 – Lower cover

9 – Sealing O-ring

The by-pass thermostat requires no adjustment.

If you suspect a malfunction, replace it.

The water temperature sensor is mounted on thermostat body.

Valve travel at 79°C ± 2°C = 0.1 mm

Valve travel at 94°C ± °C = 7 mm

Valve travels 7 mm in less than 60”.

A – Thermostatic valve closed

B – Thermostatic valve open

45 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 46

Fiat auto S.p.A.

FIAT DUCATO COURSE OUTLINE

3.2 ELECTRONIC ENGINE MANAGEMENT

FEATURES

The EDC16C39 Common Rail system is a high-pressure electronic injection system for fast directinjection diesel engines.

Its main features comprise:

- high injection pressures (1600 bar);

- pressure control range from 150 bar up to maximum operating pressure (1600 bar), regardless of

engine speed and loading;

- operation at high engine rpm (up to 6000 rpm under full loading);

- high pressure pump with three pumping elements;

- accurate injection (advance and duration) control;

- less consumption;

- less emissions.

The main features of the system are outlined below:

- fuel temperature control;

- engine coolant temperature control;

- injected fuel control;

- idle speed control;

- fuel cut-off during deceleration;

- cylinder balance control at idle speed;

- surge control;

- exhaust smoke control under acceleration;

- exhaust recirculation control (E.G.R.)

- torque limitation control;

- rpm limitation control;

- glow plug control;

- air conditioner control (where fitted);

- electric fuel pump control;

- cylinder position control;

- main and pilot injection advance control;

- closed-loop injection pressure control;

- electrical balance control;

- turbocharging pressure control;

- self-diagnosis;

- connection to Fiat CODE (Immobilizer) control unit.

Training Academy

© 2006 Fiat Auto S.p.A. - All rights reserved

46 / 182

Page 47

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

Training Academy

1 – Auxiliary fuel pump

2 – Fuel filter

3 – Fuel return manifold

4 – CP3.2 pressure pump

5 – Pressure regulator on pump

6 – Supercharging sensor

7 – Injection control unit

8 – Pressure sensor

9 – Rail

10 – Throttle body

11 – E.G.R. solenoid valve

12 – Oil level sensor

13 – E.G.R. actuator

14 – Glow plug

15 – Glow plug control unit

16 – Air flow meter

17 – Rpm sensor

18 – Timing sensor

19 – Oil minimum pressure switch

20 – Lambda sensor on pre-catalyst

21 – Main catalyst

22 – Engine wiring harness

23 – Pedal unit

24 – Vehicle wiring harness

25 – Water temperature sensor

47 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 48

Fiat auto S.p.A.

3.2.1 EDC 16 C 39 engine control

FEATURES

In this Common Rail fuel injection system equipped with CP3.2 pump, the flow regulator located at the

high pressure pump inlet controls the fuel flow required by the low pressure circuit. The high pump

pressure then feeds the Rail as appropriate.

This way, only the necessary amount of fuel is pressurised, there is less need to heat fuel in the system

and overall energy efficiency is improved

The CP3.2 pump maintains fuel at high pressure regardless of the current stroke of the cylinder that is

expecting the fuel and stores the fuel in a common duct for all electro-injectors (Rail).

As a result, fuel at the injection pressure determined by the ECU is constantly available at injector inlets.

When the ECU energises the solenoid valve of an injector, fuel is drawn from the rail and injected into the

corresponding cylinder.

The hydraulic system is comprised of a low pressure and high pressure circuit. The high pressure circuit

consists of the following pipes:

- pipe connecting high pressure pump outlet to Rail;

- Common Rail;

- feed pipes from Rail to injectors.

The low pressure circuit consists of the following pipes:

- suction pipe from tank to prefilter

- pipes feeding the mechanical supply pump and prefilter;

- pipes feeding the high pressure pump through the fuel filter;

- return pipe from high pressure pump;

- return pipe from electro-injectors;

- return pipe to tank.

Because of the high pressures in this hydraulic circuit, the following safety precautions must be strictly

observed:

- make sure to tighten the high pressure pipe fittings to the correct torque;

- do not disconnect high pressure pipes while the engine is running (DO NOT attempt to bleed the circuit,

this would be useless and dangerous!)

A low pressure circuit in good running order is critical to proper operation of the system, so do not make

changes to the circuit and repair any leaks without delay.

INJECTED FUEL CONTROL

The control unit controls fuel pressure regulator and electro-injectors based on the inputs from accelerator

pedal potentiometer, air flow meter or air pressure sensor in intake manifold and engine rpm sensor.

When the engine is started, injection timing and firing order are determined using the inputs from the

engine rpm sensor and the timing sensor (synchronisation); afterwards, injection timing is dependant on

the engine rpm sensor inputs only and the standard firing order of the 3000 JTD engine (1 – 3 – 4 – 2) is

resumed.

The control unit inhibits the injection when:

- fuel pressure exceeds 1700 bar;

- fuel pressure drops below 100 bar;

- engine rpm exceeds 5000 rpm.

FIAT DUCATO COURSE OUTLINE

Training Academy

© 2006 Fiat Auto S.p.A. - All rights reserved

48 / 182

Page 49

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

Training Academy

INJECTION ADVANCE CONTROL

The electronic control unit basically relies on two factors to calculate injection advance: the amount of fuel

to be injected and engine rpm.

Injection advance is adjusted according to engine coolant temperature so as to compensate for the

increasing injection delay during warm-up, while the combustion chambers are still cold.

INJECTION PRESSURE CONTROL

This is a critical feature, as injection pressure affects the following parameters:

- amount of fuel fed into the cylinders (injection duration being equal);

- fuel atomisation;

- injection depth;

- time delay after command signal before fuel is actually injected;

- duration of fuel injection into combustion chamber.

These parameters significantly affect engine operation and performance in terms of power output,

exhaust emissions, noise and driveability.

The engine control unit uses engine rpm and load inputs to control the pressure regulator at the high

pressure pump inlet so as to achieve and maintain optimal line pressure.

When the engine is cold, injection pressure is adjusted based on engine coolant temperature to meet

varying engine demand as operating temperature changes.

Fuel pressure is adjusted to instantaneous engine operating conditions (rpm, load, etc.).

The lower the pressure, the longer the injection times (and vice versa), also depending on load

requirements.

Up to 2800 rpm, a pre-injection feature reduces the noise typically associated with direct injection

systems.

Pre-injection advance angles, intervals between pre-injection and main injection and main injection

advance angles vary according to the instantaneous operating conditions of the engine.

ELECTRIC FUEL PRE-FEED PUMP CONTROL

The auxiliary fuel pump submerged in the tank is powered by the engine control unit through a contactor

when the ignition key is set to RUN.

Power supply to the electric pump is removed when:

- the engine has not started after the ignition key has been in the RUN position for 10 seconds;

- the inertia switch has tripped.

FUEL CUT-OFF DURING DECELERATION

Fuel cut-off occurs when the engine control unit receives an input from the potentiometer indicating that

the accelerator has been released.

In this condition, the control unit cuts off power supply to electro-injectors and restores it before idle rpm is

reached; the ECU also controls the fuel pressure regulator accordingly.

49 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 50

Fiat auto S.p.A.

FIAT DUCATO COURSE OUTLINE

Training Academy

IDLE SPEED CONTROL

The control unit controls fuel pressure regulator and electro-injector timing based on the inputs from the

engine rpm and coolant sensors so as to keep idle rpm stable. Under certain conditions, the ECU will also

use battery voltage to control idle speed.

MAXIMUM RPM LIMITATION CONTROL

The engine control unit achieves rpm limitation in two ways:

- it lowers line pressure to reduce the amount of fuel injected as the engine is approaching the maximum

rpm limit (4500 rpm);

- it shuts down the electro-injectors in the event the engine exceeds 5000 rpm.

MAXIMUM TORQUE LIMITATION CONTROL

The injection control unit uses rpm to calculate maximum torque parameters and maximum smoke rate

allowed based on the mapping stored in its memory. The control unit adjusts these parameters based on

engine coolant temperature and vehicle speed, and uses the resulting corrected parameters to meter out

the correct amount of fuel through the pressure regulators and the electro-injectors.

FUEL TEMPERATURE CONTROL

The injection control unit continually monitors fuel temperature through the sensor in the fuel filter.

When fuel reaches a predetermined temperature (80°C), the engine control unit begins to gradually

decrease maximum power and keeps cutting power up to 90°C, until achieving a minimum value of 60%

of rated power.

ENGINE COOLANT TEMPERATURE CONTROL

The injection control unit continually monitors engine coolant temperature through the sensor on the

thermostat.

If engine coolant temperature exceeds certain predetermined values, the control unit will:

- signal the fuel pressure regulator and the electro-injectors to reduce the amount of fuel injected (power

reduction starting from 106°C).

- actuate the engine cooling fan (switch-on/off temperatures: 95 / 91°C for first speed, 99 / 95°C for

second speed).

When the ignition key is turned to STOP (and temperature is higher than the cooling system switch-on

threshold), the fan will keep running for up to 20 sec., so that temperature drops below the switch-on

threshold.

When the ignition key is turned to RUN (and coolant temperature is higher than the cooling system

switch-on threshold), the fans will not switch on until engine speed rises above 770 rpm (rpm with a warm

engine is 800 rpm).

© 2006 Fiat Auto S.p.A. - All rights reserved

50 / 182

Page 51

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

Training Academy

EXHAUST SMOKE RATE CONTROL

The injection control unit also provides smoke limitation, for event smoke emissions are produced under

sharp acceleration

To meet this requirement, the control unit processes the signals sent by accelerator pedal potentiometer,

engine rpm sensor and intake air sensor (air flow meter or pressure/temperature sensor); the injection

control unit controls the fuel pressure regulator and the electro-injectors so that the right amount of fuel to

reduce exhaust smoke is injected into the combustion chamber .

EXHAUST RECIRCULATION CONTROL (E.G.R.)

To ensure compliance with EURO 4 emissions standard, the control unit reduces the amount of fresh air

taken in according to engine load and accelerator pedal potentiometer inputs, and signals the pneumatic

EGR valve to open so as to draw a portion of the exhaust gas.

AIR CONDITIONER CONTROL

The engine control unit controls the air conditioner compressor clutch so as to preserve engine

performance when the air conditioner is on.

When the air conditioner is switched on, the engine control unit provides more fuel at idle speed to meet

the increased demand from the engine and shuts down the air conditioner in the event of:

- exceeding engine coolant temperature (AC is shut down at 105°C and re-enabled at 100°C).

ENGINE IMMOBILIZER

The system offers an engine immobilizer feature. This is achieved thanks to a Fiat CODE control unit that

communicates with the engine control unit and an electronic key that incorporates a code transponder.

Each time the key is turned to STOP, the Fiat CODE system shuts down the engine control unit

completely.

When the key is turned to RUN, the following occurs in the order:

- the engine control unit (which has the secret code stored in its memory) asks the Fiat CODE control unit

to transmit the secret code required to cancel the inhibit condition;

- the Fiat CODE control unit will only send the secret code after receiving the identification code from the

key transponder;

- when the secret code is recognised, the engine control unit inhibit is disabled and the unit is restored to

normal operation.

SELF-DIAGNOSIS

The injection system can be fully diagnosed by connecting the EXAMINER equipment to the diagnostic

connector located in the engine compartment.

The system includes a self-diagnosis feature to recognise, store and warn of possible malfunctions.

In the event a sensor or actuator is found to be malfunctioning, preset signal recovery strategies ensure

acceptable engine operation. This way, the vehicle can be driven to nearest service centre for the

necessary repairs.

51 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 52

Fiat auto S.p.A.

FIAT DUCATO COURSE OUTLINE

FIXED GEOMETRY TURBINE CONTROL (VGT)

The control unit processes the supercharging sensor inputs at varying engine rpm and determines the

amount of fuel to be injected:

- the ECU adjusts injection duration;

- it adjusts the amount of exhaust gas flowing through the turbocharger so as to ensure optimal

performance under all operating conditions.

LAMBDA SENSOR CONTROL

The control unit uses the inputs from the Lambda sensor to prepare “correction maps” for the main injection

and compensate for injection component decay (EGR, injectors, pressure rail, air flow meter, Lambda

sensor)

SOLENOID VALVE CONTROL

The control unit switches on the cooling fans at the first or second speed depending on engine coolant

temperature and coolant pressure in the air conditioning system.

CRUISE CONTROL (WHERE FITTED)

The control unit directly adjusts the amount of fuel injected depending on the position of the cruise control

lever so as to control and maintain the vehicle speed stored in the memory.

It also controls a status light on the instrument panel to indicate whether the system is on or off.

The cruise control system is temporarily disabled:

- when the brake is operated,

- when the clutch is operated;

- pressing the "resume" button brings the vehicle back to the stored speed.

The cruise control is not disabled when the accelerator pedal is depressed (for instance, when overtaking)

and automatically brings the vehicle back to stored speed as soon as the accelerator is released.

For safety reasons, the ASR (antispin) feature overrides the cruise control.

3.2.2 Engine Control unit pinout

Training Academy

© 2006 Fiat Auto S.p.A. - All rights reserved

52 / 182

Page 53

Fiat Auto S.p.A.

FIAT DUCATO COURSE OUTLINE

M010A connector

1 – Key-on power source from main

contactor

2 – Control unit ground 1

3 – NC

4 – Control unit ground 2

5 – Key-on power source from main

contactor

6 – Control unit ground 3

7 – NC

8 – Accelerator pedal potentiometer 2

ground

9 – Accelerator pedal potentiometer 1

signal

10 – Fuel temperature signal (ground)

11 – Fuel temperature signal (signal)

12 – Air conditioner linear pressure sensor

(ground)

13 – Air conditioner linear pressure sensor

(signal)

14 – NC

15 – NC

16 – NC

17 – Brake pedal switch (signal)

18 – NC

19 – NC

20 – Fuel pump contactor power supply

(positive)

21 – NC

22 – Air conditioner linear pressure sensor

(power supply)

23 – NC

24 – NC

25 – K line for diagnosis

26 – NC

27 – NC

28 – Direct power supply from switch +15

29 – Compressor cut-in contactor control

30 – Accelerator pedal potentiometer 1

ground

31 – Accelerator pedal potentiometer 2

signal

32 – DPF exhaust gas temperature signal

(where fitted)

33 – DPF exhaust gas temperature ground

(where fitted)

34 – Exhaust gas temperature sensor 1

signal (where fitted)

35 – Exhaust gas temperature sensor 1

ground (where fitted)

36 – Particulate filter differential sensor

signal (where fitted)

Training Academy

37 – Particulate filter differential sensor

negative power supply (where fitted)

38 – Resume from cruise control command

39 – NC

40 – NC

41 – NC

42 – NC

43 – NC

44 – Particulate filter differential sensor

power supply (where fitted)

45 – Accelerator pedal potentiometer 1

power supply

46 – Accelerator pedal potentiometer 2

power supply

47 – NC

48 – NC

49 – NC

50 – NC

51 – Lambda sensor heating (negative)

52 – Glow plug preheating time/fault

detection feedback input

53 – NC

54 – Compressor cut-in request from

pushbutton positive signal

55 – NC

56 – Cruise control for “set / acc.”

57 – NC

58 – NC

59 – NC

60 – NC

61 – NC

62 – NC

63 – NC

64 – Lambda sensor Nerst cell reference

voltage signal

65 – Lambda sensor pumping current

66 – NC

67 – NC

68 – (Provision for) Diesel filter heater

contactor command

69 – Engine cooling fan speed contactor 2

cut-in command

70 – NC

71 – Malfunction indicator light (EOBD/MIL)

72 – Direct power supply from battery

73 – NC

74 – Water in fuel sensor (signal)

75 – NC

76 – NC

77 – Cruise control on/off control lever

positive

78 – Cruise control “set/dec.” command

positive

79 – Clutch pedal pressed positive signal

(NC switch)

53 / 182

© 2006 Fiat Auto S.p.A. - All rights reserved

Page 54

Fiat auto S.p.A.

FIAT DUCATO COURSE OUTLINE

80 – Clutch pedal pressed redundant signal

(positive), normally closed.

81 – NC

82 – NC

83 – Can line from NBC – (Can low)

84 – Can line from NBC – (Can High)

85 – NC

86 – Ground for Lambda sensor signal

87 – Lambda sensor reference current

88 – NC

89 – NC

90 – Engine cooling fan speed contactor 1

cut-in command

91 – NC

92 – NC

93 – Glow plug preheating contactor

94 – Engine cooling fan speed contactor 3

cut-in command

M010B Connector

1 – Injector no. 3, supply

2 – Injector no. 2, supply

3 – NC

4 – NC

5 – NC

6 – NC

7 – NC

8 – Fuel pressure sensor (ground)

9 – NC

10 – NC

11 – Timing sensor (power supply)

12 – Rpm sensor (negative input)

13 – Absolute pressure sensor (power

supply)

14 – NC

15 – NC

16 – Injector no. 1, supply

17 – Injector no. 4, supply

18 – NC

19 – Fuel flow regulator (power supply)

20 – Timing sensor (negative)

21 – NC

22 – Oil level sensor (ground)

Training Academy

23 – Absolute pressure sensor (negative)

24 – NC

25 – NC

26 – NC

27 – Rpm sensor (positive input)

28 – Rail pressure sensor (positive)

29 – NC