Page 1

701026_003

Festool Group GmbH & Co. KG

Wertstraße 20

73240 Wendlingen

Germany

www.festoolusa.com

Instruction manual

Page 6

IMPORTANT: Read all instructions before using.

Guide d’utilisation

Page 18

IMPORTANT: Lire toutes les instructions avant de démarrer les travaux.

Manual de instrucciones

Página 31

IMPORTANTE: Lea todas las instrucciones antes de usar.

Instruction manual

Guide d’utilisation

Manual de instrucciones

R O T E X

RO 90 DX FEQ

Page 2

Page 3

Page 4

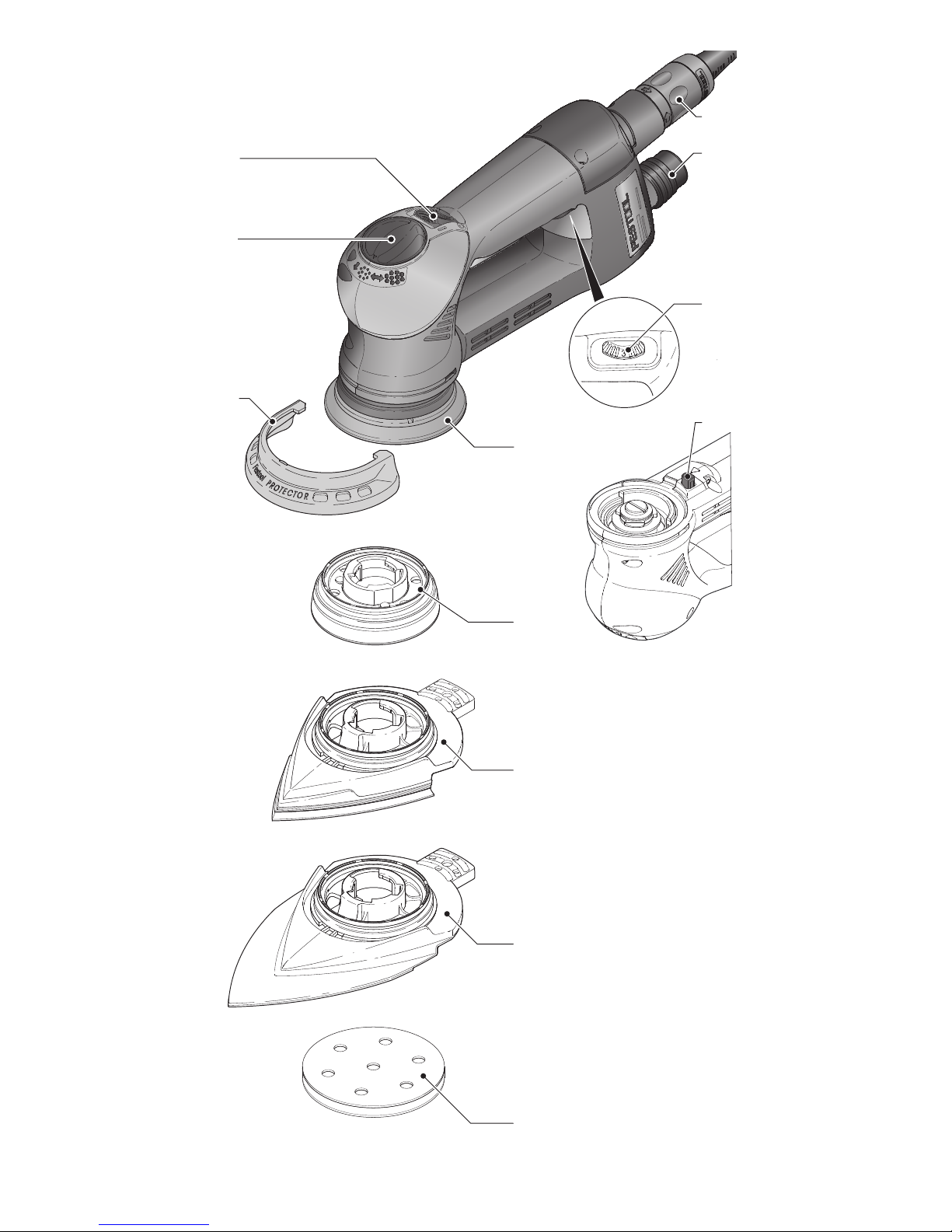

1-1

1-2

1-3

1-10

1-11

1-12

1-9

1-7

1-6

1-8

1-5

1-4

1

Page 5

Page 6

6

Contents

Symbols

The numbers in the figures indicate

in which order you should follow the

steps.

Technical data

Symbols ................................................ 6

Technical data....................................... 6

Safety instructions................................ 7

Functional description.......................... 9

Intended use......................................... 9

Operation .............................................. 9

Settings................................................. 10

Working with the machine.................... 13

Service and maintenance..................... 14

Accessories........................................... 14

Environment ......................................... 15

Warranty............................................... 15

Vvolts

A amperes

Hz hertz

~

a.c.

alternating current

d.c.

direct current

n

0

no load speed

Class II construction

rpm

min

-1

revolutions per minute

’’ inch

lb. pound

diameter

hint, tipp

Warning of general danger

Risk of electric shock

Read the Operating Instructions/Notes!

Wear protective goggles.

Wear ear protection.

Wear a dust mask.

Disconnect from the power supply!

Gear-driven eccentric

sander

RO90 DX FEQ

Power 400 W

Speed

Eccentric motion 3000 - 7000 rpm

Rotex rotary motion 220 - 520 rpm

Sanding stroke 3.0 mm (0.12’’)

FastFix sanding pad dia. 90 mm (3.54 ’’)

Weight (without mains cable,

with sanding pad)

1.45 kg (3.20 lbs)

Safety class /II

...

3

Page 7

7

Safety instructions

General safety instructions

WARNING! Read all safety warnings and all

instructions.

Failure to follow the warnings

and instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to

your mains-operated (corded) power tool or battery-operated (cordless) power tool.

1 WORK AREA SAFETY

a.

Keep work area clean and well lit.

Cluttered and

dark areas invite accidents.

b.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust.

Power tools create sparks

which may ignite the dust or fumes.

c.

Keep children and bystanders away while operating a power tool.

Distractions can cause you to

lose control.

2 ELECTRICAL SAFETY

a.

Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools.

Unmodified plugs and matching outlets

will reduce risk of electric shock.

b.

Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of elec-

tric shock if your body is earthed or grounded.

c.

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase

the risk of electric shock.

d.

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords in-

crease the risk of electric shock.

e.

When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

f.

If operating a power tool in a damp location is

unavoidable, use a residual current device

(RCD) protected supply.

Use of an RCD reduces

the risk of electric shock.

3 PERSONAL SAFETY

a.

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication.

A

moment of inattention while operating power

tools may result in serious personal injury.

b.

Use personal protective equipment. Always

wear eye protection.

Protective equipment such

as dust mask, non skid safety shoes, hard hat, or

hearing protection used for appropriate conditions will reduce personal injuries.

c.

Prevent unintentional starting. Ensure the

switch is in the off-position before connecting to

power source and/or battery pack, picking up or

carrying the tool.

Carrying power tools with your

finger on the switch or energising power tools

that have the switch on invites accidents.

d.

Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e.

Do not overreach. Keep proper footing and balance at all times.

This enables better control of

the power tool in unexpected situations.

f.

Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

Loose clothes, jewel-

lery or long hair can be caught in moving parts.

g.

If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of

dust collection can reduce dust-related hazards.

h.

Do not let familiarity gained from freuquent use

of tools allow you to become complacent and ignore, tool safety principles.

A careless action

can cause severe injury within a fraction of a second.

4 POWER TOOL USE AND CARE

a.

Do not force the power tool. Use the correct

power tool for your application.

The correct

power tool will do the job better and safer at the

rate for which it was designed.

b.

Do not use the power tool if the switch does not

turn it on and off.

Any power tool that cannot be

controlled with the switch is dangerous and must

be repaired.

c.

Disconnect the plug from the power source and/

or battery pack from the power tool before

Page 8

8

making any adjustments, changing accessories,

or storing power tools.

Such preventive safety

measures reduce the risk of starting the power

tool accidentally.

d.

Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool.

Power tools are dangerous in the

hands of untrained users.

e.

Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the power tool‘s operation. If damaged, have the power

tool repaired before use.

Many accidents are

caused by poorly maintained power tools.

f.

Keep cutting tools sharp and clean.

Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g.

Use the power tool, accessories and tool bits

etc. in accordance with these instructions taking into account the working conditions and the

work to be performed.

Use of the power tool for

operations different from those intended could

result in a hazardous situation.

h.

Keep handles dry, clean and free from oil and

grease.

Slippery handles do not allow for safe

handling and control of the tool in unexpected

situations.

5 SERVICE

a.

Have your power tool serviced by a qualified repair person using only identical replacement

parts.

This will ensure that the safety of the pow-

er tool is maintained.

Machine-related safety instructions

–

Harmful/toxic dusts can be produced during

your work (e.g. lead-containing paint, some

types of wood and metal).

Contact with these

dusts, especially inhaling them, can represent a

hazard for operating personnel or persons in the

vicinity. Comply with the safety regulations that

apply in your country. Connect the electric power

tool to a suitable extraction system.

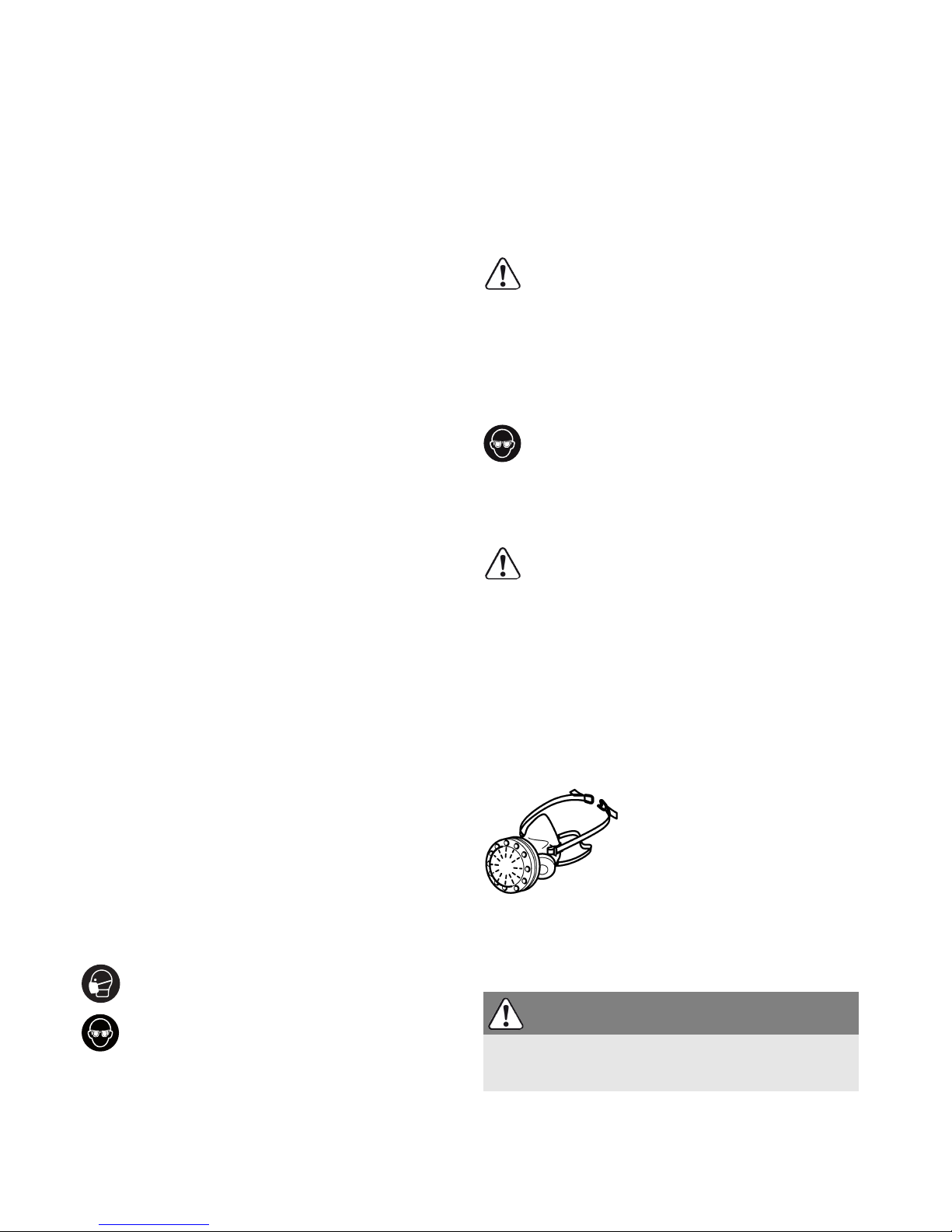

To protect your health, wear a P2 protective

mask.

Always wear protective goggles to protect

against sanding hazards.

–

Prevent liquid polish from entering the machine.

The penetration of liquid polish into the

electric power tool increases the risk of an electric shock.

–

If the power tool is dropped or falls, check for

damage to the machine and sanding pad. Remove the sanding pad for closer inspection. Repair damaged parts before using again.

Broken

sanding pads and damaged machines can cause

injuries and machine instability.

Metal processing

When processing metal, the following measures must be taken for safety reasons:

– Install an upstream residual-current circuit-

breaker (FIG, PRCD).

– Connect the machine to a suitable dust extractor.

– Regularly remove dust deposits in the motor

housing.

Health hazard by dust

WARNING!

Various dust created by power

sanding, sawing, grinding, drilling and other

construction activities contains chemicals

known (to the State of California) to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and

other masonry products, and

• arsenic and chromium from chemicallytreated

lumber.

The risk from these exposures

varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ven-

tilated area, and work with approved safety equipment, such as dust masks that

are specially designed to filter out microscopic particles. Wash hands after handling.

Wear protective goggles.

WARNING

TO REDUCE THE RISK OF INJURY, USER MUST

READ INSTRUCTION MANUAL.

Page 9

9

Functional description

The pictures for the functional description are on a

fold-out page at the beginning of the instruction

manual. When reading of the manual you can fold

out this page for having always an overview of the

machine.

* not on all versions included in the scope of delivery

Intended use

As specified, the machines is designed for sanding

and polishing plastic, metal, wood, composite materials, paint/clear coats, filler and similar materials. Materials containing asbestos must not be processed.

To guarantee electrical safety, the machine must

not be damp or operated in a damp environment.

The machine must only be used for dry sanding.

Operation

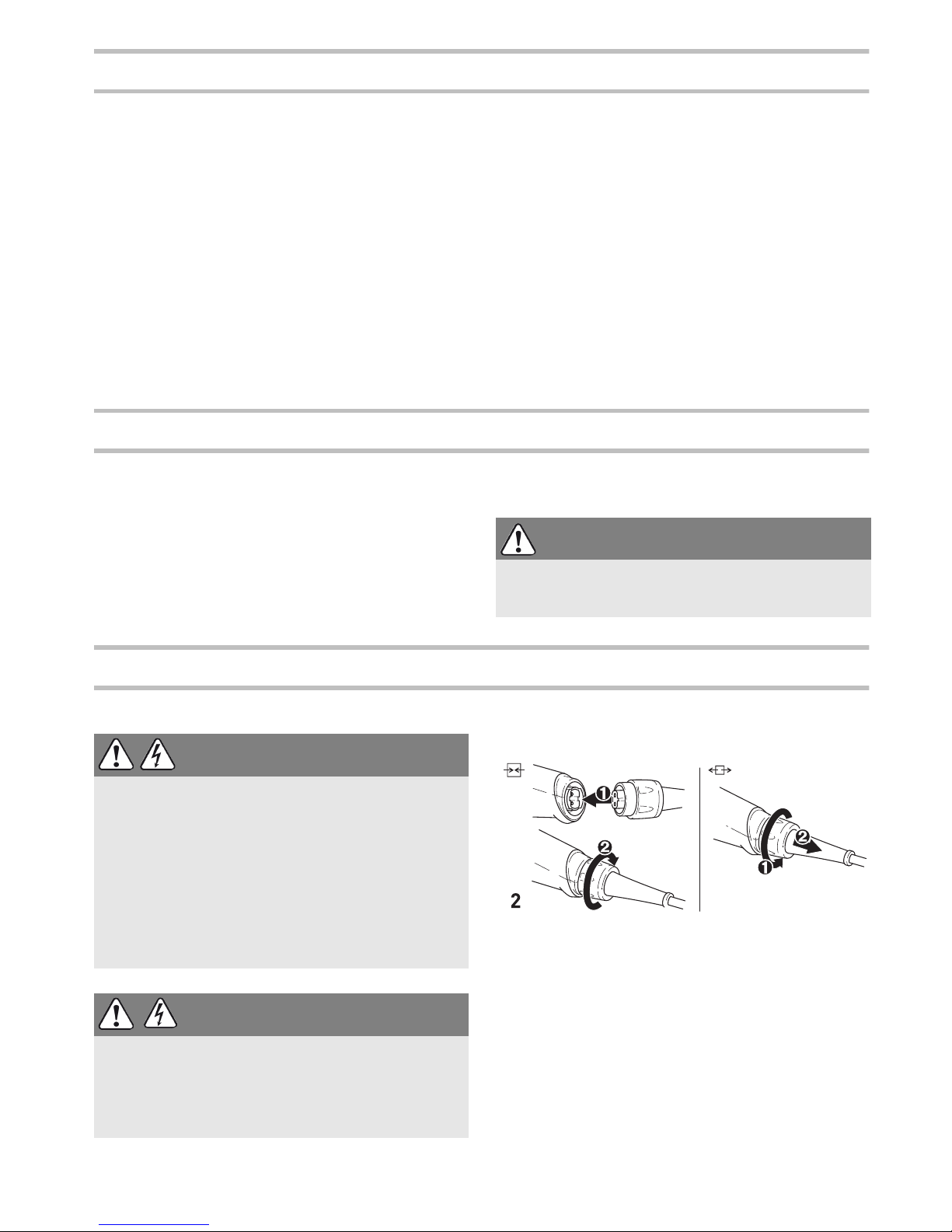

Consider the pictures on the fold-out page. Connecting and detaching the mains power cable

[1-4]

see Fig.

[2]

.

The switch

[1-3]

is an on/off switch (I = ON, 0 =

OFF).

The circuit closer can only be actuated if the

change-over switch

[1-2]

is in an engaged posi-

tion.

In case of a power failure or if the mains connector is removed, move the on/off switch immediately to the Off position. This prevents uncontrolled restarting.

[1-1]

Protector

[1-2]

Change-over switch/spindle stop

[1-3]

On/Off switch

[1-4]

Mains power cable

[1-5]

Extractor connector

[1-6]

Speed control

[1-7]

Sanding pad

[1-8]

Stop rod

[1-9]

Polishing pad*

[1-10]

Delta sanding pad

[1-11]

Slat sanding pad*

[1-12]

Interface pad*

WARNING

The user will be liable for damage due to improper use.

WARNING

Unauthorised voltage or frequency!

Risk of accident

The mains voltage and the frequency of the power source must correspond with the specifications on the machine's name plate.

In North America, only Festool machines with

the voltage specifications 120 V/60 Hz may be

used.

WARNING

Risk of injury, electric shock

Always pull the mains plug out of the socket before performing any type of work on the machine!

Page 10

10

Extension Cord

If an extension cord is required, it must have sufficient cross-section to prevent an excessive drop in

voltage or overheating. An excessive drop in voltage

reduces the output and can lead to failure of the

motor. The table below shows you the correct cord

diameter as a function of the cord length for this

tool.

Use only U.L. and CSA listed extension cords.

Never use two extension cords together. Instead,

use one long one.

The lower the AWG number, the stronger the

cord.

Settings

Consider the pictures on the fold-out page.

Electronics

The machine features full-wave electronics with

the following features:

Smooth start-up

The electronically controlled smooth start-up ensures that the machine starts up jolt-free.

Speed control

You can regulate the speed steplessly with the adjusting wheel

[1-6]

in the speed range (see Technical data). This enables you to optimise the cutting

speed to suit the surface (see table).

Constant speed

The preselected motor speed remains constant

through electronic control to ensure a uniform cutting speed even when under load.

Temperature cut-out

The machine power supply is limited and the speed

reduced if the motor exceeds a certain temperature. The machine continues operating at reduced

power to allow the ventilator to cool the motor

quickly. If the machine temperature exceeds the

maximum permitted value for longer periods, the

machine switches off completely after approx. 40

seconds and can only be switched on again once the

motor has cooled sufficiently.

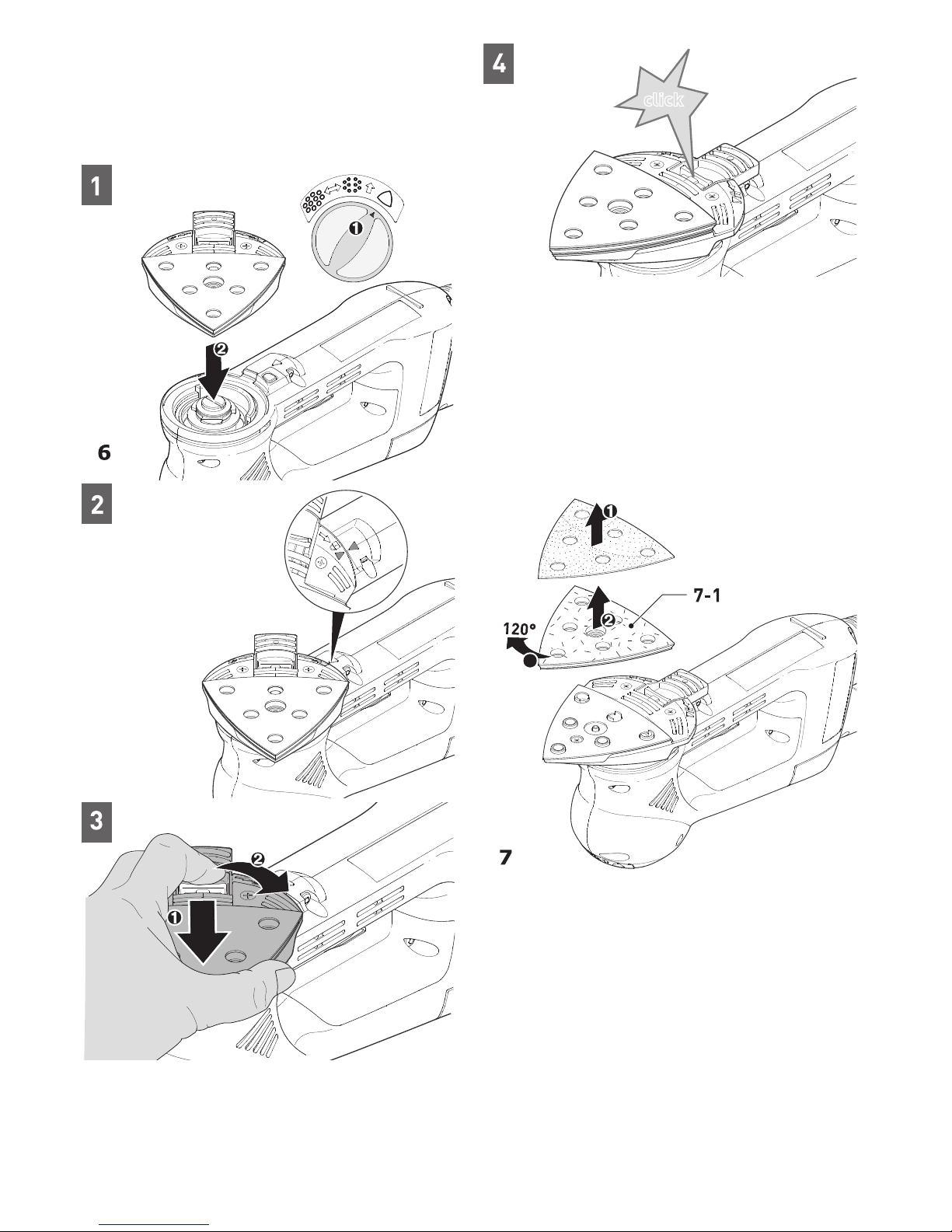

Setting sanding motion - Fig. [3]

The change-over switch

[1-2]

can be used to set

three different sanding motions.

This change-over can only be carried out with

the sanding pad stationary because the switch

is locked during operation.

Coarse sanding, polishing - ROTEX rotary motion

The Rotex rotary motion is a combination

of rotary and eccentric motions. This position is selected for sanding with high

output (coarse sanding) and polishing.

Fine sanding - eccentric motion

This position is selected for sanding with

low output for a scratch-free surface

(fine sanding).

Total Extension Cord

Length (feet)

25 50 100 150

Cable size (AWG) 18161614

WARNING

Risk of injury, electric shock

Always pull the mains plug out of the socket before performing any type of work on the machine!

+

Page 11

11

Triangular sanding and pad change - Fig. [4]

This position is used for sanding with the

delta sanding pad and slat sanding pad;

the rotary motion is blocked.

You can change the sanding pad in this

position.

The stop rod

[1-8]

blocks the installation of the

sanding pad in the change-over switch positions

ROTEX rotary motion and eccentric motion.

Changing sanding/polishing pad - Fig. [5]

Only use sanding and polishing pads that are

suitable for the maximum speed specified.

Tuned to the surface being processed, the machine

can be equipped with two sanding pads of different

hardnesses.

Hard:

Coarse and fine sanding on surfaces. Sand-

ing edges.

Soft:

Universal for coarse and fine sanding, for flat

and convex surfaces.

When the interface pad

[1-12]

is fitted on the sand-

ing pad, strength is reduced = extra soft.

Following the sanding pad change, switch the

change-over switch

[1-2]

to the desired sanding

motion.

3

3

Page 12

12

Changing sanding pad - Fig. [6]

The delta sanding pad DSS-GE-STF-RO90 can be

used for sanding close to borders, in corners or on

edges. The slat sanding pad LSS-STF-RO90 can be

used for sanding in narrow gaps, e.g. louvres.

Observe the following instructions:

Work in corners and on edges tends to subject the

tip to increased stress and results in increased heat

development. In such cases, work with reduced

contact pressure.

Delta sanding pad DSS-GE-STF-RO90 - Fig. [7]

If the front tip of the StickFix pad

[7-1]

of your delta

sanding pad is worn, take it off and turn it 120°.

click

3

Page 13

13

Slat sanding pad LSS-STF-RO90 - Fig. [8]

If the StickFix coating of the slat sanding pad is

worn, the complete table can be replaced. Open the

screws to do this

[8-1]

.

Attaching sanding accessories

The suitable StickFix sandpaper and StickFix sanding cloth can be attached quickly and simply to the

StickFix sanding pad.

Press the self-adhesive sanding accessory onto

the sanding pad

[1-7]

.

Use only abrasives with an undamaged

Stickfix hook-and-loop coating. Before use,

check that the coating has not been damaged by improper use (such as overheating).

Attaching polishing accessories

To prevent damage, PoliStick accessories (polishing sponges, polishing felt, sheepskin) must only be

used on the special polishing pad.

Press the self-adhesive polishing accessory

onto the sanding pad

[1-9]

.

Dust extraction

At the extractor connector

[1-5]

, a Festool mobile

dust extractor with an extraction hose diameter of

27 mm can be connected.

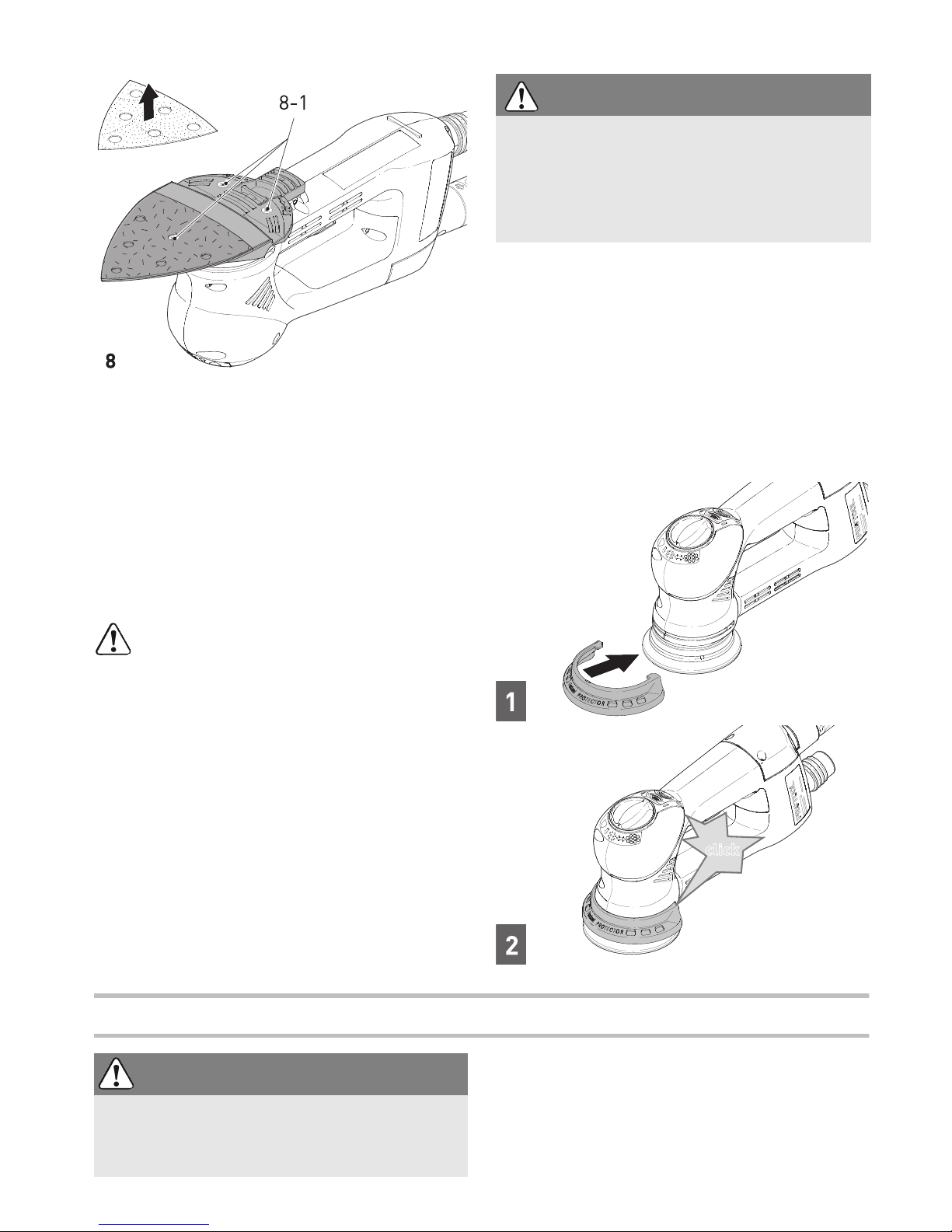

Edge protector - Fig. [9]

The edge protector

[1-1]

reduces contact of the

sanding pad circumference with a surface (e.g.

when sanding along a wall or a window), thus preventing back-kick of the machine, or machine damage.

Working with the machine

Observe the following instructions:

– Do not overload the machine by pressing with ex-

cessive force! The best sanding results are

achieved with moderate application pressure.

The sanding capacity and quality are mainly dependent on the selection of the correct abrasive.

WARNING

Dust hazard

Dust can be hazardous to health. Always work

with a dust extractor.

Always read applicable national regulations before extracting hazardous dust.

click

WARNING

Risk of injury

Always secure the workpiece in such a manner

that it cannot move while being machined.

Page 14

14

– Hold the machine with two hands, one on the mo-

tor housing and one on the gear head.

Tables A and B show the settings we recommend for different sanding and polishing work.

Service and maintenance

To ensure constant air circulation, always keep the

cooling air openings in the motor housing clean and

free of blockages.

The machine is equipped with special carbon

brushes. If they are worn, the power is interrupted

automatically and the machine comes to a standstill.

Sanding pad brake

The rubber collar

[10-1]

on the sanding pad and the

stop ring

[10-2]

on the machine prevent uncontrolled excessive turning of the sanding pad during

eccentric motion (fine sanding). As these parts are

subject to wear in the course of time, they must be

replaced when reduced braking force is observed

(for order no., see spare parts list).

Accessories

Use only original Festool accessories and Festool

consumable material intended for this machine because these components are designed specifically

for the machine. Using accessories and consumable material from other suppliers will most likely

affect the quality of your working results and limit

any warranty claims. Machine wear or your own

personal workload may increase depending on the

application. Protect yourself and your machine, and

preserve your warranty claims by always using

original Festool accessories and Festool consumable material!

Only use original sanding and polishing pads from

Festool. Low-quality sanding and polishing pads

may cause serious machine imbalance that decreases the quality of the working results and increases machine wear.

The order numbers of the accessories and tools can

be found in the Festool catalogue or on the Internet

under „www.festoolusa.com“.

WARNING

Any maintenance or repair work that requires

opening of the motor or gear housing should only

be carried out by an authorised Customer Service

Centre (name supplied by your dealer)!

Maintenance or repair work carried out by an

unauthorised person can lead to the wrong connection of the power cord or other components,

which in turn can lead to accidents with serious

consequences.

WARNING

To prevent accidents, always remove the plug

from the power supply socket before carrying out

any maintenance or repair work on the tool!

Do not use compressed air to clean the electrical

tool! Do not try to clean parts inside the tool in

this way, as you could let foreign objects in

through the openings of the tool housing.

3

Page 15

15

Systainer

Many Festool products are shipped in a unique system container, called „Systainer“. This provides

protection and storage for the tool and accessories.

The Systainers are stackable and can be interlocked together. They also can be interlocked atop

Festool CT dust extractors.

To open the Systainer

To lock the Systainer

To connect two Systainers

Place one Systainer on the top of the other (Fig.

[11

A]

).

The Systainers are connected and locked.

A new generation Systainer is connectable on

top of a previous generation Systainer by the

four latches of the previous Systainer.

Environment

Do not dispose of the device together with domestic waste!

Dispose of machines, accessories and

packaging at an environmentally responsible recycling centre. Observe the valid national regulations.

Warranty

Garantie 1 + 2

Festool offers a 3 year limited warranty, one of the

strongest in the industry. This warranty is valid on

the pre-condition that the tool is used and operated

in compliance with the Festool operating instructions. Festool warrants that the specified tool will

be free from defects in materials and workmanship

for a term of 3 years from the date of purchase.

Conditions of 1 + 2 warranty

All customers receive a free extended limited warranty (1 year + 2 years = 3 Years) on new Festool

power tools purchased from an authorized retailer.

Festool is responsible for all shipping costs during

the first year of the warranty. During the second

and third year of the warranty the customer is responsible for shipping the tool to Festool. Festool

will pay for return shipping to the customer using

UPS Ground Service. All warranty service is valid 3

years from the date of purchase on your receipt or

invoice. Proof of purchase may be required.

Excluded from the coverage under this warranty

are:

normal wear and tear, damages caused by

misuse, abuse, or neglect; damage caused by any-

Turn the T-loc

[11-1]

to this position.

Turn the T-loc

[11-1]

to this position.

Turn the T-loc

[11-1]

to one of this posi-

tions (Fig.

[11 B]

).

open

lock

connect

connect

T-loc

Page 16

16

thing other than defects in material and workmanship. This warranty does not apply to accessory

items such as circular saw blades, drill bits, router

bits, jigsaw blades, sanding belts, and grinding

wheels. Operating a tool at a voltage or frequency

different from the tool's rating will void the warranty. This includes the usage of the tool in combination with a transformer. Festool does not condone

nor support the use of any non-Festool engineered,

designed, and manufactured accessories or consumables with Festool products. Use of any nonFestool products may affect performance or void

the warranty. Festool is not responsible for any

damages or losses incurred and user assumes all

risk and responsibility with non-Festool derived

products. Also excluded are "wearing parts," such

as carbon brushes, lamellas of air tools, rubber

collars and seals, sanding discs and pads, and Festool gear (hats and shirts).

The obligations of Festool in its sole discretion under this warranty shall be limited to repair or replacement or a refund of the purchase price for any

Festool portable power tool that is found to have a

defect in materials or workmanship during the

warranty period. FESTOOL SHALL NOT BE LIABLE

FOR ANY CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES REGARDLESS OF THE THEORY OF

LAW ON WHICH THE CLAIM IS BASED. ALL WARRANTIES IMPLIED BY STATE LAW, INCLUDING THE

IMPLIED WARRANTIES OR MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE

HEREBY LIMITED TO THE DURATION OF THREE

YEARS.

Some states in the U.S. and some Canadian provinces do not allow the limitations on how long an

implied warranty lasts, so the above limitation may

not apply to you. This warranty gives you specific legal rights, and you may also have other rights that

vary from state to state in the U.S. and from province to province in Canada.

With the exception of any warranties implied by

state or province law as limited above, the foregoing express limited warranty is exclusive and in lieu

of all other warranties, guarantees, agreements,

and similar obligations of Festool. Festool makes

no other warranty, express or implied, for Festool

portable power tools. This warranty policy is only

valid for tools that are purchased in the US and

Canada. Warranty policies of other countries may

vary when obtaining warranty service outside the

US and Canada. Some countries do exclude warranty for products bought outside their territory.

Festool reserves the right to reject the repair of any

tool that is not part of the US/Canada product line.

No agent, representative, distributor, dealer, or employee of Festool has the authority to increase or

otherwise change the obligations or limitations of

this warranty.

Table A: Coarse sanding Fine sanding

Sanding

Clear coat,

filler, putty

x 5 - 6 soft x 1 - 3 extra soft

Clear coat,

paint

x 5 - 6 hard x 3 - 6 hard

Wood, veneered

surface

x 5 - 6 hard x 3 - 6 soft

Plastic x x 1-4 soft x 1 - 4 soft/ extra

soft

Steel, copper,

aluminium

x6softx3 - 6soft

VOC clear coats x 2 - 4 extra soft -

hard

Page 17

17

Table B:

Polishing Polishing Sealing High-gloss polishing

Clear coat 6 3 4 - 6

Sponge

rough/smooth

Sponge

fine/honeycombed

Sheepskin

Polishing paste Hard wax -

Plastic 6 3 6

Felt

hard

Felt

soft

Sheepskin

Polishing paste Hard wax -

Page 18

18

Sommaire

Symboles

Les numéros dans les figure montre

l’ordre du pas.

Caractéristiques techniques

Consignes de sécurité

Consignes de sécurité d'ordre général

ATTENTION ! Lire toutes les consignes de

sécurité et indications.

Le non-respect des

avertissements et instructions indiqués ci-après

peut entraîner un choc électrique, un incendie et/

ou de graves blessures.

Conserver tous les avertissements et toutes les

instructions pour pouvoir s'y reporter ultérieure-

ment.

Le terme " outil " dans les avertissements fait reference à votre outil électrique alimenté par le secteur (avec cordon d'alimentation) ou votre outil

fonctionnant sur batterie (sans cordon d'alimentation).

1 PLACE DE TRAVAIL

a.

Maintenez l'endroit de travail propre et bien

éclairé.

Un lieu de travail en désordre ou mal

Symboles.............................................. 18

Caractéristiques techniques................ 18

Consignes de sécurité.......................... 18

Description fonctionnelle..................... 21

Utilisation en conformité avec les ins-

tructions ............................................... 21

Mise en service..................................... 22

Réglages............................................... 22

Travail avec la machine........................ 26

Entretien et maintenance .................... 27

Accessoires .......................................... 27

Environnement..................................... 28

Garantie................................................ 28

VVolt

AAmpère

Hz Hertz

~

a.c.

Tension alternative

d.c.

courant continu

n

0

Vitesse de rotation à vide

Classe II conception

.../min

min

-1

tours ou course par minute

’’ pouce

lb. livre

Diamètre

Information, astuce

Avertissement de danger général

Risque d'électrocution

Lire les instructions / les remarques !

Porter des lunettes de protection !

Portez des protège-oreilles!

Porter une protection respiratoire !

Débrancher la fiche secteur !

Ponceuse roto-excentrique RO90 DX FEQ

Puissance 400 W

Vitesse de rotation

Mouvement excentrique 3000 - 7000 tr/mn

Mouvement rotatif Rotex 220 - 520 tr/mn

Course de ponçage 3.0 mm (0.12’’)

Plateau de ponçage FastFix D 90 mm (3.54’’)

Poids (hors câble secteur, avec

plateau de ponçage)

1.45 kg (3.20 lbs)

Classe de protection /II

...

3

Page 19

19

éclairé augmente le risque d'accidents.

b.

N'utilisez pas l'appareil dans un environnement

présentant des risques d'explosion et où se

trouvent des liquides, des gaz ou poussières inflammables.

Les outils électroportatifs génèrent

des étincelles risquant d'enflammer les poussières ou les vapeurs.

c.

Tenez les enfants et autres personnes éloignés

durant l'utilisation de l'outil électroportatif.

En

cas d'inattention vous risquez de perdre le

contrôle sur l'appareil.

2 SECURITE RELATIVE AU SYSTEME ELECTRIQUE

a.

La fiche de secteur de l'outil électroportatif doit

être appropriée à la prise de courant. Ne modifiez en aucun cas la fiche. N'utilisez pas de

fiches d'adaptateur avec des appareils avec

mise à la terre.

Les fiches non modifiées et les

prises de courant appropriées réduisent le risque

de choc électrique.

b.

Evitez le contact physique avec des surfaces

mises à la terre tels que tuyaux, radiateurs,

fours et réfrigérateurs.

Il y a un risque élevé de

choc électrique au cas où votre corps serait relié

à la terre.

c.

N'exposez pas l'outil électroportatif à la pluie

ou à l'humidité.

La pénétration d'eau dans un outil électroportatif augmente le risque d'un choc

électrique.

d.

N'utilisez pas le câble à d'autres fins que celles

prévues, n'utilisez pas le câble pour porter l'appareil ou pour l'accrocher ou encore pour le débrancher de la prise de courant. Maintenez le

câble éloigné des sources de chaleur, des parties grasses, des bords tranchants ou des parties de l'appareil en rotation.

Un câble

endommagé ou torsadé augmente le risque d'un

choc électrique.

e.

Au cas où vous utiliseriez l'outil électroportatif

à l'extérieur, utilisez une rallonge autorisée homologuée pour les applications extérieures.

L'utilisation d'une rallonge électrique homologuée pour les applications extérieures réduit le

risque d'un choc électrique.

f.

Si l'usage d'un outil dans un emplacement humide est inévitable, utiliser une alimentation

protégée par un dispositif à courant différentiel

résiduel (RCD).

L'usage d'un RCD réduit le

risque de choc électrique.

3 SECURITE DES PERSONNES

a.

Restez vigilant, surveillez ce que vous faites.

Faites preuve de bon en utilisant l'outil électroportatif. N'utilisez pas l'appareil lorsque vous

êtes fatigué ou après avoir consommé de l'al-

cool, des drogues ou avoir pris des médicaments.

Un moment d'inattention lors de

l'utilisation de l'appareil peut entraîner de graves

blessures sur les personnes.

b.

Portez des équipements de protection. Portez

toujours des lunettes de protection.

Le fait de

porter des équipements de protection personnels

tels que masque anti-poussières, chaussures de

sécurité antidérapantes, casque de protection ou

protection acoustique suivant le travail à effectuer, réduit le risque de blessures.

c.

Evitez une mise en service par mégarde. Assurez-vous que l'interrupteur est effectivement

en position d'arrêt avant de retirer la fiche de la

prise de courant.

Le fait de porter l'appareil avec

le doigt sur l'interrupteur ou de brancher l'appareil sur la source de courant lorsque l'interrupteur est en position de fonctionnement, peut

entraîner des accidents.

d.

Enlevez tout outil de réglage ou toute clé avant

de mettre l'appareil en fonctionnement.

Une clé

ou un outil se trouvant sur une partie en rotation

peut causer des blessures.

e.

Ne surestimez pas vos capacités. Veillez à garder toujours une position stable et équilibrée.

Ceci vous permet de mieux contrôler l'appareil

dans des situations inattendues.

f.

Portez des vêtements appropriés. Ne portez

pas de vêtements amples, ni de bijoux. Gardez

les cheveux et les vêtements à distance des

pièces mobiles.

Des vêtements amples, des bijoux ou des cheveux longs peuvent être happés

par les pièces en mouvement.

g.

Si des dispositifs servant à aspirer ou à recueillir les poussières doivent être utilisés, vérifiez

que ceux-ci soient effectivement raccordés et

qu'ils sont correctement utilisés.

L'utilisation de

tels dispositifs réduit les dangers dus aux poussières.

h.

Ne devenez pas trop sûr de vous, par habitude

suite à une utilisation fréquente de l’appareil,

de manière à ne pas respecter les principes de

sécurité de base de l’appareil.

Une action imprudente peut occasionner de graves blessures

en l’espace d’une fraction de seconde.

4 UTILISATION ET EMPLOI SOIGNEUX DE L'OUTIL

ELECTROPORTATIF

a.

Ne surchargez pas l'appareil. Utilisez l'outil

électroportatif approprié au travail à effectuer.

Avec l'outil électroportatif approprié, vous travaillerez mieux et avec plus de sécurité à la vitesse

pour laquelle il est prévu.

b.

N'utilisez pas un outil électroportatif dont l'in-

Page 20

20

terrupteur est défectueux.

Un outil électroportatif qui ne peut plus être mis en ou hors

fonctionnement est dangereux et doit être réparé.

c.

Retirer la fiche de la prise de courant avant d'effectuer des réglages sur l'appareil, de changer

les accessoires, ou de ranger l'appareil.

Cette

mesure de précaution empêche une mise en

fonctionnement par mégarde.

d.

Gardez les outils électroportatifs non utilisés

hors de portée des enfants. Ne permettez pas

l'utilisation de l'appareil à des personnes qui ne

se sont pas familiarisées avec celui-ci ou qui

n'ont pas lu ces instructions.

Les outils électroportatifs sont dangereux lorsqu'ils sont utilisés

par des personnes non initiées.

e.

Prenez soin des outils électroportatifs. Vérifiez

que les parties en mouvement fonctionnent correctement et qu'elles ne soient pas coincées, et

contrôlez si des parties sont cassées ou endommagées de telle sorte que le bon fonctionnement de l'appareil s'en trouve entravé. Faites

réparer les parties endommagées avant d'utiliser l'appareil.

De nombreux accidents sont dus à

des outils électroportatifs mal entretenus.

f.

Maintenez les outils de coupe aiguisés et

propres.

Des outils soigneusement entretenus

avec des bords tranchants bien aiguisés se

coincent moins souvent et peuvent être guidés

plus facilement.

g.

Utilisez les outils électroportatifs, les accessoires, les outils à monter etc. conformément à

ces instructions et aux prescriptions en vigueur

pour ce type d'appareil. Tenez compte également des conditions de travail et du travail à effectuer.

L'utilisation des outils électroportatifs à

d'autres fins que celles prévues peut entraîner

des situations dangereuses.

h.

Gardez les poignées dans un état sec, propre et

exempt d’huile et de graisse.

Des poignées glissantes ne permettent pas une prise en main sûre

et le contrôle de l’outil électrique dans des situations inattendues.

5 SERVICE

a.

Ne faites réparer votre outil électroportatif que

par un personnel qualifié et seulement avec des

pièces de rechange d'origine.

Ceci permet d'as-

surer la sécurité de l'appareil.

Consignes de sécurité spécifiques à la machine

–

Au cours du travail, des poussières nocives/

toxiques peuvent être générées (comme les

poussières de peintures au plomb ou certaines

poussières de bois ou de métal).

Le contact ou

l'inhalation de ces poussières peut présenter un

danger pour l'utilisateur ou les personnes se

trouvant à proximité. Veuillez respecter les prescriptions de sécurité en vigueur dans votre pays.

Raccordez l'outil électrique à un dispositif d'aspiration adapté.

Pour votre santé, portez un masque de protection respiratoire de classe P2.

Portez systématiquement des lunettes de

protection pour vous protéger des risques

inhérents au ponçage.

–

Évitez l'infiltration de produit de polissage liquide dans l'appareil.

L'infiltration de produit de

polissage liquide dans un outil électrique augmente le risque de décharge électrique.

–

En cas de chute, vérifiez que l'outil électrique et

le patin de ponçage ne sont pas endommagés.

Démontez le patin de ponçage pour un examen

minutieux. Faites réparer les pièces endommagées avant toute utilisation.

Des patins de ponçage cassés et des machines endommagées

peuvent causer des blessures et compromettre

la sûreté de la machine.

Travail sur métaux

Pour des raisons de sécurité, respectez les

mesures suivantes lorsque vous travaillez

sur des métaux :

– Installez en amont de l'appareil un disjoncteur à

courant de défaut (FI, PRCD).

– Raccordez l'outil à un aspirateur approprié.

– Nettoyez régulièrement les dépôts de poussières

accumulés dans le carter moteur.

La poussière, un risque

pour la santé

AVERTISSEMENT!

Certaines poussières

créées par le ponçage mécanique, le sciage,

le meulage, le perçage et autres activités re-

liées à la construction contiennent des substances

chimiques connues (dans l’État de la Californie)

comme pouvant causer le cancer, des anomalies

congénitales ou représenter d’autres dangers pour

la reproduction. Voici quelques exemples de telles

substances:

Porter des lunettes de protection !

Page 21

21

• plomb provenant de peintures à base de plomb,

• silice cristallisée utilisée dans les briques, le ciment et autres matériaux de maçonnerie, et

• arsenic et chrome du bois d’oeuvre traité avec un

produit chimique.

Le risque d’exposition à de tels

produits varie selon la fréquence à laquelle vous faites

ce genre de travail. Pour réduire les risques d’exposition à

ces substances chimiques : travaillez dans un endroit adéquatement ventilé et utilisez un équipement de sécurité approuvé, tel que masques antipoussières spécialement conçus pour filtrer les

particules microscopiques.

Description fonctionnelle

Des éléments fournis sont disponibles sur le volet

qui se trouve au début de cette notice d'utilisation.

Vous pouvez ainsi déplier cette page et visualiser

en permanence les différentes parties de l'outil

lorsque vous lisez la notice.

* pas compris dans le volume de livraison pour

toutes les variantes

Utilisation en conformité avec les instructions

Cet outil a été conçu pour le ponçage et le polissage

des matériaux suivants : plastique, métal, bois, aggloméré, peinture/laque, mastic et matériaux similaires. L'usinage de l'amiante est formellement interdit.

Afin de garantir la sécurité électrique, elle ne doit

pas être mouillée ou utilisée en environnement hu-

mide. Cet outil doit être exclusivement utilisé pour

le ponçage à sec.

AVERTISSEMENT

POUR RÉDUIRE LE RISQUE DE DOMMAGES,

L'UTILISATEUR DOIT LIRE LE MANUEL D'INSTRUCTION.

[1-1]

Capot de protection

[1-2]

Commutateur/blocage de broche

[1-3]

Interrupteur de marche/arrêt

[1-4]

Câble de raccordement secteur

[1-5]

Raccord d'aspiration

[1-6]

Régulation de la vitesse

[1-7]

Plateau de ponçage

[1-8]

Tige de blocage

[1-9]

Plateau de polissage*

[1-10]

Patin de ponçage Delta

[1-11]

Patin de ponçage pour lamelles*

[1-12]

Pad d’interface*

AVERTISSEMENT

Seul l’utilisateur est tenu responsable des dommages qui résulteraient d’une utilisation non

conforme aux prescriptions.

Page 22

22

Mise en service

Attention aux illustrations au début de la présente

notice d’utilisation.

Voir en figure

[2]

a connexion et la déconnexion du

câble de raccordement

[1-4]

au secteur.

L'interrupteur

[1-3]

fait office d'interrupteur

marche/arrêt (I = MARCHE, 0 = ARRÊT).

L'interrupteur ne fonctionne que si le commutateur

[1-2]

est bien enclenché.

Si une panne de courant se produit ou que la

prise secteur est débranchée, mettre immédiatement l'interrupteur marche/arrêt en position

d'arrêt. Ceci permet d'éviter tout redémarrage

intempestif.

Rallonge électrique

Si une rallonge électrique est nécessaire, elle doit

présenter une section suffisante afin d'éviter une

chute de tension excessive ou une surchauffe. Une

chute de tension excessive réduit la puissance et

peut entraîner la destruction du moteur. Le tableau

ci-dessous vous présente la section correcte de la

rallonge en fonction de sa longueur pour cette appareil.

Utilisez exclusivement des rallonges recommandées par U.L. et CSA.

N'utilisez jamais deux rallonges raccordées l'une à

l'autre, mais remplacez-les par une rallonge plus

longue.

Plus le calibre AWG est bas, plus le câble est ré-

Réglages

Attention aux illustrations au début de la présente

notice d’utilisation.

Régulation électronique

La machine dispose d'un système électronique à

ondes pleines avec les propriétés suivantes :

Démarrage progressif

Le démarrage progressif assure un fonctionnement sans à-coups de la machine.

Régulation de la vitesse

La molette

[1-6]

permet de régler en continu la vitesse de rotation dans la plage de régimes (voir Caractéristiques techniques). Vous pouvez ainsi adapter de façon optimale la vitesse à chaque surface

(voir tableau).

Vitesse de rotation constante

La vitesse sélectionnée est maintenue constante de

AVERTISSEMENT

Tension ou fréquence non admissible !

Risque d'accident

La tension et la fréquence d'alimentation électrique doivent être conformes aux indications de

la plaque signalétique.

En Amérique du nord, utilisez uniquement les

outils Festool fonctionnant sous une tension de

120 V/60 Hz.

AVERTISSEMENT

Risques de blessures, choc électrique

Débrancher la fiche de la prise de courant avant

toute intervention sur la machine !

Longueur totale de la

rallonge (pieds)

25 50 100 150

Section de la rallonge (AWG)

18 16 16 14

AVERTISSEMENT

Risques de blessures, choc électrique

Débrancher la fiche de la prise de courant avant

toute intervention sur la machine !

Page 23

23

manière électronique. Elle reste donc homogène,

même lorsque l'outil est fortement sollicité.

Sécurité thermique

L'alimentation électrique et la vitesse de rotation

sont réduites en cas de température trop élevée du

moteur. La machine ne fonctionne plus qu'à une

puissance réduite, afin de permettre un refroidissement rapide du moteur. Si la surtempérature

perdure, la machine s'arrête complètement après

env. 40 s. Une nouvelle mise en marche n'est possible qu'après refroidissement du moteur.

Réglage du mouvement de ponçage - Fig.

[3]

Le commutateur

[1-2]

permet de choisir entre trois

mouvements de ponçage différents.

Le plateau de ponçage doit être immobilisé

pour agir sur le commutateur. Lorsque le plateau est en mouvement, le commutateur est en

effet verrouillé.

Ponçage dégrossissant, polissage - mouvement

rotatif ROTEX

Le mouvement rotatif Rotex est une

combinaison de mouvements rotatifs et

excentriques. Cette position est conçue pour le

ponçage dégrossissant (grossier) et le polissage.

Ponçage fin - mouvement excentrique

Cette position est conçue pour un ponçage dégrossissant moins puissant, qui

évite les rayures superficielles (ponçage

fin).

Ponçage triangulaire et changement de plateau Fig. [4]

Cette position est réservée au ponçage

avec le patin de ponçage Delta et le patin

de ponçage pour lamelles. Le mouvement de rotation est alors bloqué.

Cette position sert à changer de plateau

de ponçage ou de patin de ponçage.

La tige de blocage

[1-8]

rend le montage d'un

patin de ponçage impossible lorsque le commutateur est en position de mouvement rotatif

ROTEX ou de mouvement excentrique.

+

3

Page 24

24

Changement de plateau de ponçage/polis-

sage - Fig. [5]

Utilisez exclusivement des plateaux de ponçage

et de polissage pouvant supporter la vitesse de

rotation maximale indiquée.

En fonction de la surface à traiter, cet appareil peut

être équipé de deux plateaux de ponçage de duretés différentes.

Surfaces dures :

ponçage dégrossissant et pon-

çage fin sur des surfaces. Ponçage des chants.

Surfaces tendres :

accessoire universel pour ponçage dégrossissant et ponçage fin, pour surfaces

planes et incurvées.

Le fait de placer le pad d'interface

[1-12]

sur le plateau de ponçage altère la résistance = support super tendre.

Après avoir changé de plateau, réglez le commutateur

[1-2]

en fonction du mouvement de

ponçage souhaité.

Changement de patin de ponçage - Fig. [6]

Le patin de ponçage Delta DSS-GE-STF-RO90 permet de poncer près des bord, dans les coins ou sur

les chants. Le patin de ponçage pour lamelles LSSSTF-RO90 sert quant à lui à intervenir dans les interstices, par exemple les persiennes.

3

Page 25

25

Observez les consignes suivantes :

Le fait d'intervenir dans les angles et sur les chants

sollicite ponctuellement la pointe et produit un fort

dégagement de chaleur. Vous devez donc exercer

moins de pression.

Patin de ponçage Delta DSS-GE-STF-RO90- Fig.

[7]

Si la pointe avant du pad StickFix

[7-1]

de votre pa-

tin de ponçage Delta est usée, retirez-la et tournez

le patin de 120°.

Patin de ponçage pour lamelles LSS-STF-RO90Fig. [8]

Si le revêtement StickFix du patin de ponçage pour

lamelles est usé, il est possible de changer le support dans son ensemble. Pour cela, dévissez les vis

[8-1]

.

Fixation des accessoires de ponçage

Le plateau et le patin de ponçage StickFix permettent de fixer des abrasifs et des feutres StickFix

adaptés de manière simple et rapide.

Placez l'accessoire de ponçage auto-agrippant

sur le plateau de ponçage

[1-7]

et appuyez bien.

Utilisez uniquement des patins Stickfix dont

l’état de la surface auto-agrippante est impeccable. Avant l’utilisation, vérifiez si la

surface n’a pas subi de dégradation suite à

un échauffement.

Fixation de l'accessoire de polissage

Pour éviter tout dommage, il convient d'utiliser exclusivement le plateau de polissage spécifique

pour fixer les accessoires PoliStick (éponge, feutre,

peau de mouton).

Placez l'accessoire de polissage auto-agrippant

sur le plateau de polissage

[1-9]

et appuyez

bien.

click

3

Page 26

26

Aspiration

Le raccord d'aspiration

[1-5]

permet de raccorder

un aspirateur Festool avec tuyau d'aspiration de

27 mm de diamètre.

Protection pour chants (Protector) - Fig.

[9]

La protection pour chants

[1-1]

évite que la circonférence du plateau de ponçage ne touche une

surface (par ex. lors du ponçage le long d'un mur ou

d'une fenêtre) et ne provoque un rebond de l'outil,

voire des dommages.

Travail avec la machine

Observez les consignes suivantes :

– Ne surchargez pas l'outil : n'exercez pas de pres-

sion trop importante ! Pour obtenir des résultats

optimaux, il convient d'exercer une pression mo-

dérée. Les performances de ponçage et la qualité du ponçage dépendent essentiellement du

choix de l'abrasif.

– Pour guider l'outil de façon sûre, maintenez-le

avec les deux mains au niveau du carter du moteur et de la tête de carter.

Les tableaux A et B montrent les réglages préconisés pour différents travaux de ponçage et

de polissage.

AVERTISSEMENT

Risques pour la santé dus aux poussières

Les poussières peuvent être dangereuses pour

la santé. Pour cette raison, ne travaillez jamais

sans aspiration.

Respectez toujours les prescriptions nationales

en vigueur lors de l'aspiration de poussières

dangereuses pour la santé.

click

AVERTISSEMENT

Risques de blessures

Fixer la pièce à usiner de manière à ce qu‘elle ne

puisse pas bouger pendant le traitement.

Page 27

27

Entretien et maintenance

Pour assurer la circulation de l'air, il est impératif

que les ouïes de ventilation du carter moteur soient

maintenues dégagées et propres.

L'appareil est équipé de charbons spéciaux à coupure automatique. Lorsque ceux-ci sont usés, l'alimentation est coupée et l'appareil s'arrête.

Frein de plateau

La rondelle en caoutchouc

[10-1]

du plateau de

ponçage et la bague d'arrêt

[10-2]

de l'outil évitent

que le plateau ne s'emballe lors du mouvement excentrique (ponçage fin). Ces composants tendent à

s'user au fil du temps et doivent donc être remplacés lorsque leur effet de freinage se fait moins efficace (voir la nomenclature des pièces de rechange

pour la référence).

Accessoires

Utilisez uniquement les accessoires Festool et

consommables Festool d'origine prévus pour cette

machine, car ces composants systèmes sont parfaitement adaptés les uns par rapport aux autres.

Si vous utilisez des accessoires et consommables

d'autres marques, la qualité du résultat peut être

dégradée et les recours en garantie peuvent être

soumis à des restrictions. L'usure de la machine ou

votre charge personnelle peuvent augmenter selon

chaque application. Pour cette raison, protégezvous, votre machine et vos droits à la garantie en

utilisant exclusivement des accessoires Festool et

des consommables Festool d'origine !

Utilisez uniquement des plateaux de ponçage et de

polissage d'origine (de marque Festool). L'utilisation de plateaux de ponçage et de polissage de

moindre qualité peut provoquer un balourd consi-

AVERTISSEMENT

Tout travail de maintenance ou de réparation, qui

nécessite l'ouverture du moteur ou du carter

d'engrenages doit uniquement être effectué par

un centre service-client autorisé (nom fourni par

votre revendeur) !

Les travaux de maintenance ou de réparation effectués par un personnel non autorisé peuvent

conduire à la mauvaise connexion de câbles

d'alimentation ou d'autres composants, ce qui

peut entraîner à son tour des accidents avec des

conséquences graves.

AVERTISSEMENT

Pour éviter les accidents, retirez toujours la fiche

mâle de la prise d'alimentation électrique avant

d'effectuer tout travail de maintenance ou de réparation sur la machine !

N'utilisez pas d'air comprimé pour nettoyer l'outil

électrique ! N'essayez pas de nettoyer des parties

à l'intérieur de la machine de cette façon, étant

donné que des corps étrangers pourraient pénétrer dans les ouvertures du carter de la machine.

3

Page 28

28

dérable, entraînant une dégradation de la qualité

du résultat et une usure prématurée de l'outil.

Les références des accessoires et des outils figurent dans le catalogue Festool ou sur Internet

sous "www.festoolusa.com".

Systainer

De nombreux produits Festool sont fournis dans

une caisse exclusive, appelée "Systainer". Celle-ci

permet de protéger et de ranger des outils et des

appareils complémentaires. Les Systainer sont

empilables et peuvent être solidarisés. En outre, il

se fixent sur les aspirateurs CT Festool.

Pour ouvrir le Systainer

Pour fermer le Systainer

Pour connecter deux Systainers

Placez un Systainer au dessus de l'autre (Fig.

[11

A]

).

Les Systainers sont combinés.

Un Systainer de la nouvelle génération peux

être attaché au dessus d' un Systainer de l'an-

cienne génération par les quatre loquets de

l'ancien Systainer.

Environnement

Ne jetez pas l'appareil avec les ordures ménagères

!

Eliminez l'appareil, les accessoires et les embal-

lages de façon compatible avec l'environnement.

Respectez les prescriptions nationales en vigueur.

Garantie

Garantie 1 + 2

Festool offre une garantie restreinte de trois ans,

une des plus longues de l'industrie. La présente

garantie est valide à la condition préalable que l'outil soit utilisé et exploité en conformité avec les

consignes d'utilisation de Festool. Festool garantit

que l'outil spécifié sera exempt de vices de matériel

ou de malfaçon durant une période de 3 ans à

compter de la date d'achat.

Conditions de la garantie 1 + 2

Tous les clients reçoivent une extension de garantie

restreinte gratuite (1 an + 2 ans = 3 ans) pour tous

les outils électriques achetés auprès d'un détaillant agréé. Festool est responsable de tous les frais

d'expédition durant la première année de la garantie. Durant la deuxième et la troisième année de la

Tournez le T-loc

[11-1]

à cette position.

Tournez le T-loc

[11-1]

à cette position.

Tournez le T-loc

[11-1]

à une de cette

positions (Fig.

[11 B]

).

ouvrir

fermer

connecter

connecter

T-loc

Page 29

29

garantie, le client a la responsabilité d'expédier

l'outil à Festool. Festool paiera les frais d'expédition de retour au client en utilisant le service terrestre d'UPS. Tout service de garantie est valide 3

ans à compter de la date d'achat indiquée sur votre

reçu ou votre facture. La preuve d'achat peut être

exigée.

Sont exclus de la couverture au titre de la présente garantie :

usure normale, dommage causé

par un usage impropre, un usage abusif ou de la

négligence ; dommage causé par toute autre chose

qu'un vice de matériel ou de malfaçon. La présente

garantie ne s'applique pas aux articles accessoires

tels que lames de scie plongeante, forets de perceuse, forets de défonceuse, lames de scie sauteuse, bandes abrasives et meules. L'utilisation

d'un outil à une tension ou fréquence différente de

la puissance nominale de l'outil annule la garantie.

L'annulation de garantie inclut l'utilisation de l'outil avec un transformateur. Festool ne tolère ni

n'approuve aucune utilisation d'accessoires ou de

consommables d'ingénierie, de conception et de fabrication autres que Festool sur des produits Festool. Toute utilisation de produits autres que Festool peut affecter le rendement de l'outil et annuler

la garantie. Festool ne peut être tenu responsable

de tous dommages ou pertes subis, l'utilisateur assumant tous les risques et l'entière responsabilité

liés à l'utilisation de produits qui ne sont pas d'origine Festool. Sont également exclues toutes les "

pièces d'usure " telles que les balais de carbone,

les lamelles de l'outillage pneumatique, les manchons et joints de caoutchouc, les disques abrasifs

et les patins de ponçage, ainsi que les vêtements

Festool (chapeaux et t-shirts).

Les obligations de Festool aux termes de la présente garantie se limitent, à sa seule discrétion, à

la réparation ou au remplacement ou au remboursement du prix d'achat de tout outil électrique Festool portable jugé comme faisant montre d'un vice

de matériel ou de malfaçon durant la période de la

garantie. FESTOOL NE PEUT ÊTRE TENU RESPONSABLE DE QUELQUE DOMMAGE CONSÉCUTIF, ACCESSOIRE OU PARTICULIER INDÉPENDAMMENT

DU PRINCIPE DE DROIT SUR LEQUEL SE FONDE

LA DEMANDE. TOUTES LES GARANTIES IMPLICITES AUX TERMES DE LA LOI ÉTATIQUE, Y COMPRIS LES GARANTIES IMPLICITES DE QUALITÉ

MARCHANDE ET D'ADAPTATION À UN USAGE

PARTICULIER, SONT PAR LES PRÉSENTES RESTREINTES À UNE DURÉE DE TROIS ANS.

Certains états américains et certaines provinces

canadiennes ne permettent pas de restrictions

quant à la durée d'une garantie implicite, de sorte

que la restriction qui précède peut ne pas s'appliquer à vous. La présente garantie vous confère des

droits légaux spécifiques, et il se peut que vous

ayez d'autres droits variant d'un état à l'autre aux

É.-U. et d'une province à l'autre au Canada.

En dehors de toute garantie imposée par une loi

d'état ou une loi provinciale telle que restreinte cidessus, la garantie restreinte qui précède est exclusive et aux lieu et place de toute autre garantie,

engagement formel, entente et autre obligation similaire de Festool. Festool ne fait aucune autre garantie, expresse ou implicite, à propos des outils

électriques. La présente garantie est valide uniquement pour les outils achetés aux É.-U. et au Canada. Les régimes de garantie d'autres pays

peuvent varier pour les cas de service obtenus en

dehors des É.-U. et du Canada. Certains pays

peuvent exclure de la garantie les produits achetés

en dehors de leur territoire. Festool se réserve le

droit de refuser la réparation de tout outil ne faisant

pas partie de la gamme de produits des É.-U. et du

Canada. Aucun agent, représentant, distributeur,

concessionnaire ou employé de Festool n'a l'autorité d'augmenter ou d'autrement modifier les obligations ou les restrictions de la présente garantie.

Page 30

30

Tableau A : Ponçage dégrossissant Ponçage fin

Ponçage

Laque, apprêt,

mastic

x 5 - 6 Tendre x 1 - 3 Super

tendre

Laque, peinture x 5 - 6 Dur x 3 - 6 Dur

Bois, placage x 5 - 6 Dur x 3 - 6 Tendre

Plastique x x 1-4 Tendre x 1 - 4 Tendre/

super

tendre

Acier, cuivre,

aluminium

x6Tendrex3 - 6Tendre

Laques contenant des COV

x2 - 4Super

tendre -

dur

TableauB:

Polissage Polissage Bouchage des pores Polissage miroir

Laque 6 3 4 - 6

Éponge

grossière/fine

Éponge

fine/gaufrée

Peau de mouton

Pâte de polissage Cire dure -

Plastique 6 3 6

Feutre

Dur

Feutre

Tend re

Peau de mouton

Pâte de polissage Cire dure -

Page 31

31

Índice

Símbolos

Los numeros en las figuras indican

el orden en cual se debe hacer los

pasos.

Datos técnicos

Indicaciones de seguridad

Indicaciones de seguridad generales

¡ATENCIÓN! Lea íntegramente las instrucciones e indicaciones de seguridad.

El incumplimiento de dichas instrucciones e indicaciones

puede dar lugar a descargas eléctricas, incendios o

lesiones graves.

Guardar todas las advertencias de peligro e instrucciones para futuras consultas.

El término herramienta eléctrica empleado en las si-

guientes advertencias de peligro se refiere a herramientas eléctricas de conexión a la red (con cable de

red) y a herramientas eléctricas accionadas por acumulador (o sea, sin cable de red).

1 PUESTO DE TRABAJO

a.

Mantenga limpio y bien iluminado su puesto de

trabajo.

El desorden y una iluminación deficiente

en las áreas de trabajo pueden provocar accidentes.

b.

No utilice la herramienta eléctrica en un entorno

Símbolos .............................................. 31

Datos técnicos...................................... 31

Indicaciones de seguridad................... 31

Descripción de las funciónes............... 34

Uso conforme a lo previsto.................. 34

Puesta en servicio................................ 34

Ajustes ................................................. 35

Trabajo con la máquina ....................... 39

Mantenimiento y cuidado..................... 39

Accesorios............................................ 40

Medio ambiente ................................... 41

Garantía ............................................... 41

V voltios

Aamperios

Hz hertzios

~

a.c.

tensión alterna

d.c.

tensión continua

n

0

revoluciones por minuto en vacío

Clase II Construcción

rpm

min

-1

revoluciones por minuto

’’ pulgada

lb. libras

Diámetro

Indicación, consejo

Aviso ante un peligro general

Peligro de electrocución

¡Leer las instrucciones e indicaciones!

¡Utilizar gafas de protección!

¡Usar protección para los oídos!

¡Utilizar protección respiratoria!

Desconecte el enchufe

Lijadora excéntrica de

engranaje

RO90 DX FEQ

Potencia 400 W

Número de revoluciones

Movimiento excéntrico 3000 - 7000 rpm

Trazado en curva Rotex 220 - 520 rpm

Órbita 3.0 mm (0.12’’)

Plato lijador FastFix D 90 mm (3.54’’)

Peso (sin cable de red, con

plato lijador)

1.45 kg (3.20 lbs)

Clase de protección /II

...

3

Page 32

32

con peligro de explosión, en el que se encuentren

combustibles líquidos, gases o material en polvo.

Las herramientas eléctricas producen chispas que

pueden llegar a inflamar los materiales en polvo o

vapores.

c.

Mantenga alejados a los niños y otras personas

de su puesto de trabajo al emplear la herramienta eléctrica.

Una distracción le puede hacer perder

el control sobre el aparato.

2 SEGURIDAD ELÉCTRICA

a.

El enchufe del aparato debe corresponder a la

toma de corriente utilizada. No es admisible modificar el enchufe en forma alguna. No emplear

adaptadores en aparatos dotados con una toma

de tierra.

Los enchufes sin modificar adecuados a

las respectivas tomas de corriente reducen el riesgo de una descarga eléctrica.

b.

Evite que su cuerpo toque partes conectadas a

tierra como tuberías, radiadores, cocinas y refrigeradores.

El riesgo a quedar expuesto a una sacudida eléctrica es mayor si su cuerpo tiene

contacto con tierra.

c.

No exponga las herramientas eléctricas a la lluvia y evite que penetren líquidos en su interior.

Existe el peligro de recibir una descarga eléctrica si

penetran ciertos líquidos en la herramienta eléctrica.

d.

No utilice el cable de red para transportar o colgar el aparato, ni tire de él para sacar el enchufe

de la toma de corriente. Mantenga el cable de red

alejado del calor, aceite, esquinas cortantes o

piezas móviles.

Los cables de red dañados o enre-

dados pueden provocar una descarga eléctrica.

e.

Al trabajar con la herramienta eléctrica en la intemperie utilice solamente cables de prolongación homologados para su uso en exteriores.

La

utilización de un cable de prolongación adecuado

para su uso en exteriores reduce el riesgo de una

descarga eléctrica.

f.

Si fuese imprescindible utilizar la herramienta

eléctrica en un entorno húmedo, es necesario conectarla a través de un fusible diferencial.

La

aplicación de un fusible diferencial reduce el riesgo

a exponerse a una descarga eléctrica.

3 SEGURIDAD DE PERSONAS

a.

Esté atento a lo que hace y emplee la herramienta

eléctrica con prudencia. No utilice la herramienta

eléctrica si estuviese cansado, ni tampoco después de haber consumido alcohol, drogas o medicamentos.

El no estar atento durante el uso de una

herramienta eléctrica puede provocarle serias lesiones.

b.

Utilice un equipo de protección y en todo caso

unas gafas de protección.

El riesgo a lesionarse se

reduce considerablemente si, dependiendo del tipo

y la aplicación de la herramienta eléctrica empleada, se utiliza un equipo de protección adecuado

como una mascarilla antipolvo, zapatos de seguridad con suela antideslizante, casco, o protectores

auditivos.

c.

Evite una puesta en marcha fortuita del aparato.

Cerciorarse de que el aparato esté desconectado

antes conectarlo a la toma de corriente.

Si transporta el aparato sujetándolo por el interruptor de

conexión/desconexión, o si introduce el enchufe en

la toma de corriente con el aparato conectado, ello

puede dar lugar a un accidente.

d.

Retire las herramientas de ajuste o llaves fijas

antes de conectar la herramienta eléctrica.

Una

herramienta o llave colocada en una pieza rotante

puede producir lesiones al ponerse a funcionar.

e.

Sea precavido. Trabaje sobre una base firme y

mantenga el equilibrio en todo momento.

Ello le

permitirá controlar mejor la herramienta eléctrica

en caso de presentarse una situación inesperada.

f.

Utilice ropa adecuada. No utilice ropa ancha ni

objetos de joyería o bisutería. Mantenga el pelo y

la ropa alejada de las piezas en movimiento.

La

ropa suelta o el pelo largo pueden quedar atrapados por piezas en movimiento.

g.

Siempre que sea posible utilizar unos equipos de

aspiración o captación de polvo, asegúrese que

éstos estén montados y que sean utilizados correctamente.

El empleo de estos equipos reduce

los riesgos derivados del polvo.

h.

No debe jamás confiarse por el uso frecuente de

las máquinas e ignorar los principios de seguridad de la herramienta.

Un manejo imprudente

puede ocasionar lesiones graves en fracciones de

segundo.

4 TRATO Y USO CUIDADOSO DE HERRAMIENTAS

ELÉCTRICAS

a.

No sobrecargue el aparato. Use la herramienta

prevista para el trabajo a realizar.

Con la herramienta adecuada podrá trabajar mejor y más seguro dentro del margen de potencia indicado.

b.

No utilice herramientas con un interruptor defectuoso.

Las herramientas que no se puedan conectar o desconectar son peligrosas y deben hacerse

reparar.

c.

Saque el enchufe de la red antes de realizar un

ajuste en el aparato, cambiar de accesorio o al

guardar el aparato.

Esta medida preventiva reduce

el riesgo a conectar accidentalmente el aparato.

d.

Guarde las herramientas fuera del alcance de los

niños y de las personas que no estén familiariza-

Page 33

33

das con su uso.

Las herramientas utilizadas por

personas inexpertas son peligrosas.

e.

Cuide sus aparatos con esmero. Controle si funcionan correctamente, sin atascarse, las partes

móviles del aparato, y si existen partes rotas o

deterioradas que pudieran afectar al funcionamiento de la herramienta. Si la herramienta eléctrica estuviese defectuosa haga repararla antes

de volver a utilizarla.

Muchos de los accidentes se

deben a aparatos con un mantenimiento deficiente.

f.

Mantenga los útiles limpios y afilados.

Los útiles

mantenidos correctamente se dejan guiar y controlar mejor.

g.

Utilice herramientas eléctricas, accesorios, útiles, etc. de acuerdo a estas instrucciones y en la

manera indicada específicamente para este aparato. Considere en ello las condiciones de trabajo

y la tarea a realizar.

El uso de herramientas eléctricas para trabajos diferentes de aquellos para los

que han sido concebidas puede resultar peligroso.

h.

Mantenga las empuñaduras secas, limpias y libres de aceite y grasa.

Las empuñaduras resbaladizas no permiten una manipulación y un control

seguros de la herramienta eléctrica en situaciones

inesperadas.

5 SERVICIO

a.

Únicamente haga reparar su herramienta eléctrica por un profesional, empleando exclusivamente piezas de repuesto originales.

Solamente

así se mantiene la seguridad de la herramienta

eléctrica.

Indicaciones de seguridad específicas

–

Al trabajar puede generarse polvo perjudicial/tóxico (p. ej., de pintura de plomo, algunos tipos de

madera y metal).

El contacto o la inhalación de

este polvo puede suponer una amenaza para la

persona que realiza el trabajo o para aquellas que

se encuentren cerca. Observe las normativas de

seguridad vigentes en su país. Conecte la herramienta eléctrica a un equipo de aspiración apropiado.

Utilice por el bien de su salud una mascarilla

de protección respiratoria con filtro P2.

Ante el peligro que supone el lijado, lleve

siempre gafas de protección

–

Evite la entrada de agentes pulidores (pulimentos) líquidos en la herramienta.

La penetración de

agentes pulidores (pulimentos) líquidos en la herramienta eléctrica aumenta el riesgo de descarga

eléctrica.

–

Tras la caída, compruebe si se han dañado la

herramienta eléctrica y el plato lijador. Desmonte el plato lijador para realizar una comprobación exacta. Haga reparar las piezas

deterioradas antes de usar la herramienta.

El

plato lijador roto y las herramientas dañadas

pueden provocar lesiones e incertidumbre al utilizar la máquina.

Tratamiento de metales

Al trabajar con metal deberá tener presente

las siguientes medidas por motivos de seguridad:

– Preconecte un interruptor de corriente de defec-

to (FI, PRCD).

– Conecte la máquina a un equipo de aspiración

apropiado.

– Limpie regularmente el polvo que se acumula en

la carcasa del motor de la máquina.

Riesgos para la salud producidos por el

polvo

ADVERTENCIA!

Algunos polvos creados por

lijadoras motorizadas, aserraderos, trituradores, perforadoras y otras actividades de

construcción contienen sustancias químicas que se

sabe (en el Estado de California) causan cáncer, defectos de nacimiento u otros daños al sistema reproductivo. Algunos ejemplos de estas sustancias

químicas son:

• Plomo de las pinturas con base de plomo

• Sílice cristalino de los ladrillos y cemento y otros

productos de mampostería, y

• Arsénico y cromo de madera tratada con sustancias químicas

El riesgo de exposición a estas

sustancias varía, dependiendo

de cuantas veces se hace este

tipo de trabajo. Para reducir el

contacto con estas sustancias

químicas: trabaje en un área

con buena ventilación y trabaje con equipo de seguridad aprobado, como mascarillas para el polvo diseñadas específicamente para filtrar partículas

microscópicas.

¡Utilizar gafas de protección!

Page 34

34

Descripción de las funciónes

Las imágenes con la dotación de suministro se encuentran en una hoja desplegable al comienzo de

este manual de instrucciones. Cuando lea este manual, le recomendamos que despliegue esta página

para disponer fácilmente de una vista general de la

máquina.

* no para todas las variantes de la dotación de suministro

Uso conforme a lo previsto

Conforme a las especificaciones, la máquina está

prevista para lijar y pulir plástico, metal, madera,

materiales compuestos, pintura/barniz, emplaste y

materiales similares. La máquina no debe emplearse para el tratamiento de materiales que contengan amianto.

Por motivos de seguridad eléctrica, la máquina no

debe mojarse ni utilizarse en entornos húmedos.

La máquina sólo puede utilizarse para el lijado en

seco.

Puesta en servicio

Tenga en cuenta las imágenes al principio del manual.

ADVERTENCIA

PARA REDUCIR EL RIESGO DE LESIÓN, EL USUARIO DEBE LEER EL MANUAL DE INSTRUCCIÓN.

[1-1]

Protector

[1-2]

Conmutador/bloqueo del husillo

[1-3]

Interruptor de conexión y desconexión

[1-4]

Cable de conexión a la red

[1-5]

Racor de aspiración

[1-6]

Regulación del número de revoluciones

[1-7]

Plato lijador

[1-8]

Barra de detención

[1-9]

Plato pulidor*

[1-10]

Zapata delta

[1-11]

Zapata de lamas*

[1-12]

Interface-Pad*

ADVERTENCIA

El usuario responde de los daños y accidentes

que puedan derivarse de un uso no conforme a lo

previsto.

ADVERTENCIA

Tensión o frecuencia no permitida

Peligro de caída

La tensión de red y la frecuencia de la red eléctrica deben coincidir con los datos que figuran en la

placa de tipo.

En Norteamérica sólo las máquinas Festool pueden utilizarse con una tensión de 120 V/60 Hz.

ADVERTENCIA

Peligro de lesiones y electrocución

Desconectar el enchufe de la toma de corriente

antes de realizar cualquier trabajo en la máquina.

Page 35

35

Ver la figura

[2]

para enchufar y desenchufar el ca-

ble de conexión

[1-4]

a la red.

El interruptor

[1-3]

sirve como interruptor de conexión y desconexión (I = CONECTADO, 0 = DESCONECTADO).

El interruptor de conexión sólo se puede pulsar

cuando el conmutador

[1-2]

está enclavado.

En caso de corte de corriente o al retirar el enchufe, colocar el interruptor de conexión y desconexión inmediatamente en la posición de desconexión. Esto impide que la máquina se vuelva

a conectar de forma incontrolada.

Alargador