Page 1

Festool GmbH

Seen at Ideal Tools.

Wertstraße 20

D-73240 Wendlingen

Tel.: 07024/804-0

Fax: 07024/804-608

http://www.festool.com

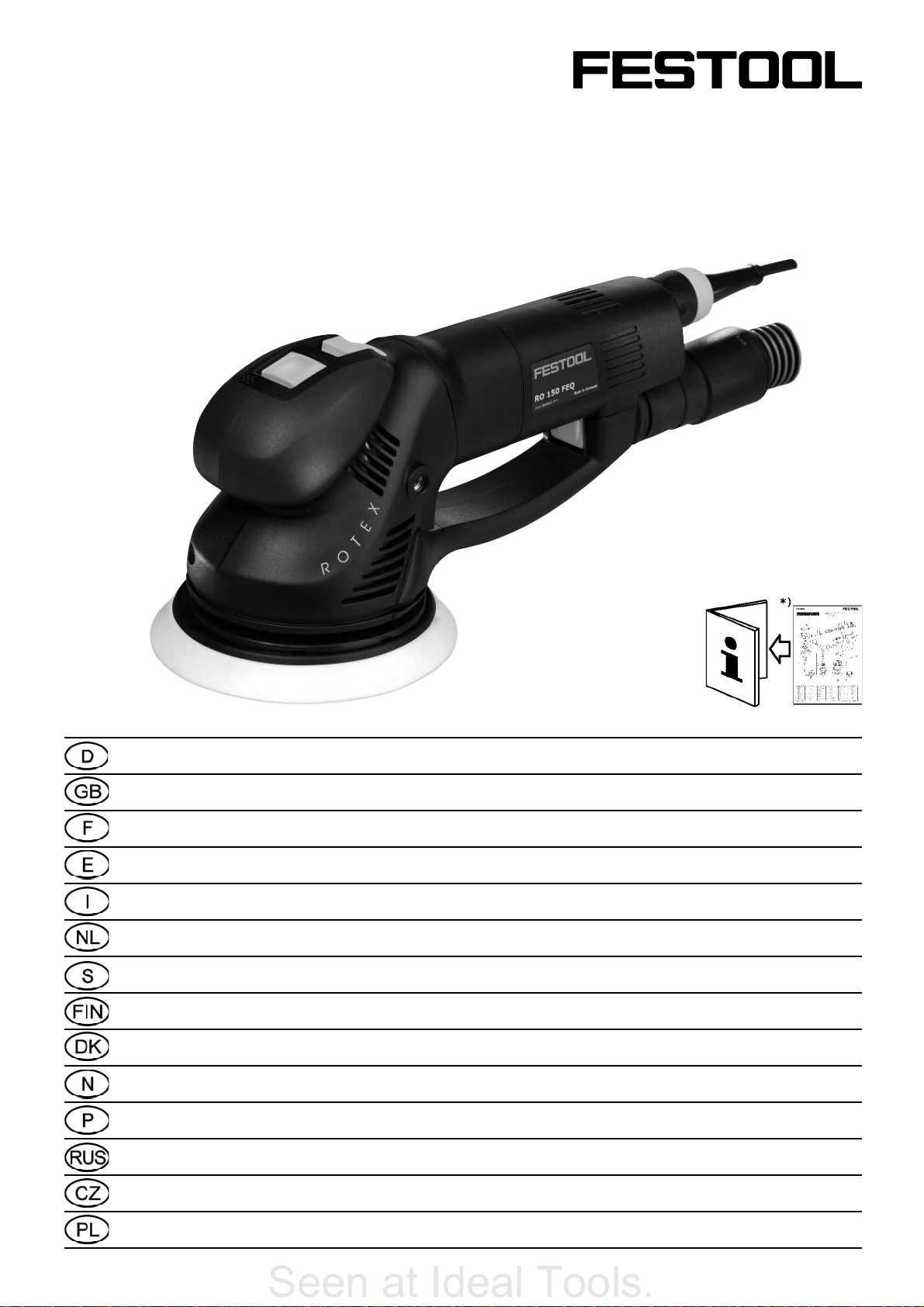

Rotex

RO 150 FEQ

Bedienungsanleitung/Ersatzteilliste*) 4 - 7

Operating Instructions/Spare parts list*) 8 - 10

Mode d’emploi/Liste de pièces de rechange*) 11 - 14

Instrucciones de servicio/Lista de piezas de repuesto*) 15 - 18

Istruzioni d’uso/Elenco parti di ricambio*) 19 - 21

Gebruiksaanwijzing/Lijst met reserveonderdelen*) 22 - 24

Bruksanvisning/Reservdelslista*) 25 - 27

Käyttöohje/Varaosaluettelo*) 28 - 30

Driftsvejledning/Reservedelsliste*) 31 - 33

Bruksanvisning/Reservedelsliste*) 34 - 36

Instruções de uso/Lista de peças sobresselentes*) 37 - 39

Руководство по эксплуатации/Перечень запасных частей*) 40 - 43

Návod k obsluze/Seznam náhradních dílù*) 44 - 46

468 064_001

Instrukcja obs³ug/Lista czêœci zamiennych*) 47 - 49

Page 2

Seen at Ideal Tools.

Page 3

Seen at Ideal Tools.

Page 4

Technical data RO 150 FEQ

Seen at Ideal Tools.

Power 720 W

Speed 3300 - 6800 rpm

Sanding stroke 5 mm

Weight (excluding cable) 2.3 kg

Degree of protection

The specifi ed illustrations can be found at the

beginning of the operating instructions.

1 Intended use

As specifi ed, the machines are designed for

sanding and polishing wood, plastic, metal,

stone, composite materials, paint/varnish, fi ller

and similar materials.

Materials containing asbestos must not be

processed.

For reasons of electrical safety the machine

must not be damp nor operated in a humid

environment. The machine may only be used

for dry sanding.

The user is liable for damage and injury

resulting from incorrect usage!

2 Before starting up, please observe

the following

2.1 Safety instructions

Before using the machine, read the

enclosed safety instructions and these

operating instructions carefully and

thoroughly.

Save all enclosed documents and pass the machine with all these documents only.

- Harmful/toxic dusts can occur during your

work (e.g. lead-containing paint, some types

of wood and metal). Contact with these dusts,

especially inhaling them, can represent a

hazard for operating personnel or persons in

the vicinity. Comply with the safety regulations that apply in your country. Connect the

electric power tool to a suitable extraction

system.

To protect your health, wear a P2 pro-

tective mask.

Always wear protective goggles because

of possible dangers when sanding.

- The manufacturer’s handling and processing

instructions must be observed without fail if

explosive or self-igniting dusts are likely to

occur during sanding.

2.2 Noise and vibration information

The typical values determined in accordance

with EN 60745 are:

Measured acceleration 5 m/s²

Sound pressure level 82 dB(A)

Sound-power level 93 dB(A)

Measuring uncertainty allowance K = 4 dB

Wear ear protection!

/ II

3 Power supply and start-up

The mains voltage must correspond to

the specifi cation on the rating plate.

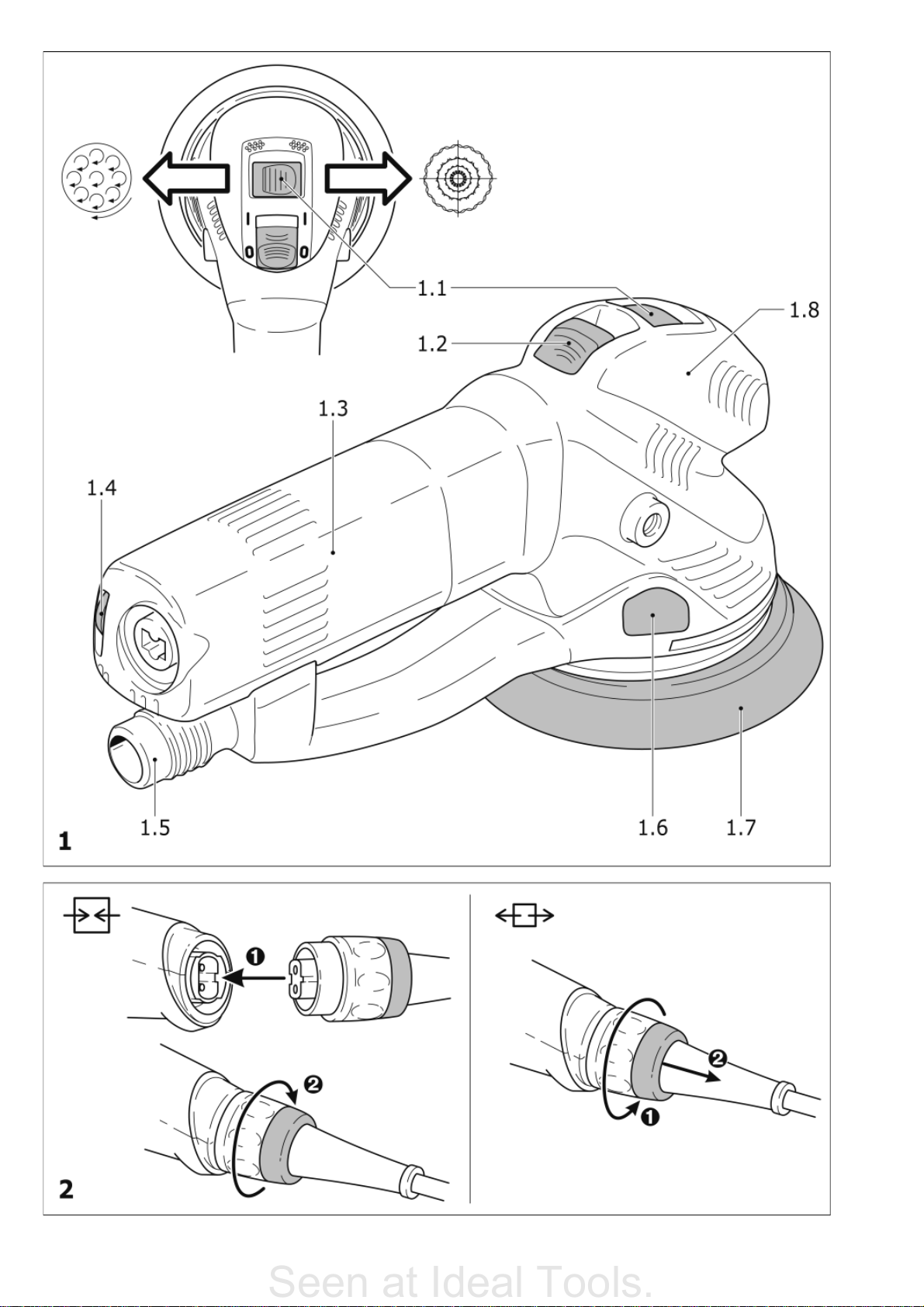

To switch on the machine, press the switch

(1.2) downwards and forwards until it locks into

place. To switch off, press the switch downwards

- this releases the switch locking and it goes

into the OFF position.

See Fig. 2 for connection and disconnection of

the power cable.

Always switch the machine off before

connecting or disconnecting the mains

lead!

4 Electronics

The machine has full-wave electronics

with the following features:

Smooth start-up

The smooth start-up ensures the machine starts

up jolt-free.

Speed adjustment

You can regulate the speed steplessly between

3300 and 6800 rpm using the adjusting wheel

(1.4). This enables you to optimise the cutting

speed to suit the material.

Constant speed

The pre-selected speed remains constant whether the machine is in operation or in neutral

position.

Temperature control

If the motor temperature becomes too high, the

power supply and speed are reduced. The tool

then only runs with reduced power to enable

rapid cooling by means of the motor ventilation.

After cooling down, the tool accelerates again

automatically.

5 Machine settings

Always remove the power supply plug

from the socket before carrying out any

work on the machine.

5.1 Sanding motion

You can use the switch (1.1) to set two different

sanding motions.

The change can only be made when the

sanding pad is stationary, as the switch

is locked in place during operation for

reasons of safety.

Rotex rotary motion (coarse sanding, polishing)

The Rotex rotary motion is a combina-

tion of rotary and eccentric motions.

This position is selected for sanding

with high output (coarse sanding) and

polishing.

Slide the switch (1.1) into the right position.

8

Page 5

Eccentric motion (fi ne sanding)

Seen at Ideal Tools.

This position is selected for sanding with

low output for a scratch-free surface

(fi ne sanding).

Press the switch (1.1) downwards and push it

into the left-hand position.

5.2 Sanding pad brake

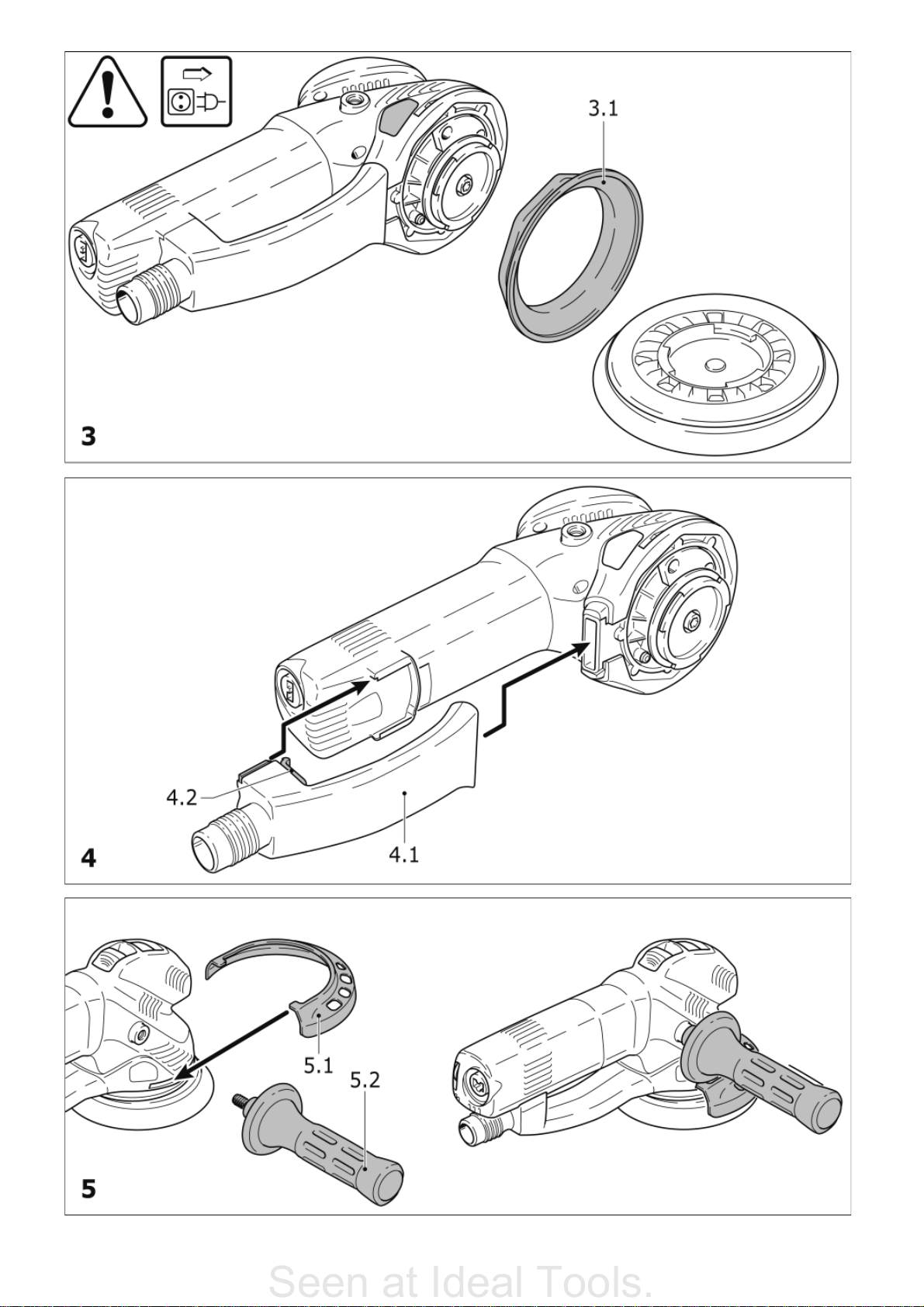

The rubber collar (3.1) prevents the sanding

pad from revving up to maximum speed in an

uncontrolled manner during eccentric motion

(fi ne sanding). Because the collar wears down

in the course of time, it has to be replaced by a

new one (order no. 465 472) as soon as there

is any reduction in the braking effect.

5.3 Choice and installation of the san-

ding disks

Choise of sanding disk

The appliance can be fi tted with three sanding

disks of different hardness depending on the

surface to be treated.

Hard: coarse sanding on surfaces, sanding at

edges.

Soft: universal for coarse and fi ne sanding for

fl at and curved surfaces.

Super-soft: fi ne sanding on formed parts,

curves, radii. Do not use on edges!

Assembly

The FastFix system enables tool-free replacement of the sanding pad:

- Set the switch (1.1) to the right, to the Rotex

rotary motion

- Press spindle stop (1.6), direction of move-

ment (3.2) fi rst to the side, then forwards

- Turn the fi tted sanding pad from the spindle

(right-handed thread)

- Keep the spindle stop pressed and screw

on the new sanding pad (in doing so, make

sure that the rubber collar (3.1) is correctly

fi tted!)

- let go of the spindle stop

Actuate the spindle stop only when the drive

spindle is stationary. Do not switch on the motor

when the spindle stop is pressed in.

5.4 Attaching sanding material

The appropriate Stickfi x sanding paper and

Stickfi x sanding felt can be fastened quickly and

easily onto the Stickfi x sanding base.

The self-adhesive sanding material is simply

pressed onto the sanding base (1.7) and held

safely in place by the Stickfi x sanding base velcro surface. After use, the StickFix sandpaper

is simply pulled off.

5.6 Dust extraction

Always connect the machine to a dust

extractor.

You can connect a Festool extractor with an extractor hose diameter of 27 mm to the extractor

connector (1.5). The extraction adapter (4.1)

can be removed if necessary. To do this, press

the locking button (4.2), draw the extraction

adapter backwards and pull off. To reattach the

extraction adapter, insert it as shown in Fig. 4

and slide it towards the sanding pad until the

locking button (4.2) latches into place.

5.7 Edge protector

The edge protector (5.1) prevents the sanding

pad from touching the edge perpendicular to a

surface (e.g. when sanding along a wall), thereby preventing the machine from rebounding.

Assembly

Slide the edge protector onto the machine until

it latches into place (see Fig. 5).

5.8 Auxiliary handle

The auxiliary handle (Accessories, 5.2) can

be screwed onto either the right or left of the

gear head.

6 Working with the machine

Always secure the workpiece in such a

manner that it cannot move while being

sawed.

For safe guidance, hold the machine with both

hands on the motor housing (1.3) and on the

gear head (1.8) and/or the auxiliary handle

(Accessories, 5.2).

Never overload the tool by using too much

pressure! The best sanding results are achieved

when applying moderate pressure. The sanding

performance and quality depend mainly on the

choice of the right sanding material.

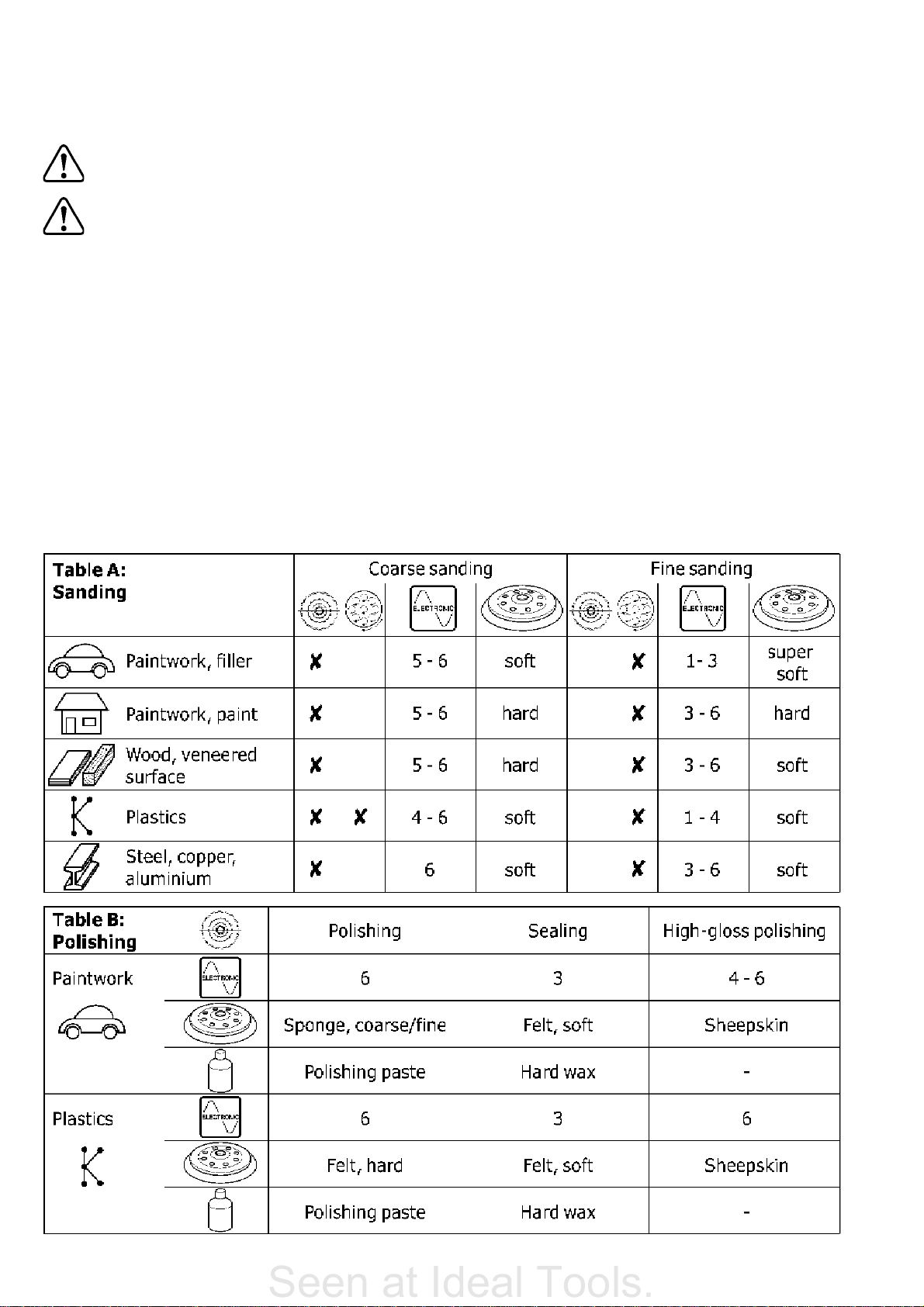

Tables A and B show the settings we recommend

for different sanding and polishing work.

6.1 Metalworking

The following precautions are to be ta-

ken when processing metals for safety

reasons:

- Pre-connect a residual current circuit-breaker

(FI, PRCD).

- Connect the machine to a suitable dust ex-

tractor.

- Clean tool regularly of dust accumulations in

the motor housing.

- Wear protective goggles.

5.5 Securing polishing attachments

To prevent damage, PoliStick polishing attachments (sponges, felt, lambswool bonnets) may

only be used on the special polishing pad that

is fi tted on the machine instead of a sanding

pad. In the same way as the StickFix abrasives,

the PoliStick polishing attachments are simply

pressed onto the polishing pad and pulled off

after use.

7 Accessories, tools

For your own safety, use only original

Festool accessories and spare parts.

Festool offers the appropriate accessories,

sanding and polishing attachments for every

application.

9

Page 6

The accessory and tool order number can be

Seen at Ideal Tools.

found in the Festool catalogue or on the Internet

under ”www.festool.com”.

8 Maintenance and care

Always remove the power supply plug

from the socket before carrying out any

work on the machine.

All maintenance and repair work which

requires the motor casing to be opened

may only be carried out by an authori-

sed service centre.

The cool air openings in the motor casing must

always be kept clean and unobstructed to ensure air circulation. The tool is fi tted with special

motor brushes with an automatic cut-out. When

the brushes become worn the power supply is

shut off automatically and the tool comes to a

standstill.

9 Warranty

Our equipment is under warranty for at least 12

months with regard to material or production

faults in accordance with national legislation.

In the EU countries, the warranty period is 24

months (an invoice or delivery note is required

as proof of purchase).

Damage resulting from, in particular, normal

wear and tear, o-verloading, improper handling,

or caused by the user or other damage caused

by not following the operating instructions, or

any fault acknowledged at the time of purchase,

is not covered by the warranty. Complaints will

only be acknowledged if the equipment has not

been dismantled before being sent back to the

suppliers or to an authorised Festool customer

support workshop.

Store the operating instructions, safety notes,

spare parts list and proof of purchase in a safe

place. In addition, the manufacturer’s current

warranty conditions apply.

Note

We reserve the right to make changes to the

technical data contained in this information as

a result of ongoing research and development

work.

10

Page 7

EG-Konformitätserklärung. Wir erklären in alleini-

Seen at Ideal Tools.

ger Verantwortung, dass dieses Produkt mit den

folgenden Normen oder normativen Dokumenten

übereinstimmt:

EN 60 745, EN 55 014, EN 61 000 gemäß den Bestimmungen

der Richtlinien 98/37/EG, 89/336/EWG.

CE-Konformitetserklæring. Vi erklærer på eget ansvar at dette produktet er i overensstemmelse med

følgende normer eller normative dokumenter: EN

60 745, EN 55 014, EN 61 000 i henhold til bestemmelsene

i direktivene 98/37/EF, 89/336/EØF.

EC-Declaration of Conformity: We declare at our

sole responsibility that this product is in conformity

with the following standards or standardised docu-

ments:

EN 60 745, EN 55 014, EN 61 000 in accordance with the

regulations 98/37/EC, 89/336/EEC.

CE-Déclaration de conformité communautaire. Nous

déclarons sous notre propre responsabilité que ce

produit est conforme aux normes ou documents de

normalisation suivants: EN 60 745, EN 55 014, EN 61 000

conformément aux prescriptions des directives 98/37/CE,

89/336/CEE.

CE-Declaración de conformidad. Declaramos bajo

nuestra exclusiva responsabilidad que este producto

corresponde a las siguientes normas o documentos

normalizados: EN 60 745, EN 55 014, EN 61 000 conforme

a las prescripciones estipuladas en las directrices 98/37/CE,

89/336/CEE.

CE-Dichiarazione di conformità. Dichiariamo sotto la

nostra esclusiva responsabilità che il presente pro-

dotto è conforme alle norme e ai documenti normativi seguenti: EN 60 745, EN 55 014, EN 61 000 conformemente

alle normative delle direttive 98/37/CE, 89/336/CEE.

CE-Declaração de conformidade: Declaramos, sob

a nossa exclusiva responsabilidade, que este produto corresponde às normas ou aos documentos

normativos citados a seguir:

EN 60 745, EN 55 014, EN 61 000 segundo as disposições

das directivas 98/37/CE, 89/336/CEE.

Заявление о конформности СЕ. Мы заявляем

в единоличной ответственности, что данное

изделие соответствует требованиям следующих

стандартов или нормативов: EN 60 745, EN 55 014, EN 61

000 в соответствии с постановлениями директив ЕС 98/37,

ЕЭС 89/336.

Prohlášení o souladu s normami CE. Prohlašujeme na

vlastní zodpovìdnost, že tento výrobek odpovídá nás-

ledujícím normám nebo normativním dokumentùm:

EN 60 745, EN 55 014, EN 61 000 v souladu s ustanoveními

smìrnic 98/37/EHS, 89/336/EHS.

Oœwiadczenie o zgodnoœci CE. Niniejszym oœwi-

adczamy z ca³¹ odpowiedzialnoœci¹, ¿e wyrób

ten odpowiada nastêpuj¹cym normom wzglêdnie

dokumentom normatywnym: EN 60 745, EN 55 014, EN

61 000 zgodnie z postanowieniami wytycznych 98/37/EG,

89/336/EWG.

EG-conformiteitsverklaring. Wij verklaren op eigen

verantwoordelijkheid dat dit produkt voldoet aan de

volgende normen of normatieve documenten. EN 60

745, EN 55 014, EN 61 000 conform de richtlijnen 98/37/EG,

89/336/EEG.

EG-konformitetsförklaring. Vi förklarar i eget ansvar,

att denna produkt stämmer överens med följande nor-

mer och normativa dokument: EN 60 745, EN 55 014,

EN 61 000 enligt bestämmelserna i direktiven 98/37/EG,

89/336/EEG.

EY-standardinmukaisuusvakuutus. Vakuutamme yk-

sinvastuullisina, että tuote on seuraavien standardien

ja normatiivisten ohjeiden mukainen: EN 60 745,

EN 55 014, EN 61 000 direktiivien 98/37/EY, 89/336/EY

määräysten mukaan.

EF-konformitetserklæring: Vi erklærer at have alene

ansvaret for, at dette produkt er i overensstem-

melse med de følgende normer eller normative

dokumenter:

EN 60 745, EN 55 014, EN 61 000 i henhold til bestemmelserne af direktiverne 98/37/EF, 89/336/EØF.

Leiter Forschung und Entwicklung

Manager Research and Development

Directeur de recherce et développement

Festool GmbH

Wertstr. 20

D-73240 Wendlingen

Dr. Johannes Steimel

455 789/II/200405

Loading...

Loading...