Festool ROTEX SERIES, RO 90 DX FEQ Plus, RO 125 FEQ Plus, RO 150 FEQ Plus Supplemental User's Manual

Page 1

Rotex Series

Dual Mode Sanders

RO 90 DX FEQ Plus, RO 125 FEQ Plus, RO 150 FEQ Plus

Supplemental User’s Manual

WARNING To reduce the risk of serious injury, read and understand all safety

precautions and instructions in this manual before using this tool.

Page 2

Limited Warranty

1

30 Day Money Back Guarantee

Buy with condence. If you are not completely satised, return

your tool2 to the selling dealer within 30 days and you will

receive a refund of either your purchase price or the lowest

retail price at which the same item has been offered since your

date of purchase. Freight charges are not refundable.

Service All-Inclusive® Warranty

Festool USA warrants that all new Festool power tools� purchased from authorized dealers in the U.S. and Canada will be

free from defects in materials and workmanship for a term of

three years from the date of original retail purchase.

Conditions of Service All-Inclusive Warranty

This warranty applies for three years from the date of original

retail purchase. Proof of purchase is required. This warranty is

void if the tool is not used, operated, repaired and maintained

in accordance with the tool’s instruction manual.

Excluded from this warranty’s coverage are:

► Accessories and/or attachments, including, but not limited to,

saw blades, drill bits, router bits, sanding discs and apparel

► Tools purchased from outside of the U.S. or Canada

► Repairs or replacements not performed by an authorized

Festool Service Center, outside of routine maintenance as set

forth in the instruction manual

► Parts or components not supplied by Festool or that have

been modied

► Damage caused by misuse, abuse, accident, impact, abnor-

mal wear and tear, improper storage and/or exposure to the

elements, or neglect

► Damage caused by anything other than defects in materials

and workmanship

► Normal adjustments and recommended maintenance as set

forth in the tool’s instruction manual

► Damage from the operation of the tool at a voltage or fre-

quency different from the tool’s rating, including the use of

transformers

1 The following is an exemplar Festool limited warranty. The actual warranty that comes

with your power tool is controlling.

2 Tool must be returned in complete and whole condition as supplied to include Systainer,

cutter, blade, power cord, etc.

3 For purposes of this warranty, power tools are dened as any Festool branded product

that bears a serial number (S.Nr. or M.Nr.).

4 To determine if your application is excluded from the warranty under this condition,

please contact the Festool Service Center at 800.554.8741

Repairs

If your Festool power tool requires repair, whether it be

warranty or non-warranty, you must contact our Service

► Damage resulting from the use of any non-Festool accessories

or attachments

► Tools used in high volume industrial applications⁴

Should any failure covered by this Limited Warranty occur, the

purchaser must contact Festool through our website, www.

festoolusa.com/SAI, or call 888.337.8600 for authorization and

shipping information. For purchases made in Canada, contact

our website, www.festoolcanada.com/SAI or call 613.363.0169.

Festool, in its sole discretion, may elect to repair, replace or

refund the purchase price of any tool covered by this Limited

Warranty that is found to be defective, at no cost to the purchaser. Warranty returns will be processed by Festool according

to normal work ow and availability of replacement parts and

components. Festool will issue a prepaid shipping label for

return of the tool to the Festool Service Center and will also

return the repaired tool freight prepaid, if the repair or replacement is covered under this Limited Warranty.

FESTOOL SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL,

INCIDENTAL OR SPECIAL DAMAGES REGARDLESS OF THE

THEORY OF LAW ON WHICH THE CLAIM IS BASED. ALL

WARRANTIES IMPLIED BY STATE LAW, INCLUDING THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE HEREBY LIMITED TO THE

DURATION OF THREE YEARS.

SOME STATES IN THE U.S. AND SOME CANADIAN PROVINCES

DO NOT ALLOW EXCLUSIONS/LIMITATIONS OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES AND/OR LIMITATIONS ON

HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE

OTHER RIGHTS THAT VARY FROM STATE TO STATE IN THE U.S.

AND FROM PROVINCE TO PROVINCE IN CANADA.

With the exception of any warranties implied by state or

province law as limited above, the foregoing limited warranty is

exclusive and in lieu of all other warranties, guarantees, agreements, and similar obligations of Festool. No agent, representative, distributor, dealer, or employee of Festool has the authority

to increase or otherwise modify the obligations or limitations of

this warranty.

Warrantor:

Festool USA Phone: USA—888.337.8600

Festool Canada Canada—613.363.0169

400 N Enterprise Dr. festoolusa.com/SAI

Lebanon, IN 46052 festoolcanada.com/SAI

Department at 888-337-8600 (613-363-0169 Canada) for

authorization and address details.

Liability Statement

This product has been built to the high standards of Festool.

Please do not attempt to operate or repair this equipment without adequate training. Any use, operation, or repair in contravention of this document is at your own risk. By acceptance of

this system you hereby assume all liability consequent to your

use or misuse of this equipment. Festool assumes no liability

for incidental, special, or consequential damage of any kind.

Equipment specications, applications, and options are subject

to change at the sole discretion of Festool without notice.

Proprietary Notice

All drawings and information herein are the property of Festool,

TTS Tooltechnic Systems AG & Co. KG. All unauthorized use and

reproduction is prohibited.

Written and Illustrated by Rick Christopherson.

© 2014 TTS Tooltechnic Systems AG & Co. KG

Festool USA is a division of Tooltechnic Systems, LLC.

2 Rotex Series Dual Mode Sanders

Festool is a trademark and service mark of TTS Tooltechnic

Systems AG & Co. KG

Plug-It and Systainer are registered trademarks of TTS

Tooltechnic Systems AG & Co. KG

www.festoolusa.com

Page 3

Contents

About This Manual ........................................... 3

Tool Symbols ................................................... 3

General Power Tool Safety Warnings .............. 4

Work Area Safety ..........................................4

Electrical Safety ............................................ 4

Personal Safety ............................................. 4

Power Tool Use and Care ................................ 4

Service ........................................................ 5

Specic Safety Rules for Sanders ....................... 5

Respiratory Exposure Safety Warnings ................ 5

Sander Overview ............................................. 5

Intended Use ................................................... 5

Technical Specications ..................................... 5

Functional Description ...................................... 6

Sanding Action/Mode ........................................ 7

Dual-Action ................................................... 7

Gear Driven (Rotex) Mode .............................. 7

Random Orbit ............................................... 7

Optimizing Random Orbit ................................ 7

Anatomy of Sandpaper ..................................... 8

Choosing the Appropriate Grit ......................... 9

Best Sandpaper for the Task ........................... 9

Setup ............................................................. 10

Changing Sanding Pads ................................... 10

Choosing the Correct Sanding Pad ................. 10

Changing Delta (RO90) Sanding Pads ............... 11

Changing Sandpaper ...................................... 12

Connecting a Dust Extractor ............................ 12

Connecting the Plug-It Power Cord ................... 12

Setting the Variable Speed .............................. 12

Installing the Sanding Bumper ......................... 13

Setting the Sanding Mode ............................... 13

Turning on the Sander .................................... 13

Operation ...................................................... 14

Using Dust Extraction ..................................... 14

Choosing Hand Positions ................................. 15

Working With Sanding Grits ............................. 15

Sanding Techniques ........................................ 16

Establishing Optimal Sanding Pressure ........... 16

Sanding Pattern and Movement ..................... 16

Maintenance and Adjustment ........................ 18

Routine Maintenance ...................................... 18

Motor Brush Replacement ............................... 18

RO 90 Motor Brushes ................................... 18

RO 125 Motor Brushes ................................. 19

RO 150 Motor Brushes ................................. 20

Troubleshooting ............................................. 21

About This Manual

Save These Instructions

It is important for you to read and understand this manual. The information it contains relates to protecting YOUR SAFETY

and PREVENTING PROBLEMS. The symbols below are used to help you recognize this information.

WARNING! Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION! Indicates a potentially hazardous situation which, if

not avoided, could result in minor or moderate injury.

NOTICE: Indicates a potential situation which, if not avoided,

can result in property damage or damage to the tool.

Note: Indicates information, notes, or tips for improving your

success using the tool.

Tool Symbols

V Volts

W Watts

Hz Hertz

~ Alternating Current (AC)

n

No-load Speed

o

Class II Double Insulated

Supplemental Owner’s Manual 3

Page 4

General Power Tool Safety Warnings

WARNING! Read all safety warnings and

instructions. Failure to follow the warnings and

instructions may result in electric shock, re, and/or

serious injury.

Work Area Safety

► Keep your work area clean and well lit. Cluttered or dark work

areas invite accidents.

► Do not operate power tools in explosive atmospheres, such

as in the presence of ammable liquids, gases, or dust. Power

Electrical Safety

► Power tool plugs must match the outlet. Never modify the

plug in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodied plugs and matching

outlets will reduce risk of electric shock.

► Avoid body contact with earthed or grounded surfaces such

as pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shock if your body is earthed or

grounded.

► Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

► Do not abuse the cord. Never use the cord for carrying, pull-

ing, or unplugging the power tool. Keep cord away from heat,

oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

► When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord for outdoor use

reduces the risk of electric shock.

Save all warnings and instructions

for future reference.

tools create sparks which may ignite the dust or fumes.

► Keep children and bystanders away while operating a power

tool. Distractions can cause you to lose control.

► If operating a power tool in a damp location is unavoidable,

use a ground fault circuit interrupter (GFCI) protected supply.

Use of a GFCI reduces the risk of electric shock.

► Never use an extension cord that is damaged, including cuts,

exposed wires, or bent/missing prongs. Damaged extension

cords increase the risk of re or electric shock.

► Use only extension cords rated for the purpose.

► Use only extension cords rated for the amperage of this tool

and the length of the cord. Using too small of an extension

cord can cause the cord to overheat.

Extension Cord Ratings

Cord Length Size (AWG)

<50 Ft. 14

50-100 Ft. 12

>100 Ft. Not recommended

Personal Safety

► Stay alert, watch what you are doing, and use common sense

when operating a power tool. Do not use a power tool while

tired or under the inuence of drugs, alcohol, or medication.

A moment of inattention while operating power tools may

result in serious personal injury.

► Use personal protective equipment. Always wear eye pro-

tection. Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

► Prevent unintentional starting. Ensure the switch is in the

off-position before connecting to power source, picking up,

or carrying the tool. Carrying power tools with your nger on

the switch or energizing power tools that have the switch on

invites accidents.

► Remove adjusting key or wrench before turning the power

tool on. A wrench or a key that is left attached to a rotating

part of the tool may result in personal injury.

► Do not overreach. Keep proper footing and balance at all

times. This enables better control of the tool in unexpected

situations.

► Dress properly. Do not wear loose clothing or jewelry. Keep

your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry, or long hair can be caught in moving parts.

► If devices are provided for the connection of dust extrac-

tion and collection facilities, ensure these are connected and

properly used. Use of dust collection can reduce dust-related

hazards.

► Always wear safety glasses complying with ANSI Z87.1.

Ordinary glasses are not proper protection.

Power Tool Use and Care

► Do not force the power tool. Use the correct power tool for

your application. The correct power tool will do the job better

and safer at the rate for which it is designed.

► Do not use the power tool if the switch does not turn it on

and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

► Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the tool.

Such preventive safety measures reduce the risk of starting

the tool accidentally.

► Store idle tools out of reach of children and do not allow

persons unfamiliar with the power tool or these instructions

4 Rotex Series Dual Mode Sanders

to operate the power tool. Power tools are dangerous in the

hands of untrained users.

► Maintain power tools. Check for misalignment or binding of

moving parts, breakage of parts and any other condition that

may affect the power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

► Keep cutting tools sharp and clean. Properly maintained tools

with sharp cutting edges are less likely to bind and are easier

to control.

► Use the power tool, accessories, and tool bits etc. in accor-

dance with these instructions, taking into account the working

Page 5

conditions and the work to be performed. Use of the power

tool for operations different from those intended could result

in a hazardous situation.

Service

► Have your power tool serviced by a qualied repair person

using only identical replacement parts. This will ensure that

Specic Safety Rules for Sanders

► Know the material you are sanding and take precautions

accordingly. Some materials contain chemicals, elements,

or bers which may be toxic or harmful when abraded. Take

caution to prevent dust or vapor inhalation and skin contact.

► Always perform sanding in a well ventilated area and use

personal respiratory protection.

► Do not use in wet environments. Ingestion of water into the

motor may result in electrocution hazard.

Respiratory Exposure Safety Warnings

Substantial or repeated inhalation of dust and other airborne

contaminants, in particular those with a smaller particle size,

may cause respiratory or other illnesses. Various dusts created

by power sanding, sawing, grinding, drilling and other construction activities contain chemicals or substances known (to the

State of California and others) to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals/

substances are: lead from lead-based paints; crystalline silica

from bricks, cement, and other masonry products; arsenic and

chromium from chemically-treated lumber; and some wood

► To reduce the risk of serious injury, never alter or misuse the

power tool.

the safety of the power tool is maintained.

► Do not use the sander if the sanding pad fails to retain the

sanding disk. Replace the sanding pad. A loose sanding disk

can come free and cause personal injury.

► Take care when disposing of ne sanding dust. Fine particle

dust may become explosive. Do not throw sanding dust on an

open ame.

► Never sand materials containing asbestos.

dusts, especially from hardwoods, but also from some softwoods such as Western Red Cedar.

The risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area and use a properly

functioning dust extraction system. When the inhalation of

dust cannot be substantially controlled, i.e., kept at or near the

ambient (background) level, the operator and any bystanders

should wear a respirator approved by NIOSH for the type of

dust encountered.

Sander Overview

Intended Use

The Rotex sanders are designed for dry sanding and polishing of wood, plastic, metal, composite materials, paint/

varnish, ller, and similar materials.

The sander must not be used when wet or damp, or operated in a damp environment for electrical safety reasons.

Use this sander only for dry sanding. The tool should not

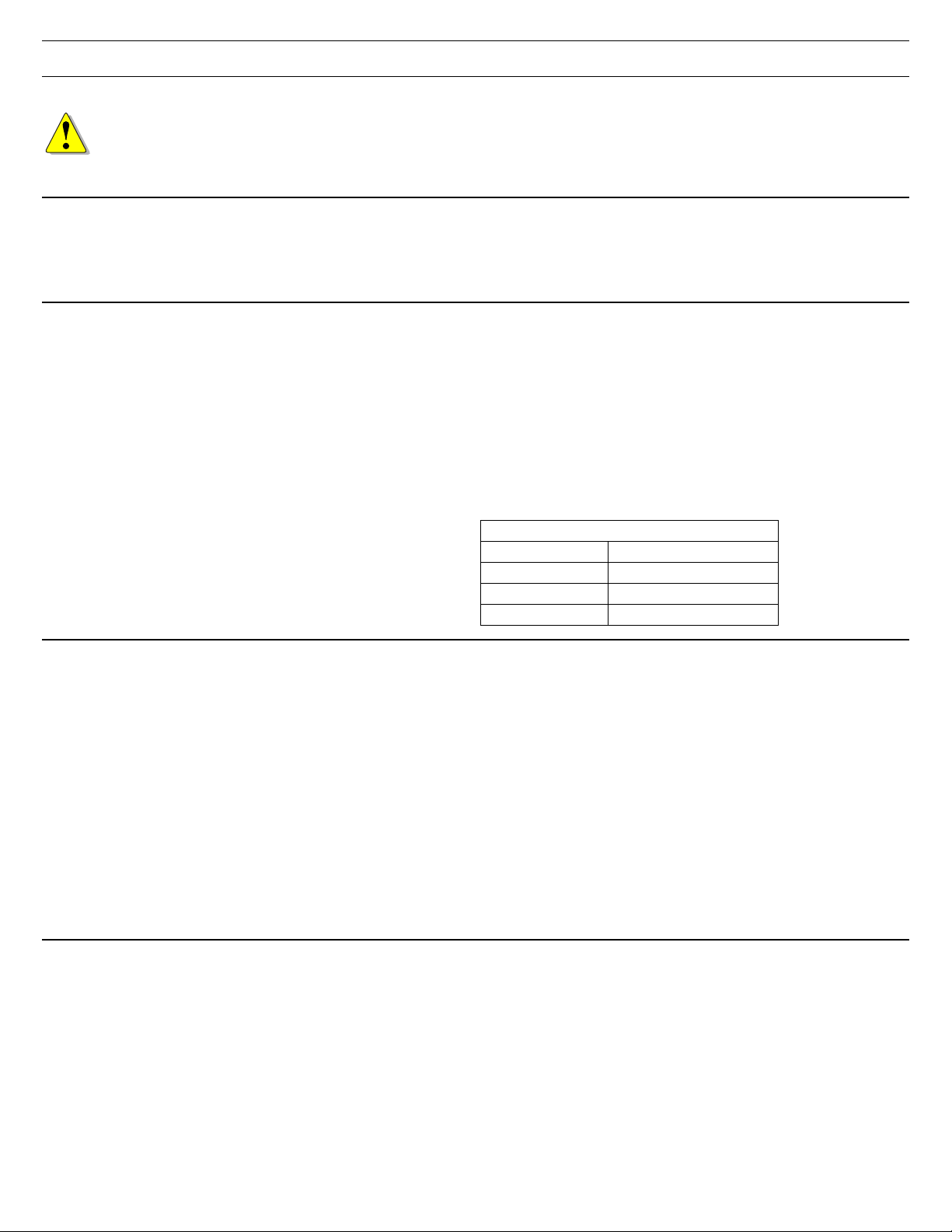

Technical Specications

RO 90 DX FEQ RO 125 FEQ RO 150 FEQ

Power Consumption 400 W 500 W 720 W

Orbital Speed 3000-7000 rpm 3000-6000 rpm 3300-6800 rpm

Rotational Speed (Rotex Mode) 260-520 spm 300-600 spm 320-660 spm

Orbital Stroke 3 mm 3.6 mm 5 mm

Sanding Pad Diameter 90 mm 125 mm 150 mm

Dust Extraction Port Size 27 mm 27 mm 27 mm

Weight 1.5 kg / 3.3 lbs 1.9 kg / 4.2 lbs 2.3 kg / 5.1 lbs

be altered or used for any other purpose, other than as

specied in these operating instructions. Using the tool in

contravention to this manual will void your warranty and

may lead to injury. The user shall be responsible and liable

for damages and accidents resulting from misuse or abuse

of this sander.

These specications are subject to change without notice.

Supplemental Owner’s Manual 5

Page 6

Functional Description

F

J

B

A

H

RO 90 DX FEQ

I

D

C

F

D

A

B

G

J

C

A

B

RO 125 FEQ

G

Detail Pad

F

RO 90 DX

M

C

D

E

G

RO 150 FEQ

Item Name or Description Ref. Page(s)

A Power Switch 13

B Mode Selector 7, 13

C Speed Control Dial 12

D Dust Collection Port 12

E Dust Channel Release (RO150) 12

6 Rotex Series Dual Mode Sanders

Item Name or Description Ref. Page(s)

F Plug-It Power Port 12

G Sanding Pad 10

H DX Sanding Pad (RO90) 11

I Sanding Bumper/Protector 13

J Fast-Fix Spindle Lock 10

Page 7

Sanding Action/Mode

Sanding is dened as scratching or abrading a surface. So

when we discuss scratches and scratch patterns, the goal is

to minimize them or make them less visible to the eye, but

they will always be present.

The Festool Rotex sander is not only a dual-action sander,

but is also a dual-mode sander. Even though those two

terms sound similar, they do not mean the same thing.

Because both of the dual modes are variations of dual-

action, it is best to describe dual-action rst.

Dual-Action

Dual-action means that the sanding pad moves in two

distinct motions simultaneously. The primary motion is an

eccentric orbit—similar to the motion of a bicycle pedal. The

center of the sanding disk moves in a small eccentric circle

about the center of the

sander. The diameter of this

orbital path ranges from

3mm to 5mm, depending

on the model sander (Refer

to “Technical Specications”

on page 5).

The second motion is the

rotation of the disk about

the disk’s center. Because

the sanding disk is eccentric

to the machine center, so is

this path of rotation.

The effect of this dual

motion is that each point

on the sanding pad traces out a geometric shape called

a roulette. You may be familiar with this shape from the

children’s drawing toy, “Spirograph”. The exact shape of this

roulette depends on the ratio between the orbital radius and

the radius of the pad rotation. This means that each part of

the sanding pad traces out a slightly different shape. This

minimizes the visibility of the scratch patterns on the wood

because each part of the sanding disk leaves slightly different scratch shapes. Dual action sanders don’t leave fewer

scratches, but the scratches are less visible because each

one is different.

Rotation

Eccentric

Orbit

Random Orbit

This name random orbit is a slight misnomer because it

isn’t the eccentric orbit that is random, but the disk rotation that is random. The motion of the sanding pad is still

considered dual-action, but the rotational component of the

motion is not constrained to follow a strict ratio of the orbits

like a gear-driven sander. The disk rotation is permitted to

freewheel about the orbit, and this includes even rotating

backward at times.

It is this freewheel motion that permits the sander to be

both fairly aggressive but to also leave very few visible

scratches. Again, it isn’t because there are fewer scratches,

but that the scratches are even less visible.

What makes the rotation of the disk somewhat random is

friction with the sanding surface. Inertia causes the disk to

want to rotate in unison with the orbital motion, but friction

with the workpiece tempers this motion, and causes the

disk to speed up, slow down, or even turn backward.

You may have noticed that when hand-sanding wood, there

is more resistance to sanding across the grain than there is

with the grain. The same is true for a random orbit sander.

As a result, when the orbital motion is moving across-thegrain, the freewheel rotational motion will resist moving

across the grain. The net result will be more scratches

being parallel to the wood grain than across the grain.

Unlike a singular orbital motion (orbital sander) or a singular rotational motion (grinder), whose scratch patterns will

be circular, a random orbital scratch pattern will be more

“V” shaped and in the direction of the wood grain. Because

these are less geometric in shape, they are less visible to

the eye. The tighter this “V” shape, the less noticeable the

scratches will be.

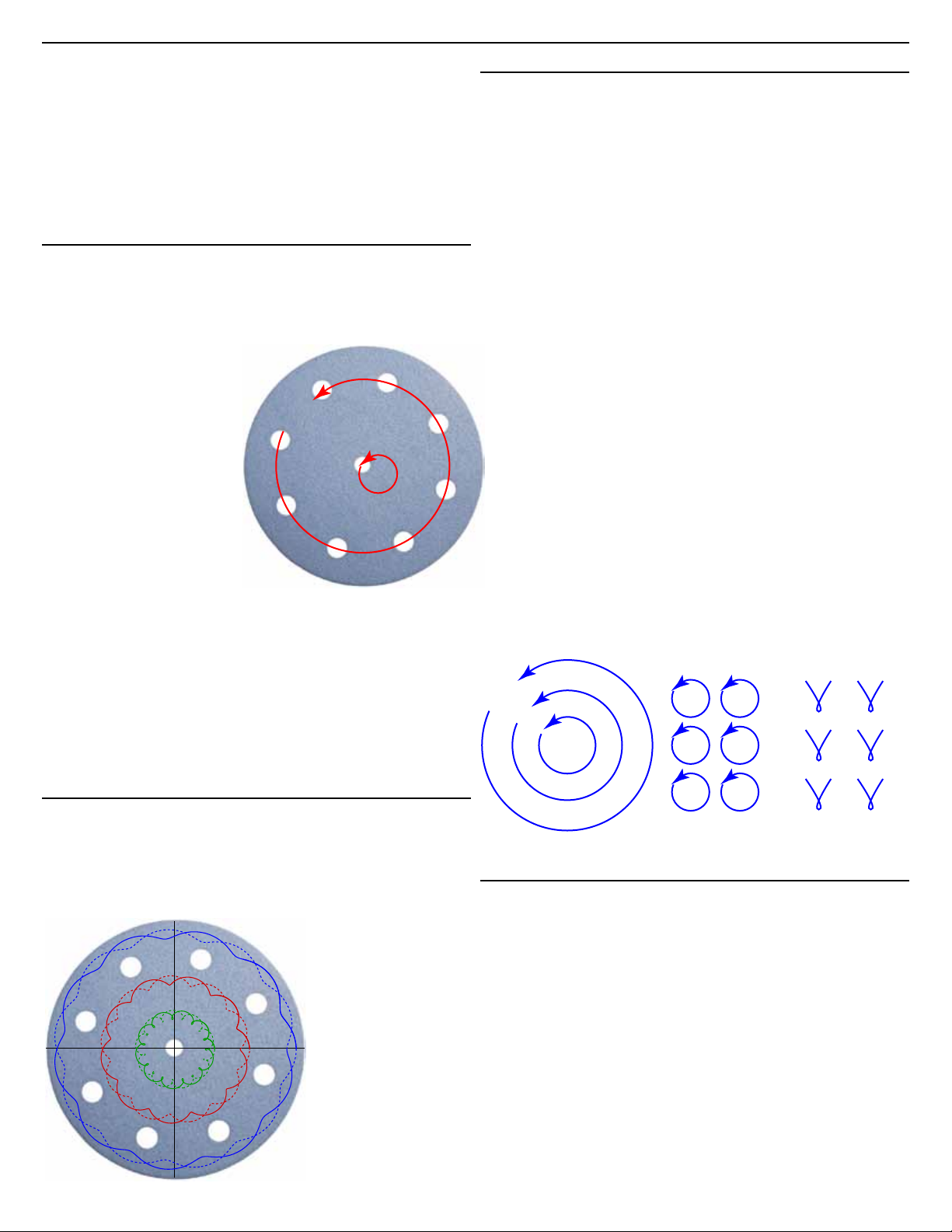

Gear Driven (Rotex) Mode

In the gear driven mode, the dual-action rotation of the

sanding pad is directly coupled to the orbital motion. For

each of the Rotex sander models, the pad rotates once for

approximately 10 orbits of the eccentric center. (In the

image below-left, this ratio is 9.5 to 1.)

This gear driven mode

provides some of the

aggressiveness of a

rotary grinder, but the

high ratio (10:1) of

the rotation-to-orbit

minimizes the visible scratches that a

grinder would impart

on the wood.

Supplemental Owner’s Manual 7

Grinder Scratch

Patterns

Optimizing Random Orbit

Optimizing the sanding doesn’t remove the number of

scratches, it just makes them less visible to the eye. The

least visible scratches are those that are not geometric and

are in-line with the wood grain. Both of these conditions are

optimized by letting the friction between the sanding pad

and sanded surface control the rotation of the sanding disk.

Many operators will apply excessive downward pressure to

the sander to slow down the freewheel motion of the pad,

but this will increase the amount of friction and make the

scratches more geometric and more visible. Instead, using

a light pressure allows the cross-grain friction to be larger

than the in-line friction, and the ideal scratch pattern shown

above will be the result.

The best random orbit motion is when the sanding pad has

very little pressure, and is permitted to freewheel on its own.

Orbital Scratch

Patterns

Random Orbit

Scratch Patterns

Page 8

Anatomy of Sandpaper

The various parts of sandpaper affect its performance.

These are shown below and explained in the subsequent

sections.

Abrasive

Dispersion

Grit

Top

Bond

Base

Bond

Backing

StickFix

StickFix is a short-nap hook and loop system for retaining

the sandpaper to the Festool sanding pad. The stiff, shortnap hooks resist heating effects, and therefore last longer.

Backing is the primary substrate for the sandpaper. The

backing type determines the performance and longevity of

the sandpaper. Stiffer backings resist the pressure of the

individual grit particles, and is therefore more aggressive in

sanding. Softer backings conform to the grit particles more,

so the result is shallower scratches from the grit particles.

Paper backing is the most common and economical type,

and comes in different thicknesses designated by a letterweight of b, c, d, or e with the higher the letter, the heavier/

stiffer the paper.

Cloth backed disks are the stiffest and intended for extreme

usage conditions where long-life is important. The extra

durability makes them ideal for a metal working environment, but they may also be used for aggressive sanding in

woodworking.

Foam backed disks provide the softest backing for the shallowest scratches. This permits the disk to better contour to

the surface being sanded and is ideal for polishing.

Abrasive is the material that performs the actual sanding

or abrasion. The two most common types of abrasive material are aluminum oxide and silicon carbide, with aluminum

oxide being the more common of the two.

Silicon carbide is a very hard material with very sharp

edges. Because silicone carbide is so hard, it fractures

easily, and this exposes new cutting edges to the sanding

operation. This keeps the sandpaper very sharp for cutting

hard materials, but the grit gets smaller with usage. A side

benet of this is that a coarse grit sandpaper will become

a ner grit with use, which is typically desired in the sanding process. Silicon carbide is best suited for nish sanding

where reduced sanding pressure reduces how frequently the

grit cleaves.

Aluminum oxide is almost as hard as silicon carbide, but the

crystals are pyramid shaped and do not cleave the edges

during use. The edges aren’t as sharp, but that is what

permits them to last longer. This long life is the reason aluminum oxide is one of the most common abrasive materials.

Grit is the size of the abrasive particles. The smaller the grit

number, the larger the grit particle size. Larger grit particles

will cut deeper into the sanded surface, and therefore, more

aggressively. However, the deeper the cut, the deeper the

scratches. This is the reason why sanding is performed with

8 Rotex Series Dual Mode Sanders

progressively ner grits; to remove the scratches left behind

from the coarser grits.

Dispersion (Coat) is the spacing between grit particles

that coat the substrate. The term “open coat” for example,

means that at least 70% of the substrate is open or

uncoated. A closed coating means that the substrate is

nearly fully coated, and a semi-open coat falls somewhere

in between the two. The dispersion is most noticeable in the

coarser grits where an open coat results in visible exposure

of the substrate (see image below).

A more open dispersion leaves more room for sanding dust

(called swarf) to clear the sanding grit to avoid buildup and

clogging, but also permits the grit to penetrate deeper into

the sanded workpiece, leaving deeper scratches.

Open Coat

Sandpaper

Base Bond and Top Bond is the material and/or method

for adhering the abrasive to the backing material. The grit

material is impregnated into the bonding agent to slightly

encapsulate the grit material for better adhesion and less

fracturing of the grit.

The thickness of the top

bond is called the level-

ing, as it tends to ll in

the valleys and level the

bond coating. An open

leveled top bond is lighter

and leaves deeper valleys

to permit greater swarf

removal.

A closed leveled top bond

is thicker and lls in the

valleys, but provides

a stronger bond of the

abrasive grit particles.

The prevents the grit from

breaking loose from the

substrate for longer lasting, durable abrasive properties, but may clog faster

when sanding materials

that generate more swarf.

Open

Leveled

Closed

Leveled

Page 9

Non-Woven Fiber, Vlies (pronounced eece) is a special

RUBIN

GRANAT

BRILLIANT

SAPHIR

CRISTAL

TITAN

PLATIN

VLIES

abrasive pad of a non-woven ber impregnated with abrasive into the ber. The exible ber mesh and 3-dimensional

abrasive make these ideal for polishing nishes and metal

surfaces.

to level the surface. With this comes the trade off between

speed versus deeper scratches. The key is to choose the

nest of the coarse grits that will provide the leveling in a

reasonable amount of time and effort. Choosing too coarse

of a grit may actually increase the amount of sanding later

to remove excess scratching. The Rotex line of sanders

provide the added benet of gear-driven mode, which can

remove material quickly with a less-coarse grit. Therefore,

before switching to a ner grit, rst switch the sander back

to random orbital mode to help reduce the scratches with

the same grit that created them. Then you can progress

through the grits normally or switching between modes.

The purpose of ne sanding is the removal of previous

scratches. The key here is to sand only up to the nest

grit necessary for the desired nish type. The nal grit size

should be commensurate with the grain or structure size of

the material being sanded. Metals, plastics, and nishes; for

Choosing the Appropriate Grit

Selecting the best sanding grit for a task is fairly subjective

and depends on the task and even the sanding mode of the

sander. The adage of working progressively up through the

grits is based on the principle of each ner grit removing the

scratches that the coarser grit leaves behind.

For initial stages of sanding with a coarse grit, the goal is

example, have a very ne structure and may be sanded to

a ner grit. Wood, on the other hand, has a relatively large

grain structure and should not be sanded beyond a medium

grit unless a burnished nished is desired. (Burnishing tends

to close the wood pores and reduces the absorption of stains

and nishes.)

In summary, you should avoid starting too coarse or nishing too ne for the particular material or surface type.

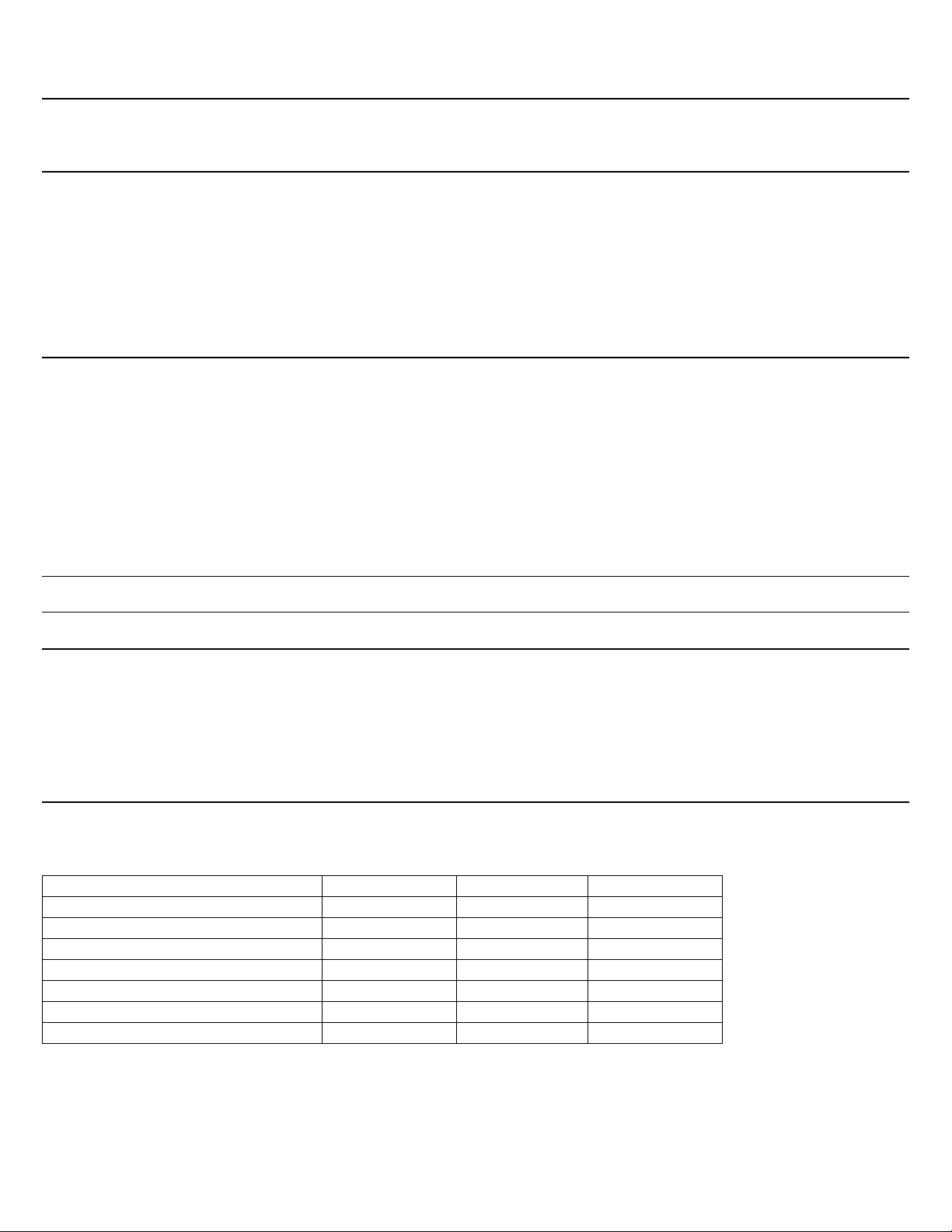

Best Sandpaper for the Task

Name Type Range Description

► Aluminum Oxide

► e-Wt Paper

► Synthetic Resin

► Closed-coat

P40-P220 The heavy weight paper backing and strong top bond make this

sandpaper very good for long lasting use on bare wood, metal, and

auto body llers.

► Aluminum Oxide

► Synthetic Resin

► Closed-coat

► Aluminum Oxide

► Synthetic Resin

► Closed-coat

► Aluminum Oxide

► Cloth-backing

► Semi-close Coat

► Closed-leveled

► Aluminum Oxide

► Phenolic Resin

► Open-coat

► Aluminum Oxide

► Synthetic Resin

► Latex Base Bond

► Semi-close Coat

► Silicon Carbide

► Synthetic Resin

► Open Coated

► Foam

P40-P1500 The non-wax stearated coating and lighter paper weight make this

a very good universal sandpaper for nished and unnished wood,

metal, plastic, solid surface, and composite materials. The high

density closed coat grit is more uniform for reduced scratches.

P40-P400 The lighter weight paper and thinner top bond results in shallower

scratches for good sanding results in harder woods, nishes, and

paints. The open-leveled top bond and anti-static coating loads less

when sanding nishes.

P24-P100 The cloth-backing, semi-closed coating, and closed-leveled bond

make these disks very durable workhorses for sanding and leveling

on hard wood, metal, berglass, and reinforced plastics.

P40-P120 The broad open-coat dispersion of this disk makes it ideal for

aggressive sanding without loading on clog-prone materials, such

as paint stripping or high-resin woods.

P40-P3000 The latex base bond provides greater exibility of the grit coating,

which makes Titan idea for polishing tasks on solid surface, plas-

tics, and nishes. The semi-closed coat and open-leveled top bond

result in ner sanding with fewer scratches. However, with the

stearate coating, it is not recommended for water borne nishes.

S400-S4000 The tight woven grit base and foam backing makes Platin ideal

for a high gloss surface in plastic, solid surface, and nishes. The

permeable foam and ber results in consistent dust extraction

across the whole disk and cooler surface temperatures.

► Al-Ox or Si-Carb

► Synthetic Resin

► Stearate Si-C

A120-A800 The elastic ber mat with impregnated grit makes Vlies ideal for

deep pore cleaning of woods and scouring or de-rusting of metals.

Supplemental Owner’s Manual 9

Page 10

Setup

Changing Sanding Pads

Each model sander may be used with a variety of sanding

pad options. It may also be necessary to change sanding

pads for different sanding purposes or when they become

worn.

CAUTION! Do not use a sanding pad if it no longer

holds the sanding disk in place. Using a worn pad

can result in the sanding disk to y off the pad and

cause injury. Sanding pads are considered a wear

item and should be replaced when the StickFix

hook-&-loop bers cannot rmly hold the sanding

disk.

NOTE: Excessive heat from sanding will cause the

sanding pads to wear faster. To maximize your pad

life, avoid operations that generate excessive friction

and heat, such as sanding stationary on a sharp edge

or applying too much pressure while sanding.

Choosing the Correct Sanding Pad

Sanding pads come in different grades of hardness/softness for improved performance for different sanding tasks.

The hardness or softness of the sanding pad determines

how much the sanding pad conforms to the surface being

sanded.

A harder sanding pad is best for course sanding on at surfaces. The rmer pad resists creating a wavy surface where

there are softer and harder portions of the wood ber. This

is especially important with woods that have a wide spacing

in their annular growth rings or signicant differences in the

density of the wood ber between rings.

A slightly softer sanding pad is best used for progressively

ner sanding of the workpiece. This permits the pad to

slightly conform to the surface to ensure previous grit sanding marks are removed, but is less prone to creating a wavy

surface because the grit is less aggressive.

Similarly, a very soft sanding pad is best used for ne

sanding or sanding of nishes. Having greater conformance

to the very small waves in the surface is desired, and with

the high grit abrasive, risk of creating deeper waves is less

likely.

Removing/Installing the Pad

1. Unplug the sander for safety.

2. Lock the sander spindle from rotating:

► For the RO90, turn the mode selector to the DX (orbital)

mode.

► For the RO125 and RO150, slide the mode selector to

the Rotex mode, and press in on the spindle lock button.

3. Rotate the pad 1/4-turn to remove or install it.

DX Mode

RO-90 DX Mode

Spindle

Lock

RO-125

Blue / Hard

Black / Soft Gray / Super Soft

Spindle

Lock

Tighten

Loosen

RO-150

10 Rotex Series Dual Mode Sanders

Page 11

Changing Delta (RO90) Sanding Pads

The RO90 sander can also use an optional detail sanding

pad. The Delta (DX) sanding pad is triangular shaped for

reaching into tight corners and along edges. The pad operates only in orbital mode, and does not rotate.

NOTICE: The RO90’s mode selection dial has an

interlock to prevent the sander from being operated in either of the rotary modes when the DX pad

is installed. Forcing the dial to turn with a DX pad

installed will damage the sander.

The standard DX sanding pad is actually a sanding pad

holder with removable sanding pads. The sanding pads

can be either a hard sanding pad or a soft sanding pad. An

extended sanding pad is also available, but does not use

the separate sanding pads. The extended sanding pad has

a longer tip for reaching into narrow spaces. Both types of

Delta pads use the same sandpaper.

Delta Pad

Holder

Installing the Pad (Holder) on the Sander

1. Unplug the sander for safety.

2. Turn the mode selector dial to the DX mode.

► This lowers the interlock pin and locks the spindle in the

only position the DX pad can be installed.

► If the interlock pin is extended, the dial is not in DX

mode and the pad cannot be installed.

► If the spindle is not locked, rotate it until it does lock.

3. Place the DX pad on the spindle at 45° counterclockwise

from its normal position so it engages the retaining tabs.

(The pad and sander bodies have alignment arrows for

this position, as shown in the image below.)

4. Rotate the DX pad clockwise until it clicks into place and

is aligned with the main body of the sander.

5. To remove the DX pad, press forward on the release button (shown in the lower left image), and rotate the pad

45° counterclockwise.

Sanding

Pad

Extended

Sanding Pad

Installing the Pad on the Holder

The sanding pad is secured to the holder with hook & loop

around the perimeter and with a snap in the center. To

install the pad, center it over the snap, align the dust ports

with the holes in the pad, and then rmly press it into place.

Retaining

Snap

Release

Button

Spindle

Release

Button

Retaining

Tabs

Interlock

Pin

Lock

Align

Arrows

Dust

Ports

Supplemental Owner’s Manual 11

Page 12

Changing Sandpaper

The sandpaper is held in place with a hook & loop system,

and can be changed by simply pulling off the old disk and

pressing on a new one. However, for the integral dust collection, make sure to align the holes in the sandpaper with the

dust extraction inlets in the sanding pad.

Connecting the Plug-It Power Cord

The sander comes equipped with a removable Plug-It power

cord. The cord can be removed for easier storage of the

tool. To install the power cord, insert the cord into the inlet

(port) on the tool with the key and keyway aligned, and

twist the locking ring ¼-turn until it clicks. Reverse the

procedure to remove the cord.

NOTICE: Make sure to fully tighten the plug-it cord

a full quarter-turn until it clicks. If the plug is not

fully locked, the socket and cord can overheat and be

damaged.

NOTE: The 18 gauge plug-it cord is interchangeable

with other tools that use the same size cord, but it

cannot be used with larger tools, such as routers and

saws. The plug has an extra key to prevent it from

being used on a larger tool that would otherwise

damage the cord. Larger cords may be used with

smaller tools, but not the reverse.

Connecting a Dust Extractor

The dust port on the back of the sander connects to a

Festool 27mm vacuum hose. To connect the hose, rock it

back and forth over the ribs while pressing inward.

27mm

Hose

The dust port on the RO150 can be removed for polishing

or other operations that do not require dust extraction by

pressing in on the release lever and sliding the port off the

sander.

Key &

Lock

Unlock

Keyway

Locking

Ring

Setting the Variable Speed

The speed of the sander is adjustable with the speed control

dial. Most operations are best performed at full speed, but

a lower speed can sometimes improve control or reduce

aggressiveness for ner operations, such as polishing or

bufng. The speed may be adjusted with the motor either

on or off. The slowest speed is 1 and the highest speed is 6.

RO 90

RO 150

RO 125

Speed

Control

Release

Lever

12 Rotex Series Dual Mode Sanders

Page 13

Installing the Sanding Bumper

The sanding bumper is used to help keep the sander from

gouging perpendicular borders around the sanding area. It

can be removed from the sander for better visibility of the

sanding disk for most operations.

To install the bumper, slide it over the front of the sander’s

housing until the tabs lock into place.

To remove the bumper, pry out on the end of the bumper

to release the tabs and slide the bumper off the sander

housing.

Setting the Sanding Mode

The Rotex sanders can be switched between gear-driven

(Rotex) mode and random orbit mode. The RO-90 has the

third option of orbital mode (Delta). The chosen mode is

dependant on the type of sanding required.

Rotex mode is the most aggressive for rapid material

removal. Random orbit mode produces the nest nish with

minimal visible scratches. Orbital mode is typically used in

conjunction with the delta sanding pad for detail sanding,

but may also be used with circular sanding pads if desired.

Changing modes should be done with the sander turned

off. For the RO-125 and RO-150 sanders, slide the selector

switch side to side to the respective mode setting. For the

RO-90, rotate the selector dial to the desired setting.

NOTICE: The RO90’s mode selection dial has an

interlock to prevent the sander from being operated in either of the rotary modes when the DX pad

is installed. Forcing the dial to turn with a DX pad

installed will damage the sander.

RO-125 and RO-150

Rotex

Turning on the Sander

For best control and sanding results, the sander should be

placed on the sanding surface with no downward pressure

before turning it on, and lifted from the surface before

turning it off. The Rotex sanders have soft-start circuitry, so

there will be a slight delay before the sander reaches the set

motor speed.

To turn the sander on, slide the power switch forward until

it clicks into the on position. To turn the sander off, slide the

power switch back.

RO-90

Random

Orbit

Random

Orbit

Rotex

Delta

On

Off

On

Off

Supplemental Owner’s Manual 13

Page 14

Operation

Aside from installing sandpaper, your Rotex sander is

ready to use right out of the box. There is no special setup,

adjustment, or break-in procedure required before using

your sander. However, new users may want to practice with

the sander to become familiar with its operation, function,

and even the best way to hold the sander.

Sanding is frequently considered one of the most important

Using Dust Extraction

Using dust extraction on a Rotex sander isn’t just a matter

of keeping the work area clean or protecting your health;

which of course is very important. The sander itself is

specically designed to perform best when used with dust

extraction.

Sanding wouldn’t be very effective if a layer of sanding

dust was permitted to accumulate between the sanding

pad and the sanded surface. Festool sanders incorporate

Airstream technology to help get the sanding dust away

from the sanding surface as efciently as possible. With

traditional sanding pads, dust accumulates at the center

of the disk because it can’t get drawn out by the vacuum.

Airstream technology creates airow from the center of the

pad radially outward to the dust extraction holes (as well as

the normal airow from the perimeter). This keeps the dust

clear and allows the sanding grit to work on the sanding

surface.

Dust

Extraction

Makeup Air

Passage

stages of any type of project because it is often the rst

stage of the nishing phase. Even given its great impor-

tance, the nuances of sanding are often overlooked, and it

is viewed as more of a chore than a productive aspect of

the overall project. Discovering the optimal nuances of your

sander will help you get the most out of your sander, but

may take some practice and learning.

performance of the sander. Too high of a vacuum pressure

can suck the sander tight to the workpiece, which reduces

sanding quality and diminishes controllability of the sander.

For best results, the power of the vacuum should be reduced

below maximum. A sign that the vacuum is too strong is a

lack of controllability, with excessive jumping and jitter in

the movement of the sander across the workpiece. Having

the vacuum set too high will also increase the depth of

sanding scratches, and make them more difcult to remove

through the higher sanding grits. The optimal vacuum power

will vary depending on the size of the sander and even the

coarseness of the sandpaper, with ner grits needing less

power.

1. To use the dust extraction system, slide the vacuum hose

over the dust collection port as described on page 14.

2. Plug the sander into the electrical receptacle on the

front of the dust extractor, and turn the power switch to

“Auto”.

► When the power switch is in the manual or off position,

the electrical outlet will not have any power.

3. Turn the speed control dial counterclockwise to reduce

the power of the vacuum.

Tool’s

Power Cord

With HEPA ltration, auto-start, and variable speed, Festool

dust extractors are ideally suited for use with Rotex sanders. The variable speed is of particular importance because

it permits adjusting the power of the vacuum for the optimal

14 Rotex Series Dual Mode Sanders

Slow

Power Switch

Set to Auto

Fast

Page 15

Choosing Hand Positions

While it may sound trivial on the face of it, how you hold

the sander plays a pivotal role in the optimal performance

of the sander. Balance, control, and comfort are the keys in

deciding what hand positions work best for you. It is recommended to spend some time practicing and rening your

handhold positions to suit your needs. They will vary from

user to user, but the information below presents the most

common starting point for many users.

The basic handhold positions are one hand forward and one

hand aft, with the forward hand providing the majority of

the control over the sander. The rear hand provides slight

guidance and balance to the sander. A grip near the power

cord works best for this.

The forward hand provides the majority of the control and

a majority of the balance. This may be over the top of the

motor or in front of the motor, with the front of the motor

being slightly more preferred by most users.

These hand positions provide the greatest separation of your

hands from the front to rear of the sander. This separation

is what results in greater control of the sander and makes it

easier to avoid tilting the sanding pad against the sanding

surface.

When experimenting with different hand grips, use varying

sandpaper grits and both modes of the sander. The goal is

to hold the sander in such a way that balance and control

are achieved, which results in the smoothest motion of the

sander as you move it about the workpiece. Here are some

signs that your grip on the sander is not balanced:

► Uneven resistance to movement: If the sander resists

more in one direction than the opposite direction, it is a

sign that you are slightly tilting the sander.

► If you experience excessive jumping and jitter, it means

your grip is not balanced, you’re moving too fast, and you

are applying too much down force to the sander.

Working With Sanding Grits

Generally speaking, the sanding process begins with the

coarser grits and progresses up to the ner grits. However,

not all sanding tasks are the same. So choosing which grits

to use will vary depending on the task. The adage of progressing through the grits holds true for nearly all sanding,

but where to begin and where to end isn’t always clear.

While the coarsest grits provide rapid material removal and

leveling, it isn’t always desired to begin sanding with the

coarsest grit available. Avoid starting with too coarse of a

grit. For example, when working with pre-planed lumber,

there should be little need to use a coarser grit that 120

unless there is the need for joint-leveling. Even with jointleveling, only a slightly coarser grit may be called for, with

coarser grits reserved for joint leveling of wider panels.

Similarly, the highest grit chosen should be commensurate

with the type of material and surface nish desired. The grit

size should be consistent with the grain size of the material.

Very high grits should be used for achieving a high gloss

surface on paints, nishes, and plastics. However, because

the grain size of wood is much larger than man-made mate-

rials, the highest (unnished) sanding grit should be much

more limited.

When sanding bare wood in preparation for applying most

surface-build nishes, a sanding grit of approximately 220

grit should be considered the maximum, or even slightly

lower for very high-build nishes. On the other hand, for

non-build nishes or when the bare wood is the nal nish,

then higher grits may be called for. Using too high of a grit

will tend to burnish the wood. With some non-build nishes

or for bare wood, this is desired. However, for most surface-

build nishes, burnishing can hinder nish penetration of the

surface.

For colorants, and especially pigmented stains, the higher

the bare wood sanding grit, the less the colorant will pen-

etrate the wood. In some cases this can even lead to a loss

of grain denition in the nal nish. However, this can also

be used to an advantage for controlling the intensity of a

colorant, by using a coarser grit for a darker intensity and a

higher grit for a lighter intensity.

The purpose of progressing through the grits from coarse

to ne is so that each successive grit is aggressive enough

to remove enough material to remove the scratches of the

previous grit, while only leaving smaller scratches itself.

This is most apparent in the coarser grits where the grit

scratches are deeper.

Supplemental Owner’s Manual 15

Page 16

Sanding Techniques

Establishing Optimal Sanding Pressure

The amount of downward force applied to the sander will

have a varying impact on how aggressive the sander will

perform, but also on the controllability and nish level too.

More downward force will make the sander operate more

aggressively, but it will also tend to make the sander more

difcult to control and reduce the quality of the nish. The

general rule for any rotational type sander is to keep minimal downward force on the sander and let the sander to the

work on its own.

The primary sign that you are applying too much down

pressure is that the sander will lurch and jitter as it moves

across the sanding surface. When this happens, reduce the

sanding pressure, which even includes lifting the sander a

little bit when necessary.

In random orbit mode, anything that diminishes the “randomness” of the pad rotation increases the occurrence of

Sanding Pattern and Movement

One key to achieving a quality sanded nish is to establish

an effective and smooth sanding pattern for moving the

sander across the workpiece. Different patterns and speeds

of motion will be optimal for different material types and

even different grits of sand paper.

Because the sanding pad is moving in a clockwise dual

motion (both in Rotex and random orbit modes), a general

clockwise sanding pattern produces the least resistance to

movement, and therefore, the smoothest pattern. As much

as possible, make your motions and direction changes in a

general clockwise direction.

For homogenous materials that do not have a discernible

grain direction, such as metals, plastics, solid surface, and

nishes; a circular pattern may be best. These types of patterns do not have a stopping or sharp transition point where

the direction of the sander is abruptly changed.

For materials with an inherent grain structure such as wood

and even some plastics, the sander motion should be kept

generally in-line with the grain as much as reasonably possible. This leads to a linear back and forth motion, but the

transitions for changing direction should be as smooth as

possible without an abrupt stop/start.

Example, Solid Surface Joint Leveling:

Solid surface material has a non-oriented grain structure. It

is therefore best to sand in a generally circular pattern. For

initial leveling, sanding emphasis should be applied to the

higher of the two surfaces, but not to the complete exclusion of both surfaces. This calls for an oval pattern overlapping onto the lower surface, yet focused on the upper

surface.

visible scratches. Initial intuition may suggest that slowing

down the pad rotation is good, but the opposite is true.

If the pad is not freely spinning, then the motion is not

random, and too much down force is being applied to the

sander.

In Rotex mode, by their nature, the sanders will be more

difcult to control because different parts of the sanding pad

will be operating in a cross-grain direction at different times.

This is what give the sander its rapid material removal rate.

So in Rotex mode, the sander will expectably have more

jitter, especially with coarser grits.

NOTE: The effect of the vacuum created below the

sanding pad from the dust extractor will add some

downward force to the sander. It is important to

reduce the power of the dust extractor so it is not

applying too much down-force on the sander.

As the joint becomes more level, the pattern should switch

to perpendicular to the joint in tight overlapping loops.

Example, Wood Panel Joint Leveling:

In a similar fashion, initial leveling should focus on the

higher surface, but not to the exclusion of the lower surface.

Some overlap across the joint is required to avoid the likelihood of creating a slight depression on the high surface just

inside the joint. As leveling progresses, the sanding pattern

should become more balanced across the two pieces.

16 Rotex Series Dual Mode Sanders

Page 17

Example, Faceframe Leveling:

While the temptation may be to focus sanding directly over

a frame’s joint, this should be avoided. To reduce the chance

of a depression at the corner, a general L-shaped pattern

should be used extending well beyond the joint. For more

emphasis at the joint, a mixture of both short and long

strokes should be used, but never just stationary over the

joint.

Once the joints are leveled, the entire frame should be

sanded, but this too should have a pattern. While not as

critical, the general approach is to sand those frame mem-

bers which are captive between other frame members rst.

In other words, sand the horizontal rails rst, followed by

the vertical stiles.

Example, Frame to Carcase Leveling:

Leveling the joint between a solid wood frame and a plywood veneer carcase is one of the most precarious sanding

operations due to the likelihood of sanding through the thin

veneer. The key is to evenly remove enough of the solid

wood frame without sanding into the veneer.

While the temptation may be to sand the frame with only

the edge of the sanding pad, this will invariably result in a

slight bevel to the frame. Instead, keep the center of the

pad centered over the frame, but held as perfectly parallel

to the surface as possible. Sand the frame ush, and then

begin working out into the veneer surface. Here are some

tips to safely achieving ush joints:

► Using a soft, wide-lead pencil, scribble across the veneer

near the joint. As long as the pencil lines remain, you will

not be sanding through the veneer.

► Use the rmest sanding pad available to avoid rounding

the edge of the frame.

► Avoid using too coarse of a disk, as the veneer can be

damaged too quickly if you tilt the sander.

► Operate the sander with authority and rm pressure to

maintain maximum control, but reduce the pressure as

the joint gets closer to ush.

► Avoid the tendency to tilt the sander away from the

veneer, as this will create a bevel on the frame.

► As the joint gets close to ush, expand your strokes to

include more of the veneer surface, and continue sanding

until the pencil marks are gone.

Pencil

Supplemental Owner’s Manual 17

Page 18

Maintenance and Adjustment

WARNING! Any maintenance or repair work

that requires opening of the motor or gear housing should be carried out only by an authorized

Customer Service Center (see your dealer for

information on locating a service center).

WARNING! To reduce the risk of electrocution or

other personal injury, always unplug the tool from

the power supply outlet before performing any

maintenance or repair work on the tool.

Routine Maintenance

Dust and debris from some materials can be extremely

abrasive and cause components within the sander to wear

prematurely. It is important to keep moving parts cleared of

abrasive dusts.

► As a general rule, keep the sander clean of all dust and

Motor Brush Replacement

Motor brushes provide electricity to the spinning motor

armature, and will wear over time. The brushes are

designed to disconnect power to the motor when they have

RO 90 Motor Brushes

WARNING! To avoid the risk of electrical shock,

make sure the sander is unplugged from power.

1. Unplug the sander from power.

2. Remove the 4 T10 Torx screws that secure the brush

cover, and remove the cover.

NOTICE: Do not use compressed air to clean the

motor housing of the tool, as you could inject foreign objects into the motor through the ventilation

openings.

NOTICE: Certain cleaning agents and solvents are

harmful to plastic parts. Some of these include, but

are not limited to: Gasoline, Acetone, Methyl Ethyl

Ketone (MEK), Carbonyl Chloride, cleaning solutions

containing Chlorine, Ammonia, and household cleaners containing Ammonia.

debris. Even soft-wood dust can be abrasive over time.

► Examine all moving parts for dust and debris.

► Sanding pads are considered a wear item and will need

to be replaced periodically. Replace the pad when it no

longer holds sanding disks in place.

warn beyond their usable life. If your sander stops working,

it is likely that the brushes have warn and need replacement. Contact Festool for replacement brushes.

Spring

on Post

Mounting

Screws (4)

Brush

Cover

3. Using a small tweezer, carefully lift the pressure spring

off the brush and rest it on the adjacent post.

4. Using tweezers or needle nose pliers, carefully remove

the wire terminal from the spade lug.

5. Slide the brush out of the brush holder, and repeat for

the second brush on the other side of the motor.

Pressure

Spring

Brush

Wire

Terminal

Post

Brush

6. Install the new brushes by reversing the procedure. Don’t

forget to move the pressure spring back over the brush.

Brush

Wire

Terminal

18 Rotex Series Dual Mode Sanders

Page 19

RO 125 Motor Brushes

WARNING! To avoid the risk of electrical shock,

make sure the sander is unplugged from power.

1. Unplug the sander from power.

2. Remove the T15 Torx screw that secures each brush

cover (one on either side of the motor), and remove the

covers.

Mounting

Screw

Brush

Cover

Spring

on Post

Brush

Post

Pressure

Spring

3. Using a small tweezer, carefully lift the pressure spring

off the brush and rest it on the adjacent post.

4. Using tweezers or needle nose pliers, carefully remove

the wire terminal from the spade lug.

5. Slide the brush out of the brush holder, and repeat for

the second brush on the other side of the motor.

Wire

Brush

6. Install the new brushes by reversing the procedure. Don’t

forget to move the pressure spring back over the brush.

Terminal

Brush

Wire

Terminal

Supplemental Owner’s Manual 19

Page 20

RO 150 Motor Brushes

WARNING! To avoid the risk of electrical shock,

make sure the sander is unplugged from power.

1. Unplug the sander from power.

2. Remove the dust port as described on page 12.

3. Remove the T15 Torx screw that secures the brush cover,

and slide the cover off the back of the sander handle.

Brush

Cover

Sander

Handle

Brush

Holder

Mounting

Screw

Wire

Terminal

Mounting

Screw

4. Remove the switch linkage that connects the green

power switch to the electrical switch inside the sander.

a. Lift the linkage yoke off the pin on the electrical

switch.

b. Tilt the linkage as shown, and slide it off the green pin

on the power switch.

A

Upper

Brush

B

Yoke

& Pin

Switch

Linkage

5. Using tweezers or needle nose pliers, carefully remove

the wire terminal from the spade lug.

6. Using a T15 Torx driver, remove the mounting screw that

secures the brush holder to the motor housing.

7. Lift the brush and brush holder out of the sander.

8. Repeat for the second brush and brush holder on the

underside of the motor.

9. If the replacement brushes do not come pre-mounted in

brush holders, install the brushes in the existing brush

holders as shown.

► Make sure the wire passes through the body of the

brush holder.

► Make sure the pressure spring is pressing against the

top of the brush.

Pressure

Spring

Brush

Holder

Brush

20 Rotex Series Dual Mode Sanders

Page 21

Troubleshooting

Symptom Possible Causes

Motor does not start ► Check that the cord is properly plugged into an outlet.

► Make sure the Plug-it connector is properly inserted and fully tightened.

► Make sure the outlet has power. Check the circuit breaker or try another outlet.

► If used with a Festool dust extractor, make sure the selector switch is pointing to “Auto”. The

auxiliary outlet on the dust extractor has power only when the selector is at Auto.

► Inspect the power cord (including extension cords) for damage or missing prongs.

► The motor brushes may have worn and need replacement.

► Please note that the power switch is a sealed pneumatically actuated switch that is not

prone to dust ingestion. Do not attempt to open the switch.

Sander runs

sporadically or looses

power

Sanding disk doesn’t

stick or ies off during

sanding

Deep scratches in

nish sanding

Excessive swirl marks ► Make sure the dust collection vacuum is set for reduced power. Too much vacuum will apply

Sander jumps or is

hard to control

► Make sure the Plug-it cord is properly tightened. Inspect the plug and tool power inlet for

signs of overheating. If signs of overheating are present, discontinue use and have the tool

serviced. If the Plug-it cord shows signs of overheating, do not use the cord for other tools,

as it can damage the inlet of the other tool.

► Make sure the disk is rmly pressed onto the pad.

► To make sure it isn’t a defective disk, try using a different disk.

► Make sure the bottom of the pad is clean and free of debris.

► The sanding pad is a wear item and may need replacement. Sanding generates heat, and

heat will degrade the Stickx hooks on the sanding pad. Avoid operations that generate

excessive heat, such as holding the sander motionless on sharp edges.

► The most likely cause is that scratches from a coarse grit paper are too deep for the cur-

rent/nal grit paper. Make sure you don’t skip a grit in progression.

► If switching from Rotex to random orbit mode, stay with the same grit.

► Rework the nish with a grit appropriate to remove the scratches and progress to nish grit.

► Avoid beginning with too coarse of a grit for the need. Begin sanding with a grit only coarse

enough to meet the smoothing and leveling needs of the project.

too much pressure to the sanding surface.

► Reduce your sanding pressure. Too much sanding force reduces the freewheel motion of the

sanding pad, which results in sanding swirls.

► With the sander turned off, inspect the freewheel motion of the sanding pad. If the free-

wheel seems too stiff, apply a thin lubricant such as paste wax between the pad brake and

sanding pad.

► Make sure you are holding the sander level on the work surface. Tilting the sander or even

applying uneven down-force can cause it to jump.

► Reduce sanding pressure and make sure the dust collection vacuum is running at reduced

power.

► Inspect the sanding pad for proper installation. A loose or misaligned sanding pad can result

in runout in the orbital motion.

Supplemental Owner’s Manual 21

Page 22

Festool USA

400 N. Enterprise Blvd

Lebanon, IN 46052

www.festoolusa.com

Service Questions:

800-554-8741

Application Questions:

888-337-8600

Loading...

Loading...