Page 1

702338_002

Originalbetriebsanleitung/Ersatzteilliste 7

Original operating manual/Spare parts list 16

Notice d’utilisation d’origine/Liste de pièces de rechange 24

Manual de instrucciones original/Lista de piezas de repuesto

33

Istruzioni per l'uso originali/Elenco parti di ricambio

42

Originele gebruiksaanwijzing/Lijst met reserveonderdelen 51

Originalbruksanvisning/Reservdelslista 59

Alkuperäiset käyttöohjeet/Varaosaluettelo 66

Original brugsanvisning/Reservedelsliste 74

Originalbruksanvisning/Reservedelsliste 81

Manual de instruções original/Lista de peças sobresselentes 89

/ 97

Originál návodu k obsluze/Seznam náhradních díl 106

Oryginalna instrukcja eksploatacji/Lista czci zamiennych 114

CLEANTEX

CTH 26 E/a

CTH 48 E/a

Page 2

1-5

1-9

1-2

1-4

1-3

1-6

1-7

1-12

1-11

1-13

1-141-15

1-8

1-10

1-1

1

1a

Page 3

3

2

2-2

2-3

2-1

1

2

3

5

1

2

3

4

SC-FIS-CT26/48

Page 4

1

2

3

6

4

5

6

7

2

3

1

8

8-1

8-2

8-3

FIS-CTH 26/48

Page 5

9-1

9-4

10-1 10-2 10-1

9

9-2

9-3

10

21

3 4

6

5

7

Page 6

6

CTH

CTH 26 E CTH 48 E

FIS-CTH (3 x)

(L, M, H

1

)

497541 497542

HF-CT H 498331 498331

NF-CT 496169 496169

1.

EN 60335-2-69: Staubklasse - dust category - catégorie de poussières - clase de polvo - classe di polvere - stofklasse

- dammklass - pölyluokitus - støvklasse - støvklasse - classe de poeiras - - tída prachu - kategorii

Volumenstrom mindestens

Volume flow of at least

Débit au minimum

Volumen de salida mínimo

Portata min.

Volumestroom minstens

Volymström minst

Tilavuusvirta vähintään

Luftmængde mindst

Volumstrøm minst

Vazão mínima

Objemový proud minimáln

Wielko przepywu minimum

Unterdruck

dépression

Depressione

Undertryck

Undertryk

Vácuo

Podtlak

Vacuum

Depresión

Onderdruk

Alipaine

Undertrykk

Podcinienie

[m3/h] [l/s] [Pa]

16 mm 14,5 4,0 20400 10300

22 mm 24,9 6,9 20000 13800

27 mm/ IAS 41,2 11,5 19600 17400

36 mm "AC" 57,9 16,1 17300 15800

36 mm 73,2 20,3 16200 15300

50 mm 141,3 39,5 8800 7600

Ø

Pa

Pa

Page 7

16

CTH

GB

Original operating manual

The specified illustrations appear at the beginning of the Operating Instructions.

1Symbols

2 Technical data

3 Machine features

1 Symbols .................................. 16

2 Technical data .......................... 16

3 Machine features ...................... 16

4 Intended use............................ 17

5 Safety instructions.................... 17

6 Operation ................................ 18

7 Settings .................................. 18

8 Working .................................. 20

9 Service and maintenance........... 21

10 Accessories.............................. 22

11 Disposal .................................. 22

12 Warranty ................................. 22

13 EU Declaration of Conformity...... 23

Warning of general danger

Risk of electric shock

Read the Operating Instructions/

Notes!

Wear a dust mask.

Do not throw in the household waste.

Warning contains asbestos

Socket with automatic switch-on

unit

Mobile dust extractors

Power consumption 350 - 1000 W

Maximum appliance socket connected load EU

CH, DK

GB 240 V/ 110 V

2400 W

1100 W

1800 W/ 500 W

Max. suction capacity (air), turbine

1

234 m³/h (3900 l/min)

Max. vacuum, turbine

1

24000 Pa

Filter surface area 6318 cm²

Suction hose D 27 mm x 3,5 m-AS

Length of the net cable 7,5 m

Sound pressure level as per EN 60704-2-1 / Uncertainty K 71 dB(A) / 3 dB

Protection category IP X4

Container capacity

CTH 26 E/a

26 l

CTH 48 E/a

48 l

Dimensions L x W x H

CTH 26 E/a

630 x 365 x 540 mm

CTH 48 E/a

740 x 406 x 1005 mm

Weight

CTH 26 E/a

13,9 kg

CTH 48 E/a

18,8 kg

1.

The suction capacity and vacuum are dependent on the selected hose diameter. For more information please refer

to page .

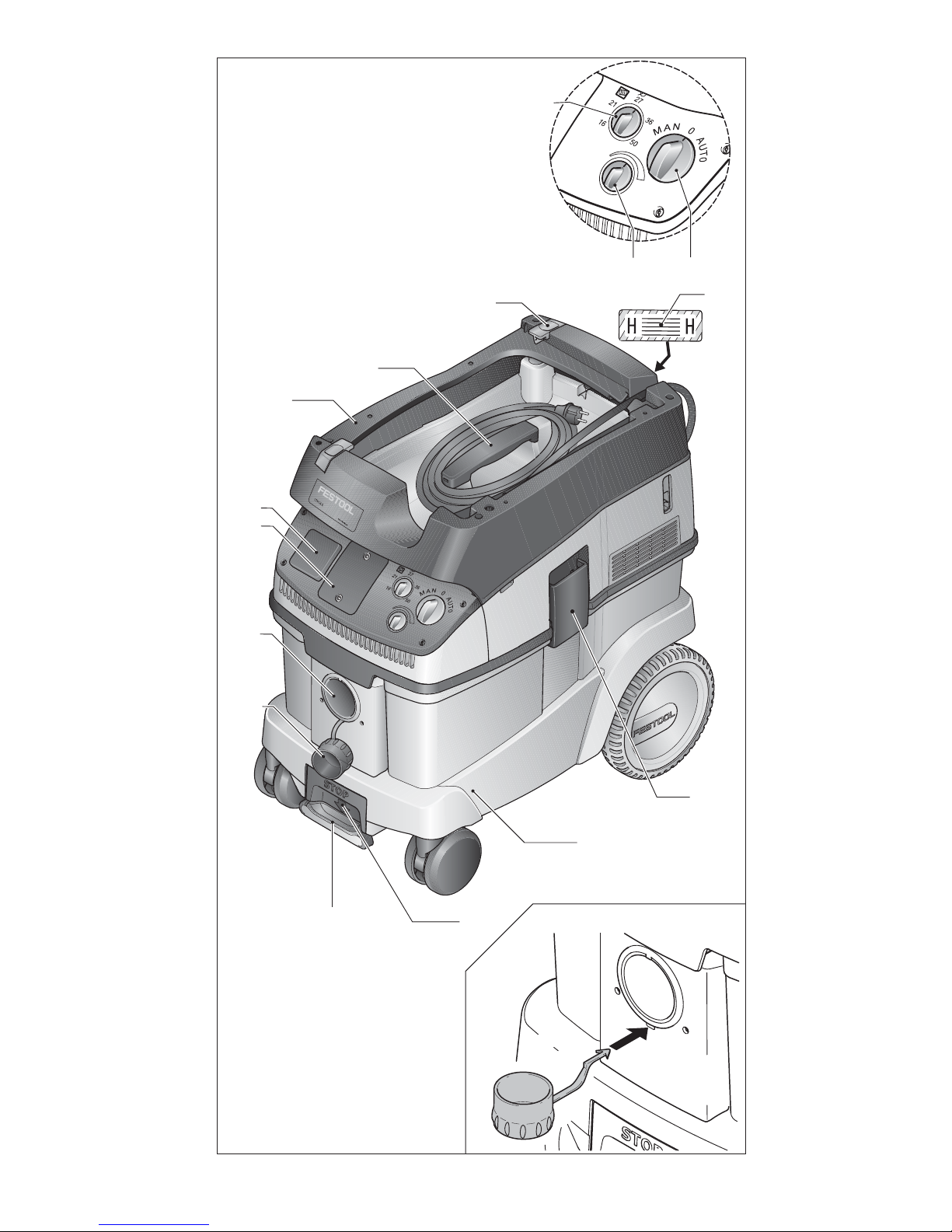

[1-1]

Sealing plug

[1-2]

Intake opening

[1-3]

Module slot

[1-4]

Appliance socket

[1-5]

Hose store

[1-6]

Handle

[1-7]

SysDoc

[1-8]

Hose diameter setting

[1-9]

Suction power adjuster

Page 8

CTH

17

GB

4 Intended use

The mobile dust extractor is suitable for the

absorption and suction of dust which is hazardous to health with limit values corresponding to dust class 'H' in accordance with

EN 60335-2-69.

The mobile dust extractor is suitable for the

absorption and suction of dust with carcinogenic and pathogenic particles, as well as asbestos dust.

The mobile dust extractor is designed to absorb water.

The mobile dust extractor is, in accordance

with EN 60335-1 and EN 60335-2-69, suitable for increased demands for commercial

use.

The user bears the responsibility for

damage and accidents caused by improper use.

5 Safety instructions

5.1 General safety instructions

Warning! Read all safety warnings

and all instructions.

Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for

future reference.

– The device is not intended for use by per-

sons (including children) with limited physical, sensory or mental ability or without

sufficient experience and/or knowledge,

unless they are supervised by a person responsible for their safety or have been instructed on how to use the device. Children

should always be supervised to ensure that

they do not play with the device.

–

WARNING:

This device contains hazardous dust. Only specialists using suitable

protective equipment in accordance with

these operating instructions may perform

emptying and maintenance tasks, including emptying the dust collection container.

Never operate the device without the complete filtration system.

– When handling and extracting dusts that

are hazardous to health, the safety regulations applicable in your country as well as

the specifications of the material manufacturer must be observed without fail.

– When extracting hazardous dust or large

quantities of oak or beech dust, only use

the machine in combination with a single

electric or pneumatic tool.

–

Risk of explosion and fire hazard:

do

not extract sparks or hot dust, flammable

or explosive dust (e.g. magnesium, aluminium), flammable or explosive fluids

(e.g. petrol, thinner), aggressive fluids/

solids (e.g. acid, leach, solvent). The extraction of wood dust is permitted. This

mobile dust extractor is suitable for extracting paint dust. Operate the machine in

a well-ventilated room (observe national

industrial safety regulations).

– Do not damage the mains power cable

(e.g. by driving over, dragging, etc.). Protect from heat, oil and sharp edges. Do not

pull the plug from the socket by the cable.

– Check the plug and the cable regularly and

have them replaced by an authorised service workshop should either become damaged cable with the type specified in the

spare parts list. Always replace the mains

power cable with the type specified in the

spare parts list.

– Do not expose the machine to rain.

– The machine should only be used by ap-

pointed persons instructed in correct machine handling.

– Before use, operators shall be provided

with information, instruction and training

for the use of the machine and the substances for which it is to be used, including

the safe method of removal and disposal of

the material collected.

– For reasons of safety, never operate the

machine from an unearthed socket.

– Always use the machine socket for the pur-

pose specified in the manual.

– Always use original Festool accessories.

– Pull the plug from the socket when the ma-

chine is not in use and prior to maintenance and cleaning work.

– Do not lift or transport the machine by the

handle using a crane or lifting gear.

[1-10]

Switch

[1-11]

Warning sticker

[1-12]

Locking clip

[1-13]

Dust container

[1-15]

Brake

Page 9

18

CTH

GB

5.2 Extracting asbestos dust

After the extractor is used to extract asbestos dust in a sealedoff area, it can no longer be used

in the white area. Exceptions are

only permitted if the asbestos

dust extractor has been completely decontaminated by an approved specialist. This

must be recorded in writing and signed by

the approved specialist.

Fixed filters may only be replaced in suitable

areas (e.g. decontamination stations) by an

approved specialist.

The applicable national regulations (for

example TRGS 519) may contain further provisions that regulate or restrict

the application areas of the mobile

dust extractor and which must be observed when extracting dust containing asbestos particles.

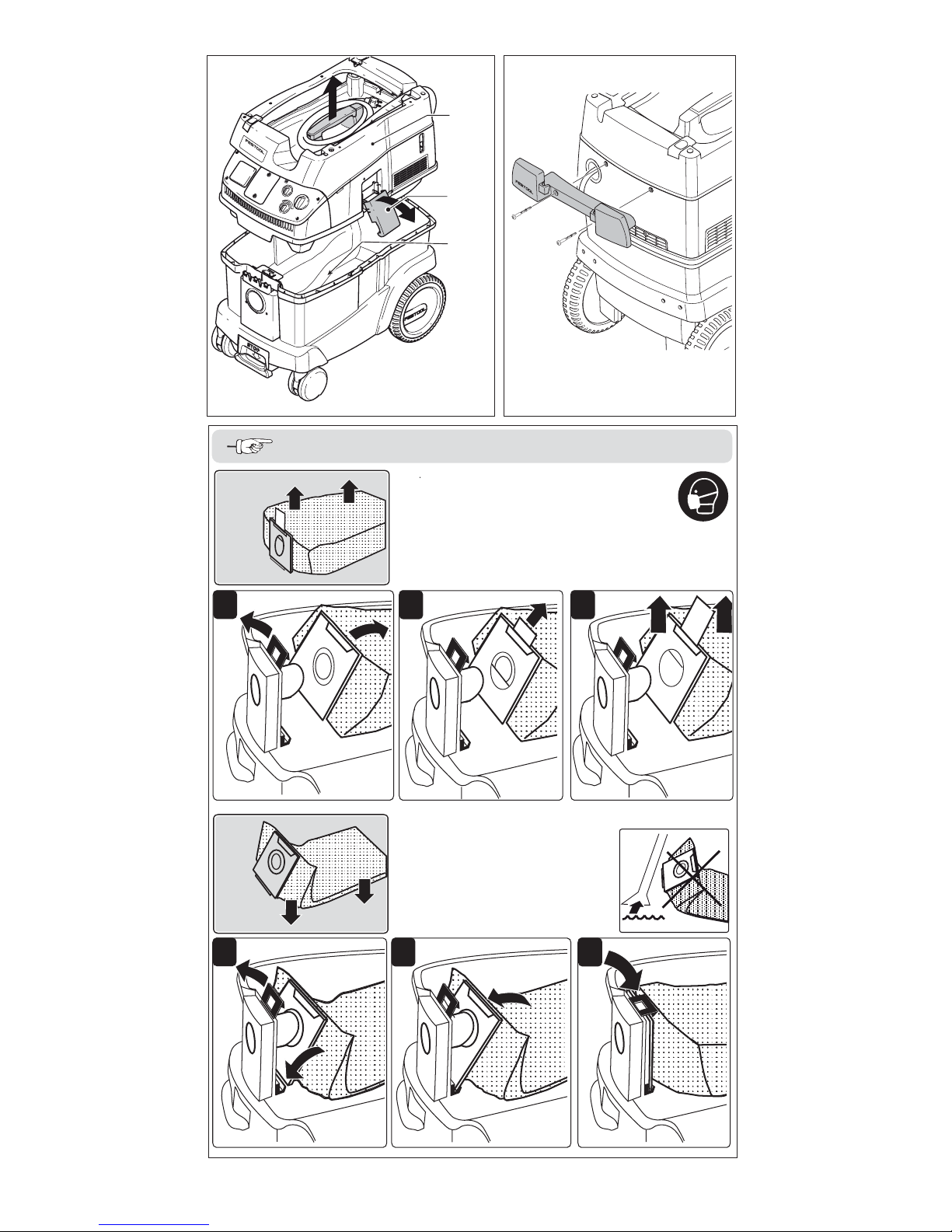

6 Operation

6.1 Initial operation

X

Open the locking clips

[2-2]

and remove

the top section of the machine

[2-1]

.

X

Remove the accessories from the dust

container

[2-3]

and the packaging!

X

Affix the accompanying sticker in your national language over the text field on the

warning sign

[1-11]

.

X

Insert the sealing plug

[1-1]

on the panel

(see Fig.

[1a]

).

X

Place a filter bag or safety filter bag in the

dirt trap in accordance with statutory requirements (see Chapter 7.7, 7.8).

X

Replace the top section

[2-1]

and close

the locking clips

[2-2]

.

X

Attach the cable holder to the rear of the

mobile dust extractor (see Fig.

[3]

).

X

Connect the suction hose to the machine.

6.2 Switch on/off

X

Insert the plug into an earthed socket.

The switch

[1-10]

serves as an on/off

switch.

Switch position "0"

Appliance socket

[1-4]

is disconnected from

the power, mobile dust extractor is switched

off.

"MAN" switch position

Appliance socket

[1-4]

is connected to the

power, the mobile dust extractor starts.

"Auto" switch position

Appliance socket

[1-4]

is connected to the

power, the mobile dust extractor starts when

the connected tool is switched on.

7 Settings

7.1 Adjusting the hose diameter

X

Adjust the hose diameter adjuster

[1-8]

to match the diameter of the connected

hose.

L

The monitoring devices will measure the

air speed in the extractor hose correctly

as a result (see chapter 7.9).

7.2 Connecting electric power tools

X

Connect the electric power tool to the appliance socket

[1-4]

.

WARNING

Unauthorised voltage or frequency!

Risk of accident

X

The mains voltage and the frequency of

the power source must correspond with

the specifications on the machine's name

plate.

X

In North America, only Festool machines

with the voltage specifications 120 V/60

Hz may be used.

WARNING

Risk of injury from tools starting up unexpectedly

X

Before setting the switch to the "AUTO" or

"MAN" position, make sure that the connected tool is switched off.

WARNING

Risk of injury

X

Observe the maximum connected loads

for the appliance socket (see chapter

"Technical data").

X

Make sure that the power tool is switched

off before connecting or disconnecting.

Page 10

CTH

19

GB

7.3 Connecting pneumatic tools

If the compressed air module

[1-3]

(496141) is installed, the automatic switchon function of the mobile dust extractor also

works in combination with pneumatic tools.

We also recommend installing the VE service

unit (495886). The service unit filters and lubricates the compressed air and enables an

adjustment of the air pressure. An IAS

adapter (454757) is available to connect Festool pneumatic tools to the IAS system.

The operating pressure of the tool must be

6 bar for the automatic switch-on unit to

function correctly.

7.4 Adjusting the suction power

You can use the suction power adjuster

[1-

9]

to adapt the machine suction power to

different applications.

7.5 Applying the brake

Folding out the black brake lever

[1-15]

prevents the mobile dust extractor from rolling.

To achieve this, lift the front end of the mobile dust extractor slightly and push the

black brake lever downwards until it latches

into place. Push the green lever

[1-14]

again to release.

7.6 Temperature cut-out

To prevent overheating, a temperature cutout switches the mobile dust extractor off

when it reaches a critical temperature.

X

Switch off the mobile dust extractor and

allow to cool for about 5 minutes.

L

If the mobile dust extractor will not switch

on again, please contact a Festool service

workshop.

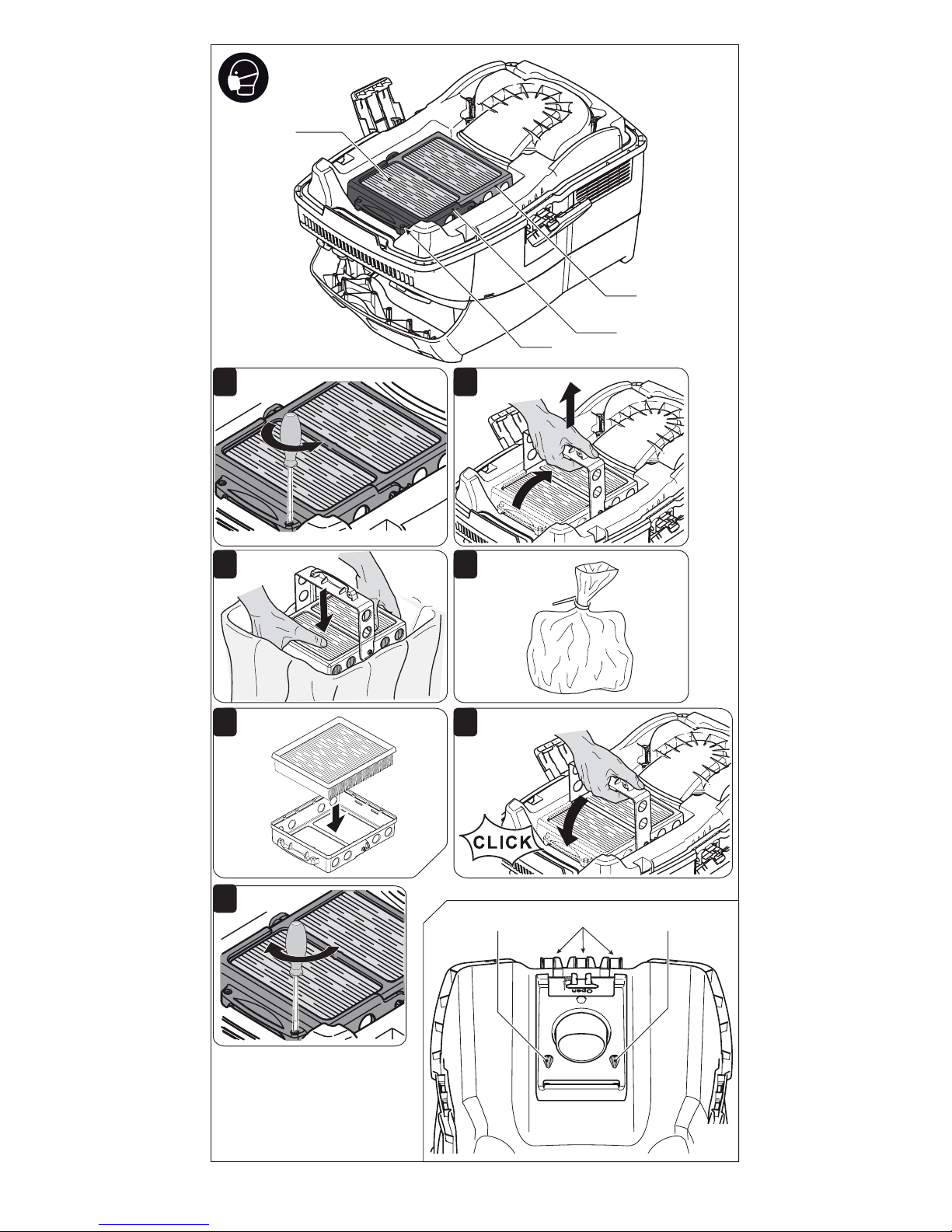

7.7 Changing the filter bag

(SC-FIS-

CT26/48)

Removing the filter bag [4]

X

Open the locking clips

[2-2]

and remove

the top section of the machine

[2-1]

.

X

Remove the filter bag.

X

Dispose of the used filter bag in accordance with statutory regulations.

X

Clean the dust container

[2-3]

.

Inserting the filter bag [5]

X

Insert a new filter bag(SC-FIS-CT26/48)

in the inlet port of the dust container and

interlock it.

Important:

be aware that

the locking engages.

L

Make sure that the filter bag is not

pinched between the top and bottom sections.

X

Replace the top section

[2-1]

and close

the locking clips

[2-2]

.

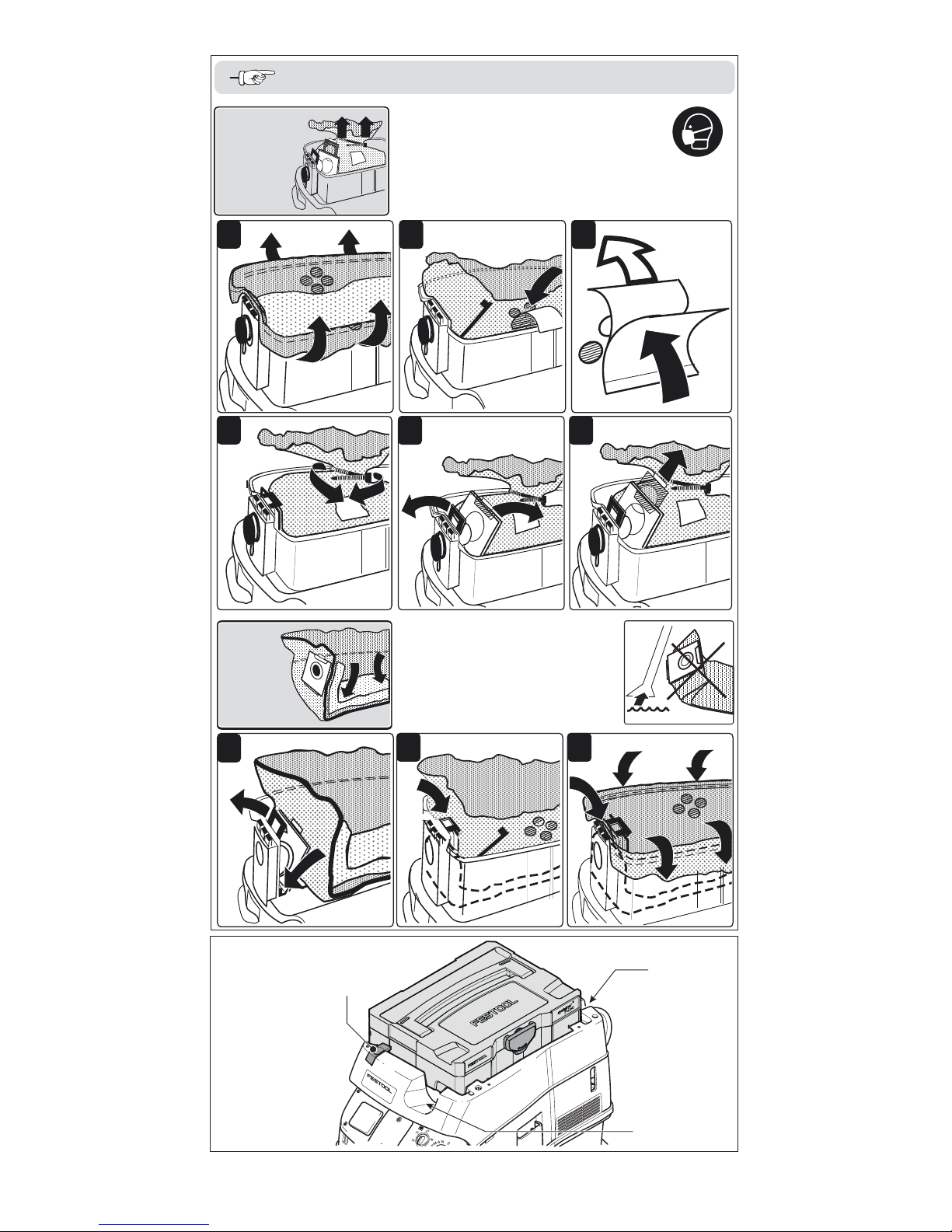

7.8 Changing the safety filter bag

(FIS-CTH 26/48)

Always use the safety filter bag for absorbing Class H dust.

Removing the safety filter bag [6]

X

Close off the extractor opening

[1-2]

us-

ing the sealing plug

[1-1]

.

X

Open the locking clips

[2-2]

and remove

the top section of the machine

[2-1]

.

X

Knock the material of the plastic bag upwards and close the lateral openings with

the adhesive tabs.

X

Close the plastic bag around the filter bag

using the cable ties supplied.

X

Remove the safety filter bag

X

Dispose of the used safety filter bag in accordance with statutory regulations.

X

Clean the dust container

[2-3]

.

Inserting the safety filter bag [7]

X

Insert a new safety filter bag (FIS-CTH

26/48) on the inlet nozzle of the container

and lock in position.

Important:

Ensure

the lock is snapped in.

X

Place the plastic bag over the edge of the

container. The lateral openings on the

safety filter bag must be positioned inside

the dirt trap.

Ensure the contacts are

[10-2]

free.

L

Make sure that the filter bag is not

pinched between the top and bottom

sections.

X

Replace the top section

[2-1]

and close

the locking clips

[2-2]

.

WARNING

Risk of injury

X

Make sure that the pneumatic tool is

switched off before connecting or disconnecting.

Page 11

20

CTH

GB

7.9 Volumetric flow monitoring

An acoustic warning signal sounds if the air speed in the suction hose falls below 20 m/s.

8Working

8.1 Handling

Hose store:

after finishing work, you can

feed the suction hose through the recess

[8-

3]

and place it in the hose store. You can do

the same with the mains cable through the

other recess

[8-2]

.

SysDoc Systainer attachment system:

a

Systainer can be attached to the storage

area via the two slides

[8-1]

.

8.2 Extracting dry materials

Observe the following

when extracting

dust generated by operating electric power

tools:

If the exhaust air is discharged back into the

room, the

air renewal rate L

within the

room must be sufficient. The volume of air

discharged back into the room must not exceed 50% of the fresh air volume flow (room

volume V

R

x air renewal rate LW). Observe all

the relevant regional regulations.

Remember:

A moist main filter clogs more

quickly when extracting dry materials.

Therefore, dry the main filter before extracting dust or replace the damp filter with a dry

one.

8.3 Extracting fluids

Before the absorption of liquids remove the

filter bag or safety filter bag (see Chapter

7.7, 7.8). The use of a special wet filter is

recommended.

The dust extractor stops automatically when

the maximum level is reached.

8.4 The antistatic system

Friction inside the extraction hose causes

static electricity to develop during extraction.

Operating personnel may receive unpleasant

electric shocks while working. The mobile

dust extractor is fitted with an antistatic system as standard to discharge any static electricity that may develop. However, always

use the enclosed antistatic extraction hose.

8.5 After finishing work

X

Switch off the mobile dust extractor and

disconnect the plug.

X

Wind up the mains power cable.

X

Empty the dust container.

X

Close off the extractor opening

[1-2]

us-

ing the sealing plug

[1-1]

.

Possible causes Solution

Value set on the suction power adjuster

[1-9]

is too low.

Set the suction power adjuster to a higher value

(see Chapter 7.4).

Rotary knob

[1-8]

not set to the correct

hose diameter.

Set the knob to the correct hose diameter (see

Chapter 7.1).

Suction hose blocked or kinked. Remove blockage or kink.

Filter bag full. Insert a new filter bag (see Chapter 7.7).

Dirty main filter. Changing the main filter (see Chapter 9.1).

Monitoring electronics malfunction. Send to a Festool service workshop for repair.

Wet extraction. Functional reliability not affected, no actions

required.

CAUTION

Hazardous dust

Damage to the respiratory passage

X

Always use a safety filter bag when extracting hazardous materials!

X

Do not use the machine if the volumetric

flow monitoring function is inactive.

CAUTION

Escaping foam and fluids

X

Switch off the machine immediately and

empty the dirt trap.

Page 12

CTH

21

GB

The machine shall be stored indoors

only.

X

Place the mobile dust extractor in a dry

room inaccessible to unauthorised users.

Observe for dust reduced transport:

X

Ensure a secure fixation during transport.

Only transport the appliance with

closed sealing plug.

9 Service and maintenance

Damaged safety devices and components

must be repaired or replaced in a recognised

specialist workshop, unless otherwise indicated in the operating manual.

Observe the following instructions:

– A dust test must be performed at least

once a year by the manufacturer or an instructed person. This test may include

checks to determine whether the filter is

damaged, the machine is sealed properly

and the monitoring features are functioning correctly.

– In addition the machine filtration efficiency

should be tested at least annually, or more

frequently as may be specified by national

requirements. The test method can be

used to verify the machine’s filter efficiency

are specified in EN 60335-2-69

AA.22.201.2.. If the test fails, it shall be

repeated with a new essential filter.

– During maintenance and repair work, all

components that cannot be cleaned satisfactorily must be replaced. The old components must be sealed in impermeable

plastic bags prior to disposal in compliance

with applicable regulations for this type of

waste.

– For user servicing, the machine must be

dismantled, cleaned and serviced, as far as

is reasonably practicable, without causing

risk to the maintenance staff and others.

Suitable precautions include, decontamination before dismantling, provision from

local filtered exhaust ventilation where the

machine is dismantled, cleaning of the

maintenance area and suitable personal

protection.

Information for sending dust extractors to repair workshops

Observe the following instructions, which are

designed to protect personnel in repair workshops and during transportation:

X

Clean the machine thoroughly (inside and

out).

X

Remove the filter/disposal bag.

X

Pack the machine in suitable airtight plastic bag.

X

Attach a list of the hazardous substances

that the machine has extracted on the

outside of the airtight packaging.

9.1 Changing the filter element

WARNING

Hazardous dust

Damage to the respiratory passage

X

Wipe down the mobile dust extractor and

clean all accessories thoroughly using the

extractor (inside and out) before removing

from the working area.

X

Parts that you were not able to clean thoroughly must be sealed in an airtight plastic

bag prior to transportation.

X

Wear a dust mask!

WARNING

Risk of injury, electric shock

X

Always disconnect the mains plug from the

socket before performing maintenance

work on the machine!

X

All maintenance and repair work which requires the motor housing to be opened

must only be carried out by an authorised

service workshop.

WARNING

Dust raised during changing filter bag

and main filter

X

Wear a dust mask!

X

If you are disposing of asbestos, wear disposable clothing.

WARNING

Risk of injury

X

Do not reuse the essential filter element

after removal out of the machine.

Page 13

22

CTH

GB

X

Open the locking clips

[2-2]

and remove

the top section of the machine

[2-1]

.

X

Turn the top section of the machine so

that the main filter

[9-1]

is facing up-

wards (Fig.

[9]

).

X

Remove the two safety bolts

[9-3]

on the

lever

[9-4]

using a screwdriver.

X

Fold over the lever

[9-4]

and remove the

retainer

[9-2]

with the main filter.

X

Insert the retainer with the main filter in

the safety bag supplied.

X

Remove the main filter from the retainer.

X

Remove the retainer from the safety bag.

X

Close and dispose of the safety bag in accordance with statutory regulations.

X

Clean any dust deposits from the area behind the main filter.

X

Insert a new main filter in the frame.

X

Insert the retainer

[9-2]

with the main fil-

ter and fold over the lever

[9-4]

until it

engages in position.

X

Tighten the safety screws

[9-3]

.

X

Replace the top section

[2-1]

and close

the locking clips

[2-2]

.

9.2 Emptying the dust container

The dust container

[2-3]

can be emptied

once the top section has been removed.

X

After extracting fluids, clean the fill level

sensors

[10-1]

regularly with a soft cloth

and inspect for damage.

10 Accessories

Use only original Festool accessories and

Festool consumable material intended for

this machine because these components are

designed specifically for the machine. Using

accessories and consumable material from

other suppliers will most likely affect the

quality of your working results and limit any

warranty claims. Machine wear or your own

personal workload may increase depending

on the application. Protect yourself and your

machine, and preserve your warranty claims

by always using original Festool accessories

and Festool consumable material!

The order numbers for the accessories and

filters can be found in the Festool catalogue

or on the Internet at "www.festool.com".

10.1 Modules

The following modules for upgrading the mobile dust extractor are available in the accessories programme. Modules must be fitted to

the module slot

[1-3]

by an authorised ser-

vice workshop:

– Compressed air module,

– Socket module with permanent power sup-

ply,

– Socket module with automatic switch-on

unit (not suitable for GB 110 V version),

– Energy box module (EAA) for using the au-

tomatic switch-on unit on the EAA.

You can find more detailed information on

the modules at "www.festool.com".

11 Disposal

Do not throw the tool in your household

waste!!

Dispose of machines, accessories

and packaging at an environmentally responsible recycling centre. Observe the valid

national regulations.

EU only:

European Directive 2002/96/EC

stipulates that used electric tools must be

collected separately and disposed of at an

environmentally responsible recycling centre.

12 Warranty

We offer a warranty for material and production defects for all our tools in accordance

with the locally applicable legal provisions,

but for a minimum of 12 months. Within the

EU member states, the warranty period is 24

months (verification through invoice or delivery note). Damage caused by the operator,

natural wear, overloading, incorrect handling

or through the use of the equipment not

specified in the operating manual, or damage

which was known at the time of purchase, is

not covered by the warranty. Furthermore,

damage caused by the use of non-original

accessories and consumable materials (e.g.

sanding pads) is also excluded.

NOTE

Motor damage

X

Never operate the extractor without a filter element fitted as the motor may become damaged.

Page 14

CTH

23

GB

Complaints can only be accepted if the tool is

returned while still assembled to the supplier

or an authorised Festool Customer Service

workshop. Keep the operating manual, safety instructions, spare parts list and purchase

receipt in a safe place. Otherwise the current

warranty conditions of the manufacturer

shall apply.

Note

Due to continuous research and development work, we reserve the right to make

changes to the technical content of this documentation.

13 EU Declaration of Conformi-

ty

We declare under sole responsibility that this

product complies with the following directives and standards:

2006/42/EG, 2004/108/EG, 2011/65/EU

(from 01.01.2013), EN 60335-1, EN 603352-69, EN 55014-1, EN 55014-2, EN 610003-2, EN 61000-3-3.

Festool GmbH

Wertstr. 20, D-73240 Wendlingen, Germany

Dr. Johannes Steimel

Head of Research, Development and Techni-

cal Documentation

04.11.2010

REACh for Festool products, its accessories and consumable materials:

REACh is a European Chemical Directive that

came into effect in 2007. As "downstream

users" and product manufacturers, we are

aware of our duty to provide our customers

with information. We have set up the following website to keep you updated with all the

latest news and provide you with information

on all the materials used in our existing products:

www.festool.com/reach

Mobile dust extractor Serial no.

CTH 26 E/a 496162, 498530,

498531

CTH 48 E/a 496163

Year of CE mark: 2010

Loading...

Loading...