Page 1

703002_002

FESTOOL GmbH

Wertstraße 20

D-73240 Wendlingen

Tel.: 07024/804-0

Telefax: 07024/804-20608

E-Mail: info@tts-festool.com

Instruction manual

Important: Read all instruc-

tions before using

.

CLEANTEX

CT 48 E LE EC/B22

Page 2

1-9

1-2

1-4

1-3

1-5

1-6

1-7

1-12

1-11

1-13

1-14

1-15

1-8

1-10

1-1

1

Page 3

1

2

3

5

1

2

3

4

3

2

2-1

2-2

2-3

SC-FIS CT 48 497 542

Page 4

7-1

6-1

6-1

7-3

7

6

7-2

1 2

3

5

4

HEPA-HF-CT48

496 171

Page 5

479 709

KLF-CT

2

3

4

1

5

9-1

8-1

9

8

Page 6

6

Original operating manual

The specified illustrations appear at the beginning of

the Operating Instructions.

Symbols

Intended use

The mobile dust extractor is suitable for the extraction of dry, combustible dust from machines and

equipment in Zone 22 in accordance with IEC 603352-69.

The mobile dust extractors are designed for extracting non-hazardous dust.

The HEPA filter corresponds to HEPA filter class 13

(degree of filtration > 99.95%).

The mobile dust extractors are designed to extract

water

as well as for heavy-duty applications and industrial

use in accordance with IEC 60335-1 and IEC 60335-2-

69.

The mobile dust extractor is not suitable for extracting dust that poses a risk of explosion (e.g. explosives), flammable liquids and mixtures of combustible dust and flammable liquids.

The mobile dust extractor is not suitable for equipment that generates sources of ignition.

The user bears the responsibility for damage

and accidents caused by improper use.

Symbols................................................ 6

Intended use......................................... 6

Machine features ................................. 7

Technical data ...................................... 7

Safety instructions ............................... 7

General safety instructions................ 7

Operation.............................................. 8

Initial operation .................................. 9

Switch on/off ...................................... 9

Settings ................................................ 9

Adjusting the hose diameter.............. 9

Connecting electric power tools ........ 9

Connecting pneumatic tools .............. 9

Connecting the energy box................. 10

Adjusting the suction power .............. 10

Applying the brake ............................. 10

Temperature cut-out.......................... 10

Changing the filter bag (SC-FIS-CT 48) 10

Volumetric flow monitoring ............... 10

Working ................................................ 11

Handling ............................................. 11

Extracting dry materials .................... 11

Extracting fluids ................................. 11

After finishing work............................ 11

Service and maintenance..................... 12

Changing the filter element............... 12

Changing the cooling air filter [8] ...... 12

Emptying the dust container.............. 12

Accessories.......................................... 13

Disposal................................................ 13

Warranty............................................... 13

Warning of general danger

Risk of electric shock

Read the Operating Instructions/Notes!

Wear a dust mask.

Do not extract glowing dust or other

ignition sources. Do not use in conjunction with machines that generate

sparks!

Do not insert or pull out the plug

under load!

Page 7

7

Machine features

Technical data

Safety instructions

General safety instructions

Warning! Read all safety warnings and all in-

structions.

Failure to follow the warnings and instructions may result in electric shock, fire and/or

serious injury.

Save all warnings and instructions for future reference.

– The device is not intended for use by persons (in-

cluding children) with limited physical, sensory

or mental ability or without sufficient experience

and/or knowledge, unless they are supervised by

a person responsible for their safety or have been

instructed on how to use the device. Children

should always be supervised to ensure that they

do not play with the device.

– Prior to use, operating personnel must receive

information and instructions on how to use the

device and handle any materials involved as well

as relevant training, including safe procedures

for disposing of the extracted materials.

– Observe all the applicable safety regulations relat-

ing to handling materials.

–

Warning:

the machine may contain hazardous

dust. Only authorised and qualified personnel with

suitable protective equipment may perform main-

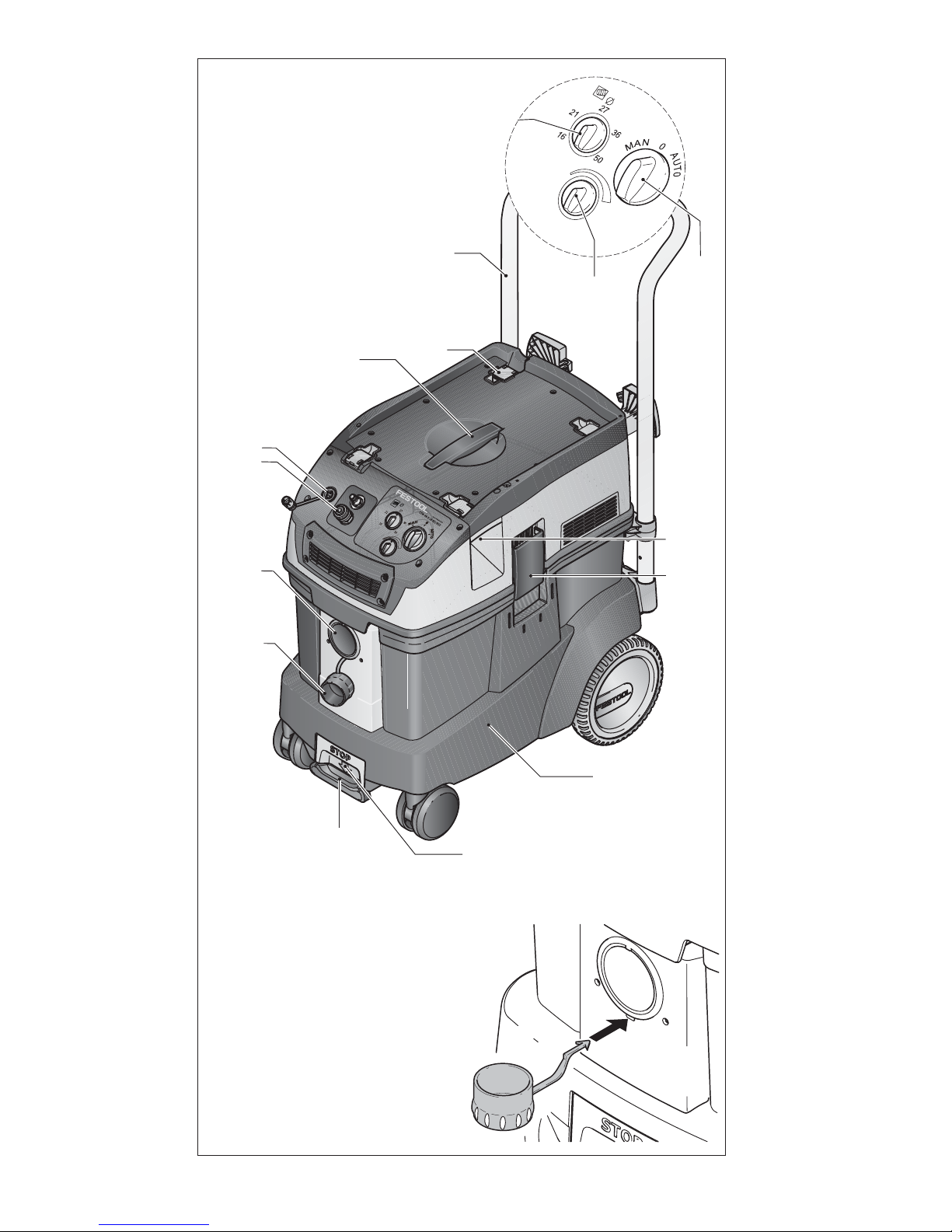

[1-1]

Sealing plug

[1-2]

Intake opening

[1-3]

Compressed air connection

[1-4]

Connection for energy box

[1-5]

Handle

[1-6]

SysDoc

[1-7]

Handle SB-CT (accessory)

[1-8]

Hose diameter setting

[1-9]

Switch

[1-10]

Suction power adjuster

[1-11]

Appliance socket with automatic on/off

function

[1-12]

Locking clip

[1-13]

Dust container

[1-15]

Brake

Mobile dust extractors

Power consumption 150 - 1100 W

Maximum appliance socket connected load AUS 1300 W

Max. suction capacity (air), turbine 204 m³/h (3400 l/min)

Max. vacuum, turbine 23000 Pa

Filter surface area 6318 cm²

Suction hose D 27 mm x 3,5 m-AS

Length of the net cable 7,5 m

Sound pressure level as per EN 60704-2-1 / Uncertainty K 72 dB(A) / 3 dB

Protection category CE 0344 EX II 3D Ex e 135°C

IP 54

Container capacity 48 l

Dimensions L x W x H 630 x 406 x 640 mm

Weight 18,6 kg

Page 8

8

tenance work, including emptying the container

and changing the filter. Do not operate the machine without a fully fitted filter system.

– When extracting hazardous dust or large quanti-

ties of oak or beech dust, only use the machine in

combination with a single electric or pneumatic

tool.

–

Risk of explosion and fire hazard:

Also observe

any other restrictions relating to dust with an ignition energy of less than 1 mJ specified by the labour authorities. Do not extract sparks or hot dust,

flammable or explosive fluids (e.g. petrol, thinner),

aggressive fluids/solids (e.g. acid, leach, solvent).

This mobile dust extractor is suitable for extracting

paint dust.

– Do not damage the mains power cable (e.g. by driv-

ing over, dragging, etc.). Protect from heat, oil and

sharp edges. Do not pull the plug from the socket

by the cable.

– Check the plug and the cable regularly and have

them replaced by an authorised service workshop

should either become damaged. Always replace

the mains power cable with the type specified in

the spare parts list.

– Do not expose the machine to rain.

– For reasons of safety, never operate the machine

from an unearthed socket.

– Always use the machine socket for the purpose

specified in the manual.

– Always use original Festool accessories.

– Pull the plug from the socket when the machine is

not in use and prior to maintenance and cleaning

work.

– Design 22 dust extractors are suitable for connect-

ing to machines in Zone 22. Care must be taken to

ensure that no sources of ignition are extracted.

Conductive machine components, including ex-

tractor hoods, and conductive parts on machines

from protection class II must be electrostatically

earthed. The electrostatic earthing can be routed

through the dust extractor or established using

separate electrostatic earthing equipment.

– Do not lift or transport the machine by the handle

using a crane or lifting gear.

– The device may only be operated if all filters are

present and undamaged, including the filter for

the motor cooling air.

– Do not insert and remove the plug under load.

– In an emergency (e.g. short circuit or other electri-

cal faults occur), switch off the machine and pull

out the mains plug.

Operation

WARNING

Unauthorised voltage or frequency!

Risk of accident

X

The mains voltage and the frequency of the power source must correspond with the specifications on the machine's name plate.

X

In North America, only Festool machines with

the voltage specifications 120 V/60 Hz may be

used.

Page 9

9

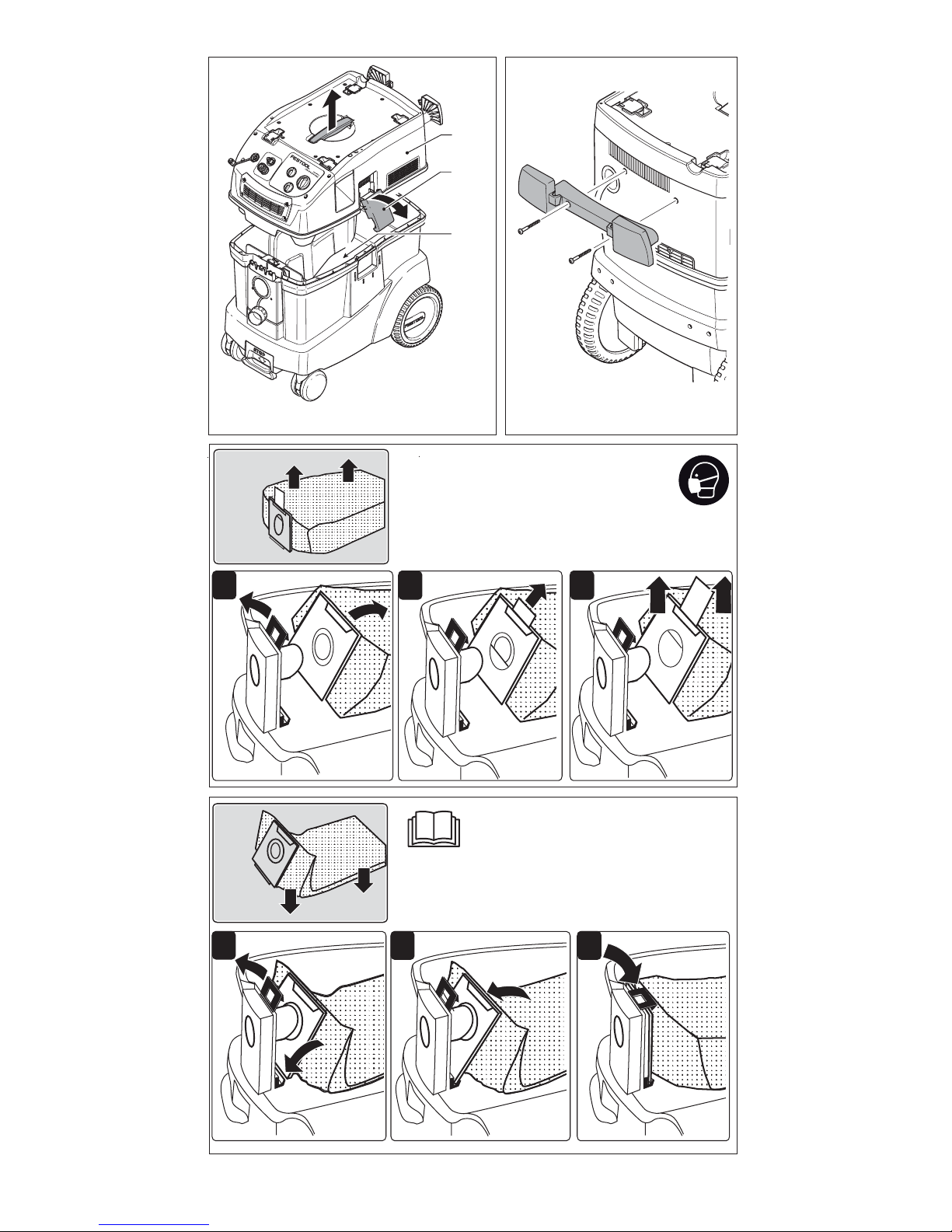

Initial operation

X

Open the locking clips

[2-2]

and remove the top

section of the machine

[2-1]

.

X

Remove the accessories from the dust container

[2-3]

and the packaging!

X

Insert a filter bag in the dust container that fulfils

statutory requirements (see chapter "

Changing

the filter bag (SC-FIS-CT 48)

").

X

Replace the top section

[2-1]

and close the lock-

ing clips

[2-2]

.

X

Attach the cable holder to the rear of the mobile

dust extractor (see Fig.

[3]

).

X

Insert the sealing plug

[1-1]

on the panel (see

Fig.

[1]

).

X

Connect the suction hose to the machine.

Switch on/off

X

Insert the plug into an earthed socket.

The use of extension cables in Zone 22 is not

permitted.

The switch

[1-9]

serves as an on/off switch.

Switch position "0"

Appliance socket

[1-11]

is disconnected from the

power, mobile dust extractor is switched off.

"MAN" switch position

Appliance socket

[1-11]

is connected to the power,

the mobile dust extractor starts.

"Auto" switch position

Appliance socket

[1-11]

is connected to the power,

the mobile dust extractor starts when the connected tool is switched on.

Settings

Adjusting the hose diameter

X

Adjust the hose diameter adjuster

[1-8]

to match

the diameter of the connected hose.

L

The monitoring devices will measure the air

speed in the extractor hose correctly as a result

(see chapter "

Volumetric flow monitoring

").

Connecting electric power tools

X

Connect the electric power tool to the appliance

socket

[1-11]

.

Connecting pneumatic tools

With the compressed air module

[1-3]

, the automatic

switch-on function for the mobile dust extractor also

works in conjunction with air tools.

We also recommend installing the VE service unit

(495886). The service unit filters and lubricates the

compressed air and enables an adjustment of the air

CAUTION

Risk of injury from tools starting up unexpectedly

X

Before setting the switch to the "AUTO" or

"MAN" position, make sure that the connected

tool is switched off.

WARNING

Risk of injury

X

Observe the maximum connected loads for the

appliance socket (see chapter "Technical data").

X

Make sure that the power tool is switched off before connecting or disconnecting.

WARNING

Risk of injury

X

Make sure that the pneumatic tool is switched

off before connecting or disconnecting.

Page 10

10

pressure. An IAS adapter (454757) is available to connect Festool air tools to the IAS system.

The operating pressure of the tool must be 6 bar for

the automatic switch-on unit to function correctly.

Connecting the energy box

The connection for the energy box (EAA)

[1-4]

allows

you to connect the mobile dust extractor with the EAA

in order to couple the automatic switch-on unit on the

mobile dust extractor with the equivalent unit on the

EAA.

Adjusting the suction power

You can use the suction power adjuster

[1-10]

to

adapt the machine suction power to different applications.

Applying the brake

Folding out the black brake lever

[1-15]

prevents the

mobile dust extractor from rolling. To achieve this,

lift the front end of the mobile dust extractor slightly

and push the black brake lever downwards until it

latches into place. Push the green lever

[1-14]

again

to release.

Temperature cut-out

A temperature cut-out switches the mobile dust extractor off when it reaches a critical temperature to

prevent overheating.

X

Switch off the mobile dust extractor and allow to

cool for approx. 5 minutes.

X

Change the cooling air filter if necessary (see

chapter "

Changing the cooling air filter [8]

").

L

If the mobile dust extractor will not switch on

again, please contact a Festool service workshop.

Changing the filter bag

(SC-FIS-CT 48)

Removing the filter bag [4]

X

Open the locking clips

[2-2]

and remove the top

section of the machine

[2-1]

.

X

Remove the filter bag.

X

Dispose of the used filter bag in accordance with

statutory regulations.

Inserting the filter bag [5]

X

Insert a new filter bag (SC-FIS-CT 48) in the inlet

port of the dust container and interlock it.

Impor-

tant:

be aware that the locking engages.

L

Make sure that the filter bag is not pinched between the top and bottom sections.

X

Replace the top section

[2-1]

and close the lock-

ing clips

[2-2]

.

Volumetric flow monitoring

An acoustic warning signal sounds if the air speed in the suction hose falls below 20 m/s.

Possible causes Solution

Value set on the suction power adjuster

[1-10]

is

too low.

Set the suction power adjuster to a higher value (see

Chapter "Adjusting the suction power").

Rotary knob

[1-8]

not set to the correct hose

diameter.

Set the knob to the correct hose diameter (see Chap-

ter "Adjusting the hose diameter").

Suction hose blocked or kinked. Remove blockage or kink.

Filter bag full. Insert a new filter bag (see Chapter "Changing the fil-

ter bag (SC-FIS-CT 48)").

Dirty main filter. Changing the main filter (see Chapter "Changing the

filter bag (SC-FIS-CT 48)").

Monitoring electronics malfunction. Send to a Festool service workshop for repair.

Wet extraction. Functional reliability not affected, no actions required.

Page 11

11

Working

Handling

SysDoc SYSTAINER attachment system:

A SYSTAINER can be attached to the storage area using

the four locking latches

[6-1]

.

Extracting dry materials

Observe the following

when extracting dust generat-

ed by operating electric power tools:

If the exhaust air is discharged back into the room,

the

air renewal rate L

within the room must be sufficient. The volume of air discharged back into the

room must not exceed 50% of the fresh air volume

flow (room volume V

R

x air renewal rate LW). Observe

all the relevant regional regulations.

Remember:

A moist main filter clogs more quickly

when extracting dry materials. Therefore, dry the

main filter before extracting dust or replace the

damp filter with a dry one.

Extracting fluids

L

The HEPA filter element shall only be used for extracting dry materials.

Before extracting fluids, remove the filter bag (see

Chapter "

Changing the filter bag (SC-FIS-CT 48)

").

We recommend using a special wet filter.

The dust extractor stops automatically when the

maximum level is reached.

After finishing work

Empty the mobile dust extractor after every

use and clean if necessary.

X

Switch off the mobile dust extractor and disconnect the plug.

X

Wind up the mains power cable.

X

Empty the dust container.

X

Close off the extractor opening

[1-2]

using the

sealing plug

[1-1]

.

The machine shall be stored indoors only.

X

Place the mobile dust extractor in a dry room inaccessible to unauthorised users.

CAUTION

Hazardous dust

Damage to the respiratory passage

X

Always use a filter bag when extracting hazardous materials!

X

Do not use the machine if the volumetric flow

monitoring function is inactive.

CAUTION

Escaping foam and fluids

X

Switch off the machine immediately and empty

the dirt trap.

Page 12

12

Service and maintenance

Damaged safety devices and components must be

repaired or replaced in a recognised specialist workshop, unless otherwise indicated in the operating

manual.

Observe the following instructions:

– A dust test must be performed at least once a year

by the manufacturer or an instructed person. This

test may include checks to determine whether the

filter is damaged, the machine is sealed properly

and the monitoring features are functioning correctly.

– During maintenance and repair work, all compo-

nents that cannot be cleaned satisfactorily must be

replaced. The old components must be sealed in

impermeable plastic bags prior to disposal in compliance with applicable regulations for this type of

waste.

– Provided maintenance personnel or other persons

in the vicinity are not endangered, the user must

dismantle and clean the machine prior to performing maintenance work. Appropriate precautionary

measures include decontaminating the machine

prior to disassembly, making provisions for locally

filtered forced ventilation at the location of machine disassembly, cleaning the maintenance area

and appropriate personal protective equipment.

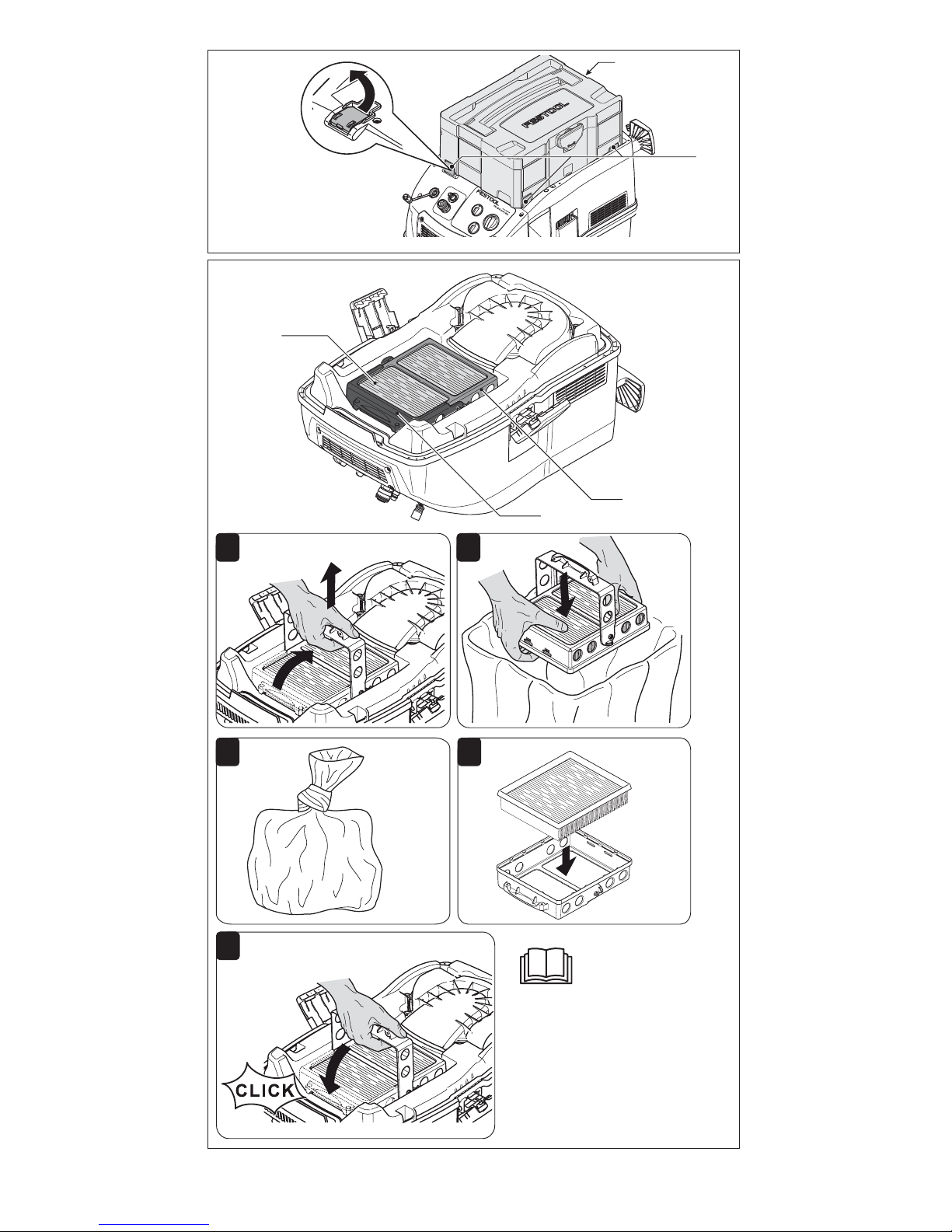

Changing the filter element

X

Open the locking clips

[2-2]

and remove the top

section of the machine

[2-1]

.

X

Turn the top section of the machine so that the

main filter is facing upwards (Fig.

[7]

).

X

Fold over the lever

[7-3]

and remove the retainer.

[7-2]

X

Remove the used main filter and replace

[7-1]

with a new one.

X

Dispose of the used filter in accordance with statutory regulations.

X

Insert the retainer

[7-2]

and fold over the lever

[7-3]

until it engages.

X

Replace the top section

[2-1]

and close the lock-

ing clips

[2-2]

.

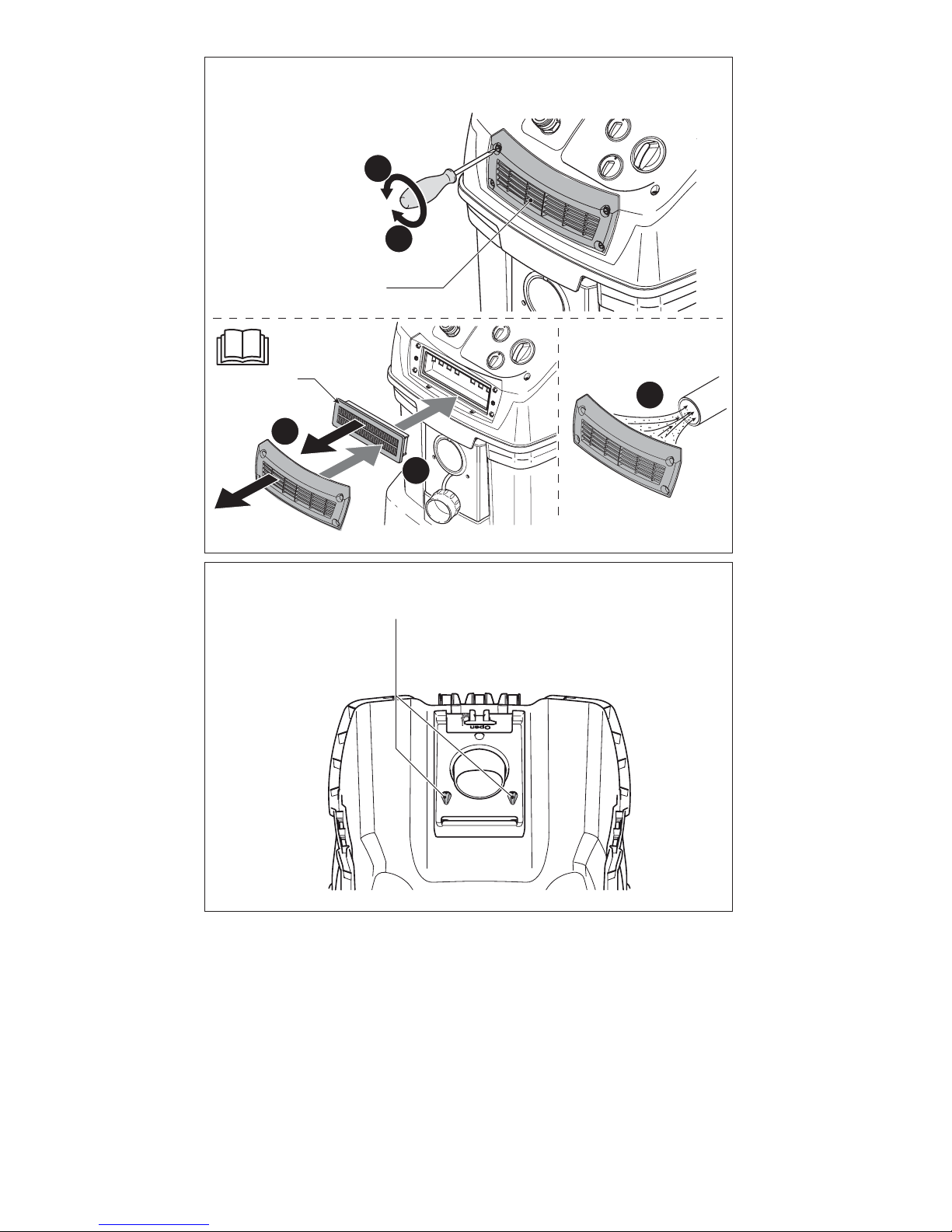

Changing the cooling air filter [8]

Replace the cooling air filter if the mobile dust extractor switches off due to excess temperature and

replace at least once a year.

L

We recommend that you always replace the cooling air filter together with the main filter.

X

Unscrew the cooling air cover

[8-1]

.

X

Remove the cooling air filter and replace with a

new one!

X

Close the cooling air cover.

Emptying the dust container

The dust container

[2-3]

can be emptied once the top

section has been removed.

X

After extracting fluids, clean the fill level sensors

[9-1]

regularly with a soft cloth and inspect for

damage.

WARNING

Risk of injury, electric shock

X

Always disconnect the mains plug from the

socket before performing maintenance work on

the machine!

X

All maintenance and repair work which requires

the motor housing to be opened must only be

carried out by an authorised service workshop.

NOTE

Motor damage

X

Never operate the extractor without a filter element fitted as the motor may become damaged.

Page 13

13

Accessories

Use only original Festool accessories and Festool

consumable material intended for this machine be-

cause these components are designed specifically

for the machine. Using accessories and consumable

material from other suppliers will most likely affect

the quality of your working results and limit any warranty claims. Machine wear or your own personal

workload may increase depending on the application.

Protect yourself and your machine, and preserve

your warranty claims by always using original Festool accessories and Festool consumable material!

The order numbers for the accessories and filters

can be found in the Festool catalogue or on the Internet at "www.festool.com".

Disposal

Do not throw the tool in your household waste!! Dispose of machines, accessories and packaging at an

environmentally responsible recycling centre. Observe the valid national regulations.

EU only: European Directive 2002/96/EC stipulates

that used electric tools must be collected separately

and disposed of at an environmentally responsible

recycling centre.

Warranty

We offer a warranty for material and production defects for all our tools in accordance with the locally

applicable legal provisions, but for a minimum of 12

months. Within the EU member states, the warranty

period is 24 months (verification through invoice or

delivery note). Damage caused by the operator, natural wear, overloading, incorrect handling or through

the use of the equipment not specified in the operating manual, or damage which was known at the time

of purchase, is not covered by the warranty. Furthermore, damage caused by the use of non-original accessories and consumable materials (e.g. sanding

pads) is also excluded.

Complaints can only be accepted if the tool is returned while still assembled to the supplier or an authorised Festool Customer Service workshop. Keep

the operating manual, safety instructions, spare

parts list and purchase receipt in a safe place. Other-

wise the current warranty conditions of the manufacturer shall apply.

Note

Due to continuous research and development work,

we reserve the right to make changes to the technical

content of this documentation.

WARNING

Using non-approved accessories and spare parts

Risk of explosion

X

Always use Festool approved accessories and

spare parts in Design 22 mobile dust extractors

- See accompanying spare parts and accessories list.

Page 14

Loading...

Loading...