Page 1

EN

Page 2

Page 3

STOP

Page 4

EN

Rotary Hammer drill 850W

HDM1030P

Thank you for buying this FERM product. By

doing so you now have an excellent product,

delivered by one of Europe’s leading suppliers.

All products delivered to you by Ferm are

manufactured according to the highest standards

of performance and safety. As part of our

philosophy we also provide an excellent customer

service, backed by our comprehensive warranty.

We hope you will enjoy using this product for

many years to come.

1. SAFETY WARNINGS

WARNING

Read the enclosed safety warnings,

the additional safety warnings and

the instructions. Failure to follow the safety

warnings and the instructions may result in

electric shock, re and/or serious injury. Save the

safety warnings and the instructions for future

reference.

The following symbols are used in the user

manual or on the product:

Read the user manual.

Denotes risk of personal injury, loss of life

or damage to the tool in case of nonobservance of the instructions in this

manual.

Wear safety gloves.

Do not dispose of the product in

unsuitable containers.

Variable electronic speed

Additional safety warnings for rotary

hammers

a) Wear ear protectors. Exposure to noise can

cause hearing loss.

b) Use auxiliary handle(s), if supplied with the

tool. Loss of control can cause personal injury.

c) Hold power tool by insulated gripping

surfaces, when performing an operation

where the cutting accessory may contact

hidden wiring or its own cord. Cutting

accessory contacting a “live” wire may make

exposed metal parts of the power tool “live”

and could give the operator an electric shock.

Electrical safety

When using electric machines always observe the

safety regulations applicable in your country to

reduce the risk of fire, electric shock and personal

injury. Read the following safety instructions and

also the enclosed safety instructions.

Always check that the voltage of the

power supply corresponds to the voltage

on the rating plate label.

Risk of electric shock

Immediately remove the mains plug from

the mains if the mains cable becomes

damaged and during cleaning and

maintenance.

Always wear eye protection!

Wear hearing protection.

If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk

of electric shock.

Replacement of power cords or plugs

If the supply cord is damaged, it must be replaced

by the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard.

Class II machine - Double insulation - You

don’t need any earthed plug.

4

Page 5

EN

Mains plug replacement (UK only)

If the moulded 3-pin plug attached to the unit is

damaged and needs replacing, it is important

that it is correctly destroyed and replaced by

an approved BS1363/13A fused plug and that

the following wiring instructions are followed.

The wires in the mains cable are coloured in

accordance with the following code:

• blue neutral

• brown live

As the colours of the wires in the mains cable

of the unit may not correspond to the coloured

markings identifying the terminals in the plug,

proceed as follows:

• The wire which is coloured blue must be

connected to the terminal which is marked

with the letter N or coloured black.

• The wire which is coloured brown must be

connected to the terminal which is marked

with the letter L or coloured red.

Use of extension leads

Only ever use approved extension leads that are

suitable for the power rating of the machine. The

minimum core thickness is 1.5 mm2. Whenever

using a reel extension lead, always fully unroll the

lead.

Immediately switch off the machine when:

• Excessive sparking of the carbon brushes.

• Interruption of the mains plug, mains lead or

mains lead damage.

• Defect switch.

• Smoke or stench of scorched isolation.

2. MACHINE INFORMATION

Intended use

This rotary hammer is intended for drilling holes

in masonry such as brick, concrete and similar

material. Furthermore, the machine can be used

as a demolition hammer in combination with the

SDS cold chisels provided. The machine is on no

account intended for other purposes.

Not suitable for construction site usage

Technical specifications HDM1030P

Mains voltage 230-240 V ~

Mains frequency 50 Hz

Power input 850 W

No-load speed 0-1250 /min

Max. Drill diameter

-Concrete

-Steel

-Wood

Weight 3.3kg

Protect yourself against the effects of vibration by

maintaining the tool and its accessories, keeping

your hands warm and organizing your work

patterns.

Ø 26 mm

Ø 13 mm

Ø 30 mm

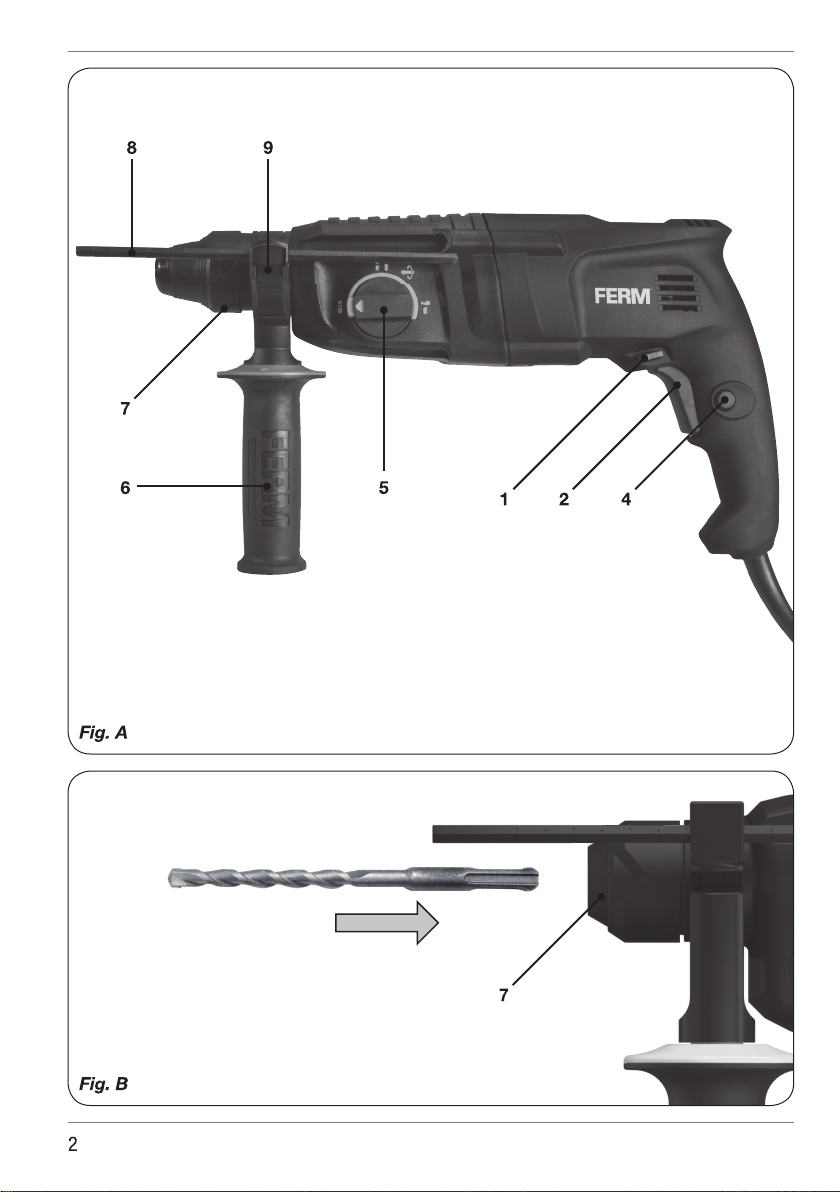

Description

The numbers in the text refer to the diagrams on

pages 2-3

Fig. A

1. Left/right rotation switch

2. On/Off switch

4. Lock-on button

5. Function selection switch

6. Side handle

7. Locking sleeve

8. Depth stop ruler

9. Depth stop button

3. OPERATING

Hammer drills require very little operator

pressure. Excessive pressure on the tool

can lead to unnecessary overheating of

the motor, and burning of the driven tool.

It also may happen the drill bit deforms

and cannot be removed from the

machine again.

Side handle

Fig. A

The side handle (6) can be rotated 360° around

the drill head, enabling safe and comfortable

operation for both left and right-handed users.

5

Page 6

EN

• Loosen the handgrip by turning it

anticlockwise.

• Rotate the handgrip to the desired position.

• Retighten the handgrip in the new position by

turning it clockwise.

Exchanging and removing drill bits

Fig. A - B

Before exchanging bits, first remove the

power plug from the wall socket.

Inspect bits regularly during use. Blunt

bits should be re-sharpened or replaced.

Lightly oil the bit shaft before inserting it

into the chuck.

• SDS drills can be inserted by pushing the drill

into the chuck until a click can be heard. If

needed rotate the SDS drill a little to ensure the

keyway in the bit fits the chuck well.

DO NOT slide the locking sleeve (7) to the

rear when inserting bits.

• To remove the SDS drill, slide the locking

sleeve (7) to the rear and remove the SDS drill

while keeping the sleeve (7) in this position.

Setting depth stop

Fig. A

• The depth stop ruler can be added to the side

handle by pushing the dept stop button (9).

• Keep pushing the depth stop button (9) and

insert the depth stop ruler (8) through the hole

on the side handle ring.

• Slide the ruler to the desired depth.

• Loosen the depth stop button (9).

The On/Off switch

Fig. A

• Switch the machine on by pressing the On/Off

switch (2). When releasing the On/Off switch

(2) the machine will turn off.

• The rotation-speed can be continuously

adjusted by pressing the On/Off switch (2)

deeper or less deep.

Lock-on button

Fig. A

• Lock the On/Off switch (2) by pressing the On/

Off switch (2) and then pressing the lock-on

button (4).

• Release the switch-lock by shortly pressing

the On/Off switch (2) again.

Switching the direction of rotation

Fig. A.

• Direction of rotation counter-clockwise: shift

left/right switch (1) to “

• Direction of rotation clockwise: shift left/right

switch (1) to “ ”.

This function is only available when the machine

is set to “drill mode” (As shown in fig. D function

A & B).

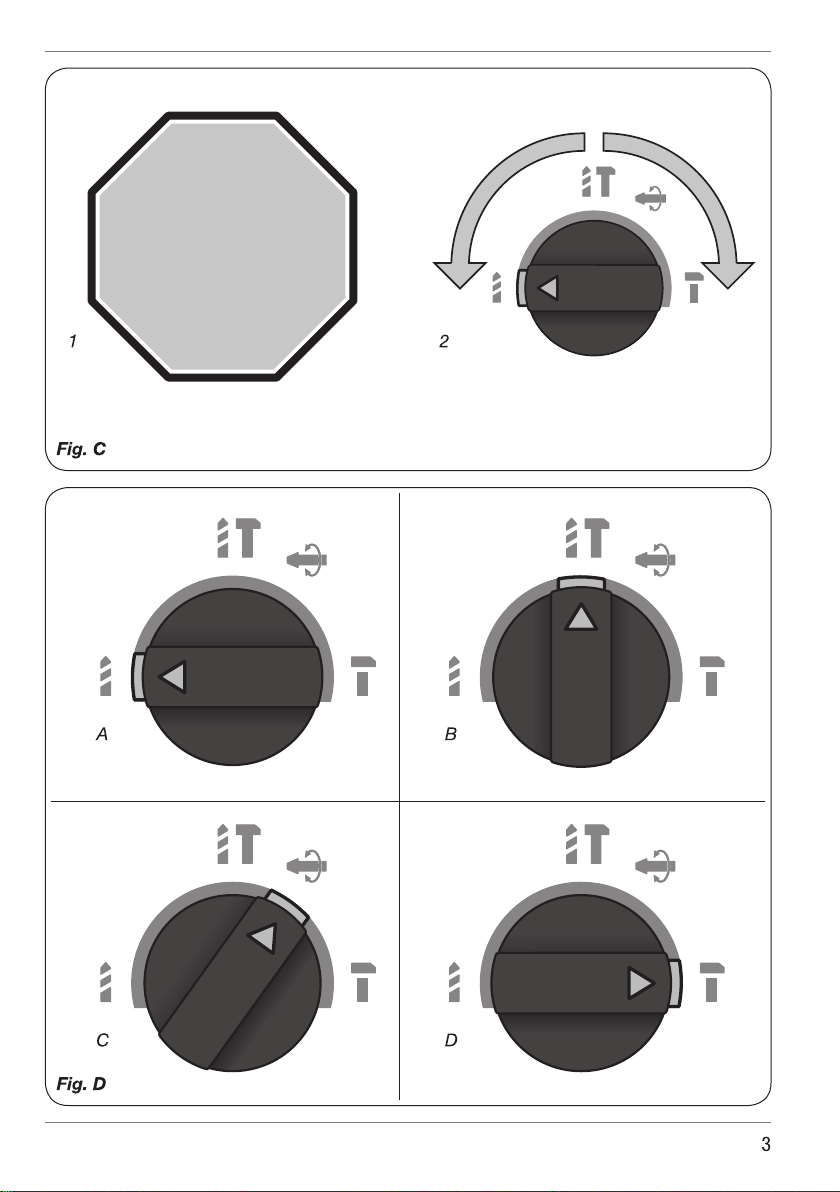

Function selection switch

In order to avoid damage to the machine,

adjusting the function selection switch (5)

shall only be done when machine is not

running. Fig. C

Fig. D

The correct position of the function selection

switch (5) for each function is shown in the

pictures in fig. D. Always make sure the function

switch clicks in the desired position.

A) Drilling (without hammer function): for drilling

in several materials.

B) Hammer Drilling (with hammer function): for

drilling in masonry such as brick, concrete and

similar material.

C) Chisel angle adjustment: for changing the

angle of the chisel. When set under right angle

switch back to position D. before using the

tool.

D) Chipping (chisel function): for chipping and

small demolition jobs.

User tips

Always use the machine with the side handle

firmly anchored in place - you will not only work

with more comfort, you will also work with more

precision.

Caution: drills and chisels can get very

hot.

”.

6

Page 7

EN

Drilling and hammer drilling (function A and B)

• For large holes, for instance in very hard

concrete, start using a smaller bit for pilot

drilling first, then drill to nominal size.

• Hold the machine firmly with 2 hands. Be

aware the drill can jam and because of that

machine might suddenly turn (especially when

drilling deep holes).

• Do not apply a lot of pressure on the machine,

let the machine do the work.

Chipping in concrete and brick (function C & D)

• It’s also possible to use the machine for

chipping.

• Only change the function when the motor has

come to a standstill.

• Do not apply a lot of pressure on the machine,

let the machine do the work.

4. MAINTENANCE

Before cleaning and maintenance, always

switch off the machine and remove the

mains plug from the mains.

Clean the machine casings regularly with a soft

cloth, preferably after each use. Make sure that

the ventilation openings are free of dust and

dirt. Remove very persistent dirt using a soft

cloth moistened with soapsuds. Do not use any

solvents such as gasoline, alcohol, ammonia

etc. Chemicals such as these will damage the

synthetic components.

WARRANTY

The warranty conditions can be found on the

separately enclosed warranty card.

ENVIRONMENT

Faulty and/or discarded electrical or

electronic apparatus have to be collected

at the appropriate recycling locations.

Only for EC countries

Do not dispose of power tools into domestic

waste. According to the European Guideline

2012/19/EC for Waste Electrical and Electronic

Equipment and its implementation into national

right, power tools that are no longer usable must

be collected separately and disposed of in an

environmentally friendly way.

The product and the user manual are subject

to change. Specifications can be changed

without further notice.

Defects

The machine should be regularly inspected for

the following possible defects and repaired if

necessary.

• Damage to power cord.

• Broken on/off trigger assembly.

• Short circuiting.

• Damaged moving parts.

Faults

Should a fault occur, e.g. after wear of a part,

please contact your seller or the service address

on the warranty card. Separate you find an

exploded view showing the parts that can be

ordered.

7

Page 8

Spare parts list

HDM1030P

No Description Position

471023 Front sleeve complete 1-9

471000 Steel ball 7.125 7

471001 Chisel lock plate complete 10-12

840709 Needle bearings 0709 12

471002 Front bearing complete 13-15

843012 Needle bearings 3012 14

471003 Selector knob complete 17-21

471004 Drive sleeve complete 23-33

471005 O ring 21.5*1.8 30

471006 Impact hammer set 34-37

471007 O ring 16.2*4.5 38

471008 O ring 10*3 39

471009 Piston complete 38-44

471010 O ring 15.2*3 43

471011 Excentric gear set 45-51, 53, 58

471012 O ring 23.5*2.4 53

471013 Needle bearings K5 57

471014 Excentral rod bearing 58

840912 Needle bearings 0912 59

471015 Selector sleeve 59-63

471016 Bearing 699-K (20*9*5) 62

471024 Capacitor 65

471017 Brush holder (2pcs) 66

471018 Carbon brush (2 pcs) 67

471019 Switch 68

471020 Stator 78

830607 Bearing 607-2RS 81

471021 Rotor assembly 81-86

830609 Bearing 609-RS 85

471022 Side handle complete 87-91, 93

8

Page 9

Exploded view

9

Page 10

10

Page 11

11

Page 12

1504-24

www.ferm.com ©2015 FERm B.V.

Loading...

Loading...