Felisatti RHF40/1100VERT User Manual [ru]

RHF40/1100VERT

RHF40/1100VERTM

ROTARY HAMMER

MARTILLO PERFORADOR

MARTEAU PERFORATEUR

ПЕРФОРАТОР РУЧНОЙ ЭЛЕКТРИЧЕСКИЙ

Original Instructions

2

GENERAL SAFETY RULES

WARNING! Read all instructions. Failure to

follow all instructions listed below may result in

electric shock, re and/or serious injury. The term

“power tool” in all of the warnings listed below refers to your

mains operated (corded) power tool or battery operated

(cordless) power tool.

SAVE THESE INSTRUCTIONS

1) Work area

a) Keep work area clean and well lit. Cluttered and

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause you to

lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodied plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will increase the

risk of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

inuence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b) Use safety equipment. Always wear eye

protection. Safety equipment such as dust mask, non-

skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is

in the off position before plugging in. Carrying power tools

with your nger on the switch or plugging in power tools

that have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left attached

to a rotating part of the power tool may result in personal

injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control of the

power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure these

are connected and properly used. Use of these devices

can reduce dust related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct power tool

will do the job better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source

before making any adjustments, changing accessories,

or storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power

tool. Power tools are dangerous in the hands of untrained

users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts and

any other condition that may affect the power tools

operation. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc., in accordance with these instructions and in

the manner intended for the particular type of power

tool, taking into account the working conditions

and the work to be performed. Use of the power tool

for operations different from intended could result in a

hazardous situation.

5) Service

a) Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the power tool is

maintained.

WARNING! Read all safety warnings and all

instructions, given in the Operating Instructions.

SPECIFIC SAFETY AND WARNINGS

• See “Safety Instructions” manual, supplied with this

instruction manual.

• Warning! When drilling in amianthus/asbestos and/

or silica stone, the dust produced is extremely harmful

to your health. Wear protection against inhalation of this

dust, in compliance with current regulations on acci-

dent prevention. Follow the insurance company’s safety

instructions regarding the responsibility of em-ployees.

• For your personal safety, always connect the machine

to a mains supply protected by a differential and ther-mal

cut-out switch, in accordance with regulations on low-

voltage wiring sitemaps.

• Do not perforate the machine casing, as this would

destroy the protective insulation (use adhesive labels).

• Always unplug the machine before doing any work on

it.

• Warning! Before each use, inspect the plug and lead.

3

Should they need replacing, have this done by an of-cial

service centre. Only plug the machine in when it is switched

off.

• Always keep the lead out of the machine’s working

area.

• Only plug the machine in when it is switched off.

• Do not allow the machine to get wet, nor should it be

used in wet environments.

• When using the machine, always wear safety goggles,

gloves and non-slip footwear, and it is advisable to wear

ear protection.

• Do not touch the bit during or immediately after working, as it becomes very hot and can cause serious burns.

• Hold the machine rmly by the handle and the

auxiliary handle, otherwise the recoil produced could cause

the machine to work imprecisely or even dangerously.

• Always use the auxiliary handle.

• Never attempt to clean off dust or shavings resulting

from drilling when the machine is operating.

• Do not use diamond core bits.

• When drilling walls, ceilings or oors, take care to

avoid electric wires and gas or water pipes.

Other safety information

Be sure the power supply is same as the voltage given

on the rating plate. The tool is tted with a two-core cable

and plug.

Remove the power plug from socket before carrying

out any adjustment or servicing.

Residual risks

Even when the power tool is used as prescribed

it is not possible to eliminate all residual risk

factors. The following hazards may arise in connection with

the power tool’s construction and design:

- Damage to lungs if an effective dust mask is not worn.

- Damage to hearing if effective hearing protection is

not worn.

- Damages to health resulting from vibration emission if

the power tool is being used over longer period of time or

not adequately managed and properly maintained.

WARNING! This power tool produces an

electromagnetic eld during operation. This eld may under

some circumstances interfere with active or passive medical

implants. To reduce the risk of serious or fatal injury, we

recommend persons with medical implants to consult their

physician and the medical implant manufacturer before

operating this machine.

DECLARATION OF CONFORMITY

Business name of the manufacturer:

12

INTERSKOL POWER TOOLS S.L.

Full address of the manufacturer:

Ctra. de St. Joan de les Abadesses, s/n

17500 RIPOLL (Girona) SPAIN

Name and address of the person

(established in the Community) compiled

the technical le:

Jordi Carbonell, Santiago López

Stra. de St. Joan de les Abadesses, s/n

17500 RIPOLL (Girona) SPAIN

Product name: Rotary hammer

Commercial name: Rotary hammer

Model: RHF40/1100VERT,

RHF40/1100VERTM

Type: Electric power tools

Serial Number: see label of the tool

Fulls all the reevant provisions of

Directives 2006//95/EC, 2006/42/EC,

2004/108/EC, 2002/96/EC, 2002/95/EC,

2009/ 251/EC

We hereby declare, under our sole

responsibility, that the FELISAT TI

brand products described in this manual

RHF40/1100VERT, RHF40/1100VERTM

comply with the following standars of

standard documents:

EN60745-1, EN60745-2-6, EN55014-1,

EN55014-2, EN61000-3-2, EN61000-3-3.

Santiago LópezJordi Carbonell

We reserve the right to make technical changes 12/2012

4

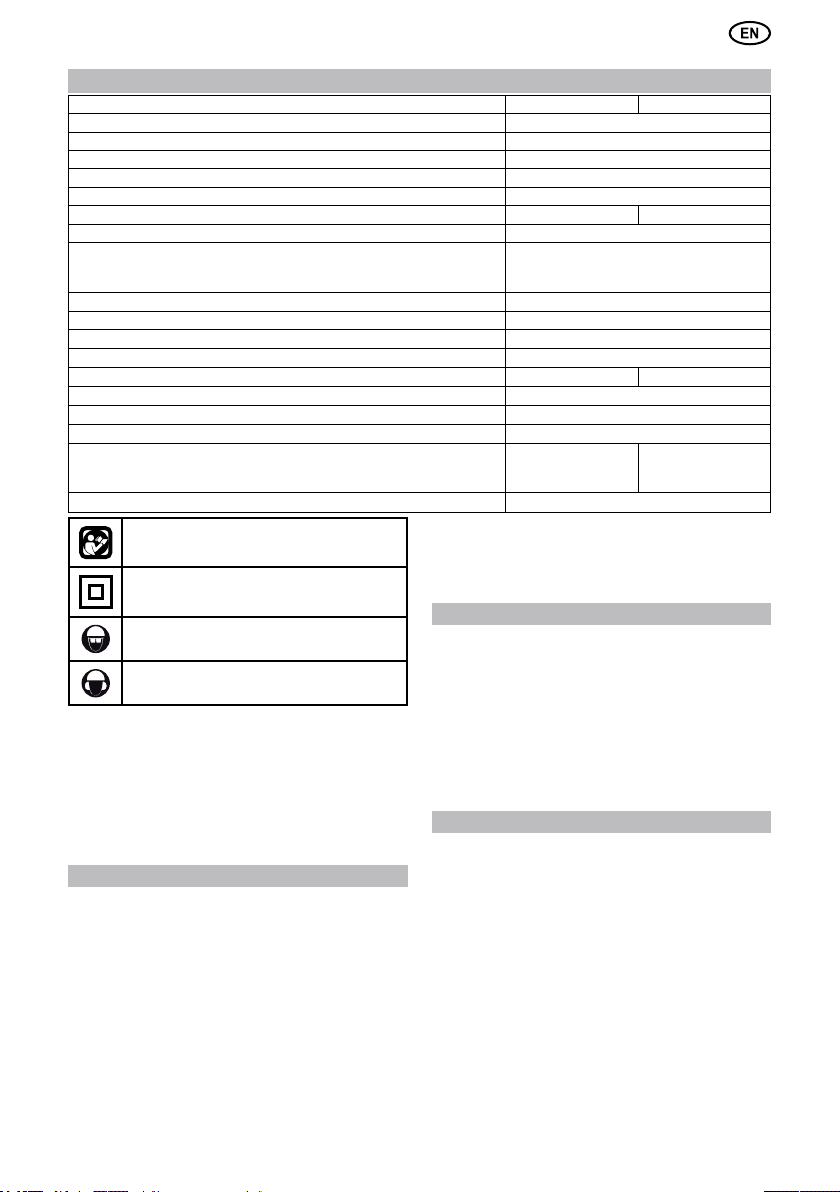

TECHNICAL DATA

Parameter RHF40/1100VERT RF40/1100VERTM

Rated Voltage, V~ 230

Rated frequency, Hz 50

Rated Input , W 1100

No-load speed (rpm), /min 235-500

No-load speed (bpm), /min 1350-2870

Impact Energy, J 2-7.5 2-7.5

Tool holder system SDS-Мах

Max. drilling Capacity, mm

- Drill bit

- Core bit

40

105

Ability to adjust speed yes

Changing the direction of tool rotation no

Chiselling mode (without tool rotation) yes

Preset angular position of the tool yes

Weight according to EPTA-Procedure 01/2003, kg 6.2 6.4

Typical A-weighted emission sound pressure level(LPA), dB(A) 93

Typical A-weighted sound power level(LWA), dB(A) 104

Uncertainty K, dB(A) 3

Triaxial vibration value (ah), m/s

hammer drilling

chiseling

Uncertainty K, m/s

2

2

:

13.0

11.0

7.0

8.5

1.5

List of Contents

Read the operating instructions

Protection category II power tool; double

insulated

Wear eye protection

- Plastic Box

- Grease tube

- Stopper

-- Operating instructions with Safety instructions

APPLICATIONS

Drilling in concrete

Chipping, chiseling, demolishing in concrete

Digging for anchor bolt

Wear ear protection

The instructions contained in this manual must be

strictly followed, it should be carefully read and kept close

at hand to use when carrying out maintenance on the

indicated parts.

If the machine is used carefully and normal

maintenance is carried out, it will work well for a long time.

The functions and use of the tool you have bought

shall be only those described in this manual. Any other

use of the tool is strictly forbidden.

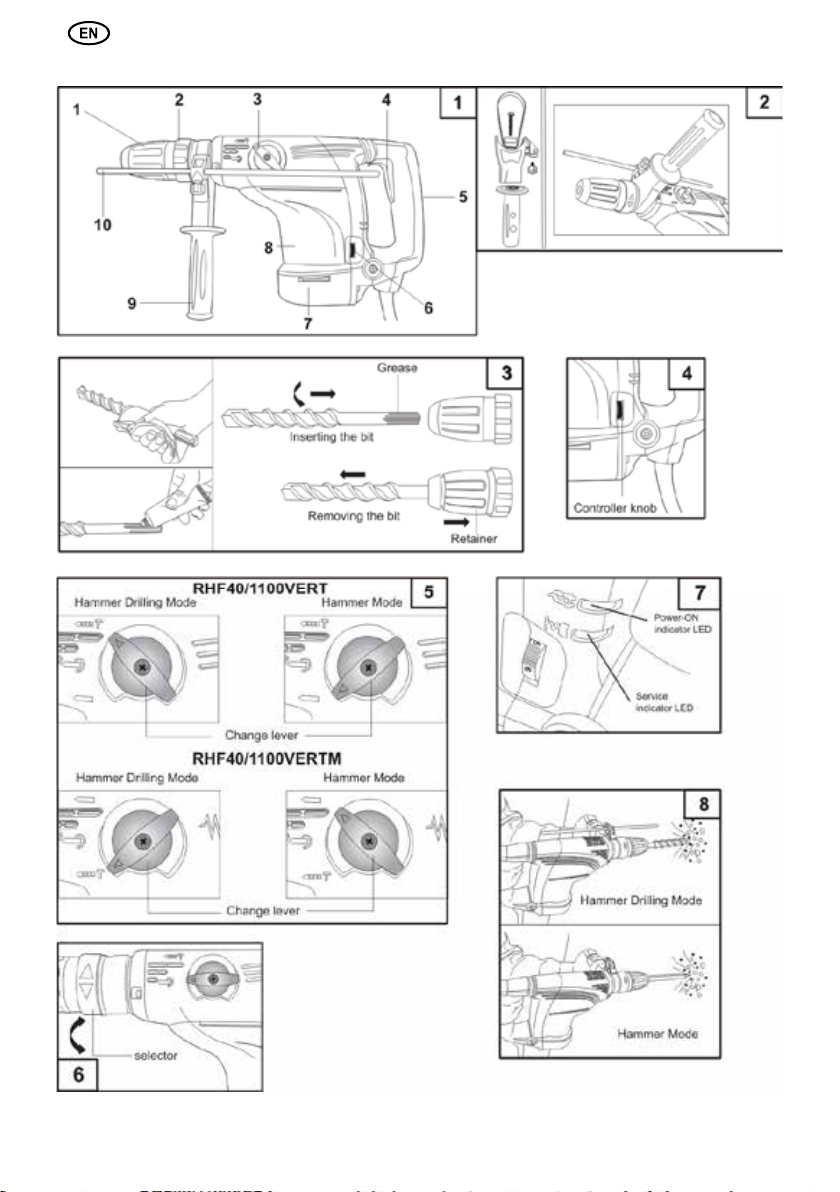

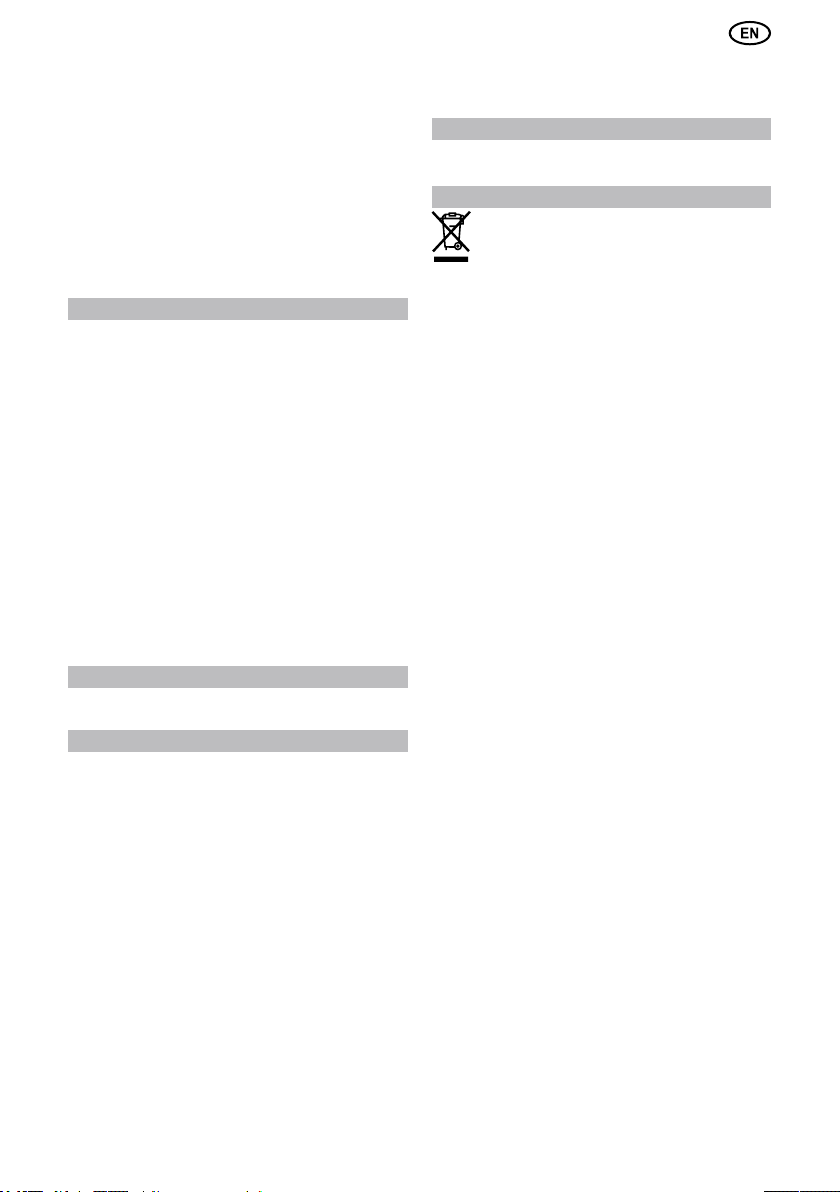

ILLUSTRATIONS

The overall look of the machine shown in Fig.1.

1 – RETAINER SDS-max®

2 - SELECTOR

3 - CHANGE LEVER

4 - TRIGGER SWITCH

5 - HANDLE

6 - CONTROLLER KNOB

7 - END COVER

8 - HOUSING

9 - SIDE HANDLE

10 - STOPPER

Crushing, grooving, squaring, cutting, hardening in

concrete

[Examples of application]

Heating & cooling work, piping work, wiring work,

sanitary facilities work, installation of machinery, water

supply & drainage works, interior decoration work,

installation of seats, harbor facilities work and other

engineering facilities work.

BEFORE USING THIS TOOL

WARNING! Before carrying out any work, check, for

instance, using a metal detector, that there are no electric

wires or gas or water pipes under the surfaces you wish to

work on.

Make sure the mains voltage is correct: it must be

the same as that on the specication label. Machines with

230V can also be connected to a 220V mains supply.

Extension Cord

Use an extension cord if the distance to the power

source requires its use. Extension cord must be of

appropriate thickness and length for the supply of electric

current. Too thin or too long cord will cause voltage to drop

reducing the motor power. Use it as short as possible.

If the cord is damaged, have it repaired or replaced at

A/S center immediately.

5

Nominal cross section of

conductor

2

0.75 mm

2

1 mm

2

1.5 mm

Max. length

30 m

40 m

60m

Maintenance and Checking of Work Area

Work area must be checked using CAUTIONs in this

manual to ensure it provides appropriate environment.

Switch Status Check

If the power plug is connected when the power switch

is in ON position, sudden rotation of the moving parts of the

Electric Rotary Hammer may cause accident.

Check if the switch lever returns to its original position

when it is pushed and pulled.

OPERATION

1. Mounting the Side handle and Stopper(Fig. 2)

For operating convenience , the side handle can be

installed in front position. Always operate the tool with the

side handle properly assembled to maximize control of the

power tool.

Mounting the side handle

1. Loosen the side handle by turning the handle

counterclockwise.

2. Slide the band over the retainer and onto the cylindrical

section at the front end

3. Mount the bolt holder and band holder, insert the hex

bolt (M8).

4. Screw the side handle to band holder.

5. Swing the side handle to the desired position.

6. Tighten the side handle by turning clockwise.

Mounting the stopper

1. Installing bit into the tool and loosen stopper holder.

2. Place drill bit onto a surface, adjust the stopper to desired depth of hole. Using the stopper will allow you to drill

a hole the depth of the distance between the bit and the

stopper.

3. Tighten the stopper holder.

2. Installing and Removing the bit CAUTION

WARNING! Wear protective gloves when changing bit

as the bit may get hot during use.

Installig and Removing the SDS-max bit (RH-

F40/1100VERT, RHF40/1100VERTM) (Fig. 3)

1. Turn off tool and disconnect from power supply.

2. Clean the bit shank and apply grease before inserting

the bit.

3. Check that the dust cap is clean and in good condition.

Clean the dust cap if necessary or have it replaced if the

dust cap is damaged.

4. Insert the bit into the tool. Turn the bit and push it in until

engages in.

5. After installing, always make sure that the bit is securely

held in place by trying to pull it out.

6. To remove the bit, pull out the bit while pushing the retainer backward in the direction of the arrow.

3. Soft Start

The soft start feature allows you to build up speed

slowly, thus preventing the drill bit from walking off the in-

tended hole position when starting. The soft starter feature

also reduces the immediate torque reaction transmitted to

the gearing and the operator if the tool is started with the

drill bit in an existing hole.

4. Safety Clutch

6

The safety clutch will actuate when a certain torque

level is reached. The motor will disengaged from the output

shaft. When this happens, the bit will stop turning. This feature prevents the gearing and motor from stalling.

CAUTION! As soon as the safety clutch actuates,

switch off the tool immediately.

5. Speed Change (Fig. 4)

The revolutions and blows per minute can be adjusted just

by turning the controller knob. The knob is marked 1(minimum speed) to 6(maximum speed). Refer to the table be-

low for the relationship between the number settings on the

controller knob and the R.P.M/B.P.M.

Number on

Controller knob

Revolutions per

minut 235 265 320 380 440 500

Blows per

minite 1350 1520 1840 2180 2530 2870

1 2 3 4 5 6

6. Mode Select (RHF40/1100VERT,

RHF40/1100VERTM) (Fig. 5)

The RHF40/1100VERT, RHF40/1100VERTM can be

used in two operating modes. In hammer drilling mode, the

tool simultaneously rotates and impact the work. This mode

is appropriate for all concrete and masonry operations. In

the hammering-only mode, the tool only impacts the work

without rotating. This mode is appropriate for light chipping,

chiseling, and demolition applications

7. Adjusting and Fixing of Bit Angle (Fig. 6)

The bit can be adjusted to 16 different

positions (in 22.5 increments). To

change the bit angle,

set the change lever to the symbol.

Turn the selector desired angle. This ensure that plat

chisels and shapes chisels can always

be set to optimum working positions.

8. Indicator LEDS (Fig. 7)

The green power-ON indicator LED lights up when the

tool is plugged. If indicator led does not light up, the mains

cord or the controller may be detective. The red service

indicator LED lights up when the carbon Brushes are worn

out to indicate that the tool needs servicing.

After approximately 8 hours of use, the motor will

automatically be shut off.

9. Operation

Hammer drilling operation (Fig. 8)

1. Turn the change lever until it engages in the hammer

drilling position.

2. Insert the appropriate drill bit

3. Fit and adjust the side handle.

4. Position the bit at the desired location for the hole, then

pull the trigger switch.

5. Push with only enough force so that the hammer beats

smoothly.

6. Keep the tool in position and prevent it from slipping

away from the hole.

7. Do not apply more pressure. This will not make the

hammer drill faster. Lower pressure extends the life of the

bit.

8. To stop the tool, release the trigger switch. Always turn

the tool off when work is nished and before unplugging.

Chipping and Chiseling

1. Turn the change lever until it engages in the hammering

position.

2. Insert the appropriate chisel.

3. Fit and adjust the side handle.

4. Pull the trigger switch and start working.

5. Push with only enough force to keep bit from bouncing.

Pressing very hard on the tool will not increase chipping

speed.

6. To stop the tool, release the trigger switch. Always turn

the tool off when work is nished and before unplugging

10. Operation time

The tools shall be operated intermittently as fallows;

- Operating time : 30 s

- esting time : 90 s

11.VCS (Multi Vibration Control System)

(RHF40/1100VERT, RHF40/1100VERTM)

The VCS function reduces occurring vibration.

NOISE AND VIBRATION

This tool has been designed and made to reduce

noise to a minimum. However, in spite of this, in certain

circumstances the maximum noise level in the place of

work could exceed 85 dBA. In this case, the operator

should wear ear protection.

Use ear protection!

WARNING! The vibration level given in these

instructions has been measured in accordance with

a standardized measurement procedure specied in

EN60745 and can be used to compare devices. Different

uses of the device give rise to different vibration levels and

in many cases they may exceed the values given in these

instructions. It is easy to underestimate the vibration load

if the electrical power tool is used regularly in particular

circumstances.

Note. If you wish to make an accurate assessment of

the vibration loads experienced during a particular period of

working , you should also take into account the intervening

periods of time when the device is switched off or is running

but is not actually in use. This can result in a much lower

vibration load over the whole of the period of working.

ACCESSORIES

Accessories and their corresponding order number

can be found in our catalogues.

MAINTENANCE

1. Checking the Tool (bit)

Using the worn-off bit will cause overloading the motor

and reduce work efciency. Either sharpen the tool or

replace with a new one.

2. Checking the Screws

Check if any screw is losen. Losen screw must be

fastened rmly.

Replacement of screw must be carried out at the

authorized A/S center using genuine parts. Otherwise

Commutator may worn out quickly shortening the service

life of the Tools.

3. Maintenance of Motor Assembly

The Commutator in the Motor Assembly is the core

part of the tool. Be careful not to cause scratch or contact

with oil or water on the surface of the Commutator.

4. Storing after Use

Store the tool in a dry place out of reach of the

children.

5. Repair

If the tool is not operating normally, do NOT attempt

to locate the problem or repair yourself. Contact nearest

authorized A/S center for service.

6. Cord

If the supply cord of this power tool is damaged, it

must be replaced by a specially prepared cord available

through the service organization.

WARRANTY

See general warranty conditions printed on the

attached sheet.

DISPOSAL

WARNING! Do not dispose of electric tools in the

household waste!

In accordance with European Directive 2002/96/EC

relating to old electrical and electronic appliances and

its translation into national law, used electric tools must

be collected separately and recycled in an ecologically

desirable way.

7

Traducción de las instrucciones originales

8

NORMAS GENERALES DE SEGURIDAD

¡ATENCIÓN! Leer todas las instrucciones. El

incumplimiento de cualquiera de las siguientes

instrucciones puede provocar cortocircuitos

eléctricos, incendios y/o lesiones graves. La expresión

“herramienta eléctrica” que aparece en todas las siguientes

advertencias se reere a herramientas eléctricas cuyo

accionamiento se efectúe mediante conexión a la línea

(con cable) o por batería (sin cable).

CONSERVAR ESTAS INSTRUCCIONES

1) Área de trabajo

a) Mantener el área de trabajo limpia y bien

alumbrada. Las áreas en desorden y oscuras pueden ser

causa de accidentes.

b) No accionar herramientas eléctricas en

atmósferas explosivas, por ejemplo en presencia de

líquidos, gases o polvo inamables. Las herramientas

eléctricas crean chispas que pueden provocar el encendido

del polvo o de humos.

c) Mantener a los niños y transeúntes a distancia

durante el accionamiento de una herramienta eléctrica.

Las distracciones pueden provocar la pérdida del control

de la herramienta.

2) Seguridad eléctrica

a) La clavija de la herramienta eléctrica tiene que

corresponder con la toma. No modicar jamás la clavija

en modo alguno. No utilizar enchufes adaptadores con

herramientas eléctricas provistas de toma de tierra (a

masa). Clavijas originales y correspondencia de enchufes

reducen el riesgo de choque eléctrico.

b) Evitar el contacto del cuerpo con supercies

conectadas a tomas de tierra o a masa, como por

ejemplo tubos, radiadores, cocinas y neveras. Si el

cuerpo está conectado a tierra o a masa, el riesgo de

choque eléctrico aumenta.

c) No exponer las herramientas eléctricas a la

lluvia ni utilizarlas en sitios húmedos. La entrada de

agua en una herramienta eléctrica aumenta el riesgo de

choque eléctrico.

d) No maltratar el cable. No utilizar nunca el cable

para transportar, tirar o desenchufar la herramienta

eléctrica. Mantener el cable distante de fuentes de calor,

aceites, cantos alados o partes en movimiento. Cables

dañados o enredados aumentan el riesgo de choque

eléctrico.

e) Al accionar una herramienta eléctrica en

exteriores debe utilizarse un cable de extensión

adecuado para ser usado en exteriores. La utilización de

un cable adecuado reduce el riesgo de choque eléctrico.

f) Si fuese imprescindible utilizar la herramienta

eléctrica en un entorno húmedo, es necesario

conectarla a través de un fusible diferencial. La

aplicación de un fusible diferencial reduce el riesgo a

exponerse a una descarga eléctrica.

3) Seguridad personal

a) No distraerse nunca, controlar lo que se está

haciendo y usar el sentido común cuando se accionan

herramientas eléctricas. No accionar la herramienta

cuando se está cansado o bajo la inuencia de drogas,

alcohol o medicamentos. Un momento de distracción

durante la utilización de herramientas eléctricas puede

provocar graves lesiones a las personas.

b) Utilizar equipos de seguridad. Ponerse siempre

protectores de los ojos. La utilización de apropiados

equipos de seguridad como caretas antipolvo, calzado

de seguridad antideslizante, casco de seguridad, o

protectores del oído reduce la posibilidad de sufrir lesiones

personales.

c) Evitar la puesta en marcha accidental. Comprobar

que el interruptor esté en la posición de apagado antes de

conectar la herramienta a la línea eléctrica. Transportar

las herramientas eléctricas con el dedo en el interruptor

o enchufarlas con el interruptor en posición de encendido

puede provocar accidentes.

d) Retirar toda llave de regulación antes de

encender la herramienta eléctrica. Una llave dejada

enganchada en una parte giratoria de la herramienta

eléctrica puede provocar lesiones a las personas.

e) No desequilibrarse. Mantener siempre la posición

y el equilibrio apropiados. Esto permite controlar mejor la

herramienta eléctrica en situaciones imprevistas.

f) Vestirse adecuadamente. No ponerse prendas

de vestir anchas ni joyas. Mantener el cabello, las

prendas de vestir y los guantes alejados de las partes

en movimiento. Vestidos anchos, joyas o cabellos largos

pueden enredarse en las partes en movimiento.

g) En presencia de dispositivos que prevean la

conexión con instalaciones para la extracción y la

recogida de polvo, comprobar su conexión y correcta

utilización. La utilización de estos dispositivos puede

reducir los riesgos vinculados al polvo.

4) Uso y mantenimiento de las herramientas

eléctricas

a) No forzar la herramienta eléctrica. Utilizar la

herramienta adecuada para la operación que debe

efectuarse. La herramienta eléctrica apropiada permite

realizar el trabajo con mayor eciencia y seguridad, sin

tener que superar los parámetros de utilización previstos.

b) No utilizar la herramienta eléctrica si el

interruptor de encendido y apagado no funciona

correctamente. Toda herramienta eléctrica que no puede

ser controlada por el interruptor es peligrosa y debe

repararse.

c) Desenchufar la clavija de la línea de

suministro eléctrico antes de efectuar una operación

de regulación, cambiar accesorios o guardar las

herramientas eléctricas. Estas medidas de seguridad

preventiva reducen el riesgo de puesta en marcha

accidental de la herramienta eléctrica.

d) Guardar las herramientas eléctricas que no se

utilizan fuera del alcance de los niños y no permitir su

utilización a personas inexpertas o que desconozcan

estas instrucciones. Las herramientas eléctricas son

peligrosas si las utilizan personas inexpertas.

e) Efectuar el mantenimiento necesario en las

herramientas eléctricas. Comprobar posibles errores

de alineación o bloqueo de las partes en movimiento,

la rotura de piezas y cualquier otra condición que

pueda inuir en el funcionamiento de las herramientas

eléctricas. Si está dañada, hacer reparar la herramienta

eléctrica antes de utilizarla. Precisamente el mal estado

de conservación de las herramientas eléctricas provoca

numerosos accidentes.

f) Mantener limpios y alados los instrumentos

de corte. Instrumentos de corte en buenas condiciones

de conservación y con cantos de corte alados es menos

probable que se bloqueen y son más fáciles de controlar.

g) Usar la herramienta eléctrica, los accesorios y

las puntas etc. conformemente con estas instrucciones

y en el modo previsto para el especíco tipo de

herramienta eléctrica, tomando en consideración

9

las condiciones de trabajo y la operación que debe

llevarse a cabo. La utilización de la herramienta eléctrica

para operaciones distintas de las previstas puede dar lugar

a situaciones peligrosas.

5) Asistencia

a) Hacer reparar la herramienta eléctrica

exclusivamente a técnicos cualicados y utilizar

únicamente recambios idénticos. Esto garantiza la

constante seguridad de la herramienta eléctrica.

¡ADVERTENCIA! Rogamos leer las indicaciones de

seguridad y las instrucciones, también las que contiene

Instrucciones de servicio.

MEDIDAS ESPECIALES DE SEGURIDAD

• Ver el manual adjunto “Instrucciones de Seguridad”

que se suministra conjuntamente con el presente ma-nual

de instrucciones.

• ¡ATENCIÓN! Al taladrar materiales de amianto/

asbesto y/o piedras de sílice, el polvo que se produce es

perjudi-cial para su salud. Protéjase de la inhalación de ese

polvo según normas de prevención de accidentes. Siga las

instrucciones de seguridad de la compañía asegura-dora

de la responsabilidad de sus empleados.

• Conecte siempre la máquina a una red protegida por

interruptor diferencial y magnetotérmico, para su seguridad personal, según normas establecidas para insta-

laciones eléctricas de baja tensión.

• No perforar la carcasa de la máquina, pues se

inte-rrumpe el aislamiento de protección (utilizar rótulos

adhesivos).

• Desconecte siempre el enchufe antes de llevar a cabo

cualquier trabajo en la máquina.

• ¡ATENCIÓN! Cada vez que vaya a utilizar la máquina

controle el estado del enchufe y del cable. Deje susti-tuirlos

por un especialista en el caso de que estén deteriorados.

Introducir el enchufe en la toma de co-rriente sólo con el

aparato desconectado.

• Mantener siempre el cable separado del radio de

acción de la máquina.

• Enchufar la máquina a la red solamente en posición

desconectada.

• El aparato no debe estar húmedo ni debe ponerse en

funcionamiento en un entorno húmedo.

• Para trabajar con la máquina, utilizar siempre gafas de

protección, guantes, calzado de seguridad antidesli-zante,

así como es recomendable usar protectores auditivos.

• No tocar la broca durante ni inmediatamente después

de trabajar, puesto que se calienta mucho y puede causar

quemaduras serias.

• Sujetar rmemente la máquina por la empuñadura

y por el puño auxiliar. De lo contrario, la contrafuerza

producida podría causar un funcionamiento impreciso e

incluso peligroso.

• Emplear siempre el puño auxiliar.

• Nunca se debe intentar limpiar el polvo o viruta procedente del taladrado con la máquina en funcionamiento.

• No usar brocas tipo corona de diamante.

• Cuando taladre en paredes, techo o suelo, tenga

cuidado para evitar los cables eléctricos y tuberías de gas

o agua.

Información de seguridad adicional

Compruebe que la tensión de la fuente de alimentación

sea la misma que la indicada en la placa de características.

La herramienta dispone de un cable de dos conductores y

de un enchufe.

Desconecte el enchufe de la toma de corriente antes

10

de realizar cualquier ajuste o reparación.

Riesgos residuales

Aunque la herramienta eléctrica se utilice de la

forma indicada, resulta imposible eliminar todos

los factores de riesgo residual. Pueden plantearse los

siguientes riesgos derivados de la fabricación y el diseño

de la herramienta eléctrica:

- Daños pulmonares si no se utiliza una mascarilla

antipolvo ecaz.

- Daños auditivos si no se utiliza una protección auditiva

ecaz.

- Daños a la salud derivados de la emisión de

vibraciones si la herramienta eléctrica se utiliza durante un

largo período de tiempo, o si no se maneja y mantiene de

forma adecuada.

¡ATENCIÓN! Esta herramienta eléctrica genera un

campo electromagnético durante su funcionamiento. Este

campo puede, en algunas circunstancias, interferir con

implantes médicos activos o pasivos. Para reducir el riesgo

de lesiones graves o letales, las personas con implantes

médicos deben consultar a sus médicos y al fabricante del

implante antes de utilizar esta máquina.

DECLARACIÓN DE CONFORMIDAD

Nombre comercial del fabricante:

12

INTERSKOL POWER TOOLS S.L.

Dirección completa del fabricante

Ctra. de Sant Joan de les Abadesses, s/n

17500 RIPOLL (Girona) ESPAÑA

Nombre y dirección de la persona

(establecida en la Comunidad) que

completó la cha técnica:

Jordi Carbonell, Santiago López

Ctra. de Sant Joan de les Abadesses, s/n

17500 RIPOLL (Girona) ESPAÑA

Nombre del producto: Martillo

perforador

Nombre comercial: Martillo perforador

Modelo: RHF40/1100VERT,

RHF40/1100VERTM

Tipo: Herramientas eléctricas

Número de serie: consulte la etiqueta de

la herramienta

Cumple con todas las disposiciones

pertinentes de las Directivas 2006/95/CE,

2006/42/CE, 2004/108/CE, 2002/96/CE,

2002/95/CE, 2009/251/CE

Declaramos bajo nuestra sola

responsabilidad que los productos marca

FELISATTI descritos en este manual

RHF40/1100VERT, RHF40/1100VERTM

están en conformidad con las normas o

documentos normalizados siguientes:

EN60745-1, EN60745-2-6, EN55014-1,

EN55014-2, EN61000-3-2, EN61000-3-3.

Santiago LópezJordi Carbonell

Reservado el derecho de modicaciones técnicas 12/2012

Loading...

Loading...