Page 1

DSP1500E-HM-4

51327 Quadrate Drive Phone: (586) 781-2100

Macomb, MI. 48042 Fax: (586) 781-0044

Web: www.fec-usa.com

enFORCE

DSP1500 Main Unit

Hardware M an u a l

SECOND Edition October 2008

Automation Systems

E-mail: support@fec-usa.com

Page 2

WARNING

All applicable national and local codes must be followed when installing and operating the equipment detailed in

this manual.

FAILURE TO ABIDE BY THESE CODES AND THE SPECIFICATIONS DESCRIBED IN THIS MANUAL

CAN RESULT IN SERIOUS INJURY TO PERSONNEL AND/OR DAMAGE TO THE EQUIPMENT!

Any questions regarding the contents of this document or any related matter should be

directed to FEC INC. at (586) 781-2100, faxed to (586) 781-0044 or emailed to support@fec-usa.com

The information set forth in the following docu ment is the prop er ty of FEC INC.

This document shall not be released to or c opied for any person and/or organization

Without the expressed prior consent of FEC INC.

Unauthorized reproduction or distribution of this manual is strictly prohibited.

Please contact FEC INC. if you require additional copies.

.

ii

Page 3

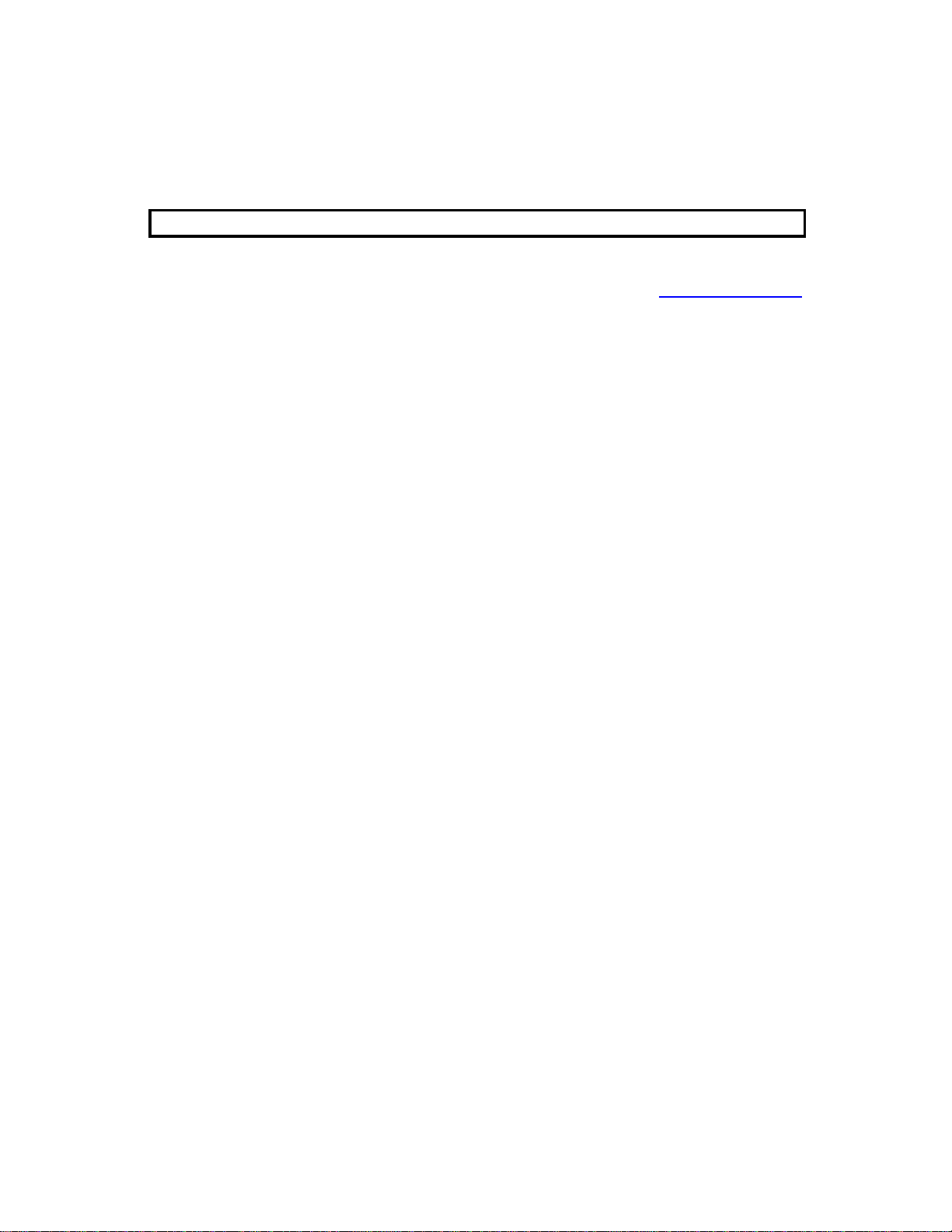

A

Revision

3 01/2007 Initial Release

4 10/2008

DSP1500 = Servo Press

DSP1500 = Servo Press

AFC1500 = Nutrunner

AFC1500 = Nutrunner

FUSION = DC Hand Tool

FUSION = DC Hand Tool

E = English Version

S = Spanish Version

I = Italian Version

*Japanese Version f urn ished b y DDK

uses DDK numbering convention.

Revision

Date

Revision His tory

dded References for Ethernet Version. Added User Console Ethernet

Port. Expanded on Control Interfaces information.

Manual Numbering Convention

DSP1500E-HM-4

Ver sion Nu mber

(Major Revision Level)

HS = SAN Unit Hardware

Operation Manual

HM = Multi / Main Unit Hardware

Operation Manual

HM-ENET = Ethernet Manual for

Multi / Main Unit

SW = Software Manual

iii

Page 4

Introduction

Thank you for purchasing our Electric Servo Press - DSP1500 System.

This instruction manual describes the procedures for installation, wiring, handling and

actions to be taken in case of any failure.

◆ This instruction manual shall be delivered to the end user who operates the equipment.

◆ Read all instructions before use and always keep this instruction manual with the

equipment.

◆ Items not described in this instruction manual shall be considered “unavailable”.

◆ The product specification and appearance described in this instruction manual is subject to

change without notice.

◆ All rights reserved. Any disclosure, copying, distribution, or use of the information

contained herein for other than its intended purpose, is strictly prohibited.

◆ It is important for you to read all “Safety Precautions” before using the equipment, and

understand and observe all instructions and recommendations included in this manual.

◆ Read all instructions and recommendations included in this manual, understand the

functions and performance of this servo press, and correctly use this machine.

◆ Wiring and para meter setting shall only be conducted by a qualified professional.

◆ Never conduct a withstand voltage test or insulation resistance test on this equipment.

◆ Indicate the following on all instruction manuals that use this equipment.

”This equipment is capable of high voltages hazardous to human life.”

Please confirm the following when unpacking this equipment:

◆ Ensure that you received the correct model as ordered.

◆ Ensure that there are no missing parts.

◆ Check for any damage caused during transportation.

For the safety of operator and equipment

Points to check when unpacking

iv

Page 5

Introduction

Warranty Period

The standard warranty period is one year from the date of purchase or one year from delivery to

the designated End User (not to exceed 18 Months). Actual terms are order specific.

Provision of warranty

If at any time during the warranty period your product proves to be defective, it will be repaired

free of charge as long as it was used properly in accordance with this instruction manual.

However, t he customer will be required to pay for repair charges in the following cases even if the

defects occurred within the warranty period.

1. Any defect due to improper conditions, improper circumstances and improper handling.

2. Any defect due to modifications or repairs performed by the customer.

3. Any defect caused by other equipment.

4. Any defect caused by customer failing to meet the equipment’ s speci fication.

5. Any defect due to natural disasters and accidents.

This warranty shall be limited to repairing or replacing this product. Any liability for indirect or

consequential loss or damage of any kind incurred or suffered by the customer due to a defect of

the product is excluded.

Warranty

v

Page 6

Safety Precau tion s

Read all instructions before operating the equipment in order to use this equipment safely and correctly.

Read this instruction manual carefully and fully understand the equipments functions, safety precautions

and instructions prior to using the equipment. Safety precautions in this manual are marked with two

symbols [Warning] and [Caution].

To prevent danger to the user and other persons as well as property damage, instructions that must be

fully observed are marked with the symbols below.

◆ This instruction manual uses the followi ng two sy mbols according to the deg ree o f damage that may

be caused when the instruction is not observed.

Even instructions that are marked with may result in severe damage if they are

not observed according to conditions.

Contents marked with the above symbols are very important instructions. For your safety, follow all

instructions and especially those marked with these symbols.

◆ This instruction manual uses the following additional symbols for instructions that shall be observed.

Warning

Caution

Warning:

Pinch Point

Caution:

Fire

Prohibited

Required

This symbol indicates that failure to observe instruction marked

with this symbol may result in severe personal injury or death.

This symbol indicates that failure to observe instruction marked

with this symbol may result in minor personal injury or material

damage.

Caution

Warning:

Electric shock

Caution:

Electric shock

Warning:

Fire

Caution:

High Temperature

Do not disassemble

Ground

vi

Page 7

Safety Precautions

Never touch press ram during operation.

Failure to do so may cause injury.

Make sure t hat no part of you r body gets near any moving par t of the tool e ven while the

equipment is at r est. The press ram m ay lower for som e r eason resulting in injury.

When performin g maintenance or inspectio n, be sure to secure the press ram with safety

blocks to prohibit the ram from lowering.

Do not remove the motor and gear case of tool.

The press ram may lower resulting in injury.

Do not repair, disassemble , or modify the equipment individual components of the system.

Failure to obser v e this instruction may cause injur y, electric shock , f ir e, and malfunction.

Never operat e the equipm ent where it i s exposed to water, near a corros ive atmospher e or

flammable gases. Failure to observe this instruction may cause fire.

Keep fingers away from the connectors while the equipment is turned ON and for a while

after the equipment is turned OFF. Failure to observe this instruction may cause electric

shock.

Wiring operation and maintenance work shall be conducted by a qualified professional.

Failure to obser v e this instruction may cause electric s hock and injury.

Turn OFF the power when conducting wiring operation and maintenance. Failure to observe

this instruction may cau se ele ctr i c sho ck and injur y.

Never damage the cables, apply excess stress to cables, or squeeze the cables. Never use

damaged cables. Failure to observe this instruction may cause electric shock and fire.

Conduct type-3 grounding of FG terminals.

Failure to observ e this instruction may cause electric s hock.

In case of an abnormal odor, noise, or operation error occurrence, stop operation

immediately and turn OFF the power source. Failure to observe this instruction may cause

injury and fire.

Install a Power shutdown device in order to ensure the safety of equipment.

Failure to observ e this instruction may cause injury.

Install an emergency stop circuit on the outside of equipment in order to stop operation

promptly. Failure to observe this instruction m ay cause injury.

Keep away from the equipment during recovery from a temporary blackout, and ensure

safety measur es are condu c ted after restarting the equipment. The equip m ent may suddenly

restart. Failure to observe this instruction may cause injury.

Warning

vii

Page 8

Safety Precautions

Transportation / Storage

Transport the equipme nt properly according to its weight.

Failure to obser v e this instruction may cause injury and malfunction.

The conditions when transporting the equipment by ship is as below.

◆Ambient temperature: -5°C~+55°C (Avoid freezing)

◆Ambient humidity: 50% RH or lower (Avoid moisture)

◆Package: Tight seal

◆Rust prevention measure: Apply grease or oil on tools.

Failure to obser v e this instruction may cause earth lea kage and malfunct ion.

Do not hold cables or press ram when transport ing the tools.

Failure to obser v e this instruction may cause injury and malfunction.

Do not hold the indictor on the front panel when transporting the SAN Unit.

The indicato r may come off and d rop from the front panel.

Failure to obser v e this instruction may cause injury and malfunction.

The equipment shall be stored under the following conditions.

◆Ambient temperature: -5°C~+55°C (Avoid freezing)

◆Ambient humidity: 90% RH or lower (Avoid moisture )

◆Atmosphere: Indoors (Avoid direct sunlight)

No

No oil m ist, dust, water, salt, iron powder

◆Avoid direct vibration or shocks

Failure to obser v e this instruction may cause earth lea kage and malfunct ion.

corrosive gases or flammable gases

Caution

viii

Page 9

Safety Precau tion s

g

Installation / Wirin

Install the tools in a place that can support the weight and maximum load during operation.

Failure to observe this instruction may cause injury and malfunction.

Install the MAIN and/or SAN Units fir m ly inside the con trol panel using the s pecified screws.

Failure to observe this instr uction may cause m alfunction.

Use the specified tool for the SAN Unit.

Failure to observe this instr uction may cause fire and malfunction.

The MAIN and/or SAN Units shall ma intain the specified distance from other devices.

Failure to observe this instr uction may cause fire and malfunction.

Do not block the ventilation hole of the MAIN and/or SAN Units.

Avoid any foreign body from entering inside the equipment.

Failure to observe this instr uction may cause fire and malfunction.

The power source shall be provided with safety measures such as breakers and circuit

protectors. Failure to observe this instruction may cause fire and malfunction.

Do not use too ls or MAIN and/o r SAN Units that are damaged or have missing parts.

Failure to observe this instr uction may cause fire, injury, and malfunction.

Do not climb on top of the equipm ent or place he avy objects on the top of equipment.

Failure to observe this instruction may cause injury, and malfunction.

Do not subject the equipment to excess shock and impact.

Failure to observe this instr uction may cause m alfunction.

Conduct wiring properly and firmly.

Failure to observe this instr uction may cause injury, false operation, and malfunction.

Operate the equipment within the specified po wer supply voltage.

Failure to observe this instruction may cause injury, electric shock, fire, and malfunction.

When operat ing the equ ipment in the follow ing condit ion s, tak e sufficien t mea sures t o shie ld

the equipment .

◆Locations where electrical nois e is generated.

◆Locations where the equipment is subjected to a strong electric field or magnetic field.

◆Locations near high power wiring.

Failure to observe this instr uction may cause injury, false operation, an d malfunction.

Caution

ix

Page 10

Safety Precautions

Operation / Adjustment

Never operate the equipme nt with wet hand s.

Failure to observe this instruction may cause e l ectric shock.

Keep fingers aw ay from the SAN U nit radiating f ins and tool motor while the equipment is

turned ON or for a while after the equipment is turned OFF. These parts may become very

hot. Failure t o observe this instr uction may cause bur ns.

Use the equipment under the following conditions.

◆Ambient temperature: 0°C~+45°C (Avoid freezing)

◆Ambient humidity: 90% RH or lower (Avoid moisture)

◆Atmosphere: Indoors (Avoid direct sunlight)

No

No oil mist, dust, water, salt, iron powder

◆Avoid direct vibration or shocks

Failure to observe this inst r uction may cause earth leak age and malfunction.

Confirm and adjust all parameters before operation in order to prevent unexpected

movement of t he equipmen t.

Failure to observe this in str uction may ca use injury, false operation and malfunction.

Never conduct extreme adjustments or setting changes that may cause instability of

operation.

Failure to observe this in str uction may ca use injury, false operation and malfunction.

The equipment may restart suddenly when the equipm ent is reset with the start signal ON.

Always ensure that the start signal is O FF before resettin g the equipment.

Failure to observe this in st r uction may ca use injury.

Do not turn ON and OFF the equipment repeatedly.

Failure to observe this instr uction may cause m alfunction.

Do not use the equipment at l oads higher than the maximum lo ad.

Failure to observe this instruction may shorten equipment life or cause malfunction due to the

high temperature caused by overload.

The magnetic brake is for holding the press ram when performing maintenance procedures.

Do not use for normal braking otherwise failure m ay result.

The magnetic brake may fail to hold near the end of its life expectancy due to wear.

Secondary braking structures should be installed on the machine side to safely secure

otherwise injury may result.

In case any abnormality occurs, remove the cause and ensure safety before resetting and

restarting the equipment.

Failure to observe this inst r uction may cause injury.

corrosive gases or flammable gases

Caution

x

Page 11

Table of Contents

Chapter 1: Outline

1.1 About this Manual......................................................................................... 1-2

1.2 Functions...............................…..……………………………………………… 1-3

1.3 Safety Precautions……….....…..………………………………………………. 1-4

Chapter 2: Specifications

2.1 Specifications.........................………………………………………………….. 2-2

2.2 Unit Dimensions……….................................…….…………………………… 2-3

Chapter 3: System Description

3.1 System Block Diagram...........………………………………………………….. 3-2

3.2 Unit Description…….....................................…….…………………………… 3-3

Chapter 4: Installation & Wiring

4.1 Unit Dimensions.....................………………………………………………….. 4-2

4.2 Installation…….............................................…….…………………………… 4-3

4.3 Power Wiring Reference........………………………………………………….. 4-4

4.4 Input Power Connection........………………………………………………….. 4-5

4.5 RS485 Connection…….........………………………………………………….. 4-5

4.6 Serial Communication Ports..………………………………………………….. 4-6

4.6.1 PC Port………............................………………………………………….. 4-7

4.6.2 Display Port…............................………………………………………….. 4-7

4.6.3 Data-Out (1) Port........................………………………………………….. 4-7

4.6.3.1 Available Output Data...........………………………………………….. 4-8

4.6.3.2 Output Data Format..............………………………………………….. 4-9

4.6.4 Data-Out (2) Port........................………………………………………….. 4-10

4.6.5 Data-In Port…............................………………………………………….. 4-10

4.6.6 Serial Communication Cables….………………………………………….. 4-11

4.7 User Console Ethernet Connection..…… ……… …………………………….. 4-12

4.8 PLC Interface Communication (I/O).………………………………………….. 4-13

4.8.1 External I/O Disable Switch…....………………………………………….. 4-14

4.9 Firmware Flash Connector………….………………………………………….. 4-14

Chapter 5: Control Interfaces

5.1 Interface Board Setup……….………………………………………………….. 5-2

5.2 Signal Timing Chart…..................................…….…………………………… 5-3

5.2.1 Sequence Operation..................………………………………………….. 5-3

5.2.2 Jog (Manual) Operation.............………………………………………….. 5-4

xi

Page 12

Table of Contents

5.3 Discrete I/O Interface….........………………………………………………….. 5-5

5.3.1 Sinking Type (NPN)…................………………………………………….. 5-5

5.3.1.1 Discrete Signal Connection (Sinking Type)………………………….. 5-6

5.3.2 Sourcing Type (PNP)..................………………………………………….. 5-7

5.3.2.1 Discrete Signal Connection (Sourcing Type).……………………….. 5-8

5.3.3 Input Signals (PLC-IN)................………………………………… ……….. 5-9

5.3.4 Output Signals (PLC-OUT).........………………………………………….. 5-11

5.3.4.1 Output Data Banks.…...........………………………………………….. 5-15

5.4 Interbus S

5.4.1 Component Descriptions............………………………………………….. 5-18

5.4.2 User Console Software Settings ………………………………………….. 5-19

5.4.3 Input Signals (Reference Layout)..……………………………………….. 5-20

5.4.4 Output Signals (Reference Layout)……………………………………….. 5-22

5.5 DeviceNet

5.5.1 Component Descriptions...........………………………………………….. 5-25

5.5.2 User Console Software Settings ………………………………………….. 5-26

5.5.3 Input Signals (Reference Layout)..……………………………………….. 5-27

5.5.4 Output Signals (Reference Layout)……………………………………….. 5-29

5.6 Profibus

5.6.1 Component Descriptions............………………………………………….. 5-32

5.6.2 User Console Software Settings ………………………………………….. 5-33

5.6.3 Input Signals (Reference Layout)..……………………………………….. 5-34

5.6.4 Output Signals (Reference Layout)……………………………………….. 5-36

5.7 Modbus Plus

5.7.1 Component Descriptions............………………………………………….. 5-39

5.7.2 User Console Software Settings ………………………………………….. 5-41

5.7.3 Input Signals (Reference Layout)..……………………………………….. 5-42

5.7.4 Output Signals (Reference Layout)……………………………………….. 5-44

5.8 CC-Link

5.8.1 Component Descriptions........... ………………………………………….. 5-47

5.8.3 Input Signals (Reference Layout)..……………………………………….. 5-49

5.8.4 Output Signals (Reference Layout)……………………………………….. 5-51

5.9 CC-Link

5.9.1 Component Descriptions............………………………………………….. 5-54

5.9.2 User Console Software Settings ………………………………………….. 5-56

5.9.3 Input Signals (Reference Layout)..……………………………………….. 5-57

5.9.4 Output Signals (Reference Layout)……………………………………….. 5-59

5.10 Allen-Bradley Remote I/O Interface………………………………………….. 5-60

5.10.1 Component Descriptions...........………………………………………….. 5-62

5.10.2 User Console Software Settings .……………………………………….. 5-63

5.10.3 Input Signals (Reference Layout).……………………………………….. 5-64

5.10.4 Output Signals (Reference Layout).…………………………………….. 5-66

Interface..…........………………………………………………….. 5-16

®

Interface.…........………………………………………………….. 5-23

®

Interface.……...... ..………………………………………………….. 5-30

®

Interface.........………………………………………………….. 5-37

®

Interface (Version 1)..……………………………………………….. 5-45

®

Interface (Version 2)..……………………………………………….. 5-52

®

xii

Page 13

Table of Contents

5.11 Ethernet-I/P Interface…........………………………………………………….. 5-67

5.11.1 Component Descriptions...........………………………………………….. 5-68

5.11.2 User Console Software Settings. .……………………………………….. 5-69

5.11. 3 Input Signals (Reference Layout).……………………………………….. 5-70

5.11.4 Output Signals (Reference Layout)..…………………………………….. 5-72

5.11.5 PLC Message Transfer Setup Example…..…………………………….. 5-73

Chapter 6: Troubleshooting

6.1 Abnormals…………………….………………………………………………….. 6-2

xiii

Page 14

Blank Page

xiv

Page 15

Chapter 1: Outline

Page 16

Chapter 1: Outline

enFORCE DSP1500 Main Unit Hardware Manual

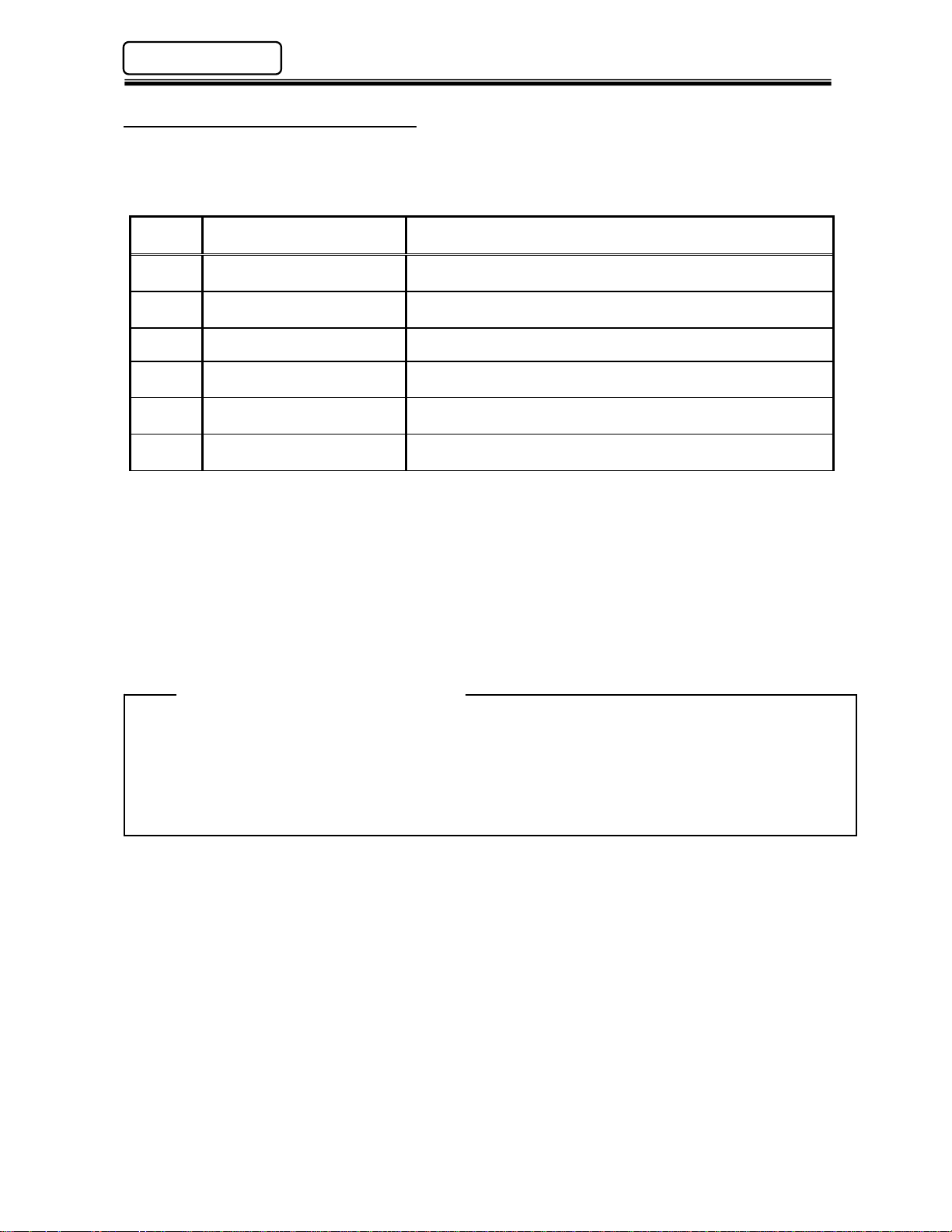

1.1 About this Main Unit Manual

This manual details the configuration, specifications and the operation of the DSP1500 Main Unit.

The following table outlines the contents of each chapter.

Chapter

1 Outline

Title Contents

Basic characteristics and requirements of the DSP1500

Main Unit.

2 Specifications General specifications of the DSP1500 Main Unit.

3 System Description Description of standard and optional system components.

4 Installation and Wiring

5 Control Interfaces

Mounting requirements, wiring connection references

including communication port specifications.

Description of standard Discrete I/O and optional Fieldbus I/O

PLC Interfaces.

6 Troubleshooting Description of Abnormal conditions.

Any questions regarding the contents of this document or any related matter should be

directed to FEC Inc. at (586) 781-2100 or faxed to (586) 781-0044.

The Information set forth in the following document is the property of FEC Inc. This

document shall not be released to or copied for any person and/or organization without

the expressed prior consent of FEC Inc.

Unauthorized reproduction or distribution of this manual is strictly prohibited. Please

contact FEC Inc. if additional copies are required.

Related Docum entation

DSP User Console Manual DSP1500E-SW-*

DSP1500 SAN Unit Operation Manual DSP1500E-HS-*

(Rev. 4.0) PAGE 1 - 2

Page 17

enFORCE DSP1500 Main Unit Hardware Manual

Chapter 1: Outline

1.2 Functions

The Main Unit is a complimentary controller device to enhance the DSP1500 capabilities by

providing the communication and the sequence control features required by larger or more

sophisticated multi press applications. When a group of DSP1500 Servo Controllers (SAN Units) are

linked to a Main Unit, the Main Unit assumes control (over these presses) of the following functions:

Input-Output (I/O) Connection (including Fieldbus interface)

Sequence Control

Parameter Programming

Pressing Data Monitoring & Communication

General Status Indication

♦ Input-Output Connection (including Fieldbus interface)

The Main Unit assumes control of the control signals (Ex.: STOP, START, RETURN,

BYPASS, etc.) to all of the DSP1500 Servo Controllers linked to it via the RS485

communication port, thus eliminating direct connection & control to the individual presses.

The control signals for the multi-press array can be of different sources: Signals manually

generated by pressing the Control Buttons on the front of the Main Unit or I/O (Input/Output)

signals from a PLC or from a PC Based Controller.

♦ Sequence Control

The Main Unit controls the pressing sequencing eliminating the need for external control

devices (PLC) to perform complicated control sequencing. All pressing sequencing is

handled by the Main Unit. This built in feature allows the Main Unit to control a variety of

complex sequencing strategies including; several pressing steps, reject (retry) strategies,

wait timing, multiple starts, etc.

♦ Parameter Programming

A Windows® compatible computer running the DSP User Console software package can be

connected to the Main Unit in order to upload or download the preset data to all the SAN

(Servo) Controllers connected in the multi press array. This eliminates the need to program

individual presses manually.

♦ Pressing Data Monitoring & Communication

The Main Unit can monitor and process the pressing results collected by the DSP1500 Servo

(SAN) Controllers connected to it. It has four (4) configurable RS232C ports to input and

output pressing data results. Data monitoring / saving is also a function of the DSP User

Console software package.

As an added feature, the Main Unit stores previous pressing data in RAM (volatile) for

uploading at another time. The number of cycles stored is based on the number of presses

connected (see chart on page 2-2). The data can be uploaded using the DSP User Console

software package.

♦ General Stat us Indi ca tio n

A set of indicator LED’s provide the status for Power On, Busy, Total Accept, Total Reject and

Abnormal conditions.

PAGE 1 - 3 (Rev. 4.0)

Page 18

Chapter 1: Outline

enFORCE DSP1500 Main Unit Hardware Manual

1.3 Safety Precautions

To ensure the most effective and extended use of all equipment, adhere to the following

precautions:

¾ Wiring

¾ Installation Environment

¾ Static Electricity

¾ Cleaning

¾ Electrical Noise Prevention

¾ Handling and Shipping

(Rev. 4.0) PAGE 1 - 4

• Use only the specified cables for all system connections.

• Do not use a high voltage circuit as a frame ground (FG). Also, the frame ground should be

separate from the power ground. The use of a grounding rod located as close as possible to

the enclosure housing the DSP1500 Main Unit is preferable.

• Circuit breakers or fuses are required on branch circuit power feeds to the Main Unit.

• PLC I/O cables must be run separate from any high voltage sources or cabling, and must not

exceed 50 feet.

• The DSP1500 Main Unit should be placed in a NEMA 12 enclosure.

• Using the equipment in the following locations may lead to malfunction or breakdown. Avoid

using in these areas or use an air conditioner.

Areas under direct sunlight or if the environmental temperature is out of the 32~122℉

(0~50℃) range.

Areas where relative humidity is out of the 20-90% range, the temperature change is

drastic or where the area is exposed to mist and water drops.

• Do not use at the following locations. (Contact FEC Inc. if necessary for clarification)

Areas where conductive powder, oil, mist, salt or organic solvents exist.

Areas that have corrosive or combustible gases.

Areas that have strong electric or magnetic fields.

Areas where strong vibration or shock could be transmitted directly to a Main Unit.

• The DSP1500 Main Unit incorporates many electronic Surface Mounted Devices (SMD). It is

advisable to strictly adhere to practices for safe electrostatic discharge in order to prevent

damage to the system components when handli ng them.

• Do not use any organic solvents, such as thinner, to clean a Main Unit. The solvent could

melt the surface paint, or penetrate inside and cause damage. A cloth dampened with

alcohol or warm water should be used to lightly wipe the components.

• Main Units must be located a minimum of 600mm from high transient voltage sources such

as transformers, motor starters, AC inverters and AC contactors. If it cannot be avoided, the

unit must be shielded.

• If high powered devices are used inside the enclosure, they must use a surge suppression

device.

• Make sure that the power supply lines and cables for connecting the unit and tool are not run

together inside the same duct.

• It is cr itical that DSP1500 System components are properly handled and shipped in order to

maintain the system’s integrity. Adhere to the following requirements for shipping and

handling:

Loose DSP1500 Main Units must be individually packaged and shipped in anti-static

containers or wrap to prevent damage from electrost ati c discharge.

If the Main Unit is to be shipped in an enclosure, tighten all mounting screws to

prevent the unit from being dislodged.

Do not ship or store the unit in environments where the temperature is out of the

23~131℉ (-5~55℃) range or where the humidity is above 90%.

Page 19

Chapter 2: Specifications

Page 20

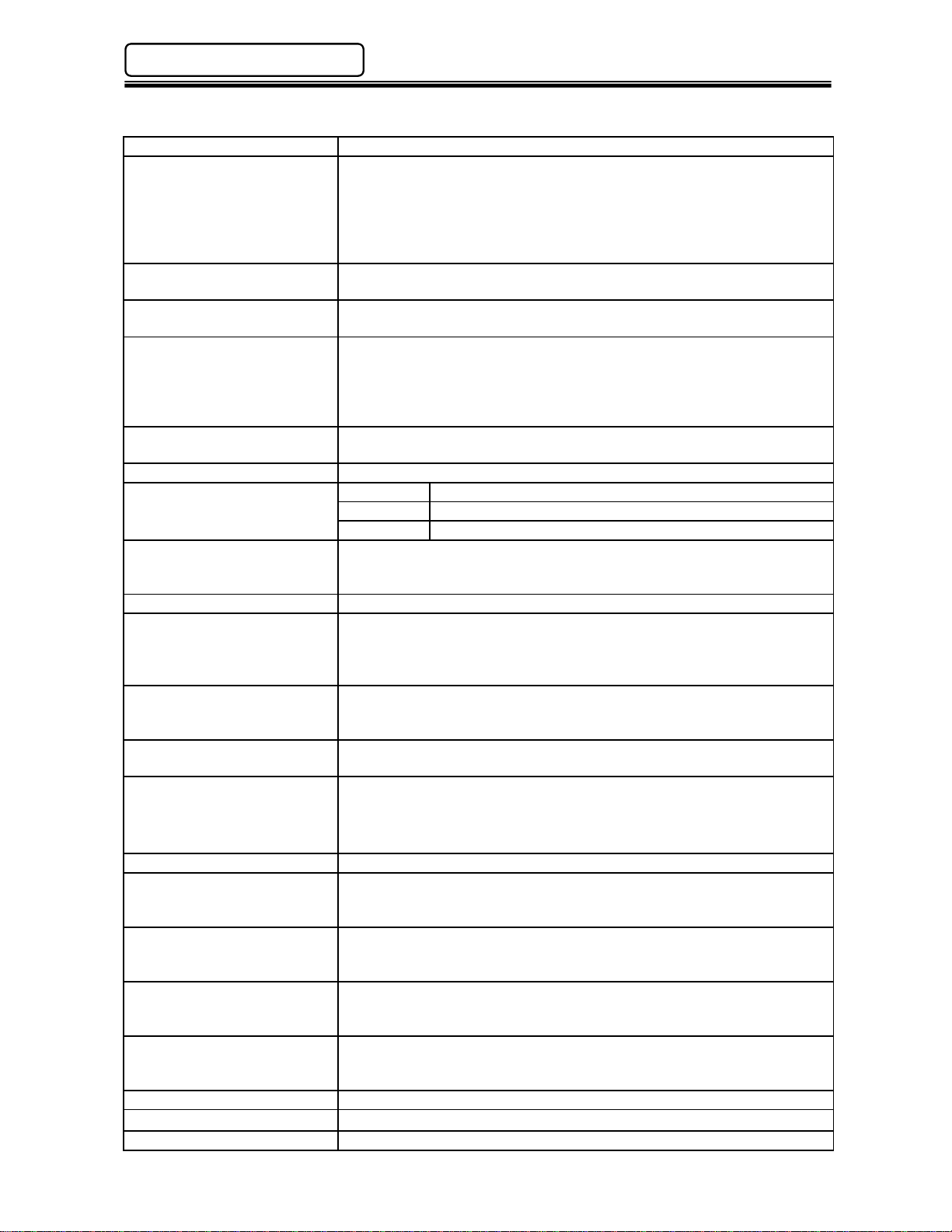

(

)

(

)

Chapter 2: Specifications

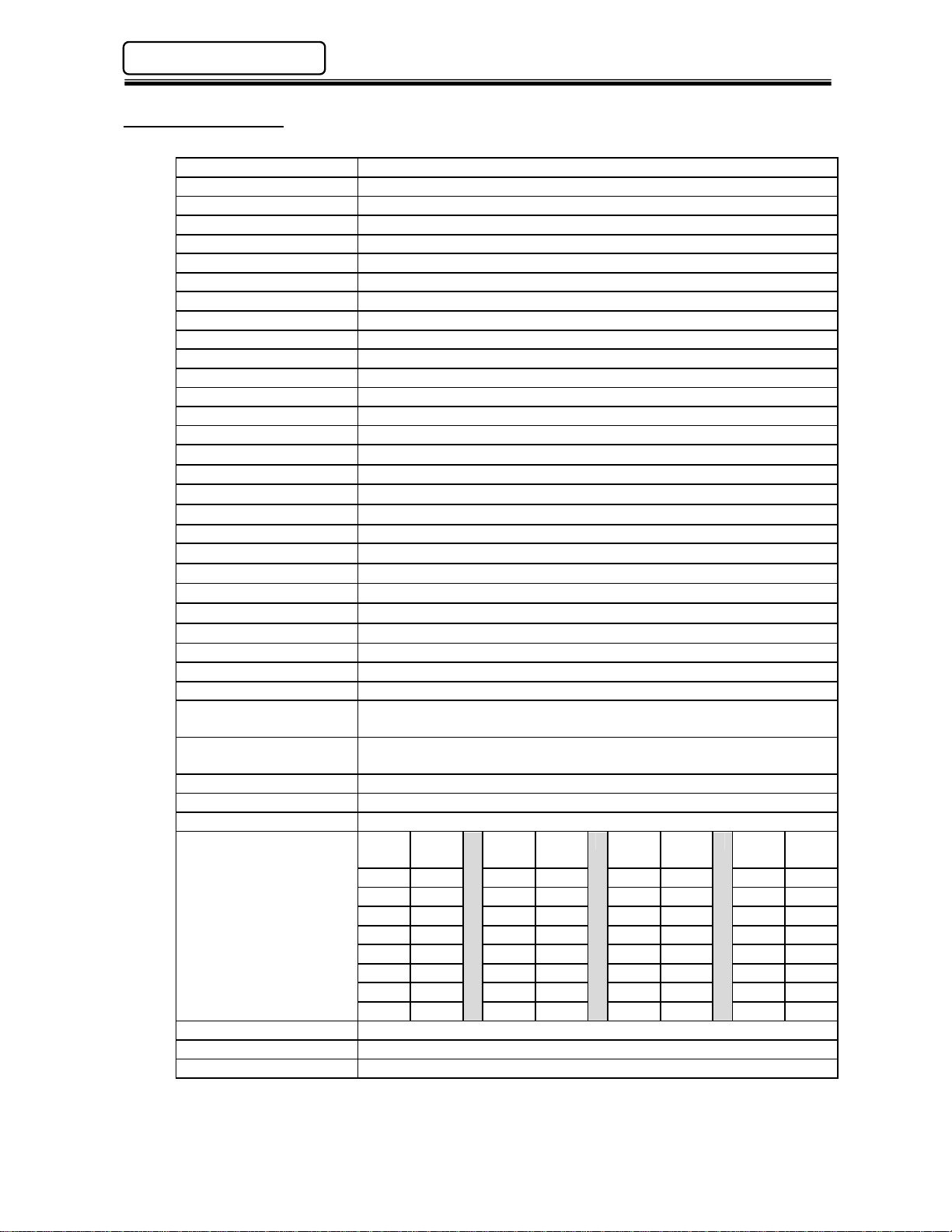

2.1 Specifications

Power Supply Voltage 100 to 220 VAC±15%, 1-phase, 50/60 Hz.

Power Consumption 9 Watt/Hour

Operating Current Less than 70 mA

In rush current Less than 160 mA

CPU NEC V53A

Data Communication RS 232C (User Console PC)

RS232C

RS232C (Data Input)

RS232C (Data Output #2)

RS422 (External Remote Display)

RS485 Servo Units Programming/Control

Ethernet - User Console (User Console PC)

Ethernet - Network Communication (2E Version Only)

Control Interfaces Discrete I/O (24Vdc Sink)

Discrete I/O (24Vdc Source)

Allen Bradley Remote I/O 1

Ethernet I/P (includes messaging capabilities)

M-Net

Pressing Sequence

Programming Steps

Pressing

Control Methods

Max. No. of presses 31 per Main Unit

Pressing Parameters 32

Pressing Sequences 32

Data Storage

(non-volatile RAM)

Based on the number of

presses connected.

Installation requirement NEMA12 Enclosure

Operation Temperature 0º to 50 ºC (32 º to 122 ºF)

Operation Humidity 20% to 90%

1) Mitsubishi CC Link & Allen Bradley Remote I/O are proprietary and licensed for use.

2) The number of cycles stored will be reduced if RS232C - DATA IN data is stored with the

pressing data.

enFORCE DSP1500 Main Unit Hardware Manual

Data Output #1

DeviceNet

Interbus-S

Profibus

Mitsubishi CC Link

Modbus Plus

CC Link

DeviceNet

Interbus-S

Profibus

Also Available: Contact FEC for special fieldbus requirements.

100

(99 plus End Step)

Load Control / Distance Control

plus 7 other special methods

Stored

# of

Press

Cycles

1 8322 9 2475 17 1434 25 1012

2 6526 10 2250 18 1350 26 984

3 5289 11 2081 19 1294 27 928

4 4445 12 1941 20 1237 28 900

2

5 3826 13 1828 21 1181 29 872

6 3375 14 1716 22 1125 30 843

7 3010 15 1603 23 1097 31 815

8 2700 16 1519 24 1040

(includes messaging capabilities)

®

®

®

1

®

®

Version 2 (includes messaging capabilities)

®

for ToolsNet®

®

for ToolsN e t®

®

for ToolsNet®

®

# of

Press

Stored

Cycles

# of

Press

Stored

Cycles

# of

Press

Stored

Cycles

(Rev. 4.0) PAGE 2 - 2

Page 21

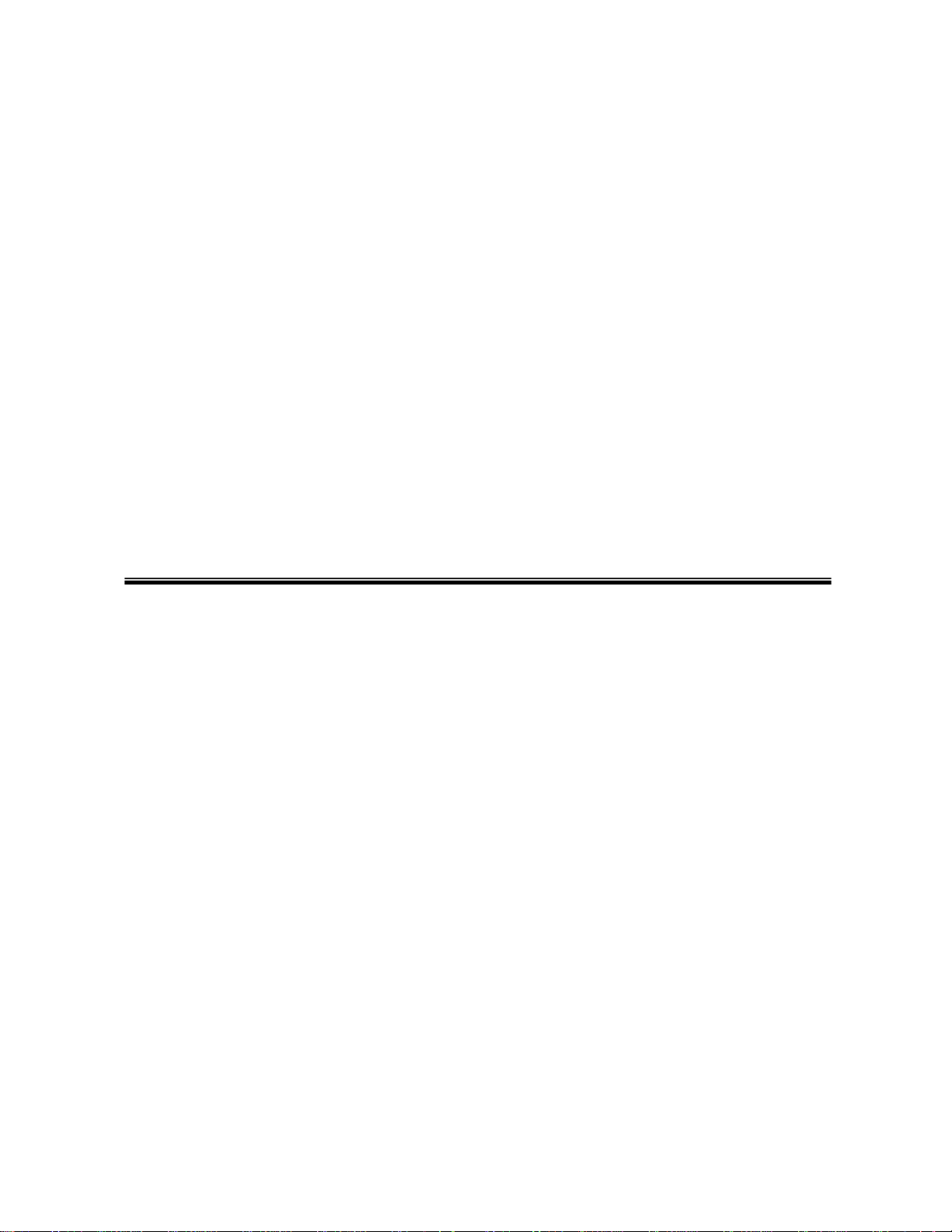

enFORCE DSP1500 Main Unit Hardware Manual

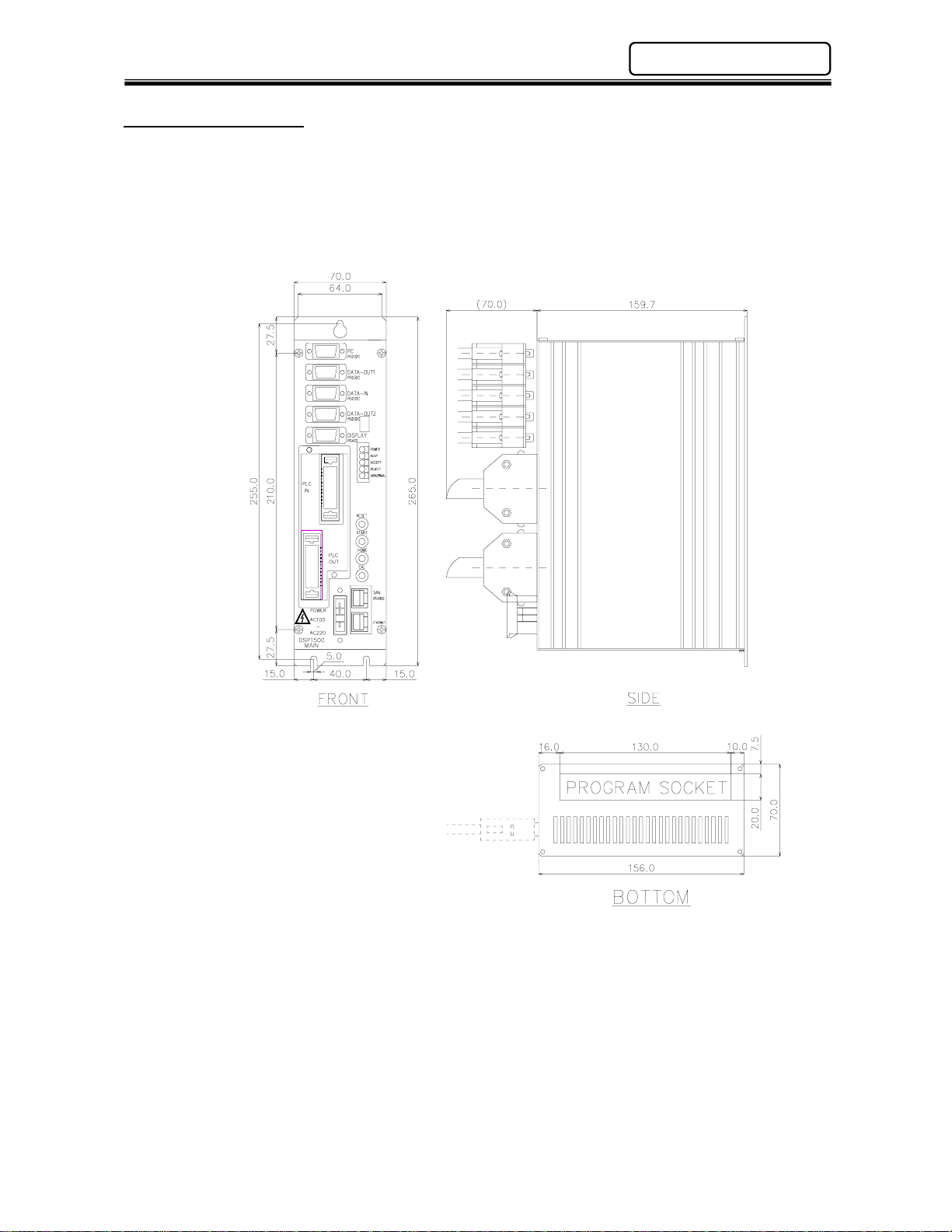

2.2 Unit Dimensions

Weight: 1.4 kg

Chapter 2: Specifications

PAGE 2 - 3 (Rev. 4.0)

Page 22

Chapter 2: Specifications

enFORCE DSP1500 Main Unit Hardware Manual

Blank Page

(Rev. 4.0) PAGE 2 - 4

Page 23

Chapter 3: System Description

Page 24

Chapter 3: System Description

enFORCE DSP1500 Main Unit Hardware Manual

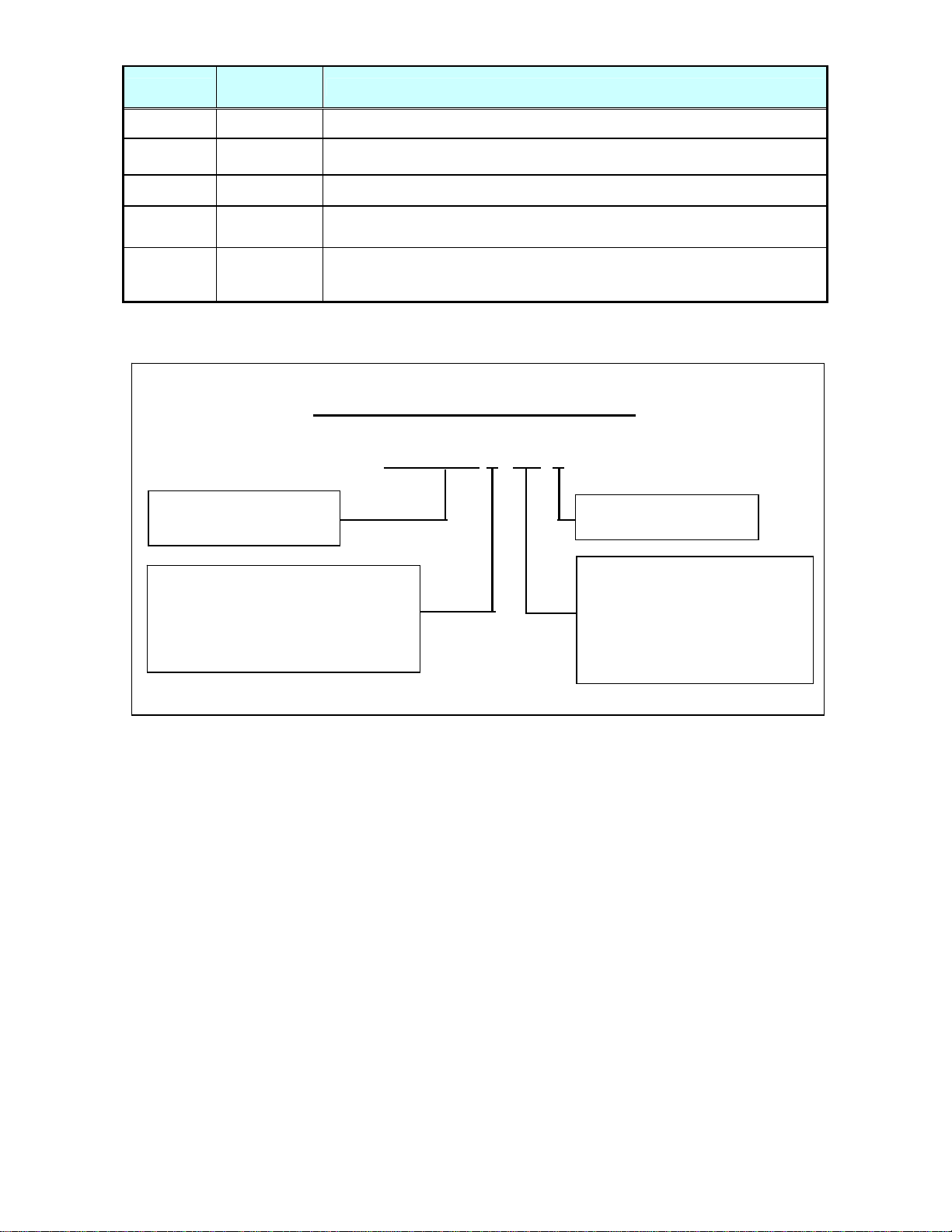

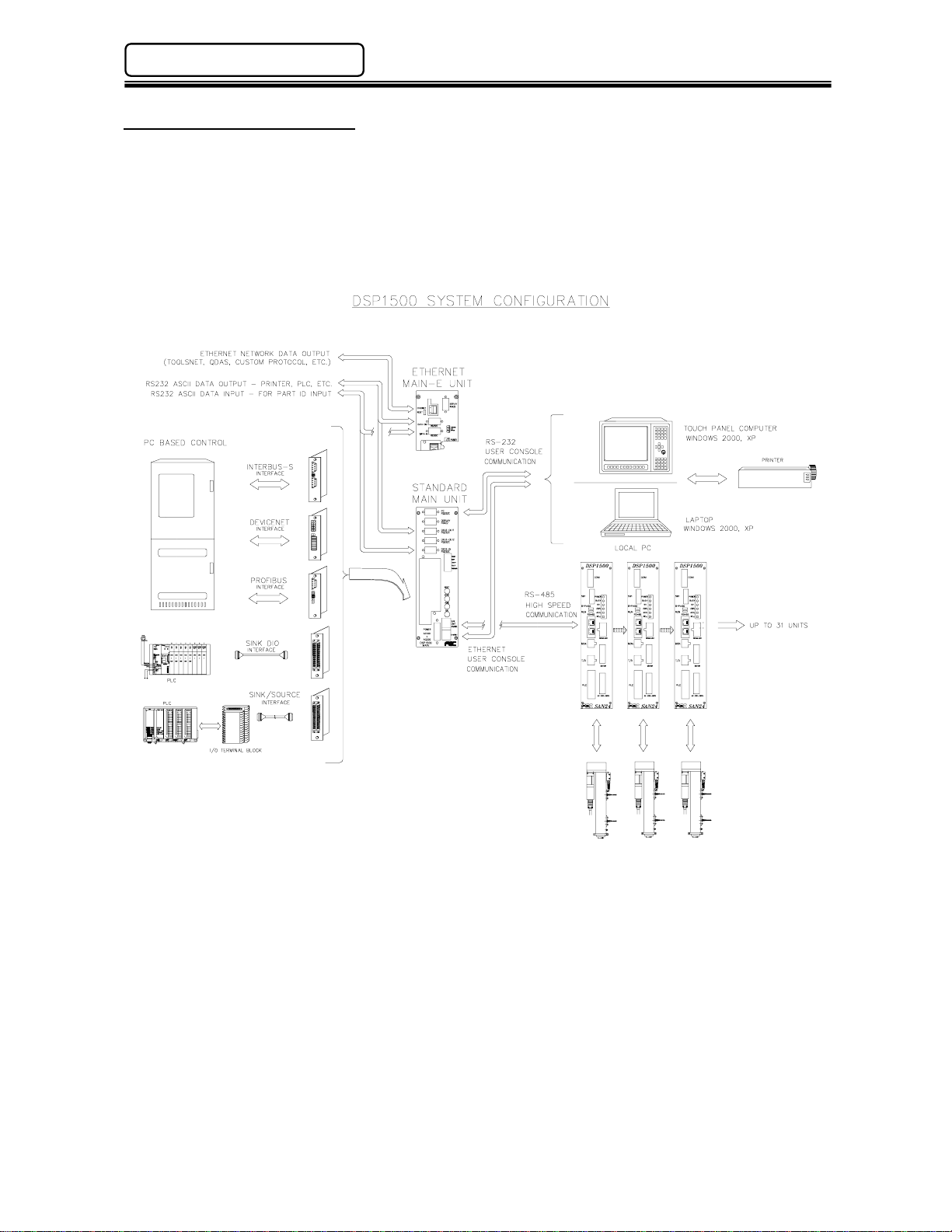

3.1 System Block Diagram

The diagram below shows how the DSP1500 Main Unit can be connected to a single unit or combined

in a multiple press configuration. The use of a Main Unit provides one set of PLC I/O for c ontrolling

multiple pressing operations. Along with discrete 24VDC (sinking or sourcing) I/O, various fieldbus

interf ac es are al s o a va i la bl e for dire c t connecti o n t o n e t wo r ks such as Profi bus, AB remote I/O , C CLink,

DeviceNet, etc.

The DSP1500 Main Unit also provides an interface for connection to the User Console PC, serial

printers, barcode readers, display units, etc.

(Rev. 4.0) PAGE 3 - 2

Page 25

enFORCE DSP1500 Main Unit Hardware Manual

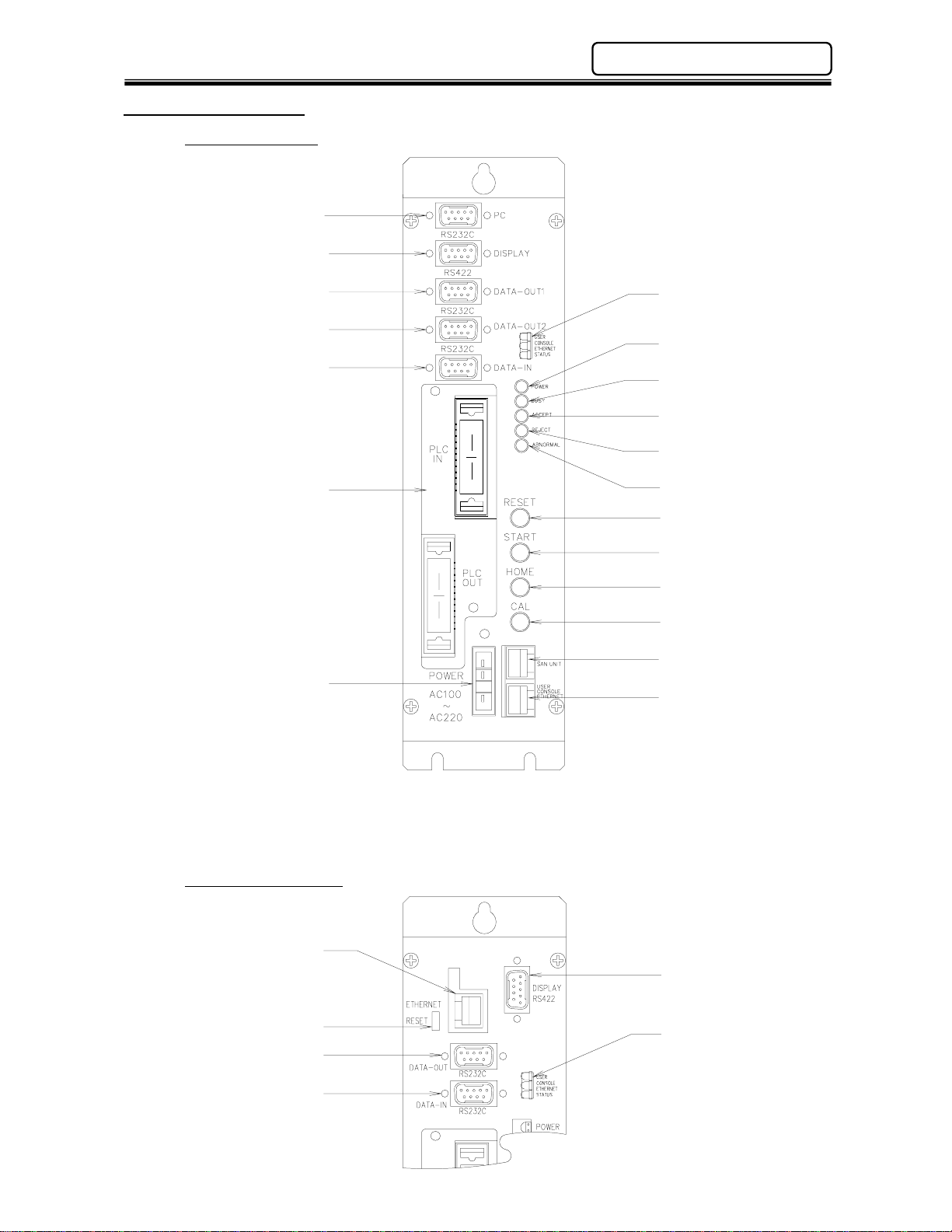

3.2 Unit Description

Chapter 3: System Descriptio n

Standard Version

(RS232C) Data-Out Port #1

(RS232C) Data-Out Port #2

(RS232C) PC Port

(RS422) Display Port

(RS232C) Data-In Port

* Discrete I/O Interface Board Shown.

Interface Board

Power Connector

Ethernet U/C

Status LED

Power ON LED

Busy LED

Accept LED

Reject LED

Abnormal LED

Reset Button

Start Button

Home Button

Calibration Button

RS485 Port

Ethernet U/C Port

Ethernet (E) Version

Ethernet Network Port

Ethernet Reset Button

(RS232C) Data-Out Port

(RS232C) Data-In Port

(RS422) Display Port

Ethernet U/C

Status LED

PAGE 3 - 3 (Rev. 4.0)

Page 26

Chapter 3: System Description

®

enFORCE DSP1500 Main Unit Hardware Manual

Main Unit Panel Description

Power On LED Indicates when power is applied to the Main Unit.

Busy LED Lights when the unit is performing a self check, Home Search, Home

Return, Sequence operation, Jog operation or is

downloading/uploading data to the DSP Software.

Blinks when clearing stored data in the Main Unit and while

communicating when “Disable Main Unit When Communicating” is

checked in the DSP Software.

Accept LED Lights if a pressing cycle or a self check test falls within acceptable

parameters. (This LED indicates status for ALL connected presses)

Reject LED Lights if a pressing cycle or a self check test is outside of acceptable

parameters. (This LED indicates status for ALL connected presses)

Abnormal LED Lights when a system abnormal condition is detected in the control

system of any connected press. (Does NOT indicate a press reject).

All operations are halted and cannot be restarted until the Abnormal

condition is corrected. Can be cleared only by the Reset function. (see

DSP1500 SAN Unit Operation Manual for Abnormal Troubleshooting)

RS485 Port RJ45 style connector used to connect to all DSP1500 Servo (SAN)

Units included in the system.

Ethernet U/C Port Communication port for the User Console PC.

Red (TX) Transmitting Data

Ethernet U/C Status LEDs

Reset Button Resets all signal and communication buffers to “clear” conditions.

Start Button Starts the pressingcycle. Must be maintained during complete cycle.

Home Button If any of the connected presses have not been “Homed”, pushing this

Cal Button Performs the Load Transducer shunt calibration test. When pressed,

Power Connector Connects to incoming power: 100 to 220VAC (auto-sensing), Single

Interface Board (I/O) Allocation socket for input/output signal Interface boards. Options

RS232C – PC Port Communication port for the User Console PC.

RS232C – Data Out Port #1 Communication port for pressing result data output to a serial printer.

RS232C – Data Out Port

(Ethernet Version)

RS232C – Data In Port Co mmuni cation port for ASCII data input fro m periphe ral devices. (Ex:

RS232C – Data Out Port #2 Communication port for pressing result data output to a host

RS422 – Display Port Communication Port for an FEC Remote Display Unit

Ethernet Network Port*

Ethernet Reset Button* for resetting the Network Ethernet Port

*On Ethernet Version only.

Yellow 10/100 Link

Green (RX) Receiving Data

Clears the Abnormal signal and performs the Load Transducer Zero

Level Check.

button will cause those presses to perform a “Home Position Search”.

If Home has been set, the connected presses will move to the Home

Position.

the Servo (SAN) Units will display either a green accept LED or red

reject LED indicating status of the individual Calibration test.

phase, 50/60 Hz.

available are Discrete I/O (Sink or Source), Interbus-S

Profibus

, CC-Link® (Version 1 or 2), Modbus Plus®, Allen Bradley

®

, DeviceNe t®,

®

Remote I/O (Rockwell License #199906006) or Ethernet-I/P

Data output format is configured using the User Console (DSP)

Software package.

Communication port for pressing result data output to any external

device, i.e.: host computer, serial printer, etc. Data output format is

configured using the User Console (DSP) Software package.

bar code readers, RF tag, etc.) Allows external ASCII data to be

merged with pressing result data.

computer. Data output format is configured using the User Console

(DSP) Software package.

for Network Connectivity (Toolsnet

, QDAS®,Custom Protocol, etc.)

(Rev. 4.0) PAGE 3 - 4

Page 27

Chapter 4: Installation & Wiring

Page 28

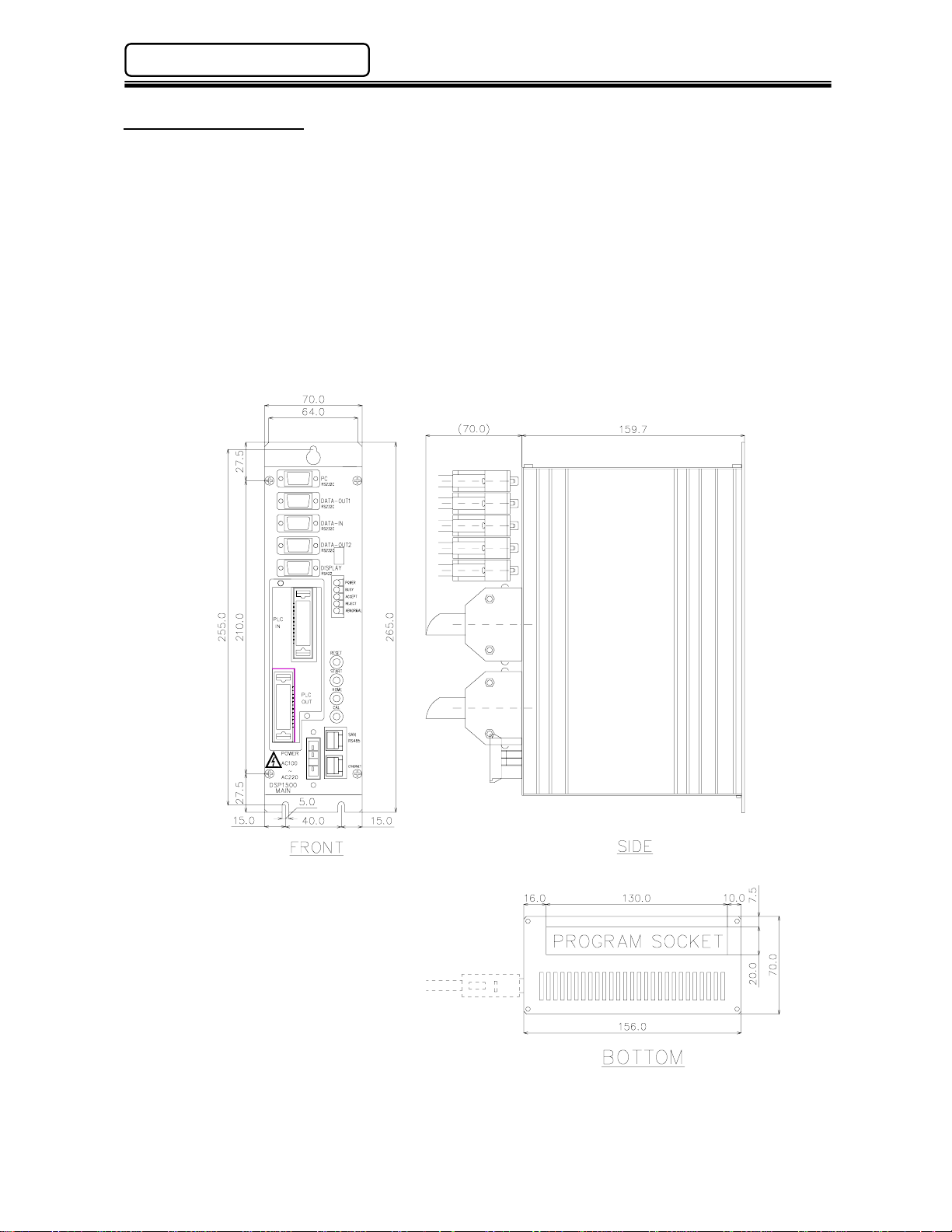

Chapter 4: Installation & Wiring

enFORCE DSP1500 Main Unit Hardware Manual

4.1 Unit Dimensions

Main Units must be mounted with a minimum clearance of 13mm on each side to allow proper heat

dissipation. Cable connections on the front of the units require 100mm of clearance. Allow a

minimum of 100mm clearance on the bottom of the unit for flash connector hook up when updating

firmware.

Mounting: Top (1) place #8-32 screw

Bottom (2) places #8-32 screw

Weight: 1.4 kg

(Rev. 4.0) PAGE 4 - 2

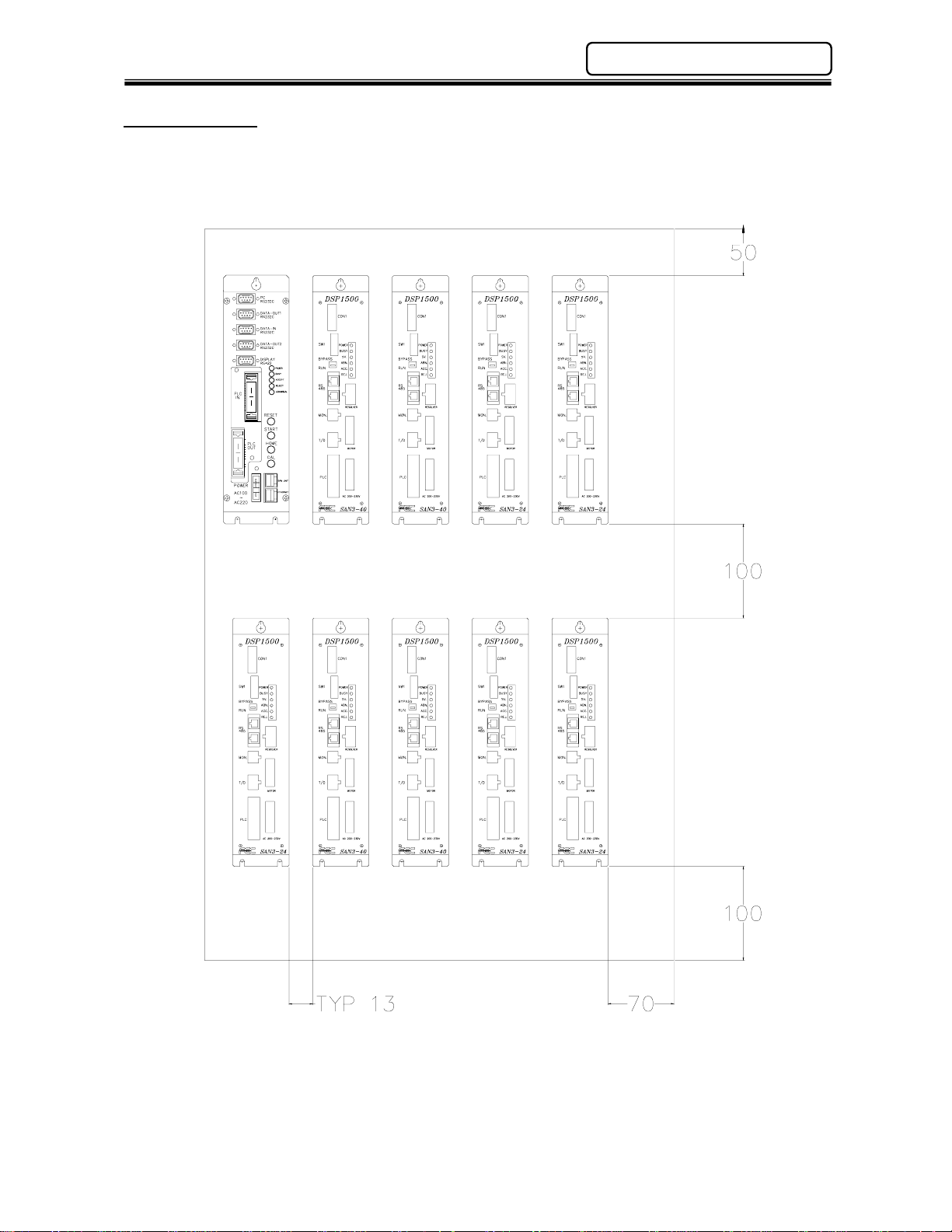

Page 29

enFORCE DSP1500 Main Unit Hardware Manual

Chapter 4: Installation & Wiring

4.2 Installation

The Main Unit should be mounted into a NEMA12 / IP52 enclosure at a minimum and spaced similar

to the DSP1500 SAN Units (Shown Below).

PAGE 4 - 3 (Rev. 4.0)

Page 30

Chapter 4: Installation & Wiring

enFORCE DSP1500 Main Unit Hardware Manual

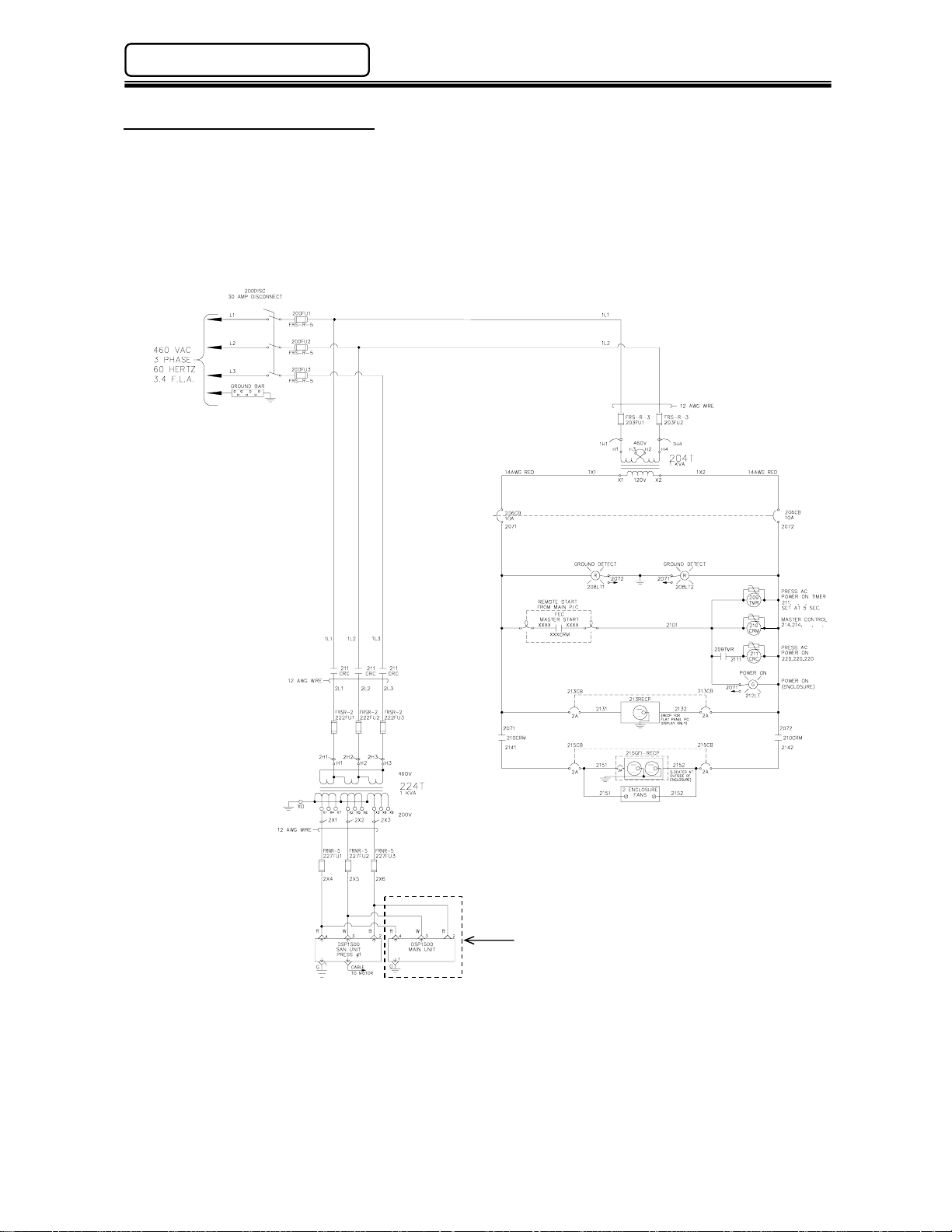

4.3 Power Wiring Reference

Even though the Main Unit power input allows it to connect to 120 VAC ~ 220 VAC power lines,

typically the unit is connected to the same power source that the SAN Units are connected to (200 to

220 VAC ± 10%) . In the example wiring diagram shown below there are two power branches; one is

for the control circuitry connected to 120 VAC and the other is for the SAN power circuitry connected

to 220 VAC. For convenience, the Main Unit is wired together with the DSP1500 Servo Controllers.

Note that the Main Unit is using one phase while the Servo Controllers use three phases.

Main Unit Power Reference

Note: Diagram shown with the Main Unit wired using same cable used for SAN Unit for

standardizing components. Pin #2 is not wired internally on the Main Unit.

(Rev. 4.0) PAGE 4 - 4

Page 31

enFORCE DSP1500 Main Unit Hardware Manual

Chapter 4: Installation & Wiring

4.4 Input Power Connection

An auto sensing power supply allows for input power in the range of 100 ~ 220VAC single phase,

50/60 hertz. Adequate circuit protection must be provided. Recommended conductor size should be

a minimum of #16AWG.

Wiring Chart

4: 100 ~ 220VAC +/-15%

3: 100 ~ 220VAC +/-15%

2: No Connection **

1: Frame Ground

4

3

2

1

Manufacture: Amp

Housing Part No.: 1-178128-4

Mating Conn ec tor

Contact Part No.: 1-175218-3 (Qty.-3)

** To standardize components, FEC cable

part #FEB-1280 may be used due to the fact

that pin #2 is not connected internally .

4.5 RS485 Connection

The Main Unit uses an RS485 port to perform the communication operations with the DSP1500

Servo (SAN) Controllers. This port has two channels CH1 and CH2. CH1 is dedicated to handle all

preset data upload and download, pressing results monitoring and collection. Channel CH2 is a high

speed connection to all DSP1500 Servo Controllers. It controls all required commands to perform

the pressing cycle.

RS485 port specifications (RJ45)

Speed 9600, 19200, 38400 baud

Cable Std Cat 5 Ethernet

Maximum number of

connected devices

Protocol Proprietary

Operating Voltage RS485 Standard

RS485 Wiring

8

Pin Signal Name Channel

1 TX+ / RX+ CH1

2 TX- / RX- CH1

3 RX+ CH2

4 TX- CH2

5 TX+ CH2

6 RX- CH2

7 GND

8 GND

31

PAGE 4 - 5 (Rev. 4.0)

Page 32

Chapter 4: Installation & Wiring

enFORCE DSP1500 Main Unit Hardware Manual

4.6 Serial Communication Ports

The Main Unit has four usable serial RS232C (two on Ethernet Versions) and one RS422

communication port. All of these ports settings and data format are fully configurable with the DSP

User Console software.

(OPTIONAL)

STANDARD VERSION ETHERNET VERSION

RS-232C Signal Layout

1 DCD (Data Carrier Detect) Used only for DATA-IN*

2 RXD (Receive Data) Serial Data Input.

3 TXD (Transmit Data) Serial Data Output.

4 DTR (Data Terminal Ready) Output signal; active when the internal device is ready to link.

5 GND (Ground Signal)

6 DSR (Data Set Ready)

7 RTS (Request to Send)

8 CTS (Clear to Send)

9 RI (Ring Indicator) Not used

* When using th e DATA-IN port, PIN 1 (DCD) must be enabled for data input (Jumper pins 1 & 4)

Input signal; in dicates that the external device is r eady to establish a

link. Can be connected directly to DTR for automatic data dump.

Output signal. Active when the internal device is ready to exchange

data.

Input signal. Indicates that the external device is ready to exchange

data. Can be connected directl y to RTS when no as yn chronous data

flow is required.

(Rev. 4.0) PAGE 4 - 6

Page 33

enFORCE DSP1500 Main Unit Hardware Manual

Chapter 4: Installation & Wiring

4.6.1 PC Port

The “PC” port is for communicating with the DSP Software in the User Console PC. The

connecting cable is a standard RS232 Null-Modem cable and can be purchased through FEC

(Part #FEB-1301) or through any authorized RS232 cable supplier. T his port is not available on

Ethernet Version units.

RS-232 Pin Layout

1 DCD

2 RXD

3 TXD

4 DTR

5 GND

6 DSR

7 RTS

8 CTS

9 Not Used

4.6.2 DISPLAY Port

“DISPLAY” port is used to connect to an FEC Remote Display Unit.

RS-422 Pin Layout

1 TX+

2 TX-

3 RX+

4 RX-

5 GND

6 Not Used

7 Not Used

8 Not Used

9 Not Used

4.6.3 DATA-OUT (1) Port

“DATA -OU T(1)” is an output port for ASCII fastening data communication to external devices.

RS-232 Pin Layout

1 DCD

2 RXD

3 TXD

4 DTR

5 GND

6 DSR

7 RTS

8 CTS

9 Not Used

PAGE 4 - 7 (Rev. 4.0)

Page 34

Chapter 4: Installation & Wiring

4.6.3.1 Available Output Data

The Main Unit is capable of outputting the press results data in an ASCII format to a serial

printer or other peripheral devices. The data is sent from the Main Unit’s RS232C “DATA

OUTPUT” ports. The output data string as well as port configuration can be configured by the

DSP User Console Software. Control Characters may also be implemented (Ex: Start of Text,

End of Text, etc.). Below is a list of data available and its byte length.

Basic Pressing Data Length in bytes

Judgment Load

Final Load

Judgment Distance

Final Distance

Cycle Time

Judgment

Extended Pressing Data Length in bytes

Distance Measureme n t Star t Dista n ce 7

Interference Check Distance 8

Part Check 1 Distanc e 8

Part Check 2 Minim um Load 6

Part Check 2 Maximum Load 6

Part Check 2 Distance at Minimum Load 7

Part Check 2 Distance at Maximum Load 7

Part Check 2 Minim um Load 6

Part Check 2 Maximum Load 6

Part Check 2 Distance at Minimum Load 7

Part Check 2 Distance at Maximum Load 7

Absolute Distance 7

Input Data* Length in bytes

RS232C data buffer 1

RS232C data buffer 2

RS232C data buffer 3

RS232C data buffer 4

System Data Length in bytes

Date 10

Time 8

Press Number 2

Sequence Number 2

Parameter Number 2

Cycle Count 7

*Input Data is input to the Main Unit using the RS232C “DATA INPUT” port. This port is

configured through the DSP User Console Software. The data must be ASCII formatted data &

is limited to 128 bytes in (4) separate data buffers. The port must be configured for the input

string which is to be received. The data received can then be married with the resultant pressing

data by selecting the RS232 data in the output format. This function is typically used to marry a

part number with the resultant pressing data for production birth history.

enFORCE DSP1500 Main Unit Hardware Manual

6

5

8

7

5

3

Up to 128

This length is determined b y t he user and

dependent upon the length of data input to

these data areas.

(Rev. 4.0) PAGE 4 - 8

Page 35

enFORCE DSP1500 Main Unit Hardware Manual

4.6.3.2 Output Data Format

The example below shows the format of the DATA-OUT (1) port connected to a printer. Actual

data output format may vary depending on the configuration and set-up of this port using the

DSP User Console Software. The data field is selectable from all the available output fields to as

little as one output field (See previous table for available data fields). Headers, footers & ASCII

control characters are all configurable using the DSP User Console Software.

2007/09/26 09 :17:57 SEQ01 [Input Data f r om DATA-IN]

SP PA F LD F DS JUG Acceptable Pressing

01 01 1.50 126.042 O

2007/09/26 09 :19:36 SEQ01

SP PA F LD F DS JUG Rejected Pressing

01 01 1.08L 130.001H X

2007/09/26 09 :21:16 SEQ01

SP PA F LD F DS JUG Cycle Stopped

01 01 0.38L 93.540L ! (Before pressing end)

2007/09/26 09 :21:34 SEQ01

SP PA F LD F DS JUG Abnormal

01 01 0.01L 0.001L A05 (Showing abnormal code)

2007/09/26 09 :21:21 SEQ01

SP PA F LD F DS JUG Press Bypassed

01 00 0. 0.

Index

SEQ: Sequence F LD: Final Load H: High

SP: Press Number F DS: Final Distance L: Low

PA: Parameter JUG: Judgment

Chapter 4: Installation & Wiring

PAGE 4 - 9 (Rev. 4.0)

Page 36

Chapter 4: Installation & Wiring

enFORCE DSP1500 Main Unit Hardware Manual

4.6.4 DATA-OUT 2 Port

“DATA - OUT 2” is an output port for ASCII fastening data communication to a Host Computer. This

port is not available on Ethernet Version units.

RS-232 Pin Layout

1 DCD

2 RXD

3 TXD

4 DTR

5 GND

6 DSR

7 RTS

8 CTS

9 Not Used

4.6.5 DATA-IN Port

The “DATA-IN” port is for inputting ASCII data to the press system for marriage to the pressing

data. It is typically used for attaching part serial number(s) to the pressing data for data storage

birth history.

RS-232 Pin Layout

1 DCD

2 RXD

3 TXD

4 DTR

5 GND

6 Not Used

7 RTS

8 CTS

9 Not Used

* When using the DATA-IN port, PIN 1 (DCD) must be enabled for data input (Jumper pins 1 & 4).

(Rev. 4.0) PAGE 4 - 10

Page 37

enFORCE DSP1500 Main Unit Hardware Manual

4.6.6 Serial Communication Cables

RS-232C PC CABLE

RS-232C DATA-IN CAB L E

RS-232C DATA-OUT 1 & 2 CABLE

Chapter 4: Installation & Wiring

PAGE 4 - 11 (Rev. 4.0)

Page 38

Chapter 4: Installation & Wiring

enFORCE DSP1500 Main Unit Hardware Manual

RS-422 CABLE DRAWING (DISP LAY)

4.7 User Console Ethernet Connection

The “User Console Ethernet” port is for communicating with the DSP Software in the User Console

PC. In order to use this connection you must first connect through the RS232 “PC” port and

configure this port using the DSP Software.

The connecting cable is a standard Ethernet “Crossover” cable (if connected to a PC or Straight

Cable if connected through an Ethernet switch) and can be purchased through FEC (Part

#FEB-1331) or through any authorized Ethernet cable supplier.

Ethernet port specifications (RJ45)

Speed 10/100Mbps (auto select)

Cable Std Cat 5 Ethernet

Protocol Proprietary

Operating Voltage Ethernet Standard

Ethernet Wiring

8

Pin Signal Name

1 Tx+

2 Tx 3 Rx+

4 5 6 Rx 7 8 -

(Rev. 4.0) PAGE 4 - 12

Page 39

enFORCE DSP1500 Main Unit Hardware Manual

Chapter 4: Installation & Wiring

4.8 PLC Interface Communication (I/O)

The Main Unit is able to operate under different Input/Output control structures through use of a

modular I/O interface board installed in the unit. With the introduction of “Open” communication

networks known as “Fieldbus”, the direct interfacing to these networks became necessary. FEC

integrated many of these Fieldbus’ directly into our system through use of a modular I/O board

interfacing these networks directly to our I/O. (See Chapter 5 for available interfaces)

Interface Board

HOME

PAGE 4 - 13 (Rev. 4.0)

Page 40

Chapter 4: Installation & Wiring

4.8.1 External I/O Disable Switch

enFORCE DSP1500 Main Unit Hardware Manual

FRONT

DIP SWITCH (Factory Setting)

No. OFF ON

4

Not Used

3

Not Used

2

1

EXT. I/O ENABLE EXT. I/O DISABLE

M-NET ENABLE

If Switch No.1 is turned ON, the Fieldbus Module will

be bypassed and the STOP signal will be enabled

allowing Manual operations through the front panel

buttons for testing when Fieldbus Interface is installed

and fieldbus network is not running.

When fin ished testing th e equipment, be sure to

turn Switch No. 1 OFF otherwise the Fieldbus

Module will not operate.

Do not change S wi tc h No. 2, 3 or 4 .

Firmware Flash Connector (CN8)

(Bottom View)

4.9 Firmware Flash Connector

Upgrades or revisions to firmware are handled easily with the on board Flash Connector located on

the bottom of each Main Unit. There is no need to remove or disassemble the unit. A flash adapter

(CONTROLLER-ROM) containing the new firmware can be connected to connector CN8 with the

power off to the unit. The power is then cycled on until the ACCEPT LED is blinking indicating the

firmware upload is complete. Turn off power and remove the flash adapter. The firmware update is

now complete.

Note: This connector is for FEC use only and it is not recommended for use other than FEC.

(Rev. 4.0) PAGE 4 - 14

Page 41

Chapter 5: Control Interfaces

Page 42

Chapter 5: Control Interfaces

enFORCE DSP1500 Main Unit Hardware Manual

The Main Unit is able to operate under different Input/Output control structures through use of a

modular I/O interface board installed in the unit. With the introduction of “Open” communication

networks known as “Fieldbus”, the direct interfacing to these networks became necessary. FEC

integrated many of these Fieldbus directly into our system through use of a modular I/O board

interfacing these networks directly to our I/O.

The available interfaces are shown in the chart below. The fieldbus interface boards are integrated

directly to internal I/O signals which eliminate associated I/O wiring thus reducing overall assembly

labor. In fieldbus systems, the communication is typically of the Master/Slave format in which the

FEC unit is a slave to the master CPU. Some fieldbus types also allow pressing result data

(Messaging) to be sent over the same connection as the I/O signals.

Base Part

Number

MAIN2(E) -1 Discrete I/O (Sink Type)

MAIN2(E)

*MAIN2E

MAIN2(E)

*MAIN2E

MAIN2(E)

*MAIN2E

MAIN2(E)

MAIN2(E)

MAIN2(E)

MAIN2(E)

MAIN2(E)

MAIN2(E)

MAIN2(E)

MAIN2(E)

Suffix Description Messaging

-2 Discrete I/O (Source Type)

-3 DeviceNet-S® (for Toolsnet®) X

-4 Reserved

-5 Interbus-S® (for Toolsnet®)

-6 Allen Bradley Remote I/O

-7 Profibus® (for Toolsnet®)

-8 Modbus Plus®

-9 DeviceNet-S® X

-10 Ethernet I/P X

-11 Interbus-S®

-12 Mitsubishi CC-Link® Ver. 2 X

-13 Profibus®

-14 Mitsubishi CC-Link® Ver. 1

-15 M-Net

*Toolsnet Interface available for MAIN2E (Ethernet) version only. See Toolsnet Interface Manual for

set up information.

5.1 Interface Board Setup

All I/O Motherboards have a DIP Switch SW1 (located at position 7D) which has to be configured so

the Main Unit can identify the type of interface installed.

Interface Type

Discrete I/O (Sink Type)

Discrete I/O (Source Type)

DeviceNet-S® (for Toolsnet®)

Reserved

Interbus-S® (for Toolsnet®)

Allen Bradley Remote I/O

Profibus® (for Toolsnet®)

Modbus Plus®

DeviceNet-S®

Ethernet I/P

Interbus-S®

Mitsubishi CC-Link® Version 2

Profibus®

Mitsubishi CC-Link® Version 1

M-Net

SW11SW1 2SW1

ON OFF OFF OFF

OFF ON OFF OF F

ON ON OFF OFF

OFF OFF ON OFF

ON OFF ON OFF

OFF ON ON OFF

ON ON ON OFF

OFF OFF OFF ON

ON OFF OFF ON

OFF ON OFF ON

ON ON OFF ON

OFF OFF ON ON

ON OFF ON ON

OFF ON ON ON

ON ON ON ON

Throughout this chapter, SW1 settings will be represented as follows:

- Represents switch position

(Rev. 4.0) PAGE 5 - 2

SW1

3

4

Page 43

enFORCE DSP1500 Main Unit Hardware Manual

5.2 Signal Timing Charts

Chapter 5: Control Inte rfaces

5.2.1 Sequence Operation

Signal Timing

OFF

STOP

READY

RESET

START

(PRESSING)

BUSY

ACCEPT

REJECT

ABNORMAL

END

COUNT UP

ON

OFF

ON

OFF

A

ON

OFF

ON

Pressing

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

Operation

A

Pressing

Operation

200 ~ 500ms (A)

Because the RESET input clears all pressing data and discrete outputs, it should only be

activated to clear a system Abnormal or to perform a Zero Level Check. The system will

automatically reset with each press start. A manual RESET activation between cycles could

result in data loss.

The START signal will not operate during RESET, HOME or ABNORMAL signal activation. The

START signal must be maintained for the duration of the pressing cycle (until BUSY goes low).

The STOP input is normally closed and enables all other functions. When open (OFF), all

operations cease and all inputs / outputs become inactive.

When the ABNORMAL signal is activated, the system must be RESET before normal operation

will resume.

REJECT & ACCEPT signals are maintained until the start of the next cycle or on a RESET.

READY indicates when the system is ready to start.

It is recommended when changing sequences that the Select outputs be used to verify that the

sequence has been changed before issuing a start signal. Delay from Sequence Select input to

Sequence Select output is approximately 5ms.

Sequence Sel ec t Timin g

Select Bit 0

Select Bit 1

Select Bit 2

Select Bit 3

Bit 0 Selected

Bit 1 Selected

Bit 2 Selected

Bit 3 Selected

START

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

Allow a minimum of 20ms to interlock the

Sequence Select Command and the Start signal.

* No bit selected = Se q u e nc e No. 1

PAGE 5 - 3 (Rev. 4.0)

Sequence Select No. 6

(Main Inputs)

Sequence No. 6 Selected

(Main Outputs)

Page 44

Chapter 5: Control Interfaces

5.2.2 Jog (Manual) Operation

Signal Timing

OFF

JOG

START

RETURN

(OPERATION)

BUSY

READY

PRESS SEL. 0

PRESS SEL. 1

PRESS 0 SEL’D

PRESS 1 SEL’D

ON

OFF

ON

OFF

ON

Jog

OFF

ON

OFF

ON

Advance

Press Selection (Press No. 4)

Allow a minimum of 20ms to interlock the Press

OFF

ON

OFF

ON

OFF

ON

OFF

ON

Select Command and the Start / Return signal.

Approximately 5ms (see notes below)

* No bit selected = Press No. 1

enFORCE DSP1500 Main Unit Hardware Manual

Jog

Return

The Jog input must be high (on) to perform manual operations.

While the Jog input is active, a Start input will advance the press as long as the signal is

maintained.

While the Jog input is active, a Return input will return the press as long as the signal is

maintained.

It is recommended when changing press selections that the Select outputs be used to verify that

the desired press number has been changed before issuing a movement signal (Start, Return).

Delay from Press Select input to Press Selected output is approximately 5ms.

The Jog operations are used to move the press under “no load” conditions unless a Bonding

type press is used. Attempting to press a part or move the press under load conditions while

using a Fitting type press may cause an abnormal. If Jog operations are required under “load”

conditions, use a Bonding type press.

(Rev. 4.0) PAGE 5 - 4

Page 45

enFORCE DSP1500 Main Unit Hardware Manual

Chapter 5: Control Inte rfaces

5.3 Discrete I/O Interface

The Discrete I/O Interface is commonly used for direct connect PLC applications. Although, each

individual DSP1500 Servo Controller can also be wired directly to a PLC through its own PLC I/O

port (for individual control).

5.3.1 Sinking Type (NPN)

CN3

12

34

22

34

1

12

23

13

HOME

22

23

1

13

CN4

Discrete I/O (Sinking Type) Board Specifi c ations

Operating Voltage 24 VDC

Maximum current (outputs) 200 ma

Logic True Low (Sinking)

PLC-IN

Mating Connectors

PLC-OUT

Connector: Honda #MR-34F

Housing: Honda #MR-34L

Connector: Honda #MR-34M

Housing: Honda #MR-34L

PAGE 5 - 5 (Rev. 4.0)

Page 46

Chapter 5: Control Interfaces

5.3.1.1 Discrete Signal Connection (Sinking Type)

DSP1500 Main Unit Device PLC

enFORCE DSP1500 Main Unit Hardware Manual

Output

Output

Input

Input

24VDC Power Source

(Rev. 4.0) PAGE 5 - 6

Page 47

enFORCE DSP1500 Main Unit Hardware Manual

5.3.2 Sourcing Type (PNP)

34

23

CN3

12

13

34

22

23

13

HOME

22

1

12

1

CN4

Discrete I/O (Sourcing Type) Board Specifications

Operating Voltage 24 VDC

Maximum current (outputs) 200 ma

Logic True High (Sourcing)

PLC-IN

Mating Connectors

PLC-OUT

Connector: Honda #MR-34F

Housing: Honda #MR-34L

Connector: Honda #MR-34M

Housing: Honda #MR-34L

Chapter 5: Control Inte rfaces

PAGE 5 - 7 (Rev. 4.0)

Page 48

Chapter 5: Control Interfaces

5.3.2.1 Discrete Signal Connection (Sourcing Type)

DSP1500 Main Unit Device PLC

Output signal

enFORCE DSP1500 Main Unit Hardware Manual

Input signal

(Rev. 4.0) PAGE 5 - 8

Page 49

enFORCE DSP1500 Main Unit Hardware Manual

5.3.3 Input Signals (PLC-IN)

The Input Signals are provided on the PLC IN connector. Inputs are assigned in the order as

shown in the table below and cannot be changed. Pins designated as “Not Used” have no

input assigned to them.

NOTE: When using Discrete I/O, “Bypass Press” input signals assigned to the PLC IN

connector can only be used for up to 10 individual presses (from the Main Unit). When using

Discrete I/O and you desire to connect this signal from additional presses, the signal must be

wired from the individual SAN Controllers using the SAN Unit’s PLC connector. An alternative

to this is to use a fieldbus interface which has control of all press bypass signals from the

interface.

Pin# Signal

1 Emergency Stop N.C.

2 Reset N.O.

3 Return N.O.

4 Start N.O.

5 Home N.O.

6 Jog (Manual Mode) N.O. Jog+Start advances the press. Jog+Return returns the press.

7 Seq. / Press Select 0 N.O. Sequence / Press Select Input.

8 Seq. / Press Select 1 N.O.

9 Seq. / Press Select 2 N.O.

10 Seq. / Press Select 3 N.O.

11 Seq. / Press Select 4 N.O.

12 Not Used N.O.

13 INPORT 1 N.O. External Sequence Input.

14 INPORT 2 N.O.

15 INPORT 3 N.O.

16 INPORT 4 N.O.

17 BYPASS Press No.1 N.O. Bypass’s press #1 - Press is ignored as if it does not exist.

18 BYPASS Press No.2 N.O. Bypass’s press #2 - Press is ignored as if it does not exist.

19 BYPASS Press No.3 N.O. Bypass’s press #3 - Press is ignored as if it does not exist.

20 BYPASS Press No.4 N.O. Bypass’s press #4 - Press is ignored as if it does not exist.

21 BYPASS Press No.5 N.O. Bypass’s press #5 - Press is ignored as if it does not exist.

22 BYPASS Press No.6 N.O. Bypass’s press #6 - Press is ignored as if it does not exist.

23 BYPASS Press No.7 N.O. Bypass’s press #7 - Press is ignored as if it does not exist.

Contact Description

Emergency Stop Input.

Signal MUST be active to perform a pressing operation.

When this signal is inactive (off), all Main Unit operation

ceases, all presses in motion will stop and all communication

ports & input/outputs will be disabled.

Reset Input.

When active (on), this signal will clear all press data and

discrete outputs. A Zero Check of all load transducers will be

completed. During the Zero Check, the CHECK lamp will

illuminate, the READY signal will turn OFF, and the ACCEPT

or REJECT lamp will light to indicate the result of the Zero

Check. If the System has been disabled by an Abnormal

output, the System will not return to normal operation until the

Abnormal condition has been corrected, and this signal has

been input for 200~500ms. Do not

cycles as part of an automatic cycle due to the potential for

press data loss.

Return Input.

When used in conjunction with the Jog Input, the selected

press will move in the return direction for as long as this signal

is activated (on) and maintained.

Start Cycle Input.

The Start input automatically resets the previous cycle, clears

all data to zero, and initiates the next pressing cycle. The start

input must be maintained "on" for the entire cycle (until the

“Busy” signal turns off).

When used in conjunction with the Jog Input, the selected

press will move in the advance direction for as long as this

signal is activated (on) and maintained.

Home Input.

If a Home Position has not been set, a Home Position Search

will be initiated. When a Home Position (Origin) has been

established this input will move all connected presses to the

returned (Job Start) position. The Home input functions the

same as the Home pushbutton on the front of the Main Unit.

These 5 inputs form a binary code which is capable of

selecting up to 32 different operation sequences. Refer to

Table 1.

When using manual operation inputs (Jog, Return), these

binary inputs are used to select the press to be operated.

These four (4) signals are external inputs to the pressing

sequence. When a [PLC INPUT WAIT] instruction is

programmed in the pressing sequence, it will stop until the

designated external input is active.

Chapter 5: Control Inte rfaces

input this signal between

PAGE 5 - 9 (Rev. 4.0)

Page 50

Chapter 5: Control Interfaces

24 BYPASS Press No.8 N.O. Bypass’s press #8 - Press is ignored as if it does not exist.

25 BYPASS Press No.9 N.O. Bypass’s press #9 - Press is ignored as if it does not exist.

26 BYPASS Press No.10 N.O. Bypass’s press #10 - Press is ignored as if it does not exist.

27 Cycle Count Up N.O.

28 Cycle Count Clear N.O.

29 Not Used

30 Data Select 0

31 Data Select 1 N.O.

32 Data Select 2

33 Input Signal Power

34 Input Signal Power Source Type +0V

Note) NC: Normal Closed, NO: Normal Open

[Table 1] Sequence / Press Selection

Seq. / Press

Select 4

OFF OFF OFF OFF OFF 1 1

OFF OFF OFF OFF ON 2 2

OFF OFF OFF ON OFF 3 3

OFF OFF OFF ON ON 4 4

OFF OFF ON OFF OFF 5 5

OFF OFF ON OFF ON 6 6

OFF OFF ON ON OFF 7 7

OFF OFF ON ON ON 8 8

OFF ON OFF OFF OFF 9 9

OFF ON OFF OFF ON 10 10

OFF ON OFF ON OFF 11 11

OFF ON OFF ON ON 12 12

OFF ON ON OFF OFF 13 13

OFF ON ON OFF ON 14 14

OFF ON ON ON OFF 15 15

OFF ON ON ON ON 16 16

ON OFF OFF OFF OFF 17 17

ON OFF OFF OFF ON 18 18

ON OFF OFF ON OFF 19 19

ON OFF OFF ON ON 20 20

ON OFF ON OFF OFF 21 21

ON OFF ON OFF ON 22 22

ON OFF ON ON OFF 23 23

ON OFF ON ON ON 24 24

ON ON OFF OFF OFF 25 25

ON ON OFF OFF ON 26 26

ON ON OFF ON OFF 27 27

ON ON OFF ON ON 28 28

ON ON ON OFF OFF 29 29

ON ON ON OFF ON 30 30

ON ON ON ON OFF 31 31

ON ON ON ON ON 32

Seq. / Press

Select 3

Seq. / Press

enFORCE DSP1500 Main Unit Hardware Manual

Cycle Count Input.

The System cycle counter will increment each time this signal

is input if the CYCLE COUNT UP is set to PLC SIGNAL in the

Main Unit. The Cycle Count input requires a pulse of 200~500

milliseconds to increment the counter. If the CYCLE COUNT

UP is set to AUTO, the cycle counter increments automatically

at the end of every pressing cycle.

The internal cycle counter is reset when this signal is inputted.

Resetting the counter value requires a 200~500ms pulse.

These 3 inputs form a binary code to select up to 8 Output

Data Banks. Used for Digital I/O interfaces. NOTE: Not used

for Fieldbus interfaces. [See Table 3 on Page 5-12]

Common for input signal.

Select 2

Seq. / Press

Select 1

Seq. / Press

Select 0

(Rev. 4.0) PAGE 5 - 10

Sink Type +24V

Selected

Sequence

No.

Selected

Press No.

Page 51

enFORCE DSP1500 Main Unit Hardware Manual

5.3.4 Ouput Signals (PLC-OUT)

The Main Unit is capable of providing over 570 Output signals to indicate the status of the

Main Unit and of all the DSP1500 SAN Controllers connected to it (up to 31 controllers).

These signals are user configurable using the DSP User Console Software and may be

programmed on any designated pin. Up to 8 separate output data “Banks” can be set up,

each with 32 different output signals. The Output “Bank” is then selected using the Data

Select inputs (Data Select 0, Data Select 1, Data Select 2).

Available Main Unit Output Signals

Total Reject

Total A ccept

Abnormal

Ready

Busy

End

Sequence / Press 0

Sequence / Press 1

Sequence / Press 2

Sequence / Press 3

Sequence / Press 4

Out Port 1

Out Port 2

Out Port 3

Out Port 4

Out Port 5

Out Port 6

Out Port 7

Out Port 8

Press i n Bypass

Always ON / OFF

[Table 2] Sequence / Press Select Output

Sequence

Output 4

OFF OFF OFF OFF OFF 1 1

OFF OFF OFF OFF ON 2 2

OFF OFF OFF ON OFF 3 3

OFF OFF OFF ON ON 4 4

… … … … … … …

ON ON ON ON OFF 31 31

ON ON ON ON ON 32

Sequence

Output 3

Output when the pressing result is a REJECT. Indicates that one or more

presses have failed achieving the pressing limits. This output remains active

until the START signal or RESET signal is input.

Output when the pressing result is a ACCEPT. Indicates all presses are

within pressing limits. This output remains active until the START signal or

RESET signal is input.

Output when an Abnormal condition occurs. This signal indicates that the

System has detected an internal fault, and can no longer proceed. The fault

maybe generated from a connected press during a self-check function.

Check the individual press status to identify which press is reporting the

abnormal condition. (see DSP1500 Operation Manual for troubleshooting)

The press reporting an abnormal may be bypassed to resume normal

operation, however, the bypassed press will be ignored and not run while in

bypass. An Abnormal condition must be corrected before the System will

resume normal operation. The RESET signal clears the abnormal condition.

Output when the system is in the READY condition. Indicates system is

ready to operate, and inputs are enabled. This signal is inactive (off) when

the BUSY output is active (on).

Output after a START signal is received, and active until the pressing cycle

is complete and the READY signal is output.

Output when a pressing cycle is complete. Remains active until the START,

RESET or HOME signal is input.

Output confirmation of SEQUENCE / PRESS SELECT 0~4 input selections.

Sequence bits are active according to what sequence is set from the

sequence select inputs. Used to confirm proper sequence before

starts. Refer to Table 2.

When in manual (Jog) operation the Press bits are active according to what

press is set from the press select inputs. Used to confirm proper press

selection before

These signals will output when the pressing sequence reaches a step that

has a [PLC OUTPUT] instruction inserted. Used to provide sequence

operation status to external PLC’s and/or control outputs for slide motion,

lights, & buzzers, etc without the use of a PLC. (The DSP User Console

Software can set these outputs on and off in the pressing sequence)

Signal is active when any of the connected Presses are bypassed either

from San Unit bypass input signals or from the San Unit bypass switch.

Can be used to set outputs ON or OFF. Typically used in conjunction with

Bank Outputs to monitor which Bank is selected.

Sequence

Output2

manual movement starts. Refer to Table 2.

Sequence

Output1

Sequence

Output0

Sequence No.

Chapter 5: Control Inte rfaces

pressing

Selected

Selected

Press No.

PAGE 5 - 11 (Rev. 4.0)

Page 52

Chapter 5: Control Interfaces

Available Individual Press Unit Output Signals

Output when the press result is a REJECT. Indicates that the press has failed

Reject

Accept

Abnormal

Ready

Busy

Bypass

Home Set

Press Returne d

Advanced

Advance Position

Return Position

Advance Direction

Return Direction

Home Returned

Servo On

achieving the press limits. This output remains active until the START signal or

RESET signal is input.

Output when the press results are an ACCEPT. Indicates the press is within

press limits. This output remains active until the START signal or RESET

signal is input.

Output when an Abnormal condition on the selected press occurs. This signal

indicates that the press has detected an internal fault, and can no longer

proceed. The fault maybe generated during a self-check function. Check the

individual press status to identify which press is reporting the abnormal

condition. (see DSP1500 Operation Manual for troubleshooting) The press

reporting an abnormal may be bypassed to resume normal operation,

however, the bypassed press will be ignored and not run while in bypass. An

Abnormal condition must be corrected before the System will resume normal

operation. The RESET signal clears the abnormal condition.

Output when the press is in the READY condition. Indicates press is ready to

operate, and inputs are enabled. This signal is inactive (off) when the BUSY

output is active (on).

Output after a START signal is received, and active until the press cycle is

complete and the READY signal is output.

Signal is active when the press is bypassed either from San Unit bypass input

signals or from the San Unit bypass switch.

Output after a Home Position Search has been performed and a Home

Position (Origin) has been set.

Output when the press is at the returned (Job Start) position.

Output when the press has reached Standard Load or Standard Distance.

Signal is output for the time designated in Load Hold Time data field. If Load

Hold Time is set to zero then the signal is not output.

Signal is active when advancing and the press has reached the Advance

Position Signal “On” Distance. Signal remains active until the press reaches

the Advance Position Signal “Off” Distance.

Signal is active when returning and the press has reached the Return Position

Signal “On” Distance. Signal remains active until the press reaches the Return

Position Signal “Off” Distance.

Output when the press is advancing.

Output when the press is returning.

Output when the press is at the Home position as defined by the distance set

in System Parameter 00-35.

Output when the Servo Motor is on (running).

Parameter Select 0

Parameter Select 1

Parameter Select 2

Parameter Select 3

Output confirmation of PARAMETER SELECT 0~4 selections. Parameter

Select bits are active according to what parameter is set from the sequence

select inputs.

Parameter Select 4

enFORCE DSP1500 Main Unit Hardware Manual

(Rev. 4.0) PAGE 5 - 12

Page 53

enFORCE DSP1500 Main Unit Hardware Manual

Available Individual Press Unit Output Signals (cont’d.)

Load Low Reject

Load High Reject

Part Check 2

Load Low Reject

Part Check 2

Load High Reject

Part Check 3

Load Low Reject

Part Check 3

Load High Reject

Distance Low Reject

Distance High Reject

Interference Check

Zone Reject

Part Check 1

Distance Low Reject

Part Check 1

Distance High Reject

Combination 1

Combination 2

Combination 3

Combination 4

Combination 5

Combination 6

Combination 7

Combination 8

Output when the press result is below the acceptable Load Low Limit. This

output remains active until the START signal or RESET signal is input.

Output when the press result is above the acceptable Load High Limit. This

output remains active until the START signal or RESET signal is input.

Output when the press result is below the acceptable Part Check 2 Load Low

Limit. This output remains active until the START signal or RESET signal is

input.

Output when the press result is above the acceptable Part Check 2 Load High

Limit. This output remains active until the START signal or RESET signal is

input.

Output when the press result is below the acceptable Part Check 3 Load Low

Limit. This output remains active until the START signal or RESET signal is

input.

Output when the press result is above the acceptable Part Check 3 Load High

Limit. This output remains active until the START signal or RESET signal is

input.

Output when the press result is below the acceptable Distance Low Limit. This

output remains active until the START signal or RESET signal is input.

Output when the press result is above the acceptable Distance High Limit.

This output remains active until the START signal or RESET signal is input.

Output if the Interference Check Load is exceeded before the press reaches

the Interference Check Distance. This output remains active until the START

signal or RESET signal is input.

Output when the press result is below the acceptable Part Check 1 Distance