Chapter 7: System Operations (Rev. 8/98)

Chapter 7: System Operations

Page 7-1

Chapter 7: System Operations (Rev. 8/98)

7.1 AFC1100 indicators, display and key operation.

FIG. 7-1 Operational controls and indicators

7.1.1 Manual Fastening controls.

wSTART.

This push-button initiates the fastening cycle.

wREV (Reverse).

Manual reverse. While this push-button is depressed, the nutrunner turns in the

counter-clockwise direction.

wCAL (Calibration).

CAL voltage checking push-button. Depress this push-button to obtain the CAL voltage

level of the tool pre-amplifier. This level is compared to the data stored in memory. If the

difference is within the allowed range the accept LED will light, otherwise the REJECT LED

will light. The calibration voltage level is converted to the full-scale torque, according to the

parameter setting and is shown in the "DATA" display.

wRESET.

This is used to reset the Axis unit. If this key is pressed during fastening, the process will

stop, and all the fastening data and output signals will be reset. At the same time, the Zero

level of the torque transducer will be checked. If it is within the acceptable range, the

ACCEPT LED will light. If it is not within range, the torque REJECT LED will light.

Page 7-2

7.1.2 Fastening Indicators.

wBUSY LED (Yellow).

Indicates when the Axis unit is performing a fastening or reverse operations.

wABNORMAL LED (Red).

Indicates when an abnormal condition occurs during fastening or during the system SELF

CHECK function.

wACCEPT LED (Green).

Indicates when the fastening results are within acceptable limits.

wBYPASS LED (Red).

Indicates by flashing when the Axis unit is in a bypass condition.

wTORQUE LED (Orange and red).

Orange indication represents a LOW TORQUE REJECT as the fastening result.

Red indication represents a HIGH TORQUE REJECT as the fastening result..

wANGLE LED (Orange and red).

Orange indication represents a LOW ANGLE REJECT as the fastening result.

Red indication represents a HIGH ANGLE REJECT as the fastening result.

Chapter 7: System Operations (Rev. 8/98)

w1ST RATE LED (Orange and red).

Orange indication represents a LOW 1ST RATE REJECT as the fastening result.

Red indication represents a HIGH 1ST RATE REJECT as the fastening result.

w2ND RATE LED (2ND RATE).

Orange indication represents a LOW 2ND RATE REJECT as the fastening result.

Red indication represents a HIGH 2ND RATE REJECT as the fastening result.

wTIME LED.

Orange indication represents a 1ST TIME REJECT as the fastening result.

Red indication represents a FINAL TIME REJECT as the fastening result.

7.1.3 Fastening Preset / Result displays.

w[D-NO] Data number indicator (2 digits).

Indicates the Display mode and data type by number.

w[DATA] Data value indicator (4 digits).

Displays the current torque value of the torque transducer while in the real-time indication

mode. Displays the data specified by [D-NO] while in the fastening data indication mode.

w[PARM/ABN] Parameter number/abnormal number indicator (1 digit).

Display for the parameter number of the last fastening. If an abnormal condition occurs, it

shows the abnormality number.

1. Parameter number "2" is shown

PARM

ABN

Page 7-3

Chapter 7: System Operations (Rev. 8/98)

2. Abnormal number "7" is shown

PARM

ABN

3. When the CAL switch is pressed, "E" is shown if the FULL-SCALE preset value is

missing or a wrong tool is connected.

PARM

ABN

Indicates the parameter number used for the previous fastening operation. Should an

abnormal condition occur the display will indicate the nature of the abnormality through a code

number (Refer to Chapter 9).

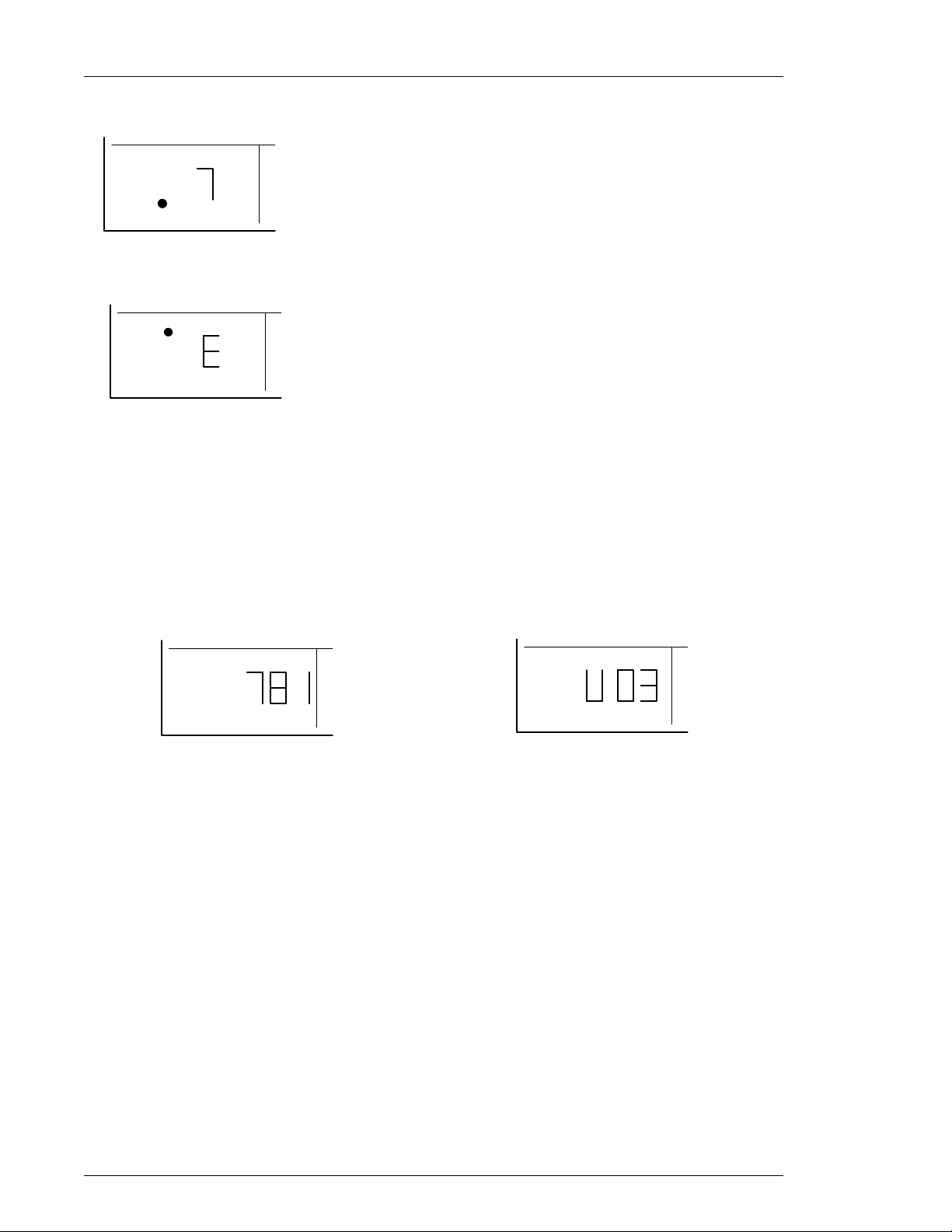

w[ANGL/SPNO] Angle data/Axis unit number indicator.

Display for the final angle value of the previous fastening operation. The angle value is

given in integers numbers. Directly after the power is turned on and while the RESET signal is

active the spindle number is displayed.

ANGLE

SPNO

ANGLE DISPLAY

ANGLE

SPNO

SPINDLE NUMBER

.

Page 7-4

Chapter 7: System Operations (Rev. 8/98)

7.1.4 Fastening Presetting / Result Display Controls.

wMODE.

PUsed to change modes while in the Run state. (Refer to 7.2)

PUsed to move the cursor while in the Bypass (program) state. (Refer to 7.3)

wSET.

PUsed to enter the Data Edit mode, and to confirm data setting change.

w[

↑↑↑↑

↓↓↓↓

] and [

] Cursor key (vertical arrows).

PUsed to scroll through available parameter numbers. (PARM)

PUsed to scroll through available data preset items. (D-NO)

PUsed to change display data values. (DATA)

PUsed as YES/NO acknowledge for Tool type and Torque unit changes. (Fig 7-3-8b)

Page 7-5

Chapter 7: System Operations (Rev. 8/98)

7.2 Run State Modes.

The AFC 1100 system has two operational states that are controlled by the selection of the

Run/Bypass switch on the front of the Axis unit or by the PLC Bypass input. The operational

modes availible in the Run State are identified below. Under this condition the BYPASS

switch on the front panel is in the RUN position and the BYPASS external signal is not active

(the BYPASS LED is off). During the RUN condition, the display mainly shows the results of

fastening, abnormalities, preset values, etc.

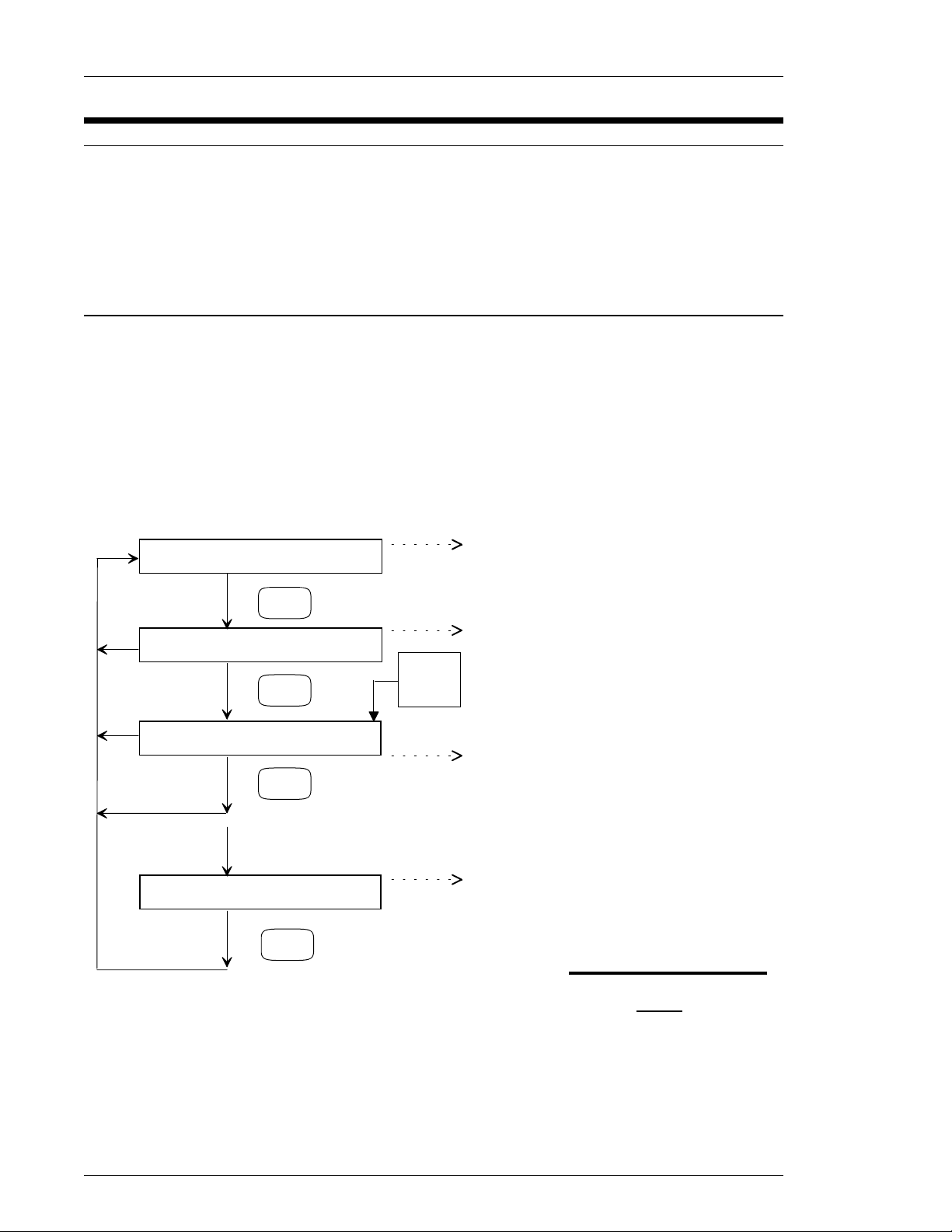

7.2.1 Display indication modes.

Three modes can be selected while in the RUN state by pressing the MODE push-button.

By using the [

parameters may be varied. The displays will remain blank, and mode selection will be

disabled while the nutrunner is active. (BUSY)

The Fastening results display mode is active when the D-No displays one digit in the right hand

FASTENING RESULTS DISPLAY MODE

START

PARAMETER DISPLAY MODE

START

REAL TIME DISPLAY MODE

↓↓↓↓

↑↑↑↑

] and [

] keys to change the D-NO selected the DATA Display contents for

location, and one, two or three dashes in the

left hand location. The results' details can

↑↑↑↑

↑↑↑↑

] and [

] and [

be scrolled by using the [

change the D-No. This display does not

function while the nutrunner is Busy.

The Parameter display mode is active

MODE

AT

MODE

MODE

POWER

ON

when the D-No displays digits in both the

right and left hand locations. The

parameter data can be scrolled by using the

↑↑↑↑

[

The Real time display mode is active

when one digit is active in the right hand

display only. When the power is turned on,

the default display mode is the REAL TIME

display mode. The display contents can be

scrolled by using the [

change D-NO.

] and [

↓↓↓↓

] keys to change D-No.

↓↓↓↓

] keys to

↓↓↓↓

] keys to

STATUS DISPLAY

MODE

The Axis unit is in Status display mode

when no digits are displayed. The STATUS

display indicates if an abnormal condition

occurs or if an emergency stop has halted

the system.

FIG. 7-2-1 Run State Display

Modes

Page 7-6

7.2.2 Real-time display indication mode.

While the mode is in real-time data indication ([D-NO] shows 0, 1 or 2. You can choose

the desired type of data by pressing the [

The indicator will show the following data in "DATA" AND "ANGL.SPNO" for the selected

D-No..

0

1

2

PTorque value: The real-time (current) torque value on the torque

transducer is shown.

PTorque voltage : The real-time (current) torque signal voltage on the torque

transducer is shown.

PMaximum torque: The peak torque, measured since the last resetting of the

switch within the current mode, is shown.

PAxis unit number: The Axis unit No. as set up on the unit via dip switches

PRotated angle: The real-time angle of rotation of the tool output shaft (in the

fastening direction CW), measured since the last resetting of

the switch within the current mode. (-119

↓↓↓↓

] and [

Chapter 7: System Operations (Rev. 8/98)

↑↑↑↑

] keys to change the [D-NO] (data number).

ANGL.SPNODATAD-No

Axis unit numberTorque value.

Axis unit numberTorque voltage.

Rotated angle.Maximum torque (maximum hold).

°

to 999°).

Key operation during the real-time data indication mode.

Indication shown in "DATA"

DATA

TORQUE VOLTAGE

PEAK TORQUE

FIG. 7-2-2 Real time display selection

OR

D-NO

0

1

2

TORQUE VALUE

(MAXIMUM HOLD)

Page 7-7

Loading...

Loading...