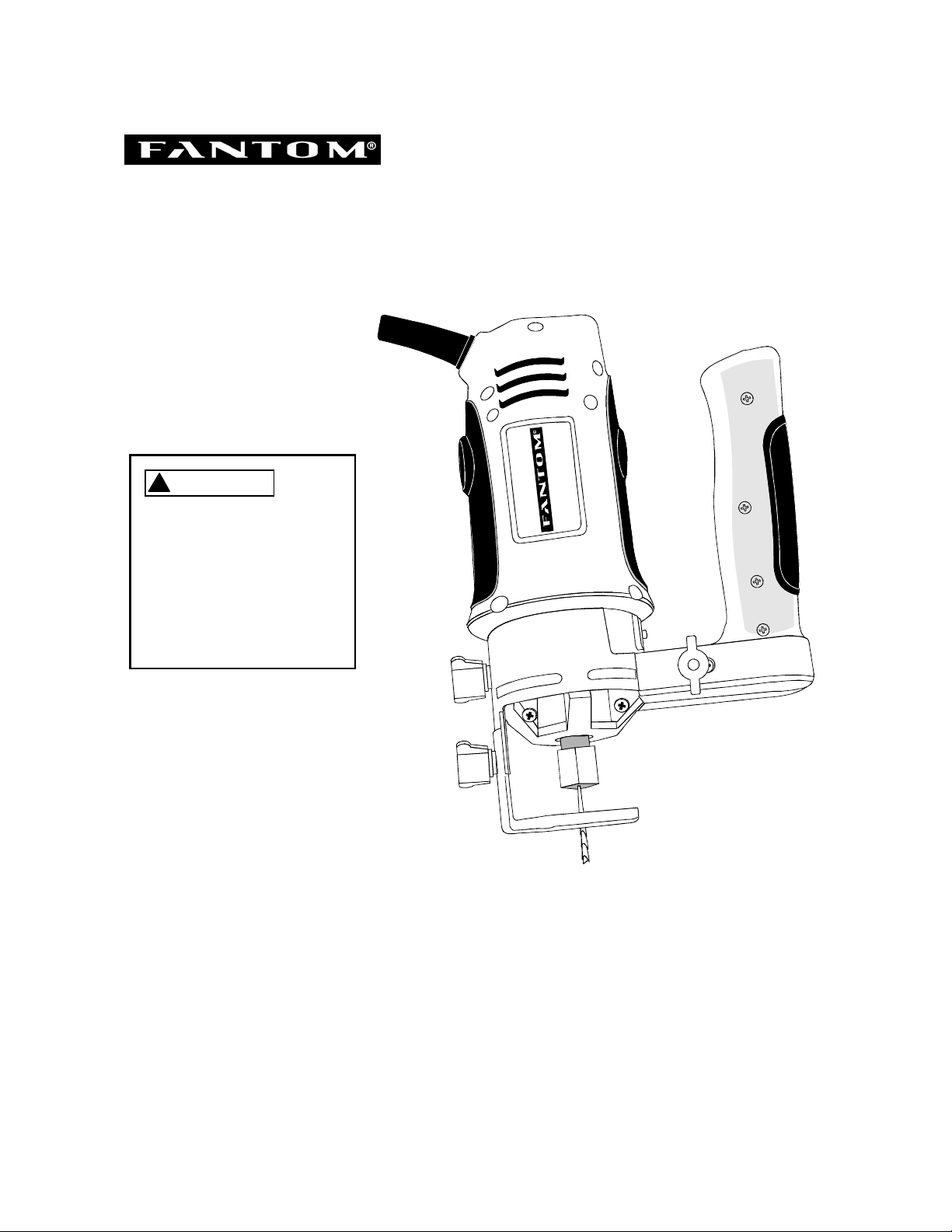

Owner’s Manual

ROTARY TOOL KIT

Model No.

PT302H

WARNING!

Always have one hand

firmly placed on the

tool body while

operating. Never

operate the tool by

holding only the tool

handle.

CAUTION:

Before using this Rotary

Tool, read this manual and

follow all its Safety Rules

and Operating Instructions.

· Safety Instructions

· Accessories

· Assembly

· Operation

· Maintenance

FANTOM, 178 West Service Road, Champlain, N.Y. 12919

TABLE OF CONTENTS

SECTION PAGE SECTION PAGE

Product Specifications …………………. 2 Carton Contents ………………………… 6, 7

Power Tool Safety ..…………………….. 3 Know Your Rotary Tool …………..…...... 8

Rotary Tool Safety .….................…... 4 Assembly & Operation …….…………… 9 – 17

Electrical Requirements & Safety …….. 5 Maintenance …………………………….. 17

Warranty ….....................................……. 18

WARNING

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contains

chemicals known (to the State of California) to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

· Lead from lead-based paints

· Crystalline silica from bricks, cement and other masonry products

· Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well ventilated area and work with approved safety equipment such as

those dust masks that are specially designed to filter out microscopic particles.

PRODUCT SPECIFICATIONS

To avoid electrical hazards, fire hazards or damage to the rotary tool, use proper circuit protection.

This rotary tool is wired at the factory for 110-120 Volt operation. It must be connected to a 110-120 Volt / 15

Ampere time delay fuse or curcuit breaker. To avoid shock or fire, replace power cord immediately if it is worn,

cut or damaged in any way.

Before using your rotary tool, it is critical that you read and understand these safety rules. Failure to follow

these rules could result in serious injury to you or damage to the rotary tool.

Motor Rating: 120V., 60Hz. 4.0 A.

No Load Speed: 30,000 RPM

Weight: 3.75 lbs.

2

Rev. 06/03

POWER TOOL SAFETY

GENERAL SAFETY RULES

WARNING

Read and understand all instructions. Failure to follow

all instructions listed below may result in electric shock, fire

and/or serious personal injury.

WORK AREA

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gasses

or dust. Power tools create sparks which may ignite the

dust or fumes.

Keep bystanders, children and visitors away while

operating the tool. Distractions can cause you to lose

control.

ELECTRICAL SAFETY

Double insulated tools are equipped with a polarized

plug (one blade is wider than the other). This plug will

fit in a polarized plug only one way. If the plug does

not fit fully in the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to install a

polarized outlet. Do not change the plug in any way.

Double insulation eliminates the need for the three

wire grounded power cord and grounded power supply

system.

Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing and gloves

away from moving parts. Loose clothing, jewelry or long

hair can be caught in moving parts.

Avoid accidental starting. Be sure switch is OFF before

plugging in. Carrying tools with your finger on the switch

or plugging in tools that have the switch ON invites

accidents.

Remove adjusting keys or wrenches before turning the

tool ON. A wrench or key that is left attached to a rotating

part of the tool may result in personal injury.

Do not overreach. Keep proper footing and balance at

all times. Proper footing and balance enables better

control of the tool in unexpected situations.

Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat or hearing

protection must be used for appropriate conditions.

TOOL USE AND CARE

Use clamps or other practical way to secure and

support the workpiece to a stable platform. Holding the

work by hand or against your body is unstable and may

lead to loss of control.

Do not force the tool. Use the correct tool for your

application. The correct tool will do the job better and

safer at the rate for which it is designed.

Avoid body contact with grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is

increased risk of electric shock if your body is grounded.

Don’t expose power tools to rain or wet conditions.

Water entering the power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord to carry the

tools or pull the plug from an outlet. Keep cord away

from heat, oil, sharp edges or moving parts. Replace

damaged cords immediately. Damaged cords increase

the risk of electric shock.

When operating a power tool outside, use an outdoor

extension cord marked “W-A” or “W”. These cords are

rated for outdoor use and reduce the risk of electric shock.

PERSONAL SAFETY

Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use the tool

while tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating

power tools may result in serious personal injury.

Do not use the tool if the switch does not turn it ON or

OFF. Any tool that cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from the power source before

making any adjustments, changing accessories or

storing the tool. Such preventive safety measures reduce

the risk of starting the tool accidentally.

Store idle tools out of reach of children and other

untrained persons. Tools are dangerous in the hands of

untrained users.

Maintain tools with care. Keep cutting tools sharp and

clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may

affect the tool’s operation. If damaged, have the tool

serviced before using. Many accidents are caused by

poorly maintained tools.

Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be

suitable for one tool may become hazardous when used on

another tool.

SAVE THESE INSTRUCTIONS FOR REFERENCE

3

ROTARY TOOL SAFETY

SERVICE

Tool service must be performed only by qualified personnel.

Service or maintenance performed by unqualified personnel

could result in risk of injury.

When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this

manual. Use of unauthorized parts or failure to follow

Maintenance instructions may create a risk of electric shock or

injury.

SPECIFIC SAFETY RULES

Hold tool by insulated gripping surfaces when performing

an operation where the cutting tool may contact hidden

wiring or its own cord. Contact with a “live” wire will make

exposed metal parts of the tool “live” and shock the operator.

Always make sure the work surface is free from nails and

other foreign objects. Cutting into a nail can cause the bit and

the tool to jump and damage the bit.

Never hold the workpiece in one hand and the tool in the

other hand when in use. Never place the hands near or

below the cutting surface. Clamping the material and guiding

the tool with both hands is much safer.

Never lay workpiece on hard surfaces like concrete, stone,

etc. Protruding cutting bit may cause tool to jump.

Always wear safety goggles and dust mask. Use only in well

ventilated area. Using personal safety devices and working in a

safe environment reduces risk of injury.

ALWAYS WEAR EYE PROTECTION. Any power tool

can throw foreign objects into your eyes

which could cause permanent eye damage.

ALWAYS wear safety goggles (not glasses)

that comply with ANSI safety standard Z87.1.

Everyday glasses have only impact resistant

lenses. They ARE NOT safety glasses. Safety goggles

are available at most hardware stores.

Glasses or goggles not in compliance with ANSI Z87.1

could cause serious injury when they break.

After changing the bits or making adjustments, make

sure the collet nut and any other adjustment devices

are securely tightened. Loose adjustment devices will be

violently thrown.

Never use dull or damaged bits. Sharp bits must be

handled with care. Damaged bits can snap during use.

Dull bits require more force to push the tool, possibly

causing the bit to break.

Never touch the bit during or immediately after use.

After use the bit is too hot to be touched by bare hands.

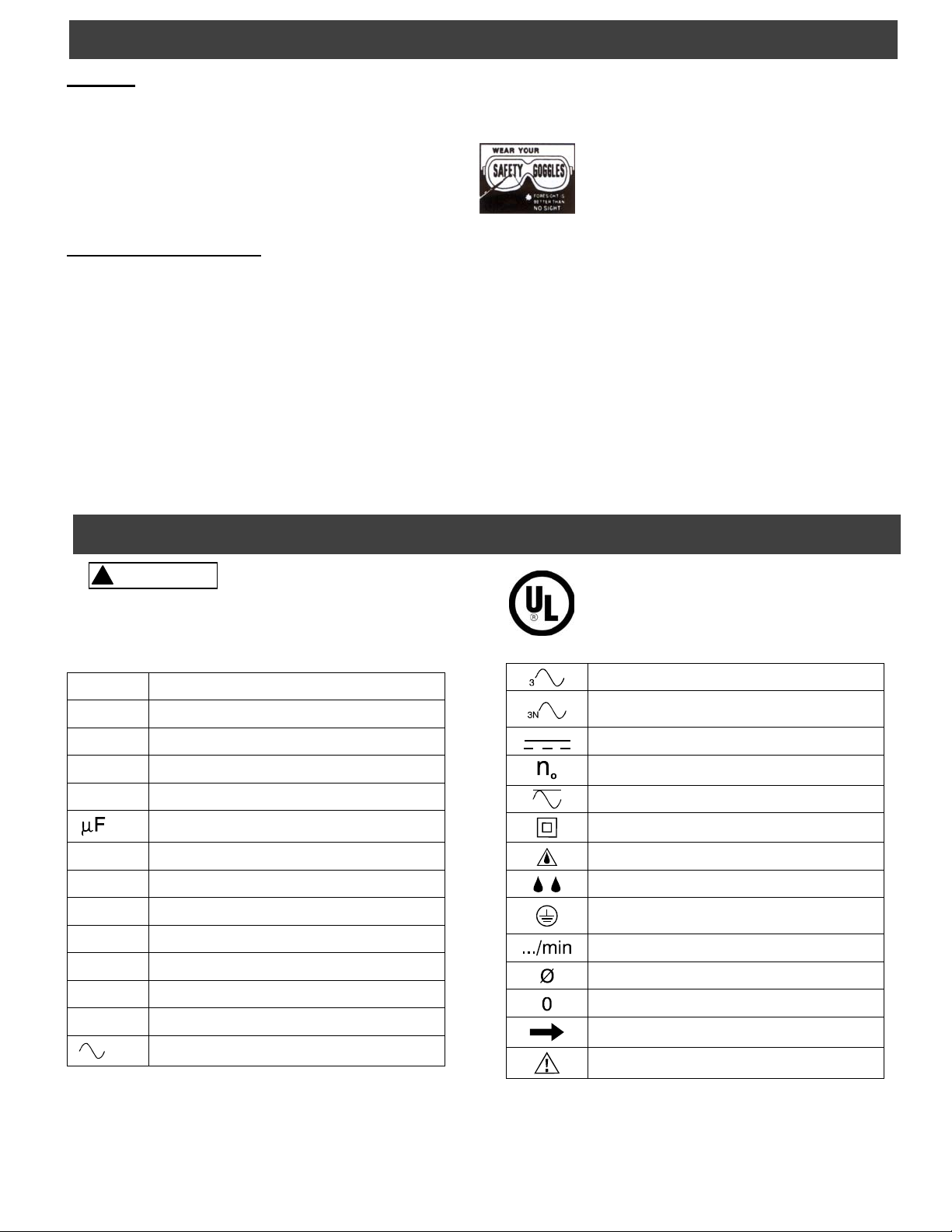

ROTARY TOOL SYMBOLS

WARNING

Some of the following symbols may be used on

your tool. Please study them and learn their

meaning. Proper interpretation of these symbols

will allow you to operate the tool better and safer.

V

A

Hz

W

kW

l

kg

N/cm

Pa

h

min

s

Volts

Amperes

hertz

watt

kilowatts

microfarads

liters

kilograms

2

newtons per square centimeter

pascals

hours

minutes

seconds

alternating current

This symbol designates that this

tool is listed with U.S.

requirements by Underwriters

Laboratories.

three-phase alternating current

three-phase alternating current with

neutral

direct current

no load speed

alternating or direct current

class II construction

splash proof construction

watertight construction

protective earthing at earthing terminal,

Class I tools

revolutions or reciprocations per minute

Diameter

Off position

Arrow

Warning symbol

SAVE THESE INSTRUCTIONS FOR REFERENCE

4

ELECTRICAL REQUIREMENTS & SAFETY

DOUBLE INSULATION

This cutting tool is double insulated to protect you from

electrical shock.

WARNING

Double insulated tools are equipped with a polarized

plug (one blade is wider than the other). This plug will

fit into a polarized outlet only one way. If the plug

does not fit fully into the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician to

install a polarized outlet. Do not alter the plug in any

way. Double insulation eliminates the need for the three

wire grounded power cord and grounded power supply

system.

Avoid body contact with grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shock if your body is grounded.

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord to carry the

tool or pull the plug from the outlet. Keep cord away

from heat, oil, sharp edges and moving parts.

Replace damaged cords immediately. Damaged cords

increase the risk of electric shock.

When operating a power tool outdoors, use an

outdoor extension cord marked “W-A” or “W”. These

cords are rated for outdoor use and reduce the risk of

electric shock.

WARNING

Always make sure the receptacle is polarized. If you

are not sure, have a qualified electrician check the

receptacle.

GUIDELINES FOR EXTENSION CORDS

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy

enough to carry the current the tool will draw. An

undersized cord will cause a drop in line voltage resulting

in loss of power and overheating. The table below shows

the correct size to use according to cord length and

nameplate ampere rating. If in doubt, use the next heavier

gauge. The smaller the gauge number the heavier the

cord.

Be sure your extension cord is properly wired and in

good condition. Always replace a damaged extension cord

or have it repaired by a qualified electrician before using it.

Protect your extension cord from sharp objects, excessive

heat and damp or wet areas.

Use a separate electrical circuit for your power tools.

This circuit must not be less than 14 gauge wire and

should be protected with either a 15 Ampere time delay

fuse or circuit breaker. Before connecting the power tool to

the power source, make sure the switch is in the OFF

position and the power source is the same as indicated on

the nameplate. Running at lower voltage will damage the

motor.

WARNING

Repair or replace damaged or worn extension cords

immediately.

WARNING

Keep the extension cord clear of the working area.

Position the cord so it will not get caught on the

workpiece, tools or any other obstructions while you

are working with the power tool.

5

ACCESSORIES

CARTON CONTENTS

AVAILABLE ACCESSORIES

WARNING

Use only accessories recommended for this rotary tool.

Follow instructions that accompany accessories. Use

of improper accessories may cause injury to the

operator or damage to the rotary tool.

WARNING

Use only accessories designed for this rotary tool to

avoid severe injury or tool damage.

Do not use any accessory unless you have completely

read the instructions or Owner’s Manual for that

accessory.

LATERAL STYLE DRYWALL CUTTING BIT

This cutting bit has a fine spiral for removing high volumes

of material when cutting and leaving a smooth edge.

Use this cutter for cutting drywall.

GENERAL PURPOSE CUTTING BIT

UNPACKING AND CHECKING CARTON CONTENTS

WARNING

If any part is missing or damaged, do not plug the

Rotary Tool into the power source until the missing or

damaged part is replaced and assembly is complete.

Carefully unpack the Rotary Tool and all its parts.

Compare against the “Rotary Tool Components” chart.

NOTE: See Page 7 for illustration of parts and chart.

WARNING

To avoid fire or toxic reaction, never use gasoline,

naphtha, acetone, lacquer thinner or similar highly

volatile solvents to clean the Rotary Tool.

This cutting bit has a coarse spiral for removing material

when being used for general cutting.

Use this general purpose cutter for cutting materials such

as wood, plastic and fiberglass.

6

CARTON CONTENTS

ROTARY TOOL COMPONENTS

KEY DESCRIPTION QTY

A Rotary Tool 1

B Precision Handle with Sole Plate 1

C Freehand Sole Plate Attachment 1

D Circle Cutter Attachment 1

E Circle Cutter Installation Adapter 1

F Router Base Attachment 1

G1/8” Collet 1

H1/4” Collet 1

1/8” Lateral Style Drywall Cutter has

I

"000028 HSS 1/8" marked on the shank

of cutter

1/8” General Purpose Cutter has

J

"000032" marked on the shank of cutter

K Straight Router Bit 1

L Round Groove Router Bit 1

M Corner Round Router Bit 1

N Collet Wrench 1

O Collet Wrench Holder 1

P Owner’s Manual 1

Q Carrying Case 1

2

2

7

KNOW YOUR ROTARY TOOL

8

ASSEMBLY & OPERATION

WARNING

Remove the plug from the power source before

assembly, changing accessories or cutters and

making adjustments. This safety action will help

prevent accidental starting of the tool which could

result in serious injury.

ON / OFF SWITCH

This Rotary Tool is equipped with a sliding ON / OFF switch

(1) located on the top of the tool (see Fig. 1).

INSTALLING CUTTING BITS – Cont’d

4. Insert new cutting bit (4) into the collet.

WARNING

Insert the bit all the way into the collet and then

pull it back between

air space between the motor shaft and the bit to

help prevent overheating the bit.

Before tightening the collet on the bit, make sure

the flutes (spiral portion) of the bit are completely

visible outside the collet. Clamping the collet on

the bit flutes will result in broken bits and

possible injury.

5. When bit is properly placed in the collet, depress the

shaft locking button and turn the collet nut clockwise

by hand as far as possible.

6. Securely tighten collet nut using the wrench.

1

/16” and 1/8”. This creates an

Fig. 1

1. To turn the tool ON, slide the switch up.

2. To turn the tool OFF, slide the switch down.

INSTALLING CUTTING BITS

WARNING

Cutting bit and router bit cutting surfaces are

extremely sharp. Handle with caution.

To insert a cutting bit, use the collet wrench which is in the

wrench holder attached to the power cord.

1. Depress the shaft locking button (1) and rotate the

collet lock nut (2) clockwise with the other hand until

the locking button drops into place, preventing the

shaft from turning (see Fig. 2).

2. While continuing to hold the shaft locking button IN,

use the collet wrench (3) to turn the collet nut counter

clockwise. Loosen the collet nut 2 or three turns.

Fig. 2

3. Remove bit if one is already installed in the tool.

9

ASSEMBLY & OPERATION

CHANGING COLLET INSERT

The cutting bits for this tool are locked into place with a

collet nut (1) and collet (see Fig. 3). The tool is

assembled at the factory with a

to hold the cutting bit. An additional ¼” collet (3) is

supplied for holding SMALL router bits with a ¼” shank.

1

/8” collet (2) which is used

Fig. 3

To change from one collet size to the other:

1. Remove bit from the tool.

2. Continue turning the collet nut counter clockwise until

it can be removed from the motor shaft (4).

INSTALLING FREEHAND SOLE PLATE – cont’d

1. Remove accessory locking knob (1) from the base of

the spin saw motor housing (see Fig. 4). Slide

freehand sole plate mounting bracket (2) onto the

bottom of motor housing (3) until the mounting hole

(4) lines up with the hole in the motor housing.

NOTE: The tab on the side of the sole plate mounting

band must be inserted into the matching slot in the

motor housing.

2. Re-insert accessory locking knob into the motor

housing and securely tighten.

3. Pull the collet out of the motor shaft and replace it with

the other one.

NOTE: Each collet is the same on both ends, so either

end can be inserted into the motor shaft.

4. Re-install the collet nut and slightly tighten it by hand.

5. Install the new bit as outlined in INSTALLING

CUTTING BITS on Page 9.

NOTE: Tightening the collet nut without a bit in the collet

will cause the collet hole to become smaller and make

installing bits difficult. When storing the tool with no bit

installed, leave collet nut loose.

FREEHAND SOLE PLATE

INSTALLING FREEHAND SOLE PLATE

The freehand sole plate is designed for basic freehand

cutting with the cutting bit. It is ideally suited for cutting

electrical outlet holes in drywall.

WARNING

Do NOT use the freehand sole plate with router bits.

Limited control with this accessory could cause you

to loose control and increase the chance of serious

injuy.

Fig. 4

ADJUSTING FREEHAND SOLE PLATE

1. Adjust freehand sole plate depth by loosening the

depth gauge knob (5) and sliding the sole plate (6) in

or out as required (see Fig. 5).

NOTE: Set the depth gauge so the cutting bit

protrudes beyond the sole plate

thickness of the material being cut. For example, if

you are cutting

beyond the sole plate.

2. Securely tighten depth gauge knob.

3. Before starting to cut you should re-check bit depth,

make sure sole plate is at right angles to the bit and

securely tightened. Re-check the collet to make sure

the bit is securely fastened.

5

/8” drywall, the bit should protrude ¾”

1

/8” more than the

10

Fig. 5

ASSEMBLY & OPERATION

WARNING

!

Have you read “POWER TOOL SAFETY”, “ROTARY

TOOL SAFETY” and “ELECTRICAL SAFETY” on

pages 3, 4 and 5 of this Manual? If not, please do it

now before you operate this ROTARY TOOL. Your

safetydepends on it!

Every time you use the Rotary Tool you should

verify the following:

1. Rotary Tool cord is not damaged.

2. Bit is correct type for the material being cut.

3. Bit is sharp, in good condition, properly

installed and securely tightened.

4. Safety glasses and dust mask are being worn.

Failure to adhere to these safety rules can greatly

increase your chances of injury.

PRACTICE CUTS USING FREEHAND SOLE PLATE

PRACTICE CUTS USING FREEHAND SOLE PLATE

6. Turn the switch ON.

7. When the motor is up to full speed, slowly tip the tool

to an upright position, letting the bit cut into the

workpiece (see Fig. 7). Once the tool has reached

the upright position and the bit has cut through the

workpiece, slowly move the tool in a clockwise

direction using slow steady pressure to make the cut.

NOTE: Except for cutting around outlet boxes in

drywall, always cut in a clockwise direction.

8. When cut is complete, turn the tool OFF, wait until it

comes to a complete stop and remove it from the

workpiece.

Before attempting to work on an actual project, take the

time to make a few practice cuts with your Rotary Tool.

Use some scraps of material that are the same material

as used in your actual project.

1. Draw a pattern similar to your first project on a scrap

piece of material.

2. Install freehand sole plate as shown in Fig. 4.

3. Install cutting bit in the collet as shown in Fig. 2.

4. Adjust depth of freehand sole plate as shown in Fig. 5.

5. Rest the edge of the sole plate on the workpiece with

the bit at an angle of about 45

NOTE: DO NOT let the bit contact the workpiece until

switch is turned ON and the tool is up to full speed.

o

(see Fig. 6).

WARNING!

Before turning the tool switch ON, make sure you

hold the tool firmly with both hands. Starting

torque will cause the tool to twist.

Fig. 7

DANGER!

Do not attempt cutting around outlet boxes in drywall

until:

1. All electricity in the vicinity of electric wires has

been disconnected by either turning the breaker

OFF or removing the fuses.

2. You have read the instructions on the following

page entitled “CUTTING OUTLET OPENINGS IN

DRYWALL”.

CUTTING TIPS

The rotating cutting action of the bit will cause a slight pull

to the left when cutting. Natural variations in the structure

of wood will cause the bit to “wander”. This tendency will

be magnified when applying too much pressure to the bit.

Slower cutting gives you better control. Excessive

pressure or fast cutting will increase bit temperature and

shorten the life of the bit.

Fig. 6

When cutting a hole in a vertical surface, avoid ending the

cut at the bottom of the hole. Always start and end the

cut at the “top” so the cut-out part will not drop onto the

rotating bit. Always turn the tool OFF before removing it

from the workpiece.

11

ASSEMBLY & OPERATION

CUTTING OUTLET OPENINGS IN DRYWALL

DANGER

Do not attempt to use this tool to make cut-outs

around any fixture or opening which has live electrical

wires or on any wall which may have electrical wiring

behind it. If a live wire is contacted, the bit could

conduct the electric current to the tool, creating an

electrocution hazard for the operator. Turn OFF

breakers or remove fuses to disconnect the electric

circuit in the area of work. Always hold the tool by its

insulated housing when working in areas where there

is a possibility of contacting electric wires. Always

wear eye protection when operating this tool.

1. Before installing drywall, push the electrical wires to

the back of the box as far as possible so they will not

be cut by the bit when cutting the opening.

2. Before fastening the drywall sheet over the electrical

box, mark the sheet as close as possible to the center

of the box opening. Mark should be on the side of the

drywall facing you.

3. When fastening the drywall in place, do not place nails

or screws closer than 12” from the box. This will

prevent the drywall from becoming deformed under

pressure.

CUTTING OUTLET OPENINGS IN DRYWALL – cont’d

6. Move the bit slowly to the right until you feel and hear

the bit contacting the inside of the box.

7. Pull the bit out far enough to slip it over the edge of

the box. Once the bit is outside the box, push it back

to full depth beside the outside edge of he box.

8. Move the tool upward while applying slight pressure

toward the center of the box. When you feel the bit

reach the top right hand corner of the box, move the

tool to the left while applying slight pressure

downward toward the center of the box.

9. Continue moving the tool around the box in a counter

clockwise direction while maintaining slight pressure

toward the center of the box. When the box cut-out is

complete. Turn the tool OFF and remove it from the

cut-out.

10. Completed electrical box cut-out will be accurately

and neatly cut (see Fig. 9).

4. Insert cutting bit and install freehand sole plate as

outlined on Pages 9 & 10 of this Owner’s Manual.

Adjust dept of cut so the bit will protrude

the thickness of the drywall.

5. Hold the tool firmly with both hands and turn it ON.

Plunge the bit through the drywall at the mark

indicating the center of the box. See Fig. 8 for cutting

pattern.

1

/8” beyond

Fig. 9

NOTE: Always move the cutting bit in a counter

clockwise direction around the outlet box. The natural

tendency of the cutting bit to move to the left will make it

easier to cut close to the box.

Fig. 8

12

ASSEMBLY & OPERATION

PRECISION HANDLE

INSTALLING PRECISION HANDLE

The precision handle is designed for use when precision

control over the tool movement is desired. The

comfortable handle can be used with either the right or left

hand.

1. Remove accessory locking knob (1) from the base of

the Rotary Tool motor housing (see Fig. 10). Slide

precision handle mounting bracket (2) onto the bottom

of motor housing (3) until the mounting hole (4) lines

up with the hole in the motor housing.

NOTE: The tab on the side of the precision handle

mounting bracket must be inserted into the matching

slot in the motor housing.

2. Re-insert accessory locking knob into the motor

housing and securely tighten.

ADJUSTING FREEHAND SOLE PLATE – Cont’d

Fig. 11

CIRCLE CUTTER

INSTALLING CIRCLE CUTTER

The circle cutter accessory is ideal for precision cutting of

circles. This circle cutter can be attached to either the

freehand sole plate or the precision handle sole plate. For

purposes of illustration, the circle cutter is shown with the

freehand sole plate.

1. Install freehand sole plate on the tool as illustrated on

Page 10 of this Owner’s Manual.

2. Insert the externally threaded circle cutter mounting

insert (1) into the bottom of the sole plate (2) (see

Fig. 12).

NOTE: Make sure the “D” shaped opening in the

mounting insert is inserted into the matching “D”

shaped opening in the sole plate.

Fig. 10

ADJUSTING FREEHAND SOLE PLATE

1. Adjust precision handle sole plate depth, by loosening

the depth gauge knob (5) and sliding the sole plate (6)

in or out as required (see Fig. 11).

NOTE: Set the depth gauge so the cutting bit

protrudes beyond the sole plate

thickness of the material being cut. For example, if

you are cutting

beyond the sole plate.

2. Securely tighten depth gauge knob.

3. Before starting to cut you should re-check bit depth,

make sure sole plate is at right angles to the bit and

securely tightened. Re-check the collet to make sure

the bit is securely fastened.

3

/4” pine, the bit should protrude 7/8”

1

/8” more than the

3. Place circle cutter mounting hole (3) over the

externally threaded circle cutter mounting insert.

NOTE: Make sure pointed pivot pin (4) is pointing

away from the tool.

4. Screw the internally threaded circle cutter mounting

disc (5) onto the externally threaded circle cutter

mounting insert and hand tighten.

NOTE: Do not over tighten the circle cutter mounting

plastic parts. Hand tighten only.

5. Adjust the circle cutting radius by loosening pivot point

knob (6), sliding it to the correct circle radius and retightening in the desired location.

NOTE: Check circle cutter radius setting by

measuring from the pivot point to the outside of the

cutting bit.

13

Fig. 12

ASSEMBLY & OPERATION

CIRCLE CUTTER

CIRCLE CUTTER OPERATION

WARNING

Unplug the tool from the power source before

changing accessories, changing bits and making

adjustments.

Before turning the tool ON, check to make sure bit

and all accessory fasteners are securely tightened.

1. Mark the center of the circle you wish to cut on the

workpiece and drill a 6 mm or

2. Adjust cutting bit depth to

of the material being cut.

3. Adjust the circle cutting radius by loosening pivot point

knob, sliding it to the correct circle radius and retightening in the desired location.

NOTE: Check circle cutter radius setting by measuring

from the pivot point to the outside of the spiral bit.

4. Rest the edge of the sole plate on the workpiece with

the bit at an angle of about 45

the circle cutter pivot point into the pilot hole drilled at

the center of the circle.

NOTE: DO NOT let the bit contact the workpiece

before switch is turned ON and the tool is up to full

speed.

15

/64” pilot hole.

1

/8” longer that the thickness

0

(see Fig. 13). Insert

CIRCLE CUTTER OPERATION – cont’d

5. Turn the switch ON.

6. When the motor is up to full speed, slowly tip the tool

and circle cutter assembly to an upright position,

letting the bit cut into the workpiece (see Fig. 14). Be

careful to keep the pivot point located at the center of

the circle to be cut. Once the tool has reached the

upright position and the bit has cut through the

workpiece, slowly move the tool in a clockwise

direction using slow steady pressure to make the cut.

Continue to cut the circle, keeping the tool upright and

rotating around the circle cutter pivot point.

7. When cut is complete, turn the tool OFF, wait until it

comes to a complete stop and remove it from the

workpiece.

Fig. 13

Fig. 14

14

ASSEMBLY & OPERATION

ROUTER BASE

The router accessory converts your Rotary Tool into a

small hobby router that is capable of handling small ¼”

shank router bits as well as the spiral cutting bit. The

tilting base is ideal for bevel cutting.

WARNING

Unplug the tool from the power source before

changing accessories, changing bits and making

adjustments.

Before turning the tool ON, check to make sure the bit

and all accessory fasteners are securely tightened.

ROUTER ACCESSORY INSTALLATION

1. Remove any accessory already installed on the tool.

2. Remove accessory locking knob (1) from the base of

the spin saw motor housing (see Fig. 15). Depress

the motor shaft locking button (2) on the back of the

motor housing (see inset).

NOTE: Rotate the collet nut while holding down on the

motor shaft locking button until the button drops into

the hole in the motor shaft.

SETTING ROUTER DEPTH

Depth of cutting is controlled by sliding the router base up

and down in the adjusting sleeves.

1. Loosen both height adjusting knobs (1) by turning

them counter clockwise (see Fig. 16).

2. Slide router base (2) up or down to obtain the desired

depth of cut.

3. Re-tighten height adjusting knobs when the desired

cut depth is reached.

Fig. 16

3. Slide router accessory mounting bracket (3) onto the

bottom of motor housing (4) until the mounting hole

(5) lines up with the hole in the mounting bracket.

NOTES:

The raised hole in the mounting bracket will slide over

the motor shaft locking button only if the button is fully

depressed and engaged in the motor shaft.

The tab on the reverse side of the router base

mounting band must be inserted into the matching slot

in the motor housing.

4. Re-insert accessory locking knob into the motor

housing and securely tighten.

SETTING ROUTER BASE BEVEL

Bevel cutting with the cutting bit can be done with the

router base tilted to the desired angle.

1. Loosen both bevel adjusting knobs (3) by turning them

counter clockwise at least 2 turns (see Fig. 17).

2. Tilt router base (2) to the desired angle.

3. Re-tighten both height adjusting knobs.

4. Check bevel angle between router base and spiral

cutter to ensure they are at correct angle.

5. Check router depth of cut and re-set the depth if

required.

NOTE: Depth of cut will usually have to be increased

after tilting the router base for bevel cutting.

Fig. 15

15

Fig. 17

ASSEMBLY & OPERATION

ROUTER BASE

FREEHAND CUTTING AND ROUTING

When the router base accessory is installed on the

Rotary Tool, it will function as a small router to be used for

freehand cutting of irregular shaped patterns. You can cut

patterns out of the workpiece with the cutting bit or route

patterns into the workpiece with small router bits.

FREEHAND CUTTING

1

1. Adjust the cutting bit depth to

thickness of the material being cut.

2. Turn the switch ON while firmly holding the tool.

3. When starting the cut inside the workpiece, place the

bit at an angle to allow the bit to cut its way into the

workpiece (see Page 11 Fig. 6).

4. Use the two height adjusting knobs to guide the bit

through the workpiece.

FREEHAND ROUTING

Use the router base with small router bits to perform

various freehand routing projects (see Fig. 18).

/8” longer than the

CUTTING STRAIGHT LINE WITH STRAIGHT EDGE

To cut a straight line, you can use a straight edge

template to guide the router base.

1. Draw a line on the workpiece where you wish to make

the cut (see Fig. 19).

1

2. Draw a parallel second line approximately 2

into the workpiece (away from the cutting line).

3. Clamp the straight edge onto the larger portion of the

workpiece that is to be clamped while cutting.

4. Place the flat side of the router base against the

straight edge with the bit near the start of the cutting

line.

NOTE: Check bit location to ensure cut will be made

in the correct location.

5. Turn the switch ON while firmly holding the tool.

6. Slide the router plate against the straight edge while

making the cut.

/8” back

1

1. Remove

Fig. 3).

2. Install router bit and securely tighten.

3. Adjust router base height to the correct routing depth.

4. Turn the switch ON making sure the router bit is not

touching anything.

5. Holding the tool by the two height adjusting knobs,

carefully lower the bit onto the workpiece and guide

the bit around the desired pattern.

/8” collet and insert ¼” collet (see Page 10

Fig. 19

Fig. 18

16

OPERATION & MAINTENANCE

ROUTER BASE

CUTTING CURVED LINE WITH A TEMPLATE

To cut a curved line, you can use a curved template to

guide the router base.

1. Make a template from hardboard or other similar

material to the shape you require (see Fig. 20).

NOTE: Radius of curve must be greater than 2 ½” for

router base to properly follow the curved template.

2. Mark the location of the cut to be made.

3. Mark the workpiece approximately 2

workpiece (away from the cutting line).

4. Clamp the template onto the larger portion of the

workpiece that is to be clamped while cutting.

5. Place the curved portion of the router base against the

template with the bit near the start of the cutting line.

NOTE: Check bit location to ensure cut will be made

in the correct location.

6. Turn the switch ON while firmly holding the tool.

7. Slide the router plate against the template while

making the cut.

7

/16” back into the

MAINTENANCE

EXTERNAL CLEANING

WARNING

DO NOT use solvents when cleaning plastic parts.

Most plastics are susceptible to damage from various

types of commercial solvents and may be damaged by

their use. Use clean cloth to remove dirt, dust, oil,

grease, etc.

Do not at any time allow brake fluids, gasoline,

petroleum-based products, penetrating oils, etc. to

come in contact with plastic parts. They contain

chemicals that can damage, weaken or destroy

plastic.

INTERNAL CLEANING

It has been found that electric tools are subjected to

accelerated wear and possible premature failure when

they are used on fiberglass boats and sports cars,

wallboard, spackling compounds or plaster. The chips

and grindings from these materials are highly abrasive to

electric tool parts such as bearings, brushes,

commutators, etc. During any use on these materials it is

extremely important that the tool is cleaned frequently by

blowing out with a compressed air jet.

Fig. 20

GENERAL

MAINTENANCE

DANGER

For your own safety, turn the switch OFF and remove

the plug from the power source before maintaining

your Rotary Tool.

When servicing, use only identical original equipment

parts. Use of any other part may create a hazard or

cause product damage.

DANGER!

It is critical that you wear safety goggles or safety

glasses with side shields and a dust mask while

blowing dust out of the Rotary Tool with a

compressed air jet. Failure to take these safety

precautions could result in permanent eye or lung

damage.

POWER CORD MAINTENANCE

WARNING!

To avoid shock or fire hazard, replace the cord

immediately if it is worn or damaged in any way.

LUBRICATION

A

ll of the bearings in this Rotary Tool are lubricated with a

sufficient amount of high grade lubricant for the life of the

unit under normal conditions. Therefore, no further

lubrication is required

17

Model PT302H

TWO (2) YEAR LIMITED WARRANTY

FANTOM warrants this product to be free from defects in material and workmanship for a period of two (2) years

from the date of the original purchase, when utilized for normal household use, subject to the following conditions,

exclusions and exceptions.

If your appliance fails to operate properly while in use under normal household conditions within the warranty

period, return the complete appliance and accessories, freight prepaid to FANTOM, 178 W. Service Rd.

Champlain, NY 12919. If the appliance is found by FANTOM to be defective in material or workmanship,

FANTOM will repair or replace it free of charge. Proof of purchase date and $ 14.95 to cover the cost of return

shipping and handling must be included. *

Non-durable parts including, without limitation, router bits, cutting bits, drill bits, carbon brushes and electrical

parts which normally require replacement are specifically excluded from warranty.

The liability of FANTOM is limited solely to the cost of the repair or replacement of the unit at our option. This

warranty does not cover normal wear of parts and does not apply to any unit that has been tampered with or used

for commercial purposes. This limited warranty does not cover damage caused by misuse, abuse, negligent

handling or damage due to faulty packaging or mishandling in transit. This warranty does not cover damage or

defects caused by or resulting from damages from shipping or repairs, service or alterations to the product or any

of its parts, which have been performed by a repair person not authorized by FANTOM.

This warranty is extended to the original purchaser of the unit and excludes all other legal and/or conventional

warranties. The responsibility of FANTOM if any, is limited to the specific obligations expressly assumed by it

under the terms of the limited warranty. In no event is FANTOM liable for incidental or consequential damages of

any nature whatsoever. Some states do not permit the exclusion or limitation of incidental or consequential

damages, so the above may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

*Important: Carefully pack item to avoid damage in shipping. Be sure to include proof of purchase date

and to attach tag to item before packing with your name, complete address and phone number with a note

giving purchase information, model number and what you believe is the problem with item. We

recommend you insure the package (as damage in shipping is not covered by your warranty). Mark the

outside of your package “ATTENTION CUSTOMER SERVICE”. We are constantly striving to improve our

products, therefore the specifications contained herein are subject to change without notice.

$

OWNERSHIP REGISTRATION CARD

Please fill out and mail the product registration card within ten (10) days of purchase in order to validate

the foregoing Limited Warranty. The registration will enable us to contact you in the unlikely event of a

product safety notification. By returning this card you acknowledge to have read and understood the

instructions for use, and warnings set forth in the accompanying instructions.

RETURN TO FANTOM: 178 W. Service Rd. Champlain, NY 12919

___________________________________________________________________

Model PT302H

Appliance model

______________________________________________________________________________

Date purchased Name of store

________________________________________________________________________________

Owner’s name

________________________________________________________________________________

Address City State Zip Code

Printed in China

Loading...

Loading...