Page 1

Industrial Dehumidifier

Industrial Dehumidifier

Déshumidificateur industriel

Deshumidificador industrial

Read and Save

These

Instructions

Lisez et

conservez ces

instructions

Lea y guarde

estas

instrucciones

Déshumidificateur industriel

Deshumidificador industrial

Owner’s Manual

Read and Save These Instructions

Lisez et conservez ces instructions

Lea y guarde estas instrucciones

Models / Modèles / Modelos

EDP150LR

EDP180CR

EDP190LR

EDP250CR

OPERATION AND MAINTENANCE MANUAL

Page 2

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

WARNING

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

ically empty the reservoir. Pressing this but-

ton allows manual emptying of the reservoir.

Press once, and the pump will operate for

20 seconds. Press and hold the button and

the pump will activate for 30 seconds.

Fig. 2

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

WARNING

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

ically empty the reservoir. Pressing this but-

ton allows manual emptying of the reservoir.

Press once, and the pump will operate for

20 seconds. Press and hold the button and

the pump will activate for 30 seconds.

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

ically empty the reservoir. Pressing this but-

ton allows manual emptying of the reservoir.

Press once, and the pump will operate for

20 seconds. Press and hold the button and

the pump will activate for 30 seconds.

Always manually purge the water reservoir

before transport or storage. Turn off the

power and allow the plugged in dehumidifier

to rest 5 minutes before the final purge.

Fig. 2

Digital Hour Counter (Fig. 3)

The counter will accumulate and display the total running hours

of the unit in 1/10 of an hour.

Hour Button (Fig. 4)

Press the HOURS button when the dehu-

midifier cannot be plugged in and the hour

meter needs to be read. The digital hour

meter will display the last saved cumulative

time for ten seconds.

Defrost Indicator (Fig. 5)

The defrost indicator will light to indicate the

dehumidifier is in defrost cycle. During this

Defrost Cycle

When ice builds up on the coils, a thermistor activates the elec-

tronic control and defrost light. The compressor is turned off by

the thermistor temperature measurement. The blower will contin-

ue to run, causing air to flow through the evaporator coil and melt

the ice. When the ice is melted, the thermistor will end the defrost

cycle and the compressor will be started.

Disconnect dehumidifier from power supply. The hour meter uses

a battery backup for display when the dehumidifier is unplugged

and the hour button is depressed. To change the battery, it is nec-

essary to remove the four (4) screws from the control panel.

Disconnect the old battery and replace with new battery. Replace

control panel and screws. Do not overtighten screws.

Fig. 3

Fig. 4

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

WARNING

Disconnect power supply before replacing battery.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Battery Replacement

Fig. 2

Fig. 4

Industrial Dehumidifier

WARNING

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Electrical Requirements

For 115V operation, a common grounded outlet on a 15

amp circuit is required. If used in a wet area, a ground fault

interrupter (GFI) is required.

Built in Electrical Safety

For your safety and protection this appliance is manufactured

with a grounded plug on its power cord. The power cord

must be plugged into a properly grounded receptacle. If a

grounded receptacle does not exist, have one installed by a

certified electrician. Do not cut or remove the grounding

prong on the power cord plug if equipped. We recommend

that this electrical circuit/receptacle operate under a

separate breaker or fuse.

If an extension cord is required, it must have a minimum of

14 gauge conductors if 25 feet long or less and 12 gauge

conductors if greater than 25 feet long.

Electrical Shock Hazard

Pump Purge Button (Fig. 2)

In normal operation, the pump will

automatically empty the reservoir.

Pressing this button allows manual

emptying of the reservoir. Press once,

and the pump will operate for 20

seconds. Press and hold the button and

the pump will activate for 30 seconds.

Always manually purge the water reservoir before transport or storage.

Fig. 2

Turn off the power and allow the plugged in dehumidifier to

rest 5 minutes before the final purge.

Digital Hour Counter (Fig. 3)

The counter will accumulate and display the total running

hours of the unit in 1/10 of an hour.

Fig. 3

Hour Button (Fig. 4)

Press the HOURS button when the

dehumidifier cannot be plugged in and

the hour meter needs to be read. The

digital hour meter will display the last

saved cumulative time for ten seconds.

Fig. 4

Battery Replacement

WARNING

Limitations of Use

Temperature: 4°C to 35°C (40°F to 95°F)

Relative Humidity: 20 to 80%

Water Removal

The dehumidifier is equipped with an internal condensate

pump to remove the water that is collected from the air. This

allows the water to be pumped 20 feet with the attached

hose. If the water needs to be pumped more than 20 feet

above the unit, a second pump must be added to relay the

water. The condensate pump automatically purges for 20

seconds every four minutes.

OPERATION

Place dehumidifier inside area to be dried. Make sure all

windows and doors are closed to the outside and seal off the

wet area from any unaffected areas. Route condensate hose

into a drain, or a very large container. Press the On/Off

button (Fig. 1) to activate the dehumidifier.

Power Button (Fig. 1)

The dehumidifier is turned on or off by

pressing the power button. When the

dehumidifier is started, the hour meter

will display the cumulative hours.

2

Fig. 1

Electrical Shock Hazard

Disconnect power supply before replacing battery.

Failure to follow these instructions can result in death, fire, or

electrical shock.

Disconnect dehumidifier from power supply. The hour meter uses

a battery backup for display when the dehumidifier is unplugged

and the hour button is depressed. To change the battery, it is

necessary to remove the four (4) screws from the control panel.

Disconnect the old battery and replace with new battery. Replace

control panel and screws. Do not overtighten screws.

Defrost Cycle

When ice builds up on the coils, a thermistor activates the

electronic control and defrost light. The compressor is turned

off by the thermistor temperature measurement. The blower will

continue to run, causing air to flow through the evaporator coil

and melt the ice. When the ice is melted, the thermistor will end

the defrost cycle and the compressor will

be started.

Defrost Indicator (Fig. 5)

The defrost indicator will light to indicate

the dehumidifier is in defrost cycle. During

this period, the compressor is not running.

Fig. 5

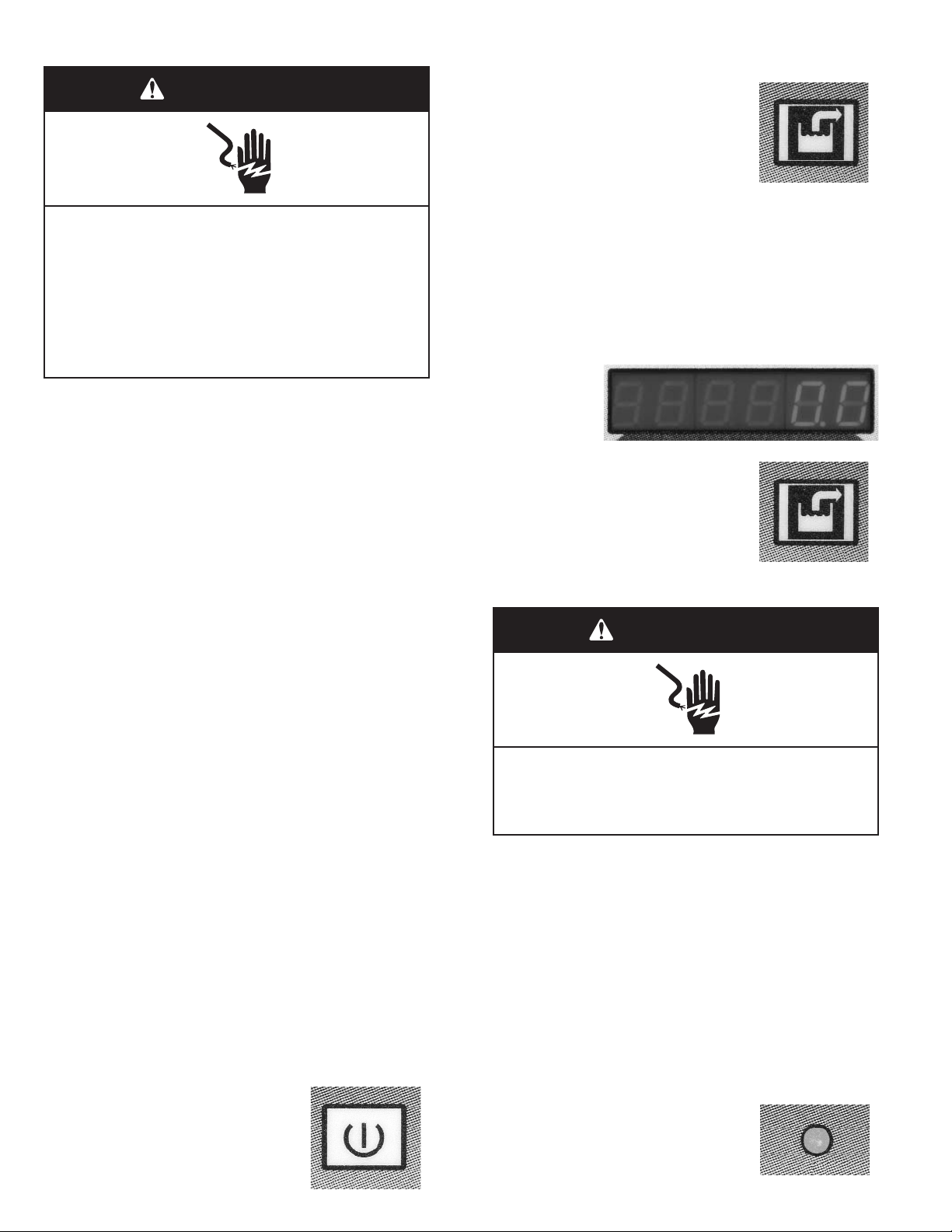

Page 3

Venting / Ducting (Fig. 6)

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

WARNING

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

ically empty the reservoir. Pressing this but-

ton allows manual emptying of the reservoir.

Press once, and the pump will operate for

20 seconds. Press and hold the button and

the pump will activate for 30 seconds.

Fig. 8

Fig. 8

Twin rear outlets can accommodate two individual 5” ducts

or one 10” lay flat duct to be

attached. This allows for warm

dry air to be directed into different areas.

Industrial Dehumidifier

Fig. 8

Fig. 6

MAINTENANCE

Air Filter (Fig. 7)

The air filter should be checked regularly. Operating the

dehumidifier with a clogged filter will reduce efficiency. To

access the filter, slide the filter frame up until it clears the

dehumidifier cabinet. Reverse procedure to re-install the filter into the dehumidifier.

Fig. 7

MAINTENANCE

Storage

Freezing temperatures and biological growth must be considered before storing the dehumidifier. The dehumidifier should

be flushed with a biofungicide before storing. When storing

the unit, ensure that water has been removed from the reservoir and hose. This will prevent damage caused by freezing

temperatures and to prevent biological growth. Use the

pump purge button to remove water and biofungicide chemicals from the dehumidifier.

Stacking (Fig. 9)

The dehumidifiers can be stacked on top of each other. The

wheels from the upper unit must be resting in the cradle of

the lower unit. DO NOT STACK MORE THAN TWO HIGH.

Fig. 9

Disconnect power supply before cleaning.

Failure to follow these instructions can result in death, fire, or

electrical shock.

External Cleaning

Use a non-flammable mild, non-abrasive soap and clean

water solution to clean the dehumidifier. Wipe dry.

Internal Cleaning

Disconnect dehumidifier from power supply.

Light cleaning: Remove the air filter and spray evaporator coil

with water. Remove the two upper screws from the fronthood.

Heavy cleaning: Remove two upper screws from front hood.

Open hood. Spray water at coils. Close hood and replace

screws. (Fig. 8)

WARNING

Electrical Shock Hazard

Service

A qualified refrigeration technician must service all refrigerant leaks.

WARNING: The dehumidifier uses a high pressure refrigerant

system and high voltage circuitry which could present a

health hazard resulting in death, serious bodily injury, and/or

property damage. Only qualified service people should service

this unit.

CAUTION: Do not operate unit without the front hood secured

in place.

The serial data plate is located on the underside of the dehumidifier. For service information contact 1-800-565-3548.

3

Page 4

TROUBLESHOOTING

The Unit is NOT working:

• Why do you believe the dehumidifier is not working?

• Is the power ON?

• Has the breaker tripped? – Reset breaker

• If in a wet area, is the unit plugged into a GFI protected cir-

cuit? – Excessive moisture will trip GFI. Remove from area.

• Is the unit being run off a generator? - Check output does

not fluctuate as the unit will not operate at low voltage.

• If using an extension cord - Is the cord of the correct

gauge for the distance run? (14 AWG up to 25’ and 12

AWG over 25’). Note: Verify voltage while unit is starting.

Start up will cause the highest current draw and largest

voltage drop. Even if plugged directly to outlet there can

be a significant voltage drop. Never assume the voltage is

ok without verifying.

• Is the unit draining? – Check the condensate receptacle.

If full, the float is up and the unit will not operate – drain

receptacle.

• Overpressure switch tripped. Check for fan failure or high

ambient temperature. Display panel indicates defrost.

The unit continually ices up: Note that some ice buildup on the

evaporator coils is normal but airflow should not be blocked.

• Is the fan working? – Fan not working, check run capacitor

and fan unit.

• Is warm air blowing out the front of the unit? - No warm

air, temperature may be too low. Raise temperature with

supplementary source.

• Is the air filter clean and airflow unobstructed? – Clean

filter. Unit should have a minimum of 10” clearance all

around it.

• Dirty evaporator coils? – Clean coils.

• Defrost thermostat loose or not working? – Secure or

replace.

• Defrost timer set incorrectly or defective? – Reset or

replace.

• Temperature in the operating space is too low? - Raise

temperature with supplementary source.

Unit runs continuously for days:

• Unit is working removing water - High Relative Humidity

in space.

• Humidity or water is getting into the space – Find source

and stop it.

• Unit is undersized for space – Use larger unit or multiple units.

• Poor air movement in space – Use air movers to

increase movement.

Unit runs but does not pump water:

• Drain hose kinked or blocked – Straighten or unblock hose.

• Pump float stuck closed – Reset or replace.

• Pump not working – Check electrical operation with out-

side supply.

• Hose disconnected internally – Reconnect hose.

• Compressor capacitor bad – Check capacitor.

Fan runs but Compressor does not:

• Condensate pump not working – Check pump and float.

• Bad connection in pump circuit – Check connections.

• Bad compressor capacitor – Check capacitor.

• Defective control board – Replace.

• Defective compressor – Replace compressor by quali-

fied technician.

• Defective time delay or Thermistor – Check and/or replace.

• Defective pressure switch – Check and replace.

Fan does not run. Compressor runs briefly but cycles on/off:

• Defective fan capacitor – Check capacitor.

• Loose connection in fan circuit – Check connections.

• Fan obstructed and not turning – Remove obstruction.

• Defective fan – Replace fan.

• Defective control board – Replace control board.

Unit moves some water but not as much as expected:

• Air temperature and Relative Humidity have dropped - Check

levels with calibrated humidity meter and/or thermostat.

• Unit is in defrost cycle – Unit will start after cycle.

• Air filter dirty or airflow obstructed - Unit should have a

minimum of 10” clearance all around it. Clean air filter and

ensure adequate airflow/space around unit.

• Evaporator coils dirty – Clean coils.

• Restrictive or kinked exhaust ducting (if used) – Straighten

out ducting.

• Defrost timer set incorrectly for conditions – Reset timer.

• Defrost thermostat defective - Replace

• Refrigerant charge is low – Have unit checked by qualified

technician

• Defective compressor – Replace compressor by qualified

technician as it requires recycling of refrigerant.

4

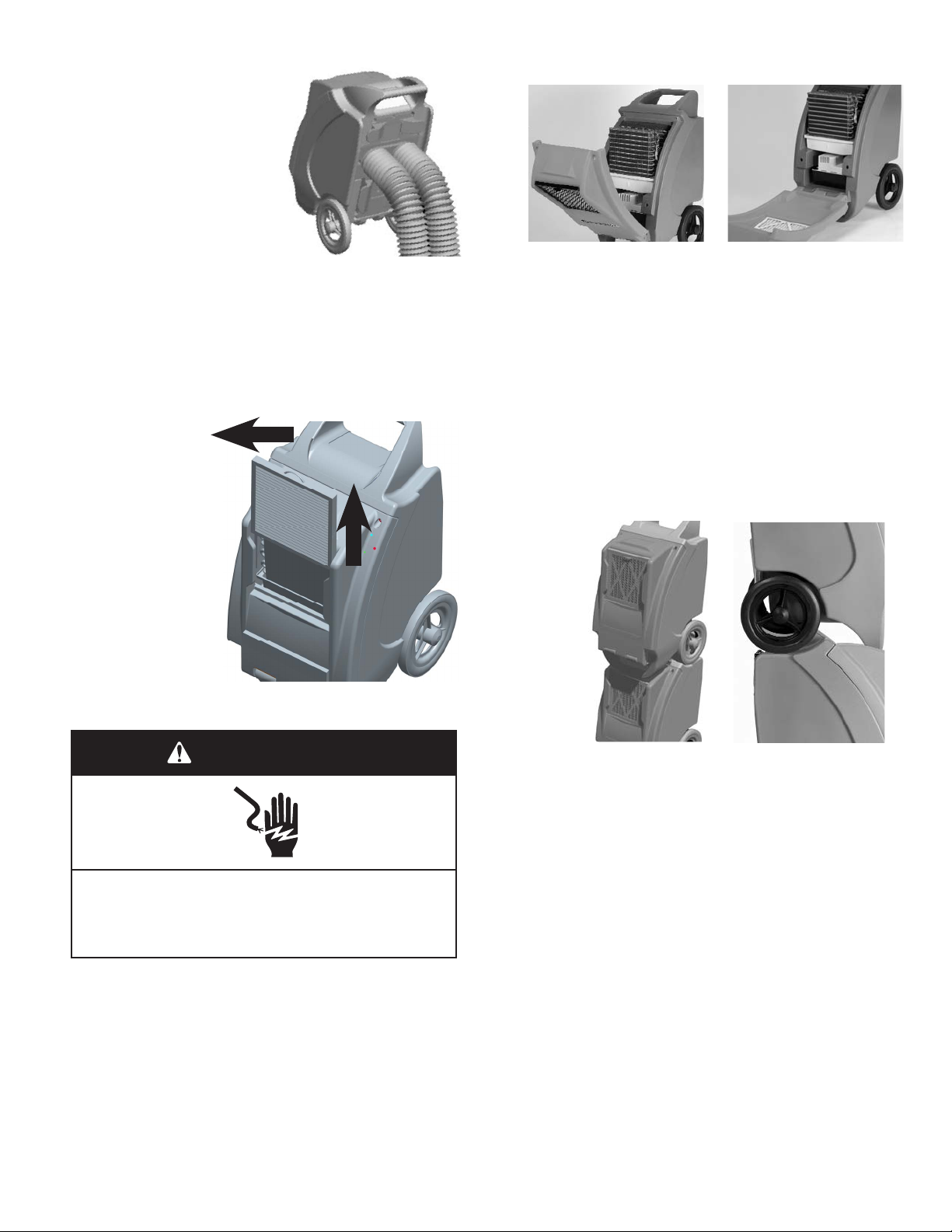

Page 5

WIRING DIAGRAMS

EPD150LR, EPD180CR

EPD190LR, EPD250CR

5

Page 6

LIMITED PRODUCT WARRANTY

Industrial Dehumidifier

WARRANTY - ONE YEAR

This product is warranted against defects in material and workmanship

for a period of one year from the date of purchase by the original purchaser. During this period, all parts and labor will be provided at no

cost. Consumable parts (ie: light bulbs and filters) are not warranted

or guaranteed for any length of time. This warranty is non transferable.

ADDITIONAL SIX YEAR WARRANTY

For a period of six years following the ONE YEAR WARRANTY components of the sealed system are warranted against defects in material.

Parts will be supplied (freight prepaid) free of charge. Installation labor

is not covered. This warranty is non transferable.

LIFETIME WARRANTY ON ROTOMOLDED HOUSING

The Rotomolded housing of this product carries a lifetime warranty.

This warranty is non transferable.

NOTICE

1. This warranty applies only to the original purchaser and applies

only within the boundaries of CANADA and CONTINENTAL USA.

2. This is the only warranty of the dealer and Fantech Limited. for

the above mentioned product and no other warranty or condition,

expressed or implied shall apply, except where specifically

excluded by law.

3. The original purchaser should complete this warranty form and

retain it in the event warranty service is required.

4. Proof of purchase date will be required for warranty claims.

Please retain bills of sale for proof.

5. Some states do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation or exclusion

may not apply to you. This warranty gives specific legal rights, and

the purchaser may have other rights which vary from state to

state. For more information regarding legal rights the purchaser

may contact the local or state consumer affairs office or the

appropriate state Attorney General.

GENERAL PROVISIONS

No warranty or insurance herein contained or set out shall apply when

damage or repair is caused by any of the following:

1. Power failure.

2. Damage in transit or when moving the appliance.

3. Improper power supply such as low voltage, defective house wiring or inadequate fuses.

4. Accident, alteration, abuse or misuse of the appliance such as

inadequate air circulation in the room or abnormal operating

conditions, (extremely high or low room temperatures).

5. Fire, water, damage, theft, war, riot, hostility, acts of God such as

hurricanes, floods, etc.

For information concerning your warranty, contact:

In Canada

Fantech

50 Kanalflakt Way,

Bouctouche, NB E4S 3M5

Phone: 800.565.3548; 506.743.9500

Fax: 877.747.8116; 506.743.9600

In Continental USA

Fantech

10048 Industrial Blvd.

Lenexa, KS 66215

Phone: 800.747.1762; 913.752.6000

Fax: 800.487.9915; 913.752.6466

email: service@fantech.net

Model Number Serial Number

Date of Purchase Customer Name

Address City

Purchased from

6

Page 7

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

WARNING

AVERTISSEMENT

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

ically empty the reservoir. Pressing this but-

ton allows manual emptying of the reservoir.

Press once, and the pump will operate for

20 seconds. Press and hold the button and

the pump will activate for 30 seconds.

Fig. 2

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

WARNING

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

ically empty the reservoir. Pressing this but-

ton allows manual emptying of the reservoir.

Press once, and the pump will operate for

20 seconds. Press and hold the button and

the pump will activate for 30 seconds.

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

ically empty the reservoir. Pressing this but-

ton allows manual emptying of the reservoir.

Press once, and the pump will operate for

20 seconds. Press and hold the button and

the pump will activate for 30 seconds.

Always manually purge the water reservoir

before transport or storage. Turn off the

power and allow the plugged in dehumidifier

to rest 5 minutes before the final purge.

Fig. 2

Digital Hour Counter (Fig. 3)

The counter will accumulate and display the total running hours

of the unit in 1/10 of an hour.

Hour Button (Fig. 4)

Press the HOURS button when the dehu-

midifier cannot be plugged in and the hour

meter needs to be read. The digital hour

meter will display the last saved cumulative

time for ten seconds.

Defrost Indicator (Fig. 5)

The defrost indicator will light to indicate the

dehumidifier is in defrost cycle. During this

Defrost Cycle

When ice builds up on the coils, a thermistor activates the elec-

tronic control and defrost light. The compressor is turned off by

the thermistor temperature measurement. The blower will contin-

ue to run, causing air to flow through the evaporator coil and melt

the ice. When the ice is melted, the thermistor will end the defrost

cycle and the compressor will be started.

Disconnect dehumidifier from power supply. The hour meter uses

a battery backup for display when the dehumidifier is unplugged

and the hour button is depressed. To change the battery, it is nec-

essary to remove the four (4) screws from the control panel.

Disconnect the old battery and replace with new battery. Replace

control panel and screws. Do not overtighten screws.

Fig. 3

Fig. 4

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

WARNING

Disconnect power supply before replacing battery.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Battery Replacement

Fig. 2

Fig. 4

Brancher sur une prise à 3 alvéoles reliée à la terre.

Ne pas enlever la broche de liaison à la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un câble de rallonge.

Le non-respect de ces instructions peut causer un décès, un

incendie ou un choc électrique.

Risque de choc électrique

Déshumidificateur industriel

Bouton de purge de la pompe (Fig. 2)

En fonctionnement normal, la pompe

videra automatiquement le réservoir. En

appuyant sur ce bouton, on peut vider

manuellement le réservoir. Si vous

appuyez une fois, la pompe fonctionnera

pendant vingt secondes. Si vous appuyez

sur le bouton et le maintenez enfoncé, la pompe sera activée

pendant trente secondes.

Purgez toujours manuellement le

réservoir d’eau avant de transporter ou d’entreposer la

pompe. Coupez l’alimentation et laissez le déshumidificateur

branché reposer pendant cinq minutes avant la purge finale.

Compteur d’heures numérique (Fig. 3)

Le compteur comptabilise et affiche le total des heures de

fonctionnement de l’unité en dixièmes d’heure.

Fig. 3

Fig. 2

Alimentation

Pour le fonctionnement sous une tension de 115 V, une prise

mise à la terre ordinaire d’un circuit de 15 ampères est

nécessaire. S’il est utilisé dans une aire humide, l’usage d’un

disjoncteur de fuite de terre (DFT) est nécessaire.

Dispositif de sécurité électrique intégré

Dans le but d'assurer votre sécurité et votre protection, cet

appareil est muni d’un cordon d’alimentation avec fiche mise

à la terre. Le cordon d’alimentation doit être branché dans

une prise convenablement mise à la terre. S’il n’y a pas de

prise mise à la terre, faites-en installer une par un électricien

agréé. Ne coupez pas et n’enlevez pas la broche de mise à

la terre de la fiche du cordon d'alimentation s'il y en a une.

Nous recommandons d’utiliser ce circuit électrique ou cette

prise avec un disjoncteur ou un fusible distinct.

Si une rallonge électrique doit être utilisée, elle doit

comporter des conducteurs d’un calibre minimum de 14 si

elle fait 25 pieds de long ou moins et des conducteurs de

calibre 12 si elle fait plus de 25 pieds.

Limitations d'usage

Limitations d'usage

Température: 4ºC à 35'C (40ºF à 95ºF)

Humidité relative: 20 à 80%

Enlèvement de l'eau

Le déshumidificateur est équipé d’une pompe à condensats

interne servant à enlever l’eau retirée de l’air. Elle permet de

pomper l’eau à vingt pieds avec le tuyau fixé à l’appareil. Si

l’eau doit être pompée à plus de vingt pieds au-dessus de

l’unité, il faut ajouter une seconde pompe à laquelle l’eau est

envoyée. La pompe à condensats se purge automatiquement

pendant vingt secondes toutes les quatre minutes.

FONCTIONNEMENT

Placez le déshumidificateur à l’intérieur de l’aire à sécher.

Assurezvous que toutes les fenêtres et les portes sont fermées

et isolez l’aire humide des ires non touchées. Faites aboutir le

tuyau à condensats à un drain ou à un très gros contenant.

Appuyez sur le bouton On/Off (Fig. 1)

pour activer le déshumidificateur.

Bouton de mise en marche (Fig. 1)

On allume ou éteint le déshumidificateur

en appuyant sur le bouton de mise en

marche. Lorsque le déshumidificateur se

met en marche, le compteur d’heures

affiche le total cumulé des heures.

Fig. 1

Bouton des heures (Fig. 4)

Appuyez sur le bouton HEURES lorsque

le déshumidificateur ne peut être

branché et qu’il faut lire l’affichage du

compteur d’heures. Le compteur

d’heures numérique affichera le dernier

total cumulé des heures sauvegardé

pendant dix secondes.

Remplacement de la pile

Fig. 4

AVERTISSEMENT

Risque de choc électrique

Débranchez l'alimentation avant de remplacer la pile.

Le fait de ne pas suivre ces instructions peut entraîner la mort,

un incendie ou un choc électrique.

Débranchez le déshumidificateur de son alimentation électrique.

Le compteur d’heures utilise une pile de secours pour l’affichage

lorsque le déshumidificateur est débranché et que le bouton des

heures est enfoncé. Pour changer la pile, il est nécessaire

d’enlever les quatre (4) vis du panneau de contrôle. Débranchez

l’ancienne pile et remplacez-la par une nouvelle. Remettez en place

le panneau de contrôle et les vis. Ne serrez pas trop les vis.

Cycle de dégivrage

Lorsque de la glace s’accumule sur les serpentins, une thermistance

active le contrôle électronique et la lumière de dégivrage. Le

compresseur est éteint par la mesure de la température par la

thermistance. Le ventilateur continue de fonctionner, ce qui fait

circuler à travers le serpentin de l’évaporateur l’air qui fait fondre

la glace. Lorsque la glace est fondue, la thermistance met fin au

cycle de dégivrage et le compresseur est mis en marche.

Indicateur de dégivrage (Fig. 5)

L’indicateur de dégivrage s’allume pour

indiquer que le déshumidificateur est en

cours de cycle de dégivrage. Au cours

de cette période, le compresseur ne

fonctionne pas.

Fig. 5

7

Page 8

Déshumidificateur industriel

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

WARNING

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

ically empty the reservoir. Pressing this but-

ton allows manual emptying of the reservoir.

Press once, and the pump will operate for

20 seconds. Press and hold the button and

the pump will activate for 30 seconds.

Fig. 8

Fig. 8

Ventilation/Canalisation (Fig. 6)

Deux évents arrières peuvent

recevoir deux canalisations distinctes de cinq pouces ou une

unique canalisation plate de dix

pouces à fixer. Ceci permet de

diriger l’air chaud et sec vers

différentes aires.

Fig. 6

ENTRETIEN

Fig. 8

Filtre à air (Fig. 7)

Le filtre à air doit être inspecté régulièrement. Si le

déshumidificateur est utilisé avec un filtre colmaté, l’efficacité

sera réduite. Pour accéder au matériau filtrant, faites

glisser le châssis du filtre vers le haut jusqu'à ce qu'il soit

sorti de la carrosserie du déshumidificateur. Inversez la

procédure pour réinstaller le filtre dans le déshumidificateur.

Fig. 7

NETTOYAGE

AVERTISSEMENT

Entreposage

Il faut tenir compte des risques de gel et de croissance biologique

avant d’entreposer le déshumidificateur. Le déshumidificateur

devrait être purgé avec un biofongicide avant l’entreposage.

Avant d’entreposer l’unité, assurez-vous que l’eau a été enlevée

du réservoir et du tuyau. Ceci permettra d’éviter les dommages

causés par le gel ainsi que la croissance biologique. Utilisez le

bouton de purge de la pompe pour enlever l’eau et les produits

chimiques biofongicides du déshumidificateur.

Empilage (Fig. 9)

Les déshumidificateurs peuvent être empilés. Les roulettes

de l’unité supérieure doivent être posées dans le berceau de

l’unité inférieure. NE PAS EN EMPILER PLUS DE DEUX.

Fig. 9

Risque de choc électrique

Débranchez l’alimentation avant le nettoyage.

Le fait de ne pas suivre ces instructions peut entraîner la mort,

un incendie ou un choc électrique.

Nettoyage externe

Utilisez une solution de détergent doux, non inflammable et

non abrasif et d’eau propre pour nettoyer le déshumidificateur. Essuyez-le bien.

Nettoyage interne

Débranchez le déshumidificateur de son alimentation électrique.

Nettoyage léger:

Enlevez le filtre à air et vaporisez de l’eau sur

le serpentin de l'évaporateur. Enlevez les deux vis supérieures

sur le capot avant.

Nettoyage en profondeur: Enlevez les deux vis supérieures sur le

capot avant. Ouvrez le capot. Vaporisez de l’eau sur les serpentins. Fermez le capot et remettez les vis en place. (Fig. 8)

8

Réparations

Toutes les fuites de fluide frigorigène doivent être réparées

par un technicien en réfrigération qualifié.

AVERTISSEMENT: Le déshumidificateur contient un système de

fluide frigorigène à haute pression et des circuits à haute tension

qui pourraient présenter un danger pour la santé et entraîner la

mort, des blessures graves et/ou des dommages matériels.

Seuls des réparateurs qualifiés devraient réparer cette unité.

ATTENTION: Ne pas faire fonctionner l’unité si le capot avant

n’est pas bien en place.

Le numéro de sériie est situé sur le dessous du déshumidificateur. Pour obtenir des informations sur l’entretien, appelez

le 1- 800-565-3548.

Page 9

DÉPANNAGE

L’unité ne fonctionne pas:

• Pourquoi pensez-vous que le déshumidificateur ne fonctionne pas?

• Est-ce que l’appareil est sous tension?

• Est-ce que le disjoncteur s’est déclenché? – Réinitialiser

le disjoncteur.

• Si l’appareil est dans un endroit humide, est-ce qu’il est

branché dans un disjoncteur de fuite de terre (DFT)?–

L’humidité excessive peut déclencher le DFT. Enlever l’appareil

de cet endroit.

• Est-ce que l’appareil est branché à une génératrice? –

Vérifiez que la sortie ne varie pas, car l’appareil ne peut pas

opérer à basse tension.

• Si vous utilisez une rallonge – Est-ce que la rallonge est du bon

calibre pour la distance nécessaire? (14 AWG jusqu’à 25pi et

12 AWG au-delà de 25pi). Note: Vérifiez la tension pendant le

démarrage de l’appareil. Le démarrage nécessitera un plus

grand courant et donc la plus grande baisse de tension. Même

si l’appareil est branché directement à une prise de courant, il

peut y avoir une baisse de tension significative. Ne jamais

assumer que la tension est correcte sans vérifier.

• Est-ce que le drainage se produit? – Vérifiez le réceptacle de

condensat. S’il est plein, le flotteur est en haut et l’appareil

ne fonctionnera pas – videz le réceptacle.

• L’interrupteur de surpression s’est déclenché. Vérifiez si le ventilateur a cessé de fonctionner ou que la température ambiante

est trop élevée. Le panneau d’affichage indique le dégivrage.

L’appareil devient glacée constamment: Notez qu’un peu de glace sur

l’évaporateur est normal, mais le passage d’air ne devrait jamais être bloqué.

• Est-ce que le ventilateur fonctionne? – Si le ventilateur ne

fonctionne pas, vérifiez le condensateur du moteur ainsi que

l’appareil du ventilateur.

• Est-ce que l’air chaud sort du devant de l’appareil? - S’il n’y a

pas d’air chaud, la température ambiante est peut-être trop

basse. Augmentez la température ambiante avec une source

externe supplémentaire.

• Est-ce que le filtre à air est propre et le passage d’air

dégagé?– Nettoyez le filtre. L’appareil devrait avoir un espace

minimum vide de 10po tout autour.

• Est-ce que l’évaporateur est sale? – Nettoyez l’évaporateur.

• Est-ce que le thermostat de dégivrage est lâche ou ne fonc-

tionne pas? – Fixez le thermostat ou remplacez-le.

• Est-ce que le thermostat de dégivrage est réglé incorrectement

ou défectueuse? – Réinitialisez le thermostat ou remplacez-le.

• Est-ce que la température ambiante est trop basse? –

Augmentez la température avec une source supplémentaire.

L’appareil accumule de l’eau, mais moins que prévu:

• La température de l’air et l’humidité relative ont baissés –

Vérifiez la température et l’humidité relative avec un

hygromètre calibré et/ou un thermostat.

• L’appareil est en cycle de dégivrage – L’appareil recommencera après le cycle.

• Filtre à air est sale ou le passage d’air est obstrué –

L’appareil devrait avoir un espace minimum vide de 10po tout

autour. Nettoyez le filtre à air et assurez un passage d’air

adéquat/espace vide autour de l’appareil.

• Est-ce que l’évaporateur est sale? – Nettoyez l’évaporateur.

• Conduits d’échappement restrictives ou déformés (si utili-

sés) – Redressez les conduits.

• Minuterie de dégivrage est réglée incorrectement –

Réinitialisez la minuterie.

• Minuterie de dégivrage est défectueuse – Remplacez la minuterie.

• La charge de réfrigérant est faible – Faites vérifiez l’appareil

par un technicien qualifié.

• Compresseur est défectueux – Faites remplacer le compresseur par un technicien qualifié car cela nécessite le recyclage

des réfrigérants.

L’appareil est en marche continuellement pendant plusieurs jours:

• L’appareil accumule beaucoup d’eau – L’humidité relative

dans l’espace est élevée.

• L’humidité ou l’eau entre dans l’espace – Trouvez la

source et arrêtez-la.

• L’appareil est trop petite pour l’espace – Utilisez un plus

grand appareil ou plusieurs appareils.

• Mauvaise circulation d’air dans l’espace – Utilisez un appareil

pour augmenter la circulation de l’air.

L’appareil fonctionne mais ne pompe pas d’eau:

• Tuyau de vidange plié ou bloqué – Redressez ou débloquez le tuyau.

• Flotteur bloqué en position fermée – Réinitialisez ou

remplacez le flotteur.

• Pompe ne fonctionne pas – Vérifiez le fonctionnement

électrique de la source externe.

• Tuyau débranché à l’interne – Rebranchez le tuyau.

• Condensateur du compresseur défectueux – Vérifiez le

condensateur.

Le ventilateur fonctionne, mais non le compresseur:

• Pompe de condensats ne fonctionne pas – Vérifiez la pompe

et le flotteur.

• Mauvaise connexion dans le circuit électrique de la pompe

– Vérifiez les connexions.

• Condensateur du compresseur défectueux – Vérifiez le

condensateur.

• Circuit électrique défectueux – Remplacez le circuit.

• Compresseur défectueux – Faites remplacer le compresseur

par un technicien qualifié.

• Minuterie de délai ou thermistance défectueuse – Vérifiez et/

ou remplacez.

• Pressostat défectueux – Vérifiez et/ou remplacez.

Le ventilateur ne fonctionne pas. Compresseur fonctionne brièvement mais en cycles (marche/arrêt):

• Condensateur du ventilateur est défectueux – Vérifiez le

condensateur.

• Mauvaise connexion dans le circuit du ventilateur – Vérifiez

les connexions.

• Ventilateur est obstrué et ne tourne pas – Enlevez l’obstruction.

• Ventilateur est défectueux – Remplacez le ventilateur.

• Circuit électrique défectueux – Remplacez le circuit.

9

Page 10

SCHÉMAS ÉLECTRIQUES

EPD150LR, EPD180CR

EPD190LR, EPD250CR

10

Page 11

GARANTIE LIMITÉE DU PRODUIT

Déshumidificateur industriel

GARANTIE – UN AN

Ce produit est garanti contre tous les défauts de pièces et de maind'oeuvre pour une période d'un an à compter de la date d’achat par

l’acheteur initial. Au cours de cette période, toutes les pièces et la

main-d'oeuvre seront fournies sans frais. Les pièces consommables

(par exemple, les ampoules électriques et les filtres) ne font l’objet

d’aucune garantie. Cette garantie n’est pas transférable.

GARANTIE SUPPLÉMENTAIRE DE SIX ANS

Les composantes du système scellé sont garanties contre les défauts

de matériaux pour la période de six ans qui suit l’expiration de la

GARANTIE D'UN AN. Les pièces seront fournies (frais de port payés

d’avance) sans frais. Les frais de main-d'oeuvre pour l’installation ne

sont pas couverts. Cette garantie n’est pas transférable.

GARANTIE À VIE SUR BOÎTIER ROTOMOULÉ

Le boîtier rotomoulé de ce produit est garanti à vie. Cette garantie

n'est pas transférable.

AVIS

1. Cette garantie ne s’applique qu’à l’acheteur initial et seulement

dans les limites des frontières du CANADA et des ÉTATS-UNIS

CONTINENTAUX.

2. La présente constitue la seule garantie offerte par le détaillant et

Fantech Limited pour le produit susmentionné et aucune autre

garantie ou condition, explicite ou implicite, ne s’appliquera, à

moins d’exclusion contraire expressément imposée par la loi.

3. L’acheteur initial devrait remplir le présent formulaire de garantie

et le conserver pour le cas où des réparations couvertes par la

garantie seraient nécessaires

4. La date de la preuve d’achat sera exigée pour les réclamations au

titre de la garantie. Veuillez conserver les actes de vente à titre

de preuve.

5. Certains États ne permettent pas l’exclusion ou la limitation des

dommages consécutifs ou indirects, de sorte que la limitation ou

l’exclusion ci-dessus pourrait ne pas s’appliquer à vous. Cette

garantie donne des droits légaux particuliers à l’acheteur et

celuici peut avoir d’autres droits qui varient d’un État à l’autre.

Pour de plus amples informations concernant ses droits,

l’acheteur peut communiquer avec le bureau de la protection du

consommateur local ou de l’État ou le secrétaire à la Justice de

l’État concerné.

DISPOSITIONS GÉNÉRALES

Aucune garantie ou assurance contenue ou exprimée dans les présentes ne s’appliquera lorsque les dommages ou le besoin de réparations

sont la conséquence d’une ou plusieurs des choses suivantes:

1. Panne d’électricité.

2. Dommages subis au cours du transport ou du déplacement de

l’appareil.

3. Alimentation électrique inappropriée (par exemple, faible tension,

câblage domestique défectueux ou fusibles inadéquats).

4. Accident, modification, mauvaises conditions de fonctionnement

ou mauvaise utilisation de l’appareil, des suites par exemple d’une

circulation inadéquate de l’air dans une pièce ou de conditions de

fonctionnement anormales (températures ambiantes extrêmement élevées ou basses).

5. Dommages par le feu ou l’eau, vol, guerre, émeute, hostilités, cas

fortuits comme les ouragans, les inondations, etc.

Pour des renseignements concernant votre garantie, contactez:

Au CANADA

Fantech

50 Kanalflakt Way,

Bouctouche, NB E4S 3M5

Phone: 800.565.3548; 506.743.9500

Fax: 877.747.8116; 506.743.9600

Aux ÉTATS-UNIS continentaux

Fantech

10048 Industrial Blvd.

Lenexa, KS 66215

Phone: 800.747.1762; 913.752.6000

Fax: 800.487.9915; 913.752.6466

email: service@fantech.net

Numéro de modèle Numéro de série

Date d’achat Nom du client

Adresse Ville

Acheté chez

11

Page 12

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

WARNING

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

ically empty the reservoir. Pressing this but-

ton allows manual emptying of the reservoir.

Press once, and the pump will operate for

20 seconds. Press and hold the button and

the pump will activate for 30 seconds.

Fig. 2

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

WARNING

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

ically empty the reservoir. Pressing this but-

ton allows manual emptying of the reservoir.

Press once, and the pump will operate for

20 seconds. Press and hold the button and

the pump will activate for 30 seconds.

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

ically empty the reservoir. Pressing this but-

ton allows manual emptying of the reservoir.

Press once, and the pump will operate for

20 seconds. Press and hold the button and

the pump will activate for 30 seconds.

Always manually purge the water reservoir

before transport or storage. Turn off the

power and allow the plugged in dehumidifier

to rest 5 minutes before the final purge.

Fig. 2

Digital Hour Counter (Fig. 3)

The counter will accumulate and display the total running hours

of the unit in 1/10 of an hour.

Hour Button (Fig. 4)

Press the HOURS button when the dehu-

midifier cannot be plugged in and the hour

meter needs to be read. The digital hour

meter will display the last saved cumulative

time for ten seconds.

Defrost Indicator (Fig. 5)

The defrost indicator will light to indicate the

dehumidifier is in defrost cycle. During this

Defrost Cycle

When ice builds up on the coils, a thermistor activates the elec-

tronic control and defrost light. The compressor is turned off by

the thermistor temperature measurement. The blower will contin-

ue to run, causing air to flow through the evaporator coil and melt

the ice. When the ice is melted, the thermistor will end the defrost

cycle and the compressor will be started.

Disconnect dehumidifier from power supply. The hour meter uses

a battery backup for display when the dehumidifier is unplugged

and the hour button is depressed. To change the battery, it is nec-

essary to remove the four (4) screws from the control panel.

Disconnect the old battery and replace with new battery. Replace

control panel and screws. Do not overtighten screws.

Fig. 3

Fig. 4

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

WARNING

Disconnect power supply before replacing battery.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Battery Replacement

Fig. 2

Fig. 4

Déshumidificateur industriel

ADVERTENCIA

Conecte a un contacto de pared de conexión a tierra de

3 terminales.

No quite la terminal de conexión a tierra.

No use un adaptador.

No use un cable eléctrico de extensión.

No seguir estas instrucciones puede ocasionar la muerte, incen-

dio o choque eléctrico.

Requisitos eléctricos

Para operar el deshumidificador a 115V, es preciso el uso de

un enchufe normal con toma de tierra y circuito de 15 amp.

Es preciso utilizar un interruptor de escape a tierra si la unidad se va utilizar en un área especialmente húmeda.

Sistema integrado de seguridad eléctrica

Para proporcionarle mayor seguridad, este electrodoméstico

está fabricado con una clavija con toma a tierra incluida en

el cable de toma de corriente. El cable debe enchufarse a un

receptáculo de corriente adecuado y con toma a tierra. Un

electricista acreditado deberá instalar un enchufe con toma

de tierra si no dispone de uno. No corte ni elimine la patilla

de toma a tierra de la clavija si ésta viniera incluida en el

equipo. Le recomendamos que el circuito eléctrico o enchufe

opere bajo un cortacircuitos o fusible aparte.

En caso de que necesite un cable de extensión, el cable

deberá contar con conductores de calibre mínimo de 14

gauge si es de 25 pies o más corto, y de calibre 12 gauge

si es más largo de 25 pies (sección de 3.31 y 2.08

milímetros cuadrados respectivamente).

Extracción de agua

El deshumidificador incluye una bomba interna de condensación

que elimina el agua sustraída del aire. Este sistema permite

evacuar el agua hasta a 20 pies de distancia utilizando la

manguera incluida. En caso de que necesite evacuar el agua a

una distancia mayor a 20 pies, deberá instalar otra bomba

capaz de evacuar el agua a partir de este punto. La bomba de

condensación evacua el agua de manera automática cada

cuatro minutos y durante 20 segundos.

FUNCIONAMIENTO

Coloque el deshumidificador en el área en la que quiera reducir

la humedad. Compruebe que las puertas y ventanas están

cerradas al exterior, y aísle la zona húmeda de cualquier otra

zona no afectada. Introduzca la manguera de condensación en un

desagüe o en un contenedor de grandes dimensiones. Presione

el interruptor On/Off para activar el deshumidificador. (Fig. 1)

Botón de corriente (Fig. 1)

Puede prender o apagar el deshumidificador

apretando el botón de corriente. El indicador

mostrará la cantidad acumulada de horas de

uso una vez comience a operar.

12

Peligro de Choque Eléctrico

Fig. 1

Botón de la bomba de evacuación (Fig. 2)

En situaciones normales de funcionamiento, la bomba vaciará el recipiente

contenedor de manera automática.

Puede presionar este botón si desea

evacuarlo de manera manual. La bomba

funcionará durante 20 segundos si lo

presiona una vez. Si lo presiona dos veces, operará durante 30

segundos.

No olvide evacuar manualmente todo el agua del

Fig. 2

recipiente siempre que vaya a almacenar o transportar el

aparato. Apáguelo y manténgalo conectado durante 5 minutos

antes de evacuar el agua del aparato por última vez.

Contador digital de horas de uso (Fig. 3)

El contador le mostrará la cantidad total de horas acumuladas de operación con una exactitud de un 1/10 de hora.

Fig. 3

Botón de horas (Fig. 4)

Presione el botón HOURS cuando no

pueda enchufar el deshumidificador

pero quiera comprobar el total de

horas acumuladas. El indicador le

mostrará durante 10 segundos la

última cantidad guardada.

Fig. 4

Cambio de la batería

AVERTISSEMENT

Peligro De Choque Eléctrico

Desconecte de la toma de corriente antes de sustituir la batería.

No seguir estas instrucciones podría provocar incendios, descar-

gas eléctricas, e incluso la muerte.

Desconecte el deshumidificador de la toma de corriente. El indicador de horas de operación utiliza una batería para que pueda ser

operativo si el aparato no está enchufado y se presiona el botón

de horas. Para cambiar esta batería, tendrá que desatornillar los

cuatro (4) tornillos del panel de instrumentos. Desconecte la

batería agotada y sustitúyala por una nueva. Vuelva a colocar el

panel de instrumentos y los tornillos, sin apretarlos en exceso.

Ciclo de deshielo

Un termistor activa el control electrónico y el indicador luminoso

de deshielo cuando existe acumulación de hielo en los serpentines.

El sistema de medición de temperatura del termistor apaga el

compresor. El ventilador seguirá funcionando, y el aire pasará por

el serpentín de evaporación hasta derretir el hielo. Una vez el hielo

se haya derretido, el termistor finalizará el ciclo de deshielo y se

reiniciará el funcionamiento del compresor.

Indicador de deshielo (Fig. 5)

El indicador de deshielo se iluminará

cuando el deshumidificador esté en un

ciclo de deshielo. El compresor no

funciona durante este periodo.

Fig. 5

Page 13

Ventilación / tubos de

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

WARNING

Pump Purge Button (Fig. 2)

In normal operation, the pump will automat-

ically empty the reservoir. Pressing this but-

ton allows manual emptying of the reservoir.

Press once, and the pump will operate for

20 seconds. Press and hold the button and

the pump will activate for 30 seconds.

Fig. 8

Fig. 8

ventilación (Fig. 6)

El aparato cuenta con dos orificios que permiten la instalación

de dos tubos individuales de 5

pulgadas (12.7 cm.), o de uno

solo de 10 pulgadas plano (25.4

cm.). De este modo se

puede dirigir el aire caliente

a zonas diferentes.

Fig. 6

MANTENIMIENTO

Filtro del aire (Fig. 7)

Debe comprobar el estado del filtro del aire con frecuencia.

Si opera el deshumidificador con un filtro taponado reducirá

su eficiencia. Puede pasar una aspiradora por el filtro para

eliminar el polvo. Para acceder al medio del filtro, deslice el

marco del filtro hacia arriba hasta extraerlo por completo del

aparato. Quite el medio del filtro de la parte trasera del

marco y pase una aspiradora. Haga el proceso a la inversa

para instalar el filtro y el marco en el deshumidificador.

Déshumidificateur industriel

Fig. 8

Almacenamiento

Considere posibles condiciones de congelación o de formación de

microorganismos antes de plantearse el almacenamiento del

deshumidificador. Debería rociar el deshumidificador con un biofungicida antes de almacenarlo. Recuerde que debe comprobar

que todo el agua ha sido extraída del receptáculo y de la

manguera para evitar daños producidos por temperaturas bajo

cero y para prevenir formación de microorganismos. Utilice el

botón de la bomba de evacuación para extraer el agua y químicos

biofungicidas del aparato.

Colocación en vertical (Fig. 9)

Puede apilar los deshumidificadores uno encima del otro. Las ruedas de la unidad que se coloque encima deberán apoyarse en los

huecos de la unidad colocada abajo. NO APILE MÁS DE DOS UNIDADES

Fig. 9

LIMPIEZA

Desconecte la toma de corriente antes de limpiar.

No seguir estas instrucciones podría provocar incendios, descar-

gas eléctricas, e incluso la muerte..

Limpieza del exterior

Utilice una solución de jabón suave, no abrasivo ni inflamable y agua

limpia para limpiar el deshumidificador. Pase un trapo para secarlo.

Nettoyage interne

Desconecte el deshumidificador de la toma de corriente.

Limpieza ligera:

evaporador con agua. Desatornille los dos tornillos de la parte

superior de la cubierta frontal.

Limpieza profunda: Desatornille los dos tornillos de la parte superior

de la cubierta frontal. Abra la cubierta. Rocíe los serpentines con

agua. Cierre la cubierta y vuelva a colocar los tornillos (Fig. 8))

Fig. 7

ADVERTENCIA

Peligro de Choque Eléctrico

Saque el aire del filtro y rocíe el serpentín

Servicio

En caso de que se produzca una fuga de líquido refrigerante

deberá contactar con un técnico cualificado en refrigeración.

ADVERTENCIA: El deshumidificador utiliza un sistema de líquido

refrigerante de alta presión y un circuito eléctrico de alto voltaje

que podrían resultar en daños materiales, peligro para la salud,

lesiones corporales graves, e incluso la muerte. Sólo personal

cualificado debe dar servicio a esta unidad.

PRECAUCIÓN: No utilice la unidad hasta haber asegurado la

cubierta frontal en posición cerrada.

La placa serial está situada en el superficie inferior del

deshumidificador. Consulte con el número 1-800-565-3548

para másinformación sobre servicio.

13

Page 14

GARANTÍA LIMITADA DE PRODUCTO

Deshumidificador industrial

GARANTÍA DE UN AÑO

Se garantiza este producto contra defectos de fabricación y materiales

por un periodo de un año a contar a partir de la fecha de compra del

comprador original. Todas las partes y la mano de obra estarán cubiertas sin coste alguno durante este periodo. Las partes de reemplazo

habitual (bombillas y filtros, por ejemplo), no están cubiertas por la

garantía ni se garantizan durante periodo de tiempo alguno. Esta

garantía no puede transferirse.

GARANTÍA ADICIONAL DE SEIS AÑOS

Durante un periodo de seis años a contar desde la finalización de la

GARANTÍA DE UN AÑO, los componentes del sistema precintado

están cubiertos en caso de que las piezas mostraran algún defecto. Se

entregarán las piezas de manera gratuita (tras prepago de costos de

envío). Los costes de mano de obra para la instalación no están cubiertos por la garantía. Esta garantía no puede transferirse.

GARANTÍA DE POR VIDA EN LA CAJA ROTOMOLDEADO

La caja rotomoldeado de este producto cuenta con una garantía de por

vida. Esta garantía no es transferible.

AVISO

1. Esta garantía es válida solamente para el comprador original y

dentro de las fronteras de Canadá y la parte continental de

Estados Unidos.

2. Esta es la única garantía del vendedor y de Fantech Limited para

el producto mencionado arriba. Ningún otro tipo de garantía o

condición, explícita o implícita, será aplicable, excepto en casos

específicamente excluidos por ley.

3. El comprador original deberá completar el formulario de garantía

y conservarlo para poder utilizarlo en caso de que sea preciso dar

servicio al producto.

4. Para cualquier reclamación de garantía será preciso contar con

una prueba de compra con fecha. Recuerde guardar el recibo

como comprobante de venta.

5. En algunos estados no se permite la exclusión o limitación de

daños consecuentes o secundarios; en estos casos, la limitación

anterior podría no aplicar a su caso. Esta garantía ofrece derechos legales específicos; el comprador puede contar con otros

diferentes dependiendo del estado. Si necesita más información

sobre los derechos legales del comprador, puede consultar con la

oficina del consumidor local o estatal, o con el fiscal de su estado.

PROVISIONES GENERALES

La garantía o seguro contenidos o establecidos aquí no serán aplicables cuando el daño o la reparación consecuentes sean resultado

de alguno de los siguientes:

1. Fallo del suministro eléctrico.

2. Daños durante el transporte o traslado del electrodoméstico.

3. Suministro eléctrico inadecuado del tipo voltaje bajo, cableado

deficiente en la casa o fusibles no adecuados.

4. Accidente, alteración, abuso o mal uso del electrodoméstico del

tipo circulación de aire inadecuado en el cuarto, o condiciones

anormales de operación (temperaturas demasiado altas o

demasiado bajas en el cuarto).

5. Fuego, agua, daño, robo, guerra, disturbios, hostilidades, casos

de fuerza mayor del tipo huracanes, inundaciones, etc.

Para obtener información relativa a la garantía, comuníquese con:

En CANADA

Fantech

50 Kanalflakt Way,

Bouctouche, NB E4S 3M5

Phone: 800.565.3548; 506.743.9500

Fax: 877.747.8116; 506.743.9600

En Estados Unidos continental

Fantech

10048 Industrial Blvd.

Lenexa, KS 66215

Phone: 800.747.1762; 913.752.6000

Fax: 800.487.9915; 913.752.6466

email: service@fantech.net

Número del modelo Número de serie

Fecha de compra Nombre del cliente

Adresse Ciudad

Comprado en

14

Page 15

15

Page 16

Distributed by:

United States

10048 Industrial Blvd.

Lenexa, KS 66215

Phone: 800.747.1762; 913.752.6000

Fax: 800.487.9915; 913.752.6466

www.fantech.net; info@fantech.net

16

Canada

50 Kanalflakt Way,

Bouctouche, NB E4S 3M5

Phone: 800.565.3548; 506.743.9500

Fax: 877.747.8116; 506.743.9600

Fantech reserves the right to modify, at any time and without notice,

any or all of its products’ features, designs, components and specifications to maintain their technological leadership position.

Item #: 405037

Rev Date: 071111

Loading...

Loading...