Page 1

IMPORTANT - PLEASE READ THIS MANUAL

BEFORE INSTALLING UNIT

CAUTION - Before installation, careful consideration must be

given to how this system will operate if connected to any other

piece of mechanical equipment, i.e. a forced air furnace or air

handler, operating at a higher static pressure.

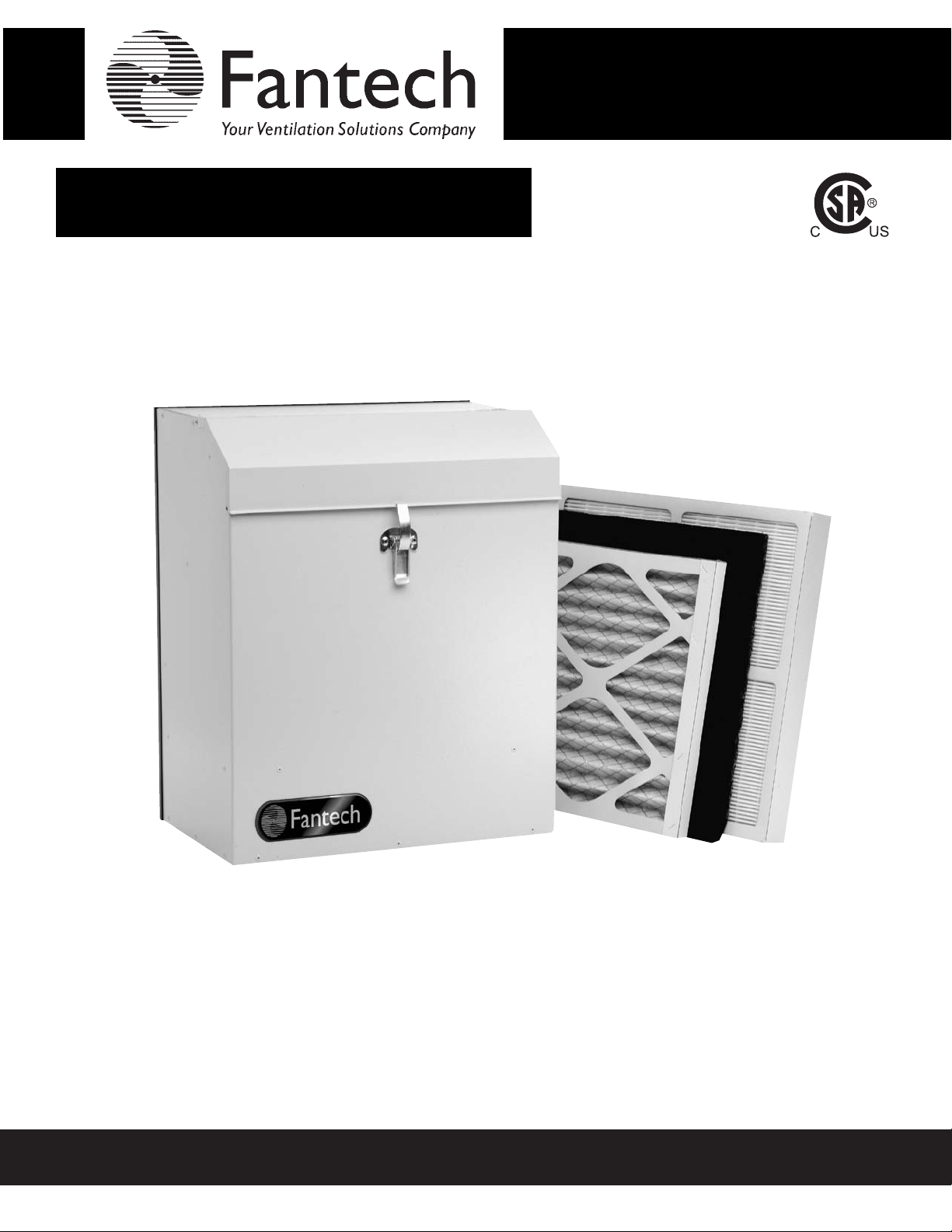

HEPA DM 3000P

Air Filtration System

Your Fantech HEPA Filtration system should be installed in conformance with the appropriate local, provincial or

state requirements or in the absence of such requirements with the current edition of the National Building

Code, and / or ASHRAE’s “ Good Engineering Practices”.

HEPA Filtration

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Page 2

TABLE OF CONTENTS

WARRANTY

SPECIFICATION.......................................................................................................................... .............................................................2

INSTALLATION ........................................................................................................................................................................................7

SERVICE.................................................................................................................................................................................................8

TROUBLESHOOTING................................................................................................ ................................................................................8

WARRANTY

The Best Limited Warranty in the Business

• The maintenance free motors are permanently lubricated and are guaranteed for 7 years. They are factory balanced to prevent vibrations and

promote silent operation.

• All other components have a 5 year limited warranty. (filters not included)

• The limited warranty covers normal use. It does not apply to any defects, malfunctions or failures as a result of improper installation, abuse,

mishandling or misapplication, fortuitous occurrence or any other circumstances outside manufacturer's control.

• The warranty is in effect for 5 years on parts and 7 years on the motor after the date of purchase, including parts replaced during this time

period. If there is no proof of purchase available, the date associated with the serial number will be used for the beginning of the warranty

period. Parts are a 1 year warranty when replaced after the initial warranty has expired.

• This warranty is the exclusive and only warranty in effect and all other warranties either expressed or implied are invalid.

• Warranty from the manufacturer is for parts only and does not include labor or shipping to service or repair them.

INTRODUCTION

HEPA AIR FILTRATION SYSTEMS

Congratulations! You have purchased a very effective air cleaning and treatment system incorporating HEPA (High Efficiency Particulate

Arrestance) filter technology. This is the type of air cleaning equipment that respiratory specialists recommend most.

To optimize the performance of your HEPA Filtration System, it should be installed by a professional contractor who is familiar with your indoor

air quality situation and the operation of other heating, ventilation and air conditioning equipment that you may have.

INTRODUCTION

SPECIFICATION

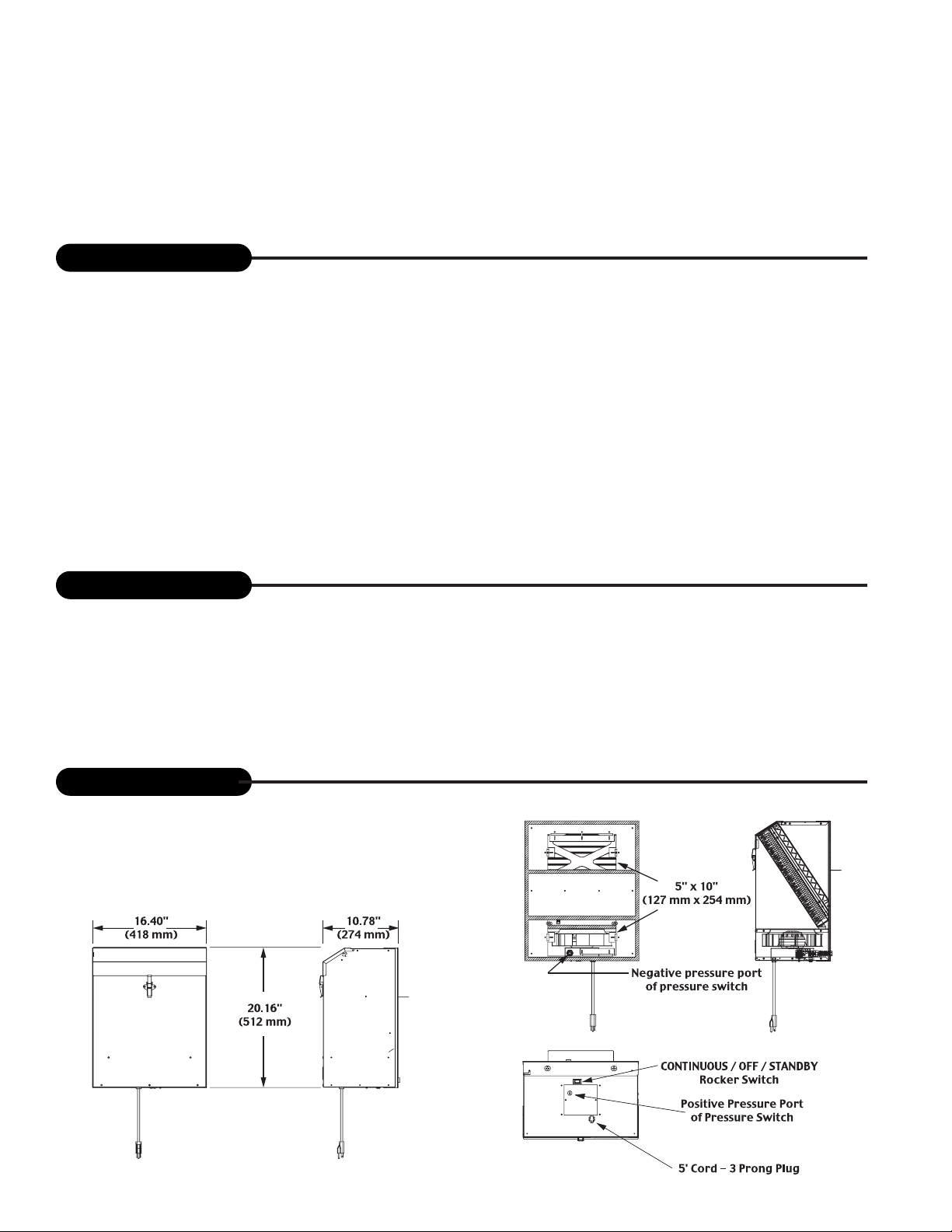

Model DM 3000P - Duct Mounted

Kit (Included): - installation manual

Page 3

Airflow

REMOVE TEMPLATE FROM MANUAL

Direction

de l’air

1. Using enclosed template,

draw holes on duct.

1. Utiliser le gabarit pour

localiser les trous à percer

dans le conduit.

Direction

de l’air

Airflow

CUT AROUND DOTTED LINE

3. Screw mounting plate to

duct.

3. Visser la plaque de distribu-

COUPER AUTOUR LIGNE POINTILLÉE

tion au conduit en repliant les

bords affaiblis de façon à faire

un “sandwich” avec le conduit.

Page 4

Direction

de l’air

Airflow

2. Cut holes in duct.

2. Découper les trous.

COUPER AUTOUR LIGNE POINTILLÉE

CUT AROUND DOTTED LINE

Direction

de l’air

Airflow

4. Attach unit to mounting

plate with screws.

4. Attacher l’unité à la plaque

en prenant soin de la glisser

dans les fentes conçues à cet

effet.

Page 5

OPERATION

Your Fantech HEPA filtration system incorporates three stages of filtration. Air is drawn from the house via one of the installation examples,

found in this manual, by a powerful efficient EBM fan. The air is cleaned as it passes through the filters, where it is then reintroduced back into

the home, cleaned of the majority of harmful particles.

The DM3000P includes a differential pressure switch. When rocker switch is set to "STANDBY" the DM3000P will remain OFF until the pressure switch detects airflow in the forced air system's duct. As airflow is detected, the DM3000P is turned ON. When the rocker switch is set

to "CONTINUOUS" the DM3000P will operate continuously irregardless of the forced air system's operation. Finally, when the rocker switch is

set to "OFF" all power to the DM3000P is disengaged.

Note: A semi-annual service schedule must be followed to ensure the HEPA unit is operating at its full potential.

* Diagrams are examples only. Actual installation may vary.

DM 3000P - Duct Mounted model

The return side of the furnace is the recommended location for the

HEPA to connect to.

IMPORTANT NOTICE:

1) The DM3000P should not be installed on its side. Should only be

installed like Option A & B.

2) Variable speed forced air systems or installation where the pressure difference between the return air and supply air ducts are

less than 18 Pa (0.07 in wg) may not provide the required differential pressure to activate the DM3000P when set on "STANDBY".

The only remedy is to set the DM3000P on "CONTINUOUS" mode.

DM 3000P - (installation instructions)

1. Using mounting plate, mark holes on

furnace return duct to be cut.

Airflow

• First drill a 1/4" to 5/16" diameter hole in the duct wall on the

supply air side of the furnace duct. Carefully insert the grommet

into the hole. (Drilling a metal duct may produce burrs. Be careful not to cut or pricked by the burrs or the duct.) Make a mark

a distance of1/2" from one end of the tubing. Slide this end of

the tubing through the center of the gr

illustrated.

2. Cut holes in desired location and

attach mounting plate to duct with

screws.

3. Make sure the negative static pressure tube from the pressure switch

is inserted into the return air duct

properly. The end of the tube should

be clear of any insulation or other

obstacles.

4. Attach HEPA unit to mounting plate

with screws.

5. Installing Grommet and Tubing

ommet up to the mark as

INSTALLATION

Option A

ter carefully then insert the carbon filter. Close and latch the

access door.

8. Switch rocker switch to "ST

ANDBY" or "CONTINUOUS".

Option B

6. Connect the other end of tube you connected to the supply air duct

to the positive port of the pressure switch located on the electrical

panel and marked "Pressure Switch"

7. Open the access door of the DM3000P and remove the carbon filter and the HEPA filter that are sealed in a plastic bag. Remove the

plastic bag and dispose of them appropriately. Insert the HEPA fil-

Page 6

SERVICE

The useful service life of the filter media in the HEPA Filtration System is directly related to the volume of air passed through the system and the

amount of contaminants in the air. In a typical residential application, Stage 1 and 2, filters should be replaced every three to six months or when

needed. The Stage 3 HEPA filter should have a life span of two to five years, again, depending on the amount of particulate in the air and the maintenance of the Stage 1 pre-filter.

PARTS LIST

Stage 1 - Prefilter: Air passes through the prefilter where larger particles are taken

out of the air. (part number 410472)

Stage 2

- Carbon: Air passes through the carbon filter where some gases and odors

are removed. (part number 410473)

Stage 3

- HEPA: Air passes through the certified HEPA media where very small par-

ticles are removed. 99.97% of all particles 0.3 microns and larger that

pass through this stage are removed. Particles smaller than 0.3 microns

are also removed with less intensity.

If the air flow through your unit is noticeably reduced, you can inspect the

HEPA filter by removing it and seeing if the filter paper is darkened on the

inlet or outer side. If it is, the filter cartridge should be replaced. (part

number 410985)

Please contact your local Fantech dealer or call HEPA Customer Service at

1.800.565.3548 regarding replacement of filter media, warranty information or if you have any questions or

concerns about the performance of your HEPA Filtration System.

Replacement parts number for motor (410035)

and for capacitor (410040).

TROUBLESHOOTING

A) Problem: When the DM3000P is on "STANDBY" it does not come ON.

1) The pressure switch's positive pressure port is not connected.

Solution: Use the supplied tube and grommet and install one end of the tube to the supply (positive pressure) air duct and the other

end of the tube to the pressure switch connection on electrical panel next to the power cord.

2) The pressure differential between the return (negative) air and the supply (positive) air of the forced air system is less than 18

Pa (0.07 in wg).

Solution: Check the static pressure difference by connecting the LOW pressure side of a manometer to the return air duct and the

HIGH pressure side of the manometer to the supply air duct. If it reads less then 18 Pa (0.07 in wg), the pressure switch will not

work. The only remedy is to set the rocker switch to "CONTINUOUS". Check this differential pressure on all available speeds of the

forced air system.

oblem: When the DM3000P is on "STANDBY" it does not turn OFF.

B) Pr

1) Other exhaust equipment in the house may interfere with the operation of the DM3000P by creating pressure differences in the

forced air system's duct work.

Solution: If this is a constant problem, disconnect the positive pressure tube from the DM3000P to the supply air duct. Check if

the DM3000P turns ON when the forced air system is on and turns OFF when the forced air system is OFF.

Depending on the furnace and the duct design, the negative static pressure in the duct may not be more than 17Pa (0.07"WC). As such, the

pressure switch will not activate the DM3000P while it is on "STANDBY" mode.

United States

1712 Northgate Blvd.,

Sarasota, FL. 34234

Phone: 800.747.1762; 941.309.6000

Fax: 800.487.9915; 941.309.6099

www.fantech.net; info@fantech.net

Canada

50 Kanalflakt Way,

Bouctouche, NB E4S 3M5

Phone: 800.565.3548; 506.743.9500

Fax: 877.747.8116; 506.743.9600

www.fantech.ca; info@fantech.ca

Fantech, reserves the right to modify, at any time and without notice, any

or all of its products’ features, designs, components and specifications to

maintain their technological leadership position.

Article #: 301085

Item #: 401451

Rev Date: 092404

Loading...

Loading...