Page 1

fantech

Installation and Operation Manual

Manuel d'installation et d'opération

DBF 4XLT

Dryer Booster Fan

Ventilateur d'appoint pour sécheuse

DBF4XLT Kit Includes:

Dryer Booster Fan, 1 pc

Fan Mounting Bracket and Hardware, 1 pc

Indicator Panel w/ 50' (15.4 m) of cable, 1 pc

FC4 Duct Clamp, 1 pc

Tubing & Grommet, 1 pc

Item #: 401456

Rev Date: 2015-05-27

La trousse du DBF4XLT inclus:

Ventilateur d'appoint pour sécheuse, 1 pc

Support de montage du ventilateur avec matériel, 1 pc

Panneau indicateur avec câble de 50pi (15.4 m), 1 pc

Brides de xation FC4, 1 pc

Tuyau et oeillet, 1 pc

United States / États-Unis

10048 Industrial Blvd., Lenexa, KS, 66215

Tel.: 800.747.1762 • Fax: 800.487.9915

Canada

50 Kanalflakt Way, Bouctouche, NB, E4S 3M5

Tel.: 800.565.3548 • Fax: 877.747.8116

Page 2

2

Note Warning /

Information Technical

Important

note

Read and Save these instructions

for future reference.

This unit has rotating parts and safety precautions should be exercised

during installation, operation and maintenance.

CAUTION: "For General Ventilation Use Only. Do Not Use To Exhaust

Hazardous Or Explosive Materials And Vapors."

CAUTION: Do not install less than 5 linear feet (1.52 linear meters) from

clothes dryer exhaust outlet.

CAUTION: Do not exhaust air in excess of 167°F (75°C).

CAUTION: Do not install in an exhaust ductwork of a clothes dryer whose

instructions prohibit the installation of a clothes dryer

booster fan.

CAUTION: Insulated dryer duct shall not be used upstream of the

ventilator.

CAUTION: The ventilator must be used in conjunction with high output

dryers.

Practical tip

information

Warnings

DO NOT CONNECT POWER SUPPLY UNTIL FAN IS COMPLETELY INSTALLED.

The DBF4XLT is provided with a 120VAC power cord.

1. WARNING! TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS - OBSERVE THE FOLLOWING:

a. Use this unit only in the manner intended by the manufacturer. If

you have questions, contact the factory.

b. Before servicing or cleaning, unplug power cord or switch power off

at service panel and lock service panel to prevent fan from being

switched on accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent warning device, such

as a tag, to the service panel.

c. Installation work and electrical wiring must be done by qualified

person(s) in accordance with all applicable codes and standards,

including fire-rated construction.

d. The combustion airflow needed for safe operation of fuel burning

equipment may be affected by this unit's operation. Follow the

heating equipment manufacturer's guidelines and safety standards

such as those published by the National Fire Protection Association

(NFPA), the American Society of Heating, Refrigeration, and Air

Conditioning Engineers (ASHRAE) and the local code authorities.

e. When cutting or drilling into wall or ceiling, do not damage

electrical wires or other hidden utilities.

f. Ducted fans must always be vented to the outdoors.

CAUTION: Do not install in an exhaust ductwork where the equivalent duct

length is < 25 feet (7.62 meters). The DBF4XLT is suitable to

overcome an equivalent duct length of 130 feet (40 meters) of

4 inch diameter galvanized steel duct, and to maintain a air

velocity of 1200fpm (6.10 m/s).

CAUTION: A secondary lint trap must be installed between the clothes

dryer and the clothes dryer booster fan if the booster fan is

located less than 15 linear feet (4.6 linear meters) from the

exhaust of the clothes dryer.

fantech

2. If a visual error indicator is activated, do not operate the clothes

dryer. See section in this instruction manual titled “Error

Indications”.

Page 3

Installation Guidelines

TO PREVENT THE POSSIBILITY OF DRYER FAN CAVITATION AND/OR EXHAUSTING EXCESS HEAT REQUIRED FOR THE DRYING CYCLE AND

COMPROMISING DRYING TIMES, BOOSTER FAN AIRFLOW MUST NOT EXCEED THE DRYER FAN CAPACITY.

Calculating Duct Run

To calculate the length of your planned duct run, measure from the dryer to external venting point in roof or wall. For each bend or elbow add 5-7

feet to your total duct run calculations. The DBF4XLT can be used on runs up to 130 feet.

Fan and Switch Mounting

The DBF4XLT is to be mounted a minimum of 5 linear (not equivalent)

feet from the dryer outlet. Exception: A secondary lint trap can be used

where required and in applications where excessive dryer lint generation

is likely or to increase the time interval between routine maintenance of

the Dryer Booster Fan. (See illustration on next page). An MB mounting

bracket (included) attached to a rafter or joist should be used to stabilize

the fan. Although not recommended, a vertical rigid duct may support

the fan if the duct is securely stabilized. (Consult local codes prior to

supporting the fan in the duct alone.) The duct work to the inlet of the

DBF4XLT is to be attached with the FC4 clamp (included) to permit

periodic inspection of the blower. Refer to maintenance instructions for

inspection recommendations. All duct connections should be properly

sealed to prevent leakage and loss of fan performance. Flex duct (if

allowed by building codes) should be stretched as smooth as possible.

DBF4XLT

FC Mounting

Clamps (optional)

3

Indicator Panel

The DBF4XLT is equipped with a remote mounted low voltage operation

indicator panel. This panel contains an LED that will indicate proper

operation of the booster fan. In the event of a problem with the system,

it will indicate the nature of the problem.

Pressure Sensor Switch

Operation

The DBF4XLT contains a positive pressure sensing switch which

recognizes dryer operation and activates the booster fan from an

independent electrical circuit. This eliminates connections through the

dryer circuit which may void the manufacturers’ warranty as well as

manual systems which require the attention of the operator or costly

current/temperature sensing systems.

Power to the booster fan is connected in series through a normally open

terminal on the switch. A pressure tap is connected to a nipple on the

side of the switch. When the dryer begins operation, positive pressure in

the duct causes the switch diaphragm to expand closing the circuit to

the booster fan. An integral delay-on-break timer in the switch will cycle

the fan on for intervals of 10 minutes. Cycle will reinitiate after a few

seconds as long as the dryer is operating. This will continue until the

dryer has stopped and the timer delay period has lapsed. Drying cycles,

the booster fan, the delay timer and the pressure switch are not

adversely affected by the starting/stopping intervals.

Alternate Location

Secondary Lint Trap

fantech

Page 4

4

DBF4XLT Fan/Switch Installation Instructions

Indicator Panel Installation

Step 1. Selecting Panel Location

The DBF4XLT indicator panel mounts near the dryer in a location that will be visible to the

operator of the dryer. The indicator panel is supplied with 50 feet of cable. Ensure that the

indicator panel and booster fan are located to allow their connection with this cable.

Step 2. Wiring and Mounting Panel

The indicator panel is a low voltage device that is not required to be installed in an electrical

junction box. If provided with clearance for the cable and terminal block it can be mounted to a

wall using appropriate fasteners.

If installer chooses to mount indicator panel in a single gang junction box (by others), it should not

be installed in a box that contains line voltage wiring or devices.

On the end of the 50 foot cable with stripped wires connect red wire to the positive (+) position

of the terminal block on the indicator panel. Connect black wire to the negative (-) position of the

terminal block on the indicator panel.

Fan Installation

Step 1. Selecting Fan Location

The indicator panel is supplied with 50 feet of cable. Ensure that the indicator panel and boost

fan are located to allow their connection with this cable.

Fan must be mounted a minimum of 5 linear feet from the dryer outlet. In order to perform

recommended maintenance, fan location should allow sufficient access for service. Refer to

dimensional drawings shown on the next page.

NOTE: Steps 2 & 3 may be reversed.

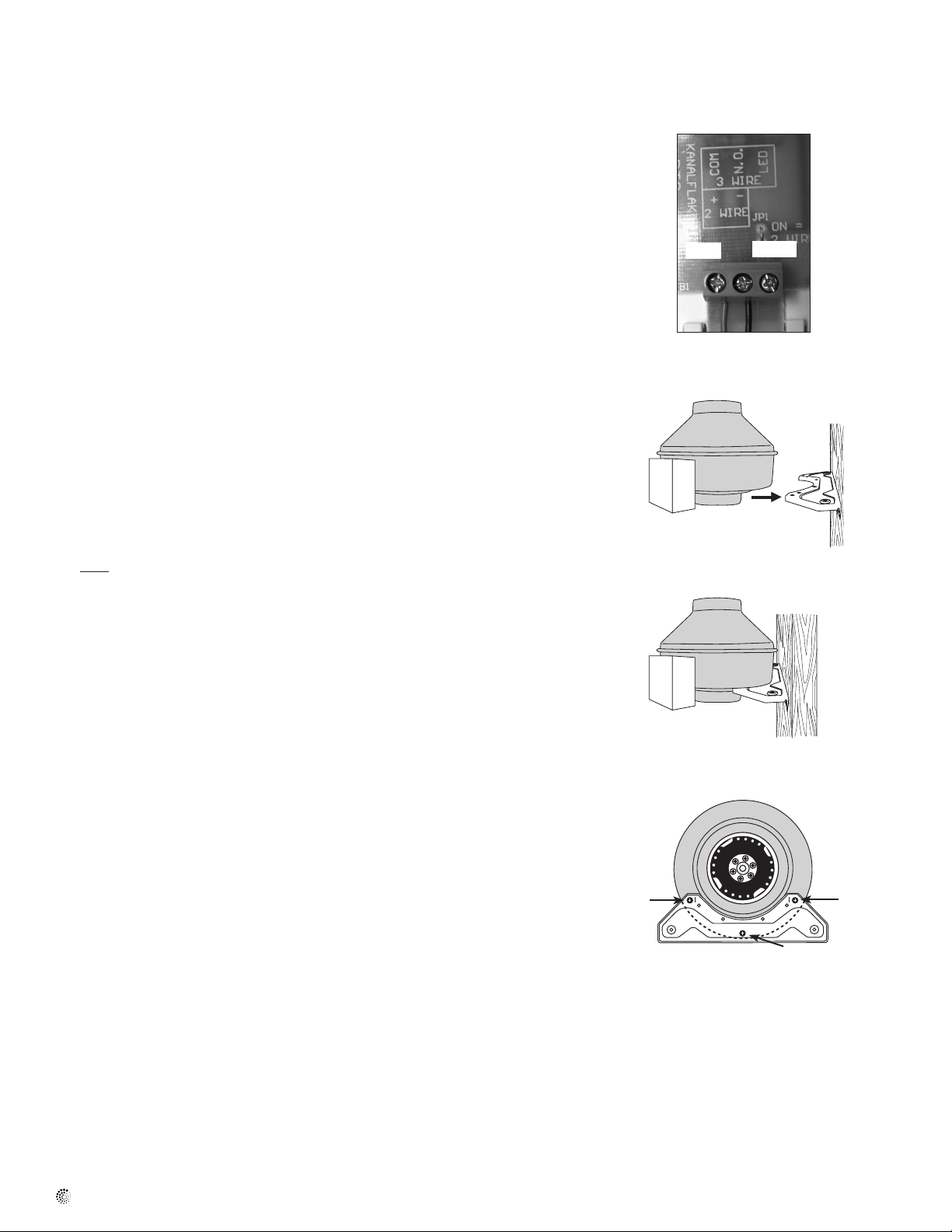

Step 2. Mount Bracket

Using the 3/4" wood screws provided, attach the mounting bracket to a support beam at the

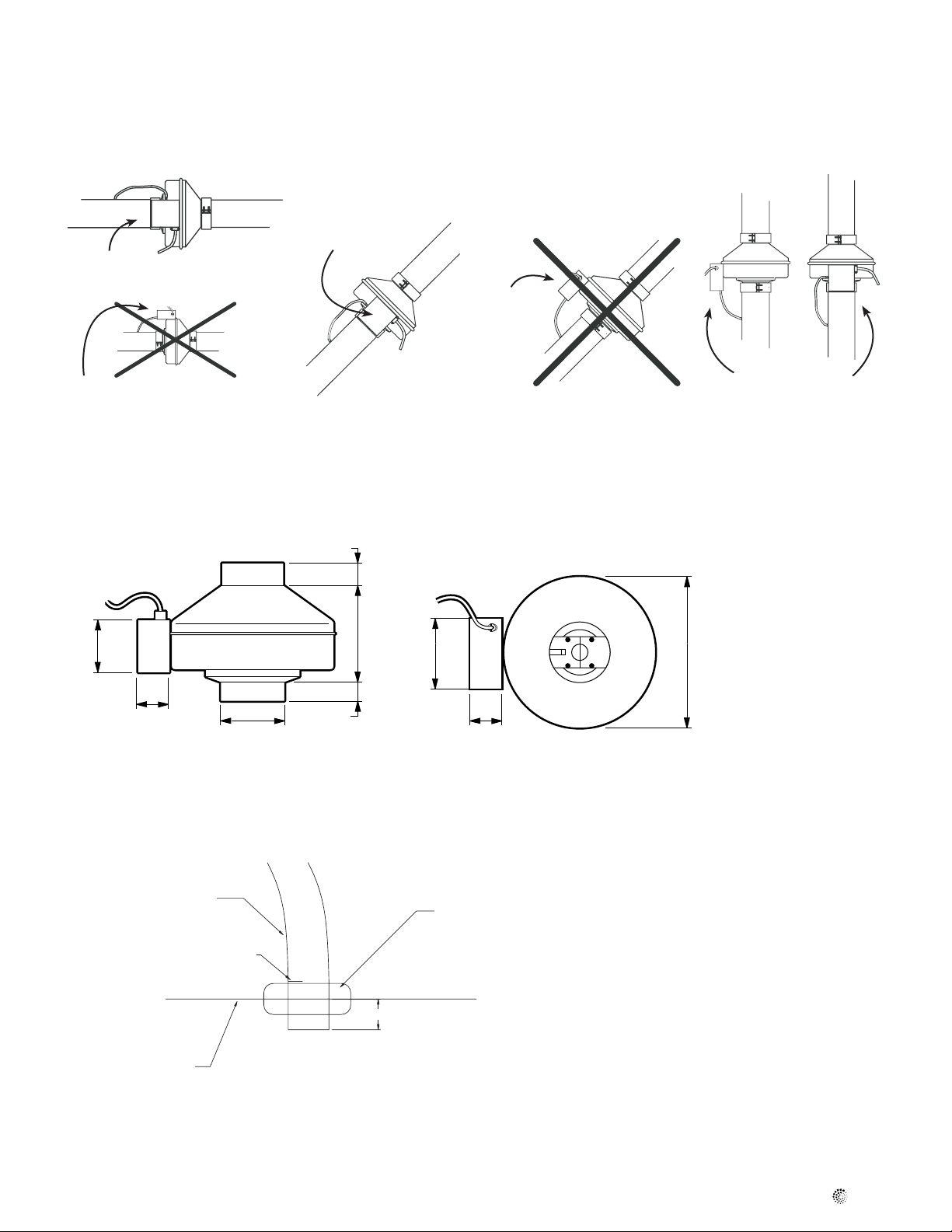

selected location. Fan mounting can be done at any angle (see illustrations on the top of the next

page), however, vertical mounting is recommended to reduce condensation buildup in the fan. If a

horizontal installation is necessary and condensation buildup may pose a problem, a 1/4" hole

drilled in the bottom of the housing (along with an NPT insert (by others) and drain tubing) may be

installed to allow condensation to drain.

RED

BLACK

Mount Bracket

(use 3/4" long wood screws)

Mount Fan

(use 1/2" long self tapping screws)

Step 3. Mount Fan

For proper operation, the control box (located on the fan) needs to be positioned properly.

Illustrations on the top of the next page show the correct control box position for fans that are

mounted horizontally, vertically and at an angle. The control box should also be positioned to provide access to the indicator panel wiring and the tubing connections. Attach fan to the mounting

bracket with the self tapping 1/2" screws provided. Care should be taken not to strip the housing.

Although screw pilot holes are not required, 3/32" (or smaller) pilot holes are recommended.

Step 4. Connect Indicator Panel Cable

Connect the end of the 50 foot cable that has a two position connector to the receptacle located

on the dryer booster fan control box.

fantech

Mounting Bracket and

Screw Locations

(using the wrong length screws

will damage the fan impeller)

Page 5

1/4" Max.

Duct Wall

Grommet

Tubing

1/2" Mark on Tubing

Pressure Switch Positioning

1

1

2

2

9

3

/

4

3

3

/

4

6

15

/

16

3

7

/

8

3

7

/

8

Correct Switch Positioning - Diaphragm Positioned Vertically

5

Horizontal Duct

Correct Control Positioning

Incorrect Control Positioning

Dimensions

Correct Control

Positioning

Angled Duct

Incorrect

Control

Positioning

Vertical Duct

Control Correct

in all Positions

All dimensions in inches,

Step 5. Installing Grommet and Tubing

Do not connect tubing in such a manner as to allow

Tubing

Grommet

condensation from the duct to collect in the tubing.

First, drill a 5/16 inch to 3/8 inch diameter hole in

1/2" Mark on Tubing

the duct wall. Carefully insert the grommet into the

hole. (Drilling a metal duct may produce burrs. Be

careful not to be cut or pricked by the burrs or the

1/4" Max.

duct.) Next, force one end of the tubing over the

nipple on the control. Make a mark a distance of 1/2

Duct Wall

inch from the other end of the tubing. Slide this end

of the tubing through the center of the grommet up

to the mark as illustrated.

fantech

Page 6

6

Recommended Maintenance

1. Since fan bearings are sealed and provided with an internal lubricating material, no additional lubrication is necessary.

2. Fan impeller may accumulate lint. Periodic inspection, based upon dryer usage, should be performed to ensure that the fan impeller is not

obstructed or loaded with lint. Under normal conditions, fan should be inspected a minimum of every Six (6) Months. Note: Excessive booster fan

noise or vibration may be an indication of lint buildup on the impeller. To inspect and clean the impeller:

a. Disconnect the incoming power supply at the source.

b. Remove the duct from the fan inlet and remove any lint buildup on the impeller.

c. Reconnect the duct to the fan. Turn power supply on.

Troubleshooting

This is a simple procedure to verify proper operation of the booster fan. It should be run at setup to verify that the system is operating correctly. In

normal operation the system will indicate the status of the booster fan; however, this process can also be repeated as a system diagnostic.

a. Generally, if the indicator LED is not illuminated it is OK to run the test. Should you notice any behavior other than that described below, shut

the dryer off and wait at least 5 minutes to allow the system to reset and then run the test again.

b. Start the dryer and run it for a period of 1 minute.

c. The indicator LED should illuminate about 10 seconds after the dryer starts.

d. The booster fan should stop 5 to 10 minutes after the dryer stops.

e. Indicator LED should remain illuminated for 5 to 10 minutes after the dryer stops.

f. If indicator LED does not illuminate or flashes, see error indication section. Otherwise, the booster fan is functioning correctly.

Error Indications

If the LED flashes or does not illuminate, check the list below for error indication and likely sources of the problem. Should your DBF4XLT show an

error other than what is listed, or if these help topics do not solve the problem, please contact Fantech's Technical Assistance Department for

further assistance.

Contacts

United States: 800.747.1762

Canada: 800.565.3548

support@fantech.net

1. The LED illuminated in a steady state indicates that the Dryer Booster Fan is operating properly.

2. If LED does not illuminate when clothes dryer is on, check the booster fan operation.

• If it is not working, verify that the booster fan is properly connected to a 120V AC power source.

• Verify that there are no obstructions in the duct between the clothes dryer and the Dryer Booster Fan.

• Verify that the clear plastic tubing is connected between the nipple on the Dryer Booster Fan and the clothes dryer duct (see Step 5 of Fan

Installation).

• If it is working

• Verify that the low voltage wire is properly plugged into the booster fan.

• Check the polarity of the low voltage connection to the indicator panel (red to positive, black to negative). If the polarity is reversed the LED will

not illuminate.

3. LED flashes evenly

• This indicates a locked rotor condition. The fan is receiving power, but the motor is not turning. Check the booster fan for obstruction or motor

failure.

4. LED flashes twice followed by a brief pause

• This indicates that the booster fan is operating at less than its standard speed. Check the boost fan for buildup of debris or motor damage.

5. LED flashes three times followed by a brief pause

• This is indicating that the system airflow has dropped. Check duct system for obstructions. LED flashes that appear after the clothes dryer has

turned off are a result of decreased airflow through the duct system caused by the clothes dryer turning off and does not require any action. If

LED flashes are present when the clothes dryer is running, corrective action should be taken.

fantech

Page 7

7

Note Avertissement

Information Information

/ Note

importante

Veillez à lire et conserver ces instructions

pour leur consultation future.

Ce dispositif est équipé de pièces mobiles et des mesures de

précautions doivent être prises pendant son installation, son

fonctionnement et son entretien.

ATTENTION: Destiné à un usage domestique. Ne pas utiliser pour

l’évacuation de matières et vapeurs dangereuses ou

explosives.

ATTENTION: Ne pas installer à moins de 5 pi linéaire (1.52 m) ou plus de

40 pi linéaire (12.2 m) de la sortie d’échappement de la

sécheuse.

ATTENTION: Ne pas évacuer de l’air ayant une température supérieure à

75°C (167°F)

ATTENTION: Ne pas installer dans le conduit d’évacuation de la sécheuse

si les instructions interdisent l’installation d’un ventilateur

auxiliaire.

Conseil

technique

pratique

AVERTISSEMENTS

NE PAS BRANCHER LE COURANT AVANT D’AVOIR ENTIÈREMENT TERMINÉ

L’INSTALLATION DU VENTILATEUR.

1. AVERTISSEMENTS POUR RÉDUIRE LES RISQUES D’INCENDIE, DE

DÉCHARGE ÉLECTRIQUE OU RISQUE DE BLESSURES. SUIVEZ LES

CONSEILS SUIVANTS:

a. N’utilisez ce dispositif que de la manière préconisée par le

fabricant. Pour toutes questions, veuillez contacter Fantech au

numéro ci-bas.

b. Avant tout entretien ou nettoyage, coupez le courant au tableau

électrique et verrouillez ce dernier pour empêcher l’activation

accidentelle du ventilateur. Quand le système de coupure de courant

ne peut être verrouillé, attachez solidement sur le tableau électrique,

un dispositif de signalisation bien en vue, tel qu’une étiquette.

c. Les travaux d’installation et de branchement électrique doivent être

faits par un personnel qualié et conformément aux dispositions

de tous les codes et normes de construction en vigueur, y compris

celles de prévention des incendies.

ATTENTION: Ne pas installer dans une conduit d’évacuation mesurant

30 pi (9.14m) de longueur ou moins. Le DBF4XLT est

adapté pour surmonter une longueur équivalente d’un conduit

de 130pi (40m) d’un diamètre de 4po en acier galvanisé et

de maintenir une vitesse d’air de 1200fpm (6.10 m/s).

ATTENTION: Un conduit isolé ne doit pas être utilisé en amont du

ventilateur.

ATTENTION: Le ventilateur ne doit pas être utilisé en conjonction avec une

sécheuse à haut rendement.

ATTENTION: Un ltre à charpie supplémentaire doit être installé entre la

sécheuse et le ventilateur auxiliaire si le ventilateur auxiliaire

est placé à moi de 15 pieds linéaire (4.57 mètres) de la

sortie d’échappement de la sécheuse.

d. Lors du perçage ou du découpage d’un mur ou d’un plafond, prenez

garde de ne pas endommager les ls électriques ou autres conduits

s’y trouvant dissimulés.

e. Les ventilateurs installés sur les conduits doivent toujours être

ventilés vers l’extérieur.

f. L’installation doit être en conformité avec les codes électrique et

mécanique du bâtiment et doit être inspecté et accepté par les

autorités ayant juridiction.

2. Si un indicateur d’erreur visuel est activé, voir la section intitulée

“Indicateurs d’erreur” de ce manuel.

fantech

Page 8

8

Directives d’installation

AVIS IMPORTANT! AFIN DE PRÉVENIR LA POSSIBILITÉ DE CAVITATION DU VENTILATEUR DE LA SÉCHEUSE ET/OU ÉVACUER DE LA CHALEUR

EXCÉDENTE REQUIS POUR LE CYCLE DE SÉCHAGE ET COMPROMETTRE LE TEMPS DE SÉCHAGE, LE DÉBIT D’AIR DU VENTILATEUR D’APPOINT

NE DOIT PAS DÉPASSER LA CAPACITÉ DE VENTILATION DE LA SÉCHEUSE.

Calculer la longueur du conduit

Pour calculer la longueur de votre conduit, mesurer la distance entre la sécheuse et le point de purge externe dans le toit ou au mur. Pour chaque

coude ajouter 5-7 pi pour le total de votre conduit. Le DBF4XLT peut être utilisé pour une longueur totale équivalente de 130 pieds (39.6 mètres)

maximum.

Montage du ventilateur et de

l’interrupteur

Le DBF4XLT doit être monté à un minimum de 5 pi (1.5 mètres) linéaire

(non équivalent) de la bouche du ventilateur.

Un ltre à charpie supplémentaire peut être installé où nécessaire

et dans une application où une production excessive de charpie de la

sécheuse est susceptible ou pour augmenter l’intervalle de temps entre

l’entretien de routine du ventilateur d’extraction. (Voir illustration à la

droite). Un support de montage MB (fourni), xé sur un chevron ou

une poutre, doit être utilisé pour stabiliser le ventilateur. Les conduits

d’entrée et de sortie du DBF4XLT doivent être xés avec des brides

de xation FC4 (inclus) pour permettre une inspection périodique

du ventilateur. Reportez-vous aux instructions d’entretien pour les

recommandations d’inspection. Les raccords et les conduits doivent

être correctement scellés an d’empêcher toutes fuites éventuelles ou

réductions de la performance du ventilateur. Les connexions en conduites

exibles installées entre le raccord du conduit du séchoir et le conduit

d’évacuation doivent être étirées aussi uniformément que possible.

DBF4XLT

DBF4XLT

Brides de

FC Mounting

Clamps (optional)

xation FC4

Panneau indicateur

Le DBF4XLT est équipé d’un panneau indicateur de fonctionnement à

basse tension monté à distance. Ce panneau contient une lumière DEL

qui indique un fonctionnement adéquat du ventilateur d’extraction. Dans le

cas d’un problème avec le système, il indiquera la nature du problème. Le

panneau doit être monté à l’intérieur de la plaque Décora de l’interrupteur

avec une étiquette d’avertissement (inclus).

Fonctionnement du détecteur de

débit d'air

Le DBF4XLT contient un détecteur de débit d’air qui indique que le

ventilateur de la sécheuse est en fonction et active alors le ventilateur

d’évacuation de manière autonome. Cela élimine non seulement les

raccords entre les circuit de la sécheuse, ce qui pourrait en annuler

la garantie, mais aussi l’installation de systèmes manuels nécessitant

l’attention d’un opérateur ou celle de coûteux systèmes de détection

électrique ou thermique.

L’alimentation électrique au ventilateur d’évacuation est fourni par le

cordon d’alimentation de 120VAC ci-joint. Lorsque l’opération de séchage

commence, la pression positive dans le conduit provoque l’ouverture

du diaphragme qui provoque alors la mise en marche du ventilateur

d’appoint.

fantech

Autre emplacement

Alternate Location

Filtre à charpie

Secondary Lint Trap

(Optionnel)

Page 9

INSTRUCTION D'INSTALLATION DU VENTILATEUR DBF4XLT

Installation du panneau indicateur

Étape 1. Sélectionner un emplacement pour le panneau

Le panneau indicateur du DBF4XLT doit être près de la sécheuse à un endroit où il sera visible. Le

panneau indicateur vient avec un câble de 50 pieds (15.2 mètres). Assurez-vous que le panneau

indicateur et le ventilateur d’appoint soient localisés dans un endroit qui permet le raccord du

câble.

9

Étape 2. Câblage et montage du panneau

Le panneau indicateur fonctionne à basse tension qui ne nécessite pas de boîte électrique. Si elle

est fournie avec dégagement pour le câblage et le bornier il peut être monté à un mur en utilisant

une xation adéquate. Une fois xé au mur installer l'étiquette fournie dans le kit pour la plaque de

recouvrement de 4 po x 4 po de l'indicateur.

Si l’installateur décide de monter le panneau indicateur à une boîte de jonction simple (fourni par

autre), il doit s’assurer que la boîte ne contient pas de câble ou de dispositifs à haute tension.

Sur l’extrémité du câble de 50 pieds (15.2 mètre) avec des ls dénudés, brancher le l rouge à la

borne positive (+) de la plaque à borne sur le panneau indicateur. Raccorder le l noir à la borne

négative (-) du bornier sur le panneau indicateur.

Installation du ventilateur

Étape 1. Sélectionner un emplacement pour le ventilateur

Le panneau indicateur est fourni avec un câble de 50 pieds (15.2 mètres). Assurez-vous que le

panneau indicateur et le ventilateur d’appoint sont localisés à un endroit qui permet la raccord à

ce câble. Le ventilateur doit être monté à un minimum de 5 pieds (1.5 mètres) de distance de la

bouche de sortir de la sécheuse, an de pouvoir facilement procéder à l’entretien recommandé,

l’emplacement choisi pour le ventilateur doit être accessible. Se référer aux dimensions indiquées

à la page suivante. Lorsque le ventilateur d’appoint est installé dans un grenier, un vide sanitaire ou

tout endroit qui peut être froid, il est fortement recommandé d’isoler le ventilateur pour éviter les

risques de condensation.

Note: Étape 2 et 3 peuvent être inversées

ROUGE

NOIR

Montage du support

Étape 2. Installation du support de montage

À l’aide des vis à bois de 3/4 po fournis, montez le support de montage sur des poutres

maîtresses présentes à l’emplacement choisi. Bien que le ventilateur puisse être monté à

n’importe quel angle, un montage vertical est recommandé an de réduire l’accumulation de

condensation dans le ventilateur. Si un montage horizontal s’avère nécessaire et que l’accumulation

de condensation se révèle être un problème potentiel, le perçage d’un trou d’environ 1/4 po dans

le fond du boîtier (accompagné d’un embout leté NPT (fourni par autre) ainsi qu’une conduite

d’écoulement) permettra l’écoulement de la condensation.

Étape 3. Montage du ventilateur

Pour un bon fonctionnement, le boîtier de commande (situé sur le ventilateur) doit être positionné

correctement. L’illustration sur le haut de la page suivante montre la position adéquate du boîtier

de commande pour les ventilateurs qui sont montés horizontalement, verticalement et à angle. Le

boîtier de commande doit être positionné pour permettre l’accès au câblage du panneau indicateur

et les branchements. Fixer le ventilateur au support de montage à l’aide des vis auto-perçantes

d’une longueur de 1/2 po fournis. Il faut prendre soin de ne pas abîmer le boîtier. Même si la

présence de trous de guidage n’est pas nécessaire, le perçage de trous d’environ 3/32 po (ou plus

petit) est préconisé.

Étape 4. Connexion du câblage du panneau indicateur

Branché le bout du câble de 50 pieds (15.2 mètres) qui a un connecteur à deux positions à la

prise située sur le boîtier de commande du ventilateur d’appoint.

Montage du ventilateur

Montage du support et

localisation des vis

fantech

Page 10

10

1/4" Max.

Duct Wall

Grommet

Tubing

1/2" Mark on Tubing

1

1

2

2

9

3

/

4

3

3

/

4

6

15

/

16

3

7

/

8

3

7

/

8

Positionnement du détecteur de pression

Positionnement adéquat du détecteur de pression - Diaphragme positionné verticalement

Conduit horizontal

Positionnement adéquat du contrôle

Positionnement incorrect du

contrôle

Dimensions

Positionnement

adéquat du

contrôle

Conduit à angle

Positionnement

incorrect du

contrôle

Conduit vertical

Positionnement

adéquat à toutes les

position

Toutes les dimensions sont en pouces.

Étape 5. Installation de la rondelle et du tuyau

Ne pas brancher le tuyau de façon à permettre

Tuyau

Rondelle

l’accumulation de condensation dans celui-ci.

Premièrement, faite un trou de 3/8 po à 7/16 po

1/2po Marquage

sur le tuyau

dans la paroi du conduit. Insérez soigneusement la

rondelle dans le trou. (Le forage d’un conduit en

métal peut causer des ébarbures. Veillez à ne pas

1/4po Max.

être coupé ou piqué par les ébarbures ou le conduit.)

Ensuite, forcez un bout du tuyau sur le raccord sur le

Mur du conduit

fantech

contrôle. Faites une marque sur une distance de 1/2

po de l’autre bout du tuyau. Faites glisser cette

extrémité du tuyau à travers le centre de la rondelle

à la marque, tel qu’illustré.

Page 11

11

Entretien recommander

1. Les paliers du ventilateur étant scellés, aucune lubrication n’est requise.

2. Des peluches peuvent s’accumuler sur la roue du ventilateur. Une inspection périodique, basée sur le niveau d’utilisation de la sécheuse, doit

être effectuée pour s’assurer que la roue en question n’est pas obstruée ou chargée de peluches. Dans des conditions normales d’utilisation, le

ventilateur devrait être inspecté au minimum tous les six (6) mois. Remarque: La présence de trop de bruits ou vibrations peut être une indication

d’une accumulation de peluches sur la roue mobile.

Pour l’inspection et le nettoyage de la roue mobile:

a. Coupez l’alimentation électrique à sa source.

b. Détachez le conduit de la bouche d’arrivée du ventilateur et enlevez les peluches accumulées sur la roue mobile.

c. Rattachez le conduit sur le ventilateur. Rebranchez l’alimentation électrique.

Réparations mineures

Ceci est une simple procédure an de vérier le bon fonctionnement du ventilateur d’appoint. Il doit être exécuté lors de l’installation pour vérier que

le système fonctionne correctement. En fonctionnement normal, le système indique l’état du ventilateur d’appoint, mais ce processus peut être répété

aussi comme un système de diagnostique.

a. Généralement si le voyant n’est pas allumé, il est OK pour faire le test. Si vous remarquez un comportement autre que celle décrite ci-

dessous, arrêtez la sécheuse et attendez au moins 5 minutes pour permettre au système de réinitialiser et puis exécutez à nouveau le test.

b. Démarrez la sécheuse et ce pendant une période de 1 minute.

c. L’indicateur doit s’allumer environ 10 secondes après que la sécheuse démarre.

d. Le ventilateur d’appoint devrait cesser 5 à 10 minutes après que la sécheuse s’arrête.

e. Indicateur DEL doit rester allumé pendant 5 à 10 minutes après que la sécheuse s’arrête.

f. Si l’indicateur DEL ne s’allume pas ou clignote, voir la section d’indication d’erreur. Dans le cas contraire, le ventilateur d’appoint fonctionne

correctement.

Identification d'erreur

Si l’indicateur DEL ne s’allume pas, vérier la liste ci-dessous pour diagnostiquer la source du problème. Si votre DBF4XLT afche une erreur autre

que ce qui est indiqué, ou si ces rubriques d’aide ne règle pas le problème, s’il vous plaît contactez le Service d’assistance technique de Fantech pour

obtenir de l’aide. Ne pas faire fonctionner la sécheuse avant de résoudre le problème.

Téléphone

États-Unis: 800.747.1762

Canada: 800. 565.3548

support@fantech.net

1. L’indicateur DEL s’illumine en permanence qui indique que le ventilateur d’appoint fonctionne correctement.

2. Si l‘indicateur DEL ne s’illumine pas lorsque la sécheuse fonctionne, vérier le fonctionnement du ventilateur d’appoint.

• S’il ne fonctionne pas, vérier que le ventilateur d’appoint est correctement branché à une source de courant de 120V VAC.

• Vériez qu’il n’y ait pas d’obstruction dans le conduit entre la sécheuse et le ventilateur d’appoint.

• Vériez que le tuyau en plastique transparent est installé entre le raccord sur le ventilateur d’appoint et le conduit de la sécheuse. (voir

l’étape 5 de l’installation du ventilateur).

• S’il fonctionne

• Vériez que le câble à faible tension est branché correctement au ventilateur d’appoint.

• Vériez la polarité de la connexion à faible tension au panneau indicateur (rouge au positif, noir au négatif). Si la polarité est inversée

l’indicateur DEL ne s’allumera pas.

3. DEL clignote régulièrement

• Ceci indique une condition de rotor bloqué. Le ventilateur est alimenté, mais le moteur ne tourne pas. Vériez le ventilateur d’appoint pour

obstruction ou une panne du moteur.

4. DEL clignote 2 fois suivit d’une brève pause.

• Ceci indique que le ventilateur d’appoint fonction à moins que sa vitesse standard. Vériez le ventilateur pour l’accumulation de débris ou

d’endommagement du moteur.

5. DEL clignote 3 fois suivit d’une brève pause.

• Ceci indique que le débit d’air du système a chuté. Vériez si le système de conduit est obstrué. DEL qui clignote apparaît après que la

sécheuse est mise hors tension est le résultat d’une diminution du débit d’air à travers le système de conduit causé par la sécheuse qui

s’arrête, et ne nécessite aucune action. Si DEL clignote lorsque la sécheuse fonctionne, des mesures correctives doivent être prises.

fantech

Page 12

12

Warranty

Five (5) Year Warranty

This warranty supersedes all prior warranties

DURING ENTIRE WARRANTY PERIOD:

Fantech will repair or replace any part which has a factory defect in

workmanship or material. Product may need to be returned to the

Fantech factory, together with a copy of the bill of sale and identified

with RMA number.

FOR FACTORY RETURN YOU MUST:

• Have a Return Materials Authorization (RMA) number. This may be

obtained by calling Fantech either in the USA at 1.800.747.1762 or

in CANADA at 1.800.565.3548. Please have bill of sale available.

• The RMA number must be clearly written on the outside of the

carton, or the carton will be refused.

• All parts and/or product will be repaired/replaced and shipped back to

buyer; no credit will be issued.

OR

The Distributor may place an order for the warranty part and/or product

and is invoiced. The Distributor will receive a credit equal to the invoice

only after product is returned prepaid and verified to be defective.

FANTECH WARRANTY TERMS DO NOT PROVIDE FOR REPLACEMENT

WITHOUT CHARGE PRIOR TO INSPECTION FOR A DEFECT.

REPLACEMENTS ISSUED IN ADVANCE OF DEFECT INSPECTION ARE

INVOICED, AND CREDIT IS PENDING INSPECTION OF RETURNED

MATERIAL. DEFECTIVE MATERIAL RETURNED BY END USERS SHOULD

NOT BE REPLACED BY THE DISTRIBUTOR WITHOUT CHARGE TO THE

END USER, AS CREDIT TO DISTRIBUTOR’S ACCOUNT WILL BE

PENDING INSPECTION AND VERIFICATION OF ACTUAL DEFECT BY

FANTECH.

THE FOLLOWING WARRANTIES DO NOT APPLY:

• Damages from shipping, either concealed or visible. Claim must be

filed with freight company.

• Damages resulting from improper wiring or installation.

• Damages or failure caused by acts of God, or resulting from improper

consumer procedures, such as:

1. Improper maintenance

2. Misuse, abuse, abnormal use, or accident, and

3. Incorrect electrical voltage or current.

• Removal or any alteration made on the Fantech label control number

or date of manufacture.

• Any other warranty, expressed, implied or written, and to any

consequential or incidental damages, loss or property, revenues, or

profit, or costs of removal, installation or reinstallation, for any breach

of warranty.

WARRANTY VALIDATION

• The user must keep a copy of the bill of sale to verify purchase date.

• These warranties give you specific legal rights, and are subject to an

applicable consumer protection legislation. You may have additional

rights which vary from state to state.

Limitation of Warranty and Liability

This warranty does not apply to any Fantech product or part which has

failed as a result of faulty installation or abuse, incorrect electrical

connections or alterations made by others, or use under abnormal

operating conditions or misapplication of the product or parts. We will

not approve for payment any repair not made by us or our authorized

agent without prior written consent. The foregoing shall constitute our

sole and exclusive warranty and our sole exclusive liability, and is in lieu

of any other warranties, whether written, oral, implied or statutory.

There are no warranties which extend beyond the description on the

page hereof. In no event, whether as a result of breach of contract, or

Warning

Fantech products are designed and manufactured to provide reliable

performance, but they are not guaranteed to be 100% free from

defects. Even reliable products will experience occasional failures and

this possibility should be recognized by the user. If these products are

warranty or alleged negligence, defect incorrect advice or other causes,

shall Fantech be liable for special or consequential damages, including,

but not limited to, loss of profits or revenue, loss of use of equipment or

any other associated equipment, cost of capital, cost of substitute

equipment, facilities or services, downtime costs, or claims of

customers of purchase for such damages. Fantech neither assumes or

authorizes any person to assume for it any other liability in connection

with the sale of product(s) or part(s). Some jurisdictions do not allow the

exclusion or limitation of incidental or consequential damages so the

above limitations and exclusions may not apply to you.

used in a life support ventilation system where failure could result in loss

or injury, the user should provide adequate backup ventilation,

supplementary natural ventilation, failure alarm system, or acknowledge

willingness to accept the risk of such loss or injury.

fantech

Page 13

Garantie

Garantie de 5 ans

Cette garantie remplace toutes les garanties précédentes.

13

DURANT TOUTE LA PÉRIODE DE GARANTIE:

Fantech s'engage à réparer ou à remplacer toute pièce présentant un

défaut d'usine en matière de qualité d'exécution ou de matériau. Il sera

peut être nécessaire de retourner le produit à l'usine Fantech,

accompagné d'une copie du contrat de vente et du numéro d'autorisation

de retour.

POUR RETOURNER UN PRODUIT À L'USINE, VOUS DEVEZ:

• Obtenir un numéro d'autorisation de retour; pour ce faire,

communiquer avec Fantech aux États-Unis au numéro

1.800.747.1762, ou au Canada, au numéro 1.800.565.3548.

Veuillez avoir votre contrat de vente à portée de la main.

• S'assurer que le numéro d'autorisation de retour est lisible sur

l'extérieur de la boîte, sinon la boîte sera refusée.

• Toutes les pièces et/ou le produit seront réparés ou remplacés puis

retournés à l'acheteur. Aucun crédit ne sera accordé.

OU

Le Distributeur peut commander une pièce ou un produit couvert par la

garantie; la facture lui sera envoyée. Le distributeur ne sera crédité du

montant de sa facture qu'après que le produit a été retourné port payé

et qu'il a été trouvé défectueux.

LES TERMES DE LA GARANTIE DE Fantech NE PRÉVOIENT PAS DE

REMPLACEMENT SANS FRAIS AVANT QUE LA PIÈCE OU LE PRODUIT

DÉFECTUEUX AIT ÉTÉ INSPECTÉ. LES PRODUITS OU PIÈCES

REMPLACÉS AVANT L'INSPECTION DE LA DÉFECTUOSITÉ SERONT

FACTURÉS ET LE MONTANT DU CRÉDIT EST FONCTION DE

L'INSPECTION DE LA PIÈCE OU DU PRODUIT RETOURNÉ. LE

DISTRIBUTEUR NE DOIT PAS REMPLACER SANS FRAIS POUR

L'UTILISATEUR FINAL L'ÉQUIPEMENT DÉFECTUEUX RETOURNÉ PAR

L'UTILISATEUR FINAL, CAR LE COMPTE DU DISTRIBUTEUR NE SERA

CRÉDITÉ QU'APRÈS L'INSPECTION ET LA VÉRIFICATION PAR FANTECH

DE LA DÉFECTUOSITÉ.

LES GARANTIES NE S'APPLIQUENT PAS DANS LES CAS SUIVANTS:

• Dommages dus au transport (dissimulés ou visibles). Les

réclamations doivent être faites à la compagnie de fret.

• Dommages dus au mauvais câblage ou à l'installation inappropriée.

• Dommages ou défectuosité causés par une calamité naturelle ou

résultant d'une procédure irrégulière de l'acheteur, notamment :

1. Entretien irrégulier

2. Mauvais usage, usage abusif, usage anormal ou accident

3. Tension ou courant électrique incorrect

• Enlèvement ou toute modification du numéro de contrôle ou de la date

de fabrication de l'étiquette Fantech

• Toute autre garantie expresse, écrite ou implicite, pour les dommages

accidentels ou indirects, perte de biens, de recettes, manque à

gagner ou coûts relatifs à la dépose, à l'installation ou à la

réinstallation, en cas de violation de garantie.

CERTIFICATION DE LA GARANTIE:

• L'utilisateur doit conserver une copie du contrat de vente pour

confirmer la date d'achat.

• Les présentes garanties vous donnent des droits spécifiques reconnus

par la loi et sont régies par les lois sur la protection du

consommateur appropriées. Il est possible que différents états offrent

d'autres droits.

Limites de garanties et de responsabilités

Cette garantie ne s’applique à aucun produit de Fantech ou à aucune

pièce détachée dont la défectuosité relève d’une erreur d’installation ou

d’abus ou de mauvaise installation électrique ou dut à des modifications

extérieures ou utilisées dans des conditions anormales ou encore une

mauvaise installation du produit ou des pièces détachées. Nous

n’approuverons aucun remboursement pour des réparations qui ne sont

pas effectuées par un agent américain ou un agent autorisé sans un

accord écrit. Ce dernier constituera notre seule et exclusive garantie et

notre seule exclusive responsabilité et tient lieu de toute autre garantie

ou bien écrite ou orale implicite ou statuaire. Aucune garantie ne

s’appliquera au-delà des descriptions faites de la page ci-dessus. En

aucun cas, que ce soit pour une rupture de contrat ou de garanties ou

Avertissement

Les produits de Fantech sont conçus et fabriqués pour produire des

performances fiables, mais il n’y a aucune garantie qu’ils soient 100%

sans défaut. Les plus produits les plus fiables ont occasionnellement des

défectuosités et cette possibilité devraient être reconnu par les usagers.

Si ces produits sont utilisés comme une source de ventilation ou leur

panne risque de mettre en danger des vies humaines ou entraîner des

des dommages dut à la négligence ou a des conseils incorrects ou

autres causes, Fantech ne pourra être tenu pour responsable des

dommages particuliers ou consécutifs, incluant mais pas limités aux

pertes et profits ou bénéfices perte de matériel ou autres matériels

associés. Coût du capital, coût des équipements de remplacement,

matériels ou services, coût de temps d’arrêt ou les réclamations des

clients pour de tels dommages. Fantech ne délègue ou autorise aucune

personne d’assumer sa responsabilité sur la vente du produit ou des

pièces détachées. Certaines juridictions ne permettent pas l’exclusion de

la limitation des dommages accidentels ou consécutifs ainsi ces

limitations ci-dessus et les exclusions ne s’appliquent pas à vous.

blessures, les usagers devront avoir une source de ventilation de

secours en addition à une ventilation naturelle, le défaut de système

d’alarme ou la connaissance de ces conditions entraînent sa

responsabilité envers de telles pertes ou blessures.

fantech

Page 14

14

Notes

fantech

Page 15

Notes

15

fantech

Page 16

fantech

Fantech reserves the right to make technical changes.

For updated documentation please refer to www.fantech.net

Fantech®

Fantech se réserve le droit de faire des changements techniques. Pour de la documentation à jour, s'il vous plaît se

référer au www.fantech.net

Loading...

Loading...