Page 1

DBF110 DRYER EXHAUST BOOSTER SYSTEM

INSTALLATION INSTRUCTIONS

DISPOSITIF DBF110 D’AMPLIFICATION DU SYSTÈME DE VENTILATION

DES SÉCHOIRS À LINGE INSTRUCTIONS D’INSTALLATION

SISTEMA DE REFUERZO DE ESCAPE DE LA SECADORA DBF110

INSTRUCCIONES DE INSTALACION

Page 2

DBF110 DRYER EXHAUST BOOSTER SYSTEM INSTALLATION INSTRUCTIONS

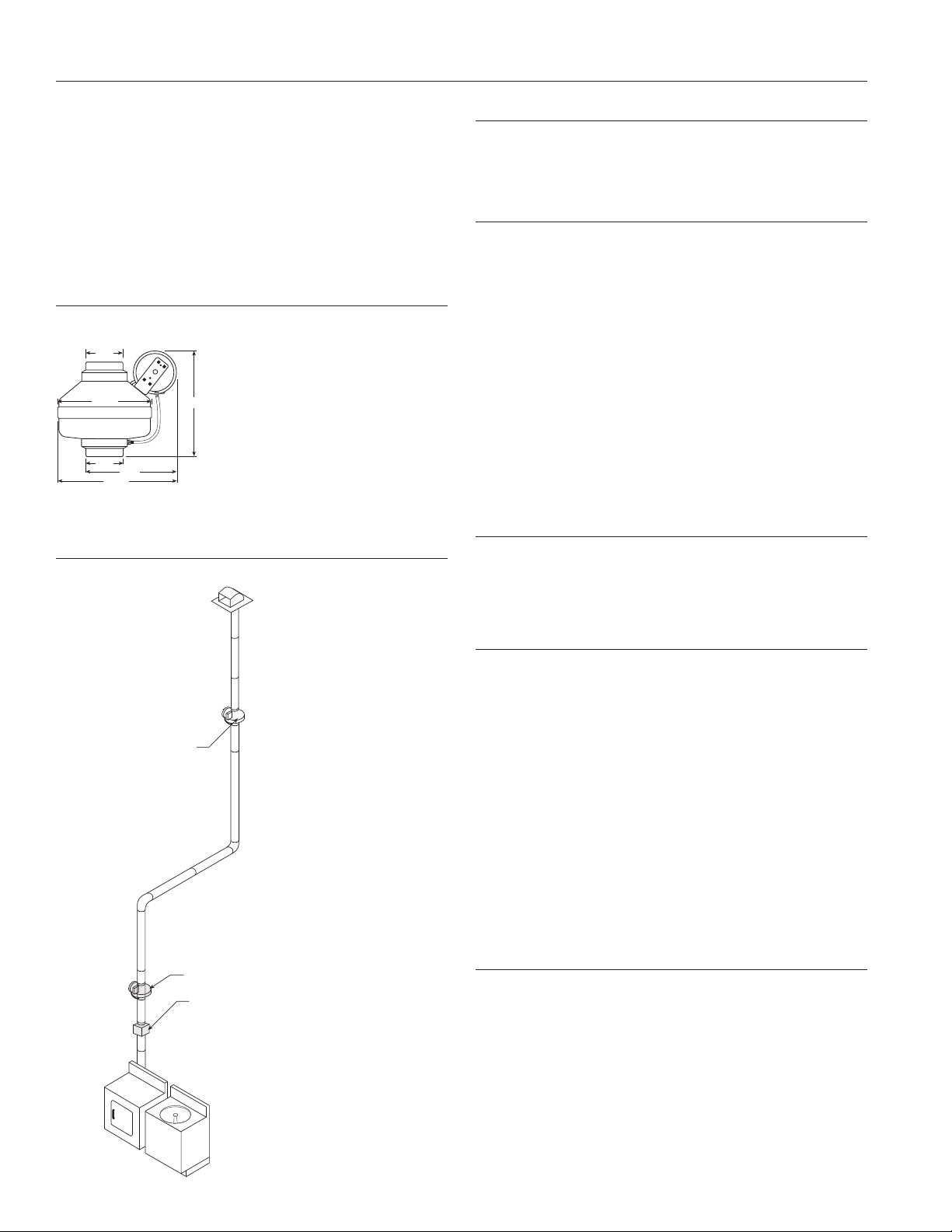

3″

1″

³|₄″

4″

12¹|₂″

9¹|₂″

4″

9¹|₂″

11¹|₄″

4¹|₂″

Installation Guidelines

DBF110 Includes:

1 DBF 110 Dryer Booster Fan

1 Fan Mounting Bracket and Hardware

1 Small Wall Sign Indicating Proper Operating Procedure

mportant Notice

I

Read and Save these instructions for future reference.

Dimensional Data

(DBF110)

Please note: DBF 110 fans are not explosion proof. Do not use the fans if

a potentially explosive situation may exist.

DO NOT USE with heated air in excess 140˚F (60˚C).

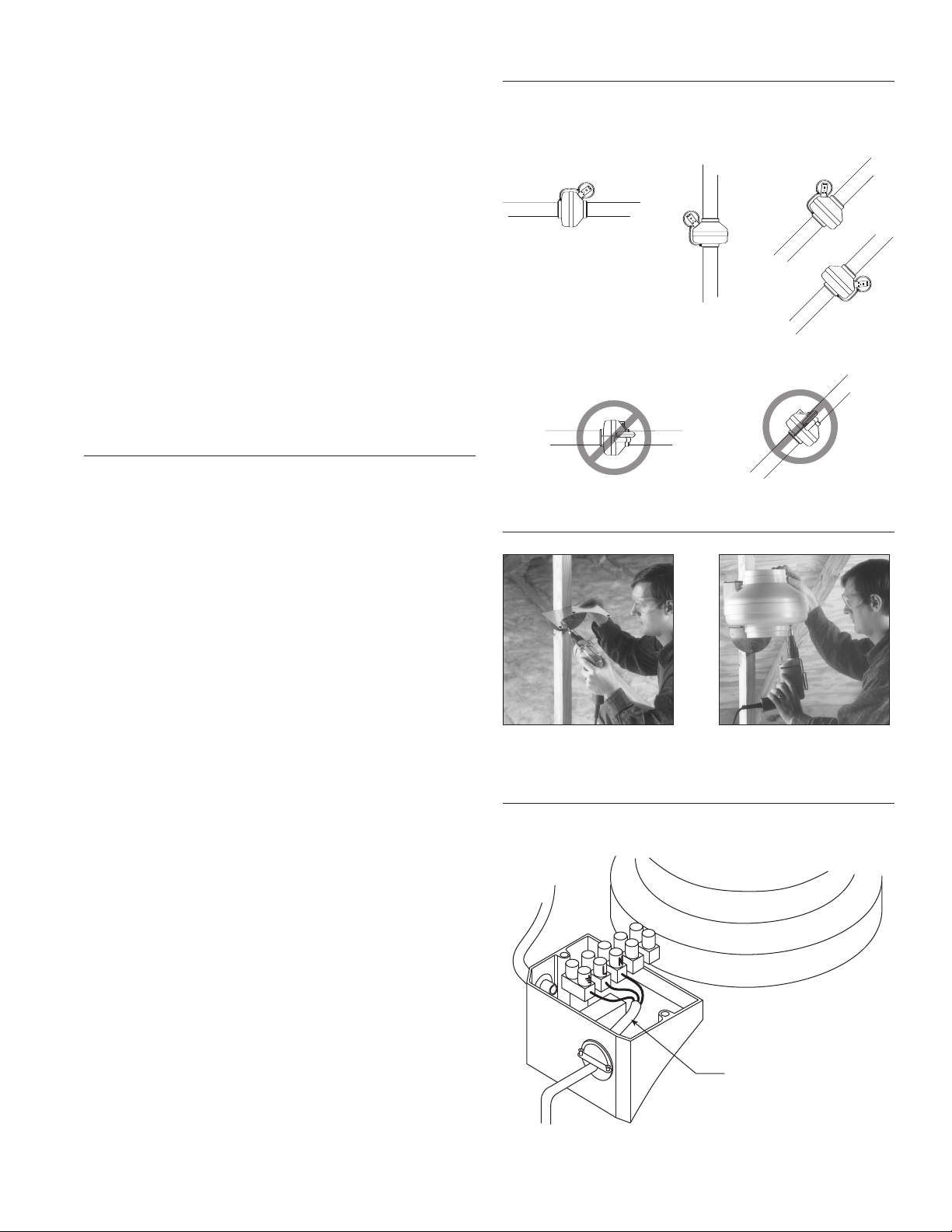

Fan and Switch Mounting

The recommended location of the booster fan is a minimum of 15 linear (not

quivalent) feet of duct from the dryer outlet. If the fan is mounted closer

e

than the recommended 15 feet, it may develop enough pressure to lift wet

int into the fan impeller resulting in excessive lint loading in the fan. The best

l

location for the fan to be mounted is as close as possible to the termination

of the duct work.

dryer and the booster fan, the booster fan may be mounted within the minimum distance otherwise recommended (See illustration to left).

mounting bracket attached to a rafter or joist should be used to stabilize the

fan. Although not recommended, a vertical rigid duct may support the fan if

the duct is securely stabilized. (Consult local codes prior to supporting the

fan in the duct alone.) Duct work should be attached to the inlet and outlet

of the fan by means of FC vibration isolation clamps

tape. The duct connection should be properly sealed to prevent leakage and

loss of fan performance. Flex duct connections between the dryer duct connection and exhaust duct should be stretched as smooth as possible.

(Exception: If a secondary lint filter is installed between the

(not included)

An NB

or duct

Illustration 1

DBF110

native Location

Alter

Secondar

y Lint T

rap

Calculating Duct Run

To calculate the length of your planned duct run, measure from the dryer

to external venting point in roof or wall. For each bend or elbow add 5-7

feet to your total duct run calculations. The DBF4XL can be used on runs

up to 108 feet.

Pressure Sensor Switch Operation

Fantech’s DBF110 is equipped with Fantech's Patented DB10 pressure

switch. The DB10 is a positive pressure sensing switch which

recognizes dryer operation and activates the booster fan from an

independent electrical circuit. This eliminates connections through the

dryer circuit which may void the manufacturers’ warranty as well as manual systems which require the attention of the operator or costly current/temperature sensing systems.

The electricity to the booster fan is connected in series through a

normally open terminal on the switch. A pressure tap is connected to a

fitting on the side of the switch. When the dryer begins operation, posi-

essure in the duct causes the switch diaphragm to expand, closing

tive pr

the circuit to the booster fan. An integral delay-on-break timer in the

switch will cycle the fan on for intervals of 10 minutes. This will continue

until the dryer has stopped and the timer delay period has lapsed. Drying

cycles, the booster fan, the delay timer and the pressur

adversely affected by the starting/stopping intervals.

e switch are not

Fan Installation

Step 1. Selecting Fan Location

Fan

must

be mounted a minimum of 15 feet from the dryer outlet.

If the fan is mounted closer than the recommended 15 feet, it may develop enough pressure to lift wet lint into the fan impeller resulting in excessive lint loading in the fan.

between the dryer and the booster fan, the booster fan may be mounted

within the minimum distance otherwise recommended (See illustration to

The best location for the fan to be mounted, in any application, is as

left).

close as possible to the ter

ecommended maintenance, fan location should allow suf

r

vice. Refer to dimensional drawings shown above.

for ser

(Exception: If a secondary lint filter is installed

m

mination of the duct work. In or

der to per

ficient access

for

Page 3

Step 2. Mount Bracket

Using the wood screws provided, attach the mounting bracket to a support beam at the selected location. Bracket is provided with grommets

n order to isolate any vibration and prevent the transmission of sound

i

through the structure. Be careful not to overtighten. Fan mounting can

e in any angle (see ill. 2), however, vertical mounting is recommended

b

to reduce condensation buildup in the fan. If a horizontal installation is

hole

ecessary and condensation buildup may pose a problem, a

n

rilled in the bottom of the housing (along with an NPT insert [by oth-

d

ers] and drain tubing) will allow condensation to drain.

tep 3. Mount Fan

S

For proper operation, the switch diaphragm must be positioned verti-

ally. (Illustrations below show diaphragm position for horizontal, verti-

c

cal and ducts installed at an angle.) Wiring box should be positioned for

easy access. Attach fan to the mounting bracket with the self tapping

screws provided. Care should be taken not to strip the plastic housing.

Although screw pilot holes are not required,

are recommended.

³|₃₂" (or smaller) pilot holes

¹|₄"

NOTE: Steps 2 & 3 may be reversed.

Electrical Connection

DO NOT CONNECT POWER SUPPLY UNTIL FAN IS COMPLETELY INSTALLED.

MAKE SURE ELECTRICAL SERVICE TO THE FAN IS LOCKED IN "OFF" POSITION.

1. This unit has rotating parts and safety precautions should be exercised during installation, operation and maintenance.

CAUTION: "For General Ventilation Use Only. Do Not Use To Exhaust

2.

Hazardous Or Explosive Materials And Vapors."

3.

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS - OBSERVE THE FOLLOWING

a. Use this unit only in the manner intended by the manufac-

turer. If you have questions, contact the factory.

b. Before servicing or cleaning, switch power off at service

panel and lock service panel to prevent fan from being

switched on accidentally. When the service disconnecting

means cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

c. Installation work and electrical wiring must be done by qual-

ified person(s) in accordance with all applicable codes and

ds, including fire-rated construction.

standar

d. The combustion airflow needed for safe operation of fuel

burning equipment may be affected by this unit's operation.

Follow the heating equipment manufacturer's guidelines and

safety standards such as those published by the National

Fire Protection Association (NFPA), the American Society of

Heating, Refrigeration, and Air Conditioning Engineers

(ASHRAE) and the local code authorities.

e. When cutting or drilling into wall or ceiling, do not damage

electrical wires or other hidden utilities.

f. Ducted fans must always be vented to the outdoors.

g. Install fan at least five feet above the floor.

4. WARNING! Check voltage at the fan to see if it corresponds to the

motor nameplate.

GUARDS MUST BE INSTALLED WHEN FAN IS WITHIN REACH OF PERSONNEL OR WITHIN SEVEN (7) FEET OF WORKING LEVEL OR WHEN DEEMED

ADVISABLE FOR SAFETY.

:

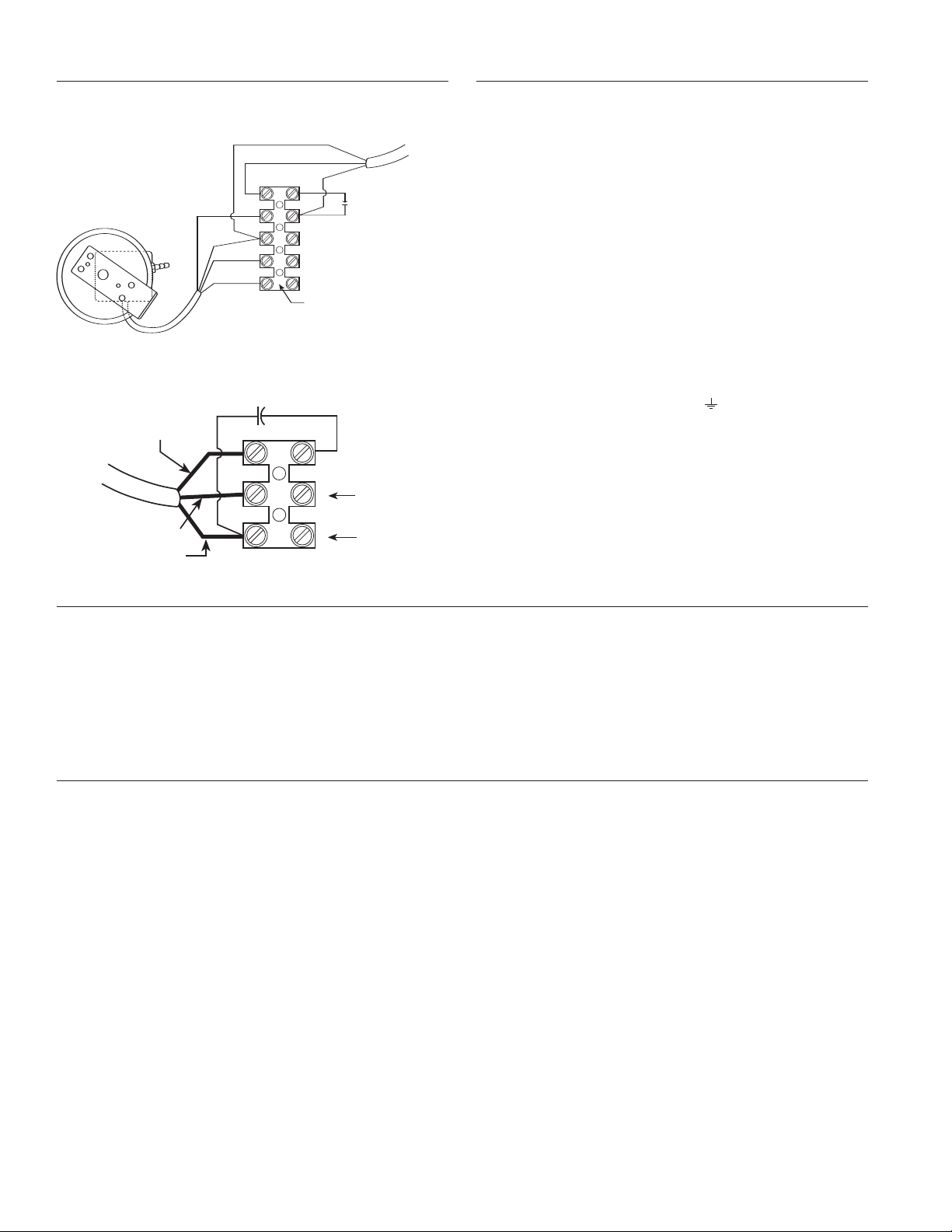

Illustration 2

Correct Mounting of Diaphragm Switch

Horizontal Vertical Angled

Switch mounted

properly above

duct.

Incorrect Mounting of Diaphragm Switch

Illustration 3

Attach Mounting Bracket to

stud using screws provided.

Illustration 4

Switch Cir

cuit

Switch mounted

properly

above and

below

duct.

Attach Fan to Mounting

Bracket using screws provided.

Electrical Supply fr

Breaker Panel

om

Page 4

N

L

Illustration 5

DBF110 Wiring – Fan and Pressure Switch

Blue

Brown

ed

R

White

Black

Green

Fan Only Wiring

Reference for Troubleshooting Step 8c)

(

Capacitor

Brown (Z2)

Black

Capacitor

eutral

N

15V Line (Supply) Electrical supply, 115V

1

Ground

Terminal block in

fan wiring box

Power

to Fan

Wiring Procedure

Please Note: The fan motor, capacitor and pressure switch connec-

ions are pre-wired from the factory.

t

Step 1.

Remove the screws securing the terminal box cover plate located on

the side of the fan. All fan motor connections are prewired to an elec-

trical terminal strip. A

be needed to secure the wiring through the knockout provided on the

side of the terminal box.

Step 2.

ring incoming electrical service through the romex connector and

B

the fan knockout. Be sure to place the connector nut over the wiring

oming into the terminal box. There are three open ports on the ter-

c

minal strip. Using a small regular screwdriver, tighten the Neutral

(White) wire of the incoming supply under the open terminal labeled

"N". Tighten the Line (Black) wire of the incoming supply under the

open terminal labeled "L". Tighten the Ground (Green) wire of the

incoming supply under the open terminal marked " ". For reference,

a wiring diagram is included on the inside of the terminal box lid.

³|₈" romex type cable restraint connector will

Motor

Leads

Neutral side of

115V supply

Blue (U2)

Black (TK)

Line side of

115V supply

Warranty and Maintenance

Recommended Maintenance

1. Since fan bearings are sealed and provided with an internal lubricating material, no additional lubrication is necessary.

2. Fan impeller may accumulate lint. Periodic inspection, based upon

dryer usage, should be performed to ensure that the fan impeller

is not obstructed or loaded with lint. Under normal conditions, fan

Troubleshooting

Important Notice: Prior to performing Steps 1 - 4, be certain that the

electrical supply to the fan/switch is turned off.

If fan fails to start when the dryer cycle begins, please follow the procedure listed below:

1. Check the incoming supply for proper voltage.

2. Consult schematic shown above (also included on inside of fan

wiring terminal lid) to ensure proper connection.

If possible, use a meter to test for continuity across the fan

3.

motor leads. In order to do this, the capacitor and pressure

switch must be disconnected (do not test the capacitor - it will

not meter continuity). If motor leads show continuity, rewire the

fan, capacitor and pressure switch.

4. Turn on the electrical supply and restart the dryer cycle. Check to

be certain that fan starts.

If fan still fails to start after performing Steps 1 – 4, continue follow-

ing the procedure as listed below:

5. Verify that the pressure switch diaphragm is vertical as shown in

Illustration 2 of these instructions. If the diaphragm is not vertical, reposition the pressure switch and check for fan operation

against another dryer cycle.

Step 3.

Secure the romex connector. Secure the incoming supply with the

romex connector. Replace the fan terminal box cover.

should be inspected a minimum of every Six (6) Months. Note:

Excessive booster fan noise or vibration may be an indication of

lint buildup on the impeller. To inspect and clean the impeller:

a. Disconnect the incoming power supply at the source.

b. Remove the duct from the fan inlet and remove any lint

buildup on the impeller.

c. Reconnect the duct to the fan. Turn power supply on.

erify that the tubing is not crimped and that the tubing connec-

V

6.

tor nipples ar

e not obstructed.

7. If switch diaphragm is vertical and fan still fails to start, with the

electrical supply on:

a. Remove the tubing from the nipple on the fan and blow

gently into the tubing;

b. If fan starts, consult Fantech for additional technical sup-

port.

8. If fan fails to start after blowing into the tubing:

a. Disconnect incoming power supply at the sour

ce.

b. Remove the pressure switch leads from the wiring terminal

block

c. Connect the incoming power supply directly to the fan

motor as shown in "FR110 Wiring" diagram below.

d. Turn on power to fan.

If fan fails to star

9.

t, please consult Fantech for additional techni-

cal support.

Page 5

DISPOSITIF DBF110 D’AMPLIFICATION DU SYSTÈME DE VENTILATION DES SÉCHOIRS À LINGE

10,16

2

4,13

2

4,13

10,16

31,75

28,57

11,43

2,54

1,91

7,62

INSTRUCTIONS D’INSTALLATION

Guides d’installations

Important ! Pour éviter l’éventuelle du ventilateur du séchoir l’évacuation d’un

trop grand volume de l’air chaud nécessaire au cycle de séchage, tout comme la

compromission des temps de séchage, le ventilateur d’amplification ne doit pas

dépasser la capacité du ventilateur du séchoir équipé.

Veuillez noter que les ventilateurs DBF110 à monter sur conduits d’évacuation

ne sont pas à l’épreuve des explosions. Ne pas utiliser les ventilateurs dans des

situations potentiellement explosives.

N’EMPLOYEZ PAS si que l’air est supérieur a 140˚F (60˚C).

Installation du ventilateur et du rupteur

L’emplacement recommandé pour l’installation du ventilateur d’amplification est

au minimum après 4,6 m (15 pieds) linéaires de conduit (et non pas l’équivalent), comptés à partir de la bouche du séchoir. Si le ventilateur est installé

avant la distance recommandée, il peut développer une pression suffisante à

l’aspiration de peluches mouillées dans roue du ventilateur, entraînant par-là la

charge excessive de peluches dans le ventilateur. Le meilleur emplacement pour

l’installation du ventilateur est le plus près possible de la fin du conduit.

Exception : Si un filtre à peluches supplémentaire est installé entre le séchoir et

le ventilateur d’amplification, ce dernier peut être installé avant la limite

autrement recommandée (Voir l’illustration de droite).

Un support de montage approprié au diamètre nominal, fixé sur un chevron ou

une poutre, doit être utilisé pour la stabilisation du ventilateur. Bien que cela ne

soit pas recommandé, un conduit vertical et rigide peut servir de soutien au ventilateur à condition que le conduit en question soit solidement stabilisé

(Consultez les codes de construction localement en vigueur avant de ne soutenir

le ventilateur que par le conduit). Le conduit doit être rattaché à la bouche d’arrivée et de sortie du ventilateur au moyen de pinces

adhésif empêchant la propagation des vibrations. Les raccords du conduit

doivent être correctement scellés afin d’empêcher toutes fuites éventuelles ou

réductions des performances du ventilateur. Les connexions en conduites flexibles installées entre le raccord du conduit du séchoir et le conduit d’évacuation

doivent être étirées aussi uniformément que possible.

(non-inclus)

ou de ruban

Le DBF110 contient :

1 DBF 110

support de montage pour le ventilateur avec quincaillerie

1

Important:

Veillez à lire et conserver ces instructions pour leur consultation future

Illustration pour les dimensions

Dimensions en centimeters

DBF10

Illustration 1

Fonctionnement du rupteur de détection de la

pression

Le DBF110 est equipepé avec le mano-contact DB10 breveté de Fantech. Le

DB10 de Fantech

le fonctionnement du séchoir et active le ventilateur d’amplification à partir d’un

circuit électrique indépendant. Cela élimine non seulement les connexions transitant par les circuits du séchoir, ce qui peut en annuler la garantie, mais aussi

l’installation de systèmes manuels nécessitant l’attention d’un opérateur ou celle

de coûteux systèmes de détection électrique ou thermique.

Le circuit électrique du ventilateur d’amplification est branché en série via une

borne de travail équipant le rupteur. Un robinet de pression est branché sur un

embout positionné sur le côté du rupteur. Quand le séchoir se met en marche,

la pression positive présente dans le conduit entraîne l’expansion du diaphragme

du rupteur, fermant ainsi le circuit du ventilateur d’amplification. Le minuteur de

temporisation à la demande équipant le rupteur activera le ventilateur par cycles

de 10 minutes. Cela continuera jusqu’à ce que le séchoir s’arrête et que le

temps d’activité indiqué par le minuteur s’écoule. Les cycles de séchage, le ventilateur d’amplification, le minuteur de temporisation et le rupteur de pression

ne sont pas négativement affectés par les intervalles de départ/arrêt.

est un rupteur de détection de pression positive qui identifie

Installation du ventilateur

1ère Étape. Sélectionner un emplacement pour le ventilateur

Le ventilateur

la bouche du séchoir.

recommandée, il peut développer une pression suffisante à l’aspiration de

peluches mouillées dans roue du ventilateur, entraînant ainsi la charge excessive

de peluches dans le ventilateur. Exception : Si un filtre à peluches supplémentaire est installé entre le séchoir et le ventilateur d’amplification, ce dernier peut

être installé avant la limite autrement recommandée (Voir l’illustration de

droite).

Le meilleur emplacement pour l’installation du ventilateur, et ce pour

n’importe quelle application, est le plus près possible de la fin du conduit. Afin

de pouvoir facilement procéder à l’entretien recommandé, l’emplacement choisi

pour le ventilateur doit être suffisamment accessible. Se référer aux dimensions

indiquées sur les illustrations ci-dessus.

e monté au minimum à 4,6 m (15 pieds) de distance de

doit

êtr

Si le ventilateur est installé avant les 4,6 m de distance

DBF110

e emplacement

Autr

Piège supplémentair

e à peluches

Page 6

Illustration 2

Bon positionnement diaphragme du rupteur

Horizontal Vertical Incliné

Bon positionnement du

rupteur dessus du conduit.

Mauvais positionnement du rupteur

Illustration 3

Support de montage. À l’aide

des vis à bois fournies, montez le

support de montage sur une des

poutres maîtresses présentes à

l’emplacement choisi.

Illustration 4

Illustration de la bar

cuit du

Cir

upteur

r

ette à bor

r

nes

Bon positionnement

du rupteur

dessus au

dessous

du conduit.

Montage du ventilateur. Fixez

le ventilateur au support de mon-

tage à l’aide des vis

auto-perçantes fournies.

2ème Étape. Le support de montage

À l’aide des vis à bois fournies, montez le support de montage sur une des

poutres maîtresses présentes à l’emplacement choisi. Le support est fourni

équipé de joints d’étanchéité servant à isoler toutes les éventuelles vibrations et

à empêcher la transmission des bruits dans la structure. Prenez garde à ne pas

trop serrer. Bien que le ventilateur puisse être monté dans n’importe quel angle,

un montage vertical est recommandé afin de réduire l’accumulation de condensation dans le ventilateur. Si un montage vertical s’avère nécessaire et que l’accumulation de condensation se révèle être un problème potentiel, le perçage

d’un trou d’environ 1 cm (

embout fileté NPT [fourni par autre]et d’une conduite d’écoulement) permettra

l’écoulement de la condensation.

¹|₄ pouces) dans le fond du boîtier (accompagné d’un

3ème Étape. Le montage du ventilateur

Pour meilleur opération, le diaphragme du rupteur doit être positionné verticalement. (Les illustrations ci-dessous indiquent la position du diaphragme pour

les conduites installées horizontalement, verticalement ou autrement.) Le boîtier électrique doit être positionné de façon à être facilement accessible. Fixez le

ventilateur au support de montage à l’aide des vis auto-perçantes fournies.

Faites attention de ne pas endommager ou érafler le boîtier en plastique. Même

si la présence de trous de guidage n’est pas nécessaire, le perçage de trous

d’environ 1 cm (³|₃₂ pouces) (ou plus petit) est préconisé.

REMARQUE : L’ordre des étapes 2 et 3 peut être inversé

Branchements électriques

NE BRANCHEZ PAS LE COURANT AVANT D’AVOIR ENTIÈREMENT TERMINÉ L’INSTALLATION DU VENTILATEUR. S’ASSUREZ QUE L’ALIMENTATION ÉLECTRIQUE DU

VENTILATEUR EST VERROUILLÉE EN POSITION “OFF” (ARRÊT).

1. Ce dispositif est équipé de pièces tournantes et des mesures de précautions doivent être prises pendant son installation, son fonctionnement et

son entretien.

ATTENTION : “Uniquement à usage de ventilation ordinaire. Ne pas utiliser

2.

pour l’évacuation de matières et vapeurs dangereuses ou explosives”

Attention : Pour la réduction des risques d’incendie, d’électrocution et de

3.

blessures corporelles, respectez les instructions suivantes :

a. N’utilisez ce dispositif que de la manière préconisée par le fabri-

cant. Pour toutes questions, veuillez contacter l’usine de fabrication.

b. Avant tout entretien ou nettoyage, coupez le courant au tableau

électrique et verrouillez ce dernier pour empêcher l’activation accidentelle du ventilateur. Quand le système de coupure de courant ne

peut pas être verrouillé, attachez solidement sur le tableau électrique, un dispositif de signalisation bien en vue, tel qu’une étiquette.

c. Les travaux d’installation et de branchement électrique doivent être

faits par un personnel qualifié et conformément aux dispositions de

tous les codes et normes de construction en vigueur, y compris

celles de prévention des incendies.

d. Une ventilation suffisante à la bonne combustion et évacuation des

gaz par le conduit (la cheminée) des équipements fonctionnant au

carburant est nécessaire de façon à empêcher les refoulements.

Suivez les instructions données et les normes de sécurité communiquées par le fabricant, telles que celles publiées par l’Association

nationale de protection contre les incendies (National Faire

Protection Association [NFPA]), l’Association américaine des

ingénieurs en chauffage, réfrigération et climatisation (American

Society of Heating, Refrigeration, and Air Conditioning [ASHRAE])

et les autorités localement en charge de la construction.

e. Lors du perçage ou du découpage d’un mur ou d’un plafond, prenez

garde de ne pas endommager les fils électriques ou autres conduits s’y trouvant dissimulés.

f. Les ventilateurs installés sur les conduits doivent toujours être ven-

tilés vers l’extérieur.

Installez le ventilateur à au moins 1,55 m (5 pieds) du sol.

g.

4.

ATTENTION ! Vérifiez la tension sur le ventilateur pour voir si elle correspond

à celle indiquée par la plaque signalétique du moteur.

Alimentation électrique en

provenance du tableau élec-

DES PROTECTIONS DOIVENT ÊTRE INSTALLÉES QUAND LE VENTILATEUR EST À LA

PORTÉE DU PERSONNEL OU À MOINS DE 2,14 M (7 PIEDS) DU NIVEAU DE TRA-

VAIL OU QUAND DES PRÉCAUTIONS DE SÉCURITÉ SONT JUGÉES NÉCESSAIRES.

Page 7

Procédure de branchement

N

L

Veuillez noter que les raccords du moteur du ventilateur, du condensateur et du

rupteur de pression ont été câblés à l’avance en usine.

1ère Étape.

Enlevez les vis retenant le couvercle du boîtier électrique installé sur le côté du

ventilateur. Toutes les connexions électriques du ventilateur sont pré-câblées sur

une barrette à bornes. Un connecteur de type romex permettant le blocage d’un

câble de 0,375 cm (³|₈") de diamètre sera nécessaire pour attacher les fils électriques dans le trou pratiqué sur le côté du boîtier électrique.

2ème Étape.

Amenez l’arrivée éclectique en la faisant passer dans le connecteur romex et

dans le trou pré-découpé pratiqué dans le ventilateur. N’oubliez pas d’enfiler

l’écrou du connecteur sur le fil électrique arrivant dans le boîtier électrique. La

barrette à bornes est équipée de trois ports de travail. À l’aide petit tournevis

plat, pincez le fil blanc (neutre) de l’arrivée d’alimentation sous la borne marquée

“N”. Puis, pincez le fil de ligne (noir) sous la borne marquée “L”. Et, pincez le fil

de terre (vert) sous la borne marquée “ ”. Pour votre information, un schéma

de câblage est affiché sous le couvercle du boîtier électrique.

3ème Étape.

Fixez le connecteur romex, puis attacher l’arrivée d’alimentation à l’aide de ce

dernier. Remettez le couvercle du boîtier du ventilateur en place.

Garantie et entretien

Illustration 5

Diagrammes de câblage

Câblage Ventilateur seul

mineures)

Marron (Z2)

Fils d’amenée

du moteur

Bleu (U2)

Noir (TK)

Fils d’a-

menée du

Bleu

Marron

Noir

Rouge

Blanc

Noir

Vert

(Illustration de référence pour l’étape 8c des réparations

Capaciteur

Neutre

Ligne Alimentation électrique de 115 V

Terre

Capaciteur

Répartiteur

Côté neutre de l’ali-

mentation en 115 V

Côté ligne de l’alimen-

moteur

tation en 115 V

Entretien recommandé

1. Les paliers du ventilateur étant scellés et déjà lubrifiés par de la matière de

lubrification interne, aucune autre lubrification n’est nécessaire.

2. Des peluches peuvent s’accumuler sur la roue du ventilateur. Une inspection

périodique, basée sur l’utilisation qui est faite du séchoir, doit être effectuée

pour s’assurer que la roue en question n’est pas obstruée ou chargée de

peluches. Dans des conditions normales d’utilisation, le ventilateur devrait

être inspecté au minimum tous les six (6) mois.

Remarque : La présence

Réparations mineures

Important : S’assurer que l’alimentation électrique du ventilateur/rupteur est

coupée avant de ne passer aux étapes 1-4.

Veuillez appliquer la procédure ci-dessous, si le ventilateur ne démarre pas

quand le cycle du séchoir commence :

1. Vérifiez que la tension de l’alimentation électrique est bonne.

2. Consultez les schémas ci-dessus (également illustrés sous le couvercle du

boîtier électrique) pour vérifier les raccords.

3. Dans la mesure du possible, utilisez un compteur pour tester la continuité

du courant dans les fils d’amenée du ventilateur. Pour cela, il faut que le

capaciteur et le rupteur de pression soient déconnectés (Ne pas tester le

capaciteur ; aucune continuité n’y sera mesurée.) Si les fils d’amenée

indiquent une continuité, recâblez le ventilateur, le capaciteur et le rupteur

de pression.

4. Rebranchez l’alimentation électrique et redémarrez le cycle du séchoir.

Vérifiez que le ventilateur démarre.

e toujours pas après que vous êtes passés par

Si le ventilateur ne démar

les étapes 1-4, continuez la pr

5. Vérifiez que le diaphragme du rupteur de pression est bien positionné verticalement comme illustré à Illustration 2 de ces instructions. Si le diaphragme

n’est pas vertical, repositionnez le rupteur de pression et vérifiez le fonctionnement du ventilateur en déclenchant un autre cycle de séchage.

r

e telle qu’indiqué ci-dessous :

océdur

de trop de bruits ou vibrations peut être indicative d’une accumulation de

peluches sur la roue mobile.

mobile :

a. Coupez l’alimentation électrique à sa source.

b. Détachez le conduit de la bouche d’arrivée du ventilateur et enlevez

les peluches accumulées sur la roue mobile.

c. Rattachez le conduit sur le ventilateur. Rebranchez l’alimentation

électrique.

6. Vérifiez que les tubes ne sont pas pincés et que les embouts de connexion

des tubes ne sont pas obstrués.

7. Si le diaphragme du rupteur est positionné verticalement et que le ventilateur ne démarre toujours pas quand l’alimentation électrique est branchée

:

a. Sortez le tube de son embout sur le ventilateur et soufflez douce-

ment dans le tube.

b. Si cela fait démarrer le ventilateur, consultez Fantech pour l’obten-

tion d’une assistance technique plus poussée.

8. Si souffler dans le tube ne fait pas démarrer le ventilateur :

a. Coupez l’alimentation électrique à la source.

b. Sortez les fils d’amenée du rupteur de pression attachés au répar-

titeur.

c. Branchez l’alimentation électrique directement sur le moteur du

ventilateur comme illustré par le diagramme “Câblage du FR110”

ci-dessous.

Appliquez le courant au ventilateur

d.

Si le ventilateur ne démarre toujours pas, veuillez consulter Fantech pour

9.

l’obtention d’une assistance technique plus poussée

Pour l’inspection et le nettoyage de la roue

.

Page 8

SISTEMA DE REFUERZO DE ESCAPE DE LA SECADORA DBF110

1

0,16

24,13

2

4,13

10,16

31,75

28,57

11,43

2

,54

1

,91

7

,62

INSTRUCCIONES DE INSTALACION

El DBF 110 incluye:

1 ventilador de refuerzo de la secadora DBF 110

1 soporte de montaje y herrajes del ventilador

1 letrero pequeño de pared que indica el procedimiento

adecuado de operación

AVISO IMPORTANTE

Lea y guarde estas instrucciones para referencia futura

Dimensiones

FR110 con Interruptor DB10

Ilustración 1

Interruptor de

Presión DB10

Instrucciones para la Instalación

Advertencia: Los ventiladores DBF 110 no son a prueba de explosión. No utilice

los ventiladores si existiera la posibilidad potencial de que se produjera una

explosión.

NO UTILICE con aire calendo en el axceso 140˚F (60˚C).

Montaje del Ventilador e Interruptor

La ubicación recomendada para el ventilador de refuerzo es a un mínimo de 15

pies lineales (no sólo equivalentes) de conducto partiendo de la salida del ventilador. Si se coloca el ventilador a menos de los 15 pies recomendados, puede

enerar presión suficiente para succionar hilacha mojada hasta el impulsor del

g

entilador, y por consiguiente sobrecargar el mismo de hilacha. El sitio idóneo para

v

ontar el ventilador es lo más cerca posible al final del de hilacha conducto.

m

Excepción: Si se instalara un filtro secundario para peluza entre la secadora y el

ventilador de refuerzo, dicho ventilador de refuerzo puede ser instalado a la distancia mínima normalmente recomendada (Véase la ilustración de la izquierda).

Para estabilizar el ventilador, se debe usar un soporte de montaje de tipo NB

sujetado a una viga o riostra. Aunque no es recomendable, se puede apoyar el

ventilador en un conducto rígido vertical, estando el conducto firmemente estabilizado. (Consulte las normas locales vigentes antes de apoyar el ventilador

enteramente en el conducto.) El conducto se debe conectar a la entrada y salida del ventilador mediante grapas antivibratorias o cinta para conductos. Dichas

conexiones deben sellarse adecuadamente para impedir fugas y pérdida de

rendimiento del ventilador. Las conexiones flexibles del conducto entre la conexión de la secadora y el conducto de escape, se deben estirar para que queden

lo más lisas posible.

Operación del Interruptor

Sensor de Presión

El DBF110 de Fantech está equipado con un interruptor de presión DB10 patentado por FanTech. El

tiva que capta la operación de la secadora y activa el ventilador de refuerzo mediante un circuito eléctrico independiente. De esta manera se eliminan las conexiones a través del circuito de la secadora, las cuales podrían anular la garantía de

los fabricantes, así como sistemas manuales que requieren la atención del operador, o bien sistemas costosos sensores de temperatura o corriente.

La alimentación del ventilador de refuerzo se conecta en serie a través de un terminal normalmente abierto en el interruptor. Hay una toma de presión conectada

a un adaptador en el costado del interruptor. Al comenzar a funcionar la secadora, la presión positiva en el conducto dilata el diafragma del interruptor, cerrando

el circuito alimentador del ventilador de refuerzo. El interruptor incorpora un temporizador integral de activación retardada, el cual opera el ventilador en ciclos a

intervalos de 10 minutos. Esto continúa hasta que se desactive la secadora y se

haya vencido el tiempo de retardo controlado por el temporizador. Los ciclos de

secado, el ventilador de refuerzo, el temporizador de retardo y el interruptor de

presión no sufren ningún deterioro ante los intervalos de arranque y parada.

DB10 de Fantech

es un interruptor sensor de presión posi-

Instalación del Ventilador

Paso 1. Ubicación del Ventilador

El ventilador

secadora. De montarse el ventilador a menos de los 15 pies recomendados,

puede generar presión suficiente para levantar hilacha mojada hasta el impulsor

del ventilador, y en consecuencia sobrecargar de hilacha el ventilador. La mejor

Ubicación Alterna

Colector Secundario de Hilacha

ubicación del ventilador en cualquier aplicación , es lo más cerca posible al final

del conducto de salida.

peluza entre la secadora y el ventilador de refuerzo, dicho ventilador de refuerzo puede ser instalado a la distancia mínima normalmente recomendada (Véase

la ilustración de la izquierda).

ventilador debe situarse de manera de dar acceso para dicho servicio. Vea las

ilustraciones anteriores.

tiene que montarse

Excepción: Si se instalara un filtro secundario para

A los efectos del mantenimiento recomendado, el

a no menos de 15 pies de la salida de la

Page 9

Paso 2. Soporte para Montaje

Utilice los tornillos tirafondo para fijar el soporte de montaje a una viga en el

sitio seleccionado. El soporte está provisto de anillos protectores para aislar

cualquier vibración y evitar la transmisión de ruidos a través de la estructura.

Tenga cuidado de no apretar los tornillos en exceso. Aunque el ventilador se

puede instalar a cualquier ángulo, (vea la Ilustración 2), es recomendable orientarlo en sentido vertical a fin de reducir la acumulación de condensado dentro

del mismo. Si resulta necesario instalar el ventilador en posición horizontal y

puede que la acumulación de condensado presente problemas, se puede barrenar un agujero de

un suplemento insertado de rosca NPT [por otros] y tubería de drenaje) para

drenar el condensado.

¹|₄ de pulgada (6 mm.) por el fondo de la carcasa (junto con

Paso 3. Montaje del Ventilador

Para un funcionamiento adecuado, se debe orientar el diafragma del interruptor

en posición vertical (los grabados muestran el diafragma en conductos de orientación horizontal, vertical y angular). La caja de conexiones se debe ubicar

para facilitar el acceso a la misma. Fije el ventilador al soporte con los tornillos

autorroscantes suministrados. Tenga cuidado de no desgarrar la carcasa de

plástico. Aunque no es menester perforar agujeros piloto para los tornillos, es

recomendable barrenar agujeros de ³|₃₂ de pulgada (1 mm.) o menores.

NOTA: Se puede invertir el orden de los Pasos 2 y 3.

Conexiones Eléctricas

NO CONECTE LA CORRIENTE HASTA TANTO EL VENTILADOR QUEDE COMPLETAMENTE INSTALADO. TENGA CUIDADO DE QUE LA ALIMENTACION ELECTRICA DEL

VENTILADOR QUEDE ASEGURADA EN LA POSICION “OFF” (DESCONECTADA).

1. Debido a que esta unidad tiene piezas rotatorias, se deben tomar precauciones de seguridad durante su instalación, operación y mantenimiento.

2. PRECAUCION: “Sólo para ventilación en general. No Utilizar como Extractor

de Materiales Peligrosos o Explosivos ni Vapores”.

3. Advertencia: Para reducir el riesgo de incendio, conmocion electrica o

lesiones personales, observe lo siguiente:

a. Sólo utilice esta unidad de la manera prescrita por el fabricante. Si

tiene cualquier pregunta, favor consultar a la fábrica.

b. Antes del mantenimiento o limpieza, desconecte la alimentación en

el tablero de control y ciérrelo con llave para impedir la activación

accidental del ventilador. En caso de no poder cerrarse con llave el

dispositivo de desconexión, fije firmemente al tablero de control un

dispositivo prominente de advertencia, por ejemplo, una etiqueta.

c. La labor de instalación y cableado eléctrico debe ser realizada por

personal calificado, acorde a todas las normas del caso incluso

construcción calificada para incendios.

d. Hace falta aire suficiente para la debida combustión y extracción de

gases a través de la chimenea de quemadores de combustible, a

fin de impedir el contratiro. Siga las directrices del fabricante de

los equipos de calefacción y normas de seguridad tales como las

publicadas por la National FireProtection Association (NFPA Asociación Nacional de Protección Contra Incendios), la American

Society of Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE -Asociación Americana de Ingenieros de Calefacción,

Refrigeración y Aire Acondicionado), y porlas autoridades competentes de la localidad.

e. Al perforar o cortar paredes o techos, evite dañar cables eléctri-

cos u otros servicios empotrados.

f.

Los ventiladores instalados en conductos siempre deben ventilarse

al exterior

g. Instale el ventilador por lo menos a cinco pies (152 cm.) por enci-

ma del piso.

4. ADVERTENCIA: Compruebe el voltaje de entrada al ventilador para constatar que corresponda al voltaje de placa del motor.

.

Ilustración 2

Posición Correcta del Diafragma Interruptor

Horizontal Vertical Angular

Posición correcta del interruptor

sobre el conducto.

Interruptor Mal Colocado

Ilustración 3

Utilice los tornillos tirafondo para

fijar el soporte de montaje a una

viga en el sitio seleccionado.

los tornillos autorroscantes sum-

Ilustración 4

Vista de la Regleta de Conexión

Circuito del

interruptor

Posición

Correcta del

Interruptor

bajo y

debajo

del

conducto.

Fije el ventilador al soporte con

inistrados.

Hay que instalar guardas donde quiera que el ventilador este al alcance

del personal o a menos de siete (7) pies del nivel

de trabajo, o bien donde se considere aconsejable por

motivos de seguridad.

Alimentación Eléctrica

desde el Tablero de

Disyuntores

Page 10

N

L

Ilustración 5

Cableado del DBF110 — Ventilador e Interruptor de Presión

Cableado

Favor observar: El motor, el capacitor y el interruptor de presión del ventilador

vienen cableados de fábrica.

Cableado de FR110, Sólo V

Paso 8c del Análisis)

Marrón (Z2)

Contactos

del Motor

Azul (U2)

Negro (TK)

Rojo

Blanco

Negro

Verde

entilador

Azul

Marrón

egro

N

Capacitor

Neutro

Linea alimentacion electrica 115V

Tierra

Regleta de Conexiones en

la Caja de Conexiones del

Ventilador

(Regleta de Conexiones en la Refer

Capacitor

Neutro alimentacion

electrica 115V

Linea alimenta-

cion electrica

115V

Contactos

del Motor

ncia del

e

Paso 1.

Desenrosque los tornillos de la tapa de la caja de conexiones ubicada al costado del ventilador. Todas las conexiones del motor del ventilador vienen precableadas a una regleta de conexiones eléctricas. Hará falta un conector romex

restrictor de cable, de ³|₈" (95 mm.), para asegurar el cableado a través del agujero ciego provisto en el costado de la caja de conexiones.

Paso 2.

Pase la alimentación eléctrica a través del conector romex y el agujero ciego del

ventilador. Tenga cuidado de presentar la tuerca del conector por encima del

cableado entrante a la caja de conexiones. Hay tres lumbreras en la regleta de

conexiones. Con un pequeño destornillador ordinario, apriete el hilo Neutro

(Blanco) entrante de la alimentación, por debajo del contacto abierto marcado

“N”. Apriete el hilo de Línea (Negro) entrante de la alimentación por debajo del

contacto abierto marcado “L”. Apriete el hilo de Tierra (Verde) entrante de la alimentación por debajo del contacto abierto marcado “ “. Como referencia hay

un diagrama eléctrico en el interior de la tapa de la caja de conexiones.

Paso 3.

Asegure el conector romex. Fije la alimentación entrante al conector romex.

Vuelva a tapar la caja de conexiones.

Garantia y Mantenimiento

Mantenimiento Recomendado

1. Debido a que los rodamientos del ventilador vienen sellados y lubricados

internamente de fábrica, no hay necesidad de lubricación posterior.

2. En vista de que el impulsor del ventilador puede acumular hilacha, se deben

practicar inspecciones periódicas según el empleo de la secadora, para asegurar que no se obstruya o sobrecarga de hilacha el impulsor del ventilador.

Bajo condiciones normales se debe inspeccionar el ventilador cada seis (6)

Análisis de Fallas

Aviso Importante: Antes de realizar los Pasos 1 al 4, tenga cuidado de que esté

desconectada la alimentación del interruptor del ventilador.

Si el ventilador no arranca al comenzar el ciclo de la secadora, favor hacer el

procedimiento siguiente:

1. Compruebe el voltaje correcto de entrada.

2. Vea el diagrama eléctrico que aparece en los grabados a continuación (también ilustrados en el interior de la tapa de. terminal de cableado del ventilador) para comprobar las conexiones debidas.

3. De ser posible, utilice un medidor para comprobar la continuidad entre los

contactos del motor del ventilador. Para esto hay que desconectar el capacitor y el interruptor de presión. (No compruebe el capacitor, ya que el mismo

no da continuidad.) Si los contactos del motor tienen continuidad, vuelva a

conectar el ventilador, el capacitor y el interruptor de presión.

4. Conecte la alimentación eléctrica y reactive el ciclo de la secadora.

Compruebe la activación del ventilador.

Si el ventilador no logra ponerse en marcha al haber dado los Pasos 1 al 4,

continúe con el procedimiento siguiente:

uptor de presión esté vertical con-

uebe que el diafragma del inter

Compr

5.

me la Ilustración 2 de estas instr

for

ción ver

operación del ventilador en otr

eoriente el inter

tical, r

r

ucciones. Si no se encuentra en posi

uptor de presión y vuelva a ensayar la

r

o ciclo de operación de la secadora.

meses. Nota: Un exceso de ruido o vibración en el ventilador de refuerzo

puede indicar que el impulsor esté atascado de hilacha. Para inspeccionar

y limpiar el impulsor:

a. Desconecte la alimentación eléctrica a la entrada.

b. Desmonte el conducto a la entrada del ventilador y limpie el impulsor

c. Vuelva a conectarle el conducto al ventilador. Reconecte la ali-

mentación eléctrica.

6. Compruebe que la tubería no esté aplastada y que los niples conectores de

la tubería no estén obstruidos.

7. Si el diafragma del interruptor está en posición vertical y aún no arranca el

ventilador estando activada la alimentación:

a. Desmonte la tubería del niple del ventilador y sople suavemente

hacia el interior de la tubería;

b. Si el ventilador arranca, diríjase de nuevo a Fantech para la con-

sulta técnica.

8. Si el ventilador aún no arranca tras de haberle soplado la tubería:

a. Desconecte la alimentación eléctrica.

b. Desconecte los contactos del interruptor de presión, de la regleta

de conexiones.

Conecte la alimentación eléctrica dir

c.

lador confor

FR110”.

d. Active el ventilador.

Si el ventilador aún no ar

9.

-

ta técnica.

me el diagrama a continuación titulado “Cableado del

ranca, diríjase de nuevo a Fantech para la consul

ectamente al motor del venti

.

-

-

Page 11

Garantie de 5 ans

DURANT TOUTE LA PÉRIODE DE GARANTIE:

FANTECH, INC. s'engage à réparer ou à remplacer toute pièce présentant un

défaut d'usine en matière de qualité d'exécution ou de matériau. Il sera peut

être nécessaire de retourner le produit à l'usine FANTECH, accompagné d'une

copie du contrat de vente et du numéro d'autorisation de retour.

Garantía por cinco (5) años

DURANTE EL PERÍODO INTEGRO DE LA GARANTÍA:

FANTECH reparará o reemplazará toda parte que presente un defecto en el

material o en la mano de obra. Es posible que el producto deba ser devuelto a

la fabrica FANTECH, juntamente con una copia de la constancia de compraventa e identificado con el número de RMA.

POUR RETOURNER UN PRODUIT À L'USINE, VOUS DEVEZ:

• Obtenir un numéro d'autorisation de retour; pour ce faire, communiquer

avec FANTECH, INC. aux États-Unis au numéro 1 800 747-1762, ou au

Canada, au numéro 1 800 565-3548. Veuillez avoir votre contrat de vente

à portée de la main.

• S'assurer que le numéro d'autorisation de retour est lisible sur l'extérieur

de la boîte, sinon la boîte sera refusée.

• Toutes les pièces et/ou le produit seront réparés ou remplacés puis

retournés à l'acheteur. Aucun crédit ne sera accordé.

OU

Le Distributeur peut commander une pièce ou un produit couvert par la

garantie; la facture lui sera envoyée. Le distributeur ne sera crédité du montant de sa facture qu'après que le produit a été retourné port payé et qu'il a

été trouvé défectueux.

LES TERMES DE LA GARANTIE DE F

PLACEMENT SANS FRAIS AVANT QUE LA PIÈCE OU LE PRODUIT

DÉFECTUEUX AIT ÉTÉ INSPECTÉ. LES PRODUITS OU PIÈCES REMPLACÉS

AVANT L'INSPECTION DE LA DÉFECTUOSITÉ SERONT FACTURÉS ET LE MONTANT DU CRÉDIT EST FONCTION DE L'INSPECTION DE LA PIÈCE OU DU PRODUIT RETOURNÉ. LE DISTRIBUTEUR NE DOIT PAS REMPLACER SANS FRAIS

POUR L'UTILISATEUR FINAL L'ÉQUIPEMENT DÉFECTUEUX RETOURNÉ PAR

L'UTILISATEUR FINAL, CAR LE COMPTE DU DISTRIBUTEUR NE SERA CRÉDITÉ

QU'APRÈS L'INSPECTION ET LA VÉRIFICATION PAR FANTECH DE LA

DÉFECTUOSITÉ.

LES GARANTIES NE S'APPLIQUENT PAS DANS LES CAS SUIVANTS:

• Dommages dus au transport (dissimulés ou visibles). Les réclamations

doivent être faites à la compagnie de fret.

• Dommages dus au mauvais câblage ou à l'installation inappropriée.

• Dommages ou défectuosité causés par une calamité naturelle ou résultant

d'une procédure irrégulière de l'acheteur, notamment:

1. Entretien irrégulier

2. Mauvais usage, usage abusif, usage anormal ou accident

3. Tension ou courant électrique incorrect

• Enlèvement ou toute modification du numéro de contrôle ou de la date de

fabrication de l'étiquette FANTECH

• Toute autre garantie expresse, écrite ou implicite, pour les dommages accidentels ou indirects, perte de biens, de recettes, manque à gagner ou

coûts relatifs à la dépose, à l'installation ou à la réinstallation, en cas de

violation de garantie.

CERTIFICATION DE LA GARANTIE:

• L'utilisateur doit conserver une copie du contrat de vente pour confirmer la

date d'achat.

• Les présentes garanties vous donnent des droits spécifiques reconnus par

la loi et sont régies par les lois sur la pr

priées. Il est possible que différents états offrent d'autres droits.

ANTECH NE PRÉVOIENT PAS DE REM-

otection du consommateur appr

o

PARA DEVOLUCIÓN A FÁBRICA USTED DEBE:

• Tener un número de Autorización de Devolución de Material (RMA). Esto se

puede obtener llamando a FANTECH ya sea en los Estados Unidos al

1.800.747.1762 o en Canadá al 1.800.565.3548. Tenga a mano la constancia de compraventa.

• El número de RMA deberá estar claramente escrito en la parte exterior de

la caja, de lo contrario la caja será rechazada.

• Todas las partes y/o el producto serán reparados/reemplazados y devueltos

al comprador; no se otorgará crédito.

O BIEN

El Distribuidor puede colocar una orden por la parte y/o producto en garantía y

facturarla/o. El Distribuidor recibirá un crédito igual a la factura sólo después

de que se haya devuelto el producto con pago previo y con verificación de

defecto.

LAS CONDICIONES DE LA GARANTÍA DE F

REEMPLAZO SIN CARGO ANTES DE REALIZAR LA INSPECCIÓN PARA DETECTAR DEFECTOS. LOS REEMPLAZOS EMITIDOS ANTES DE INSPECCIONAR

POR DEFECTOS SON FACTURADOS, Y EL CRÉDITO ESTÁ A LA ESPERA DE

INSPECCIÓN DEL MATERIAL DEVUELTO. EL MATERIAL DEFECTUOSO

DEVUELTO POR LOS USUARIOS FINALES NO DEBERÁ SER REEMPLAZADO

POR EL DISTRIBUIDOR SIN CARGO PARA EL USUARIO FINAL, YA QUE EL

CRÉDITO DE LA CUENTA DEL DISTRIBUIDOR ESTARÁ A LA ESPERA DE

INSPECCIÓN Y VERIFICACIÓN DEL DEFECTO REAL POR FANTECH.

LAS SIGUIENTES GARANTÍAS NO SE APLICAN:

• Daños durante el envío, ya sean encubiertos o visibles. Se deberá presentar

el reclamo a la compañía transportadora.

• Daños ocasionados por cableado o instalación indebidos.

• Daños o fallas causados por hechos fortuitos, u ocasionados por procedimientos impropios por parte del usuario, tales como:

1. Mantenimiento indebido

2. Uso indebido, abuso, uso anormal o accidente y

3. Tensión o corriente eléctrica incorrecta.

• Remoción o modificación realizada al número de control del rótulo

de FANTECH o de la fecha de fabricación.

• Toda otra garantía, expresa, implícita o escrita, daños y perjuicios, pérdida

de propiedad, de ingresos, o de beneficios, o costo de remoción, instalación

o reinstalación por incumplimiento de la garantía.

VALIDACIÓN DE LA GARANTÍA:

• El usuario debe conservar una copia de la constancia de compraventa para

verificar la fecha de compra.

Estas garantías le otor

•

-

una legislación aplicable para protección del consumidor. Usted puede tener

echos adicionales que varían de estado en estado.

der

echos legales específicos, y están sujetas a

gan der

ANTECH NO CONTEMPLAN EL

Page 12

Five (5) Year Warranty

DURING ENTIRE WARRANTY PERIOD:

FANTECH will repair or replace any part which has a factory defect in workmanship or material. Product may need to be returned to the Fantech factory,

together with a copy of the bill of sale and identified with RMA number.

FOR FACTORY RETURN YOU MUST:

• Have a Return Materials Authorization (RMA) number. This may be obtained

by calling FANTECH either in the USA at 1.800.747.1762 or in CANADA at

.800.565.3548. Please have bill of sale available.

1

• The RMA number must be clearly written on the outside of the carton, or

the carton will be refused.

• All parts and/or product will be repaired/replaced and shipped back to buyer;

no credit will be issued.

OR

The Distributor may place an order for the warranty part and/or product and is

invoiced. The Distributor will receive a credit equal to the invoice only after

product is returned prepaid and verified to be defective.

FANTECH WARRANTY TERMS DO NOT PROVIDE FOR REPLACEMENT WITHOUT CHARGE PRIOR TO INSPECTION FOR A DEFECT.

REPLACEMENTS ISSUED IN ADVANCE OF DEFECT INSPECTION ARE

INVOICED, AND CREDIT IS PENDING INSPECTION OF RETURNED

MATERIAL. DEFECTIVE MATERIAL RETURNED BY END USERS SHOULD NOT

BE REPLACED BY THE DISTRIBUTOR WITHOUT CHARGE TO THE END USER,

AS CREDIT TO DISTRIBUTOR’S ACCOUNT WILL BE PENDING INSPECTION AND

VERIFICATION OF ACTUAL DEFECT BY FANTECH.

THE FOLLOWING WARRANTIES DO NOT APPLY:

• Damages from shipping, either concealed or visible. Claim must be filed with

freight company.

• Damages resulting from improper wiring or installation.

• Damages or failure caused by acts of Gad, or resulting from improper con-

sumer procedures, such as:

1. Improper maintenance

2. Misuse, abuse, abnormal use, or accident, and

. Incorrect electrical voltage or current.

• Removal or any alteration made on the FANTECH label control number or

• Any other warranty, expressed, implied or written, and to any consequential

WARRANTY VALIDATION

• The user must keep a copy of the bill of sale to verify purchase date.

• These warranties give you specific legal rights, and are subject to an applica-

3

date of manufacture.

or incidental damages, loss or property, revenues, or profit, or costs of

removal, installation or reinstallation, for any breach of warranty.

ble consumer protection legislation. You may have additional rights which

vary from state to state.

United States

1712 Northgate Blvd.,

Sarasota, FL. 34234

Phone: 800.747.1762; 941.309.6000

Fax: 800.487.9915; 941.309.6099

.fantech.net; info@fantech.net

www

Canada

50 Kanalflakt Way,

Bouctouche, NB E4S 3M5

Phone: 800.565.3548; 506.743.9500

Fax: 877.747.8116; 506.743.9600

.fantech.ca; info@fantech.ca

www

Fantech, reserves the right to modify, at any time and without notice, any

or all of its pr

maintain their technological leadership position.

oducts’ featur

es, designs, components and specifications to

Item #: 401441

Rev Date: 120606

Loading...

Loading...