Fantech DBF110 User Manual

fantech

Installation and Operation Manual

Manuel d'installation et d'opération

Manual de Instalación y Mantenimiento

DBF110

Dryer Booster Fans

Amplicateur de séchoir

Booster Secadora

DBF110 Kit Includes:

Dryer Booster Fan, 1 pc

Fan Mounting Bracket and Hardware, 1 pc

Small Wall Sign Indicating Proper Operation

Procedure, 1 pc

Item #: 401441

Rev Date: 042514

La trousse du DBF110 inclus:

Ventilateur en ligne, 1 pc

Support de montage pour le ventilateur avec

quincaillerie,1 pc

Petit panneau indiquand la bonne procédure

d'opération, 1 pc

El DBF110 incluye:

Ventilador de Refuerzo de la Secadora, 1 pc

Soporte de Montaje y Herrajes del Ventilador, 1 pc

Letrero Pequeño de Pared que Indica el

Procedimiento Adecuado de Operación, 1 pc

United States

10048 Industrial Blvd., Lenexa, KS, 66215

Tel.: 800.747.1762 • Fax: 800.487.9915

Canada

50 Kanalflakt Way, Bouctouche, NB, E4S 3M5

Tel.: 800.565.3548 • Fax: 877.747.8116

2

Note Warning /

Read and Save these instructions for

future reference.

1. DBF 110 fans are not explosion proof. Do

not use the fans if a potentially explosive

situation may exist.

2. Because this unit has rotating parts, safety

precautions should be exercised during this

phase of installation, operation and

maintenance.

3. CAUTION: For General Ventilation Use Only.

Do Not Use To Exhaust Hazardous Or Explosive

Material and Vapors.

4. The fan motor, capacitor and pressure

switch connections are pre-wired from the

factory.

Information Technical

Important

information

note

Veillez à lire et conserver ces

instructions pour leur consultation

future

1. Veuillez noter que les ventilateurs DBF110

à monter sur conduits d’évacuation ne sont pas

à l’épreuve des explosions. Ne pas utiliser les

ventilateurs dans des situations potentiellement

explosives.

2. Étant donné ses parties amovibles,

certaines précautions doivent être prises lors

de l’installation, l’opération et l’entretien.

3. ATTENTION: “Pour usage de ventilation

générale seulement.Ne pas utiliser pour

l’évacuation de matériaux et de vapeurs

dangereux ou explosifs.”

4. Veuillez noter que les raccords du moteur

du ventilateur, du condensateur et du rupteur

de pression ont été câblés à l’avance en usine.

Practical tip

Lea y guarde estas instrucciones para

referencia futura

1. Los ventiladores DBF 110 no son a prueba de

explosión. No utilice los ventiladores si existiera

la posibilidad potencial de que se produjera una

explosión.

2. Debido a que esta unidad tiene piezas

rotativas, hay que tomar precauciones de

seguridad durante la instalación, operación y

mantenimiento.

3. PRECAUCION: “Sólo para Ventilación en

General. No trate de Utilizarse como Extractor

de materiales y Vapores Peligrosos o Explosivos.”

4. El motor, el capacitor y el interruptor de

presión del ventilador vienen cableados de

fábrica.

fantech

3

WARNINGS

DO NOT CONNECT POWER SUPPLY UNTIL FAN IS

COMPLETELY INSTALLED. MAKE SURE ELECTRICAL

SERVICE TO THE FAN IS LOCKED IN "OFF" POSITION.

1. TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS - OBSERVE

THE FOLLOWING:

a. Use this unit only in the manner intended by

the manufacturer. If you have questions,

contact the factory.

b. Before servicing or cleaning, switch power off

at service panel and lock service panel to

prevent fan from being switched on

accidentally. When the service disconnecting

means cannot be locked, securely fasten a

prominent warning device, such as a tag, to

the service panel.

c. Installation work and electrical wiring must

be done by qualified person(s) in accordance

with all applicable codes and standards,

including fire-rated construction.

d. The combustion airflow needed for safe

operation of fuel burning equipment may be

affected by this unit's operation. Follow the

heating equipment manufacturer's guidelines

and safety standards such as those

published by the National Fire Protection

Association (NFPA), the American Society of

Heating, Refrigeration, and Air Conditioning

Engineers (ASHRAE) and the local code

authorities.

e. When cutting or drilling into wall or ceiling,

do not damage electrical wires or other

hidden utilities.

f. Ducted fans must always be vented to the

outdoors.

g. Install the fan a minimum of 5 linear feet

from the dryer outlet.

2. WARNING! Check voltage at the fan to see if

it corresponds to the motor nameplate.

3. DO NOT USE with heated air in excess 140F

(60C).

ADVERTISSEMENTS

NE BRANCHEZ PAS LE COURANT AVANT D’AVOIR

ENTIÈREMENT TERMINÉ L’INSTALLATION DU

VENTILATEUR. S’ASSUREZ QUE L’ALIMENTATION

ÉLECTRIQUE DU VENTILATEUR EST VERROUILLÉE EN

POSITION “OFF” (ARRÊT).

1. AVERTISSEMENTS POUR RÉDUIRE LES

RISQUES D’INCENDIE, DE DECHARGE

ELECTRIQUE OU RISQUE DE BLESSURES. SUIVEZ

LES CONSEILS SUIVANTS:

a. N’utilisez ce dispositif que de la manière

préconisée par le fabricant. Pour toutes

questions, veuillez contacter l’usine de

fabrication.

b. Avant tout entretien ou nettoyage, coupez le

courant au tableau électrique et verrouillez ce

dernier pour empêcher l’activation

accidentelle du ventilateur. Quand le système

de coupure de courant ne peut pas être

verrouillé, attachez solidement sur le tableau

électrique, un dispositif de signalisation bien

en vue, tel qu’une étiquette.

c. Les travaux d’installation et de branchement

électrique doivent être faits par un personnel

qualifié et conformément aux dispositions de

tous les codes et normes de construction en

vigueur, y compris celles de prévention des

incendies.

d. Une ventilation suffisante à la bonne

combustion et évacuation des gaz par le

conduit (la cheminée) des équipements

fonctionnant au carburant est nécessaire de

façon à empêcher les refoulements. Suivez

les instructions données et les normes de

sécurité communiquées par le fabricant,

telles que celles publiées par l’Association

nationale de protection contre les incendies

(National Faire Protection Association

[NFPA]), l’Association américaine des

ingénieurs en chauffage, réfrigération et

climatisation (American Society of Heating,

Refrigeration, and Air Conditioning [ASHRAE])

et les autorités localement en charge de la

construction.

e. Lors du perçage ou du découpage d’un mur

ou d’un plafond, prenez garde de ne pas

endommager les fils électriques ou autres

conduits s’y trouvant dissimulés.

f. Les ventilateurs installés sur les conduits

doivent toujours être ventilés vers l’extérieur.

g. Installez le ventilateur à ua moins 1,55m

(5 pi.) linéaires à partir de la sortie du

ventilateur.

2. ATTENTION : Vérifier le voltage afin de voir s’il

correspond à celui indiqué sur la plaque du

moteur.

ADVERTENCIAS

NO CONECTE LA CORRIENTE HASTA TANTO EL

VENTILADOR QUEDE COMPLETAMENTE INSTALADO.

TENGA CUIDADO DE QUE LA ALIMENTACION

ELECTRICA DEL VENTILADOR QUEDE ASEGURADA EN

LA POSICION “OFF” (DESCONECTADA).

1. ADVERTENCIA: PARA REDUCIR EL RIESGO DE

INCENDIO, CONMOCION ELECTRICA O LESIONES

A PERSONAS, OBSERVE LO SIGUIENTE:

a. Sólo utilice esta unidad de la manera

prescrita por el fabricante. Si tiene cualquier

pregunta, favor consultar a la fábrica.

b. Antes del mantenimiento o limpieza,

desconecte la alimentación en el tablero de

control y ciérrelo con llave para impedir la

activación accidental del ventilador. En caso

de no poder cerrarse con llave el dispositivo

de desconexión, fije firmemente al tablero de

control un dispositivo prominente de

advertencia, por ejemplo, una etiqueta.

c. La labor de instalación y cableado eléctrico

debe ser realizada por personal calificado,

acorde a todas las normas del caso incluso

construcción calificada para incendios.

d. Hace falta aire suficiente para la debida

combustión y extracción de gases a través

de la chimenea de quemadores de

combustible, a fin de impedir el contratiro.

Siga las directrices del fabricante de los

equipos de calefacción y normas de

seguridad tales como las publicadas por la

National FireProtection Association (NFPA Asociación Nacional de Protección Contra

Incendios), la American Society of Heating,

Refrigeration and Air Conditioning Engineers

(ASHRAE -Asociación Americana de

Ingenieros de Calefacción, Refrigeración y

Aire Acondicionado), y porlas autoridades

competentes de la localidad.

e. Al perforar o cortar paredes o techos, evite

dañar cables eléctricos u otros servicios

empotrados.

f. Los ventiladores instalados en conductos

siempre deben ventilarse al exterior.

g. Instale el ventilador con un minimo de

distancia de 5 pies lineales de la salida del

secador.

4. ADVERTENCIA: Compruebe el voltaje de

entrada al ventilador para constatar que

corresponda al voltaje de placa del motor.

3. NO UTILICE con aire calendo en el axceso 140F

(60C).

3. N’EMPLOYEZ PAS si que l’air est supérieur a

140F (60C).

fantech

4

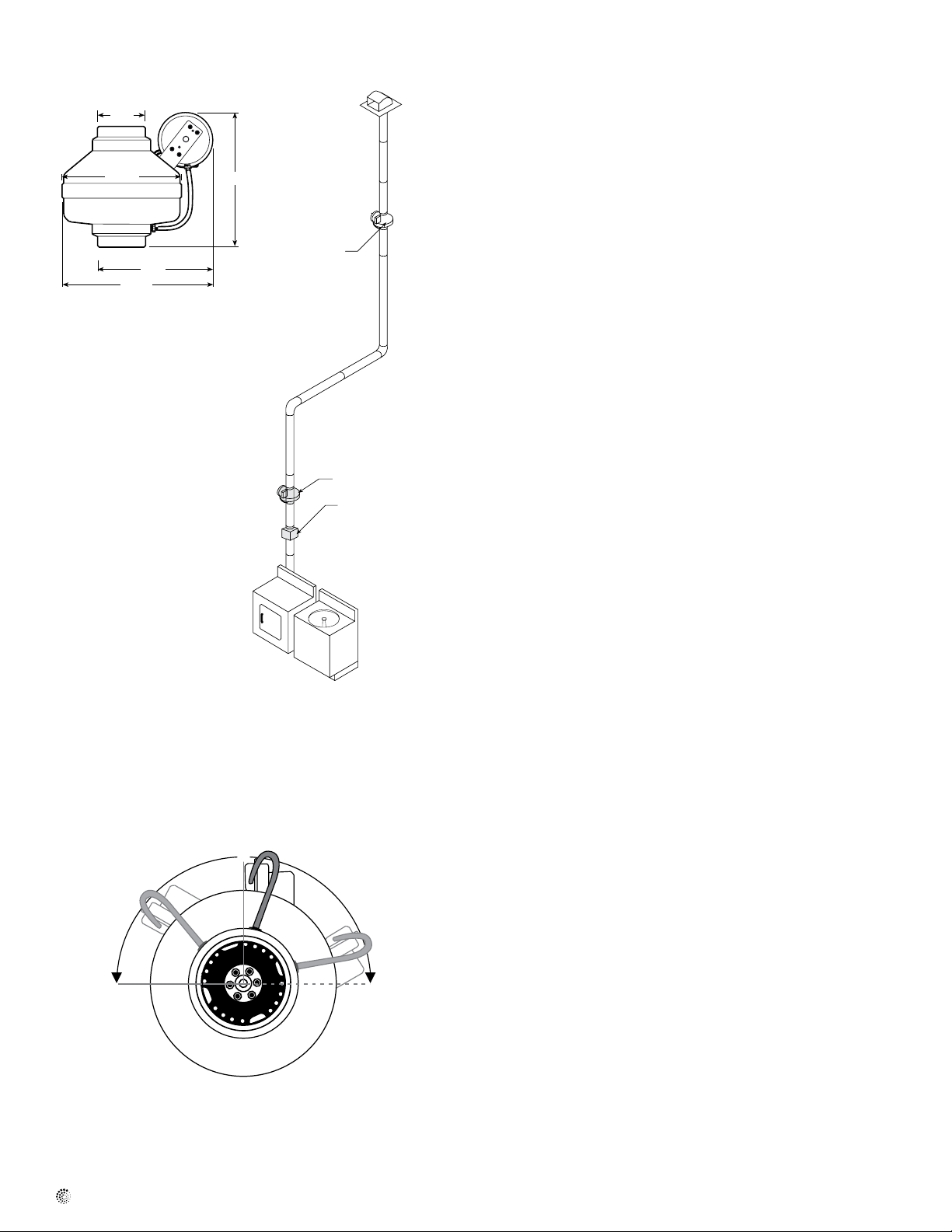

121/2”

111/4”

91/2”

91/2”

37/8”

Dimensional Data

Dimensions are in inches.

12-o-clock

Illustration 1

DBF110

Alternative Location

Secondary Lint Trap

Installation Guidelines

Fan and Switch Mounting

The DBF110 is to be mounted a minimum of 5 linear (not equivalent) feet

from the dryer outlet. A secondary lint trap (DBLT 4W) is recommended

if the fan is installed between 5 and 15 linear (not equivalent) feet from

the dryer outlet in applications, where excessive dryer lint generation is

likely or to increase the time interval between routine maintenance of the

Dryer Booster Fan (See illustration to left). An NB mounting bracket

attached to a rafter or joist should be used to stabilize the fan. Although

not recommended, a vertical rigid duct may support the fan if the duct is

securely stabilized. (Consult local codes prior to supporting the fan in the

duct alone.) Duct work should be attached to the inlet and outlet of the

fan by means of FC vibration isolation clamps (not included) or duct tape.

The duct connection should be properly sealed to prevent leakage and

loss of fan performance. Flex duct connections between the dryer duct

connection and exhaust duct should be stretched as smooth as possible.

Calculating Duct Run

To calculate the length of your planned duct run, measure from the dryer

to external venting point in roof or wall. For each bend or elbow add 5-7

feet to your total duct run calculations. The DBF110 can be used on runs

up to 108 feet.

Pressure Sensor Switch Operation

Fantech’s DBF110 is equipped with Fantech's Patented DB10 pressure

switch. The DB10 is a positive pressure sensing switch which

recognizes dryer operation and activates the booster fan from an

independent electrical circuit. This eliminates connections through the

dryer circuit which may void the manufacturers’ warranty as well as

manual systems which require the attention of the operator or costly

current/temperature sensing systems.

The electricity to the booster fan is connected in series through a

normally open terminal on the switch. A pressure tap is connected to a

fitting on the side of the switch. When the dryer begins operation,

positive pressure in the duct causes the switch diaphragm to expand,

closing the circuit to the booster fan. An integral delay-on-break timer in

the switch will cycle the fan on for intervals of 10 minutes. This will continue until the dryer has stopped and the timer delay period has lapsed.

Drying cycles, the booster fan, the delay timer and the pressure switch

are not adversely affected by the starting/stopping intervals.

fantech

10-o-clock

2-o-clock

Sensitivity Adjustment Instruction

a. Disconnect power to the booster fan.

b. Looking from the inlet (dryer side), the switch should be at the

12-o-clock position.

c. Remove the 2 mounting screws holding the switch to the fan.

d. Rotate the switch to the 10-o-clock position for less sensitivity or

2-o-clock position for more sensitivity then secure it there, you may

have to adjust (bend) the bracket to fit. Secure the switch with the

2 screws previously removed.

e. Apply power to the fan and check for operation.

5

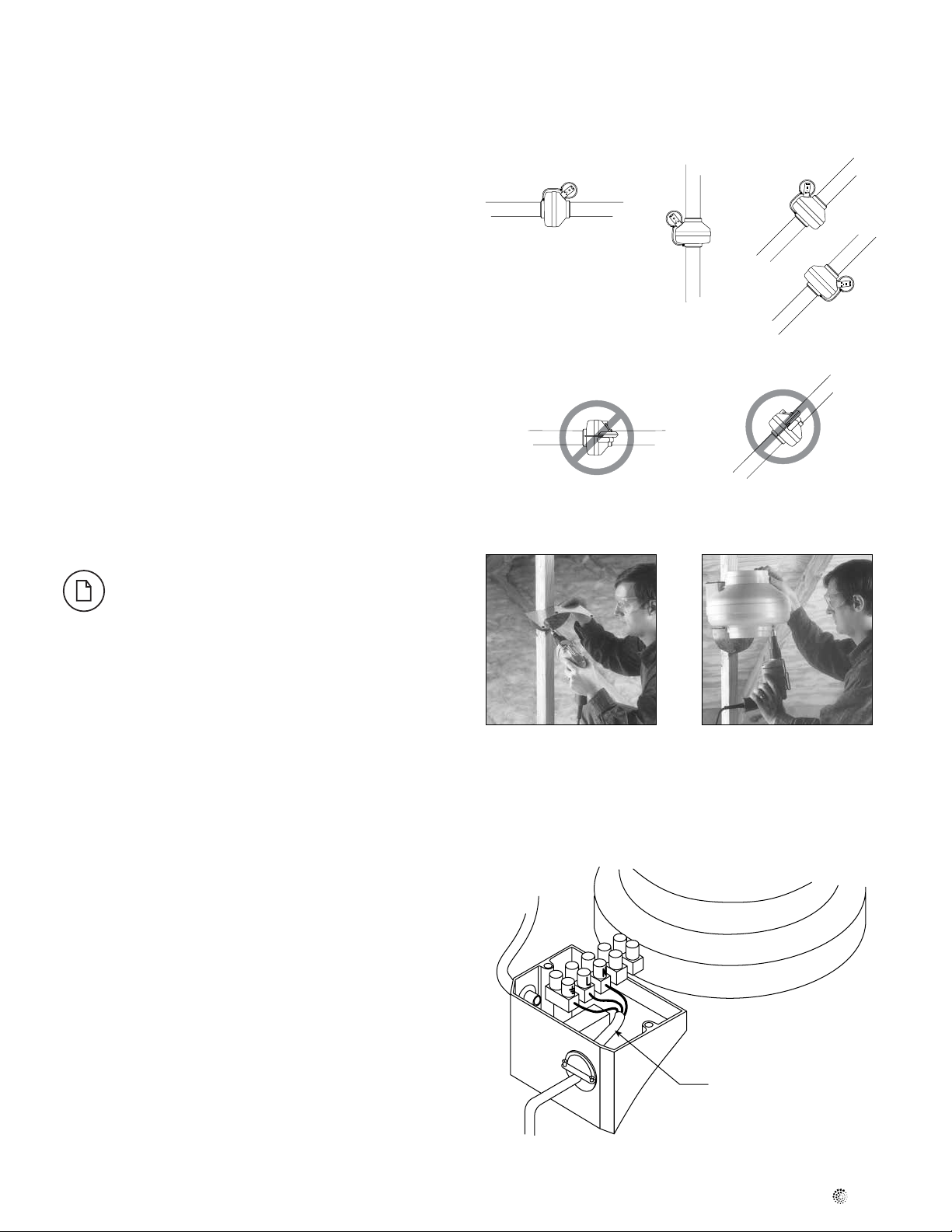

Fan Installation

Step 1. Selecting Fan Location

Fan must be mounted a minimum of 15 feet from the dryer outlet.

In order to perform recommended maintenance, fan location should allow

sufficient access for service. Refer to dimensional drawings shown above.

Step 2. Mount Bracket

Using the wood screws provided, attach the mounting bracket to a support

beam at the selected location. Bracket is provided with grommets in order

to isolate any vibration and prevent the transmission of sound through the

structure. Be careful not to overtighten. Fan mounting can be in any angle

(see ill. 2), however, vertical mounting is recommended to reduce

condensation buildup in the fan. If a horizontal installation is necessary and

condensation buildup may pose a problem, a ¼" hole drilled in the bottom

of the housing (along with an NPT insert [by others] and drain tubing) may

be installed to allow condensation to drain.

Step 3. Mount Fan

For proper operation, the switch diaphragm must be positioned vertically.

(Illustrations below show diaphragm position for horizontal, vertical and

ducts installed at an angle.) Wiring box should be positioned for easy

access. Attach fan to the mounting bracket with the self tapping screws

provided. Care should be taken not to strip the plastic housing. Although

screw pilot holes are not required, 3/32" (or smaller) pilot holes are

recommended.

Illustration 2

Correct Mounting of Diaphragm Switch

Horizontal Vertical Angled

Switch mounted

properly

above and

below

Switch mounted

properly above

duct.

Incorrect Mounting of Diaphragm Switch

duct.

Illustration 3

Steps 2 & 3 may be reversed.

Attach Mounting Bracket to

stud using screws provided.

Illustration 4

Switch Circuit

Attach Fan to Mounting

Bracket using screws provided.

Electrical Supply from

Breaker Panel

fantech

Loading...

Loading...