Page 1

fantech

Installation, Operation and Maintenance Manual

HEPA Series

Air Filtration System

Item #: 401482

Rev Date: 091914

Your Fantech HEPA Filtration system should be installed in conformance with the appropriate local, provincial or state

requirements or in the absence of such requirements with the current edition of the National Building Code, and / or

ASHRAE’s “ Good Engineering Practices”.

United States

10048 Industrial Blvd., Lenexa, KS, 66215

Tel.: 800.747.1762 • Fax: 800.487.9915

Canada

50 Kanalflakt Way, Bouctouche, NB, E4S 3M5

Tel.: 800.565.3548 • Fax: 877.747.8116

Fantech reserves the right to modify, at any time and without notice, any or all of its products’ features, designs,

components and specifications to maintain their technological leadership position.

Please visit our website www.fantech.net for more detailed technical information.

Page 2

2

Note Warning/

Important

Information Technical

information

Practical tip

note

PLEASE READ THIS MANUAL BEFORE INSTALLING UNIT

Before installation, careful consideration must be given to how this system will operate if connected to any other

piece of mechanical equipment, i.e. a forced air furnace or air handler, operating at a higher static pressure.

Products are designed and manufactured to provide reliable performance, but they are not guaranteed to be 100%

free of defects. Even reliable products will experience occasional failures, and this possibility should be recognized

by the user. If these products are used in a life support ventilation system where failure could result in loss or injury,

the user should provide adequate back-up ventilation, supplementary natural ventilation or failure alarm system, or

acknowledge willingness to accept the risk of such loss or injury.

Your Fantech HEPA Filtration system should be installed in conformance with the appropriate local, provincial or

state requirements or in the absence of such requirements with the current edition of the National Building Code,

and / or ASHRAE’s “ Good Engineering Practices”.

fantech

Page 3

Table of content

INTRODUCTION..............................................................................4

DIMENSIONS ...............................................................................4

SPECIFICATIONS .............................................................................4

OPERATION ................................................................................4

INSTALLATION ..............................................................................5

CM 3000 – Uninsulated model

Option A.......................................................................5

Option B.......................................................................5

Option C.......................................................................5

Option D.......................................................................6

CM 3000 I – Insulated model

Option A.......................................................................7

Option B.......................................................................7

Option C.......................................................................8

Option D.......................................................................8

Whole House – Connecting a ventilation system (HRV/ERV) to HEPA system ...........................9

3

SERVICE .................................................................................10

PARTS LIST ...............................................................................10

MAINTENANCE SCHEDULE ....................................................................11

fantech

Page 4

4

Introduction

HEPA Air Filtration Systems

You have purchased a very effective air cleaning and treatment system incorporating HEPA (High Efciency Particulate Arrestance) lter technology.

This is the type of air cleaning equipment that respiratory specialists recommend most. To optimize the performance of your HEPA Filtration System, it

should be installed by a professional contractor who is familiar with your indoor air quality situation and the operation of other heating, ventilation and

air conditioning equipment that you may have.

Two Units to Choose From

The Fantech HEPA Filtration system is available in two different models, depending on your choice of installation. Typically the CM 3000 is used in

geographical locations where the HEPA unit can be installed in a conditioned space such as a basement, closet or heated crawl space, (Example on

page 5 & 6). The CM 3000 I (Insulated version) is normally installed in the southern U.S. states where it's common to locate the HVAC equipment in an

unconditioned space such as a garage or attic (Example on pages 7 & 8).

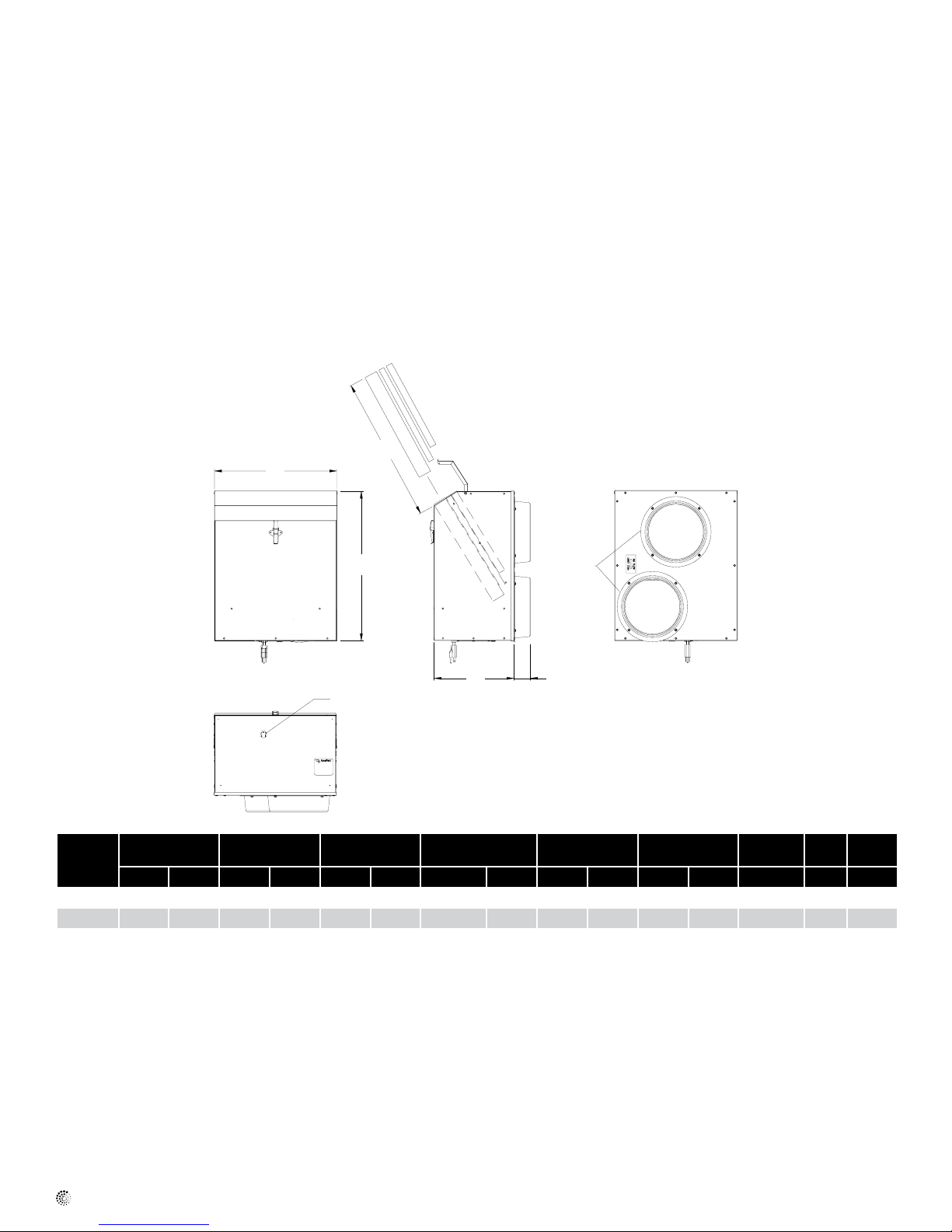

Dimensions

C

A

B

Front

3" Cord- 3 Prong Plug

Model A B C* D E F

in mm in mm in mm in mm in mm in mm V Amps cfm

CM 3000 16 4/5418 20 508 16 1/2420 10 11/

CM 3000 I 18 3/5434 22 3/10524 16 1/2420 13 288 2 3/

* Clearance required for servicing the unit

D E

Side

272 2 3/

16

F

55 8 203 115/V1/60 1 240

10

55 8 203 115/V1/60 1 240

10

Air In

Air Out

Back

Voltage Amp Delivery

Duct Size

Specifications

Model CM 3000 (uninsulated)

Insulated skin can be purchased separately and installed in the eld if required

Kit (included): – Two pcs. of uninsulated 8" ex (UL Listed)

– Four 8" round port collar

– Hanging Chains and hardware

– Installation manual

fantech

Model CM 3000 I (insulated)

Unit (included): – Two 8" round port collar

– Hanging Chains and hardware

– Installation manual

Page 5

Operation

Your Fantech HEPA ltration system incorporates three stages of ltration. Air is drawn from the house via one of the installation examples, found

in this manual, by a powerful efcient EBM fan. The air is cleaned as it passes through the lters, where it is then reintroduced back into the home,

cleaned of the majority of harmful particles.

A semi-annual service schedule must be followed to ensure the HEPA unit is operating at its full potential.

Installation

CM 3000 - Uninsulated model

Option A & B

* Diagrams are examples only. Actual installation may vary.

The return side of the furnace is the recommended location for the HEPA to connect to. The supply side is normally avoided due to the higher static

pressure.

Furnace fan should operate continuous or when HEPA unit is on and running. (Options A & B)

5

Air Return

Option A Option B

Option C

* Diagrams are examples only. Actual installation may vary.

Duct work can be concealed in walls or closets. If the floor is the only choice, special care should be taken to avoid noise or drafts.

fantech

Page 6

6

Installation (Cont'd)

Option D

* Diagrams are examples only. Actual installation may vary.

Unit can be installed in a closet. Air drawn from a hallway or living area is cleaned by the HEPA unit and reintroduced back into a bedroom or other

room.

fantech

Page 7

Installation (Cont'd)

CM 3000 I - Insulated model

* Diagrams are examples only. Actual installation may vary.

In options A & B, the air handler should operate continuously or when HEPA unit is on and operating.

Special care and attention must be given to ensure that all openings in unit, and its duct connections, are sealed, to prevent vehicle

exhaust from entering the unit. Always follow local and state building codes as well as good engineering practices.

7

Option A – Garage installation

Option B – Attic installation connected to return of or handler

fantech

Page 8

8

Installation (Cont'd)

CM 3000 I - Insulated model (continued)

* Diagrams are examples only. Actual installation may vary.

When unit is installed in an unconditioned space such as option C or option D, ductwork (not included) must be insulated and installed according to

local and state codes.

Unit should always be installed in a location that will allow the best possible access for service. Flexible ducting can be restrictive to airflow and

should be kept to a minimum. Avoid excessive turns, cramped ductwork and pinching.

*Proper airflow should be confirmed after installation

30" max

recommended

16.5" of clearance is

needed from front of unit to

access lter for service.

Option C – Independently ducted

Unconditioned

crawl space

Option D – Independently ducted installation in crawled space

fantech

Page 9

Installation (Cont'd)

Whole House – Connecting a ventilation system (HRV/ERV) to a HEPA system

* Diagrams are examples only. Actual installation may vary.

Installation may vary drastically from picture depending on location of all appliances. After installation, proper operation of all the appliances must be

confirmed by a qualified contractor.

3" to 3" (1m)

Fresh air

from outside

Recommended

9

Minimum of 3' - 3"

(1m) separation of

ducts is recommended

Ventilation system (HRV/ERV) should be installed and balanced in accordance with its installation manual.

Furnace fan must be on when either the ventilation system (HRV/ERV) or the HEPA filtration system is operating.

A power damper is recommended to prevent backdrafting of some models of air to air changers, when in the off or standby position. This damper will

be installed between the HRV/ERV and the HEPA unit.

Models Flex100H, VHR100R, 70R, 150R, 1405R, 2005R, SHR1505R, 2005R & 3005R have an automatic backdraft damper build in that

activates when units are in standby position and do not need this additional damper.

All units should be checked after installation for compatibility and proper operation.

fantech

Page 10

10

Service

The useful service life of the lter media in the HEPA Filtration System is directly related to the

volume of air passed through the system and the amount of contaminants in the air. In a typical

residential application, Stage 1 and 2, lters should be replaced every three to six months or when

needed. The Stage 3 HEPA lter should have a life span of two to ve years, again, depending on

the amount of particulate in the air and the maintenance of the Stage 1 pre-lter.

Parts list

Stage 1

Stage 3

Stage 2

Warranty

• The maintenance free motors are

permanently lubricated and are

guaranteed for 7 years. They are

factory balanced to prevent

vibrations and promote silent

operation.

• All other components have a 5 year

limited warranty. (filters not included)

• The limited warranty covers normal

use. It does not apply to any defects,

malfunctions or failures as a result

of improper installation, abuse,

mishandling or misapplication,

fortuitous occurrence or any other

circumstances outside

manufacturer's control.

• The warranty is in effect for 5 years

on parts and 7 years on the motor

after the date of purchase, including

parts replaced during this time

period. If there is no proof of

purchase available, the date

associated with the serial number

will be used for the beginning of the

warranty period. Parts are a 1 year

warranty when replaced after the

initial warranty has expired.

Motor

Stage 1 - Prelter: Air passes through the prelter where larger particles are taken out of the

air. (part number 40195, also available in packs of 24 part numer 40196)

Stage 2 - Carbon: Air passes through the carbon lter where some gases and odors are

removed. (part number 40195, also available in packs of 24 part numer 40196)

Stage 3 - HEPA: Air passes through the certied HEPA media where very small particles are

removed. 99.97% of all particles 0.3 microns and larger that pass through this stage

are removed. Particles smaller than 0.3 microns are also removed with less intensity.

(part number 40193, also available in packs of 12 part numer 40194)

If the air ow through your unit is noticeably reduced, you can inspect the HEPA lter by removing it

and seeing if the lter paper is darkened on the inlet or outer side. If it is, the lter cartridge should

be replaced.

Please contact your local Fantech dealer or call HEPA Customer Service at 1.800.747.1762

regarding replacement of lter media, warranty information or if you have any questions or

concerns about the performance of your HEPA Filtration System.

Replacement parts number for motor (40323) .

• This warranty is the exclusive and only

warranty in effect and all other

warranties either expressed or

implied are invalid.

• Warranty from the manufacturer is

for parts only and does not include

labor or shipping to service or repair

them.

fantech

Page 11

Maintenance

Schedule

Date Type of Service performed Service Technician

11

fantech

Page 12

fantech

Fantech reserves the right to make technical changes.

For updated documentation please refer to www.fantech.net

Fantech®

Loading...

Loading...