Fantech AEV Series Installation Manual

AEV Series

Air Exchanger Ventilator

Item #: 401334

Rev Date: 2017-06-21

Installation Manual

Your ventilation system should be installed in conformance with the appropriate provincial requirements or, in the absence of

such requirements, with the current edition of the National Building Code, and / or ASHRAE’s “Good Engineering Practices”.

United States

10048 Industrial Blvd., Lenexa, KS, 66215

Tel.: 800.747.1762 • Fax: 800.487.9915

Canada

50 Kanalflakt Way, Bouctouche, NB, E4S 3M5

Tel.: 800.565.3548 • Fax: 877.747.8116

Fantech reserves the right to modify, at any time and without notice, any or all of its products’ features, designs,

components and specifications to maintain their technological leadership position.

Please visit our website www.fantech.net for more detailed technical information.

2

Note Warning/

Important note

Note Avertissement/

Note importante

Information Technical

Information Information

PLEASE READ THIS MANUAL

BEFORE INSTALLING UNIT

Products are designed and manufactured to provide

reliable performance, but they are not guaranteed

to be 100% free of defects. Even reliable products

will experience occasional failures, and this possibility

should be recognized by the user. If these products are

used in a life support ventilation system where failure

could result in loss or injury, the user should provide

adequate back-up ventilation, supplementary natural

ventilation or failure alarm system, or acknowledge

willingness to accept the risk of such loss or injury.

Your ventilation system should be installed in

accordance with the local building code that is in effect,

in absence of such requirements, it is recommenced

to check with local authorities having jurisdiction in

your area prior to installing this product.

Practical tip

information

Conseil

technique

pratique

VEUILLEZ LIRE LE MANUEL AVANT

D’INSTALLER L’APPAREIL

Les produits sont conçus et fabriqués pour fournir une

performance able, mais ils ne sont pas garantis à

100% sans défaut. Même les produis ont des pannes

occasionnelles et cette possibilité devrait être reconnue

par l'utilisateur. Si ces produits sont utilisés dans un

système de ventilation qui maintien des fonctions vitales

où une défaillance pourrait entraîner des pertes ou

des blessures, l'utilisateur doit fournir une ventilation

de secours adéquate, une ventilation supplémentaire

naturelle, un système d'alarme de défaillance ou

d'accepter les risques de pertes ou de blessures.

Votre système de ventilation doit être installé en

conformité avec le code du bâtiment local qui est

en vigueur, en l’absence de telles exigences, il est

recommandé de vérier auprès des autorités locales

ayant juridiction dans votre région avant d’installer ce

produit.

Table of content

DETERMINING YOUR AIRFLOW REQUIREMENT ..................................................... 4

OPERATION ................................................................................5

OPTIONAL CONTROL..........................................................................5

INSTALLATION EXAMPLES......................................................................6

EXTERIOR DUCTING INSTALLATION

Weatherhood Location ................................................................. 7

Installing the ducting to the weatherhood ................................................... 7

INTERIOR DUCTING INSTALLATION

Exhaust Air Ducting ....................................................................8

Dedicated Installation for Existing Home .....................................................8

3

AEV INSTALLATION

Location ............................................................................9

Mounting ...........................................................................9

AIRFLOW BALANCING........................................................................10

PITOT TUBE BALANCING PROCEDURE ............................................................11

MAINTENANCE .............................................................................12

WIRING DIAGRAM ..........................................................................13

TROUBLESHOOTING .........................................................................14

AEV MAINTENANCE CHART....................................................................15

PARTS LIST ...............................................................................31

4

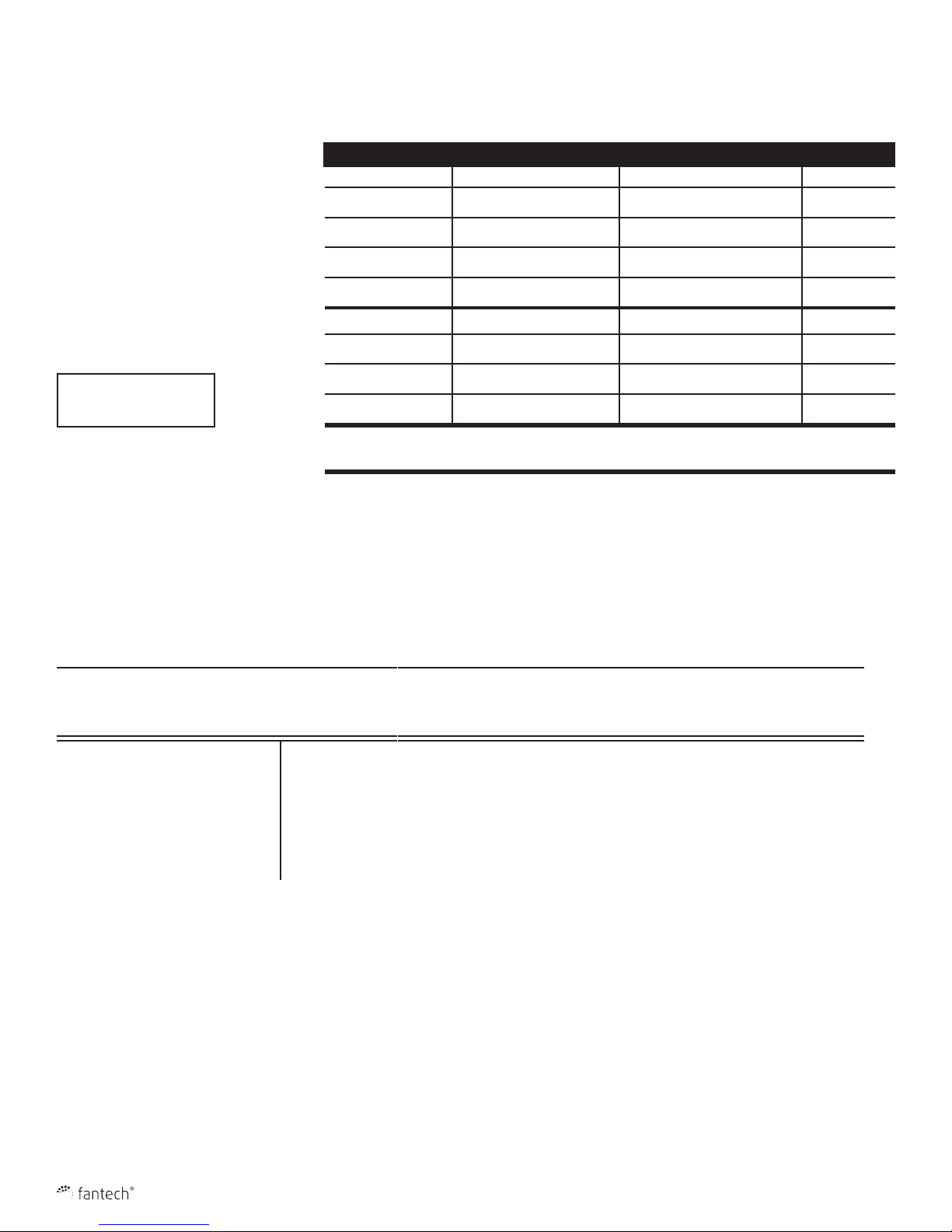

Determining your airflow requirement

Room Count Method

1 CFM = 0.47 L/s

1 L/s = 2.13 CFM

ASHRAE method

Room classification Number of rooms CFM (L/s)

Master bedroom x 10 L/s (20 CFM) =

Basement yes or no =

Bedrooms x 5 L/s (10 CFM) =

Living room x 5 L/s (10 CFM) =

Others x 5 L/s (10 CFM) =

Kitchen x 5 L/s (10 CFM) =

Bathroom x 5 L/s (10 CFM) =

Laundry room x 5 L/s (10 CFM) =

Utility room x 5 L/s (10 CFM) =

Total Ventilation Requirements (add last column ) =

if yes add 10 L/s (20 CFM)

if no = 0

CFM Required

Ventilation Air requirements

Floor area Bedrooms

0-1 2-3 4-5 6-7 >7

2

Ft

< 1500 <139 30 14 45 21 60 28 75 35 90 42

1501-3000 139.1-279 45 21 60 28 75 35 90 42 105 50

3001-4500 279.1-418 60 28 75 35 90 45 105 50 120 57

4501-6000 418.1-557 75 35 90 42 105 50 120 57 135 64

6001-7500 557.1-697 90 42 105 50 120 57 135 64 150 71

>7500 >697 105 50 120 57 135 64 150 71 165 78

* ASHRAE 62.2-2010 Table 4.1, Ventilation and Acceptable Indoor Air Quality in Low-Rise Residential Buildings.

2

m

CFM L/s CFM L/s CFM L/s CFM L/s CFM L/s

4

Operation

A Air Exchangers (AEV) is designed to bring fresh air into a building while exhausting an equal amount of stale air. During the winter months, the

incoming cold fresh air is warmed by utilizing the heat recovered from the stale air before it is exhausted to the outdoors. During summer months

when the indoor space is air conditioned, the AEV will help in cooling the incoming fresh air with the stale air that is being exhausted.

Our AEV’s are designed to run continuous or on intermittent, giving the homeowner complete control over their air quality. Continuous low speed

ventilation is recommended, which will help eliminate carbon dioxide, voc’s and other gases as well as freshen up the home. Intermittent high speed

ventilation can be obtained through a variety of optional remote controls found in this manual. Below are some examples of seasonal operation of an

AEV.

5

Winter:

Humidity control is very important during the winter

months. This is when problems will be most

apparent since condensation on the windows will

often occur. The colder the outside temperature, the

greater the risk of condensation in the home. The

average relative humidity should be maintained

between 30-60% to avoid condensation. Low speed

continuous ventilation with high speed override is

recommended.

Spring:

warmer each day. To keep the humidity and

temperature uniform, set the dehumidistat higher (if

installed). You may also switch the AEV to standby

mode if desired.

Optional control

Summer:

The air is sometimes hot and humid. To stop the

warm humid air from entering, set the dehumidistat

at its highest level.

Fall:

Rain and rapid temperature changes make it difficult

to control the internal humidity level and may result in

condensation on the windows. A remote dehumidistat

may help give greater control over the inside

environment.

To avoid window condensation:

• It is not necessary to change

the humidity control every

day. Monitor the average

weekly temperature or

experiment with various

settings until you nd a level

that is comfortable for you.

• Adjust the control when

needed.

Dehumidistat I

The wall mount dehumidistat monitors the humidity level in the area it is

installed. When the humidity level rises above the desired set-point, the

AEV will activate to high speed/override mode. Once the humidity level

returns to desired condition, the unit will return to the normal mode.

2 low voltage wires required for operation.

6

Installation examples

Example only

RADIANT, HYDRONIC AND ELECTRIC BASEBOARD

HEATING

1. This diagram shows the installation of your unit with radiant hydronic or

baseboard heating. As shown, the stale air is extracted from the rooms with high

humidity levels, and the fresh air is delivered in the living areas. In this case, a

complete ducting system for ventilation must be installed.

2. Follow local building codes

Supply Air Out

(Bedrooms)

Exhaust Air In

(Closest To Bathroom)

Bathroom

Fresh Air To

Living Room

Central Dehumidistat

Exhaust Air In

(Kitchen Area)

Air Exchanger

Exhaust Air Out

Supply Air In

Exterior ducting installation

7

A well designed and installed ducting system will allow the AEV to operate at

its maximum efficiency. Always try to keep duct runs as short and straight as

possible.

OUTSIDE CORNER INSIDE CORNER

36" (1m)

min.

Weatherhood location

• Decide where your intake and exhaust hoods will be located.

Locating the Intake Weatherhood

INTAKE

• Should be located upstream (if there are prevailing winds) from the

exhaust outlet.

18" (460mm) min.

• At a minimum of 2m (6’) away from dryer vents and furnace exhaust

(medium or high efficiency furnaces), driveways, oil fill pipes, gas meters,

or garbage containers.

• At a minimum height of 460mm (18’’) above the ground, or above the level of expected snow accumulation.

• At a minimum distance of 1m (3’) from the corner of the building.

• Do not locate in the garage, attic, crawl space, or underneath deck.

Locating the Exhaust Weatherhood

• At least 6’ (2m) from the ventilation air intake

• At least 460mm (18") above ground or above the depth of expected snow accumulation

• At least 1m (3’) away from the corner of the building

• Not near a gas meter, electric meter or a walkway where fog or ice could create a

hazard

• Do not locate in a garage, workshop or other unheated space

Installing the ducting to the weatherhoods

The inner liner of the flexible insulated duct must be clamped to the sleeve of the

weatherhoods (as close to the outside as possible) and to the appropriate port on the

AEV. The insulation should remain full and not be squished. The outer liner, which acts as

a vapor barrier must be completly sealed to outer wall and the AEV using tape and or

caulking. A good bead of high quality caulking (preferably acoustical sealant) will seal the

inner flexible duct to both the AEV port and the weatherhood prior to clamping.

To minimize air flow restriction, the flexible insulated duct that connects the two outside

weatherhoods to the AEV should be stretched tightly and be as short as possible.

Twisting of folding the duct will severely restrict air flow.

See “Installation Diagram Examples” for installation examples.

6' (2m)

min.

36” (1m)

min.

EXHAUST

18" (460mm) min.

Steps for hood installation:

1 Using the duct connection of

the outside hood, outline the

intake & exhaust holes to be

cut. The holes should be slightly

larger than the duct connection

to allow for the thickness of the

insulated flexible duct. Cut a

hole for both the intake and

exhaust hoods.

2 Pull the insulated flexible duct

through the opening until it is

well extended and straight.

Slide the duct’s inner vinyl

sleeve over the hood duct

connection and secure. Pull the

insulation over the duct and

pull the vapor barrier over the

sleeve. Secure with

appropriate tape or sealant.

3 Push the hood into the opening

and then attach the hood to the

outside wall with mounting

screws.

Repeat the installation

procedure for both the supply

and exhaust hoods.

4 Using a caulking gun, seal

around both hoods to prevent

any leaks.

8

Interior ducting installation

Exhaust air ducting

The stale air exhaust system is used to draw air from the points in the house where the worst air quality problems occur. It is recommended that

return air ducts be installed in the bathroom, kitchen, and laundry room. Additional return air ducts from strategic locations (i.e. greenhouse, atrium,

swimming pool, sauna, etc.) may be installed. This method has become popular and provides good ventilation when installed in accordance with the

instructions.

• For new construction, the rigid ducts are run in the walls.

• Choose the loction your Supply and Exhaust grille (metal) or (plastic). The Supply grilles should be located in every habitable room

and the Exhaust Grilles should be located in the wet rooms.

• A piece of flexible ducting should be placed between the Suppy Air In and Out collar of the AEV and the rigid ducting to absorb

any noise or vibrations.

• For proper network of ducting, see TYPES OF INSTALLATIONS.

• The grilles are to be installed on the ceiling or on the wall 6” (152 mm) to 12” (305 mm) from the ceiling.

Dedicated installation for existing home - non force air heating / cooling system.

1 Begin with the duct collar

marked “Exhaust Air In”. Slide a

short piece (12”) of flexible duct

over the duct collar. Insert one

to two screws through the duct

and into the plastic duct collar

to secure it into place. Apply

sealant or aluminum tape to the

edge of the ducting. Run the

flexible ducting to the main rigid

duct trunk line, which connects

to the remainder of the ducts

going to and from rooms in the

house. Repeat the steps for the

“Supply Air Out” on the side of

the AEV.

2 Working from a closet, attic or

inside your joist wall, run the

length of ducting required for

the proper grille location and

cut a hole in the gyprock.

Fasten the mounting collar

(optional) to the ducting and

fasten the collar to the wall or

ceiling with screws.

3 The grille (metal) or (plastic)

airflow can be adjusted by

rotating the inside unit. It is

recommended that the grilles

be completely opened at first

and then adjusted later as

needed.

4 Push the grille (metal) or

(plastic) into the optional

mounting collar or directly into

installed elbow.

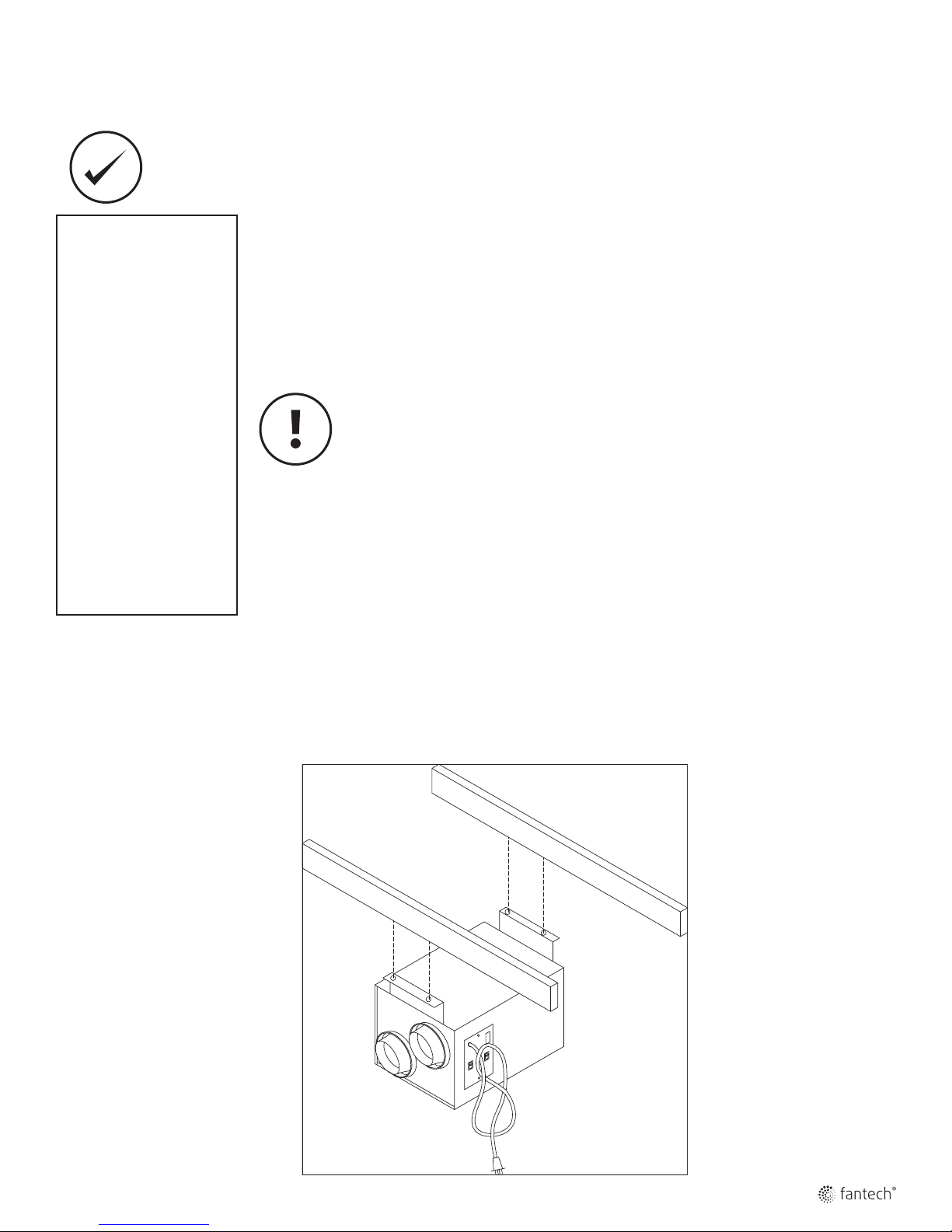

AEV installation

• Install the unit close to the

outside wall on which the

supply and exhaust hoods

will be mounted.

• Have a nearby power

supply 120 Volts, 60 Hz.

• Have the possibility of

mounting the unit to

supporting beams.

• Mount the unit as level as

possible.

• Have a certain amount

of heat around the unit

(attic installation is not

recommended).

• Minimize any noise level

that would be created by

the unit in the living area.

• Have access for future

maintenance.

9

Location

The Air Exchanger must be located where it will be possible to conveniently service the unit. Typically the AEV would

be located in an area close to the outside wall where the weatherhoods will be mounted. If a basement area is not

convenient or does not exist, a utility or laundry room may be used.

Connecting appliances to the AEV is not recommended. These include:

• Clothes dryer

• Range top

• Stovetop fan

• Central vacuum system

These appliances may cause lint, dust or grease to collect in the HRV, damaging the unit.

Connecting any of these types of appliances to the AEV will void your warranty.

Mounting

1. Although we recommend installing the unit as shown, the flexibility offered by our centrifugal external rotor motor allows for the unit to be installed

in any position.

2. Use screws and mounting bracket supplied with the unit.

10

Flow

Airflow balancing

The balancing procedure consists of measuring the exhaust air leaving the system and the supply

air entering the system and ensuring that these two are equal. A deviation of 10% or less is

acceptable. In such cases, it is recommended to have a greater amount of exhaust air than supply

air as so to increase the supply air’s temperature.

• If the unit’s airflows are not properly balanced...

- The unit may not operate at it’s maximum efficiency.

- The unit’s use could cause negative or positive pressure in your home causing

cold air to enter or other combustible equipment to backdraft.

A The duct’s airflow velocity is measured with a magnehelic gauge and a pitot tube. See “Pitot Tube

Balancing Procedure” next page.

Duct

B This airflow measuring station reads the airflow by being connected to the ducting.

Air

Pitot

Tube

Magnehelic

c

eli

gne h

a

M

Gauge

To avoid airflow turbulence and incorrect readings, the airflow velocity should be measured on steel

ducting a minimum of 18” (457 mm) from the unit or elbow and before any transition.

18”

(460 mm)

Measure

here

Loading...

Loading...