Page 1

C

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

IMPORTANT - PLEASE READ THIS

AEV Series

Air Exchange Ventilator

MANUAL BEFORE INSTALLING UNIT

CAUTION -

tem will operate if connected to any other piece of mechanical equipement,i.e. a forced air

furnace or air handler,operating at a higher static.After installation, the compatibility of the

two pieces of equipment must be confirmed by measuring the airflow’s of the Air Exchange

Ventilator by using the balancing procedure found in this manual.

It is always important to assess how the operation of any AEV may interact with vented

combustion equipment (i.e. Gas Furnaces,Oil Furnaces,Wood Stoves,etc.).

NEVER - install a ventilator in a situation where its normal operation,lack of operation

or partial failure may result in the backdrafting or improper functioning of vented combustion equipment!!!

Before installation,careful consideration must be given to how this sys-

C

C

R

US

Your ventilation system should be installed in conformance with the appropriate provincial or state requirements or in the absence of such requirements with the current edition of the National Building Code, and /

or ASHRAE’ s “ good Engineering Pratice”.

AEV Models

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

AEV 1000

Fan Tech at

kitchen

U N L I M I T E D

::

accessories

Page 2

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

The Best

Limited W arranty

in the Business

• The motors found in all Fantech AEV’s

require no lubrication,and are factory

balanced to prevent vibration and

promote silent operation.

• The limited warranty covers normal use.

It does not apply to any defects,

malfunctions or failures as a result of

improper installation,abuse, mishandling,

misapplication,fortuitous occurrence or

any other circumstances outside

Fantech’s control.

• Inappropriate installation or

maintenance may result in the

cancellation of the warranty.

• Any unauthorized work will result in

the cancellation of the warranty.

• Fantech is not responsible for any

incidental or consequential damages

incurred in the use of the ventilation

system.

• Fantech is not responsible for providing

an authorized service centre near the

purchaser or in the general area.

TABLE OF CONTENTS

TECHNICAL DATA

AEV Series ......................................................................................................................1

OPERATION ................................................................................................................................. 2

Modes Of Operation ................................................................................................................2

Optional Remote Controls..................................................................................................... 3

INSTALLATION............................................................................................................................ 4

Mounting the Unit ................................................................................................................... 4

Location & Ducting................................................................................................................... 5

Examples ..................................................................................................................... 7

Air Flow Balancing ................................................................................................................... 8

MAINTENANCE .....................................................................................................................11

TROUBLESHOOTING.............................................................................................................13

• Fantech reserves the right to supply

refurbished parts as replacements.

• Transportation,removal and installation

fees are the responsibility of the purchaser.

• The purchaser is responsible to adhering

to all codes in effect in his area.

• The warranty is limited to 5 y

parts and 7 years on the motor from the

date of purchase,including par ts replaced

during this time period.If there is no

proof of purchase available, the date

associated with the serial number will be

used for the beginning of the warranty

period.

* This warranty is the exclusive and only

warranty in effect relative to the ventilation

system and all other warranties either

expressed or implied are invalid.Please fill

out the warranty registration and return it

within two weeks of purchase or the

warranty will be voided.

ears on

Sizining (Example) for maximum airflow normally required.

AEV’s are typicaly sized to be able to ventilate the whole house at a maximum of 1/3 of an

air change per hour.To calculate this simply take the square footage of the home (including

basement)

multiply by the height of the ceiling to get cubic volume,and then multiply that by .005.

Example: SQFT of House 1100

Basement 1100

Total SQFT 2200

Height of ceiling x 8

Cubic volume 17600

x .005

Maximum airflow required (CFM) 88

* Always consult your local code for sizing requirements in your area.

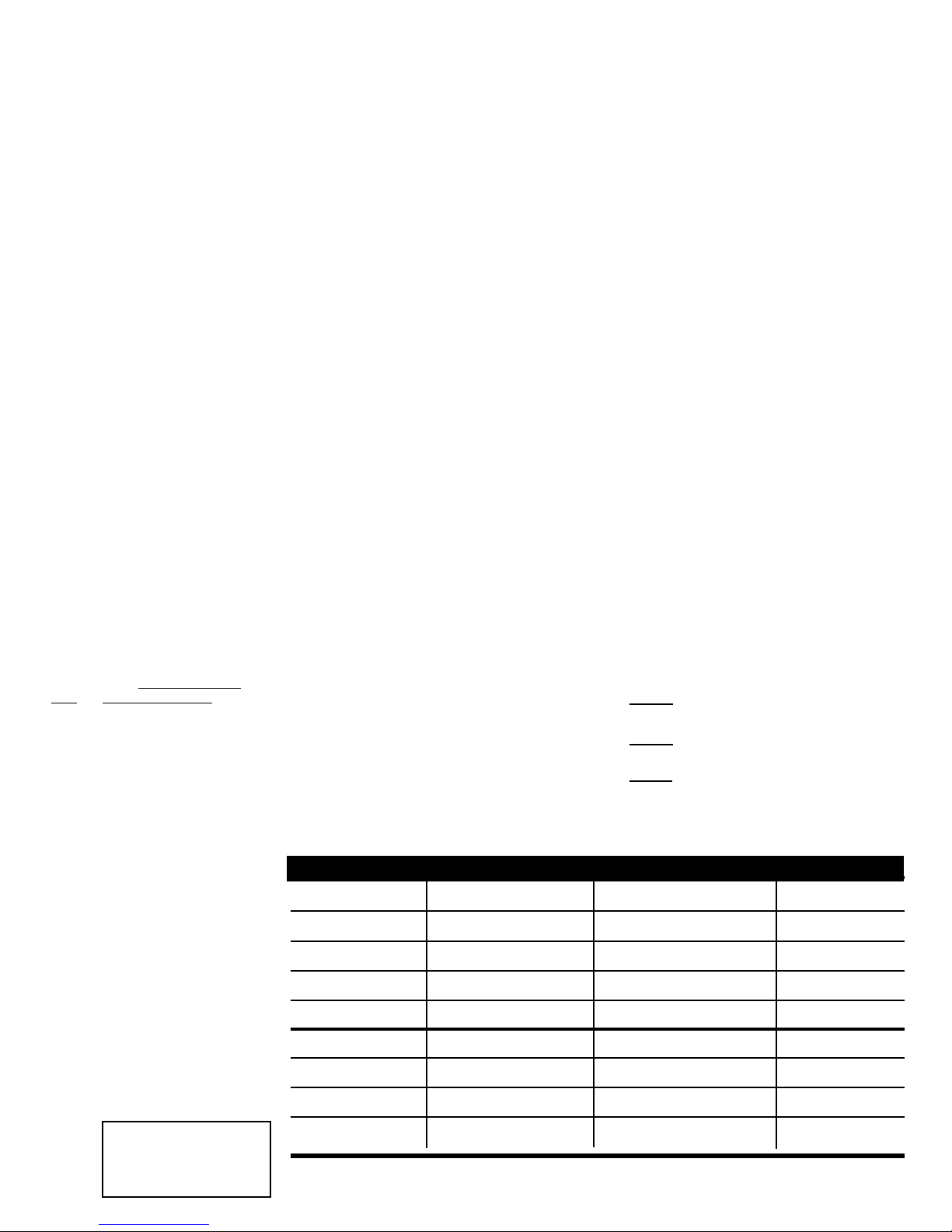

Room classification Number of rooms CFM (L/s) CFM Required

Master bedroom x 20 cfm (10 l/s) =

Basement yes or no =

Bedrooms x 10 cfm (5 l/s) =

Living room x 10 cfm (5 l/s) =

if yes add 20 cfm / 10 l/s

if no = 0

Others x 10 cfm (5 l/s) =

Kitchen x 10 cfm (5 l/s) =

Bathroom x 10 cfm (5 l/s) =

Laundry room x 10 cfm (5 l/s) =

1 cfm = 0.47189 l/s

1 l/s = 3.6 m

3

/hr

Utility room

Fan Tech at

x 10 cfm (5 l/s) =

Total ventilation Requirements

kitchen

U N L I M I T E D

::

accessories

(add last column )

=

Page 3

TECHNICAL DATA

C

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

Components

CASE - 22 gauge galvanized steel with powder coat paint, lined with strong top

quality insulation.

FILTER - Synthetic high quality filter for better indoor air quality and clean air .

UNIT CONTROLS - Case mounted rocker switches provide the following functions.

ON/OFF switch is to engage the operations of the ventilation system.

At OFF position,the system can still achieve high speed from the

remote dehumidistat or optional timer switch.LOW/MED switch is to

control the continuous ventilation mode. At LOW speed, the system

will be operating at its lowest ventilation requirement.At MED speed,

the system will operate to meet building codes requirements according

to sizing and design conditions.

REMOTE OVERRIDE -24 volts (low voltage) remote switching circuit for high speed

operation to reduce the humidity level in the dwelling.This is archieved

by a dehumidistat,an optional timer switch or any indoor air quality

(IAQ) remote sensor

BLOWERS - The motors are factory-balanced to prevent vibrations,providing

greater comfort without noise pollution.

-Fans equipped with motors of insulation class “B”

- The motors are completely sealed , keeping out moisture, dust and

lint.

- The motors feature maintance-free bearings and are the most

dependable and efficient on the market.

- Built-in thermocontact prevents overheating

- Increased corrision protection

AEV Series Performance Data

Airflow Cap.L/s (cfm)

Model

AEV 1000 49 (104) 38 (60) 20 (42)

High

Med Low

AEV Series Electrical Data

Model Volts Amp Rating

AEV 1000 115 V 0.6 A

All of the AEV models are 120V unless specified otherwise.

C

C

R

US

Dimensions

Fan Tech at

kitchen

U N L I M I T E D

::

accessories

1

Page 4

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

OPERATION

An Air Exchanger Ventilator (AEV) is designed to provide fresh air into a building while exhausting an equal amount of stale air.

During the winter months,the incoming cold fresh air is warmed by mixing it with return air before it is supplied to the home.

During summer months when the indoor space is air conditioned,the AEV will help in cooling the incoming fresh air with the

stale air that is being exhausted.

Fantech AEV’s are designed to run continuous or on intermittent,giving the homeowner complete control over their air quality.

Continuous low speed ventilation is recommended,which will help eliminate carbon dioxide, voc’s and other gases as well as

freshen up the home.Intermittent high speed ventilation can be obtained through a variety of optional remote controls found in

this manual (page 3 ).Below are some examples of seasonal operation of an AEV.

Winter:

Humidity control is very important during the winter months. This is when problems will be most apparent since

condensation on the windows will often occur. The colder the outside temperature,the greater the risk of condensation in the home.The average relative humidity should be maintained between (30-60) to avoid condensation.Low speed continuous ventilation with high speed override is recommended.

Spring:

Temperatures are more moderate and become warmer each day. To keep the humidity and temperature uniform,

set the dehumidistat higher and the switch on the AEV to standby.

Summer:

The air is sometimes hot and humid. To stop the warm humid air from entering,set the dehumidistat at its highest level and the switch on the AEV to standby.

Fall:

Rain and rapid temperature changes make it difficult to control the internal humidity level and may result in condensation on the windows.A remote dehumidistat may help give greater control over the inside environment.

NOTE:Some products may not be exactly as illustrated in the Installation,Operation and Maintenance Manual.

Fantech Inc. reserves the right to modify,at any time and without notice, any or all of its products’ features,designs, components

and specifications,to maintain their technological leadership position.

2

Fan Tech at

kitchen

U N L I M I T E D

::

accessories

Page 5

OPERATION (CON’T)

OPTIONAL REMOTE CONTROLS

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

PRACTICAL

TIPS

To avoid window

condensation:

• It is not necessary to change

the humidity control every

day.Monitor the average

weekly temperature or

experiment with various

settings until you find a level

that is comfortable for you.

Adjust the control when

needed.

Dehumidistat I

The wall mount dehumidistat monitors the humidity level in

the area it is installed.When the humidity level rises above the

desired set-point, the AEV will activate to high speed/override

mode. Once the humidity level returns to desired condition,

the unit will return to the normal mode.

2 low voltage wires required for operation.

Air Quality Sensor

The wall mount Air Quality Sensor (AQS) monitors indoor

air quality and activates the override mode when carbon

monoxide,formaldehyde,benzene, volatile organic

compounds and other pollutants are detected. The unit will

then return to normal mode once the air pollutants are

reduced to a pre-determined lower level.

Three low voltage wires are required for operation with

transformer

* This control is not a warning device.

* All controls are low voltage. 18 to 24 gauge wire is recommended.

Fan Tech at

kitchen

U N L I M I T E D

::

accessories

3

Page 6

INSTALLATION

PRACTICAL

TIPS

• Install the unit close to

the outside wall on

which the supply and

exhaust hoods will be

mounted.

• Have a nearby power

supply 120 Volts,60 Hz.

• Have the possibility of

mounting the unit to

supporting beams .

• Mount the unit as

level as possible.

• Have a certain amount

of heat around the unit

(attic installation is not

recommended).

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

LOCATION

The Air Exchanger must be located in a heated space where it will be possible to conveniently service the unit.Typically the AEV would be located in the mechanical room or an

area close to the outside wall where the weatherhoods will be mounted.If a basement area

is not convenient or does not exist,a utility or laundr y room may be used.

Attic installations are not normally recommended due to:

- the complexity of work to install

- freezing conditions in the attic

- difficulty of access for service and cleaning

Connecting appliances to the AEV It is not recommended,incuding:

- clothes dryer

- range top

- stovetop fan

- central vacuum system

These appliance may cause lint,dust or grease to collect in the AEV ,damaging the unit.

NOTE: Connecting any of these type of appliances to the AEV will invalidate your warranty

MOUNTING

• Although we recommend installing the unit as shown,the flexibility offered by our centrifugal

external rotor motor allows for the unit to be installed in any position.

• Use #10 wood screws plus vibration insulator grommets supplied with the unit.

• Minimize any noise

level that would be

created by the unit in

the living area.

• Have access for future

maintenance.

4

Fan Tech at

kitchen

U N L I M I T E D

::

accessories

Page 7

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

INSTALLING DUCTS GOING TO / FROM OUTSIDE

A well designed and installed ducting system will allow the AEV to operate at its maximum efficiency.

Always try to keep duct runs as short and straight as possible.

See Installation Diagrams for installation examples.

PRACTICAL

TIPS

• Decide where your intake and

exhaust hoods will be located.

Locating the Intake

Weatherhood

• Should be located upstream

(if there are prevailing winds)

from the exhaust outlet

• At least 6’(2m) from the

exhaust weatherhood

• At least 6’(2m) away from

dryer vents and furnace

exhaust ( medium or high

efficiency furnaces)

• A minimum of at least 6’

(2m) from driveways,oil fill

pipers, gas meters, or

garbage containers

• At least 18”(457mm) above

the ground,or above the

depth of expected snow

accumulation

• At least 3’(1m) from the

corner of the building

• Do not locate in a garage,

attic or crawl space

INST ALLING THE DUCTING

TO THE WEA THERHOODS

The inner liner of the flexible insulated duct

must be clamped to the sleeve of the

weatherhoods (as close to the outside as

possible) and to the appropriate port on the

AEV. The insulation should remain full and

not be squished. The outer liner,which acts

as a vapor barrier must be completly sealed

to outer wall and the AEV using tape and or

caulking. A good bead of high quality

caulking (preferably acoustical sealant) will

seal the inner flexible duct to both the AEV

port and the weatherhood prior to

clamping.

To minimize air flow restriction, the flexible

insulated duct that connects the two

outside weatherhoods to the AEV should be

stretched tightly and be as short as possible.

Twisting of folding the duct will severely

restrict air flow.

Locating the Exhaust

Weatherhood

• At least 6’(2m) from the

ventilation air intake

• At least 18”(457mm) above

ground or above the depth of

expected snow accumulation

• At least 3’(1m) away from

the corner of the building

• Not near a gas meter, electric

meter or a walkway where

fog or ice could create a

hazard

• Not into a garage, workshop

or other unheated space

When installing the

weatherhood,it’s outside

perimeter must be sealed with

exterior caulking.

1 Using the collar of

the outside hood,

outline the intake &

exhaust holes to be

cut. The holes should

be slightly larger

than the collar to

allow for the

thickness of the

insulated flexible

duct.Cut a hole

fo r both th e intake

and exhaust hoods.

2 Pull the insulated

Fan Tech at

flexible duct through

the opening until it is

well extended and

straight.Slide the

duct’s inner vinyl

sleeve over the hood

collar and secure,

pull the insulation

over the duct and

then the vapour

barrier over the

sleeve and secure

with duct tape.

kitchen

U N L I M I T E D

::

accessories

3 Push the hood into

the opening.Attach

the hood to the

outside wall with

mounting screws.

Repeat the

installation procedure

for both the Supply

and Exhaust hood.

4 Using a caulking

gun,seal around

both hoods to prevent any leaks.

5

Page 8

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

INSTALLING DUCTS TO / FROM INSIDE (CON’T)

Exhaust Air ducting

The stale air exhaust system is used to draw air from the points in the house where the worst air quality problems occur. It is

recommended that return air ducts be installed in the bathroom,kitchen, and laundr y room. Additional return air ducts from

strategic locations (i.e. greenhouse, atrium,swimming pool, sauna, etc .) may be installed. The furnace return duct may be also

used to exhaust from. In this method,the exhaust air is not ducted back from bathrooms,kitchens, etc to the AEV with “dedicated lines”.

This method has become popular and provides good ventilation when installed in accordance with the instructions. The furnace

blower must be running when the AEV is operating for this method to be effective.

PRACTICAL

TIPS

• For new construction,

the rigid ducts are run

in the walls.

• Choose the loction your

Supply and Exhaust

Fantech grille {MGE

(metal) or PGE

(plastic)}s. The Supply

grilles should be located

in every habitable room

and the Exhaust Grilles

should be located in the

wet rooms.

• A piece of flexible

ducting should be placed

between the Suppy Air In

and Out collar of the AEV

and the rigid ducting to

absorb any noise or

vibrations.

Dedicated installation for existing home - non force air

heating / cooling system.

1 Begin with the duct collar marked “Exhaust Air In”. Slide a short piece

(12”) of flexible duct over the duct collar.Using duct tape, tape the

flexible duct to the collar.Run the flexible ducting to the main rigid

duct trunk line, which connects to the remainder of the ducts going to

and from rooms in the house..Repeat the steps for the “Supply Air

Out” on the side of the AEV.

2 Working from a closet,attic or inside your joist wall, run the length of

ducting required for the proper grille location and cut a hole in the

gyprock.Fasten the mounting collar (optional) to the ducting and

fasten the collar to the wall or ceiling with screws.

3 The Fantech grille {MGE (metal) or PGE (plastic)} airflow can be

adjusted by rotating the inside unit.It is recommended that the grilles

be completely opened at first and then adjusted later as needed.

• For proper network

of ducting,see TYPES

OF INSTALLATIONS.

• The grilles are to be

installed on the ceiling or

on the wall 6”(152 mm)

to 12”(305 mm) from

the ceiling.

4 Push the Fantech grille {MGE (metal) or PGE (plastic)} into the optional mounting collar or

directly into installed elbow.

6

Fan Tech at

kitchen

U N L I M I T E D

::

accessories

Page 9

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

INSTALLATION (CON’T)

Radiant, Hydronic and Electric Baseboard Heating

• This diagram shows the installation of your unit with radiant hydronic or baseboard heating.

As shown,the stale air is extracted from the rooms with high humidity levels,and the fresh air is delivered in the living areas.In

this case,a complete ducting system for ventilation must be installed.

PRACTICAL

TIPS

*Follow local building codes*

Fan Tech at

kitchen

U N L I M I T E D

::

accessories

7

Page 10

AIR FLOW BALANCING

PRACTICAL

TIPS

• If the unit’s airflows are not

properly balanced...

- The unit may not operate at

it’s maximum efficiency.

- The unit’s use could cause

negative or positive pressure

in your home causing cold air

to enter or other combustible

equipment to backdraft.

• The balancing procedure consists of measuring the exhaust air leaving the system and the

supply air entering the system and ensuring that these two are equal.A deviation of 10% or

less is acceptable. In such cases, it is recommended to have a greater amount of exhaust air

than supply air as so to increase the supply air’s temperature.

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

A*

Pitot tube and gauge

Duct

Flow

Air

e

gn

Ma

Pitot

Tube

Magnehelic

c

i

l

e

h

Gauge

AThe duct’s airflow velocity

is measured with a

magnehelic gauge and a

pitot tube. See “Pitot Tube

Balancing Procedure” next

page.

B*

B This airflow measuring

station reads the

airflow by being

connected to the

ducting.

18”

(460 mm)

Measure

here

• To avoid airflow

turbulence and

incorrect readings,the

airflow velocity should

be measured on steel

ducting a minimum of

18” (457 mm) from the

unit or elbow and

before any transition.

8

Fan Tech at

kitchen

U N L I M I T E D

::

accessories

Page 11

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

AIR FLOW BALANCING (CONT’)

B

1 For this flow measuring station,cut

the duct and place the flow

measuring station between each

station.Make sure that the flow

measuring station’s air direction

arrow points in the direction of the

airflow.Secure the flow measuring

station with duct tape.

PITOT TUBE BALANCING PROCEDURE

PITO T TUBE

BALANCING PROCEDURE

The following is a method of field balancing an AEV using a Pitot

tube, advantageous in situations when flow stations are not

installed in the ductwork. Procedure should be performed with

the AEV on high speed.

The first step is to operate all mechanical systems on high

speed,which have an influence on the ventilation system,i.e.the

AEV itself and the forced air furnace or air handler if applicable.

This will provide the maximum pressure that the AEV will need

to overcome,and allow for a more accurate balance of the unit.

Drill a small hole in the duct (about 3/16), three feet downstream of any elbows or bends, and one foot upstream of any

elbows or bends.

These are recommended distances but the actual installation

may limit the amount of straight duct.

The Pitot tube should be connected to a magnehelic gauge or

other manometer capable of reading from 0 to 0.25 in (0-62 Pa)

of water, preferably to 3 digits of resolution. The tube coming

out of the top of the pitot is connected to the high pressure side

of the gauge. The tube coming out of the side of the pitot is

connected to the low pressure or reference side of the gauge.

Insert the Pitot tube into the duct; pointing the tip into the airflow.For general balancing it is suffivient to move the pitot tube

around in the duct and take an a v erage or typical reading.Repeat

this procedure in the other (supply or return) duct. Determine

Fan Tech at

kitchen

U N L I M I T E D

2 Before taking the reading,make sure

that the magnehelic gauge is level

and at 0.Refer to the flow

measuring station’s chart to

determine your unit’s airflow

velocity.

which duct has the highest airflow (highest reading on the

gauge). Then damper that airflow back to match the lower reading from the other duct. The flows should now be balanced.

Actual airflow can be determined from the gauge reading. The

value read on the gauge is called the velocity pressur e. The Pitot

tube comes with a chart that will give the air flow velocity based

on the velocity pressure indicated b y the gauge. This velocity will

be in either feet per minute or metres per second. To determine

the actual airflow,the velocity is multiplied by the cross sectional areas of the duct being measured.

This is an example for determining the airflow in a 6” duct.

The Pitot tube reading was 0.025 inches of water.

From the chart,this is 640 feet per minute.

The 6” duct has cross sectional area of

The airflow is then:

640 ft./min.x0.2 square feet-128cfm

For your conv enience,the cross sectional area of some common

round duct is listed below:

DUCT DIAM.(inches) CROSS SECTION AREA (sq ft.)

5 0.14

6 0.20

7 0.27

The accuracy of the air flow reading will be affected by how

close to any elbows or bends the readings are taken. Accuracy

can be increased by taking an av erage of multiple r eadings as out-

::

accessories

lined in the literature supplied with the Pitot tube.

3 The airflow is regulated by a

balancing damper located inside the

collar of the AEV.Adjust the “Supply

Air Out” damper until you reach

the desired velocity.Follow the

previous

steps to adjust the “Exhaust Air

Out” damper.

= [3014x(6” 12)2 4

=0.2 squeare feet

9

Page 12

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

PITOT TUBE BALANCING PROCEDURE (CONT’)

M

a

g

neh

e

l

ic

c

i

l

e

h

e

n

g

a

M

* Pitot tube should be kept at least 12” away from fans elbows and dampers to ensure acurate reading.

10

Fan Tech at

kitchen

::

accessories

U N L I M I T E D

Page 13

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

MAINTENANCE

CAUTION MAKE SURE UNIT IS UNPLUGGED BEFORE ATTEMPTING ANY MAINTENANCE WORK

The following components should also be inspected regularly and well maintained.

PRACTICAL

TIPS

• To prevent electrical shock,

check that the unit is

unplugged before doing any

repairs or maintenance.

• A yearly inspection is

recommended to ensure the

efficiency and trouble-free

use of your system. Run

through the system

and verify the different

operating modes.

The motor - The motor

are factory balanced and

lubricated for life. They

require no maintenance.

The unit - The inside of

the unit should be vacuumed yearly. Be careful not

to damage any of the

mechanical components

and electrical connections.

Outside hoods - The outside hoods need to be

checked every season to

make sure there are no

leaves or insects blocking

the airflow. Check regularly that there are no pollutants near the intake hood.

Make sure they are clear of

any snow accumulation

during the winter months.

FILTER

The filter needs to be checked

and cleaned every three months

or when it appears dirty. To

clean, remove the filter and vacuum. If the filter still appears

dirty, it can be washed in warm

sudsy water (mild detergent).

Replace the filter if it becomes

too soft after washing. The filter

should be replaced yearly or

when it can no longer be

cleaned properly. You may have

to change the synthetic filter

after washing a few times.

OUTSIDE HOODS

The outside hoods need to be

checked every season to make

sure there are no leaves or

insects blocking the airflow.

Check regularly that there are

no pollutants near the intake

hood. Make sure they are clear

of any snow accumulation

during the winter months.

NOTE:Some products may not be exactly as illustrated in Installation,Operation and Maintenance manual.

Fan Tech at

kitchen

U N L I M I T E D

::

accessories

11

Page 14

SERVICING

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

PARTS LIST

Description Part #

1 Motorized Impeller 500000

2 Filter 017068

3 Override Relay Board 410150

4 Capacitor 410428

5 Auto-Transformer 410350

6 Control Panel 200422

7 5” Collar 530172

8 Filter Door 200426

9 Access Panel 203939

12

Fan Tech at

kitchen

U N L I M I T E D

::

accessories

Page 15

TROUBLESHOOTING

Call 1-800-667-8721 anywhere in the US and Canada - www.kitchensource.com

Problem

Air is too dry

Air is too humid

Persistent condensation

on window

Poor Air Flows

Dehumidistat control is set too low

AEV out of balance

Dehumidistat control is set too high

Sudden change in temperature

Storing too much wood for heating

Dryer vent exhaust is inside home

Poor air circulating near windows

AEV out of balance

Basement door is closed

Improper adjustment of dehumidistat

control

AEV out of balance

-1/4” (6mm) mesh on the outsid hoods

is plugged

-filter plugged

-house grilles closed or blocked

-dampers are close if installed

-poor power supply at site

-ductwork is restricting AEV

-improper speed control setting

-AEV airflow improperly balance

SolutionsCauses

Increase the desired level of humidity. Change ventilation mode from

continuous mode to standby.

Balance AEV

Reduce the desired level of humidity.Combine this step with use of

continuous exchange mode.

Wait until outside temperature stabilizes (winter).Heating will also

improve situation.

Store a majority of your wood outside.Even dried, a cord of wood

contains more than 20 gallons of water.

Arrange outside vent for dryer.

Open curtains or blinds. Bay or bow windows may require mechanical

method.

Balance AEV

Open the door or install a grill on the door.

Reduce the desired level of humidity.Combine this with the use of

continuous exchange mode.

Balance AEV

-clean exterior hoods or vents

-remove and clean filter

-check and open grilles

-have electrician check supply voltage at house

-check duct installation

-increase the speed of the AEV.

-have contractor balance AEV

Supply air feels cold

-poor location of supply grilles,the airflow may irritate the occupant

-outdoor temperature extremely cold

AEV and / or Ducts

Frosting up

Condensation or Ice

Build Up in Insulated

Duct to the Outside

-AEV air flows are improperly balanced

-malfunction of the AEV system

-incomplete vapour barrier around

insulated duct

-a hole or tear in outer duct covering

Fan Tech at

-locate the grilles high on the walls or under the baseboards,install

ceiling mounted diffuser or grilles so as not to directly spill the supply

air on the occupant (eg.Over a sofa)

-turn down the AEV supply speed. A small duct heater (1kw) could

be used to temper the supply air

-placement of furniture or closed doors is restricting the movement

of air in the home

-if supply air is ducted into furnace return,the furnace fan may need

to run continuously to distribute ventilation air comfortably

-Note:minimal frost build-up is expected

-have HVAC contractor balance the AEV

-Duct heaters

-tape and seal all joints

-tape any holes or tears made in the outer duct covering

-ensure that the vapour barrier is completely sealed.

kitchen

U N L I M I T E D

::

accessories

13

Loading...

Loading...