Page 1

OPERATING MANUAL

Manual version 0111

FAGOR NC-200 PB

NC FOR

PRESS BRAKES

Page 2

Operating Manual NC-200 PB

INDEX

Diagram of a typical press BRAKE..................................................................... 0

Introduction....................................................................................................... 1

Description of the various machine models .......................................................... 1

1. Unit description.................................................................................... 2

1.1 Front panel............................................................................................. 2

2. Coordinate display. Auxiliary modes ................................................... 4

2.1 Display modes........................................................................................ 5

2.2 Selection of tools and types of material to bend ....................................... 6

2.3 Type of material ...................................................................................... 7

2.3.1 Generate the whole elasticity factor table for a new unknown material........ 9

2.3.2 Generate the elasticity factor of a single angle by testing

the bending depth .................................................................................. 10

2.3.3 Generate the elasticity factor by trial and error and correct the angle ......... 12

2.3.4 Saving and recalling the material-type tables through

the serial line RS-232 ............................................................................. 13

2.3.5 Restoring initial tables ............................................................................ 14

3 Operating modes................................................................................ 14

3.1 Manual /set mode .................................................................................. 14

3.1.1 Manual movement from the NC keyboard ............................................... 15

3.1.2 Movement with the foot switches. "C" model ......................................... 15

3.1.3 Manual movement to a particular "X" position, "Y" depth or "a" angle.... 16

3.1.4 Manual movement by external means ...................................................... 16

3.2 Machine reference (home) search ........................................................... 17

3.2.1 Sequence for axes with mandatory home search on power-up ................. 17

3.2.2 Sequence for axes without mandatory home search................................. 18

3.2.3 Sequence for the Y axis. Model B .......................................................... 18

3.3 Tool table loading .................................................................................. 19

3.3.1 Recall initial tool values .......................................................................... 19

Page 3

NC-200 PB Operating Manual

4 Programming ..................................................................................... 20

4.1 Program editing ..................................................................................... 20

4.1.1 Editing / Deleting an existing program ..................................................... 20

4.1.2 Editing a new program ........................................................................... 22

4.2 Inserting / deleting blocks in a previously edited program ........................ 27

4.3 Deleting all the programs ........................................................................ 27

5 Execution Modes with control from the foot switches and

manual station. Models A1, B, C....................................................... 28

5.1 Program execution................................................................................. 30

5.2 Execution in semiautomatic mode........................................................... 32

6 Operation with the RS-232-C serial line ........................................... 32

6.1 Saving and restoring data ....................................................................... 32

6.2 Parameter transmitting format ................................................................. 33

6.3 Program transmitting format ................................................................... 33

6.4 Transmission of material-type tables ....................................................... 33

Appendix ........................................................................................................ 34

Error codes ...................................................................................................... 34

Maintenance...................................................................................................... 35

Page 4

Operating Manual NVP-200 PB - page 0 -

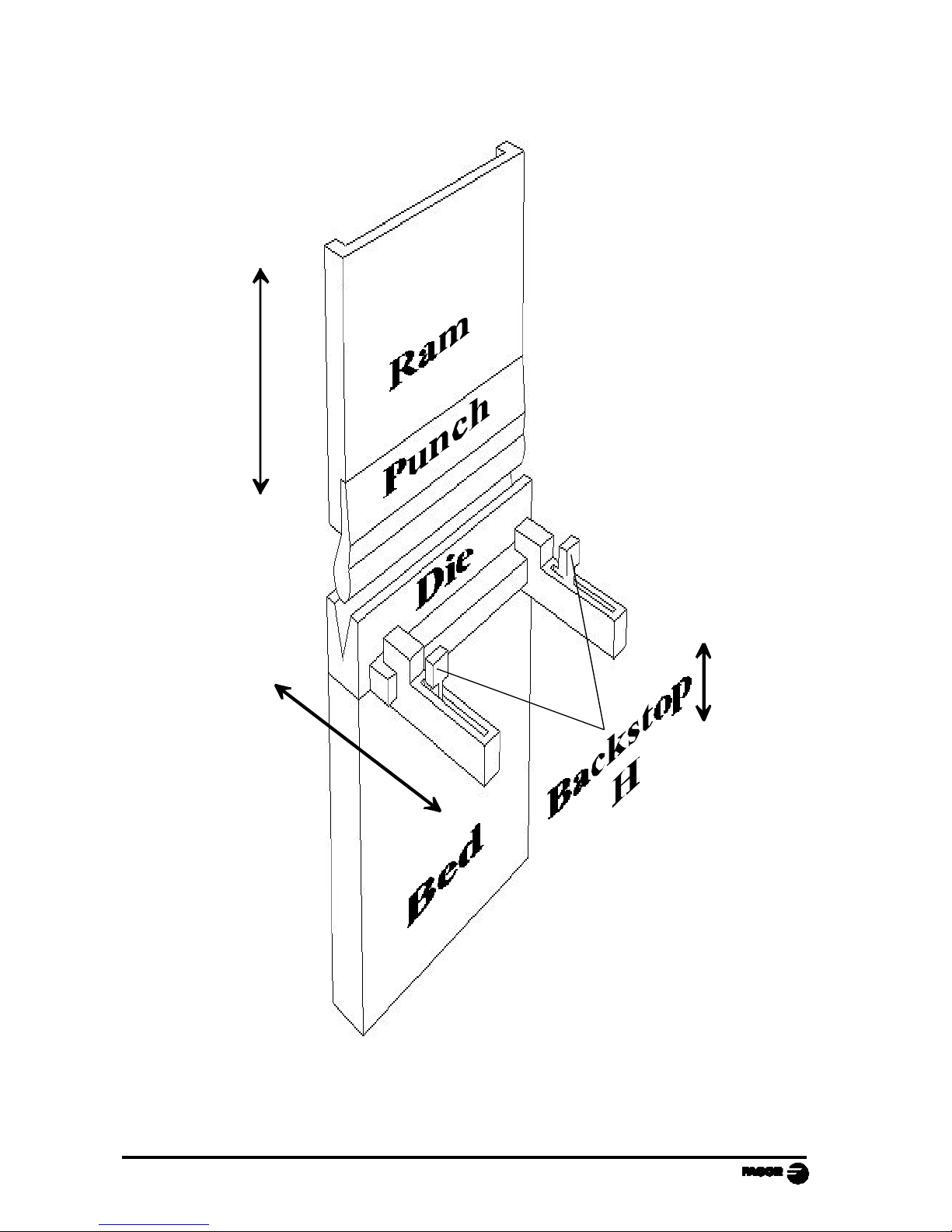

Y

X

+

-

-

+

DIAGRAM OF A TYPICAL PRESS BRAKE

Page 5

NC-200 PB - Operating Manual - Page: 1

INTRODUCTION

Throughout this manual, certain installation parameters are referred to which

affect the description of certain NC functions.

These parameters have been set by the installer and may be modified by the

operator.

These parameters are described in the installation manual supplied with this unit.

DESCRIPTION OF THE VARIOUS MACHINE MODELS

This manual mentions different machine models (A, A1, B, C) that are built quite

differently; but they don't differ as much when using the resources of this

numerical control whether they are up-stroke or down-stroke models.

A. Controlling only the final position of the bend for simple machines that do not

require distinguishing 4 execution modes.

The foot switches, the execution modes and the hydraulic circuit are not handled

by this unit.

The intermediate positions of the ram cannot be preset.

They are detected with electrical micro-switches.

A1. Same as model A with foot switch control and outputs to control the hydraulic

valves handling the 4 EXECUTION modes.

Especially indicated for conventional down-stroke machines.

B. Same as model A1 with a linear feedback or digital potentiometer to read the

actual position of the ram or the table. This allows detecting the intermediate

positions that may be selected at the NC:

- Top dead point. FAST/SLOW change position.

- FAST/SLOW change position.

- Sheet metal holding position. End of the bend.

Very useful for up-stroke models.

C. Control of the actual movement of the ram / table / apron and presetting of

intermediate positions.

Page 6

Page: 2 - Operating Manual - NC-200 PB

1. UNIT DESCRIPTION

This NC is especially designed to be used on press brakes. It allows displaying

the position of the vertical and horizontal axes as well as executing partprograms and also moving the axes manually from this NC's keyboard or by

external means.

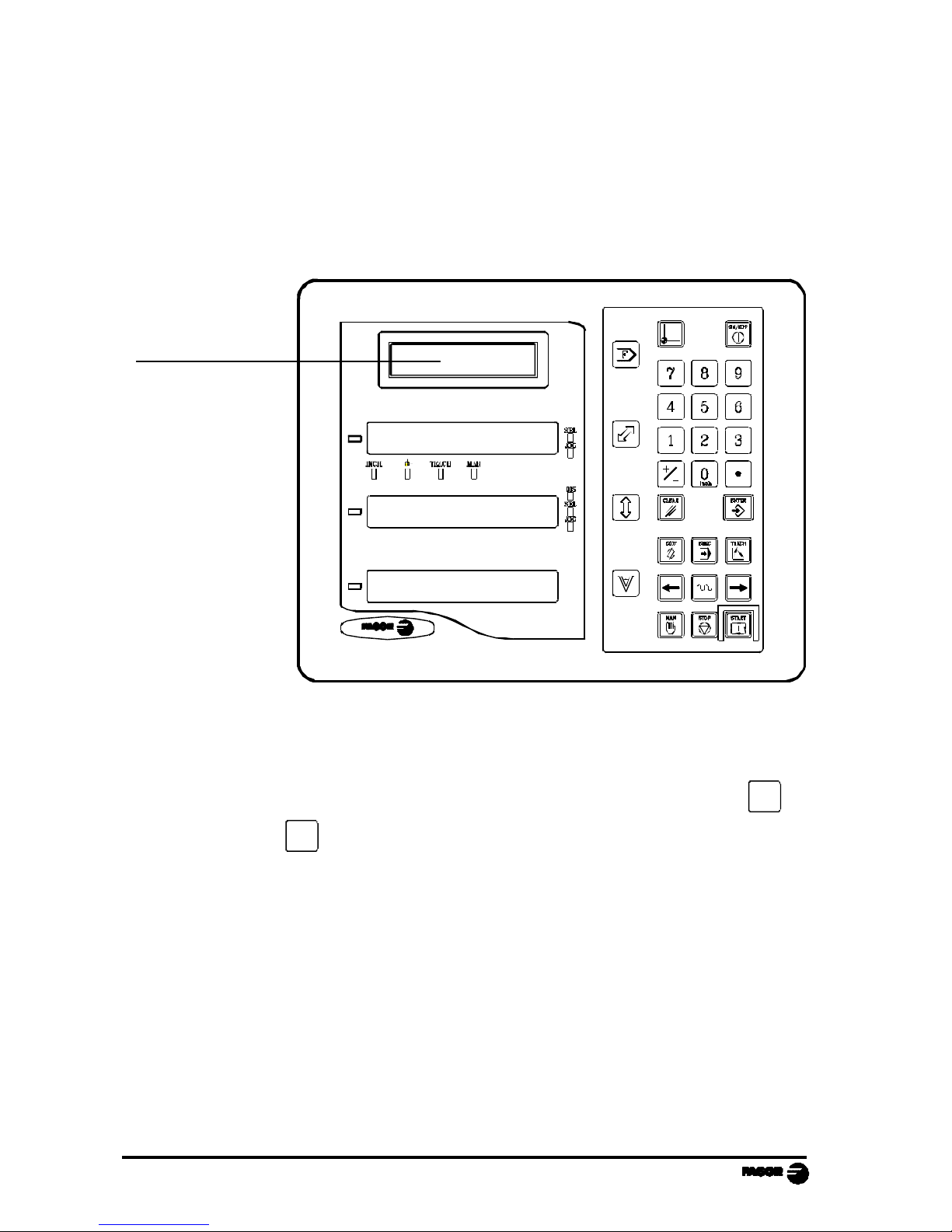

1.1 FRONT PANEL

Message display

The message display offers assistance to facilitate the operating modes of

this NC.

When using an LCD screen,

its contrast may be adjusted by pressing 3 to

decrease it or

9

to increase it.

Page 7

NC-200 PB - Operating Manual - Page: 3

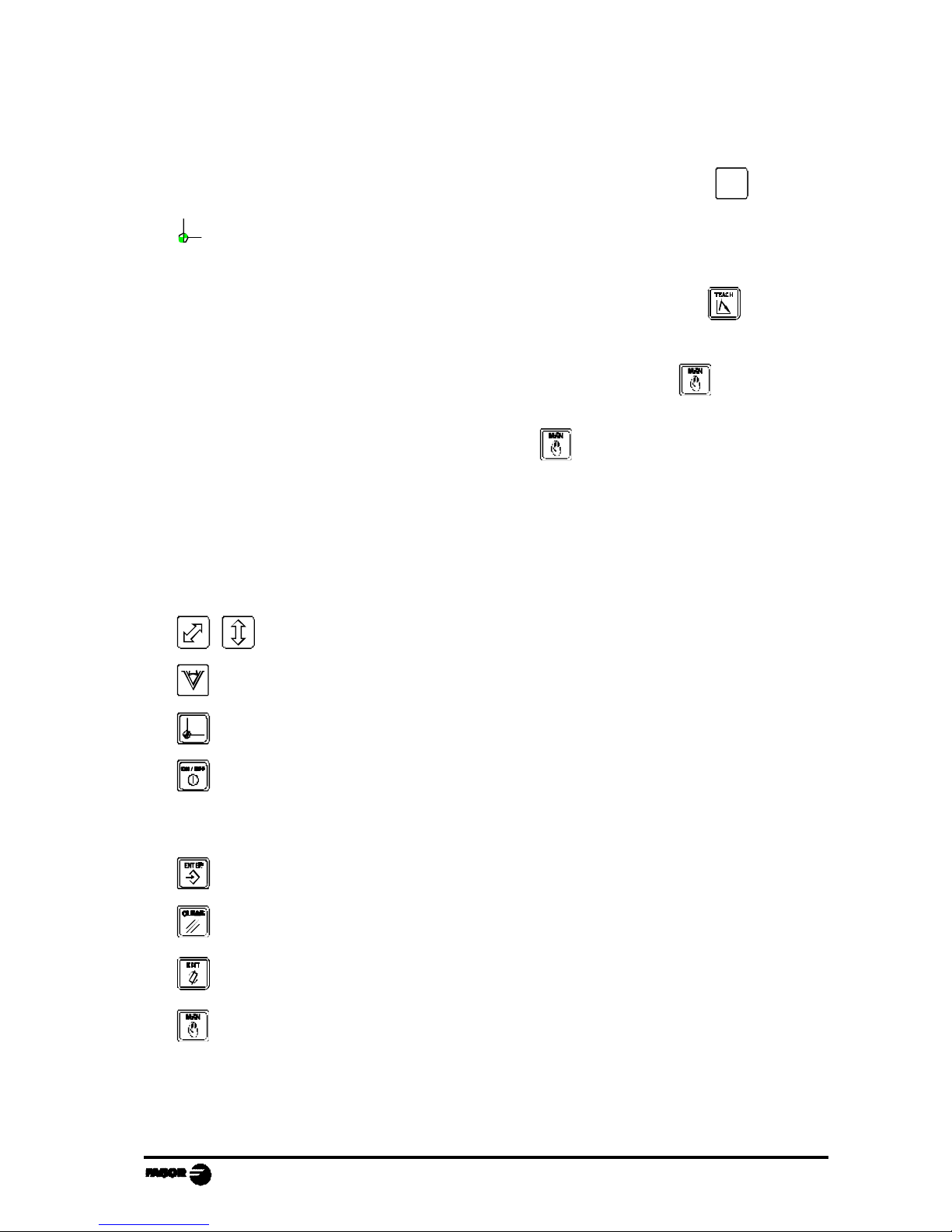

Each axis display has eight 14.1 mm high LEDs and another one for the minus

sign (-).

INCH- Inch mode selection. To access it or quit it, press

0

inch

Machine reference search mode which is accessed by selecting

the SET mode.

TEACH - TEACH-In mode which is accessed by pressing

when the

editing mode is selected (on the screen for coordinate selection).

MAN - Manual mode which is accessed by pressing

There are two ways to access it:

Models A and B . Using the

keyy

Model C - By selecting the SET mode.

SEL - Axis selected.

JOG - Axis moving.

DIS - Y axis disabled (selector switch in position 5).

Select the X and Y axis respectively.

Program the bending angle or the width of the die's "V".

Machine reference zero (home) search.

Turn the display off while keeping track of the axes position at all times.

This key must be pressed before turning the unit's power off by the main

switch on the back of the unit.

Validate an operation.

Cancel or abort an operation already initiated.

Access the program or tool editing mode.

Access the manual mode.

Page 8

Page: 4 - Operating Manual - NC-200 PB

Access the program execution mode.

Program blocks after moving the axes to the desired position while in

editing mode (Teach-in mode).

Move the axes in MANUAL mode in both directions and to move

back and forth from one menu option to another.

Move the axes manually at fast feedrate.

Execute and interrupt, respectively, the execution of a program.

987

4 5 6

321

-

+

0

inch

Enter data.

-

+

Change the sign of the value being entered and to eliminate the last digit

of the X and Y axes.

0

inch

Toggle between metric and inch display.

F Access the special operation modes, parameter setting, communications

via RS-232-C, etc.

2. COORDINA TE DISPLAY. AUXILIARY MODES

Turning the unit ON

The unit is turned on by actuating on the power switch of the rear panel

This NC runs a self-test and its LCD screen shows the text:

Fagor NC-200 PB, the 1st and 2nd displays show "Fagor NC". Press and

if there is an error, the displays will show the error number if otherwise. See the

appendix at the end of this manual.

Page 9

NC-200 PB - Operating Manual - Page: 5

Turning the unit OFF

If you press key the NC turns off the displays while maintaining the power

supply to the feedback systems and goes on reading the position of the axes at

all times. This is not the case when the equipment is turned off by means of the

switch on the rear panel of the same.

To reset the displays, just press this key again as long as that the NC is getting

voltage (plugged in and with the switch on the rear panel on).

Notes:

- Before powering the NC down with the switch on the rear panel or disconnecting

it from mains, it is a good idea to press the key in order to store the current

position of the axes permanently.

- If the unit is powered down with its rear panel switch or there is a power outage

without previously having pressed , the NC will keep the last position of

the axes for at least 30 minutes.

- The unit will display ERROR 2 when powered back up if the position reading

was lost when turned off while the axes were moving or after the accidental

backup period has expired without having saved the current position by

previously pressing

.

2.1 DISPLAY MODES

Language selection

On this NC, it is possible to select the language used for displaying the help on

the LCD screen. To do this:

- Access parameter PAR50 (language) directly by pressing

5

0

inch

- Press

-

+

repeatedly until the desired language appears (English, Spanish,

French, German, Italian, Portuguese, custom*) and press .

Press to quit the language selection mode.

"Custom" may be any user defined language. (See section 3.4 PAR52 of the

installation manual).

Page 10

Page: 6 - Operating Manual - NC-200 PB

Conversion mm into inches

This NC can displayed the position of the axes in millimeters or inches by

pressing

0

inch

key depending on whether the INCH led is off or on respectively..

Turning off the last digit of the X and Y displays

This NC allows a decimal digit to be switched off (coarse resolution) when the

resolution is excessive, simply by pressing

-

+

. For example 0.01 instead of

0.012.

2.2 SELECTION OF TOOLS AND TYPES OF MATERIAL TO BEND

In the initial mode, it is possible to set a particular punch-die set and also the

bending pressure as well as the characteristics of a particular material.

This data will only be assumed when machining in MANUAL mode. Section 3.1.

·Press F

· Use to select <Tool> and press to access to the selection page:

[punch number] [·] [die number] and press

Maximum pressure when using a pressure gage (transducer),

[Sheet thickness]

[Number of associated table (0 to 19)]

Press to exit.

This unit assumes the offsets indicated in the tool table. See section 3.3.

· The screen shows the number of the selected tooling.

Punch, die 1.1

· The position shown on the Y axis display corresponds to the relative distance

between the edge of the punch and the top side of the die.

The final bend position is always negative.

Page 11

NC-200 PB - Operating Manual - Page: 7

2.3 TYPE OF MA TERIAL

The type of material depends on a number of factors that make it impossible to

foresee its behavior in order to calculate the depth "Y" of the punch according

to the programmed angle αα.

This problem is solved using the TEACH-IN editing mode that forces the

operator to make several bends by trial and error until obtaining an acceptable

result and memorize the "Y" depth associated with the requested angle αα.

This is a very time-consuming task because it has to be repeated for all the

programmed angles. A program stored in memory must be executed with the

same tools used in the TEACH-IN process. The width of the die forces its

geometry.

Using the elasticity factor associated with each material exceeds the capabilities

of a conventional TEACH-IN editor that only requests the depth of the bend:

· It is a programmable parameter that is assumed together with the thickness of

the sheet metal in the N0 block of each program.

· It associates certain constants, in a table format, for 8 fixed values multiple of

10 between 50º and 120º.

· It calculates (prorates) the factor corresponding to intermediate angles.

· It is also possible to store in the table 5 special values associated non-multiple

of 10 or out of the 50º-to-120º range, if they will be repetitive in future bends

with the same material.

· The TEACH-IN editor (section 4.1.2) offers the option to load a new factor for

special angles or modify the value stored in the table that matches a typical angle

to be corrected.

· This unit has resources to generate the tables for unknown material types and

to set corrections based on the original ones to adapt them to materials

supposedly very similar to the standard ones offered here and described in later

chapters.

· For white sweet sheet metal F114 (resistance < 50 Kg), the factor is barely

affected by the width of the die. The same program may be executed with

different tools with results very similar results as for the mentioned materials and

similar punch radii. It will only require a slight correction.

If the A aperture of the die is larger than the one used in the tries, the resulting

angle will be slightly greater.

Page 12

Page: 8 - Operating Manual - NC-200 PB

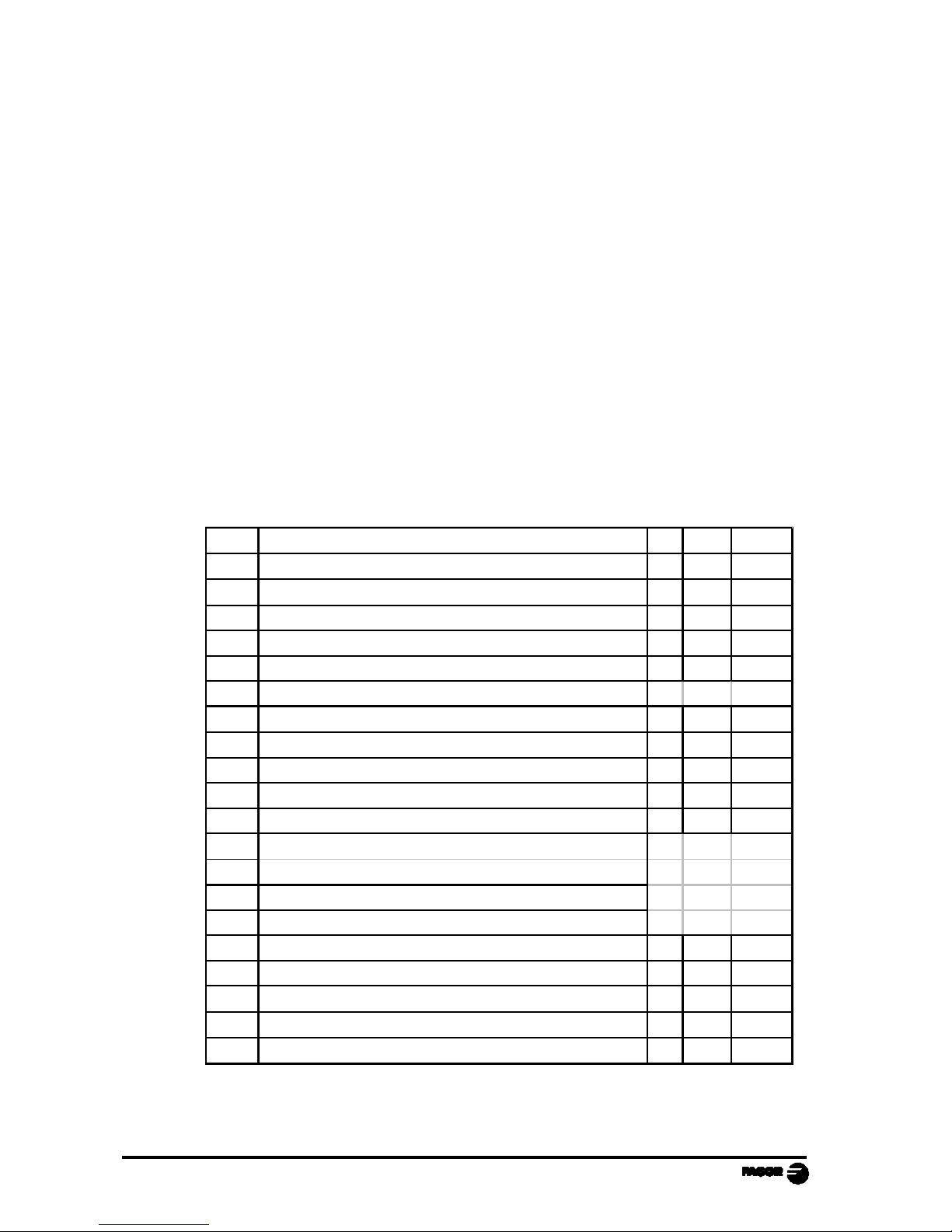

By default, this unit has some initial tables stored in nonvolatile memory and

cannot be modified. This table may be used as a sample for typical materials and

there is a modifiable copy of this table under factor numbers M0 to M19.

Either the non-modifiable factors M21 through M41 or the modifiable ones M0

through M20 when programming the header page N0.

There is a specific way, section 2.3.3, to recover the initial tables that serve as

a reference and correspond with the following materials and tools where:

Punch radius of 1 mm:

A = Die width

r = Die edge radius

e = Material thickness

Ri = Inside bending radius.

In order to obtain the same results with the suggested tables, we

recommend to use dies with an edge radius r = A/10 and an aperture

A = 8 x e. On sweet steel, Ri = A/6

Material A r e

M0 Reserved for inflexible materials

M1 Aluminum 12 1 1

M2 Aluminum 16 1.5 1.5

M3 Aluminum 20 2 2

M4 Aluminum 24 2.5 3

M5 Reserved

M6 White sheet < 48 Kg mm2 12 1 1

M7 White sheet < 48 Kg mm2 16 1.5 1.5

M8 White sheet < 48 Kg mm2 16 1.5 2

M9 White sheet < 48 Kg mm2 20 2 2.5

M10 White sheet < 48 Kg mm2 24 2.5 3

M11 Reserved

M12 Reserved

M13 Reserved

M14 Reserved

M15 Stainless steel 12 1 0.5

M16 Stainless steel 12 1 0.75

M17 Stainless steel 12 1 1

M18 Stainless steel 16 1.5 1.5

M19 Stainless steel 16 1.5 2

Page 13

NC-200 PB - Operating Manual - Page: 9

2.3.1 GENERA TE THE WHOLE ELASTICITY FACTOR TABLE FOR

A NEW UNKNOWN MA TERIAL

Tables 0 through 19 are open to the machine operator. They may be changed

with the NC's own resources or uploaded from a PC. They represent each

operator's experience.

M0 should be reserved for inflexible materials that do not require bending radius

compensation. See example in Section 2.3.2

In initial mode, press F

On the "Materials" menu, select <New> and press

The EXECUTION mode is accessed in the same way adding a canned cycle that

offers a sequence to check the elastic behavior of the new material.

The first page defines the tools:

[Punch number] [·] [Die number]

[Sheet thickness]

[number of the associated table (1 to 19)

Knowing the tool dimensions and the sheetmetal thickness, this NC has the

necessary geometrical data to suggest consecutive trial bends for 8 angles

between α = 130º and the minimum α supported by the die selected for the trial.

Press to test the 1st angle of 130º:

The axis displays the sequential trial number, from 1 to 8.

The axis displays the approximate bending depth to know the trial stage.

· Press , the Y axis positions at the theoretical depth corresponding to 130º

to execute the first bend.

Once executed and when the ram or the base reaches the withdrawal position,

go to the new page that requests an angle. Enter the real angle obtained and

press .

The reading and entering of data may be automatic when using the FAGOR

electronic angle measuring device connected directly to this NC.

· Repeat this sequence until completing the whole table.

Page 14

Page: 10 - Operating Manual - NC-200 PB

After accepting the last angle, it calculates the whole table of elasticity factors

associated with the angles multiple of 10, thus concluding the trial.

These factor are stored in the selected table.

This trial may be aborted by pressing after completing a bend, but the factors

of the angles already tested will not be stored.

Take certain precautions and maintain a criterium that helps classifying the

materials according to their elasticity, hardness or traction resistance factors:

Type Characteristics of the material

1,2,3,4 Aluminum of different thickness and very hard sheet metal (70 HRB)

that breaks when bent.

5-14 White sweet sheet metal (F114) of different thickness and hardness.

15-20 Very flexible sheet metal: stainless steel, steel 134, etc.

Once their bending limit has been exceeded, the characteristics of the material

change. The limit angle depends on the thickness, type of material and punch

radius on inflexible materials.

The material type number must be indicated for the 8 suggested angles with sheet

metal that should not have been previously bent at greater angles.

This NC does not offer resources to display the data saved in the tables. It is

recommended to write down the values of the "αα" angle and "Y" depth related

to each type of material and the die number used in the trials.

2.3.2 GENERA TE THE ELASTICITY F ACTOR OF A SINGLE ANGLE

BY TESTING THE BENDING DEPTH

This method is recommended to determine very accurately a single bending

angle by testing an unknown material or an angle way out of the 50º-120º range

even if it belongs to a table already tested.

In initial mode, press F

Use to select <mat> (materials) and press

On the "Materials" menu, select <1> and press

Page 15

NC-200 PB - Operating Manual - Page: 11

The TEACH-IN EDITING mode is accessed in the same way.

The first page defines the tools and type of material.

[punch number] [·] [die number]

[sheetmetal thickness]

[number of associated table (0 to 19)]

Once all four data have been entered, the NC may access the TEACH-IN mode.

Press (at the "C" model, select "SET" first).

·Press and key in the αα value to be tested and press to make the trial

bend. An approximative result will be obtained.

·Using the resources of the continuous or incremental MANUAL mode, fine

tune the Y coordinate and repeat the trial.

·Select position 5 of the MANUAL selector switch to disable the Y axis and the

"DIS" led will turn on.

Some manufacturers offer resources to move the axis with means external to the

NC (typical method on up-stroke machines with a handwheel for manually

correcting the leadscrew position.

Once the right angle has been achieved, usually by trial and error, press

Select <Yes> and press

Measure and indicate the obtained angle.

and press

The relevant elasticity factor is stored. This procedure may be repeated for

several angles until its full capacity is filled: 8 multiples of 10 (from 50º to º120º)

+ 5 intermediate. When exceeded, it displays the message: "Memory full".

Save correction?

Yes<No>

Save correction?

Angle

Page 16

Page: 12 - Operating Manual - NC-200 PB

Practical examples:

With a factor of M0, the material is supposed

to be inflexible without inside bending radius.

a) - With M0, r = 0, e = 0, α = 90,

A = 24

Bending depth Y = -12

b) - With M0, r = 0, e = 3, α = 90,

A = 24

Bending depth Y = -7.726

2.3.3 GENERATE THE ELASTICITY FACTOR BY TRIAL AND ERROR

AND CORRECT THE ANGLE

Method recommended when trying to correct the elasticity factor of some

material that has been already tested and shows some dispersions.

In initial mode, press F

Use to select <Mat> and press

On the "Materials" menu, select <2> and press

The first page defines the type of material.

[punch number] [·] [die number]

[sheetmetal thickness]

[Number of associated table (0 to 19)]

Once all the data has been entered, this NC is ready to access the correction

mode.

Press . The display blinks "000".

Set the bending angle and press

The "Y" axis reaches the position corresponding to the selected angle and

makes the trial bend.

The characteristics of the material must be close to the selected elasticity

factor.

The result is an angle close to the suggested one. It must only differ in ±5º

for the correction to be accurate.

Page 17

NC-200 PB - Operating Manual - Page: 13

· Press

The screen shows the option:

Select "Yes" and press . The blinks "000".

· Indicate the actual resulting angle with a maximum resolution of 0.1º and

press

2.3.4 SAVING AND RECALLING THE MATERIAL-TYPE TABLES

THROUGH THE SERIAL LINE RS-232

The material type number is an empirical value (obtained through a custom

algorithm) that cannot be interpreted.

It is recommended to save the initial tables offered by this NC and use them as

references for certain very specific materials.

Each press brake operator may create his/her own tables and save them using

a PC with a communications software like HYPERTERMINAL (available in

Windows version) or "Procom" in MS-DOS version.

This method is only recommended when wanting to have the tables of more than

20 materials.

The procedure and format are described in chapter 5.

Save correction?

Yes<No>

Page 18

Page: 14 - Operating Manual - NC-200 PB

2.3.5 RESTORING INITIAL T ABLES

In initial mode, press F

Select <Mat> (Materials) with and press

Select <Delete> and press

· To restore the material type (elasticity factor) for a single material:

Indicate the table number, 1 to 19, displayed on the 3rd display and press

· To recover all the initial tables:

Indicate Nr. 99 and press

A dot comes on at the 1st and 2nd display.

Press again. Two dots are lit.

Press F . 2 dots are lit and it offers two choices (are you sure?).

Use to select <Yes> and press

While the tables are being loaded, the message screen shows the message:

"Deleting materials...". M0 to M19 restore the initial values of the table.

3 OPERATING MODES

3.1 MANUAL /SET MODE

There are two ways to access: Models A & B: With

Model C: Selecting the "SET" mode.

The MAN led turns on.

This mode also sets the slow Y axis speed below the speed change position

(PAR33).

If any of the axes reaches the software limits set by PAR12 and PAR13 or the

travel limit switches are activated, this unit issues an error message; but it allows

moving the axes in the opposite direction to return to the work area.

Page 19

NC-200 PB - Operating Manual - Page: 15

If PAR16 has been set with leadscrew backlash value, position reading will be

ignored when reversing the turning direction. Once the backlash has been made

up for, this unit resumes position reading. This is particularly noticeable when

using continuous jogging or the Y axis has been enabled and it is moved by

external means.

If PAR17 has been set to "1" or "2", when moving the axes in continuous or

incremental jog mode, in back and forth movements, this unit assumes the

unidirectional approach.

To quit the MANUAL mode, press or change the switch to a position other

than SET.

3.1.1 MANUAL MOVEMENT FROM THE NC KEYBOARD

- Select the axis to be moved with its relevant key or .

- Press

or and the axis will start moving in either direction at slow

feedrate. To move it fast, press

at the same time and keep it pressed..

- To stop the movement,

1st release the key and 2nd release SLOW..

Otherwise, it keeps moving at the feedrate set by PAR26.

Depending on the position of the

MANUAL switch, the movement will be

continuous or incremental . Positions 1

through 4 (clockwise) in the drawing

below.

3.1.2 MOVEMENT WITH THE FOOT SWITCHES. "C" MODEL

In SET mode, actuating upon any foot switch forces the (Y) axis preset.

In MANUAL mode, using the up and down foot switches is the same as using

the keys that only affect the Y axis.

The foot switches are also operative in INCREMENTAL JOG mode.

Cont.

jog

Incr.1

Incr.2

Incr.3

Disable Y

Semiauto

1

2

3

4

5

Page 20

Page: 16 - Operating Manual - NC-200 PB

3.1.3 MANUAL MOVEMENT TO A PARTICULAR "X" POSITION,

"Y" DEPTH OR "αα" ANGLE

- Select the MANUAL mode with or with "SET" at the "C" model.

- Select the axis:

or to define the position.

For negative values, press

-

+

after the coordinate.

To define the bending angle compensating the active tools and

type of material.

The selected display keeps blinking.

- Request a value and press . The axis will move until it reaches the indicated

position.

To interrupt this movement before reaching its target, press

To resume the movement, repeat this process selecting the a new position value.

In MANUAL mode, it always assumes the "SET" type work mode. Two foot

switches control the up and down movement of the ram in sensitive mode while they

are pressed (A1, B and C models).

The associated elasticity table cannot be modified.

Press to exit.

3.1.4 MANUAL MOVEMENT BY EXTERNAL MEANS

- When disabling the "Y" axis by setting the jog switch in the corresponding

position (position 5 in the drawing below), the "DIS" led will turn on and the "Y"

axis will be free to be moved by external means. The NC will display the axis

position and will watch for its travel limits.

Cont.

jog

Incr.1

Incr.2

Incr.3

Disable Y

Semiauto

1

2

3

4

5

Page 21

NC-200 PB - Operating Manual - Page: 17

3.2 MACHINE REFERENCE (HOME) SEARCH

If machine parameter PAR14.4 = 1, the home search is mandatory on one or

both axes on power-up. Whenever any axis has been moved while the NC was

turned off, the axis that has been moved must be homed.

Parameter PAR14.1 distinguishes the sequence depending on whether home

switches or used or not.

3.2.1 SEQUENCE FOR AXES WITH MANDA TORY HOME SEARCH

ON POWER-UP

On power-up, pressing activates the mode. Select or .

a. If the axis has a home switch, this unit displays the word: "START".

If it is the Y axis, make sure that the ram is at the top position touching

the home switch.

Press to force the automatic search.

b. If the axis does not use home switches, usually on Y, it will indicate a value that

corresponds with the value of PAR10.

Actuate on the "BEND" foot switch until the ram reaches its final position.

Measure the distance between the support sides of the punch and die and preset

that value (Yref).

A wrong value too different from the real one may cause uncontrolled

movements of the axis.

Press . It displays the Y coordinate (Y = Yref - Hpunch - Hdie) compensating

the height of the active tools.

Exit pressing . The led turns off.

If on power-up, you wish to quit the home search mode without actually homing,

press and key in the access (or quit) code: 719200.

Page 22

Page: 18 - Operating Manual - NC-200 PB

3.2.2 SEQUENCE FOR AXES WITHOUT MANDATORY HOME

SEARCH

In initial mode, press . Depending on the characteristics of the machine,

there are two choices:

a. If both axes have home switches, the turns on. This unit displays the word

"START" when accessing freely or accessing only when the ram is at

the top position.

Press .

b. If any axis does not have a home switch, usually the Y, this unit requests the

password 719200 to access the mode and assumes that the values set by the

OEM are to be modified. This is only recommended in case of a breakdown

or when updating this unit's software version.

For the affected axis, proceed as described in section 3.2.1b

3.2.3 SEQUENCE FOR THE Y AXIS. MODEL B

Proceed as indicated in 3.2.1a. and add the synchronization sequence:

a.- with a linear encoder.

At the reference position, bend to the bottom until the ram is stopped and

press to balance the reading of the axes Y-Y'.

b.-With a linear potentiometer.

1- Press and it displays the potentiometer value in volts in

MANUAL mode.

2- Press

3- Move the "Y" axis with to the far end position, towards Y-.

Activate the BEND foot switch again up to the final position.

Press again.

Press to exit.

Page 23

NC-200 PB - Operating Manual - Page: 19

Edit

Prg Punch Die

3.3 TOOL T ABLE LOADING

With this NC, it is possible to load the data of up to 10 sets of punches and dies.

This data refers to the height of the punch (from 0.000 mm and 9999.999 mm),

to the height of the die, width of the die, "V" (from 0.000 mm to

9999.999 mm), die angle that limits the bending depth and its edge radius (from

0 to 99.9).

To do this:

- Access the editing mode by pressing

The screen shows three options:

Select "Punch" and press

- Choose the tool number using or keying the number..

- Indicate the punch height: [value]

- Press to exit.

Select "Die" and press

- Choose the tool number.

- Indicate the die aperture with: [value]

- Indicate the die height with: [value]

- Indicate the die angle with: [value]

- Indicate the die edge radius with: [value]

- Press to exit

· Before quitting this mode, it is recommended to check that none of the 9 table

positions contains data exceeding the range with a code EEEEEEEE.

By default, the whole table contains some initial values:

Hpunch = 0, Hdie = 0, A = 16, r = 1.6 that may be recalled.

3.3.1 RECALL INITIAL TOOL VALUES

While in punch or die editing mode, press the sequence:

F F

The unit will request confirmation of this command. Select <Yes> and

press to restore the initial values.

Page 24

Page: 20 - Operating Manual - NC-200 PB

4 PROGRAMMING

This NC can store up to 200 program blocks.

The program memory may be locked setting installation parameter PAR51(1)=1

This way, the program blocks cannot be edited or deleted.

In the initial teach-in stage, it is recommended to work with the simple resources

only as a positioning dro without attributes and with a material factor M0 which

only compensate for the rounding radius Rex = sheet metal thickness.

Once familiarized with them, it is possible to expand the resources of the materialtype tables, program ANGLES with the same capabilities as specific CNC's for

press brakes. To access this simple mode (without attributes):

(The assumes the default values of D and T set by PAR29 and PAR30).

·Press

5 1

·Press

8

to activate the bit and confirm with

· Exit by pressing

Programs edited in conversational mode keep the attributes even when not

displayed in EDITOR mode if PAR51.8 has been activated

4.1 PROGRAM EDITING

In a program, it is possible to "Edit" new blocks, "Modify" the data already

programmed in the blocks or "Delete" all their contents leaving them free (empty).

4.1.1 EDITING / DELETING AN EXISTING PROGRAM

- Press to access the block editing

mode.

- Select "Prg" using the keys and

press

- Use the keys to select the desired

program to be modified (they are not

stored sequentially).

- Press

Edit

Prg Punch Die

Program Editing

Program ....: 0000

Program Editing

Program ....: 0007

Page 25

NC-200 PB - Operating Manual - Page: 21

- Use the keys to select the option

(Edit or Delete).

- Select "Delete" to delete a program from memory..

- Select "Edit" to modify..

It access the program block N0.

Only some values of the parameters affecting the geometry of the bend

may be modified:

· Die number (with different width).

· Elasticity factor (type of material).

· Sheet metal thickness.

When pressing , if the corrector has been stored, it recalculates all the

following blocks that have been programmed by indicating the ANGLE

in order to adapt them the new parameters of the N0 block and it will

confirm that each one of them with two beeps.

- Use the keys to move to the

previous and next blocks respectively.

Edit the data of the block using the

procedures of the Editing mode described

in section 4.1.2 and press .

When modifying on the "Select axis" or "Attributes" screen, it may require

pressing two or three times to accept the new value and assume it. The

sequence ends with a blinking of the "#" symbol at the upper right hand of the

screen and it is confirmed with two beeps.

- To learn how to insert a new block, see section 4.2

- To quit the Editing mode, press .

Editing P0007 N00

Select Tool

Program Nr. Block Nr.

Program Editing

Edit Delete

Page 26

Page: 22 - Operating Manual - NC-200 PB

4.1.2 EDITING A NEW PROGRAM

To edit a new program, pressing gives access to editing the header of the

program (Block N00). The specific data for each bend take two screens pages.

Use the key to go from one page or one block to the next while validating the

data just entered.

Use the keys to select the page to be displayed; but only on the block

being edited (it is not possible to go back to the previous block).

After validating a block, it is not possible to go back to it in order to change a value

in it. To do this, finish editing the whole program and then proceed as described

in section 4.1.1.

Before accepting a data on the "Y" axis, in all the editing modes, it analyzes the

requested bending depth and it cannot be written if they exceed the width of the

die.

The "angle" indicated when loading the tool data serves as a reference to force the

safety limit Yminimum.

Editing with the key indicating the angle as described in this chapter marks

the relevant block to recalculate the bending depth "Y" when modifying any data

of the header block N0: active die, elasticity factor or sheetmetal thickness.

If programmed with the , depth only, it is not recalculated when changing the

data of block N0.

It must be machined with the same die that was chosen in editor mode.

Page 27

NC-200 PB - Operating Manual - Page: 23

The program editing procedure is as follows:

1st page. Header / Tool selection page

Select the "punch Nr./die Nr." set to

be used.

Select the maximum pressure in tons.

(Only on machines with electronic pressure

reading).

Sheet metal thickness, press

Material type, between 1 and 19, press

The last two data define the characteristics of the sheet metal and are displayed

together on the 3rd display.

Once accepted, press to go on to...

2nd page. Select X, Y values of 1st block, N1

It offers 3 modes:

a. Conventional editing: Presetting numeric values.

- Press and key in the X position of the bend.

- There are two ways to set the depth of the bend:

1-Pressing and keying in the final Y position of the bend or---

2-Pressing and keying in the angle a directly..

When pressing , this unit analyzes the material type table and

calculates the bending depth based on the thickness of the sheet metal

and the opening and radius of the die and it stores this value on the Y

axis (always negative).

The data for bending depth and angle are displayed at the same time.

Editing P0007 N00

Select Tool

Program Nr. Block Nr.

Page 28

Page: 24 - Operating Manual - NC-200 PB

b. Teach-in editing. Storing only the bending depth

With this method, it is also possible to execute parts by making single bends

without leaving the editing mode and it is ideal for individual bending operations

with unknown materials.

The X value is set in the conventional way, by setting a value.

- On a "C" model. Select the SET position.

- Press . The TEACH and MAN leds turn on. By default, the is selected.

( may be forced only to modify the X axis position).

This unit then offers all the resources of the MANUAL mode for positioning the

axes with the following options:

1- Key in the position and press

The selected axis will move to this position.

2- Continuous or incremental manual movement using the keys or the

foot switches on the "C" model.

3- When selecting position 5 of the MANUAL selector switch, the Y axis is

disabled and the "DIS" led turns on. Some manufacturers offer the possibility

to move the "Y" axis by external means (not using this NC). This is very

common on "A" type up-stroke presses having handwheels.

Once the correct angle has been achieved through trial and error if the material is

unknown, press . It suggests the position reached as the coordinate to be

edited; but it may be corrected.

Press to go on to the attributes page.

To exit the Teach-in mode, press or

Page 29

NC-200 PB - Operating Manual - Page: 25

c. Teach-in editing storing the angle with resources to correct the active

elasticity table.

Ideal method for materials with known elastic behavior identifiable with a

table already tested.

The X value is defined using the conventional method.

At the "C" model, select the "SET" position.

· Press . The TEACH and MAN leds turn on.

It selects the axis .

· Press , indicate the bending angle and press

The "Y" axis reaches the position corresponding to the angle selected for

the trial bend.

The characteristics of the material must be close to the selected elasticity

factor.

The resulting angle will be close to the suggested one. It must only differ

in ±5º for the correction to be accurate.

· Press

The screen shows the option:

Select "Yes" and press . The display blinks "000".

· Indicate the resulting actual angle with a maximum resolution of 0.1º and

press to go on to the attributes page.

Going back with it is possible to confirm the correction of the "Y" depth

corresponding to the suggested angle which will be indicated on the

display with the proper elasticity factor.

The same result is assured in the following blocks having the same angle

and edited the conventional way [angle]

If at the end of the trial, there are data changed out of the range for the "Y"

depth value , the selected table should be erased to restore the initial values.

See section 2.3.5.

Save correction?

Yes<No>

Page 30

Page: 26 - Operating Manual - NC-200 PB

3rd page. Attributes

Key in the number of times that block

is to be executed.

If n = 0, the block is ignored.

Auxiliary data.

Each function is represented by its

abbreviation on the display. Each attribute

is activated or canceled by pressing its

associated key, 1, 2, 3 or 4.

"t" (timing) . Apply a delay at the beginning of the block before moving the

X axis. By default, it shows the time period set by PAR30.

To set another value, press again, key in a value between 0 and

9.9 seconds (shown on the 1st display) and validate it with .

"h" (height). Activate the "H" output.

"b" (back). Retract the X axis when the punch presses on the sheet metal

according to the conditions set by parameters PAR36, PAR37.

4

"d" (delay). Hold the punch back at the end position once the bend has been

completed. By default, it shows the value set by PAR29.

To set another value, press

4

again, key in a value between 0 and

9.9 seconds (shown on the 1st display) and validate it with .

Top dead point. By default, it offers the value of PAR28; but any other value

may be preset (only on machines with ram / table position decoder).

To store the data, press . It is confirmed with two beeps and it access the page

for selecting the X and Y values, of the next bend, press .

The values set for the "t" and "d" attributes accessed with the

1

and

4

keys

exclude each other. It is assigned to the last attribute from the one it was requested

(and shown on the 1st display "t=2" or "d=4"). If one of the two attributes is active,

but it is not shown on the 1st display, it assumes the value set by the relevant

parameter PAR30 or PAR29.

Editing P0000-N01

Attributes

Editing P0000 N01

1T 2H 3B 4D

Page 31

NC-200 PB - Operating Manual - Page: 27

The attributes are assumed at the beginning of each block before executing the

movements of the axes.

The "t" attribute is only active if it corresponds with an approach movement of the

X axis.

In EXECUTION mode, they appear on the screen with the letters: T, H, B, D

blinking if they are affecting the bending operation.

The end of the program does not require any special instruction. To quit the editing

mode, press . The last block opened when recognizing the block edited last

is not stored.

To modify a value, go back to , select the program, move to the desired block

using the key, replace the value and validate it by pressing

(see section 4.1.1).

4.2 INSERTING / DELETING BLOCKS IN A PREVIOUSL Y EDITED

PROGRAM

Select the previous block as described in section 4.1.1

- Press F .

The LCD screen will shows the options to "Insert" and "Delete ".

- With the "Insert" option, an empty block is created and inserted after

the selected block and the numbers of the next blocks are increased by

one.

Note : No block may be inserted after the header block N00.

- The "delete" option eliminates the selected block. The following numbers

decrease by 1.

- Block N0 cannot be deleted.

- To delete a whole program, see section 4.1.1.

4.3 DELETING ALL THE PROGRAMS

To delete all the programs, once in "program edit" mode, press the

sequence: F F

It requests confirmation Yes/No with

Page 32

Page: 28 - Operating Manual - NC-200 PB

5 EXECUTION MODES WITH CONTROL FROM THE FOOT

SWITCHES AND MANUAL STATION. MODELS A1, B, C

5 stages may be distinguished when executing a block:

1. Previously positioning of the X and Y axes.

Some machines have a specific button that the operator must press to force the

X axis approach.

To start the bending sequence, both axes must reach the programmed position.

A buzzer may be installed to indicate the order to the operator.

2. RAPID approach.

It is only possible if activated from the manual station.

When reaching the speed change point, it changes to SLOW.

3. Bending from the foot switch station depending on the selected mode. RUN1

and RUN2 are the most common ones.

Conditioned by the "B" attribute, the X axis may be forced to return when

holding the sheet metal.

4. Delay at the final position at maximum pressure conditioned by the

programmable "D" attribute.

5. Return to the top dead point.

In the RUN 1 and RUN 2 modes, the return is automatic once the delay time

has elapsed.

At the "C" model with safety pressure gage the bending process is aborted when

exceeding the limit value and it returns to the top dead point thus preventing tool

damage.

Up to 4 modes may be selected with an external switch. These modes distinguish

the way the "BEND" or "RETURN" foot switches respond. The rapid approach

controlled from the manual station is not described here.

If the pressure gage has a manometer key, in RUN1 and RUN2 modes, the return

of the ram may be timed ("D" attribute) if PAR51.7=1 is activated (recommended

only for small parts that are easy to handle).

RUN 1

SET

JOG

RUN 2

1

2

3

4

Page 33

NC-200 PB - Operating Manual - Page: 29

RUN 1 - CONTINUOUS, STOP WHEN RELEASING THE FOOT SWITCH

a. Hold the "BEND" foot switch down so the axis starts moving SLOWLY.

b. Releasing the foot switch interrupts the movement.

Pressing the "RETURN" foot switch, it returns to the top dead point.

c. Once the position and the bending pressure have been reached, the foot

switch may be released. The return is not affected by the status of the foot

switch. It is automatic when the bending time has elapsed.

d. To go on to the next block, release the pedal if it was kept pressed until the

top dead point is reached.

RUN 2 - SIMPLE, RETURN TO THE TOP DEAD POINT WHEN

RELEASING THE FOOT SWITCH

a. Hold the "BEND" foot switch down so the axis starts moving SLOWLY.

b. When releasing the foot switch, it returns to the top dead point.

c. Once the position and the bending pressure have been reached, the foot

switch may be released. The return is not affected by the status of the foot

switch. It is automatic when the bending time has elapsed.

d. To go on to the next block, release the foot switch if it was kept pressed until

the top dead point is reached.

SET - IT FORCES THE MANUAL MODE IN THE "C" MODEL

BEND ALL DAY DOWN AND RETURN WITH TWO FOOT

SWITCHES

It is also assumed in Manual mode, home search and TEACH-IN.

a. Hold the "BEND" foot switch down so the axis starts moving SLOWLY.

b. Releasing the foot switch interrupts the movement.

Pressing the "RETURN" foot switch forces the return movement in

sensitive mode while it is being pressed.

c. While the "BEND" foot switch is kept pressed, the cycle is interrupted when

both the final position and pressure have been reached.

The return is not automatic.

d. To return to the top dead point, press the "RETURN" foot switch.

The preset bending delay "D" is ignored.

Page 34

Page: 30 - Operating Manual - NC-200 PB

JOG - APPROACH AND RETURN CONTROLLED BY A SINGLE FOOT

SWITCH

a. Holding the "BEND" foot switch pressed, it starts moving SLOWLY.

b. Releasing it interrupts the movement.

Keeping the "RETURN" foot switch pressed forces the return movement in

the sensitive mode.

c. Once the final position has been reached, keep the "BEND" foot switch

pressed to complete the bend and start the return movement.

Releasing the foot switch interrupts the sequence even in the final return

movement to the top dead point.

d. To go on to the next block, release the foot switch after the top dead point

is reached.

5.1 PROGRAM EXECUTION

To execute a program:

- Access the "Execution" mode by

pressing .

- Select the desired program by keying

its number and pressing or using

the keys.

The message screen shows the status of the

program:

Program Number: P100

Tools assumed: P1 M1

Block Nr. and Nr. of repetition: N01.02

Active attributes: T H B D

When requesting a new program at the display, the word "START" appears

to indicate that the key must be pressed to begin the first bend:

Execution

Program : 0000

Page 35

NC-200 PB - Operating Manual - Page: 31

1.- . Position the axes and approach the ram using the manual station.

Feed the sheet metal.

2.- Press the "BEND" foot switch for bending according to the selected

EXECUTION mode and the active attributes.

3.- Once the bend is completed, the ram returns to the top dead point.

The sequence for the second bend begins automatically.

The axes position at the coordinate set in the 2nd block repeating the successive

bends until the 1st part is completed.

At the end of the last bend, the axes position at the coordinate set in the 1st block

without having to press . It is possible to feed the sheet metal and go on to the

2nd part.

To quit the EXECUTION mode, press twice.

The block may be interrupted at any stage of the bending operation by pressing

and it may be resumed by pressing

In EXECUTION mode, The and axis displays show the actual (real) X

Y position.

El 3rd display offers additional information in real time once the punch touches

the sheet.

· On the "B" and "C" models, it shows the value of the effective angle on the

bending stage.

· On the "A" model, for machines equipped with a pressure gage, it shows the

programmed angle and the real effective pressure on the bending stage when

touching the sheet metal.

Page 36

Page: 32 - Operating Manual - NC-200 PB

5.2 EXECUTION IN SEMIAUTOMATIC MODE

Having the MANUAL selector in position "5" (semiautomatic), this unit does not

execute the next block automatically. The same bend may be repeated over and

over again until the selector switch is turned to a position other than "5".

If while in this execution mode, the key is pressed, the NC will go on to

execute the next block. By pressing the several times, it is possible to select

the desired block to be executed in semiautomatic mode or ignore the ones not to

be executed.

6 OPERATION WITH THE RS-232-C SERIAL LINE

6.1 SAVING AND RESTORING DATA

With this NC, it is possible to save data into a PC or peripheral device and later

restore it by using the RS-232-C serial communications line.

This data is sent out in the following format:

Baudrate as set by PAR90, 8 data bits, 1 stop bit and no parity.

To access this mode:

- Press

F

- Select the "Comm" option (communications) of the LCD display by means

of the and press .

- Select: < Send> and press to send the data out to a PC or peripheral device

or select <Receive > and press to receive data from a PC or peripheral

device.

- Select the type of data to transmit Parameters, Program, and Materials by

means of the keys and press .

Cont.

jog

Incr.1

Incr.2

Incr.3

Disable Y

Semiauto

1

2

3

4

5

Page 37

NC-200 PB - Operating Manual - Page: 33

6.2 PARAMETER TRANSMITTING FORMAT

The format of the transmitted parameters are:

For value parameters: P00 123.123

For binary parameters: P00 10101010

For option parameters: P00 0

For axis parameters: P?? X 123.123 Y 123.123

The number of decimals depends on the selected resolution.

6.3 PROGRAM TRANSMITTING FORMAT

The format is: P000 P0.M0 G0.000 P999.9 X Y R T H B D U

Where: P0000 Program number.

P0 - M0 Punch number . Die number

G0.000 Sheet metal thickness

P999.9 Pressure (LF)

X Y Bend position

R Block execution number

T Delay between blocks (timing).

H Auxiliary output H (high)

B X axis retract

D Punch delay at the end of the bend (Delay)

U Top dead point (up)

6.4 TRANSMISSION OF MATERIAL-TYPE TABLES

In <Send> mode, this NC can send the full table stored in it out to a PC.

In <Receive > mode, this NC can receive one or several materials M00 through

M19 from a PC.

Page 38

Page: 34 - Operating Manual - NC-200 PB

APPENDIX

ERROR CODES

Message Description

FAGOR dro

Power outage or turned off by main switch after saving the data.

Error 02

Power outage or turned off by main switch without having saved

the data.

The unit has been turned off without previously pushing the

[ON/OFF] key. It will only lose the position count (will be reset to

zero) and the status of the operating modes (inch, abs, etc.).

Error 04

Wrong parameter values

Error 05 Wrong internal configuration

Error 06

Errors in data backup memory (Service Dept.)

Error 07

Emergency input active. Press [C] or cancel emergency signal.

Error 08 Wrong software memory or the software has been changed

Error 09

Errors in work memory (Service Dept.)

Error 12

Error while searching a coded marker pulse (Io)

Error 20 Travel limit switch pressed on that axis.

Error 31

Internal malfunction (Service Dept.)

Error 32

Internal malfunction (Service Dept.)

Error 90 Internal malfunction (Service Dept.)

Error 99

Internal malfunction (Service Dept.)

. . . . . . . . .

Feedback alarm fromthe feedback device (scale, encoder, etc) or

weak signal.

l.4.3.6.5.7.2.5

Feedback speed too high.

EEEEEEEE

Maximum position reading or speed exceeded when searching

Home

Page 39

NC-200 PB - Operating Manual - Page: 35

If any message other than the first two from the table were to come up, the equipment

should be switched off and on again until one of the first two are seen.

After pressing to access the counting mode, check the parameters.

If any of the errors shown as (Service Department) are often repeated, ask Fagor

Automation’s Customer Services Department about this.

The feedback alarm error will appear if the bit of the corresponding alarm activating

parameter for the axis has been set to "1" PAR08(1) = 1.

In either case, to clear the display, press .

If the axis value is flashing, this means that one of the travel limits established by

machine parameter has been exceeded. This error will be displayed if the alarm

activation parameter for the axis PAR08(2) = 1. All outputs are deactivated

If the NC does not come on or goes out while running, check that the voltage and

ground outlets are as they should be. If an axis does not count, disconnect the

feedback connectors one by one. If the NC comes on, it indicates a fault in the

feedback device. If the fault persists get in touch with Fagor Automation’s Customer

Services Department about it.

MAINTENANCE

Cleaning:

An accumulation of dirt in the equipment can act as a screen preventing proper

dissipation of the heat generated by the internal electronic circuits with the consequent

danger of overheating and NC fault.

Accumulated dirt can also, in some cases, provide a conductive path for electricity which

could give rise to faults in the internal circuits of the equipment, especially in high

humidity conditions.

To clean the equipment nonabrasive dish-washing detergents are recommended (in

liquid, never powder form) or 75% isotropic alcohol with a clean cloth. DO NOT USE

aggressive solvents, (benzol, acetones, etc.) which could damage the materials the

equipment is made with.

Do not use high pressure compressed air to clean the item as this could give rise to an

accumulation of charges which in turn lead to electrostatic discharges.

The plastics used in the front panel of the NC stand up to:

1. Grease and mineral oils.

2. Alkalis and bleaches.

3. Dissolved Detergents.

4. Alcohol

Avoid the effect of solvents such as Chlorohydrocarbons, Benzol, Esters and Ethers

because these could damage the plastics with which the front of the equipment is made.

Preventive Inspection

If the NC does not come on press the rear switch for starting, make sure it is properly

Loading...

Loading...