Page 1

INSTALLATION MANUAL

FAGOR NC-200 PB

NC FOR

PRESS BRAKES

Manual version: 0111

Page 2

Page: 2 - Installation Manual - NC-200 PB

INDEX

Declaration of conformity................................................................................... 4

Safety conditions ............................................................................................... 5

Warranty terms................................................................................................... 7

Material returning terms ...................................................................................... 8

Description of the different models (they may be selected with PAR64) ................ 9

Diagram of a typical press brake ....................................................................... 10

1. Unit description .............................................................................. 11

1.1 Front panel (See operation manual) ..................................................... 11

1.2 Rear panel ......................................................................................... 11

1.3 General technical characteristics......................................................... 12

2. Connections and characteristics ....................................................13

2.1 connection of the feedback systems................................................... 13

2.2 Input/Output characteristics (X2) ....................................................... 14

2.3 Input/output Connection (X2). ........................................................... 15

2.3.1 Input description. .............................................................................. 15

2.3.2 Output description ............................................................................ 17

2.3.3 Input/output connection .................................................................... 18

2.3.3.1 Input/output connection. Model A ..................................................... 18

2.3.3.2 Input/output connection. Model A1 ................................................... 19

2.3.3.3 Input/output connection. Model B ..................................................... 20

2.3.3.4 Input/Output connection. Model C .................................................... 21

2.3.4 Block change synchronism. Models A, A1......................................... 22

2.3.5 Block change synchronism. Model B................................................. 24

2.4 Machine reference (home) search....................................................... 26

2.4.1 X axis home search........................................................................... 26

2.4.2 Y axis reference (home) search. Models A and A1 ............................. 27

2.4.3 Y axis home search. Model "B" ......................................................... 28

2.4.4 Y axis home search. Model "C"......................................................... 29

2.4.5 Precautions when home searching...................................................... 30

2.5 RS-232-C connection (connector X7)............................................... 31

2.6 Power and machine connection .......................................................... 32

2.7 Turning the unit on and off ................................................................ 32

3. Installation Parameters ..................................................................33

3.1 Parameter setting............................................................................... 34

Page 3

NC-200 PB - Installation Manual - Page: 3

Warning:

Before starting up the DRO, carefully read the instructions of

Chapter 2 in the Installation Manual.

The DRO must not be powered-on until verifying that the

machine complies with the "89/392/CEE" Directive.

4. Operation with the RS-232-C serial line ....................................... 49

4.1. Saving and restoring data ................................................................... 49

4.2 Parameter transmitting format ............................................................. 49

5 SETUP............................................................................................ 50

5.1 Test mode ......................................................................................... 50

5.1.1 Direct access to the parameters .......................................................... 53

5.2 Axis setting........................................................................................ 54

5.2.1 Open loop without analog voltage output. P46(3)=0, P46(5)=0 ............ 54

5.2.2 Open loop with analog voltage output. PAR46(3)=1, PAR46(5)=0 ....... 55

5.2.3 Closed loop. PAR 46(3)=1, PAR46(5)=1............................................ 55

Appendix ........................................................................................................ 57

Error codes ...................................................................................................... 57

Maintenance...................................................................................................... 58

Page 4

Page: 4 - Installation Manual - NC-200 PB

DECLARA TION OF CONFORMITY

Manufacturer: Fagor Automation, S. Coop.

Barrio de San Andrés s/n, C.P. 20500, Mondragón -Guipúzcoa

(ESPAÑA)

We hereby declare, under our responsibility that the product:

NC Fagor NC-200 PB

meets the following directives:

SAFETY:

EN 60204-1 Machine safety. Electrical equipment of the machines.

ELECTROMAGNETIC COMPATIBILITY:

EN 50081-2Emission

EN 55011 Radiated. Class A, Group 1.

EN 55011 Conducted. Class A, Group 1.

EN 50082-2 Immunity

EN 61000-4-2 Electrostatic Discharges.

EN 61000-4-4 Bursts and fast transients.

EN 61000-4-5 Power surges

EN 61000-4-11 Voltage fluctuations and Outages.

ENV 50140 Radiofrequency Radiated Electromagnetic Fields.

ENV 50141 Conducted disturbance induced by radio frequency

fields.

As instructed by the European Community Directives on Low Voltage:

73/23/EEC, on Machine Safety 89/392/EEC and 89/336/EEC on Electromagnetic Compatibility.

In Mondragón, on April 1st, 2001

Page 5

NC-200 PB - Installation Manual - Page: 5

SAFETY CONDITIONS

Read the following safety measures in order to prevent damage to personnel,

to this product and to those products connected to it.

Fagor Automation shall not be held responsible for any physical or material

damage derived from the violation of these basic safety regulations.

Do not open this unit

Only personnel authorized by Fagor Automation may open this

unit.

Do not handle the connectors with the unit connected to AC

power.

Before handling the connectors (mains, feedback, etc.) make sure

that the unit is not connected to AC power.

Use proper Mains AC power cables

To avoid risks, use only the Mains AC cables recommended for this unit.

Avoid electrical overloads

In order to avoid electrical discharges and fire hazards, do not apply electrical

voltage outside the range indicated in chapter 2 of this manual

Ground connection

In order to avoid electrical discharges, connect the ground terminals of all the

modules to the main ground terminal. Before connecting the inputs and outputs

of this unit, make sure that all the grounding connections are properly made.

Before powering the unit up, make sure that it is connected to ground

In order to avoid electrical discharges, make sure that all the grounding

connections are properly made.

Ambient conditions

Respect the temperature and humidity ranges specified on the chapter about

technical characteristics in this manual (1.3).

Do not work in explosive environments

In order to avoid risks, damage, do not work in explosive environments.

Page 6

Page: 6 - Installation Manual - NC-200 PB

Working environment

This unit is ready to be used in Industrial Environments complying with the

directives and regulations effective in the European Community

Install the unit in the right place

It is recommended, whenever possible, to instal the DRO so its power switch

of the back panel is at a distance between 0.7 m (27.5 inches) and 1.7 m (5.6

ft) off the floor and away from direct sunlight, hot air, coolants, chemical

products, blows as well as from relays, or high electromagnetic fields (about

0.5m or 20 inches) that could damage it.

This unit complies with the European directives on electromagnetic compatibility.

Nevertheless, it is recommended to keep it away from sources of electromagnetic

disturbance such as.

- Powerful loads connected to the same AC power line as this equipment.

- Nearby portable transmitters (Radio-telephones, Ham radio transmitters).

- Nearby radio / TC transmitters.

- Nearby arc welding machines.

- Nearby High Voltage power lines.

- Disturbance generating elements of the machine.

- Etc.

Safety symbols

Symbols which may appear on the manual

WARNING. symbol

It has an associated text indicating those actions or operations may hurt

people or damage products.

Symbols that may be carried on the product

WARNING. symbol

It has an associated text indicating those actions or operations may hurt

people or damage products.

"ELECTRICAL SHOCK" symbol

It indicates that point may be under electrical voltage

"GROUND PROTECTION" symbol

It indicates that point must be connected to the main ground point of

the machine as protection for people and units.

Page 7

NC-200 PB - Installation Manual - Page: 7

WARRANTY TERMS

WARRANTY

All products manufactured or marketed by Fagor Automation has a warranty

period of 12 months from the day they are shipped out of our warehouses.

The mentioned warranty covers repair material and labor costs, at FAGOR

facilities, incurred in the repair of the products.

Within the warranty period, Fagor will repair or replace the products verified

as being defective.

FAGOR is committed to repairing or replacing its products from the time

when the first such product was launched up to 8 years after such product

has disappeared from the product catalog.

It is entirely up to FAGOR to determine whether a repair is to be considered

under warranty.

EXCLUDING CLAUSES

The repair will take place at our facilities. Therefore, all shipping expenses as

well as travelling expenses incurred by technical personnel are NOT under

warranty even when the unit is under warranty.

This warranty will be applied so long as the equipment has been installed

according to the instructions, it has not been mistreated or damaged by accident or negligence and has been manipulated by personnel authorized by

FAGOR.

If once the service call or repair has been completed, the cause of the failure is

not to be blamed the FAGOR product, the customer must cover all generated

expenses according to current fees.

No other implicit or explicit warranty is covered and FAGOR AUTOMATION shall not be held responsible, under any circumstances, of the damage

which could be originated.

SERVICE CONTRACTS

Service and Maintenance Contracts are available for the customer within the

warranty period as well as outside of it.

Page 8

Page: 8 - Installation Manual - NC-200 PB

MATERIAL RETURNING TERMS

When returning the DRO, pack it in its original package and with its original

packaging material. If not available, pack it as follows:

1.- Get a cardboard box whose three inside dimensions are at least 15 cm (6 inches)

larger than those of the unit. The cardboard being used to make the box must

have a resistance of 170 Kg (375 lb.).

2.- When sending it to a Fagor Automation office for repair, attach a label indicating

the owner of the unit, person to contact, type of unit, serial number, symptom

and a brief description of the problem.

3.- Wrap the unit in a polyethylene roll or similar material to protect it.

4.- Pad the unit inside the cardboard box with poly-utherane foam on all sides.

5.- Seal the cardboard box with packing tape or industrial staples.

Page 9

NC-200 PB - Installation Manual - Page: 9

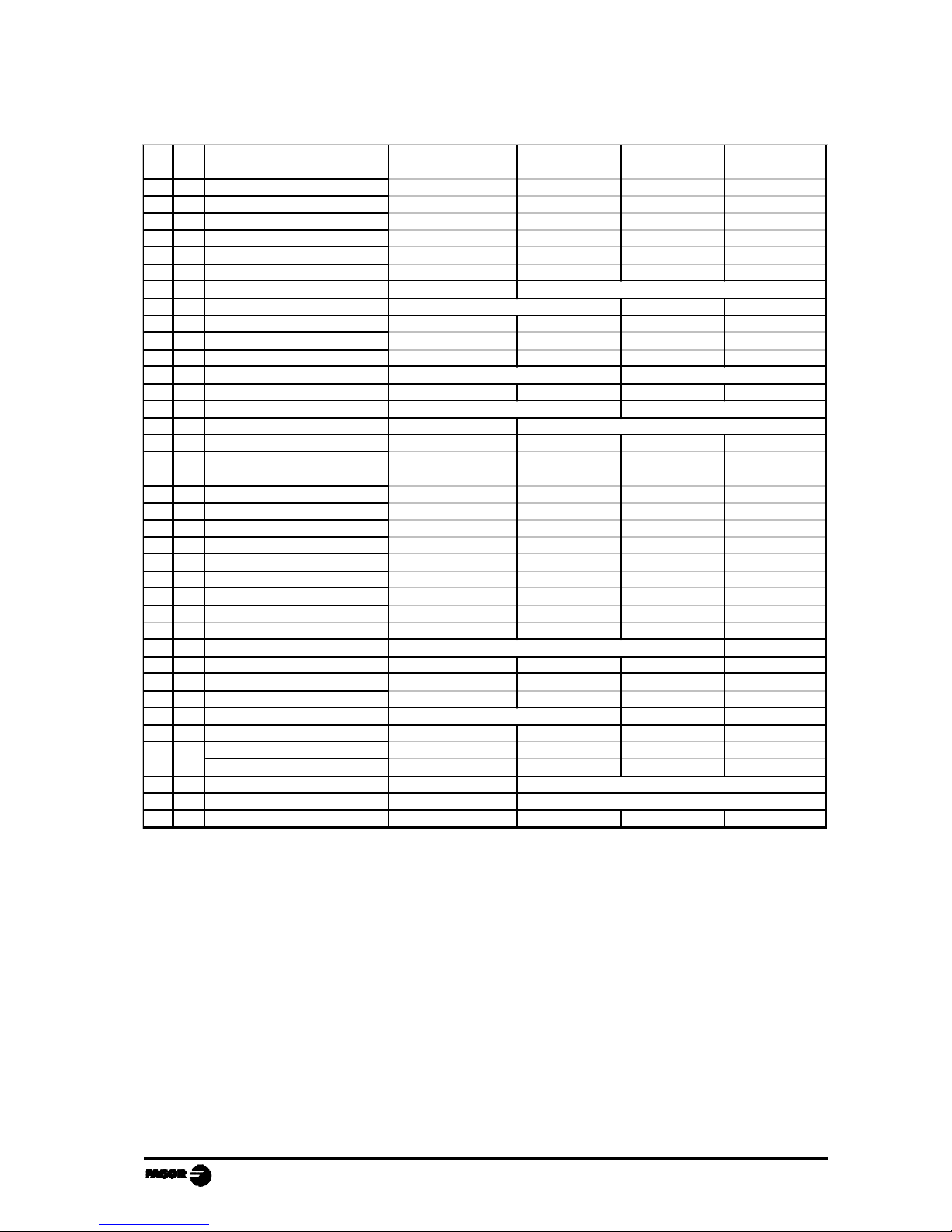

DESCRIPTION OF THE DIFFERENT MODELS

(THEY MA Y BE SELECTED WITH PAR64)

A. Controlling only the final position of the bend.

The foot switches and the hydraulic circuit are not controlled by this NC. The

intermediate positions of the ram are detected by electrical microswitches.

A1. Same as model "A" with footswitch treatment and outputs for governing the

hidraulic valves for the 4 EXECUTION modes.

The rapid approach feed is not managed.

Especially indicated for conventional down-stroke machines.

B. Same as model "A" with a linear encoder or potentiometric scale for decoding

the intermediate ram or bed positions affecting the bending approach speed and

depth:

With outputs to relays or to a PLC:

STOP - Top dead point overrun

S9 Fast ram approach.

S29 Slow speed controlled by the footswitches.

S28 Ram retraction.

With internal processing: (without external output).

· Going through "Y=sheet thickness" position to withdraw the X axis.

· Bend position reached to start bending timing on upstroke models that do

not have a presostat.

C- Control of the actual ram/bed position.

With internal processing of all the intermediate positions.

The footswitches control directly the position of the bending tool, Y axis.

Page 10

Page: 10 - Installation Manual - NC-200 PB

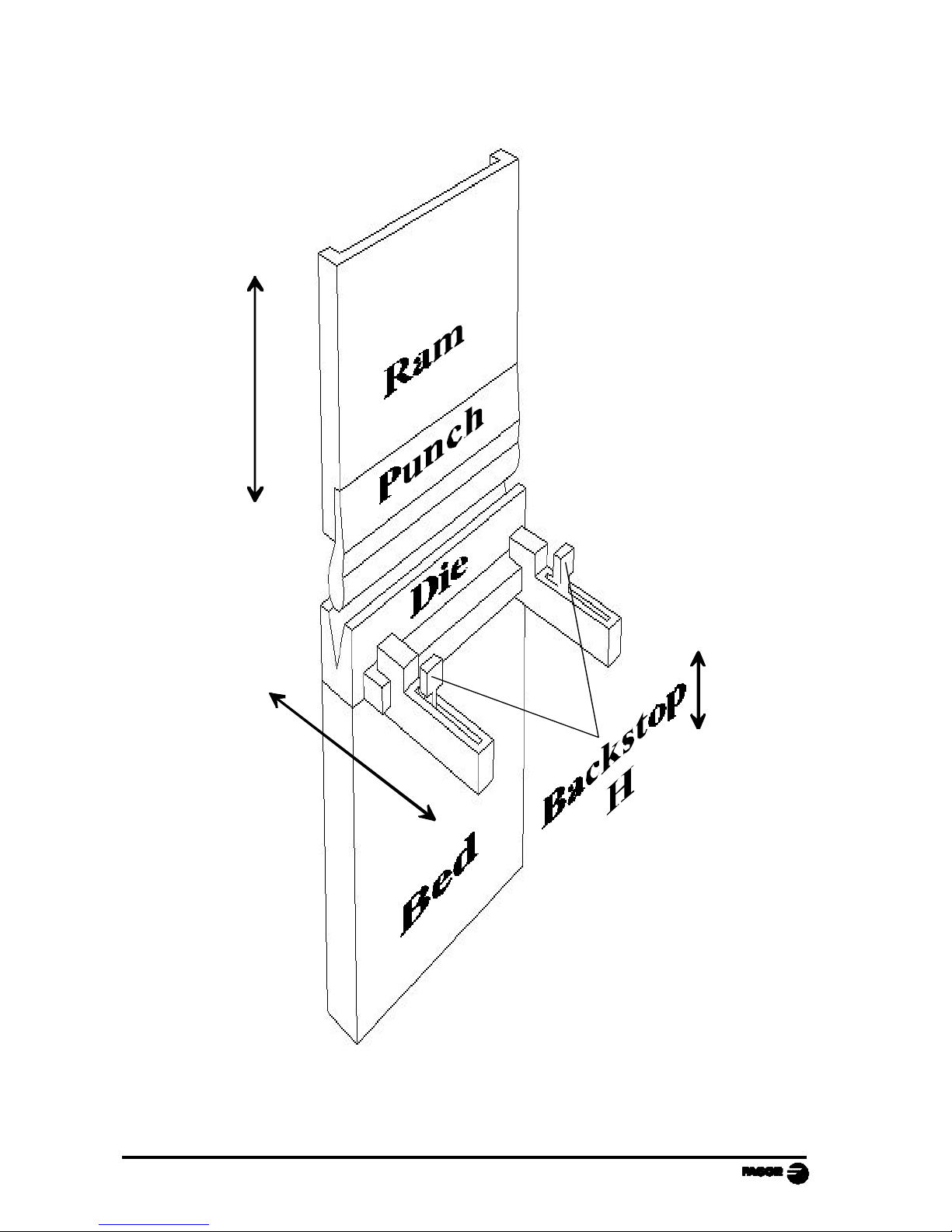

DIAGRAM OF A TYPICAL PRESS BRAKE

Y

X

+

-

-

+

Page 11

NC-200 PB - Installation Manual - Page: 11

1. UNIT DESCRIPTION

This unit is especially designed to be used on punch presses. It allows displaying

the position of the X and Y axes, controlling them as well as the raising device

(H), editing and executing part programs etc. The axes may also be moved

manually from the dro keyboard or externally with footswitches.

1.1 FRONT PANEL (SEE OPERATION MANUAL)

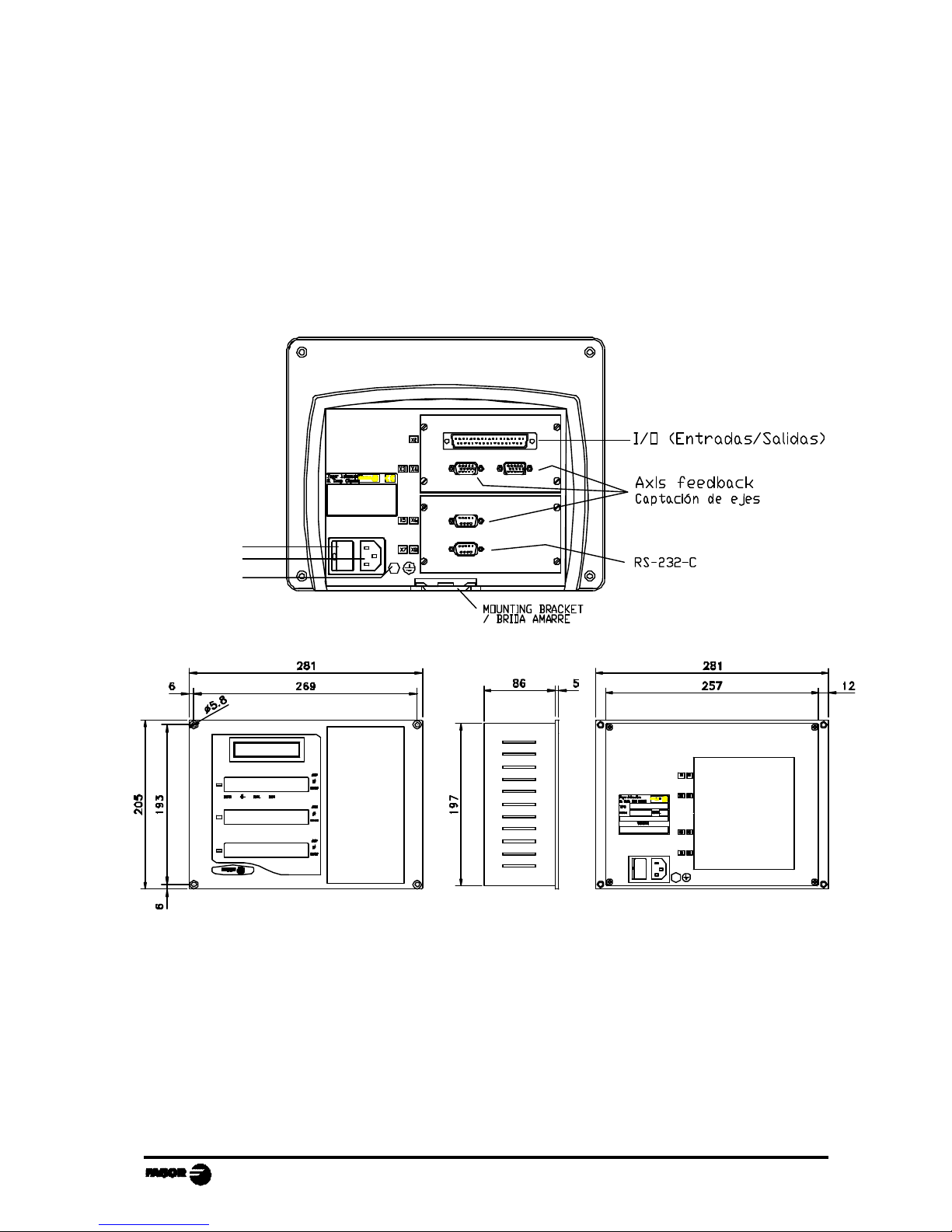

1.2 REAR PANEL

Dimensions of the Built-in model (in mm):

On the back of the unit, the following items may be found:

1.- Power switch.

2.- Three-prong power connector for AC and ground connection.

3.- M6 mm terminal for general machine ground connection.

2

1

3

Page 12

Page: 12 - Installation Manual - NC-200 PB

X2.- SUB-D type 37 pin female connector to connect the digital inputs and

outputs as well as the analog outputs.

X3.- SUB-D HD type 15-pin female connector for X axis feedback device.

X4.- SUB-D HD type 15-pin female connector for Y axis feedback device.

X5.- SUB-D HD type 15-pin female connector for 2nd axis feedback device.

auxiliary Y' axis (only on model "B").

X7.- SUB-D type 9 pin male connector for the RS-232-C serial line connection.

WARNING

Do not handle the connectors while the unit is under power.

Before handling the connectors (mains, feedback, etc.) make

sure that the unit is not under power.

It is NOT enough to turn the display off by using the key

at the keyboard.

1.3 GENERAL TECHNICAL CHARACTERISTICS

Universal Power Supply between 100V AC and 240V AC ±10% at a mains

frequency between 45 Hz and 400Hz, between 120Vdc and 300Vdc

Mains frequency of 0 Hz (DC) and from 45 Hz to 400 Hz.

Power outages of up to 20 milliseconds.

10-year memory backup of installation parameter even when the unit is off.

The operating temperature inside the DRO enclosure must be between 5º C and

45º C (41ºF and 113ºF).

The storage temperature inside the DRO enclosure must be -25º C and +70º C

(-13º F and 158º F).

Maximum relative humidity: 95% non condensing at 45ºC (113ºF).

Front Panel Sealing: IP54 (DIN 40050), Rear panel: IP4X (DIN40050) except

for built-in models in which case is: IP20.

Page 13

NC-200 PB - Installation Manual - Page: 13

2. CONNECTIONS AND CHARACTERISTICS

The connection for the RS-232 serial line (optional X1 connector) is not

described in this manual; but in a supplement for it.

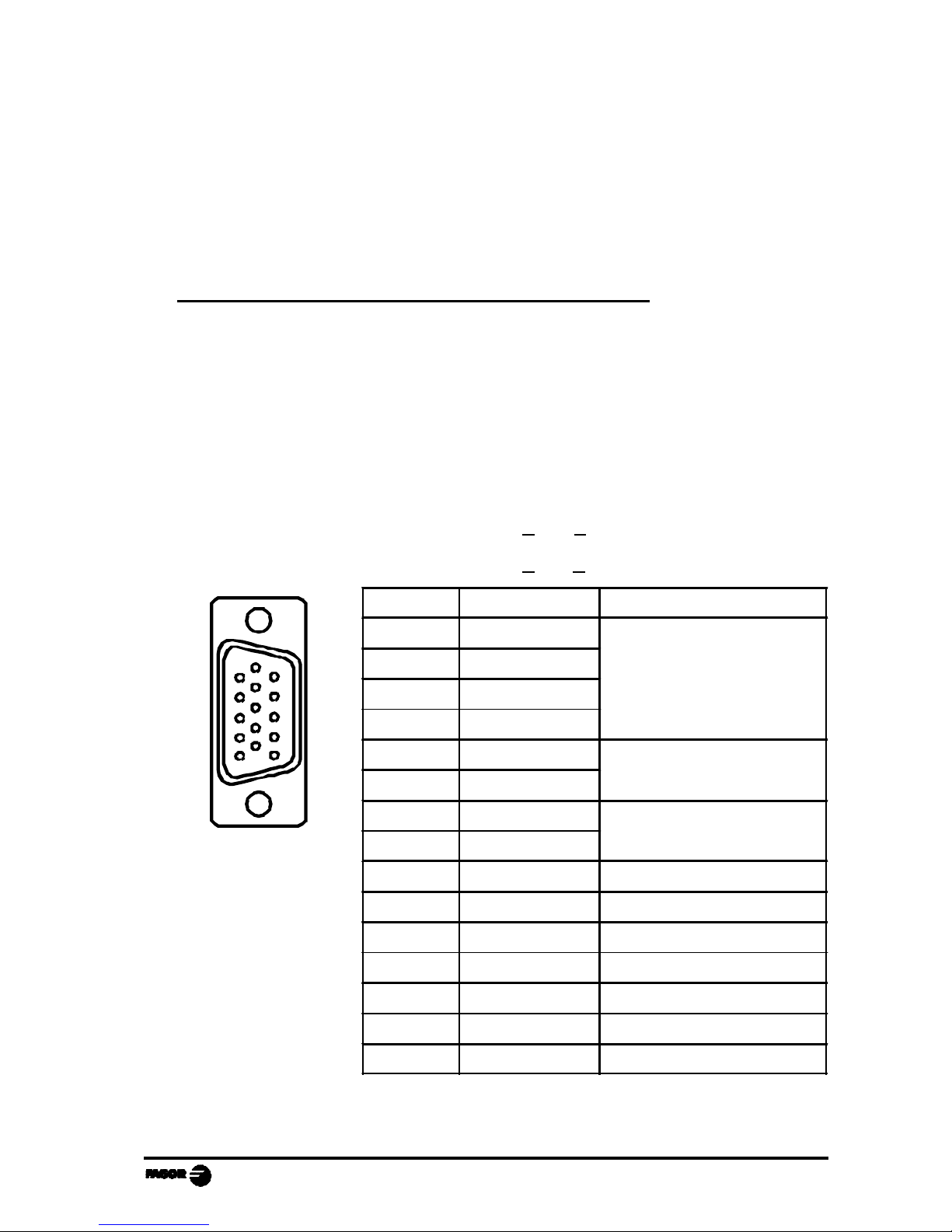

2.1 CONNECTION OF THE FEEDBACK SYSTEMS

The feedback systems (scales or encoders) are connected via SUB-D HD type

15-pin female connectors: X3 and X4.

Characteristics of feedback inputs: X3, X4 and X5:

- +5V input consumption: 250 mA

- Admits square-wave signal (TTL). (A, B, Io)

- Maximum frequency: 250 KHz,

minimum separation between flanks: 950 nsec.

- Phase shift 90º ±20º, hysteresis 0.25 V, Vmax 7V,

maximum input current: 3 mA.

- High threshold (logic state 1) 2.4V < VIH < 5V

- Low threshold (logic state 0) 0.0V < VIL < 0.8V

* They depend on the type of feedback and may not be connected

1

Pin Signal Function

1 A

Feedback signals

2 /A *

3 B

4 /B *

5 Io

Reference signal

6 /Io *

7 Alarm

Feedback alarm

8 /Alarm *

9 +5V Power for feedback

10 Not connected Not being used at this time

11 0V Power for feedback

12 Not connected Not being used at this time

13 Not connected Not being used at this time

14 Not connected Not being used at this time

15 Chassis Shield

Page 14

Page: 14 - Installation Manual - NC-200 PB

2.2 INPUT/OUTPUT CHARACTERISTICS (X2)

A 37-pin female connector is used.

Signal characteristics of connector "X2":

The supply voltage is at +24V (±25%), thus the threshold

between a "0" and a "1" will be about +6V.

Characteristics of the inputs at 24V :

- Maximum load current: 100mA

- Minimum DC voltage: 18V

- Maximum DC voltage: 30V

The main characteristics of the digital outputs are:

(optocoupled with solid state relay with a normally open

contact)

- Maximum AC or DC voltage: 48V

- Maximum load current: 150 mA

- Maximum internal resistance: 24Ohm

- Maximum peak current: 500mA for 100ms

at 25ºC

- Through current when open: ≤ 1µA

- Leak current: 200nA (Vload=100V)

- Galvanic isolation voltage: 1500V for 1 minute

- Activation time: ≤ 3ms

- Deactivation time: ≤ 3ms

Main characteristics of the analog outputs

Voltage range: ±10V Resolution: 4.88mV

Maximum current: 10mA Offset: ±30mV

Impedance: 120 Ohm referred to GND

Page 15

NC-200 PB - Installation Manual - Page: 15

2.3 INPUT/OUTPUT CONNECTION (X2).

2.3.1 INPUT DESCRIPTION.

Section 2.3.3 shows the electrical diagrams for the indicated models. The

parameters mentioned there are described in chapter 3 of this manual.

The inputs are active high at 24V (PAR21 and PAR22 = 1....1).

Pin 18 may be configured as an analog input with a 0V to +10V range. When

installing a linear potentiometer, it should be supplied with the 5V from the digital

feedback devices (pin 5 of X3, X4).

Pin I/O Common signals Model "A" Model "A1" Model "B" Model "C"

1 Chassis

2 I 0V External

3 I 24V External

4 O 24V User

5 O X enable

6 O 1 = X fast, 0 = X slow

7 O X direction

8 I Not being used

9 O Fast approach Buzzer

10 O Height H, 1 = up

11 I X limit + (Io X)

12 I X- limit

13 I

14 I BCD 1 switch

15 I

16 I External key 1 External key

17 Chassis

Pressure or scale input

X analog output

19 I/O 0V Analog.

20 I 0V External

21 I 24V External

22 O 24V User

23 I Emergency

24 O Y enable

25 O 1 = Y fast, 0 = Y slow

26 O Y direction

27 O Manual mode

28 O Not used

29 O X, Y in position Feed ram Bend slowly Not used

30 I Y limit + (Io Y)

31 I Y- limit

32 I X forward Not used

33 I BCD 2 switch

Y disable

Semiautomatic

35 I External key

36 I External key

37 O Y analog voltage

RETURN footswitch

Ram retract

X forward / retract

BEND footswitch

"BCD 1" EXECUTION mode

Buzzer

New block

Not being used

Presostat

Manual station

"BCD 2" EXECUTION mode selector

18 I/O

34 I

Page 16

Page: 16 - Installation Manual - NC-200 PB

PIN FUNCTION

Models A1, B and C 36 16

1 - RUN 1 0 0

2 - RUN 2 0 1

3 - SET 1 0

4 - JOG 1 1

Model A

External key

simulation. PAR 31

Model A1, B and C

footswitch connection

Models A, A1

Next block

Models A, A1

Double function

F1 + F2

Model A, A1

Mode B, C

The change to SLOW is forced at a previous programmable position

DESCRIPTION

32

15

Not connected. if the machine does not have a pressure sensor.

Pressure sensor

section 2.3.4

FAST approach before the bend conditioned to the maneouver safety

that requires "busy hands".

Model B

A - Electrical signal from the pressure sensor

Allows duplicating any 3 keys that may be selected - PAR 31

35, 36,

16

F2 - Forced X axis feed at the beginning of the bending sequence if

PAR65.2 = 1

8, 35 They respond according to the logic defined with the "BCD" selector

Confirmation of RAM at top dead position. Make sure that I13=1 to

begin the home search (A, A1, B)

If PAR65.1=1, requires previous input at I32

A1 - Confirmation that the programmed maximum pressure has been

exceeded to begin the delay "D".

13

F1 - Retracts the backstop X if there 's a conflict when bending,

conditioned by the editing attribute B in the slow speed stage

The X backstop automatically retracts at the position:

Y = sheet thickness

Only F2

Disables the axes

Disables the outputs

11, 12,

30, 31

Limit switches.

Hardware

23

EXTERNAL

EMERGENCY

In MANUAL mode, they limit the movement in the corresponding

direction.

In EXECUTION mode, they abort the program.

In HOME SEARCH mode, they respond as home switches in the

positive direction

"BCD" selector

36, 16

Displays error 20

2, 3, 4 - Incremental feed with the pitch set by PAR 32

1 - Continuous feed

14, 33,

34

5-position BCD

selector in MANUAL

mode - PAR32

5 - Y axis disable in EDITOR / TEACH-IN mode. It only displays it. It

allows withdrawing the punch by external means in "C" mode.

Semiautomatic in EXECUTION mode

Page 17

NC-200 PB - Installation Manual - Page: 17

2.3.2 OUTPUT DESCRIPTION

If any of the outputs is going to be connected to some highly inductive device,

a "1N4000" type diode must be installed in antiparallel. It is not required on

auxiliary relays of less than 20 mA.

The drives are enabled with auxiliary relays (section 5.2).

PIN FUNCTION

5, 6, 7,

24, 25, 26

Axis enable

FAST/SLOW

DIRECTION PAR46

27 MANUAL mode

10 H output

Models A, A1, B

Ram retraction.

Section 2.3.4

Model A

Axes in position

Model A1

Approach and

bending

Model B

Model B

Model A, A1, C

DESCRIPTION

Analog voltage

outputs. PAR 64,

PAR65

18, 37

It activates the auxiliary output to raise the X axis backstop. R

axis function, ON /OFF conditioned by the "H" editing attribute.

Enabling drives or frequency inverters for open loop control.

To control drives in closed loop drives.

When installing a pressure transducer or potentiometric scale,

connect it to pin 18 and change the position of the internal

jumper.

MANUAL mode selection confirmation.

SLOW approach.

Section 2.3.4

A - Retraction control by trigger time of the thermostat

conditioned by the "D" attribute.

Single output.

The FAST/SLOW change is handled with external resources

from the electrical cabinet that manages the FAST buttons and

the change switch.

I15 when exceeding the bending pressure

29

9

I32 (A, A1) or Y = e (B, C) at the beginning of the bend if

attribute B

A1, B - Forced retraction up to the top dead point. Bending time

conditioned by the "D" attribute.

28

At all models, it is reset with :

It resets in the programmable change position that forces the

slow motion output O29.

Fast movement

handling. Ram

approach.

Buzzer to warn the operator about "permission to bend"

Signal to the electrical cabinet to enable the FAST approach

buttons or SLOW bend footswitch.

Page 18

Page: 18 - Installation Manual - NC-200 PB

2.3.3 INPUT/OUTPUT CONNECTION

2.3.3.1 INPUT/OUTPUT CONNECTION. MODEL A

Without footswitch connection or ram controlling outputs.

M

Encoder

24V

EXTERNAL

MOTOR

CONTROL

21

3

20

2

4

22

EXTERNAL

KEY

SIMULATION

18

27

NC- 200 PB

ANALOG X

GNDA

EMERGENCY

0V

24V

24V USER

X ENABLE

X SPEED

X DIRECTION

M

Encoder

MOTOR

CONTROL

ANALOG Y

GNDA

Y ENABLE

Y SPEED

Y DIRECTION

8

35

23 14 33

7

6

5

19

37

26

25

24

31301211

LIMIT YLIMIT Y+

LIMIT X+

LIMIT X-

x1

x50

x100

Y Dis.

ß

10

13

32

29

MANUAL

H AXIS

IN POSITION

NEXT BLOCK

FEED/RETRACT X AXIS

19

36

28

RETRACT RAM

34

Semiauto

BUZZER

9

Interface

15

PRESSURE SENSOR

16

FREE

BCD

X2

X3 X4

Page 19

NC-200 PB - Installation Manual - Page: 19

2.3.3.2 INPUT/OUTPUT CONNECTION. MODEL A1

With footswitch connection. Manual control and ram controlling outputs.

M

Encoder

24V

EXTERNAL

MOTOR

CONTROL

21

3

20

2

4

22

18

27

NC- 200 PB

ANALOG X

GNDA

EMERGENCY

0V

24V

24V USER

X ENABLE

X SPEED

X DIRECTION

M

Encoder

MOTOR

CONTROL

ANALOG Y

GNDA

Y ENABLE

Y SPEED

Y DIRECTION

23 14 33

7

6

5

19

37

26

25

24

31301211

LIMIT YLIMIT Y+

LIMIT X+

LIMIT X-

x1

x50 x100

Y Dis.

ß

10

13

32

29

MANUAL

H AXIS

FEED RAM

NEXT BLOCK

FEED/RETRACT X AXIS

19

28

RETRACT RAM

34

Semiauto

BUZZER

9

Interface

15

PRESSURE SENSOR

BCD

8

35 36

16

"RETRACT" FOOTSWITCH

"BEND" FOOTSWITCH

RUN 1

RUN 2 SET

JOG

"BCD"

X2

X3

X4

Page 20

Page: 20 - Installation Manual - NC-200 PB

2.3.3.3 INPUT/OUTPUT CONNECTION. MODEL B

With footswitch connection. Manual control and ram controlling outputs.

M

Encoder

24V

EXTERNAL

MOTOR

CONTROL

21

3

20

2

4

22

18

27

NC- 200 PB

ANALOG X

GNDA

EMERGENCY

0V

24V

24V USER

X ENABLE

X SPEED

X DIRECTION

M

Encoder

MOTOR

CONTROL

ANALOG Y

GNDA

Y ENABLE

Y SPEED

Y DIRECTION

23 14 33

7

6

5

19

37

26

25

24

31301211

LIMIT YLIMIT Y+

LIMIT X+

LIMIT X-

x1

x50 x100

Y Dis.

ß

10

13

32

29

MANUAL

H AXIS

RAM SLOW

TABLE TRAVEL LIMIT

FEED X AXIS

19

28

RETRACT RAM

34

Semiauto

RAM FAST

9

Interface

15

MANUAL STATION

FAST FEED

BCD

8

35 36

16

"RETRACT" FOOTSWITCH

"BEND" FOOTSWITCH

RUN 1

RUN 2 SET

JOG

"BCD"

X2

X3 X4X5

Page 21

NC-200 PB - Installation Manual - Page: 21

2.3.3.4 INPUT/OUTPUT CONNECTION. MODEL C

With footswitch connection and manual control.

M

Encoder

24V

EXTERNAL

MOTOR

CONTROL

21

3

20

2

4

22

18

NC- 200 PB

ANALOG X

GNDA

EMERGENCY

0V

24V

24V USER

X ENABLE

X SPEED

X DIRECTION

M

Encoder

MOTOR

CONTROL

VALVE

ANALOG Y

GNDA

Y ENABLE

Y SPEED

Y DIRECTION

23 14 33

7

6

5

19

37

26

25

24

31301211

LIMIT YLIMIT Y+

LIMIT X+

LIMIT X-

x1

x50 x100

Y Dis.

ß

MANUAL

H AXIS

BUZZER

FREE

19

34

Semiauto

Interface

MANUAL STATION

FAST FEED

BCD

8

35 36

16

"RETRACT" FOOTSWITCH

"BEND" FOOTSWITCH

RUN 1

RUN 2 SET

JOG

"BCD"

27

10

13

32

29

28

9

15

FREE

FREE

FREE

X2

X3

X4

Page 22

Page: 22 - Installation Manual - NC-200 PB

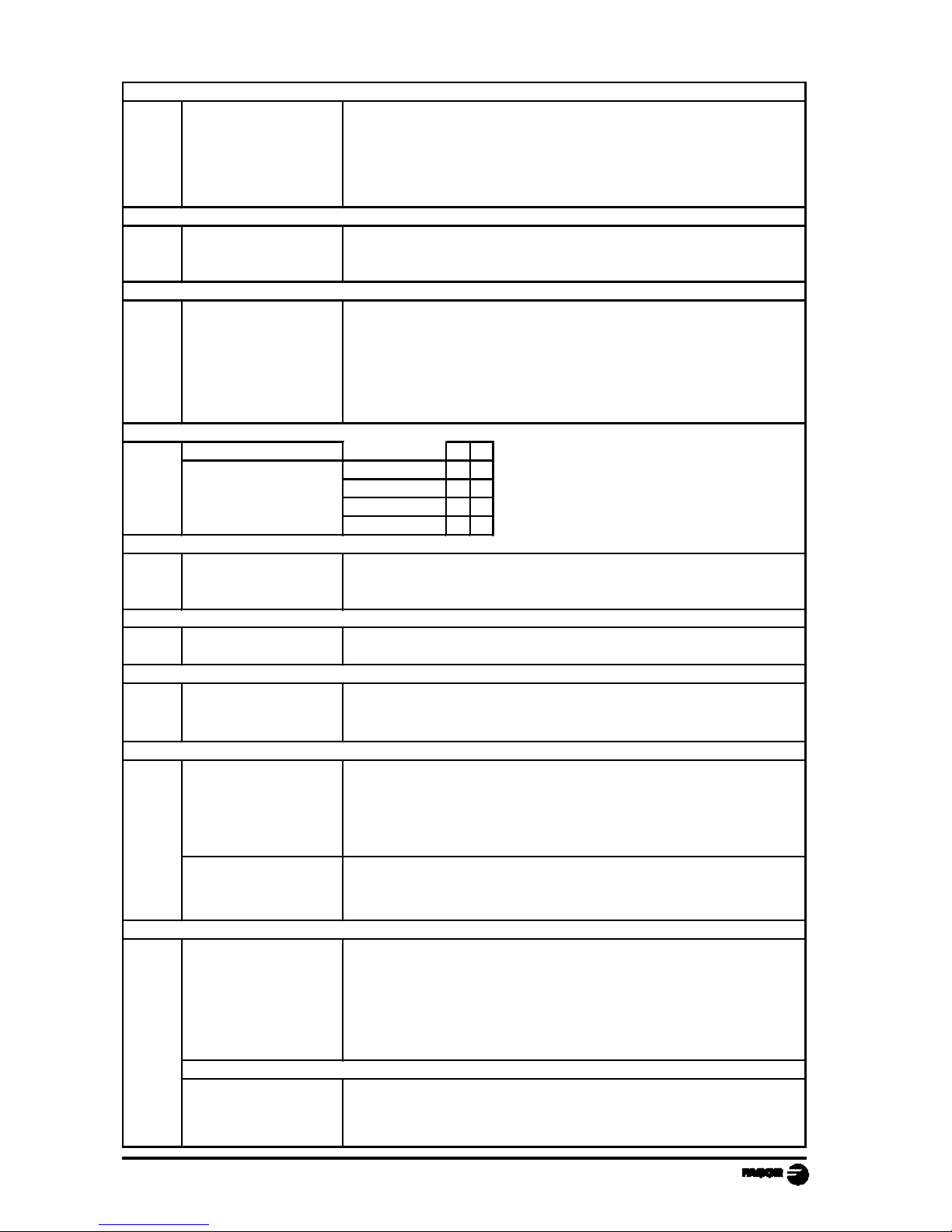

2.3.4 BLOCK CHANGE SYNCHRONISM. MODELS A, A1

Description of the diagrams according to positions a, b and c.

There are three ways to synchronize when going from one block to the next at

the end of a bend. If a pressure gage (transducer) is installed, P64.6 = 1, the

editor offers the possibility to program the work pressure on the header page

N0.

1. With the transducer connected to input I18 (P64.7=0), this positioning dro

(NC) compares the active pressure with the one programmed and provokes

the block changing sequence.

2. If the comparator is external (P64.7=1), this positioning dro (NC) waits for

a signal at I15 that confirms that the programmed pressure has been exceeded

in order to begin the change sequence.

In either case:

a. Output O29 is deactivated (INPOS) in order to prevent the ram from going

down.

It starts the delay "D", bending time, at maximum programmed pressure.

b. At the end of the bend, output O28 is activated to force the ram to return

automatically and it resets the analog output for pressure.

c. When it reaches the top dead point I13=1, it resets O28 and goes on to the

next block. If PAR65.1=1, it requires a flank at I32 to confirm the contact

of the punch with the sheet.

3. With pressure sensor signal, P64.6=0, connected to I15 and programmable

delay for RAM UP.

When the pressure sensor triggers:

a. It deactivates O29 (INPOS) to prevent the ram from going down.

It activates O28 to force the ram to return automatically. It is affected by

the timer (PAR29 + D). As a precaution, a minimum delay is forced

(PAR29).

b. It resets O28 and it goes on to the next block.

There are three possibilities:

b1 With a "D" value too high, the ram reaches the top dead point, it

activates I13 before the delay is over.

b2 If D = 0, after the PAR29 delay.

b3 If the delay is over (PAR29 + D), it forces it to go to the next block

without waiting for I13.

In the "b1" and "b2" modes, I13 resets the timer and O28.

If it reaches the top dead point, it goes on to the next block.

If PAR65.1=1, it requires a previous flank at I32.

Page 23

NC-200 PB - Installation Manual - Page: 23

I18

CHANGE I13

BLOCK

Analog Input

(A) IN_POS O29

BEND

RETURN O28

1- Pressure analog input

Par64 (6) = 1

Par64 (7) = 0

cba

I18

CHANGE I13

BLOCK

Analog Output

(A) IN_POS O29

BEND

RETURN O28

2- Pressure analog output

I15

Pressure level

Par64 (6) = 1

Par64 (7) = 1

abc

BLOCK I13

CHANGE

(A) IN_POS O29

BEND

RETURN O28

I15

Pressure level

Block change

3- Pressure gage input

Par64 (6) = 0

a

b1b2b1

b3

Page 24

Page: 24 - Installation Manual - NC-200 PB

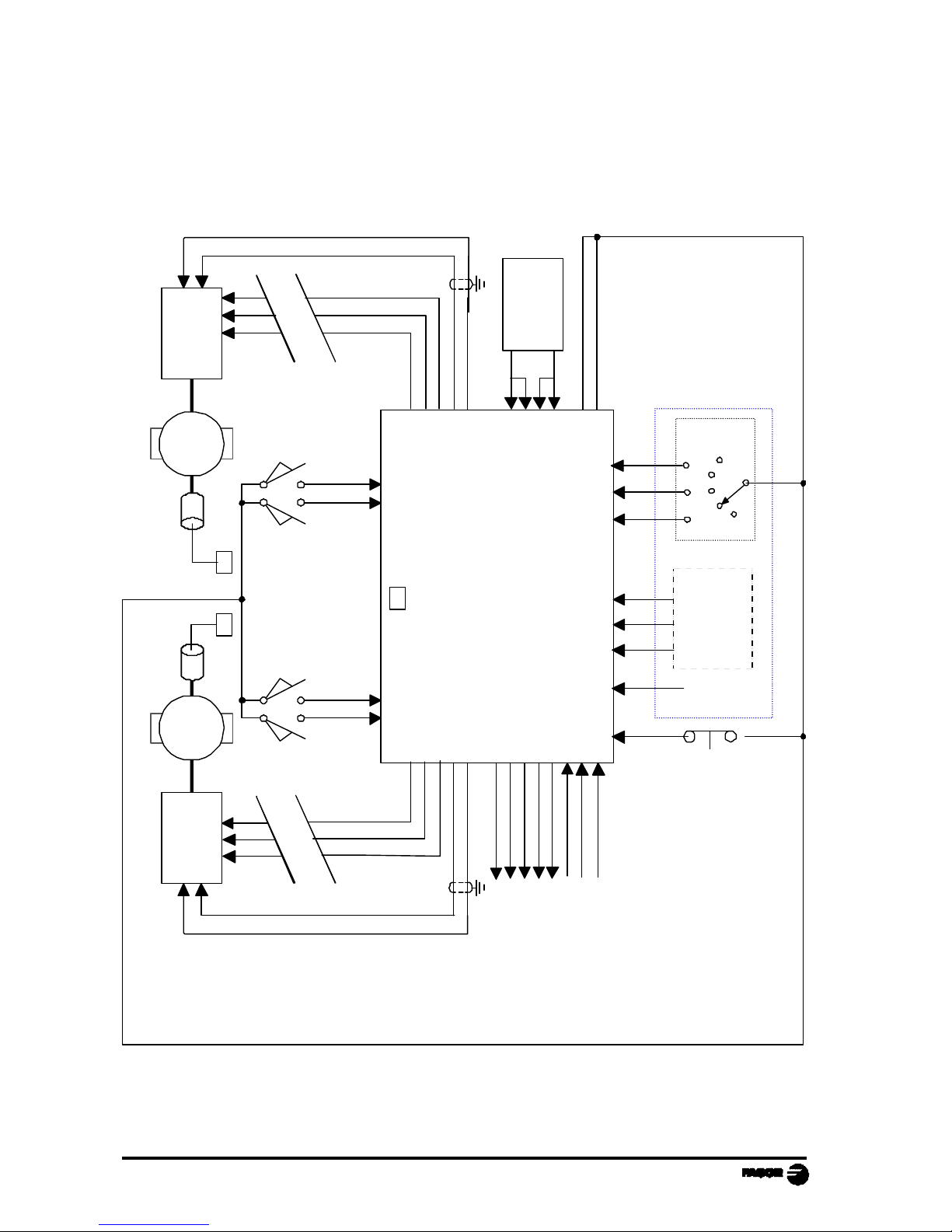

2.3.5 BLOCK CHANGE SYNCHRONISM. MODEL B

Description of the diagram according to positions 1 through 6:

1. With X and Y axis already in position, the FAST approach is activated from

the MANUAL control station IE15 or only SLOW from the "BEND"

footswitch (I8).

2. In the change position, Y= PAR33 or programmable, the SLOW speed is

activated with the "BEND" footswitch.

3. When pinching the sheet metal, Y = thickness, it resets O29 to wait for the

return of the X axis.

4. Once the programmed bending depth has been reached, the auxiliary

feedback Y compares the difference Y -Y' < PAR18 to begin the bending

delay, "D" attribute.

5. After the delay "D" and depending on the selected cycle, it activates the

return:

If RUN1, RUN2 - Automatic or when interrupting with I35.

If SET- With return footswitch I35.

6. When reaching the final dead point, PAR28 or programmable, it begins the

next block.

Page 25

NC-200 PB - Installation Manual - Page: 25

- Position

Y' - Auxiliary scale

PAR33

Programmed Y coordinate

Y' = e

FAST/SLOW

change

Programmable

top dead point

By default: PAR28

SLOW

O29

programmable

By default: P29

D

·I8·I8 I8

FAST

09

Retract X

·I15

RAM DOWN

O28

MANUAL-SET

·I35 JOG

BEND

footswitch

I35 in EXEC.

RUN1, RUN2

1 2 3 4 5 6

X, Y axes IN POSITION. To enable O29, O9 O28

MANUAL CONTROL

STATION I15

Begin bend

FOOT CONTROL

STATION, BEND I8

STOP

Cut off valve

Sheet pinched

FOOT

CONTROL

STATION

E35

Fina

bend

position

X + Y in

motion

·I8

Page 26

Page: 26 - Installation Manual - NC-200 PB

2.4 MACHINE REFERENCE (HOME) SEARCH

In this mode, the initial values are preset in a fixed reference position.

If PAR14.4 = 1 on any axis, home search is mandatory on that axis every time

the machine is turned on.

This unit starts in mode.

To quit this mode without homing, press and key in the access/exit code:

719200

If PAR14.4 = 0, home search is only required on machine setup. At the beginning,

the software limits PAR12 and PAR13 should be opened to their maximum

values to prevent this NC from forcing uncontrolled movements in order to

position the axes within these travel limits.

Should this happen by mistake, the movement may be stopped by pressing .

Being PAR14.1 = 1 (Floating home search), if while in this state you press

[access code], the affected axis will show the value: PAR12 + PAR26 as initial

value. When pressing the relevant key , , it will suggest the PAR10 value

by default with an option to select any other as described in later chapters.

2.4.1 X AXIS HOME SEARCH

PAR14 establishes how the machine reference (home) search is to be carried out.

All models perform this home search in the positive direction.

The X axis usually has a travel limit switch: PAR 14 bit 1 = 0 and a rotary encoder.

The home searching sequence is as follows:

· Set the NC in Home search mode by pressing .

The led will turn on.

If the home search for any of the axes is defined as "floating"

(P14.1 = 1), it requests the password (719200) after pressing .

· Select the axis. The unit will display the text "START".

· Press .

The Axis moves in the positive direction, backwards, in rapid until reaching the

positive travel limit switch.

Once the switch is pressed, it returns at slow speed until the reference mark (I0)

of the rotary encoder is detected. At that point, this unit displays the value set

at PAR10 (that will correspond to the real value from the center of the die to the

support side of the X axis). See section 2.4.5

Page 27

NC-200 PB - Installation Manual - Page: 27

2.4.2 Y AXIS REFERENCE (HOME) SEARCH. MODELS A AND A1

a- If the machine has travel limit switches, the home search procedure is the

same as the one described for the X axis; but it is only enabled if I13 = 1,

ram at top dead position.

b- If the machine does NOT have travel limit switches (which is very common

on down stroke models), set PAR14 bit 1 = 1 to indicate that the reference

position is floating.

The homing sequence is as follows:

· In MANUAL mode, move the Y axis in the Y+ direction to make sure that

the backlash is properly compensated for.

If P17 = 1, the Y- movement will be affected by the unidirectional approach

and will return in the Y+ direction.

· Press the "BEND" footswitch until the ram reaches its final position. Output

O27 is active ("A" model) to enable the footswitch.

· Measure the distance between the support bases of the punch and die.

This distance will be the Yref to be preset.

· Press . The led will turn on. Enter the password (719200).

This unit displays the real position and the axis remains on stand by.

· Select the axis, (by default, it suggests the PAR10 value) and preset the

reference value Yref and press to assume it. It displays the coordinate

( Y = Yref - Hpunch - Hdie) compensating the height of the tools that are active.

See section 2.4.5

Page 28

Page: 28 - Installation Manual - NC-200 PB

2.4.3 Y AXIS HOME SEARCH. MODEL "B"

Usually, this axis has home switches on UP-STROKE models.

· Position the table or the ram at the far-end position activating the limit switch

I13.

· Press . The led turns on.

· Select the axis. It displays the word "START".

· Press to reach the home position.

· Actuate on the "BEND" footswitch until the punch or the die (on up-stroke

models) goes to its final position.

a) With a linear encoder:

· Press to synchronize the Y axis home value set in PAR10 with that

of its associated axis Y'.

b) With a linear potentiometer:

It requires two synchronization points for the value of the Y axis with the

position of the table in order to obtain the V/mm constant of the

potentiometer and set an initial reference value.

1- Pressr , it displays the value of the potentiometer cursor in volts.

It enables the MANUAL mode.

2- Press

3- Use to move the Y axis to the far-end position towards Y-.

Activate the BEND footswitch again until the final position.

Press again.

Quit by pressing

Page 29

NC-200 PB - Installation Manual - Page: 29

2.4.4 Y AXIS HOME SEARCH. MODEL "C"

An up-stroke or down-stroke model "C" has a linear encoder and controls the

actual (real) position of the ram using foot switches. It usually has travel limit

switches.

If PAR00 bit 6 = 0, has been set for a linear encoder with a regular reference

mark (without distance-coded reference marks), the homing procedure is the

same as described in section 2.4.2 (a)

If PAR00 bit 6 = 1 has been set for a linear encoder with distance-coded reference

marks.

The homing sequence is as follows

· Set the NC in Home search mode by pressing .

The led will turn on.

· Select the axis. The unit will display the text "START".

· Press .

The axis moves upwards in the positive direction until detecting two consecutive

reference marks (I0's) and it displays the reference value set at PAR10.

PAR10 = D - O + ε

Where D = Distance between the support bases between the punch and the die.

O = Offset value indicated on the label of the linear encoder

ε = (See the next section 2.4.4)

Page 30

Page: 30 - Installation Manual - NC-200 PB

2.4.5 PRECAUTIONS WHEN HOME SEARCHING

The software limits set by PAR12 and PAR13 will indicate the real values referred

to machine zero and they will correspond to the + and - limits slightly short of

the positions of the travel limit switches or hard stops.

The floating-home search on the Y axis (PAR14.1 = 1) is a little risky if the home

value is wrong and does not match the actual distance between the supporting

sides of the punch and die. The software limits set by the OEM may be overshot.

The Y axis tries to recover a position within the software limits with the risk of

exceeding the limits of the worm gear mechanism.

As a precaution, make sure that the ram is in the upper area (I13 = 1) to make

the home search sequence possible.

If the machine has home switches (PAR14.1 = 0), the contact point of the microswitch with the cam should not be too close to the position of the first reference

mark (I0) of the encoder. The + limit switch is also the reference input that is

deactivated when reversing the movement direction. A certain margin should be

kept in order to reach a stable slow feedrate before receiving the reference mark

(I0) also overshooting the amount of backlash set at PAR16. Standard clamps

allow some rotation of the encoder body to make this adjustment easily.

Once the home search is finished, the axis moves towards X- until it reaches the

software travel limit (always less than the hardware limit set by the X+ home

switch) until reaching the position = PAR13 - PAR26.

On open-loop controls, the I0 signal sends a stop command; but there is no

assurance that the axis will be held at that position. There is a slight overshooting

even when selecting a slow home search speed.

Selecting the reference value for PAR10 takes three steps:

1- Set PAR10 with any value and execute a home search for a first rough

approach.

Calculate the "ε" difference: ε = PAR10 - final position reached (+ value)

2- The final value for PAR10 will be: The requested distance between the

support bases between the punch and the die + ε.

3- Set the software travel limits PAR12 and PAR13.

Page 31

NC-200 PB - Installation Manual - Page: 31

2.5 RS-232-C CONNECTION (CONNECTOR X7)

The RS-232-C serial communications line uses a 9-pin male SUB-D type

connector.

Parameter PAR90 sets the transmission speed through this line. See section 3.5 in

this manual.

The operating mode for this feature is described in chapter 5 of the Operating

Manual.

Pin Signal Function

1 NC Not connected

2 RxD Receive Data

3 TxD Transmit Data

4 NC Not connected

5 GND Ground

6-9 NC Not connected

Page 32

Page: 32 - Installation Manual - NC-200 PB

2.6 POWER AND MACHINE CONNECTION

This NC can be connected to an AC voltage anywhere between 100V AC and 264 V AC

±10% at a frequency between 45 Hz and 400 Hz. Between 120Vdc and 300Vdc without

having to select it depending on the country where they are installed thanks to their

universal power supply.

Always mount it vertically so its keyboard is within operator's reach and its digits are

easily visible (at operator's eye level).

Do not connect or disconnect this NC connectors while it is under power.

Connect all metallic parts to a common point on the machine tool and it to the general

ground point. Use cables of enough gage (no thinner than 8 mm2).

2.7 TURNING THE UNIT ON AND OFF

Turning the unit ON

The unit is turned on by actuating on the power switch of the rear panel

This NC runs a self-test and shows on the LCD display the text: “Fagor NC-200PB, Press

and the and displays show "Fagor dro" if everything is OK and the error

number if otherwise. See the appendix at the end of this manual.

Turning the unit OFF

If you press this NC turns off the displays while maintaining the power supply to

the feedback systems and goes on reading the position of the axes at all times. This is

not the case when the equipment is switched off by means of the switch on its rear

panel.

To reset the displays, just press this basta again, as long as this NC is getting

voltage (plugged in and with the switch on the rear panel on).

Notes:

- Before powering this NC down with the switch on the rear panel or disconnecting it

from mains, it is a good idea to press the key in order to store the current

position of the axes permanently.

- If the unit is powered down with its rear panel switch or there is a power outage without

previously having pressed , this NC will keep the last position of the axes for at

least 30 minutes.

- The unit will display ERROR 2 when powered back up if the position reading was lost

when turned off while the axes were moving or after the accidental backup period has

expired without having saved the current position by previously pressing

.

Page 33

NC-200 PB - Installation Manual - Page: 33

3. INSTALLATION PARAMETERS

These NC's have a number of installation parameters to configure it for a

particular application.

These parameters may be saved into a peripheral or uploaded from it through

the RS-232-C serial communications line.

The format for these parameters depends on whether they are general or

particular for each axis.

. If it affects the axes, press the corresponding axis key to modify it.

. If it is a general parameter, the X display will show its current value.

. The LCD display will show the description of the parameter and its number.

There are several kinds of parameters depending on how to set them:

· Binary values (1/0) are displayed in an 8-digit row identified as 1 through 8

from right to left.

Their state changes by pressing their associated number key

1

to

8

.

· With decimal values, select the axis and key in the value.

· Options, the value is selected by pressing

-

+

which will show the various options

in a rollover way.

· Simulated key code, by accessing the corresponding key.

Page 34

Page: 34 - Installation Manual - NC-200 PB

3.1 PARAMETER SETTING

Machine parameters PAR50, PAR51 and PAR90 enable special features of this NC.

The user may access them directly.

In initial mode, press [parameter number] .

The rest can only be accessed by installers and technicians.

Press and hold for at least 2 seconds, when the displays start blinking,

press .

Key in the access code: 060496 to access the general parameters.

Once on the menu, to access a particular parameter, press:

[Parameter number]

The LCD display will shows the parameter number and a short description.

. If it is a general parameter, its value is only shown on the first display.

. If it is an axis parameter, each axis display will show its current value.

In this case, select the axis by pressing its key ( or ) and key in its

new value.

- To go to the next parameter saving the changes:

Press or to go to the next one.

To return to the previous one, press

- Pressing the key of the other axis ( or ) saves the value of the previous

axis and it goes on to edit the new selected axis.

- Pressing will quit the parameter editing mode.

- If while changing the value of a parameter, is pressed, the unit will ignore

the new value and will assume the previous one.

Page 35

NC-200 PB - Installation Manual - Page: 35

Binary values (1/0) are displayed in an 8-digit row identified as 1 through 8 from right

to left.

X X X X X X X X

8 7 6 5 4 3 2 1

PARAMETER FUNCTION

PAR00 Feedback configuration, different per axis. Binary type.

This parameter sets the specific characteristics of the feedback

device (rotary or linear encoder) used to read the axis position.

Digit

8 Direction of the distance-coded Io (0 = Increasing, 1 = Decreasing)

Fagor offers two types of linear encoders depending on the type of

reference marks they use (Io): the standard one with several reference

marks every 50 mm and the one with distance-coded reference marks

(models with "O", e.g.: MOVX, FOP, etc.).

When using a rotary encoder or a standard Fagor linear encoder

(without "O") for this axis, this bit must be set to "0".

When using an "M" or "F" series Fagor linear encoders with

distance-coded reference marks (e.g.: MOVX, FOP) for this

axis, this bit must be set to "0".

When using a "C" type linear encoder with distance-coded reference

marks, (e.g.: COX, COVP) for this axis, this bit must be set to "1".

7 Pitch of the distance-coded Io (0 = 20 mm, 1 = 100 mm)

This bit is ignored if bit 6 has been set to "0".

When using Fagor M or C series linear encoders, this bit must be "0".

When using Fagor F series linear encoders, this bit must be "1".

6 Type of linear scale's Io (0 = Fix, 1 = Coded)

Fagor offers two types of linear encoders depending on the type of

reference marks they use (Io): the standard one with several reference

marks every 50 mm and the one with distance-coded reference marks

(models with "O" e.g.: MOVC, COS, etc.).

When using a rotary encoder or a standard Fagor linear encoder, this

bit must be set to "0".

Page 36

Page: 36 - Installation Manual - NC-200 PB

5 Axis units: 0 = mm, 1 = inches

These units refer to the feedback and not to the display which may

be changed with the key..

4 Not being used at this time. It must be set to "0"

3 Not being used at this time. It must be set to "0"

2 Type of feedback signals (0 = TTL)

This bit must be set to "0". A value of "1" will be ignored.

1 Counting direction (0 = normal, 1 = reverse)

Regulation for press brakes:

X axis retraction in the positive direction.

Ram up movement in the positive direction.

If an axis count increases or decreases in the opposite direction to the

one desired, change the value of this digit. It conditions the setting of

the sign bit PAR46(2) and the sign of the analog voltage.

PAR01 Feedback resolution, independent for each axis,

Possible values: from 0.0001 mm to 1 mm.

From 0.000001 to 0.03937 inch

factory setting: 0.0050 (mm).

PAR02 TTL multiplying factor (subdivision). Independent for each axis.

Options: x4, x2, x1 and x0.5.

The selection of these values rotates by pressing

The factory setting is: x4 and it is the one used for FAGOR scales.

When using an encoder, its number of pulses should be calculated

according to the leadscrew pitch, the desired resolution and the

multiplying factor to be applied as per the formula:

Encoder (lines/turn) = Leadscrew pitch (mm/turn)

Resolution (mm/pulse) x F

Where "xF" would be the multiplying factor to be applied.

Page 37

NC-200 PB - Installation Manual - Page: 37

PAR03 External multiplying factor (EX E type) when using linear encoders

with distance-coded reference marks and TTL feedback signals.

Independent for each axis.

Options: 1, 5, 10, 20, 25, 50. Factory setting: 1

These values are selected by pressing

For example:

For standard Fagor linear encoders with squarewave signals (without

"O" or "P") e.g.: MX, CT, CX, etc. it must be set to "1".

For Fagor linear encoders with squarewave signals and distance-

coded reference marks (models with "O"), eg.: MOX, COX, etc.

it must be set to "5".

For Fagor linear encoders with squarewave signals and distance-

coded reference marks (models with "O") and 0.5µm resolution,

eg.: MOY, COY, etc. it must be set to "10".

PAR05 Resolution (PAR01) correction factor.

It may be used for adapting any resolution, even fractional, when

the encoder is affected by a mechanical gear reduction.

PAR08 Feedback alarm enable. On if = 1 and Off if = 0.

Digit

3 Detects the feedback alarm provided by the encoder through pins

7 and 8.

Fagor models DO NOT provide this signal.

rest Not being used at this time. They must be set to "0".

Page 38

Page: 38 - Installation Manual - NC-200 PB

PAR10 Absolute value set on each axis at the end of the home search.

On press brakes, it coincides with (see section 2.4):

On the X axis:the distance from the center of the die to the support

side of the X carriage.

On the Y axis:The distance between the support sides of the punch

and the die.

Factory setting: 0.

This value will be in mm or inches depending on whether the INCH

LED is off or on.

PAR12 To set the minimum axis travel limit.

Possible values: within ±99999.999

This value will be in mm or inches depending on whether the INCH

LED is off or on.

If PAR08(2)=1 (limit alarms ON), when the axis exceeds this

distance, the corresponding axis display starts blinking until it is

moved back into the work zone.

PAR13 To set the maximum axis travel limit.

Possible values: within ±99999.999

This value will be in mm or inches depending on whether the INCH

LED is off or on.

If PAR08(2)=1 (limit alarms ON), when the axis exceeds this

distance, the corresponding axis display starts blinking until it is

moved back into the work zone.

PAR 14 It sets how the machine reference search (I0) will be carried out .

Digit

8, 7, 6, 5 Not being used at this time. They must be set to "0".

4 If =1, mandatory home search on power-up.

3 If =1, The whole home search is carried out at slow speed.

2 It does not use a home switch.

Home search begins slowly in the negative direction. It ends when

detecting the 1st marker pulse (home signal) of the encoder.

Page 39

NC-200 PB - Installation Manual - Page: 39

1 If = 0, The selected axis moves in rapid in the positive direction up tot

home switch and returns at slow speed until detecting the home pulse.

If = 1, the home position is floating.

When pressing , it requests the password (719200).

PAR 16 It sets the value of the leadscrew backlash to compensate for.

Range of possible values: ±99999.999

PAR 17 It sets how the leadscrew backlash compensation will be applied with

unidirectional approach.

0 = There is no unidirectional approach.

X axis: 2 = It will be applied when moving in the positive direction.

Y axis: 1 = It will be applied when moving in the negative direction.

PAR18 It indicates the multiplying factor applied onto leadscrew backlash,

PAR16, in order to calculate the overshooting distance in unidirectional

approach. In order to assure that the return will be done at slow speed,

set P26 > P16 x P18

Possible values: 1 to 255

PAR19 Indicates the reduction factor of the Kv gain. It affects exponentially in

base 2.

For example: PAR19 = 3 means a reduction factor of 23 = 8.

Possible values: between 0 and 20. Recommended value: 10

Positive (X)

+0- +0-

Page 40

Page: 40 - Installation Manual - NC-200 PB

PAR21 Indicates the active level of the first 8 inputs.

By default, they are set to "1" meaning that they are activated with 24V.

Digit Pin

8 33 BCD 2

7 14 BCD

6 32 Retract X axis / Feed in forced mode.

5 13 Go to next block

4 31 Y axis negative travel limit

3 12 X axis negative travel limit

2 30 Y axis positive travel limit

1 11 X axis positive travel limit

PAR22 Indicates the active level of the next 7 inputs.

By default, they are set to "1" meaning that they are activated with 24V.

Digit Pin

8 Not being used at this time. It must be set to "0".

7 23 Emergency

6 8 "Return" foot switch.

5 36 External key 3 (A). EXECUTION mode selector

4 35 External key 2 (A). "BEND" foot switch.

3 16 External key 1 (A). EXECUTION mode selector

2 34 Disable the "Y" axis (Teach-in)

1 15 Hands-on palm switches / pressure level.

PAR23 Indicates the active level of the first 8 outputs.

By default, they are set to "1" meaning that when activated, they

provide 24V.

Digit Pin

8 10 "H" output

7 27 Manual mode active

6 26 "Y" axis moving direction

5 7 "X" axis moving direction

4 25 "Y" axis fast movement

3 6 "X" axis fast movement

2 24 "Y" axis enable

1 5 "X" axis enable

PAR24 Indicates the active level of the next 3 outputs.

By default, they are set to "1".

Digit Pin

8-4 Not being used at this time. They must be set to "0".

3 29 Axes in position (A). RAM down.

2 9 Buzzer. RAPID approach (B)

1 28 Retract RAM.

Page 41

NC-200 PB - Installation Manual - Page: 41

PAR25 In-position zone.

It is the distance before and behind the point where the axis is considered

to have reached its target position.

(Model B). On up-stroke machines, it represents the maximum deviation

allowed between the Y axis position and that of its

associated linear encoder or potentiometer to confirm the

end of the bend.

(See the following time diagram)

Possible values: From 0.0001mm to 99999.999 mm

(From 0.000005" to 3937").

Recommended value: between 0.02 mm and 0.05 mm

PAR26 Indicates the braking distance (slowdown point)

By default, this unit sets P26=P27 if P26<P27

(See the following time diagram)

Possible values: From 0.0001mm to 99999.999 mm

(From 0.000005" to 3937").

Recommended value: between 1 and 5 mm.

PAR27 Indicates the stopping distance (stop offset).

It does not admit PAR27 = 0.

(See time diagram below)

Possible values: From 0.0001mm to 99999.999 mm

(From 0.000005" to 3937").

Recommended value: between > 0 mm and 0.5 mm

The description of Par27 continues on the next page.

PAR27 and PAR47 must be coordinated in order to ensure that the

known final position is within the in-position zone (PAR25). See

chapter 5.

Par27

Par26

Enable

Speed

Fast

Slow

Par25

Page 42

Page: 42 - Installation Manual - NC-200 PB

PAR28 Top dead point. Default value of the relative distance between the punch

and the die to return ram after each bend.

Possible values: From 0.0001mm to 9999.9999 mm

(From 0.000005" to 393.700").

It may be forced from the editor. "B" and "C" models.

PAR29 Default value of the delay of the punch in contact with the sheet metal

at the end of the bend.

Possible values: between 0 seconds to 9.9 seconds.

It may be forced from the editor. It is referred to as the "d" attribute.

PAR30 Default value of the delay applied to the X axis movement before the next

positioning move (only if when moving towards X-).

Possible values: between 0 seconds to 9.9 seconds.

It may be forced from the editor. It is referred to as the "t" attribute.

PAR31 (Model "A"). Configuration of the 3 inputs for external key simulation

through pins 16, 35 and 36 of 37-pin connector X2.

· To assign a key to input I16:

Press and then the key to be assigned.

· To assign a key to input I35:

Press and then the key to be assigned.

· To assign a key to input I36:

Press and then the key to be assigned.

Page 43

NC-200 PB - Installation Manual - Page: 43

PAR32 Configuration of the INCREMENTAL MANUAL SWITCH positions

(pins 14, 33 and 34 of the 37-pin connector X2) to externally select

the jog increments.

Normally, a 5-position BCD switch is used (positions 1 to 5).

Position 1 is used for continuous jog, position 5 to disable the "Y" axis

and to select the semiautomatic mode (pin 34) and the three in between

for incremental movements.

The message screen shows "PAR32.N" where "N" is a value

between 0 and 3 related to the switch dial position.

PAR32.0 is reserved as CONTINUOUS JOG mode. It does not

affect the resolution.

PAR32.1 to PAR32.3 Value of the INCREMENTAL JOG in

multiples of resolution units (according to PAR01).

For example, if the resolution selected in PAR01 is 5 microns and

with the switch set to position 4 the axis is to be moved 500 microns

(0.5 mm) every time are pushed, PAR32.3 must be assigned

the value of 100.

The maximum value is 255 units of resolution.

PAR33 Speed change position. Models B and C.

It sets the relative height between the punch and the top side of the

sheet where the speed is to be changed from fast to slow in the down

stroke. Possible values: From 0 mm to ±99999.999 mm

(From 0" to ±3937").

PAR33 = 0 means that the speed change takes place when the ram

touches the sheet.

SWITCH

POSITION

BCD

VALUE

PIN 14 PIN 33 PIN 34 FUNCTION

1 0 0 0 0 CONTINUOUS JOG

2 1 1 0 0 1st INCREMENTAL POSITION

3 2 0 1 0 2nd INCREMENTAL POSITION

4 3 1 1 0 3rd INCREMENTAL POSITION

5 0 0 1 DISABLE Y / SEMIAUTOMATIC

Cont.

jog

Incr.1

Incr.2

Incr.3

Disable Y

Semiauto

1

2

3

4

5

Page 44

Page: 44 - Installation Manual - NC-200 PB

On the model A. Set the upper negative value for the maximum

bending depth.

PAR35 Indicates the duration of the "in-position" output O29 that enables

the "BEND" foot switch.

Possible values: between 0.1 seconds and 9.9 seconds.

If = 0, the signal stays active until the pressure gage signal is received

at pin 15 of connector X2 or the programmed level is exceeded.

The output is canceled if there is a backwards movement of the X axis

in the bending stage.

PAR36 Configuration of the X axis withdrawal (retract).

0 = Move it in incremental mode in the X+ direction the distance set

by PAR37.

1 = Move it in absolute mode the value set by PAR37 .

PAR37 X axis retraction distance (incremental) or position (absolute) when

activating the I32 signal of the 37-pin connector X2 on Model "A"

or when the punch reaches the "Y=sheet thickness" position on B

and C models.

Possible values: From 0 mm to 99999.999 mm

(From 0" to 3937").

PAR39 Analog voltage centering. Back-and-forth movement for balancing

the sign of the analog voltages.

Measure the analog voltages of this unit in both directions in any of

the ranges (fast or slow). Calculate the difference and divide by two.

Try different values of multiples of 5 mV to obtain the best balance.

For example: 6.135 and -6.120 => (0.015 difference)/2 = 0.007

Round it off to the closest value: 0.005 or 0.010

Page 45

NC-200 PB - Installation Manual - Page: 45

PAR40 Proportional gain Kv of the position loop in the positive direction if

PAR46(5) = 1. Axis controlled in closed loop.

(See section 5.2).

Possible values: Between 0 and 255.

PAR41 Proportional gain Kv of the position loop in the negative direction if

PAR46(5) = 1. Axis controlled in closed loop.

(See section 5.2).

Possible values: Between 0 and 255.

PAR42 Conversion factor of the pressure gage.

Kp = Tons/volt.

Possible values: Between 0 and 99.9

PAR44 Minimum analog voltage set for movements in the positive direction

(only if closed loop). Dynamic improvement with proportional hydraulic

valves that usually require a considerable voltage threshold in order to

allow a linear response.

Possible values: Between 0V and 10V

PAR45 Minimum analog voltage set for movements in the negative direction

(only if closed loop). Dynamic improvement with proportional hydraulic

valves that usually require a considerable voltage threshold in order to

allow a linear response.

Possible values: Between 0V and 10V

PAR46 Axis control.

Digit

8, 7, 6 Not being used at this time. They must be set to "0".

5 If =1, axis controlled in closed loop (the enable is maintained within

the in-position zone

If =0, "Axis controlled in open loop". The enable is canceled when

reaching the in-position zone. It is restored if the axis gets out

of position.

4 Not being used at this time. It must be set to "0".

3 Use analog voltage for feedrate.

2 Sign of the positive movement. Change it if the axis does not get in

position.

1 Bipolar voltage for speed.

Page 46

Page: 46 - Installation Manual - NC-200 PB

PAR47 Analog voltage for slow axis feedrate in the positive direction.

Value range: Between 0 and 10V.

PAR48 Analog voltage for slow axis feedrate in the negative direction.

Value range: Between 0 and 10V.

PAR49 Analog voltage for fast axis feedrate in both directions.

Value range: Between 0 and 10V.

PAR50 Language selection for the messages appearing on the LCD display.

0 = English; 1 = Spanish; 2 = German; 3 = French; 4 = Italian;

5 = Portuguese; 6 = User defined.

PAR51

Digits

8 If =1, the EDITOR no longer shows the "attributes" page for

machines or programs that do not require those resources.

This unit will assume the attribute values set by parameters

PAR29 (d) and PAR30 (t).

7 On "A" and "A1" models with an electrical signal from the pressure gage,

the top dead point may be preset with the "D" variable, timing the ramup movement. Productivity may be improved when dealing with small

parts:

If =1, to activate this feature.

If =0, to deactivate this feature. The block change is only forced when

the ram reaches the top dead point, I13=1.

6 to 3 Not being used at this time. They all must be set to "0".

2 To turn on (=0) or off (=1) the confirmation beep when pressing the

keys.

1 Program memory lock, 0 = unlocked; 1 = locked.

PAR52 Loading of the user defined language.

When accessing this parameter, the NC requests the password.

After keying 5564, the NC is ready to receive the file containing the

user defined language.

Page 47

NC-200 PB - Installation Manual - Page: 47

PAR64 Press brake model definition

digit

8 Not being used at this time. It must be set to "0".

7 If = 0, pin 18 of connector X2 is selected as the analog input for the

PRESSURE/VOLTAGE gage or potentiometric scale.

Both options are incompatible .

This operation requires a position change at the selector installed in

the circuit of connector X2 which is accessed by removing the rear

board: To set pin 18 as analog input, put the jumper towards "U4".

Set PAR46.5 and PAR46.3 to "0" to configure the X axis in open

loop.

If = 1 and jumper towards "U7", it is set as an analog output.

6 Setting of pin 18

If = 0, it is selected as analog output for the X axis.

If = 1, it is selected as an input or output (PAR64.7) for the pressure

gage.

The X axis will be controlled in open loop without using the analog

output PAR46.5 = 0, PAR46.3 = 0.

2 If =0, LCD screen

If =1, VFD screen (blue)

1 Not being used at this time. It must be set to "0".

5 4 3

Press brake

model

Description

0 0 0

A

Only the final bend position is controlled

1 0 0

A1

Same as model A with footswitch handling

0 1 0 B

Same as model A1 with linear encoder for

decoded intermediate ram-bed positions

0 0 1 C

Control of actual ram-bed position with footswitch

and "busy hands" handling.

Page 48

Page: 48 - Installation Manual - NC-200 PB

PAR65 Special configurations.

Digit

8 to 5 Not being used at this time. They must be set to "0".

4 Only for the "B" model.

If = 0, the feedback device for the ram/table position is a linear encoder.

If = 1, the feedback device for the ram/table position is linear potentiometer.

3 Axis positioning mode.

If =0, The axes move at the same time.

If =1, The axes move one after the other (1st X and then Y).

Both axes may be positioned with the same inverter using the relevant

enable signals to toggle the power connection fine tuning the adjustment

of the X axis to avoid rebounds at the final positioning.

2 If = 1, the feed towards "X-" will be forced with I32 (safety regulations

for rapid feed).

Install a push button on the operator panel for starting each bending

sequence when moving towards "X-". I32 is shared with the micro switch

detecting the contact between the punch and sheet metal.

1 If = 1, There is a detector for punch-sheet contact.

Use the "B" attribute to provoque the return of the X axis.

It requires a previous flank at I32 to confirm the change of block with

I13.

If = 0, there is no detector. The "B" attribute is ignored.

If the bending sequence is interrupted and the ram returns to the top dead

position, I13=1, it provoques the uncontrolled block feed.

PAR90 Indicates the transmission speed of the RS 232 line.

Options: 75, 150, 300, 600, 1200, 2400, 4800 & 9600 baud.

Factory setting: 9600 baud

This NC sends and receive data at the speed set by PAR90 and with

the following configuration:

Stop bits: 1

Data bits: 8

Parity: None

Protocol: XON/XOFF

Page 49

NC-200 PB - Installation Manual - Page: 49

4. OPERATION WITH THE RS-232-C SERIAL LINE

4.1. SAVING AND RESTORING DA TA

With this NC, it is possible to save data into a PC or peripheral device and later

restore it by using the RS-232-C serial communications line.

This data is sent out in the following format:

Baudrate as set by PAR90, 8 data bits, 1 stop bit and no parity.

To access this mode:

- Press

F

- Select the "Com" option (communications) of the LCD display by means of

the and press .

- Select: <Send> and press to send the data out to a PC or peripheral

device or select <Receive> and press to receive data from a PC or

peripheral device.

- Select the type of data to transmit Parameters, Program, Materials by means

of the keys and press .

4.2 PARAMETER TRANSMITTING FORMA T

The format of the transmitted parameters are:

For value parameters: P?? 123.123

For binary parameters: P?? 10101010

For option parameters: P?? 0

For axis parameters: P?? X 123.123 Y 123.123

The number of decimals depends on the selected resolution.

Page 50

Page: 50 - Installation Manual - NC-200 PB

5 SETUP

5.1 TEST MODE

A special mode has been created in order to make machine setup easier. This

mode is accessed from the main menu. Special care must be taken since software

and hardware limits are ignored in this mode.

Section 3.1, PAR21 through PAR24 describes the correspondence between the

display digit number and the number of the connector pin to be tested.

· Press F

· Use to select TEST and press .

This unit requests a password to access this mode: 719200

The message display offers four options that may be selected with

INPUT- Testing inputs <In>

· The 1st line shows 0's and 1's indicating the status of inputs I1 through I8

from right to left.

· The 2nd line shows the status of inputs I9 through I15.

OUTPUT- Forcing outputs <out>

Digital outputs

· The 1st line shows 0's and 1's indicating the status of outputs O1 through

O8 from right to left.

The outputs are activated or reset by pressing their relevant key.

1

for O1 and

8

for O8.

· The 2nd line shows the status of outputs O9, O10 and O11; but they can

be neither activated nor reset.

· The

9

key activates all the outputs.

· The

0

inch

key resets all the outputs.

Page 51

NC-200 PB - Installation Manual - Page: 51

Analog input / outputs <Ana>

In this mode, it is possible to force a value to the analog outputs in order to move

the axes and set reference values in parameters PAR44 through PAR48.

· Select the or axis

The enable signal of the relevant axis is activated.

· Every time or is pressed, the value is increased or decreased in 0.01V

within a range of ±10V.

· To force a particular analog voltage, press: [decimal value]

To reset the analog voltage, press or

If it is a B model and a potentiometric scale has been installed,

PAR64.4=1, 65.4 = 1, it can read the analog input at pin 18:

· Select

While moving the ram or the base, it is possible to compare the

maximum/minimum values of the cursor.

<Auto>

It is enabled in automatic mode to fine tune the values of the two parameters involved in the adjustment of the axes:

<Vmin> to adjust the minimum voltage.

· Select the or axis

An auxiliary mode is available to operate with the axis in open loop and display

the offsets of the drives on the 1st display.

Adjust it until the offset is stabilized at "0" and confirm it by pressing

· This unit generates an increasing positive voltage (command) to move the

axis. This process is interrupted when it accumulates more than 100 feedback

pulses and it set PAR44 with the current voltage value.

This process is repeated with an increasing negative voltage for PAR45.

Page 52

Page: 52 - Installation Manual - NC-200 PB

<Kv> to set the gain with automatic back-and-forth movements.

· Select the or axis.

Indicate the coordinate of the positive limit,

Indicate the coordinate for the negative limit,

A back-and-forth movement is generated to analyze the dynamic response on

reversal movements. If overshooting occurs, the corresponding Kv factor is

decreased in 5 units at each reversal until achieving a 1st order system without

overshooting in either direction and it sets PAR40 and PAR41 with the

corresponding Kv values. It acknowledges the end of this process with two

beeps.

Pressing aborts the active movement and increases Kv in 10 units.

This test may be interrupted by pressing

Selecting ">" and pressing offers three options:

I0s- Testing of the encoder I0's

The 2nd line shows 0's and 1's indicating the level of the encoder I0's for

the X and Y axis from right to left.

Moving the axis slowly by hand, the I0 will be detected with a short blinking.

PULSES- Testing the number of encoder pulses/turn

When selecting the axis, the 1st line displays "PULSES 1" and when

selecting the axis, it displays "PULSES 2".

Moving the axis by hand far enough to detect the I0 twice, the 2nd line will

show the number of pulses per turn x PAR01 x PAR02.

DATE

The 1st line shows the software version and the 2nd line its release date,

day, month, year.

To exit to the initial menu, press

Page 53

NC-200 PB - Installation Manual - Page: 53

5.1.1 DIRECT ACCESS TO THE PARAMETERS

In order to get better acquainted with the operation of this unit without having

to connect the 24V input, there is a special way to access the installation

parameters on power-up:

· While the unit is off, hold the keys pressed at the same time for a few

seconds and turn the unit on. The unit will access directly to PAR00 of the

parameter table.

· Press [22] to go to PAR22.

By default, all the digits are set to "1" indicating that the inputs recognize a "1"

when activated with 24V.

· If parameter PAR22(7) has been changed to "0", press

7

to force a "1". This

cancels the external emergency even when the emergency input I15 is not

connected.

· Exit to the main menu by pressing .

Safety regulations dictate to connect the emergency input with a "1" level at 24V.

The emergency button interrupts the connection causing the machine to stop.

Page 54

Page: 54 - Installation Manual - NC-200 PB