Page 1

FAGOR 8025/8030 CNC

Models: M, MG, MS, GP

INSTALLATION MANUAL

Ref. 9707 (in)

Page 2

ABOUT THE INFORMATION IN THIS MANUAL

This manual is addressed to the machine manufacturer.

It includes the necessary information for new users as well as advanced subjects for

those who are already familiar with the 8025 CNC.

It may not be necessary to read this whole manual. Consult the list of "New Features

and Modifications" and the appendix related to the machine parameters. Practically

all of them are cross referenced indicating the chapter and section of the manual

where they are described.

This manual explains all the functions of the 8025 CNC family. Consult the

Comparison Table for the models in order to find the specific ones offered by your

CNC.

To install the CNC onto your machine, we suggest that you consult the appendix

regarding the enclosures required to mount the CNC as well as chapter 1 (CNC

configuration) which indicates the CNC dimensions and details the pin-out of its

connectors.

If your CNC has an integrated PLC (PLCI), the I/O pin-out is different. Therefore,

the PLCI manual must also be consulted.

Chapter 2 (Power and Machine Interface) shows how to connect the CNC to A.C.

power (Mains) and to the electrical cabinet.

To adapt the CNC to the machine, set the CNC machine parameters. Consult chapters

3, 4 and 5 as well as the appendix concerning machine parameters.

There are 2 appendices; one where the parameters are ordered by subject and the

other one where the parameters are in numerical order.

Both appendices offer cross references indicating the section of the manual describing

each parameter.

When explaining each parameter in detail, chapters 3, 4 and 5, they sometimes refer

to chapter 6 (Concepts) where some of them are dealt with in further detail indicating

how to perform various adjustments of the CNC-machine interface.

Once all machine parameters are set, we suggest that you write their settings down

on the charts provided for this purpose in the appendix on "Machine Parameter Setting

Chart".

There is also an appendix on error codes which indicates some of the probable reasons

which could cause each one of them.

Also, if you wish this CNC to communicate with other FAGOR products, you must

use the Fagor Local Area Network (LAN). To do that, refer to the manual on FAGOR

LAN.

Notes

: The information described in this manual may be subject to variations due

to technical modifications.

FAGOR AUTOMATION, S. Coop. Ltda. reserves the right to modify the

contents of this manual without prior notice.

Page 3

INDEX

Section Page

Comparison Table for 8025/8030 CNC models .......................................................ix

New features and modifications ................................................................................xv

INTRODUCTION

Declaration of Conformity ........................................................................................3

Safety Conditions ......................................................................................................4

Warranty Terms .........................................................................................................7

Material Returning Terms .........................................................................................8

Additional Remarks ...................................................................................................9

Fagor Documentation for the 800T CNC ..................................................................11

Manual Contents .......................................................................................................12

Chapter 1 CONFIGURATION OF THE CNC

1.1 8025 CNC..................................................................................................................1

1.1.1 Dimensions and installation of the 8025 CNC ........................................................2

1.2 8030 CNC..................................................................................................................3

1.2.1 Central Unit of the 8030 CNC..................................................................................4

1.2.1.1 Keyboard connector ..................................................................................................6

1.2.1.2 Video connector ........................................................................................................8

1.2.2 Monitor/keyboard of the 8030 CNC ........................................................................9

1.2.2.1 Dimensions of the monitor/keyboard ........................................................................9

1.2.2.2 Elements of the monitor/keyboard ...........................................................................10

1.2.2.3 Connectors and monitor/keyboard interface.............................................................11

1.2.3 Operator panel of the 8030 CNC ..............................................................................12

1.3 Connectors and 8025/8030 CNC interface ...............................................................13

1.3.1 Connectors A1, A2, A3, A4.......................................................................................15

1.3.1.1 Dip-switches for connectors A1, A2, A3, A4 ............................................................16

1.3.2 Connector A5 ............................................................................................................17

1.3.2.1 Dip-switches for connector A5..................................................................................18

1.3.3 Connector A6 ............................................................................................................19

1.3.3.1 Machine with "V" axis and handwheel or spindle encoder .....................................20

1.3.3.2 Machine without "V" axis and with electronic handwheel or spindle encoder.......20

1.3.4 RS232C connector ....................................................................................................21

1.3.5 RS485 connector .......................................................................................................24

1.3.5.1 Recommended cable for the RS485..........................................................................24

1.3.6 Connector I/O 1.........................................................................................................25

1.3.6.1 Inputs of connector I/O 1 ..........................................................................................26

1.3.6.2 Outputs of connector I/O 1 .......................................................................................29

1.3.7 Connector I/O 2.........................................................................................................31

1.3.7.1 Outputs of connector I/O 2 .......................................................................................32

Page 4

Section Page

Chapter 2 POWER AND MACHINE INTERFACE

2.1 Power interface......................................................................................................... 1

2.1.1 Internal power supply ............................................................................................... 1

2.2 Machine interface ..................................................................................................... 2

2.2.1 General considerations ............................................................................................. 2

2.2.2 Digital outputs .......................................................................................................... 4

2.2.3 Digital inputs ............................................................................................................ 4

2.2.4 Analog outputs.......................................................................................................... 5

2.2.5 Feedback inputs ........................................................................................................ 5

2.3 Set-up........................................................................................................................ 6

2.3.1 General considerations ............................................................................................. 6

2.3.2 Precautions................................................................................................................ 6

2.3.3 Connection ................................................................................................................ 7

2.3.4 System input/output test ........................................................................................... 8

2.4 Emergency input/output connection......................................................................... 10

Chapter 3 MACHINE PARAMETERS

3.1 Introduction .............................................................................................................. 1

3.2 Operating with parameter tables............................................................................... 3

3.3 General machine parameters .................................................................................... 4

3.3.1 Machine parameters for axis configuration.............................................................. 6

3.3.2 Input/output parameters ............................................................................................ 9

3.3.3 Handwheel parameters.............................................................................................. 14

3.3.4 Touch probe parameters ........................................................................................... 16

3.3.5 Tool parameters ........................................................................................................ 18

3.3.6 Machine parameters for the RS232C serial line....................................................... 22

3.3.7 Jog parameters .......................................................................................................... 24

3.3.8 Parameters related to the emergency subroutine...................................................... 25

3.3.9 Parameters related to operating and programming modes ....................................... 26

Chapter 4 MACHINE PARAMETERS FOR THE AXES

4.1 Parameters related to axis resolution........................................................................ 2

4.2 Parameters related to the analog outputs .................................................................. 5

4.3 Parameters related to travel limits............................................................................ 6

4.4 Feedrate related parameters...................................................................................... 7

4.5 Parameters related to axis control ............................................................................ 10

4.6 Parameters related to machine reference zero.......................................................... 12

4.7 Parameters for acceleration/deceleration of the axes ............................................... 15

4.7.1 Linear acceleration/deceleration ............................................................................... 15

4.7.2 Bell-shaped acceleration/deceleration ...................................................................... 16

4.7.3 Feed-forward gain..................................................................................................... 17

4.8 Parameters for unidirectional approach.................................................................... 18

4.9 Leadscrew related parameters .................................................................................. 19

4.9.1 Leadscrew backlash .................................................................................................. 19

4.9.2 Leadscrew error ........................................................................................................ 20

4.10 Parameters related to cross compensation................................................................ 23

4.10.1 Double cross compensation ...................................................................................... 24

4.11 Pallet related parameters........................................................................................... 25

4.12 Special machine parameters ..................................................................................... 27

Page 5

Section

Chapter 5 SPINDLE MACHINE PARAMETERS

5.1 Parameters related to spindle speed range change ................................................... 2

5.2 Parameters for analog spindle speed output............................................................. 3

5.3 Parameters for spindle speed output in BCD ........................................................... 4

5.4 Parameters used for spindle control ......................................................................... 6

5.5 Parameters related to spindle orientation (M19)...................................................... 7

5.6 Parameters related to rigid tapping (G84R) ............................................................. 10

Chapter 6 CONCEPTS

6.1 Axes and coordinate systems.................................................................................... 1

6.1.1 Nomenclature and selection of the axes................................................................... 1

6.2 Feedback systems ..................................................................................................... 2

6.2.1 Counting frequency limits ........................................................................................ 3

6.3 Axis resolution.......................................................................................................... 4

6.4 Adjustment of the axes............................................................................................. 13

6.4.1 Adjustment of the drift (offset) and maximum feedrate (G00) ................................ 14

6.4.2 Gain adjustment ........................................................................................................ 16

6.4.3 Proportional gain adjustment.................................................................................... 17

6.4.3.1 Calculation of K1, K2 and gain break-point............................................................ 19

6.4.4 Feed-Forward gain adjustment ................................................................................. 21

6.4.4.1 Calculation of feed-forward gain ............................................................................. 21

6.4.5 Leadscrew error compensation ................................................................................. 22

6.5 Reference systems .................................................................................................... 25

6.5.1 Reference points ....................................................................................................... 25

6.5.2 Machine reference (home) search ............................................................................ 26

6.5.2.1 Home search on gantry axes .................................................................................... 27

6.5.3 Adjustment on a system without coded Io ............................................................... 28

6.5.3.1 Machine reference point (home) adjustment............................................................ 28

6.5.3.2 Considerations .......................................................................................................... 29

6.5.4 Adjustment on axis with coded Io............................................................................ 30

6.5.4.1 Scale Offset adjustment............................................................................................ 30

6.5.4.2 Considerations .......................................................................................................... 31

6.5.5 Software travel limits for the axes ........................................................................... 32

6.6 Unidirectional approach ........................................................................................... 33

6.7 Auxiliary functions M, S, T ..................................................................................... 34

6.7.1 Decoded M function table ........................................................................................ 35

6.7.2 M, S, T function transfer .......................................................................................... 37

6.7.3 M, S, T function transfer using the M-done signal.................................................. 38

6.8 Spindle...................................................................................................................... 40

6.9 Spindle speed range change ..................................................................................... 43

6.10 Spindle control.......................................................................................................... 45

6.11 Tools and tool magazine .......................................................................................... 47

6.11.1 Machine without tool magazine ............................................................................... 47

6.11.2 Not-random tool magazine ....................................................................................... 48

6.11.3 Random tool magazine ............................................................................................. 51

6.11.4 Application examples ............................................................................................... 54

6.11.4.1 Not-random magazine with tool changer arm .......................................................... 54

6.11.4.2 Not-random magazine without tool changer arm..................................................... 54

6.12 Pallet work................................................................................................................ 55

Page

Page 6

Section

APPENDICES

A Technical characteristics of the CNC ....................................................................... 2

B Enclosures ................................................................................................................. 5

C Recommended Probe connection diagrams .............................................................. 6

D CNC inputs and outputs ........................................................................................... 7

E 2-digit BCD coded "S" output conversion table ...................................................... 8

F Machine parameter summary chart .......................................................................... 9

G Sequential machine parameter list............................................................................ 15

H Machine parameter setting chart .............................................................................. 24

I Decoded "M" function setting chart ......................................................................... 26

J Leadscrew error compensation setting chart ............................................................ 27

K Cross compensation setting chart ............................................................................ 29

L Maintenance ............................................................................................................. 30

ERROR CODES

Page

Page 7

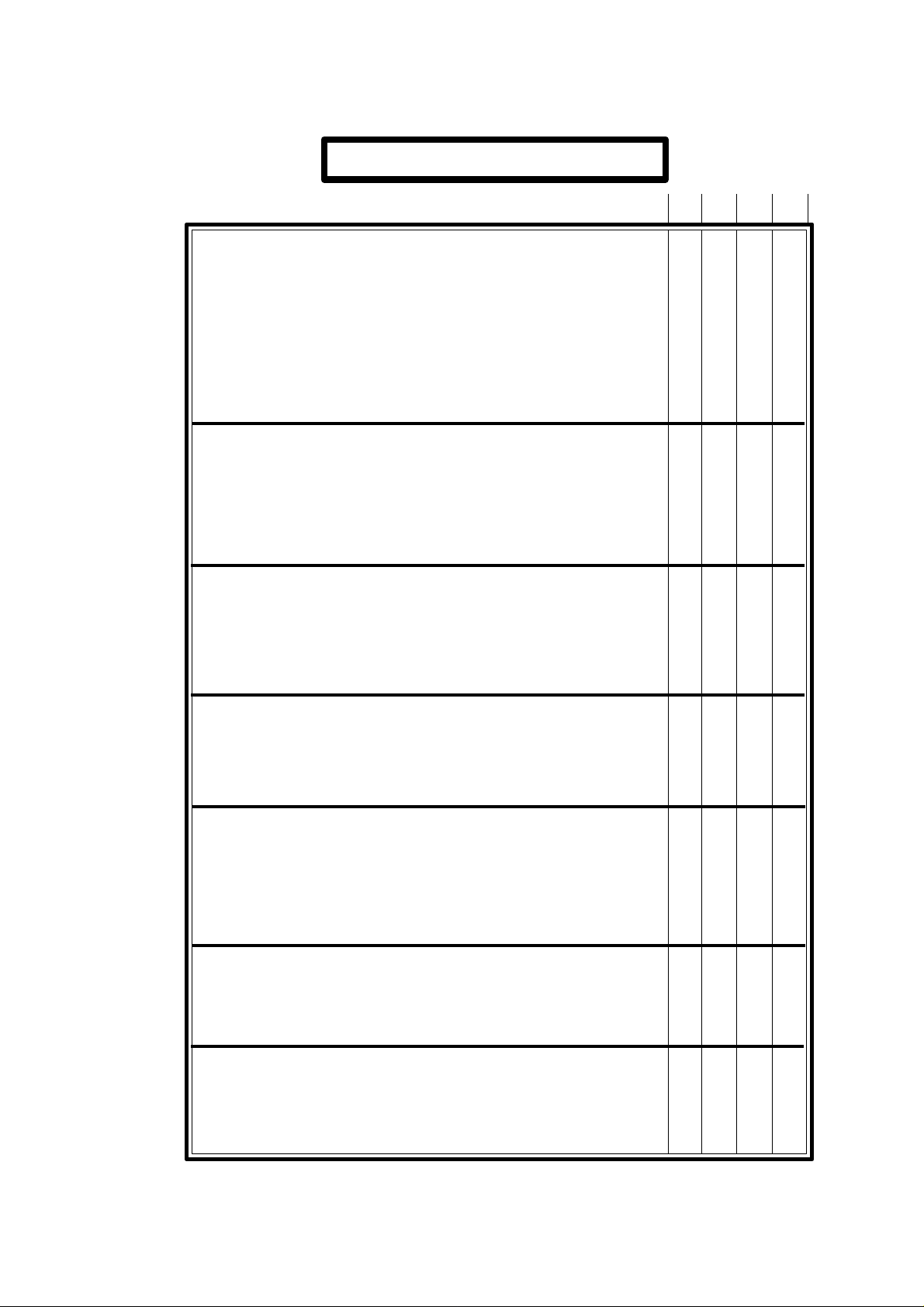

COMPARISON TABLE

FOR MILL MODEL

FAGOR 8025/8030 CNCs

Page 8

8025/8030 MILL MODEL CNCS

Fagor offers the 8025 and 8030 mill type CNCs.

Both types operate the same way and offer similar characteristics. Their basic difference is that

the former is compact and the latter is modular.

Both CNC types offer basic models. Although the differences between the basic models are

detailed later on, each model may be defined as follows:

8025/8030 GP Oriented to General Purpose machines

8025/8030 M Oriented to Milling machines of up to 4 axes.

8025/8030 MG Same as the M model, but with dynamic graphics.

8025/8030 MS Oriented to Machining Centers (up to 5 axes).

When the CNC has an Integrated Programmable Logic Controller (PLCI), the letter "I" is added

to the CNC model denomination: GPI, MI, MGI, MSI.

Also, When the CNC has 512Kb of part-program memory, the letter "K" is added to the CNC

model denomination: GPK, MK, MGK, MSK, GPIK, MIK, MGIK, MSIK.

Basic With PLCI Basic With PLCI

With 512Kb and 512Kb

General Purpose GP GPI GPK GPKI

Mills up to 4 axes M MI MK MIK

Up to 4 axes with graphics MG MGI MGK MGIK

Machining Centers MS MSI MSK MSIK

Page 9

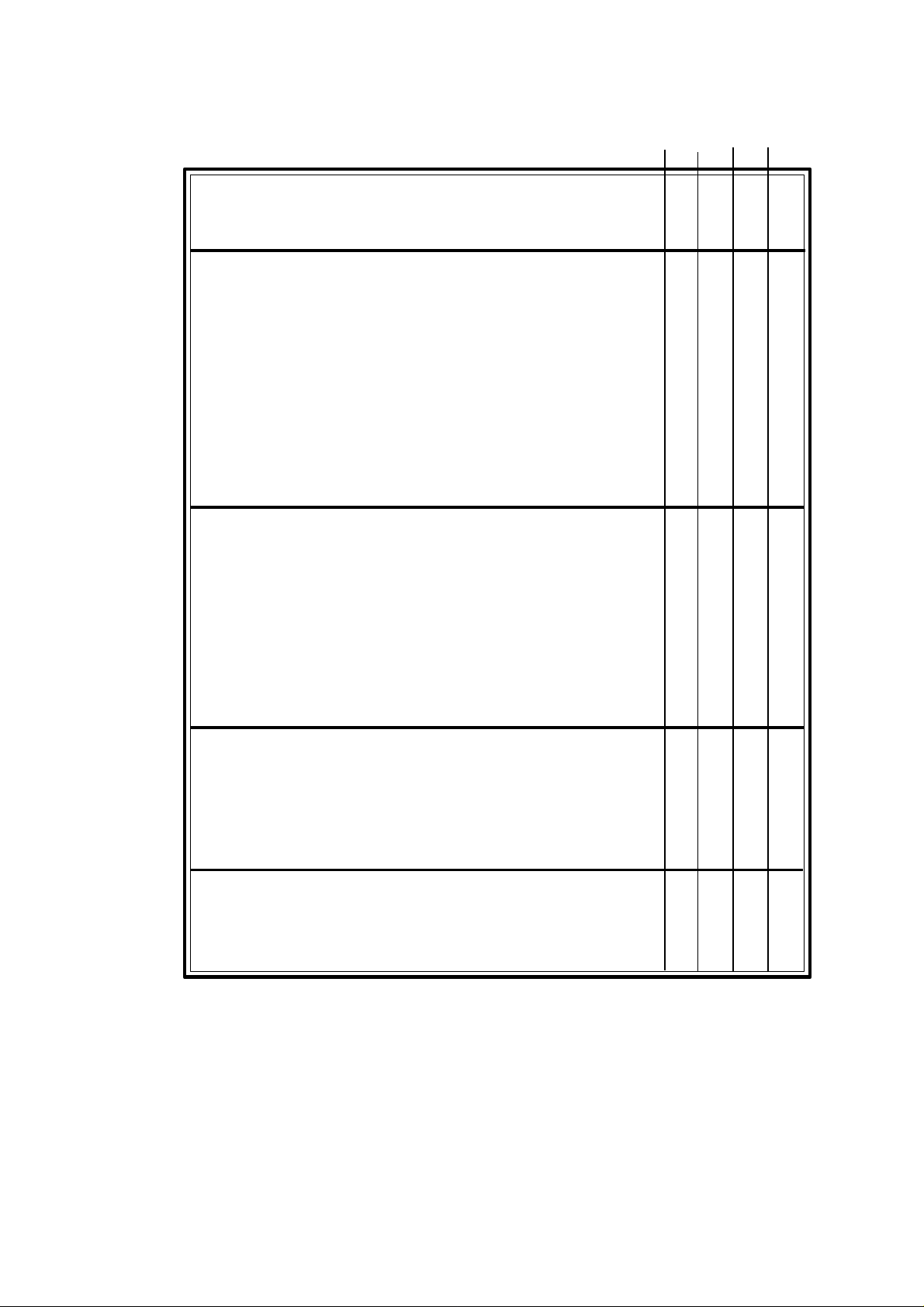

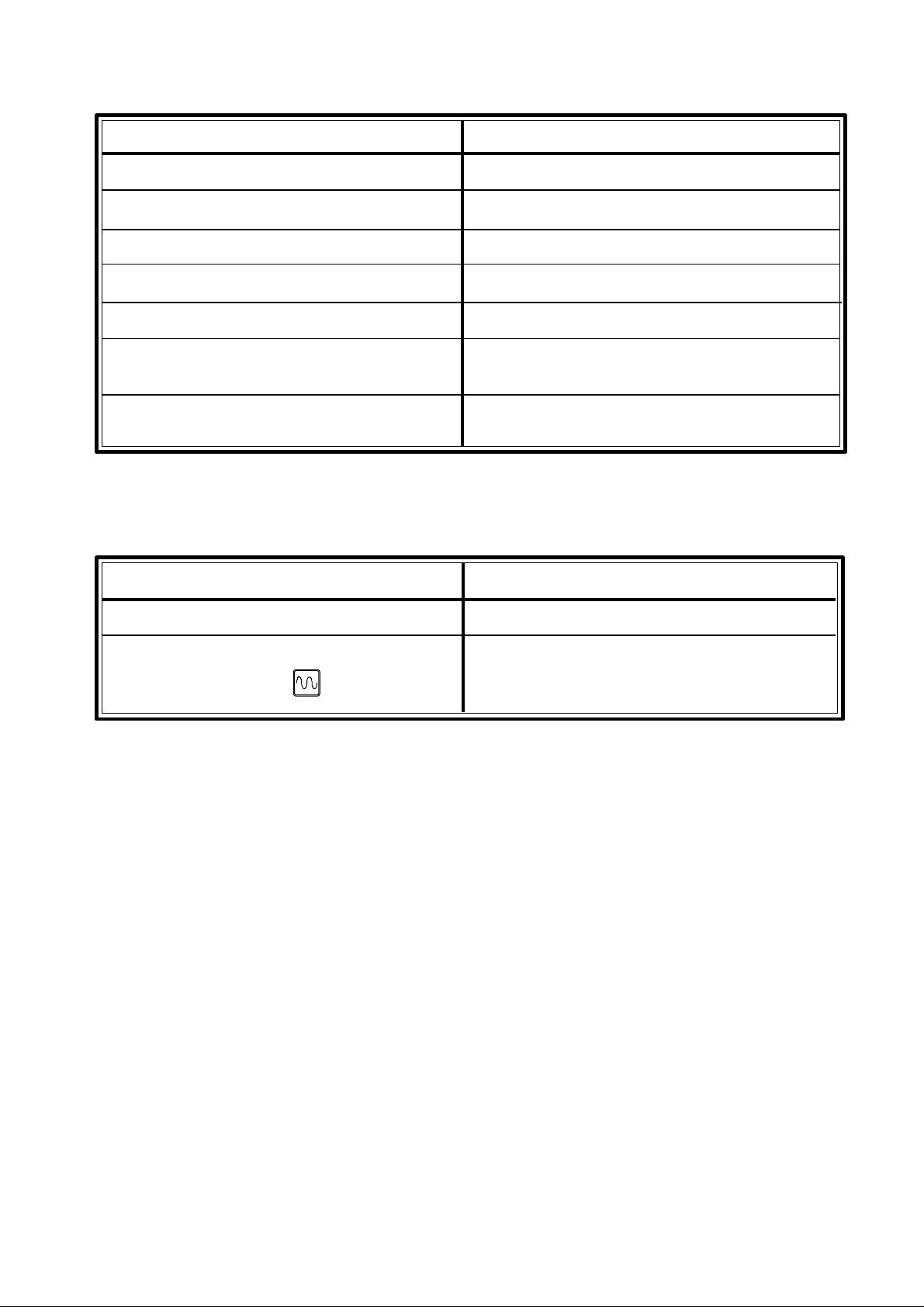

TECHNICAL DESCRIPTION

GP M MG MS

INPUTS/OUTPUTS

Feedback inputs...................................................................................... 6 6 6 6

Probe input .......................................................................................... x x x x

Square-wave feedback signal multiplying factor, x2/x4........................... x x x x

Sine-wave feedback signal multiplying factor, x2/x4/10/x20 ................... x x x x

Maximum counting resolution 0.001mm/0.001°/0.0001inch ................... x x x x

Analog outputs (±10V) for axis servo drives ........................................... 4 4 4 5

Spindle analog output (±10V)................................................................. 1 1 1 1

AXIS CONTROL

Axes involved in linear interpolations ..................................................... 3 3 3 3

Axes involved in circular interpolations .................................................. 2 2 2 2

Helical interpolation ............................................................................... x x x x

Electronic threading ............................................................................... x x x

Spindle control ....................................................................................... x x x x

Software travel limits.............................................................................. x x x x

Spindle orientation ................................................................................. x x x x

Management of non-servo-controlled Open-Loop motor ......................... x

PROGRAMMING

Part Zero preset by user .......................................................................... x x x x

Absolute/incremental programming ........................................................ x x x x

Programming in cartesian coordinates..................................................... x x x x

Programming in polar coordinates .......................................................... x x x x

Programming in cylindrical coordinates (radius, angle, axis) ................... x x x x

Programming by angle and cartesian coordinate...................................... x x x x

Linear axes ........................................................................ 4 4 4 5

Rotary axes ........................................................................ 2 2 2 2

Spindle encoder ................................................................. 1 1 1 1

Electronic handwheels ....................................................... 1 1 1 1

COMPENSATION

Tool radius compensation ....................................................................... x x x

Tool length compensation....................................................................... x x x x

Leadscrew backlash compensation.......................................................... x x x x

Leadscrew error compensation ............................................................... x x x x

Cross compensation (beam sag) .............................................................. x x x x

DISPLAY

CNC text in Spanish, English, French, German and Italian ...................... x x x x

Display of execution time ....................................................................... x x x x

Piece counter.......................................................................................... x x x x

Graphic movement display and part simulation ....................................... x x

Tool base position display ...................................................................... x x x x

Tool tip position display ......................................................................... x x x x

Geometric programming aide ................................................................. x x x x

COMMUNICATION WITH OTHER DEVICES

Communication vía RS232C................................................................... x x x x

Communication via DNC ....................................................................... x x x x

Communication via RS485 (FAGOR LAN) ............................................ x x x x

ISO program loading from peripherals .................................................... x x x x

OTHERS

Parametric programming ........................................................................ x x x x

Model digitizing ..................................................................................... x x x x

Possibility of an integrated PLC.............................................................. x x x x

Sheetmetal tracing on LASER machines ................................................. x

Jig Grinder .......................................................................................... x

Page 10

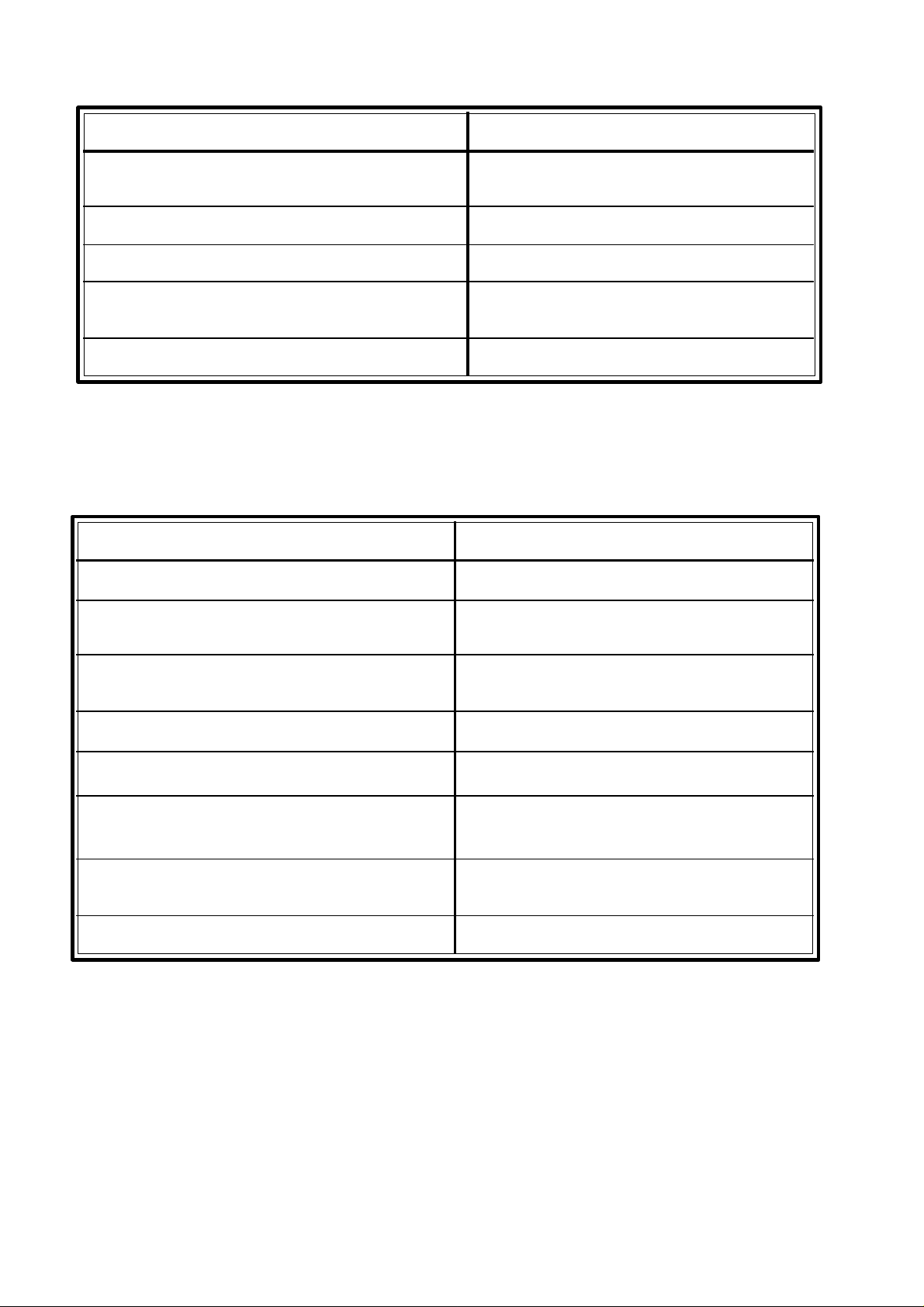

PREPARATORY FUNCTIONS

GP M MG MS

AXES AND COORDINATE SYSTEMS

XY (G17) plane selection ....................................................................... x x x x

XZ and YZ plane selection (G18,G19).................................................... x x x x

Part measuring units. Millimeters or inches (G70,G71) ........................... x x x x

Absolute/incremental programming (G90,G91) ...................................... x x x x

Independent axis (G65) .......................................................................... x x x x

REFERENCE SYSTEMS

Machine reference (home) search (G74) ................................................. x x x x

Coordinate preset (G92) ......................................................................... x x x x

Zero offsets (G53...G59)......................................................................... x x x x

Polar origin preset (G93) ........................................................................ x x x x

Store current part zero (G31) .................................................................. x x x x

Recover stored part zero (G32) .............................................................. x x x x

PREPARATORY FUNCTIONS

Feedrate F .......................................................................................... x x x x

Feedrate in mm/min. or inches/minute (G94) .......................................... x x x x

Feedrate in mm/revolution or inches/revolution (G95) ............................ x x x x

Constant surface speed (G96) ................................................................. x x x x

Constant tool center speed (G97) ............................................................ x x x x

Programmable feedrate override (G49) ................................................... x x x x

Spindle speed (S).................................................................................... x x x x

S value limit (G92) ................................................................................. x x x x

Tool and tool offset selection (T) ............................................................ x x x x

AUXILIARY FUNCTIONS

Program stop (M00) ............................................................................... x x x x

Conditional program stop (M01)............................................................. x x x x

End of program (M02)............................................................................ x x x x

End of program with return to first block (M30)...................................... x x x x

Clockwise spindle start (M03) ................................................................ x x x x

Counter-clockwise spindle start (M04).................................................... x x x x

Spindle stop (M05)................................................................................. x x x x

Tool change in machining centers (M06) ................................................ x x x x

Spindle orientation (M19)....................................................................... x x x x

Spindle speed range change (M41, M42, M43, M44) .............................. x x x x

Functions associated with pallets (M22, M23, M24, M25) ...................... x x x

PATH CONTROL

Rapid traverse (G00) ............................................................................ x x x x

Linear interpolation (G01) ....................................................................x x x x

Circular interpolation (G02,G03) ..........................................................x x x x

Circular interpolation with absolute center coordinates (G06)................x x x x

Circular path tangent to previous path (G08).........................................x x x x

Arc defined by three points (G09)......................................................... x x x x

Tangential entry at beginning of a machining operation (G37) .............x x x x

Tangential exit at the end of a machining operation (G38).....................x x x x

Controlled radius blend (G36) ..............................................................x x x x

Chamfer (G39) .....................................................................................x x x x

Electronic threading (G33) ..................................................................... x x x

ADDITIONAL PREPARATORY FUNCTIONS

Dwell (G04 K) .....................................................................................x x x x

Round and square corner (G05, G07).................................................... x x x x

Mirror image (G10,G11,G12) ............................................................... x x x x

Mirror image along the Z axis (G13).....................................................x x x x

Scaling factor (G72) .............................................................................x x x x

Pattern rotation (G73)...........................................................................x x x x

Slaving/unslaving of axes (G77, G78)...................................................x x x x

Single block treatment (G47, G48)........................................................x x x x

User error display (G30) .......................................................................x x x x

Automatic block generation (G76) .......................................................... x

Communication with FAGOR Local Area Network (G52) ....................x x x x

Page 11

GP M MG MS

COMPENSATION

Tool radius compensation (G40,G41,G42) ............................................. x x x

Tool length compensation (G43,G44) .................................................... x x x x

Loading of tool dimensions into internal tool table (G50) ....................... x x x x

CANNED CYCLES

Multiple arc-pattern machining (G64) .................................................... x x x

User defined canned cycle (G79) ........................................................... x x x x

Drilling cycle (G81) .............................................................................. x x x

Drilling cycle with dwell (G82) ............................................................. x x x

Deep hole drilling cycle (G83)............................................................... x x x

Tapping cycle (G84).............................................................................. x x x

Rigid tapping cycle (G84R) ................................................................... x x x

Reaming cycle (G85)............................................................................. x x x

Boring cycle with withdrawal in G00 (G86)........................................... x x x

Rectangular pocket milling cycle (G87) ................................................. x x x

Circular pocket milling cycle (G88) ....................................................... x x x

Boring cycle with withdrawal in G01 (G89)........................................... x x x

Canned cycle cancellation (G80)............................................................ x x x x

Return to starting point (G98) ................................................................ x x x

Return to reference plane (G99) ............................................................. x x x

PROBING

Probing (G75) ....................................................................................... x x x x

Tool length calibration canned cycle (G75N0) ....................................... x

Probe calibration canned cycle (G75N1) ................................................ x

Surface measuring canned cycle (G75N2).............................................. x

Surface measuring canned cycle with tool offset (G75N3)...................... x

Outside edge measuring canned cycle (G75N4) ..................................... x

Inside edge measuring canned cycle (G75N5) ........................................ x

Angle measuring canned cycle (G75N6) ................................................ x

Outside edge and angle measuring canned cycle (G75N7)...................... x

Hole centering canned cycle (G75N8).................................................... x

Boss centering canned cycle (G75N9).................................................... x

Hole measuring canned cycle (G75N10) ................................................ x

Boss measuring canned cycle (G75N11) ................................................ x

SUBROUTINES

Number of standard subroutines............................................................. 99 99 99 99

Definition of standard subroutine (G22) ................................................. x x x x

Call to a standard subroutine (G20)........................................................ x x x x

Number of parametric subroutines ......................................................... 99 99 99 99

Definition of parametric subroutine (G23) ............................................. x x x x

Call to a parametric subroutine (G21) ................................................... x x x x

End of standard or parametric subroutine (G24) ..................................... x x x x

JUMP OR CALL FUNCTIONS

Unconditional jump/call (G25) .............................................................. x x x x

Jump or call if zero (G26) ...................................................................... x x x x

Jump or call if not zero (G27) ................................................................ x x x x

Jump or call if smaller (G28) ................................................................. x x x x

Jump or call if equal or greater (G29)..................................................... x x x x

Page 12

NEW FEATURES

AND

MODIFICATIONS

Date: February 1991 Software version: 2.1 and newer

FEATURE MODIFIED MANUAL AND SECTION

Error 65 is not issued while probing (G75) Installation Manual Section 3.3.4

It is possible to select the home searching Installation Manual Section 4.6

direction for each axis

New 1, 2, 5, 10 resolution values for Installation Manual Section 4.1

sine-wave feedback signals of each axis

PLCI register access from the CNC Programming Manual G52

Sheetmetal tracing on laser machines Applications Manual

Jig Grinder Applications Manual

Date: June 1991 Software version: 3.1 and newer

FEATURE MODIFIED MANUAL AND SECTION

Repetitive emergency subroutine Installation Manual Section 3.3.8

New function F29. It takes the value of the Programming Manual Chapter 13

selected tool

Function M06 does not execute M19 Installation Manual Section 3.3.5

Greater speed when executing several

parametric blocks in a row.

xv

Page 13

Date: March 1992 Software version: 4.1 and newer

FEATURE MODIFIED MANUAL AND SECTION

Bell-shape acceleration/deceleration control Installation Manual Section 4.7

Expansion of cross compensation Installation Manual Section 4.10

Rigid Tapping G84 R Programming Manual G84

Possibility to enter the sign of the leadscrew Installation Manual Section 4.9

backlash for each axis

Independent execution of an axis Programming Manual G65

Date: July 1993 Software version: 5.1 and newer

FEATURE MODIFIED MANUAL AND SECTION

Double cross compensation Installation Manual Section 4.10

Linear and bell-shaped acc./dec. ramp Installation Manual Section 4.7

combination for the axes

Acceleration/deceleration control for the Installation Manual Section 5.

the spindle

Multiple arc pattern machining Programming Manual G64

Tool tip position display Installation Manual Section 3.3.5

The associated subroutine is executed before Installation Manual Section 3.3.5

the T function

The additional circular sections of a Installation Manual Section 3.3.8

compensated path are executed in G05 or G07

VGA monitor 8030 CNC. Installation Manual Chapter 1

xvi

Page 14

Date: March 1995 Software version: 5.3 and newer

FEATURE MODIFIED MANUAL AND SECTION

Management of feedback with coded Io Installation Manual Section 4.6 & 6.5

Spindle inhibit by PLC Installation Manual Section 3.3.9

Handwheel management by PLC Installation Manual Section 3.3.3

Rapid (JOG) key simulation via PLC PLCI Manual

Non-servo-controlled open-loop motors Applications Manual

Function G64, multiple machining in an arc. Installation Manual Section 3.3.9

To be selected by machine parameter.

Initialization of machine parameters after

memory loss.

Date: September 1995 Software version: 6.0 and newer

FEATURE MODIFIED MANUAL AND SECTION

512 Kb of part-program memory Operating Manual Section 3.6

When conditional input (block skip) active

while in JOG mode, the

key is ignored Installation Manual Section 1.3.6

xvii

Page 15

Atention:

INTRODUCTION

Before starting up the CNC, carefully read the instructions of Chapter

2 in the Installation Manual.

The CNC must not be powered-on until verifying that the machine

complies with the "89/392/CEE" Directive.

Introduction - 1

Page 16

DECLARATION OF CONFORMITY

Manufacturer: Fagor Automation, S. Coop.

Barrio de San Andrés s/n, C.P. 20500, Mondragón -Guipúzcoa- (ESPAÑA)

We hereby declare, under our responsibility that the product:

Fagor 8025 M CNC

meets the following directives:

SAFETY:

EN 60204-1 Machine safety. Electrical equipment of the machines.

ELECTROMAGNETIC COMPATIBILITY:

EN 50081-2 Emission

EN 55011 Radiated. Class A, Group 1.

EN 55011 Conducted. Class A, Group 1.

EN 50082-2 Immunity

EN 61000-4-2 Electrostatic Discharges.

EN 61000-4-4 Bursts and fast transients.

EN 61000-4-11Voltage fluctuations and Outages.

ENV 50140 Radiofrequency Radiated Electromagnetic Fields.

ENV 50141 Conducted disturbance induced by radio frequency fields.

As instructed by the European Community Directives on Low Voltage: 73/23/EEC,

on Machine Safety 89/392/EEC and 89/336/EEC on Electromagnetic Compatibility.

In Mondragón, on January 2nd, 1997

Introduction - 3

Page 17

SAFETY CONDITIONS

Read the following safety measures in order to prevent damage to personnel, to

this product and to those products connected to it.

This unit must only be repaired by personnel authorized by Fagor Automation.

Fagor Automation shall not be held responsible for any physical or material

damage derived from the violation of these basic safety regulations.

Precautions against personal damage

Module interconnection

Use the cables supplied with the unit.

Use proper Mains AC power cables

To avoid risks, use only the Mains AC cables recommended for this unit.

Avoid electrical overloads

In order to avoid electrical discharges and fire hazards, do not apply electrical voltage

outside the range selected on the rear panel of the Central Unit.

Ground connection

In order to avoid electrical discharges, connect the ground terminals of all the

modules to the main ground terminal. Before connecting the inputs and outputs of this

unit, make sure that all the grounding connections are properly made.

Before powering the unit up, make sure that it is connected to ground

In order to avoid electrical discharges, make sure that all the grounding connections

are properly made.

Do not work in humid environments

In order to avoid electrical discharges, always work under 90% of relative humidity

(non-condensing) and 45º C (113º F).

Do not work in explosive environments

In order to avoid risks, damage, do not work in explosive environments.

Precautions against product damage

Working environment

This unit is ready to be used in Industrial Environments complying with the directives

and regulations effective in the European Community

Fagor Automation shall not be held responsible for any damage suffered or caused

when installed in other environments (residential or homes).

Install the unit in the right place

Introduction - 4

It is recommended, whenever possible, to instal the CNC away from coolants,

chemical product, blows, etc. that could damage it.

Page 18

This unit complies with the European directives on electromagnetic compatibility.

Nevertheless, it is recommended to keep it away from sources of electromagnetic

disturbance such as.

- Powerful loads connected to the same AC power line as this equipment.

- Nearby portable transmitters (Radio-telephones, Ham radio transmitters).

- Nearby radio / TC transmitters.

- Nearby arc welding machines

- Nearby High Voltage power lines

- Etc.

Enclosures

The manufacturer is responsible of assuring that the enclosure involving the equipment

meets all the currently effective directives of the European Community.

Avoid disturbances coming from the machine tool

The machine-tool must have all the interference generating elements (relay coils,

contactors, motors, etc.) uncoupled.

Use the proper power supply

Use an external regulated 24 Vdc power supply for the inputs and outputs.

Grounding of the power supply

The zero volt point of the external power supply must be connected to the main ground

point of the machine.

Analog inputs and outputs connection

It is recommended to connect them using shielded cables and connecting their shields

(mesh) to the corresponding pin (See chapter 2).

Ambient conditions

The working temperature must be between +5° C and +45° C (41ºF and 113º F)

The storage temperature must be between -25° C and 70° C. (-13º F and 158º F)

Monitor enclosure

Assure that the Monitor is installed at the distances indicated in chapter 1 from the

walls of the enclosure.

Use a DC fan to improve enclosure ventilation.

Main AC Power Switch

This switch must be easy to access and at a distance between 0.7 m (27.5 inches) and

1.7 m (5.6 ft) off the floor.

Protections of the unit itself

It carries two fast fuses of 3.15 Amp./ 250V. to protect the mains AC input.

All the digital inputs and outputs have galvanic isolation via optocouplers between

the CNC circuitry and the outside.

They are protected by an external fast fuse (F) of 3.15 Amp./ 250V. against over

voltage and reverse connection of the power supply.

The type of fuse depends on the type of monitor. See the identification label of the

unit.

Introduction - 5

Page 19

Precautions during repair

Do not manipulate the inside of the unit

Only personnel authorized by Fagor Automation may manipulate the

inside of this unit.

Do not manipulate the connectors with the unit connected to AC

power.

Before manipulating the connectors (inputs/outputs, feedback, etc.)

make sure that the unit is not connected to AC power.

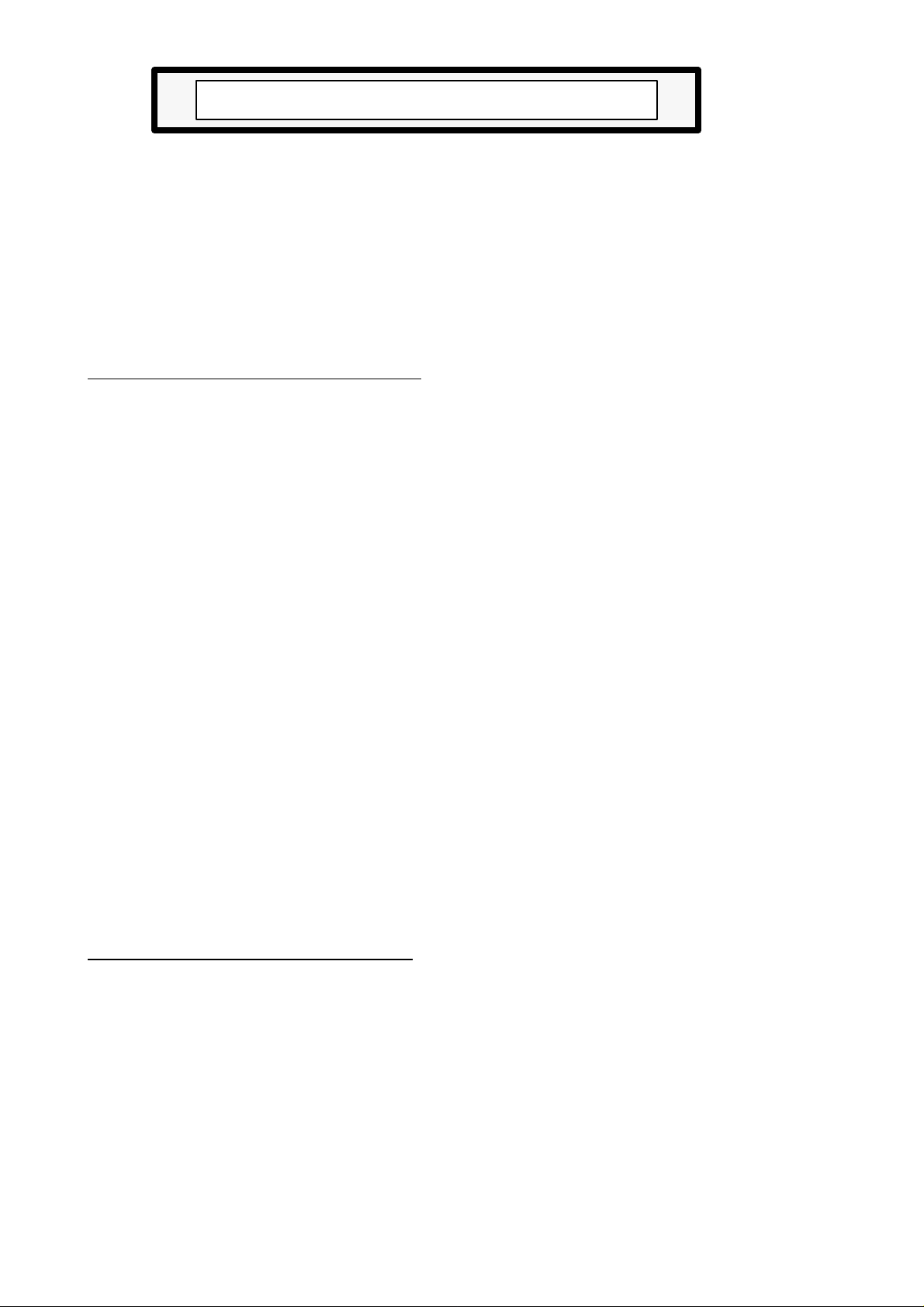

Safety symbols

Symbols which may appear on the manual

WARNING. symbol

It has an associated text indicating those actions or operations may hurt

people or damage products.

Symbols that may be carried on the product

WARNING. symbol

It has an associated text indicating those actions or operations may hurt

people or damage products.

"Electrical Shock" symbol

It indicates that point may be under electrical voltage

"Ground Protection" symbol

It indicates that point must be connected to the main ground point of the

machine as protection for people and units.

Introduction - 6

Page 20

WARRANTY

All products manufactured or marketed by Fagor Automation has a warranty period

of 12 months from the day they are shipped out of our warehouses.

The mentioned warranty covers repair material and labor costs, at FAGOR facilities,

incurred in the repair of the products.

Within the warranty period, Fagor will repair or replace the products verified as being

defective.

FAGOR is committed to repairing or replacing its products from the time when the

first such product was launched up to 8 years after such product has disappeared from

the product catalog.

It is entirely up to FAGOR to determine whether a repair is to be considered under

warranty.

WARRANTY TERMS

EXCLUDING CLAUSES

The repair will take place at our facilities. Therefore, all shipping expenses as well

as travelling expenses incurred by technical personnel are NOT under warranty even

when the unit is under warranty.

This warranty will be applied so long as the equipment has been installed according

to the instructions, it has not been mistreated or damaged by accident or negligence

and has been manipulated by personnel authorized by FAGOR.

If once the service call or repair has been completed, the cause of the failure is not to

be blamed the FAGOR product, the customer must cover all generated expenses

according to current fees.

No other implicit or explicit warranty is covered and FAGOR AUTOMATION shall

not be held responsible, under any circumstances, of the damage which could be

originated.

SERVICE CONTRACTS

Service and Maintenance Contracts are available for the customer within the

warranty period as well as outside of it.

Introduction - 7

Page 21

MATERIAL RETURNING TERMS

When returning the CNC, pack it in its original package and with its original packaging

material. If not available, pack it as follows:

1.- Get a cardboard box whose three inside dimensions are at least 15 cm (6 inches) larger

than those of the unit. The cardboard being used to make the box must have a

resistance of 170 Kg (375 lb.).

2.- When sending it to a Fagor Automation office for repair, attach a label indicating the

owner of the unit, person to contact, type of unit, serial number, symptom and a brief

description of the problem.

3.- Wrap the unit in a polyethylene roll or similar material to protect it.

When sending the monitor, especially protect the CRT glass.

4.- Pad the unit inside the cardboard box with poly-utherane foam on all sides.

5.- Seal the cardboard box with packing tape or industrial staples.

Introduction - 8

Page 22

ADDITIONAL REMARKS

* Mount the CNC away from coolants, chemical products, blows, etc. which could

damage it.

* Before turning the unit on, verify that the ground connections have been properly

made. See Section 2.2 of this manual.

* To prevent electrical shock at the Central Unit, use the proper mains AC connector at

the Power Supply Module. Use 3-wire power cables (one for ground connection)

* To prevent electrical shock at the Monitor, use the proper mains AC connector at the

Power Supply Module. Use 3-wire power cables (one for ground connection)

* Before turning the unit on, verify that the external AC line fuse, of each unit, is the right

one.

Central Unit

Must be 2 fast fuses (F) of 3.15 Amp./ 250V.

Introduction - 9

Page 23

Monitor

Depends on the type of monitor. See identification label of the unit itself.

* In case of a malfunction or failure, disconnect it and call the technical service. Do not

manipulate inside the unit.

Introduction - 10

Page 24

FAGOR DOCUMENTATION

FOR THE 8025/30 M CNC

8025 M CNC OEM Manual Is directed to the machine builder or person in charge of installing and starting

up the CNC.

It contains 2 manuals:

Installation Manual describing how to isntall and set-up the CNC.

LAN Manual describing how to instal the CNC in the Local

Sometimes, it may contain an additional manual describing New Software

Features recently implemented.

8025 M CNC USER Manual Is directed to the end user or CNC operator.

It contains 3 manuals:

Operating Manual describing how to operate the CNC.

Programming Manual describing how to program the CNC.

Applications Manual describing other applications for this CNC

Sometimes, it may contain an additional manual describing New Software

Features recently implemented.

DNC 25/30 Software Manual Is directed to people using the optional DNC communications software.

Area Network.

non-specific of Milling machines

DNC 25/30 Protocol Manual Is directed to people wishing to design their own DNC communications

software to communicate with the 800 without using the DNC25/30 software..

PLCI Manual To be used when the CNC has an integrated PLC.

Is directed to the machine builder or person in charge of installing and starting

up the PLCI.

DNC-PLC Manual Is directed to people using the optional communications software: DNC-PLC.

FLOPPY DISK Manual Is directed to people using the Fagor Floppy Disk Unit and it shows how to use

it.

Introduction - 11

Page 25

MANUAL CONTENTS

The installation manual consists of the following chapters:

Index

Comparison table of FAGOR models: 8025 M CNCs

New Features and modifications.

Introduction Warning sheet prior to start-up:

Declaration of Conformity.

Safety conditions.

Warranty terms.

Material returning conditions.

Additional remarks.

FAGOR documentation for the 8025 M CNC.

Manual contents.

Chapter 1 CNC configuration.

Indicates the possible compositions: modular and compact.

Description and dimensions of the Central Unit.

Description and dimensions of the Monitor.

Description and dimensions of the Operator Panel.

Detailed description of all the connectors.

Chapter 2 Machine and Power connection

Chapter 3 Machine parameters.

Chapter 4 Machine parameters for the axes.

Chapter 5 Machine Parameters for the spindle.

Chapter 6 Concepts.

Indicates how to connect the main AC power

The ground connection.

The characteristics of the digital inputs and outputs.

The characteristics of the analog output.

The characteristics of the feedback inputs.

CNC set-up and start-up.

System input/output test.

Emergency input and output connection.

How to operate with the machine parameters.

How to set the machine parameters.

Detail description of the general machine parameters.

Detail description of the machine parameters for the axes.

Detail description of the machine parameters for the spindle.

Axes and coordinate systems. Nomenclature and selection.

Feedback systems, resolution.

Axis and gain adjustment.

Reference systems; Reference points, search and adjustment.

Software axis travel limits.

Acceleration / deceleration.

Unidirectional approach.

Spindle: speed control, range change.

Tools and tool magazine.

Treatment of the «Feed-hold» and «M-done» signals.

M, S, T auxiliary function transfer.

Pallet work.

Appendix Technical characteristics of the CNC. Enclosures.

Error codes.

Introduction - 12

Recommended probe connection circuits.

CNC inputs and outputs.

2-digit BCD spindle output conversion table.

Machine parameters. Summary chart, sequential list and setting chart.

Auxiliary «M» functions. Setting chart.

Leadscrew error compensation and cross compensation tables.

Maintenance.

Page 26

1. CONFIGURATION OF THE CNC

Atention:

The CNC is prepared to be used in Industrial Environments, especially on

milling machines, lathes, etc. It can control machine movements and devices.

It can control machine movements and devices.

1.1 8025 CNC

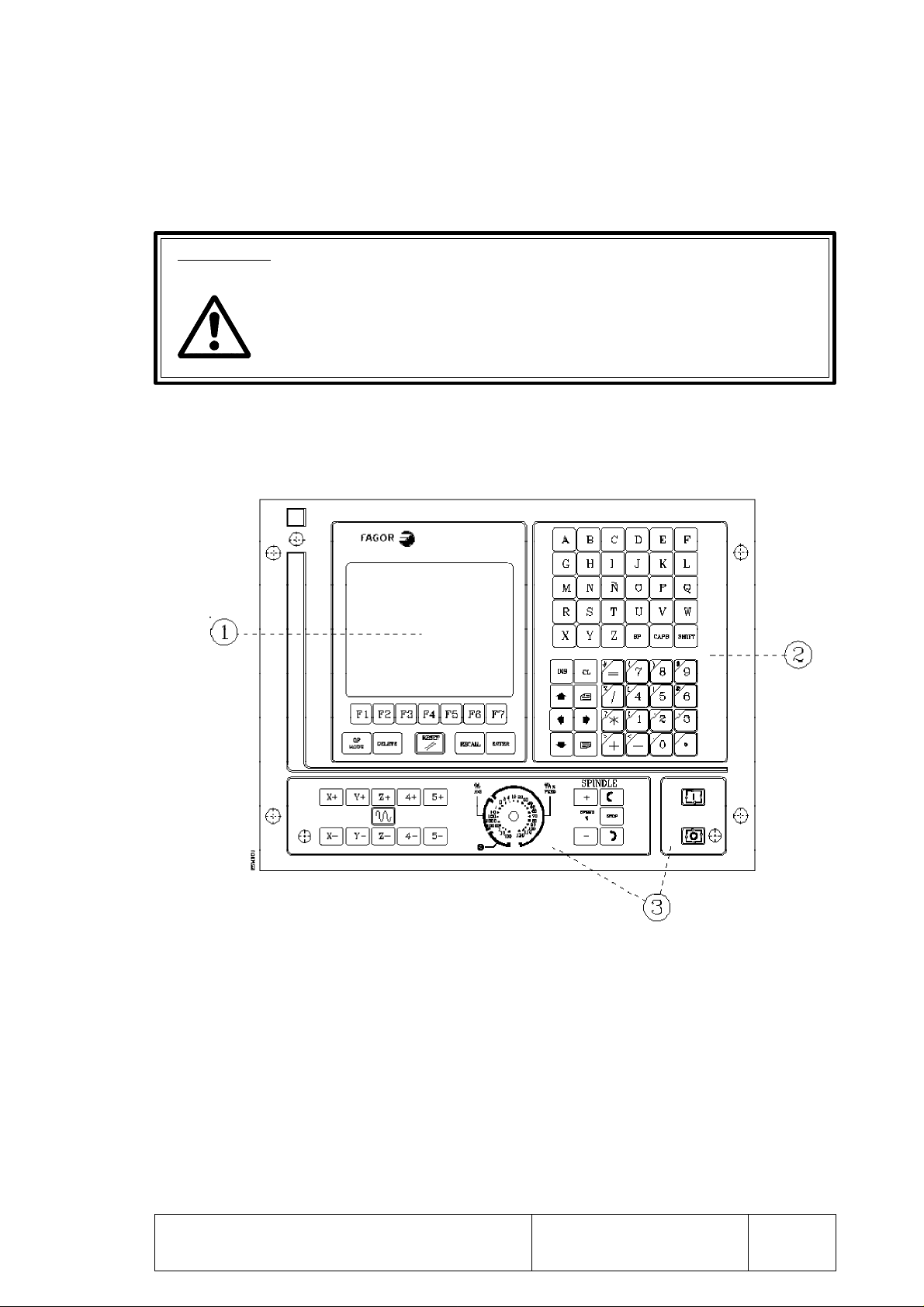

The 8025 CNC is an enclosed compact module whose front view offers:

1. An 8" monochrome amber monitor or CRT screen used to display the required system

information.

2. A keyboard which permits communications with the CNC; being possible to request

information or change the CNC status by generating new instructions.

3. An operator panel containing the necessary keys to work in JOG mode as well as the

Cycle Start/Stop keys.

PageChapter: 1 Section:

CONFIGURATION OF THE CNC

8025 CNC

1

Page 27

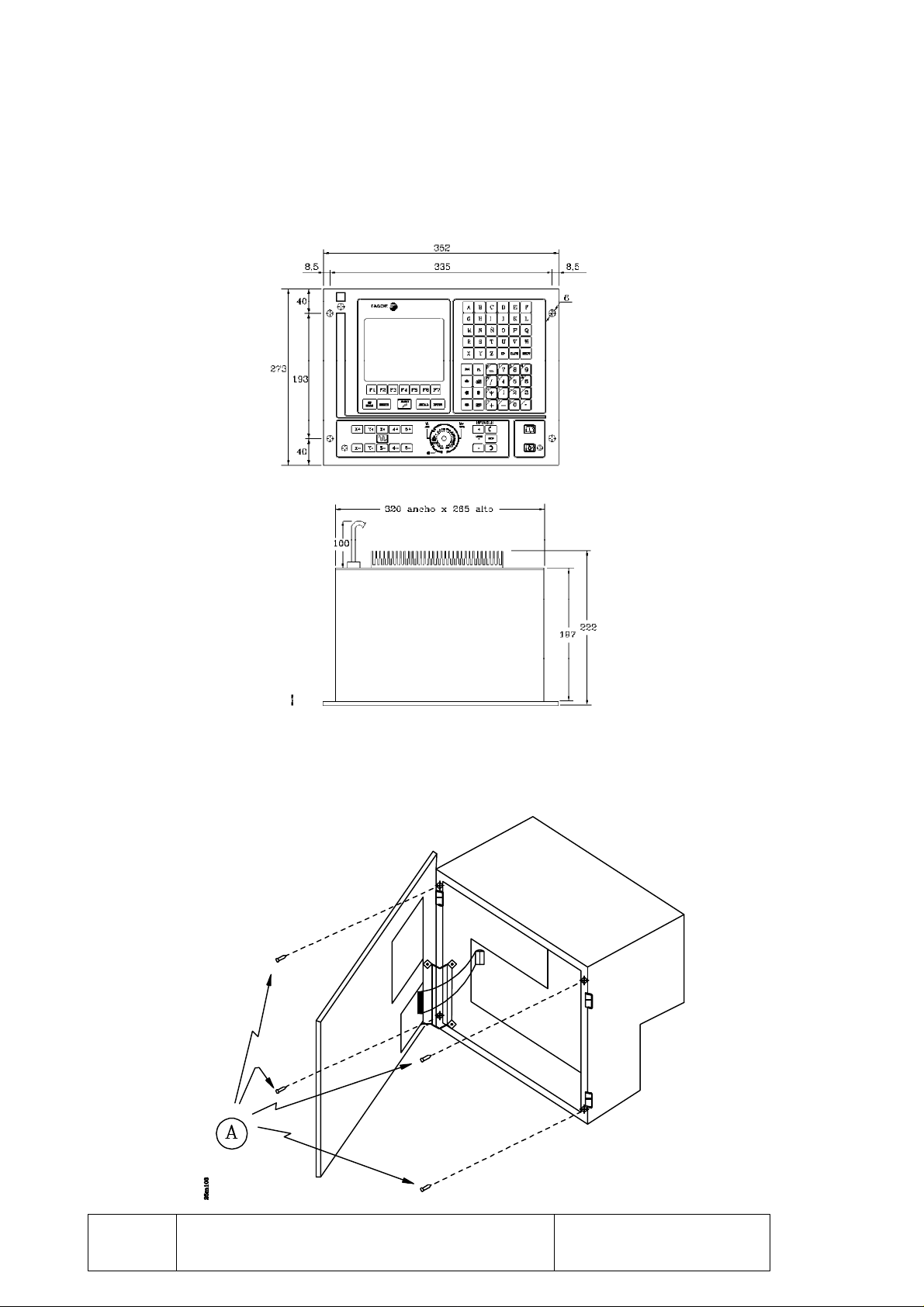

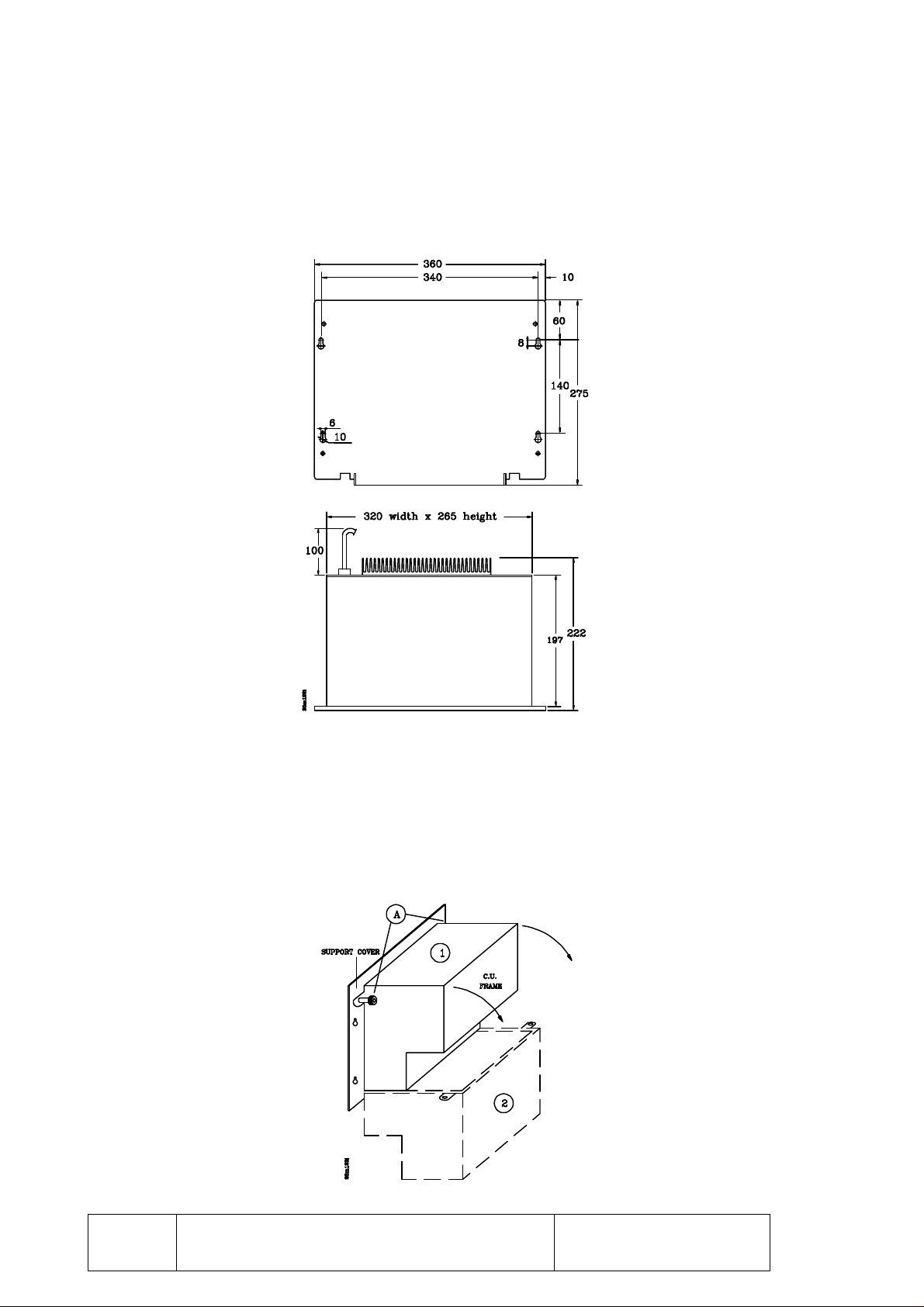

1.1.1 DIMENSIONS AND INSTALLATION OF THE 8025 CNC

This CNC, usually mounted on the machine pendant, has 4 mounting holes.

When installing it, leave enough room to swing the FRONT PANEL open in order to allow

future access to its interior.

To open it, undo the 4 allen-screws located next to the CNC mounting holes.

Page

2

CONFIGURATION OF THE CNC

Section:Chapter: 1

8025 CNC

Page 28

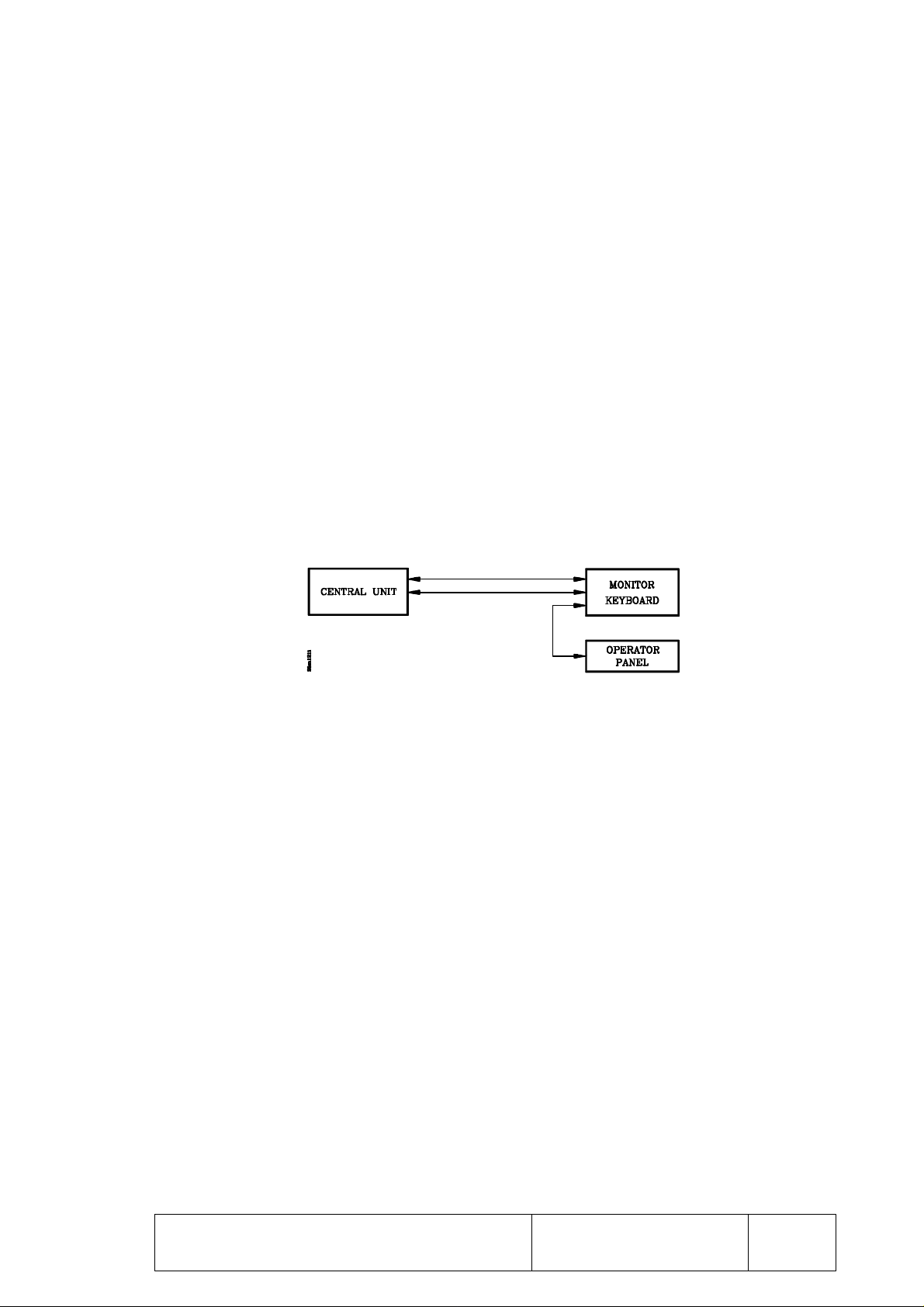

1.2 8030 CNC

This model CNC consists of 3 independent interconnected modules. These modules can be

mounted on different locations and they are:

- CENTRAL UNIT

- MONITOR/KEYBOARD

- OPERATOR PANEL

The OPERATOR PANEL module is connected to the MONITOR/KEYBOARD module

via a cable supplied with that module.

These two modules will be placed next to each other and must be connected with the

CENTRAL UNIT module which could be located somewhere else. The two cables used

to connect them together are also supplied with these modules. Their maximum length is 25

meters (82 feet) and they are referred to as:

- Video cable.

- Keyboard cable.

CONFIGURATION OF THE CNC

8030 CNC

PageChapter: 1 Section:

3

Page 29

1.2.1 CENTRAL UNIT OF THE 8030 CNC

The CENTRAL UNIT is usually mounted in the electrical cabinet (machine enclosure) and

it is secured by means of the mounting holes located on the support cover.

When installing it, observe enough clearance to swing the CENTRAL UNIT open in case

of future inside manipulation.

To swing it open, once the support cover is secured on the machine enclosure, undo the two

knurled nuts on top and swing it open while holding the body of the CENTRAL UNIT.

Page

4

CONFIGURATION OF THE CNC

Section:Chapter: 1

CENTRAL UNIT

8030 CNC

Page 30

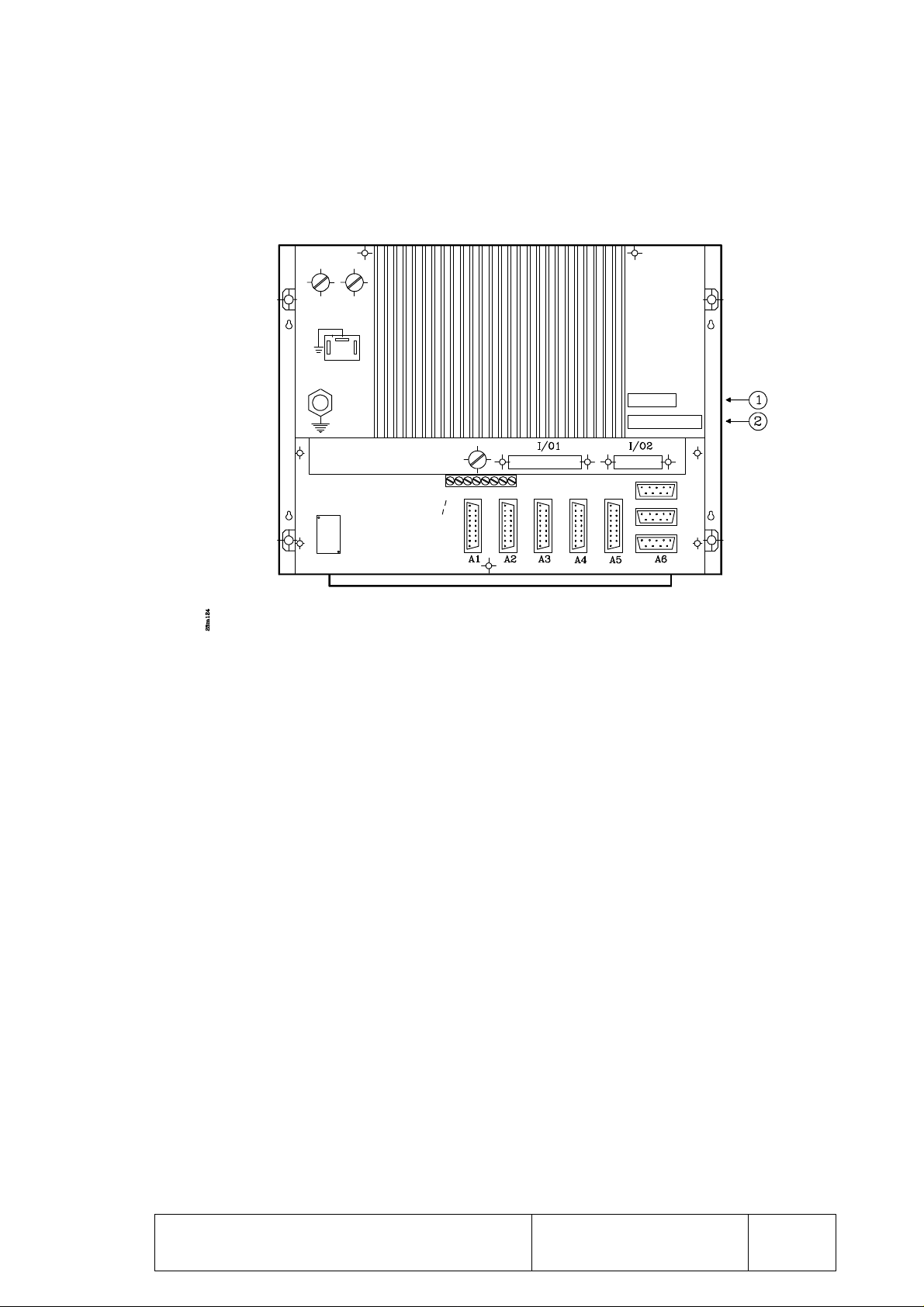

The CENTRAL UNIT has two connectors to connect it with the MONITOR/KEYBOARD

module by means of the video and keyboard signal cables.

1.- 15-pin SUB-D type female connector for for video signals.

2.- 25-pin SUB-D type female connector for keyboard signals.

CONFIGURATION OF THE CNC

CENTRAL UNIT

8030 CNC

PageChapter: 1 Section:

5

Page 31

1.2.1.1KEYBOARD CONNECTOR

It is a 25-pin SUB-D type female connector to connect the CENTRAL UNIT module to

the MONITOR/KEYBOARD module.

FAGOR AUTOMATION provides the cable required for this connection. It comes with

a 25-pin SUB-D type male connector at each end.

Both connectors have a latching system UNC4.40 by means of two screws.

PIN SIGNAL

1 GND

2 C9

3 C11

4 C13

5 C15

6 C1

7 C3

8 C5

9 C7

10 D1

11 D3

12 D5

13 D7

14 C8

15 C10

16 C12

17 C14

18 C0

19 C2

20 C4

21 C6

22 D0

23 D2

24 D4

25 D6

Metal hood Shield

The supplied cable has 25 wires (25 x 0.14mm²) with overall shield and acrylic cover. Its

maximum length must be 25 meters (82 feet).

Page

6

CONFIGURATION OF THE CNC

Section:Chapter: 1

CENTRAL UNIT

8030 CNC

Page 32

The cable shield is soldered to the metal hoods (housings) of both connectors and connected

to pin 1 at both the CENTRAL UNIT and the MONITOR/KEYBOARD connectors.

CONFIGURATION OF THE CNC

CENTRAL UNIT

8030 CNC

PageChapter: 1 Section:

7

Page 33

1.2.1.2VIDEO CONNECTOR

It is a 15-pin SUB-D type female connector used to interconnect the CENTRAL UNIT

module and the MONITOR/KEYBOARD module.

FAGOR AUTOMATION provides the cable required for this connection. It comes with

a 15-pin SUB-D type male connector at one end and a 15-pin SUB-D type female connector

at the other.

Both connectors have a latching system UNC4.40 by means of two screws.

PIN SIGNAL

1 GND

2 H

3 V

4 I

5 R

6 G

7 B

8 not connected

9 not connected

10 H

11 V

12 I

13 R

14 G

15 B

Metal hood shield

The supplied cable has 6 twisted-pairs of wires (6 x 2 x 0.34mm²) with overall shield and

acrylic cover. It has a specific impedance of 120 Ohm. Its maximum length must be 25

meters (82 feet).

The cable shield is soldered to the metal hoods (housings) of both connectors and connected

to pin 1 at both the CENTRAL UNIT and MONITOR/KEYBOARD connectors.

Page

8

CONFIGURATION OF THE CNC

Section:Chapter: 1

CENTRAL UNIT

8030 CNC

Page 34

1.2.2 MONITOR/KEYBOARD OF THE 8030 CNC

This module can be mounted on the machine pendant and it lets the operator get the

necessary information at the MONITOR as well as operate the CNC by means of its

KEYBOARD and OPERATOR PANEL.

This module has the connectors to connect it with the CENTRAL UNIT module.

1.2.2.1 DIMENSIONS OF THE MONITOR/KEYBOARD

CONFIGURATION OF THE CNC

MONITOR/KEYBOARD

8030 CNC

PageChapter: 1 Section:

9

Page 35

1.2.2.2 ELEMENTS OF THE MONITOR/KEYBOARD

X1 25-pin SUB-D type female connector for keyboard signals.

X2 15-pin SUB-D type male connector for video signals.

X3 15-pin SUB-D type female connector to connect the MONITOR/KEYBOARD

module to the OPERATOR PANEL module.

1.- A.C. power plug. Use the plug supplied with the unit to connect it to A.C. power and

ground.

2.- Ground terminal. Used for general machine ground connection. Metric 6 screw.

3.- Buzzer

Atention:

Do not manipulate inside this unit

Only personnel authorized by Fagor Automatin may manipulate inside

this module.

Do not manipulate the connectors with the unit connected to main AC

power

Before manipulating these connectors, make sure that the unit is not

connected to main AC power.

Page

10

CONFIGURATION OF THE CNC

Section:Chapter: 1

MONITOR/KEYBOARD

8030 CNC

Page 36

1.2.2.3 CONNECTORS AND MONITOR/KEYBOARD INTERFACE

Connectors X1, X2

They are described in the chapter corresponding to the CENTRAL UNIT.

Connector X3

It is a 15-pin SUB-D type female connector used to connect the MONITOR/

KEYBOARD with the OPERATOR PANEL.

FAGOR AUTOMATION supplies the cable required for this connection. It is a

250mm-long 15-wire ribbon cable.

To obtain a greater distance between the Monitor/Keyboard and the Operator

Panel, replace this cable with a round 15-conductor cable (15 x 0.14 mm²) with

overall shield and acrylic rubber cover. The length of this cable plus the length of

the one used between the Central Unit and the Keyboard (X1) must not exceed 25

meters (82 feet).

PIN SIGNAL

1

2 uC13

3 uC12

4 jC11

5 jC10

6 jC9

7 D7

8 D6

9 D5

10 D4

11 D3

12 D2

13 D1

14 D0

15 C14

CONFIGURATION OF THE CNC

MONITOR/KEYBOARD

8030 CNC

PageChapter: 1 Section:

11

Page 37

1.2.3 OPERATOR PANEL OF THE 8030 CNC

This module is connected to the MONITOR/KEYBOARD module via a ribbon cable and

it contains the JOG keys, Feedrate Override knob, Cycle Start and Stop keys, spindle keys

as well as an Emergency-stop push-button (mushroom) or an optional electronic handwheel.

X1 15-pin SUB-D type female connector to connect the MONITOR/KEYBOARD

module to the OPERATOR PANEL module.

It is described in the chapter corresponding to the MONITOR/KEYBOARD.

1.- Not being used at this time.

2.- Optional mounting location for the E-Stop button or Electronic handwheel.

Page

12

CONFIGURATION OF THE CNC

OPERATOR PANEL

Section:Chapter: 1

8030 CNC

Page 38

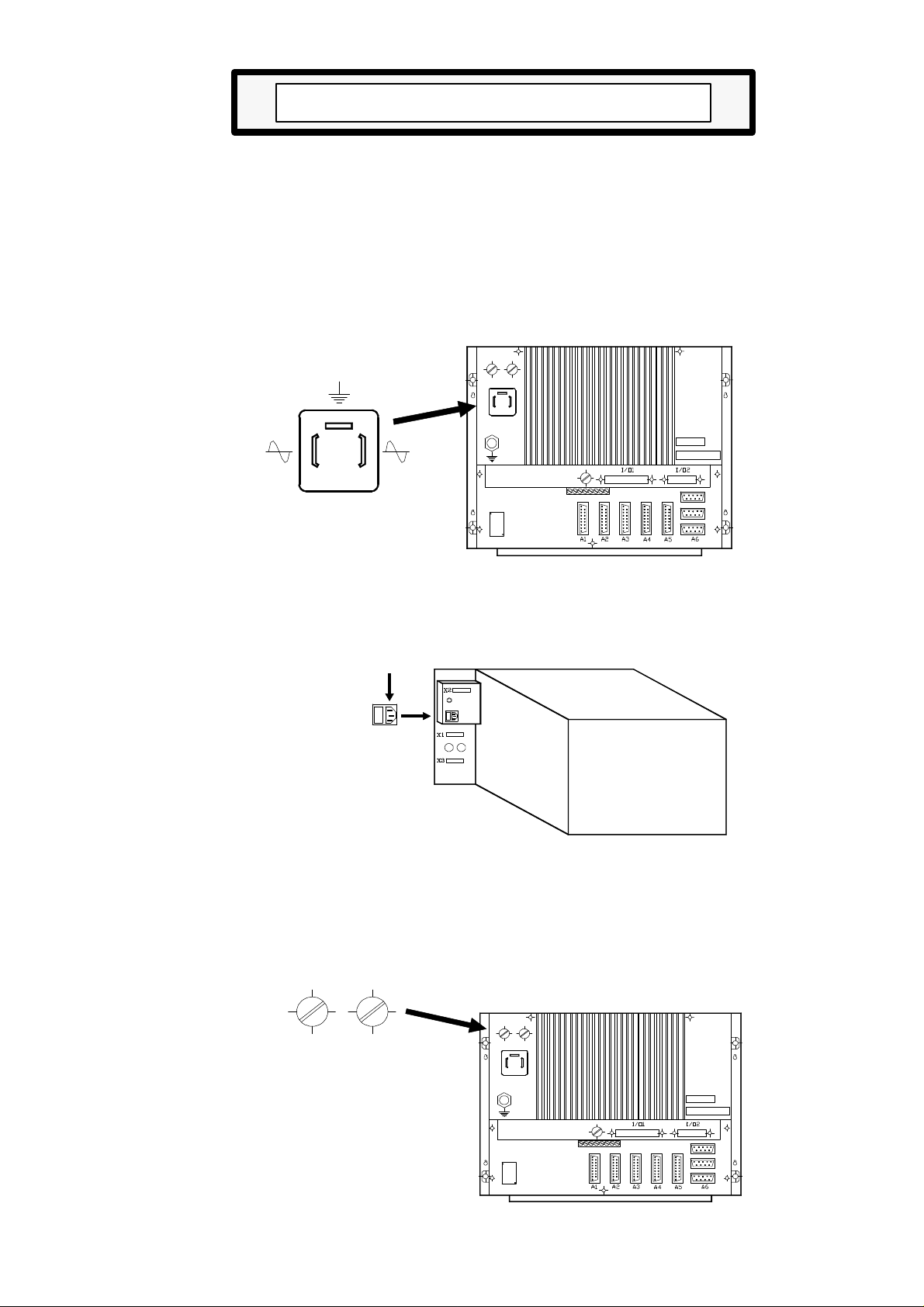

1.3 CONNECTORS AND 8025/8030 INTERFACE

A1 15-pin SUB-D type female connector to connect the X axis feedback system. It

accepts sine-wave signal.

A2 15-pin SUB-D type female connector to connect the Y axis feedback system. It

accepts sine-wave signal.

A3 15-pin SUB-D type female connector to connect the Z axis feedback system. It

accepts sine-wave signal.

A4 15-pin SUB-D type female connector to connect the W axis feedback system. It

accepts sine-wave signal.

A5 15-pin SUB-D type female connector to connect the 5th axis (V) feedback system.

It does not accept sine-wave signal.

When using the spindle encoder and an electronic handwheel, the CNC will only

control up to 4 axes. This connector will then be used for the spindle encoder or the

electronic handwheel (the other device will be connected to A6).

A6 9-pin SUB-D type female connector to connect the spindle encoder or an electronic

handwheel and a touch probe. It does not accept sine-wave signal.

RS485 9-pin SUB-D type female connector to connect the RS485 serial line.

RS232C 9-pin SUB-D type female connector to connect the RS232C serial line.

CONFIGURATION OF THE CNC

CONNECTORS AND

INTERFACE

PageChapter: 1 Section:

13

Page 39

I/O1 37-pin SUB-D type female connector to interface with the electrical cabinet

offering 10 digital inputs, 16 digital outputs and 4 analog outputs for servo drives

(range: ±10 V.).

I/O2 25-pin SUB-D type female connector to interface with the electrical cabinet

offering 16 digital outputs and 2 analog outputs for servo drives (range: ±10V.).

1- Main AC fuse. It has two 3.15Amp./250V. fast fuses (F), one per AC line, to protect

the main AC input.

2- AC power connector To power the CNC. It must be connected to the power

transformer and to ground.

3- Ground terminal. It must be connected to the general machine ground point. Metric

6.

4- Fuse. 3.15Amp./250V fast fuse (F) to protect the internal I/O circuitry of the CNC.

5- Lithium battery. Maintains the RAM data when the system's power disappears.

6- Adjustment potentiometers for the analog outputs. ONLY TO BE USED BY

THE TECHNICAL SERVICE DEPARTMENT.

7- 10 dip-switches. There are 2 under each feedback connector (A1 thru A5) and they are

utilized to set the CNC according to the type of feedback signal being used.

8 CRT brightness adjustment potentiometer

9 Heat-sink.

Atention:

Do not manipulate the connectors with the unit connected to main AC

power

Before manipulating these connectors, make sure that the unit is not

connected to main AC power.

Page

14

CONFIGURATION OF THE CNC

Section:Chapter: 1

CONNECTORS AND

INTERFACE

Page 40

1.3.1 CONNECTORS A1, A2, A3, A4

They are 15-pin SUB-D type female connectors used to connect the feedback signals.

* Connector A1 for X axis feedback signals.

* Connector A2 for Y axis feedback signals.

* Connector A3 for Z axis feedback signals.

* Connector A4 for W axis feedback signals.

The cable must have overall shield. The rest of the specifications depend on the feedback

system utilized and the cable length required.

It is highly recommended to run these cables as far as possible from the power cables of the

machine.

PIN SIGNAL AND FUNCTION

1 A

2 A Differential square-wave feedback signals

3 B

4 B

Atention:

When using square-wave rotary encoders, their signals must be TTL compatible.

5 Io Machine Reference Signals (marker pulses)

6 Io

7 Ac Sine-wave feedback signals

8 Bc

9 +5V. Power to feedback system.

10 Not connected.

11 0V. Power to feedback system.

12 Not connected.

13 -5V. Power to feedback system.

14 Not connected.

15 CHASSIS Shield

Encoders with open collector outputs MUST NOT be used.

Do not manipulate the connectors with the unit connected to main AC

power

Before manipulating these connectors, make sure that the unit is not

connected to main AC power.

CONFIGURATION OF THE CNC

CONNECTORS

A1, A2, A3 & A4

PageChapter: 1 Section:

15

Page 41

1.3.1.1 DIP-SWITCHES FOR CONNECTORS A1, A2, A3, A4

There are 2 dip-switches below each feedback input connector (A1 thru A4) to set the CNC

according to the type of feedback signal being used.

Switch 1 indicates whether the feedback signal is sine-wave or square-wave and switch 2

indicates whether the feedback signal is single- or double-ended (differential).

The possible types of feedback signals to be used at connectors A1 thru A4 are:

* Sine-wave (Ac, Bc, Io)

* Single-ended square-wave (A, B, Io)

* Double-ended (differential) square-wave (A, A, B, B, Io, Io)

To select the type of signal for each axis, use the switch combinations below:

Dip-switch SIGNAL AND FUNCTION

1 2

ON ON Single-ended sine-wave signal (Ac,Bc,Io)

ON OFF Double-ended sine-wave signal "Not allowed"

OFF ON Single-ended square-wave signal (A,B,Io)

OFF OFF Double-ended square-wave (A, A,B, B, Io, Io)

There is a label next to each dip-switch pair indicating the meaning of each switch.

Page

16

CONFIGURATION OF THE CNC

Section:Chapter: 1

CONNECTORS

A1, A2, A3 & A4

Page 42

1.3.2 CONNECTOR A5

It is a 15-pin SUB-D type female connector for the 5th axis (V) feedback signal.

It does not accept sine-wave signals.

When using the spindle encoder and an electronic handwheel, the CNC will only control

up to 4 axes. This connector will then be used for the spindle encoder or the electronic

handwheel (the other device will be connected to A6).

The cable must have overall shield. The rest of the specifications depend on the feedback

system utilized and the cable length required.

It is highly recommended to run these cables as far as possible from the power cables of the

machine.

PIN SIGNAL AND FUNCTION

1 A

2 A Double-ended square-wave signal.

3 B

4 B

5 Io Machine Reference signals (marker pulse)

6 Io

Atention:

7 Micro Io "V" axis home switch input.

8 0V. "V" axis home switch 0V input. (elec.cabinet)

9 +5V. Power to feedback system.

10 Not connected.

11 0V. Power to feedback system.

12 Not connected.

13 -5V. Power to feedback system.

14 Not connected.

15 CHASSIS Shield.

When using square-wave rotary encoders, their signals must be TTL compatible.

Encoders with open collector outputs MUST NOT be used.

Do not manipulate the connectors with the unit connected to main AC

power

Before manipulating these connectors, make sure that the unit is not

connected to main AC power.

CONFIGURATION OF THE CNC

CONNECTOR A5

PageChapter: 1 Section:

17

Page 43

1.3.2.1 DIP-SWITCHES FOR CONNECTOR A5

There are 2 dip-switches below this feedback input connector to set the CNC according to

the type of feedback signal being used.

Switch 1 indicates whether the feedback signal is sine-wave or square-wave and switch 2

indicates whether the feedback signal is single- or double-ended (differential).

The possible types of feedback signals to be used at connector A5 are:

* Single-ended square-wave (A, B, Io)

* Double-ended (differential) square-wave (A, A, B, B,Io, Io)

To select the type of signal for each axis, use the switch combinations below:

Dip-switch SIGNAL AND FUNCTION

1 2

ON ON Single-ended sine-wave signal "Not allowed"

ON OFF Double-ended sine-wave signal "Not allowed"

OFF ON Single-ended square-wave signal (A,B,Io)

OFF OFF Double-ended square-wave (A, A,B, B, Io, Io)

There is a label next to each dip-switch pair indicating the meaning of each switch.

Page

18

CONFIGURATION OF THE CNC

Section:Chapter: 1

CONNECTOR A5

Page 44

1.3.3 CONNECTOR A6

It is a 9-pin SUB-D type female connector to connect the spindle encoder or the electronic

handwheel and a touch probe. It does not take sine-wave signals.

The cable must have overall shield. The rest of the specifications depend on the feedback

system utilized and the cable length required.

It is highly recommended to run these cables as far as possible from the power cables of the

machine.

There are two probe inputs (5V and 24V) and the 0V of the external power supply must be

connected to the "probe 0V input" (pin 8).

The appendix of the manual includes information about these probe inputs as well as

recommended probe connection diagrams.

All cable shields must be connected to ground ONLY at the CNC end through the connector

leaving the other end of the cable not connected. The wires of a shielded cable must not be

unshielded (sticking out) for more than 75mm (about 3 inches).

PIN SIGNAL AND FUNCTION

Atention:

When using square-wave rotary encoders, their signals must be TTL compatible.

Encoders with open collector outputs MUST NOT be used.

When using a FAGOR 100P handwheel, the axis selector signal must be

connected to pin 3.

1 A Square-wave signals from the spindle

2 B encoder or from the electronic handwheel

3 Io Home marker pulse (Machine Reference)

4 +5V. Power to spindle encoder or handwheel

5 0V.

6 PROB 5 Probe input: 5 V. TTL

7 PROB 24 Probe input: 24 Vcc

8 0 PROB Probe input: 0 V.

9 CHASSIS Shield.

Do not manipulate the connectors with the unit connected to main AC

power

Before manipulating these connectors, make sure that the unit is not

connected to main AC power.

CONFIGURATION OF THE CNC

CONNECTOR A6

PageChapter: 1 Section:

19

Page 45

1.3.3.1 MACHINE WITH "V" AXIS" AND HANDWHEEL OR SPINDLE

ENCODER

When using a "V" axis, machine parameter P616(4) must be set to "1". In this case, it is

possible to use connector A6 to connect the electronic handwheel or the spindle encoder;

but not both at the same time.

A1 A2 A3 A4 A5 A6

X Y Z W V S

X Y Z W V Handwheel

Machine parameter P800 must also be set with the corresponding value to indicate which

one of them is being connected.

1.3.3.2 WITHOUT "V AXIS" AND WITH ELECTRONIC HANDWHEEL

OR SPINDLE ENCODER

When the machine does not have a "V" axis, machine parameter P616(4) must be set to "0".

In this case, it is possible to connect the electronic handwheel or the spindle encoder or both

at the same time.

It is also possible to select the connector (A5 or A6) where each device is being

connected.

A1 A2 A3 A4 A5 A6

X Y Z W Handwheel S

X Y Z W S Handwheel

Page

20

CONFIGURATION OF THE CNC

Section:Chapter: 1

CONNECTOR A6

Page 46

1.3.4 RS232C CONNECTOR

9-pin SUB-D type female connector to connect the RS 232 C serial port.

The cable shield must be soldered to pin 1 at the CNC end and to the metallic housing at

the peripheral end.

PIN SIGNAL FUNCTION

1 FG Shield

2 TxD Transmit Data

3 RxD Receive Data

4 RTS Request To Send

5 CTS Clear To Send

6 DSR Data Send Ready

7 GND Ground

8 —- Not connected

9 DTR Data Terminal Ready

SUGGESTIONS FOR THE RS232C INTERFACE

* Connect/disconnect peripheral.

The CNC must be powered off when connecting or disconnecting any

peripheral through this connector.

* Cable length. EIA RS232C standards specify that the capacitance of the cable must

not exceed 2500pF; therefore, since average cables have a capacitance between 130pF

and 170pF per meter, the maximum length of the cable should not be greater than 15m

(49ft).

For greater distances, it is suggested to intercalate RS232C-to-RS422A signal converters

(and vice-versa). Contact the corresponding distributor.

Shielded cable with twisted-pair wires should be used to avoid communication

interference when using long cables.

Use shielded 7-conductor cable of 7*0.14mm² section.

* Transmission speed (baudrate). The baudrate normally used with peripherals is 9600

baud.

All unused wires should be grounded to avoid erroneous control and data signals.

* Ground connection. It is suggested to reference all control and data signals to the same

ground cable (pin 7 GND) thus, avoiding reference points at different voltages

especially in long cables.

CONFIGURATION OF THE CNC

RS232C CONNECTOR

PageChapter: 1 Section:

21

Page 47

RECOMMENDED CONNECTIONS FOR THE RS232C INTERFACE

* Complete connection

* Simplified connection

To be used when the peripheral or the computer meets one of the following requirements:

- It does not have the RTS signal.

- It is connected via DNC.

- The receiver can receive data at the selected baudrate.

Nevertheless, it is suggested to refer to the technical manuals of the peripheral

equipment in case there should be any discrepancy.

Page

22

CONFIGURATION OF THE CNC

RS232C CONNECTOR

Section:Chapter: 1

Page 48

CONFIGURATION OF THE CNC

RS232C CONNECTOR

PageChapter: 1 Section:

23

Page 49

1.3.5 RS485 CONNECTOR

---

Not connected

Impedance

107± 5% Ohm at 1 MHz.

It is a 9-pin SUB-D type female connector to connect the RS485 serial line.

This serial line is used to integrate the CNC into the FAGOR LOCAL AREA

NETWORK (LAN) in order to communicate with other FAGOR CNCs and PLCs

(FAGOR PLC 64).

PIN SIGNAL FUNCTION

1 --2 --3 TxD Transmit Data

4 --5 --6 --7 --8 TxD Transmit Data

9

Not connected

Not connected

Not connected

Not connected

Not connected

Not connected

Atention:

Do not manipulate the connectors with the unit connected to main AC

power

Before manipulating these connectors, make sure that the unit is not

connected to main AC power.

For better immunity of the RS485 serial line against conducted electromagnetic

disturbances, it is recommended to solder the cable mesh to the metal hood

of the connector.

1.3.5.1 RECOMMENDED CABLE FOR THE RS485

TECHNICAL CHARACTERISTICS

CABLE “TWINAXIAL”

SPECIFICATIONS

Conductor

Insulator

Shields

Covering

Type: