Fagor LA-11 TP2, LA-14 TP2, LA-18 TP2 Product information

WASHER

EXTRACTORS

LA-11-14-18

HIGH SPIN

—

G FORCE = 450 | 11 - 14 - 18 kg

MAXIMUM EFFECTIVENESS,

ENERGY SAVING AND RESPECT FOR THE ENVIRONMENT

· G Force = 450.

· Drum and jacket in AISI-304

stainless steel.

· Unit exterior manufactured in

sandwich board, colour grey,

stainless steel appearance,

easy to clean, and which does

not reflect fingerprints.

· Detergent tray with 4 compartments.

· 8 signals for automatic liquid dosing,

programmable in time and delay.

6 extra signals available optionally.

· 3 standard water inlets.

· Variable-frequency drive (standard 5060 Hz). Balancing system controlled by

the same drive.

· New second-generation TOUCH

PLUS programmer with 7” touch

screen in colour, 37 available

languages and which lets you create

an indefinite number of programs

(29 pre-set), as well as play videos.

· Allows programming, importing and

exporting of programs and software

updates via USB.

· Traceability as standard: the whole

wash process (temperatures, water

levels) is stored on the washer

and is extractable to a PC by USB

memory.

· The programmer includes the

characteristics to create any Wet

Cleaning program (modifiable water

levels and washing speed).

· EFFICIENT MIX. These machines

are equipped with an automatic

water mixer (mixing dif ferent water

temperatures) which provides

energy savings and reduces

washing times.

TOUCH

PLUS

CONTROL

CHARACTERISTICS

· BALANCE CONTROL.

Thanks to an advanced

technological development, and by

means of the inverter, the washers

detect the imbalance at an early

stage. This way the operation

is much smoother, elongating

components lifetime and reducing

washing times, thus saving energy

as well.

· MULTICHOICE INLET. All washers

are equipped with a third water inlet

as standard, which allows you to

save filling time, or which can be

used for decalcified water, ozone

or recycled water.

· WET CLEANING.

WET CLEANING. All washers

incorporate the necessary features

to use the WET CLEANING system

as standard, avoiding investment in

expensive applications to work with

this advanced washing concept.

This feature replaces most dr ycleaning washing systems, bringing

maximum reduction in costs.

· MAINTENANCE KARE. A simple

and reliable design with easy-toaccess mechanical parts that

combines perfectly with the use of

intelligent electronics.

All components have been

designed and manufactured with

top quality and prestige, focusing

on optimum accessibility for all

points and components key to

maintenance. Moreover, all the

controls have been developed

down to the finest detail:

complete technical menus, fault

self-diagnosis systems, alarms,

restricted access areas, etc.

EFFICIENT

MIX

BALANCE

CONTROL

MULTI-

CHOICE

INLET

—

· OPTIMIZED DRUM. This system

has been developed to improve

wash quality to the maximum and to

do it in as short a time as possible.

Through a series of perforations

in the paddles of the machine, a

water cascade effect is achieved

which increases the mechanical

action of the drum during operation

and greatly reduces the amount

of water needed for each wash.

The effective design of the drum

and tank with minimal spaces

between them, allows the energy

consumption necessary to heat the

water, as well as the superfluous

use of chemical products, to be

reduced.

· OPTIMAL CONSUMPTION.

All washers are equipped with an

efficient system by means of which

you can indicate the load which

is introduced in the machine. The

washer automatically adapts the

quantit y of water and chemicals to

be used for that load.

· “LOADING AID” system. Water

inlet and spin control for loading the

linen.

· The standard model can be

converted to self-service by installing

a pay station kit, coin mechanism kit

or other payment system. RS-485

communication.

· Washers compatible with water

recovery tanks.

· CE, WRAS and EAC product

certications. Optional ETL-certified

version of the machine.

WET

CLEANING

MAINT.

KARE

OPTIMIZED

DRUM

OPTIONS:

· Unit exterior in AISI-304

stainless steel.

· Front panels in AISI-304

stainless steel.

· Different levelling plinth kits to

level machines by total height

or by loading height (850 mm

between door base and floor).

· Double drain kit to recover the

water, with important savings.

· NC Option: drain normally

closed.

· Drain pump kit (11 and 14 kg).

· Levelling feet.

· Reversible door opening.

· Silicone seal for 11 and 14 kg

models.

· 6 extra signals for dosing.

· AUTO WEIGHT Automatic linen

weighing system. Up to 30%

savings. (Automatic adjustment

of water and soap consumptions

as well as energy savings,

according to the load inserted,

measured automatically by the

washer).

· Timed opening system.

· Printer.

· Marine electric versions for ships.

· Tropicalised models with

protective covering for the

electronics system.

· Shower system:

water recirculation for very

delicate linen (wet cleaning

complement).

OPTIMAL

CONSUMP.

AUTO

WEIGHT

FAGOR INDUSTRIAL S. COOP.

Santxolopetegi auzoa, 22

20560 Oñati, Gipuzkoa (Spain)

www.fagorindustrial.com

T. (+34) 943 71 80 30

info@fagorindustrial.com

LAUNDRY | WASHERS

TECHNICAL DATA

—

UNIT. LA-11 TP2 LA-14 TP2 LA-18 TP2

DRUM

Load capacity 1:9 / 1:10 kg 11/10 14/13 20/18

Volume Lit 100 130 180

Diameter mm 532 620 700

Depth mm 425 430 470

GENERAL DATA

Wash speed / Spin speed r.p.m. 50/ 1,231 50/ 1,138 47/ 1,071

G Force - 450 450 450

Maximum force transmitted kN 2.08 ±0.75 2.49 ±1.05 3.41 ±1.4

Dynamic force frequency Hz 16.7 16.7 16

Noise level dB 70 70 70

Self-service version - Ye s Yes Yes

Double drain - No Opt. Opt.

Weighing system - Opt. Opt. Opt.

DOOR

Height door centre / Height door base mm 630/370 700 / 440 765 / 450

Diameter mm 373 373 460

POWER

Motor kW 0.75 1.5 2.2

Heating electric mod. kW 6 9 12

Maximum electrical power kW 6.25 9.4 12.75

Maximum steam and hot water power kW 0.75 1.1 2.2

CONNECTIONS ELECTRIC STEAM / HOT WATER ELECTRIC STEAM / HOT WATER ELECTRIC STEAM / HOT WATER

Voltage 230V - I + N Nº x mm2 / A 3 x 4 / 32 A 3 x 1.5 / 6 A 3 x 10 / 50 A 3 x 1.5 / 10 A 3 x 16 / 63 A 3 x 1.5 / 10 A

Voltage 230V - III Nº x mm2 / A 4 x 2.5 / 20 A - 4 x 4 / 25 A - 4 x 6 / 40 A -

Voltage 400V - III + N Nº x mm2 / A 5 x 1.5 / 10 A - 5 x 1.5 / 16 A - 5 x 2.5 / 20 A -

Steam input (Steam mod.) inch 1/2” 1/2” 1/2”

Maximum steam consumption (Steam mod.)

Water inlet inch 3/4” 3/4” 3/4”

Grid pressure kg/cm

Maximum water consumption * Lit/h 71.4 88.8 118.3

Drain mm/inch 3” 3” 3”

Drainage capacity Lit/min 200 200 200

DIMENSIONS / DIMENSIONS WITH PACKAGING

Width / Width mm 692 / 730 788 / 830 884 / 930

Depth / Depth mm 788 / 1,000 869 / 1,010 913 / 1,030

Height / Height mm 1,185 / 1,417 1,307 / 1,560 1,415 / 1,700

Net weight / Gross weight kg 230 / 239 250 / 283 360 / 393

Gross volume (with packaging) m

kg/h 7 8.5 12

2

3

2-4 2-4 2-4

1.03 1.31 1.63

* Program n° 20, 75 % load.

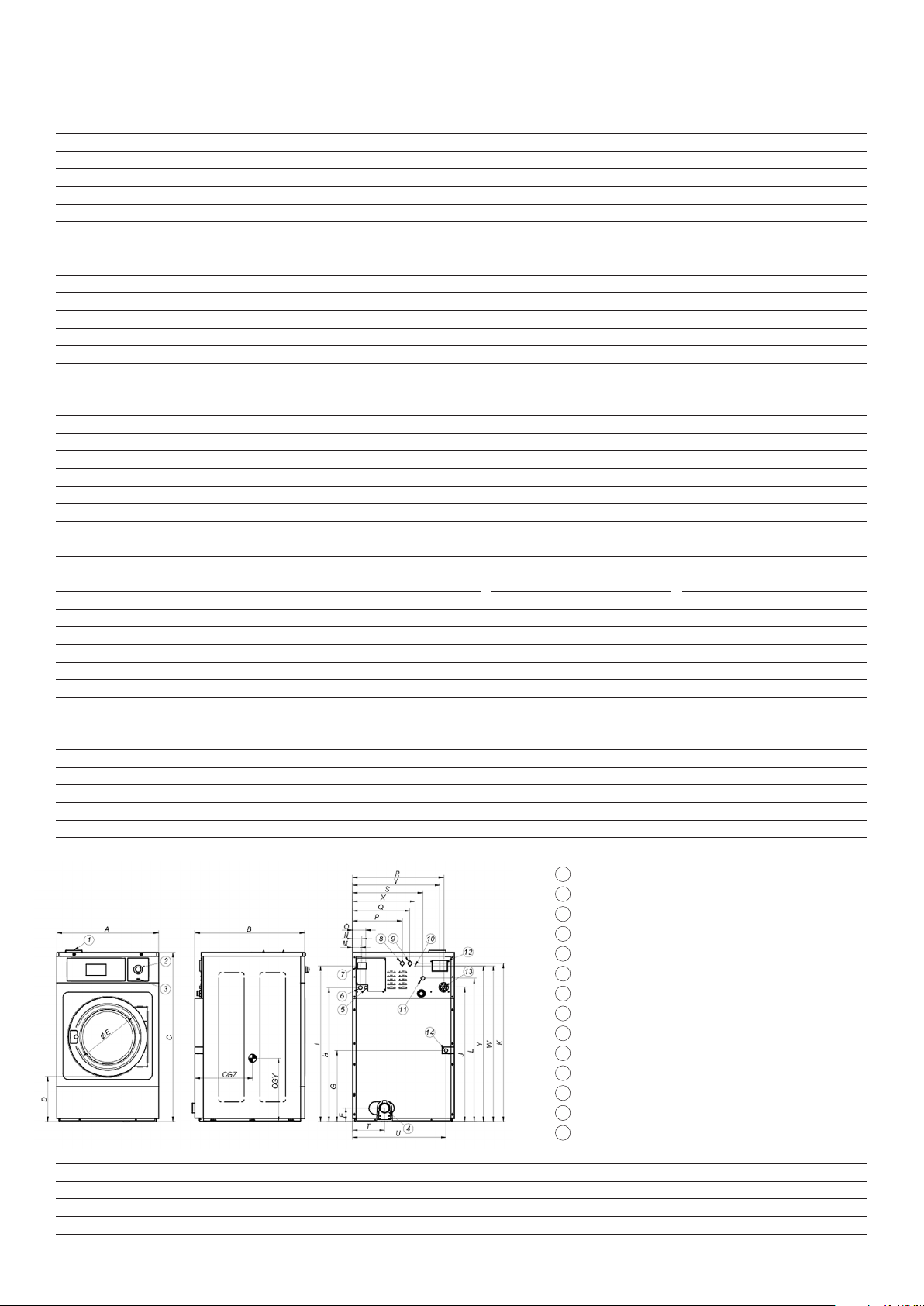

1

Soap dispenser.

2

Emergency stop.

3

USB port.

4

Drain.

5

Electrical connection to liquid soap pumps.

6

Electrical connection.

7

Main switch.

8

Auxiliary water inlet.

9

Hot water inlet.

10

Earth connection.

11

Cold water inlet.

12

Water overow.

13

Connection for liquid soap.

14

Steam connection.

A B C D E F G H I J K L M N O P Q R S T U V W X Y CGY CGZ

LA-11 TP2

LA-14 TP2

LA-18 TP2 884 913 1,415 450 460 95 380 1,135 1,303 1,138 1,322 1,207 61 74 101 429 509 802 640 348 814 772 1,303 569 1,297 464 702

692 788 1,185 370 373 125 354 913 1,085 916 1,100 985 61 74 101 316 371 610 448 226 626

788 869 1,307 440 373 243 385 1,034 1,202 1,037 1,221 1,106 61 74 101 385 445 706 544 243 718

580 1,080 461 1,145 424 577

676 1,202 485 1,201 450 651

Loading...

Loading...