Page 1

N51J015F1-00

USER INSTRUCTIONS

AND

TECHNICAL INSTRUCTIONS

FE-24E // FE-27E

TTo Domestic Hot W

o Domestic Hot W

ater:

ater:

FE-24E

Minimum 7.6 kW (25,932.26 Btu/h)

Maximum 23.7 kW (80,867.71 Btu/h)

FE-27E

Minimum 7.8 kW (26,614.69Btu/h)

Maximum 27 kW (92,127.78Btu/h)

T

T

o Central Heating:

o Central Heating:

FE-24E

Minimum 7.6 kW (25,932.26 Btu/h)

Maximum 23.7 kW (80,867.71 Btu/h)

FE-27E

Minimum 7.8 kW (26,614.69 Btu/h)

Maximum 27 kW (92,127.78 Btu/h)

BOILER OUTPUT

BOILER OUTPUT

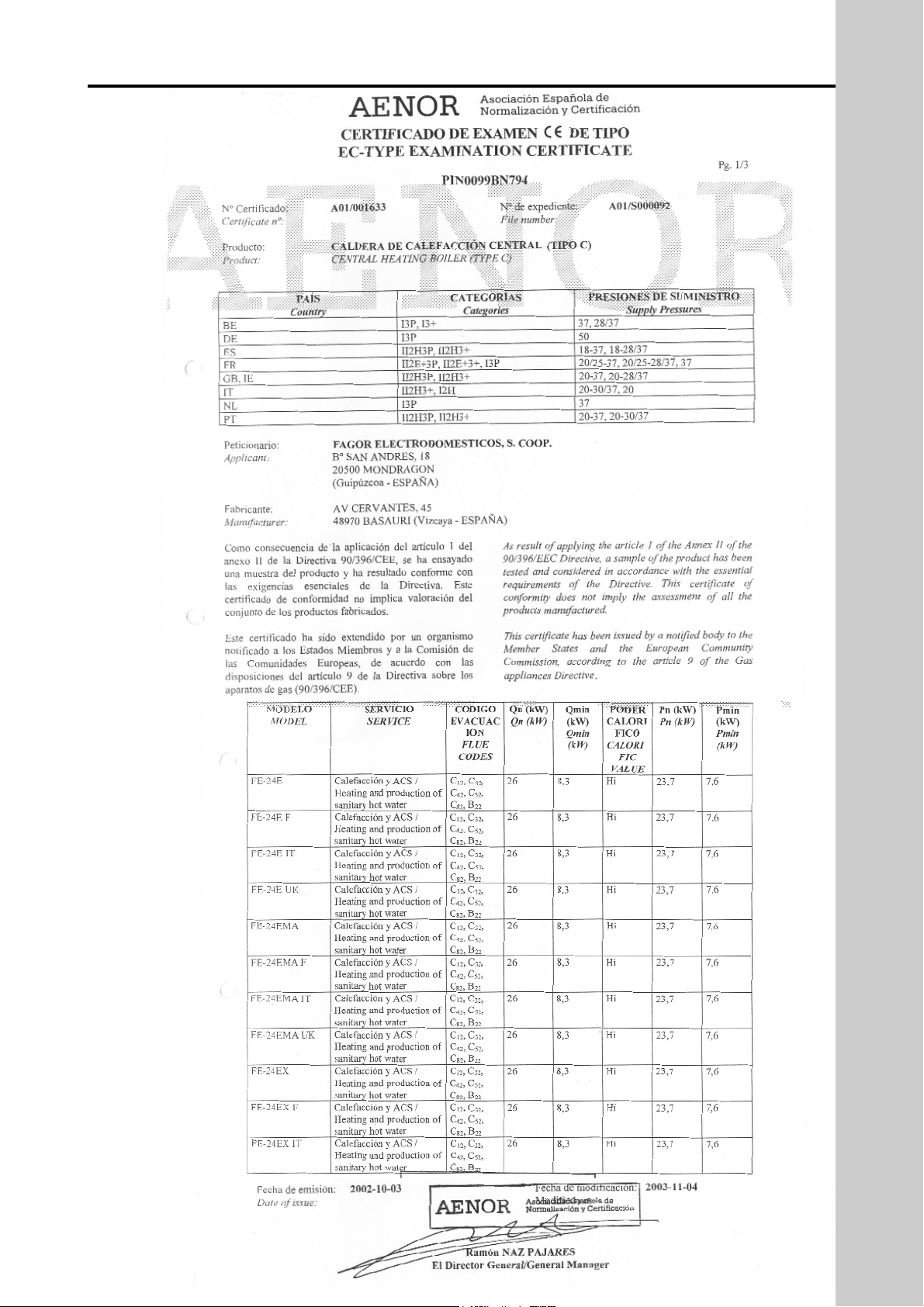

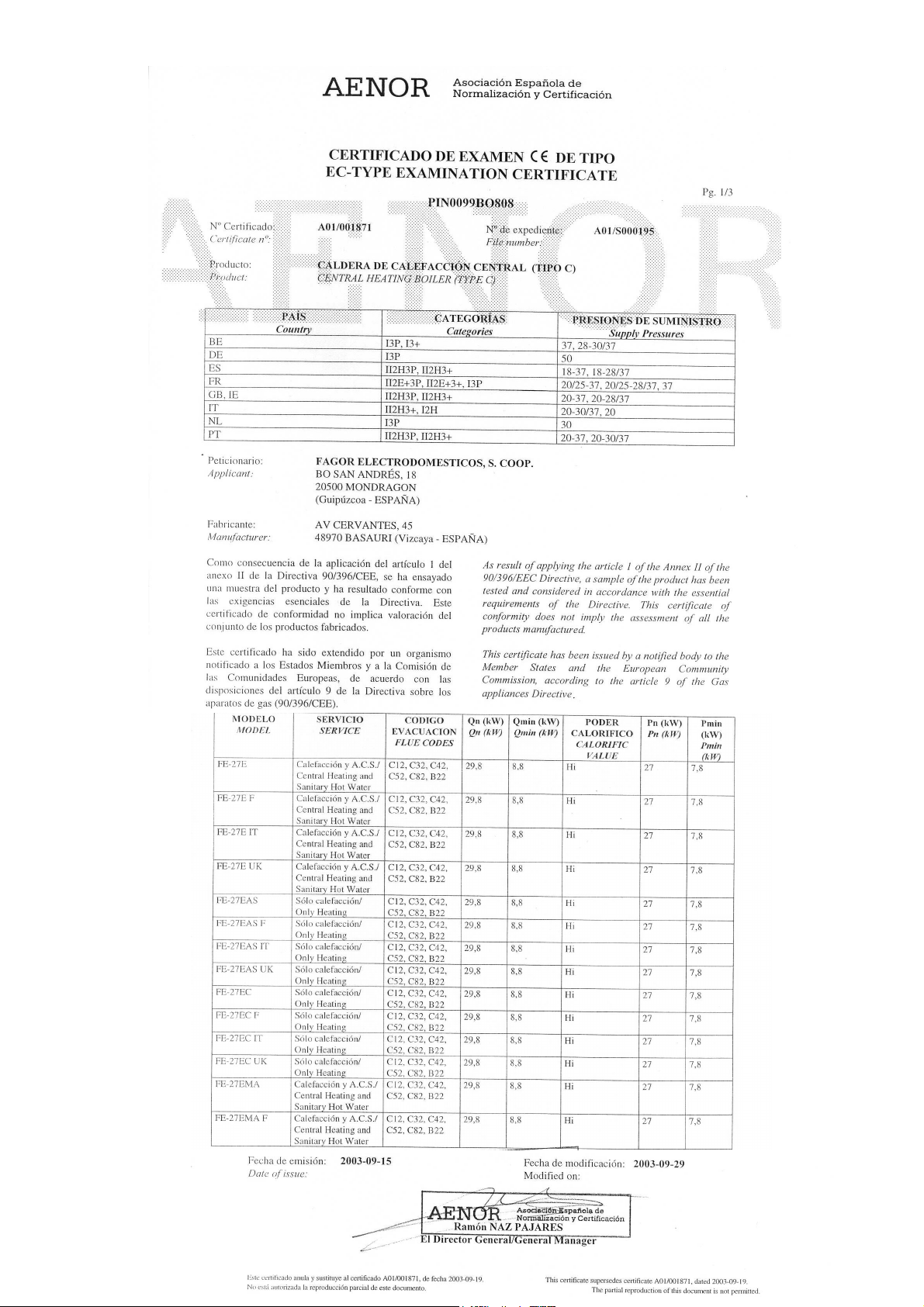

EC-TYPE EXAMINATION CERTIFICATE

PIN0099BN794 (FE-24E)

PIN0099BO808 (FE-27E)

Page 2

2

The compliance with a British Standard does not, of itself, confer immunity from legal obligations. In particular the installation of this appliance must be in accordance with the relevant requirements of the Gas

Safety(Installation and Use) Regulations 1984 as amended, current IEE Wiring Regulations, local Building

Regulations, Building Standards (Scotland)(Consolidation) and byelaws of the local Water Company. Health

and Safety Document No. 635 (Electricity at Work Regulation). It should in accordance with the relevant recommendations of the following British Standards.

BS 6798:1987 Specifications for installation of gas fired hot water boilers of rated input not exceeding 60 kW

BS 5449:1990 Central Heating for Domestic Premises.

BS 5546:1990 Installation for gas hot water supplies for domestic purposes.

BS 5440:1990 Flues and Ventilation for gas appliances of rated input not exceeding 60 kW: Flues.

BS 5440:1990 Flues and Ventilation for gas appliances of rated input not exceeding 60 kW: Air Supply.

BS 6891:1988 Installation of low pressure gas pipework installations up to 28 mm (R1)

To ensure that the installation will perform to the highest standards, the system and components should conform to any other relevant British Standards in addition to those mentioned in the instructions.

The appliance is not suitable for external installation.

Page 3

USER INDEX

Pág.

1.- CONTROL PANEL 4

2.- PREPARING THE BOILER FOR SERVICE 4

3.- USER INSTRUCTIONS 5

4.- MAINTENANCE 5

5.- PRECAUTION AGAINST FREEZING 6

6.- ANTI PUMP SEIZURE DEVICE 6

7.- FAULT CODES 6

INSTALLER INDEX

8.- HOMOLOGATION CERTIFICATE 7

9.- DESCRIPTION OF THE APPLIANCE 8

*Principal components 8

*Operation and safety controls 8

10.-TECHNICAL DATA 9

11.-FUNCTIONAL DIAGRAMS 10

*Gas and water system 10

*Electrical circuit diagrams 10

12.-DIMENSIONS AND CONNECTION DETAILS 11

13.-HYDRAULIC SYSTEM CHARACTERISTICS 11

*Domestic hot water 11

*Central heating 11

14.-INSTALLATION OF THE BOILER 12

15.-Ø 60-100 mm HORIZONTAL CONCENTRIC COMBUSTION PRODUCT EXTRACTION AND

AIR INTAKE 13

16.-Ø 80-125 mm HORIZONTAL CONCENTRIC COMBUSTION PRODUCT EXTRACTION AND

AIR INTAKE 14

17.-Ø 80 mmTWIN-PIPE COMBUSTION PRODUCT EXTRACTION AND AIR INTAKE 15

18.-80-125 mm VERTICAL CONCENTRIC COMBUSTION PRODUCT EXTRACTION AND AIR

INTAKE. 16

19.-ELECTRICAL CONNECTIONS 17

*Connection of a room thermostat (optional) 17

20.-CONTROL PANEL 17

21.-PREPARING THE BOILER FOR SERVICE 18

22.- USER INSTRUCTIONS 18

23.-MAINTENANCE 19

24.-PRECAUTION AGAINST FREEZING 20

25.-ANTI PUMP SEIZURE DEVICE 20

26.-GAS CHANGE 21

27.-FAULT CODES 22

28.-FAULT FINDING 23

Page 4

4

2.- COMMISSIONING THE BOILER

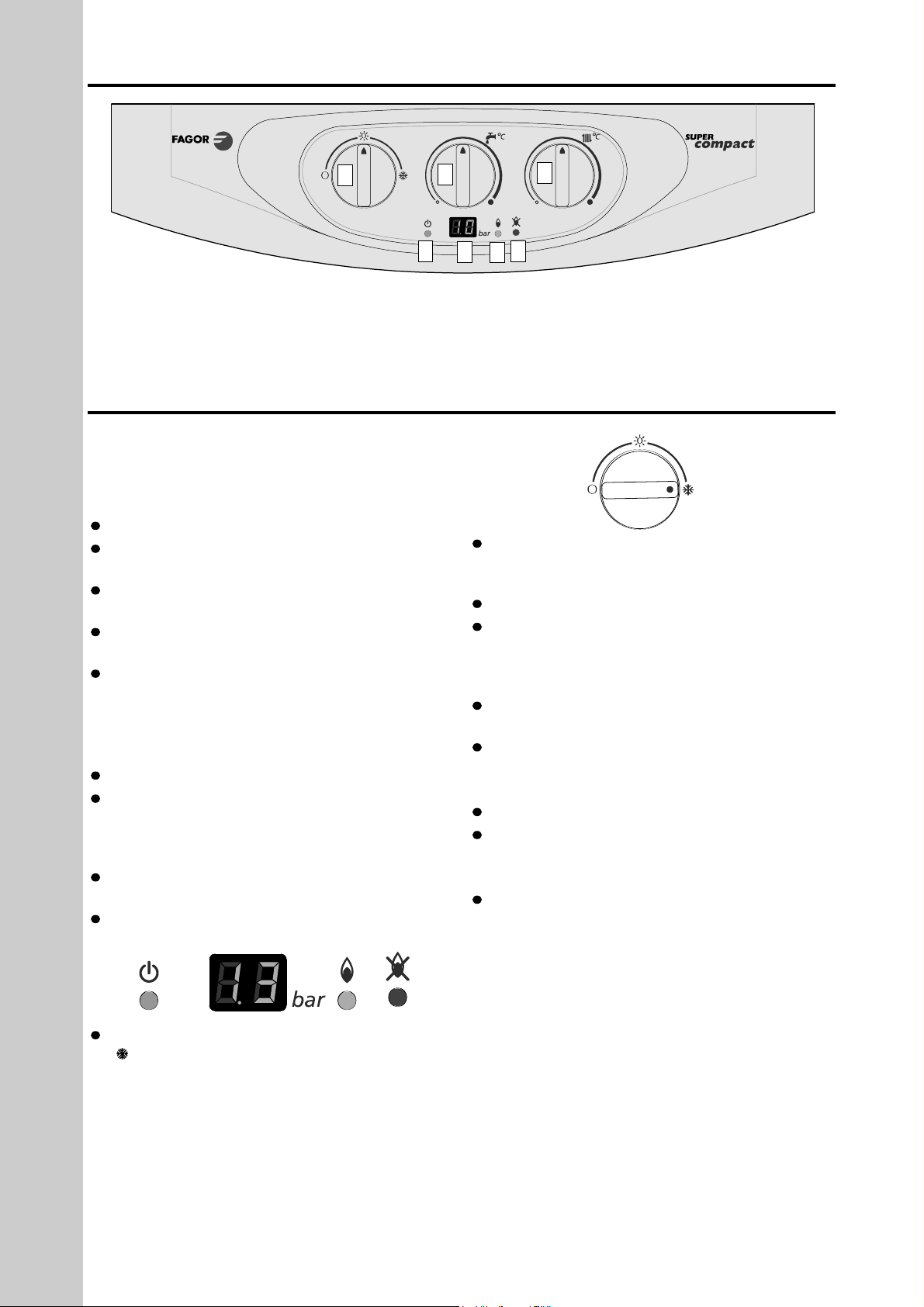

1.- CONTROL PANEL

USER

FE-24E

5

6

7

1

2

3

4

1.- Digital Display

2.- Heating temperature selector

3.- D.H.W temperature selector

4.- Main control switch and reset

5.- Boiler ON indicator light

6.- Burner on indicator light

7.- Reset indicator light

Connect the boiler to a 230V ~50 Hz mains supply.

VERY IMPORTANT: before turning the boiler on

make sure that the installation has been filled.

Domestic hot water

Turn on the cold water stopcock beneath the boiler.

Fill the unit by turning on the various hot water taps

in the installation.

Make sure that the assembly is completely airtight

and watertight.

The installation of a scale reducer/water softener is

recommended in hard water areas

To increase the hot water temperature, reduce the

flow of water at the hot water tap. This may be necessary in winter months.

Central heating system

The correct installation is to be carried out as follows:

Open the radiator air vents.

With the stopcock on and domestic cold water

going through to the boiler, fill the central heating system by opening the filling tap provided by your

installer.

Close the air vents off once water starts coming out

of each of them.

Close the filling tap when the pressure gauge

exceeds the pressure of 1.3 bar. Max = 1.5 bar.

By turning the main control switch to the winter setting . When the pump works the pressure in the digital display increases.

Vent the central heating system once more. Then

let the pressure in the system settle at 1.3 bar. Max =

1.5 bar..

Make sure that there are no leaks in the installation.

Make sure that the heating system is completely

full and vented. The pressure gauge should show

between 1.3 and 1.5 bar with cold water in the heating system.

Make sure that the boiler is wired to the correct volt-

age.

Make sure that the combustion flue outlet is not

restricted.

Gas circuit

Turn on the gas stopcock to the installation.

Check that the whole gas circuit and gas connec-

tions to the boiler are airtight.

Settings

Before leaving the factory the boiler is pre-set in

accordance with the information on the adhesive data

plate, and therefore needs no further adjustment.

Should the type of gas need to be changed, check

with the corresponding section.

Page 5

5

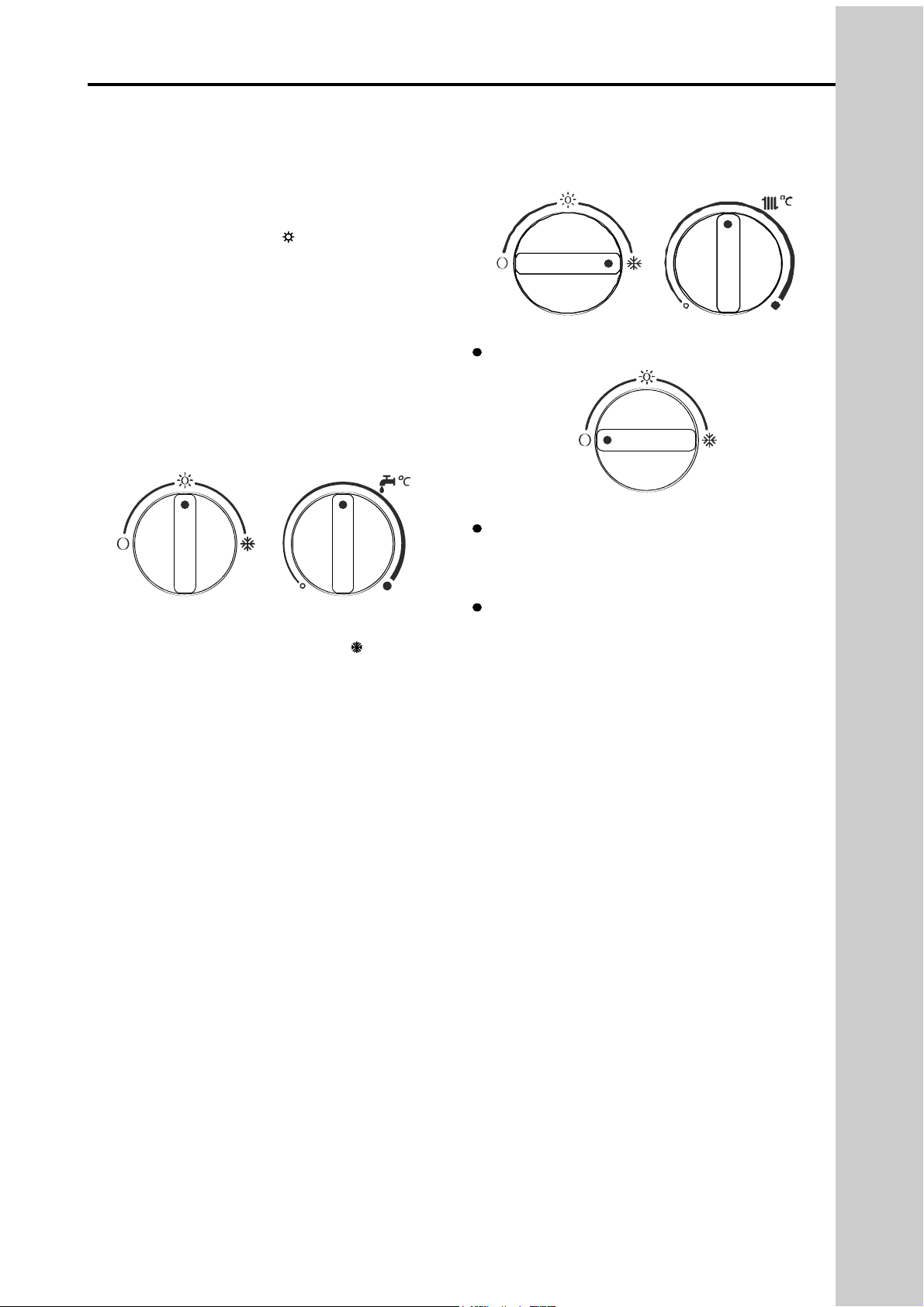

3.- USERS INSTRUCTIONS

Domestic hot water service.

Turn the main control switch in the summer setting in

order to turn the boiler on , see the figure below

(the green light turns on). At that moment the boiler

will be ready to supply domestic hot water whenever

there is a demand for it.

When you turn on any of the hot taps the boiler will

automatically come on with the pilot light switching on

first of all followed by the burner. A water temperature

of between 35° and 60° C can be selected by turning

the domestic hot water temperature regulating knob.

When the D.H.W. temperature regulating knob is

turned the digital display will show the values of the

temperature.

Hot water and central heating service.

Turn the switch to the winter setting . The burner

will automatically fire up if the clock and/or the roomthermostat are calling for heat. A temperature of

between 60° and 85° C can be selected by turning

the heating temperature regulating knob. This will

stay on until it achieves the temperature selected

either in the room thermostat or in the boiler itself.

Whenever domestic hot water is required when it is at

the central heating setting, the boiler is designed to

give priority to the supply of domestic hot water, with

the central heating on hold, until the demand for

domestic hot water ceases. When the D.H.W. temperature regulating knob is turned the digital display

will show the values of the temperature.

Switching off the boiler.

Turn the main switch to the setting O.

Reset of the boiler.

This unit has a built-in reset indicator. Whenever

any fault is detected in the ignition process, the boiler goes to lock out and the reset indicator switches

on and the fault code is shown in the display.

To reset the boiler turn the main switch to position

O. The reset indicator should then turn off.

When the system pressure either falls down to 0.6

bar or goes over 2.8 bar, the display will shown F-3.

It needs to fill it up to 1.3-1.5 bar (when system cold).

IMPORTANT: If the boiler has not been used for a

length of time, or a new gas bottle is connected, the

unit could lock out due to the presence of air in the

pipes. Should this happen, the ignition procedure

should be repeated until the gas circuit is cleared of

all air in the gas supply.

USER

Check the gas connections and make sure that the gas is coming into the boiler (that the gas tap is open)

Make sure that the heating system is completely full and vented. The pressure gauge should show between

1.3 and 1.5 bar with cold water in the heating system.

Make sure that the electricity supply to the boiler is switched on.

Page 6

6

4.- FROST PROTECTION

5.- ANTI PUM SEIZURE DEVICE

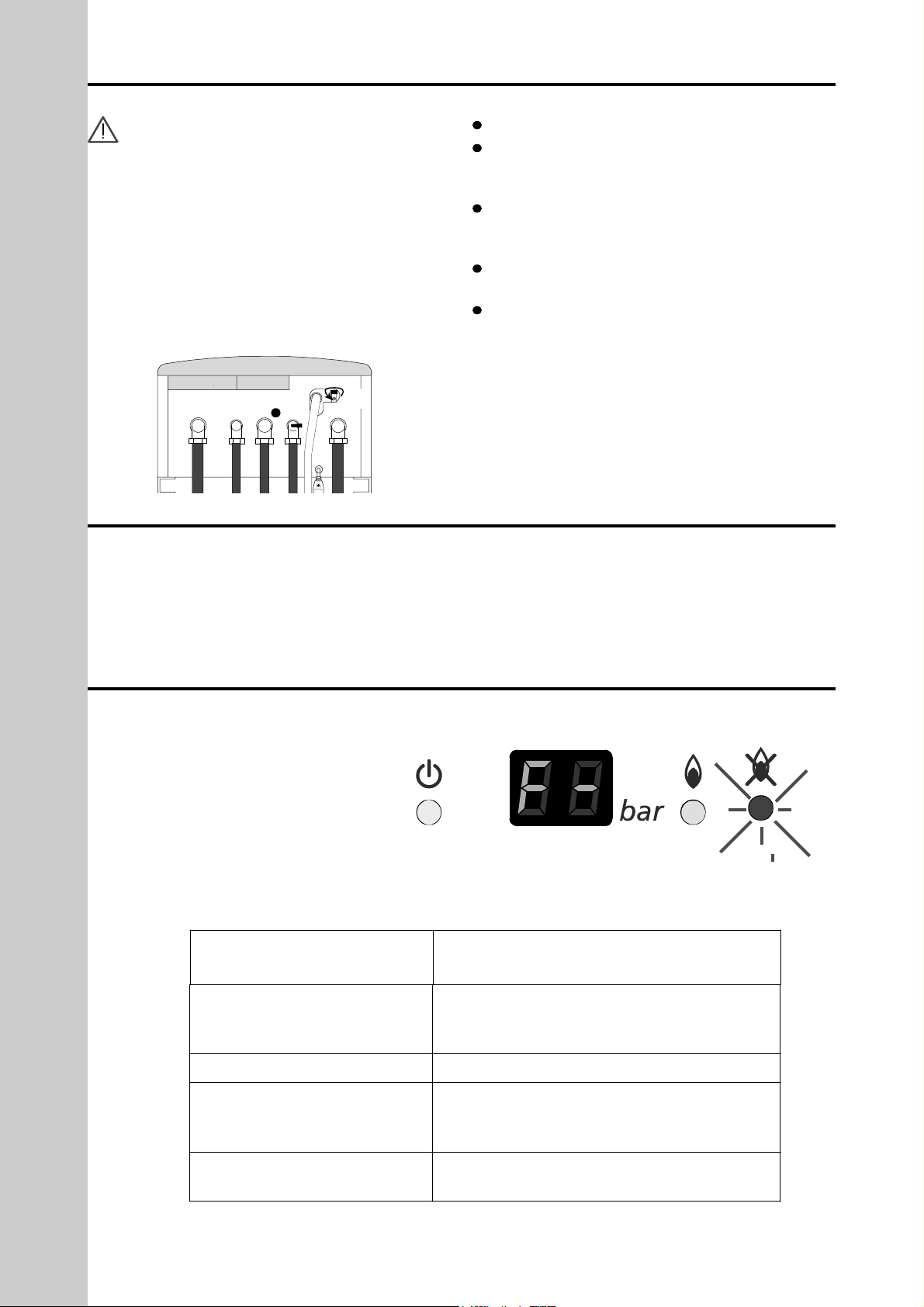

6.- FAULT CODES

Should a fault develop within the boiler

(diagnostic), the P.C.B. will diagnose the

possible cause via the reset indicator light

(Red Neon) and the digital display. The

fault will be shown in the display.

Each fault code begins with an “F” followed by a number. Ranging from 1 - 13.

To reset the fault use the reset switch (4)

(see Control Panel page 4)

The boiler has an frost protection security system.

IMPORTANT: the boiler must be electrically

supplied and gas connected for this to operate.

Frost protection

When the heating thermistor detects a temperature of

6ºC, only the pump will switch and will continue to run

until a temperature of 9ºC is obtained.

If the temperature drops to 3ºC, the boiler will start on

minimum power until the temperature of 20ºC is

obtained.

NOTE: If the boiler is not to be used for a long period drain the heating installation using the valve (Z)

beneath the boiler and the D.H.W. installation.

The D.H.W circuit must be drained down as follows:

Turn off the cold water supply.

Open all the hot water outlet taps in the installation

(at least one tap should be found at a level lower than

the boiler).

Release the tap to drain the flow switch to allow air

to come in and for the stored water in the boiler to be

able to leave.(see figure)

When the operation is finished, close the hot water

outlet taps and the draining tap.

To put the boiler back into service, open the cold

water inlet tap.

When the boiler is not being used, the pump will automatically run for one minute every 24 hours to prevent seizure. TO ENSURE OPERATION OF THIS

DEVICE ELECTRICAL SUPPLIES MUST BE ON.

If the pump jammed when the appliance is turned

back on, consult your installer or service engineer.

USER

Z

NUMBER OF 1 SEC

‘FLASHES’

FAULT

1

Lack of gas or ignition problems; Flame

supervision failure

Burner on but flame Indicator Off; H L

2

Air Pressure Switch Failure

3

If the central heating pressure drops

below 0.6 bar or gets above 2.8 bar ,

the boiler goes to lock out

4

The overheat thermostat blocks out the

boiler

Page 7

7.- CERTIFICATE

INSTALLER

Page 8

Page 9

9

The FE-24E and the FE-27E are a wall hung, room

sealed, fan assisted, microprocessor controlled fully

modulating gas combination boilers for providing

both central heating and domestic hot water.

1.- Casing

2.- Air pressure switch

3.- Fan

4.- High limit stat

5.- Copper heat exchanger

6.- Expansion vessel

7.- Combustion chamber

8.- Flame sensing electrode

9.- Ignition electrodes

10.- Circulation Pump with Automatic Air Vent

11.- Modulating gas valve

12.- Low water pressure sensor

13.- Plate heat exchanger

14.- Compact hydraulic group including 3 way valve

15.- Printed Circuit Board (PCB)

16.- Control panel

Principal Components

HEAT EXCHANGER copper.

BURNER stainless steel.

MODULATING GAS VALVE with double safety

valves.

PLATE HEAT EXCHANGER stainless steel

(D.H.W.).

THREE-WAY VALVE part of the compact hydraulic

group.

CIRCULATION PUMP with automatic air vent and

speed selector.

EXPANSION VESSEL, on right hand side of the

boiler.

FAN for the extraction of combustion products and

induction of combustion air.

Operation and Safety Controls

THERMISTORS (NTC) There are two thermistors

fitted for automatic control of the domestic hot water

and the central heating flow temperature.

OVERHEAT THERMOSTAT for the boiler's protec-

tion against overheating (closes the gas valve).

PRESSURE RELIEF VALVE opens at 3.5 bar. Must

be terminated externally in a downward direction

ELECTRONIC CONTROL CARD allows amongst

others, the following:

- Temperature selection for central heating from 60

to 85°C.

- Temperature selection for domestic hot water from

35 to 60°C.

- Flame control

- Continuous modulation of the gas valve.

- Ignition control

- Frost protection in the central heating circuit.

- Seizure of the pump.

AIR PRESSURE SWITCH. Prevents the boiler fir-

ing if there is insufficient air supply due to a fault or

blockage.

FLAME SENSING ELECTRODE, controls the

flame in the burner.

LOW WATER PRESSURE SENSOR, prevents the

boiler operating with insufficient circuit pressure and

when the pump is not working.

8.- DESCRIPTION OF THE APPLIANCE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Page 10

10

9.- TECHNICAL DATA

Models

FE-24E

FE-27E

Category

II

2H3P

Type

C12,C32,C42,C52,C82,B

22

kW

23.7

27

Maximum output

kcal/h

20,382

23,220

kW

7,6

7.8

Central heating performances

Minimum output

kcal/h

6,536

6,708

kW

23.7

27

Maximum output

kcal/h

20,382

23,220

kW

7.6

7.8

Domestic hot water performances

Minimum output

kcal/h

6,536

6,708

Domestic hot water flow 25ºC increase (l/min)

13.6

15.48

Domestic hot water flow rate (l/min)

10

(34ºC i ncrease)

13

(29,76ºC increase)

Minimum flow rate for activating D.H.W. (l/min)

2

Maximum

Central hea ting

3

Maximum

D.H.W.

10

Operating pressure (bar)

Minimum D.H.W. activation

0,3

Expansion vessel capacity (L)

7

Central heating circuit

60-85

Temperature selection range (ºC)

D.H.W. circuit

35-60

Natural G20

20

Gas inlet pressure (mbar)

Propane G31

37

Natural G20 (m3/h)

2.78

3.19

Gas consumption (Hi)

Propane G31 (kg/h)

2.1

2.41

Electrical suplly (V/Hz)

230V∼50 Hz

Max power consumption (W)

120

120

Height

680

Width

390

Dimensions (mm)

Depth

250

Gas Inlet

¾”/ Ø18

Domestic cold water Inlet

½”/ Ø15

Domestic hot water Outlet

½”/ Ø15

Central heating Flow

¾”/ Ø22

Connections / Interior Ø in (mm)

Central heating return

¾”/ Ø22

Flue gas exit temperature (ºC)

140

Net weight (kg)

29

Natural G20

X

Gas type

Propane G31

X

CE type examination certificate

99BN794

99BO808

NOx (according to prNE 483)

3

2

Page 11

11

Schematic diagram- Hydraulic

circuit

1.- Expansion vessel

2.- Pump with Automatic air

bleed

3.- Low water pressure sensor

4.- Central heating thermistor

5.- Three way valve

6.- Overheat thermostat

7.- Air pressure switch

8.- Venturi

9.- Fan

10.- Sealed air box

11.- Copper heat exchanger

12.- Combustion chamber

13.- Ignition electrode

14.- Burner

15.- Flame sensing electrode

16.- Modulating gas valve

17.- Gas inlet

18.- D.H.W Thermistor

19.- Hot Water outlet

20.- Plate heat exchanger

21.- C.H flow

23.- Cold water inlet

24.- C.H return

25.- Pressure relief valve

26.- Automatic By-pass

27.- Expansion vessel valve

28.- Draining valve

17

S3

P3

P2

P1

FIL

2

3

1

5

6

78

101112

13

15

16

21

S1

S2

S4

22

2

1

3

4

5

J10

J9

J8

J11

J4

J6

J1

J5

J19

J12

J2

4

23

9

Electrical Circuit Diagrams.

1.- Surge arrestor

2.- Mains connection

3.- Earth

4.- Fan

5.- Pump

6.- Ignition

7.- Burner solenoid valve 1

8.- Burner solenoid valve 2

9.- Front panel control

10.- 3 way valve

11.- Air pressure switch

12.- Room stat (optional)

13.- Connector bipolar

15.- Modulating solenoid valve

16.- Flame sensor

17.- High limit stat

21.- Hot water thermistor

22.- Central heating thermistor

23.- Pressure switch

S4 Gas change bridge. Made-

Propane. Break- Nat. Gas

P1 Maximum power adjustment

P2 Minimum Lighting pressure

P3 Output for central heating adjust-

ment

10.- FUNCTIONAL DIAGRAMS

1

3

4

7

5

6

8

9

10

11

12

13

14

15

16

17

18

19

20

21

23

24

25

26

27

28

2

Page 12

12

11.- DIMENSIONS AND CONNECTION DETAILS

390

25

60

65

128

85.5

651

72

58

58

65

72

Ø100

65

100

250

705.8

146

GAZ

GAS

195

680

6 5 4 3 1

6

5 4

3

1

8

7

2

9

50

100

1.- 3/4” BSP Central heating return

2.- Mains cable

3.-1/2” BSP Domestic cold water inlet

4.- 3/4” BSP Gas inlet

5.- 1/2” BSP D.H.W. outlet

6.- 3/4” BSP Central heating flow

8.- Pressure Relief Valve

9.- Draining valve

T.A.:Room thermostat connection

12.- HYDRAULIC SYSTEM CHARACTERISTICS

Domestic Hot Water

The boiler is controlled by a microprocessor giving

immediate response.

The diagram for the D.H.W temperature at the outlet

as a function of the water flow for an input of cold

water at 15° C is as follows

Central Heating

The boiler is supplied with a circulation pump whose

operational graph is as follows:

The capacity of the heating installation as a function

of the temperature is as follows:

Manual Filling and Make Up

Provision should be made to fill and replace water

lost from the system. A double check valve assembly

must be used as shown below.

Filling of the system must be carried out in a manner

approved by the local water undertaking. Where

allowed, the system may be filled via a temporary

connections shown in Figure above.

4

35

30

25

20

213

60

55

40

50

45

7651110981412 13

35 °C

10 l/min

60 °C

2.42 l/min

35 °C

5.45 l/min

60 °C

7.55 l/min

49 °C

10 l/min

COLD WATER INLET TEMPERATURE =15ºC

FLOW D.H.W. (l/min)

50 100 150 200 250

1

1,2

1,4

1,6

1,8

2,0

2,2

P

C

85º C

75º C

60º C

P: Cold pressure (bar)

C: System capacity (litres)

T.A.

CENTRAL

HEATING

RETURN

STOP

VALV E

DOBLE

CHECK

VALV E

ASSEMBLY

AIR

INLET

VALV E

HOSE

UNIONS

TEMPORARY

HOSE

STOP

VALV E

MAIN

WATER

SUPPLY

4

35

30

25

20

213

60

55

40

50

45

7651110981412 13

60 °C

2.5 l/min

35 °C

5.6 l/min

60 °C

8.6 l/min

44.7 °C

13 l/min

35 °C

13 l/min

COLD WATER INLET TEMPERATURE =15ºC

FLOW D.H.W. (l/min)

0

100

200

300

400

500

0 200 400 600 800 1000

0

100

200

300

400

500

600

0 200 400 600 800 1000

Pressure (mbar)

Pressure (mbar)

Flow (l/h)

by-pass open

by-pass closed

Flow (l/h)

Page 13

13

13.- INSTALLATION OF THE BOILER

The installation must only be carried out by specialised companies, which are qualified to do so,

adhering to the technical instructions and keeping to

all current regulations governing the installation.

See page 1 “Installation regulations”

The installer must also comply with all local regulations, which may be in force.

The boilers are supplied in different packagings:

- Boiler

- Flue system (separate packaging)

The following are the parts, which are supplied with

the boiler:

- paper installation template

- wall bracket

- 3 plastic screw plugs

- 3 screws

- 3 brass bend pipes ¾" with bicone(central heating

and gas)

- 1 brass bend pipes ½" with bicone (D.H.W.)

- Domestic Cold Water inlet stopcock ½" with

bicone

- 5 joints

- Restrictor ring

- Central heating inlet filter

The following are the instructions for the correct

installation of the unit.

The installation must be carried out by specialised

companies, which are qualified to do so, adhering to

the technical instructions and keeping to all current

regulations governing the installation.

The installer must also comply with all local regulations, which may be in force.

Boiler Location

- The boilers are not suitable for external installation.

The boiler must be mounted on a noncombustible flat

wall sufficiently robust to take the weight of the boiler- see technical data (page 10). If the wall is of combustible material, it should be protected by a sheet of

fireproof material.

- If the boiler is to be installed in a timber framed

building, refer to the British gas publication “Guide for

Gas Installation in timber framed housing”reference

DM2.

- Installation may be in any room, although particular attention is drawn to the requirements of the current IEE Wiring Regulations and, in Scotland, the

Electrical Provision of the Building Regulations applicable in Scotland, with respect to the installation of

the boiler in a room containing a bath or shower.

- Where a room sealed boiler is installed in a room

containing a bath or shower, it must not be possible

for a person entering or using the bath or shower to

touch any electrical switch or boiler control using

mains electricity.

- Air supply: the room or compartment in which the

boiler is installed does not require a purpose provided vent when using the standard concentric flue.

- No combustible surface must be within 70 mm of

the boiler case, this includes any cupboard door.

Gas supply: (Natural gas) minimum=22 mm within 2

meters of gas valve for correct pressure see page 22,

chart 1.

Required clearances (minimum):

- 5 mm left hand side

- 5 mm right hand side

- 240 mm bottom of the boiler

- 130 mm top of the boiler

- 50 mm front of the boiler

Total access as per the dimensions above, are

required for service and/or repairs.

A tube descending frame (code 988010914) and a

cover plate (code 988010950) are available as

options.

Sitting the flue terminal fan flue room sealed

Detailed recommendations for flueing are given in

BS5440 Part 1: The following notes are intended to

give general guidance. The boiler must be installed

so that the flue terminal is exposed to external air.

The boiler must NOT be installed so that the terminal

discharge into another room or space such as an

outhouse, leanto or roof space. It is important that the

position of the terminal outlet allows a free passage

of air cross all times. the minimum acceptable spacings from the terminal to obstructions and ventilation

openings are specified below.

Terminal Position Min. Spacing

1. Directly below an openable window 300mm (12”)

air vent or any other ventilation opening

2. Below guttering, drain pipes or soil pipes 75mm (3”)

3. Below balconies or eaves 200mm (8”)

4. Above adjacent ground or balcony 300mm (12”)

5. From vertical drain pipes or soil pipes 75mm (3”)

6. From internal or external corners 300mm (12”)

7. From a surface facing the terminal 600mm (24”)

8. From a terminal facing a terminal 1200mm (48”)

9. From site of window 300mm (12”)

Note: the flue can be extended to clear a projection.

Where the terminal is fitted within 850mm (34”) of a

plastic or painted eaves, an aluminium shield of at

least 750mm (30”) long should be fitted to the underside of the gutter or painted surface. Where the lowest part of a terminal is less than 2m (6.5’) above a

balcony, above ground level or above a flat roof or

place to which any person has access, the terminal

must be protected by a guard of durable material.

The air inlet/combustion outlet pipe and the terminal

of the appliance must not be closer than 50mm (2”)

to any combustible material. Detailed recommendations on the protection of combustible material are

given in BS5440 Part 1: 1978 (Sub clause 20:1)

Page 14

14

14.- Ø 60-100 MM HORIZONTAL CONCENTRIC COMBUSTION PRODUCT EXTRACTION AND AIR INTAKE

The boiler comes supplied with the Ø 60-100 mm

concentric flue kit.

The extraction of the combustion products and the air

intake is carried out by means of Ø 60 mm concentric

pipes for the extraction of the combustion products

and Ø 100 mm pipes for the intake of air.

The maximum length of the combustion and intake

pipes which may be used with the boiler is 4 meters,

measured from the 90° bend. Each 90° bend, or two

45° bends, reduces the available length by 1 m. (See

installation examples).

It is recommendable to fit the pipe at a slight 2° or 3°

downward incline to prevent any water or condensation from entering in the boiler.

IMPORTANT: Use the flue restrictors ( Ø 80mm

with FE-24E and 2 flue restrictors Ø 85 and 50 mm

with FE-27E) when the length of the pipes is

equal or lower than 1 meter (this flue restrictor is

supplied with the boiler).

INSTALLATION EXAMPLES

Max. length =4 m

>0,1 m

2 x 45° bends

1 x 90° bend

Max. length = 3 m

Max. length =3 m

L

50

90° Concentric bend Ø 60 - 100

Concentric flue kit Ø 60-100

Concentric Pipe Ø 60 - 100

L=0.5 m.

L=1 m.

Restrictor Ring

927

860

20

Ø60.8

15

25

25°

25

95

Ø 60.8

18

45

Ø 100

45

25

45° Concentric bend Ø 60 - 100

Page 15

15

15.- Ø 80-125 MM HORIZONTAL CONCENTRIC COMBUSTION PRODUCT EXTRACTION AND AIR INTAKE

The extraction of the combustion products and the air

intake is carried out by means of Ø 80 mm concentric

pipes for the extraction of the combustion products

and Ø 125 mm pipes for the intake of air do it with the

Ø80-125mm concentric flue kit.

The maximum length of the combustion and intake

pipes which may be used with the boiler is 10 meters,

measured from the 90° bend. Each 90° bend, or two

45° bends, reduces the available length by 1m. (See

installation examples).

It is recommendable to fit the pipe at a slight 2° or 3°

downward incline to prevent any water or condensation from entering in the boiler.

IMPORTANT: Use the flue restrictor ( Ø 80mm

with FE-24E and 2 flue restrictors Ø 85 and 50 mm

with FE-27E) when the length of the pipes is

equal or lower than 2 meter (this flue restrictor is

supplied with the boiler).

INSTALLATION EXAMPLES

Max. length = 10 m

Max. length = 9 m

Max. length = 9 m

2 x 45° bends

1 x 90° bend

>0,1 m

30

50

10

80Ø

125

Ø

Ø

125

80

Restrictor Ring

Ø

95

Ø

45°Concentric bend Ø 80-12590°Concentric bend Ø 80-125

Concentric flue kit Ø 80-125

180 mm

1000

50

35

1m. Concetric pipe Ø 80-125

Ø 80 MM TWIN-PIPE SYSTEM COMBUSTION PRODUCT EXTRACTION AND AIR

INTAKE:

Maximum length 40m . For further information contact Fagor

Page 16

16

16.- Ø 80-125 MM VERTICAL CONCENTRIC COMBUSTION PRODUCT EXTRACTION

AND AIR INTAKE

The extraction of the combustion products and the air

intake is carried out by means of Ø 80 mm concentric

pipes for the extraction of the combustion products

and Ø 125 mm pipes for the intake of air do it with the

Ø80-125mm vertical concentric flue kit.

The vertical maximum length of the combustion and

intake pipes which may be used with the boiler is 10

meters. Each 90° bend, or two 45° bends, reduces

the available length by 1m. (See installation examples).

It is recommendable to connect the condensing pipe

to prevent any water or condensation from entering in

the boiler.

IMPORTANT: Use the flue restrictor ( Ø 80mm

with FE-24E and 2 flue restrictors Ø 85 and 50 mm

with FE-27E) when the length of the pipes is

equal or lower than 2 meter (this flue restrictor is

supplied with the boiler).

1000

50

35

1m. Concentric pipe Ø 80-125

INSTALLATION EXAMPLES

Ø80

Ø125

Restrictor Ring

396

132.5

Ø

485

Ø 80

Ø 125

30

50

10

Ø

Ø

125

80

Vertical concentric flue kit Ø 80-125

45° Concentric bend Ø 80-125

90° Concentric bend Ø 80-125

Código 988010567

(15°-45°) Black slope tile Ø 125 adaptor

Black tile Ø 125 adaptor

Condensing pipe

2 x 45° bends

2 x 90° bend

Sloping

roof

Horizontal roof

Page 17

17

18.- CONTROL PANEL

FE-24E

5

6

7

1

2

3

4

C

17.- ELECTRICAL CONNECTIONS

General

(See section of the electrical diagram)

This appliance must be efficiently earthed. A mains

supply of 230V ~ 50Hz is required. It is provided with

a rigid feed wire and a bridge in the room stat connector, which should be removed if a room thermostat is connected.

All external wiring to the boiler must be in accordance

with the current Wiring Regulations.

IMPORTANT: Whenever you are working on

the electric wiring of the unit, make sure

that the boiler is disconnected.

Should the supply cable ever need changing, the

new one to be installed must be of the same technical specifications as the one, which comes, supplied

with the boiler.

The boiler must be wired to a double poled fused

only 3 amp fuse.

Connection of a room thermostat (optional)

There is provision for the connection of a room stat,

which should be rated for 24 volts across its contacts,

those contacts should be prepared for low voltage

and low Intensity. Proceed as follows:

Unscrew the screw (A) as it shows figure 1, open

the bottom cover, where the connector of the room

thermostat is placed.

Press out the plastic disc (B) using a screwdriver to

form a hole so you can pass through the wires of the

room stat.

Replace cover.

Connection for 24 volts room thermostat and/or clock

with volt free clock contacts only, see wiring appendix

1.- Digital Display

2.- Heating temperature selector

3.- D.H.W temperature selector

4.- Main control switch and reset

5.- Boiler ON indicator light

6.- Burner on indicator light

7.- Reset indicator light

EARTH

(Green /Yellow)

FUSE at

3amp

LIVE

(Brown)

NEUTRAL

(Blue)

Three-pin plug

Page 18

18

19.- COMMISSIONING THE BOILER

Connect the boiler to a 230V ~50 Hz mains supply.

VERY IMPORTANT: before turning the boiler on

make sure that the installation has been filled.

Domestic hot water

Turn on the cold water stopcock beneath the boiler.

Fill the unit by turning on the various hot water taps

in the installation.

Make sure that the assembly is completely airtight

and watertight.

The installation of a scale reducer/water softener is

recommended in hard water areas

To increase the hot water temperature, reduce the

flow of water at the hot water tap. This may be necessary in winter months.

Central heating system

The correct installation is to be carried out as follows:

Open the radiator air vents.

With the stopcock on and domestic cold water

going through to the boiler, fill the central heating system by opening the filling tap provided by your

installer.

Close the air vents off once water starts coming out

of each of them.

Close the filling tap when the pressure gauge

exceeds the pressure of 1.3 bar. Max = 1.5 bar.

By turning the main control switch to the winter setting , make sure that the pump runs. When the

pump works the pressure in the digital display

increases.

Vent the central heating system once more. Then

let the pressure in the system settle at 1.3 bar. Max =

1.5 bar. (pump off).

Make sure that there are no leaks in the installation.

Check the gas connections and make sure that

there is gas coming into the boiler (that the gas tap is

open).

Make sure that the heating system is completely

full and vented. The pressure gauge should show

between 1.3 and 1.5 bar with cold water in the heating system.

Make sure that the boiler is wired to the correct volt-

age.

Make sure that the combustion flue outlet is not

restricted.

Gas circuit

Turn on the gas stopcock to the installation.

Check that the whole gas circuit and gas connec-

tions to the boiler are airtight.

Settings

Before leaving the factory the boiler is pre-set in

accordance with the information on the adhesive

plate, and therefore needs no further adjustment.

Should the type of gas need to be changed, check

with the corresponding section.

20.- USERS INSTRUCTIONS

Domestic hot water service.

Turn the main control switch in the summer setting in

order to turn the boiler on , see the figure below

(the green light turns on). At that moment the boiler

will be ready to supply domestic hot water whenever

there is a demand for it.

When you turn on any of the hot taps the boiler will

automatically come on with the pilot light switching on

first of all followed by the burner. A water temperature

of between 35° and 60° C can be selected by turning

the domestic hot water temperature regulating knob.

When the D.H.W. temperature regulating knob is

turned the digital display will show the values of the

temperature.

Hot water and central heating service.

Turn the switch to the winter setting . The burner

will automatically fire up if the clock and/or the room-

Check the gas connections and make sure that the gas is coming into the boiler (that the gas tap is open)

Make sure that the heating system is completely full and vented. The pressure gauge should show between

1.3 and 1.5 bar with cold water in the heating system.

Make sure that the electricity supply to the boiler is switched on.

Page 19

19

Annual maintenance for the boiler is compulsory

according to the terms of current legislation.

Once a year, the following checks must be carried out

by qualified personnel and is a condition of a 2 year

warranty.

These are the checks, which will be carried out:

Water pressure in the heating installation, on cold

must be between 1.3 and 1.5 bar. Otherwise it needs

to be raised up to these values.

The control and safety devices (gas valve, thermostats) must work correctly.

The burner and heat exchanger must be clean. To

clean, you are advised to use soft brushes or compressed air so as not to damage them. Do not use

chemical products.

Check the electrode gaps and position ensuring

that the ignition electrode tips are.

Directly over a flame port

3mm apart

5mm above the burner blade

Check that the flame sensing electrode tip is

6mm above the burner blade.

The expansion vessel must be full of air at a pres-

sure of 1 bar.

The gas and water installations must be tight.

The flue must be free of blockages.

The gas flow and pressure have to be kept at the

indicated values.

Check correct operation of the pump.

Every 3 years is recommended to change the flame

sensing electrode.

Cleaning The Cover

Clean the cover with a damp cloth without using

abrasive detergents.

21.- MAINTENANCE

thermostat are calling for heat. A temperature of

between 60° and 85° C can be selected by turning

the heating temperature regulating knob. This will

stay on until it achieves the temperature selected

either in the room thermostat or in the boiler itself.

Whenever domestic hot water is required when it is at

the central heating setting, the boiler is designed to

give priority to the supply of domestic hot water, with

the central heating on hold, until the demand for

domestic hot water ceases. When the D.H.W. temperature regulating knob is turned the digital display

will show the values of the temperature.

Switching off the boiler.

Turn the main switch to the setting O.

Reset of the boiler.

This unit has a built-in reset indicator. Whenever

any fault is detected in the ignition process, the boiler goes to lock out and the reset indicator switches

on.

To reset the boiler turn the main switch to position

O. The reset indicator should then turn off.

When the pressure of the digital display blinks the

central heating must be filled minimum t0 1.3-1.5

maximum (system cold)

IMPORTANT: If the boiler has not been used for a

length of time, or a new gas bottle is connected, the

unit could lock out due to the presence of air in the

pipes. Should this happen, the ignition procedure

should be repeated until the gas circuit is cleared of

all air in the gas supply.

Page 20

20

24.- CHANGING TO A DIFFERENT TYPE OF GAS

Should a different gas be used from the gas for which

the boiler has been equipped, the following parts

must be replaced.

Burner injectors (12).

Burner pressure must be regulated.

These modifications, together with the regulating

process, must only be carried out either by the

Technical Assistance Service or by a qualified expert.

Remove the front panel. As it will be held in place

by means of four fastening bolts, pull it off to remove

it. Remove the front panel of the close chamber.

Unscrew the 8 screws from the front panel of the

combustion chamber and then remove it.

Unscrew the four screws from the electronic box.

There are two screws on the front and another two at

the bottom of the unit. Move down the electronic box.

Remove the flame sensing electrode and the igni-

tion plug conectors.

Unscrew the four screws (A) which hold the manifold onto the burner. Remove the manifold

Unscrew the hexagonal screw (B) which hold the

manifold to the gas valve.

Change 12 burner injectors (see chart 1).

Put the manifold in place. Put the flame sensing

electrode and the ignition plug conectors in place.

Put the front panel of the combustion chamber and

the front panel of the close chamber.

To adjust the pressures of the burner to the new

type of gas, proceed as follows:

Take off the plastic cover (D) of the electronic box.

The bridge S4:

- For LPG must be connected

- For natural gas must be disconnected

Dismantle the protective hood C (see gas valve

details 1) of the gas valve and set the burner in

D.H.W.

Set the maximun Output:

Set the D.H.W. temperature selector at maximum.

Place the variable resistance of the electronic card

P1 (see figure 3) in the maximum position (rotate

clockwise).

Open a D.H.W. tap.

Adjust the burner maximum pressure (see chart 2).

Using a hexagonal spanner rotate the screw E of the

gas valve (see gas valve details 2). Rotating clockwise the pressure increases.

Act on the variable resistance P1 rotating it anticlockwise until the burner pressure gets the same

value as what we got on the mechanical adjustment.

Set the minimal pressure

Open a D.H.W. tap.

Adjust the burner minimal pressure (see chart 2).

Disconnect one of the modulating electrovalve terminals (electrovalve on which you are acting) of the gas

valve.

Adjust burner pressure to the value indicated in

chart 2 rotating the hexagonal screw E. Maintaining

blocked the hexagonal screw E rotate the star screw

T (see figure 2). Rotating clockwise the pressure

increases.

Once concluded the minimal output setting operation,

connect the terminal again.

Adjust the starting pressure acting on the variable

resistance P2 (rotating clockwise the pressure

increases). It is 4 mbar in natural gas, and 8 mbar. in

LPG. To make this operation you have to:

Disconnect the air connection of the ionisation

22.- FROST PROTECTION

23.- ANTI PUMP SEIZURE DEVICE

The boiler has an frost protection security system.

IMPORTANT: the boiler must be electrically

supplied and gas connected for this to operate.

Frost protection

When the heating thermistor detects a temperature of

6ºC, only the pump will switch and will continue to run

until a temperature of 9ºC is obtained.

If the temperature drops to 3ºC, the boiler will start on

minimum power until the temperature of 20ºC is

obtained.

NOTE: If the boiler is not to be used for a long period drain the heating installation using the valve (Z)

beneath the boiler and the D.H.W. installation.

The D.H.W circuit must be drained down as follows:

Turn off the cold water supply.

Open all the hot water outlet taps in the installation

(at least one tap should be found at a level lower than

the boiler).

Release the tap to drain the flow switch to allow air

to come in and for the stored water in the boiler to be

able to leave.(see figure)

When the operation is finished, close the hot water

outlet taps and the draining tap.

To put the boiler back into service, open the cold

water inlet tap.

When the boiler is not being used, the pump will automatically run for one minute every 24 hours to prevent seizure. TO ENSURE OPERATION OF THIS

DEVICE ELECTRICAL SUPPLIES MUST BE ON.

If the pump jammed when the appliance is turned

back on, consult your installer or service engineer.

Z

Page 21

Burner pressure

mm of water

column

mbar

Output

(kW)

Natural

Propane

Natural

Propane

23.7

180

350

18

35

7.6

20

44 2 4.4

Lighting

Pressure

40

80 4 8

Ø Injectors

(mm)

1.14

0.75

1.14

0.75

Burner pressure

mm of water

column

mbar

Output

(kW)

Natural

Propane

Natural

Propane

27

180

350

18

35

7.8

20

44 2 4.4

Lighting

Pressure

40

80 4 8

Ø Injectors

(mm)

1.23

0.80

1.23

0.80

C

E

Llave

Bloqueada

T

1

2

3

Gas valve details

E

plug.

Turn on the boiler and during the starting time

adjust the pressure to the value indicated using the

variable resistance P2.

Once concluded this operation connect again the ionisation plug.

To regulate the maximum heating output you should

act on the variable resistance P3. To make this operation the boiler should be working in heating mode

and the temperature should be in the maximum position. According to the output that is wanted the burner pressure will be the one indicated in chart 2.

Rotating the P3 variable resistance clockwise the

pressure increases.

Mount the protective cap C on the electrovalve.

Put the front panel again.

Note: Do not forget to put the seals in their corresponding places. Replace the old ones for new ones

if they are damaged.

IMPORTANT: Once finished the regulation, make

sure that the outlet burner pressure nipple is close

21

A

B

C

D

Figure 2

Figure 1

chart 1

FE-24E

FE-27E

Page 22

22

S3

P3

P2

P1

S1

S2

S4

2

1

3

4

5

J10

J9

J8

J11

J4

J6

J1

J5

J19

J12

J2

Figure 3

25.- FAULT CODES

FE-24E

1.- Digital Display

4.- Main control switch and reset

6.- Burner on indicator light

7.- Reset indicator light

1

6

7

4

If a Fault develops within the boiler, The P.C.B. will diagnose the possible cause via the reset indicator light

(Red Neon) and the digital display. To identify the fault it is necessary to check the fault in the digital display.

Each fault code begins with an “F” and the number of the fault. These range goes from 1 - 13. To reset the

fault use the reset switch (4)

NUMBER OF 1 SEC

‘FLASHES’

FAULT

1

Lack of gas or ignition problems; Flame

supervision failure

Burner on but flame Indicator Off; H L

2

Air Pressure Switch Failure

3

If the central heating pressure drops

below 0.6 bar or gets above 2.8 bar ,

the boiler goes to lock out

4

The overheat thermostat blocks out the

boiler

5

Printed Circuit board Failure

6

Flame supervision failure indicator light

on burner off

7

Water over heating

9

Temp detection Failure

10

Gas valve control circuit failure

11

Domestic hot water thermistor failure

13

Central Heating flow thermistor Failure

P1 Maximum power adjustment

P2 Minimum Lighting pressure

P3 Output for central heating

adjustment

Page 23

23

26. -FAULT FINDING

PROBLEM

CAUSE

SOLUTION

Broken or poorly placed ignition

electrode

Replace the electrode or position it

correctly

Lack of spark for

the ignition

False contact between the

terminal and the wire

Insert through the terminals in the

ignition wire

Lack of gas

Lack of water

Lack of electricity

Carry out the necessary checks

(incoming gas, water present,

connectors, fuses...)

Blocked burner injectors

Clean them through

Presence of air in the gas circuit

May occur after a prolong ed stop. Vent

the gas circuit

Failure of room thermostat /clock

or defective connection

Regulate the room thermostat /clock

and check connections

Failure of safety thermostat

Check the pump operation. Reset the

safety thermostat

Defective gas valve

Repair or change the valve

The boiler does

not start up

Deactivated boiler

Reset the boiler

Problems in the gas supply

Check the gas pressure in the burner

Explosions in the

burner

Dirty burner

Check and clean the burner

Gas leak

Check the whole gas circuit is airtig ht,

using soapy water or a gas detector

Dirty burner

Check and clean the burner

Smell of gas

Poor flame regulation

Check if gas consumption in the meter

is correct and check the burner

pressure

Insufficient water pressure in the

mains

Install a pressure unit

Blocked water filter

Dismantle and clean the filter

Heat exchanger with pipes partly

or wholly blocked

Clean the inside of the heat exchanger

(Descale)

Little or no hot

water comes out

3 way valve not closing properly

Replacement of valve or membrane

Noise in the

heating installation

Air in the installation or poor water

pressure in the system

Vent the heating installation and check

that the water pressure is correct

Main switch in summer position

Put the switch in winter positi on

Room thermostat/clock set too low

or defective

Set the thermostat/clock at a higher

temperature or replace the room

thermostat

Poor flow balance

Balance the flows

Cold radiators in

winter

The pump does not turn because

it has seized

Dismantle the front screw on the pump

and turn the ceramic spindle using a

piece of plastic to avoid breaking it

Main switch in winter position

Put the main switch in summer position

Hot radiators in

summer

3 way valve not closing properly

Replacement of valve or membrane

Page 24

Loading...

Loading...