Page 1

CNC

8070

Operating manual

(Ref: 1309)

Page 2

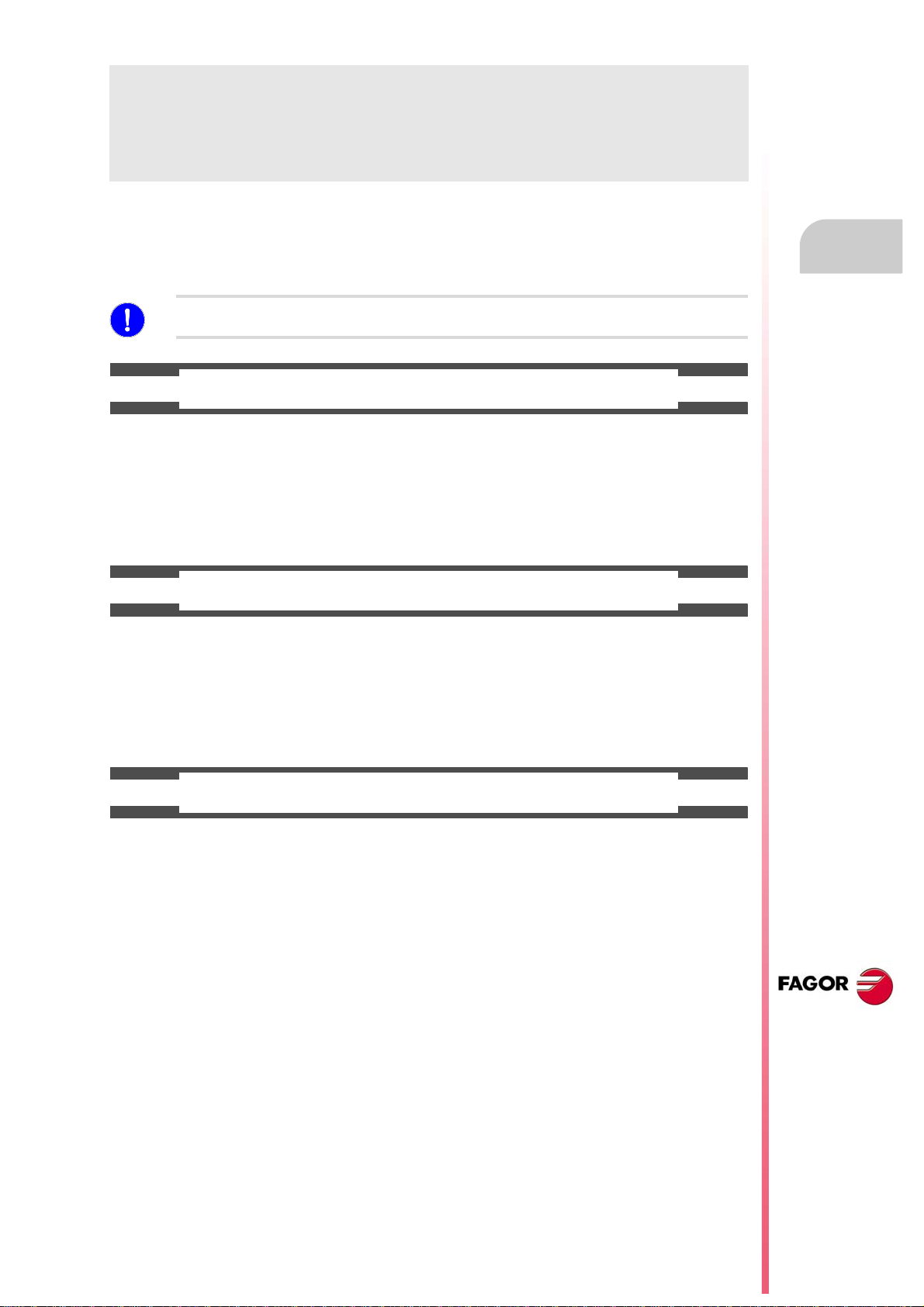

MACHINE SAFETY

It is up to the machine manufacturer to make sure that the safety of the machine

is enabled in order to prevent personal injury and damage to the CNC or to the

products connected to it. On start-up and while validating CNC parameters, it

checks the status of the following safety elements. If any of them is disabled, the

CNC shows a warning message.

• Feedback alarm for analog axes.

• Software limits for analog and sercos linear axes.

• Following error monitoring for analog and sercos axes (except the spindle)

both at the CNC and at the drives.

• Tendency test on analog axes.

FAGOR AUTOMATION shall not be held responsible for any personal injuries or

physical damage caused or suffered by the CNC resulting from any of the safety

elements being disabled.

HARDWARE EXPANSIONS

FAGOR AUTOMATION shall not be held responsible for any personal injuries or

physical damage caused or suffered by the CNC resulting from any hardware

manipulation by personnel unauthorized by Fagor Automation.

If the CNC hardware is modified by personnel unauthorized by Fagor Automation,

it will no longer be under warranty.

COMPUTER VIRUSES

FAGOR AUTOMATION guarantees that the software installed contains no

computer viruses. It is up to the user to keep the unit virus free in order to

guarantee its proper operation.

Computer viruses at the CNC may cause it to malfunction. An antivirus software

is highly recommended if the CNC is connected directly to another PC, it is part

of a computer network or floppy disks or other computer media is used to transmit

data.

FAGOR AUTOMATION shall not be held responsible for any personal injuries or

physical damage caused or suffered by the CNC due a computer virus in the

system.

If a computer virus is found in the system, the unit will no longer be under warranty.

All rights reserved. No part of this documentation may be transmitted,

transcribed, stored in a backup device or translated into another language

without Fagor Automation’s consent. Unauthorized copying or distributing of this

software is prohibited.

The information described in this manual may be changed due to technical

modifications. Fagor Automation reserves the right to make any changes to the

contents of this manual without prior notice.

All the trade marks appearing in the manual belong to the corresponding owners.

The use of these marks by third parties for their own purpose could violate the

rights of the owners.

It is possible that CNC can execute more functions than those described in its

associated documentation; however, Fagor Automation does not guarantee the

validity of those applications. Therefore, except under the express permission

from Fagor Automation, any CNC application that is not described in the

documentation must be considered as "impossible". In any case, Fagor

Automation shall not be held responsible for any personal injuries or physical

damage caused or suffered by the CNC if it is used in any way other than as

explained in the related documentation.

The content of this manual and its validity for the product described here has been

verified. Even so, involuntary errors are possible, thus no absolute match is

guaranteed. Anyway, the contents of the manual is periodically checked making

and including the necessary corrections in a future edition. We appreciate your

suggestions for improvement.

The examples described in this manual are for learning purposes. Before using

them in industrial applications, they must be properly adapted making sure that

the safety regulations are fully met.

Page 3

Operating manual

INDEX

About the product ......................................................................................................................... 9

Declaration of conformity............................................................................................................ 11

Version history............................................................................................................................ 13

Safety conditions ........................................................................................................................ 23

Warranty terms ........................................................................................................................... 27

Material returning terms.............................................................................................................. 29

CNC maintenance ...................................................................................................................... 31

CHAPTER 1 DESCRIPTION OF THE KEYS

1.1 Monitor LCD-15. ............................................................................................................ 33

1.2 Monitor LCD-10K. ......................................................................................................... 34

1.3 HORIZONTAL KEYB / HORIZONTAL KEYB + MOUSE. ........................................ 36

1.4 VERTICAL KEYB / VERTICAL KEYB + MOUSE. .................................................... 37

1.5 OP PANEL / OP PANEL + SPDL RATE. ................................................................. 38

1.6 Keyboard shortcuts........................................................................................................ 39

CHAPTER 2 GENERAL CONCEPTS

2.1 Turning the CNC on and off ........................................................................................... 41

2.1.1 Emergency shutdown with battery ............................................................................. 43

2.2 Work modes and software protection at the CNC.......................................................... 44

2.3 Network connection (Ethernet) ...................................................................................... 46

2.4 Directory structure..........................................................................................................47

2.4.1 MTB (Machine Tool Builder) directory........................................................................ 48

2.4.2 USERS directory........................................................................................................ 49

CHAPTER 3 HOW TO OPERATE THE CNC

3.1 General description of the interface. .............................................................................. 51

3.2 Detailed description of the CNC status bar.................................................................... 52

3.2.1 Channel synchronization window............................................................................... 53

3.2.2 PLC messages........................................................................................................... 54

3.3 Horizontal softkey menu ................................................................................................ 55

3.4 Operating modes ........................................................................................................... 56

3.4.1 Description of the various operating modes............................................................... 58

3.5 Task window ..................................................................................................................60

3.6 Windows for warnings and errors .................................................................................. 61

3.6.1 CNC warnings and errors........................................................................................... 61

3.6.2 PLC errors.................................................................................................................. 62

3.7 File selection window..................................................................................................... 63

3.8 Calculator....................................................................................................................... 65

3.8.1 Defining expressions.................................................................................................. 67

3.9 Dialog boxes .................................................................................................................. 69

CHAPTER 4 AUTOMATIC MODE

4.1 Interface description....................................................................................................... 71

4.1.1 Softkey menus. .......................................................................................................... 73

4.2 Display the status of the program or of the active subroutines. ..................................... 74

4.3 Program simulation and execution................................................................................. 75

4.3.1 Select program........................................................................................................... 75

4.3.2 Select the first and last blocks of the execution. ........................................................ 76

4.3.3 Execute a program..................................................................................................... 79

4.3.4 Resume the execution of a program from the block where it was canceled. ............. 80

4.3.5 Cancel the execution and resume from another block while keeping the history. ..... 81

4.3.6 Simulated execution of a program. ............................................................................ 82

4.3.7 Execute a program (retrace). ..................................................................................... 85

4.3.8 Executing a program in 8055 MC/TC language. ........................................................ 88

4.4 Executing program blocks separately. ........................................................................... 89

4.5 Tool inspection. ............................................................................................................. 90

4.5.1 Tool inspection (execution in retrace mode, independent interpolator or rigid tapping).

93

4.6 Block search. ................................................................................................................. 95

4.6.1 Treatment of functions M, H, F, S. ............................................................................. 97

CNC 8070

(REF: 1309)

·3·

Page 4

CHAPTER 5 MANUAL (JOG) MODE

5.1 Interface description. ..................................................................................................... 99

5.1.1 Softkey menus. ........................................................................................................ 101

5.2 Operations with the axes. ............................................................................................ 102

5.2.1 Home search............................................................................................................ 102

5.2.2 Jog ........................................................................................................................... 103

5.2.3 Jogging the axes with handwheels .......................................................................... 105

5.2.4 Moving an axis to a particular position (coordinate)................................................. 107

5.2.5 Coordinate preset .................................................................................................... 107

5.3 Spindle control ............................................................................................................. 108

5.4 Tool selection and tool change .................................................................................... 109

5.5 Setting the feedrate and spindle speed. ...................................................................... 110

5.6 Setting and activating the zero offsets and the fixture offsets. .................................... 111

CHAPTER 6 MANUAL (JOG) MODE. TOOL CALIBRATION

6.1 Manual calibration. Calibration without a probe........................................................... 115

6.2 Semi-automatic calibration. Calibration with a probe................................................... 119

6.3 Automatic calibration with a probe and a canned cycle............................................... 122

6.3.1 Mill or lathe model ("trihedron" geometrical configuration)....................................... 122

6.3.2 Lathe model ("plane" geometrical configuration) ..................................................... 125

CHAPTER 7 MANUAL (JOG) MODE. PART CENTERING (MILL MODEL)

7.1 How to define the data................................................................................................. 128

7.2 Data programming. ...................................................................................................... 129

7.3 Basic operation. ........................................................................................................... 132

Operating manual

CNC 8070

CHAPTER 8 EDISIMU MODE (EDITING AND SIMULATION)

8.1 Interface description. ................................................................................................... 135

8.1.1 Softkey menus. ........................................................................................................ 137

8.2 Program editing and simulation ................................................................................... 138

8.2.1 Program editing........................................................................................................ 138

8.2.2 Editing a program in the 8055 CNC language ......................................................... 139

8.2.3 Program simulation .................................................................................................. 141

8.2.4 Simulation errors...................................................................................................... 143

8.3 Editing window............................................................................................................. 144

8.3.1 Softkey and hotkey menus....................................................................................... 146

8.3.2 Contextual programming assistance........................................................................ 147

8.3.3 Help for programming subroutines........................................................................... 148

8.3.4 Syntax errors when editing ...................................................................................... 149

8.4 Working in the editing window. .................................................................................... 150

8.4.1 Select a program...................................................................................................... 150

8.4.2 Operations with blocks. Cut and paste. ................................................................... 150

8.4.3 Find a line or a text in the program. ......................................................................... 151

8.4.4 Undo and redo. ........................................................................................................ 152

8.4.5 Operations with files................................................................................................. 153

8.4.6 Customizing the editor. ............................................................................................ 154

8.4.7 TEACH-IN ................................................................................................................ 156

8.4.8 Import DXF files ....................................................................................................... 157

8.4.9 Profile editor............................................................................................................. 158

8.4.10 Canned cycle editor. ................................................................................................ 158

8.4.11 Inclined planes (·M· model)...................................................................................... 159

8.4.12 Geometric-help editor (·M· model) ........................................................................... 160

8.5 Graphics window ......................................................................................................... 161

8.6 Program window .......................................................................................................... 162

8.7 Working in the program window. ................................................................................. 163

8.7.1 Select the first and last blocks of the execution. ...................................................... 163

8.7.2 Simulate program blocks separately........................................................................ 164

8.7.3 Display the status of the program or of the active subroutines. ............................... 165

8.8 Statistics window ......................................................................................................... 166

8.8.1 Time estimates......................................................................................................... 167

(REF: 1309)

·4·

CHAPTER 9 PROFILE EDITOR

9.1 Interface description. ................................................................................................... 169

9.1.1 How to use the profile editor. ................................................................................... 171

Page 5

Operating manual

9.2 Define a new profile, enlarge an existing one or import one from a file. ...................... 172

9.2.1 Define any profile using straight and curved sections.............................................. 173

9.2.2 Define a circular profile. ........................................................................................... 175

9.2.3 Define a rectangular profile. ..................................................................................... 176

9.2.4 Enlarge a profile....................................................................................................... 176

9.2.5 Import a profile from a DXF file. ............................................................................... 177

9.3 Modify a profile and insert corners............................................................................... 179

9.4 Configuring the profile editor. Displayed area.............................................................. 181

9.5 Configuring the profile editor. Define the work plane. .................................................. 181

9.6 End the session at the editor. ...................................................................................... 181

9.7 Examples of how to define profiles. ............................................................................. 182

9.7.1 Profile editor. Example 1 (milling). ........................................................................... 182

9.7.2 Profile editor. Example 2 (milling). ........................................................................... 183

9.7.3 Profile editor. Example 3 (milling). ........................................................................... 185

9.7.4 Profile editor. Example 4 (lathe)............................................................................... 186

CHAPTER 10 GRAPHIC ENVIRONMENT (MILL MODEL)

10.1 Description of the graphic environment. ...................................................................... 187

10.1.1 Softkey menus. ........................................................................................................ 188

10.2 Type of graphics .......................................................................................................... 189

10.3 Zoom............................................................................................................................ 190

10.4 Dimensions .................................................................................................................. 191

10.5 Point of view................................................................................................................. 191

10.6 Measurement ............................................................................................................... 192

10.7 Clear screen................................................................................................................. 193

10.8 Colors........................................................................................................................... 193

10.9 Options......................................................................................................................... 194

10.10 Real coordinates .......................................................................................................... 195

10.11 Real coordinates with enlarged error ........................................................................... 195

10.12 Simulation speed ......................................................................................................... 195

CHAPTER 11 HD GRAPHIC ENVIRONMENT (MILL MODEL)

11.1 Description of the graphic environment. ...................................................................... 197

11.1.1 Softkey menus. ........................................................................................................ 198

11.2 Move, rotate and zoom in or out on the graphic. ......................................................... 199

11.3 Select the type of view................................................................................................. 200

11.4 Configure the graphics (number of windows, colors, etc.). .......................................... 201

11.5 Actions (move sections and print graphics). ................................................................ 204

11.6 Delete the graphic........................................................................................................ 205

11.7 Define the dimensions of the parts and the size of the graphic. .................................. 205

11.8 Measure the part.......................................................................................................... 206

11.9 Simulation speed. ........................................................................................................ 206

CHAPTER 12 GRAPHIC ENVIRONMENT (LATHE MODEL)

12.1 Description of the graphic environment. ...................................................................... 207

12.1.1 Softkey menus. ........................................................................................................ 208

12.2 Type of graphics .......................................................................................................... 209

12.3 Zoom............................................................................................................................ 210

12.4 Dimensions .................................................................................................................. 211

12.5 Measurement ............................................................................................................... 211

12.6 Clear screen................................................................................................................. 212

12.7 Colors........................................................................................................................... 212

12.8 Options......................................................................................................................... 213

12.9 Real coordinates .......................................................................................................... 214

12.10 Real coordinates with enlarged error ........................................................................... 214

12.11 Simulation speed ......................................................................................................... 214

CHAPTER 13 HD GRAPHIC ENVIRONMENT (LATHE MODEL)

13.1 Description of the graphic environment. ...................................................................... 215

13.1.1 Softkey menus. ........................................................................................................ 216

13.2 Move, rotate and zoom in or out on the graphic. ......................................................... 217

13.3 Select the type of view................................................................................................. 218

13.4 Configure the graphics (number of windows, colors, etc.). .......................................... 219

13.5 Actions (move sections and print graphics). ................................................................ 222

13.6 Delete the graphic........................................................................................................ 223

13.7 Define the dimensions of the parts and the size of the graphic. .................................. 223

13.8 Measure the part.......................................................................................................... 224

13.9 Simulation speed. ........................................................................................................ 224

CNC 8070

(REF: 1309)

·5·

Page 6

CHAPTER 14 MDI/MDA MODE

14.1 Interface description. ................................................................................................... 225

14.1.1 Softkey menus. ........................................................................................................ 226

14.2 Edit and execute individual blocks............................................................................... 227

14.3 Block history. ............................................................................................................... 228

CHAPTER 15 USER TABLES

15.1 User table presentation................................................................................................ 229

15.1.1 Softkey menus. ........................................................................................................ 230

15.2 Zero offset tables ......................................................................................................... 231

15.3 Fixture table ................................................................................................................. 233

15.4 Arithmetic parameter tables......................................................................................... 234

15.5 Operations with tables ................................................................................................. 235

15.5.1 Data editing.............................................................................................................. 235

15.5.2 Save and recall tables.............................................................................................. 235

15.5.3 Find text. ................................................................................................................. 237

CHAPTER 16 TOOL AND MAGAZINE TABLE

16.1 Presentation of the tool tables and magazine tables. ................................................. 239

16.1.1 Softkey menus. ........................................................................................................ 240

16.1.2 Search for a text in the tables .................................................................................. 241

16.1.3 Save and load the tables ......................................................................................... 242

16.1.4 Printing the tables .................................................................................................... 244

16.2 Tool table ..................................................................................................................... 245

16.2.1 Softkey menus. ........................................................................................................ 246

16.2.2 The tool list............................................................................................................... 247

16.2.3 Description of the tool data ...................................................................................... 248

16.3 Operations with the tool table ...................................................................................... 256

16.3.1 Editing the tool table ................................................................................................ 256

16.4 Active-tools table ......................................................................................................... 257

16.4.1 Softkey menus. ........................................................................................................ 258

16.4.2 Changing the tool of the spindle .............................................................................. 258

16.5 Table for the status of the tool change process........................................................... 259

16.6 Magazine table ............................................................................................................ 260

16.6.1 Softkey menus. ........................................................................................................ 261

16.6.2 List of magazine positions........................................................................................ 262

16.6.3 Magazine information............................................................................................... 263

16.7 Operations with the magazine table ............................................................................ 265

16.7.1 Loading / unloading tools to / from the magazine .................................................... 265

16.7.2 Load / unload a tool to / from the tool changer arm ................................................. 267

Operating manual

CNC 8070

(REF: 1309)

CHAPTER 17 UTILITIES MODE

17.1 Interface description. ................................................................................................... 269

17.1.1 Softkey menus. ........................................................................................................ 270

17.2 Set how to display the list of programs. ....................................................................... 271

17.3 Select files and create folders...................................................................................... 272

17.4 Search in files .............................................................................................................. 273

17.5 Protection passwords .................................................................................................. 274

17.6 Data safety backup. Backup - Restore ........................................................................ 276

17.7 Encrypting files ............................................................................................................ 278

CHAPTER 18 PLC

18.1 Appearance of the PLC mode ..................................................................................... 279

18.1.1 Icon description (vertical softkeys)........................................................................... 280

18.2 "Programs" service ...................................................................................................... 281

18.2.1 Softkey menus. PLC project. ................................................................................... 282

18.2.2 Softkey menus. Files of the PLC project.................................................................. 283

18.3 Program editing ........................................................................................................... 284

18.4 Editing in C language or mnemonic language. ............................................................ 286

18.4.1 Softkey "Analyze"..................................................................................................... 287

18.4.2 Softkey "File". .......................................................................................................... 287

18.4.3 Softkey "Undo"......................................................................................................... 287

18.4.4 Softkey "Operations with blocks". ............................................................................ 288

18.4.5 Softkey "Find/Replace". ........................................................................................... 289

18.4.6 Softkey "Customize". ............................................................................................... 290

·6·

Page 7

Operating manual

18.5 Editing in contact (ladder) language (softkeys)............................................................ 291

18.5.1 Softkey "Analyze"..................................................................................................... 292

18.5.2 Softkey "File". .......................................................................................................... 292

18.5.3 "Edit" softkey. .......................................................................................................... 293

18.5.4 Softkey "View". ........................................................................................................ 295

18.5.5 Softkey "Marks". ...................................................................................................... 295

18.5.6 Softkey "Find"........................................................................................................... 296

18.5.7 Softkey "Customize"................................................................................................. 296

18.6 Program monitoring ..................................................................................................... 297

18.6.1 Softkey menus. Monitoring in C language or mnemonic language. ........................ 298

18.6.2 Softkey menus. Monitoring in contact (ladder) language. ....................................... 299

18.7 "Commands" service.................................................................................................... 301

18.7.1 Softkey menus. Options of the "Commands" service............................................... 301

18.8 "Outputs" service ......................................................................................................... 302

18.8.1 Softkey menus. Options of the "Outputs" service. ................................................... 303

18.9 "Logic analyzer" service............................................................................................... 304

18.9.1 Editing logic analyzer data ....................................................................................... 305

18.9.2 Save, load and reset the analyzer configuration ...................................................... 307

18.9.3 Execute and analyze trace....................................................................................... 308

18.9.4 Customize the appearance of the logic analyzer ..................................................... 308

18.10 "Monitoring" service ..................................................................................................... 309

18.10.1 Description of resource tables.................................................................................. 310

18.10.2 Definition of the table resources............................................................................... 311

18.10.3 Options of the "Monitoring" service (softkeys). ........................................................ 312

18.11 "Cross references" service........................................................................................... 313

18.11.1 Softkey menus. Options of the "Cross reference" service. ...................................... 314

18.12 "Statistics" service........................................................................................................ 315

18.12.1 Softkey menus. Options of the "Statistics" service................................................... 316

18.13 "Messages" service...................................................................................................... 317

18.13.1 Softkey menus. Options of the "Messages" service................................................. 318

18.13.2 Editing the message and error table ........................................................................ 319

18.13.3 Displaying PLC messages ....................................................................................... 320

18.13.4 Displaying PLC errors .............................................................................................. 321

18.13.5 Grouping the additional information text files in a single file. ................................... 322

18.13.6 Save, load and print a message and error table ...................................................... 323

CHAPTER 19 MACHINE PARAMETERS

19.1 Appearance of the machine parameter tables ............................................................. 325

19.1.1 Softkey menus. ........................................................................................................ 326

19.2 Parameter table description ......................................................................................... 327

19.2.1 "M" function setting table.......................................................................................... 328

19.2.2 Compensation table ................................................................................................. 329

19.2.3 OEM parameters...................................................................................................... 330

19.3 Operations with tables ................................................................................................. 331

19.3.1 Data editing and validation....................................................................................... 331

19.3.2 Save and recall tables.............................................................................................. 332

19.3.3 Find text. ................................................................................................................. 333

19.3.4 Importing and exporting compensation tables. ........................................................ 334

CHAPTER 20 SETUP ASSISTANCE

20.1 Oscilloscope................................................................................................................. 336

20.1.1 Interface description................................................................................................. 337

20.1.2 Softkey menus. ........................................................................................................ 338

20.1.3 Configuration screen ................................................................................................ 341

20.1.4 Configure and execute the oscilloscope function..................................................... 342

20.1.5 Machine parameter editing. ..................................................................................... 343

20.2 The Bode diagram ....................................................................................................... 346

20.2.1 Interface description................................................................................................. 347

20.2.2 Softkey menus. ........................................................................................................ 348

20.2.3 Machine parameter editing. ..................................................................................... 351

20.2.4 Configuration screen ................................................................................................ 353

20.3 The circularity (roundness) test.................................................................................... 356

20.3.1 Interface description................................................................................................. 357

20.3.2 Softkey menus. ........................................................................................................ 359

20.3.3 Configuring and executing the circularity (roundness) test ...................................... 360

20.3.4 Configure the graphic environment .......................................................................... 361

20.3.5 Define and execute the movement subroutine......................................................... 362

20.3.6 Data capture for the graphic..................................................................................... 363

20.3.7 Adjustment of the machine parameters involved ..................................................... 364

20.3.8 Validate the changes and save the configuration used............................................ 366

20.3.9 Machine parameters that may be modified .............................................................. 367

CNC 8070

(REF: 1309)

·7·

Page 8

CHAPTER 21 DDSSETUP

21.1 Appearance of the DDSSetup mode ........................................................................... 369

21.1.1 Icon description (vertical softkeys)........................................................................... 370

21.2 List of devices connected to the bus............................................................................ 371

21.3 Drives accessing level (only Sercos). .......................................................................... 373

21.4 –Parameters and variables– service. .......................................................................... 374

21.5 –Error management– service. ..................................................................................... 376

21.6 –Monitoring– service.................................................................................................... 377

21.7 –Information– service .................................................................................................. 379

21.8 Command generator (only Sercos). ............................................................................ 381

21.9 Command line.............................................................................................................. 382

21.10 File for setting the parameters of Mechatrolink servos. ............................................... 384

CHAPTER 22 DIAGNOSIS

22.1 Appearance of the diagnosis mode. ............................................................................ 387

22.1.1 Softkey menus. ........................................................................................................ 388

22.2 Configuration diagnosis ............................................................................................... 389

22.2.1 System diagnosis..................................................................................................... 389

22.2.2 Software diagnosis................................................................................................... 390

22.2.3 Hardware diagnosis. Bus CAN, Sercos and Mechatrolink. ...................................... 391

22.3 Sercos diagnosis ......................................................................................................... 393

22.4 Save the CAN configuration for the start-up test. ........................................................ 394

22.5 Report generation ........................................................................................................ 395

22.6 View the history of errors and warnings issued by the CNC........................................ 396

22.7 Generating the Fagor file for error diagnosis. .............................................................. 396

Operating manual

CNC 8070

(REF: 1309)

·8·

Page 9

Operating manual

ABOUT THE PRODUCT

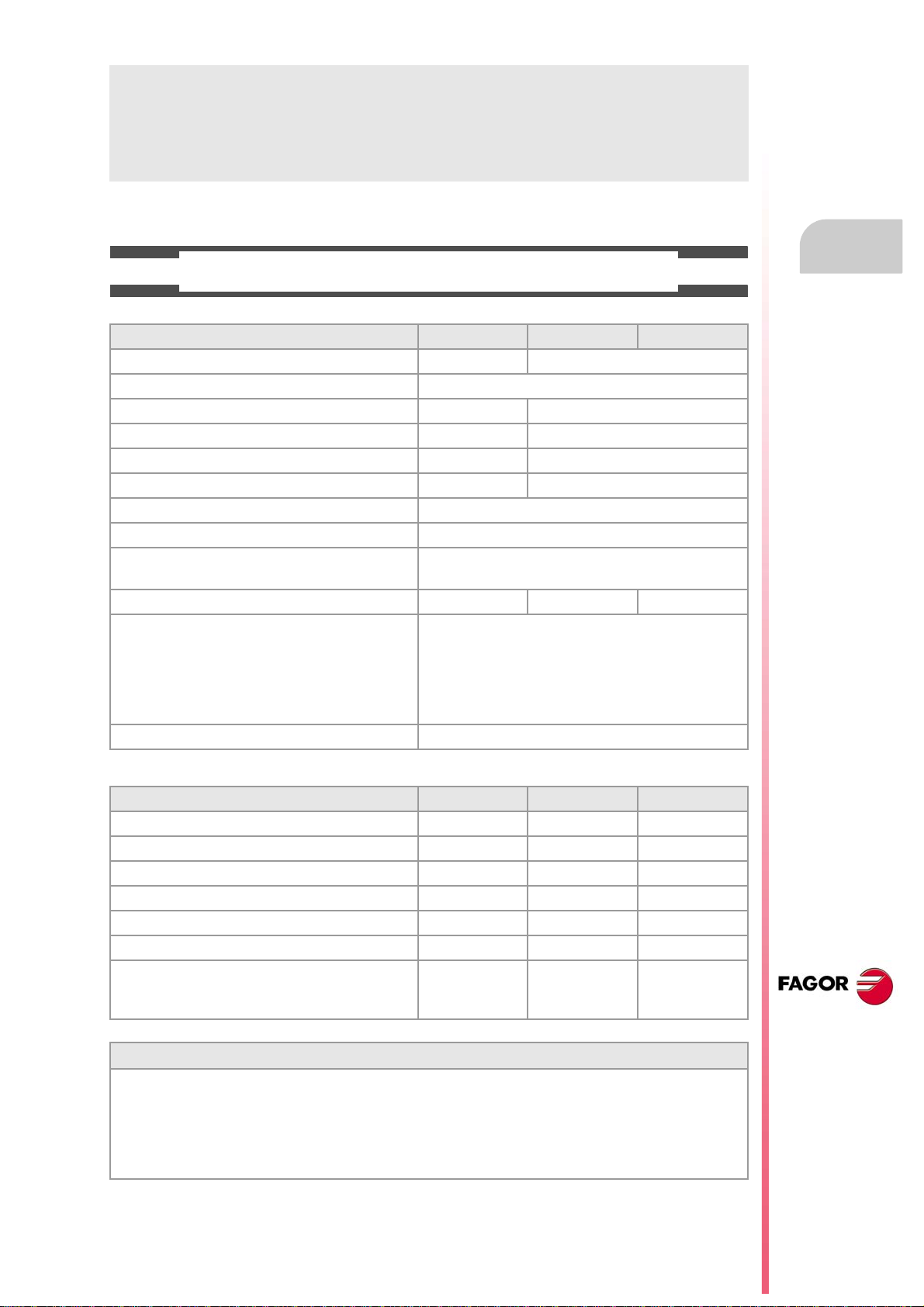

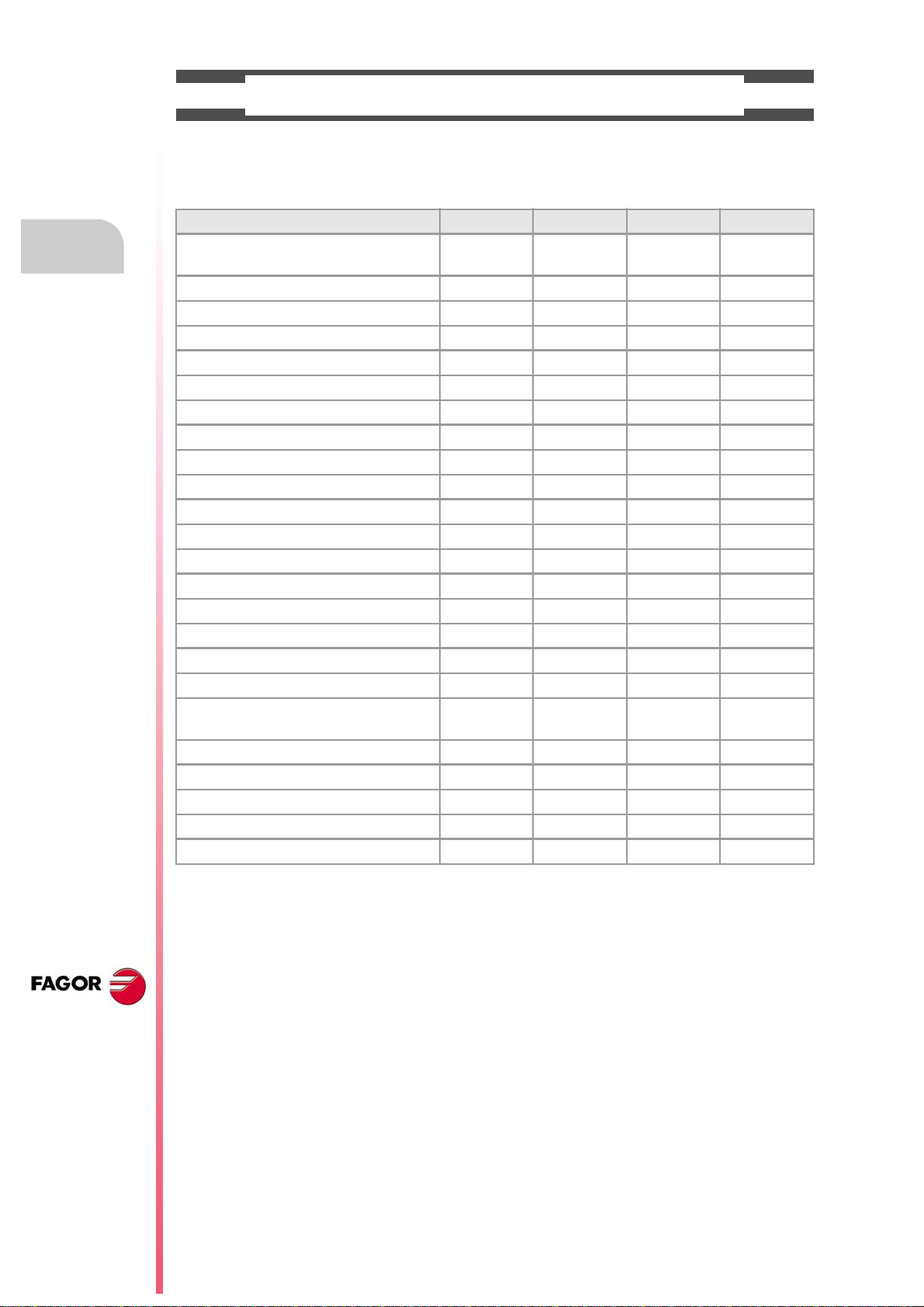

BASIC CHARACTERISTICS.

Basic characteristics. ·BL· ·OL· ·M· / ·T·

PC-based system. Closed system Open system

Operating system. Windows XP

Number of axes. 3 to 7 3 to 28

Number of spindles. 1 1 to 4

Number of tool magazines. 1 1 to 4

Number of execution channels. 1 1 to 4

Number of handwheels. 1 to 12

Type of servo system. Analog / Digital Sercos / Digital Mechatrolink

Communications. RS485 / RS422 / RS232

Ethernet

PCI expansion. No Option No

Integrated PLC.

PLC execution time.

Digital inputs / Digital outputs.

Marks / Registers.

Timers / Counters.

Symbols.

Block processing time. < 1 ms

< 1ms/K

1024 / 1024

8192 / 1024

512 / 256

Unlimited

Remote modules. RIOW RIO5 RIO70

Communication with the remote modules. CANopen CANopen CANfagor

Digital inputs per module. 8 16 or 32 16

Digital outputs per module. 8 24 or 48 16

Analog inputs per module. 4 4 8

Analog outputs per module. 4 4 4

Inputs for PT100 temperature sensors. 2 2 - - -

Feedback inputs. - - - - - - 4

Differential TTL

Sinusoidal 1 Vpp

Customizing.

PC-based open system, fully customizable.

INI configuration files.

FGUIM visual configuration tool.

Visual Basic®, Visual C++®, etc.

Internal databases in Microsoft® Access.

OPC compatible interface

CNC 8070

(REF: 1309)

·9·

Page 10

Operating manual

SOFTWARE OPTIONS.

Bear in mind that some of the features described in this manual depend on the software options that are

installed. The information of the following table is informative only; when purchasing the software options,

only the information provided in the ordering handbook is valid.

-BL- model -OL- model -M- model -T- model

Open system.

Access to the administrator mode.

Editing and simulation environment. - - - Standard Standard Standard

Number of execution channels 1 1 to 4 1 to 4 1 to 4

Number of axes 3 to 7 3 to 28 3 to 28 3 to 28

Number of spindles 1 1 to 4 1 to 4 1 to 4

Number of tool magazines 1 1 to 4 1 to 4 1 to 4

Number of interpolated axes (maximum) 4 28 - - - - - -

Limited to 4 interpolated axes Option Option Option Option

IEC 61131 language Option Option - - - - - -

HD graphics - - - Option Option Option

Conversational IIP - - - - - - Option Option

Non-Fagor digital drive Option Option - - - - - -

Tool radius compensation Option Option Standard Standard

"C" axis Option Option Standard Standard

Dynamic RTCP Option Option - - - Option

HSSA machining system. Option Option Standard Standard

Probing canned cycles - - - - - - Option Standard

Profile editor - - - - - - Standard Standard

Drilling ISO cycles for the OL model.

(G80, G81, G82, G83).

Tandem axes - - - Option - - - Option

Synchronism and cams Option Option - - - - - -

Tangential control Option Option - - - Standard

Volumetric compensation (up to 10 m³). Option Option Option Option

Volumetric compensation (more than 10 m³). Option Option Option Option

- - - Option - - - - - -

- - - Option - - - - - -

CNC 8070

(REF: 1309)

·10·

Page 11

Operating manual

DECLARATION OF CONFORMITY

The manufacturer:

Fagor Automation S. Coop.

Barrio de San Andrés Nº 19, C.P.20500, Mondragón -Guipúzcoa- (Spain).

Declares:

The manufacturer declares under their exclusive responsibility the conformity of the product:

8070 CNC

Consisting of the following modules and accessories:

8070-BL-ICU, 8070-OL-ICU

8070-BL-MCU, 8070-OL-MCU , 8070-OL-MCU-PCI

MONITOR-LCD-10K, MONITOR-LCD-15, MONITOR-SVGA-15

HORIZONTAL-KEYB, VERTICAL-KEYB, OP-PANEL

BATTERY, MOUSE UNIT

Remote Modules RIOW, RIO5, RIO70, RCS-S.

Note.Some additional characters may follow the model references indicated above. They all comply with the

directives listed here. However, compliance may be verified on the label of the unit itself.

Referred to by this declaration with following directives:

Low-voltage regulations.

IEC 60204-1:2005/A1:2008 Electrical equipment on machines. Part1. General requirements.

Regulation on electromagnetic compatibility.

EN 61131-2: 2007 PLC. Part 2. Equipment requirements and tests.

According to the European Community Directives 2006/95/EC on Low Voltage and 2004/108/EC

on Electromagnetic Compatibility and their updates.

In Mondragón, September 1st, 2013.

CNC 8070

(REF: 1309)

·11·

Page 12

Page 13

Operating manual

VERSION HISTORY

Here is a list of the features added to each manual reference. Each manual reference is valid for the indicated

software version and newer versions.

Ref. 0201

Software V01.00

First version. Milling model.

Ref. 0212

Software V01.10

New repositioning feedrate after tool inspection. • Machine parameter: REPOSFEED.

New treatment of the JOG keys. Different keys to select the axis and the

direction.

Know the dimensions of the kinematics on an axis. • Variable: (V.)A.HEADOF.xn

Keyboard simulation from the PLC. • Variable: (V.)G.KEY

Jog mode. Tool calibration with or without probe.

Jog mode. Automatic loading of zero offsets table.

Jog mode. Programming of feedrate "F" and spindle speed "S".

MDI mode. Block syntax check.

Utilities mode. Define protection passwords.

Block search. Define the first block.

Improved tool table.

Axis selection/deselection to move it with a handwheel.

Simulate the theoretical path.

Confirm the execution of a program pressing the [START] key in a mode other

than automatic.

General scaling factor. • New instruction, #SCALE.

Probe selection. • New instruction, #SELECT PROBE.

Probing canned cycles. • New instruction, #PROBE.

Programming of warnings. • New instruction, #WARNING.

Block repetition. • New instruction, #RPT.

Know the active general scaling factor. • Variable: (V.)G.SCALE

Knowing which is the active probe. • Variable: (V.)G.ACTIVPROBE

Improved programming of high speed machining. • #HSC instruction.

Improved programming of axis swapping. • Instructions #SET, #CALL, #FREE, #RENAME.

The number of macros in a program is now limited to 50. • Macros.

• Machine parameter: JOGKEYDEF.

Ref. 0501

Software V02.01

Windows XP operating system.

Emergency shutdown with battery (central unit PC104).

Multi-channel system, up to 4 channels. Swapping of axes and spindles,

communication and synchronization between channels, common arithmetic

parameters, access variables by channel, etc.

Multi-spindle system, up to 4 spindles.

Tool management with up to 4 magazines.

New languages (Basque and Portuguese). • Machine parameter: LANGUAGE.

Placing the vertical softkeys on the left or on the right. • Machine parameter: VMENU.

Tool radius compensation mode (G136/G137) by default • Machine parameter: IRCOMP.

OEM generic machine parameters. • Machine parameter: MTBPAR.

Reading Sercos variables from the CNC. • Machine parameter: DRIVEVAR.

Electronic-cam editor. • Machine parameter: CAM.

New behavior for rotary axes.

The "(V.).TM.MZWAIT " variable is not necessary in the subroutine associated

with M06.

Know the software version. • Variable: (V.)G.SOFTWARE

Variables related to loop adjustment. Gain setting via PLC. • Variables:

Variables related to loop adjustment. Position increment and sampling period. • Variables:

• Subroutine associated with M6.

• Variable: (V.).TM.MZWAIT

(V.)A.PLCFFGAIN.xn (V.)A.PLCACFGAIN.xn

(V.)A.PLCPROGAIN.xn

(V.)A.POSINC.xn (V.)A.TPOSINC.xn

(V.)A.PREVPOSINC.xn

CNC 8070

(REF: 1309)

·13·

Page 14

Operating manual

Software V02.01

Variables related to loop adjustment. Fine adjustment of feedrate, acceleration

and jerk.

Variables related to the feedback inputs. • Variables:

Optimize the reading and writing of variables from the PLC. Only the access

to the following variables will be asynchronous.

• The tool variables will be read asynchronously when the tool is neither the

active one nor in the magazine.

• The tool variables will be written asynchronously whether the tool is the

active one or not.

• The variables referred to local arithmetic parameters of the active levels

will be read and written asynchronously.

Spindle parking and unparking. • Instructions #PARK, #UNPARK.

Tool radius compensation.

• Behavior of the beginning and end of tool radius compensation when not

programming a movement.

• Changing the type of radius compensation while machining.

Via program, loading a tool in a specific magazine position.

Programming of modal subroutines. • New instruction, #MCALL.

Executing a block in a channel. • New instruction, #EXBLK.

Programming the number of repetitions in the block. • NR command.

Direct resolution of 2D and 3D pockets without requiring a softkey.

Simulating a canned cycle of the editor separately.

Importing DXF files from the program editor or from the profile editor.

Importing programs of the 8055/8055i CNC from the program editor.

Use a softkey to select the repositioning of the spindle after tool inspection.

Backup-restore utility.

Improved profile editor.

Assistance in the program editor. Contextual programming assistance.

• When programming "#", it shows the list of instructions.

• When programming "$", it shows the list of instructions.

• When programming "V.", it shows the list of variables.

Specific password for the machine parameters for kinematics.

Save the CAN configuration for testing it when starting up the system.

The diagnosis mode shows detailed information on the Sercos connection

(Type and version of the drive and motor connected to it).

It is possible to print all the information on the configuration from any section

of the diagnosis mode.

It is possible to simulate a cycle separately from the cycle editor.

Setup assistance. Oscilloscope, Bode diagram, circularity test.

• Variables:

(V.)A.FEED.xn (V.)A.TFEED.xn

(V.)A.ACCEL.xn (V.)A.TACCEL.xn

(V.)A.JERK.xn (V.)A.TJERK.xn

(V.)A.COUNTER.xn (V.)A.COUNTERST.xn

(V.)A.ASINUS.xn (V.)A.BSINUS.xn

• Reading and writing of variables from the PLC.

CNC 8070

(REF: 1309)

Ref. 0504

Software V02.03

New values of machine parameter SERPOWSE for the "Sercos II" board. • Machine parameters: SERPOWSE.

The simulated axes are ignored regarding the validation code.

Electronic cam programming (real coordinates). • New instruction, #CAM.

Synchronization of independent axis (real coordinates). • New instruction, #FOLLOW.

Movement of the independent axis. • New instruction, #MOVE.

DDSSetup mode.

G31. Temporary polar origin shift to the center of interpolation. • G31 function.

G112. Change the drive's parameter set. • G112 function.

Ref. 0509

Software V03.00

Lathe model. Machining canned cycles, lathe tool calibration, variables to

consult the geometry of lathe tools, etc.

Incline axis.

Permit using the G95 function in jog mode. • Machine parameter: FPRMAN.

Lathe model. Select graphics configuration. • Machine parameter: GRAPHTYPE.

Lathe model. Select axis configuration. • Machine parameter: GEOCONFIG.

Select the set of parameters for synchronization. • Machine parameter: SYNCSET.

"C" axis maintained. • Machine parameter: PERCAX.

Magazine-less system.

Ground tools for a turret magazine.

Variable to read the accumulated PLC offset. • Variable: (V.)[ch].A.ACTPLCOF.xn

Variable to obtain a linear estimation of the following error. • Variable: (V.)[ch].A.FLWEST.xn

Variables to read the instant value of feed-forward or AC-forward. • Variables:

Variable to know the line number of the file being executed. • Variable: (V.)[ch].G.LINEN

Variable to know what kind of cycle is active. • Variable: (V.)[ch].G.CYCLETYPEON

Variable to know the tool orientation. • Variable: (V.)[ch].G.TOOLDIR

(V.)[ch].A.ACTFFW.xn (V.)[ch].A.ACTACF.xn

·14·

Page 15

Operating manual

Software V03.00

Variable to know whether the HSC mode is active or not. • Variable: (V.)[ch].G.HSC

Variable to know the theoretical feedrate on 3D path. • Variable: (V.)[ch].G.F3D

Variable to know the number of the warning being displayed. • Variable: (V.)[ch].G.CNCWARNING

The variable (V.)G.CNCERR is now per channel. • Variable: (V.)G.CNCERR

Select the type of loop, open or closed, for the spindle. • New instruction, #SERVO.

Spindle synchronization. • New instruction, #SYNC.

Spindle synchronization. • New instruction, #TSYNC.

Spindle synchronization. • New instruction, #UNSYNC.

Select milling cycles at a lathe model. • New instruction, #MILLCY.

Select turning cycles at a milling model. • New instruction, #LATHECY.

Define a kinematics when activating the C axis. • #CYL instruction.

Define a kinematics when activating the C axis. • #FACE instruction.

Improved coordinate transformation (#CS/#ACS).

• Keep the part zero when deactivating the transformation.

• Working with 45º spindles. Select between the two choices.

• Keep the rotation of the plane axes with MODE 6.

G33. New parameter (Q1) to define the entry angle. • G33 function.

G63. Tool inspection is possible during rigid tapping. • G63 function.

Function G112 is not valid for the spindle. • G112 function.

New criteria when assuming a new master spindle in the channel.

Improved tool table.

• Instructions #CS, #ACS.

Ref. 0601

Software V03.01

Axis slaving. Configuring the default status of an axis slaving (coupling). • Machine parameters: LINKCANCEL.

Tool radius compensation. The way tool radius is canceled. • Machine parameters: COMPCANCEL.

Screen test on power-up, if any element is missing, it restores the relevant

backup.

Editing mode. Editing programs in the 8055 CNC language.

DDSSetup mode. Saving and loading the data of all the drives at the same

time.

Using the ":" character to program a comment in a part-program.

Variables. Geometry of the lathe tools.

Variables. Number of the tool in the claws of the changer arm. • Variables:

Automatic mode. It allows executing a program independently.

The instruction #EXEC does not issue an error if the channel is busy; the

instruction waits for the operation in progress to end.

The instruction #EXBLK does not issue an error if the channel is busy; the

instruction waits for the operation in progress to end.

(V.)TM.TOOLCH1[mz] (V.)TM.TOOLCH2[mz]

• #EXEC instruction.

• #EXBLK instruction.

Ref. 0606

Software V03.10

Feedrate. Maximum machining feedrate. • Machine parameter: MAXFEED.

Feedrate. Default machining feedrate when none has been programmed. • Machine parameter: DEFAULTFEED.

The user keys may be configured as jog keys. • Machine parameter: USERKEYDEF.

Disabling a keyboard or jog panel integrated into the CAN bus. • PLC mark: PANELOFF.

Handwheel with push-button. Selecting an axis sequentially for jogging it with

the handwheel.

New parameter to set whether or not the CNC sends the M, H, S functions to

the PLC during block search.

The CNC allows changing the spindle override during electronic threading

(G33) and in the threading canned cycles of the ·T· model (G86, G87 and their

equivalent of the cycle editor).

OEM machine parameters.

• Range of parameters that can be written from the part-program, from the

PLC or from the interface.

• Range of parameters affected by the change of units.

• Each parameter may have a different describing comment associated

with it.

Home search. New home searching method for spindles with home switch.

The spindle goes through the home switch twice.

The CNC displays the warnings generated at the drive.

M function table. New field to define whether the function is sent out to the PLC

or not during block search.

M function table. Each M function may have a different describing comment

associated with it.

General handwheel. The CNC may have several general handwheels.

General handwheel. A general handwheel can move several axes at the same

time.

Improvements in the looks of some softkeys of the editor.

Improvements in the looks of some softkeys of the graphics window.

Editing mode. Programming help files for OEM and global subroutines.

Editing mode. Help file with the list of available subroutines.

• PLC mark: NEXTMPGAXIS.

•

• Machine parameter: FUNPLC.

• Machine parameters:

THREADOVR, OVRFILTER.

• Field: MPLC.

• Field: COMMENT.

CNC 8070

(REF: 1309)

·15·

Page 16

Operating manual

Software V03.10

Editing mode. Improved contextual assistance.

Editing mode. New softkey for deactivating the contextual assistance.

Editing mode. Improvements in the looks of the softkeys.

The automatic mode offers a softkey for selecting the program that is being

edited.

In automatic and jog modes, the CNC shows the status of the _FEEDHOL

mark.

In automatic and jog modes, the CNC shows the status of the INHIBIT mark

of the axes and spindle.

Automatic mode. It shows information on all the spindles.

Jog mode. It shows information on all the spindles.

"Retrace" function.

Tangential control.

Tool table. New softkey for initializing the positions; T1 in position 1, T2 in

position 2, etc.

Tool table. New softkeys for copying and pasting the data of a tool offset.

The CNC checks whether the programmed turning direction (M3/M4) matches

the one preset in the tool table.

Generating the warranty registration report.

Hiding the window for errors and warnings.

M02/M30. There is no need to program M02 or M30 to end a part program. • Functions M02/M30.

Canceling the preset turning direction of a tool. • Variables: (V.)G.SPDLTURDIR

Change the maximum feedrate allowed in the channel from the PLC. • Variables: (V.)[ch].PLC.PLCG00FEED

Show the status of the emergency relay. • Variables: (V.)G.ERELAYST

HSC. New FAST mode. • #HSC instruction.

"C" axis. The #CYL instruction requires programming the radius. • #CYL instruction.

Improved block search.

Tool calibration.

• Manual calibration. When calibration is done, pressing [START] assumes

the new values.

• Semi-automatic calibration. Calibration of lathe tools.

• Semi-automatic calibration. When calibration is done, pressing [START]

assumes the new values.

• Automatic calibration. When calibration is done, the CNC assumes the

new values.

• PLC mark: _FEEDHOL.

• PLC mark: INHIBIT.

CNC 8070

(REF: 1309)

Ref. 0608

Software V03.11

Simulator Possibility to use the dongle (hardware key) in a network.

Line graphics. Improved resizing of the graphics on the screen.

"Retrace" function. Several improvements to the retrace function.

HSC. New command CORNER. • #HSC instruction.

The default value of some machine parameters is different for the CNC and

for the simulator installed on a PC.

G33. The override limitation is maintained while returning to the beginning of

the thread.

RTCP. Home search is now possible on the axes that are not involved in RTCP.

Abort the execution of the program and resume it somewhere else. • New instruction, #ABORT.

• G33 function.

Ref. 0704 / Ref. 0706

Software V03.13

Sign criteria for tool offsets (dimensions) and tool wear. • Machine parameters: TOOLOFSG.

Define the tool wear with incremental or absolute values. • Variables:

Variables V.TM.TOOLCH1[mz] / V.TM.TOOLCH2[mz] may be written from the

PLC.

MDI mode. Cancel the block being executed while keeping the machining

conditions.

Software V03.14

MCU and ICU central unit. battery powered RAM. Connecting handwheels to

the central unit. local I/O. Local feedback inputs. Loca probes.

Define whether the spindle is homed automatically with the first movement or

not.

The application may be restarted while turning the CNC off.

The task window may be accessed by clicking on the OEM icon (top left of the

status bar).

The channels may be accessed by clicking on the icons of the status bar).

The pages of an operating mode may be accessed by clicking on the mode

name (top right of the status bar).

The turning speed limitation (G192) is also applied when the spindle is working

at constant turning speed (G97)

(V.)TM.TOOLCH1[mz] (V.)TM.TOOLCH2[mz].

• G192 function.

·16·

Page 17

Operating manual

Ref. 0707

Software V03.15

Know the type of hardware. • Variable: (V.)G.HARDTYPE

Theoretical tool feedrate along the path. • Variable: (V.)[ch].G.PATHFEED

Every time the diagnosis mode is accessed, the CNC creates the files

SystemInfo.txt and SercosInfo.txt.

PLC errors may have an additional data file associated with them, same as

PLC messages.

User tables. The zero offset table shows the spindles that may be activated

as C axis.

Zero offsets for the C axis.

The CNC shows a warning when a channel is expecting a tool that is being

used in another channel.

Ref. 0709

Software V03.16

Tandem spindles.

Diagnosis mode. Monitoring of the temperature of the CPU, board and

enclosure.

The CNC uses the combined feedback to calculate the velocity command, but

it uses the direct feedback to calculate the compensations, circularity test, etc.

The CNC does not assume any kinematics on power-up. • Machine parameters: KINID

Machine parameters: KINID

The CNC allows modifying the override while threading if it detects that the

feed forward (parameter FFWTYPE) is not active in a gear or if the active feed

forward is lower than 90%

Ref. 0712

Software V03.17

C axis maintained after executing M02, M30 or after an emergency or reset. • Machine parameter: PERCAX.

Ref. 0801

Software V03.20

The CNC has a different MTB folder for each type of software installed; MTB_T

for lathe, MTB_M for mill and MTB_MC for motion control.

By default, the feedback alarms of the analog axes are activated.

Set change.

• For the CNC to assume the new parameter set, it must wait for the PLC

to receive the confirmation of one of the marks GEAR1 to GEAR4.

• The gear change concludes when the PLC receives the confirmation

signal AUXEND.

• Sercos spindle. The set change only affects the drive when it implies a

change of gear ratio.

• The CNC lets change the gear of the slave axis or spindle of a tandem.

Coordinate latching with the help of a probe or a digital input. • Variables:

PLC. The PLC program can have several mnemonic files (extension "plc").

PLC. When defining each PLC error, it is possible to select whether it opens

the emergency relay or not.

PLC. Grouping the additional information text files in a single file.

PLC. Contact (ladder) editor.

Status of the local probes. • Variables: (V.)G.PRBST1 (V.)G.PRBST2.

Axis synchronization. Managing a rotary axis as an infinite axis making it

possible to increase the feedback count of the axis indefinitely (wihout limits)

regardless of the value of the module.

Errors and warnings.

• From the errors and warnings, it is possible to access the errors solving

(troubleshooting) manual.

• CNC errors between 10000 and 20000 are reserved for the OEM so he

can create his own warning or error texts in different languages.

Show a warning and interrupt program execution. • New instruction, #WARNINGSTOP.

Electronic cam programming (theoretical coordinates). • New instruction, #TCAM.

Dynamic distribution of the machining operations between channels. • New instruction, #DINDIST.

The CNC can park the main axes.

The axes may be programmed using the "?" wild card that refers to the axis

position in the channel.

Functions G130 (percentage of acceleration) and G132 (percentage of jerk)

may be applied to the spindles.

Profile editor. Axes coordinated with auto-scale and name of the axes.

Profile editor. Zoom and movement of the graphics area via keyboard.

Profile editor. At the lathe model, the orientation of the axes is defined by

parameter GRAPHTYPE.

Edisimu mode. Inclined plane programming assistance.

(V.)[ch].A.LATCH1.xn (V.)[ch].A.LATCH2.xn

• Variables: (V.)[ch].A.ACCUDIST.xn

•Wild card "?".

• Functions G130 and G132.

• Machine parameter: GRAPHTYPE.

CNC 8070

(REF: 1309)

·17·

Page 18

CNC 8070

(REF: 1309)

Operating manual

Software V03.20

Edisimu mode. To simulate the program, when pressing the "START" softkey,

the CNC assumes the real configuration of the spindles of the channel and the

configuration of the machine parameters. The starting coordinates for

simulation will be the real coordinates that the CNC had on power-up.

Edisimu mode. New window for consulting the status of the subroutines,

canned cycles, block repetition and loops.

Edisimu mode. The "START" softkey saves the program being edited.

Automatic mode. New functions and instructions that cancel the retrace

function.

Automatic mode. New window for consulting the status of the subroutines,

canned cycles, block repetition and loops.

Automatic mode. The [START] key saves the program being edited.

Diagnosis mode. Generate the Fagor file for error diagnosis.

Tool table. When selecting an incremental wear, it is possible to define the

maximum increment possible; by default 0.5 mm (0.019685 inch).

Machine parameters tables. Import and export leadscrew compensation

tables.

Within a work mode, select the different pages in reverse order using the

[SHIFT] key.

Setup assistance. Bode.

Interface related variables.

Ref. 0809

Software V04.00 (it does not include the features of version V03.21)

Unicode.

New language (Chinese).

In the machine parameter table, an icon indicates which parameters are

involved in parameter matching.

Handwheels. There can now be up to 12 handwheels. • Machine parameter: NMPG.

The CNC applies module compensation throughout the entire revolution of the

axis.

Home search moving the axis to the reference point. • Machine parameter: POSINREF.

PLC. There can now be up to 1024 PLC messages. • PLC resources: MSG.

PLC. There can now be up to 1024 PLC errors. • PLC resources: ERR.

Handwheels. Inhibit the handwheels of the system. • PLC mark: INHIBITMPG1/INHIBITMPG12.

Cancel spindle synchronization after executing M02, M30 or after an error or

a reset.

Positioning a turret magazine whether there is a tool in the indicated position

or not.

A channel maintains its master spindle after executing M02, M30 or after an

emergency or a reset or restarting the CNC.

Force the change of gears and/or of the parameter set of a Sercos drive • Variable: (V.)A.SETGE.xn

Set a machine coordinate. • G174 function.

There can now be up to 99 zero offsets. • G159 function.

There can now be up to 100 synchronization marks. • Instructions #MEET, #WAIT and #SIGNAL.

Select a turret position. • #ROTATEMZ instructions.

Axis synchronization. Managing a rotary axis as an infinite axis making it

possible to increase the feedback count of the axis indefinitely (wihout limits)

regardless of the value of the module.

Variables. The variable (V.)[ch].E.PROGSELECT can be written via partprogram, PLC and interface. This variable can only be written with the value

of ·0·

Variables. The following variables are valid for the spindle. • Variables: (V.)[ch].A.MEAS.sn

Profile editor.

• Programming in Polar coordinates.

• Programming in incremental coordinates.

• Best zoom, display part zero and auto-zoom from the keyboard.

• Improved softkey menu.

Jog mode. New softkey to turn the CNC off.

Jog mode. In handwheel mode, next to each axis, the CNC indicates whether

that axis has an individual handwheel associated with it or not.

Jog mode. The screen shows the tool dimensions.

Automatic mode. The screen shows the tool dimensions.

Handwheels. The general handwheels can move axes with an associated

individual handwheel.

Handwheels. Number of pulses sent by the handwheel since the system was

started up.

Feed handwheel.

Diagnosis mode. View the error and warning history issued by the CNC.

• Machine parameter: MODCOMP.

• Instructions #SYNC and #TSYNC.

• #ROTATEMZ instructions.

• #MASTERinstruction.

• Variables: (V.)[ch].A.PREVACCUDIST.xn

• Variables: (V.)[ch].E.PROGSELECT

(V.)[ch].A.ATIPMEAS.sn

(V.)[ch].A.MEASOF.sn

(V.)[ch].A.MEASOK.sn

(V.)[ch].A.MEASIN.sn

• Variables: (V.)G.HANDP[hw]

·18·

Page 19

Operating manual

Software V04.00 (it does not include the features of version V03.21)

Edisimu mode and PLC mode.

• New hotkey to redo an operation.

• The editor shows the line number.

• The option "Find/replace" permits selecting the search direction, up or

down. New softkey to look for the text without replacing it.

• The editor adjusts the long blocks to the size of the window dividing the

block into several lines.

• The editor offers hotkeys [CTRL]+[+] and [CTRL]+[–] to increase or

decrease the size of the editor font. If the CNC has a mouse with a wheel,

the [CTRL] key combined with this wheel can also be used to increase

and decrease the size of the text font.

• In large files (more than 200 kB), the editor cancels the syntax coloring.

• In large files (more than 200 kB), the editor does not save the program

when changing blocks; the editor saves the program when the user has

not modified the program for about 5 seconds.

Edisimu mode.

• Comments having an asterisk (*) and programmed at the beginning of the

block allow to group blocks. Blocks programmed between these

comments will be grouped and may be expanded or shrunk the same way

as the cycles or profiles.

• Having the "Hide cycles/profiles" option active, when the cursor moves

over a hidden element, it expands automatically; when the cursor moves

out of the element, it shrinks again.

• The editor offers the [ALT]+[–] hotkey to expand y hide cycles, profiles and

grouped blocks. If the CNC has a mouse, click on the symbol located to

the right of the cycle, profile or group of blocks to expand them and hide

them.

• In large files (more than 200 kB), the editor does not hide the canned

cycles or the profiles.

PLC mode. New softkeys to sort the files that make up the PLC project.

Ref. 0811

Software V03.21 (features not included in version V04.00)

There can now be up to 1024 PLC messages. • PLC resources: MSG.

There can now be up to 1024 PLC errors. • PLC resources: ERR.

Ref. 0907

Software V04.01

The CNC turns the internal fan on and off as necessary. The CNC turns the

fan on when the temperature exceeds 50 ºC (122 ºF) and turns it off when it

gets under 45 ºC (113 ºF).

Communication with servos (axis and spindle) and inverters (spindle) through

the Mechatrolink bus, in Mlink-I (17 bytes) and Mlink-II (17 or 32 bytes) mode.

Define the maximum acceleration and jerk allowed on the tool path. • Machine parameters:

Variable to know the following error (lag) when feedback combination is active. • Variables:

Variable to know the position value of the first feedback when feedback

combination is active.

Diagnosis mode. Monitor battery voltage.

MAXACCEL, MAXJERK.

• Variables:

(V.)[ch].G.MAXACCEL (V.)[ch].G.MAXJERK

(V.)[ch].A.FLWE.xn (V.)[ch].A.FLWACT.xn

• Variable: (V.)[ch].A.POSMOTOR.xn

Ref. 1007