Page 1

Owner’s Manual

Model 9210, 9220, 9230

Vehicular Slide Gate Operators

DoorKing, Inc.

120 Glasgow Avenue

Inglewood, California 90301

U.S.A.

Phone: 310-645-0023

Fax: 310-641-1586

www.doorking.com

P/N 9210-065 Rev F, 11/07

Copyright 2001 DoorKing, Inc. All rights reserved.

Page 2

Page 2 9210-065-F-11-07

Page 3

Use this manual with the following models only.

Models 9210-080, 9210-081, 9210-082, 9210-083, 9210-084, 9210-086, 9210-087, 9210-088,

9210-089, 9210-090, 9210-091, 9220-080, 9220-081, 9220-082, 9220-083, 9220-084, 9220-085,

9220-086, 9220-087, 9230-080, 9230-081 with circuit board 4404-010.

DoorKing, Inc. reserves the right to make changes in the products described in this manual

without notice and without obligation of DoorKing, Inc. to notify any persons of any such revisions

or changes. Additionally, DoorKing, Inc. makes no representations or warranties with respect to

this manual. This manual is copyrighted, all rights reserved. No portion of this manual may be

copied, reproduced, translated, or reduced to any electronic medium without prior written consent

from DoorKing, Inc.

9210-065-F-11-07 Page 3

Page 4

Glossary

GATE: A moving barrier such as a swinging, sliding, raising, lowering, or the like, barr ier, that is a stand-alone

passage barrier or is that portion of a wall or fence s ystem that controls entrance and/or egress by persons or

vehicles and completes the perimeter of a defined area.

RESIDENTIAL VEHICULAR GATE OPERATOR – CLASS I: A vehicular gate operator (or s ystem) intended for

use in a home of one-to four single family dwelling, or garage or parking area associated there with.

COMMERCIAL / GENERAL ACCESS VEHICULAR GATE OPERATOR - CLASS II: A vehicular gate operator

(or system) intended for use in a commercial location or buil d ing suc h as a multi-family housin g unit (five or mor e

single family units), hotels, garages, retail store, or other building servicing the general public.

INDUSTRIAL / LIMITED ACCESS VEHICULAR GATE OPERATOR - CLASS III: A vehicular gate operator (or

system) intended for use in an industrial location or building suc h as a factory or loading dock area or other

locations not intended to service the general public.

RESTRICTED ACCESS VEHICULAR GATE OPERATOR - CLASS IV: A vehicular gate operator (or system)

intended for use in a guarded industrial location or buil ding such as an airport security area or other restricted

access locations not servicing the general public, in which unauthorized access is prevented v ia supervision by

security personnel.

VEHICULAR BARRIER (ARM) OPERATOR (OR SYSTEM): An operator (or system) that controls a cantilever

type device (or system), consisting of a mechanical arm or barrier that moves in a vertical arc, intended for

vehicular traffic flow at entrances or exits to areas such as parking garages, lots or toll areas.

VEHICULAR HORIZONTAL SLIDE-GATE OPERATOR (OR SYSTEM): A vehicular gate operator (or system)

that controls a gate which slides in a horizontal direction that is intended for use for vehicular entrance and exit to

a drive, parking lot, or the like.

VEHICULAR SWING-GATE OPERATOR (OR SYSTEM): A vehicular gate operator (or system) that controls a

gate which moves in an arc in a horizontal plane that is intended for use for vehicular entrance and exit to a

drive, parking lot, or the like.

SYSTEM: In the context of these requirements, a system refers to a group of interacting devices intended to

perform a common function.

WIRED CONTROL: A control implemented in a form of fixed physical interconn ections between the control, the

associated devices, and an operator to perform predetermined functions in response to input signals.

WIRELESS CONTROL: A control implemented in means other than fixed physical interconnections (such as

radio waves or infrared beams) between the control, the associated devices, and an operator to perform

predetermined functions in response to input signals.

INHERENT ENTRAPMENT PROTECTION SYSTEM: A system, examples being a motor current or speed

sensing system, which provides protection against entrapment upon se nsing an object and is incorporated as a

permanent and integral part of the operator.

EXTERNAL ENTRAPMENT PROTECTION DEVICE: A device, examples being an edge sensor, a photoelectric

sensor, or similar entrapment protection device, which provides protection against entrapment when activated

and is not incorporated as a permanent part of an operator.

ENTRAPMENT: The condition when an object is caught or held in a position that increases the risk of injur y.

Page 4 9210-065-F-11-07

Page 5

Entrapment Protection

Protection Against Entrapment

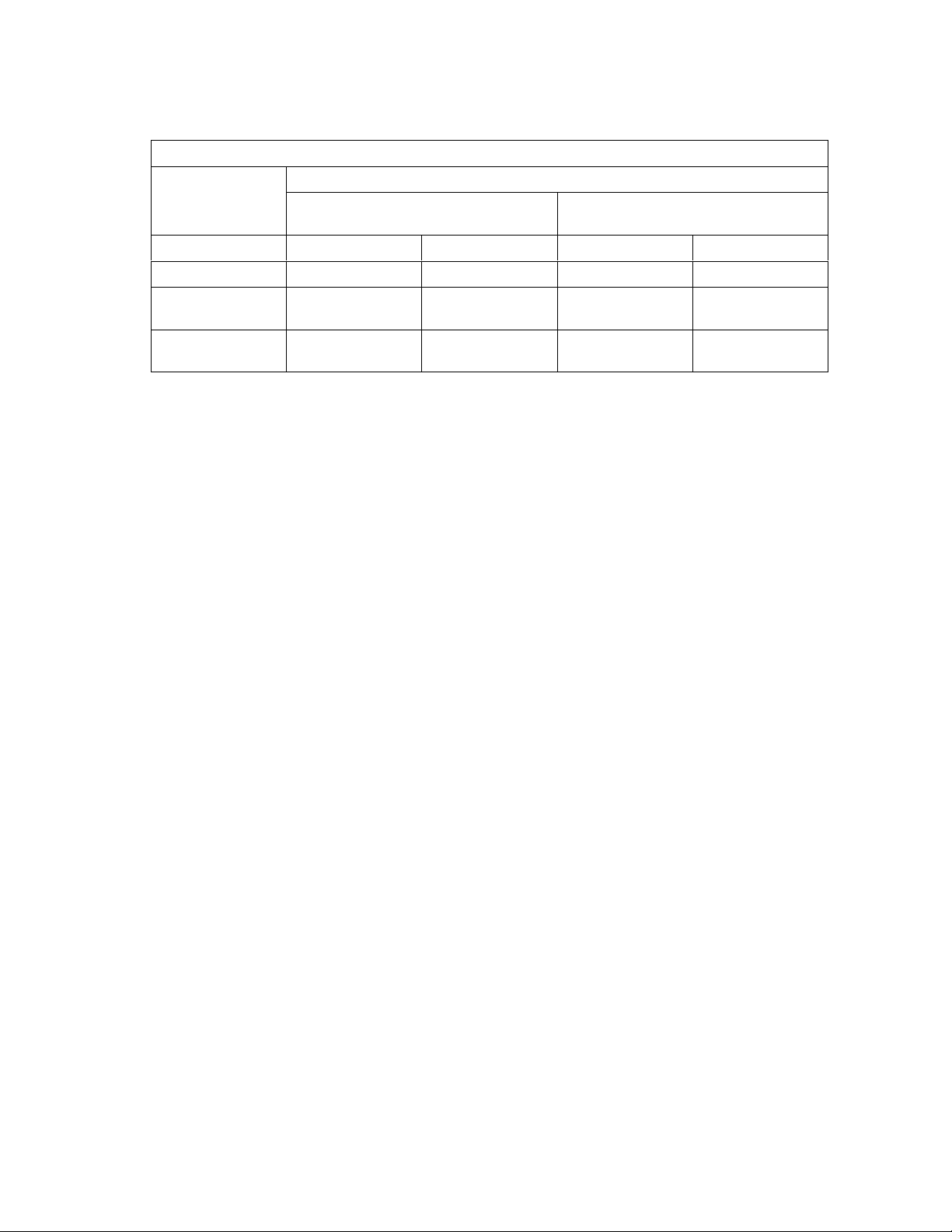

Gate Operator Category

Horizontal Slide, Vertical Lift,

Vertical Pivot

Usage Class Primary Secondary Primary Secondary

Vehicular I and II A B1, B2 or D A or C A, B1, B2, C or D

Vehicular III A, B1 or B2 A, B1, B2, D or E A, B1, B2 or C A, B1, B2, C,

Vehicular IV A, B1, B2 or D A, B1, B2, D or E A, B1, B2, C or D A, B1, B2, C,

TYPE A: Inherent entrapment protection system.

TYPE B1: Provision for connection of, or supplied with, a non-contact sensor

(photoelectric sensor or the equivalent). When used as the PRIMARY

device, must be monitored.

TYPE B2: Provision for connection of, or supplied with, a contact sensor (edge

device or the equivalent). When used as the PRIMARY device, must be

monitored.

TYPE C: Inherent adjustable clutch or pressure relief device.

TYPE D: Provision for connection of, or supplied with, an actuating device

requiring continuous pressure to maintain opening or closing motion of

the gate.

TYPE E: An inherent audio alarm.

Swing and Vertical Barrier (arm)

D or E

D or E

9210-065-F-11-07 Page 5

Page 6

Important Notices

Vehicular gate operator products provide convenience and security. However, gate operators must

use high levels of force to move gates and most people underestimate the power of these systems

and do not realize the potential hazards associated with an incorrectly designed or installed system.

These hazards may include:

• Pinch points

• Entrapment areas

• Reach through hazards

• Absence of entrapment protection devices

• Improperly located access controls

• Absence of vehicle protection devices

• Absence of controlled pedestrian access

In addition to these potential hazards, automated vehicular gate systems must be installed in

accordance with the UL-325 Safety Standard and the ASTM F2200 Construction Standard. Most lay

persons are unaware of, or are not familiar with, these standards. If an automated vehicular gate

system is not properly designed, installed, used and maintained, serious injuries or death can result.

Be sure that the installer has instructed you on the proper operation of the gate and gate operator

system. Be sure that the installer has trained you about the basic functions of the required reversing

systems associated with your gate operating system and how to test them. These include reversing

loops, inherent reversing system, electric edges, photoelectric cells, or other external devices.

• This Owner’s Manual is your property. Keep it in a safe place for future reference.

• Be sure that all access control devices are installed a minimum distance of 10 feet

away from the gate and gate operator, or in such a way that a person cannot touch the

gate or gate operator while using the device. If access control devices are installed in

violation of these restrictions, immediately remove the gate operator from service and contact

your installing dealer.

Loops and loop detectors, photo-cells or other equivalent devices must be installed to prevent the

gate from closing on vehicular traffic.

• The speed limit for vehicular traffic through the gate area is 5 MPH. Install speed bumps and

signs to keep vehicular traffic from speeding through the gate area. Failure to adhere to

posted speed limits can result in damage to the gate, gate operator, and to the vehicle.

• Be sure that all persons who will use the gate system are familiar with the proper use of the

gate and gate operator and are familiar with the possible hazards associated with the gate

system.

• Be sure that warning signs are permanently installed on both sides of the gate in an area

where they are fully visible to traffic.

• It is your responsibility to periodically check all entrapment protection devices. If any of these

devices are observed to function improperly, remove the operator from service immediately

and contact your installing or servicing dealer.

• Follow the recommended maintenance schedule.

• Do not allow children to play in the area of the operator or to play with any gate-operating

device.

• To remove the gate operator from service, operate the gate to the full open position and then

shut off power to the operator at the service panel.

Page 6 9210-065-F-11-07

Page 7

Important Safety Instructions

WARNING - To reduce the risk of injury or death:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with gate controls. Keep the remote control away

from children.

3. Always keep people and objects away from gate. NO ONE SHOULD CROSS THE

PATH OF THE MOVING GATE.

4. Test the operator monthly. The gate MUST reve rse on con tact ( contac t sens ors must

be installed) with a rigid object or stop or reverse when an object activates the noncontact sensors. After adjusting the force or the limit of travel, retest the gate

operator. Failure to adjust and retest the gate operator properly can increase the risk

of injury or death.

5. Use the emergency release only when the gate is not moving.

6. KEEP GATES PROPERLY MAINTAINED. Read the owner's manual. Have a

qualified service person make repairs to gate hardware.

7. The entrance is for vehicles only. Pedestrians must use separate entrance.

8. SAVE THESE INSTRUCTIONS!

Gate Construction

Vehicular gates should be constructed and installed in accordance with ASTM F2200; Standard

Specification for Automated Vehicular Gate Construction. For a copy of this standard, contact ASTM

directly at 610-832-9585; service@astm.org; or www.astm.org

.

9210-065-F-11-07 Page 7

Page 8

Instructions regarding intended installation:

Install the gate operator only if:

1. The operator is appropriate for the construction of the gate and the usage class of

the gate.

2. All openings of a horizontal slide gate are guarded or screened from the bottom of

the gate to a minimum of 4 feet (1.22 m) above the ground to prevent a 2 ¼ inch

(57.2 mm) diameter sphere from passing through the openings anywhere in the gate,

and in that portion of the adjacent fence that the gate covers in the open position.

3. All exposed pinch points are eliminated or guarded.

4. Guarding is supplied for exposed rollers.

The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied

with a separate access opening. The pedestrian access opening shall be designed to promote

pedestrian usage. Locate the gate such that persons will not come in contact with the vehicular gate

during the entire path of travel of the vehicular gate.

The gate must be installed in a location so that enough clearance is supplied between the gate and

adjacent structures when opening and closing to reduce the risk of entrapment. Swinging gates

should not open into public access areas.

The gate must be properly installed and work freely in both directions prior to the installation of the

gate operator. Do not over-tighten the operator clutch, pressure relief valve or reduce reversing

sensitivity to compensate for a damaged gate.

For gate operators utilizing Type D protection:

1. The gate operator controls must be placed so that the user has full view of the gate

area when the gate is moving.

2. A warning placard shall be placed adjacent to the controls.

3. An automatic closing device (such as a timer, loop sensor, or similar device) shall not

be employed.

4. No other activation device shall be connected.

Controls intended for user activation must be located at least ten feet (10’) away from any moving

part of the gate and where the user is prevented from reaching over, under, around or through the

gate to operate the controls. Outdoor or easily accessible controls should have a security feature to

prevent unauthorized use.

The Stop and/or Reset button must be located in the line-of-sight of the gate. Activation of the reset

control shall not cause the operator to start.

A minimum of two (2) WARNING SIGNS shall be installed, one on each side of the gate where easily

visible.

For gate operators utilizing a non-contact sensor:

1. See the instructions on the placement of non-contact sensors for each type of

application.

2. Care shall be exercised to reduce the risk of nuisance tripping, such as when a

vehicle trips the sensor while the gate is still moving in the opening direction.

3. One or more non-contact sensors shall be located where the risk of entrapment or

obstruction exist, such as the perimeter reachable by a moving gate or barrier.

Page 8 9210-065-F-11-07

Page 9

For gate operators utilizing contact sensors:

1. One or more contact sensors shall be located where the risk of entrapment or

obstruction exist, such as at the leading edge, trailing edge, and post mounted both

inside and outside of a vehicular horizontal slide gate.

2. One or more contact sensors shall be located at the bottom edge of a vehicular

vertical lift gate.

3. One or more contact sensors shall be located at the pinch point of a vehicular vertical

pivot gate.

4. A hardwired contact sensor shall be located and its wiring arranged so that the

communication between the sensor and the gate operator is not subjected to

mechanical damage.

5. A wireless contact sensor such as one that transmits radio frequency (RF) signals to

the gate operator for entrapment protection functions shall be located where the

transmission of the signals are not obstructed or impeded by building structures,

natural landscaping or similar obstructions. A wireless contact sensor shall function

under the intended end-use conditions.

7. One or more contact sensors shall be located at the bottom edge of a vertical barrier

(arm).

9210-065-F-11-07 Page 9

Page 10

Slide Gate Requirements

All openings of a horizontal slide gate are guarded or screened from the

bottom of the gate to a minimum of four (4) feet (1.22 m) above the ground to

prevent a 2 1/4 inch (57.2 mm) diameter sphere from passing through the

openings anywhere in the gate and in that portion of the adjacent fence that

the gate covers in the open position.

(ref. UL325 56.8.4.a.2 and ASTM F2200 6.1.2)

Fence

A

A gap, measured in the horizontal plane parallel to

the roadway, between a fixed stationary object

nearest the roadway (such as a gate support post)

and the gate frame when the gate is in either the

fully open position or the fully closed position, shall

not exceed 2 1/4 inch (57.2 mm).

(ref. ASTM F2200 6.1.4)

Fence

The operator is intended for installation only on gates used for vehicles.

Pedestrians must be supplied w ith a seperate access openi ng. The

pedestrian access opening shall be designed to promote pedestrian

usage. Locate the gate such that persons will not come in contact with

the vehicular gate during the entire path of travel of the vehicular gate.

(ref. UL325 56.8.4.b)

Roadway

Vehicular Gate

Operator

Gate

Pedestrian

Access

Sidewalk

4 ft.

min

Fence

A

Gate

Fence

Operator

Entrapment Area

Pad

This area between the gate and fence has a high risk of entrapment. The gap between the fence and gate should not exceed

A

2 ¼ inches. Install a filler or barrier in this area to reduce this gap to 2 ¼ inches or less.

Install a contact sensor (type B2) on the fence to help minimize the risk of entrapment in this area.

B

B

2 1/4"

Max

2 1/4"

Max

Page 10 9210-065-F-11-07

Page 11

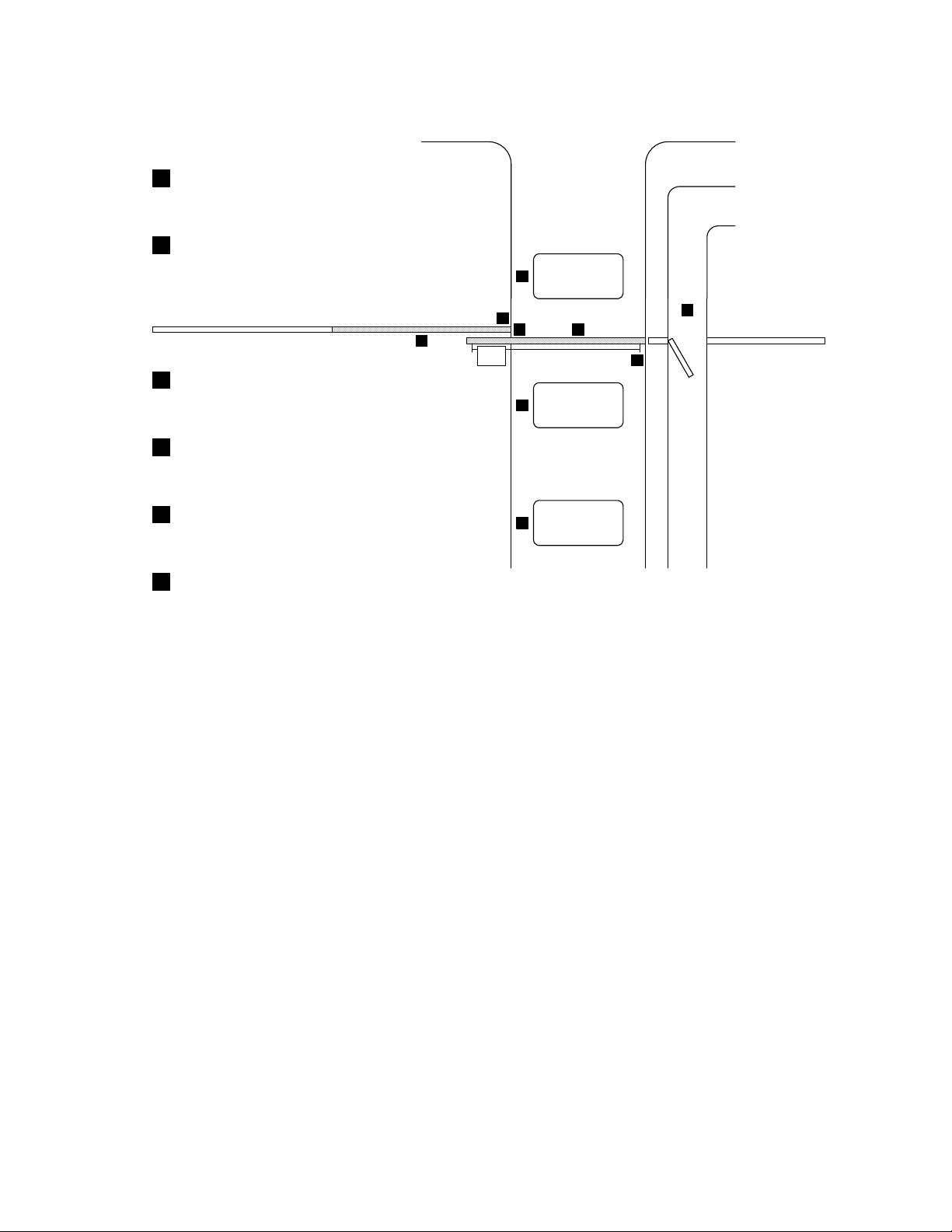

Slide Gate Protection

Loops to help minimize t h e pot e nt ia l of th e ga t e to

1

close when a vehicle is present. Number and

placement of loops is dependent on the application.

Contact sensor installed on the fence to help minimize

2

the potential of entrapment between the gate and

fence.

Reverse

1

Loop

Fence

Non-contact sensor to help minimize the potential

3

of the gate closing on vehicular or other traffic that

loops cannot sense.

Non-contact sensor to help minimize the potential

4

of entrapment during the back travel of the gate.

Warning signs are to be place d on eac h si de of the

5

gate so that they are easily visible from either side

of the gate.

A separate pedestrian access located so

6

pedestrians cannot come in contact with the

vehicular gate.

5

Operator

2 3

Reverse (Open)

1

Open Loop

1

(Optional)

5

Loop

4

6

Pedestrian

Access

Sidewalk

Fence

9210-065-F-11-07 Page 11

Page 12

Table of Contents

Section 1 – Installation

1.1 Specifications ...........................................................................................................................................15

1.2 Mounting Options .....................................................................................................................................16

1.3 Chain Guide Adjustment...........................................................................................................................17

1.4 Pad Mount Installation..............................................................................................................................18

1.5 Mounting Stand Installation......................................................................................................................20

1.6 Chain Installation......................................................................................................................................22

1.7 Warning Sign Installation..........................................................................................................................24

Section 2 – Wiring

Conduits ...................................................................................................................................................25

2.1 High Voltage Connections........................................................................................................................26

2.2 Control Wiring...........................................................................................................................................27

2.3 Loop Detector Wiring................................................................................................................................28

2.4 Auxiliary Device Wiring.............................................................................................................................29

2.5 Primary / Secondary (Bi-Parting) Wiring...................................................................................................30

2.6 Terminal Identification and Description

2.6.1 Main Terminals.........................................................................................................................31

2.6.2 Limit Switch Connector.............................................................................................................32

2.6.3 Reversing Device Connector....................................................................................................32

Section 3 – Adjustments

3.1 Circuit Board Adjustments........................................................................................................................33

3.2 Switch Settings.........................................................................................................................................34

3.2.1 SW 1 (Right Switch) Description and Function ........................................................................35

3.2.2 SW 2 (Left Switch) Description and Function...........................................................................35

3.3 Limit Switch Adjustment ...........................................................................................................................36

3.4 Reverse Adjustment.................................................................................................................................37

3.5 Speed Control...........................................................................................................................................38

3.6 Current Sensor Wiring Information...........................................................................................................38

Page 12 9210-065-F-11-07

Page 13

Section 4 – Operating Instructions

4.1 Power and Reset Switches ......................................................................................................................39

4.2 Shutdown Conditions

4.2.1 Soft Shutdown..........................................................................................................................40

4.2.2 Resetting a Soft Shutdown.......................................................................................................40

4.2.3 Hard Shutdown ........................................................................................................................41

4.2.4 Resetting a Hard Shutdown .....................................................................................................41

4.3 Manual Gate Operation............................................................................................................................42

Section 5 – Maintenance and Troubleshooting

5.1 Maintenance Schedule.............................................................................................................................43

5.2 Operator Diagnostics................................................................................................................................44

5.3 Troubleshooting........................................................................................................................................45

5.4 Accessories..............................................................................................................................................47

Wire Diagrams

115 VAC .................................................................................................................................................48

230 VAC, 1-Phase....................................................................................................................................49

208 VAC, 3-Phase....................................................................................................................................50

230 VAC, 3-Phase....................................................................................................................................51

460 VAC, 3-Phase....................................................................................................................................52

208 VAC, 1-Phase Variable Speed..........................................................................................................53

208 VAC, 3-Phase Variable Speed..........................................................................................................54

230 VAC, 1-Phase Variable Speed..........................................................................................................55

230 VAC, 3-Phase Variable Speed..........................................................................................................56

9210-065-F-11-07 Page 13

Page 14

Page 14 9210-065-F-11-07

Page 15

SECTION 1 - INSTALLATION

Prior to beginning the installation of the slide gate operator, we suggest that you become familiar with

the instructions, illustrations, and wiring guide-lines in this manual. This will help insure that your

installation is performed in an efficient and professional manner. The proper installation of the

vehicular slide gate operator is an extremely important and integral part of the overall access control

system. Check all local building ordinances and building codes prior to installing this operator. Be

sure your installation is in compliance with local codes.

1.1 Specifications

Class of Operation: Class III, IV

Type of Gate: Vehicular Slide Gates Only

Horsepower: 9210/9220: 1 HP; 9230: 3 HP

Voltage / Phase: 9210/9220: 115, 208, 230 VAC 1

9230: 208, 230 VAC 3Ø

Current: 9210/9220: 1

9210/9220: 3

9230 3

Max Gate Wt.

1

9210: 3000 Lbs; 9220: 2000 Lbs; 9230: 5000 Lbs.

Ø

: 15 A @ 115V, 7.5 A @ 208V, 7.4 A @ 230V

Ø

Ø

: 3.4 A @ 208V, 3.3 A @ 230V, 1.7 A @ 460V

: 12.4 A @ 208/230V

Max Gate Length: 100 Feet

Cycles / Hr: 60/Hr

Speed: 9210: Approx 1 Ft./Sec.

9220/9230: Adjustable ½ - 2 Ft./Sec.

Entrapment Protection: Primary – Inherent (Type A)

Secondary – Provision for connection of a non-contact

sensor (Type B1) and/or a contact sensor (Type B2).

Secondary entrapment protection devices are not supplied

with the operator and must be ordered separately.

Note 1: Assumes gate is in good working condition installed on a level

surface.

Ø

/ 208, 230, 460 VAC 3

Ø

2

35.25

16

9210-065-F-11-07 Page 15

16

Page 16

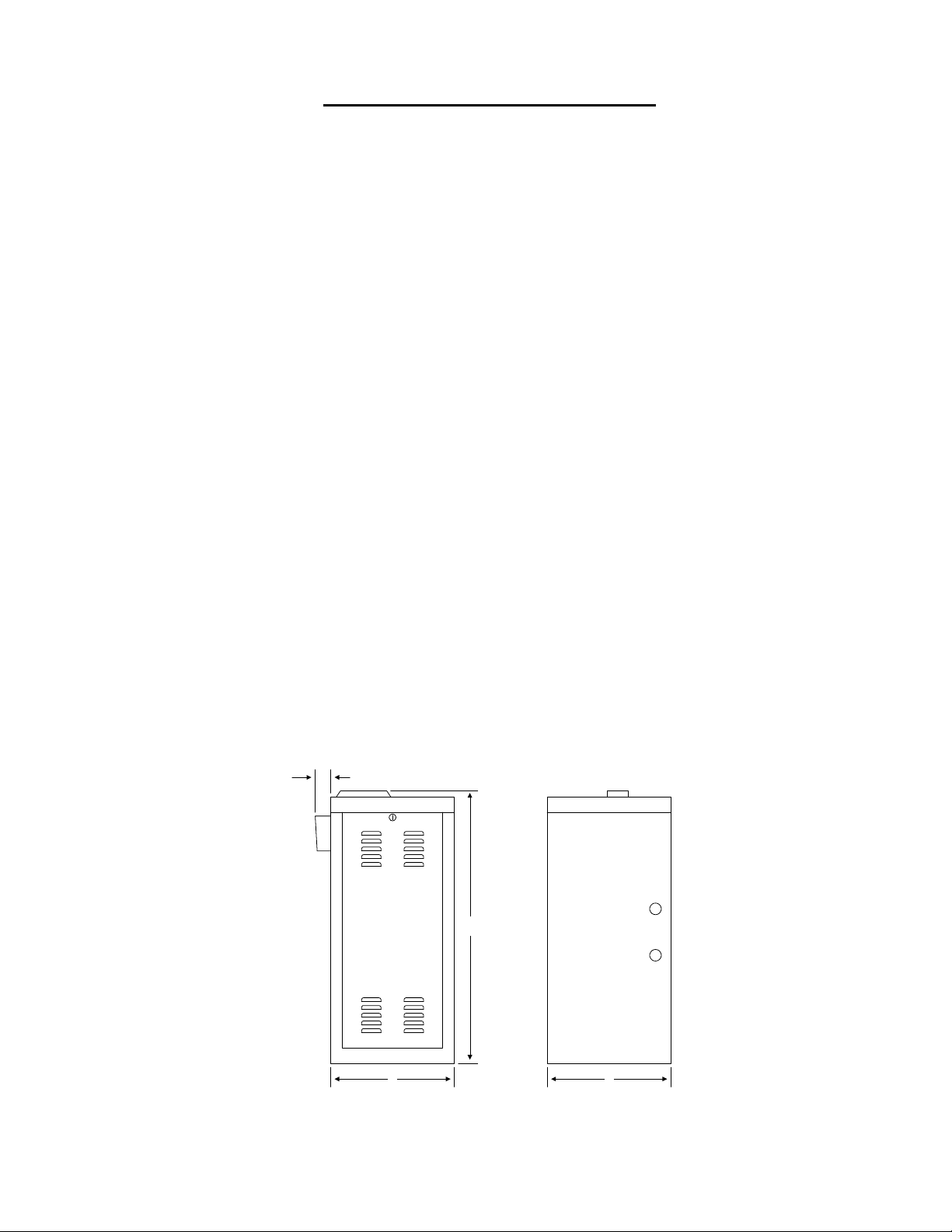

1.2 Mounting Options

The 9210, 9220 and 9230 vehicular gate operators are designed to be mounted on the optional

mounting stand (p/n 9200-135) or directly to a concrete pad. The mounting stand option is

recommended if the gate length exceeds 30 feet since this mounting method will allow a “chain rest”

to be mounted on the gate.

Pad mounting is typically

used with gates that are less

than 30 feet in length.

Requires use of the pad

mounting plate that is

included with the operator.

Pedestal mounting is

typically used with gates that

are greater than 30 feet in

length since this method

allows a chain rest to be

installed on the gate.

Requires use of the pad

mounting plate that is

included with the operator.

Requires use of the

OPTIONAL operator

mounting stand.

Page 16 9210-065-F-11-07

Page 17

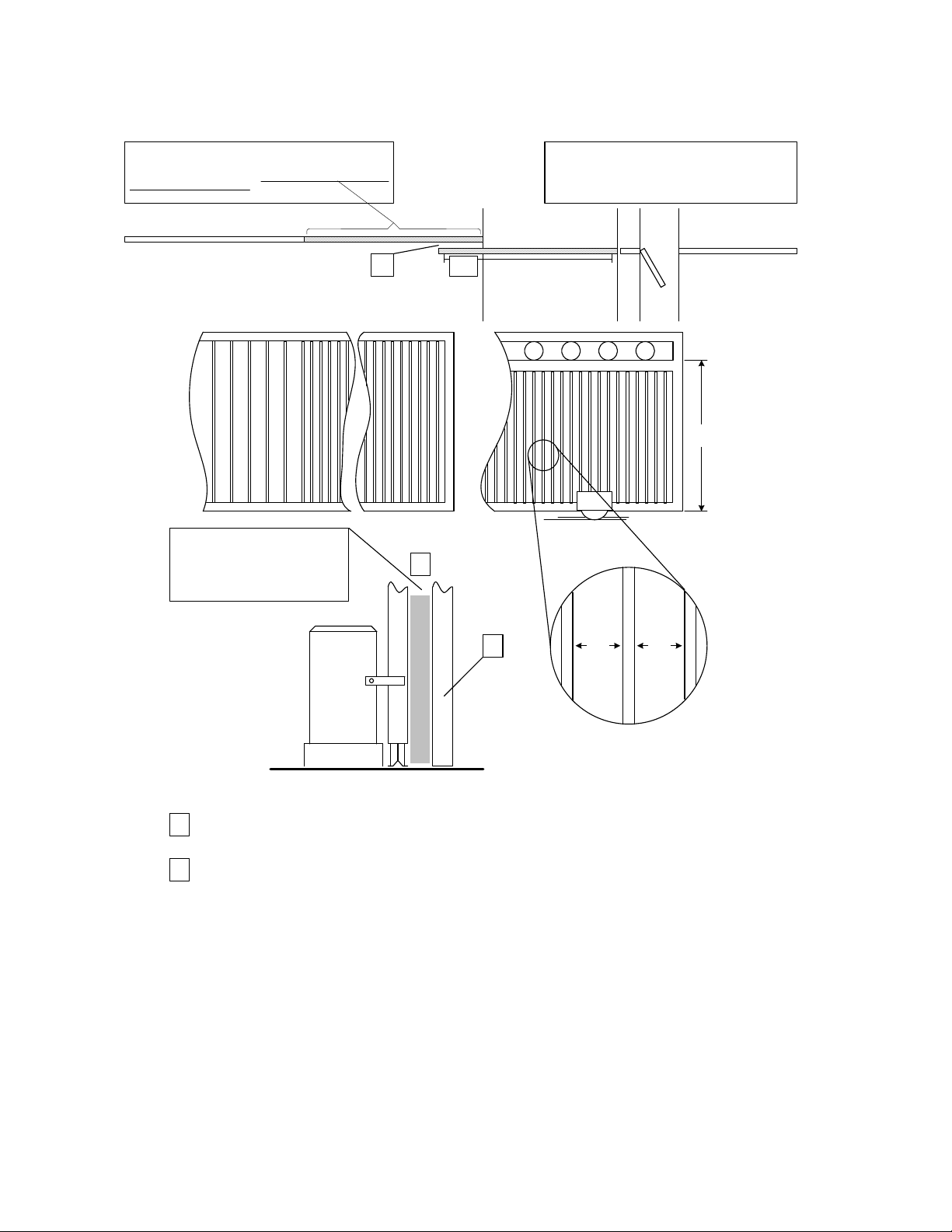

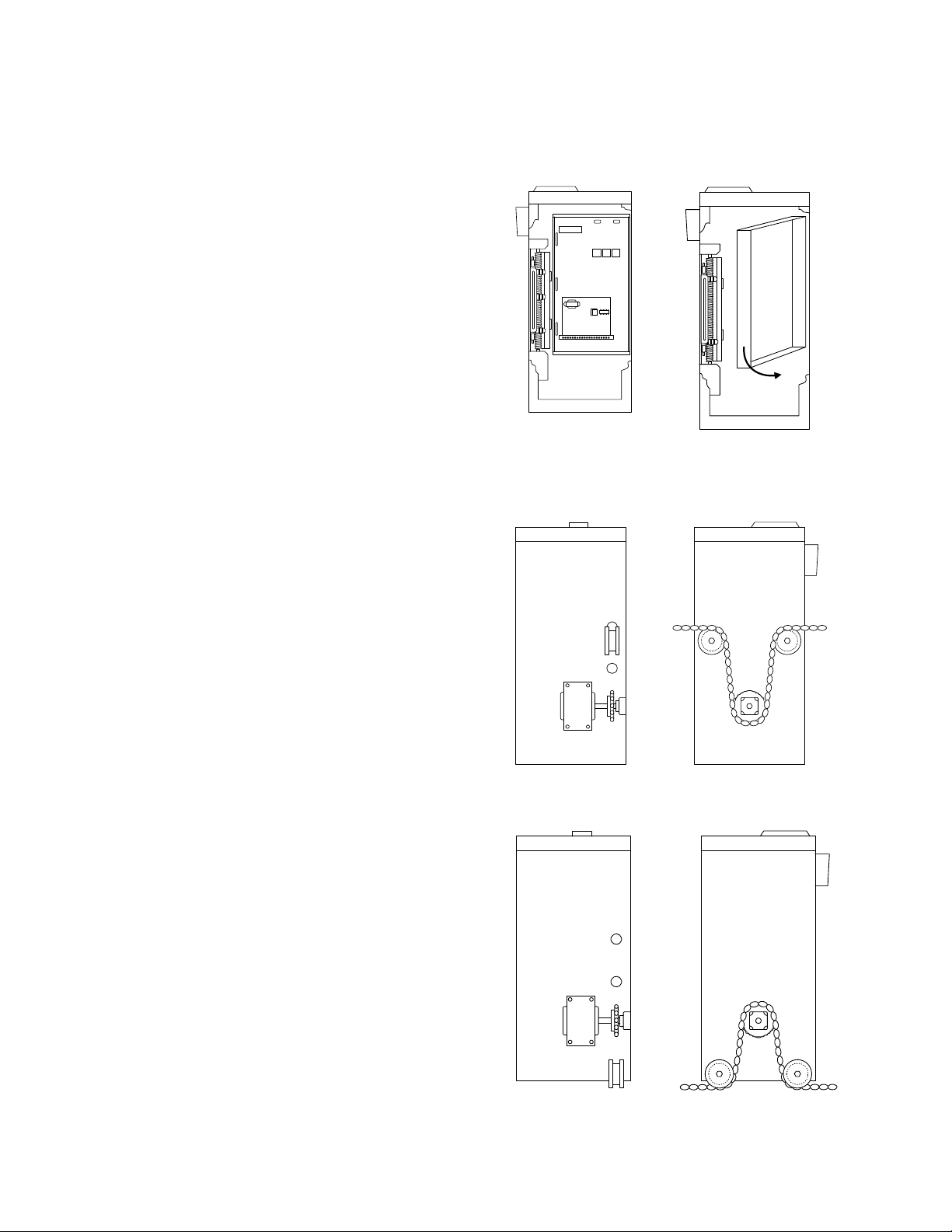

1.3 Chain Guide Adjustment

f

After determining which mounting method is to be used (pad or mounting stand), adjust the chain

guides according to the mounting method being used.

To gain access to the inside of the operator,

remove three hex-head nuts from the left side o

the control panel housing.

Pull the housing out and away.

OPEN

For pad mounted operators, remove the UPPER

hole knockouts from each side of the operator.

Adjust the chain guides as shown.

Chain will be routed OVER the chain guides and

UNDER the drive sprocket.

For operators mounted on the mounting stand,

DO NOT remove any hole knockouts.

Adjust the chain guides as shown.

Chain will be routed UNDER the chain guides

and OVER the drive sprocket.

9210-065-F-11-07 Page 17

Page 18

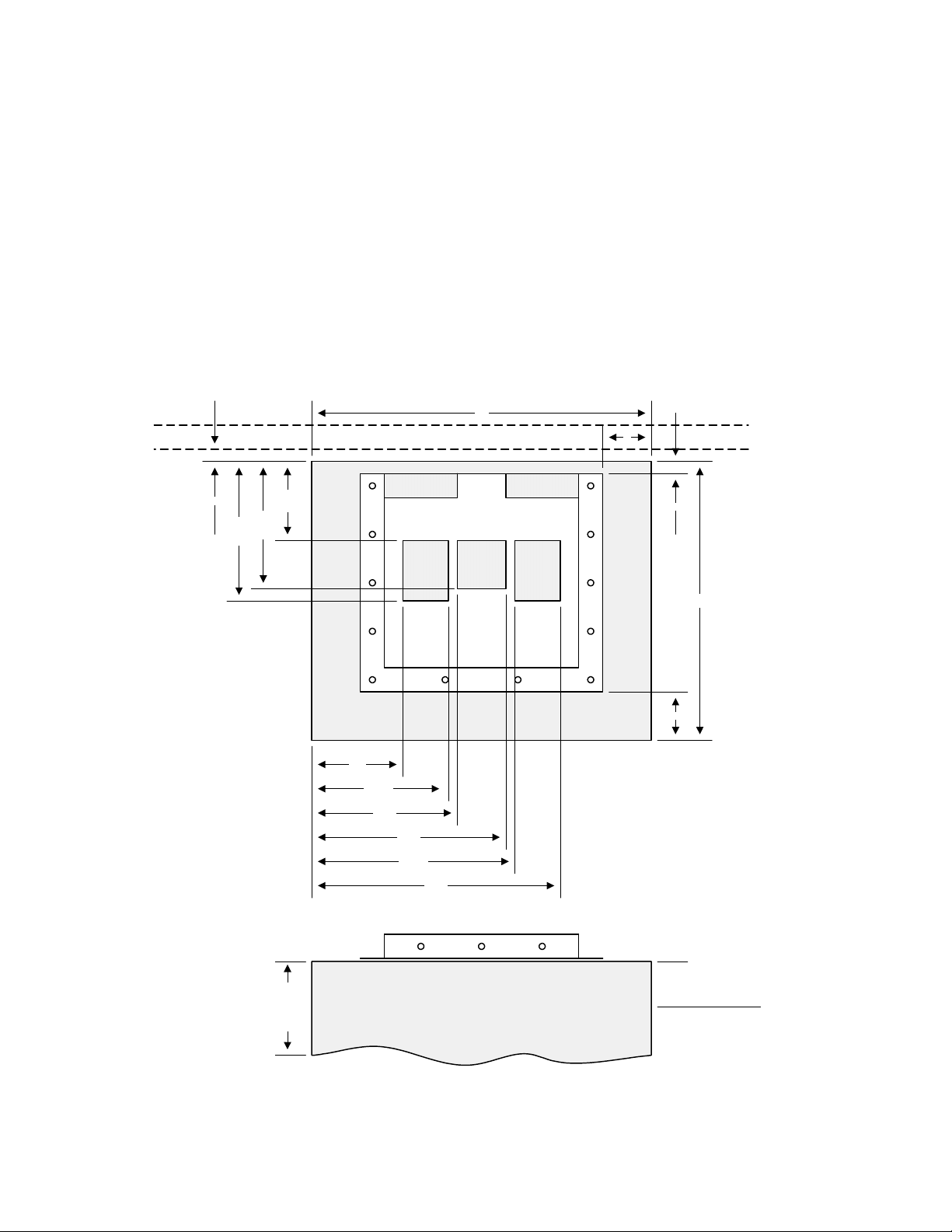

1.4 Pad Mount Installation

1. Construct a form for the mounting pad according to the specifications shown below. Be

sure to level the top edge of the form and that the top of the form is a minimum of four (4)

inches above ground level. We suggest that you contact the local building department to

determine the required depth of the pad since soil conditions and code requirements vary

from city to city.

2. Set conduits, reinforcing bars and/or wire mesh if required. The number of conduits is

determined by the application requirements. We suggest using a minimum of four (4)

conduits. 1-High voltage power lines; 2-Low voltage control lines; 3-Loop lead-in wires

(open loop); 4-Loop lead-in wires (reverse loops). Conduits can be set in the areas

indicated in the illustration. See SECTION 2. Set additional conduits as required for your

application. NOTE: If conduits are not set in the pad, they can be routed to a J box

where connections to the operator can be made after it is installed. There are four (4) ½inch knockouts in the operator for this purpose.

28

GATE

GATE GATEGATE

4

1

11.75

10.75

6.75

1

23

4

7.5

11.25

12.0

16.0

16.75

20.5

Minimum 4 inches

Pad depth determined by soil

conditions and local building codes.

Minimum depth is 18 inches.

above ground level.

3. Mix the concrete according to the manufacturers instructions. Pour the mixture into the

form and tamp. Level and finish the surface after pouring is complete. Do not set anchor

Page 18 9210-065-F-11-07

Page 19

bolts in the concrete. Sleeve anchors should be used to secure the operator to the

pad. This allows greater flexibility in positioning the operator on the pad.

4. Allow the pad to cure for 48 hours before removing the forms or mounting the operator.

5. Once the pad has cured, place the operator / mounting plate on the pad in the proper

position; 4-inches from the front and sides of the pad and 1-inch from the rear of the pad.

The operator mounting plate must be parallel to the gate. CAUTION: the operator

is heavy. Two persons are required to lift the operator onto the mounting pad.

6. Once the operator is in the proper position on the pad, secure the operator mounting

plate directly to the pad using 3/8 or 1/2 x 3 sleeve anchors. Be sure that the operator

mounting plate is parallel to the gate.

9210-065-F-11-07 Page 19

Page 20

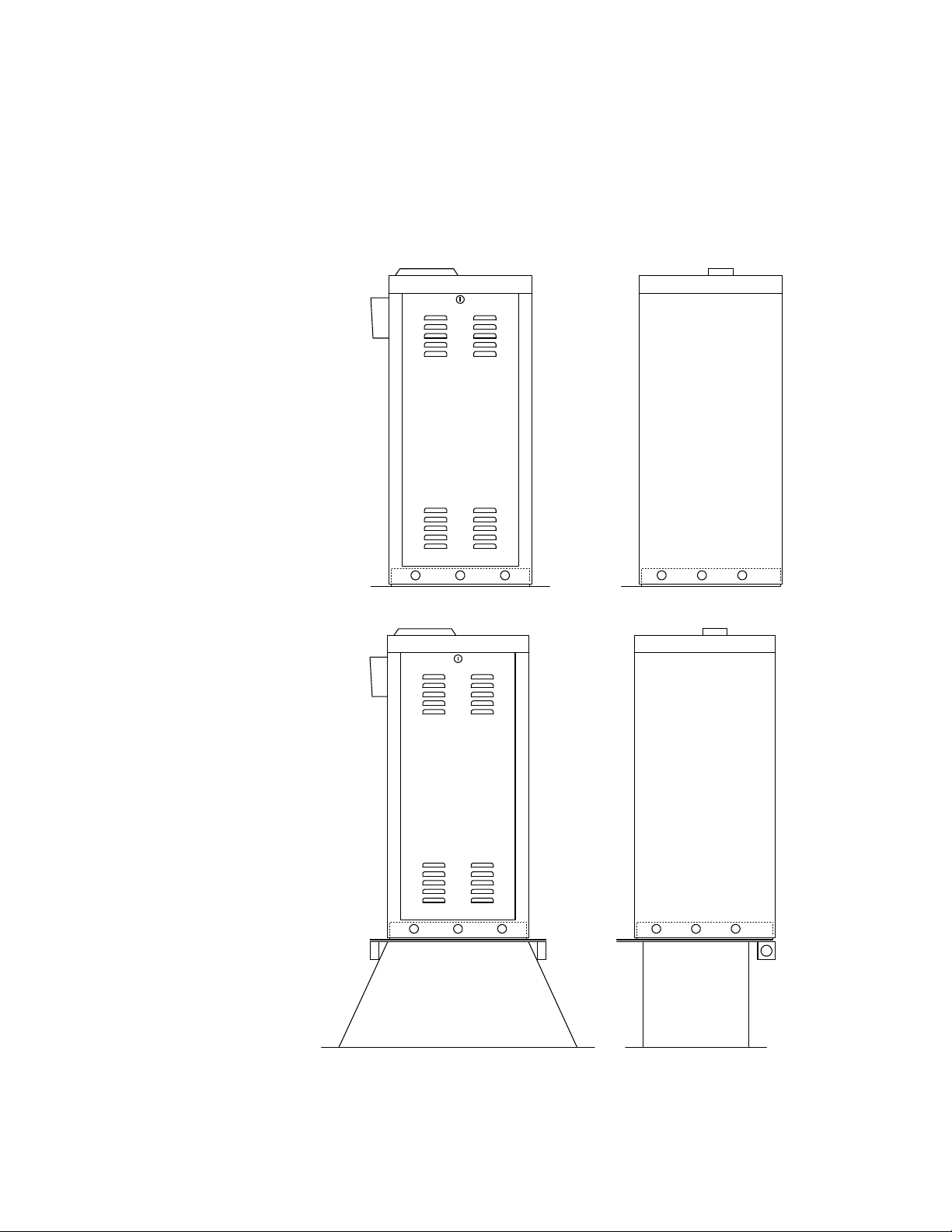

1.5 Mounting Stand Installation

1. Construct a form for the mounting pad according to the specifications shown below. Be

sure to level the top edge of the form and that the top of the form is a minimum of four (4)

inches above ground level. We suggest that you contact the local building department to

determine the required depth of the pad since soil conditions and code requirements vary

from city to city.

2. Set conduits, reinforcing bars and/or wire mesh if required. The number of conduits is

determined by the application requirements. We suggest using a minimum of four (4)

conduits. 1-High voltage power lines; 2-Low voltage control lines; 3-Loop lead-in wires

(open loop); 4-Loop lead-in wires (reverse loops). Conduits can be set in the areas

indicated in the illustration. See SECTION 2. Set additional conduits as required for your

application. NOTE: If conduits are not set in the pad, they can be routed to a J box

where connections to the operator can be made after it is installed. There are four (4) ½inch knockouts in the operator for this purpose.

GATEGATE GATE GATE

1

Pad depth determined

by soil conditions and

local building codes.

Minimum depth is 18

inches.

39.25

4

Minimum 4

inches above

ground level.

1.75

22.0

4

4

Page 20 9210-065-F-11-07

Page 21

3. Mix the concrete according to the manufacturers instructions. Pour the mixture into the

form and tamp. Level and finish the surface after pouring is complete. Do not set anchor

bolts in the concrete. Sleeve anchors should be used to secure the operator to the

pad. This allows greater flexibility in positioning the operator on the pad.

4. Allow the pad to cure for 48 hours before removing the forms or mounting the operator.

5. Once the pad has cured, place the operator-mounting stand on the pad in the proper

position; 4-inches from the front and sides of the pad and 1-inch from the rear of the pad.

The operator-mounting stand must be parallel to the gate.

6. Once the stand is in the proper position on the pad, secure the operator-mounting stand

directly to the pad using 3/8 or 1/2 x 3 sleeve anchors. Be sure that the operator-

mounting stand is parallel to the gate.

7. After securing the mounting stands to the pad, place the operator onto the mounting

stand and secure it with the hardware provided. CAUTION: the operator is heavy.

Two persons are required to lift the operator onto the mounting plate.

Chain Rest

9210-065-F-11-07 Page 21

Page 22

1.6 Chain Installation

1. Secure the chain brackets to each end of the gate so that the brackets will be level with

the chain where it exits the operator.

Brackets should be attached to the inside of

the frame so that the chain bolts, when

attached, do not protrude beyond the frame

of the gate.

2. Route the chain through the gate operator.

3. Attach the chain to the chain bolts using the

master links supplied, and then attach the

chain bolts to the chain brackets using the

hardware supplied. Make any adjustments to

the chain length at this time.

4. Adjust the chain bolts to tighten the chain.

The chain should sag no more than one (1)

inch per 10 feet of travel. Do not over tighten the chain. IMPORTANT!! Be sure that the

chain is parallel to the gate. Installing the chain in any other manner will cause

excessive noise, chain idler wear and chain stretching.

Page 22 9210-065-F-11-07

Page 23

20

10.5

9210-065-F-11-07 Page 23

Page 24

1.7 Warning Sign Installation

This DoorKing slide gate operator is shipped with two warning signs. The purpose of the warning

signs is to alert uniformed persons, and to remind persons familiar with the system, that a potential

hazard may exist so that appropriate action can be taken to avoid the hazard or to reduce exposure

to the hazard.

1. Permanently install the supplied warning signs in locations

so that the signs are visible by persons on both sides of

the gate.

2. Use appropriate hardware such as wood or metal screws

(not supplied) to install the warnings.

WARNING

Moving Gate Can Cause

Serious Injury or Death

KEEP CLEAR! Gate may move at any time

without prior warning.

Do not let children operate the gate or play

in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance.

Page 24 9210-065-F-11-07

Page 25

SECTION 2 – WIRING

Before attempting to connect any wiring to the operator, be sure that the circuit breaker in the

electrical panel is in the OFF position. Permanent wiring must be installed to the operator as required

by local electrical codes. It is recommended that such work be performed by a licensed electrical

contractor.

Since building codes vary from city to city, we highly recommend that you check with your

local building department prior to installing any permanent wiring to be sure that all wiring to

the operator (both high and low voltage) complies with local code requirements.

THIS GATE OPERATOR MUST BE PROPERLY GROUNDED!!

PRIMARY

OPERATOR

SLIDE GATE CONDUIT REQUIREMENTS

Low Voltage Control Devices

Loop Lead-In Wires

High Voltage Power

(Typical)

SECONDARY

OPERATOR

The conduit requirements shown are for a typical slide gate operator installation (the secondary

operator is shown for those applications where a secondary operator may be used). The conduit

requirements for your application may vary from this depending on your specific needs.

Use only sweeps for conduit bends. Do not use 90° connectors as this will make wire pulls very

difficult and can cause damage to wire insulation.

We suggest that minimum ¾-inch conduit be used.

Be sure that all conduits are installed in accordance with local codes.

9210-065-F-11-07 Page 25

Page 26

2.1 High Voltage Connections

Use the table below to determine high voltage wire size requirements. The distance shown in the

chart is measured in feet from the operator to the power source. If power wiring is greater than the

maximum distance shown, it is recommended that a service feeder be installed. When large gauge

wire is used, a separate junction box must be installed for the operator connection. The wire table is

based on stranded copper wire. Wire run calculations are based on a maximum 3% voltage drop on

the power line, plus an additional 10% reduction in distance to allow for other losses in the system.

WIRE SIZE / DISTANCE IN FEET INPUT POWER AMPS

12 AWG 10 AWG 8 AWG 6 AWG

1 HP: 115 VAC – 1Ø 15 60 90 150 240

1 HP: 208/230 VAC – 1Ø 7.5/7.4 200 330 520 840

1 HP: 208/230 VAC – 3Ø 3.4/3.3 530 840 1340 2100

1 HP: 460 VAC – 3Ø 1.7 2400 3900 6200 9500

3 HP: 208/230 VAC 3Ø 12.4 190 310 490 790

Route incoming high voltage power through conduit and into the operator up the right side of the

control box.

Be sure wiring is installed in accordance with local codes. Be sure to color code all wiring.

It is recommended that a surge suppresser be installed on the high voltage power lines to help

protect the operator and circuit board from surges and power fluctuations.

DETAIL A

DETAIL A

L1 L2 L5L4L3

HIGH VOLTAGE

INPUT

POWER TERMINALS

115 VAC SINGLE PHASE L1 - L2

230 VAC SINGLE PHASE L1 - L2

208 VAC THREE PHASE L1 - L2 - L3

230 VAC THREE PHASE L1 - L2 - L3

460 VAC THREE PHASE L1 - L2 - L3

GROUND

115 VAC

OUTPUT

INCOMING

POWER WIRES

Page 26 9210-065-F-11-07

L1 = HOT (BLACK)

L2 = NEUTRAL (WHITE)

Page 27

2.2 Control Wiring

Controls must be far enough from the gate so that the user is prevented from coming in

contact with the gate while operating the controls. Outdoor or easily accessible controls

should have a security feature to prevent unauthorized use.

Fence

C

A

B

Roadway

Gate

D

Receiver

Telephone

Entry

Stand-Alone

Card Reader

Stand-Alone

Keypad

Key

Switch

Common

Relay

Power

Fire

Dept

Open contact

sensor placed

C

on fence.

Open direction non-contact sensor.

1234567891011121314

OPEN

CLOSE

A

Z

Call

STOP

4

15

16 17 18

4404-010

Circuit Board

1

2

3

Open Photo

Close Photo

Open Edge

Close Edge

Common

Common

Protection Inputs

Secondary Entrapment

Diagram above is for illustration purposes. The actual placement

of the secondary protection devices is dependent on the specific

installation requirements.

Secondary entrapment protection devices must be installed with

this gate operator. This protection may be provided by noncontact or contact sensors, or a combination of both.

Secondary device wiring shows inputs to the circuit board only.

Photo-cells must be supplied with power.

Refer to the safety instructions in the front of this manual for

more information.

Controls must be installed a minimum of 10-feet from the gate or

installed in such a way that the person using the control cannot

come in contact with the gate or gate operator.

All inputs to the 4404 circuit board are Normally Open (N.O.).

A

Close direction non-contact sensor.

B

Open direction contact sensor.

C

Close direction contact sensor.

D

Close contact sensor

placed on gate.

D

Wireless option

available.

1

Radio receiver power only. Power here is limited to 250 ma.

2

Partial open input. Devices connected here will open the gate to the partial open limit setting only.

3

Reverse input functions only when gate is in the closing cycle.

4

Must use a DoorKing 3-button control station. Others will not work.

DOORKING, INC., INGLEWOOD, CA 90301

Model 9210, 9220, 9230, 9530

Title:

Control and Secondary Device Wiring

11/07

Date: Rev.Dwg. No.

9210-065-F-11-07 Page 27

4404-CNTRL-1

A

Page 28

2.3 Loop Detector Wiring

Loops and loop detectors must be installed with this gate operator to prevent the gate from

accidentally closing on vehicles that may be in the path of the gate.

8 Loops and loop detectors MUST be installed with this gate

operator to help prevent the gate from accidentally closing on

vehicular traffic.

8 Loop detector wiring is shown for DoorKing plug-in loop

detectors only. If other loop detectors are used, refer to the

installation instructions supplied with those detectors for

wiring instructions.

8 If other detectors are used, use a separate power supply to

power these detectors.

8 Loop layout shown is for a typical slide gate application with

two-way traffic, or one-way exit only traffic.

8 Reverse loops are wired in series. See detail A.

8 Refer to the Loop Information Manual (available from

www.dkaccess.com) for more information on loops and loo p

detectors.

Exit

Reverse

P8

From outside

Reverse loop

P6

P7

TB 1

DoorKing

Loop Detector

Detail A

REVERSE

LOOP

REV SENS

OPEN

REV SENS

CLOSE

RELAY CONTACT

From inside

Reverse loop

TIME

DELAY

POWER

DoorKing

Loop Detector

EXIT

LOOP

LMT

LIMIT SWITCH

CONNECTOR

4 3 2 1 8 7 6 5 4 3 2 1

ON

Reverse

Detail A

P2

REVERSING DEVICE

CONNECTOR

P5

111 10 9 8 7 6 5 4 3 220 19 18 17 16 15 14 13 12

DOORKING, INC., INGLEWOOD, CA 90301

Model 9210, 9220, 9230, 9530

Title:

Loop Detector Wiring

Date: Rev.Dwg. No.

11/07

4404-LOOP-1

A

Page 28 9210-065-F-11-07

Page 29

2.4 Auxiliary Device Wiring

The auxiliary stop switch will stop a moving gate when activated or will prevent the gate operator from starting w hen activat ed. Note that

this input is normally open and that a switch closure is required to activate the stop function. Because of this, the auxiliary stop

1

shown must NEVER be used as a safety interlock device.

Jumper is placed across terminals 7 and 8 ONLY WHEN THE AUXILIARY STOP INPUT IS USED.

2

The Remote Alarm Reset Station MUST be mounted in the line-of-sight of t he gate operator.

3

Using a 2351-010 Tracker Expan sion Board, operator data can be sent to the access controller (DoorKing 1833, 1835, 1837 or 1838 only).

4

Refer to Installation Manual 2351-065 for detailed information .

Auxiliary Stop Using Magnetic Switch

1

Operator

Stopped

N.O.

Normal

Operation

N.C.

N.O.

N.C.

123456789101112

4404-010

Circuit Board

DoorKing 1404-080

3

Remote Reset Switch

DoorKing 2351-010

4

Tracker Expansion Board

Secondary Entrapment

COM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Circuit Board

18

2351-010

COM

2

White

Red

Green

13 14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

16 17 18

19 20

DOORKING, INC., INGLEWOOD, CA 90301

Model 9210, 9220, 9230, 9530

Title:

Auxiliary Device Wiring Diagram

11/07

Date: Rev.Dwg. No.

Open Photo

Close Photo

Open Edge

Close Edge

Common

Common

Protection Inputs

4404-AUXDEV-1

A

9210-065-F-11-07 Page 29

Page 30

2.5 Primary – Secondary (Bi-Parting) Gate Wiring

The interface wiring between the two operators requires seven (4) wires (18 AWG minimum) for

control and secondary entrapment protection device connection. Each operator must be connected to

its own power source as described in section 2.1.

A B C

D E

Connect the Primary / Secondary interconnection wiring as shown. Wire colors are based

1

on DoorKing interconnection cable (P/N 2600-75x).

Place a jumper from terminal 2 to terminal 4 in the PRIMARY operator only.

2

Set SW 1, Switch 3 to the OFF position in the PRIMARY operator.

Plug a two-channel (P/N 9409-010) loop detector into the OPEN loop port in the

3

PRIMARY operator. Connect loops and loop detector as shown.

Connect radio receiver as shown. If partial open feature is desired with radio receiver,

4

connect receiver relay to terminal 5. Connect other OPEN devices to terminal 4 (Full

Open) or terminal 5 (Partial Open) as required.

Connect standard reverse devices to terminal 6 and/or connect secondary non-contact

5

and/or contact sensors to Secondary Entrapment Protection inputs as shown.

6

Connect chassis ground to chassis ground.

Common

Reverse Loop

Reverse Loop

Relay

Power

4

Yellow

Brown

2

Orange

D E

A

B

C

D

E

1234567891011121314

4404-010

Circuit Board

5

Open Photo

Close Photo

Open Edge

Close Edge

Common

Common

Secondary Entrapment

Protection Inputs

Gray

5 5

Open direction non-contact sensor - Primary Operator.

Close direction non-contact sensor -Both Operators.

Open direction non-contact sensor - Secondary Operator.

Open direction contact sensor - Prim ar y Oper at or.

Open direction contact sensor - Secondary Operator.

Yellow

Brown

Orange

1234567891011121314

4404-010

Circuit Board

Protection Inputs

Open Photo

Close Photo

Open Edge

Close Edge

Common

Common

Secondary Entrapment

Gray

Exit Loop

TB1 TB2 TB3

DoorKing

9409-010

3

15

16 17 18

Primary

Operator

19

20

Green

6 6

15

16 17 18

Secondary

Operator

19

20

Conduit

1

DOORKING, INC., INGLEWOOD, CA 90301

Model 9210, 9220, 9230, 9530

Title:

Primary / Secondary Wiring Diagram

Date: Rev.Dwg. No.

11/07

4404-DUAL-1

Green

A

Page 30 9210-065-F-11-07

Page 31

2.6 Terminal Identification and Description

2.6.1 Main Terminal (P1)

1. LOW VOLTAGE COMMON

2. OPEN / CLOSE INPUT

When gate is closed, input will open gate to full position.

When gate is open and auto close timer is turned on, input will re-set and hold timer.

When gate is open and auto close timer is turned off, input will close gate.

When gate is closing, input will reverse gate.

3. 24 VAC RADIO RECEIVER POWER, 250 MA MAXIMUM

4. FULL OPEN – CLOSE / EXIT LOOP LOGIC OUTPUT

If SW 1, switch 3 is OFF, this terminal becomes the logic output of the loop detector

plugged into the EXIT loop port (DoorKing loop detectors only).

If SW 1, switch 3 is ON, this terminal is identical to terminal 2.

5. PARTIAL OPEN INPUT

This input will open the gate to the mid-limit switch setting.

6. REVERSE / STOP INPUT

When gate is fully closed or in the opening cycle, this input has no affect on the gate

operator.

When gate is open and auto close timer is turned ON, input will re-set and hold timer.

When gate is open and auto close timer is turned OFF, input will prevent gate from

closing.

When gate is closing, input will REVERSE gate if SW 1, switch 7 is OFF.

When gate is closing, input will STOP gate if SW 1, switch 7 is ON.

7. 3-BUTTON OPEN INPUT - Use with DoorKing 3 button control stations only (P/N

1200-006 and 1200-007).

8. 3-BUTTON CLOSE INPUT - Use with DoorKing 3 button control stations only (P/N

1200-006 and 1200-007).

9. GATE TRACKER - DATA

10. GATE TRACKER - BUSY

11. DRY RELAY CONTACT

Operation of relay is dependent on setting of SW 1, switches 4 and 5. Relay contacts

can be set for Normally Open (NO) or Normally Closed (NC) operation. Contact

rating is 1 amp maximum at 24 Volts.

12. DRY RELAY CONTACT

13. LOW VOLTAGE COMMON

14. ALARM OUTPUT – Can also be connected to external alarm reset (P/N 1404-080)

15. ALARM RESET – Can also be connected to external alarm reset (P/N 1404-080)

16. CURRENT SENSOR

17. CURRENT SENSOR

18. 120 VAC HOT INPUT TO CIRCUIT BOARD

19. 120 VAC NEUTRAL INPUT TO CIRCUIT BOARD

20. EARTH GROUND / CHASSIS

9210-065-F-11-07 Page 31

Page 32

2.6.2 Limit Switch Connector

The limit switch connector is located at the upper left-hand corner of the 4404 circuit board and

provides input to the circuit board from the limit switches.

1. FULL LIMIT

2. SLOW DOWN

3. PARTIAL LIMIT

4. SLOW DOWN

5. FULL LIMIT

6. LIMIT ENABLE

7. LIMIT COMMON

8. LIMIT COMMON

2.6.3 Reversing Device Connector

External entrapment prevention devices are connected here.

1. OPEN PHOTO-BEAM

This input is only active when the gate is in the opening cycle. An open photo-beam input

during the opening cycle will cause the gate to stop. The gate will remain stopped until

the photo-beam input is cleared, at which time the gate will resume the open cycle.

2. CLOSE PHOTO-BEAM

This input is only active when the gate is in the closing cycle. A close photo-beam input

during the closing cycle will cause the gate to stop. The gate will remain stopped until the

photo-beam input is cleared, at which time the gate will resume the close cycle.

3. OPEN EDGE

This input is only active when the gate is in the opening cycle. An open edge input during

the opening cycle will cause the gate to stop and then reverse.

If the gate reaches the full closed position, the gate will remain closed, ignore any

maintained inputs and enter a soft shutdown condition. NOTE: If the gate was initially

activated by a time clock with a contact closure across the gate operator open input, this

input will be ignored until another input (open loop, reverse loop. etc.) is received by the

gate operator.

If a close edge sensor is activated prior to the gate reaching the full closed position, the

gate will stop and enter a soft shutdown condition.

4. CLOSE EDGE

This input is only active when the gate is in the closing cycle. A close edge input during

the closing cycle will cause the gate to stop and then reverse.

If the gate reaches the full open position, the timer will automatically close the gate (if it is

turned on). Once the gate starts to close again, if the close edge input is activated a

second time prior to the gate reaching the full closed position, the operator will stop and

reverse and will enter a soft shutdown condition.

If an open edge sensor is activated prior to the gate reaching the full open position, the

gate will stop and enter a soft shutdown condition.

5. COMMON

Common terminal for the secondary entrapment protection device inputs.

6. COMMON

Page 32 9210-065-F-11-07

Page 33

SECTION 3 - ADJUSTMENTS

The switch settings and adjustments in this chapter should be made after your installation and wiring

to the operator(s) is complete. Whenever any of the programming switches on the circuit board are

changed, power must be shut-off, and then turned back on for the new setting to take effect.

3.1 Circuit Board Adjustments

Set the DIP-switches on the circuit board to the desired setting. See switch-setting charts in section

3.2.

Auto close timer (when turned on) can be set from 1 second (full counter clockwise) to approximately

23 seconds (full clockwise).

Dry contact relay (terminals 11-12) can be set for Normally Open (NO) or Normally Closed (NC)

operation by placing the relay shorting bar on the NO or NC pins respectively.

Power LED indicates that low voltage power is applied to the circuit board.

Input LEDs should be OFF and will only illuminate when the input is activated.

The limit LED will be ON when the respective limit switch is activated.

REVERSE

LOOP

POWER

LMT

REV SENS

OPEN

P6

REV SENS

CLOSE

TIME

DELAY

RELAY CONTACT

4 3 2 1 8 7 6 5 4 3 2 1

ON

P4

EXIT

LOOP

LIMIT SWITCH

CONNECTOR

REVERSING DEVICE

CONNECTOR

P5

111 10 9 8 7 6 5 4 3 220 19 18 17 16 15 14 13 12

9210-065-F-11-07 Page 33

Page 34

3.2 Switch Settings

The two DIP-switches located on the circuit board are used to program the operator to operate in

various modes and to turn on or off various operating features. Whenever a switch setting is

changed, power to the operator must be turned OFF and then turned back on for the new setting to

take affect. Check and review ALL switch settings prior to applying power to the operator.

CAUTION: Switches on the circuit board are numbered right to left, not left to right.

SWITCH FUNCTION SETTING DESCRIPTION

1 Direction OFF

2 Auto Close

3 Open Loop

Timer

Output

ON

OFF

ON

OFF

ON

4 & 5 Relay & LED 4-OFF 5-OFF

6 Warn Before

7 Reverse

8 Quick Close OFF

Operate

Stop

4-OFF 5-ON

4-ON 5-OFF

4-ON 5-ON

OFF

ON

OFF

ON

ON

SWITCH FUNCTION SETTING DESCRIPTION

1 Self Test

2 Open Uphill OFF

(see note 1)

3 Open Downhill OFF

4 Spare OFF

OFF

ON

ON

ON

ON

NOTES:

1. Do not run the self-test while the gate operator is connected to the gate. This self-test

feature is designed for bench-testing only.

SW 1 (RIGHT SWITCH)

Changes open / close direction of operator.

Auto-close timer is OFF. Manual input required to close gate.

Auto-close timer is ON. Adjustable from 1-23 seconds.

Switches logic-level output of EXIT loop port to terminal 4.

Normal Setting. Control board responds internally to loop

detector plugged into exit loop port.

Relay activated and LED on when gate is FULL OPEN.

Relay activated and LED on when gate is NOT CLOSED.

Relay activated and LED on when gate is OPENING and OPEN.

Relay activated and LED on when gate is OPENING or CLOSING.

Normal setting.

Alarm will sound 2-3 seconds prior to the gate starting.

Normal Setting. Input to terminal 7 will REVERSE gate during

close cycle.

Input to terminal 7 will STOP gate during close cycle.

Normal gate operation.

Opening gate will stop and begin to close as soon as all reversing

inputs (loops, beams) are clear regardless of the open position of

the gate.

SW 2 (LEFT SWITCH)

Normal setting.

Run self-test – bench test only.

Normal setting.

Turn ON if gate opens in an uphill direction.

Normal setting.

Turn ON if gate opens in a downhill direction.

Normal Setting.

Page 34 9210-065-F-11-07

Page 35

3.2.1 SW 1 (Right Switch) Description and Function

Switch 1: Set so that the operator cycles open upon initial power up and open command. If the

operator cycles close, turn power off and change the setting on this switch.

Switch 2: Turns the auto close timer on or off. Set from 1 to 23 seconds. Loops and loop

detectors, photoelectric cells, or other like devices must be installed when the auto close

timer is used to prevent the gate from closing on vehicular traffic.

Switc h 3: Determines if the output of the loop detector (DoorKing loop detectors only) plugged into

the EXIT port will be sent directly to the microprocessor to open the gate, or if the output is directed to

terminal 4 where it can then be connected to other input terminals

Switches 4-5: These work in conjunction with each other and determine when the relay on the board

will be activated. This relay can be used as a switch for various functions such as illuminating a

warning light when the gate is moving, or turning on a green light when the gate is full open. If a

magnetic lock is used with the gate operator, these switches must be set for magnetic lock operation

which limits the relay to activate only when the gate is opening and full open.

Switc h 6: Warn Before Operate, When set to the ON position, the internal alarm in the operator will

sound 2-3 seconds prior to the gate starting.

Switc h 7: Determines if an input to terminal 7 will reverse or stop a closing gate. If this switch is set

to stop the gate (ON), once the input to terminal 7 is cleared, the gate will continue to close. This is

typically used to help prevent tailgating.

Switc h 8: Turning the quick-close feature on will cause the auto close timer to close the gate after 1

second, regardless of the setting of the auto close timer potentiometer. This will also cause an

opening gate to stop and reverse when the reverse (loop) inputs are cleared. This feature, along with

switch 7 above, is useful to prevent tailgating.

3.2.2 SW 2 (Left Switch) Description and Function

Switc h 1: This switch must be in the OFF position for normal operation. The self-test feature checks

various functions of the operator. CAUTION - Do not run self-test with the operator connected to the

gate. The drive chain must be disconnected from the operator to run the self-test.

Switc h 2: Set to the OFF position for normal operation. Set to the ON position if gate OPENS in an

UPHILL direction.

Switc h 3: Set to the OFF position for normal operation. Set to the ON position if gate OPENS in a

DOWNHILL direction.

Switch 4: Spare – leave switch in the OFF position.

9210-065-F-11-07 Page 35

Page 36

3.3 Limit Adjustment

1. Turn power off.

2. Push the lock plate handle down to adjust the Open and Close limit nuts.

3. After adjusting the limit-nuts, be sure that the lock-plate is engaged in the slots on the

limit-nuts to prevent them from slipping.

4. Turn power on and activate the gate operator.

5. Re-adjust the limit-nuts as necessary for full-open and full-close gate travel.

6. If using the partial open feature (input to terminal 5), adjust the middle limit nut being

sure to align the magnet in the limit nut with the magnetic pick-up.

Partial Open Limit

Be sure the magnet

imbedded in the partial

open (center) limit nut is

aligned with the partial

open magnetic pick-up

Page 36 9210-065-F-11-07

Page 37

3.4 Reverse Adjustment

This vehicular gate operator is equipped with an inherent (Type A) entrapment sensing system. This

system will sense an obstruction in either the opening or closing gate cycles and will cause the gate

to reverse direction should an obstruction be encountered. For this system to function correctly,

the gate must be properly installed and work freely in both directions. A good set of ball

bearing wheels (or rollers) is essential for proper slide gate operation.

1. Activate the gate operator by momentarily shorting terminal 1 and 5 with a 1-foot piece of

18 AWG wire. Be sure that the limit adjustment has been completed as described in

section 3.3.

2. While the gate is running open, slowly rotate the open reverse sensitivity potentiometer

clockwise until the gate reverses travel, then rotate the potentiometer 1/8 turn counter

clockwise. Note: Rotating the sensitivity adjustment clockwise INCREASES the reverse

sensitivity. Rotating this adjustment counter-clockwise DECREASES the reverse

sensitivity. NOTE: After the gate has reversed, the operator will assume a "soft

shutdown" making it necessary to initiate the cycle again by momentarily shorting across

terminals 1 and 5 as in step 1.

3. While the gate is running closed, slowly rotate the close reverse sensitivity potentiometer

clockwise until the gate reverses travel, then rotate the potentiometer 1/8 turn counter

clockwise. Note: Rotating the sensitivity adjustment clockwise INCREASES the reverse

sensitivity. Rotating this adjustment counter-clockwise DECREASES the reverse

sensitivity. NOTE: After the gate has reversed, the operator will assume a "soft

shutdown" making it necessary to initiate the cycle again by momentarily shorting across

terminals 1 and 5 as in step 1

4. Operate the gate a few times to be sure that it cycles completely.

5. Place an immobile object along the path of the gate so that the gate will strike it while in

the open cycle. The gate must reverse direction after striking the object. If it does not,

increase the reverse sensitivity by turning the potentiometer 1/8 turn clockwise, then

repeat this test. NOTE: After the gate has reversed, the operator will assume a "soft

shutdown" making it necessary to initiate the cycle again by momentarily shorting across

terminals 1 and 5 as in step 1.

6. Place an immobile object along the path of the gate so that the gate will strike it while in

the close cycle. The gate must reverse direction after striking the object. If it does not,

increase the reverse sensitivity by turning the potentiometer 1/8 turn clockwise, then

repeat this test. NOTE: After the gate has reversed, the operator will assume a "soft

shutdown" making it necessary to initiate the cycle again by momentarily shorting across

terminals 1 and 5 as in step 1 to reactivate the automatic close timer.

7. You may have to repeat step 2 several times to find the correct sensitivity adjustment.

INCREASE INCREASE

REV SENS

CLOSE

9210-065-F-11-07 Page 37

REV SENS

OPEN

Page 38

3.5 Speed Control (9220, 9230 Only)

The models 9220 and 9230 are equipped with

a speed control module that allows you to

adjust the speed of the gate from 1/2 to 2 Ft./

Sec. To adjust the speed, simply rotate the

speed control knob clockwise to increase the

gate speed, or counter clockwise to decrease

the gate speed. The digital readout on the

speed controller will display the gate speed.

3.6 Current Sensor Wiring

.5

ft/s

0 ft/s

ft/s

L1 L2 L3 B- B+

1

1.5

ft/s

2 ft/s

125

UVW PEPE

1.0

6

251617

13A1113B

13E

This vehicular gate operator uses a current

sensing device to detect any obstructions in the

path of the opening or closing gate. The current

sensor uses a sensing coil with a given number of

turns through it to monitor the current flow into the

operator. The number of turns through the

sensing coil is dependant on the operating voltage

of the operator.

Voltage and Phase Complete

Turns Through

Sensor Coil

115 Single Phase 1

230 Single Phase 2

208 Three Phase 5

230 Three Phase 6

460 Three Phase 7

Page 38 9210-065-F-11-07

Page 39

SECTION 4 – OPERATING INSTRUCTIONS

WARNING - To reduce the risk of injury or death:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with gate controls. Keep the remote control away

from children.

3. Always keep people and objects away from gate. NO ONE SHOULD CROSS THE

PATH OF THE MOVING GATE

4. Test the operator monthly. The gate MUST reverse on contact with a rigid object or

stop or reverse when an object activates the non-contact sensors. After adjusting the

force or the limit of travel, retest the gate operator. Failure to adjust and retest the

gate operator properly can increase the risk of injury or death.

5. Use the emergency release only when the gate is not moving and power has been

shut-off.

6. KEEP GATES PROPERLY MAINTAINED. Read the owner's manual. Have a

qualified service person make repairs to gate hardware.

7. The entrance is for vehicles only. Pedestrians must use separate entrance.

8. SAVE THESE INSTRUCTIONS.

4.1 Power and Reset Switches

Open the power switch cover located on the side of the operator to access the MAIN POWER switch

and the operator RESET switch.

The RESET switch is used to turn off the

entrapment alarm and to reset the operator after

RESET

a hard shutdown has occurred.

The AC POWER toggle switch turns power to

the operator ON (toggle up) or OFF (toggle

down).

AC

POWER

OFF

9210-065-F-11-07 Page 39

Page 40

4.2 Shutdown Conditions

Under various entrapment conditions the operator will assume either a soft or hard shutdown (alarm)

condition. To determine what type of reset action is required, you will need to understand how the

different entrapment conditions affect the gate operator.

4.2.1 Soft Shutdown

This occurs in various situations where the inherent or secondary entrapment protection devices have

been activated. In a soft shutdown condition, the operator will not respond to any input that was

present when the entrapment protection device sensed an obstruction. If the gate stops at the open

position, the operator will not respond to the automatic close timer.

Example 1: A time clock keys the gate open in the morning and an entrapment protection device

senses an obstruction prior to the gate reaching the full open position. If the entrapment is sensed by

the inherent system, the gate will reverse and run back to the closed position. The time clock input is

still present, but the gate will not re-open.

NOTE: In some systems, the time clock input comes from the telephone entry system relay. This

same relay may also provide open commands for a card reader, MicroPLUS transmitters and the

visitor telephone entry. If so, these devices will also be disabled in a soft shutdown condition.

Example 2: If the gate is closing and an entrapment protection device is activated, the gate will either

stop or reverse and run back to the open position, depending upon if the secondary or inherent

device was activated. The automatic close timer will not close the gate.

Example 3: Vehicle arrives at open loop and the gate runs towards the open position. The inherent

entrapment protection is activated. The gate reverses and runs back to the closed position. If the

vehicle is still present at the open loop a soft shutdown condition does not occur. The loop input

provides an immediate reset of the operator and the gate will again run to the open position.

4.2.2 Resetting a Soft Shutdown

In some conditions, a soft shutdown will reset as soon as the entrapment condition clears. For

example, if a non-contact sensor (photo cell) is sensing an obstruction, the operator will stop the gate

and assume a soft shutdown condition. When the photocell clears, the operator will return to normal

operation.

When the operator is in a soft shutdown, activation of any "intended input" will reset the operator. An

"intended input" includes any command, any standard safety input and any loop input. Activating any

of these inputs will reset the gate. At that point the gate will return to normal operation. If the gate is

open, the automatic close timer will then time out and close the gate.

Page 40 9210-065-F-11-07

Page 41

4.2.3 Hard Shutdown

A hard shutdown condition occurs when the inherent entrapment protection system has sensed two

consecutive obstructions before the gate reaches the full open or full closed position. It can also be

an indication that the gate is too heavy or that the gate hardware (wheels, rollers) is in poor

condition and needs to be corrected. Do not reduce the operator reversing sensitivity in an

attempt to correct for a poorly designed gate or for hardware that is in need of repair.

Example: The gate is closing and the inherent entrapment protection system senses an obstruction

and causes the gate to reverse direction. As the gate begins to run in the open direction, a second

obstruction is sensed prior to the gate reaching the full open position. Once the second obstruction

has been sensed, the operator will stop, the audio alarm will be activated and all standard inputs are

shut down (including open commands, safety commands, loop inputs, etc.).

NOTE: The audio alarm will remain activated for a maximum of five minutes, or until the operator

receives a reset input. The hard shutdown condition will remain in affect even if the audio alarm

shuts off after five minutes.

After 5 minutes, the audio alarm will “chirp” every 5 seconds. This indicates that the operator is in a

hard shutdown condition and the reset switch must be activated to reset the operator and silence the

alarm.

4.2.4 Resetting a Hard Shutdown

When the operator is in a hard shutdown condition (audio alarm activated or audio alarm “chirps”

every 5 seconds), the only way to reset the gate operator and return it to normal operation is to

activate the alarm reset input. An alarm-reset switch can be mounted external of the gate operator

provided that it is installed in the line of sight of the gate and gate operator (see 2.6.1).

Before resetting a hard shutdown, determine why the shutdown occurred. Inspect the gate for any

obstructions along its path that could have activated the inherent entrapment sensing system.

Inspect the gate and gate hardware.

NOTE: DoorKing operators have a built-in alarm reset push button mounted on the operator above

the power ON-OFF toggle switch. Activating this button will return the gate operator to normal

operation, but will not activate the gate operator.

Once the gate has been reset, an open or close command is needed to start the gate operator. Most

activating commands will cause the gate operator to cycle to the open position. This includes

activation of a key switch or open command and activation of an open loop. Activation of a close

command will run the gate to the closed position.

NOTE: The gate operator will not lose its limit settings when a hard shutdown occurs.

9210-065-F-11-07 Page 41

Page 42

4.3 Manual Gate Operation

This operator is equipped with a manual system that will allow the gate to be cranked open in the

event of a power outage or equipment failure.

NOTE: Never attempt to manually open any gate with an operator attached to it until you have

verified that power to the operator has been shut-off.

1. Unlock the manual release access panel

located on the top of the gate operator and

open it. Opening this access panel

automatically activates an interlock switch

that will prevent the gate operator motor

from starting.

2. Insert the supplied manual hand crank into

the access hole until it engages with the

motor shaft. Turn the crank to open the

gate.

3. After the gate is opened, remove the crank

and lock the access panel closed.

Page 42 9210-065-F-11-07

Page 43

SECTION 5 – MAINTENANCE AND TROUBLESHOOTING

Inspection and service of this gate operator by a qualified technician should be performed anytime a

malfunction is observed or suspected. High cycle usage may require more frequent service checks.

5.1 Maintenance

When servicing the gate operator, always check any secondary (external) reversing devices (loops,

photo eyes, etc.) for proper operation. If external reversing devices cannot be made operable, do not

place this operator in service until the malfunction can be identified and corrected.

Always check the inherent reversing system when performing any maintenance. If the

inherent reversing system cannot be made operable, remove this operator from service until

the cause of the malfunction is identified and corrected. Keeping this operator in service

when the inherent reversing system is malfunctioning creates a hazard for persons which can

result in serious injury or death should they become entrapped in the gate.

When servicing this gate operator, always turn power OFF!!

Fire Dept. Check emergency vehicle access device for proper operation.

Primary Reverse

Release Check manual release for proper operation.

Secondary

Reverse Device

Sprockets Check setscrews for tightness.

Complete Complete check of gate and gate operating system.

MAINTENANCE SCHEDULE

Alarm Activate the primary (inherent) reverse system by blocking the gate

Chain Check for sagging. Tighten if necessary.

Gate Inspect for damage. Check gate wheels, rollers and guides for

Grease Wheels and guide rollers if necessary.

Loop(s) Check vehicular reverse and shadow loops for proper operation.

System

with a solid object. When the gate reverses, block the gate in the

opposite direction prior to the limit being reached. The entrapment

alarm should activate. Press the reset button to silence the alarm.

wear and grease if necessary.

Check that the gate reverses on contact with an object in both the

opening and closing cycles. Adjust reversing sensitivity if

necessary.

Check that secondary (external) reverse device(s) stop or reverse

the gate when activated.

MONTHLY

INTERVAL

3 6 12

9210-065-F-11-07 Page 43

Page 44

5.2 Operator Diagnostics

This gate operator is designed with built-in diagnostics that will alert you to potential or existing

problems that the microprocessor has detected. Specific fault conditions are checked and the

operator will signal that a fault exist through the built-in alarm.

Constant tone is heard when power is applied:

This indicates that the limit switch wire harness is not connected to the circuit board. In this condition,

the operator will not run and the tone will continue until the fault is corrected. Check to be sure that

the limit switch plug is properly inserted into P2.

Constant tone is heard:

This indicates that the operator is in a hard shutdown condition (section 4.2.3). The tone will continue

to sound for five minutes, and then will beep once every five seconds. The operator-reset button

must be pressed or power must be removed and then reapplied to return the operator to normal

operation.

Short tone is heard every five seconds:

This indicates that the operator has been in a hard shutdown condition in excess of five minutes.

This will continue until the operator-reset button is pressed or until power is removed from the

operator.

Operator runs for 1 second and stops, two short tones are heard:

This indicates that there may be a fault with the current sensor circuit.

Page 44 9210-065-F-11-07

Page 45

5.3 Trouble Shooting

Have a good VOM meter to check voltages and continuity. A Meg-Ohm meter capable of checking

up to 500 meg-ohms of resistance is necessary to properly check the integrity of the ground loops.

When a malfunction occurs, isolate the problem to one of three areas: 1) the operator, 2) the loop

system, 3) the keying devices. Use caution when checking high voltage terminals, motor

capacitor and the motor.

1. Check the input indicator LEDs. They should only come ON when a keying device (card