Page 1

ENGLISH

ENGLISH

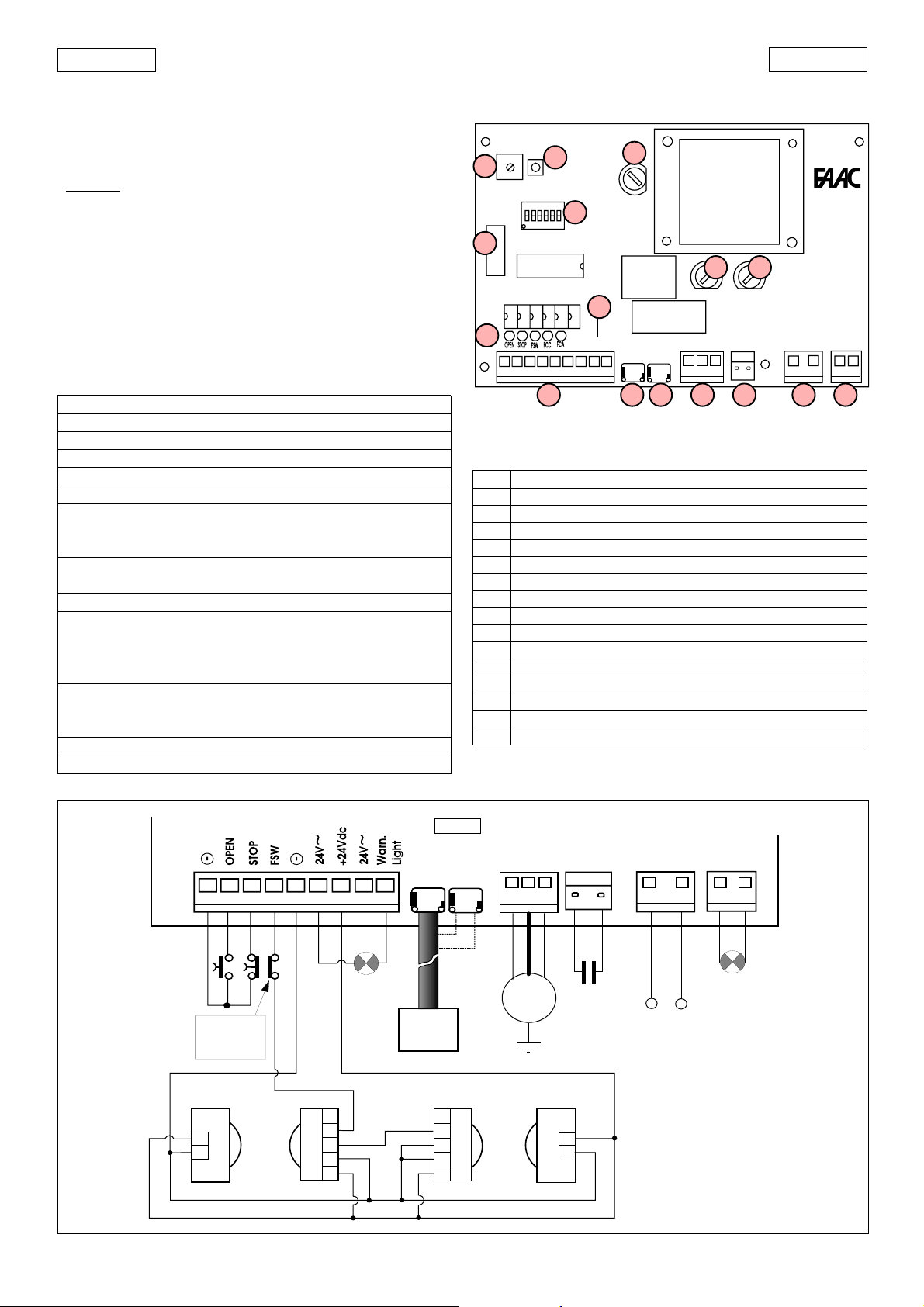

5. START-UP

5. 1. 2. 844MPS LAY-OUT

5.1. CONNECTION TO ELECTRONIC CONTROL UNIT

ÜAlways disconnect the electrical power supply before carrying

out any operations on the control unit (connections, programming,

maintenance).

Warning: On disconnecting connector J6, high voltages may be

present on the capacitor output.

Observe points 10, 11, 12, 13 and 14 in the GENERAL SAFETY

INSTRUCTIONS.

As shown in Fig. 3, lay the conduits and make the electrical

TR1

BRAKE

J1

J1

connections from the 844 MPS electronic control unit to the

chosen accessories.

Always route the power supply cables separately from the

control and safety cables (keyswitch, receiver, photocells,

etc.). Use separate conduits to avoid any interference.

5.1.1. 844MPS ELECTRONIC CONTROL UNIT

Led

J2

TABLE 2 TECHNICAL CHARACTERISTICS OF 844MPS

Power supply 230V~ (+6 -10 %) 50Hz

Motor max. load 650 W

Accessories power supply 24Vdc/24V~

Accessories max. load 500 mA

Warning light power supply 24V~ (5W max)

Temperature range - 20°C + 55°C

transformer primary

Fuses motor

accessories

Quick connectors - for decoding cards or RP receivers-

- capacitor - limit switch -

Inputs OPEN/STOP/CLOSING SAFETY/LIMIT-SWITCH

warning light

Outputs flashing light

motor

24Vdc/24V~power supply for accessories

pause time (5-10-15-30-60-120-180 sec.)

Logic programming (automatic A1/S1/S2 - semiautomatic E1)

pre-flashing

Motor braking Adjustable by trimmer

TABLE 3 844MPS Control unit components

F1 Fast-acting fuse F1 5x20 F5A/250V (motor )

F2 Time delay fuse F2 5x20 T1,6A/250V (accessories)

F3 Time delay fuse F3 5x20 T250mA/250V (transformer)

P1 RESET button

TR1 Braking adjustment trimmer

DS1 Programming dipswitches

Led Input status indicator LEDs

LK1 Jumper for warning lamp contact

J1 Quick connector for decoding cards/RP receiver

J2 Low voltage inputs/accessories terminal block

J3 Quick connector for limit switch (LH closure)

J4 Quick connector for limit switch (RH closure)

J5 Motor output terminal block

J6 Quick connector for capacitor

J7 Flasher unit output terminal block (230V

J8 Line input terminal block

Safety timing 255 sec.

5. 1. 3. ELECTRICAL CONNECTIONS

F2

F2

TR1

P1

RESET

P1

DS1

DS1

IC1

LK1

1 2 3 4 5 6 7 8 9

J2 J5 J6 J8 J7

LK1

J3

RL2

F3

RL1

J5

J4J3

CH- DXCH- SX

J4

F1F3

F1

J6

844MPS

J8

Fig. 23

~ max 60W)

J7

J2

1 2 3 4 5 6 7 8 9

Altre sic urezze

Other s afeties

Autres sécurités

Andere Sicherh eiten

Otros disp. seg.

a

2

1

1

2

3

4

5

Warn.Li ght

5W max

844MPS

FINECORSA

LIMIT SWITCH

FIN DE COURSE

ENDSCHALTER

FIN DE CARRERA

1

2

3

4

5

CH-DXCH-SX

18

J4J3

J5 J6

M

C

35µF

J8

LN

230V~ 50Hz

(+6% -10%)

J7

(L)

FAACLAMP

MINILAMP

b

2

1

Fig. 24

Page 2

ENGLISH

ENGLISH

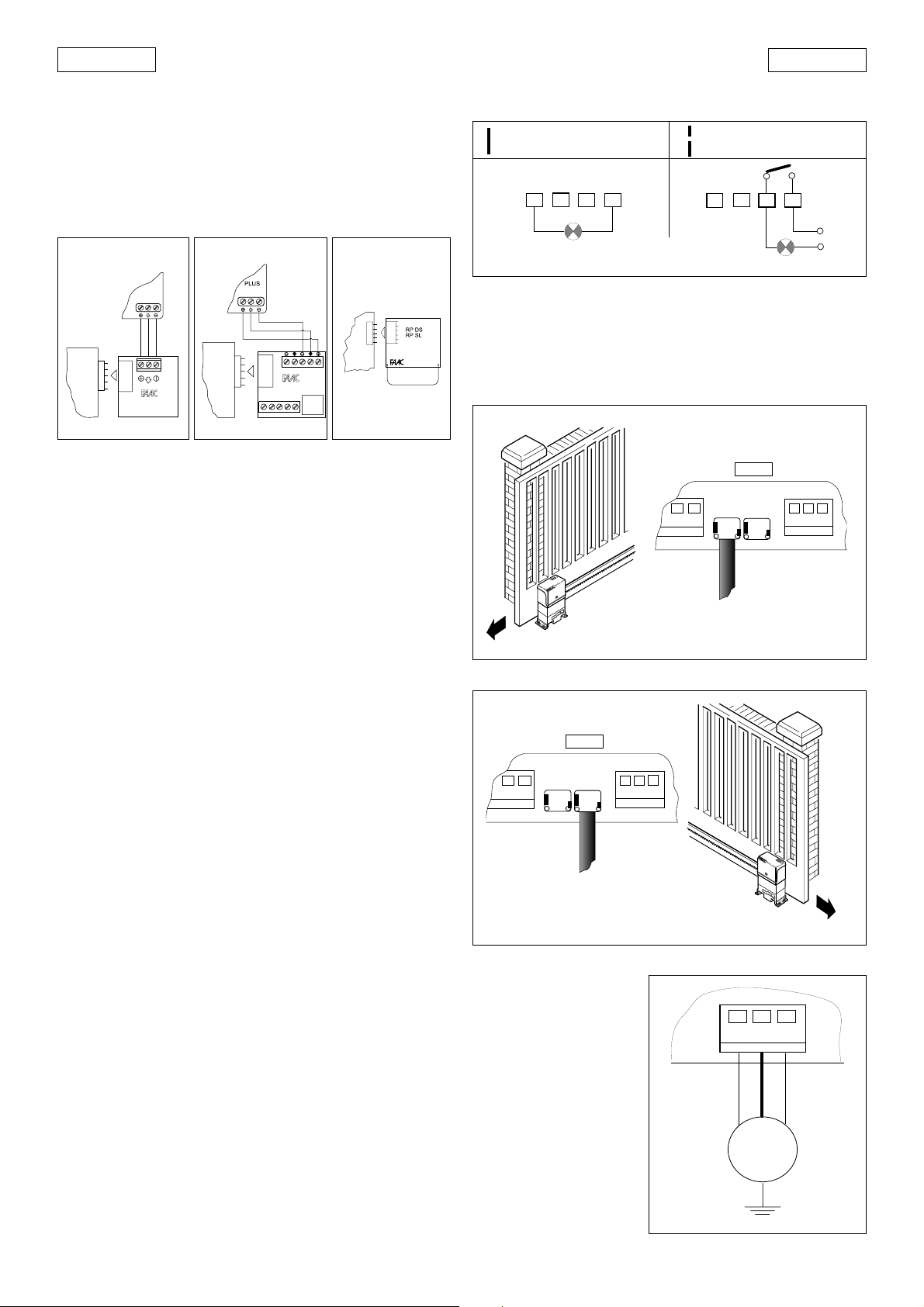

5.2. DESCRIPTION

5.2.1. CONNECTOR J1

The connector J1 is used for the quick connection of

MINIDEC,DECODER, RP RECEIVER boards (Figs. 25,26,27).

Accessory boards are to be inserted with their component

sides facing the inside of the 844MPS electronic control unit.

Always disconnect the power supply before inserting or

removing accessory boards.

Fig. 27

844MPS

844MPS

PLUS

MINIDEC

SL/DS

Fig. 26Fig. 25

844MPS

DECODER

SL/SLP/DS

5.2.2. TERMINAL BLOCK J2 (low voltage)

1& 5

=Common/Negative of accessory power supply (-)

2 = OPEN control device (N.O.)

Any control device (pushbutton, detector,..) which,

on closing the contact, relays an open and/or close

impulse to the gate.

To install more than one Open control device,

connect the N.O. contacts in parallel.

3 = STOP control device (N.C.)

Any control device (e.g. pushbutton) which, on

opening a contact, stops the movement of the gate.

T o install more than one Stop control de vice, connect

the N.C. contacts in series.

ÜIf no Stop control devices are to be connected,

place a jumper across the input and the common

terminal (terminal 1 or 5).

4 = FSW closure safety device (N.C.)

Any control device (photocells, safety edges,

magnetic loops) with an N.C. contact which

interrupts the movement of the gate when an

obstacle is detected within the protected area.

The task of the closure safety device is to safeguard

the area occupied by the gate during the closing

movement.

The intervention of safety devices during gate

closure causes the direction of gate movement to

be reversed. These devices do not intervene during

gate opening movements. If a closure safety device

is tripped when the gate is open or during a pause

time, they will prevent gate closure.

To install more than one safety device, connect the

N.C. contacts in series.

ÜIf no closure safety devices are to be installed,

place a jumper across this input and the commmon

terminal (terminal 1or5).

&

8 = 24V~ accessories power supply

6

The maximum load of the accessories is 500mA.

To calculate power draw, refer to the instructions for

the individual accessories.

ÜIf the jumper LK1 is broken, the 24V~ accessories

power supply is no longer available (Fig.28).

7 = 24Vdc

accessories power supply positive (+)

The maximum load of the accessories is 500mA.

To calculate power draw, refer to the instructions for

the individual accessories.

9 = Warning Light output

For information regarding operation of the warning

light, refer to the section on dipswitch programming.

Jumper LK1 allows you to free the warning light contact (Fig.28).

LK1 BROKEN

LK1 INTACT

7

6

8

24V~ 5W max

9

Fig. 28

)

(free contact)

7

6

8

2A max

9

5.2.3. CONNECTORS J3-J4 (limit switch)

J3 = Connection of limit switch for left-hand closure

J4 = Connection of limit switch for right-hand closure

Refer to Figs. 29-30 for quick connection of the inductive limit

switch sensor for the corresponding gate closure direction.

844MPS

J4J3

CH-DXCH-SX

J5

Fig. 29

844MPS

J4J3

CH-DXCH-SX

J5

Fig. 30

5.2.4. TERMINAL

BLOCK J5 (high

voltage)

Terminal block for motor

J5

connection.

ÜConnect the wires to

the terminals of J5 as

shown in Fig.31.

B

LACK AND BROWN WIRES

=

BLUE

BROWNBLACK

electric motor supply

phases

B

LUE WIRE

= electric motor

M

common

Fig. 31

19

Page 3

ENGLISH

ENGLISH

5.2.5. CONNECTOR J6 (high voltage)

Connector for quick connection of the capacitor.

5.2.6. TERMINAL BLOCK J7 (high voltage)

230V~ terminal block for connection of the flashing light (max

60W).

5.2.7. TERMINAL BLOCK J8 (high voltage)

Terminal block for connection of the 230V~ 50Hz power supply

(L=Line N=Neutral)

Connect the earth wire to the operator as shown in Fig.32.

Fig. 32

5.2.8. INDICATOR LEDS

5 LEDs on the board indicate the status of the terminal imputs:

LED

ON

= contact closed

LED

OFF

= contact open

To program the operation of the automation, set the dipswitches

as shown in the diagram above.

Ü Press the RESET button after all programming operations.

Operating logics

There are four operating logics available:

A1 = Automatic S1 = Safety

S2 = Safety Plus E = Semi-automatic

Operation of the different logics is described in tables 5-6-7-8.

Pause time

The pause time is amount of time the gate remains open before

it re-closes when an automatic control logic is selected.

Pause times include the pre-flashing time, if selected.

Warning light operation

Allows you to vary the flashing rate of the warning light during

gate closure.

Pre-flashing

It is possible to select 5 seconds pre-flashing of the flashing light

before any gate movement. This serves to warn any persons in

the vicinity that the gate is about to start moving.

TABLE 5 LOGIC A1 (AUTOMATIC)

LOGIC A1

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

OPEN

opens and recloses after

pause time (1)

recloses after 5 s (2)

inverts motion

no effect

recloses (1)

IMPULSES

STOP

no effect

stops counting

stops

stops

no effect

SAFETY

no effect

freezes pause until

disengagement

inverts motion

no effect

no effect

LK1

J2

1 2 3 4 5 6 7 8 9

TABLE 4 MEANING OF STATUS INDICATOR LEDS

LED ON OFF

OPEN

STOP

FSW

FCC

FCA

Command active Command not active

Command not active Command active

Safeties disengaged Safeties engaged

Closing limit disengaged Closing limit engaged

Opening limit disengaged Opening limit engaged

5.3. DIPSWITCH SETTINGS

Logic SW1 SW2

E1 ON ON

A1 ON OFF

S2 OFF O N

S1 OFF OFF

ON

123456

OFF

Fig. 33

Pause time (sec)

Logic

A1 - S2 S1 SW3 SW4

515ONON

10 30 OFF ON

30 60 ON OFF

120 180 OFF OFF

TABLE 6 LOGIC S1 (SAFETY)

LOGIC S1

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

OPEN

opens and recloses after

pause time (1)

recloses immediately

(1 and 2)

inverts motion

inverts motion

recloses (1)

TABLE 7 LOGIC S2 (SAFETY PLUS)

LOGIC S2

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

OPEN

opens and recloses after

pause time (1)

recloses immediately

(1 and 2)

inverts motion

inverts motion

recloses (1)

TABLE 8 LOGIC E1 (SEMI-AUTOMATIC)

LOGIC E1

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

OPEN

opens (1)

recloses (1)

inverts motion

stops

recloses (reopens when safety

devices are engaged) (1)

IMPULSES

STOP

no effect

stops counting

stops

stops

no effect

IMPULSES

STOP

no effect

stops counting

stops

stops

no effect

IMPULSES

STOP

no effect

no effect

stops

stops

no effect

SAFETY

no effect

recloses after 5 s

from disengagement

inverts motion

no effect

no effect

SAFETY

no effect

freezes pause until

disengagement

stops and inverts motion

when disengaged (1)

no effect

no effect

SAFETY

no effect

no effect

inverts motion

no effect

no effect

Warning light operation

Gate status

SW5

Closed Opening/Open Closing

ON

OFF Steady light

OFF

Steady light

Flashing

Pre-flashing SW6

YES ON

NO OFF

(1) With the pre-flashing selected, movement starts after 5 seconds.

(2) If the impulse is sent during pre-flashing, the timer is reset to zero.

20

Loading...

Loading...