Page 1

User Guide

Multifunction Process Calibrator

Model PRC50

Page 1 PRC50-EN-V2.1 11/11

Page 2

1 Introduction

This multifunction process calibrator is a handheld, battery-operated instrument that measures and sources electrical and

physical parameters.

Main Features:

z Measure: DC-voltage, DC-current, frequency and continuity

z Source: DC-voltage, DC-current, simulation transmitter, frequency and pulse

Additional features:

z Manual step source, auto-step and sweeping–step source

z Measure/source mA% display

z Wave-filter function

z Manual-hold function

2 Standard Accessories

Ensure that the package contains all of the accessories listed below. If items are damaged, please contact the vendor from

which the product was purchased.

z One (1) set of Industrial Test Leads

z One (1) set of Standard Test Leads

z One (1) set of Alligator clips

z User's Guide

z Two (2) Fuses 50mA/250V and 63mA/250V

Page 2 PRC50-EN-V2.1 11/11

Page 3

3 Safety Information

For the correct and safe use of the instrument, be sure to follow the cautionary notes stated in this manual whenever

handling the instrument. Extech Instruments shall not be held liable for any damage resulting from use of the instrument in a

manner other than prescribed in the cautionary notes.

A

Warning identifies conditions and actions that pose hazards to the user; a Caution identifies conditions and actions that

may damage the meter or the equipment under test.

Refer to Table 1 for the international electric symbols adopted by the calibrator.

Table 1 - International Electrical Symbols

EARTH GROUND

Warning

To avoid possible electric shock or personal injury:

z Do not apply more than the rated voltage, as marked on the calibrator, between terminals or between any terminal and

earth ground;

z Before use, verify the meter’s operation by measuring a known voltage;

z Follow all equipment safety procedures;

z Do not connect the probe of the test leads with any live power when the other end has been inserted into the current

jack;

z Do not use the meter if it is damaged. Before using the meter, inspect the case. Look for cracks or missing plastic. Pay

particular attention to the insulation surrounding the connectors;

z Select the proper function and range for the measurement;

z Make sure the battery door is closed and latched before operating the meter;

z Remove test leads from the meter before opening the battery door;

z Inspect the test leads for damaged insulation or exposed metal. Check test lead continuity. Replace damaged test leads

before using the meter;

z When using the probes, keep fingers behind the finger guards on the probes;

z Connect the common test lead before connecting the live test lead. When disconnecting test leads, disconnect the live

test lead first;

z Do not use the meter if it operates abnormally. Protection may be impaired. When in doubt, have the meter inspected;

z Do not operate this instrument in areas where inflammable or explosive gases or vapor exists. It is extremely hazardous

to use the instrument under such environments;

z Do not operate the meter near explosive gas, vapor, or dust;

z Use only four (4) AAA 1.5V batteries, properly installed in the meter case, to power the meter;

z Disconnect the test leads before changing source or measurement functions;

z When servicing the meter, use only specified replacement parts.

z To avoid false readings, which could lead to possible electric shock or personal injury, replace the batteries as soon as

the low battery indicator (

) appears.

WARNING

INFORMATION

Page 3 PRC50-EN-V2.1 11/11

Page 4

Caution

To avoid possible damage to meter or to equipment under test:

z Disconnect the power and discharge all high-voltage capacitors before testing resistance or continuity.

z Use the proper jacks, functions, and ranges for the measurement or source operation in question.

4 Calibrator Description

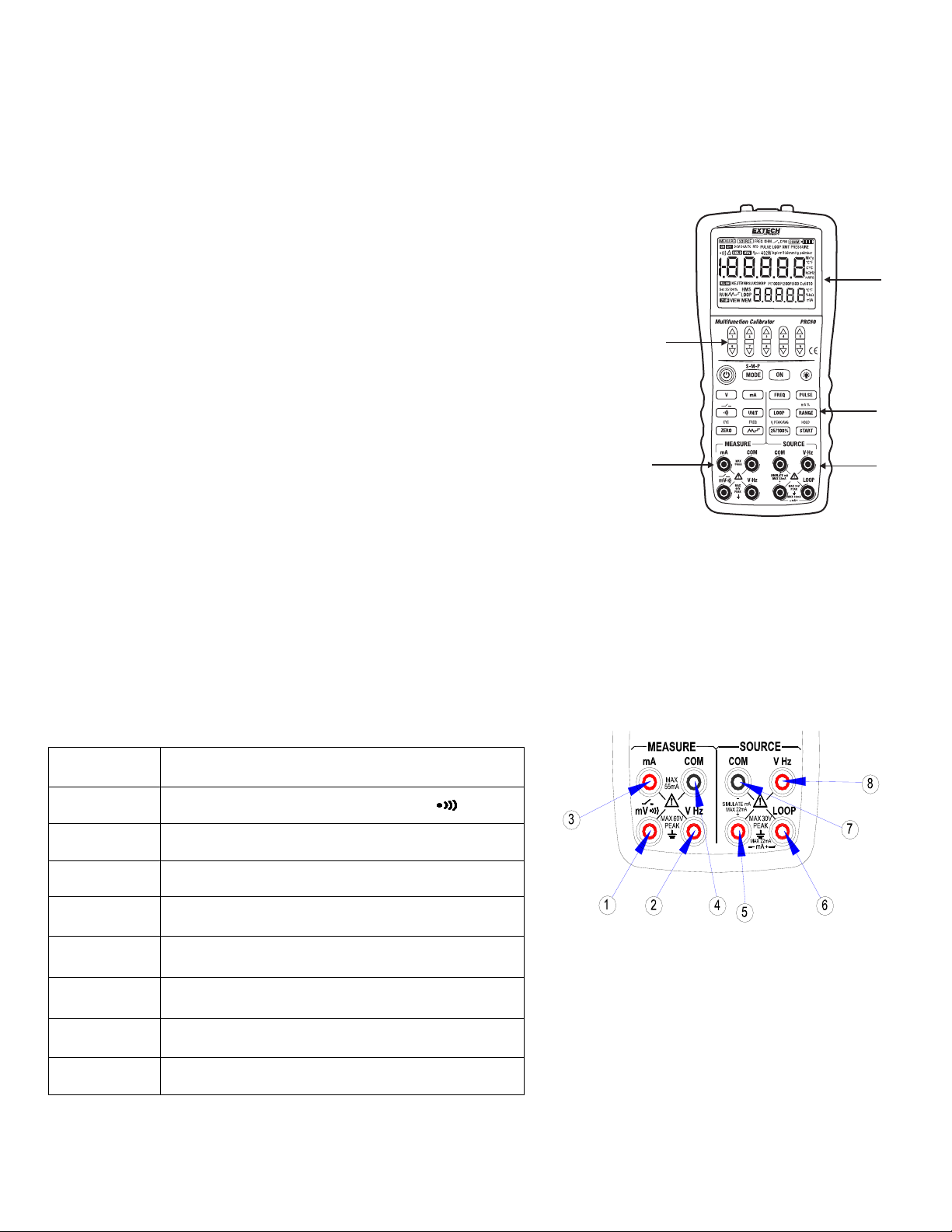

Refer to Figure 1

1. LCD display

2. Digit up/down adjust buttons

3. Control keypad

4. Measurement terminals

5. Source terminals

Figure 1 – Meter Description

4.1 Measurement/ Source Terminals

Figure 2 shows the calibrator’s measurement /source terminals. Table 2 explains their use.

Figure 2 - Measurement/ Source Terminals

Table 2 - Measurement/ Source Terminals

2

4

1

3

5

Terminal Function

1

2

3

4

5

6

7

8

Measurement Signals(+):DCmV、

Measurement Signals(+):DCV、FREQ

Measurement Signals(+):DCmA

Common (return ) (-) terminal for all

measurement functions

Source Signals:(-)DCmA

Source Signals:(+) Simulate mA

Source Signals:(+)DCmA

LOOP Terminal:+24VDC Loop Power Terminal

Common (return ) (-)terminal for source

functions

Source Signals:(+)DCV、FREQ、PULSE

Page 4 PRC50-EN-V2.1 11/11

Page 5

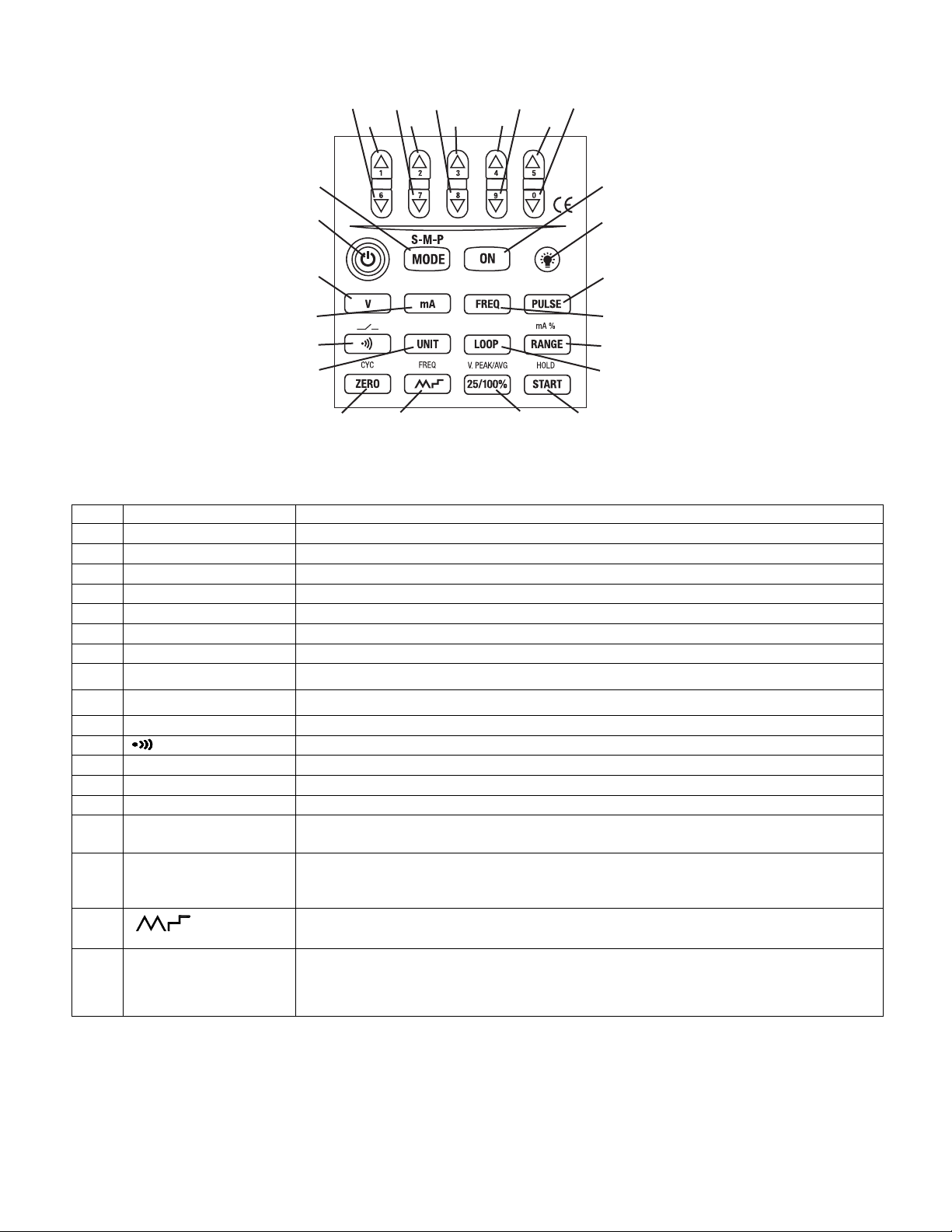

4.2 Keys

Figure 3 lists the calibrator’s function keys and Table 3 explains their use.

6

12

8910

7

3

4

5

11

13

15

17

19

21

23 2425 26

Figure 3 – Calibrator Function Keys

Table 3 – Function Key Descriptions

No. Name Function

1~5 Source value set keys Increment source set point

6~10 Source value set keys Decrement source set point

11

12

13 Power key Switch ON/OFF power

14 Backlight Switch ON/OFF backlight

15

16

17

18

19 Key Select measurement continuity function

20

21

22

23

24

25

26

MODE key

ON key

V Key

PULSE Key

mA Key

FREQ Key

RANGE Key

UNIT Key

LOOP key

ZERO Key

START Key

Key

25/100% Key

Mode key (press to change the function mode)

Switch ON/OFF measurement/ source function

Select measurement/source DCV function

Select source pulse function

Select measurement/source mA function

Select measurement/source FREQ function

Select measurement/source range; mA /percentage toggle key

not used

Switch ON/OFF 24V Loop power

Set the source value to its default value;

In pulse source function, set the pulse value

Source auto-pulse value;

Switch ON the mA auto-stepping or sweeping function;

HOLD (freeze) the measured value;

In DCmA source function ,select the auto-wave type;

In frequency or pulse source, set the frequency value.

In mA source function, select 25% or 100% manual step output type;

In pulse number mode, frequency source, set the amplitude value;

Measure the average value.

12

14

16

18

20

22

Page 5 PRC50-EN-V2.1 11/11

Page 6

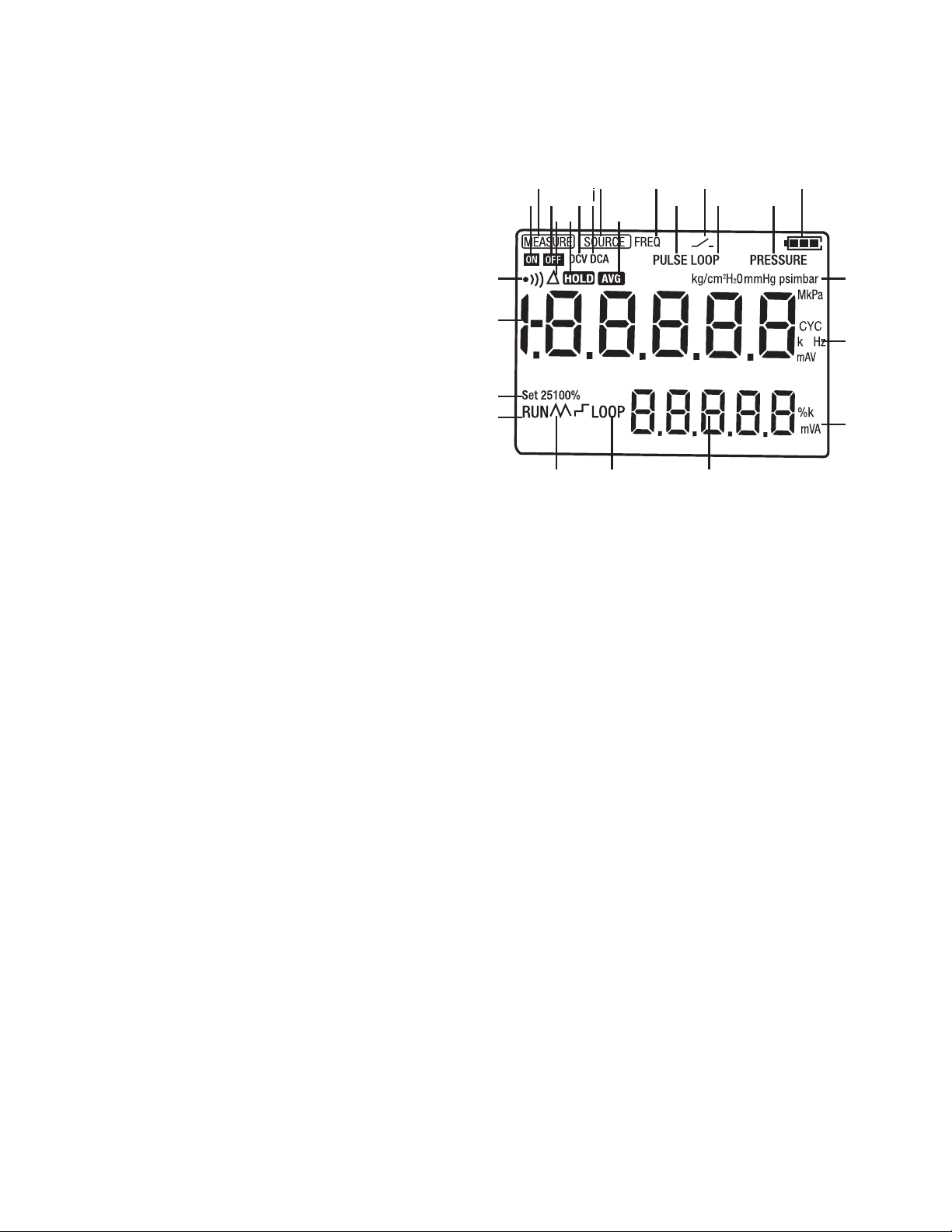

4.3 Display Screen

Figure 4 shows a typical display screen.

Figure 4 - LCD display

a. Measurement

b. Source

c. Measurement/Source frequency

d. Not used

e. Battery level indicator

f. Measurement/Source function ON

g. Source function OFF

h. Measurement/Source voltage

i. Measurement/Source current

j. Source pulse

k. 24V Loop Power Supply ON

l. Not used

m. Beeper for measurement continuity

n. Not used

o. Measured value HOLD

p. Measurement average value

q. Not used

r. Main numerical display

s. Unit of measure for main display

t. DCmA 25% or 100% manual step source

u. Start source number of pulses / DCmA auto-stepping or sweeping source function

v. 24V Loop Power Supply ON

w. DCmA auto-stepping or sweeping source

x. Unit of measure for secondary display

y. Secondary numerical display

m

r

t

u

abcd e

g

f

h

j

no p

wv y

kl

q

s

x

Page 6 PRC50-EN-V2.1 11/11

Page 7

Source/Measurement Preparations

Precautions for Safe Use of the Instrument

z When using the instrument for the first time, be sure to read the instructions given in Section 4 “Precautions for Safe

Use of the Instrument.”

z Do not open the instrument’s case. Contact the vendor for service.

z In case of failure: Should the instrument begin to emit smoke, give off an unusual odor, or show any other anomaly,

immediately switch OFF the POWER. Also switch OFF power to the object under test that is connected to the input

terminals. Contact the vendor.

General Handling Precautions

z Before transporting the instrument, switch OFF power to the object under test, and then power off the meter. Finally,

detach all lead cables from the instrument. Use a dedicated carry case when transporting the instrument.

z Do not bring any electrified object close to the input terminals, since this may damage the internal circuitry.

z Do not apply any volatile chemical to the instrument’s case or operation panel. Do not leave the instrument in contact

with any product made of rubber or vinyl for a prolonged period. Be careful not to let a soldering iron or any other heat-

emitting object come into contact with the operation panel (panel is made of thermoplastic resin).

z Use a soft, damp cloth to gently wipe the outer surfaces of the instrument. Water that is allowed into the instrument can

result in malfunction.

z For handling precautions regarding the batteries, see “Installing or Replacing the Batteries”.

z Never use the instrument with the cover of the battery holder opened.

Environmental Requirements

Use the instrument in locations that meet the following environmental requirements:

o

z Ambient temperature range: 32 to 122

z Place the instrument on flat and level areas

Do not use the instrument in locations that are:

z Exposed to direct sunlight or close to any heat source.

z Exposed to frequent mechanical vibration.

z Close to an electrical noise source, such as high-voltage equipment or motive power sources.

z Close to any source of intensive electric or electromagnetic fields.

z Exposed to large amounts of grease fumes, hot steam, dust or corrosive gases.

z Exposed to unstable areas such as where a risk of explosion due to the presence of flammable gases exists.

Notes:

z Use the instrument under the following environmental conditions when precise measurements are required:

o

Ambient temperature range: 74

F (23oC) ±5o; ambient humidity range: 20 to 80% RH (non-condensing)

z When using the instrument within a temperature range of 32 to 64

based on the temperature coefficient shown in the “Specifications” section to the given accuracy rating.

z When using the instrument at an ambient humidity of 30% or lower, prevent electrostatic charges by using an anti-static

mat or other alternative means.

z Condensation may occur if the instrument is relocated from places with low temperature and humidity to places with

high temperature and humidity, or if the instrument experiences a sudden temperature change. In these cases, leave

the instrument under the given ambient temperature for at least one hour to ensure that the instrument is free from

condensation before using the instrument.

F (0 to 50oC); ambient humidity range: 20 to 80% RH; non-condensing.

o

F (0 to 18oC) or 82 to 122oF (28 to 50oC), add a value

Page 7 PRC50-EN-V2.1 11/11

Page 8

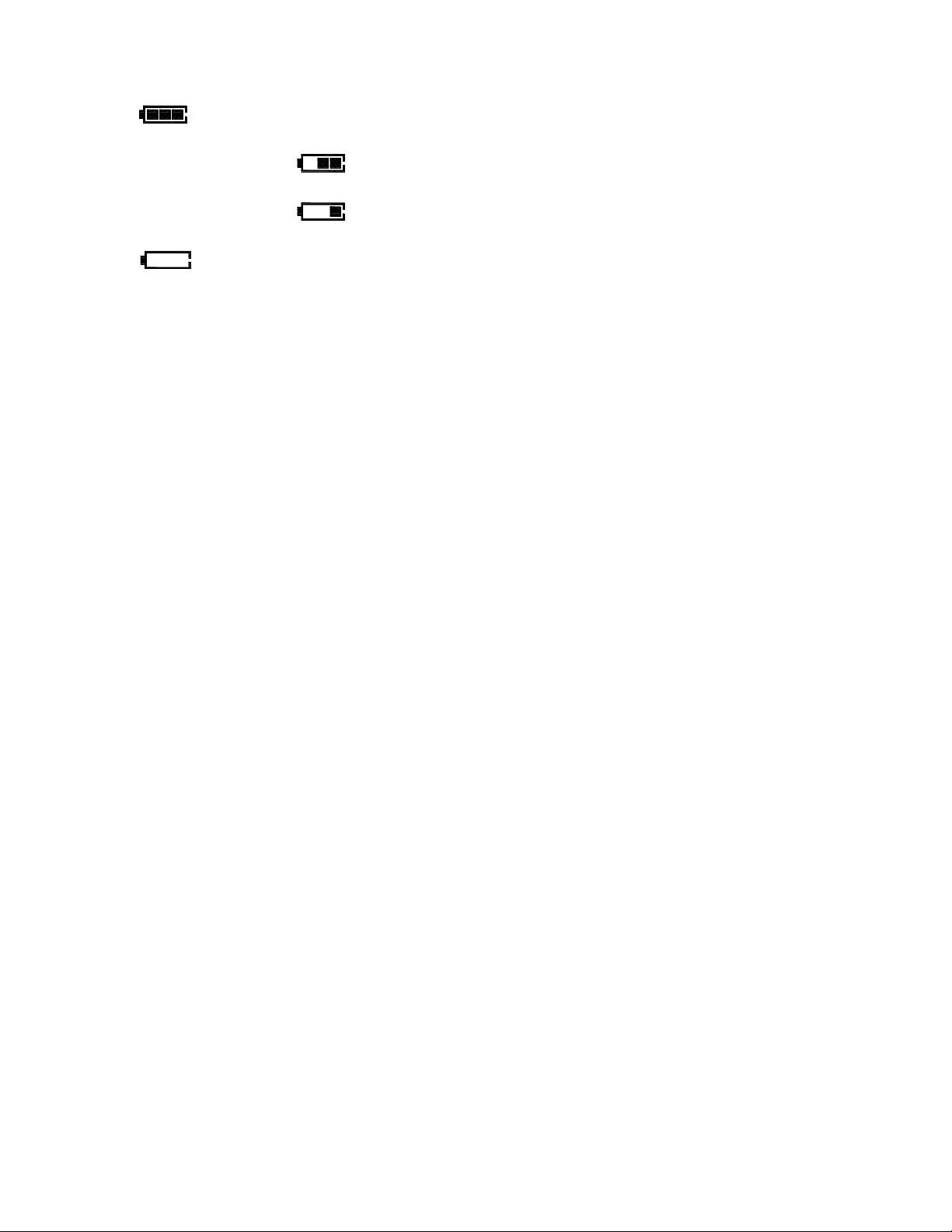

Indication of Battery Level

The battery replacement indicator shows the battery level in five stages.

Full battery:

The battery level is below 50% full:

The battery level is below 25% full:

Low battery:

The battery icon flashes in sequence when charging.

Note that the battery replacement indicator is driven by directly measuring the battery voltage when the calibrator is in actual

operation. Consequently, the indicator may read differently depending on the battery load condition (e.g., the load condition

of the source output or on/off state of the measurement function).

To replace batteries and/or fuses refer to Section 12 of this User Guide.

Switching Power ON

Press the Power key once to switch ON the calibrator. Press and hold the Power key for 2 seconds to switch it OFF.

Automatic Power OFF

When the calibrator is running on batteries and no key is pressed for approximately ten minutes, the calibrator switches OFF

automatically. The automatic power-off time can be programmed or set to the factory default state, see the “Global Settings”

section.

Switching the LCD Backlight ON and OFF

Press the backlight key to switch ON the backlight; press again to switch it OFF. Battery life is shortened by backlight

overuse.

Notes: The backlight automatically switches OFF after 10 seconds. The time can be programmed or reset to the factory

default condition, see the “Global Settings” section.

Page 8 PRC50-EN-V2.1 11/11

Page 9

5 Source

The calibrator can source a DC voltage, DC current, resistance, frequency, and pulse signal.

Warning

To avoid electrical shock, do not apply more than the rated voltage, as marked on the calibrator, between terminals or

between any terminal and earth ground. Always use the calibrator in locations with a voltage to ground value below

30Vpeak.

Caution

z Do not apply any voltage to the output terminals for ranges other than 4-20mA simulating transmitter outputs.

Otherwise, the internal circuitry may be damaged.

5.1 Connecting Cables to Terminals

For DC voltage, frequency, or pulse (see Figure 5)

Step 1: Connect the black lead cable for source to the COM output terminal and the red lead cable to the “Vhz” output

terminal.

Step 2: Connect the other ends of the cables to the input of equipment under test while making sure the polarities are

correct.

Figure 5 - Sourcing DC voltage, frequency, and pulse

For DC current (see Figure 6)

Step 1: Connect the black lead cable for source to the “mA-” output terminal and the red lead cable to the ‘’mA+/LOOP’’

output terminal.

Step 2: Connect the other ends of the cables to the input of equipment under test while making sure the polarities are

correct.

Figure 6 - Sourcing DC Current

Page 9 PRC50-EN-V2.1 11/11

Page 10

5.2 Sourcing DC Voltage

Step 1: Use the〔V〕key to select the DC voltage source function and then select the desired range from 1000mV, 10V by

pressing the〔RANGE〕key. The default value, the unit of the selected source function, and the source DC Current range

will be displayed on the LCD.

Step 2: Set the output value, digit by digit, using〔S〕/〔T〕keys.

Each pair of〔S〕/〔T〕keys corresponds to each digit of the LCD reading. Each press of the〔S〕/〔T〕key increases

or decreases the digit. Increasing the digit from 9 or decreasing it from 0 causes the digit to overflow or underflow, allowing

the output value to be set without interruption. Holding down the〔S〕/〔T〕key continuously changes the digit in question

quickly. The value won’t change if it is increased or decreased to the Maximum or Minimum value. Pressing the (ZERO) key

initializes the output set point to the default value (0).

Step 3: Pressing the〔ON〕key causes the indicator on the LCD to change from ‘’OFF‘’ to ‘’ON ‘’. The calibrator sources the

present DC voltage between the output terminals.

Step 4: To turn off the output, press the〔ON〕key again. The’’ OFF ‘’ icon appears on the LCD and no signals are sourced

between the terminals.

5.3 Sourcing DC Current

Step 1: Use the〔mA〕key to select the desired source function 20mA. The default value and unit of the selected source

function will be displayed on the LCD.

Step 2: Set the output value digit by digit using〔S〕/〔T〕keys.

Each pair of〔S〕/〔T〕keys corresponds to each digit of the LCD reading. Each press of the〔S〕/〔T〕key increases

or decreases the digit. Increasing the digit from 9 or decreasing it from 0 causes the digit to overflow or underflow, allowing

the output value to be set without interruption. Holding down the〔S〕/〔T〕key continuously changes the digit in question

quickly. The value won’t change if it is increased or decreased to the Maximum or Minimum value. Pressing the (ZERO) key

initializes the output set point to the default value (0).

Step 3: Pressing the〔ON〕key causes the indicator on the LCD to change from ‘’OFF‘’ to ‘’ON ‘’. The calibrator sources the

preset DC current between the output terminals.

Step 4: To turn off the output, press the〔ON〕key again. The’’ OFF ‘’icon appears on the LCD and no signals are sourced

between the terminals.

Page 10 PRC50-EN-V2.1 11/11

Page 11

5.3.1 Manually Set 25%, 100% 4–20 mA Function

The source value in 4 mA or 16mA increments or decrements can be set within the 4–20 mA current range.

Step 1: In the DC current function, press the〔25%100%〕key to display “25%SET” on the lower part of the screen, and

press it again to display “100%SET”. The default source value will be displayed.

Step 2: Using each pair of 〔S〕/〔T〕output setting keys, set the signal in a step-by-step manner. In 25% set point mode,

set the signal in 4 mA increments in the order 4-8-12-16-20 with each press of the key. In 100% set point mode, set the

signal in 16 mA increments in the order 4-20 with each press of the key. Pressing the〔ZERO〕key initializes the signal set

point to the default value (4mA).

Step 3: Pressing the〔ON〕key causes the indicator on the LCD to change from ‘’OFF‘’ to ‘’ON ‘’. The calibrator sources the

preset 4–20 mA current signal between the output terminals.

Step 4: To turn off the output, press the〔ON〕key again. The’’ OFF ‘’icon appears on the LCD and no signals are sourced

between the terminals.

5.3.2 Auto-stepping and auto-sweeping 4-20mA function

The user can set a 4–20 mA range within which to source current in 4-20mA increments or decrements in auto-stepping

mode or in auto-sweeping mode. 80 seconds are required to finish a 4-20mA cycle in auto-sweeping mode and 20 seconds

are required for auto-stepping mode.

Step 1: In the DC current mode, press the 〔

of the screen, and press it again to display the auto-sweeping mode signal “

〕key to display the auto-stepping mode signal “ ” on the lower part

”.The default source value will be shown.

Step 2: Pressing the (ON) key causes the indicator on the LCD to change from ‘’OFF‘’ to ‘’ON ‘’. The calibrator sources the

default 4–20 mA current signal between the output terminals.

Step 3: Pressing the (START) key starts the auto-stepping and auto-sweeping mode. The “RUN” icon is displayed in the

lower part of the LCD.

Step 4: Pressing the (START) key again stops the auto-stepping and auto-sweeping mode. The “RUN“ icon switches OFF.

Step 5: Pressing the (ON) key stops sourcing and the ‘’OFF’’ icon is displayed on the screen. No signals are sourced

between the terminals.

Notes:

z Press the (START) key again to continue the auto-stepping and auto-sweeping mode after stopping them; The “RUN”

icon is displayed on the lower part of the screen.

z The ability to use the (START) key to start mA auto-stepping and auto-sweeping mode is only available when the

source function is in the ON state.

Page 11 PRC50-EN-V2.1 11/11

Page 12

5.3.3 mA% display

In the mA source mode, the preset value is displayed on the primary numerical display and the ma% is displayed on

the smaller secondary numerical display.

100 (current measured value mA-4mA)

mA % = %

16 mA

Note: Increment/decrement set is not available in mA% mode.

5.3.4 4-20 mA simulate transmitter source

Connect the calibrator and loop power as shown in Figure 7. Operate as described in the DC current Source section.

Figure 7 - 4-20 mA simulation transmitter source

5.4 Sourcing Frequency

The calibrator can source a constant pulse signal responding to the preset frequency and amplitude.

Step 1: Using the〔FREQ〕key, select frequency source function. The LCD shows the default frequency value 10 Hz.

Step 2: Using the〔RANGE〕key, select a frequency range from 100Hz, 1KHz, 10KHz. The selected function, the default

range source value, and the unit will be shown on the LCD.

Step 3: Set the output value digit by digit using each pair of〔S〕/〔T〕output setting keys.

Each pair of〔S〕/〔T〕keys corresponds to each digit of the LCD reading. Each press of the〔S〕/〔T〕key increases

or decreases the digit. Increasing the digit from 9 or decreasing it from 0 causes the digit to overflow or underflow, allowing

the output value to be set without interruption. Holding down the〔S〕/〔T〕key continuously changes the digit quickly.

The value won’t change if it is increased or decreased to the Maximum or Minimum value.

Step 4: Pressing the〔Vpeak〕key once switches to amplitude setting mode. The LCD provides a reading of 1V.

Step 5: Set the output value digit by digit using each pair of〔S〕/〔T〕output setting keys.

Each pair of〔S〕/〔T〕keys corresponds to each digit of the LCD reading. Each press of the〔S〕/〔T〕key increases

or decreases the digit. Increasing the digit from 9 or decreasing it from 0 causes the digit to overflow or underflow, allowing

the output value to be set without interruption. Holding down the〔S〕/〔T〕key continuously changes the digit quickly.

The value won’t change if it is increased or decreased to the Maximum or Minimum value.

Page 12 PRC50-EN-V2.1 11/11

Page 13

Step 6: To re-enter into the frequency set mode, press the〔FREQ〕key to set the frequency.

Step 7: Pressing the〔ON〕key causes the SOURCE indicator on the LCD to change from ‘’OFF‘’ to ‘’ON ‘’. The calibrator

sources constant pulse signals responding to the preset frequency and amplitude between the output terminals.

Step 8: To turn off the output, press the〔ON〕key again. The ‘’OFF‘’ icon appears on the LCD and no signals are sourced

between the terminals.

Notes:

z The frequency range can only be changed by pressing the〔RANGE〕key in the frequency set mode.

z The frequency value and range can be changed when the frequency source function is in the ‘’ON ‘’ or the ‘’OFF‘’ state.

5.5 Sourcing a Number of Pulses

The calibrator can source a preset number of pulse signals according to the preset frequency and amplitude.

Step 1: Using the〔PULSE〕key, select the pulse source function. The LCD shows the default value 10 Hz.

Step 2: Using the (RANGE) key, select a frequency range (100Hz / 1KHz / 10Hz). The selected function, the default range

source value, and the unit of measure are shown in the lower portion of the LCD.

Step 3: Set the output value digit by digit using each pair of〔S〕/〔T〕output setting keys.

Each pair of〔S〕/〔T〕keys corresponds to each digit of the LCD reading. Each press of the〔S〕/〔T〕key increases

or decreases the digit. Increasing the digit from 9 or decreasing it from 0 causes the digit to overflow or underflow, allowing

the output value to be set without interruption. Holding down the〔S〕/〔T〕key continuously changes the digit quickly.

The value won’t change if it is increased or decreased to the Maximum or Minimum value.

Step 4: Pressing the〔VPEAK〕key switches to the amplitude setting mode. The LCD shows a reading of 1V.

Step 5: Set the output value digit by digit using each pair of 〔S〕/〔T〕output setting keys.

Each pair of〔S〕/〔T〕keys corresponds to each digit of the LCD reading. Each press of the〔S〕/〔T〕key increases

or decreases the digit. Increasing the digit from 9 or decreasing it from 0 causes the digit to overflow or underflow, allowing

the output value to be set without interruption. Holding down the

The value won’t change if it is increased or decreased to the Maximum or Minimum value.

Step 6: Press the (CYC) key to enter the pulse number set mode; the LCD will show the default number of 1 CYC.

Step 7: Set the output value digit by digit using each pair of〔S〕/〔T〕output setting keys.

Each pair of〔S〕/〔T〕keys corresponds to each digit of the LCD reading. Each press of the〔S〕/〔T〕key increases

or decreases the digit. Increasing the digit from 9 or decreasing it from 0 causes the digit to overflow or underflow, allowing

the output value to be set without interruption. Holding down the〔S〕/〔T〕key continuously changes the digit quickly.

The value won’t change if it is increased or decreased to the Maximum or Minimum value.

Step 8: To re-enter the frequency set mode, press the〔FREQ〕key.

〔S〕/〔T〕key continuously changes the digit quickly.

Page 13 PRC50-EN-V2.1 11/11

Page 14

Step 9: Pressing the (ON) key causes the SOURCE indicator on the LCD to change from ‘’OFF‘’ to ‘’ON ‘’, and the

calibrator sources low level signals between its output terminals.

Step 10: Press the (START) key to allow the calibrator to source the set number of pulses responding to the preset

frequency and amplitude, the LCD will show the “RUN” icon.

Step 11: When source is complete, the calibrator automatically switches OFF the output and ceases operation. The “RUN”

symbol also switches OFF.

Step 12: To switch OFF the output, press the (ON) key again. The ‘’OFF‘’ icon appears on the LCD and no signals will be

sourced between the terminals.

Notes:

z The frequency range of the pulse can only be changed by pressing (RANGE) in the frequency set mode.

z When the “RUN” symbol switches OFF, the user can change the frequency and amplitude when the source function is

in ‘’ON ‘’ or ‘’OFF‘’.

z During the pulse sourcing process, pressing the (START) key causes the calibrator to switch OFF the output; the “RUN”

icon switches OFF also. Press the (START) key again to restart the sourcing function.

z Restarting the pulse output requires that the source function be in the ‘’ON ‘’state.

5.6 Zero-off function

In any range of DC voltage or DC current pressing the (ZERO) key initializes the preset source value. In the frequency and

pulse modes, the (ZERO) key function is unavailable.

Page 14 PRC50-EN-V2.1 11/11

Page 15

6 Measurements

The calibrator measures DC voltage, DC current, frequency, and continuity.

Warning

z In applications where the calibrator is used together with the supplied test lead cables for measurement, the allowable

voltage to ground of the input terminals is 60 V peak maximum. To avoid electrical shock, do NOT use the calibrator at

voltages exceeding the maximum voltage to ground.

Notes:

z Using the〔HOLD〕key, the measured value can be frozen on the display.

z The LCD shows all dashes (- - - - -) on the upper area when the range is changed by the user. If the input is over loaded

(over range), the measured value on the LCD indicates “oL”.

6.1 Connecting Cables to Terminals

For DC voltage (mV) and continuity (Figure 8)

Step 1: Connect the black test lead cable for measurement to the “COM” input terminal and the red test lead cable to the

“mV” input terminal.

Figure 8 - Measuring DC voltage and continuity

Step 2: Connect the other end of the cables to the terminal points of the equipment under test while ensuring that the

polarities are correct.

For DC Voltage (V) signal (Figure 9)

Step 1: Connect the black test lead cable for measurement to the “COM” input terminal and the red test lead cable to the

“VHz” input terminal.

Step 2: Connect the other end of the cable to the measuring terminals of the equipment under test while making sure the

polarities are correct.

Figure 9 - Measuring DC Voltage and Frequency

Page 15 PRC50-EN-V2.1 11/11

Page 16

For DC Current signal (Figure 10)

Step 1: Connect the black test lead cable for measurement to the “COM” input terminal and the red test lead cable to the

“mA” input terminal.

Step 2: Connect the other end of the cable to the measuring terminals of the equipment under test while making sure the

polarities are correct.

Figure 10 - Measuring DC Current

Warning

z Before connecting the calibrator to the device under test, switch OFF the power to the device.

z Do not apply voltage or current exceeding the allowable voltage (60 V peak) or current (55 mA). Exceeding the limits will

endanger the instrument and create a risk of personal injury due to electrical shock.

z Mistaking the voltage input terminal for the mA current input terminal, and vice versa, when wiring, is extremely

dangerous. Take great care in making connections; always check the accuracy of the connection configuration.

z The current input terminals are equipped with a built-in current input protection fuse. Over-current input to the terminals

will cause the fuse to blow. If the fuse is blown, replace it with one with the specified ratings. For details on fuse

replacement, see the “Replacing the battery and fuse” section.

Warning

Wiring or operational errors can lead to damage to the instrument and personal injury due to electrical shock. Exercise the

utmost care when carrying out the measurement tasks.

6.2 Measuring DC Voltage

Step 1: Ensure that the test lead cables are not connected to the instrument or device under test.

Step 2: Using the function key (V), select DC Voltage measurement function.

Step 3: Connect the test lead cables to the terminals of the instrument under test.

Step 4: Using the (RANGE) key, select a desired range from 200mV, 5V, 50V. The selected function, the measured value,

and the unit of measure are shown in the upper area of the LCD.

Page 16 PRC50-EN-V2.1 11/11

Page 17

6.3 Measuring DC Current

Step 1: Ensure that the test lead cables are not connected to the instrument or device under test.

Step 2: Using the function key (mA), select the DC Current measurement function.

Step 3: Connect the test lead cables to the measuring terminals of the instrument under test.

Step 4: The selected function, the measured value, and the unit is shown in the upper area of the LCD.

6.3.1 mA % Display

In the mA measurement mode, the preset value is displayed on the primary numerical display area and the mA% is

displayed on the smaller, secondary numerical display area. See the equation below.

100 (current measured value mA-4mA)

mA %= %

16 mA

6.3.2 Using the Calibrator as a 24-V Loop Power Supply

This function helps to switch ON a 24V loop power supply connected in line with the measured DC current circuit, in which

the calibrator can be used as a loop power supply that can calibrate a 2-wire converter:

Step 1: When the calibrator is in the current measurement mode, pressing the〔LOOP〕key causes the LCD to show the

LOOP symbol and the built-in 24V loop power of the calibrator will be switched ON.

Step 2: Connect the calibrator with the loop current terminals of the converter as shown in Figure 11.

Figure 11 – A 24v loop power circuit supply

Note: Since the function discussed above requires a significant amount of DC current (25 mA), battery operation will reduce

the battery life considerably.

Page 17 PRC50-EN-V2.1 11/11

Page 18

6.4 Measuring Frequency

Step 1: Ensure that the test lead cables are not connected to the instrument under test.

Step 2: Using the function selector key (FREQ), select the frequency measurement function.

Step 3: Connect the test lead cables to the measuring terminals of the instrument under test.

Step 4: Using the measurement (RANGE) key, select the suitable range (500Hz, 5KHz, 50KHz).The selected function, the

measured value, and the unit is shown in the upper part of the LCD.

6.5 Measuring Continuity

Continuity measurements are used to detect the completeness of a circuit or wire (e.g. a resistance smaller than 250 ohms).

Using the function selector key (

”on the upper area. Connect the device as shown in Figure 8; the beeper will sound continuously if the loop circuit

“

resistance is below 250Ω; The LCD shows the circuit OPEN or CLOSED icon.

), select the continuity measurement function. The LCD displays the continuity symbol

6.6 Measurement-filtering function

The measurement-filtering function stabilizes the measured value displayed on LCD. In the DCV or DCmA function, pressing

the〔AVG〕key facilitates an averaging calculation of the samples and the LCD shows the “AVG” symbol. Pressing the〔

AVG〕key again cancels the calculation and the “AVG” symbol switches OFF.

6.7 Measured Value holding function

The read-hold function can be used to freeze a measurement (the held measurement is shown on the upper area of the

LCD). Pressing the〔HOLD〕key selects the read-hold mode and the LCD displays the “HOLD” symbol. To cancel the

selection, press the〔HOLD〕key again and the “HOLD” symbol will switch OFF.

Page 18 PRC50-EN-V2.1 11/11

Page 19

7 Programming the Calibrator’s Global Settings

Press and hold the (ZERO) key while switching the meter ON. Release the (ZERO) key 3 seconds after the LCD switches

ON. The following parameters can be programmed by the user when the meter is in this state. The top row of the LCD

display shows the parameter name and the bottom row of the LCD shows the setting. Use the (MODE) key to scroll the

parameters and then follow the instructions below to configure each parameter.

7.1 Setting Auto-power off time (AP.OFF)

Step 1: Use the (MODE) key to move to the “AP.OFF” parameter at the top of the LCD (if it’s not already displayed).

Step 2: Set the time from 0-60 minutes using the second pair of 〔S〕/〔T〕keys counting right to left. Each press of the〔

S〕/〔T〕key equals one 10 -minute increment or decrement. Press and hold a key to scroll quickly.

Step 3: To save the setting, press the (ON) key and the LCD will show the “SAVE” symbol.

Tip: The value (0) indicates that the automatic power-off function is disabled.

7.2 Setting Backlight time

Step 1: Use the (MODE) key to move to the “BL.OFF” parameter at the top of the LCD (if it’s not already displayed).

Step 2: Set the time using the 〔S〕/〔T〕keys (the unit of measure for the time is ‘seconds’ and the range is 0-3600

seconds). Each pair of〔S〕/〔T〕keys corresponds to each digit of the LCD reading. Each press of the〔S〕/〔T〕key

increases or decreases the digit. Increasing the digit from 9 or decreasing it from 0 causes the digit to overflow or underflow,

allowing the output value to be set without interruption. Holding down the〔S〕/〔T〕key continuously changes the digit

quickly. The value won’t change if it is increased or decreased to the Maximum or Minimum value.

Step 3: To save the setting, press the (ON) key and the LCD will show the “SAVE” symbol.

Note: When value is (0), the backlight will not switch OFF automatically.

7.3 Setting the frequency

Step 1: Use the (MODE) key to display the “FRSET” parameter at the top of the LCD (if it’s not already displayed).

Step 2: Shift between 50Hz and 60Hz using the right pair of 〔S〕/〔T〕keys.

Step 3: To save the setting, press the (ON) key and the LCD will show the “SAVE” symbol.

Page 19 PRC50-EN-V2.1 11/11

Page 20

7.4 Setting CMSET

Step 1: Use the (MODE) key to move to the “CMSEt” parameter at the top of the LCD (if it’s not already displayed).

Step 2: From selections (PCM, DPM) select DPM using the right pair of 〔S〕/〔T〕keys.

Step 3: To save the setting, press the (ON) key and the LCD will show the “SAVE” symbol.

7.5 Factory default

Step 1: Use the (MODE) key to move to the “FACry” parameter at the top of the LCD (if it’s not already displayed).

Step 2: Press the (ON) key to revert to the default values as shown below:

AP.OFF: 10 minutes

BL.OFF: 10 seconds

FRSET: 50 Hz

CMSET: PCM

Page 20 PRC50-EN-V2.1 11/11

Page 21

8 Replacing Batteries or fuses

Warning

To avoid possible electric shock, remove the test leads from the calibrator before opening the battery door and ensure that

the battery door is tightly closed before switching the calibrator ON.

Caution

z To avoid battery leakage and possible explosion ensure correct battery polarity.

z Do not short circuit the batteries.

z Do not disassemble, heat, or expose batteries to fire.

z When replacing the batteries, use only the specified type (four AAA 1.5V).

z Remove the batteries if the meter is to be stored for a long period.

Step 1: Remove the test leads and charger before replacing the batteries or fuses, and switch OFF the meter.

Figure 16 - Replacing batteries and fuses

Step 2: Remove the rubber protective holster as shown in Figure 16. With a standard blade screwdriver, turn each battery

door screw a quarter turn counter-clockwise to remove the battery door.

Step 3: Replace with four (4) new AAA alkaline batteries using the instructions shown on the battery door. Replace the

blown fuses with same type F1 (50mA/250V) or F2 (50mA/250V) or F3 (63mA/250V).

Step 4: Reinstall and tighten the battery door, affix the protector before using the meter.

Page 21 PRC50-EN-V2.1 11/11

Page 22

9 Maintenance

9.1 Cleaning the calibrator

Warning

To avoid electrical shock or damage to the meter, service the meter with specified replacement parts only and do not allow

water to enter the meter housing.

Caution

To avoid damaging the plastic lens and case, do not use solvents or abrasive cleansers.

Clean the Calibrator with a soft cloth dampened with a mild soap.

9.2 Calibration, Repair, and Technical Support Services

Extech offers repar and calibration services for the products we sell. Extech also provides NIST certification for most

products. Call the Customer Care Department for information on calibration services available for this product. Extech

recommends that annual calibrations be performed to verify

Page 22 PRC50-EN-V2.1 11/11

Page 23

10 Specifications

General Specifications for Measurement Mode; these specifications assume:

• A 1-year calibration cycle

• An operating temperature of 64

• Relative humidity of 35% to 70% (non condensing)

Accuracy is expressed as ± (percentage of reading + percentage of range)

Function

DCV

Reference

200mV

Range Resolution Accuracy Remark

-20.00mV~220.00mV

o

F to 82oF (18°C to 28°C)

10μV 0.02 rdg + 0.02 range Input Resistance: 100MΩ

5V

50V

DCmA 50mA

FREQUENCY

CONTINUITY

500Hz

5KHz

50KHz

-0.5000V~5.5000V

-5.000V~55.000V

-4.000mA~55.000mA

3Hz~500.00Hz

3Hz~5.0000KHz

3Hz~50.000KHz

≤250Ω beeper Open circuit voltage: 2.5V

0.1mV 0.02 rdg +0.01 range

1mV 0.03 rdg +0.01 range

1μA 0.02 rdg +0.01 range Input Resistance: 5Ω

0.01Hz

0.1Hz

1Hz

±2 digits

Input Resistance: 1MΩ

Input Impedance:100kΩ min.

Sensitivity:3Vp-p min.

Duty Cycle: 50%

Notes:

z DCV: Normal Mode Rejection Ratio (NMRR) ≥60dB (at 50Hz or 60Hz); Common Mode Rejection Ratio (CMRR) ≥120dB (at

50Hz or 60Hz)

z Reading rate: 2 readings per second

z Temperature Coefficient: 0.1 times the applicable accuracy specification per degree from 41

o

104

F (28°C to 40°C).

o

F to 64oF (5°C to 18°C) and 82oF to

z Maximum voltage between VΩHz terminal and COM terminal: 60 Vp-p; Maximum Input current: 55mA.

Protected with a 63mA, 250V fast blow fuse

Page 23 PRC50-EN-V2.1 11/11

Page 24

General Specifications for Source Mode

These specifications assume:

• 1-year calibration cycle

• Operating temperature of 64

o

F to 82oF (18°C to 28°C)

• Relative humidity of 35% to 70% (non condensing)

Accuracy is expressed as ± (percentage of set value + percentage of range)

Function

Reference Range Resolution

1000mV

10V

-100.00mV~1100.00mV

-1.0000V~11.0000V

10μV 0.02 rdg +0.01 range Maximum output current: 2mA DC voltage

0.1mV 0.02 rdg +0.01 range Maximum output current: 5mA

Accuracy

Remark

DC current 20mA

FREQ

PULSE

LOOP 24V

100Hz

1KHz

10KHz

100Hz

1KHz

10KHz

0.000mA~22.000mA

1.00Hz~110.00Hz

0.100KHz~1.100KHz

1.0KHz~11.0KHz

1 to 100,000cycles

1μA 0.02 rdg +0.02 range External supply for simulate mA: 5V–

0.01Hz

1Hz

0.1KHz

1cyc

±2 counts

±10%

Notes:

z Temperature Coefficient: 0.1 times the applicable accuracy specification per degree from 41

o

104

F (28°C to 40°C).

z Maximum voltage between any output terminal and earth ground: 30Vpeak

z Maximum output current: Approximately 25mA.

Copyright©2011ExtechInstrumentsCorporation(aFLIRcompany)

Allrightsreservedincludingtherightofreproductioninwholeorinpartinanyform.

28V

Maximum load 1KΩ at 20mA

Output voltage: +1~+11 V

based waveform);

Amplitude accuracy: ±(10% +0.5V);

Maximum load: >100 KΩ;

Duty Cycle: 50%.

Maximum current: 25 mA

Short circuit protected

o

F to 64oF (5°C to 18°C) and 82oF to

(zero

p-p

Page 24 PRC50-EN-V2.1 11/11

Loading...

Loading...