Page 1

User's Guide

PM200

Fiber Optic Power Meter

Introduction

Congratulations on your purchase of the Extech PM200 Fiber Optic Power Meter. The

PM200 is a high accuracy high resolution optical power meter. It is NIST traceable at

850, 1300, 1310 and 1550nm making it ideal for both single-mode and multimode fiber

testing. The PM200 can store up to 100 measured datapoints. This stored data can be

downloaded via the software to produce formatted certification reports. Careful use of

this meter will provide years of reliable service.

Page 2

Table of Contents

Specifications 3

Description 4

Operation 6

1.0 Applications 6

1.1 Precautions 6

1.1.1 Safety 6

1.1.2 Operational 6

1.2 Required Accessories 6

1.2.1 Cleaning Supplies 6

1.2.2 Patch Cords 6

1.2.3 Optical Fiber Adaptors 6

1.3 Typical Applications 7

1.3.1 Optical Power Measurement 7

1.3.2 Optical Loss Measurement 7

1.4 Optical Power Measurement 8

1.5 Optical Loss Measurement (Set Reference) 9

1.6 Optical Loss Measurement 10

1.7 Data Storage 11

1.8 Downloading Data into PC with Reporter Software 12

1.8.1 Standard Selection 13

1.8.2 Fiber Type Selection 14

1.8.3 Fiber Length Input 15

1.8.4 Connectors and Splices Input 16

1.8.5 Company Selection 17

1.8.6 Name Input 18

1.8.7 Summary View 19

1.8.8 Report Printing 19

1.8.9 Example Printout 20

1.9 Clearing Data 21

2.0 PC Based Meter Control 22

3.0 Battery Replacement 23

4.0 PM200 Data Storage Error Codes 23

Warranty 24

2

PM200 V1.0 11/04

Page 3

Specifications

Optical Specifications

Detector Type Germanium (Ge)

Calibrated Wavelengths (nm) 850, 1300, 1310, 1550

Measurement Range (dBm) +5 to -60

Accuracy (dB) ±0.15

Resolution (dB) 0.01

General Specifications

Battery Life 100+ hours (9-volt)

Optical Connector 2.5mm universal

Data Storage up to 100 storage points

Download DB-9 serial

Software Reporter

Dimensions 4.94 x 2.75 x 1.28 in

Weight (with battery) 10 ounces

3

PM200 V1.0 11/04

Page 4

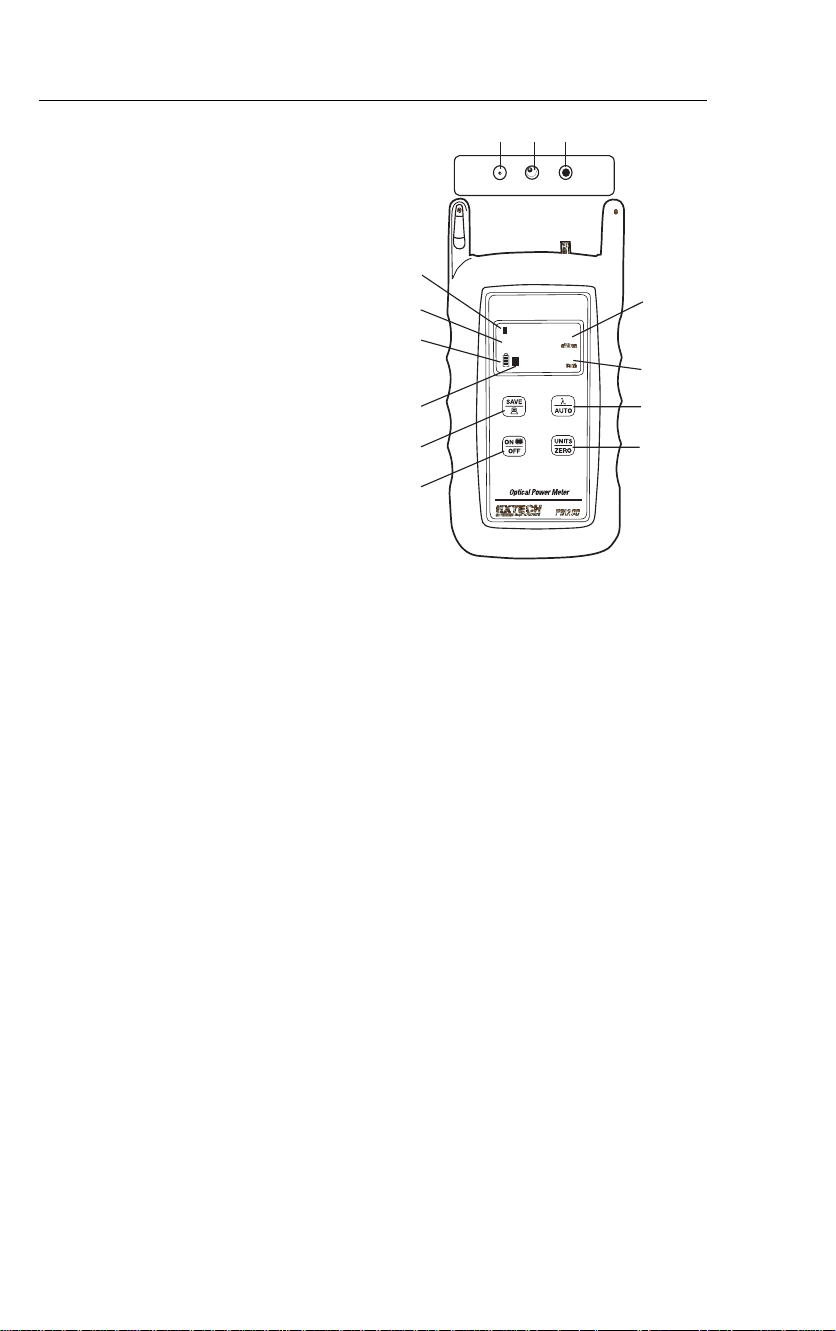

Meter Description

1. Battery Charging Port

2. Download Port

3. Detector Port

4. Tone Mode

5. Power Reading

6. Battery Indicator

7. Data Indicator.

8. Units Indicator

9. Wavelength Indicator

10. SAVE / DOWNLOAD button

11. ON / OFF / Backlight button

12. λ / AUTO button

13. UNITS / ZERO button

123

4

5

6

-20.28

uW

mW

1310

7

10

11

8

9

12

13

4

PM200 V1.0 11/04

Page 5

1. Battery Charging Port - If rechargeable 9-volt batteries are used in the PM200, the

battery charging port is used to re-charge them when used with an approved wall

transformer. NOTE: DO NOT USE BATTERYCHARGING PORT WITH NONRECHARGEABLEBATTERIES. THERE IS THE POTENTIAL FOREXPLOSION

AND DAMAGE MAY OCCUR TO THE UNITAND/OR THE USER.

2. Download Port - The download port is used to download stored data into a PC via

the supplied serial cable.

3. Detector Port - The detector port is a fixed 2.5mm universal port, and connects to

ST, SC, or FC connectors equally well without any loss of accuracy. There is no

need to change or maintain expensive adapter caps.

4. Tone Mode - When ‘Hz’ is visible on the display, the PM200 is checking for the

presence of a modulated optical signal. These modulated signals are used to

automatically switch wavelengths when they are sent by an OWL light source with

modulation capability.

5. Power Reading - The power reading displays the level of optical power being

received by the photo detector, and is displayed in either dBm, dB, milliwatts, or

microwatts.

6. Battery Indicator - The battery indicator shows the amount of life is remaining in the

battery. Also, when the battery recharger is in use, the bars in the battery icon are

animated to show that the recharger is active.

7. Data Indicator - This icon shows whether there is data stored in the PM200.

8. Units Indicator - The units indicator shows which units are being currently displayed.

Units are shown in either dBm, dB, uW, or mW.

9. Wavelength Indicator - The wavelength indicator shows the currently selected

wavelength in nanometers (nm).

10. SAVE / DOWNLOAD button - To store a data point, press this button. Hold the

button to down load data points in comma-delimited format. This button can also be

used to erase all stored data if it is held while the meter is being powered ON.

11. ON / OFF / Backlight button - When the unit is off, press this button to power on.

When the unit is on, press this button to toggle the backlight on and off. When the

unit is on, hold this button to power off.

12. λ / AUTO button - Press this button to change wavelengths. Hold this button to set

the meter in AUTO mode. AUTO mode scans incoming power for modulated optical

signals, and switches wave lengths automatically when a corresponding modulated

signal is received (for use with WaveSource light sources only.)

13. UNITS / ZERO button - Press this button to change display units - either dBm, dB,

uW or mW. Holding this button will set a ZERO reference for the currently selected

wavelength.

5

PM200 V1.0 11/04

Page 6

Operation

1.0 Applications

1.1 Precautions

1.1.1 Safety - Caution must be exercised when working with optical equipment.

Most transmission equipment and light sources use light that is invisible to the

human eye. High energy light is potentially dangerous, and can cause serious,

irreparable damage to the eye. Thus, it is recommended to look into the connector

port of a light source or the end of a fiber.

1.1.2 Operational - In order to ensure accurate and reliable readings, it is vitally

important to clean ferrules containing optical fibers and optical connector ports. If

dirt, dust, and oil is allowed to build up inside connector ports, this may scratch the

surface of the photodetector, producing erroneous results. Replace dust caps after

each use.

1.1.3 Operational - In order to ensure accurate and reliable readings, it is vitally

important to clean ferrules containing optical fibers and optical connector ports. If

dirt, dust, and oil is allowed to build up inside connector ports, this may scratch the

surface of the photodetector, producing erroneous results. Replace dust caps after

each use.

1.2 Required Accessories

1.2.1 Cleaning Supplies - It is recommended to clean fiber ferrules before each

insertion with 99% or better isopropyl alcohol and a lint free cloth. A can of

compressed air should be available to dry off the connector after wiping, and to

blow out dust from bulkheads.

1.2.2 Patch Cords - Patch cords may be needed to connect the PM200 to the

system under test. The connector styles on the patch cord must match the type on

the PM200 and the type of the system under test.

1.2.3 Optical Fiber Adapters - Optical fiber adapters are used to connect two

connectorized fibers together, and may be necessary to adapt your patch cords to

the system under test.

6

PM200 V1.0 11/04

Page 7

1.3 Typical Applications

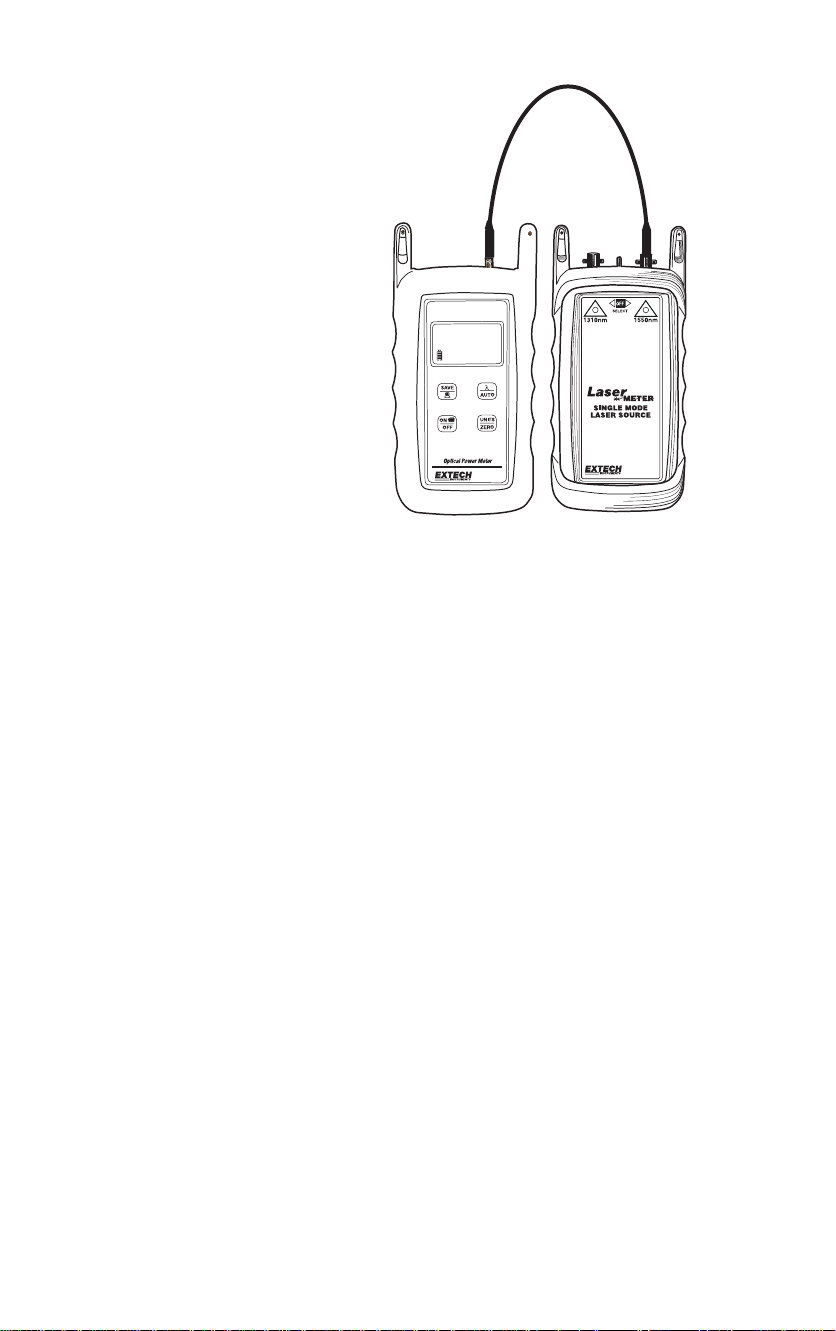

PM200 test kits can be used as diagnostic and measurement tools of optical

transmission systems and fiber optic links. These applications can be found in several

industries, including premise, LAN, CATV, and Telco.

Two types of measurements are possible with the PM200 optical power meter: optical

power and optical loss.

1.3.1 Optical Power Measurement - When displaying power in dBm mode, the

PM200 will measure the absolute amount of power being received in the 2.5mm

Universal detector port. Absolute power is shown in dBm (decibels referenced to a

milliwatt), meaning the power being received by the photodetector is compared to 1

milliwatt of optical energy. Optical power measurement is useful for checking the

output power and/or stability of an optical transmission system or stabilized fiber

optic light sources.

1.3.2 Optical Loss Measurement - When displaying power in dB mode, the PM200

can be used to measure the optical power through a fiber optic link relative to an

optical reference point. Setting a reference point is also known as “zeroing” the

meter with a light source. Optical loss measurements are useful for measuring the

attenuation, or loss, of a fiber link. The loss value can then be compared to a precalculated link budget, which is used to determine if the fiber link will operate within

the parameters of the transmission equipment.

The formula for calculating loss in a fiber link is: L = P - P a r

where L is the amount of optical loss in dB, P is the absolute power in dbm, and P

is the reference power in a r dBm.

Optical loss measurements can also be used for fiber optic link certification. Link

certification is a process where optical loss measurements are compared to a link

budget calculated using fiber optic cabling standards.

Data stored in the PM200 can be downloaded into the Reporter certification report

software. Fiber optic links can be certified against one of several popular fiber optic

cabling standards or one of two user configurable standards. Many fiber optic

installation bids are requiring certification reports, which makes the PM200 an

invaluable tool for fiber optic professionals.

7

PM200 V1.0 11/04

Page 8

1.4 Optical Power Measurement

a) Connect the PM200 to the

equipment under test (EUT). In the

example below, the EUT is a fiber

optic light source.

b) Power on the EUT, set it to the

desired wavelength, and allow it to

stabilize.

c) Power on the PM200, and set it to

match the wavelength of the EUT.

d) Set the units to dBm. The resultant

reading is the output power. (The

example in Figure 2 shows an

optical output power of -20.58 dBm).

This reading should be within the light

source manufacturer’s specified power

level. If the reading is not within the

specification, clean and check the

connections and take another

measurement.

dBm

-20.58

nm

1310

PM200

Figure 2

8

PM200 V1.0 11/04

Page 9

1.5 Optical Loss Measurement (Set Reference)

Two patch cords are required for this procedure - one for the meter side and one for the

light source side.

a) Connect the PM200 to a light source using the first patch cord.

b) Power on the light source and allow it to stabilize according to the manufacturer’s

specifications.

c) Power on the PM200, and set it to match the current wavelength of the light

source.

d) Check to make sure the power level displayed on the PM200 is approximately

equal to the calibrated power level of the light source (see Figure 2 on the previous

page). If it is good, then remove it from the PM200 and light source and set it aside.

This will be the patch cord for the meter side.

e) Connect the other patch cord to the

PM200 and light source as shown in

Figure 3. The example shows a

reference setting procedure for

multimode light sources. Notice the

insertion of a 1/2” mandrel. Mandrels

½” MANDREL

are used to achieve EMD (Equilibrium

Mode Distribution) when setting the

reference from a multimode light

source. EMD is achieved by wrapping

the reference patch cord around the

mandrel 5-7 times. Single-mode

sources do not require a mandrel.

f) Press the λ / AUTO button on the

PM200 to set it to the desired

0.00

1310

dB

nm

wavelength.

g) Set the light source to the match the

wavelength on the PM200.

h) Press and hold the UNITS / ZERO

button on the PM200. This will set the

reference for the currently selected

PM200

wavelength. The display will switch to

show dB units, and should show

approximately 0.00 dB.

Figure 3

If there is a second wavelength to ‘zero’, repeat steps f through h. The indicator LED will

change colors for the second wavelength.

The PM200 is now ‘zeroed’, and is ready to test fiber links.

NOTE: DO NOT REMOVE THE PATCH CORD FROM THE LIGHT SOURCE, AS THIS

WILL MAKE THE OPTICAL REFERENCE INVALID.

9

PM200 V1.0 11/04

Page 10

1.6 Optical Loss Measurement

a) Leaving the patch cord attached to the light

source, remove the patch cord from the PM200

optical power meter.

b) Connect the PM200 and light source to opposite

ends of the link under test.

c) The PM200 will show the amount of loss in the

link (in dB). Figure 4 shows a power level of -2.45

dB. This means that the optical power being

received by the meter is 2.45 dB below the

optical reference, which is the same as saying

there is 2.45 dB of optical loss in the link.

Optical loss measurements are compared to a precalculated link budget. If the optical loss does not

exceed the link budget calculation, the link will

perform as installed within the specifications

shown on the link budget.

-2.45

dB

nm

1310

PM200

LINK UNDER TEST

PATCHPANELSPATCHPANELS

Figure 4

10

PM200 V1.0 11/04

Page 11

1.7 Data Storage

a) Connect the PM200 and light source to opposite ends of the link under test.

b) Press the SAVE / DOWNLOAD button. The PM200 will store a data point for each

wavelength, and will briefly show the number of data points currently stored in

place of the wavelength. The presence of the data storage icon ( ) shows that

there is data stored in the meter. From time to time, an error code may appear.

These error codes and descriptions are located later in this manual.

c) Connect the units to the next fiber in the link, and repeat step b. Notice the number

of data points will increment by 2 (one data point per wavelength).

NOTE: the PM200 can store up to 100 data points. It is highly recommended to

download the stored data periodically using the Reporter software.

11

PM200 V1.0 11/04

Page 12

1.8 Downloading Data to a PC With Reporter Software

Once testing is complete or the PM200’s memory is full, the stored data points may be

downloaded to a PC running the Reporter software. A Pentium PC (or better) running

Windows 95 or later operating system is required for Reporter Software. Please use the

included CD to install the software. Insert the CD to begin the installation. Follow the onscreen steps to install. Once Reporter is installed on the PC, it is ready to download the

data points from the PM200.

Connect the PM200 to the PC COM port via the supplied download cable.

First, prepare the PM200 for download to PC. Follow the steps below:

With the PM200 powered ON, run Reporter. The shortcut is located in the Start Menu,

under Programs, Extech, and is named Reporter. There may also be a shortcut on the

desktop.

Begin the data download by pressing the download button which is highlighted on the

screen shot at the right. The software automatically downloads all that is stored in the

meter. First, the software searches for the meter, then it transfers the data, then gives a

confirmation of download success.

If the download fails, communications cannot continue and no data will download into the

PC. Check the cable connections, test the current COM port, and/or try a different COM

port or try a different PC.

The following pages explain the steps of the Link Wizard in Reporter. This will allow

certification of fiber links using a fiber cabling standard.

12

PM200 V1.0 11/04

Page 13

1.8.1 - Standard

Selection

1.8.1.1 - View the list of

cabling standards.

The list will appear

when you click the

down arrow.

1.8.1.2 - Select the cabling

standard from the

drop-down list.

1.8.1.3 - Once the cabling

standard has been

chosen, the

wavelengths and

fiber types that the

standard supports

appear in the boxes

on the right.

Click Next to continue.

13

PM200 V1.0 11/04

Page 14

1.8.2 - Fiber Type

Selection

1.8.2.1 - View the list of

available fiber types.

The list will appear

when the down

arrow is clicked.

1.8.2.2 - Select the fiber

type from the list.

The selected fiber

type should match

the type of fiber of

the link under test.

1.8.2.3 - Once the fiber

type has been

chosen, it appears

in the dropdown

box.

Click Next to continue.

14

PM200 V1.0 11/04

Page 15

1.8.3 - Fiber Length Input

1.8.3.1 - Enter the length

of the fiber link under test.

This length will apply to all

of the data points

downloaded from the

PM200. Type the length in

the input box, and select

the length units at the

right.

1.8.3.2 - Once the fiber link

length and the length units

are entered.

Click Next to continue.

15

PM200 V1.0 11/04

Page 16

1.8.4 - Connectors and Splices Input

1.8.4.1 - If there are

any connections or

splices in the link,

enter them into the

input boxes.

1.8.4.2 - Once the

number of

connections and

splices have been

entered.

Click Next to

continue.

16

PM200 V1.0 11/04

Page 17

1.8.5 - Company Selection

1.8.5.1 - Select the

company name from the

drop-down list. If it is not

listed, click the New

Organization button.

1.8.5.2 - Type in the

organization’s name and

telephone number into the

input boxes.

1.8.5.3 - Once the

organization’s name and

telephone number have

been entered, click OK to

continue.

1.8.5.4 - The organization

name should now appear

in the dropdown box.

Click Next to continue.

17

PM200 V1.0 11/04

Page 18

1.8.6 - Name Input

1.8.6.1 - Enter a

descriptive name for

the link into the

input box.

1.8.6.2 - Once the

link name has been

entered, click Finish

to continue.

18

PM200 V1.0 11/04

Page 19

1.8.7 - Summary View

By default,

Reporter opens

up into Detail

View. However,

Summary view

may be more

useful for fiber

loss test

evaluation. To

switch between

Summary View

and Detail View,

press the button

that looks like an

arrow, highlighted

at the right. After

you press this

button, the view

will change to

look like the

screen shot at the

right. This screen

shows the Link

ID, each stored

data point, and whether the test passed or failed.

1.8.8 - Report Printing

To print the

current view to a

PC printer, press

the print button

highlighted at

right to print the

Summary report.

The printed

report will look

very much like

the screen. See

an example

report on the next

page.

19

PM200 V1.0 11/04

Page 20

1.8.9 - Example Printout

Below is an example of the Circuit Summary Report. Below are descriptions of the

columns:

Circuit ID - this is the name of the fiber that was tested

P/F - shows whether the test passed or failed

850nm - shows the amount by which the test passed or failed by at the wavelength tested

20

PM200 V1.0 11/04

Page 21

1.9 - Clearing Data

After data has been downloaded to the PC with the Reporter software, it is recommended

to save the data to a file, and clear the memory from the PM200.

To clear data from the PM200, while the unit is OFF, press and hold the

SAVE / DOWNLOAD button and press the ON / OFF / Backlight button. The icon

will disappear from the display when the data has been successfully erased.

21

PM200 V1.0 11/04

Page 22

2.0 PC-Based Meter Control

When connected to the RS-232 port on a PC using a terminal program (such as

Hyperterminal), many of the PM200’s functions can be activated from the PC keyboard.

The list of functions follows:

Key: A

Function: Auto mode

Description: Pressing the ‘A’ key is the equivalent to holding the / AUTO button on the

PM200. The wavelength display will begin toggling between the currently selected

wavelength and ‘AUO’. Auto mode scans incoming power for modulated optical signals,

and switches wavelengths automatically when a corresponding modulated signal is

received.

Key: C

Function: Clear memory

Description: Pressing the ‘C’ key is the equivalent to holding the SAVE / DOWNLOAD

button on the PM200 while the unit is powered ON. The data indicator icon will disappear

from the display.

Key: D

Function: Download memory

Description: Pressing the ‘D’ key is the equivalent to holding the SAVE / DOWNLOAD

button on the PM200. This will download all data into the PC in comma-delimited format.

The display will say ‘done’ when the download is complete.

Key: M

Function: Monitor mode

Description: Pressing the ‘M’ key will cause the meter to send wavelength and power

level information to the serial port. This data will appear in the terminal window. Monitor

mode is useful for checking the stability and power level of a source over a long period of

time. Most terminal programs have a data capture function. Data captured this way can

be imported as a comma-delimited file into a spreadsheet for creating a chart.

Key: U

Function: Units set

Description: Pressing the ‘U’ key is the equivalent to pressing the UNITS / ZERO button

on the PM200. Each time the ‘U’ key is pressed, the display units will change between

dBm, dB, and uW or mW.

Key: W

Function: Wavelength set

Description: Pressing the ‘W’ key is the equivalent to pressing the / AUTO button on the

PM200. Each time the ‘W’ key is pressed, the display wavelength will change between

the PM200’s calibrated wavelengths.

Key: Z

Function: Zero function

Description: Pressing the ‘Z’ key is the equivalent to holding the UNITS / ZERO button

on the PM200. Once the PM200 display changes to ‘dB’ units, an optical reference has

been set for the currently selected wavelength, otherwise known as ‘zeroed’.

Key: ?

Function: Firmware version display

Description: Pressing the ‘?’ button will send the firmware version to the serial port.

22

PM200 V1.0 11/04

Page 23

3.0 Battery Replacement

The battery compartment is covered by a sliding plate on the back of the unit. Remove

the rubber boot to expose the back of the unit. One 9v battery is required for operation.

4.0 PM200 Data Storage Error Codes

ERR - the user has not waited long enough to get data stored for both wavelengths

BAD - data can only be stored for a maximum of 3 wavelengths

FUL - memory is full, and no more data can be stored

23

PM200 V1.0 11/04

Page 24

Warranty

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects

in parts and workmanship for one year from date of shipment (a six month limited warranty

applies to sensors and cables). If it should become necessary to return the instrument for

service during or beyond the warranty period, contact the Customer Service Department at

(781) 890-7440 ext. 210 for authorization or visit our website www.extech.com for contact

information. A Return Authorization (RA) number must be issued before any product is

returned to Extech. The sender is responsible for shipping charges, freight, insurance and

proper packaging to prevent damage in transit. This warranty does not apply to defects

resulting from action of the user such as misuse, improper wiring, operation outside of

specification, improper maintenance or repair, or unauthorized modification. Extech

specifically disclaims any implied warranties or merchantability or fitness for a specific

purpose and will not be liable for any direct, indirect, incidental or consequential damages.

Extech's total liability is limited to repair or replacement of the product. The warranty set

forth above is inclusive and no other warranty, whether written or oral, is expressed or

implied.

Calibration and Repair Services

Extech offers repair and calibration services for the products we sell. Extech also

provides NIST certification for most products. Call the Customer Service Department for

information on calibration services available for this product. Extech recommends that

annual calibrations be performed to verify meter performance and accuracy.

Technical support: Extension 200; E-mail: support@extech.com

Repair & Returns: Extension 210; E-mail: repair@extech.com

Product specifications subject to change without notice

For the latest version of this User’s Guide, Software updates, and other

up-to-the-minute product information, visit our website: www.extech.com

All rights reserved including the right of reproduction in whole or in part in any form.

Support line (781) 890-7440

Copyright © 2004 Extech Instruments Corporation

24

PM200 V1.0 11/04

Loading...

Loading...