Exquisit WA7214, WA7212, WA6212 Operating Instructions

OPERATION MANUAL

AUTOMATIC WASHING MACHINES

GEBRAUCHSANWEISUNG

VOLLAUTOMATISCHE

WASCHMASCHINEN

DearPurchaser!

The operationmanualreflectspeculiartechnicalfeaturesoftheautomaticwashingmachine(hereinafter referredtoasthemachine),itcontainstherequiredinformationaboutitsoperation,theusefulinformation aboutwashing.Afterattentivelystudying theoperationmanualbeforeconnectingandusingthemachine, youwillbeabletoproperlyandsafelyoperate it..

Keeptheoperationmanualduringthewholeperiodofitsservice.

1 GENERAL

1.1In accordance with figure 1 the automatic washing machine (hereinafter referred to as the machine) is intended for washing textile goods, sports footwear with the use of synthetic washing means of low foaming, as wellasforrinsingandwringingout.Alloperationsoftreatingthegoodsareautomaticallyperformedincompliance with the preset program.

1.2The machine is intended for operation only in household conditions. The use for industrial purposes (in restaurants, cafes, o ces, kinder gardens, hospitals, etc.) is not allowed.

1.3Modernwashingtechnologiesareusedinthemachinewhichallowto achievemaximalresultsofwashing withtheminimal consumptionofwaterandelectricalpower.Therefore,whenthemachineoperates,thewaterlevel may not visually be determined through the door glass.

1.4Theelectroniccontrolsystem isstipulatedinthemachinewhichcontributesto uniformdistributionofthe linen in the drum before every wringing out for exclusion of excessive vibrations and noise.

1.5Theprotectingsysteminthefillinghosestipulatedinthemachinedependingonthemodeldeterminesthe waterleakagewhenthehoseisdamaged–watersupplyisterminatedtothemachinefrom thewaterline,washing is stopped and a malfunction is shown on the display.

1.6Anadditionalprotectingsystem“Aquastop”preventingwaterleakageinsidethemachine,whichisstipulated in some models, stops water supply from the water line to the machine when the latter is damaged – washing is stopped, water is drained from the tank and a malfunction is shown on the display

Control panel

Dispenser drawer

Door

Drum

Gasket

Filter cap

Figure1

2

1.7The main specifications of the machine are shown in table 1.

1.8The machine should be operated:

—at the ambient temperature (25 ± 10) °С and relative humidity not exceeding 75%;

—at pressure in the water line from 0.05 to 1 МPа;

—from a single phase AC electrical circuit having frequency (50±1) Hz;

—in the range of rated AC voltages 230V.

ATTENTION!Temperaturereductioninthepremisebelow0°Сmayresultinwaterfreezinginthemachine andoutageofthemachine.

1.9Themanufacturerconstantly worksforfurtherimprovingthemachineconstructionanditsquality,therefore he is entitled to introduce amendments to design and completing the machine by keeping its main specifications intact.

1.10After transportation at ambient temperature below 0 °С the machine should be kept at the room temperature for at least 24 hours before connection to the electrical mains.

ATTENTION!Themanufacturer(seller)bearsnoresponsibility(including duringtheguaranteedoperationperiod) fordefectsanddamagesoftheproductoccurredduetoviolationsoftheoperationtermsorits storageorforcemajeurecircumstances(afire,naturaldisasters,etc.)

Table 1

Product fiche for household washing machines according to Delegated Regulation (EU) 1061/2010.

Brand name |

|

EXQUISIT |

|

||

Model |

WA6212 |

WA7210 |

WA7212 |

WA7214 |

|

Energy e ciency class1 |

А+ |

А++ |

А++ |

А++ |

|

Washing index |

>1,03 |

>1,03 |

>1,03 |

>1,03 |

|

Spin-drying e ciency class2 |

B |

C |

B |

B |

|

Annual energy consumption [kW·h/year] |

190 |

|

195 |

|

|

Annual water consumption [l/annum] |

8800 |

|

10000 |

|

|

Consumptionpercycle7kgCotton60°C[kW·h/l], |

- |

0,99 kW·h/50l, |

0,99 kW·h/50 l, |

0,99 kW·h/50 l, |

|

Programmetime[min.] |

170' |

172' |

172' |

||

|

|||||

Consumptionpercycle3,5kgCotton60°C[kW·h/l], |

- |

0,93 kW·h/42l, |

0,93 kW·h/42 l, |

0,93 kW·h/42 l, |

|

Programmetime[min.] |

163' |

165' |

165' |

||

|

|||||

Consumptionpercycle3,5kgCotton40°C[kW·h/l], |

- |

0,58 kW·h/42l, |

0,58 kW·h/42 l, |

0,58 kW·h/42 l, |

|

Programmetime[min.] |

115' |

117' |

117' |

||

|

|||||

Consumptionpercycle6kgCotton60°C[kW·h/l], |

1,05 kW·h/45 l, |

|

- |

|

|

Programmetime[min.] |

172' |

|

|

||

|

|

|

|||

Consumptionpercycle3,0kgCotton60°C[kW·h/l], |

0,85kW·h/37l, |

|

- |

|

|

Programmetime[min.] |

162' |

|

|

||

|

|

|

|||

Consumptionpercycle3,0kgCotton40°C[kW·h/l], |

0,55kW·h/37l, |

|

- |

|

|

Programmetime[min.] |

115' |

|

|

||

|

|

|

|||

Remaining moisture [%] |

<54 |

<63 |

<54 |

<48 |

|

Power Left on/Power o [W] |

<1,0/<0,5 |

<1,0/<0,5 |

<1,0/<0,5 |

<1,0/<0,5 |

|

Maximum rotational speed during the |

1200 |

1000 |

1200 |

1400 |

|

wringing [rpm] |

|

|

|

|

|

Maximum loading in the cotton washing mode |

6,0 |

|

7,0 |

|

|

[kg] |

|

|

|

|

|

Water supply system pressure [MPa] |

|

0,05 – 1,0 |

|

||

Voltage/Frequency [V/Hz] |

|

230/50 |

|

||

Nominal power consumed [W] |

1900 |

|

2100 |

|

|

Overall dimensions [H/W/D mm] |

846х596х475 |

|

846х596х565 |

|

|

Net weight [kg] |

63 |

63 |

65 |

66 |

|

Noise level:Washing /Wringing [dB(A)] |

59/75 |

59/73 |

59/75 |

59/78 |

|

1 A + + + (highest e ciency) to D (least e ective). |

|

|

|

|

|

2 A (highest e ciency) to G (least e ective). |

|

|

|

|

|

3

2 SAFETY REQUIREMENTS

2.1The machine is an electrical household appliance, therefore general electric safety rules should be fulfilled during its operation.

2.2Theapplianceisnotintendedforusebythepersons(includingchildren)having loweredphysical,sensualor mentalabilities,oriftheyhavenoexperienceorknowledge,iftheyarenotundercontrolorhavenotbeeninstructed about the use of the appliance by a person responsible for their safety.

Children must be under control in avoidance of any playing with the appliance.

2.3By the type of protection from electricity shock the machine is related to class I.

2.4Adouble-polesockethavingtheearthingcontactforconnectionofthemachinemustbelocatedataplace accessible for urgent disconnection of the machine from the electrical mains.

2.5Before connection of the machine to the electrical mains absence of damages of the power supply cord should visually be checked.The cord must not be twisted and compressed.

Whenthepowersupplycordisdamagedinordertoavoidanydanger itmustbereplaced bythemanufacturer or a service company.

2.6Safety precautions should be observed during handling and transportation of the machine as it has a big

mass.

ATTENTION! Do not use the machine as a pad, a pedestal, etc. Do not lean on the opened door of the machine.

2.7IT IS PROHIBITED to install the machine outside the premise so that not to subject it to atmospheric

impact.

2.8IT IS PROHIBITED to operate the machine without installation of plugs in accordance with clause 3.1.2.

2.9When the machine is connected to the cold water supply network only a new filling hose should be used which is included to a supply set.

2.10ITISPROHIBITEDtouseinthemachinethesubstancescontaining solvents,asthereisadangerofrelease of poisonous gases, machine damage, ignition and explosion.

2.11Intheprocessofwashingitisnotrecommendedto touchthemachinedoorglass,asitisheatedandmay become the reason of a fire.

2.12After the end of a washing the machine is to be switched o , disconnected from the electrical mains, the plug is to be pulled out of the socket, and the water supply cock is to be closed (see fig. 8).

2.13For provision of electrical and fire safety the following IS PROHIBITED:

—to connect the machine to the electrical circuit having malfunctioned protection from current overloads;

—to use a socket without an earthing contact for machine connection;

—to use adapters, multi-seat (having two or more points of connection) sockets and elongation cords for machine connection to the electrical mains;

—to disconnect the machine from the electrical mains by pulling the supply cord;

—to insert and pull out the power supply plug from the socket, as well as to touch the operating machine with wet hands;;

—to wash the machine under a water jet;

—toindependentlyrepairandintroduceamendmentstothemachinedesign,aswellastoitswaterandelectric powersupply.Thismayresultinseriousdamagesofthemachineanddepriveofthewarrantyrepair.Therepairmust only be performed by a qualified mechanical expert of a service company.

2.14Ifanymalfunctionisfoundinmachineoperationrelatedto electricalcrackling,smoking,etc.Themachine shouldimmediatelybedisconnectedfromtheelectricalmains,bypullingtheplugfromthesocket,thewatersupply cock should be closed, and a mechanical expert of a service company should be called.

In case of a fire the machine should immediately be disconnected from the electrical mains, the water supply cock should be closed, measures are to be taken for fire extinguishing and a fire brigade is to be called.

ATTENTION! After expiry of the machine service period the manufacturer bears no responsibility for safety of the product. The further operation may be non-safe, as probability of occurrence of electrical and firedangeroussituationsisconsiderablyincreasedduetonatural degradationofmaterialsandwear-o of machinecomponents.

4

3 MACHNE PREPARATION TO OPERATION

3.1PREPARATIONTOINSTALLATION

3.1.1 Packaging materials (polyethylene film, foamed polystyrene parts) are to be removed from the machine. The protecting film is to be removed from the display.

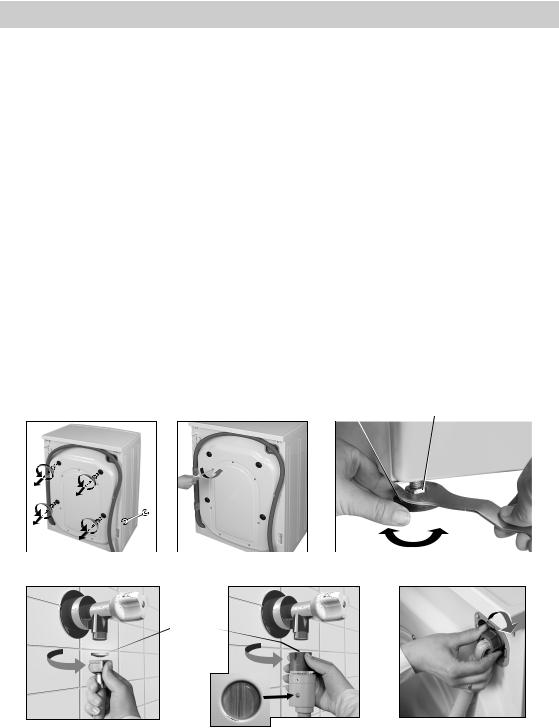

ATTENTION! In avoidance of machine damage do not move it by taking a chute, the door or seal in accordancewithfig.1.Formachinetransportation thetankisfixedwithblockingscrews.

Four screws should be turned out with the aid of a spanner and rubber and plastic sleeved are to be removed inaccordancewith figure2.Ifthesleevesareleftinsidethemachineandtheycouldnotberemoved,therearpanel shouldbetakenoutinaccordancewithfig.3withtheaidofacrossscrewdriver andthesleevesshouldberemoved. The panel is to be reinstalled. Holes are to be closed with plastic plugs included to a supply set.

Screws and sleeves are to be kept for possible machine transportation in future.

ATTENTION!Inavoidanceofpossibledamageofthecasingdonotswitchonthemachinewiththeinstalledblockingscrews,rubber andplasticsleeves.

3.2MACHINEINSTALLATION

3.2.1The machine must be installed onto a strong, even and dry surface.

The soft floor cover (a carpet, coating based on foamed polyurethane, etc.) is not suitable for installation, as it contributes to vibration and worsening of machine ventilation.

The machine should be installed on a wooden floor by preliminarily strongly fixing a slab made of wooden materials to the floor having thickness at least 15 mm. It is recommended to install it in a premise corner on the wooden floor in the process of operation for better machine stability.

3.2.2Themachineistoleveledstrictlyhorizontallyinrelationtothefloorbyscrewingtheadjustablesupportsin andoutinaccordancewith figure4:counter-nutsaretobereleasedatsupportswiththeaidofaspanner,heightof supportsistobeadjusted,counter-nutsaretobetightened.Wronglevelingofthemachineorinsu cient tightening of counter-nuts may become a source of vibration and increased noise during machine operation.

ATTENTION! In order to provide maximum stability of the machine unscrewing of supports must be minimal.

panel |

support |

locknut |

Figure2 |

Figure3 |

Figure4 |

filter

Figure5 |

Figure6 |

Figure7 |

5

3.3CONNECTION TOELECTRICALMAINS

ATTENTION!Themachinemustbeearthed.

The machine must be connected to the electrical mains via a double-pole socket with an earthing contact, whereintheallowedcurrentisatleast16A.Athree-wirecablewithcopperwireshavingsectionatleast1.5mm2or aluminium wires having section at least 2.5 mm2 must be supplied to the socket.The phase wire must be connected via an automatic device of electric mains protection intended for the maximal current (operating current) 16 A having operation time not exceeding 0.1 s.

Ifthesockethasnotsupplyoftheaforesaidcableoritisfarfromtheplaceofmachineinstallation,theelectrical mainsandsocketinstallationshouldbeimproved.Improvement oftheelectricalmainsandsocketinstallationmust be carried out by the qualified personnel.

IT IS PROHIBITED to provide earthing by means of an individual wire, as well as with the aid of the heating, water supply or sewerage equipment.

ATTENTION!Themanufacturer(theSeller) bearsnoresponsibilityforcausedharmto healthandproperty ifitiscausedbynon-fulfillment oftheaforesaidrequirementstoconnection.

3.4WATERLINECONNECTIONTOSEWERAGE

3.4.1The machine is to only be connected to the cold water supply network via a water supply cock having a ¾-inch threaded branch.

3.4.2The following should be done before connection of the machine to the water line:

—thewaterlinecockistobeopenedandwateristobedrainedsothattowashoutsandandrust frompipes;

—filter cleanness is to be checked in the filling hose in accordance with figure 5 and 6 and to the machine;

—ifthefillinghosehasaprotectingsystem inaccordancewithfigure6,attention shouldbepaidtothecolour in a special window of the hose.The yellow colour of the window shows the good state of the hose;

—thefillinghoseistobeconnectedto thethreadedbranchofthewatersupplycockinaccordancewithfigure 5 and 6 and to the machine in accordance with figure 7 by tightly screwing in nuts by hand.

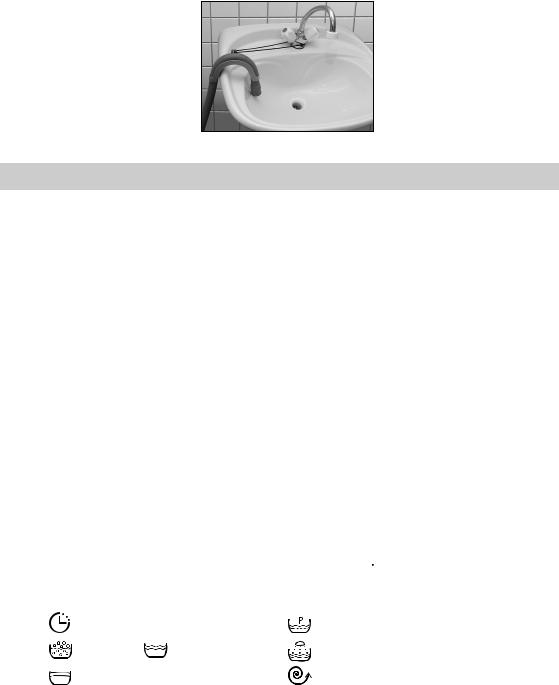

3.4.3 During washing the water supply cock must fully be opened in accordance with figure 8.

3.4.4 In accordance with figure 9 the drain hose must be located at the height of at least 60 and not exceeding 90 cm from the floor level. If this rule is not observed, the machine will not work.

3.4.5 For water drainage directly to sewerage the drain hose of the machine is to be installed above the discharge elbow (a siphon) to a sewage pipe having the internal diameter at least 40 mm so that to avoid back suction of e uent water to the machine.

Thedrainhosemaydirectlybeconnectedtothesiphoninaccordancewithfigure 10,ifthesiphon hasabranch for its connection.

3.4.6Whenwaterisdrained toabasinorabaththehoseshouldbefixedintheplaceofbendingbymeansofa special bracket included to the supply in accordance with figure 11.The hose must not be immersed to water.

ATTENTION! Filling and drain hoses must not be twisted or compressed after connection to the water lineandsewage.

3.4.7Afterconnectionofthemachinetothewaterlineandsewagetightconnectionofhosesshouldbechecked

–places of connection must be dry.

OPEN CLOSED

MIN60CM

MIN60CM

MAX90CM

Figure8 |

Figure9 |

Figure10 |

6

Figure11

4 MACHINE OPERATION

4.1CONTROLS

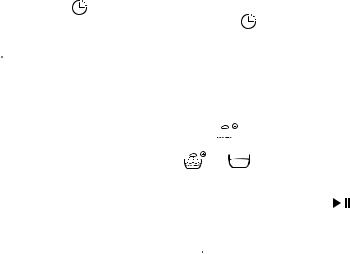

4.1.1 Machine controls include a knob for washing program selection (hereinafter – a knob), a push button for selection of extra functions, bush button

, push button

, push button  in accordance with figures 12,13.

in accordance with figures 12,13.

A knob is intended for switching the machine on/o and selection of a washing program. Titles of programs andsymbol  aremarkedaroundtheknob.Theknobisturnedinbothdirections(clockwiseandcounterclockwise) andpreciselysettotherespectivepointoftheselectedprogram.Whentheknobissettosymbol

aremarkedaroundtheknob.Theknobisturnedinbothdirections(clockwiseandcounterclockwise) andpreciselysettotherespectivepointoftheselectedprogram.Whentheknobissettosymbol  themachineis switched o and the selected program is cancelled.

themachineis switched o and the selected program is cancelled.

Pushbuttonsofselectionofextrafunctions(see 4.3)

Every push button is marked with a symbol on the control panel in accordance with figure 13. Pushing the button will allow to additionally select an extra function to the washing program.

Apushbuttonofdrumrotationfrequencyselectionduringwringingout(hereinafterreferredaswringing outspeed)  Pressingpushbutton

Pressingpushbutton  makesitpossibletoselectthewringingoutspeedbelowthemaximum value stipulated in the washing program. The selected value of wring-out speed is illuminated with a respective indicator.

makesitpossibletoselectthewringingoutspeedbelowthemaximum value stipulated in the washing program. The selected value of wring-out speed is illuminated with a respective indicator.

Temperatureselectionpushbutton

Thisallowsselectingthetemperaturebelowthemaximalvaluestipulatedbythewashingprogram.Theselected value of temperature is illuminated with a respective indicator.

Pushbutton

(START/PAUSE)isstipulatedforbeginning(start)ofmachineoperationaccordingtotheselected program, as well as for setting a pause in machine operation without cancellation of the washing program.

(START/PAUSE)isstipulatedforbeginning(start)ofmachineoperationaccordingtotheselected program, as well as for setting a pause in machine operation without cancellation of the washing program.

Night mode push button  When a push button illuminates at the time indicator before «

When a push button illuminates at the time indicator before « » value is lighted up at the time indicator before duration value.Washing is carried out at lowered wring-out speeds, as well as with the disconnected sound alarm by providing the noiseless machine operation.

» value is lighted up at the time indicator before duration value.Washing is carried out at lowered wring-out speeds, as well as with the disconnected sound alarm by providing the noiseless machine operation.

4.2LIGHTINDICATORS

4.2.1Lightindicatorsoftime,washingoperationsandpushbuttonsofselectionofextrafunctionsareoperated in the area of machine operation indication in compliance with figures 12, 13.

4.2.2The time indicator is intended for representation of washing duration, as well as time before washing beginning if the function of delayed washing beginning has been selected  .

.

4.2.3Indicatorsofwashingoperations:

– time of the delayed washing beginning; |

– preliminary washing, |

|

– wetting, |

– main washing, |

– ringing, |

– stoppage in water in the tank, |

– wringing out and drainage. |

|

4.2.4Theswitch-onindicatorispossessedbyeverypushbuttonofselectionofextrafunctionsandpushbutton

Push buttons of temperature and wringing out speed selection have a number of indicators with numerical values.

Push buttons of temperature and wringing out speed selection have a number of indicators with numerical values.

7

Dispenser drawer |

START/PAUSE button |

|

|

Push buttons of selection of extra |

Program selection knob |

|

|

|

functions |

|

|

|

Figure 12—Control Panel |

|

||

time |

indicators of washing |

temperature |

wring out speed indicators* |

|

indicator |

operations |

indicators |

|

|

START/PAUSE

START/PAUSE

night mode

selection of wring out speed mode

selection of wring out speed mode

temperature selection

temperature selection

light ironing

light ironing

stoppage in with water in a tank

stoppage in with water in a tank

additional rinsing

additional rinsing

watering

watering

preliminary washing, delayed washing

preliminary washing, delayed washing

* Wringing out speeds depend on machine model

Figure 13

4.3EXTRAFUNCTIONS

4.3.1 Possibility of inclusion of extra functions depends on the program of washing (see table 2).The required

function is to be selected by pressing the required push button. |

|

4.3.2 Setting the time of delayed washing beginning |

will make it possible to postpone washing beginn- |

ing from 1 to 24 hours.When this function is selected the time shall successively be changed with the interval of 1 hour.

4.3.3Preliminarywashing |

is stipulated for strongly contaminated cotton fabrics. |

|

Whenthisfunctionisselectedthearticlesshalladditionallybewashedinwaterwithadetergentattemperature |

||

30 °С by providing the qualitative elimination of contamination during the main washing.. |

||

4.3.4 Wetting |

is stipulated for strongly contaminated cotton fabrics. The articles shall be kept in water |

|

for2hourswithdetergents(byperiodicallyturningthearound),thentheyshallbewashedaccordingtotheselected according to the selected program. During function selection the preliminary function of washing shall simultane-

8

ously be switched on  — two respective indicators are flashing. Wetting shall be carried out after the end of preliminary washing when the wetting indicator starts blinking.

— two respective indicators are flashing. Wetting shall be carried out after the end of preliminary washing when the wetting indicator starts blinking.

Forreductionoftimeofwettingpushbutton  shallrepeatedlybepressed–Thefunctionwillbereleased and the machine will be operated according to the selected program.

shallrepeatedlybepressed–Thefunctionwillbereleased and the machine will be operated according to the selected program.

4.3.5Extrawringout is intended for clothes for children, goods of persons having an allergy for detergents or for washing in very mild water wherein the detergent is repeatedly rinsed.

is intended for clothes for children, goods of persons having an allergy for detergents or for washing in very mild water wherein the detergent is repeatedly rinsed.

When this function is selected one more rinsing shall be added to the washing program.

4.3.6Stoppagewithwater in the  is used during washing of articles made of thin fabrics for reduction of crumpled fabrics.

is used during washing of articles made of thin fabrics for reduction of crumpled fabrics.

Whenafunctionisselectedthedrainageandfinalwring-outcycleisexcluded.Aftertheendofwashingwatershall be drained: the selection knob shall be set to symbol  ,“DRAINAGE”program shall be selected and carried out.

,“DRAINAGE”program shall be selected and carried out.

4.3.7Lightironing  shall be stipulated for reduction of crumpling the fabrics in the process of washing and wringing out, easy subsequent ironing.The use of this function maintains the spare washing mode and careful wringing out with the minimal number of tucks after washing.

shall be stipulated for reduction of crumpling the fabrics in the process of washing and wringing out, easy subsequent ironing.The use of this function maintains the spare washing mode and careful wringing out with the minimal number of tucks after washing.

5FIRST SWITCH-ON

5.1FIRSTWASHING

5.1.1Everymachineshallbetestedbythemanufacturer,andtherefore,themachinemaycontainslightamount ofwater.Foreliminationofwaterafterthetest,aswellasformachinecleaningfrominsidethefirstwashingshallbe carried out without loading any clothes.

5.1.2The first washing shall be carried out by setting the program“COTTON”and temperature — 90 °Сin accordance with pp. 6.4 - 6.6, 6.11.

ATTENTION!Forthefirstmachineswitchingon themachinetodivision2ofthetrayinaccordancewith figure15ahalfdetergentstandardshardshallbeloaded formaximalloadingofclothesbytakingintoaccount recommendationsofthedetergentmanufacturer.

5.2GENERALRECOMMENDATIONSBEFOREWASHINGBEGINNING

5.2.1Beforeswitchingonthemachineawatercockshouldbeopenedandbydischargingwateroneshouldbe made sure that water does not contain contaminations in the form of sand, rust, etc.

ATTENTION! The manufacturer (the seller) shall not be responsible (including during the warranty operation period) for washing quality, as well as for defects and damages of the machine related to the use of waterwhichiscontaminatedwithrust,sand,scale,etc.

5.2.2Correct setting of filling and discharge hoses shall be checked (see 3.4).

If the machine has not been used for a long period the stilled water shall be drained from the filling hose by turning out a nut and disconnecting a hose from the water supply cock.The filling hose shall be connected to the water line in accordance with clause 3.4.2.

6OPERATIONPROCEDURE

6.1 It should be checked whether there are any odd subjects or domestic animals in the drum. Clothes shall be prepared and loaded to the machine (see 7.1).

Closethemachinedoorbyahearableclickofthelockbypreliminarilyremovingthedoorlockingfromclosing (if it was installed in accordance with clause 6.13).

ATTENTION!The clothes shall not be seized between the door and the sealant.

6.2Therespectivechutesectionshallbeloadedwiththedetergentintendedforautomaticwashingmachines and means for special treatment (see 7.2).The chute shall uniformly be closed.

6.3Thepowersupplycordshallbeinsertedtothesocketandthewatersupplycockshallbeopened(seefig.8).

6.4MACHINESWITCHINGONANDPROGRAMSELECTION

6.4.1Forswitchingonthemachinetheknobshouldbesettothepointoftherequiredwashingprograminaccordancewithfigure12.Thefollowingisflashingintheindicationareaofmachineoperation:washingduration,indicators of washing operations of the selected program, indicators of washing temperature and wringing out speed.

When programs are selected in accordance with table 2 the main parameters of washing set up by the manufacturer are provided (wring out speed, washing temperature, its duration, etc.).

6.4.2Washing duration reflected at the time indicator is determined under laboratory conditions. It may be

changed (increased or reduced) during machine operation depending on water temperature and pressure in the

9

water line, mass of the loaded clothes, type of fabrics, change of voltage in the mains, etc.

ATTENTION!Mismatchoftimereadingisallowedwiththemomentofactualwashingcompletionbefore theendofwashingonthedisplay.

6.4.3Theprogramshallonlybeselectedbeforewashingbeginning.Settingtheknobtothepointofanewprogram duringmachineoperation(withoutmachineswitchingo )doesnotallowchangingtheformerlyselectedprogram.

6.4.4After program selection washing parameters may be changed and extra functions may be selected in compliance with 6.5-6.7.

6.5TEMPERATURESELECTION

By pressing on push button  in accordance with figure 13 one may decrease the washing temperature stipulatedbytheprogram.Whenthepushbuttonispressed,indicatorsarelightedupinsuccessionwiththenume-

in accordance with figure 13 one may decrease the washing temperature stipulatedbytheprogram.Whenthepushbuttonispressed,indicatorsarelightedupinsuccessionwiththenume-

ricaltemperaturevaluesfrommaximalto  alongwiththesuccessfulrepetition.Washingdurationreadingwillbe changed at the same time with temperature selection.

alongwiththesuccessfulrepetition.Washingdurationreadingwillbe changed at the same time with temperature selection.

Theselectedwashingtemperaturevaluesinthemachine:: (withoutwaterheating),30°С,40°С,60°С,90°С.

(withoutwaterheating),30°С,40°С,60°С,90°С.

6.6SELECTIONOFWRINGINGOUTSPEED

Bypressingthepushbutton

inaccordancewithfigure13thewringingoutspeedmaybereducedwhich is stipulated by the washing program.When the push button is pressed, the indicators are lighted up in succession

inaccordancewithfigure13thewringingoutspeedmaybereducedwhich is stipulated by the washing program.When the push button is pressed, the indicators are lighted up in succession

with numerical values of wringing out speed from the maximal one to  with the subsequent repetition.

with the subsequent repetition.

The selected values of wring out speed – from the maximal one (depending on the machine model) to the

minimal one – zero  (wringing out is disconnected).

(wringing out is disconnected).

ATTENTION! Speed of wringing between the main operations of washing is not regulated, and it does notdependontheselectedprogram.

ATTENTION!Incaseofirregulardistributionofclothesinthedrumthewringingoutspeedinthedrum shallautomaticallybeloweredorthereisnowringingoutatall.

6.7SELECTIONOFEXTRAFUNCTION

6.7.1For selection of an extra function the respective push button shall be pressed – an indicator will flash in accordance with figure 13. In case of the repeated pressing the light indicator will go out, the function will be cancelled.

Selectionofextrafunctionsisonlyallowedbeforethebeginningofwashing.Whenthepushbuttonsarepressed during machine operation a triple sound signal is heard – the extra function is not switched on.

ATTENTION! If the selected function mismatches the selected program the indicator will not flash, and thefunctionwillnotbeswitchedon(atriplesoundsignalisheard).

6.7.2Setting the time of delayed beginning of washing

Pressingthepushbutton |

—thepushbuttonindicatorwillflashandthemaximaltimeofwashingbegin- |

|

ning delay 24 hours («24:Н») will appear. By pressing the push button |

, the required time should be set up (the |

|

reading interval - 1 hour).

If this function should be cancelled the time“0:H”should be set up (before washing beginning), by pressing push button  , — the push button indicator will go out.

, — the push button indicator will go out.

6.8SWITCHINGOFFSOUNDALARM

The sound alarm is stipulated in the machine. The sound alarm accompanies the beginning and completion of machine operation, as well as it is provided during setting up the incombustible functions, in case of accidental pressing the push buttons during machine operation according the selected program.

By simultaneous pressing and holding down push buttons  and

and  during 3 seconds sound signals of machine operation are disconnected,except for the signalsinforming on malfunctions («Sn-0» islighted up atthe

during 3 seconds sound signals of machine operation are disconnected,except for the signalsinforming on malfunctions («Sn-0» islighted up atthe

display). During the repeated pressing the push buttons |

and |

the sound signal is switched on («Sn-1» is |

|

lighted up at the display). |

|

|

|

6.9WASHINGBEGINNING |

|

|

|

For machine operation beginning by the selected washing program the push button |

should be pressed |

||

and a sound signal will be provided, the door blocking device will operate and washing will begin.The countdown will begin at the time indicator before the end of washing. Also, during washing the indicator of the fulfilled washing operation, indicators of temperature, wringing out speed and additional functions will flash (if selected). If the additional function“Time of delayed washing beginning”( ) has been selected, countdown of time before the washing beginning will be started.

) has been selected, countdown of time before the washing beginning will be started.

10

ATTENTION! It is not recommended to use the water line when water is filled to the machine during washing. Due to pressure fluctuation in the water line the volume of filled water may be insu cient for fulfillmentofqualitativewashingandrinsing.

ATTENTION! Cessation of voltage supply in the electrical mains during washing does not influence the subsequentmachineoperation:afterresumingthevoltagesupplyintheelectricalmainsthemachinecontinuesprogramfulfillmentsincethemomentofitsstoppage.

6.10PAUSEDURINGMACHINEOPERATION

Ifmachineoperationshouldbeterminatedwithoutprogramcancellationthepressedpushbutton

shouldbe heldduring2seconds–asoundsignalwillbeprovided,theindicatorof

shouldbe heldduring2seconds–asoundsignalwillbeprovided,theindicatorof

pushbutton willblink,timecountdown and washing are stopped. For continuation of the stopped program the push button

pushbutton willblink,timecountdown and washing are stopped. For continuation of the stopped program the push button

should be pressed.

should be pressed.

Inprograms“DELICATEFABRICS”,“WOOL”,“MANUALWASHING”,“COMBIWASHING”machineoperationcannotbe suspendedaswashingisstipulatedwiththebigamountofwater.Ifthedoorshouldbeopenedduringperformance of these programs water should preliminarily be drained: the program shall be cancelled (see clause 6.11), then the program“DRAINAGE”shall be selected and switched on.

ATTENTION!Donotopenthemachinedoorifthewaterlevelinthedrumisvisuallydeterminedviathe doorglass.

6.11PROGRAMCANCELLATION

For cancellation of the fulfilled program the knob should be set to symbol  — the machine is switched o and the fulfilled program is cancelled. If the door should be opened water should be drained by selecting and switching on the program“DRAINAGE”.

— the machine is switched o and the fulfilled program is cancelled. If the door should be opened water should be drained by selecting and switching on the program“DRAINAGE”.

6.12MACHINESWITCHINGOFF

6.12.1Aftertheendofthelastwashingoperationtheinscription“END”appearsatthetimeindicator,thedoor blocking device is disconnected, a triple sound signal appears, indicators of washing operations and the indicator

go o .

go o .

If the machine is not disconnected from the mains the sound signal will be provided five times more with the interval of one minute.

Themachineshallbeswitchedo bysettinguptheknobtosymbol  ,thesupplycordplugshallberemoved from the socket and the water supply cock shall be closed.The clothes shall be taken out.

,thesupplycordplugshallberemoved from the socket and the water supply cock shall be closed.The clothes shall be taken out.

The tray should slightly be pulled out and the door shall be left half-opened until the internal machine parts become dry. In avoidance of any smell in the machine the door shall remain in the half-opened position by the following washing.

It is recommended to prevent from closing the door blocking.

DOOR BLOCKING AGAINST CLOSING

ItisprovidedtopreventaccidentalpoweringontheMachinebykids.Toblockthedooragainstclosing,turnthe sleeve with screwdriver clockwise up to the stop.The sleeve will come forward not allowing the door to be closed. To remove the blocking, prior washing start, perform the acts in reverse sequence.

7 RECOMMENDATIONS AND ADVICE

7.1PREPARATIONANDLOADINGOFGOODS

7.1.1The following is required before the beginning of washing:

—to sort out goods and clothes by separating the coloured and white goods;

—to distribute goods by types of fabrics by checking the symbols on labels;

—to make sure that pockets on clothes are empty, broken parts ofclothesshouldbestitched,zippers,belts,claspsandhooksshouldbe

sleeve

door

fastened, hardly removable stains should preliminarily be eliminated (see. 7.3);

—sand is to be removed from clothes (pockets, lapels);

—goods with applications are to be turned inside out.

ATTENTION! Penetration of metal objects (coins, clamps, etc)

11

to the machine together with the goods may become a reason of damage of the rubber seal and the plastic tankofthemachine.Thesemalfunctionsarenotsubjecttowarrantyrepair.

7.1.2Smallgoods(handkerchiefs,socks,etc.),brassiereswithbeads,aswellasdelicategoods(thintights,stockings) should be put to a special bag before washing.

7.1.3For getting better results of washing and wringing out it is recommended to wash big and small goods

together.

IT IS PROHIBITED to load only the goods made of fabrics absorbing a big amount of water (terry towels, dressing gowns, carpets, etc).

7.1.4Before starting sports footwear washing the following is required:

—shoe strings are to be taken out of the shoes; ;

—sand is to be removed and the external surface of the footwear is to be washed.

ATTENTION!Itisnotrecommendedtowash thesportswearmadeofnaturalleatherorsuede,aswellas having thesolemadeof hardplasticormetalcomponents.

7.2USEOFSYNTHETICDETERGENTS

7.2.1A chute is intended in the machine for detergents in accordance with figures 1, 14. The chute has three sections, marked with figures and a symbol:

1 — for preliminary washing with the use of powder detergents and bleaching substances;

2 — for the main washing;

— for special treating substances (conditioning, smoothening, starching, aromatizing additives). The following is installed in addition to a chute section:

— for special treating substances (conditioning, smoothening, starching, aromatizing additives). The following is installed in addition to a chute section:

— a chute for the liquid bleacher marked with letters Cl;

— a curtain for the use of liquid detergents.

7.2.2Detergents, bleachers and conditioning additives should be used for washing which are intended for automatic washing machines with the account of recommendations of the detergent manufacturer.

ATTENTION!Itisnotrecommendedtousebleachinggelsforwashing.

7.2.3Dozingofdetergents shouldbecarriedoutwiththeaccountofthemassofgoods,theirsoilingandwater

hardness.

ATTENTION!Overdozingofdetergents,aswellastheuseofdetergentsfor manual washingmayresult inexcessivefoaming,whichmakesthewashingqualitylowerandmayleadtomachineoutage.

7.2.4Whenapowderdetergentisusedacurtainshouldberemovedfromsection2ofthechute(ifitisinstalled).

Check so that the powder should not get to a section for special treating substances  in accordance with figure 15, as in the process of rinsing foam will be formed and white spots may appear on goods.

in accordance with figure 15, as in the process of rinsing foam will be formed and white spots may appear on goods.

7.2.5When additional functions  ,

,  are chosen the powder detergents are to be used which are to be placed to section 1 in accordance with figure 14.

are chosen the powder detergents are to be used which are to be placed to section 1 in accordance with figure 14.

7.2.6When the liquid detergent is used a curtain must be installed to section 2 in accordance with figure 16, andfigurelevelsinmillilitersaremarkedonbothsidesof thecurtain.Inorderto freelymovethecurtain byguiding slots to the lower position it should be inserted to the chute section by the front surface with figures;

—200,150,100,50

7.2.7Overfilling of special treating substances in section  (above the MAX mark on the cap), as well as penetration to neighboring sections will result in lower quality of washing.

(above the MAX mark on the cap), as well as penetration to neighboring sections will result in lower quality of washing.

7.2.8Bleachingsubstancesduringselectionoftheprogram“SOILS”aretobeplacedtosection1 inaccordance with figure 14, and bleaching takes place directly after the main washing.

Beforetheuseof theliquidbleacherachutefortheliquidbleacheristobeinsertedtosection1inaccordance with figures 14,15. A mark on the cap CL MAX determines the maximal level of bleacher filling to the chute.

ATTENTION! When a bleacher is used setting the additional function of the preliminary washing  isnotallowed.

isnotallowed.

7.2.9Forimprovementofwashingqualityandmachineprotectionfrom limesedimentsduringwashinginwater havinghardnessdegree IIorIIIawatersmootheningagentistobeusedalongwithadetergent.Itshouldbeadded to the detergent to section 2 in accordance with figure 14 as per manufacturer’s recommendations.

The water hardness degree is to be determined as per table 1. Information about the water hardness may be obtained at the local water supply company.

ITISPROHIBITEDtoremovethechutefordetergents duringmachineoperationinavoidanceof waterleakage

12

Loading...

Loading...