Page 1

IQS-3150

Variable Attenuator for IQS Platforms

User Guide

Page 2

Copyright © 2006–2008 EXFO Electro-Optical Engineering Inc. All rights

reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted in any form, be it electronically,

mechanically, or by any other means such as photocopying, recording or

otherwise, without the prior written permission of EXFO Electro-Optical

Engineering Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Patents

EXFO’s Universal Interface is protected by US patent 6,612,750.

Version number: 2.0.0

ii IQS-3150

Page 3

Contents

Contents

Certification Information ........................................................................................................v

1 Introducing the IQS-3150 Variable Attenuator ........................................... 1

Models and Options ...............................................................................................................1

Typical Applications ................................................................................................................3

Main Software Features ..........................................................................................................4

Conventions ............................................................................................................................8

Laser Safety Information .........................................................................................................9

2 Getting Started with Your Variable Attenuator ....................................... 11

Inserting and Removing Test Modules ..................................................................................11

Starting the Variable Attenuator Application ........................................................................15

Entering Values Using Sliders and Numeric Boxes .................................................................19

Exiting the Application .........................................................................................................20

3 Setting Up Your Variable Attenuator ........................................................ 21

Basic Settings ........................................................................................................................21

Control Center Settings and Controls ...................................................................................29

Creating a Test Sequence ......................................................................................................35

Managing Sequence Files .....................................................................................................42

Saving and Recalling Configurations .....................................................................................44

4 Operating the IQS-3150 ............................................................................. 47

Cleaning and Connecting Optical Fibers ...............................................................................47

Installing the EXFO Universal Interface (EUI) .........................................................................48

Nulling Electrical Offsets .......................................................................................................48

Running an Attenuation Sequence .......................................................................................50

Using the Power Tracking Function (Self-Adjusting Modules) ...............................................52

Using the Shutter ..................................................................................................................53

5 Controlling Multiple Variable Attenuators ............................................... 55

Starting a Multimodule Application ......................................................................................55

Selecting Modules to Control ...............................................................................................56

Controlling a Single IQS-3150 Variable Attenuator ...............................................................57

Navigating and Closing Multiple Module Windows ..............................................................58

6 Monitoring Variable Attenuator Modules ................................................ 59

Using Monitor Windows .......................................................................................................59

Using QuickTools ...................................................................................................................62

7 Measuring Multimode Insertion Loss ....................................................... 65

Variable Attenuator iii

Page 4

Contents

8 Maintenance ................................................................................................67

Cleaning Fixed Connectors ....................................................................................................68

Cleaning EUI Connectors ......................................................................................................70

Cleaning Detector Ports ........................................................................................................72

Homing the Variable Attenuator (User Calibration) ..............................................................73

Recalibrating the Unit ...........................................................................................................74

Recycling and Disposal (Applies to European Union Only) ....................................................75

9 Troubleshooting ..........................................................................................77

Viewing Online Documentation ............................................................................................77

Finding Information on the EXFO Web Site ..........................................................................77

Contacting the Technical Support Group ..............................................................................78

Transportation ......................................................................................................................80

10 Warranty ......................................................................................................81

General Information .............................................................................................................81

Liability .................................................................................................................................81

Exclusions .............................................................................................................................82

Certification ..........................................................................................................................82

Service and Repairs ...............................................................................................................83

EXFO Service Centers Worldwide ..........................................................................................84

A Technical Specifications ..............................................................................85

B SCPI Command Reference ..........................................................................87

Quick Reference Command Tree ...........................................................................................88

Product-Specific Commands—Description ............................................................................90

Index ...............................................................................................................151

iv IQS-3150

Page 5

Certification Information

Certification Information

F.C.C. Information

Electronic test equipment is exempt from Part 15 compliance (FCC) in

the United States. However, compliance verification tests are

systematically performed on most EXFO equipment.

Information

Electronic test equipment is subject to the EMC Directive in the European

Union. The EN61326 standard prescribes both emission and immunity

requirements for laboratory, measurement, and control equipment.

This unit has undergone extensive testing according to the European Union

Directive and Standards.

Variable Attenuator v

Page 6

Certification Information

Application of Council Directive(s): 73/23/EEC - The Low Voltage Directive

89/336/EEC - The EMC Directive

And their amendments

Manufacturer’s Name: EXFO Electro-Optical Engineering Inc.

Manufacturer’s Address: 400 Godin Avenue

Quebec, Quebec

Canada G1M 2K2

(418) 683-0211

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: IQS-3150

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Safety Requirements for Electrical Equipment for Measurement, Control,

EN 55022: 1998 +A2:

2003

EN 61326:1997 +A1:1998

+A2:2001 + A3:2003

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

and Laboratory Use, Part 1: General Requirements.

Limits and Methods of Measurement of Radio Disturbance

Characteristics of Information Technology Equipment.

Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements

DECLARATION OF CONFORMITY

Variable Attenuator

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Address: 400 Godin Avenue, Quebec

Date: November 27, 2006

Development

(Quebec), Canada, G1M 2K2

vi IQS-3150

Page 7

1 Introducing the IQS-3150

Variable Attenuator

The IQS-3150 is a versatile variable attenuator. It can be used as a regular

attenuator or it can be equipped with an integrated power meter, which

allows you to work not only in attenuation but also in power level

requirements. The following is a description of the IQS-3150 features and

its typical applications.

Models and Options

The IQS-3150 module is a high-performance attenuator, part of the IQS

product line.

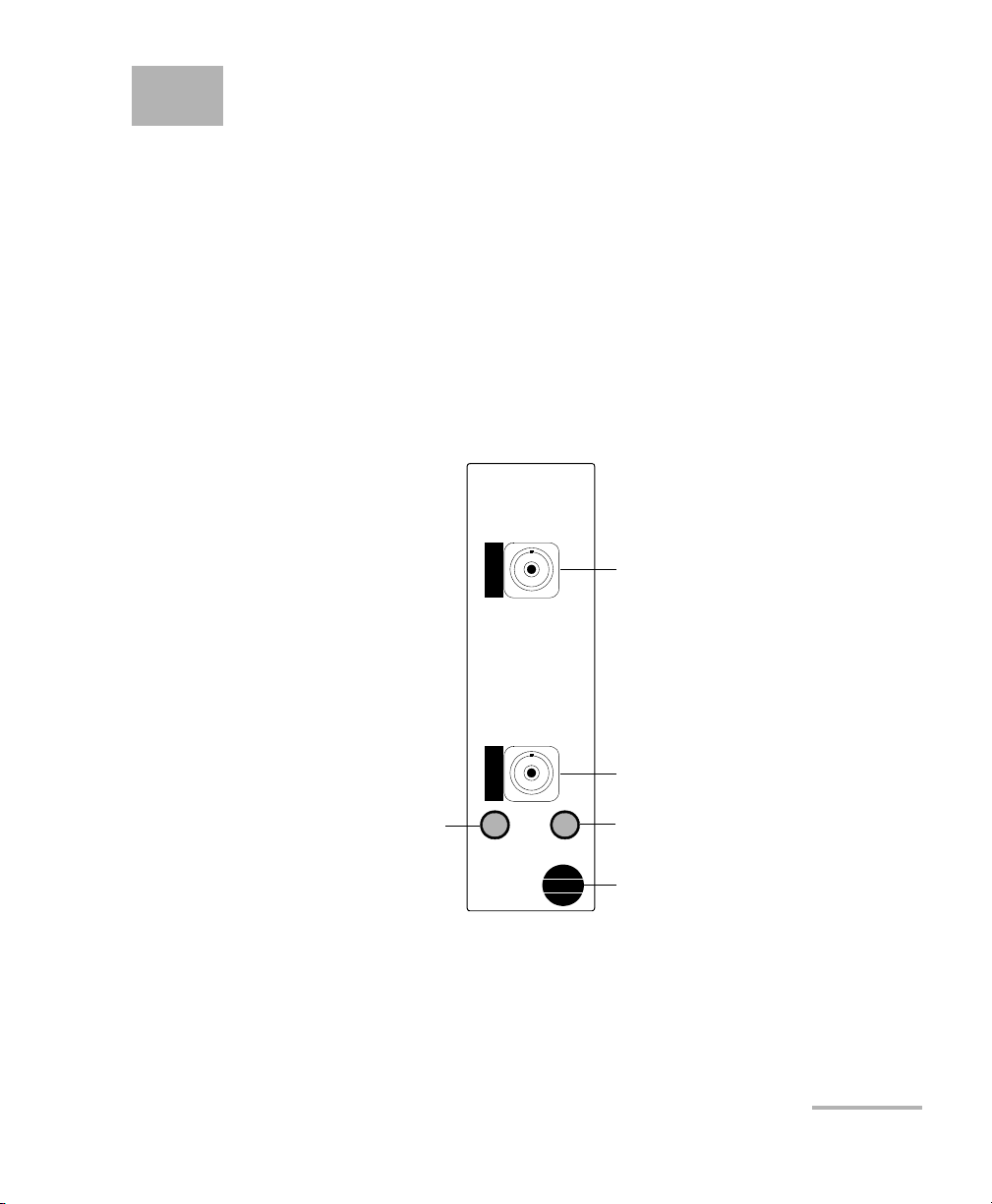

Input port

Output port

Green LED push button

to start the IQS-3150

software

IQS-3150

Vari abl e

Attenuator

Shutter

Red LED push button to close and

lock, or to open the shutter. When

lit, the shutter is closed.

Retaining screw knob

The module is configured for singlemode or multimode fibers and

complies with optical return loss measurement (ORL) standards on

transmission equipment.

Variable Attenuator 1

Page 8

Introducing the IQS-3150 Variable Attenuator

Models and Options

The IQS-3150 Variable Attenuator is available in four models:

³ Standard singlemode

³ Standard multimode

³ Self-adjusting singlemode (added Output Power contro l m o d e)

³ Self-adjusting multimode (added Output Power control mode)

The self-adjusting modules offer two operation modes: Attenuation

and Power Output. The Attenuation mode allows you to work with a

wide range of attenuation levels. The Output Power mode allows you

to request a fixed output power value and the module automatically

adjusts the attenuation according to that value.

Compatibility with various fiber cores is an option that you can add to your

IQS-3150.

Local and Remote Control

The IQS-3150 Variable Attenuator supports local control (via the

IQS Manager software) and remote control (through GPIB, RS-232, or

Ethernet TCP/IP using SCPI commands or the provided LabVIEW drivers).

For more information, refer to the IQS platform user guide.

Note: With IQS-3100 modules, you can use the LabVIEW drivers created for the

IQS-3150 module. However, the documentation and especially the

examples provided with the drivers are focused on the new functionalities

of the IQS-3150.

2 IQS-3150

Page 9

Introducing the IQS-3150 Variable Attenuator

Typical Applications

Typical Applications

The IQS-3150 Variable Attenuator can be used in a number of test

situations. It is ideal for manufacturing and laboratory applications:

³ Erbium-doped-fiber amplifier (EDFA) and system characterization

³ Component and system loss simulation

³ Optical margin analysis

³ Instrument calibration

³ Power meter linearity measurement

³ Spectral tuning.

The IQS-3150 is perfectly suited for WDM applications by providing the

same attenuation level on all channels simultaneously for a complete

characterization of amplifiers or subsystems.

Variable Attenuator 3

Page 10

Introducing the IQS-3150 Variable Attenuator

Main Software Features

Main Software Features

The dedicated software functions are very similar whether you are using a

self-adjusting or standard module. The following is an overview of the

main features.

Control Center

For the standard module, the output power value does not appear on the

data display and there is no Output Power tab in the Control Center.

Self-adjusting module

Standard module

4 IQS-3150

Page 11

Introducing the IQS-3150 Variable Attenuator

Main Software Features

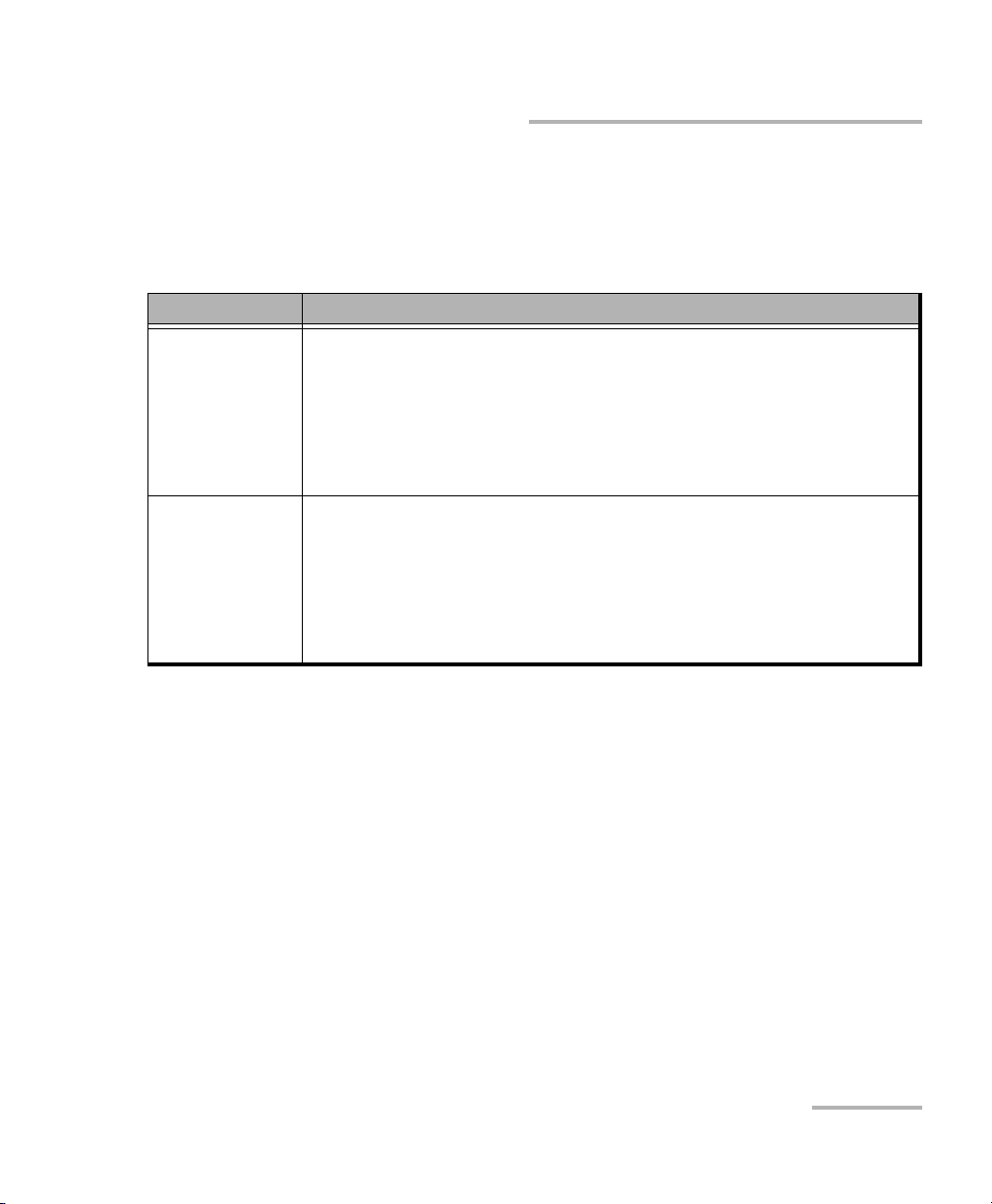

Control Modes (Self-Adjusting Modules)

With the self-adjusting modules, you can select between two control

modes: Attenuation and Output Power.

Control Mode Description

Attenuation The instrument applies the attenuation values you have selected.

The value appearing at the top of the data display (dB) represents

your attenuation setting whether it was entered in a test sequence or

on the Instrument function tab.

The value appearing underneath the attenuation value is the output

power.

Output Power The instrument produces the output power level you have selected.

The value appearing at the top of the data display (dBm) represents

your power level setting whether it was entered in a test sequence or

on the Instrument function tab.

The value appearing underneath the attenuation value is the output

power.

Variable Attenuator 5

Page 12

Introducing the IQS-3150 Variable Attenuator

Main Software Features

Display Modes

Both standard and self-adjusting modules give you a choice of three

display modes: Absolute, Reference, and X+B.

Attenuation

Display Mode Description

Absolute

(default mode)

The displayed attenuation takes into account both the absolute value

and the offset value.

Displayed att. = absolute att. + offset value

Reference The displayed attenuation value is relative to a defined reference value

(see Selecting a Display Mode on page 30).

Displayed att. = absolute att. – reference value + offset value

X+B The displayed attenuation is the sum of two elements:

³ X = physical attenuation introduced by the unit.

³ B = correction factor (dB). You must define the correction factor

for the test wavelength before enabling the X+B mode (refer to

Setting the B Value on page 23).

Displayed att. = absolute att. + correction factor

³ B = input power value (dBm)

Displayed att. = (absolute att. × –1) + input power

a. The correction factor and the input power value are specific to the wavelength.

a

+ offset value

a

+ offset value

6 IQS-3150

Page 13

Introducing the IQS-3150 Variable Attenuator

Output power

Display Mode Description

Main Software Features

Absolute

(default mode)

The displayed output power takes into account both the absolute

output power value and the offset value.

Displayed power = absolute power + offset value

Reference The displayed output power value is relative to a defined reference

value (see Selecting a Display Mode on page 30).

Displayed power = absolute power – reference value + offset value

X+B The displayed output power is the sum of two elements:

³ X = output power of the unit.

³ B = correction factor. You must define the correction factor for the

test wavelength before enabling the X+B mode (refer to Setting

the B Value on page 23).

Displayed power = absolute power + correction factor

a. The correction factor value is specific to the wavelength.

a

+ offset value

Multiple Module Control

The multimodule application is used to control and monitor several

IQS-3150 variable attenuators at the same time.

Variable Attenuator 7

Page 14

Introducing the IQS-3150 Variable Attenuator

Conventions

Conventions

Before using the product described in this manual, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

8 IQS-3150

Page 15

Introducing the IQS-3150 Variable Attenuator

Laser Safety Information

Laser Safety Information

Your IQS-3150 Variable Attenuator does not include laser components in

itself. However, other modules or units you will use may do so. Please,

make sure to follow all laser safety rules.

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

Use of controls, adjustments and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

Variable Attenuator 9

Page 16

Page 17

2 Getting Started with Your

Variable Attenuator

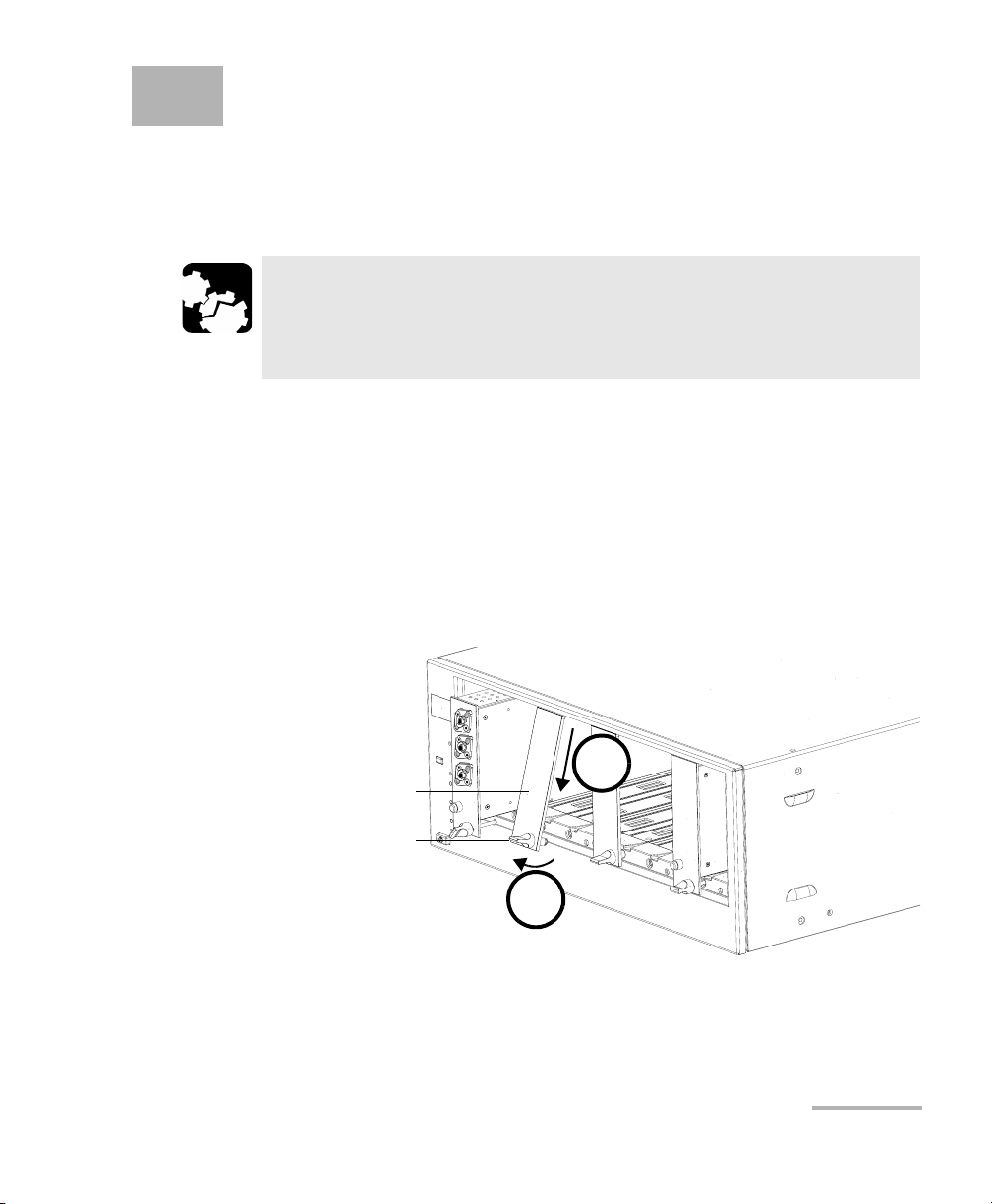

Inserting and Removing Test Modules

CAUTION

Never insert or remove a module while the controller unit and its

expansion units are turned on. This will result in immediate and

irreparable damage to both the module and unit.

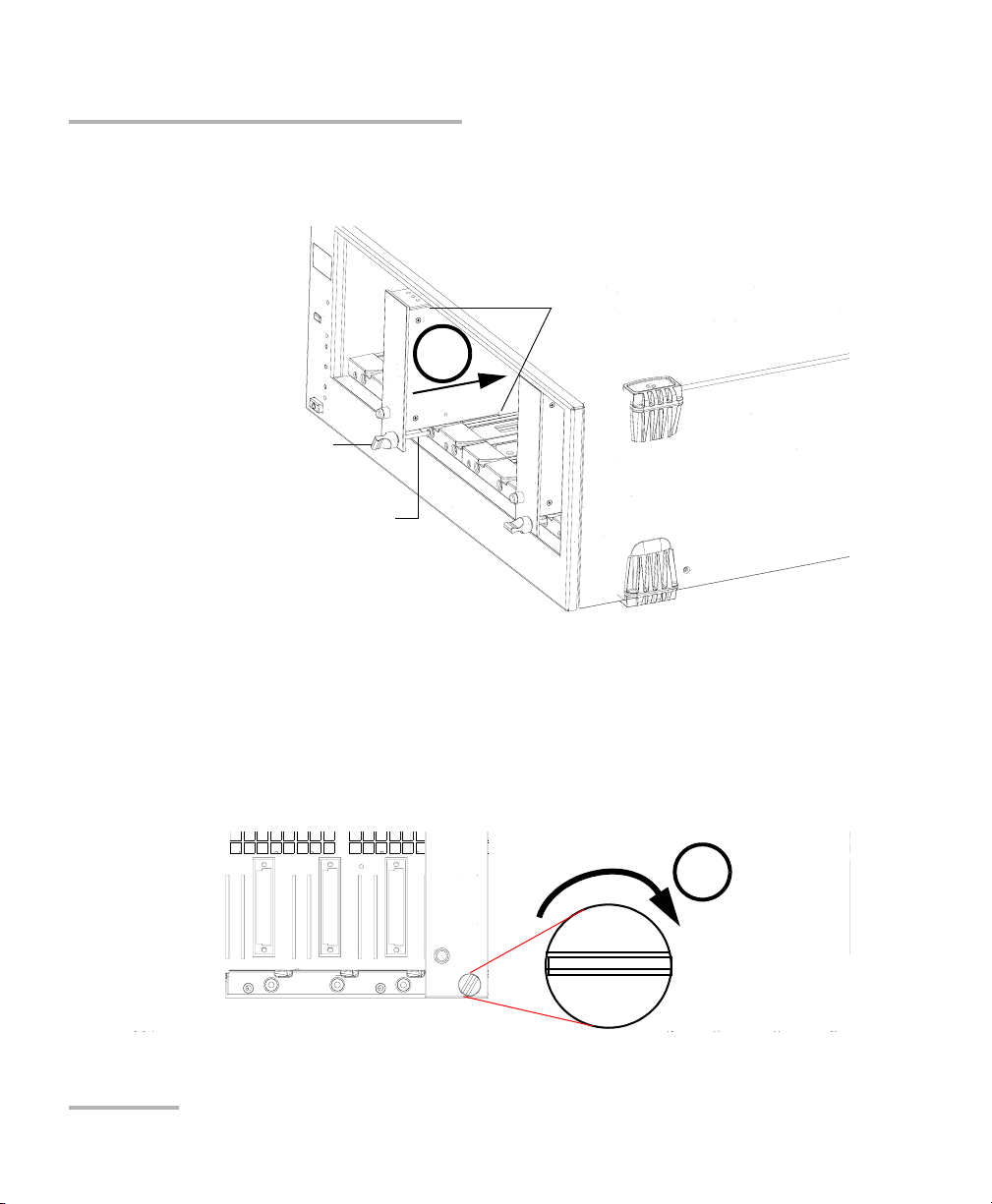

To insert a module into the controller or expansion unit:

1. Exit IQS Manager and turn off all your units.

2. Remove the protective cover from the desired unused module slot.

2a. Pull the retaining screw knob firmly towards you and release the

bottom of the cover.

2b. Gently pull the top of the protective cover downwards, to remove

it from the unit grooves.

Protective cover

Retaining screw

knob

2a

3. Position the module so that its front panel is facing you and the top and

bottom protruding edges are to your right.

Variable Attenuator 11

2b

Page 18

Getting Started with Your Variable Attenuator

Inserting and Removing Test Modules

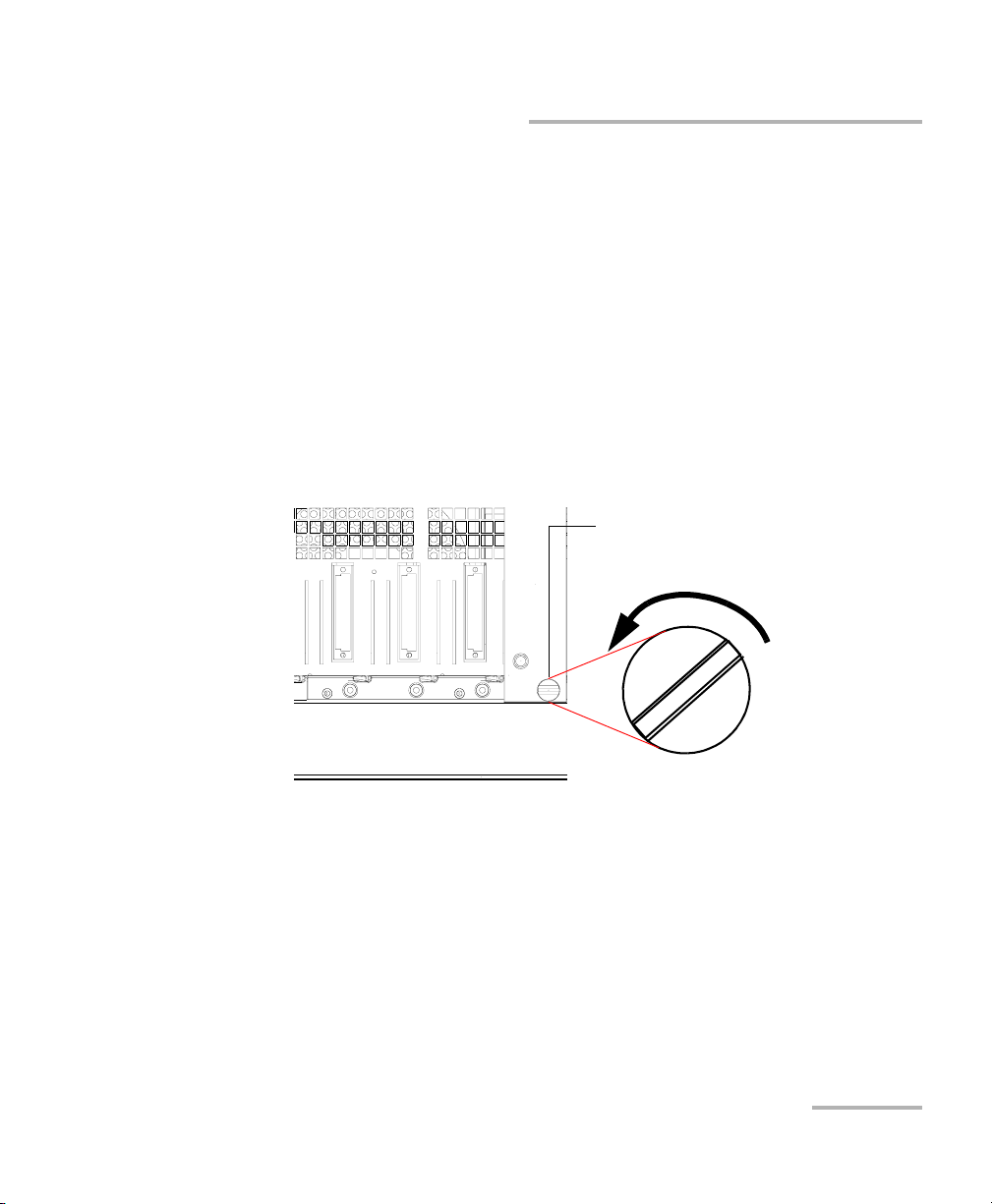

4. Insert the protruding edges of the module into the grooves of the unit’s

module slot.

5

Retaining screw knob

Retaining screw

Protruding edges

(right side of module)

5. Push the module all the way to the back of the slot, until the retaining

screw makes contact with the unit casing.

6. While applying slight pressure to the module, turn the retaining screw

knob (located at the bottom of the panel) clockwise until the knob is

horizontal.

This will secure the module into its “seated” position.

6

12 IQS-3150

Page 19

Getting Started with Your Variable Attenuator

Inserting and Removing Test Modules

The module is correctly inserted when its front panel is flush with the front

panel of the controller or expansion unit.

When you turn on the controller unit, the startup sequence will

automatically detect your module.

Note: You can insert IQ modules into your controller or expansion unit; the

IQS Manager software will recognize them. However, the IQS-3150 locking

mechanism (retaining screw) will not work for IQ modules.

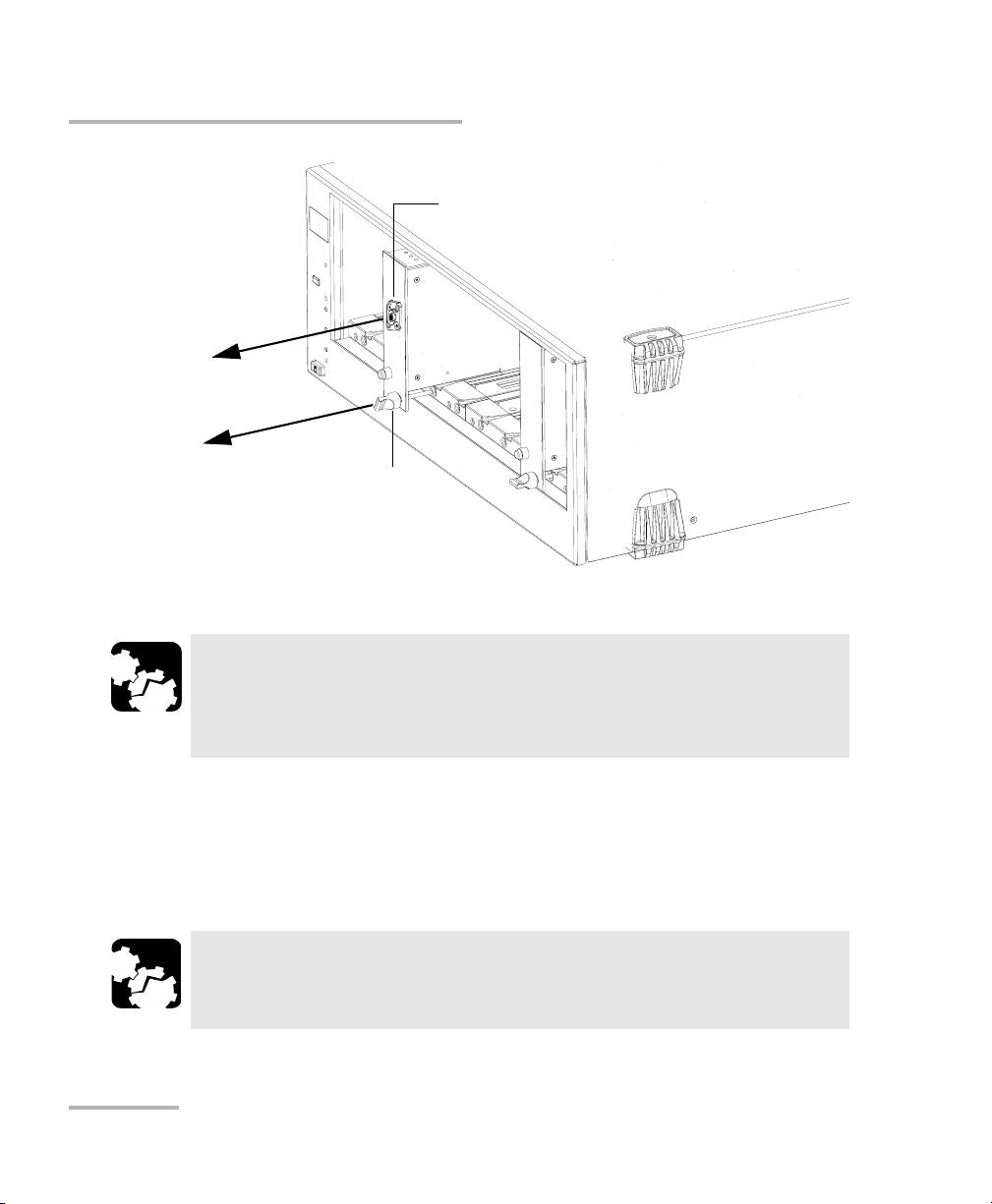

To remove a module from your controller or expansion unit:

1. While pulling gently on the knob, turn it counterclockwise until it stops.

The module will slowly be released from the slot.

Retaining screw knob

2. Place your fingers underneath the module or hold it by the retaining

screw knob (NOT by the connector) and pull it out.

Variable Attenuator 13

Page 20

Getting Started with Your Variable Attenuator

Inserting and Removing Test Modules

Connector

NO

YES

Retaining screw

knob

CAUTION

Pulling out a module by a connector could seriously damage both

the module and connector. Always pull out a module by the

retaining screw knob.

3. Cover empty slots with the supplied protective covers.

3a. Slide the top of the protective cover into the upper grooves of the

unit.

3b. Snap the cover into place by pushing the retaining screw knob.

CAUTION

Failure to reinstall protective covers over empty slots will result in

ventilation problems.

14 IQS-3150

Page 21

Getting Started with Your Variable Attenuator

Starting the Variable Attenuator Application

Starting the Variable Attenuator Application

Your IQS-3150 Variable Attenuator module can be configured and

controlled from its dedicated IQS Manager application.

Note: For details about IQS Manager, refer to the IQS platform user guide.

To start the application:

1. From the Current Modules function tab select the module to use.

It will turn white to indicate that it is highlighted.

Note: When starting the application for the first time after a firmware update, it is

possible that the wait period extends over two minutes. Please wait until

the application start is finished before using other commands.

Variable Attenuator 15

Page 22

Getting Started with Your Variable Attenuator

Starting the Variable Attenuator Application

2. Click Start Application.

OR

Press the green LED push button on the front of the corresponding

module.

You can also double-click its row.

Note: Pressing the LED push button will not activate or turn on the module.

Note: To start the corresponding monitor window at the same time, click Start

App. & Monitor. The window opens on the Monitors function tab.

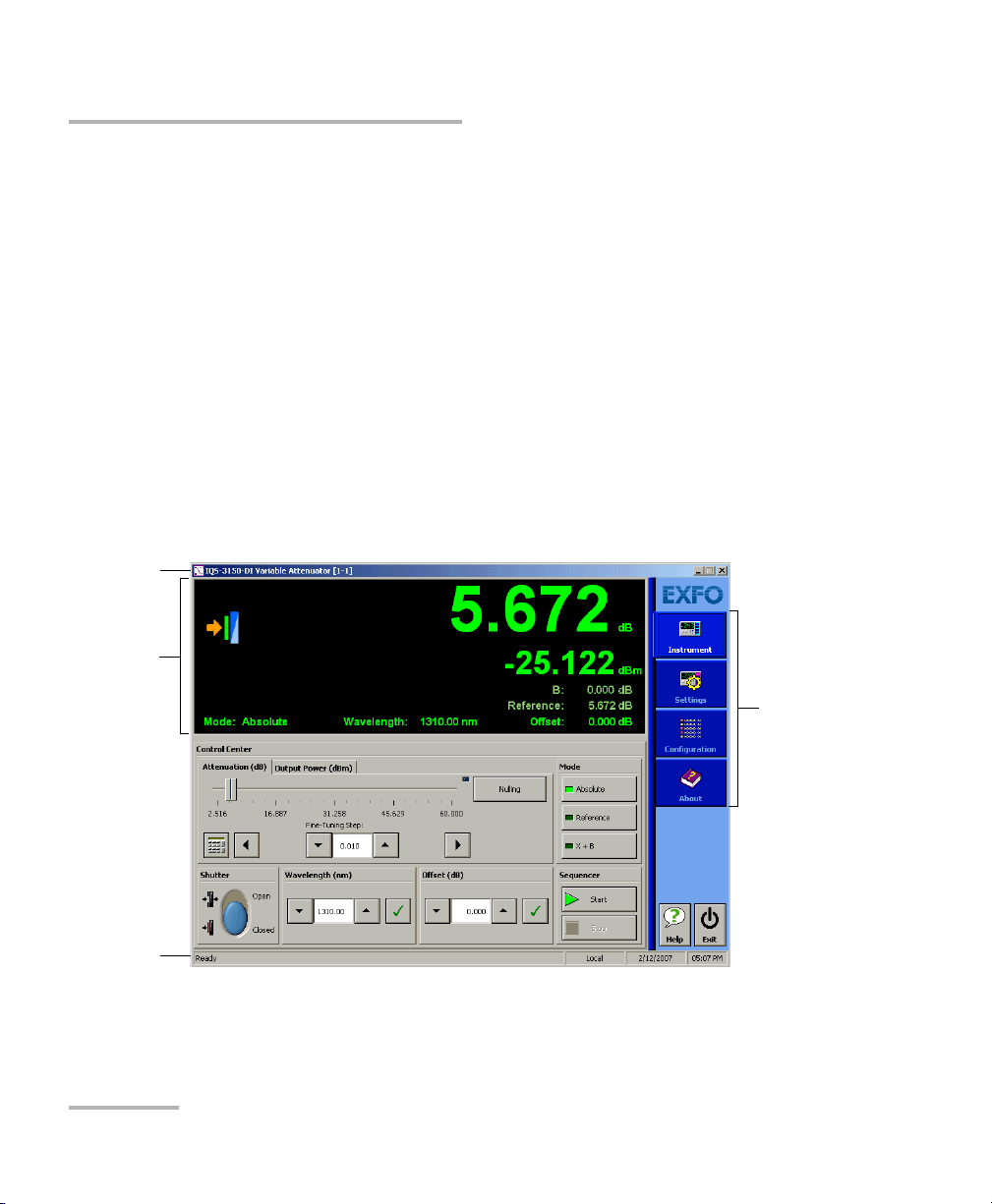

The main window (shown below) contains all the commands required to

control the Variable Attenuator:

Title bar

Data

display

Function

tabs

Status bar

16 IQS-3150

Page 23

Data Display

Some elements of the data display differ depending on the type of module

you are using (standard or self-adjusting).

Self-adjusting module

Getting Started with Your Variable Attenuator

Starting the Variable Attenuator Application

Current attenuation (Attenuation

control mode) or selected output

power (Output Power control mode)

Output power

Standard module

Current

attenuation

Shutter status and

message area

Variable Attenuator 17

Page 24

Getting Started with Your Variable Attenuator

Starting the Variable Attenuator Application

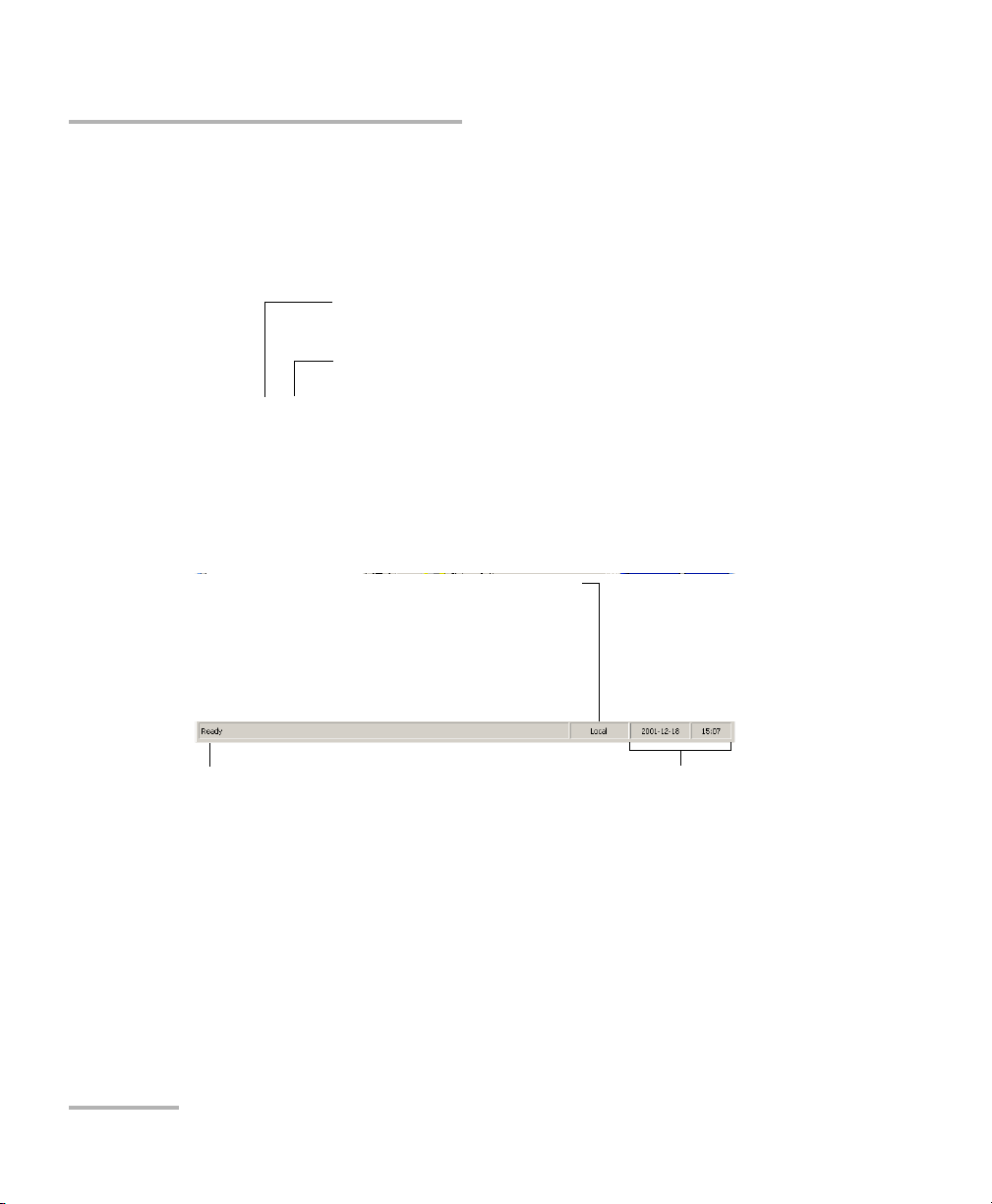

Title Bar

The title bar is located at the top of the main window. It displays the

module name and its position in the controller or expansion unit. The

module position is identified as follows:

Controller unit or expansion unit (1 to 999) housing

the module

Slot number in which module is inserted

(0 identifies first slot)

[ 999 – 1 ]

Status Bar

The status bar, located at the bottom of the main window, identifies the

operational status of the IQS-3150 Variable Attenuator.

Control mode

Local: Module controlled locally only.

Remote: Module controlled remotely, but

local commands can also be used.

Lockout: Module controlled remotely only.

Current date and timeModule/unit status

For more information about automating or remotely controlling the

IQS-3150 Variable Attenuator, refer to your platform user guide.

18 IQS-3150

Page 25

Getting Started with Your Variable Attenuator

Entering Values Using Sliders and Numeric Boxes

Entering Values Using Sliders and Numeric

Boxes

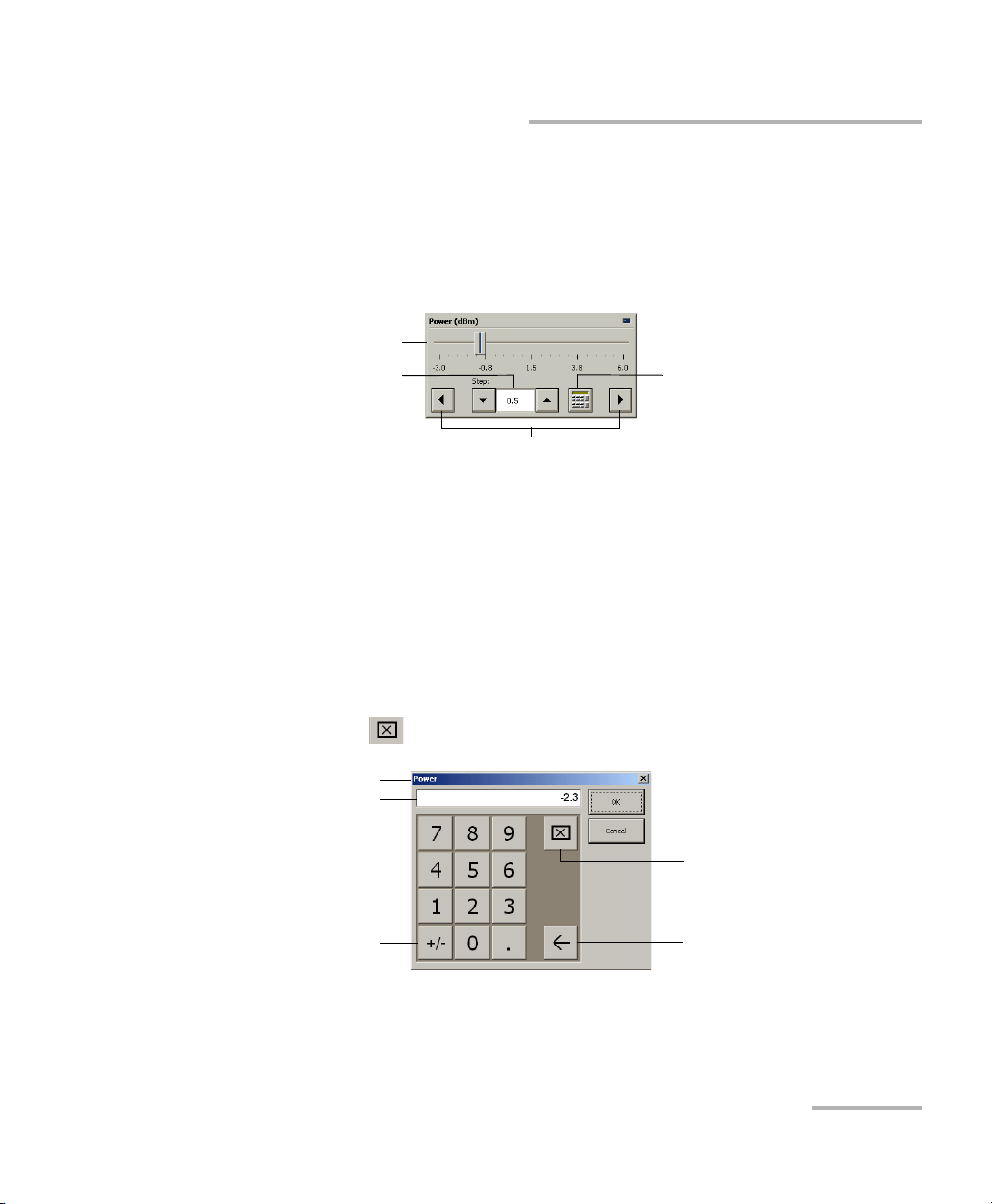

Many parameters in IQS Manager and module applications can be set

using the following tools.

Slider

Fine-tuning

box

Navigation buttons

³ Slider: Drag it to the desired value on the scale below.

³ Navigation buttons: Click either buttons to move the slider. The slider

moves by steps corresponding to the number in the fine-tuning box,

which you can change by using the up and down arrow buttons next to

the box. You cannot change the list of fine-tuning values from here.

³ Numeric box: Click it to display the on-screen numeric pad, which you

can use to enter a powe value.

Numeric box

button

To enter a value using the numeric box:

1. Use the button to clear the entry display.

Parameter identification

Entry display

Clear button

Toggle button

Backspace button

(to correct a value)

2. Enter the value.

3. Click OK to confirm the value.

Variable Attenuator 19

Page 26

Getting Started with Your Variable Attenuator

Exiting the Application

Exiting the Application

Closing any application that is not currently being used is a good way to

free system memory.

To close the application from the main window:

Click in the top right corner of the main window.

OR

Click the Exit button located at the bottom of the function bar.

To close all currently running applications:

From IQS Manager, click Close All Applications.

20 IQS-3150

Page 27

3 Setting Up Your Variable

Attenuator

The IQS-3150 comes with factory default settings; however, you can create

custom settings and save them in configuration files.

Basic Settings

When you start the Variable Attenuator dedicated application, it opens the

Instrument function tab. To start building your own test settings, click the

Settings function tab.

Variable Attenuator 21

Page 28

Setting Up Your Variable Attenuator

Basic Settings

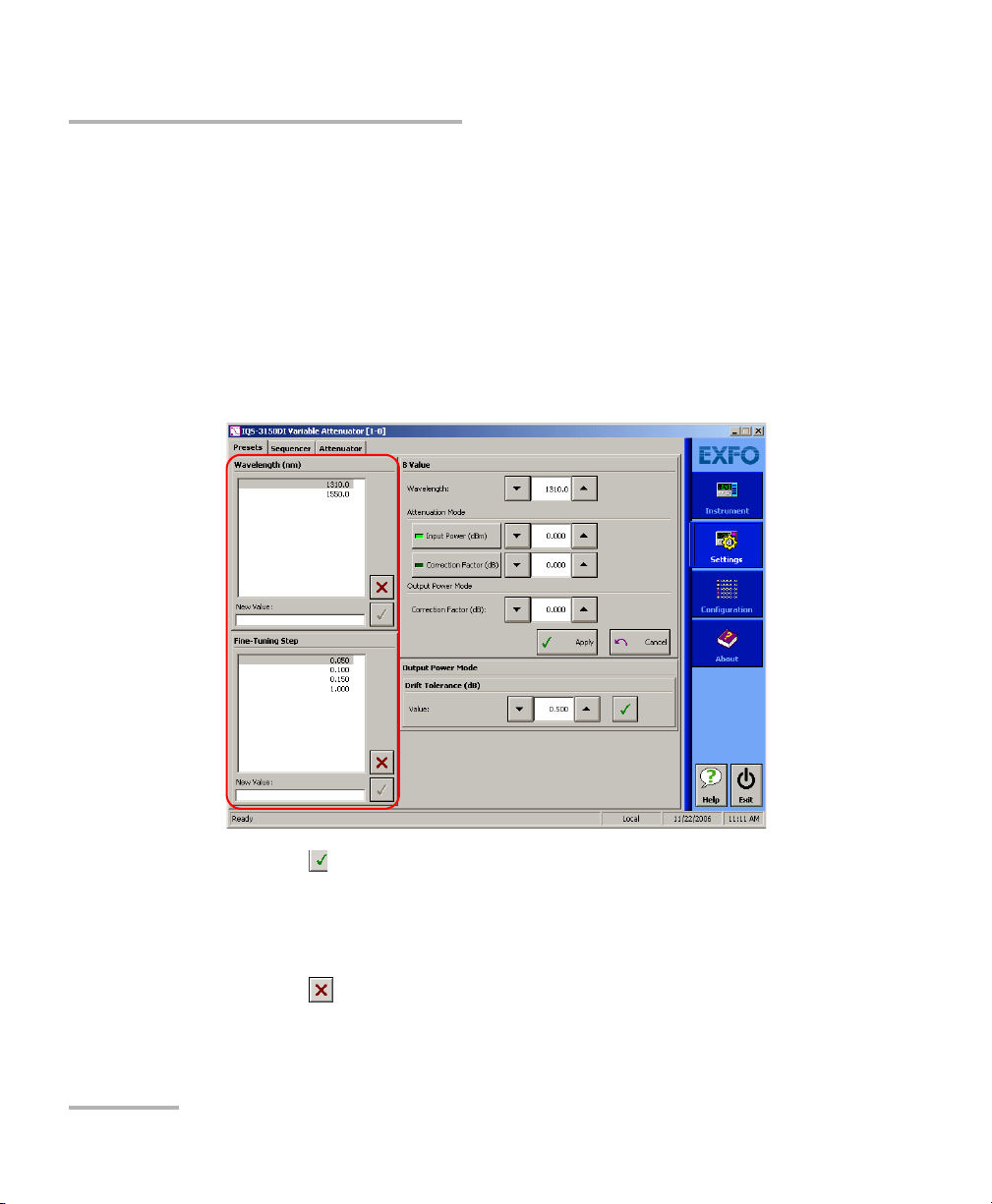

Customizing the Wavelength and Fine-Tuning Step

Lists

You can define lists of wavelengths and fine-tuning steps that will be

available during operation.

To add a value to the lists:

1. On the Settings function tab, click the Presets tab and, under

Waveleng th or Fine-Tuning Step, enter the value in the New Value

box.

2. Click the button to add the value to the list.

To delete a value from the lists:

1. On the Settings function tab, click the Presets tab and, under

Waveleng th or Fine-Tuning Step, click a value in the list to select it.

2. Click the button to delete the value.

22 IQS-3150

Page 29

Setting Up Your Variable Attenuator

Basic Settings

Setting the B Value

The B value settings are necessary for the X+B display mode. These

settings apply to one or many wavelengths defined in the Wa velength list

and are only enabled when using this display mode. The B value settings

are available for both standard and self adjusting modules.

The B value is defined as a correction factor or defined as an input power

value representing the attenuation in the equivalent output power in dBm.

Correction Factor

The Correction factor is available for both Attenuation and Output Power

control modes. This feature can be used to correct a difference in

attenuation or output power from the original specification due to some

changes in the equipment, such as a connector replacement.

Variable Attenuator 23

Page 30

Setting Up Your Variable Attenuator

Basic Settings

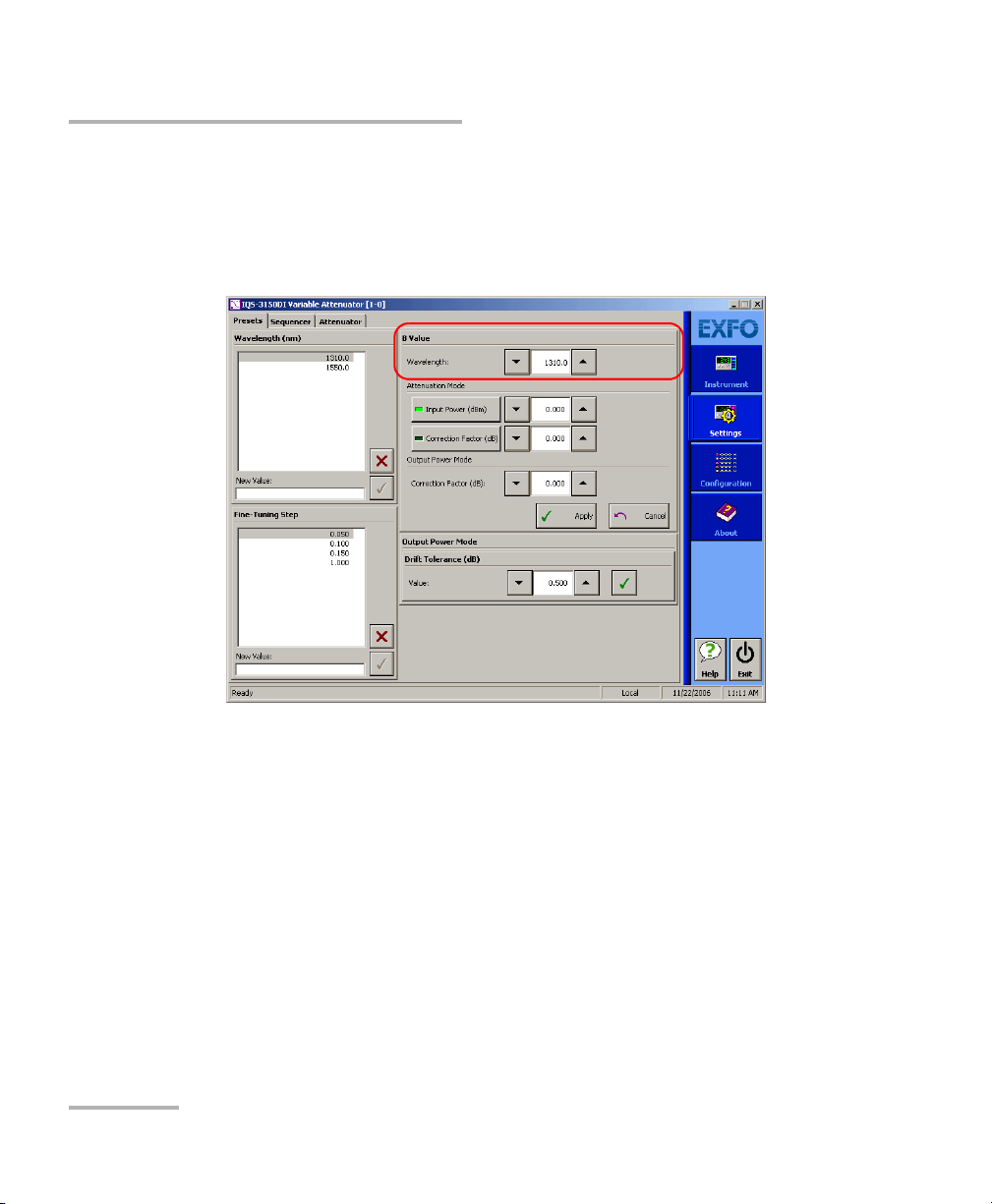

To set a correction factor for a wavelength:

1. On the Settings function tab, click the Presets tab.

2. Under BValue, in the Wa velength list, use the up/down arrows to

select the wavelength for which you want to add a correction factor.

24 IQS-3150

Page 31

Setting Up Your Variable Attenuator

Basic Settings

3. According to the control mode used, select the correction factor as

follows:

³ For the Attenuation mode, under Attenuation Mode, click the

Correction Factor button, and enter the correction value in the

box next to it.

³ For the Output power mode, under Output Power Mode, enter the

correction value in the Correction Factor box.

Self-adjusting module

Standard module

4. Click Apply.

Variable Attenuator 25

Page 32

Setting Up Your Variable Attenuator

Basic Settings

Input Power

The Input Power setting, only available in the Attenuation control mode,

allows you to set the source power in dBm. This changes the attenuation

scale values in the Control Center to the equivalent values of the output

power in dBm. You can then use the slider to select an output power value

rather than an attenuation value. It is not as precise as the Output Power

control mode but it is still useful for certain test applications.

To select an input in dBm:

1. On the Settings function tab, click the Presets tab.

2. Under BValue, under Attenuation Mode, click the Input Power

button.

3. In the box next to Input Power, enter the source power in dBm.

4. Click Apply.

26 IQS-3150

Page 33

Setting Up Your Variable Attenuator

Basic Settings

Setting the Drift Tolerance

The drift tolerance setting is only available for the self-adjusting modules

and is only applicable for the Power Tracking function (see Using the

Power Tracking Function (Self-Adjusting Modules) on page 52).

When you use the power tracking function, the internal power meter

monitors the output power level and constantly adjust the attenuation to

ensure that the output power does not exceed the limits set by the user

(drift tolerance). For example, if the power of the source used for the test

drifts over time, the attenuation is adjusted so that the output power

remains within the preset limits.

Requested

power

Output power (dBm)

Time (minutes)

Source power

fluctuation

Drift

tolerance

Power adjusted

by the attenuator

Variable Attenuator 27

Page 34

Setting Up Your Variable Attenuator

Basic Settings

To set the drift tolerance:

1. On the Settings function tab, click the Presets tab.

2. Under Output Power Mode, in the Valu e box, enter the tolerance

value.

3. Click the button to accept the value.

28 IQS-3150

Page 35

Setting Up Your Variable Attenuator

Control Center Settings and Controls

Control Center Settings and Controls

Once the basic settings are entered, you can set parameters in the Control

Center to create your test configuration.

Start creating your configuration by selecting a control mode (self-adjusting

modules only).

Variable Attenuator 29

Page 36

Setting Up Your Variable Attenuator

Control Center Settings and Controls

Selecting a Display Mode

The active display mode determines the significance of the value

appearing on the data display. For a description of each display mode, refer

to Display Modes on page 6.

For the IQS-3150 Variable Attenuator, the absolute (or total)

attenuation is the actual optical insertion loss between the input

and output ports, including connector losses.

Reference

Before clicking the Reference button, select the reference attenuation

or output power (Output Power control mode) value using either the

slider, the left/right arrows, or the numeric box. Upon clicking the

Reference button, the instrument uses the selected attenuation as

reference.

IMPORTANT

Slider

Numeric box

Arrows

X+B

Before clicking the X+B button, make sure that the B value is correctly

set (refer to Setting the B Value on page 23).

30 IQS-3150

Page 37

To select a display mode:

1. Click the Instrument function tab.

The selected

display mode

Setting Up Your Variable Attenuator

Control Center Settings and Controls

2. Under Control Center, enter the appropriate settings.

3. Under Mode click the appropriate button.

The selected display mode appears next to Mode on the data display.

Variable Attenuator 31

Page 38

Setting Up Your Variable Attenuator

Control Center Settings and Controls

Selecting a Wavelength and a Fine-Tuning Step

The attenuator wavelength must be set as closely as possible to the

wavelength of the optical source. The IQS-3150 Variable Attenuator module

provides a wide range of wavelengths: 1250 nm to 1650 nm for singlemode

modules and 700 nm to 1350 nm for multimode modules.

The fine-tuning step can be as low as 0.002.

The lists of available values are built on the Settings tab (refer to

Customizing the Wavelength and Fine-Tuning Step Lists on page 22).

To select a wavelength and a fine-tuning step:

1. Click the Instrument function tab.

2. Under Wa v e l e ngth, use the up/down arrows to select the wavelength,

and click .

3. Under Fine-Tuning Step, use the up/down arrows to select the

fine-tuning value.

32 IQS-3150

Page 39

Setting Up Your Variable Attenuator

Control Center Settings and Controls

Changing the Attenuation or the Output Power

You can change the attenuation or the output power (self-adjusting module

only) value while performing your tests.

In the Attenuation control mode, you can select any value between the

minimum insertion loss and the maximum permitted by the module

specifications. Although EXFO guarantees that the minimum insertion loss

is below a specified value (refer to specification sheet), it may vary slightly

from one wavelength to another and from one IQS-3150 Variable

Attenuator to another.

To change the attenuation or output-power level:

1. Click the Instrument function tab.

2. Click the Attenuation or the Output Power tab.

3. In the Fine-Tuning Step box, enter the step value.

4. Using either the slider, the left/right arrows, or the numeric box, change

the attenuation or output power value.

Variable Attenuator 33

Page 40

Setting Up Your Variable Attenuator

Control Center Settings and Controls

Defining an Offset Value

The offset value is not applied to a particular wavelength. It does not affect

the filter attenuation. It can be used to compensate for the loss generated

elsewhere in the system.

To define an offset value:

1. Click the Instrument function tab.

2. Under Offset, enter de desired value in the box and click to accept

the value.

Note: The offset values must be between -99.999 dB and 99.999 dB. The

attenuation value is positive; therefore, when the offset value is positive,

the displayed attenuation increases.

34 IQS-3150

Page 41

Setting Up Your Variable Attenuator

Creating a Test Sequence

Creating a Test Sequence

The IQS-3150 allows you to create test sequences so that the attenuation or

output power steps are performed automatically without your intervention.

The sequences can be saved and retrieved to be used as is or to be used as

a template in which you can insert or remove steps. To build a new

sequence starting with an old one, under Sequence File, click the Open

button.

To create a completely new sequence, under Sequence File, click the New

button.

IMPORTANT

When you click the New button, all parameters previously set on

the Sequencer tab are erased. Make sure you save the sequence

parameters you want to keep before clicking this button.

A duration can be applied to each step individually, the duration value must

be between 0:00:00 and 999:59:59.

3. You can also set the time at which the sequence will start using one of

the following starting time modes:

³ Absolute: allows you to select a precise time (for example, 10:30:30

am) at which the sequence starts.

³ Relative: allows you to select a countdown between the moment you

start the sequence and the moment it actually starts.

In both modes, you cannot enter a value greater than 23:59:59.

You can also have the sequence repeated for a fixed number of times

(between 1 and 99999) or continuously.

Sequences can be created for both Attenuation and Output Power

(self-adjusting modules) modes.

Variable Attenuator 35

Page 42

Setting Up Your Variable Attenuator

Creating a Test Sequence

Adding, Inserting, and Removing Steps

You can customize test sequences:

³ by adding steps, either to a new sequence or an existing one

³ by inserting steps to an existing sequence.

To add, insert, and remove steps:

1. On the Settings function tab, click the Sequencer tab.

2. Under Sequence Steps, select the control mode.

36 IQS-3150

Page 43

Setting Up Your Variable Attenuator

Creating a Test Sequence

3. In the Attenuation or the Output Power box (depending on the

selected control mode) enter the attenuation or the output power level

you need.

In Attenuation mode In Output Power mode

4. In the Duration box, enter the length of time this level will be applied

before the next step.

5. Click Add (the new step is added at the end of the step list).

OR

Click a step in the Steps list to select it and click Insert (the step is

added before the selected step).

6. To remove a step from the list, click a step in the Steps list to select it

and click Remove.

7. Under Sequence File, click Save As if you want to save that sequence.

Variable Attenuator 37

Page 44

Setting Up Your Variable Attenuator

Creating a Test Sequence

Setting a Starting Time

The start of a test sequence can be set to a definite time of day (Absolute)

or be delayed by a countdown (Relative).

To set a sequence starting time:

1. On the Settings function tab, click the Sequencer tab.

2. Under Sequence File, open a test sequence or create one (refer

to Adding, Inserting, and Removing Steps on page 36).

38 IQS-3150

Page 45

Setting Up Your Variable Attenuator

Creating a Test Sequence

3. Under Starting Time, click the Relative or the Absolute button.

4. In the box below the buttons, enter one of the following value:

³ The amount of time you need between the moment you click the

Start button and the moment the sequence starts (Relative).

³ The time (in the next 24 hours) at which you want the sequence to

start (Absolute).

IMPORTANT

When using the Absolute start time mode, make sure that the clock

of your IQS Platforms is correctly set. The IQS-3150 dedicated

hardware uses that clock setting as time reference.

5. Under Sequence File, click Save As if you want to save that sequence.

Variable Attenuator 39

Page 46

Setting Up Your Variable Attenuator

Creating a Test Sequence

Setting Repetition Scheme

The test sequence can be set to repeat itself for a certain number of times

or on a continuous basis.

Note: If you have entered a setting for the sequence start, the delay or start time

will only apply for the first sequence in the loop.

To set the sequence repetition scheme:

1. On the Settings function tab, click the Sequencer tab.

40 IQS-3150

Page 47

Setting Up Your Variable Attenuator

Creating a Test Sequence

2. Under Sequence File, open a test sequence.

OR

Create a sequence (refer to Adding, Inserting, and Removing Steps on

page 36).

3. Under Sequence Loop, click Loop Count and, in the text box, enter

the number of times the sequence must be repeated.

OR

Click the Continuous Loop button.

4. Under Sequence File, click Save As if you want to save that sequence.

Variable Attenuator 41

Page 48

Setting Up Your Variable Attenuator

Managing Sequence Files

Managing Sequence Files

The commands to open new or existing sequence files and to save them

are located on the Sequencer tab of the Settings function tab.

³ Clicking the New button clears all previous settings allowing you to

build a completely new sequence.

42 IQS-3150

Page 49

Setting Up Your Variable Attenuator

Managing Sequence Files

³ Clicking the Open button opens the Open Sequence File dialog box

from which you can select a sequence file.

³ Clicking the Save As button opens the Save Sequence File dialog box

from which you can select a directory to save your sequence file.

Note: To facilitate the search of sequence files, EXFO recommends that you use

the following elements in the file name: step attenuation or output power

level, step duration, and sequence repetition scheme.

Variable Attenuator 43

Page 50

Setting Up Your Variable Attenuator

Saving and Recalling Configurations

Saving and Recalling Configurations

Once you have set the IQS-3150 Variable Attenuator parameters, you can

save your custom configuration and recall it at any time. You can also recall

the factory-defined settings.

Saved configurations include all parameters set in the Control Center

(Instrument function tab) and in the Settings function tab (if present).

To save a configuration:

1. Select the Configuration function tab.

2. In the Current Module Configuration panel, enter the name you wish

to use for your configuration file.

To always use the last saved

parameters when starting.

To save parameters being used

just before shutting down,

overwriting the previous file.

It will be saved in

D:\IQS Manager\Configuration Files\(your_module)\.

3. Click Save.

44 IQS-3150

Page 51

Setting Up Your Variable Attenuator

Saving and Recalling Configurations

To recall a configuration:

1. Select the Configuration function tab.

2. Click Open.

3. Select the configuration file you wish to recall and confirm your action.

You are returned to the application and the new parameters are set.

To revert to factory settings:

1. Select the Configuration function tab.

2. Click the Reset Module to Factory Settings button.

IMPORTANT

Reverting to the factory settings will interrupt any module

operation in progress.

IMPORTANT

The operation may take a few seconds to complete.

Note: The sequence parameters that you could have set are not part of the data

saved when you click the Save button for the configuration. You must save

your sequence settings by clicking the Save As button under Sequence File

on the Sequencer tab of the Settings function tab. This way your test

configuration and your sequence settings are all saved.

Note: When recalling a saved configuration, the fine-tuning step appearing in the

Control Center reverts to the default value.

Variable Attenuator 45

Page 52

Page 53

4 Operating the IQS-3150

This section presents basic operations using the Variable Attenuator.

Cleaning and Connecting Optical Fibers

IMPORTANT

To ensure maximum power and to avoid erroneous readings:

³ Always clean fiber ends as explained below before inserting

them into the port. EXFO is not responsible for damage or

errors caused by bad fiber cleaning or handling.

³ Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Clean the fiber ends as follows:

1a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl

alcohol.

1b. Use compressed air to dry completely.

1c. Visually inspect the fiber end to ensure its cleanliness.

2. Carefully align the connector and port to prevent the fiber end from

touching the outside of the port or rubbing against other surfaces.

If your connector features a key, ensure that it is fully fitted into the

port’s corresponding notch.

3. Push the connector in so that the fiber-optic cable is firmly in place,

thus ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector

enough to firmly maintain the fiber in place. Do not overtighten, as this

will damage the fiber and the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you will

notice heavy loss and reflection.

Variable Attenuator 47

Page 54

Operating the IQS-3150

Installing the EXFO Universal Interface (EUI)

Installing the EXFO Universal Interface (EUI)

The EUI fixed baseplate is available for connectors with angled (APC) or

non-angled (UPC) polishing. A green border around the baseplate

indicates that it is for APC-type connectors.

Green border

indicates APC

option

To install an EUI connector adapter onto the EUI baseplate:

1. Hold the EU connector adapter so the dust cap opens downwards.

Bare metal

(or blue border)

indicates UPC

option

2 3 4

2. Close the dust cap in order to hold the connector adapter more firmly.

3. Insert the connector adapter into the baseplate.

4. While pushing firmly, turn the connector adapter clockwise on the

baseplate to lock it in place.

Nulling Electrical Offsets

Temperature and humidity variations affect the performance of electronic

circuits and optical detectors, which can offset measurement results. To

compensate for this offset, the IQS-3150 is equipped with an offset nulling

function.

EXFO recommends performing a nulling of the electrical offsets whenever

environmental conditions change.

48 IQS-3150

Page 55

Operating the IQS-3150

Nulling Electrical Offsets

IMPORTANT

Light must not reach the detector when nulling offsets.

The nulling function is only available for the self-adjusting modules.

To perform the power meter nulling:

1. Click the Instrument function tab.

2. Click the Nulling button.

Variable Attenuator 49

Page 56

Operating the IQS-3150

Running an Attenuation Sequence

Running an Attenuation Sequence

Attenuation sequences allow you to automate and ease your testing

process. Prepare the test sequence as described in Creating a Test

Sequence on page 35.

To start an attenuation sequence:

1. Click the Instrument function tab.

Note: Once a sequence is started, all controls in the Instrument function tab are

disabled to avoid accidental interruptions. However, the monitor and

multimodule applications are not disabled, so you can make changes in

these applications while a sequence is running.

2. Under Sequencer, click the Start button.

The Start button changes to Pause.

50 IQS-3150

Page 57

Operating the IQS-3150

Running an Attenuation Sequence

You can interrupt a sequence at any time by clicking Pause; click Resume

when you are ready to continue.

Note: When you click the Pause button, the sequence will not be restarted at the

point you paused it. Upon clicking the Resume button, the acquisition will

start with the next step in the sequence.

If you click Pause between two steps, when you click Resume the system

will go directly to the next step.

When you have programmed a start time or a start delay, upon clicking the

Start button, a message appears on the data display.

Variable Attenuator 51

Page 58

Operating the IQS-3150

Using the Power Tracking Function (Self-Adjusting Modules)

Using the Power Tracking Function

(Self-Adjusting Modules)

The power tracking function is used to monitor, when in the Output Power

control mode, the output power level and automatically adjust the

attenuation to keep the output power to the requested level.

In order to use the power tracking function, you must define a range of

power levels (see Setting the Drift Tolerance on page 27).

To activate the power tracking function:

From the Instrument function tab, click the Power Tracking button.

52 IQS-3150

Page 59

Operating the IQS-3150

Using the Shutter

Using the Shutter

The shutter is used to let light through the input or block it.

CAUTION

Using the shutter continuously, at a rate of one cycle per three

seconds, may damage the instrument permanently or seriously

reduce its life cycle.

To use the shutter:

1. Click the Instrument function tab.

2. Under Shutter, click the switch to open or close the shutter.

IMPORTANT

Using the Shutter LED push button on the module front panel to

close the shutter disables the software shutter controls. You must

press the push button again to unlock the software controls. The

lock status is indicated by a padlock on the data display.

Variable Attenuator 53

Page 60

Operating the IQS-3150

Using the Shutter

Shutter Status

The status of the shutter is shown on the left of the data display.

It is also shown on the Shutter (red) LED push button on the front panel of

the module; when lit, the shutter is closed.

High-Power Detection

The module is equipped with a sensor that detects the presence of

unusually high power at the input. When high power is detected, the

shutter automatically closes and the high power status is indicated by a

laser-radiation sign on the data display.

Open Close

The red LED push button on the front panel of the module lights up.

54 IQS-3150

Page 61

5 Controlling Multiple Variable

Attenuators

With your platform, you can set common parameters and simultaneously

operate several modules of the same kind in a single interface, which is

particularly useful in larger systems.

Note: You should be familiar with the configuration and operation of a single

module before controlling multiple modules simultaneously.

Starting a Multimodule Application

The multimodule applications available will change according to your

module configuration (model, type, etc.).

Note: When you start a multimodule application, you cannot open a monitor

window at the same time, as it is possible with a single-module

application. You must open the monitor window independently.

To start a multimodule application:

1. In IQS Manager, select the Integrated Applications function tab.

2. Click the appropriate Multiple Module Controller button.

The multimodule application appears in a new window.

Note: More than one Multiple Module Controller button may be displayed if

different models are present in your platform.

Variable Attenuator 55

Page 62

Controlling Multiple Variable Attenuators

Selecting Modules to Control

Selecting Modules to Control

Before you can modify the module parameters, you must specify which

modules you intend to use.

To select IQS-3150 Variable Attenuator modules:

1. On the Modules/Config function tab, select the boxes corresponding

to the modules you want to control.

OR

Click Select All if you want to work with all IQS-3150 Variable

Attenuator modules.

2. Click Apply Selections and click the Instruments function tab.

56 IQS-3150

Page 63

Controlling Multiple Variable Attenuators

Controlling a Single IQS-3150 Variable Attenuator

On the Instruments function tab, you can set parameters for any number

of modules at a time. Select the modules for which you want to set the

parameters and use the functions in the control center. (For more

information on settings and controls, refer to Control Center Settings and

Controls on page 29.)

Controlling a Single IQS-3150 Variable

Attenuator

You may want to control a specific module among all the IQS-3150 Variable

Attenuator modules that you have in the system.

To control a specific IQS-3150 Variable Attenuator:

1. Make sure that the row corresponding to the module you want to

control appears in bold or that it is highlighted.

2. Use the Control Single Instrument button to open the IQS-3150

Variable Attenuator application.

Variable Attenuator 57

Page 64

Controlling Multiple Variable Attenuators

Navigating and Closing Multiple Module Windows

Navigating and Closing Multiple Module

Windows

When controlling multiple modules, a number of windows are open at the

same time. To close a window, use the Exit button located under the

function tabs. You will return to the preceding window.

The following diagram illustrates the navigation between windows:

IQS Manager - Integrated

Open

Applications (Multi-modules)

Apply Selections

Control Single

Instrument

Your modu l e Multiple Module

Controller - Modules/Config tab

Your modu l e Multiple Module

Controller - Instruments tab

Your module main application

window (single module)

Exit

Exit

58 IQS-3150

Page 65

6 Monitoring Variable

Attenuator Modules

When using your IQS-3150 Variable Attenuator module, either alone or with

other modules in a test setup, you can view module data and status using

its monitor window in IQS Manager.

Using Monitor Windows

Monitor windows display basic data about modules. A combination of

resizable windows allows you to create an integrated data display (refer to

the platform user guide).

From the monitor window, you can change module parameters either by:

³ opening the module application to access all the functions

OR

³ using the QuickTools utility, which provides frequently used functions

from the application.

Variable Attenuator 59

Page 66

Monitoring Variable Attenuator Modules

Using Monitor Windows

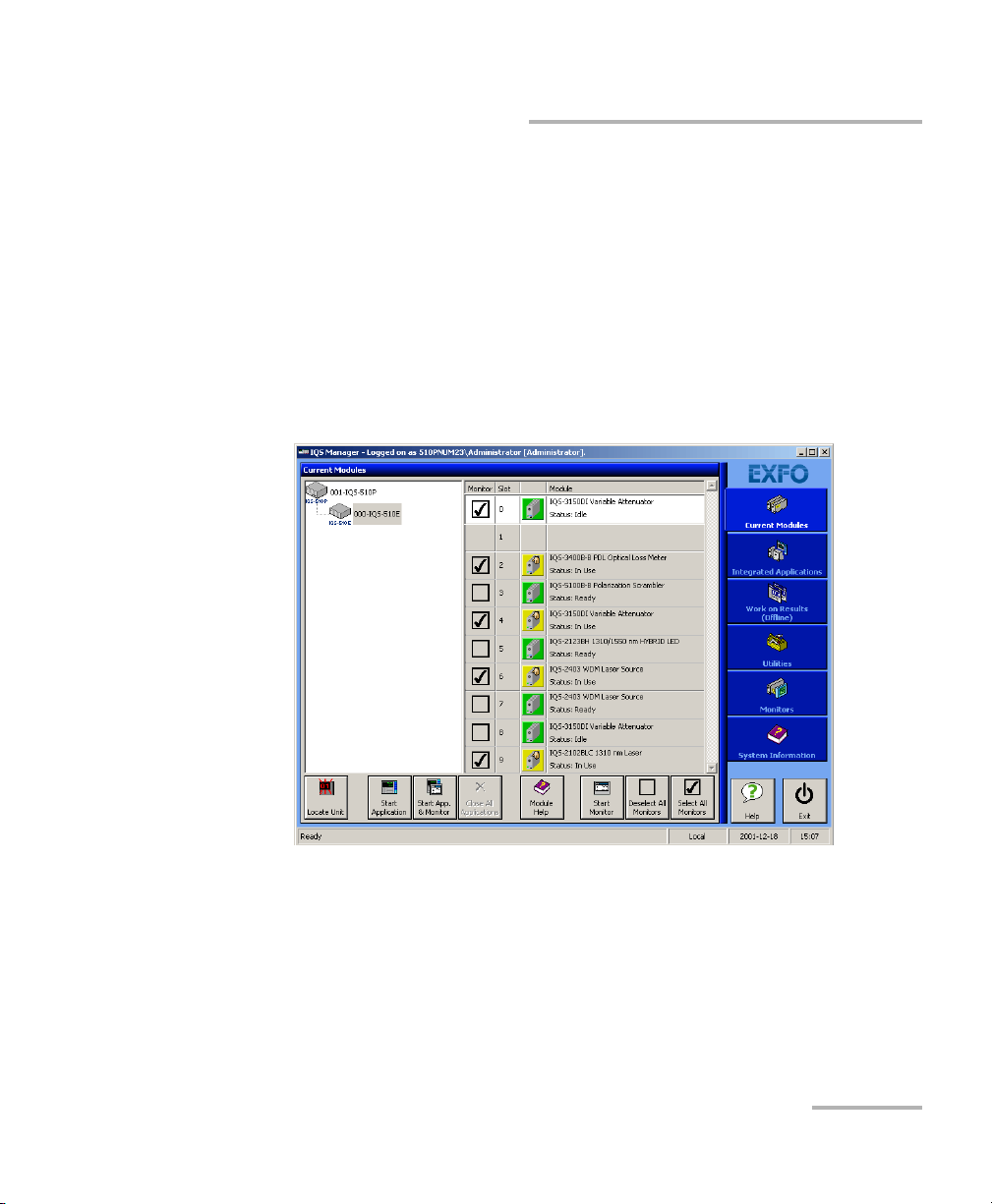

To select modules and display their monitor windows:

1. On the Current Modules function tab, select the controller or

expansion unit containing the modules you want to monitor.

Selected modules

(checked)

2. In the Monitor column, select the box next to each module you want

to monitor.

If you want to monitor all the modules in the current unit, click Select

All Monitors. If you want to clear your choices, click Deselect All

Monitors.

60 IQS-3150

Page 67

Monitoring Variable Attenuator Modules

Using Monitor Windows

3. Click Start Monitor to apply your selection.

IQS Manager will display the selected monitor windows on the

Monitors function tab.

Note: To start t h e highlighted module’s corresponding application at the same

time, click Start App. & Monitor. The application will appear in a different

window.

Monitor

window

menu

Monitor window

selection buttons

Variable Attenuator 61

Page 68

Monitoring Variable Attenuator Modules

Using QuickTools

Using QuickTools

With QuickTools, you can fine-tune your module directly, while keeping an

eye on your entire test setup.

Note: You can only access QuickTools if the module’s monitor window is selected

from the Monitors function tab and is currently active.

To start QuickTools:

1. From the Monitors function tab, elect the monitor window of the

module you wish to control.

2. Using the arrow button in the upper left corner, select QuickTools.

The corresponding monitor window flashes when QuickTools is

activated.

Note: If you want to open the actual application for your module rather than

QuickTools, click Show Controller.

Attenuation

control mode

For more information on settings and

controls, refer to Control Center Settings

and Controls on page 29.

62 IQS-3150

Output Power

control mode

Page 69

Monitoring Variable Attenuator Modules

Using QuickTools

To c l os e Q u ic k Too ls :

³ Click the Close button located at the top of the window.

OR

³ Click outside the QuickTools window.

To close a monitor window:

Click the button on the upper left of the monitor window and select

Remove Monitor.

OR

Click the Close All button at the bottom of the window.

Variable Attenuator 63

Page 70

Page 71

7 Measuring Multimode

Insertion Loss

Often, when using a multimode source (mostly LED sources), part of the

optical energy is transmitted into the fiber cladding. These cladding modes

attenuate rapidly, but will affect power meter readings if the source is

connected using only a short jumper, as would be the case when taking a

reference before measuring insertion loss.

short distance

long distance

Due to the internal optics of the Variable Attenuator (and the majority of

attenuators), most of the cladding modes are filtered out. This means that,

with the attenuator connected, the power meter will display a loss greater

than the attenuation setting of the attenuator (cladding modes have been

partially stripped).

Cladding modes are not used in communication systems and, therefore,

should not have been part of the source power measurement in the first

place.

Variable Attenuator 65

Page 72

Measuring Multimode Insertion Loss

There are several methods of eliminating these cladding modes:

³ A cladding mode stripper (preferred method) is a material with a

refractive index greater than that of the cladding. With the cladding

exposed, the fiber is immersed in the mode stripper (glycerin, oil, or

other suitable liquid). Due to the greater refractive index of the stripper,

light energy is not reflected at the cladding-stripper interface and

passes through the stripper.

³ Cladding modes attenuate to insignificant levels over relatively short

distances. Therefore, we recommend using a long fiber jumper.

³ A mandrel wrap can be introduced by making a minimum of five turns

around a 0.5 in. diameter mandrel. This method will introduce slight

losses in the multimode core and remove some of the cladding modes.

A mandrel wrap is not the preferred method of controlling cladding

modes in multimode fibers.

66 IQS-3150

Page 73

8 Maintenance

To help ensure long, trouble-free operation:

³ Always clean fiber-optic connectors before using them.

³ Keep the unit free of dust.

³ Clean the unit casing and front panel with a cloth slightly dampened

with water.

³ Store unit at room temperature in a clean and dry area. Keep the unit

out of direct sunlight.

³ Avoid high humidity or significant temperature fluctuations.

³ Avoid unnecessary shocks and vibrations.

³ If any liquids are spilled on or into the unit, turn off the power

immediately and let the unit dry completely.

Use of controls, adjustments, and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

WARNING

Variable Attenuator 67

Page 74

Maintenance

Cleaning Fixed Connectors

Cleaning Fixed Connectors

Regular cleaning of connectors will help maintain optimum performance.

Do not try to disassemble the unit. Doing so would break the connector.

To clean fixed connectors:

1. Fold a lint-free wiping cloth in four to form a square.

2. Moisten the center of the lint-free wiping cloth with only one drop of

isopropyl alcohol.

Alcohol may leave traces if used abundantly. Avoid contact between

the tip of the bottle and the wiping cloth, and do not use bottles

that distribute too much alcohol at a time.

3. Gently wipe the connector threads three times with the folded and

moistened section of the wiping cloth.

IMPORTANT

IMPORTANT

Isopropyl alcohol takes approximately ten seconds to evaporate.

Since isopropyl alcohol is not absolutely pure, evaporation will

leave microscopic residue. Make sure you dry the surfaces before

evaporation occurs.

4. With a dry lint-free wiping cloth, gently wipe the same surfaces three

times with a rotating movement.

5. Throw out the wiping cloths after one use.

68 IQS-3150

Page 75

Maintenance

Cleaning Fixed Connectors

6. Moisten a cleaning tip (2.5 mm tip) with only one drop of isopropyl

alcohol.

IMPORTANT

Alcohol may leave traces if used abundantly. Avoid contact between

the tip of the bottle and the cleaning tip, and do not use bottles

that distribute too much alcohol at a time.

7. Slowly insert the cleaning tip into the connector until it reaches the

ferrule inside (a slow clockwise rotating movement may help).

7

8

9

8. Gently turn the cleaning tip one full turn.

9. Continue to turn as you withdraw the cleaning tip.

10. Repeat steps 7 to 9, but this time with a dry cleaning tip (2.5 mm tip

provided by EXFO).

Note: Make sure you don’t touch the soft end of the cleaning tip and verify the

cleanliness of the cotton tip.

11. Throw out the cleaning tips after one use.

Variable Attenuator 69

Page 76

Maintenance

Cleaning EUI Connectors

Cleaning EUI Connectors

Regular cleaning of EUI connectors will help maintain optimum

performance. There is no need to disassemble the unit.

If any damage occurs to internal connectors, the module casing will

have to be opened and a new calibration will be required.

To clean EUI connectors:

1. Remove the EUI from the instrument to expose the connector

baseplate and ferrule.

IMPORTANT

Turn

Push

2. Moisten a 2.5 mm cleaning tip with one drop of isopropyl alcohol

(alcohol may leave traces if used abundantly).

3. Slowly insert the cleaning tip into the EUI adapter until it comes out on

the other side (a slow clockwise rotating movement may help).

Pull

3

4

5

4. Gently turn the cleaning tip one full turn, then continue to turn as you

withdraw it.

70 IQS-3150

Page 77

Cleaning EUI Connectors

5. Repeat steps 3 to 4 with a dry cleaning tip.

Note: Make sure you don’t touch the soft end of the cleaning tip.

6. Clean the ferrule in the connector port as follows:

6a. Deposit one drop of isopropyl alcohol on a lint-free wiping cloth.

IMPORTANT

Isopropyl alcohol may leave residues if used abundantly or left to

evaporate (about 10 seconds).

Avoid contact between the tip of the bottle and the wiping cloth,

and dry the surface quickly.

6b. Gently wipe the connector and ferrule.

6c. With a dry lint-free wiping cloth, gently wipe the same surfaces to

ensure that the connector and ferrule are perfectly dry.

6d. Verify connector surface with a portable fiber-optic microscope

(for example, EXFO’s FOMS) or inspection probe (for

example, EXFO’s FIP).

Maintenance

WARNING

Verifying the surface of the connector WHILE THE UNIT IS ACTIVE

WILL result in permanent eye damage.

7. Put the EUI back onto the instrument (push and turn clockwise).

8. Throw out cleaning tips and wiping cloths after one use.

Variable Attenuator 71

Page 78

Maintenance

Cleaning Detector Ports

Cleaning Detector Ports

Regular cleaning of detectors will help maintain measurement accuracy.

Always cover detectors with protective caps when unit is not in use.

To clean detector ports:

1. Remove the protective cap and adapter (FOA) from the detector.

2. If the detector is dusty, blow dry with compressed air.

3. Being careful not to touch the soft end of the swab, moisten a cleaning

tip with only one drop of isopropyl alcohol.

Alcohol may leave traces if used abundantly. Do not use bottles that

distribute too much alcohol at a time.

IMPORTANT

IMPORTANT

4. While applying light pressure (to avoid breaking the detector window),

gently rotate the cleaning tip on the detector window.

5. Repeat step 4 with a dry cleaning tip or blow dry with compressed air.

6. Discard the cleaning tips after one use.

72 IQS-3150

Page 79

Maintenance

Homing the Variable Attenuator (User Calibration)

Homing the Variable Attenuator (User

Calibration)

The variable attenuator contains mechanical elements used to change

attenuation or output power (self-adjusting modules) levels. It is a good

practice to have the instrument mechanism return to the zero (home)

position to reestablish its relative position on the range of attenuation or

output power levels.

EXFO recommends that you perform the homing procedure when the

homing icon appears on the data display.

To home the attenuator:

1. On the Settings function tab, click the Attenuator tab.

2. Click the User Calibration button.

The attenuator mechanism is moved to the zero (home) position.

Variable Attenuator 73

Page 80

Maintenance

Recalibrating the Unit

Recalibrating the Unit

Manufacturing and service center calibrations are based on the

ISO/IEC 17025 Standard, which states that calibration documents must not

contain a recommended calibration interval, unless this has been

previously agreed upon with the customer.

Validity of specifications depends on operating conditions. For example,

the calibration validity period can be longer or shorter depending on the

intensity of use, environmental conditions and unit maintenance. You

should determine the adequate calibration interval for your unit according

to your accuracy requirements.

Under normal use, EXFO recommends calibrating your unit every year.

74 IQS-3150

Page 81

Maintenance

Recycling and Disposal (Applies to European Union Only)

Recycling and Disposal

(Applies to European Union Only)

Recycle or dispose of your product (including electric and

electronic accessories) properly, in accordance with local

regulations. Do not dispose of it in ordinary garbage receptacles.

This equipment was sold after August 13, 2005 (as identified by

the black rectangle).

³ Unless otherwise noted in a separate agreement between EXFO and a

customer, distributor or commercial partner, EXFO will cover costs

related to the collection, treatment, recovery and disposal of

end-of-lifecycle waste generated by electronic equipment introduced

after August 13, 2005 to an European Union member state with

legislation regarding Directive 2002/96/EC.

³ Except for reasons of safety or environmental benefit, equipment

manufactured by EXFO, under its brand name, is generally designed to

facilitate dismantling and reclamation.

For complete recycling/disposal procedures and contact information, visit

the EXFO Web site at www.exfo.com/recycle.

Variable Attenuator 75

Page 82

Page 83

9 Troubleshooting

Viewing Online Documentation

An online version of the IQS-3150 Variable Attenuator user guide is

conveniently available at all times from the application.

To access the online user guide:

Click Help in the function bar.

Finding Information on the EXFO Web Site

The EXFO Web site provides answers to frequently asked questions (FAQs)

regarding the use of your IQS-3150 Variable Attenuator.

To a c c e ss F A Qs :

1. Ty pe http://www.exfo.com in your Internet browser.

2. Click the Support tab.

3. Click FAQs and follow the on-screen instructions. You will be given a

list of questions pertaining to your subject.

The EXFO Web site also provides the product’s most recent technical

specifications.

Variable Attenuator 77

Page 84

Troubleshooting

Contacting the Technical Support Group

Contacting the Technical Support Group

To obtain after-sales service or technical support for this product, contact

EXFO at one of the following numbers. The Technical Support Group is

available to take your calls from Monday to Friday, 8:00 a.m. to 7:00 p.m.

(Eastern Time in North America).

For detailed information about technical support, visit the EXFO Web site at

www.exfo.com.

Technical Support Group

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

To accelerate the process, please have information such as the name and

the serial number (see the product identification label—an example is

shown below), as well as a description of your problem, close at hand.

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

support@exfo.com

P/N

**************** A

542392-3D

S/N

Made in Canada QST442B

January 2020

Ver.

Mfg.

date

465 Godin Avenue

Vanier (Quebec) G1M 3G7 CANADA

IQS-3150-X XX

Option

Connector code

78 IQS-3150

Page 85

Troubleshooting

Contacting the Technical Support Group

You may also be requested to provide software and module version

numbers. This information, as well as technical support contact

information, can be found in the About function tab.

³ Select the Technical Support tab to view phone numbers and active

Internet links to EXFO’s Technical Support Group. Use these links to

send an information request by email or to access EXFO’s web site.

³ Select the Module Information tab to view the module identification,

serial number and firmware version.

Variable Attenuator 79

Page 86

Troubleshooting

Transportation

Transportation

Maintain a temperature range within specifications when transporting the

unit. Transportation damage can occur from improper handling. The

following steps are recommended to minimize the possibility of damage:

³ Pack the unit in its original packing material when shipping.

³ Avoid high humidity or large temperature fluctuations.

³ Keep the unit out of direct sunlight.

³ Avoid unnecessary shocks and vibrations.

80 IQS-3150

Page 87

10 Warranty

General Information

EXFO Electro-Optical Engineering Inc. (EXFO) warrants this equipment

against defects in material and workmanship for a period of two years from

the date of original shipment. EXFO also warrants that this equipment will

meet applicable specifications under normal use.

During the warranty period, EXFO will, at its discretion, repair, replace,

or issue credit for any defective product, as well as verify and adjust the

product free of charge should the equipment need to be repaired or if the

original calibration is erroneous. If the equipment is sent back for

verification of calibration during the warranty period and found to meet all

published specifications, EXFO will charge standard calibration fees.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED,

IMPLIED, OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL EXFO BE LIABLE FOR

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

Liability

EXFO shall not be liable for damages resulting from the use of the product,

nor shall be responsible for any failure in the performance of other items to

which the product is connected or the operation of any system of which

the product may be a part.

EXFO shall not be liable for damages resulting from improper usage or

unauthorized modification of the product, its accompanying accessories

and software.

Variable Attenuator 81

Page 88

Warranty

Exclusions

Exclusions

EXFO reserves the right to make changes in the design or construction of

any of its products at any time without incurring obligation to make any

changes whatsoever on units purchased. Accessories, including but not

limited to fuses, pilot lamps, batteries and universal interfaces (EUI) used

with EXFO products are not covered by this warranty.

This warranty excludes failure resulting from: improper use or installation,

normal wear and tear, accident, abuse, neglect, fire, water, lightning or

other acts of nature, causes external to the product or other factors beyond

EXFO’s control.

Certification

EXFO certifies that this equipment met its published specifications at the

time of shipment from the factory.

82 IQS-3150

Page 89

Warranty

Service and Repairs

Service and Repairs

EXFO commits to providing product service and repair for five years

following the date of purchase.

To send any equipment for service or repair:

1. Call one of EXFO’s authorized service centers (see EXFO Service

Centers Worldwide on page 84). Support personnel will determine if

the equipment requires service, repair, or calibration.

2. If equipment must be returned to EXFO or an authorized service

center, support personnel will issue a Return Merchandise

Authorization (RMA) number and provide an address for return.

3. If possible, back up your data before sending the unit for repair.

4. Pack the equipment in its original shipping material. Be sure to include

a statement or report fully detailing the defect and the conditions under

which it was observed.

5. Return the equipment, prepaid, to the address given to you by support

personnel. Be sure to write the RMA number on the shipping slip. EXFO

will refuse and return any package that does not bear an RMAnumber.

Note: A test setup fee will apply to any returned unit that, after test, is found to

meet the applicable specifications.

After repair, the equipment will be returned with a repair report. If the

equipment is not under warranty, you will be invoiced for the cost

appearing on this report. EXFO will pay return-to-customer shipping costs

for equipment under warranty. Shipping insurance is at your expense.

Routine recalibration is not included in any of the warranty plans. Since

calibrations/verifications are not covered by the basic or extended

warranties, you may elect to purchase FlexCare Calibration/Verification

Packages for a definite period of time. Contact an authorized service center

(see EXFO Service Centers Worldwide on page 84).

Variable Attenuator 83

Page 90