Page 1

IQS-1600

High Speed Power Meter for IQS Platforms

User Guide

Page 2

Copyright © 2002–2008 EXFO Electro-Optical Engineering Inc. All rights

reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted in any form, be it electronically,

mechanically, or by any other means such as photocopying, recording or

otherwise, without the prior written permission of EXFO Electro-Optical

Engineering Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Version number:

ii IQS-1600

2.0.2

Page 3

Contents

Contents

Certification Information ....................................................................................................... vi

1 Introducing the IQS-1600 High Speed Power Meter .................................. 1

Main Features .........................................................................................................................1

Typical Applications ................................................................................................................4

Conventions ............................................................................................................................5

2 Safety Information ....................................................................................... 7

3 Getting Started with Your High Speed Power Meter ................................. 9

Inserting and Removing Test Modules ....................................................................................9

Starting the High Speed Power Meter Application ................................................................14

Entering Values Using Sliders and Numeric Boxes .................................................................17

Exiting the Application .........................................................................................................18

4 Setting Up Your High Speed Power Meter ................................................ 19

Setting Channel Display(IQS-1620, IQS-1640) .......................................................................20

Selecting the Wavelength .....................................................................................................26

Managing Wavelength Lists ..................................................................................................27

Selecting the Measurement Unit ...........................................................................................28

Setting the Display Resolution ..............................................................................................29

Setting the Refresh Rate .......................................................................................................31

Setting the Measurement Range ..........................................................................................32

Saving and Recalling Configurations .....................................................................................35

5 Preparing Your High Speed Power Meter for a Test ................................. 37

Cleaning and Connecting Optical Fibers ...............................................................................37

Nulling Offsets ......................................................................................................................38

6 Measuring Power ....................................................................................... 41

Displaying Absolute Power ...................................................................................................41

Measuring Relative Power .....................................................................................................43

Selecting the Reference Value ...............................................................................................44

Editing the Reference List .....................................................................................................45

Measuring Corrected Power ..................................................................................................46

Using the Offset Function .....................................................................................................48

Averaging Measurements ....................................................................................................49

7 Recording Power Signal Variations ........................................................... 51

High Speed Power Meter iii

Page 4

Contents

8 Performing Acquisitions .............................................................................55

Selecting the Sampling Type .................................................................................................56

Selecting the Acquisition Mode ............................................................................................59

Starting the Acquisition ........................................................................................................66

Consulting Acquired Data .....................................................................................................68

9 Performing and Analyzing Graph Acquisitions .........................................73

Setting Up Graph Parameters ...............................................................................................73

Printing Graph Results ..........................................................................................................76

Clearing Graph Display .........................................................................................................76

Using the Zoom Function .....................................................................................................77

Displaying and Moving Markers ...........................................................................................79

10 Using the External Trigger and Analog Outputs .......................................81

External Trigger .....................................................................................................................82

Analog Output (IQS-1610, IQS-1620) ...................................................................................83

11 Monitoring Power Meter Modules ............................................................87

Using Monitor Windows .......................................................................................................87

Using QuickTools ...................................................................................................................90

12 Typical Applications ....................................................................................93

Performing Absolute Power Measurements ..........................................................................94

Measuring Insertion Loss ......................................................................................................96

Testing Instrument Linearity ..................................................................................................98

Characterizing an Optical Switch ........................................................................................100

13 Maintenance ..............................................................................................103

Cleaning Fixed Connectors ..................................................................................................104

Cleaning Detector Ports ......................................................................................................106

Cleaning the Analog Output and External Trigger Ports ......................................................107

Recalibrating the Unit .........................................................................................................107

Recycling and Disposal (Applies to European Union Only) ..................................................108

14 Troubleshooting ........................................................................................109

Solving Common Problems .................................................................................................109

Viewing Online Documentation ..........................................................................................111

Finding Information on the EXFO Web Site ........................................................................112

Contacting the Technical Support Group ............................................................................113

Transportation ....................................................................................................................114

iv IQS-1600

Page 5

Contents

15 Warranty ................................................................................................... 115

General Information ...........................................................................................................115

Liability ...............................................................................................................................115

Exclusions ...........................................................................................................................116

Certification ........................................................................................................................116

Service and Repairs .............................................................................................................117

EXFO Service Centers Worldwide ........................................................................................118

A Technical Specifications ........................................................................... 119

B SCPI Command Reference ....................................................................... 121

Quick Reference Command Tree .........................................................................................122

Product-Specific Commands—Description ..........................................................................126

Index .............................................................................................................. 225

High Speed Power Meter v

Page 6

Certification Information

Certification Information

F.C.C. Information

Electronic test equipment is exempt from Part 15 compliance (FCC) in

the United States. However, compliance verification tests are

systematically performed on most EXFO equipment.

Information

Electronic test equipment is subject to the EMC Directive in the European

Union. The EN61326 standard prescribes both emission and immunity

requirements for laboratory, measurement, and control equipment.

This unit has undergone extensive testing according to the European Union

Directive and Standards.

Use of shielded remote I/O cables, with properly grounded shields

and metal connectors, is recommended in order to reduce radio

frequency interference that may emanate from these cables.

IMPORTANT

vi IQS-1600

Page 7

Certification Information

Application of Council Directive(s): 73/23/EEC - The Low Voltage Directive

Manufacturer’s Name: EXFO Electro-Optical Engineering Inc.

Manufacturer’s Address: 400 Godin Avenue

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: IQS-1600

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Safety Requirements for Electrical Equipment for Measurement, Control,

EN 55022: 1998 +A2: 2003 Limits and Methods of Measurement of Radio Disturbance

EN 61326:1997 +A1:1998

+A2:2001 + A3:2003

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

and Laboratory Use, Part 1: General Requirements.

Characteristics of Information Technology Equipment.

Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements

DECLARATION OF CONFORMITY

89/336/EEC - The EMC Directive

And their amendments

Quebec, Quebec

Canada G1M 2K2

(418) 683-0211

High-Speed Power Meter

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Address:

Date: January 7, 2002

Development

400 Godin Avenue, Quebec (Quebec),

Canada, G1M 2K2

High Speed Power Meter vii

Page 8

Page 9

1 Introducing the IQS-1600 High

Speed Power Meter

Designed for the IQS platforms, the IQS-1600 High Speed Power Meter is a

module available in three different models. It is used with the OHS-1700

Optical Head.

Main Features

The IQS-1600 High Speed Power Meter is offered in different

configurations:

³ Standard option—IQS-1600 Series

³ Low-PDL option—IQS-1600-PL Series

³ Wide-Area Detector (3 mm) option—IQS-1600W Series

All configurations come in the single-, dual- or quadruple-connector

models.

High Speed Power Meter 1

Page 10

Introducing the IQS-1600 High Speed Power Meter

Main Features

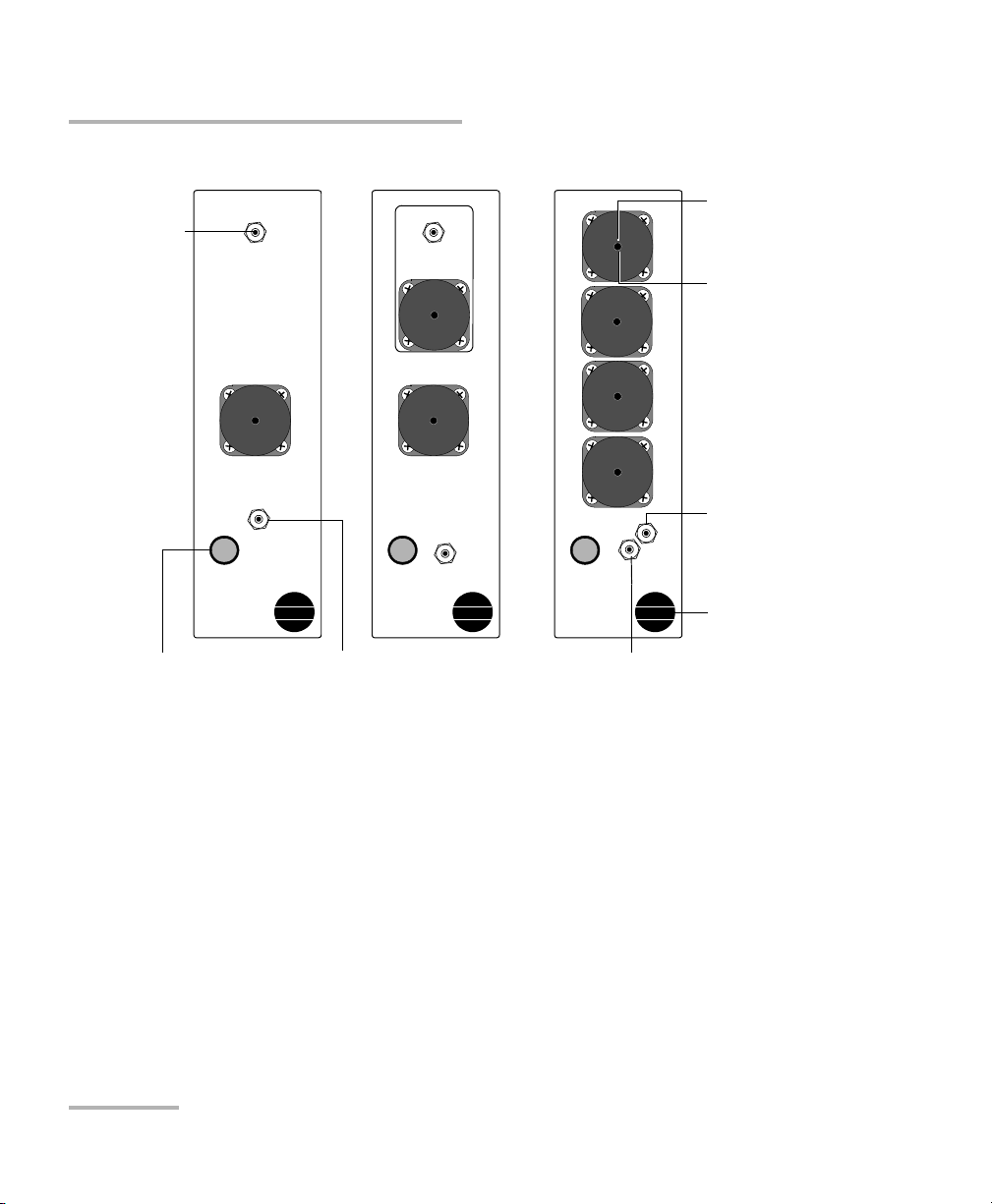

IQS-1610 IQS-1620 IQS-1640

Analog

output

port

ANALOG OUT

EXT.

TRIG

IQS-1600

Power Meter

ANALOG OUT

C1

C2

IQS-1600

2-Ch Power Meter

EXT.

TRIG

C1

C2

C3

C4

IQS-1600

4-Ch Power Meter

C

F

-

T

T

N

E

X

F

O

adapter

Optical

detector port

External trigger

Fiber-optic

port (SMB

Sync

connector)

Out

Sync In

Trig

Retaining

screw knob

LED push

button

External trigger port

(SMB connector)

External connector (used only

with the IQS-12004B system)

It features a high sampling rate and fast stabilization, and comes in one-,

two- or four-channel options (each detector is independent). It also

provides you with power level and TTL voltage synchronization triggers.

The synchronization triggers will operate simultaneously on dual- and

quadruple-channel models.

The graphical display mode shows all channels on a real-time graph,

which you can analyze afterwards.

The IQS-1600 High Speed Power Meter supports local control (via the

IQS Manager software) and remote control (through GPIB, RS-232, or

Ethernet TCP/IP using SCPI commands or the provided LabVIEW drivers).

For more information, refer to the IQS platform user guide.

2 IQS-1600

Page 11

Introducing the IQS-1600 High Speed Power Meter

Main Features

Moreover, a special model was designed for the IQS-12004B DWDM

Passive Component Test System The IQS-1643T-PL-SN presents

specifications that are very close to the IQS-1643-PL-SN standalone

module.

Every customer purchasing the IQS-12004B system for applications

covering both the C- and L-bands will receive an IQS-1643T-PL-SN. Even

though the power meter has been modified to work in the IQS-12004B

system, it can still be used as a standalone unit using an IQS-500 Intelligent

Test System.

Both the facia of the module and the title bar in the software reflect

whether you are using an IQS-1643T-PL-SN or a standard IQS-1643-PL-SN.

Note: The instrument is only guaranteed within the IQS-12004B operating

temperature range of 23

o

C ±3 oC. Any other functionality or specification,

particularly those concerning the accuracy and linearity of the instrument,

will not be affected by the design change to the IQS-1600T-PL-SN.

High Speed Power Meter 3

Page 12

Introducing the IQS-1600 High Speed Power Meter

Typic a l A pp l icatio n s

Typical Applications

Your power meter is suitable for numerous applications, including the

following:

³ Insertion loss of passive components in the production environment

³ Component and system monitoring

³ Source stability characterization

³ Absolute power measurements

³ Manual or automated splice loss measurement

³ Characterization of MUX/DEMUX, used in conjuction with a tunable

laser source, or within the IQS-12004B DWDM Passive Component Test

System

³ Optical switch characterization (switching time, insertion loss)

³ Measurement on bare or unconnectorized fibers

4 IQS-1600

Page 13

Introducing the IQS-1600 High Speed Power Meter

Conventions

Conventions

Before using the product described in this manual, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

High Speed Power Meter 5

Page 14

Page 15

2 Safety Information

Your power meter does not contain laser components in itself. However,

you will be using it with light sources.

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

Use of controls, adjustments and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

High Speed Power Meter 7

Page 16

Page 17

3 Getting Started with Your

High Speed Power Meter

This chapter contains information on how to insert and remove test

modules. You will also find how to connect your optical head to your

power meter and how to start and exit the application.

Inserting and Removing Test Modules

CAUTION

Never insert or remove a module while the controller unit and its

expansion units are turned on. This will result in immediate and

irreparable damage to both the module and unit.

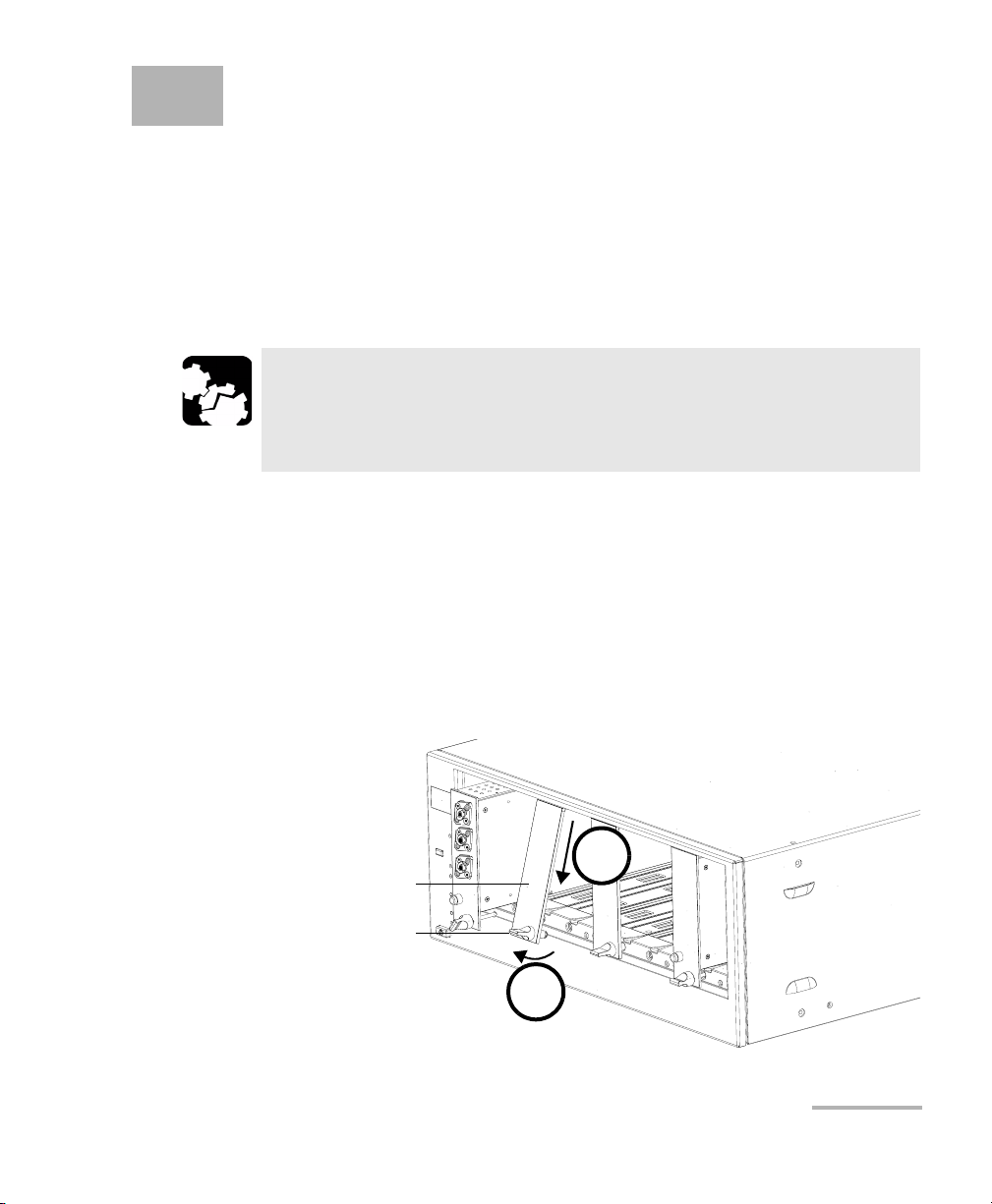

To insert a module into the controller or expansion unit:

1. Exit IQS Manager and turn off all your units.

2. Remove the protective cover from the desired unused module slot.

2a. Pull the retaining screw knob firmly towards you and release the

bottom of the cover.

2b. Gently pull the top of the protective cover downwards, to remove

it from the unit grooves.

2b

Protective cover

Retaining screw

knob

2a

High Speed Power Meter 9

Page 18

Getting Started with Your High Speed Power Meter

Inserting and Removing Test Modules

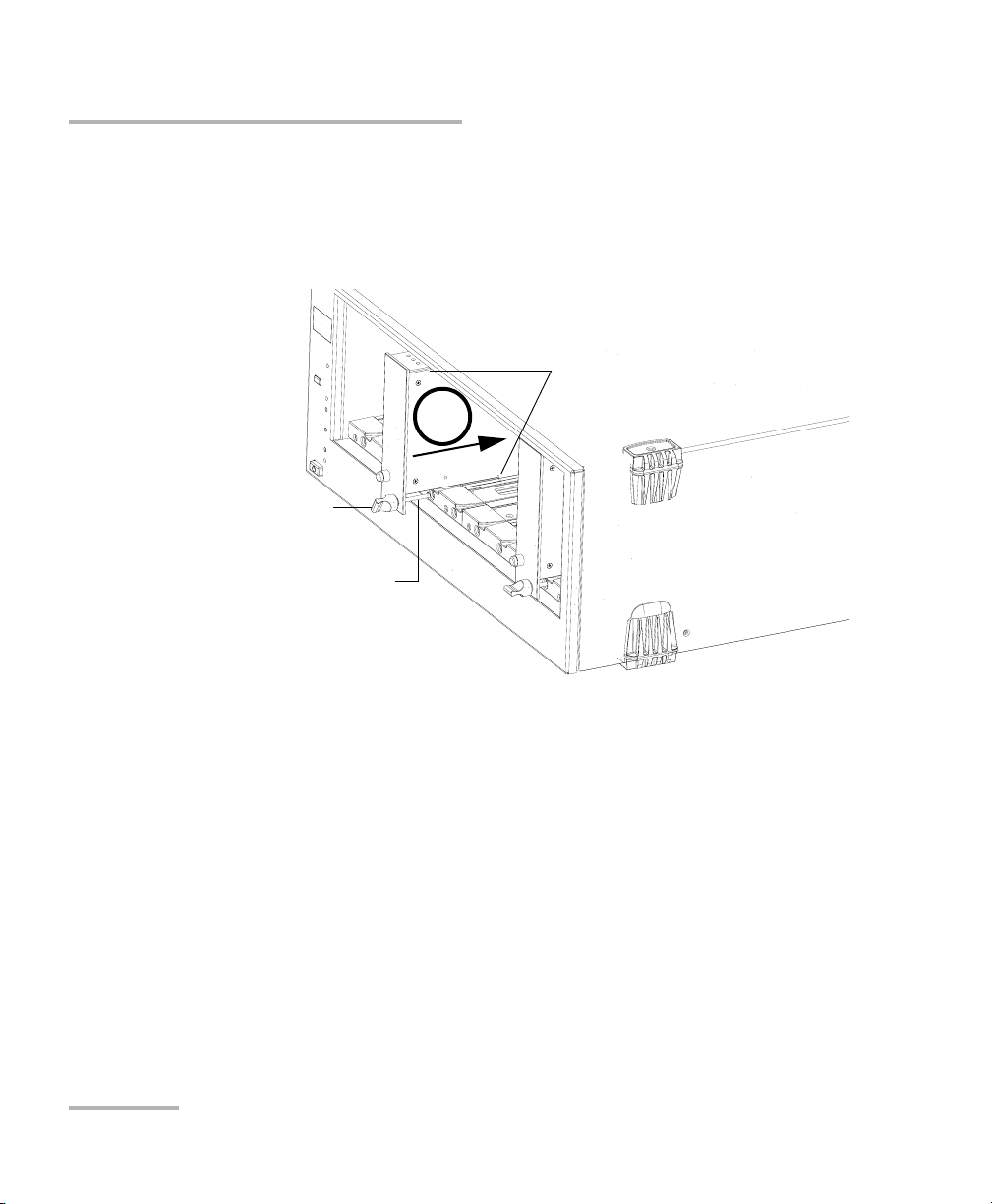

3. Position the module so that its front panel is facing you and the top and

bottom protruding edges are to your right.

4. Insert the protruding edges of the module into the grooves of the unit’s

module slot.

Protruding edges

(right side of module)

5

Retaining screw knob

Retaining screw

5. Push the module all the way to the back of the slot, until the retaining

screw makes contact with the unit casing.

6. While applying slight pressure to the module, turn the retaining screw

knob (located at the bottom of the panel) clockwise until the knob is

horizontal.

This will secure the module into its “seated” position.

10 IQS-1600

Page 19

Getting Started with Your High Speed Power Meter

Inserting and Removing Test Modules

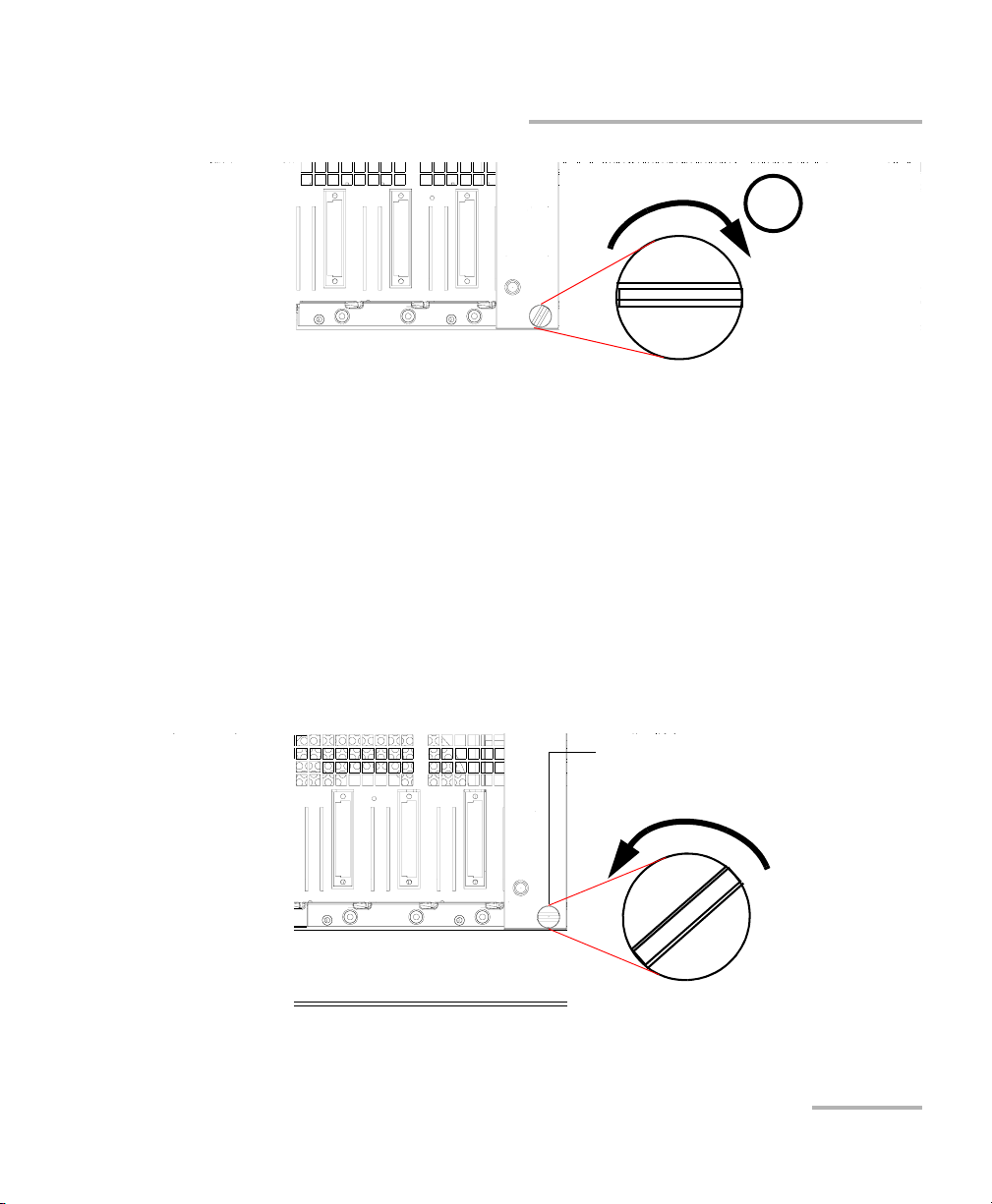

6

The module is correctly inserted when its front panel is flush with the front

panel of the controller or expansion unit.

When you turn on the controller unit, the startup sequence will

automatically detect your module.

Note: You can insert IQ modules into your controller or expansion unit; the

IQS Manager software will recognize them. However, the IQS-1600 locking

mechanism (retaining screw) will not work for IQ modules.

To remove a module from your controller or expansion unit:

1. While pulling gently on the knob, turn it counterclockwise until it stops.

The module will slowly be released from the slot.

Retaining screw knob

High Speed Power Meter 11

Page 20

Getting Started with Your High Speed Power Meter

Inserting and Removing Test Modules

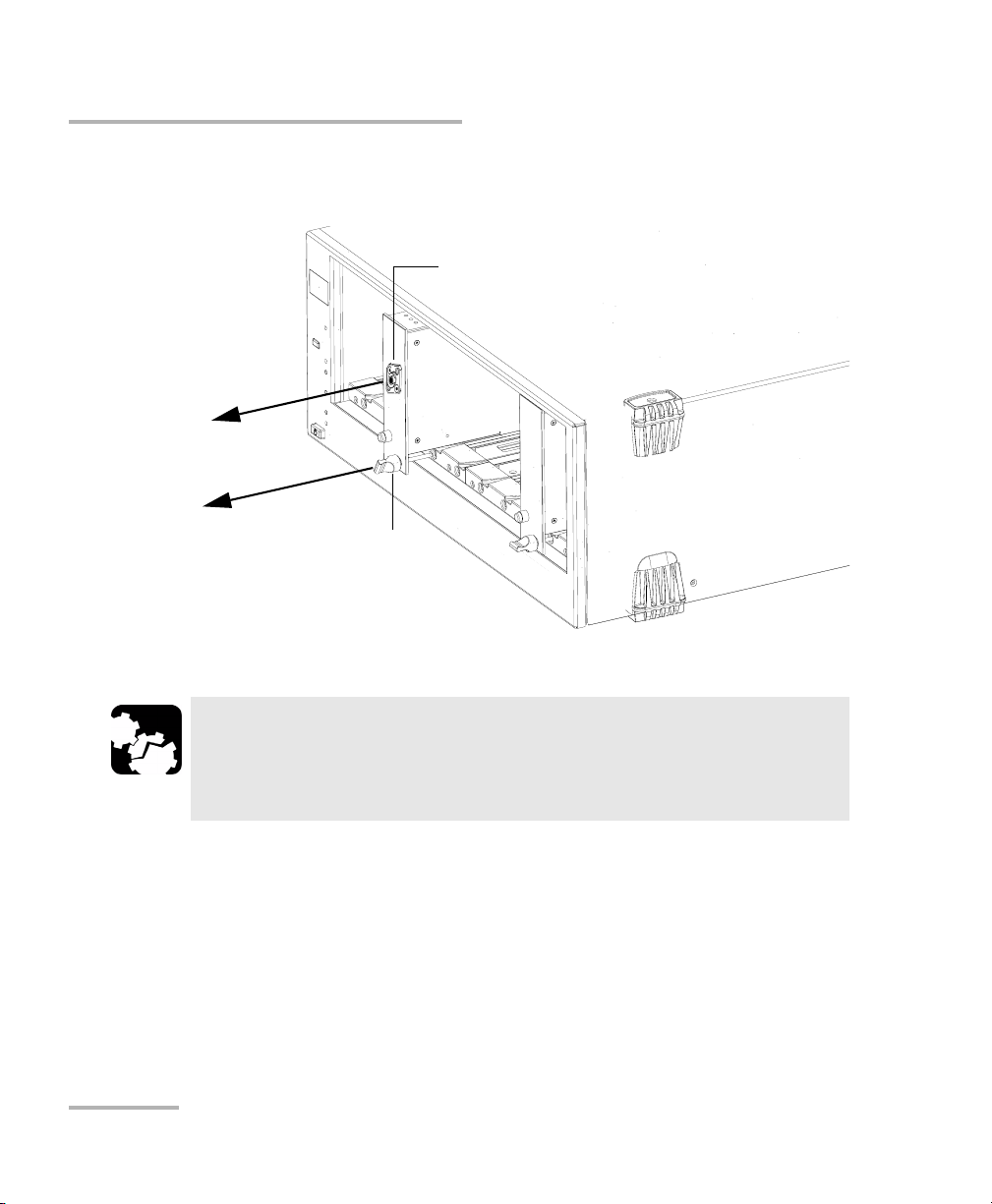

2. Place your fingers underneath the module or hold it by the retaining

screw knob (NOT by the connector) and pull it out.

Connector

NO

YES

Retaining screw

knob

CAUTION

Pulling out a module by a connector could seriously damage both

the module and connector. Always pull out a module by the

retaining screw knob.

3. Cover empty slots with the supplied protective covers.

3a. Slide the top of the protective cover into the upper grooves of the

unit.

3b. Snap the cover into place by pushing the retaining screw knob.

12 IQS-1600

Page 21

Getting Started with Your High Speed Power Meter

Inserting and Removing Test Modules

CAUTION

Failure to reinstall protective covers over empty slots will result in

ventilation problems.

High Speed Power Meter 13

Page 22

Getting Started with Your High Speed Power Meter

Starting the High Speed Power Meter Application

Starting the High Speed Power Meter

Application

Your IQS-1600 High Speed Power Meter module can be configured and

controlled from its dedicated IQS Manager application.

Note: For details about IQS Manager, refer to the IQS platform user guide.

To start the application:

1. From the Current Modules function tab select the module to use.

It will turn white to indicate that it is highlighted.

2. Click Start Application.

OR

Press the green LED push button on the front of the corresponding

module.

You can also double-click its row.

Note: Pressing the LED push button will not activate or turn on the module.

Note: To start the corresponding monitor window at the same time, click Start

App. & Monitor. The window opens on the Monitors function tab.

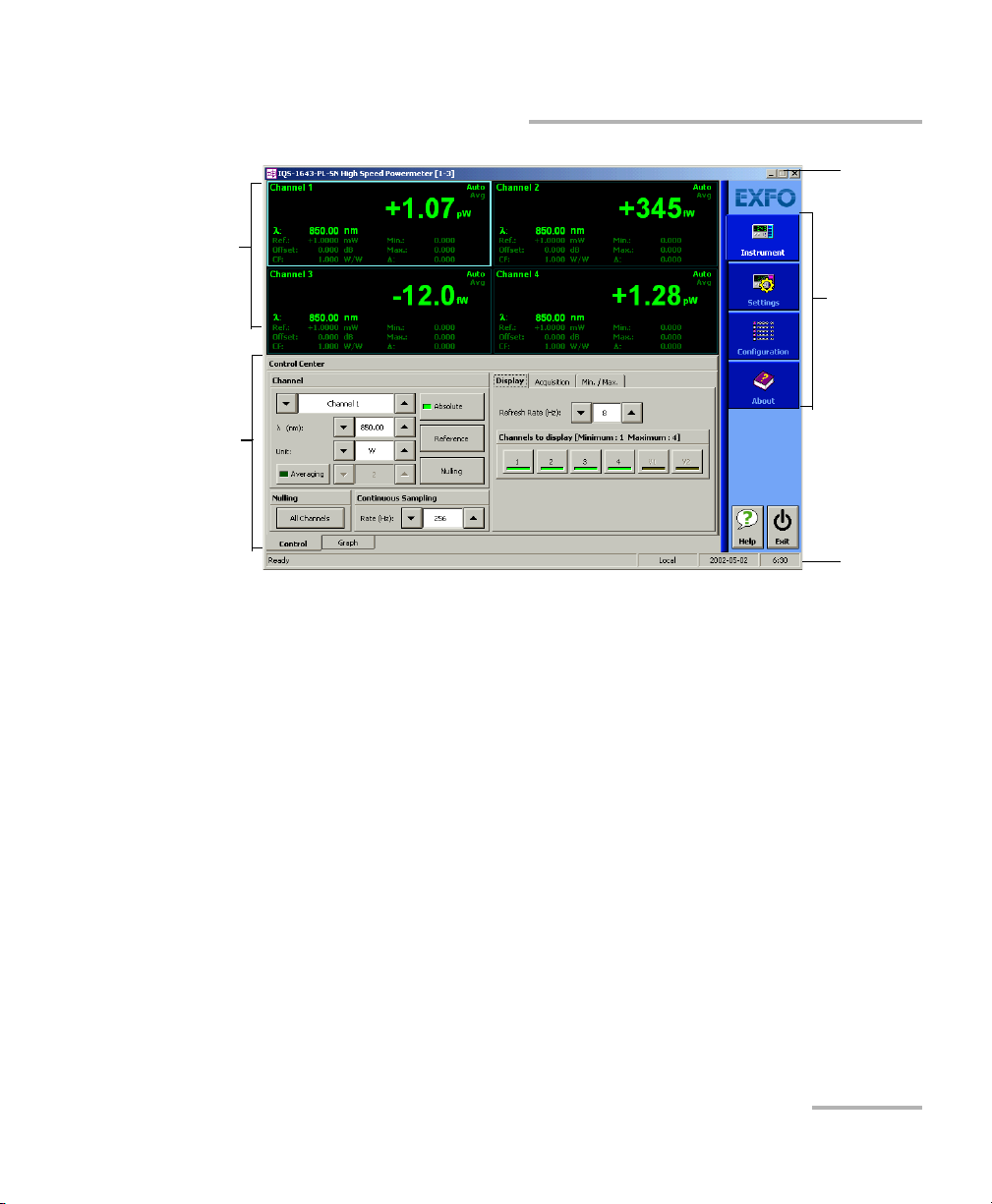

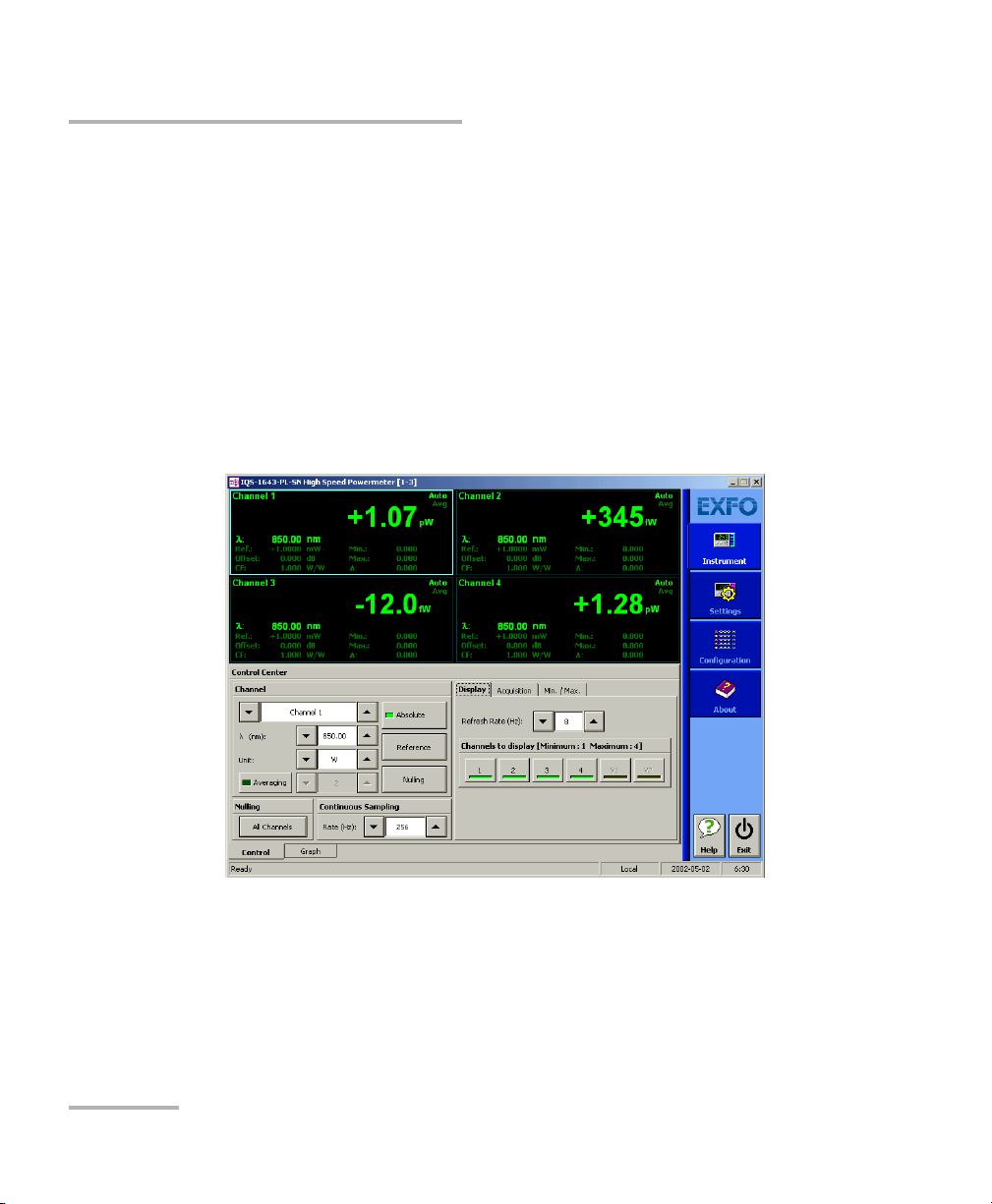

The main window (shown below) contains all the commands required to

control the High Speed Power Meter:

14 IQS-1600

Page 23

Data

display

Parameter

definition

controls

Getting Started with Your High Speed Power Meter

Starting the High Speed Power Meter Application

Title bar

Function

buttons

Status bar

High Speed Power Meter 15

Page 24

Getting Started with Your High Speed Power Meter

Starting the High Speed Power Meter Application

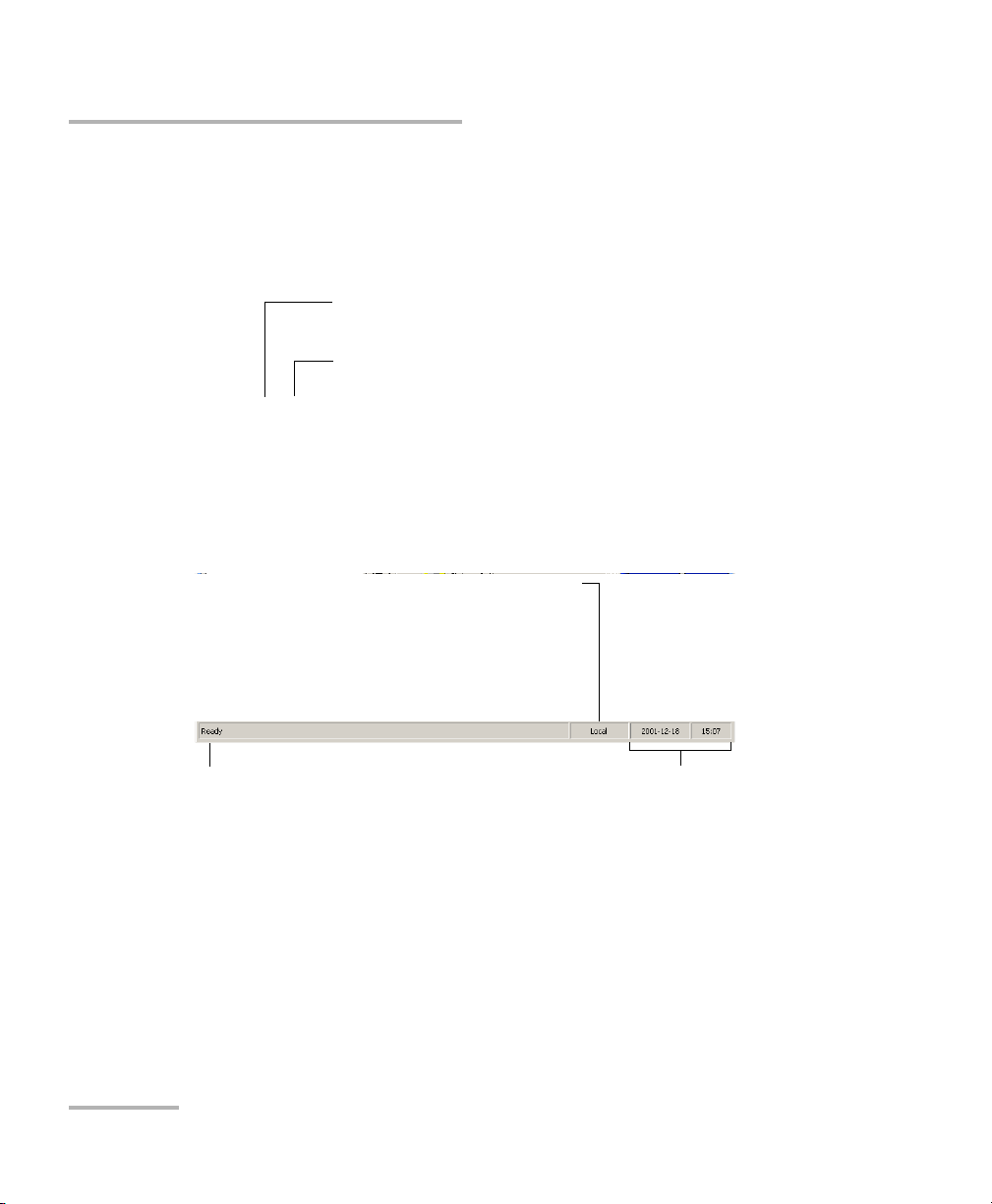

Title Bar

The title bar is located at the top of the main window. It displays the

module name and its position in the controller or expansion unit. The

module position is identified as follows:

Controller unit or expansion unit (1 to 999) housing

the module

Slot number in which module is inserted

(0 identifies first slot)

[ 999 – 1 ]

Status Bar

The status bar, located at the bottom of the main window, identifies the

operational status of the IQS-1600 High Speed Power Meter.

Control mode

Local: Module controlled locally only.

Remote: Module controlled remotely, but

local commands can also be used.

Lockout: Module controlled remotely only.

Current date and timeModule/unit status

For more information about automating or remotely controlling the

IQS-1600 High Speed Power Meter, refer to your platform user guide.

16 IQS-1600

Page 25

Getting Started with Your High Speed Power Meter

Entering Values Using Sliders and Numeric Boxes

Entering Values Using Sliders and Numeric

Boxes

Many parameters in IQS Manager and module applications can be set

using the following tools.

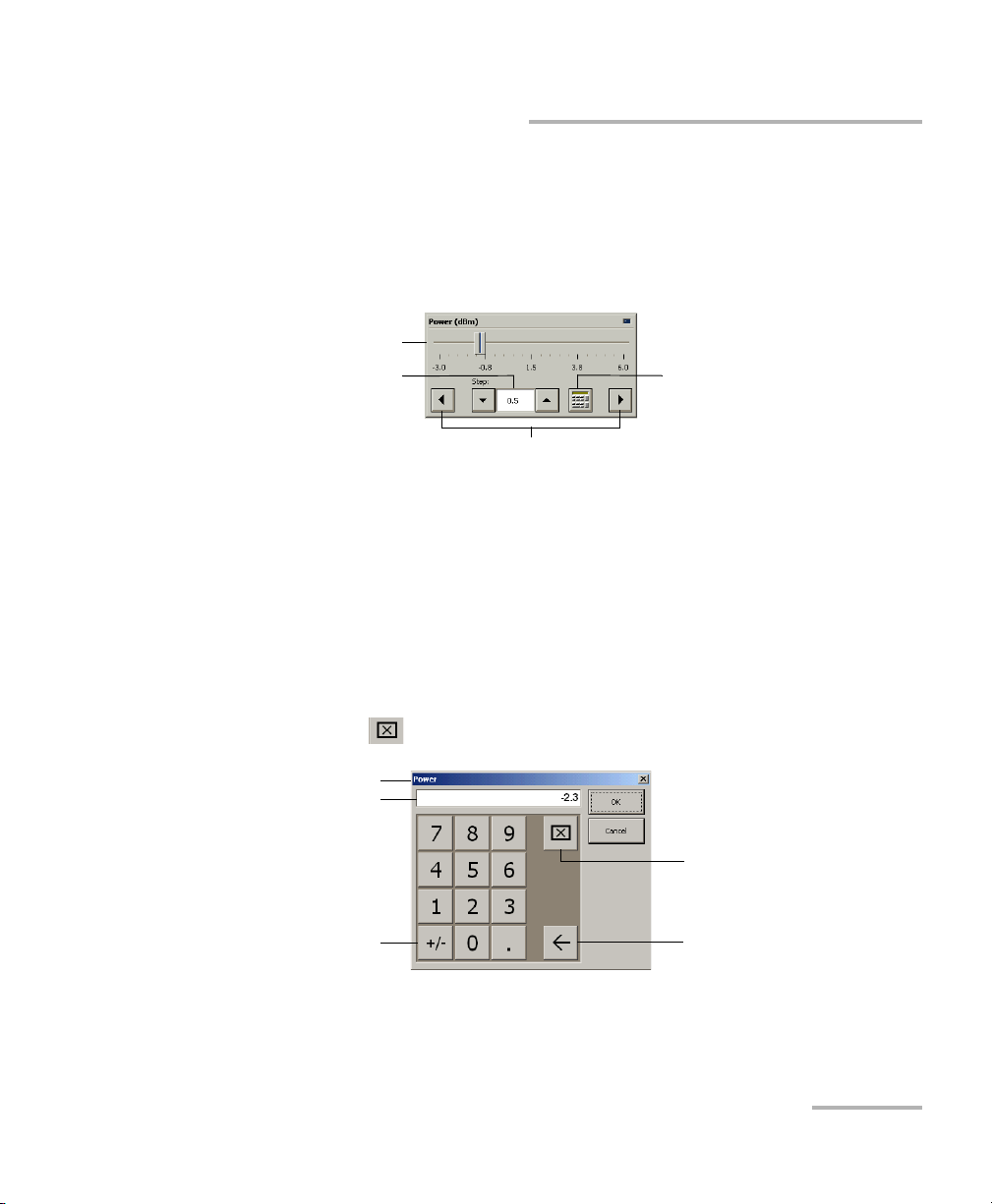

Slider

Fine-tuning

box

Navigation buttons

³ Slider: Drag it to the desired value on the scale below.

³ Navigation buttons: Click either buttons to move the slider. The slider

moves by steps corresponding to the number in the fine-tuning box,

which you can change by using the up and down arrow buttons next to

the box. You cannot change the list of fine-tuning values from here.

³ Numeric box: Click it to display the on-screen numeric pad, which you

can use to enter a powe value.

Numeric box

button

To enter a value using the numeric box:

1. Use the button to clear the entry display.

Parameter identification

Entry display

Clear button

Toggle button

Backspace button

(to correct a value)

2. Enter the value.

3. Click OK to confirm the value.

High Speed Power Meter 17

Page 26

Getting Started with Your High Speed Power Meter

Exiting the Application

Exiting the Application

Closing any application that is not currently being used is a good way to

free system memory.

To close the application from the main window:

Click in the top right corner of the main window.

OR

Click the Exit button located at the bottom of the function bar.

To close all currently running applications:

From IQS Manager, click Close All Applications.

18 IQS-1600

Page 27

4 Setting Up Your High Speed

Power Meter

You can set the following paameters on your IQS-1600:

³ Chanel display

³ Wavelength selection and management

³ Measurement unit selection

³ Display resolution

³ Refresh rate

³ Measurement range

³ Saving and recalling configuration

High Speed Power Meter 19

Page 28

Setting Up Your High Speed Power Meter

Setting Channel Display(IQS-1620, IQS-1640)

Setting Channel Display(IQS-1620, IQS-1640)

The channel display allows you to select which channels you want to view

when using a multichannel power meter. You can display up to three

optical channels using a dual-channel power meter (the two normal

channels, plus the virtual channel) and up to four optical channels using a

four-channel power meter. These channels may include one or two virtual

channels respectively.

To set the channel displayon IQS-1620 or IQS-1640 models:

1. From the Instrument function tab, click the Display tab to view the

available channels.

2. Select the desired channel.

The data display immediately reflects your selection and the selected

channel indicator will turn light green.

20 IQS-1600

Page 29

Setting Up Your High Speed Power Meter

Setting Channel Display(IQS-1620, IQS-1640)

Selecting a Channel (IQS-1620, IQS-1640)

The IQS-1620 and IQS-1640 have two and four independent optical

channels respectively.

To select an optical channel:

From the Instrument function tab, go to Channel and use the arrow

buttons next to the channel number to change it.

OR

Click the appropriate data display zone.

A colored frame will indicate your selection.

High Speed Power Meter 21

Page 30

Setting Up Your High Speed Power Meter

Setting Channel Display(IQS-1620, IQS-1640)

Selecting a Virtual Channel (IQS-1620, IQS-1640)

In addition to the optical channels, your application offers one virtual

channel for the dual-channel power meter and two virtual channels for the

quadruple-channel power meter.

A virtual channel is a combination (sum or difference when using dB or

dBm as units, product or ratio when using watts or watts/watts as units—

see the table on page 24) of the measured power from any two optical

channels. This feature provides an extremely flexible comparative

measurement display. A virtual channel is used and controlled in the same

way as an optical channel.

The virtual channel is an excellent tool for comparing two optical channels.

For example, if two devices (connected to channels 1 and 2) are supposed

to have identical power levels, displaying a virtual channel (defined as

channel 1 minus channel 2) provides quick monitoring of both devices and

indicates any power fluctuations. You may also want to reference the drift

of a source in real time by cancelling it out in a virtual channel.

22 IQS-1600

Page 31

Setting Up Your High Speed Power Meter

Setting Channel Display(IQS-1620, IQS-1640)

To define a virtual channel:

1. Click on the Settings function tab, then select the Virtual Channels

tab.

2. Click on the desired virtual channel (when using a dual-channel power

meter, only virtual channel 1 is available).

Note: If you change settings, such as the units or trigger options, in the Channels

tab, your virtual channel(s) may be deactivated. Ensure your settings are

defined before selecting one or more virtual channels.

3. Click on Active to use the channel, then enter a name for it if desired.

4. In the first box of the Operation area, select the first optical channel

using the arrow buttons.

5. In the second box, select the virtual channel operator (+, −, *, or /).

6. In the third box, select the second channel in the same way.

7. Click on Apply to set the virtual channel.

High Speed Power Meter 23

Page 32

Setting Up Your High Speed Power Meter

Setting Channel Display(IQS-1620, IQS-1640)

Since operations between channels cannot be made with any type of

measurement unit, the second channel and the operator can be selected

according to the unit of the first channel as described in the following table.

First

Channel Unit

Second

Channel Unit

Virtual Channel Unit and

Allowed Operators

dBm dBm dB (operator −)

dBm dB dBm (operators + and −)

dB dBm dBm (operator +)

dB dB dB (operators + and −)

W W W/W (operator /)

W W/W W (operators * and /)

W/W W W (operator *)

W/W W/W W/W (operators * and /)

Note: Since a virtual channel consists of a mathematical operation using two

optical channels, the only parameter that can be set for a virtual channel is

its name.

24 IQS-1600

Page 33

Setting Up Your High Speed Power Meter

Setting Channel Display(IQS-1620, IQS-1640)

Naming Channels

A user-selected name can be given to each power meter channel,

including virtual channels. The channel name appears in the main

window. Naming individual channels is particularly useful when you need

to display more than one power channel at the same time, especially in

Monitor Window mode with several optical power meters displayed

simultaneously. The name should be as self-explanatory as possible (for

example, Power-Fiber 3).

To enter a channel name:

1. Click the Settings function tab.

2. From the Channels tab, select the channel to name by clicking the

corresponding button.

3. Type in a self-explanatory name in the Name box.

4. Click Apply to confirm your new setting.

High Speed Power Meter 25

Page 34

Setting Up Your High Speed Power Meter

Selecting the Wavelength

Selecting the Wavelength

When taking accurate measurements, your power meter must be set to

the correct wavelength to compensate for the photodetector responsivity

at the incident wavelength. Ideally, the power meter’s wavelength should

be set as close as possible to that of the optical source being used.

The wavelength must be selected from the wavelength list. To set the

wavelength list, see Managing Wavelength Lists on page 27.

To select the wavelength (either from the Instrument or Settings

function tab):

1. Select the channel for which you want to set the wavelength

(if you have a multiple-channel power meter).

Wavelength field

2. Select the wavelength using the arrow buttons next to the λ list.

3. If you are in the Channels tab of the Settings function tab, click Apply

to confirm your new setting.

Note: You can also use the All Channels button to modify all channels identically.

Values previously set will turn red to indicate that the new setting differs.

26 IQS-1600

Page 35

Setting Up Your High Speed Power Meter

Managing Wavelength Lists

Managing Wavelength Lists

The wavelengths you want to use with your IQS-1600 and OHS-1700 must

be entered in the Wavelength list. Please refer to the Certificate of

Compliance supplied with your power meter for information on the

wavelength range.

To add a wavelength to the list:

1. From the Settings function tab, select the Lists tab.

In the New Value list, enter the wavelength value to be added.You can

enter a value with a 0.01 nm resolution.

2. Click to confirm the new wavelength.

Note: A warning message is displayed if the new wavelength is not within the

power meter’s wavelength range.

To delete a wavelength from the list:

1. From the Settings function tab, click the List tab.

2. From, the Wavelength list,select the wavelength to be deleted.

3. Click to confirm the operation.

Note: It is not possible to delete a wavelength that is currently being used.

High Speed Power Meter 27

Page 36

Setting Up Your High Speed Power Meter

Selecting the Measurement Unit

Selecting the Measurement Unit

Power measurements can be displayed in dB, dBm, W, or W/W (the latter

indicating the ratio between the power received and the reference for the

current wavelength and channel). When W or W/W is selected, the

software automatically selects W units (pW, nW, μW, mW), depending on

the measured power and sensitivity of the detector.

When a relative unit is selected (dB or W/W), the most recent reference

value used will become the current reference value.

To select the measurement unit (either from the Instrument or

Settings function tab):

1. Select the channel for which you want to set the measurement unit

(if you have a multiple-channel power meter).

2. Use the arrow buttons next to the Unit list to change the value.

3. click Apply to confirm your new setting.

Note: You can also use the All Channels button to modify all channels identically.

If other values were set before, but are different from those you are setting,

any value you change will turn red to indicate that it is different.

28 IQS-1600

Page 37

Setting Up Your High Speed Power Meter

Setting the Display Resolution

Setting the Display Resolution

Depending on the required resolution and operating power level, 0, 1, 2, 3,

or 4 digits can be displayed after the decimal point. When the auto setting

is selected, the display resolution is determined by the power level being

measured.

Note: The Auto marker in the data display does not refer to the automatic display

resolution but to the measurement range (see Setting the Measurement

Range on page 32).

To select the display resolution of a power measurement

expressed in dB or dBm:

1. Click the Settings function tab, then click the Channels tab.

If necessary, select the channel for which you want to set the display

resolution.

High Speed Power Meter 29

Page 38

Setting Up Your High Speed Power Meter

Setting the Display Resolution

2. Use the arrow buttons to select the value in the Display Res. list.

If you have previously selected watts as units, the Display Res. list will

be grayed out.

3. Click Apply to confirm your new setting.

Note: You can also use the All Channels button to modify all channels at once. If

other values were set previously, but are different from those you are

currently setting, any value you change will turn red to indicate that it is

different.

Note: When W or W/W is selected, the display resolution changes to Auto (the

appropriate W unit will be used according to the power of the signal

detected). It is then impossible to access the display resolution list.

30 IQS-1600

Page 39

Setting Up Your High Speed Power Meter

Setting the Refresh Rate

Setting the Refresh Rate

This function allows you to define the refresh rate of the power readings on

the display. The refresh rate is the number of times per second that a new

power measurement will be displayed on the screen. The refresh rate

applies to all channels when using a multichannel power meter.

To set the refresh rate:

1. From the Instrument tab, select the Display tab.

2. Use the arrow buttons to select the refresh rate you want to use.

Note: The refresh rate can be faster or slower than the sampling rate; however,

only a refresh rate slower than the sampling rate will have an effect.

High Speed Power Meter 31

Page 40

Setting Up Your High Speed Power Meter

Setting the Measurement Range

Setting the Measurement Range

The measurement range and gain scale applied to the power detector can

be manually selected to prevent the automatic scale adjustment

performed by the instrument. A manual adjustment of the dynamic gain

scale will lock the measurement range to a specific level.

The measuring range should be locked when the analog output is used—

seeUsing the External Trigger and Analog Outputs on page 81—in order to

avoid variations in voltage outputs due to an automatic switch of gain

scales. It is also necessary to use a manual range to achieve high-rate

acquisitions (see Performing Acquisitions on page 55).

Two manual ranges are available:

The Low range (LR1 to LR6) provides a lower dynamic range (typically

35 dB) per scale with better signal-to-noise ratio and resolution. The High

range (HR1 to HR4) provides a higher dynamic range (typically 42 dB) per

scale with a lower signal-to-noise ratio.

Each channel is adjusted independently in the case of a multichannel

power meter.

32 IQS-1600

Page 41

Setting Up Your High Speed Power Meter

Setting the Measurement Range

To set the measurement range:

1. Click the Settings function tab, then select the Channels tab.

2. If necessary, select the channel for which you want to set the range.

3. Use the arrow buttons next to the Range list to select the range you

want to use.

Note: Select Manual range for a Continuous acquisition when the input signal

has unstable or modulated variations. This prevents !!!!!!! from

appearing on the display when changing gain cales often.

High Speed Power Meter 33

Page 42

Setting Up Your High Speed Power Meter

Setting the Measurement Range

4. Use the arrow buttons next to the Scale list and highlight the scale you

wish to use.

The table on the following page displays the permitted scales when the

currently selected measurement unit is dB or dBm. The power values

displayed are typical at 1550 nm.

Permitted Scales

Low Range (LR) High Range (HR)

−3.90 to 18.30 dBm (LR1)

−12.50 to 9.90 dBm (LR2)

a

a

−32.49 to −10.09 dBm (LR3) −58.29 to −10.09 dBm (HR3)

−52.27 to −29.87 dBm (LR4) −78.00 to −29.87 dBm (HR4)

−29.60 to 18.30 dBm (HR1)

−38.20 to 9.90 dBm (HR2)

a

a

−72.01 to −49.61 dBm (LR5)

—

(−64.60 to −44.04 dBm for 16XXW models)

−90.00 to −69.61 dBm (LR6)

—

(−75.00 to −64.10 dBm for 16XXW models)

a. InGaAs detector has a +9 dBm saturation limit for a 1 mm detector, and +8 dBm

saturation limit for a 3 mm detector.

Note: You can have a high acquisition rate only if a manual range is set on all

channels.

5. Click Apply to confirm your new setting.

Note: You can also use the All Channels button to modify all channels identically.

If other values were set previously, but are different from those you are

currently setting, any value you change will turn red to indicate that it is

different.

34 IQS-1600

Page 43

Setting Up Your High Speed Power Meter

Saving and Recalling Configurations

Saving and Recalling Configurations

Once you have set the IQS-1600 High Speed Power Meter parameters, you

can save your custom configuration and recall it at any time. You can also

recall the factory-defined settings.

Saved configurations include all parameters set in the Control Center

(Instrument function tab) and in the Settings function tab (if present).

To save a configuration:

1. Select the Configuration function tab.

To always use the last saved

parameters when starting.

To save parameters being used

just before shutting down,

overwriting the previous file.

2. In the Current Module Configuration panel, enter the name you wish

to use for your configuration file.

It will be saved in

D:\IQS Manager\Configuration Files\(your_module)\.

3. Click Save.

High Speed Power Meter 35

Page 44

Setting Up Your High Speed Power Meter

Saving and Recalling Configurations

To recall a configuration:

1. Select the Configuration function tab.

2. Click Open.

3. Select the configuration file you wish to recall and confirm your action.

You are returned to the application and the new parameters are set.

To revert to factory settings:

1. Select the Configuration function tab.

2. Click the Reset Module to Factory Settings button.

IMPORTANT

Reverting to the factory settings will interrupt any module

operation in progress.

IMPORTANT

The operation may take a few seconds to complete.

Note: Reverting to factory settings will not change the name given to the

channels. It will not change the user reference or correction factor lists

either.

36 IQS-1600

Page 45

5 Preparing Your High Speed

Power Meter for a Test

Cleaning and Connecting Optical Fibers

IMPORTANT

To ensure maximum power and to avoid erroneous readings:

³ Always clean fiber ends as explained below before inserting

them into the port. EXFO is not responsible for damage or

errors caused by bad fiber cleaning or handling.

³ Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Clean the fiber ends as follows:

1a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl

alcohol.

1b. Use compressed air to dry completely.

1c. Visually inspect the fiber end to ensure its cleanliness.

2. Carefully align the connector and port to prevent the fiber end from

touching the outside of the port or rubbing against other surfaces.

If your connector features a key, ensure that it is fully fitted into the

port’s corresponding notch.

3. Push the connector in so that the fiber-optic cable is firmly in place,

thus ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector

enough to firmly maintain the fiber in place. Do not overtighten, as this

will damage the fiber and the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you will

notice heavy loss and reflection.

High Speed Power Meter 37

Page 46

Preparing Your High Speed Power Meter for a Test

Nulling Offsets

Nulling Offsets

Temperature and humidity variations affect the performance of electronic

circuits and optical detectors, which can offset measurement results. To

compensate for this offset, the unit is equipped with an offset nulling

function.

Your unit is designed not to require offset nulling under normal operation,

but you should perform it whenever environmental conditions change

significantly or when measuring very low power values.

Your IQS-1600 High Speed Power Meter automatically performs nulling of

the offset each time you turn it on.

However, you might need to perform a manual nulling of the offset when

environmental conditions change significantly or when you are measuring

very low power.

Note: The manual nulling offset is valid for the current test session only; it no

longer applies when you turn off your power meter. The next time you turn

it on, the automatic offset nulling is performed again. You will achieve

better results if you perform the manual offset nulling at a temperature

around 23

o

C after a running period of 45 minutes.

IMPORTANT

When the application is launched after a cold start, allow the power

meter to warm up for about 20 minutes (30 minutes for IQS-1600W

modules) until the electronics stabilize before nulling offsets.

IMPORTANT

Light must not reach the detector when performing an offset

nulling operation. Always use a protective screw cap. Do not use a

soft rubber cover

38 IQS-1600

Page 47

Preparing Your High Speed Power Meter for a Test

Nulling Offsets

To perform an offset nulling on one channel:

1. Install the protective cap over the detector port.

2. If necessary, select the desired channel (on a multichannel high-speed

power meter).

To set the channel, see Selecting a Channel (IQS-1620, IQS-1640) on

page 21.

Offset nulling values are applied to the channel until a new nulling is

performed.

3. Under Channel, click the Nulling button. A message prompts you to

ensure that the detector cap is properly installed.

4. Select OK to perform the offset nulling, or Cancel to exit.

A red message appears beneath the power value of the channel for

which you are performing a nulling.

If you are using a multichannel power meter, you will notice that the

other channels will stop reading power while nulling is in progress.

High Speed Power Meter 39

Page 48

Preparing Your High Speed Power Meter for a Test

Nulling Offsets

To perform an offset nulling on all channels (two- and

four-channel power meters):

1. Install the protective caps over all of the detector ports.

2. Under Nulling, click the All Channels button.

Offset nulling values are applied to the channel until a new nulling is

performed. A message prompts you to ensure that the detector caps

are properly installed.

3. Click OK to perform the offset nulling, or Cancel to exit.

A red message appears beneath the power value of the channel for

which you are performing a nulling.

40 IQS-1600

Page 49

6 Measuring Power

Power measurements can be displayed in two ways:

³ absolute

³ relative

It is also possible to use a correction factor at specific wavelengths and to

add an offset value to your power measurement.

Displaying Absolute Power

When in absolute power, measured values are displayed in either dBm or

W units (pW, nW, μW, mW...) and the displayed value represents the

absolute optical power reaching the detector within specified uncertainty.

High Speed Power Meter 41

Page 50

Measuring Power

Displaying Absolute Power

To display absolute power:

1. Select the Instrument function tab or the Channels tab of the Settings

function tab (you can use either).

2. Select the channel for which you want to set the offset if you are using

a multichannel power meter.

Note: Step 3 is not mandatory, but will help you achieve more precise results).

3. Select the appropriate wavelength by using the arrow buttons next to

the corresponding list.

4. Select the appropriate unit by using the arrow buttons next to the

corresponding list.

5. If you are in the Settings function tab, click Apply to confirm your new

setting.

6. Return to the Instrument function tab and click Absolute to activate

the mode.

An absolute power measurement in negative W units indicates that the

nulling of the offset was improperly done. If this happens, repeat the offset

nulling operation (see Nulling Offsets on page 38).

42 IQS-1600

Page 51

Measuring Power

Measuring Relative Power

Measuring Relative Power

Power measurements can be displayed as a deviation from an absolute

reference value. The relative power is particularly useful when performing

loss measurements.

Relative power is displayed in dB when the reference value is measured in

dBm. In this case, the value will be either positive or negative, as the actual

measured power is higher or lower than the reference power.

If the reference value is in W, the relative power will be displayed in W/W.

In this case, the relative power is the deviation ratio from the reference and

will always be a positive value (unless operation was improperly done).

To display significant relative power values, it is important to have an

appropriate reference value, which you activate by clicking the Reference

button in the Instrument function tab.You can either apply the current

module power as a reference or edit a value to be used as the reference.

High Speed Power Meter 43

Page 52

Measuring Power

Selecting the Reference Value

Selecting the Reference Value

The reference value influences your measurements once selected and

activated. Whether you select the current module’s power or a set value

from the list, this becomes the basis for your future acquisitions.

To select the reference value:

1. From the Settings function tab, select the Channels tab.

2. Use the arrow buttons next to Reference to select either the current

module’s power or a value from the list, which you can then edit as

explained in the following section.

3. Click Apply to confirm your new setting.

4. From the Instrument function tab, click the Reference button to use

your new reference value.

44 IQS-1600

Page 53

Measuring Power

Editing the Reference List

Editing the Reference List

The Reference list can be changed to adapt to your testing requirements.

To add a reference to the list:

1. From the Settings function tab, select the Lists tab.

2. Under Reference List, enter the name of the new reference value in

the Name box.

3. In the Ref (dBm) box, enter a reference between −100.000 dBm and

100.000 dBm.

4. Click to enter the value.

Note: Although the wavelength list applies to all channels, the selected reference

applies to the wavelength and channel at which it was set.

High Speed Power Meter 45

Page 54

Measuring Power

Measuring Corrected Power

To delete a user reference from the list:

1. From the Settings function tab, select the Lists tab.

2. Select the value to remove by clicking it once.

3. Click to remove the value.

Measuring Corrected Power

Applying a correction factor to the measured power is useful when

compensating for known inaccuracies (power gains or losses) at specific

wavelengths.

A correction factor (CF) can be applied to any measurement that is

displayed in either dB, dBm, W, or W/W.

When a dB correction factor different from 0.000 is defined, the displayed

power is equal to the actual power plus the value of the correction factor.

When a W/W correction factor different from 1.000 is defined, the

displayed power is equal to the actual power times the value of the

correction factor.

Note: With an active correction factor, the CF marker appears in the data display

for the matching channel.

Note: Special care must be taken when setting a CF as it emulates a new

calibration (the module calibration is not affected and will be restored by

setting back the CF to a null value).

When expressed in dB, the CF can be a positive or negative value. When

the currently selected measurement unit is W, the correction factor is

expressed in W/W, indicating a multiplication factor for the current

wavelength and channel. The CF expressed in W/W will always be a

positive value.

46 IQS-1600

Page 55

Measuring Power

Measuring Corrected Power

To set a correction factor:

1. From the Settings function tab, select the Channels tab.

2. Select the channel for which you want to set the CF (in the case of a

two- or four-channel power meter).

3. Select the wavelength to which the CF will be applied by using the up

and down arrow buttons next to the list or by clicking it once in the

Correction Factors list.

4. In the Factor (unit) box, enter a CF between −10.000 dB and

10.000 dB, or between 0.100 W/W and 10.000 W/W, then click .

Note: Although the wavelength list applies to all channels, the CF applies to the

wavelength and channel at which it was set.

To remove the offset from a wavelength, select the wavelength,

then click .

High Speed Power Meter 47

Page 56

Measuring Power

Using the Offset Function

Using the Offset Function

The offset function is used when you want to take into account, in the

power displayed, a known gain or loss in the link that is not already

included in the signal reaching the detector.Contrary to the correction

factor, which applies to a specific wavelength, the offset value applies to

any wavelength when it is enabled in a specific channel.

To enter an offset value:

1. From the Settings function tab, select the Channels tab.

2. Select the channel for which you want to set the offset if you are using

a multichannel power meter.

3. From the Offset list, use the arrow buttons to adjust the value.

4. Click Apply to confirm your new setting.

48 IQS-1600

Page 57

Measuring Power

Averaging Measurements

Averaging Measurements

When the averaging function is enabledIQS-1600 High Speed Power Meter,

the most recent measurement samples, for which you can set the number,

are used to compute an unweighted average. This average is displayed as

the measured value. The AVG marker will also be displayed to the right of

the value for the matching channel, indicating that averaging is enabled.

If n < M, then

yn[]

1

-- -

xn[]⋅ 1

n

1

⎛⎞

-- -

–

⎝⎠

yn 1–[]⋅+=

n

If n ≥ M, then

yn[]

---- M

1

xn[]⋅ 1

1

⎛⎞

---- -

–

M

yn 1–[]⋅+=

⎝⎠

Where

³ n is the number of the current acquisition

³ M is the number of points to average (value you set)

³ x[n] is the current sample in watts

³ y[n] is the result of the present average in watts

³ y[n-1] is the value before the average in watts

Note: When measurement conditions change, the number of the acquisition is

reset to zero in order to start a new averaging measurement with the new

settings.

To select the number of samples for averaging, whether you are in the

Instrument function tab or the Channels tab of the Settings function tab,

use the arrow buttons to change the value in the Average (in the Settings

function tab) or Averaging (in the Instrument function tab) lists.

High Speed Power Meter 49

Page 58

Measuring Power

Averaging Measurements

If you are setting the average value in the Instrument function tab, you

must first press the Averaging button to activate the list.

Average /Averaging lists

To toggle between averaged and unaveraged power

measurement:

1. If necessary, select the desired channel from the Instrument function

tab.

2. Click the Averaging button to activate or deactivate it.

50 IQS-1600

Page 59

7 Recording Power Signal

Variations

The Min./Max. function allows you to record the extremes of a varying

power signal when performing a continuous acquisition. For example,

it could be used to determine the stability of a light source over time or to

measure the polarization-dependent loss (PDL) of a passive component

when combined with a polarization state controller.

The function is started manually and can be stopped manually or

automatically using the timer function. Minimum (Min.) and maximum

(Max.) values can be recorded and displayed in any measurement unit

(dB, dBm, W, or W/W; see Selecting the Measurement Unit on page 28).

In logarithmic scales (dB and dBm), the difference between the maximum

and minimum values is expressed as Max.−Min. In linear scales (W and

W/W), the difference is expressed as a ratio (Min./Max.).

To use the Min./Max. function:

1. Select the Continuous acquisition rate (see Selecting the Sampling

Typ e on page 56).

High Speed Power Meter 51

Page 60

Recording Power Signal Variations

o

2. Select the channel for which you want to see the power variation data

on-screen by clicking the corresponding buttons in the Min./Max. tab.

In the case of dual-channel power meters, you can select up to three

channels (the two normal channels, plus the virtual channel) and in

the case of the four-channel power meter, you can select up to six

channels, including the virtual channels.

Note: For four-channel power meters, since the display allows only four channels

to be viewed at once, you will have to modify your display, either during or

after your acquisition in order to view the remaining two channels.

3. If you want to specify the duration of power measurements, click the

Use Timer button, then enter a span using the arrow buttons on each

side of the list. If you are using the numeric box to enter a time value,

you must enter it in seconds (for example, 120 seconds for 2 minutes).

Selecti

indicat

4. Click Start to start power measurements.

52 IQS-1600

Page 61

Recording Power Signal Variations

These can be stopped at any time by clicking Stop. If the timer is set,

power measurements will stop automatically after the specified

duration.

Note: The remaining duration is indicated under the Start and Stop button.

The Reset button will reinitialize the Min./Max. acquisition results in the

data display.

The results of the Min./Max. function are continuously updated in the

matching lists. When a logarithmic scale is used, the Max.−Min.

calculation is made to continuously provides the difference between the

two extremes. In a linear scale, the Min./Max. ratio is computed to provide

valuable information.

³ If the power reaches the saturation level, +++++++ will be

recorded as the Max. value. The Max.-Min. or Min./Max. calculation will

also be +++++++.

³ If the detected power decreases below the lowest measurable power,

the Min. value will be ––––––– and both Max.-Min. or Min./Max. will

display –––––––.

³ If a Min./Max. calculation is made with a null Min. value, !!!!!!! will

be displayed.

³ If a channel is shown in the data display but is not part of the selected

channels for a Min./Max. acquisition, ******* will be displayed to

indicate that no power reading is being performed at that time.

Selecting Autorange for this channel will prevent these symbols from

appearing.

High Speed Power Meter 53

Page 62

Page 63

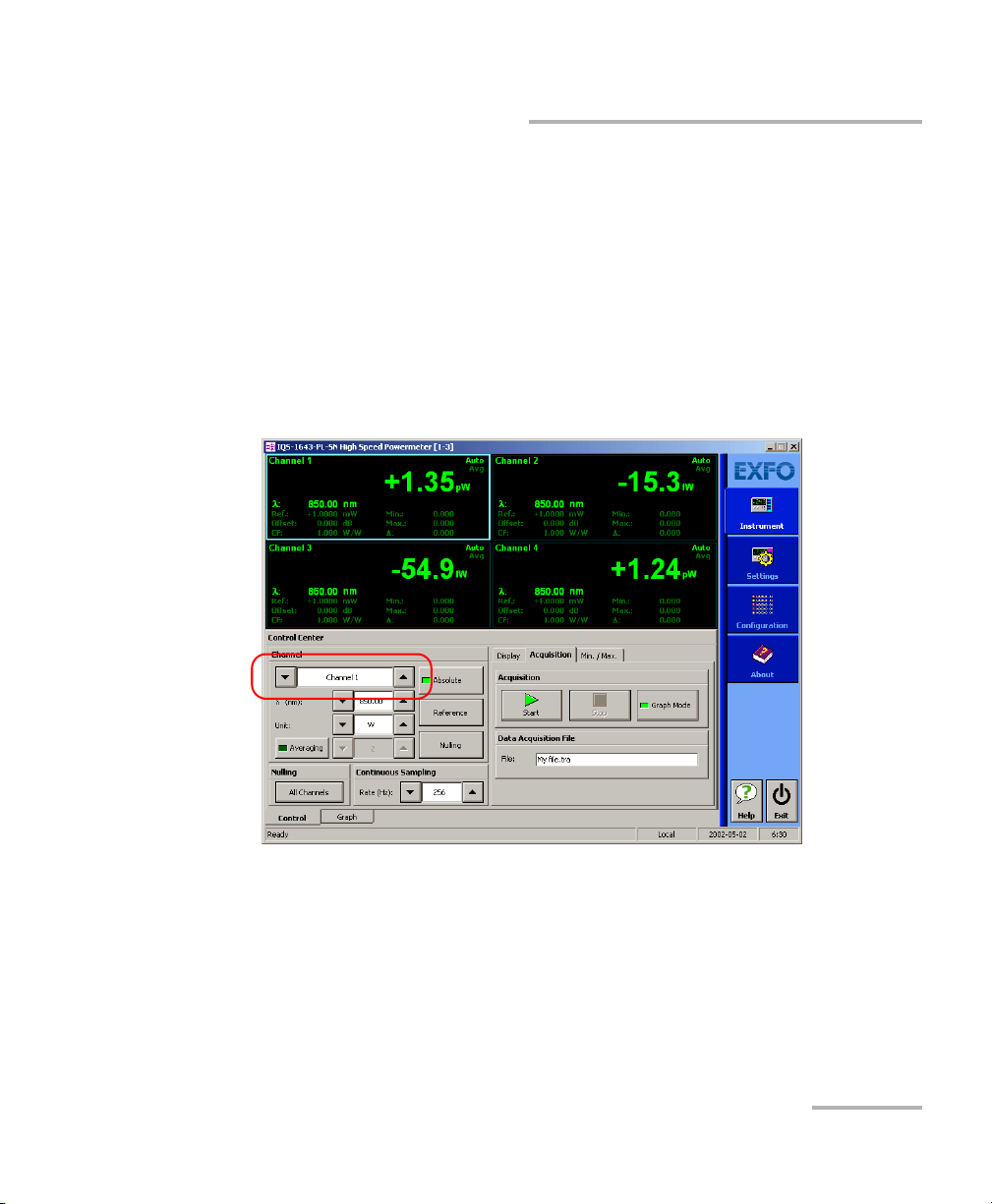

8 Performing Acquisitions

You can perform your acquisition on one or several channels at the same

time (in the case of multichannel power meters).

To select which channel will be affected by your acquisition:

1. From the Settings function tab, select the Data Acquisition tab.

2. Press on the corresponding button in the Channels To Be Included in

Sample.

To select a path for storing your acquisitions:

1. From the Settings function tab, select the Data Acquisition tab.

2. Use to select the folder to save your file.

High Speed Power Meter 55

Page 64

Performing Acquisitions

Selecting the Sampling Type

Selecting the Sampling Type

You can perform different types of samplings with your power meter:

³ Continuous sampling signifies that power measurements are

constantly updated on the measurement display for an unlimited time

period. You can select a rate that will optimize instrument flexibility

and measurement stability as well as determine the quantity of data

generated during data acquisition.

³ Single sampling signifies that power measurements will be taken

once, at the rate you have selected. This type of acquisition is

particularly useful when using a high acquisition rate, since the higher

the rate, the more data is transmitted. It will be easier for your power

meter module to manage one huge input of points as opposed to

several at the same time (it will stop analyzing if overwhelmed by

data).

³ User Defined sampling signifies that you can enter the rate and the

time units you wish to use. The value you enter in the 1/ list is the

number of time units the acquisition process will use. For example, if

you enter a value of 10, and select seconds as the unit, an acquisition

will be performed once every ten seconds; if you enter a value of 1 and

select seconds as the unit, an acquisition will occur every second, etc.

56 IQS-1600

Page 65

Performing Acquisitions

Selecting the Sampling Type

To select a sampling type:

1. From the Settings function tab, select the Data Acquisition tab.

2. Select the sampling type by clicking the corresponding button.

If you select Continuous, select the rate to use with the arrow buttons.

The acquisition rate applies to all channels when using a multichannel

power meter.

High Speed Power Meter 57

Page 66

Performing Acquisitions

Selecting the Sampling Type

You can also change the continuous sampling rate in the Instrument

function tab in the same manner.

If you select Single, select the rate to use with the arrow buttons. The

acquisition rate applies to all channels when using a multichannel

power meter.

Note: If a Single acquisition rate is selected while one or more channels have

been set to autoranging power measurement (seeSetting the Measurement

Range on page 32), the file acquisition will not start and a warning

message will prompt you to set a manual power measurement range for

the channels concerned.

If you select User Defined, select the rate by entering a value in the 1/

list, then select a time unit using the arrow buttons. Remember to click

to confirm your settings.

Note: Use a lower sampling rate with averaging set to active (see Averaging

Measurements on page 49) for greater repeatability when measuring very

low power.

58 IQS-1600

Page 67

Performing Acquisitions

Selecting the Acquisition Mode

Selecting the Acquisition Mode

You can use three data acquisition modes, regardless of the type of

acquisition you are performing.

³ Timer: the acquisition will last for the length of time you have

previously set.

³ Trigger: the power meter will wait for an incoming trigger signal

before starting its next acquisition.

³ Delay: the power meter will wait for a set length of time between

acquisitions.

Note: You can use one, several or all modes at the same time. If you use both the

trigger and delay modes simultaneously, the power meter will first wait for

the set delay time to elapse, then wait again for the incoming trigger signal.

If you add the timer mode, the acquisitions will be performed during a set

length of time, using both the trigger and delay modes.

In each case, measurements are taken at the selected sampling rate and

saved to a user-specified data file. The size of the data files created during

acquisition is proportional to the sampling rate and duration of the

acquisition. Higher sampling rates and longer durations generate larger

quantities of data.

High Speed Power Meter 59

Page 68

Performing Acquisitions

Selecting the Acquisition Mode

To select the acquisition mode:

1. From the Settings function tab, select the Data Acquisition tab.

2. From Mode, select the desired mode or combination of modes.

60 IQS-1600

Page 69

Performing Acquisitions

Selecting the Acquisition Mode

Setting Up Timed Acquisition Duration

A timed acquisition starts when you start the process, and continues for the

time you have previously specified.

To set the duration for your acquisition:

Click inside the Timer edit box of the Data Acquisition tab and enter the

value (or use the arrow buttons next to the list to adjust it).

If you are using the numeric box, enter the value in seconds

(for example, 120 seconds if you want to enter two minutes).

The acquisition length displayed for a single acquisition includes the time

set in the Settings tab for the acquisition, plus the time needed to transfer

data according to the sampling rate selected. During the acquisition, you

will notice the message Acquisition in progress, then Data transfer in

progress in the Instrument function tab. If you click Stop before the data

transfer is complete, you will lose your acquisition data.

High Speed Power Meter 61

Page 70

Performing Acquisitions

Selecting the Acquisition Mode

Setting Up Delayed Acquisition Delay

Delayed acquisition starts at a specified time after you start the process,

and continues for the time you have previously specified if you have

selected a combination of Timed and Delayed acquisition types.

To set a delay for your acquisition:

1. From the Data Acquisition tab, locate Delay.

2. Click inside the corresponding edit box and enter the value using the

numeric box, or use the arrow buttons to adjust the value.

If you are using the numeric box, enter the value in seconds

(for example, 120 seconds if you want to enter two minutes).

62 IQS-1600

Page 71

Performing Acquisitions

Selecting the Acquisition Mode

Setting Trigger Acquisition Parameters

Conditional data acquisition can be performed using a triggered

acquisition, meaning that data recording begins when a specified

condition is met. Different trigger conditions are available, which are

explained in the following table, where A and/or B represent the channel

on which the condition is to be met, and x and/or y represent the desired

power level threshold.

Trigger Description

A > x Acquisition will start when measured power is greater

than the specified x value.

A < x Acquisition will start when measured power is lower

than the specified x value.

A > x AND A < y Acquisition will start when measured power in

channel A is inside the interval set by the values

xandy.

A or B < x Acquisition will start when power in either channel A

or channel B is lower than the specified x value.

x<A or B<y

(multichannel

power meters

only)

Acquisition will start when measured power in

channel A goes over a specified value (A > x).

OR

Acquisition will start when measured power in

channel B falls under a specified value (B < y).

A<B

(multichannel

Acquisition will start when measured power of

channel A is lower than measured power of channel B.

power meters

only)

External trigger Acquisition in single rate will be triggered by an

external signal, whether on positive or negative TTL

voltage transitions (SeeExternal Trigger on page 82 for

additional information on this feature).

High Speed Power Meter 63

Page 72

Performing Acquisitions

Selecting the Acquisition Mode

Note: The trigger defines the condition for starting data acquisition. Once begun,

acquisitions will continue for the specified duration, regardless of the

measured power.

To set up the power level trigger condition:

1. From Trigger of the Data Acquisition tab, use the arrow buttons next

to the Type list to select the desired condition.

2. Select a channel (if applicable) to be taken as A and B It is possible to

select a virtual channel in the case of a multichannel power meter.

64 IQS-1600

Page 73

Performing Acquisitions

Selecting the Acquisition Mode

Note: The X and Y values are displayed in the currently selected unit.

3. Enter the appropriate X or Y values in the corresponding lists.

4. Click to confirm your setting.

If you select a Single acquisition rate, the External Trigger switch and

Trigger Position (%) options become available.

The External Trigger switch allows you to select whether the acquisition

will be externally triggered on positive or negative TTL voltage transitions.

Choose to select positive (from 0 to 5 V) transitions, or to select

negative (from −5 to 0 V) transitions.

The Trigger Position (%) list allows you to set the number of points that

will be acquired on the file before the trigger position is met by using the up

and down arrow buttons on each side of the list.

For more information about the external trigger function, seeExternal

Trigger on page 82.

Once you have launched your acquisition, you will notice a message

indicating that the power meter is waiting for the trigger. This message will

remain until the trigger condition is met.

High Speed Power Meter 65

Page 74

Performing Acquisitions

Starting the Acquisition

Starting the Acquisition

Once you have set your parameters, you can start the acquisition.

To start an acquisition:

1. Select the Instrument function tab.

2. From the Acquisition tab, press Start.

Data acquisition can be terminated at any time by clicking Stop. The

accumulated data is available in the data file.

If you want to start a graph acquisition at the same time, you must enable

the Graph function in the same tab (for more information on the graph

acquisition and visualization mode, see Performing and Analyzing Graph

Acquisitions on page 73).

Note: You cannot activate Graph mode after the acquisition has already been

started.

66 IQS-1600

Page 75

Performing Acquisitions

Starting the Acquisition

You can also start the acquisition in the Graph tab by clicking the Start

button the same way you would in the Control tab.

IMPORTANT

If you change units on one or more channels using Relative or

Absolute mode and that you had enabled Graph mode, the Graph

and Start buttons might automatically disable themselves if the

resulting changes are not compatible with the base unit used in the

graph.

To enter a name for your acquisition, type it in the File box of Data

Acquisition File. The default extension is .tra.

High Speed Power Meter 67

Page 76

Performing Acquisitions

Consulting Acquired Data

Consulting Acquired Data

Once you have acquired data, it is possible to view the results in

IQS Manager.

To view data previously acquired:

1. In IQS Manager, select the Work on Results (Offline) function tab.

2. Click the tab, then click the button corresponding to the application for

which you want to see information.

68 IQS-1600

Page 77

Performing Acquisitions

Consulting Acquired Data

3. In the viewer, retrieve the corresponding file using the button.

³ To view the details pertaining to the channels used for the

acquisition, select the General tab.

High Speed Power Meter 69

Page 78

Performing Acquisitions

Consulting Acquired Data

³ To view your acquisition data, select the Data tab.

70 IQS-1600

Page 79

Performing Acquisitions

Consulting Acquired Data

³ To view the graph corresponding to your acquisition data, select

the Graph tab.

To move along the time scale, use the arrow buttons.

The single arrow buttons will move by increments or decrements

representing 10 % of the current trace scale value.

The double arrow buttons will move by increments or

decrements of the current screen display (for example, the 10 to

40 seconds display would become 40 to 70 seconds in the figure

above).

To center on a specific value, type it in the Set position time scale

to box.

The other buttons and tabs are identical to those found in your

power meter application’s Graph tab. See Performing and

Analyzing Graph Acquisitions on page 73 for details.

High Speed Power Meter 71

Page 80

Performing Acquisitions

Consulting Acquired Data

If you want to save your acquisition file as a text file, use the Export button

located on the upper right-hand corner of the window. Save the file as you

would any other text file, then confirm your choice. You can now view your

data in any word processing program.

Note: If your acquisition file is too large for the viewer, you will be notified by a

pop-up message. Only the first part of your acquisition file will be displayed

in the viewer; to see complete results, you must export the file and view it in

a word processing program.

To exit the window and return to IQS Manager, click Exit.

72 IQS-1600

Page 81

9 Performing and Analyzing

Graph Acquisitions

The Graph mode of your power meter allows you to view your acquisition

as it is performed, and analyze it once it has been completed.

Setting Up Graph Parameters

Before acquiring data, you should set the parameters that will help you

achieve a better viewing afterwards.

To select which channels will be displayed:

Click the corresponding button when you are in the Display tab of the

Graph Center.

Once you have acquired a trace, you can also show or hide the channels

by clicking the corresponding buttons.

High Speed Power Meter 73

Page 82

Performing and Analyzing Graph Acquisitions

Setting Up Graph Parameters

Note: You can only hide or display channels actually used for this acquisition.

Moreover, only channels in the type of unit selected for the acquisition

(absolute or relative) will be displayed. For example, if your graph was set

to dBm units before the acquisition, you will see the graphs for channels

using W or dBm as the unit. If your graph was set to W/W units, you will

see the graph for channels using dB or W/W as the unit.

To select which type of display to use during the acquisition:

Go to the Settings tab of the Graph Center and click the button

corresponding to your choice:

³ Continuous Scroll: The display will scroll along to the right as the

acquisition progresses.

³ Wraparound: Once the acquisition has reached the end of the screen

to the right, it will begin on the left again and cover the previous trace.

74 IQS-1600

Page 83

Performing and Analyzing Graph Acquisitions

Setting Up Graph Parameters