Page 1

IQS-12004B

DWDM Passive Component Test System

User Guide

Page 2

Copyright © 2002–2007 EXFO Electro-Optical Engineering Inc. All rights

reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted in any form, be it electronically,

mechanically, or by any other means such as photocopying, recording or

otherwise, without the prior written permission of EXFO Electro-Optical

Engineering Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Version number 1.3.1.

ii IQS-12004B

Page 3

Contents

Contents

Certification Information ....................................................................................................... ix

1 Introducing the IQS-12004B DWDM Passive Component Test System ...... 1

Step-by-Step Approach ...........................................................................................................2

Test Features and Results ........................................................................................................3

Modularity and Flexibility .......................................................................................................3

System Overview ....................................................................................................................4

Testing Many Devices with the MultiPath Testing Option .......................................................5

Hardware Components Description ........................................................................................6

Tunable Laser Source ..............................................................................................................7

Module Description ................................................................................................................8

Testing Procedure ...................................................................................................................9

Database Structure ...............................................................................................................11

Using GPIB or COM to Control the System ............................................................................12

Conventions ..........................................................................................................................14

2 Safety Information ..................................................................................... 15

Laser Safety Information .......................................................................................................15

Safety Information ...............................................................................................................15

3 Getting Started with Your DWDM Passive Component Test System ....... 17

Inserting and Removing Test Modules .................................................................................17

Installing Hardware Components .........................................................................................22

Installing the IQS-12004B DWDM Passive Component Test System Software .......................28

Installing the MultiPath Testing Option Software ..................................................................29

Starting and Exiting the DWDM Passive Component Test System Application ......................31

Accessing a Specific Test Step ...............................................................................................34

Starting and Exiting the MultiPath Testing Option Application .............................................35

4 Setting Up the DWDM Passive Component Test System ......................... 37

Configuring DUT Parameters for Pass/Fail Analysis ................................................................37

Configuring an Optical Port ..................................................................................................39

Configuring a DUT ................................................................................................................42

Configuring DUT Company/Customer Parameters .................................................................44

Customizing the Channel List ...............................................................................................46

Preparing the Test Setup .......................................................................................................49

Identifying the Current DUT .................................................................................................54

Modifying System Settings ...................................................................................................56

DWDM Passive Component Test System iii

Page 4

Contents

5 Operating the DWDM Passive Component Test System ...........................59

Working with Access Levels ..................................................................................................59

Opening a New Test Database ..............................................................................................61

Opening an Existing Test Database .......................................................................................64

Viewing a Recent Test ...........................................................................................................65

Hiding the Welcome/New Test Window ................................................................................65

Cleaning and Connecting Optical Fibers ...............................................................................66

Connecting DUT and Modules ..............................................................................................67

Starting the ORL Measurement Scan ....................................................................................69

Testing Another Component .................................................................................................70

Sharing the Power Meters and WRM with an External Application .......................................70

Monitoring Modules in Local Mode ......................................................................................71

Viewing System Information .................................................................................................72

6 Calibrating the DWDM Passive Component Test System .........................73

Calibrating the System ..........................................................................................................73

Performing Reference Measurements ...................................................................................82

7 Interpreting the DWDM Passive Component Test System Results ...........87

Optimizing Performance .......................................................................................................87

Viewing Test Results ..............................................................................................................90

Exporting Data ......................................................................................................................94

Viewing the Results Graph ....................................................................................................97

Printing Test Results ............................................................................................................103

Organizing Tests .................................................................................................................107

Running Windows Explorer from the Application ...............................................................108

Clearing Database Files from the List ..................................................................................108

8 Using the Database Browser ....................................................................109

Opening the Database Browser ..........................................................................................109

Browsing the Database .......................................................................................................110

Viewing Test Results ............................................................................................................110

Printing a Report ................................................................................................................111

Typing Items to Find ...........................................................................................................111

Exiting the Database Browser .............................................................................................111

9 Referencing the System with MultiPath Testing Option ........................113

Nulling Electrical Offsets .....................................................................................................113

Calibrating the System Wavelength Response ....................................................................114

Calibrating Your System for ORL Testing .............................................................................115

Optimizing Power ...............................................................................................................115

Performing Reference Measurements .................................................................................116

iv IQS-12004B

Page 5

Contents

10 Testing Multiple DUTs with the LabVIEW Application ............................ 117

Starting a New Test .............................................................................................................118

Opening an Existing Test Database .....................................................................................119

Setting Up Device (DUT) Connectivity Configuration ..........................................................120

Configuring Test Parameters ...............................................................................................122

Nulling Electrical Offsets .....................................................................................................124

Calibrating the System Wavelength Response ....................................................................125

Calibrating your System for ORL Testing .............................................................................127

Performing Reference Measurements .................................................................................129

Performing a Test ................................................................................................................131

Monitoring Modules in Local Mode ....................................................................................132

Viewing System Information ...............................................................................................134

Adjusting Result Settings ....................................................................................................134

Modifying the Supplied MPT Application ............................................................................138

11 Using the Wavelength Calibration Software .......................................... 139

Overview of the Application ...............................................................................................139

Initializing the Modules ......................................................................................................140

Preparing the Calibration ....................................................................................................141

Performing the Acquisition .................................................................................................143

Analyzing the Results ..........................................................................................................144

Using Calibration Tools .......................................................................................................145

Viewing and Printing a Calibration Certificate ....................................................................146

12 Using the Power Meter Linearity Verification Tool ................................ 149

Starting and Exiting the Application ...................................................................................151

Connecting the Modules for Linearity Testing .....................................................................152

Initializing Hardware ...........................................................................................................154

Nulling Electrical Offsets .....................................................................................................155

Selecting the DUT and Reference Power Meter ...................................................................157

Setting Up the Acquisition Parameters ...............................................................................158

Verifying Linearity on a Specific Channel ............................................................................160

Viewing and Printing Test Results .......................................................................................163

Viewing Online User Guide .................................................................................................165

Getting Technical Support Information ...............................................................................166

DWDM Passive Component Test System v

Page 6

Contents

13 Automating or Remotely Controlling the System ..................................167

Initializing the Hardware ....................................................................................................169

Nulling Electrical Offsets .....................................................................................................170

Optimizing the Power .........................................................................................................170

Calibrating the System ........................................................................................................171

Referencing the System ......................................................................................................173

Testing the DUT ..................................................................................................................175

Retrieving Results ...............................................................................................................176

Controlling Instruments with GPIB .....................................................................................176

Starting the GPIB Remote Application ................................................................................177

Modifying GPIB Parameters ................................................................................................178

Opening a GPIB Connection ................................................................................................179

Closing a GPIB Connection .................................................................................................181

Editing GPIB Information ....................................................................................................181

Logging GPIB Information ..................................................................................................182

Monitoring the Power Meter ..............................................................................................182

Printing GPIB Information ...................................................................................................183

GPIB Command Structure ...................................................................................................184

GPIB General Commands—Quick Reference .......................................................................186

GPIB Specific Commands—Quick Reference .......................................................................187

GPIB Error Messages Format ...............................................................................................194

SCPI Error Messages ...........................................................................................................195

Configuring Your DWDM Passive Component Test System as a GPIB Controller ..................200

COM Objects ......................................................................................................................205

IQS-12004B DWDM Passive Component Test System (Standard) COM Error Messages .......208

MultiPath Testing Option COM Error Messages ..................................................................211

14 Maintenance ..............................................................................................213

Cleaning Fixed Connectors ..................................................................................................214

Cleaning EUI Connectors ....................................................................................................216

Cleaning Detector Ports ......................................................................................................218

Cleaning Fiber Ends ............................................................................................................218

Recalibrating the Unit .........................................................................................................219

Disposing of Old CKT Modules ...........................................................................................219

Recycling and Disposal (Applies to European Union Only) ..................................................220

15 Troubleshooting ........................................................................................221

Viewing the Online User Guide ...........................................................................................221

Consulting the About Window of the LabVIEW Application ...............................................221

Finding Information on the EXFO Web Site ........................................................................222

Contacting the Technical Support Group ............................................................................223

Transportation ....................................................................................................................224

vi IQS-12004B

Page 7

Contents

16 Warranty ................................................................................................... 225

General Information ...........................................................................................................225

Liability ...............................................................................................................................226

Exclusions ...........................................................................................................................226

Certification ........................................................................................................................226

Service and Repairs .............................................................................................................227

EXFO Service Centers Worldwide ........................................................................................228

A Technical Specifications ........................................................................... 229

IQS-12004B DWDM Passive Component Test System ..........................................................229

IQS-12004B MultiPath Testing Option .................................................................................230

B SCPI Commands Reference ...................................................................... 231

General Commands ............................................................................................................231

Specific Commands ............................................................................................................233

DWDM Passive Component Test System vii

Page 8

Contents

C COM Objects Reference ............................................................................269

DWDMAcq Interface—Properties ........................................................................................270

Measures Interface—Methods ............................................................................................274

Measures Interface—Properties ..........................................................................................280

Modules Interface—Methods .............................................................................................286

Modules Interface—Properties ............................................................................................290

Results Interface—Methods ................................................................................................304

Results Interface—Properties ..............................................................................................304

Test Parameters Interface—Properties .................................................................................309

clsDescModule Object—Properties .....................................................................................314

clsChannel Object—Properties ............................................................................................317

Event ..................................................................................................................................318

Available Enumerations ......................................................................................................328

Switch Interface—Methods ................................................................................................335

Switch Interface—Properties ...............................................................................................338

Analysis Interface—Methods ..............................................................................................347

Analysis Interface—Properties .............................................................................................358

ChannelResult Object ..........................................................................................................363

ChannelResult Object—Properties ......................................................................................364

BandPass Object .................................................................................................................367

BandPass—Properties .........................................................................................................368

BandPassResult Object ........................................................................................................372

BandPassResult—Methods ..................................................................................................374

BandPassResult—Properties ................................................................................................375

Notch Object ......................................................................................................................386

Notch—Properties ..............................................................................................................387

NotchResult Object .............................................................................................................393

NotchResult—Properties .....................................................................................................394

Undefined ...........................................................................................................................399

D Definitions and Calculation Methods ......................................................405

viii IQS-12004B

Page 9

Certification Information

Certification Information

F.C.C. Information

Electronic test equipment is exempt from Part 15 compliance (FCC) in

the United States. However, compliance verification tests are

systematically performed on most EXFO equipment.

Information

Electronic test equipment is subject to the EMC Directive in the European

Union. The EN61326 standard prescribes both emission and immunity

requirements for laboratory, measurement, and control equipment.

This unit has undergone extensive testing according to the European Union

Directive and Standards.

IMPORTANT

Use of shielded remote I/O cables, with properly grounded shields

and metal connectors, is recommended in order to reduce radio

frequency interference that may emanate from these cables.

DWDM Passive Component Test System ix

Page 10

Certification Information

DECLARATION OF CONFORMITY

Application of Council Directive(s): 73/23/EEC - The Low Voltage Directive

Manufacturer’s Name: EXFO ELECTRO-OPTICAL ENG.

Manufacturer’s Address: 400 Godin Avenue

Equipment Type/Environment: Light Industrial Scientific Equipment

Trade Name/Model No.: IQS-12004B DWDM Passive Components Test

Year of Conformity Assessment: 2002

Standard(s) to which Conformity is Declared:

EN 61010-1:1993/

A2:1995

EN 60825-1:1994 / A2:

2001

EN 55022: 1998 / A2:

2003

EN 61326:1997 /

A3:2003

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Safety Requirements for Electrical Equipment for Measurement, Control,

and Laboratory Use, Part 1: General Requirements

Safety of Laser products-Part 1: Equipment classification, requirement,

and user’s guide.

Limits and methods of measurement of radio disturbance characteristics

of information technology equipment.

Electrical Equipment for Measurement, Conttrol and Laboratory Use EMC Requirements

89/336/EEC - The EMC Directive

Quebec, Quebec

Canada G1M 2K2

(418) 683-0211

System

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Address: 400 Godin Avenue Quebec, Quebec,

Date: March 11, 2002

Development

Canada

x IQS-12004B

Page 11

Certification Information

DECLARATION OF CONFORMITY

Application of Council Directive(s): 73/23/EEC - The Low Voltage Directive

Manufacturer’s Name: EXFO ELECTRO-OPTICAL ENG.

Manufacturer’s Address: 400 Godin Avenue

Equipment Type/Environment: Industrial Scientific Equipment

Trade Name/Model No.: Polarization State Adjuster Module

Standard(s) to which Conformity is Declared:

EN 61010-1:1993/ A2: 1995 Safety Requirements for Electrical Equipment for Measurement, Control,

EN 55022: 1998 / A2: 2003 Limits and M ethods of Measurement of Radio Disturbance

EN 61326:1997 / A3:2003 Electrical Equipment for Measurement, Control, and Laboratory Use –

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Address: 400 Godin Avenue Quebec, Quebec,

Date: March 11, 2002

Development

Canada

and Laboratory Use, Part 1: General Requirements.

Characteristics of Information Technology Equipment.

EMC Requirements

89/336/EEC - The EMC Directive

Québec, Quebec

Canada G1M 2K2

(418) 683-0211

IQS-51X0B

DWDM Passive Component Test System xi

Page 12

Certification Information

DECLARATION OF CONFORMITY

Application of Council Directive(s): 73/23/EEC - The Low Voltage Directive

Manufacturer’s Name: EXFO ELECTRO-OPTICAL ENG.

Manufacturer’s Address: 400 Godin Avenue

Equipment Type/Environment: Industrial Scientific Equipment

Trade Name/Model No.: IQS-9401 Wavelength Reference Module

Year of Conformity Assessment: 2002

Standard(s) to which Conformity is Declared:

EN 61010-1:1993/ A2: 1995 Safety Requirements for Electrical Equipment for Measurement,

EN 55022: 1998 / A2: 2003 Limits and Methods of Measurement of Radio Disturbance

EN 61326:1997 / A3:2003 Electrical Equipment for Measurement, Control, and Laboratory Use –

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Address: 400 Godin Avenue Quebec, Quebec,

Date: March 11, 2002

Development

Canada

Control, and Laboratory Use, Part 1: General Requirements.

Characteristics of Information Technology Equipment.

EMC Requirements

89/336/EEC - The EMC Directive

Quebec, Quebec

Canada G1M 2K2

(418) 683-0211

xii IQS-12004B

Page 13

1 Introducing the IQS-12004B

DWDM Passive Component

Test System

The IQS-12004B DWDM Passive Component Test System, an automated

test solution for component manufacturers and system integrators, consists

of a series of IQS modular test and measurement instruments that are

completely integrated by an off-the-shelf software application. This

revolutionary system rapidly analyzes important parameters to help you

improve your production efficiency and decrease your product time to

market.

Characterization of multiplexers, demultiplexers, filters, and other passive

components is a critical step in ensuring the optimum performance of a

wavelength-division multiplexing (WDM) system.

DWDM Passive Component Test System 1

Page 14

Introducing the IQS-12004B DWDM Passive Component Test System

Step-by-Step Approach

The system performs DWDM component characterization and measures

insertion loss, spectral uniformity, bandwidth, crosstalk, channel central

wavelength, polarization dependence and optical return loss

measurements on multiplexers, demultiplexers, filters, and other passive

devices. These parameters must be controlled and tested throughout the

entire life cycle of a component, from research and development through

to production and even deployment.

The rapidity of the test procedure is achieved by scanning a very-low-noise

tunable laser source (in this case the IQS-2600B or IQS-2600CT Tunable

Laser Source) across the DUT’s spectral band while power is measured

simultaneously on all device ports. Due to the medium coherence and

unmatched sidemode suppression of the IQS-2600B/IQS-2600CT, a

dynamic range of nearly 60 dB is easily attained.

The standard configuration includes IL and ORL measurements. Adding

the IQS-5150 PSA will enable you to perform PDL measurements.

Step-by-Step Approach

Guided by your selection parameters, the software based on Windows

2000 controls the test procedure from start to finish. This systematic

approach eliminates the possibility of data entry and reporting errors, and

avoids costly procedural mistakes. In addition, time-saving features such as

Pass/Fail testing, filter masks and a part number database simplify the job

of DWDM component characterization.

2 IQS-12004B

Page 15

Introducing the IQS-12004B DWDM Passive Component Test System

Test Features and Results

Test Features and Results

Each test step may be accessed either automatically or manually.

Complete results are calculated at the end of the scan and are available

both graphically and in a data table; values outside the defined test limits

are highlighted. All data is saved to a database for archiving and future

display or printing.

Create as many port types as you require. Once defined, they will be used

to build a database of part numbers, enabling you to quickly reconfigure

parameters simply by selecting the appropriate part number. The

parameters in the port mask are used in the automatic Pass/Fail analysis.

Modularity and Flexibility

The system is built with the future in mind; the modular nature of the

hardware and the flexibility of the software make it easy for you to upgrade

or expand your test station. A single-channel system for measuring filters or

gratings can be expanded to 32, 64, or more channels by simply adding the

necessary plug-in modules. The system is also very compact: an entire

16-channel system, including PDL, will fit into a 4U (standard rackmount

units) rackmount space.

DWDM Passive Component Test System 3

Page 16

Introducing the IQS-12004B DWDM Passive Component Test System

System Overview

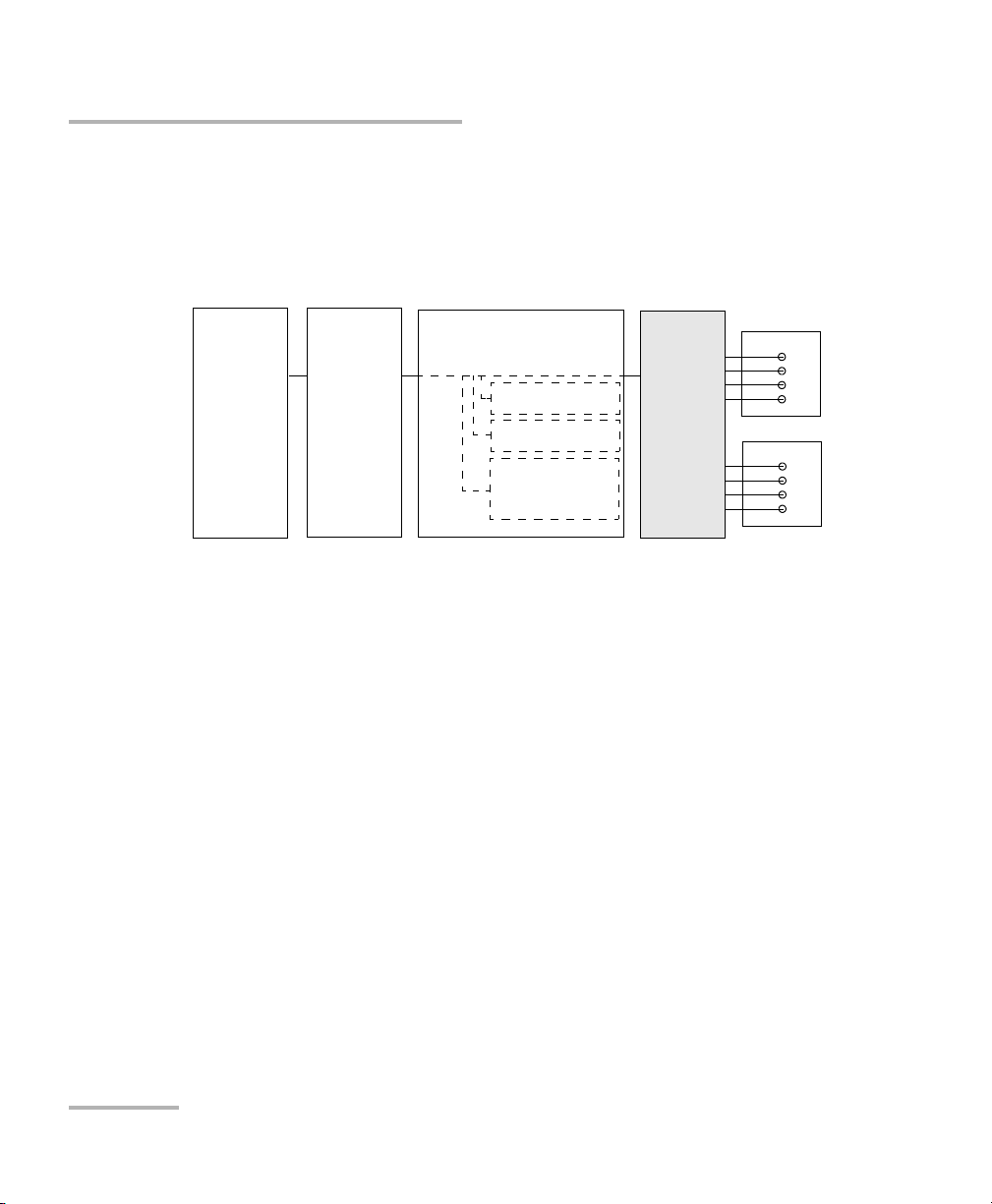

System Overview

The IQS-12004B DWDM Passive Component Test System provides spectral

insertion loss (IL), polarization-dependent loss (PDL), and optical return

loss (ORL) measurements with high resolution and accuracy.

IQS-2600B

or

IQS-2600CT

Tunable

Laser

Source

IQS-5150

Polarization

State

Adjuster

IQS-9401

Wavelength Reference

Module

Power Reference

ORL

Wavelength

Reference

Device

Under Test

IQS-1643T

IQS-1643T

The DWDM Passive Component Test System sweeps a very-low-noise

tunable laser source across the spectral band of interest (C-band or

C+L-band). While the source is sweeping, synchronized measurements

from the Wavelength Reference Module (WRM) and the measurement

power meters are acquired into the system software. At the end of the

sweep, advanced signal processing is applied to the data, resulting in

accurate IL, PDL, and ORL data.

This configuration ensures quick testing time that is practically

independent of the number of device ports (there is a nominal data

transfer and analysis penalty per channel). Because of the low source

spontaneous emissions (SSE) of the IQS-2600B/IQS-2600CT Tunable Laser

Source, a dynamic range of 60 dB is easily attained. The wavelength

reference module ensures wavelength and loss accuracy by providing

a fast and continuous wavelength and power reference throughout the

sweep.

The numerous software features are explained later in this user guide.

4 IQS-12004B

Page 17

Introducing the IQS-12004B DWDM Passive Component Test System

Testin g M a n y D e vices with the MultiPath Testing Option

Testing Many Devices with the MultiPath

Testing Option

With the MultiPath Testing Option, you will be able to use the standard

IQS-12004B DWDM Passive Component Test System along with an optical

switch to perform tests on one or many DUTs with a variable number of In

ports and Out ports.The MultiPath Testing Option provides:

³ A LabVIEW application that can be either used as is to perform

references, calibrations and tests, or can be tailored to your needs.

³ COM objects offering all the necessary properties and methods to build

your own multipath software.

The MultiPath Testing Option can be used for:

³ Environmental testing of DWDM passive components.

³ Testing arrayed components like variable optical attenuators (VOAs).

³ Testing multiplexers (IL, ORL, PDL, directivity).

³ Testing optical cross-connections (OXC) and other switches.

DWDM Passive Component Test System 5

Page 18

Introducing the IQS-12004B DWDM Passive Component Test System

Hardware Components Description

Hardware Components Description

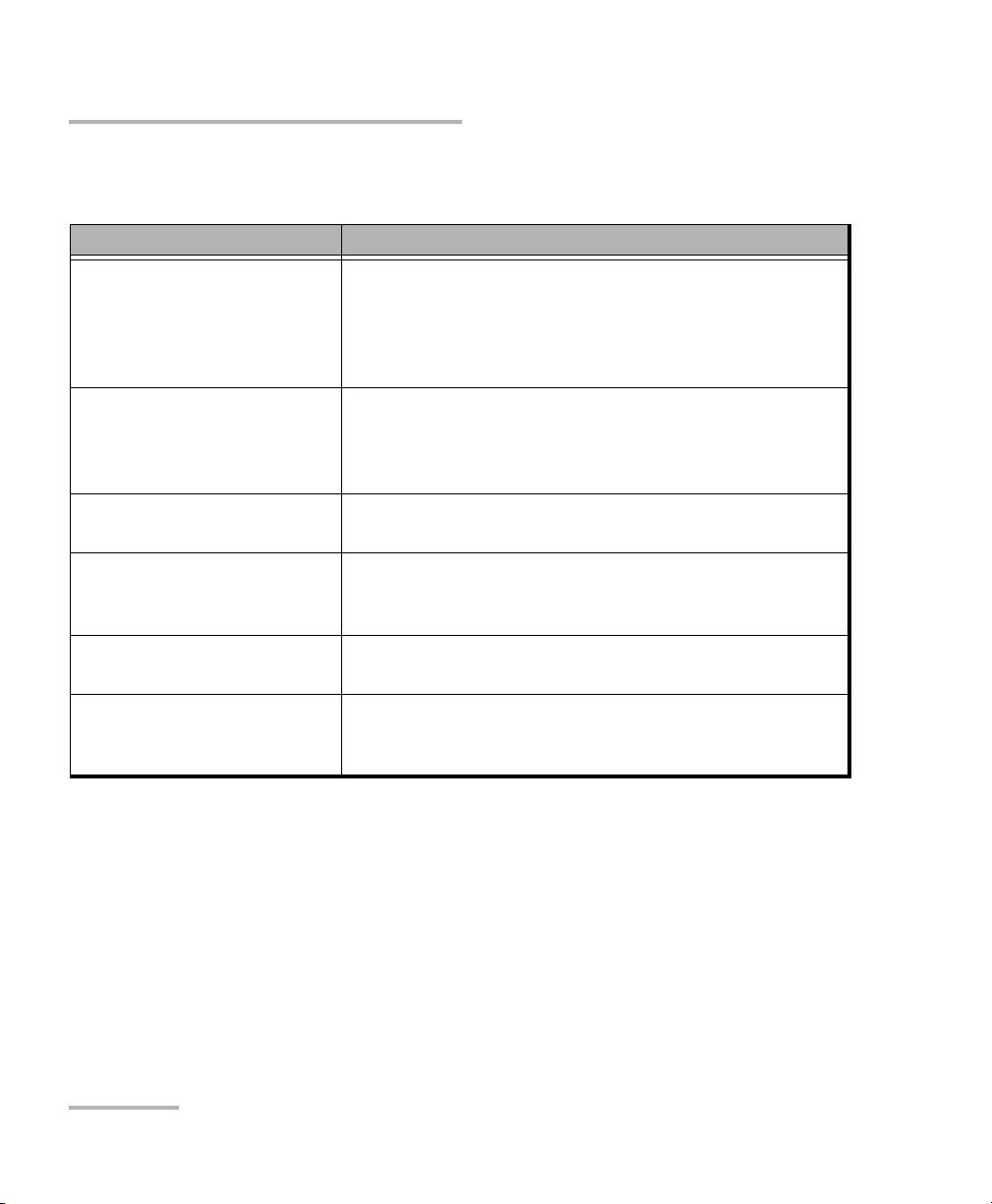

Module Usage

IQS-510P Controller Unit Controls the measurement process as well as data

interpretation and storage. The controller unit is supplied

with the necessary equipment for connection to a local

area network (LAN). For more information, refer to the

IQS-500 Intelligent Test System user guide.

IQS-510E Expansion Units Houses the instruments required by the system. If

necessary, a maximum of nine expansion units may be

connected to the controller unit. For more information,

refer to the IQS-500 Intelligent Test System user guide.

IQS-2600B or IQS-2600CT

Tunable Laser Source

IQS-1643 Power Meter Allows DWDM filters and multiplexers characterization.

IQS-5150 Polarization State

Adjuster (optional)

GPIB-controlled switch

(optional)

For more information, refer to the IQ-2600 user guide or

IQS-2600B Tunable Laser Source user guide.

For more information, refer to the IQS-1600 High-Speed

Power Meter user guide.

Allows PDL measurements.

Allows to use the MultiPath Testing Option to perform

tests on one or many DUTs with a variable number of In

ports and Out ports.

6 IQS-12004B

Page 19

Introducing the IQS-12004B DWDM Passive Component Test System

Tunable L aser Source

Tunable Laser Source

EXFO has modified its IQS-2600B Tunable Laser Source in order to

integrate it into the IQS-12004B DWDM Passive Component Test System. To

optimize the performance of the system, the optical attenuator which

ensures a constant power output from the tunable laser source has been

removed.

You can easily identify which tunable laser source you have. The unit

designed for the DWDM Passive Component Test System bears the

mention 2600CT, while the standalone unit bears the mention 2600B.

Every customer purchasing the IQS-12004B DWDM Passive Component

Test System for applications covering both the C- and L-bands will receive

an IQS-2600CT model. Even though the tunable laser source has been

modified, it can still be used as a standalone instrument using an IQS-500

Intelligent Test System.

However, you will notice a warning message when turning the instrument

on. This warning informs you that the automatic level control (ALC) is

disabled. Also note that the power stability and repeatability values

presented in the IQS-2600B specification sheet do not apply to the

IQS-2600CT.

Any other functionality or specification, particularly those concerning the

accuracy of the instrument and wavelength stability, will not be affected by

this design change.

DWDM Passive Component Test System 7

Page 20

Introducing the IQS-12004B DWDM Passive Component Test System

Module Description

Module Description

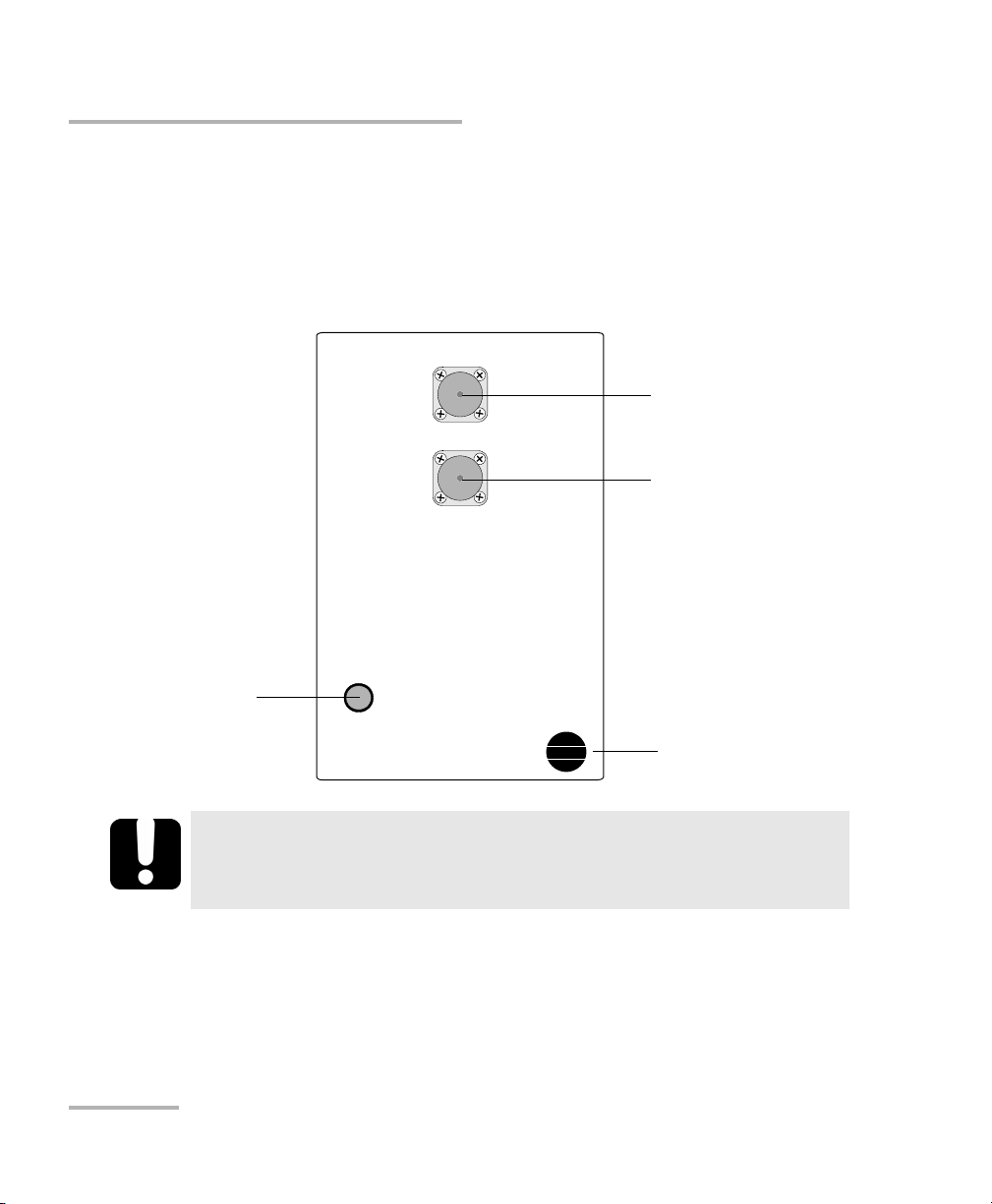

This section describes the IQS-9401 Wavelength Reference Module and the

IQS-5150 Polarization State Adjuster. For a description of the other modules

used in the DWDM Passive Component Test System, refer to the modules’

user guides.

LED push button

lights up when the

controller unit is

turned on

In order to keep the optical ports clean, the protective caps should

always be installed when the module is not being used.

IN

OUT

IQS-5150

Polarization State Adjuster

IMPORTANT

Input port,

UPC connector

Output port,

UPC connector

Retaining screw knob

8 IQS-12004B

Page 21

Introducing the IQS-12004B DWDM Passive Component Test System

Testin g Pro c e d u r e

Testing Procedure

The IQS-12004B DWDM Passive Component Test System prompts the

operator to perform a series of steps, after which it controls the different

IQS modules to perform measurements on a device under test (DUT).

The testing procedure used by the system is outlined below.

³ You can configure different test parameters in the Setup step.

³ System calibration is performed the first time the system is used. It can

also be performed as needed. Calibration comprises three elements:

detector null measurement of power meters and the WRM,

wavelength response calibration, and return loss calibration.

³ IL/PDL and ORL reference measurements are required each time the

system is turned on and are recommended whenever there is a

significant change in environmental conditions.

³ The measurement scan(s) is performed. The insertion loss (IL)

measurement requires one scan, the IL/PDL measurement requires

four scans, and the ORL measurement requires one scan.

³ At the end of the scan(s), the results are calculated and analyzed. You

can view the results and print reports as required.

DWDM Passive Component Test System 9

Page 22

Introducing the IQS-12004B DWDM Passive Component Test System

Testin g Pro c e d u r e

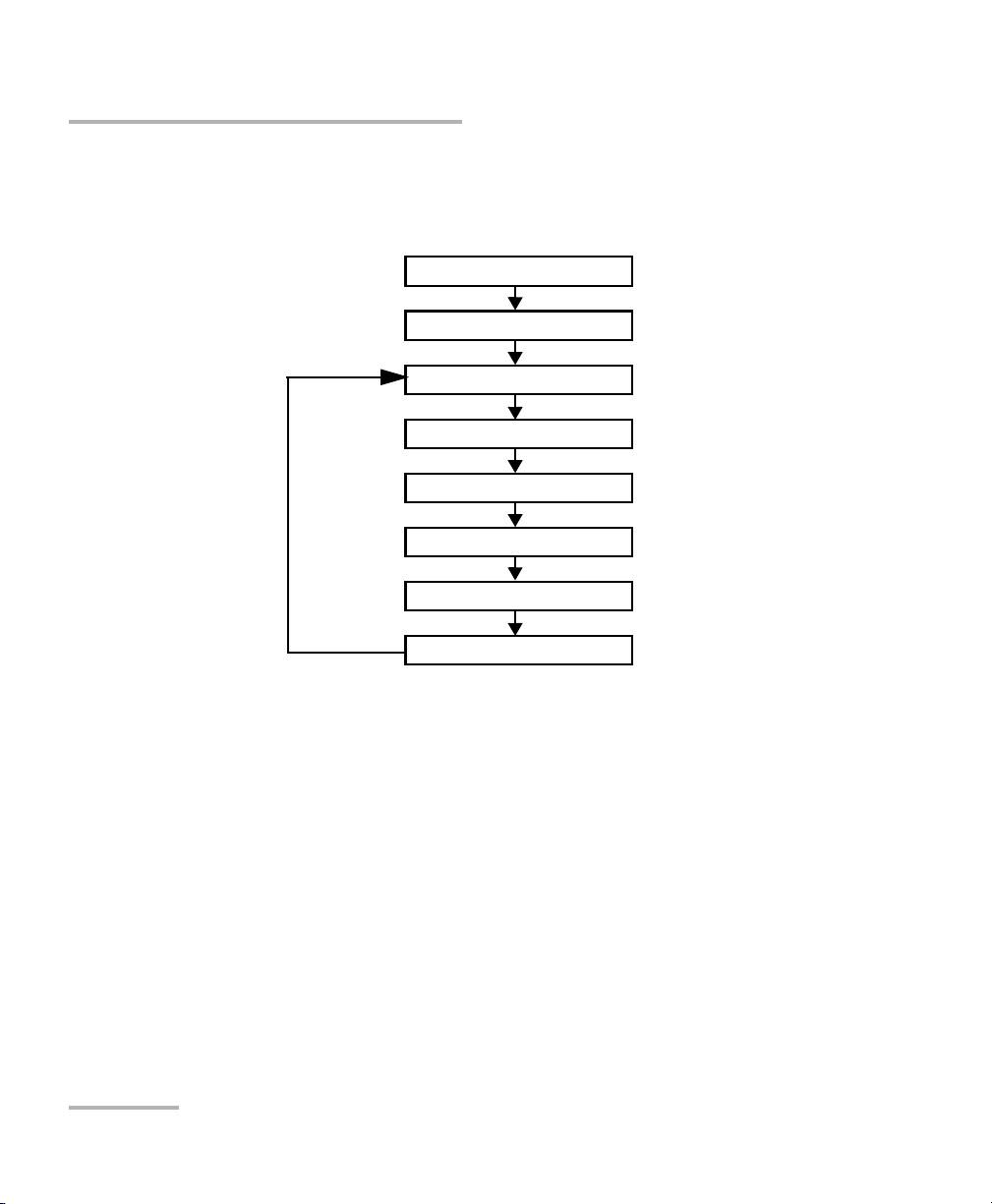

Once a supervisor has configured the IQS-12004B DWDM Passive

Component Test System, a typical test sequence would be similar to the

flow chart shown below.

Open database

Perform a reference

Select DUT

Connect DUT

Measure

View results

Print report

Test another component

10 IQS-12004B

Page 23

Introducing the IQS-12004B DWDM Passive Component Test System

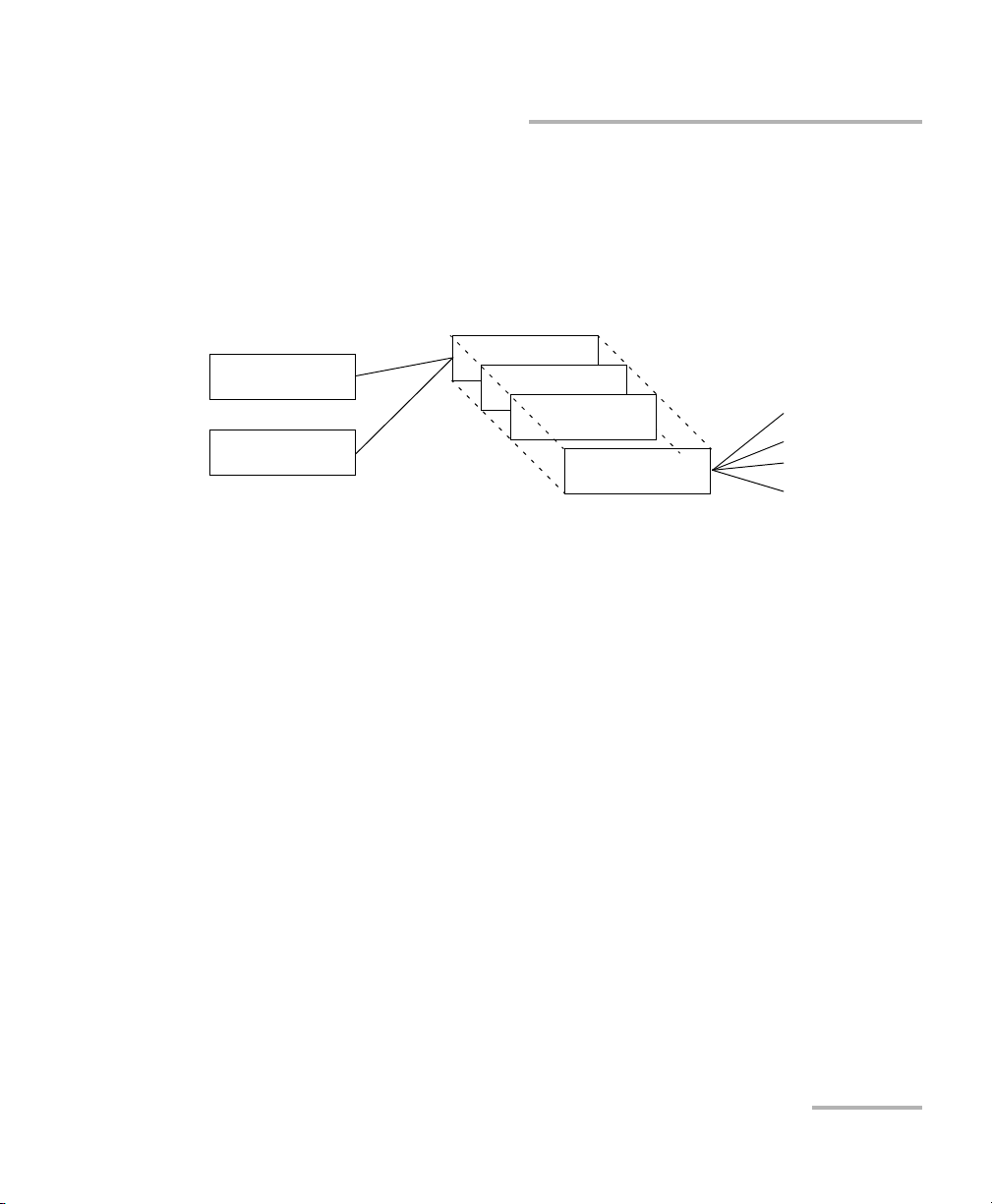

Database Structure

Database Structure

The IQS-12004B DWDM Passive Component Test System uses several

different databases for storing test results and configuration information.

You have full control over the results database file name and location. The

database structure is organized as shown below.

Customer.MDB

DUTPort.MDB

Results1.MDB

Results2.MDB

Results3.MDB

ResultsN.MDB

Scan data files

Scan data files

Scan data files

Scan data files

To save test results for later analysis, the IQS-12004B DWDM Passive

Component Test System uses three databases:

³ Customer.MDB: This database contains information about your

customers. It is managed internally by the system.

³ DUTPort.MDB: This database contains Pass/Fail information about the

devices that you want to test. It is managed internally by the system.

³ ResultsN.MDB: This database contains test results. You can create as

many files as you want. For example, it might be practical to have

different files for different customers, components, or test sessions.

Basically, the system has built-in flexibility to let you choose the best

way of saving test results.

DWDM Passive Component Test System 11

Page 24

Introducing the IQS-12004B DWDM Passive Component Test System

Using GPIB or COM to Control the System

The IQS-12004B DWDM Passive Component Test System also uses scan

data files. These files are the test results data files containing the IL vs. λ,

PDL vs. λ, and ORL vs. λ data. These files are created and managed by the

DWDM Passive Component Test System. They are saved only if Save

Results Curves is selected in the System Settings window.

When you create a new database in the system, you are creating only a

new ResultsN database. The customer and DUT information that you

previously entered in the first two databases (Customer and DUTPort) will

be available for the new ResultsN database.

If you need information or details about the database structure, please

contact EXFO (see Contacting the Technical Support Group on page 223).

Using GPIB or COM to Control the System

The IQS-12004B DWDM Passive Component Test System gives you the

opportunity to develop your own applications using either SCPI commands

(GPIB control) or COM objects.

The MultiPath Testing Option allows you to develop your tailored

applications using COM objects.

In order to be able to take IL, ORL, and PDL measurements with the

standard DWDM Passive Component Test System or the MultiPath Testing

Option, there are a number of required steps and procedures to follow.

12 IQS-12004B

Page 25

Introducing the IQS-12004B DWDM Passive Component Test System

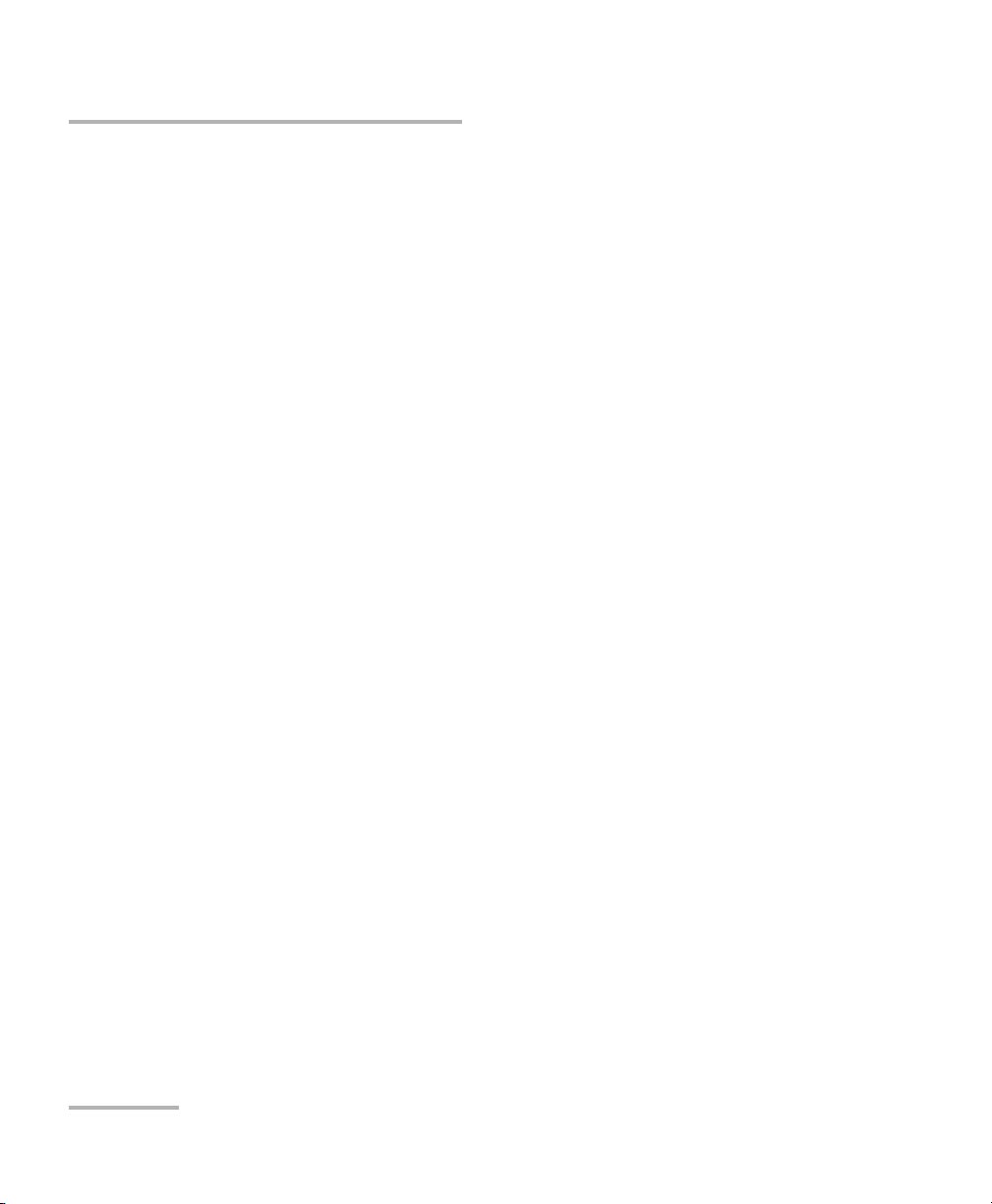

A typical test sequence would be similar to the flow chart below.

Standard IQS-12004B

DWDM Passive

Component Test System

(one DUT at a time)

Using GPIB or COM to Control the System

Initialize hardware

Null power meter

Optimize power

Calibrate system

IL/PDL

ORL

Reference system

IL/PDL

ORL

MultiPath Testing

option (possibility of

several DUTs at a time)

Te s t D UT

Retrieve results

Tes t D UT

h

c

t

i

Select input port

w

s

e

h

t

Measure/analyze

g

n

i

s

u

g

n

i

l

c

y

C

Retrieve data

Each time a new test sequence is started, the above steps are required or

highly recommended. In some cases, the system will generate error

messages where the prerequisite steps have not been performed.

DWDM Passive Component Test System 13

Page 26

Introducing the IQS-12004B DWDM Passive Component Test System

Conventions

Conventions

Before using the product described in this manual, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

14 IQS-12004B

Page 27

2 Safety Information

Laser Safety Information

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

Use of controls, adjustments and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

Safety Information

Your instrument is a Class 1 laser product in compliance with standards

IEC 60825-1 Amendment 2: 2001 and 21 CFR 1040.10. Laser radiation may

be encountered at the output port.

The following label indicates that a product contains a Class 1 source:

CLASS 1

LASER PRODUCT

Note: Label shown for information purposes only. It is not affixed to your product.

The DWDM Passive Component Test System may be equipped with the

IQS-2600B or the IQS-2600CT tunable laser sources. For more information

on these modules, refer to the IQS-2600B Tunable Laser Source user guide.

DWDM Passive Component Test System 15

Page 28

Page 29

3 Getting Started with Your

DWDM Passive Component

Test System

This chapter contains a description of hardware components and modules

used in the system, information on how to install hardware components

and how to install and start the IQS-12004B DWDM Passive Component

Test System software. You will also find a description of the utility to

organize test files as well as a description of the application main window.

Inserting and Removing Test Modules

CAUTION

Never insert or remove a module while the controller unit and its

expansion units are turned on. This will result in immediate and

irreparable damage to both the module and unit.

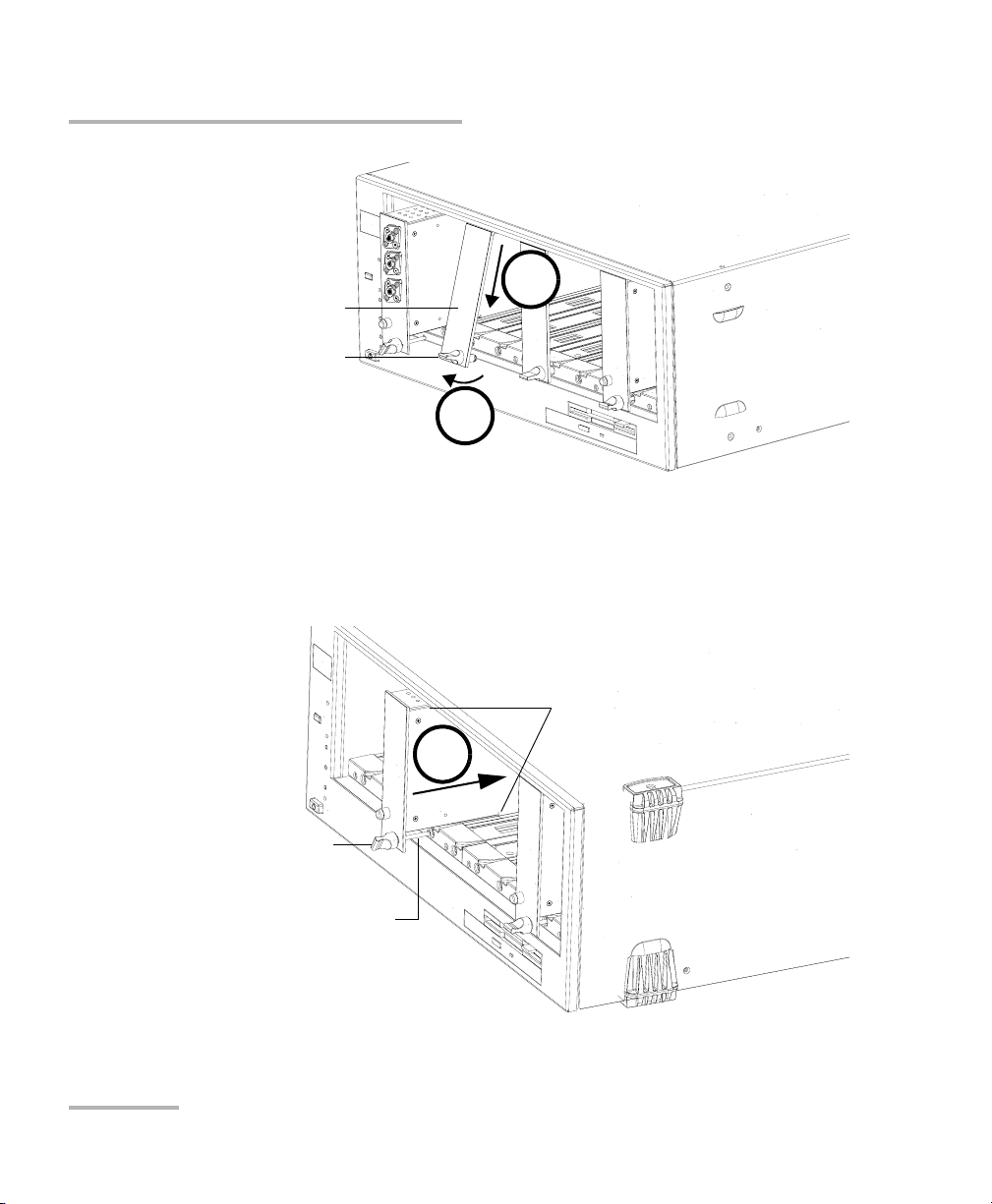

To insert a module into the controller or expansion unit:

1. Exit IQS Manager and turn off all your units.

2. Remove the protective cover from the desired unused module slot.

2a. Pull the retaining screw knob firmly towards you and release the

bottom of the cover.

2b. Gently pull the top of the protective cover downwards, to remove

it from the unit grooves.

DWDM Passive Component Test System 17

Page 30

Getting Started with Your DWDM Passive Component Test System

Inserting and Removing Test Modules

Protective cover

Retaining screw

knob

2a

2b

3. Position the module so that its front panel is facing you and the top and

bottom protruding edges are to your right.

4. Insert the protruding edges of the module into the grooves of the unit’s

module slot.

Protruding edges

(right side of module)

5

Retaining screw knob

Retaining screw

18 IQS-12004B

Page 31

Getting Started with Your DWDM Passive Component Test System

Inserting and Removing Test Modules

5. Push the module all the way to the back of the slot, until the retaining

screw makes contact with the unit casing.

6. While applying slight pressure to the module, turn the retaining screw

knob (located at the bottom of the panel) clockwise until the knob is

horizontal. This will secure the module into its “seated” position.

6

The module is correctly inserted when its front panel is flush with the front

panel of the controller or expansion unit.

When you turn on the controller unit, the startup sequence will

automatically detect your module.

Note: You can insert IQ modules into your controller or expansion unit; the IQS

Manager software will recognize them. However, the IQS-500 locking

mechanism (retaining screw) will not work for IQ modules.

To remove a module from your controller or expansion unit:

1. While pulling gently on the knob, turn it counterclockwise until it stops.

The module will slowly be released from the slot.

DWDM Passive Component Test System 19

Page 32

Getting Started with Your DWDM Passive Component Test System

Inserting and Removing Test Modules

Retaining screw knob

2. Place your fingers underneath the module or hold it by the retaining

screw knob (NOT by the connector) and pull it out.

Connector

NO

YES

Retaining screw

knob

20 IQS-12004B

Page 33

Getting Started with Your DWDM Passive Component Test System

Inserting and Removing Test Modules

CAUTION

Pulling out a module by a connector could seriously damage both

the module and connector. Always pull out a module by the

retaining screw knob.

3. Cover empty slots with the supplied protective covers. Simply slide the

top of the protective cover into the upper grooves of the unit, and then

snap into place by pushing the retaining screw knob.

CAUTION

Failure to reinstall protective covers over empty slots will result in

ventilation problems.

DWDM Passive Component Test System 21

Page 34

Getting Started with Your DWDM Passive Component Test System

Installing Hardware Components

Installing Hardware Components

The DWDM Passive Component Test System has been configured and

tested at the factory, under normal conditions, and installed by an EXFO

authorized installation engineer. The following information is provided in

the event that it is necessary to move, transport, or reinstall the system.

Controller and Expansion Units

Please refer to the IQS-500 Intelligent Test System user guide for detailed

information about installing and connecting the controller and expansion

unit(s).

Source, Wavelength Reference, and PSA

The source (IQS-2600B or IQS-2600CT), the wavelength reference module

(IQS-9401), and the optional polarization state adjuster (IQS-5150) must be

installed in the same expansion unit and in a specific order.

The recommended configurations are presented hereafter.

CAUTION

Never insert or remove a module while the controller or expansion

unit is turned on. This will result in immediate and irreparable

damage to both the module and unit.

22 IQS-12004B

Page 35

Getting Started with Your DWDM Passive Component Test System

Installing Hardware Components

Configuration with PDL

Connect the tunable output of the IQS-2600B/IQS-2600CT to the input of the

IQS-5150 using the rigid patchcord supplied with the

IQS-2600B/IQS-2600CT. Connect the output of the IQS-5150 to the input of

the IQS-9401, as illustrated below.

IN

OUT

IQS-9401

Wavelength Reference Module

Sync

Out

ACTIVE

IQS-2600CT

Tunable Laser Source

OUTPUT

MONITOR

OUTPUT

TRIG IN

TRIG OUT

IN

OUT

IQS-5150

Polarization State Adjuster

Connect the launch fiber to the output of the IQS-9401.

Note: The IQS-9401 has an angled (APC) output connector.

DWDM Passive Component Test System 23

Page 36

Getting Started with Your DWDM Passive Component Test System

Installing Hardware Components

Configuration without PDL

Connect the tunable output of the IQS-2600B/IQS-2600CT to the input of the

IQS-9401 using the rigid patchcord supplied with the tunable source, as

illustrated below.

IN

OUT

IQS-9401

Wavelength Reference Module

Sync

Out

ACTIVE

IQS-2600CT

Tunable Laser Source

OUTPUT

MONITOR

OUTPUT

TRIG IN

TRIG OUT

Connect the launch fiber to the output of the IQS-9401.

Note: The IQS-9401 has an angled (APC) output connector.

24 IQS-12004B

Page 37

Getting Started with Your DWDM Passive Component Test System

Installing Hardware Components

Configuration of Power Meters

The IQS-1643T power meters must be installed sequentially in the unit. Use

the short synchronization cables to connect power meters in the same

unit, and the long synchronization cables to connect power meters in

different units. It is also necessary to install a synchronization cable

between the IQS-9401 and the first power meter, as illustrated below.

ACTIVE

IQS-2600CT

Tunable Laser Source

OUTPUT

MONITOR

OUTPUT

TRIG IN

TRIG OUT

IN

OUT

IQS-5150

Polarization State Adjuster

IN

OUT

IQS-9401

Wavelength Reference Module

SYNC OUT

C

F

-

T

T

N

C1

X

F

O

C2

C3

C4

Sync

Out

IQS-1600T

4-Ch Power Meter

Sync In

Trig

SYNC IN

C

F

-

T

T

N

C1

E

Sync

Out

C2

C3

C4

IQS-1600T

4-Ch Power Meter

X

F

O

Sync In

Trig

C

F

-

T

T

N

C1

E

Sync

Out

C2

C3

C4

IQS-1600T

4-Ch Power Meter

X

F

O

Sync In

Trig

C

F

-

T

T

N

C1

E

C2

C3

C4

Sync

Out

IQS-1600T

4-Ch Power Meter

IMPORTANT

The power meters must be correctly installed and configured before

starting IQS Manager or before turning the unit on. If modules need

to be repositioned, you will have to restart the system.

IMPORTANT

To keep the optical ports clean, ensure that protective caps are

always installed when the module is not being used.

E

X

F

O

Sync

Out

Sync In

Trig

DWDM Passive Component Test System 25

Page 38

Getting Started with Your DWDM Passive Component Test System

Installing Hardware Components

To work with the MultiPath Testing Option, you will have to add a switch to

your standard IQS-12004B DWDM Passive Component Test System to

benefit from its inherent features.

CAUTION

Never insert or remove a module while the controller or expansion

unit is turned on. This will result in immediate and irreparable

damage to both the module and unit.

The minimum hardware components required for multipath testing are:

³ Tunable laser source (IQS-2600B or IQS-2600CT).

³ Wavelength reference module (IQS-9401).

³ Power meter (IQS-1643T), one or more.

³ Switch (either the IQS-9100, or a GPIB-controlled switch. Check with

EXFO to see if a specific model is supported.).

Regardless of whether you will be using an EXFO switch or any of the

supported switches, the connection of the switch in the system will remain

the same.

The switch has to be connected to the Wavelength Reference Module ()

and to the power meters. Use the supplied to link the Out port of the WRM

to the common port of the switch. Connect the DUT(s) between the power

meter and the switch.

26 IQS-12004B

Page 39

Getting Started with Your DWDM Passive Component Test System

Installing Hardware Components

To work in high-power mode, you will have to add a switch and an EDFA

to your standard IQS-12004B DWDM Passive Component Test System.

IMPORTANT

In order to be able to control the EDFA, the GPIB address of the

EDFA must be smaller than the GPIB address used for the switch.

CAUTION

Never insert or remove a module while the controller or expansion

unit is turned on. This will result in immediate and irreparable

damage to both the module and unit.

The minimum hardware components required for multipath testing in high

mode are:

³ Tunable laser source (IQS-2600B or IQS-2600CT).

³ Wavelength reference module (IQS-9401).

³ Power meter (IQS-1643T), one or more.

³ The KPS-AMP-C-20 fiber amplifier (EDFA).

³ A high-power GPIB-controlled switch.

DWDM Passive Component Test System 27

Page 40

Getting Started with Your DWDM Passive Component Test System

Installing the IQS-12004B DWDM Passive Component Test System Software

Installing the IQS-12004B DWDM Passive

Component Test System Software

For the DWDM Passive Component Test System to function properly, the

IQS Manager software must be installed on your IQS-500 Intelligent Test

System.

Normally, you wouldn’t have to install the IQS Manager software or the

DWDM Passive Component Test System software, except in particular

circumstances (such as after having reinstalled Microsoft Windows).

For information on installing IQS Manager software, refer to the IQS-500

Intelligent Test System user guide.

To install the DWDM Passive Component Test System on an

IQS-500 controller unit:

1. Insert CD of the DWDM Passive Component Test System in the CD-ROM

drive.

2. Select Run from the Windows Start menu.

3. Ty pe F:\ setup.exe in the Open text field.

4. Click OK to start the wizard and follow the on-screen instructions.

28 IQS-12004B

Page 41

Getting Started with Your DWDM Passive Component Test System

Installing the MultiPath Testing Option Software

Installing the MultiPath Testing Option

Software

Before installing the MultiPath Testing Option software, ensure that the

IQS-12004B DWDM Passive Component Test System software has been

installed on the IQS-500 controller unit. For more information, see Installing

the IQS-12004B DWDM Passive Component Test System Software on

page 28.

To install the MultiPath Testing software on an IQS-500 controller

unit:

1. Insert the MultiPath Testing software CD-ROM in the drive.

2. Select Run from the Windows Start menu. The Run window appears.

3. Use the Browse button to find the setup.exe file on the CD-ROM.

4. Click OK to start the installation.

EXFO recommends that you keep the default names and paths suggested

by the setup program.

Follow the on-screen instructions. Once the LabVIEW demo is installed,

the installation of the files required to run LabVIEW will begin.

DWDM Passive Component Test System 29

Page 42

Getting Started with Your DWDM Passive Component Test System

Installing the MultiPath Testing Option Software

If the following dialog box appears, that means that LabVIEW has been

installed in a previous session.

If this is the case, choose Modify, click Next and follow the on-screen

instructions.

IMPORTANT

Selecting an option other than Modify may prevent the MultiPath

Test i ng Op t ion software from working properly.

For information on how to use the MultiPath Testing Option application, see

Testing Multiple DUTs with the LabVIEW Application on page 117.

30 IQS-12004B

Page 43

Getting Started with Your DWDM Passive Component Test System

Starting and Exiting the DWDM Passive Component Test System Application

Starting and Exiting the DWDM Passive

Component Test System Application

To start the DWDM Passive Component Test System application:

³ On the Windows taskbar, click Start, select Programs > EXFO >

IQS-12004B > IQS-12004B DWDM Test System.

OR

³ Double-click the IQS-12004B DWDM Test System desktop icon.

To exit the DWDM Passive Component Test System application:

Select Exit from the File menu.

At the starting of the application, a message may appear, indicating that the

regional settings of your system were temporary changed. This change

consists in using a period for the decimal symbol and using the

YYYY-MM-DD date style.

DWDM Passive Component Test System 31

Page 44

Getting Started with Your DWDM Passive Component Test System

Starting and Exiting the DWDM Passive Component Test System Application

By default, the Welcome/New Test window appears first when you start the

DWDM Passive Component Test System (see Opening a New Test

Database on page 61).

The Welcome/New Test window gives you the possibility to open a new

test database, to open an existing test database, or to view the content of

recent test databases.

32 IQS-12004B

Page 45

Menu bar

Getting Started with Your DWDM Passive Component Test System

Starting and Exiting the DWDM Passive Component Test System Application

Clicking Cancel takes you to the application main window, as shown on

the figure below.

The DWDM Passive Component Test System main window is the central

location from where you access all functionalities.

Title bar

Function

buttons

Position of

modules in

IQS unit

Status bar

Details the procedure

in progress

DWDM Passive Component Test System 33

Page 46

Getting Started with Your DWDM Passive Component Test System

Accessing a Specific Test Step

Accessing a Specific Test Step

During the step-by-step procedure, it is possible to access the Te s t Steps

dialog box to manually go to a specific step via the Step button from the

main window.

To p r o cee d w ith

the current step

To s k i p th e

current step

34 IQS-12004B

Page 47

Getting Started with Your DWDM Passive Component Test System

Starting and Exiting the MultiPath Testing Option Application

Starting and Exiting the MultiPath Testing

Option Application

You may want to use the provided LabVIEW application to work with the

MultiPath Testing option .

To start the LabVIEW application:

³ On the Windows taskbar, click Start, select Programs > EXFO >

IQS-12004B > IQS-12004B Multi Path DWDM Test System.

OR

³ Double-click the IQS-12004B MPT desktop icon.

The application main window is displayed.

To close the application, select Exit from the File menu.

DWDM Passive Component Test System 35

Page 48

Page 49

4 Setting Up the DWDM Passive

Component Test System

The DWDM Passive Component Test System has been designed to let you

define DUTs and optical ports that can be used for future tests.

Configuring DUT Parameters for Pass/Fail Analysis

Note: You must be working at the Supervisor level to access this window.

The DUT Configuration window allows you to define specific parameters

for the optical ports and DUTs you will be testing. Information entered in

this window is used to construct and maintain two internal lists: one for

port types and one for DUTs. These two lists provide an efficient way of

identifying the Pass/Fail limits for all your commonly tested components.

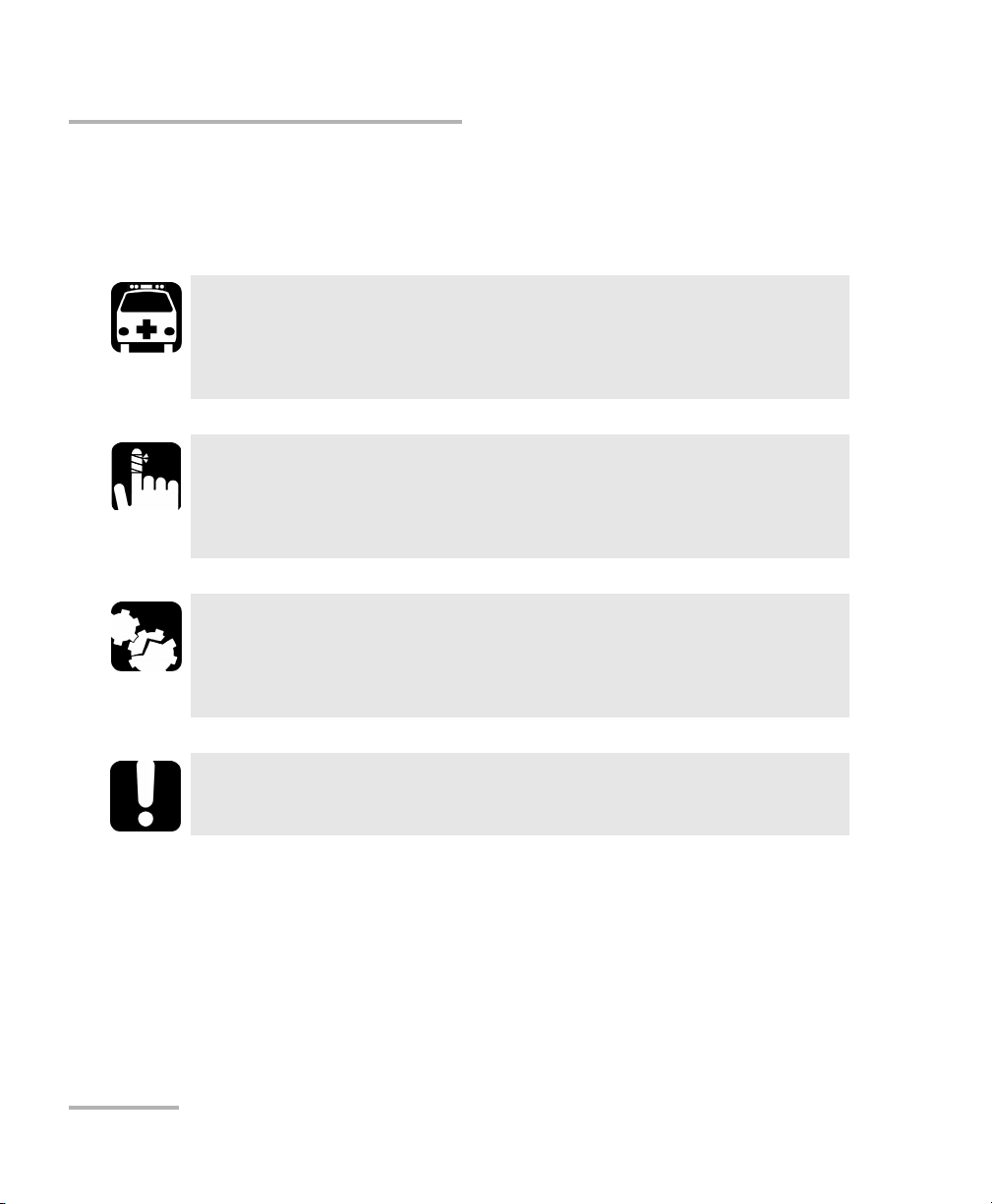

The relationship between optical ports and DUTs is illustrated below. In this

example, the DUT is a four-channel device with one common port and four

output ports.

Port 1 (200 GHz bandpass)

1x4 Demultiplexer

(DUT)

To identify the Pass/Fail criteria for this type of component, you must define

the different parameters (IL, PDL, BW, etc.) for each port. In most cases,

the characteristics for all ports will be identical, except for the wavelength.

The most efficient way of describing the above device would be to create a

port (200 GHz bandpass) and define all its Pass/Fail criteria. When you

define the DUT, you simply have to select a port type for each output and

assign a wavelength to the port mask. This 200 GHz bandpass port will also

be used for defining other devices. There is no practical limit to the number

of different ports or DUTs that can be defined.

DWDM Passive Component Test System 37

Port 2 (200 GHz bandpass)

Port 3 (200 GHz bandpass)

Port 4 (200 GHz bandpass)

Page 50

Setting Up the DWDM Passive Component Test System

Configuring DUT Parameters for Pass/Fail Analysis

This window can be accessed via the Configure DUTs icon from the

Welcome/New Test window. For information on how to display this

window, see Opening a New Test Database on page 61.

³ Optical Ports Configuration: This section contains the list of all

configured ports. You can add new ports (click Add), modify the port

indicated in the Port Type list box (click Modify), or delete an existing

optical port (click Delete).

For information about the configuration of an optical port type, see

Configuring an Optical Port on page 39.

³ DUT Configuration: This section allows you to configure DUTs based

on the optical port types. You can add new DUTs (click Add), modify

the DUT indicated in the Part Number list box (click Modify), or delete

an existing DUT (click Delete).

For information about the configuration of a DUT, see Configuring a

DUT on page 42.

38 IQS-12004B

Page 51

Setting Up the DWDM Passive Component Test System

Configuring an Optical Port

Configuring an Optical Port

Note: You must be working at the Supervisor level to access this window.

This window can be accessed via the Configure DUTs icon from the

Welcome/New Test window. For information on how to display this

window, see Opening a New Test Database on page 61.

When you click Add or Modify in the Optical Ports Configuration section,

the following window appears where you can enter or modify port

information. For details about the parameters contained in this window,

see Definitions and Calculation Methods on page 405.

Note: Some parameters can be disabled (grayed out) when you select a certain

mask type.

³ Port Type: Use this text box to give a unique name to the optical port

defined.

³ Mask Type: This list box allows you to select one of two different mask

types (bandpass and notch).

DWDM Passive Component Test System 39

Page 52

Setting Up the DWDM Passive Component Test System

Configuring an Optical Port

The Spectral Parameters section is used to specify the limits or the

acceptable values that will determine the Pass/Fail result of the tests.

³ BW1, BW2, and BW3: These text boxes allow you to specify the relative

power levels (in dB) at which bandwidth is tested, and the acceptable

bandwidth (in nm). Note that only BW2 and BW3 are tested when the

Defined Bandwidth calculation method is selected.

³ BWx Tolerance: These text boxes allow you to specify the tolerance

interval for the bandwidth test. For a DUT to pass this test, the

measured BWx value must fall within BWx ±BWx tolerance.

³ Wavelength Tolerance: This text box is used to enter the central

wavelength tolerance of the specified port. This test is not performed

when the Defined Bandwidth calculation method is selected.

The Loss Parameters section is used to specify the flatness, crosstalk,

rejection as well as the IL, ORL and PDL values.

³ Flatness: This text box is used to enter the acceptable flatness (in dB)

of the curve in the measured BW1 interval.

³ Crosstalk: This text box allows you to enter the acceptable channel

crosstalk (in dB) for the DUT. This option is disabled (grayed out) when

the notch mask type is selected.

³ Rejection: This text box allows you to enter the acceptable rejection

level (in dB) for the DUT. This option is disabled (grayed out) when the

bandpass mask type is selected.

³ IL: This field allows you to specify the acceptable insertion loss value

(dB).

³ ORL: This field allows you to specify the ORL limit value (dB).

³ PDL: This field allows you to specify the PDL limit value (dB).

40 IQS-12004B

Page 53

Setting Up the DWDM Passive Component Test System

Configuring an Optical Port

The Calculation Method Based On section is used to select which

method will be used to calculate some of the different test results. For

details about these methods, see Definitions and Calculation Methods on

page 405.

³ Measured Bandwidth: This option allows BW1 to be determined from

the measured data.

³ Defined Bandwidth: This option allows you to define BW1 yourself.

When selecting defined bandwidth, you will enter the defined

bandwidth in the BW1 box. During the data analysis, the software will

use the CW ±BW1/2 as the analysis range for IL, crosstalk, ripple, etc.

DWDM Passive Component Test System 41

Page 54

Setting Up the DWDM Passive Component Test System

Configuring a DUT

Configuring a DUT

Note: You must be working at the Supervisor level to access this window.

This window can be accessed via the Configure DUTs icon from the

Welcome/New Test window. For information on how to display this

window, see Opening a New Test Database on page 61.

Once the optical ports are correctly defined, you can configure DUTs based

on these ports. When clicking Add or Modify in the DUT Configuration

section, the following window appears where you can enter or modify

information about the DUT.

In the upper section of the DUT Configuration window, you enter

identification and test parameters. These parameters will automatically be

selected when performing a scan on a defined device.

Note: Once a device has been created, the Number of Ports cannot be modified.

³ Part Number: the part number for the DUT.

³ Description: a short description of the DUT.

³ Manufacturer: the name of the manufacturer.

42 IQS-12004B

Page 55

Setting Up the DWDM Passive Component Test System

Configuring a DUT

³ Analysis from X nm to Y nm: the default range of the analysis. The

analysis limits can be modified later in the IQS-12004B Setup window.

³ Number of Ports: the number of ports, excluding the common port.

³ Port Number: In this list box, you select the port for which you will

configure the type and central wavelength. You can also use the

Previous and Next buttons to move from one port to another.

³ Port Type: In this list box, you select the type of port from the list of

available ports that you configured previously. Usually for a device, all

ports are of the same type, but this is not always the case; and the

software allows you to configure devices with different port types. For

more information, see Configuring an Optical Port on page 39.

³ Center Wavelength: You can specify a wavelength yourself (using the

Specified Wavelength option button), or select one of the ITU

wavelengths from the list (using the From List option button). The ITU

wavelength values correspond to the list defined in the Channel List

dialog. For more information, see Customizing the Channel List on

page 46.

³ ORL Analysis: Select this option to perform an ORL analysis.

³ The PDL Analysis section allows you to select options for PDL testing.

³ If you intend to export detailed IL results, check the

Keep IL traces for all states of polarization (4) box.

³ If you need to get the results from the polarization-dependent

wavelength analysis, check the

Polarization Dependent Wavelength box.

Note: These two options can also be selected when you set the test parameters.

For more information, see Preparing the Test Setup on page 49. If you omit

to check the boxes, you won’t be able to export the corresponding traces.

For more information on exporting, see Exporting Data on page 94.

³ Center Wavelength: The PDL value is taken at the central wavelength

for each port.

DWDM Passive Component Test System 43

Page 56

Setting Up the DWDM Passive Component Test System

Configuring DUT Company/Customer Parameters

³ Operating Wavelength Range: The highest PDL value in the BW1

range is taken.

³ Relative Range (CW)±X nm: allows you to indicate the highest PDL

value in the relative range ± X nm.

³ From X nm to Y nm: allows you to indicate the highest PDL value

between X nm and Y nm.

Click OK to add the DUT to the list of available components to test.

Configuring DUT Company/Customer

Parameters

Note: You must be working at the Supervisor level to access this window.

The Company/Customer Configuration window contains identification

and system information including the name of the company (organization

performing the tests) and the customer (organization for which the tests

are performed).

All this information is saved in a database and is useful for documentation

and traceability purposes.

To access the Company/Customer Configuration window:

From the Configuration menu, select Company/Customer

Configuration.

44 IQS-12004B

Page 57

Setting Up the DWDM Passive Component Test System

Configuring DUT Company/Customer Parameters

³ Company Information: This section indicates the name of the

company performing the tests. You can modify the information by

clicking Modify.

³ Customer List: This section allows you to enter data about the

different customers. You can add new customers to the database (click

Add), modify a customer indicated in the list box (click Modify), or

delete an existing customer (click Delete). When clicking Add or

Modify, the following window appears where you can enter or modify

customer information.

DWDM Passive Component Test System 45

Page 58

Setting Up the DWDM Passive Component Test System

Customizing the Channel List

Customizing the Channel List

Note: You must be working at the Supervisor level to use this feature.

This feature allows you to view and customize the channel list, which

contains predefined ITU wavelengths. New wavelengths can also be added

to this list. The DWDM Passive Component Test System displays the

channel list when a choice of wavelength is required.

The number of digits displayed after the decimal point can be changed to

better suit your needs.

You can access the Channel List window by selecting Channel List from

the Options menu.

To modify the number of digits displayed after the decimal point:

Use the Decimal Places box to set the desired value.