Page 1

R&D AND MANUFACTURING

CALIBRATION SYSTEM

IQS-12002B

USER GUIDE

Page 2

Copyright © 2006– EXFO Electro-Optical Engineering Inc. All rights

reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted in any form, be it electronically,

mechanically, or by any other means such as photocopying, recording or

otherwise, without the prior written permission of EXFO Electro-Optical

Engineering Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Version number: 1.0.1.4

ii IQS-12002B

Page 3

Contents

Contents

1 Introducing the IQS-12002B Calibration System ........................................ 1

Calibration and Verification: Assessing Conformity .................................................................3

System Overview ....................................................................................................................9

Conventions ..........................................................................................................................10

2 Getting Started with Your Calibration System ......................................... 11

Inserting and Removing Test Modules .................................................................................11

Installing Hardware Components .........................................................................................15

Starting and Exiting the Calibration System Application .......................................................16

Reinstalling or Upgrading the IQS-12002B Calibration System Application ..........................18

3 Setting Up Your Calibration System .......................................................... 19

Configuring Areas Specific for Instruments ...........................................................................19

Configuring Access Levels and Passwords .............................................................................20

Configuring the Due-for-Calibration Reminder .....................................................................22

Activating or Deactivating the Warmup Confirmation ..........................................................23

Configuring Main Window Appearance ................................................................................24

4 Operating Your Calibration System .......................................................... 25

Installing the EXFO Universal Interface (EUI) .........................................................................25

Cleaning and Connecting Optical Fibers ...............................................................................26

Viewing the Required Instruments ........................................................................................27

Launching a Manual Warmup ...............................................................................................28

Locating IQS Modules ...........................................................................................................28

Performing a Test ..................................................................................................................29

Printing or Exporting Results ................................................................................................37

Printing Reports ....................................................................................................................39

5 Troubleshooting ......................................................................................... 43

Solving Common Problems ...................................................................................................43

Finding Information on the EXFO Web Site ..........................................................................44

Contacting the Technical Support Group ..............................................................................45

Transportation ......................................................................................................................46

6 Maintenance ............................................................................................... 47

Cleaning EUI Connectors ......................................................................................................48

Cleaning Fixed Connectors ....................................................................................................50

Cleaning Detector Ports ........................................................................................................52

Cleaning the FOA Connector Adapter ...................................................................................53

Using a Standard after Recalibration ....................................................................................54

Calibration System iii

Page 4

Contents

A Calibration Methods ...................................................................................57

Power Meter .........................................................................................................................57

FTB-7000D and FTB-7000B-B OTDR Modules ........................................................................68

B Configuring the FTB-7000D OTDR on the IQS-12002B ...............................79

Creating the GP-121311: 4.4-km Fiber Spool as a Calibration Instrument ............................81

Creating the GP-121317: 17.6-km Fiber Spool as a Calibration Instrument ..........................83

Creating the IQS-3100BW Variable Attenuator as a Calibration Instrument ..........................84

Creating the GP-121723: 50-m Launch Fiber as a Calibration Instrument .............................86

Creating the GP-121392: Distance Reference Standard ........................................................89

Creating the GP-121310: Calibration Instrument for Singlemode, Front-Connector Position

(UPC Connectors) ............................................................................................................92

Creating the GP-120963: Singlemode Dead-Zone Calibration Instrument ............................95

Creating the GP-121310: Calibration Instrument for Singlemode, Front-Connector Position

(APC Connectors) ............................................................................................................98

Index ...............................................................................................................101

iv IQS-12002B

Page 5

1 Introducing the IQS-12002B

Calibration System

The IQS-12002B Calibration System has been designed to calibrate, verify,

and adjust several types of devices. Some concept pertaining to the system

are described here:

³ Calibration is a set of operations that establish, under specified

conditions, the relationship between values of quantities indicated by a

measuring instrument (DUT) and the corresponding values realized by

standards.

³ Verification consists in comparing calibration results with established

limits. It is the confirmation that, through the explanation of a given

item and a provision of objective evidence, it fulfils specified

requirements.

³ Adjustment is the operation of bringing a measuring instrument into a

state of performance suitable for its use.

³ Uncertainty is the parameter that quantitatively characterizes the

dispersion of values that could be attributed to the measures.

Uncertainty is given with a specific level of confidence.

Note: Accuracy is the qualitative expression of the capacity of an instrument to

give results close to the true value.

Note: Precision is the closeness of agreement between quantity values obtained

by replicate measurements of a quantity under specified conditions.

Calibration System 1

Page 6

Introducing the IQS-12002B Calibration System

Some units (DUT) cannot be adjusted using the IQS-12002B. Depending on

the DUT model, adjustment will or will not be possible. When adjustment

is not possible, you can only perform calibration and verification of the unit.

If adjustment is possible, you will be asked to perform calibration and

verification of the DUT before and after adjustment.

The provided application helps you to comply to the ISO/IEC 17025

standard with the use of the following features:

³ The application keeps (in the database) the complete history of the

operations performed by a user on a DUT.

³ You can report all DUTs that have been verified or adjusted using a

specific standard.

³ For some procedures, the system allows taking uncertainties into

account when judging on compliance.

2 IQS-12002B

Page 7

Introducing the IQS-12002B Calibration System

Calibration and Verification: Assessing Conformity

Calibration and Verification: Assessing

Conformity

The latest international standards require that calibration uncertainties be

evaluated and taken into account when a declaration of conformity is

given for a specification. Our uncertainty evaluations are carried out in

accordance with the guidelines stated in the Guide to the Expression of

Uncertainty in Measurement by ISO, IEC, BIPM (Bureau International des

Poids et Mesures) and other international organizations.

In order to ensure coherence, EXFO makes every effort to establish

correspondence between calibration uncertainties, guaranteed

specifications, allowed deviation between the unit and the standard, as

well as the conformance assessment of the power meter status upon

reception of the unit.

Calibration System 3

Page 8

Introducing the IQS-12002B Calibration System

Calibration and Verification: Assessing Conformity

Calibration Uncertainties

Calibration uncertainties are expressed in the certificate. It states the

combined uncertainties of the following factors:

³ Reference standard calibration uncertainty

³ Dependence of the reference standard on measurement conditions

³ Dependence of the tested meter on measurement conditions

³ Other uncertainties due to the setup and measurement method

As an example, for power meter absolute power calibration, the

dependence of the detector response at each point is evaluated for the

wavelength uncertainty of the source, output stability and output

bandwidth of the light, temperature uncertainty, connector-adapter

combination, fiber type, repeatability of the measurement, power meter

linearity, and other factors.

Guaranteed Specifications

Guaranteed specifications are EXFO's published specifications for the unit.

In fact, the calibration process foresees the possibility of making some

adjustments to ensure compliance. Written proof is given in the "As left"

section of the calibration certificate when the Within specifications box is

selected.

Allowed Deviation

The allowed deviation is the difference between the measurement of the

power meter under test and the reference standard; this is a key factor in

the determination of whether or not a unit conforms to its specifications.

4 IQS-12002B

Page 9

Introducing the IQS-12002B Calibration System

Calibration and Verification: Assessing Conformity

The Concepts behind the IQS-12002B Calibration

System

The IQS-12002B Calibration System is used to verify and/or adjust a DUT

(device under test) of a certain type (e.g., FPM-300) and of a certain model

(e.g., FPM-302X). The application keeps a history of each tested device.

To test a device, the system needs various instruments such as sources,

power meters, fiber spools, etc. In the system, there may be several

instruments of a given type and model. By default, the system uses the first

instrument available, unless you specify one.

Some of the instruments are considered as “standards”, for which the

system keeps an history. Since the system relies on the accuracy of these

standards, you must respect the recommended calibration frequency. The

system does not allow tests with a standard that is due for calibration.

To test a device, the application will need a test sequence. This test

sequence consists in several substeps identified as “scenarios”. A scenario

is based on a general procedure (e.g., insertion loss) that it adapts with

particular specifications for a particular DUT model (e.g., variable

attenuator insertion loss at 1310 nm).

The specifications are the different values the application uses to

determine the compliance of a DUT. For certainties compliant with

ISO 17025, there are four possible collections when assessing conformity:

³ Inside specifications

³ Inside specifications*

³ Outside specifications*

³ Outside specifications

Note: Please refer to the section Conformance Assessment of the Unit Status for a

Certificate Compliant with ISO 17025 for further details on verification of a

device when taking into account measurement uncertainties.

Calibration System 5

Page 10

Introducing the IQS-12002B Calibration System

Calibration and Verification: Assessing Conformity

Conformance Assessment of the Unit Status for a

Certificate Compliant with ISO 17025

The conformance assessment of the power unit status, upon reception,

requires a judgement on the compliance or non-compliance with

specifications. The result of this judgement depends on the allowed

deviation and on the gray zone introduced by calibration uncertainties. As a

consequence of this gray zone, it is not always possible to draw a firm

conclusion regarding the unit status when it is received from the customer.

Following the indications given by ISO/IEC 17025, EXFO provides, in the "As

found" section of the certificates, four conclusions depending on deviation,

guaranteed specifications (Spec), and calibration uncertainty (Ucal):

³ Inside specifications

When measured deviation is within the following limits, the unit is said

to be within specifications with a level of confidence of 95 %:

de viat ion spec 0.825 Ucal•–()≤

³ Inside specifications

When all results are within specification limits. In conformance with

ISO/IEC 17025, full compliance cannot be achieved because of

measurement uncertainties. Nevertheless, results indicate that the

instrument is likely to perform according to specifications. Results are

bound by the following limits:

spec 0.825– Ucal⋅ deviation< spec≤

6 IQS-12002B

Page 11

Introducing the IQS-12002B Calibration System

Calibration and Verification: Assessing Conformity

³ Outside specifications

When some results are outside specification limits. Nevertheless,

non compliance cannot be established because of measurement

uncertainties. Results are bound by the following limits:

spec deviation< spec≤ 0.825+ Ucal⋅

When one of the two first conclusions applies to the unit under test, it is up

to you to determine if measurements taken with that unit, before

verification, are considered valid. This depends on the following:

Whether a deviation outside published specifications can be tolerated

for these measurements.

The proximity of the measurements, taken with the unit, to the

maximum allowed deviation.

³ Outside specifications

The unit is definitely not within specifications. The deviation is larger

than the sum of the specification and the calibration uncertainty.

deviation spec> 0.825+ Ucal⋅

For example, for power meter models whose specification and

calibration uncertainties are respectively ±5 % and ±3.1 % (at

1550 nm), the deviation will allow us to conclude the following:

Inside specifications

deviation 2.5 %≤

Inside specifications*

2.5 % deviation< 5%≤

Calibration System 7

Page 12

Introducing the IQS-12002B Calibration System

Calibration and Verification: Assessing Conformity

³ Outside specifications*

5 % deviation< 7.5 %≤

Outside specifications |deviation| > 9 %

deviation 7.5 %>

IMPORTANT

For a pass/fail certificate (not compliant with ISO 17025),

uncertainties are not taken into account for conformance

assessment, therefore, there are only two zones: pass or fail.

8 IQS-12002B

Page 13

Introducing the IQS-12002B Calibration System

System Overview

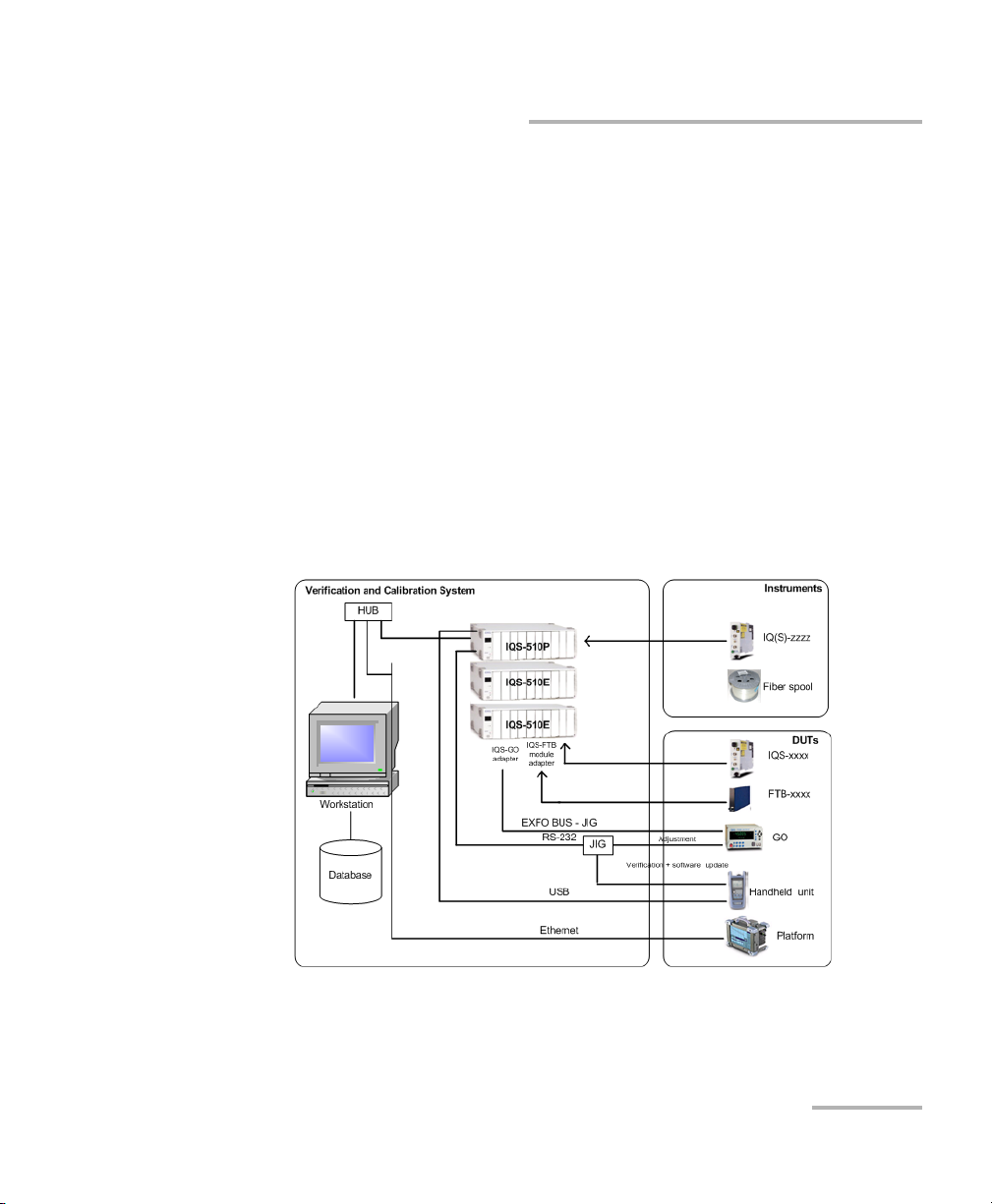

System Overview

The system includes:

³ a computer, on which the application and database are located

³ an IQS-500 controller unit that contains the instruments requiring a

warmup period

³ one or several IQS-500 expansion units that could contain both

instruments that do not require a warmup period and DUTs.

Both instruments and DUTs can be inserted in the same IQS-500

expansion unit (in specific areas, refer to Configuring Areas Specific for

Instruments on page 19). You may find useful to insert only instruments

that do not require a warmup period in an expansion unit that also

houses DUTs. This way, turning off the expansion unit to insert your

DUTs, will not affect the instruments warmup.

The required instruments vary according to the DUTs and the type of

verification and adjustment you want to perform.

Calibration System 9

Page 14

Introducing the IQS-12002B Calibration System

Conventions

Conventions

Before using the product described in this manual, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

10 IQS-12002B

Page 15

2 Getting Started with Your

Calibration System

Inserting and Removing Test Modules

CAUTION

Never insert or remove a module while the controller unit and its

expansion units are turned on. This will result in immediate and

irreparable damage to both the module and unit.

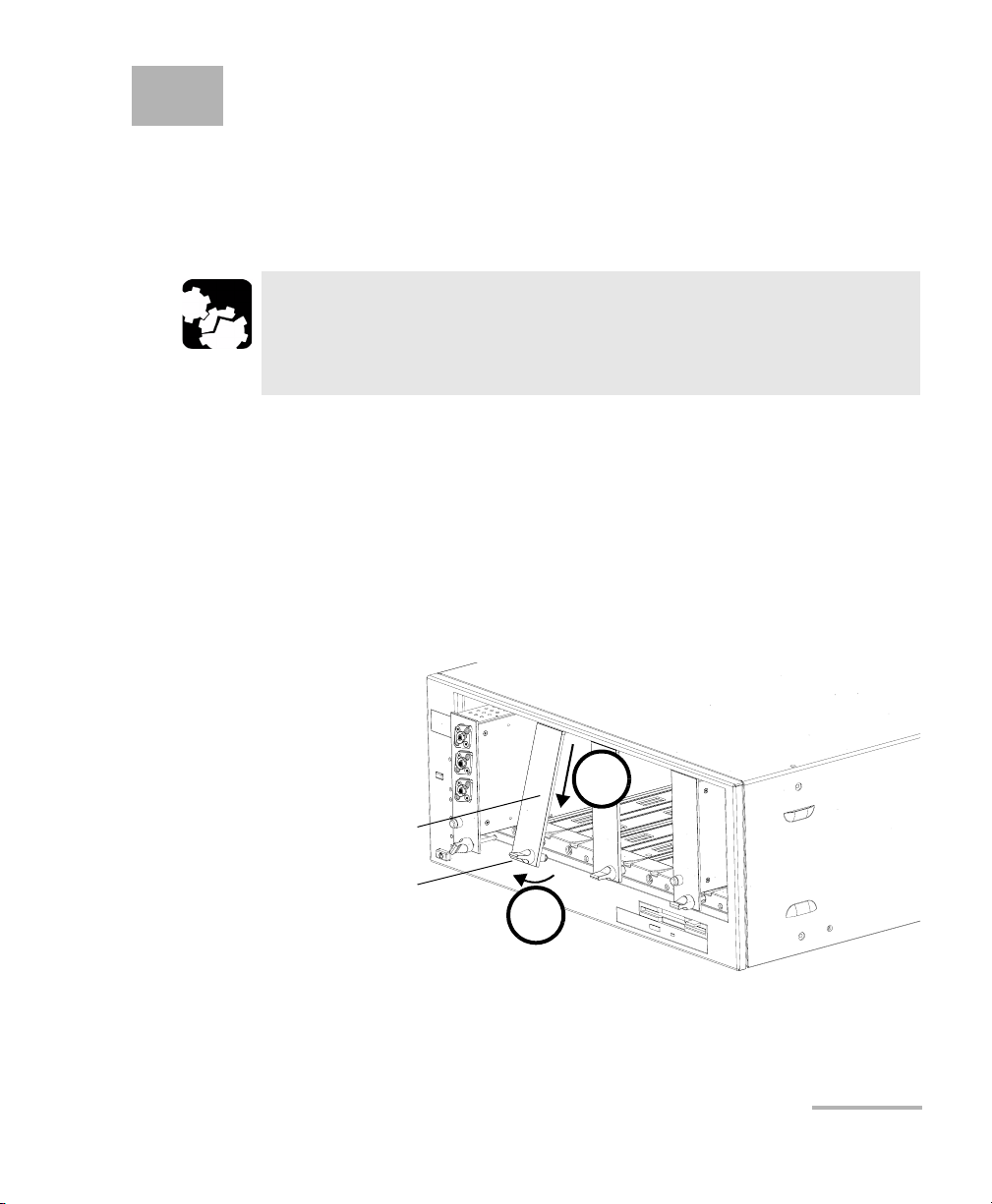

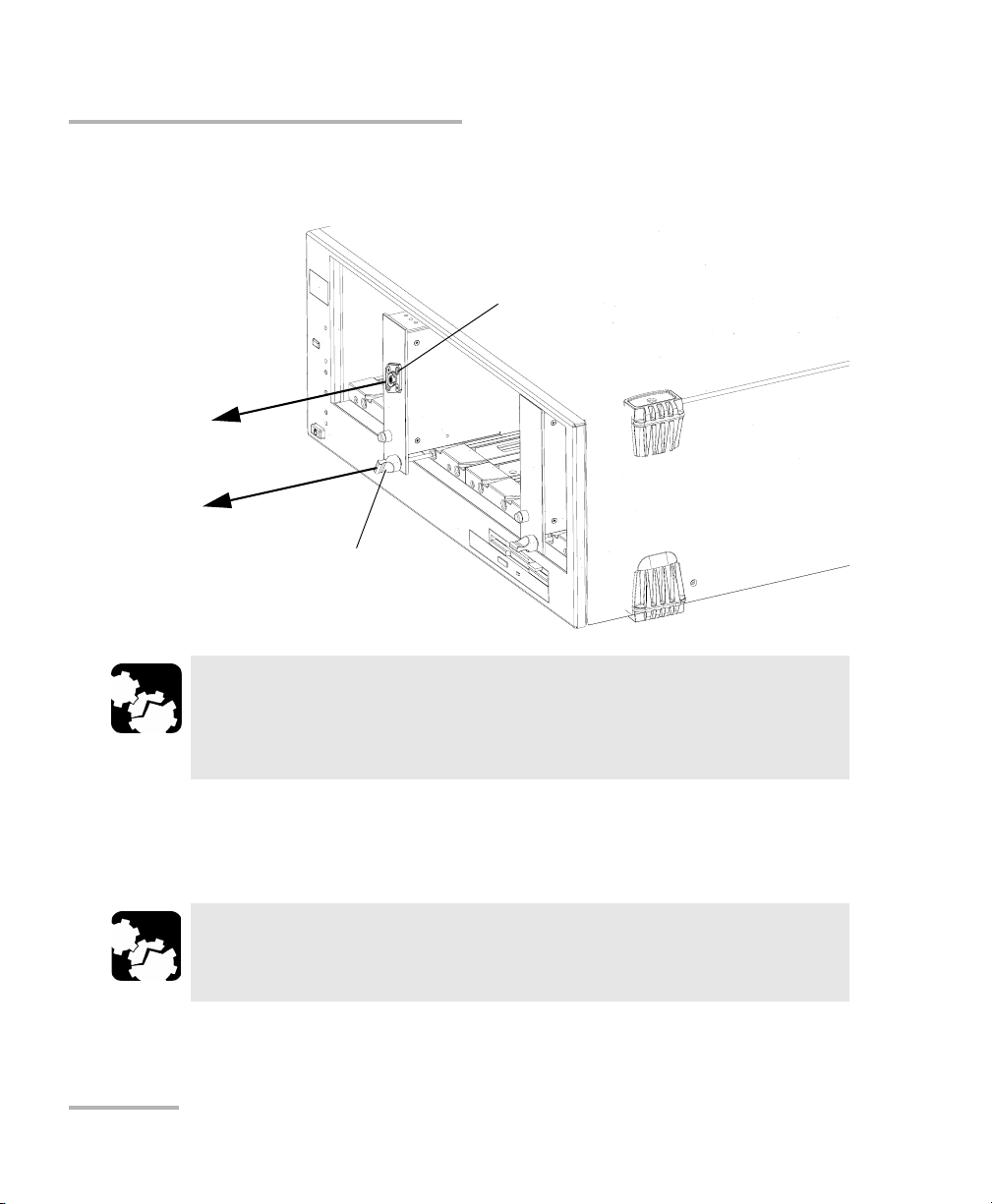

To insert a module into the controller or expansion unit:

1. Exit IQS Manager and turn off all your units.

2. Remove the protective cover from the desired unused module slot.

2a. Pull the retaining screw knob firmly towards you and release the

bottom of the cover.

2b. Gently pull the top of the protective cover downwards, to remove

it from the unit grooves.

2b

Protective cover

Retaining screw

knob

2a

3. Position the module so that its front panel is facing you and the top and

bottom protruding edges are to your right.

Calibration System 11

Page 16

Getting Started with Your Calibration System

Inserting and Removing Test Modules

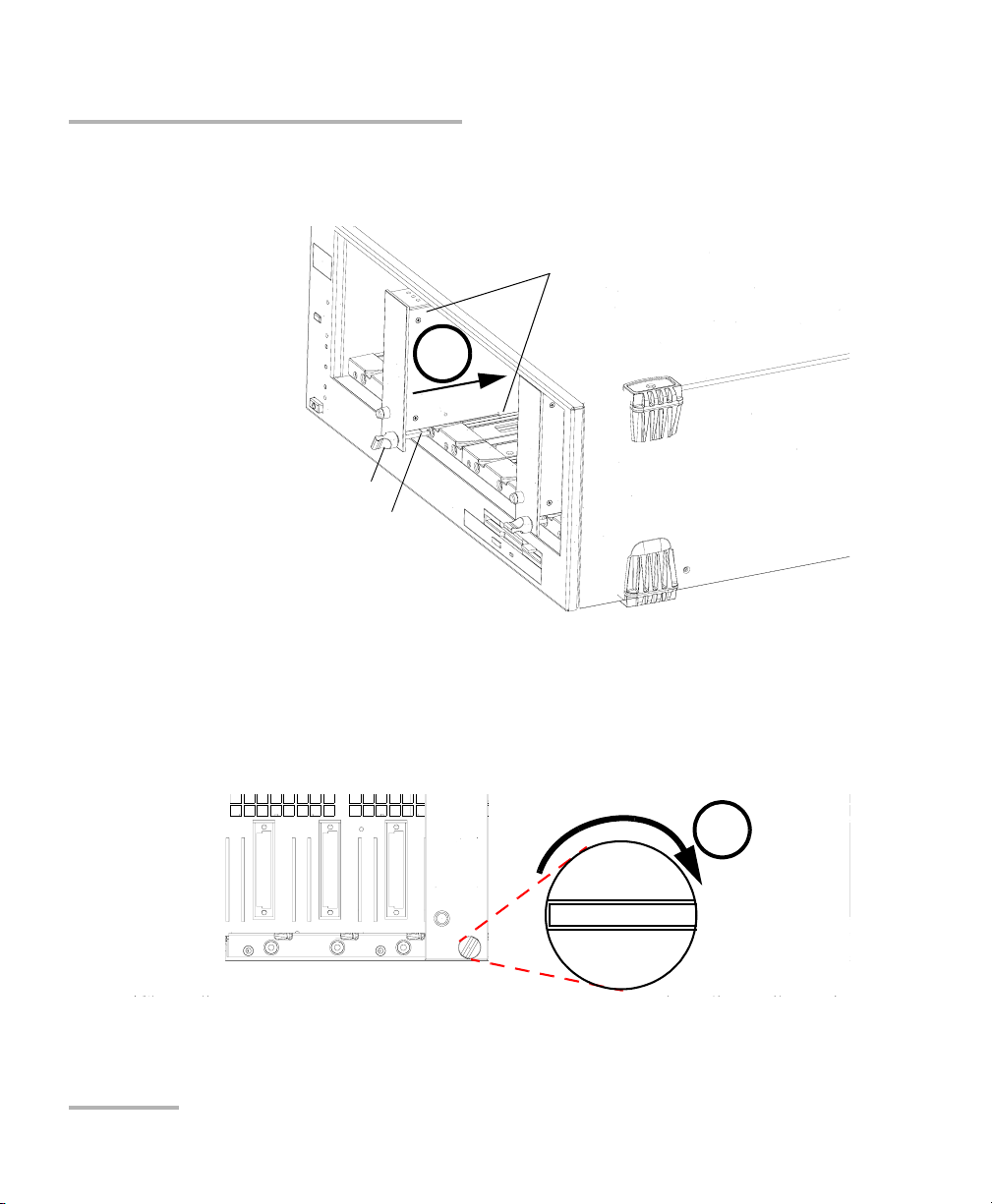

4. Insert the protruding edges of the module into the grooves of the unit’s

module slot.

5

Retaining screw knob

Retaining screw

Protruding edges

(right side of module)

5. Push the module all the way to the back of the slot, until the retaining

screw makes contact with the unit casing.

6. While applying slight pressure to the module, turn the retaining screw

knob (located at the bottom of the panel) clockwise until the knob is

horizontal. This will secure the module into its “seated” position.

6

The module is correctly inserted when its front panel is flush with the front

panel of the controller or expansion unit.

12 IQS-12002B

Page 17

Getting Started with Your Calibration System

Inserting and Removing Test Modules

When you turn on the controller unit, the startup sequence will

automatically detect your module.

Note: You can insert IQ modules into your controller or expansion unit; the IQS

Manager software will recognize them. However, the IQS-500 locking

mechanism (retaining screw) will not work for IQ modules.

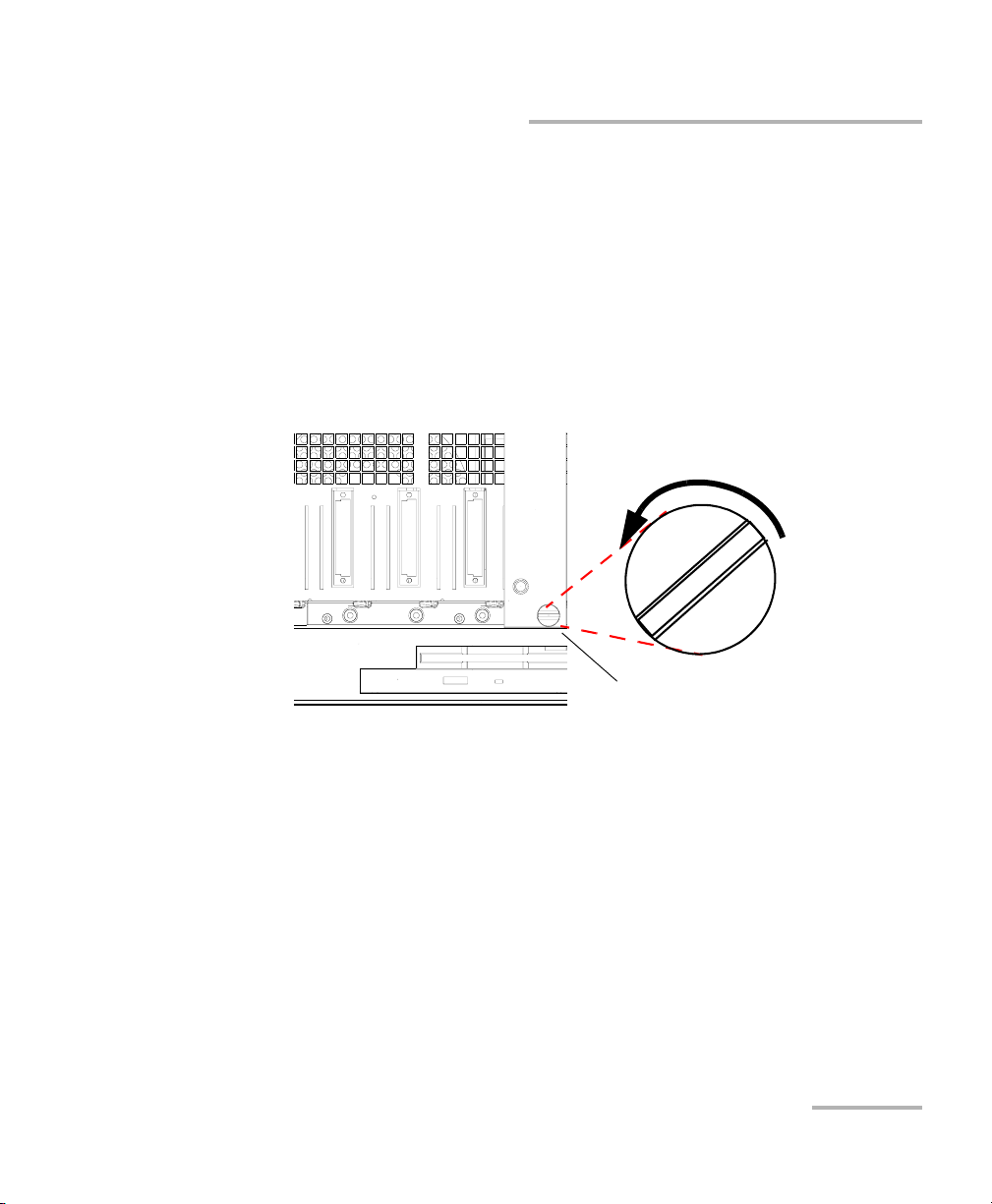

To remove a module from your controller or expansion unit:

1. While pulling gently on the knob, turn it counterclockwise until it stops.

The module will slowly be released from the slot.

Retaining screw knob

Calibration System 13

Page 18

Getting Started with Your Calibration System

Inserting and Removing Test Modules

2. Place your fingers underneath the module or hold it by the retaining

screw knob (NOT by the connector) and pull it out.

Connector

NO

YES

Retaining screw

knob

CAUTION

Pulling out a module by a connector could seriously damage both

the module and connector. Always pull out a module by the

retaining screw knob.

3. Cover empty slots with the supplied protective covers. Simply slide the

top of the protective cover into the upper grooves of the unit, and then

snap into place by pushing the retaining screw knob.

CAUTION

Failure to reinstall protective covers over empty slots will result in

ventilation problems.

14 IQS-12002B

Page 19

Getting Started with Your Calibration System

Installing Hardware Components

Installing Hardware Components

Both instruments and DUTs can be inserted in the same IQS-500 expansion

unit (in specific areas). You may find useful to insert only instruments that

do not require a warmup period in an expansion unit that also houses

DUTs. This way, turning off the expansion unit to insert your DUTs, will not

affect the instruments warmup. For more information on how to define the

area reserved to instruments, see Configuring Areas Specific for

Instruments on page 19.

To avoid multiple warmup periods, you can consult the list of required

instruments for the test you want to perform.

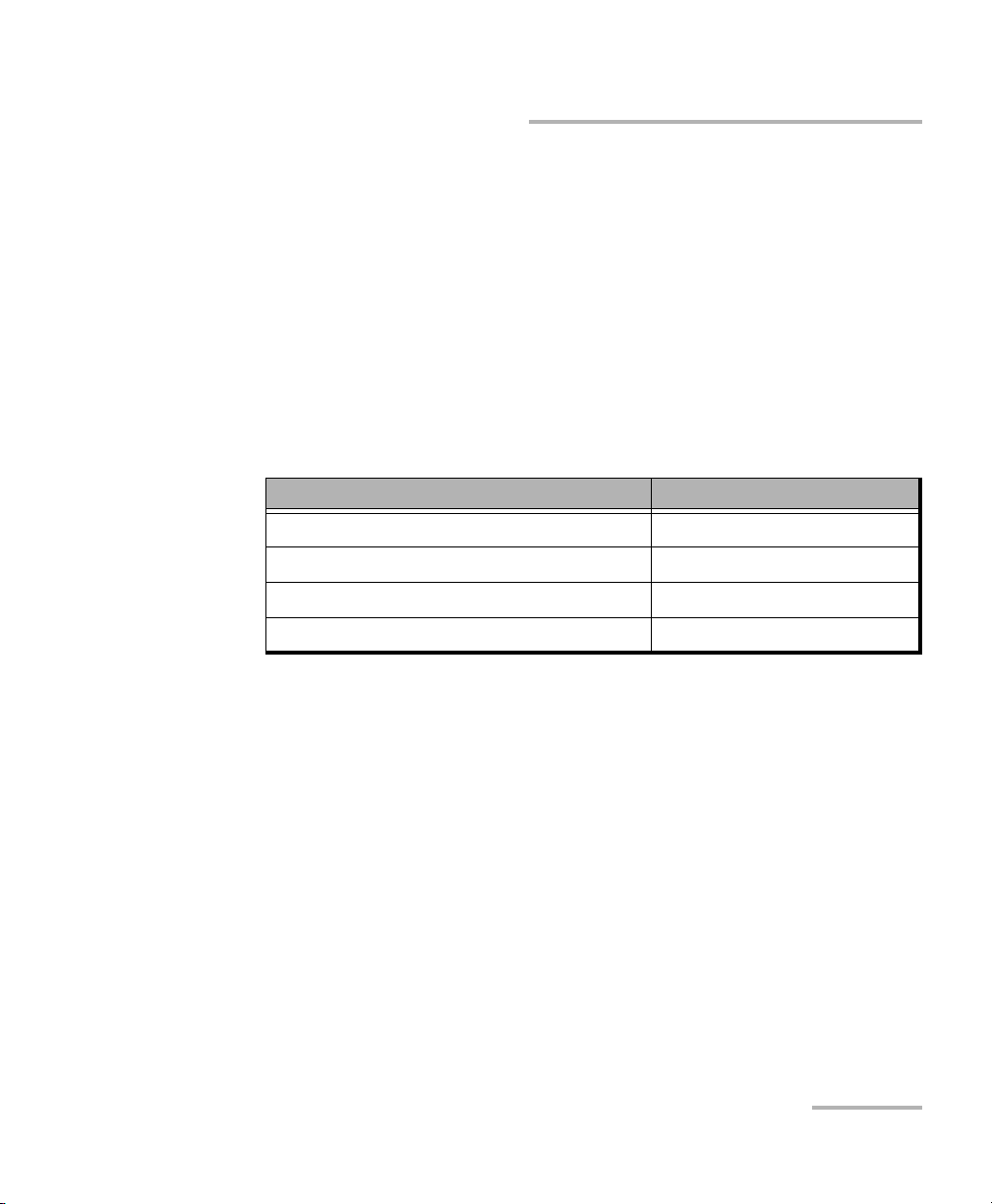

Instrument Warmup period

Source 60 minutes

EDFA 60 minutes

Power meter 15 minutes

Others no warmup

The application will show you the required connections, step by step,

during the test.

Calibration System 15

Page 20

Getting Started with Your Calibration System

Starting and Exiting the Calibration System Application

Starting and Exiting the Calibration System

Application

To start the Calibration System application:

1. Turn on the IQS-500 controller and expansion units.

IMPORTANT

Wait until the LED push button of all the modules (except the

polarization or mode scrambler) light up before starting the

application. Otherwise, the application will not be able to link to

the hardware.

2. Turn on the computer on which the application is installed and log on

as “operator” or “manager” and enter the password.

3. From the computer, on the Windows taskbar, click the Start button

and select Programs > EXFO > IQS-12002B.

OR

Double-click the IQS-12002B Calibration System icon.

4. When the application prompts you, log on to the system.

16 IQS-12002B

Page 21

Getting Started with Your Calibration System

Starting and Exiting the Calibration System Application

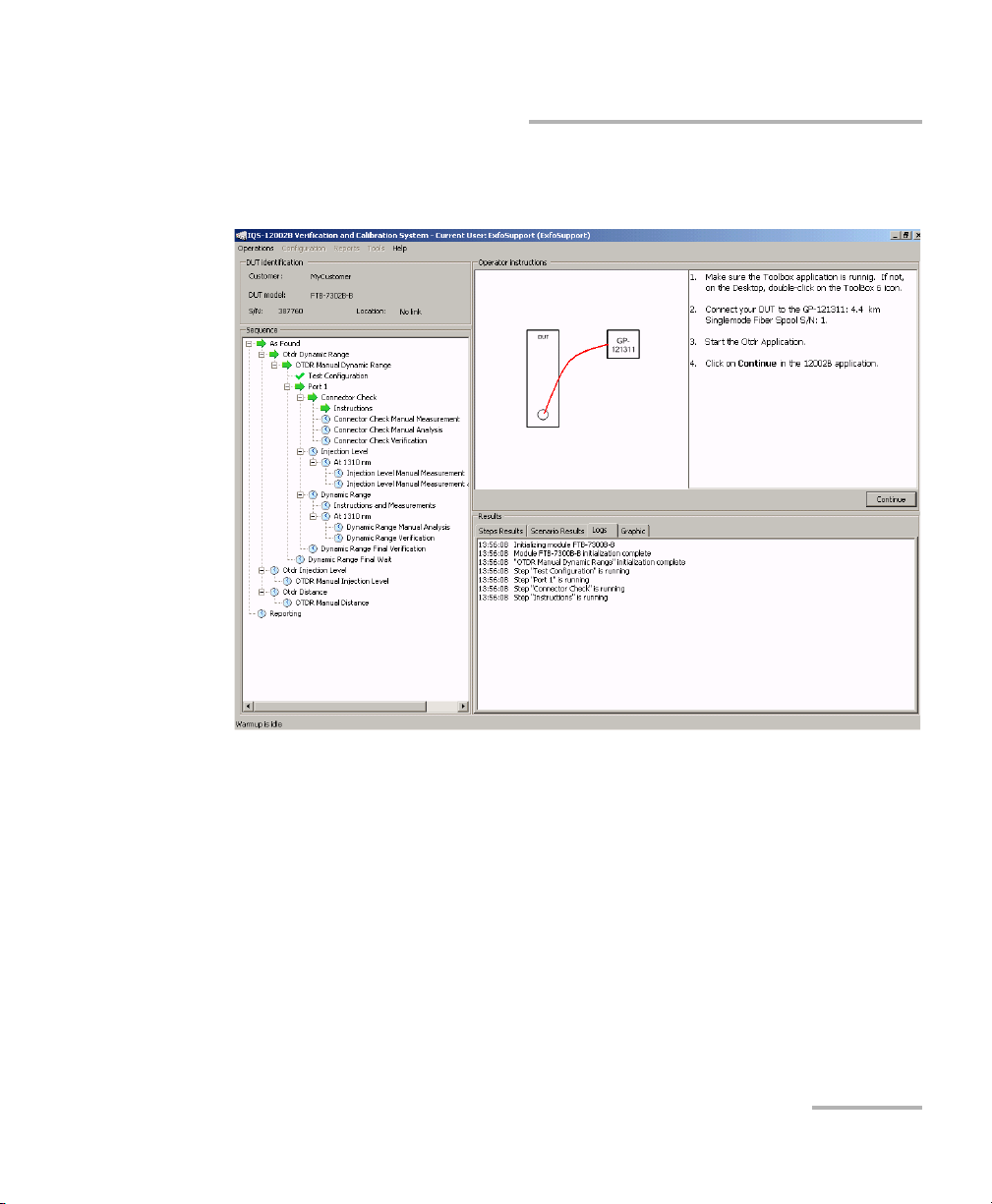

The main window (shown below) contains all the commands required to

control your system.

To exit the Calibration System application:

1. From the File menu, click Exit.

2. Turn off the controller and expansion units.

Calibration System 17

Page 22

Getting Started with Your Calibration System

Reinstalling or Upgrading the IQS-12002B Calibration System Application

Reinstalling or Upgrading the IQS-12002B

Calibration System Application

Please be careful before uninstalling the application. When processed, all

data saved in the database will be lost. This include the DUT results, DUT

creation, standards creation, standard traceability, DUT traceability,

certificates, all users modifications, etc.

Normally you would not have to install the Calibration System application,

except in particular circumstances (such as after having reinstalled

Microsoft Windows).

Please contact the customer’s service to proceed with the

installation/upgrade of the system.

18 IQS-12002B

Page 23

3 Setting Up Your Calibration

System

Configuring Areas Specific for Instruments

Since the system can house instruments and DUTs in the same expansion

unit, you must specify which area is dedicated to the instruments. The

application will then be able to identify which modules must be

considered as instruments and which as DUTs.

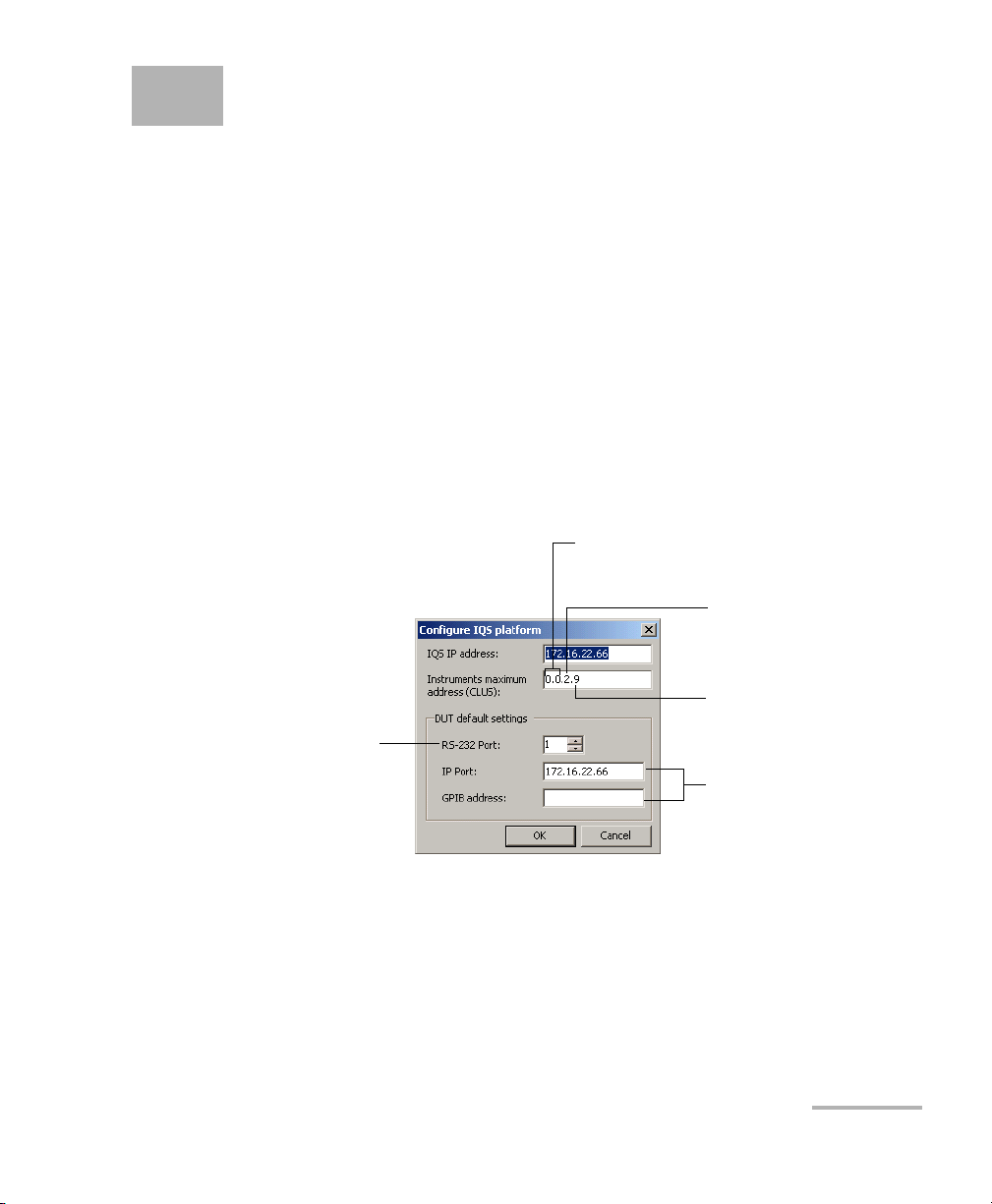

To configure the area for instruments:

1. From the Too ls menu, select System > Configure IQS Platform.

2. In the Instruments maximum address (CLUS) box, enter the address

of the last slot you want to use for instruments. The application will

assign the next slots to DUTs.

Do not modify the first

two numbers

Unit number

(indicated on front panel of

controller or expansion unit)

Slot number

Increase when DUT is

connected to the unit

Calibration System 19

by RS

-232

3. Click OK to confirm.

Do not modify

Page 24

Setting Up Your Calibration System

Configuring Access Levels and Passwords

Configuring Access Levels and Passwords

To comply with standard ISO 17025, you must be able to identify who

(which user) verified and/or adjusted a particular DUT.

There are three types of users:

³ Operator: verifies and adjusts DUTs, and generates certificates.

³ Manager: has the same rights as the operator and can also configure

the system.

³ Administrator: has the same rights as the manager and can also install

components and complete the initial system configuration.

Each system user must have a password.

Only users with administrator rights can create, modify, and delete user

profiles in the system. A user profile contains a user name, a password, a

permitted access level, etc.

20 IQS-12002B

Page 25

Setting Up Your Calibration System

Configuring Access Levels and Passwords

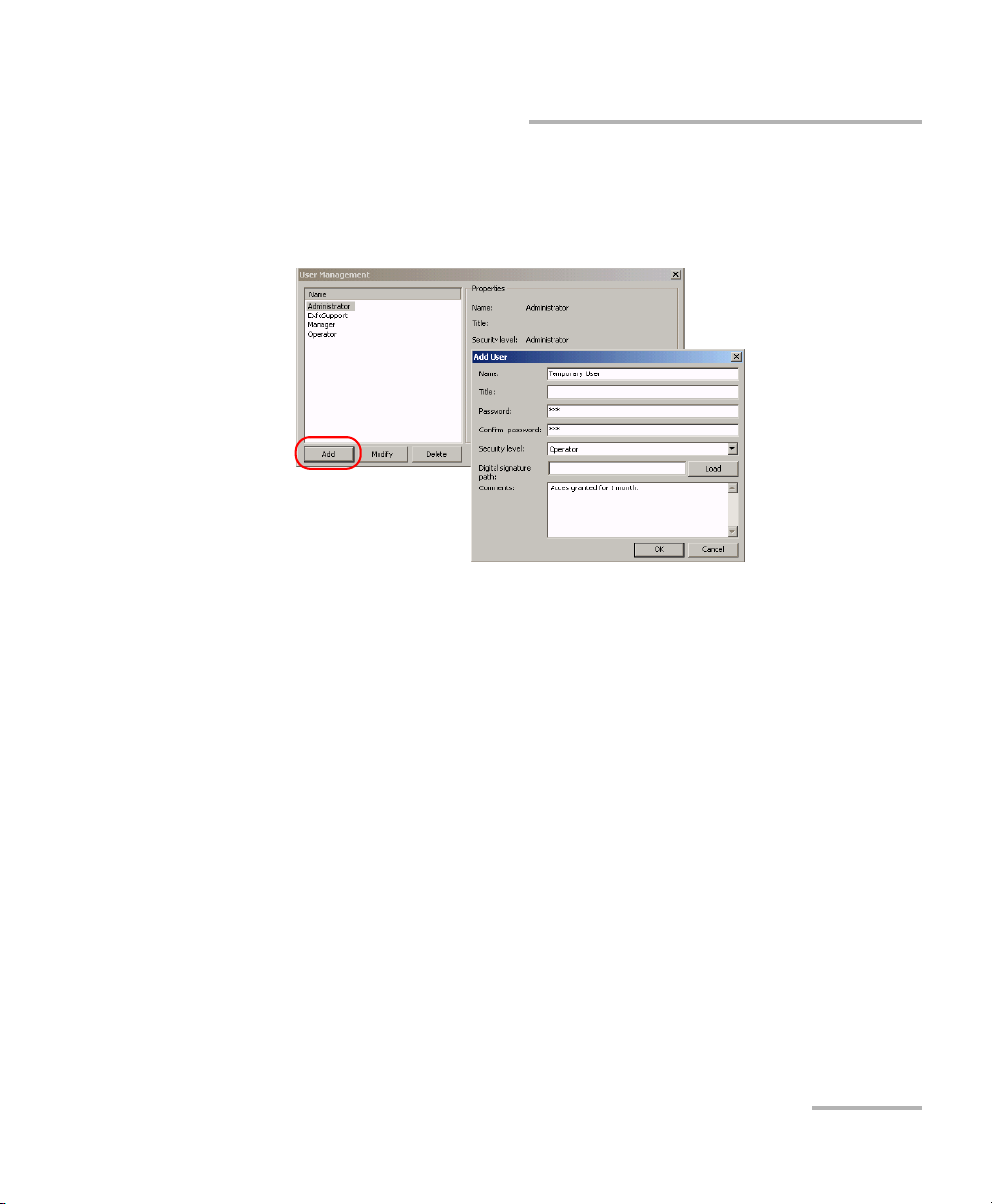

To create a user profile:

1. From the Tools menu, select System > User Management.

2. Click Add to create a user.

3. In the Add User box, fill in the information and click OK to confirm.

Clicking Cancel takes you back to the main window.

To modify a user profile:

1. From the Tools menu, select System > User Management.

2. From the Name list, select the user profile you want to modify.

3. Click Modify.

4. Modify the information and click OK to confirm.

Clicking Cancel takes you back to the main window.

To delete a user profile:

1. From the Tools menu, select System > User Management.

2. From the Name list, select the user profile you want to delete.

3. Click Delete and confirm deletion.

Clicking Cancel takes you back to the main window.

Calibration System 21

Page 26

Setting Up Your Calibration System

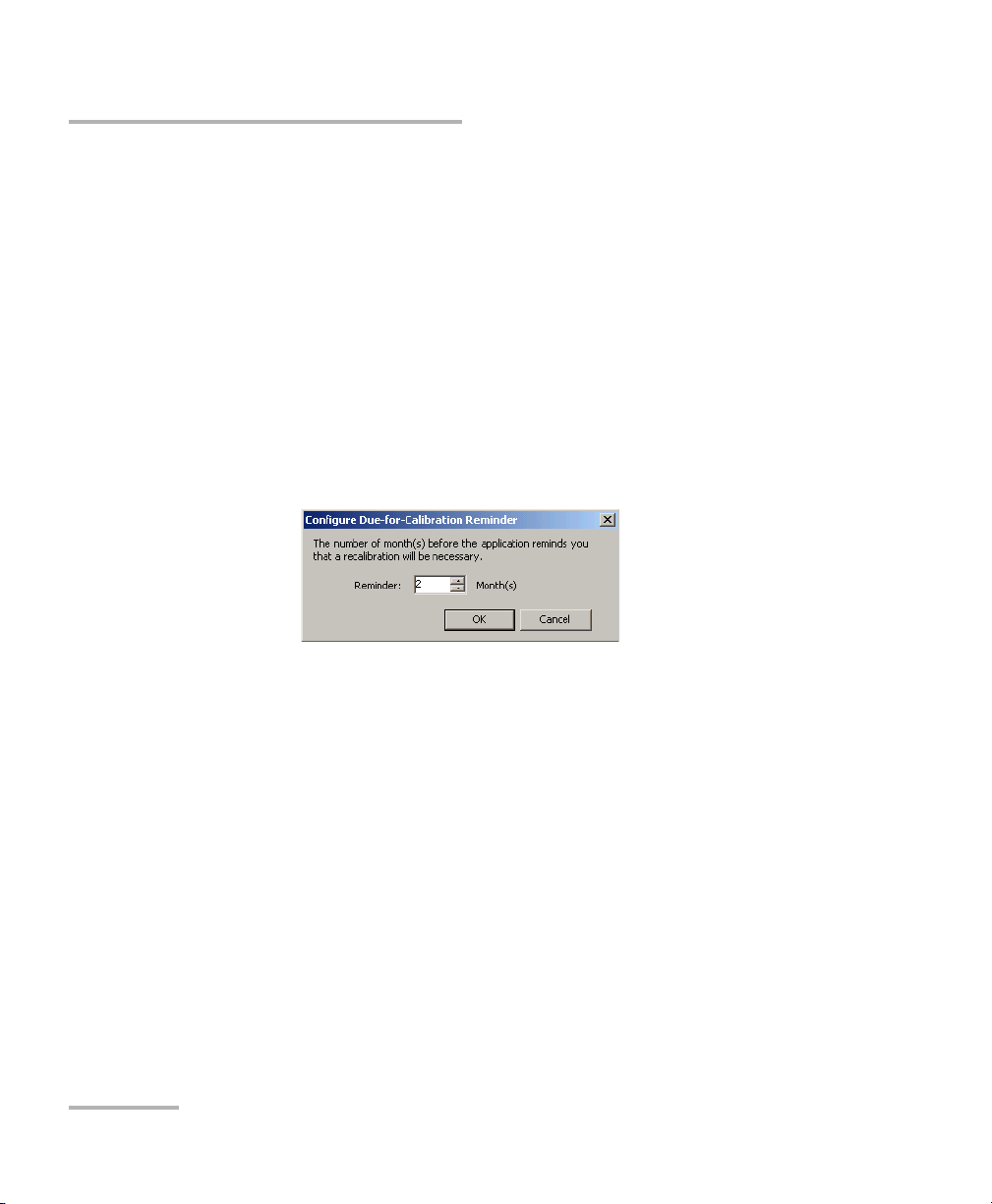

Configuring the Due-for-Calibration Reminder

Configuring the Due-for-Calibration Reminder

Since the system relies on the accuracy of standards, the application will

warn you before a standard is due for recalibration (by default, 2 months

ahead). You can set the number of months before the application reminds

you that a recalibration will be necessary. For information on how to

proceed when a standard is back from calibration, see Using a Standard

after Recalibration on page 54.

To configure the due-for-calibration reminder:

1. From the Tools menu, select System > Configure

Due-for-Calibration Reminder.

2. Enter the desired number of months and click OK.

22 IQS-12002B

Page 27

Setting Up Your Calibration System

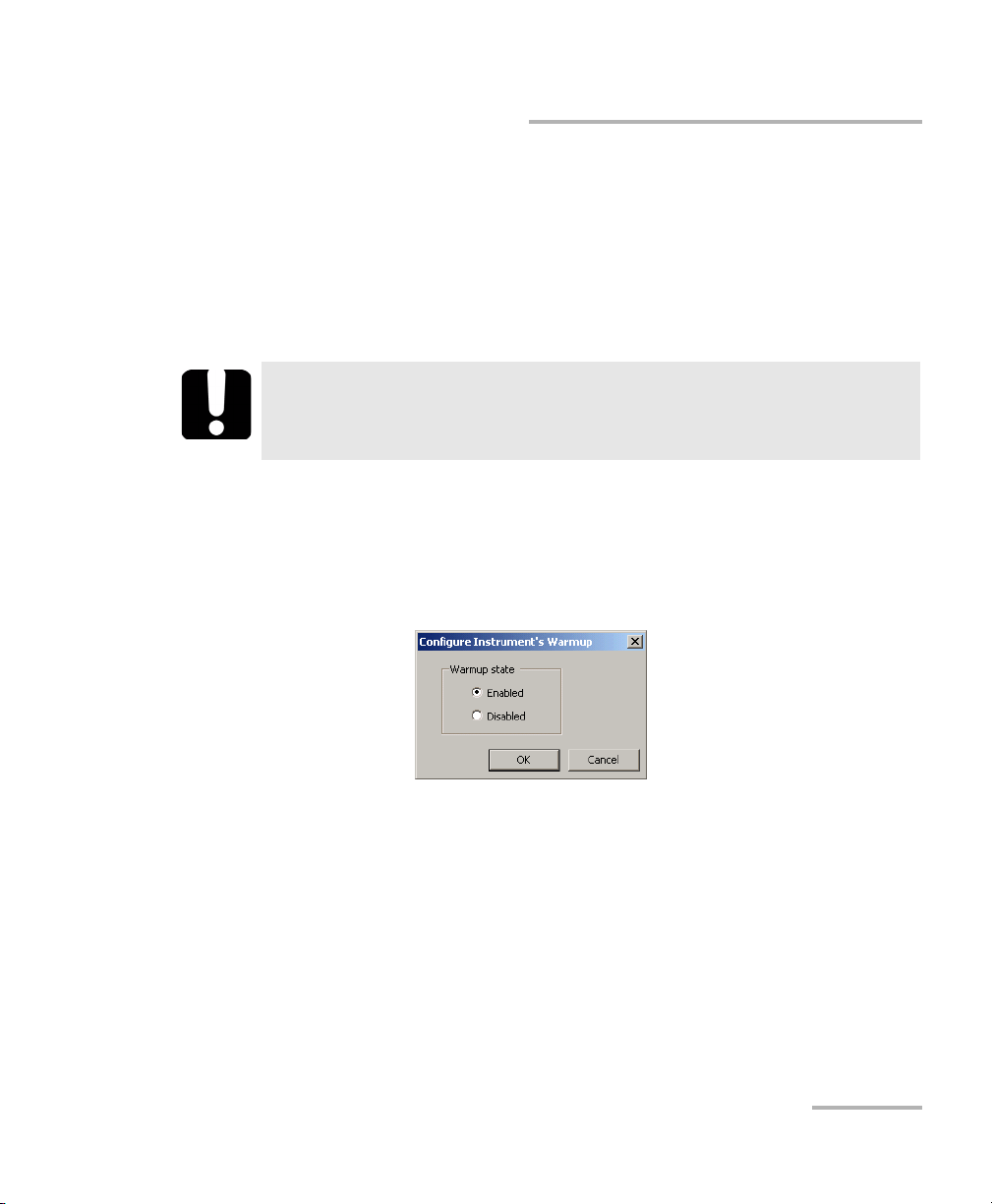

Activating or Deactivating the Warmup Confirmation

Activating or Deactivating the Warmup

Confirmation

By default, the application prompts you to select the instruments and DUT

for which a warmup is wanted. You can deactivate the warmup

confirmation. It is always possible to perform a warmup manually

afterwards (see Launching a Manual Warmup on page 28).

IMPORTANT

To ensure accurate results, EXFO recommends to always perform

warmup.

To activate or deactivate the automatic warmup confirmation:

1. From the Tools menu, select System > Configure Instrument’s

Warmup.

2. Select the desired option and click OK to confirm.

The application will take the new setting into account the next time you

start the application or turn on the expansion unit.

Calibration System 23

Page 28

Setting Up Your Calibration System

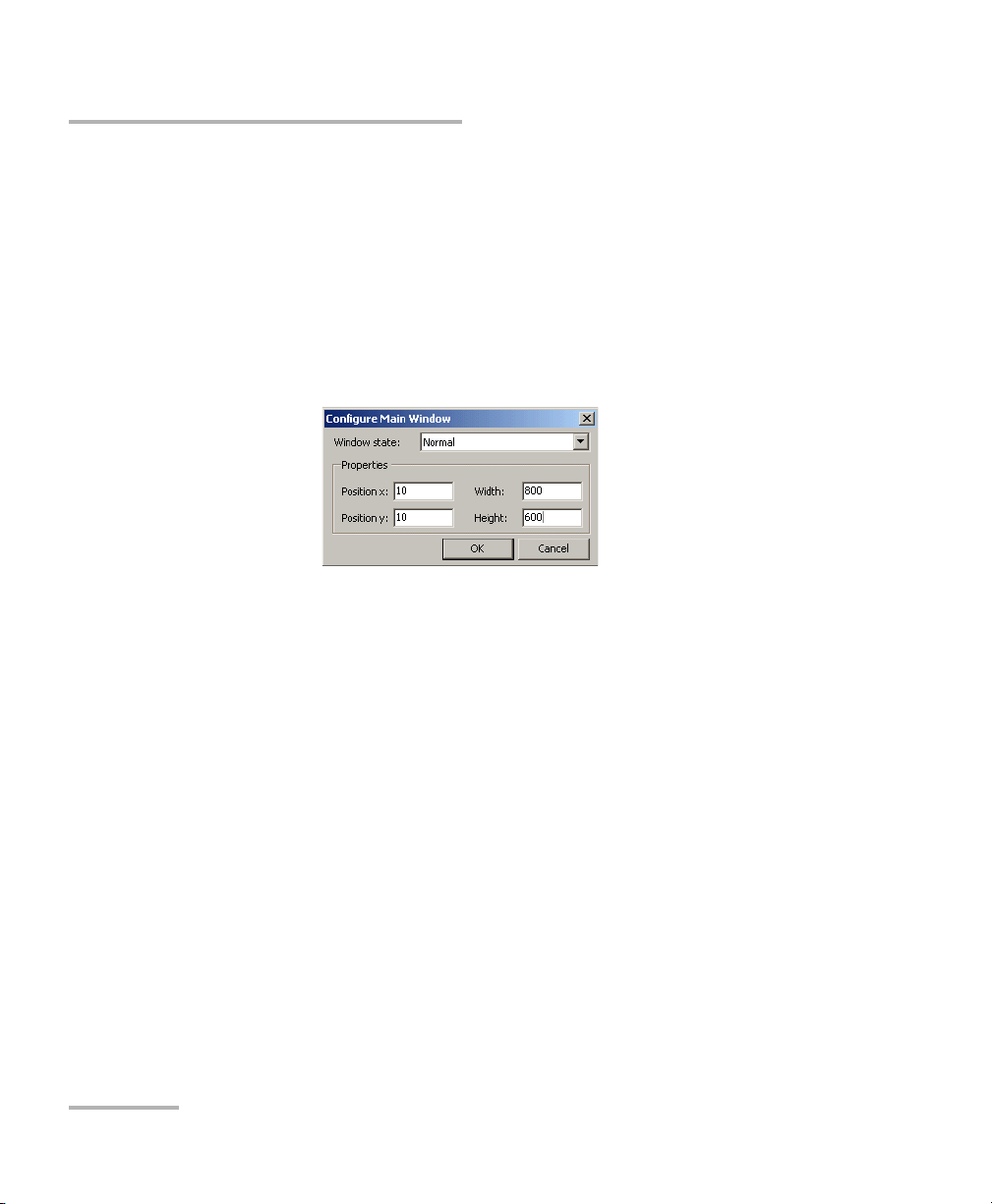

Configuring Main Window Appearance

Configuring Main Window Appearance

By default, the main window is maximized. However, you can configure its

size and position.

To configure main window appearance:

1. From the Tools menu, select System > Configure Main Window.

2. From the Window state list, select the desired appearance. If you

select Normal, you can also specify the size and position.

24 IQS-12002B

Page 29

4 Operating Your Calibration

System

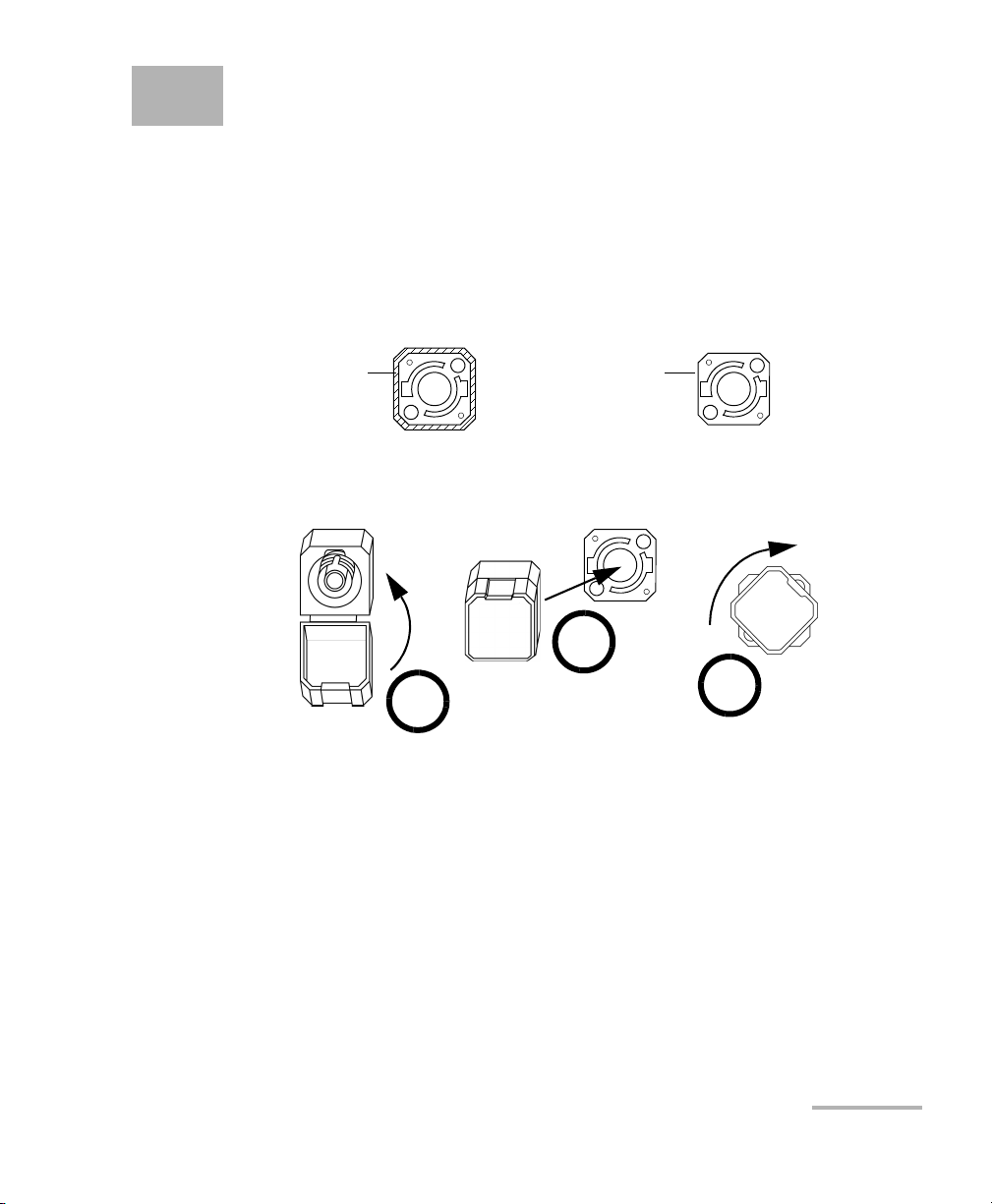

Installing the EXFO Universal Interface (EUI)

The EUI fixed baseplate is available for connectors with angled (APC) or

non-angled (UPC) polishing. A green border around the baseplate

indicates that it is for APC-type connectors, as shown below:

Green border

indicates APC

option

To install an EUI connector adapter onto the EUI baseplate:

1. Hold the EUI connector adapter so the dust cap opens downwards.

Bare metal

(or blue border)

indicates UPC

option

3

4

2

2. Close the dust cap in order to hold the connector adapter more firmly.

3. Insert the connector adapter into the baseplate.

4. While pushing firmly, turn the connector adapter clockwise on the

baseplate to lock it in place.

Calibration System 25

Page 30

Operating Your Calibration System

Cleaning and Connecting Optical Fibers

Cleaning and Connecting Optical Fibers

To ensure maximum power and to avoid erroneous readings:

³ Always clean fiber ends as explained below before inserting

them into the port. EXFO is not responsible for damage or

errors caused by bad fiber cleaning or handling.

³ Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Clean the fiber ends as follows:

1a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl

alcohol.

1b. Use compressed air to dry completely.

IMPORTANT

1c. Visually inspect the fiber end to ensure its cleanliness.

2. Carefully align the connector and port to prevent the fiber end from

touching the outside of the port or rubbing against other surfaces. If

your connector features a key, ensure that it is fully fitted into the port’s

corresponding notch.

3. Push the connector in so that the fiber-optic cable is firmly in place,

thus ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector

enough to firmly maintain the fiber in place. Do not overtighten, as this

will damage the fiber and the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you will

notice heavy loss and reflection.

26 IQS-12002B

Page 31

Operating Your Calibration System

Viewing the Required Instruments

Viewing the Required Instruments

Before launching a test sequence, you can view the instruments that are

required. This way, you will not have to turn off the controller or expansion

units to insert the instruments and wait for the warmup period.

To view the required instruments:

1. From the Configuration menu, click Scenario.

2. Select the desired DUT type and model, and click Search.

3. From the Scenarios box, select a test scenario.

4. Click Calibration Instruments to view the list of instruments required

for the selected scenario.

5. Repeat steps 3 and 4 for every scenario to be included in the sequence.

6. Close the windows to return to the application main window.

Calibration System 27

Page 32

Operating Your Calibration System

Launching a Manual Warmup

Launching a Manual Warmup

By default, the application prompts you at startup to select the instruments

for which a warmup is wanted. If you have deactivated the warmup

confirmation or if you have cancelled the warmup at the application

startup, you can still launch it manually.

To launch a manual warmup:

From the Too ls menu, select System > Start Warmup.

Note: If the War mup window does not appear, the warmup has already been

completed.

Locating IQS Modules

You can access the list of all IQS modules inserted in the system. The list

includes instruments and DUTs, and their position in the system (unit and

slot number). This allows you to retrieve the model and serial number of

the modules without having to turn off the IQS-500 controller or expansion

units.

To locate IQS modules:

From the Too ls menu, select System > Detect IQS Modules.

28 IQS-12002B

Page 33

Operating Your Calibration System

Performing a Test

Performing a Test

The test sequence you have built can be used immediately or saved it for

future use. Once a test is underway, you can stop it and resume it later

from the point it was stopped.

The application will guide you through the necessary steps from DUT

creation to printing results. You can generate reports that are ISO/IEC 17025

compliant. They can take into account measurement uncertainties or not

(i.e. pass or fail status without considering uncertainties). You can also

export results to a PDF file.

Note: It is also possible to perform several tasks, such as adding a new DUT or a

new customer, directly from the application menus.

Note: When creating a new sequence, the system verifies that all necessary

connected standards are present in the platform. If there are more

connected standards of a particular kind than needed, the system reserves

them in the detection order (unit 1 and slot 1, unit 1 and slot 2, and so on).

If you would like to use other connected standards than the reserved ones,

you must remove the undesired standards from the platform.

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

Use of controls, adjustments and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

Calibration System 29

Page 34

Operating Your Calibration System

Per formin g a Tes t

To launch a test sequence:

1. From the Operations menu, click Create Sequence.

2. Select Search an existing DUT and enter the DUT serial number.

If the DUT already exists in the database, the application will retrieve it.

If it does not exist, the application will create it.

If necessary, confirm the creation of the DUT.

Note: If you click Next without entering a serial number, the application displays

the list of created DUTs.

30 IQS-12002B

Page 35

Operating Your Calibration System

Performing a Test

3. Enter the information in the appropriate boxes. Mandatory information

is indicated by a “*”.

To visualize DUTs and

their serial numbers

To create a customer in

the database

4. Click OK to confirm.

5. The application displays DUT information; click Next.

6. Prepare your DUT as shown on screen and click Next.

Calibration System 31

Page 36

Operating Your Calibration System

Per formin g a Tes t

7. Under Wo r k type, select the operation you want to perform. The

available choices depend on the type of device you are testing and on

available instruments.

To indicate if the

test is performed

by your company

or on behalf of

EXFO.

8. Under Additional info, enter the information that will appear in the

report.

9. Click Next.

10. In the Fiber selection box, specify the fiber connector, the fiber

adapter, and the fiber type you are using.

To a d d t h e s e le c te d

comments to your

report.

11. Click Next

32 IQS-12002B

Page 37

Operating Your Calibration System

Performing a Test

12. From the Measurement and Adjustment Procedure Selection box,

select the scenarios you want to include in your test sequence.

Note: Some scenarios cannot be cleared from the list. These are mandatory

scenarios and must be performed for the selected DUT.

13. To create custom specifications for a scenario, proceed as follows:

13a.Select the scenario you want to customize and click Create.

13b.From the Based on list, select a set of specifications to be used as

a template.

13c. Click Customize to create the new set of specifications and

values.

13d.Click OK.

Calibration System 33

Page 38

Operating Your Calibration System

Per formin g a Tes t

14. Back in the Measurement and Adjustment Procedure Selection box,

make sure Custom Specifications appears in the Specification

revision list.

15. Click Next and click Complete to close the wizard.

The application will prompt you to confirm if you want to perform the

acquisition now or later.

16. If the required standards have not been added to the database yet, the

application will prompt you to add them; proceed as follows:

16a.Click OK.

16b.Enter the required information and click OK.

16c. Confirm the authority name and calibration date.

16d.Click and link the calibration certificate file provided by the

calibration authority.

16e.Click OK.

34 IQS-12002B

Page 39

Operating Your Calibration System

Performing a Test

17. When the application prompts you, select the instruments that must

have a warmup period and click OK.

18. Follow the instructions appearing on screen.

At the end of a scenario, the application displays the results.

Note: Before printing the report, you can still modify the information it contains,

but you cannot modify the measures.

Calibration System 35

Page 40

Operating Your Calibration System

Per formin g a Tes t

19. The application displays a preview of the report. It will also be possible

to print or export results afterwards (see Printing or Exporting Results

on page 37).

Note: To let the application consider the test sequence completed, you must

perform a print or export of the report. As long as this is not done, the

sequence will remains in the Open Sequence dialog windows and the

results will not be accessible in the DUT history or traceability reports.

To change the default

location of the .pdf file

When you have finished, click Close.

To launch an existing test sequence:

1. From the Operations menu, click Open Sequence.

2. Follow the instructions appearing on screen.

To resume a test sequence:

From the Operations menu, click Run Sequence.

The application will resume the test from where it stopped.

36 IQS-12002B

Page 41

Operating Your Calibration System

Printing or Exporting Results

Printing or Exporting Results

You can print or export results of the DUTs for previous test sequences.

To print or export results:

1. From the Configuration menu, select DUT > Search.

2. Enter criteria to retrieve the DUT information and click Search.

IMPORTANT

If you leave the Serial number box empty, the system will retrieve

all DUTs matching the information entered in the other boxes and

lists.

3. Click History.

Calibration System 37

Page 42

Operating Your Calibration System

Printing or Exporting Results

4. From the DUT History box, select the row indicating that the report

has been printed and click Certificate.

Note: Upon clicking Certificate, the systems offers you the possibility to make

modifications before printing the report. If you choose to do so, a box opens

to let you make the changes and a note is automatically added in the “As

found” and “As left” fields of the report.

5. In the View Report box, click Print, or click Export to save the report

in the PDF format.

6. Click Close.

38 IQS-12002B

Page 43

Operating Your Calibration System

Printing Reports

Printing Reports

You can view or print traceability results of the DUTs or Standards you have

tested or used in previous test sequences.

To view or print Forward Traceability results:

1. From the Report menu, click Forward Traceability.

2. In the Serial number box, type the DUT serial number (leave the box

empty to get all tested DUTs) and click Search.

3. Select the desired DUT in the list.

4. Click History.

Calibration System 39

Page 44

Operating Your Calibration System

Printing Reports

5. From the DUT History box, select the event for which you want to

view the traceability information.

Note: The information depends on the date of the selected event. On the Forward

Traceability Report, the information starts with the date the DUT was

added and ends with the date of the selected event. To see all the

information, you must select the event with the most recent date.

6. When the event is selected, click Forward Traceability to see the

results.

To view or print Reverse Traceability results:

1. From the Report menu, click Reverse Traceability.

2. In the Serial number box, type the Standard serial number (leave the

box empty to get all Standards) and click Search.

40 IQS-12002B

Page 45

Operating Your Calibration System

Printing Reports

3. Select the desired Standard in the list.

4. Click History.

5. From the Standard History box, select the event for which you want

to view the traceability information.

Note: The information depends on the date of the selected event. On the Reverse

Traceability Report, the information starts with the date of the last

calibration and ends with the current date. To see all the information, you

must select the event with the most recent date.To see all the information,

you must select the date the Standard was first calibrated.

6. Click Reverse Traceability to see the results.

Calibration System 41

Page 46

Page 47

5 Troubleshooting

This chapter presents a list of common problems and their solution, the

technical support offered on the web and at EXFO facilities, and product

shipping information.

Solving Common Problems

Problem Possible cause Solution

Communication loss

between PC and IQS

system

Instruments do not

warm up properly

Error message

“Warm-up has

encountered an

error.”

Getting a French

message while

calibrating the

FTB-100B power

meter.

You have logged

yourself out.

The computer has

gone into the stand-by

mode.

Logging out closes the communication

port. Make sure that all operations of the

IQS system are completed before you

log out.

Change the stand-by mode settings as

follows: on the computer desktop,

make a right-click and, on the

contextual menu, click Properties. On

the Screen Saver tab, click Power and,

under Settings for Home/Office Desk

power scheme, select Never in the

three lists.

Try installing all your instruments

(sources and calibration power meter)

in the controller unit instead of the

expansion units.

Restart the warm-up period as follows:

From the To ols menu, select System >

Start Warmup.

If the instruments still do not warm-up

properly, restart the system.

It means that the serial link is available

for calibration.

Calibration System 43

Page 48

Troubleshooting

Finding Information on the EXFO Web Site

Problem Possible cause Solution

Error message

“Catastrophic failure”

Calibration has a Fail

in Distance result.

Interruption of the

dead zone calibration

Impossible to print

information on a

specific DUT.

Finding Information on the EXFO Web Site

The EXFO Web site provides answers to frequently asked questions (FAQs)

regarding the use of your IQS-12002B Calibration System.

Incorrect connections

for the FOT-10A or

FOT-10A unit.

The automatic

positioning of events

for an FTB-7000B-B

OTDR is incorrect.

The automatic

positioning of the

events is incorrect.

This DUT has never

been tested.

Disconnect the unit, close all

applications, and restart the system.

Make sure the connection procedure is

properly done.

Positioning must be done manually. Set

marker A right before the reflective

event at 50 m and marker B right before

the end of fiber event.

Make sure that the standard distance

information include the 3-m patchcord

as described in Configuring the

FTB-7000D OTDR on the IQS-12002B on

page 79.

Test the DUT and try again.

To access FAQs:

1. Ty pe http://www.exfo.com in your Internet browser.

2. Click on the Support tab.

3. Click on FAQs and follow the on-screen instructions. You will be given

a list of questions pertaining to your subject.

The EXFO Web site also provides the product’s most recent technical

specifications.

44 IQS-12002B

Page 49

Troubleshooting

Contacting the Technical Support Group

Contacting the Technical Support Group

To obtain after-sales service or technical support for this product, contact

EXFO at one of the following numbers. The Technical Support Group is

available to take your calls from Monday to Friday, 7:30 a.m. to 8:00 p.m.

(Eastern Time in North America).

Technical Support Group

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

To accelerate the process, please have information such as the name and

the serial number (see the product identification label—an example is

shown below), as well as a description of your problem, close at hand.

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

support@exfo.com

P/N

**************** A

S/N

542392-3D

Made in Canada QST442B

January 2020

Ver.

Mfg.

date

465 Godin Avenue

Vanier (Quebec) G1M 3G7 CANADA

IQS-12002B

Calibration System 45

Page 50

Troubleshooting

Transportation

Transportation

Maintain a temperature range within specifications when transporting the

unit. Transportation damage can occur from improper handling. The

following steps are recommended to minimize the possibility of damage:

³ Pack the unit in its original packing material when shipping.

³ Avoid high humidity or large temperature fluctuations.

³ Keep the unit out of direct sunlight.

³ Avoid unnecessary shock and vibration.

46 IQS-12002B

Page 51

6 Maintenance

To help ensure long, trouble-free operation:

³ Always clean fiber-optic connectors before using them.

³ Keep the unit free of dust.

³ Clean the unit casing and front panel with a cloth slightly dampened

with water.

³ Store unit at room temperature in a clean and dry area. Keep the unit

out of direct sunlight.

³ Avoid high humidity or significant temperature fluctuations.

³ Avoid unnecessary shocks and vibrations.

³ If any liquids are spilled on or into the unit, turn off the power

immediately and let the unit dry completely.

Use of controls, adjustments and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

WARNING

Calibration System 47

Page 52

Maintenance

Cleaning EUI Connectors

Cleaning EUI Connectors

Regular cleaning of EUI connectors will help maintain optimum

performance. There is no need to disassemble the unit.

If any damage occurs to internal connectors, the module casing will

have to be opened and a new calibration will be required.

To clean EUI connectors:

1. Remove the EUI from the instrument to expose the connector

baseplate and ferrule.

IMPORTANT

Turn

Push

2. Moisten a 2.5 mm cleaning tip with one drop of isopropyl alcohol

(alcohol may leave traces if used abundantly).

3. Slowly insert the cleaning tip into the EUI adapter until it comes out on

the other side (a slow clockwise rotating movement may help).

Pull

3

4

5

48 IQS-12002B

Page 53

Cleaning EUI Connectors

4. Gently turn the cleaning tip one full turn, then continue to turn as you

withdraw it.

5. Repeat steps 3 to 4 with a dry cleaning tip.

Note: Make sure you don’t touch the soft end of the cleaning tip.

6. Clean the ferrule in the connector port as follows:

6a. Deposit one drop of isopropyl alcohol on a lint-free wiping cloth.

IMPORTANT

Isopropyl alcohol may leave residues if used abundantly or left to

evaporate (about 10 seconds).

Avoid contact between the tip of the bottle and the wiping cloth,

and dry the surface quickly.

6b. Gently wipe the connector and ferrule.

6c. With a dry lint-free wiping cloth, gently wipe the same surfaces to

ensure that the connector and ferrule are perfectly dry.

Maintenance

6d. Verify connector surface with a portable fiber-optic microscope

(e.g., EXFO’s FOMS) or fiber inspection probe (e.g., EXFO’s FIP).

WARNING

Verifying the surface of the connector WHILE THE UNIT IS ACTIVE

WILL result in permanent eye damage.

7. Put the EUI back onto the instrument (push and turn clockwise).

8. Throw out cleaning tips and wiping cloths after one use.

Calibration System 49

Page 54

Maintenance

Cleaning Fixed Connectors

Cleaning Fixed Connectors

Regular cleaning of connectors will help maintain optimum performance.

Do not try to disassemble the unit. Doing so would break the connector.

To clean fixed connectors:

1. Fold a lint-free wiping cloth in four to form a square.

2. Moisten the center of the lint-free wiping cloth with only one drop of

isopropyl alcohol.

Alcohol may leave traces if used abundantly. Avoid contact between

the tip of the bottle and the wiping cloth, and do not use bottles

that distribute too much alcohol at a time.

3. Gently wipe the connector threads three times with the folded and

moistened section of the wiping cloth.

IMPORTANT

IMPORTANT

Isopropyl alcohol takes approximately ten seconds to evaporate.

Since isopropyl alcohol is not absolutely pure, evaporation will

leave microscopic residue. Make sure you dry the surfaces before

evaporation occurs.

4. With a dry lint-free wiping cloth, gently wipe the same surfaces three

times with a rotating movement.

5. Throw out the wiping cloths after one use.

6. Moisten a cleaning tip (2.5 mm tip) with only one drop of isopropyl

alcohol.

50 IQS-12002B

Page 55

Maintenance

Cleaning Fixed Connectors

IMPORTANT

Alcohol may leave traces if used abundantly. Avoid contact between

the tip of the bottle and the cleaning tip, and do not use bottles

that distribute too much alcohol at a time.

7. Slowly insert the cleaning tip into the connector until it reaches the

ferrule inside (a slow clockwise rotating movement may help).

7

8

9

8. Gently turn the cleaning tip one full turn.

9. Continue to turn as you withdraw the cleaning tip.

10. Repeat steps 7 to 9, but this time with a dry cleaning tip (2.5 mm tip

provided by EXFO).

Note: Make sure you don’t touch the soft end of the cleaning tip and verify the

cleanliness of the cotton tip.

11. Throw out the cleaning tips after one use.

Calibration System 51

Page 56

Maintenance

Cleaning Detector Ports

Cleaning Detector Ports

Regular cleaning of detectors will help maintain measurement accuracy.

Always cover detectors with protective caps when unit is not in use.

To clean detector ports:

1. Remove the protective cap and adapter (FOA) from the detector.

2. If the detector is dusty, blow dry with compressed air.

3. Being careful not to touch the soft end of the swab, moisten a cleaning

tip with only one drop of isopropyl alcohol.

Alcohol may leave traces if used abundantly. Do not use bottles that

distribute too much alcohol at a time.

IMPORTANT

IMPORTANT

4. While applying light pressure (to avoid breaking the detector window),

gently rotate the cleaning tip on the detector window.

5. Repeat step 4 with a dry cleaning tip or blow dry with compressed air.

6. Discard the cleaning tips after one use.

52 IQS-12002B

Page 57

Maintenance

Cleaning the FOA Connector Adapter

Cleaning the FOA Connector Adapter

Make sure that the FOA connector adapter is properly cleaned to assure its

accuracy during calibration.

To clean your FOA connector adapter:

1. Remove the FOA from the instrument.

2. Slowly insert and gently rotate a cleaning tip that has been dipped in

isopropyl alcohol into the FOA.

3. Insert a dry cleaning tip to dry.

4. Blow away any remaining lint with clean compressed air.

5. Use a metal wire (diameter smaller than 150 μm) and carefully insert it

through the sleeve until it comes the other way through the pin-hole

(200 μm).

6. Gently rotate the FOA around the wire to ensure that no particle

remains.

7. Finally, whenever the proper instrumentation is available, a visual

camera with enough magnification might allow to inspect the

cleanliness of the FOA pin-hole.

Calibration System 53

Page 58

Maintenance

Using a Standard after Recalibration

Using a Standard after Recalibration

When a standard is back from recalibration, you must add its calibration

information and certificate to the application’s database. Otherwise, you

will not be able to use the module.

To use a standard after recalibration:

1. From the Configuration menu, click Calibration Instruments>

Standards.

2. Select the appropriate standard from the list.

3. Click History.

54 IQS-12002B

Page 59

Maintenance

Using a Standard after Recalibration

4. Click Add Calibration Event.

5. The authority name and calibration date are automatically set.

Click and add the calibration certificate file.

6. When you have finished, click OK. Close all windows to return to the

main window.

The newly calibrated standard is now available.

Calibration System 55

Page 60

Page 61

A Calibration Methods

This chapter presents the methods, on which are based the procedures of

the IQS-12002B Calibration System., for the calibration of power meters

and OTDRs.

Power Meter

The calibration of a power meter includes the calibration of its absolute

power and, for a high-end unit (e.g., IQS power meter), the calibration of

its linearity.

Absolute Power Calibration

Power meter calibration is performed by comparing it with an

IQS-1502 Calibration Power Meter (working standard). Comparison

between the two is done by measuring the output power of a laser source,

such as the IQS-2400 (usually a DFB laser), having excellent wavelength

and power stability.

In order to improve accuracy, the system can integrate a polarization

scrambler, which reduces the uncertainty due to the polarization

dependant response (PDR) of photo detectors.

For calibration at the 850-nm wavelength, the IQS-2400 uses a stabilized FP

laser with the mandatory mode scrambler in order to obtain a stable laser

source.

Calibration System 57

Page 62

Calibration Methods

Pow er Me ter

At all wavelengths, the output power of the laser sources is measured

several times alternating between the calibration power meter and the

power meter under test (DUT). A minimum of five responsivity constants

are calculated for the DUT and are statistically analyzed to ensure that they

are within appropriate limits (e.g. the calculated values must all be inside a

certain range of values). Whenever one or more responsivity constants are

outside the acceptable range, the measured values are considered invalid

and the measurements have to be redone.

The number of measurements taken with the calibration power meter and

the DUT, and the number of comparisons between the two units are set so

as to reduce uncertainties of Type A. These uncertainties include

connection uncertainty and interference due to reflections.

The system uses expanded uncertainty (U) values that are included in the

report. The following tables present the method used to establish the

uncertainty for calibration made at four wavelengths.

58 IQS-12002B

Page 63

Calibration Methods

Power Meter

Calibration System 59

Page 64

Calibration Methods

u(xi

Pow er Me ter

Power meter calibration at 1310 nm and 1550 nm @ 23 °C ± 1 °C

influence uncertainty Unit probability

iXi

1 Factors related to the reference standard rectangular 1.73205 0.000 1 0.000

2 Incertitude d'étalonnage 2.00 % normal 2 1.000 1 1.000

3 Ref non-linearity 0.25 % rectangular 1.73205 0.144 1 0.144

4 Ageing 0.00 % rectangular 1.73205 0.000 1 0.000

5 Ref temperature dependance 1.00 %/°C rectangular 1.73205 0.577 0.01 °C (variation) 0.006

6 Ref PDR (½ (max-min)) 0.64 % rectangular 1.73205 0.370 0.1 ratio applicabilit y 0.037

7 Ref Dependance on spectral bandwith 0.00 % rectangular 1.73205 0.000 1 0.000

8 1/2 Ref's Resolution 0.01 % rectangular 1.73205 0.006 1 0.006

9 Factors related to the DUT rectangular 1.73205 0.000 1 0.000

10 DUT tem perature dependance 1.00 %/°C rectangular 1.73205 0.577 1 °C (variation) 0.577

11 DUT's Dependanc e on spectral bandwith 0.00 % rectangular 1.73205 0.000 1 0.000

12 DUT's PDR (½ (max-min)) 0.35 % rectangular 1.73205 0. 202 0.1 ratio applicability 0.020

13 1/2 DUT's Resolution 0.120 % rectangular 1.73205 0. 069 1 0.069

14 rectangular 1.73205 0.000 1 0.000

15 rectangular 1.73205 0.000 1 0.000

16 Combined effects rectangular 1.73205 0.000 1 0.000

17 Wavelength dependance DUT versus reference std 1.000 %/nm rectangular 1. 73205 0.577 0.5 nm 0.289

18 Source s tability 0.12 % rectangular 1.73205 0. 069 1 0.069

19 rectangular 1.73205 0.000 1 0.000

20 rectangular 1.73205 0.000 1 0.000

21 U-shaped 1.41421 0.000 1 0.000

22 rectangular 1.73205 0.000 1 0.000

23 rectangular 1.73205 0.000 1 0.000

24 TYPE A UNCERTAINTY (includes i nterferance and FOA) 1.50 % 3 measures 1.73205 0.866 1 0.866

y 1.483

Note 1: If there is a polarisation scrambler, the Detector's PDR can be neglected S= 5.0

distribution

divisor standard

uncertainty

expanded uncertainty

sensitivity

coefficient

)

coverage f actor

Unit uncertainty

ci

k= 2

U= 3.0

Limit 1= 2.6

Limit 3= 7.4

contribution

ui(y)(dB)

60 IQS-12002B

Page 65

Calibration Methods

u(xi

Power Meter

influence uncertainty Unit probability

iXi

1 Factors related to the reference standard rectangular 1.73205 0.000 1 0.000

2 Incertitude d'étalonnage 3.00 % normal 2 1.500 1 1.500

3 Ref non-linearity 0.25 % rectangular 1.73205 0.144 1 0.144

4 Ageing 0.00 % rectangular 1.73205 0.000 1 0.000

5 Ref temperature dependance 1.00 %/°C rectangular 1.73205 0.577 0.01 °C (variation) 0.006

6 Ref PDR (½ (max-min)) 0.90 % rectangular 1.73205 0.520 0.1 0.052

7 Ref Dependance on spectral bandwith 0.00 % rectangular 1.73205 0.000 1 rat io applicabil ity 0.000

8 1/2 Ref's Resolution 0.01 % rectangular 1.73205 0.006 1 0.006

9 Factors related to the DUT rectangular 1.73205 0.000 1 0.000

10 DUT tem perature dependance 1.00 %/°C rectangular 1.73205 0.577 1 °C (variation) 0.577

11 DUT's Dependanc e on spectral bandwith 0.00 % rectangular 1.73205 0.000 1 0.000

12 DUT's PDR (½ (max-min)) 0.90 % rectangular 1.73205 0.520 0.1 ratio applicability 0.052

13 1/2 DUT's Resolution 0.120 % rectangular 1.73205 0.069 1 0.069

14 rectangular 1.73205 0.000 1 0.000

15 rectangular 1.73205 0.000 1 0.000

16 Combined effects rectangular 1.73205 0.000 1 0.000

17 Wavelength dependance DUT versus reference std -1.250 %/nm rectangular 1. 73205 -0.722 0.5 nm -0.361

18 Source s tability 0.12 % rectangular 1.73205 0. 069 1 0.069

19 rectangular 1.73205 0.000 1 0.000

20 rectangular 1.73205 0.000 1 0.000

21 U-shaped 1.41421 0.000 1 0.000

22 rectangular 1.73205 0.000 1 0.000

23 rectangular 1.73205 0.000 1 0.000

24 TYPE A UNCERTAINTY (includes i nterferance and FOA) 1.50 % 3 measures 1.73205 0.866 1 0.866

y 1.871

Note 1: If there is a polarisation scrambler, the Detector's PDR can be neglected S= 5.0

Power meter calibration at 1625 nm @ 23 °C ± 1 °C

distribution

divisor standard

uncertainty

expanded uncertainty

)

sensitivity

coefficient

ci

coverage f actor

Unit uncertainty

contribution

ui(y)(dB)

k= 2

U= 3.7

Limit 1= 1.9

Limit 3= 8.1

Calibration System 61

Page 66

Calibration Methods

ℜ

Pow er Me ter

Linearity Calibration

The nonlinearity of the power meter should be calibrated to ensure

accurate measurements at power levels different from the calibration level

and for relative measurements such as loss and gain measurements.

Nonlinearity is the relative difference between the response at a given

power (P) and the reference power (P

The calibration should be made by increasing and decreasing the power

level to detect nonlinearities over each amplifier range and, whenever

possible, at both sides of each amplifier boundary in order to include

nonlinearities at the switching between scales. Detector nonlinearity is

dependent on the wavelength. For example, an InGaAs detector linear at

1310 nm and 1550 nm may be nonlinear at 850 nm.

The method privileged by the international standard on power meter

calibration (IEC 61315 Ed. 2.0 b:2005) is the superposition method. It is the

most accurate and does not require a reference standard as it is a

self-calibrating (ratio-type) method. It consists in verifying that the sum of

the power read in each branch of a 1 × 2 coupler is equal to the total

power read when measuring the two branches simultaneously. This is

performed over the useful dynamic range of the DUT.

NL

):

0

)(

P

1

=

ℜ

−

)(

P

0

62 IQS-12002B

Page 67

Calibration Methods

Power Meter

However, before performing the linearity calibration, both branch of the

coupler have to be balanced (i.e. have the same output power). Balancing

the linearity setup is the basis of this method. It requires a subscript coupler

to split the power in two and a shutter on both branches in order to block

light or let it through. Power is then recombined using a second coupler

before sending the light to the power meter under test. A variable

attenuator on each path is very useful in order to match the output power

of each branch of the coupler. Finally, the power coming from each

individual branch (P

measured on the photo detector. The deviation of P

and Pb) and also from both branches (P

a

from Pa + Pb is the

total

total

) is

local nonlinearity (NLL).

By using an attenuator between the source and the first splitter, the total

power is attenuated by a factor of 2 (~3 dB) with respect to the previous

step. Adding the local nonlinearities and referencing to the reference

power, we obtain the total linearity error (NLglobal), starting from the

reference power level where the nonlinearity is zero. This process is

repeated throughout the desired range.

The following is the procedure to measure nonlinearity using the

superposition method.

Calibration System 63

Page 68

Calibration Methods

Pow er Me ter

To measure nonlinearity:

1. Set the attenuators in the two paths so that the power measured on the

meter is the same whether the light is coming from branch a or from

branch b.

2. Open both shutters and measure the total power from both branches

simultaneously: P

3. Close the shutter on branch b and measure the power on branch a:

P

.

a,i

4. Close the shutter on branch a, open the shutter on branch b, and

measure the power on branch b: P

5. Add the individual power measurements.

If the sum is not equal to the total power measurement, the DUT

presents nonlinearity.

:

NL

total,i

×=

.

.

b,i

P

itotal,

10i

(dB)log10

PP

+

ib,ia,

6. Using the first attenuator, attenuate the total power by the following

factor to the level of the sum of the individual power measurements

calculated in step 5.

10 2log 3,01 dB≅

7. Repeat steps 2 through 6 to cover the desired range.

64 IQS-12002B

Page 69

Calibration Methods

=

Power Meter

8. At the end, the global nonlinearity is the sum of all the local

nonlinearities expressed in decibels (dB), starting calculations from

the reference power level where the nonlinearity is zero (higher order

terms are negligible).

The equations to use are as follows:

For n < 0

+

1

n

−=

)(

∑

=

i

NLPNL

inglobal

0

For n = 0

0)(

PNL

0global

For n > 0

n

+=

∑

i

=

NLPNL

inglobal

1

)(

where:

n < 0 indicates power levels lower than the reference power.

n > 0 indicates power levels higher than the reference power.

NL

is the local nonlinearity for the step (i = 0 for the step where Pab is

i

the reference power).

The result is a list of global nonlinearities for the whole power range in

steps of 3,01 dB.

The largest nonlinearity relative to the reference power is:

NL

max

max NLglobal()dB()±=

This procedure can be performed with decreasing and/or increasing the

power sent to the DUT.

Calibration System 65

Page 70

Calibration Methods

Pow er Me ter

To cover a bigger area of the power meter range, once the test done by

decreasing the power is completed, shift the first attenuator by 1.5 dB and

then start the test at increasing power levels.

Typical uncertainties of this method include:

³ All possible power fluctuations while measuring P

, Pb, and P

a

total

such

as fluctuations of the source due to drifts.

³ Improper balancing of the output powers of each coupler branch (P

and P

). If balancing is not correctly done, the global linearity cannot

b

be easily inferred).

³ Sensitivity to changing reflections.

³ Instabilities due to interference if the coherence length of the laser is

too large.

³ Polarization sensitivity of the power meter and attenuators (when

applicable).

³ Resolution of the power meter.

³ Difference between the individual powers of each step (P

compared to the total power of the next step (P

total,i+1

and Pb,i)

a,i

) (for calculating

global linearity).

a

66 IQS-12002B

Page 71

Calibration Methods

Power Meter

The errors for each step are cumulative and will add to the errors of the

preceding steps.

The system uses an expanded uncertainty (U) value that is included in the

report. The following table presents the method used to establish the

uncertainty for the linearity calibration.

Calibration System 67

Page 72

Calibration Methods

FTB-7000D and FTB-7000B-B OTDR Modules

FTB-7000D and FTB-7000B-B OTDR Modules

Calibration of the FTB-7000D OTDR includes the event and attenuation

dead zones, dynamic range, injection levels, linearity, front connector

position, and distance. Calibration of the FTB-7000B-B family, includes test

or verification of event and attenuation dead zones, dynamic range,

injection level, and distance.

The verification of the technical specifications such as dead zones,

linearity, and dynamic range are more a validation of the expected

instrument performance. However, for an OTDR to produce accurate

distance measurements, a calibration is required and may include some

adjustments.

For any test or calibration, make sure that the front connector of the OTDR

is clean and does not present scratches. If the connector is damaged, it

must be replaced, and Repair must be selected in the Work type box (refer

to step 7 on page 32) of the IQS-12002B application: no measurements, for

which the results would appear in the “As found” section of the report, will

be performed.

Note: All measurements performed on the FTB-7000B-B are to be manually done

and entered as per the instructions given in the IQS-12002B system.

68 IQS-12002B

Page 73

Calibration Methods

FTB-7000D and FTB-7000B-B OTDR Modules

Dynamic Range Test

The dynamic range is verified using various combinations of pulse duration

and distance range with the averaging time set at 45 s. Only one pulse

duration is included in the calibration report, usually 10 μs for singlemode

and 1 μs for multimode. The dynamic range is the difference (in dB)

between the launch level (backscatter trace extrapolated at distance zero)

and the noise floor. The noise floor has many definitions, but the one

mostly accepted in the fiber-optic industry is when the signal-to-noise ratio

equals 1 (SNR = 1). For EXFO OTDRs, we use custom software that

measures the noise floor on the raw data (before conversion in dB), which

is the only way to properly evaluate the standard deviation at the noise

floor level.

When trying to measure the dynamic range, the main difficulty is to

determine the proper noise floor. In general, alternative noise floor

definitions are used (e.g. peak noise level or 98 % noise level) and are then

converted to SNR = 1. Because the interpretation of noise is difficult and

the correct evaluation of the noise floor, when the raw data is not available,

is hard to make, and also because noise has different definitions, it is not

uncommon to find deviations of up to 2 dB between measurements done

with EXFO’s IQS-12002B software and done manually without raw data.

The software indicator of the injection level at each pulse is also verified

when measuring the dynamic range. The results might indicate that an

adjustment is required for one or more pulses. Note that a failure on an

injection level test does not imply a failure on the dynamic range; these are

separate parameters. Moreover, the injection level being only a visual

indicator, its result is not shown on the calibration certificate.

Note: There is no uncertainty value associated with this measurement.

Calibration System 69

Page 74

Calibration Methods

FTB-7000D and FTB-7000B-B OTDR Modules

Linearity Test

Linearity is verified by looking at variations in loss measurements made

over a same portion of fiber at different levels of attenuation (a variable

optical attenuator (VOA) is included in the IQS-12002B Calibration System).

This is performed at the shortest wavelength present in the unit both each

multimode and singlemode ports. The pulse used for multimode

wavelengths is 1 μs and, for singlemode wavelengths, it is 10 μs. In both

cases, the averaging time is set at 45 s.

Linearity is not tested on FTB-7000B-B OTDR modules.

The setup for linearity measurements of multimode OTDRs (7000D series)

is as follows:

Multimode fiber (1 km) Multimode fiber (4 km)

IMPORTANT

OTDR

IQS-3100B-D

The setup for linearity measurements of singlemode OTDRs (7000D series)

is as follows:

Singlemode fiber (4.4 km) Singlemode fiber (17.6 km)

OTDR

Singlemode fiber (17.6 km)

IQS-3100BW

for the FTB-7400D-NS-431

Note: For the FTB-7400D-NS-431, a second fiber length of 17.6 km is required.

70 IQS-12002B

Page 75

Calibration Methods

FTB-7000D and FTB-7000B-B OTDR Modules

The fiber section chosen for the loss measurement must be as far as

possible from the VOA to reduce errors due to recovery on the OTDR.

Usually, the fiber section is chosen to roughly emulate a 0.5-dB loss.

The initial measurement, performed at the minimum attenuation of the

VOA, is considered as the reference loss (A

). Following measurements

ref

are done at higher attenuation. The OTDR loss measurements (A

meet the linearity criteria where nonlinearity (NL) is calculated this way:

A

otdr

NL

1max −±=

A

ref

The linearity specification must be met for a given attenuation range. This

range depends on the OTDR type, the pulse, and the wavelength. The

attenuation range is limited by noise on the trace or recovery after the VOA.

Note: There is no uncertainty value associated with this measurement.

otdr

) must

Calibration System 71

Page 76

Calibration Methods

FTB-7000D and FTB-7000B-B OTDR Modules

Distance Calibration

An OTDR calculates the length of a fiber section by measuring the time of

flight of a light pulse between its launch point and the detection of a

fraction of its reflection. Using the time of flight, the speed of light, and the

index of refraction of the fiber, one can calculate the length of a fiber link.

Before starting the distance calibration procedure, the position of the front