Page 1

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

EVF818

Split execution controller for temperature-

controlled blast chillers

(with capacitive touch-key user interface,

which can be integrated into the unit)

ENGLISH

INSTALLER MANUAL ver. 1.0

CODE 144F818E104

page 1 of 76

Page 2

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

Important

Important

Read this document thoroughly before installation and before use of the device and follow all recommendations; keep

this document with the device for future consultation.

The following symbols support reading of the document:

indicates a suggestion

indicates a warning.

The device must be disposed of in compliance with local Standards regarding the collection of electric and electronic

equipment.

page 2 of 76

Page 3

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

Index

1

INTRODUCTION ...................................................................................................................................6

1.1

Introduction ....................................................................................................................................6

1.2

Summary table of the main features and the models available...............................................................7

2

DESCRIPTION....................................................................................................................................10

2.1

Description of the user interface.......................................................................................................10

2.2

Description of the control module.....................................................................................................11

3

DIMENSIONS AND INSTALLATION........................................................................................................13

3.1

User interface dimensions ...............................................................................................................13

3.2

Control module dimensions .............................................................................................................13

3.3

User interface installation................................................................................................................14

3.4

Control module installation..............................................................................................................14

3.5

Installation warnings ......................................................................................................................14

4

ELECTRIC CONNECTION......................................................................................................................15

4.1

Electric connection .........................................................................................................................15

4.1.1 Connection of the terminating resistors.........................................................................................16

4.2

Warnings for the electric connection .................................................................................................16

5

USER INTERFACE...............................................................................................................................17

5.1

Foreword.......................................................................................................................................17

5.2

Switching the device on/off .............................................................................................................17

5.3

The display....................................................................................................................................17

5.4

Cabinet temperature display............................................................................................................18

5.5

Evaporator temperature display .......................................................................................................18

5.6

Condenser temperature display........................................................................................................18

5.7

Display of the temperature detected by needle probe 1, needle probe 2 and needle probe 3....................19

5.8

Defrosting activation in manual mode...............................................................................................19

5.9

Switch-on/off of the cabinet light in manual mode..............................................................................19

5.10 Locking/unlocking the keyboard.......................................................................................................19

5.11 Silencing the buzzer .......................................................................................................................20

6

OPERATION.......................................................................................................................................21

6.1

Foreword.......................................................................................................................................21

6.1.1 Foreword regarding needle probe .................................................................................................21

6.2

Temperature-controlled blast chilling and storage...............................................................................21

6.3

Temperature-controlled hard blast chilling and storage .......................................................................22

6.4

Time-controlled blast chilling and storage..........................................................................................24

6.5

Time-controlled hard blast chilling and storage ..................................................................................24

6.6

Continuous blast chilling..................................................................................................................25

6.7

Temperature-controlled deep freezing and storage .............................................................................26

6.8

Temperature-controlled soft deep freezing and storage.......................................................................27

6.9

Time-controlled deep freezing and storage ........................................................................................28

6.10 Time-controlled soft deep freezing and storage ..................................................................................29

6.11 Continuous deep freezing................................................................................................................30

6.12 Blast chilling/deep freezing intensity.................................................................................................30

6.12.1 Selecting the evaporator fan speed...............................................................................................31

6.13 Pre-cooling start-up........................................................................................................................32

6.14 Management of the test regarding correct insertion of the needle probe................................................32

6.15 Switching on UV light for sterilisation cycle........................................................................................32

6.16 Needle probe heating......................................................................................................................32

page 3 of 76

Page 4

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

6.17

Data print-out................................................................................................................................33

7

“PROGRAMS” FUNCTION .....................................................................................................................34

7.1

Foreword.......................................................................................................................................34

7.2

Memorisation of a program..............................................................................................................34

7.3

Execution of a program...................................................................................................................34

8

“HACCP” FUNCTION............................................................................................................................36

8.1

Foreword.......................................................................................................................................36

8.2

Display of information relative to the HACCP alarms ...........................................................................36

8.3

Deleting the information relative to the HACCP alarms........................................................................37

9

COMPRESSOR OPERATING HOURS COUNT............................................................................................38

9.1

Display of compressor operating hours..............................................................................................38

9.2

Deleting the compressor operating hours ..........................................................................................38

10

CONFIGURATION ...............................................................................................................................39

10.1 Setting the real date and time .........................................................................................................39

10.2 Setting the configuration parameters................................................................................................39

10.3 Restoring the factory settings ..........................................................................................................40

10.4 List of configuration parameters.......................................................................................................40

11

SIGNALS AND INDICATIONS ...............................................................................................................53

11.1 Signals..........................................................................................................................................53

11.2 Indications ....................................................................................................................................55

12

ALARMS............................................................................................................................................56

12.1 Alarms..........................................................................................................................................56

13

ERRORS............................................................................................................................................59

13.1 Errors ...........................................................................................................................................59

14

ACCESSORIES ...................................................................................................................................62

14.1 EVKEY programming key.................................................................................................................62

14.1.1 Introduction...............................................................................................................................62

14.1.2 Description ................................................................................................................................62

14.1.3 Dimensions................................................................................................................................63

14.1.4 Uploading the configuration parameters ........................................................................................63

14.1.5 Downloading the configuration parameters ....................................................................................63

14.2 Data recording device EVUSBREC01 .................................................................................................64

14.2.1 Introduction...............................................................................................................................64

14.2.2 Description ................................................................................................................................64

14.2.3 Dimensions................................................................................................................................65

14.2.4 Connection to the device .............................................................................................................65

14.3 Optoisolated RS-485/RS-232 serial interface EVIF21RS7I....................................................................65

14.3.1 Introduction...............................................................................................................................65

14.3.2 Description ................................................................................................................................66

14.3.3 Dimensions................................................................................................................................67

14.3.4 Connection to the device .............................................................................................................67

14.4 Phase cut speed regulator for single phase fans EVDFAN1 ...................................................................67

14.4.1 Introduction...............................................................................................................................67

14.4.2 Description ................................................................................................................................68

14.4.3 Dimensions................................................................................................................................68

14.4.4 Connection to the device .............................................................................................................68

14.5 Print module PM 100A X9S001.........................................................................................................69

14.5.1 Introduction...............................................................................................................................69

14.5.2 Description ................................................................................................................................69

page 4 of 76

Page 5

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

14.5.3

Dimensions................................................................................................................................70

14.5.4 Connection to the device .............................................................................................................70

15

TECHNICAL DATA...............................................................................................................................71

15.1 Technical data ...............................................................................................................................71

page 5 of 76

Page 6

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

1 INTRODUCTION

1.1 Introduction

EVF818 is a digital controller studied to manage temperature-controlled blast chillers, which can be mechanically and

aesthetically integrated into the unit.

The controller is fitted with:

- clock

- signal buzzer and alarm

- 6 analogue inputs (cabinet probe, “multipoint” needle probe with up to three sensors, evaporator probe and

condenser probe) for PTC/NTC probes

- 4 digital inputs (door micro switch, high pressure, low pressure and compressor circuit breaker protection)

- 1 PWM analogue output for management of the evaporator fan

- 8 digital outputs (electromechanical relays), 1 x 30 A res. @ 250 VAC for compressor management, 1 x 16 A

res. @ 250 VAC for management of needle probe heating, 6 x 8 A res. @ 250 VAC for management of

defrosting, evaporator fan, condenser fan, door heating elements, of a seventh utility that can be set for the

cabinet light or UV light and an eighth utility that can be configured for pump down valve or alarm output.

- TTL type serial port

- RS-48 serial port with MODBUS communication protocol.

The device can manage both temperature-controlled and time-controlled and hard and soft blast chilling and storage

cycles and deep freezing and storage cycles, with intensity management via the use of a PWM analogue output and

phase cut speed regulator for EVDFAN1 single phase fans.

Every operating cycle can be preceded by pre-cooling. The temperature-controlled cycles are also preceded by a test

for checking the correct connection of the needle probe, with "multipoint" probes management (up to three sensors).

The device is available in “split” execution (user interface + control module).

The user interface is behind a Plexiglas sheet and is made up from a custom 3 + 4 + 1 digit display (with function

icons) and 10 capacitive touch-keys; installation is envisioned on rear of panel with studs.

The control module is without cover and installation is envisioned on flat surface with spacers.

The "programs" function can be used to memorise some settings in a program and start an operating cycle with the

settings it has memorised.

Via the "HACCP" function, up to 9 events can be memorised for each of the 3 HACCP alarms (temperature-controlled

blast chilling or deep freezing not concluded within the maximum duration alarm, maximum temperature during

storage alarm and power cut during storage alarm); the critical value, date and time at which the alarm occurred and

the duration can be memorised for each HACCP alarm.

The configuration parameters can be uploaded and downloaded using the EVKEY programming key (to be ordered

separately).

It is also finally possible to connect the controller to the Parameters Manager set-up software system, to the

monitoring and surveillance system of the RICS plants, to the data recording device and to download the recorded

data (via USB) EVUSBREC01 or to the print module PM 100A X9S001.

The following are indicated among the many other features:

- IP65 protection rating of the user interface

- management of three types of backlight

- memorisation of the defrosting interval

- management of temperature alarms

- compressor operating hours count, "keyboard block" function.

page 6 of 76

Page 7

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

1.2 Summary table of the main features and the models

available

The following table illustrates the main features of the device and the models available.

“ / “ indicates the feature can be set via a configuration parameter.

User interface (without cover) EVF818

340.0 x 84.0 mm (13.385 x 8.400 cm; L x H) •

custom 3 + 4 + 1 digit display (with function icon) •

number of keys (capacitive touch-key type) 10

Control module (without cover) EVF818

166.0 x 116.0 mm (6.535 x 11.598 cm; L x H) •

Connections EVF818

faston + fixed screw terminal board + removable screw

terminal board

Power supply EVF818

115... 230 VAC •

Analogue inputs EVF818

cabinet probe PTC/NTC

needle probe 1 PTC/NTC

needle probe 2 PTC/NTC

needle probe 3 PTC/NTC

evaporator probe PTC/NTC

•

condenser probe PTC/NTC

Digital inputs (for NO/NC contact) EVF818

door micro switch •

high pressure •

low pressure •

page 7 of 76

Page 8

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

compressor circuit breaker protection •

Analogue outputs (PWM) EVF818

evaporator fan (1)

Digital outputs (electromechanical relays; A res. @

250 VAC)

EVF818

compressor 30 A

defrosting 8 A

evaporator fan (1)

condenser fan 8 A

door heating elements 8 A

needle probe heating 16 A

cabinet light/UV light 8 A

pump down valve/alarm 8 A

Communication port EVF818

TTL type serial port •

RS-48 serial port with MODBUS communication protocol •

Other features EVF818

IP65 protection rating of the user interface IP65

clock •

signal buzzer and alarm •

management of three types of backlight •

management of blast chilling and storage/deep freezing

and storage cycles

management of temperature/time controlled operation

cycles

•

•

hard/soft operating cycles management •

page 8 of 76

Page 9

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

management of the test regarding correct insertion of

the needle probe

•

memorisation of the defrosting interval •

management of temperature alarms •

compressor operating hours count •

“programs” function •

“HACCP” function •

"keyboard lock" function •

configuration parameters access password •

restoring the factory settings •

Codes EVF818

codes EVF818P9

Notes:

(1) The evaporator fan control signal can be analogue or digital.

For further information, see chapter 15 "TECHNICAL DATA"; for other models contact the EVCO sales network.

page 9 of 76

Page 10

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

2 DESCRIPTION

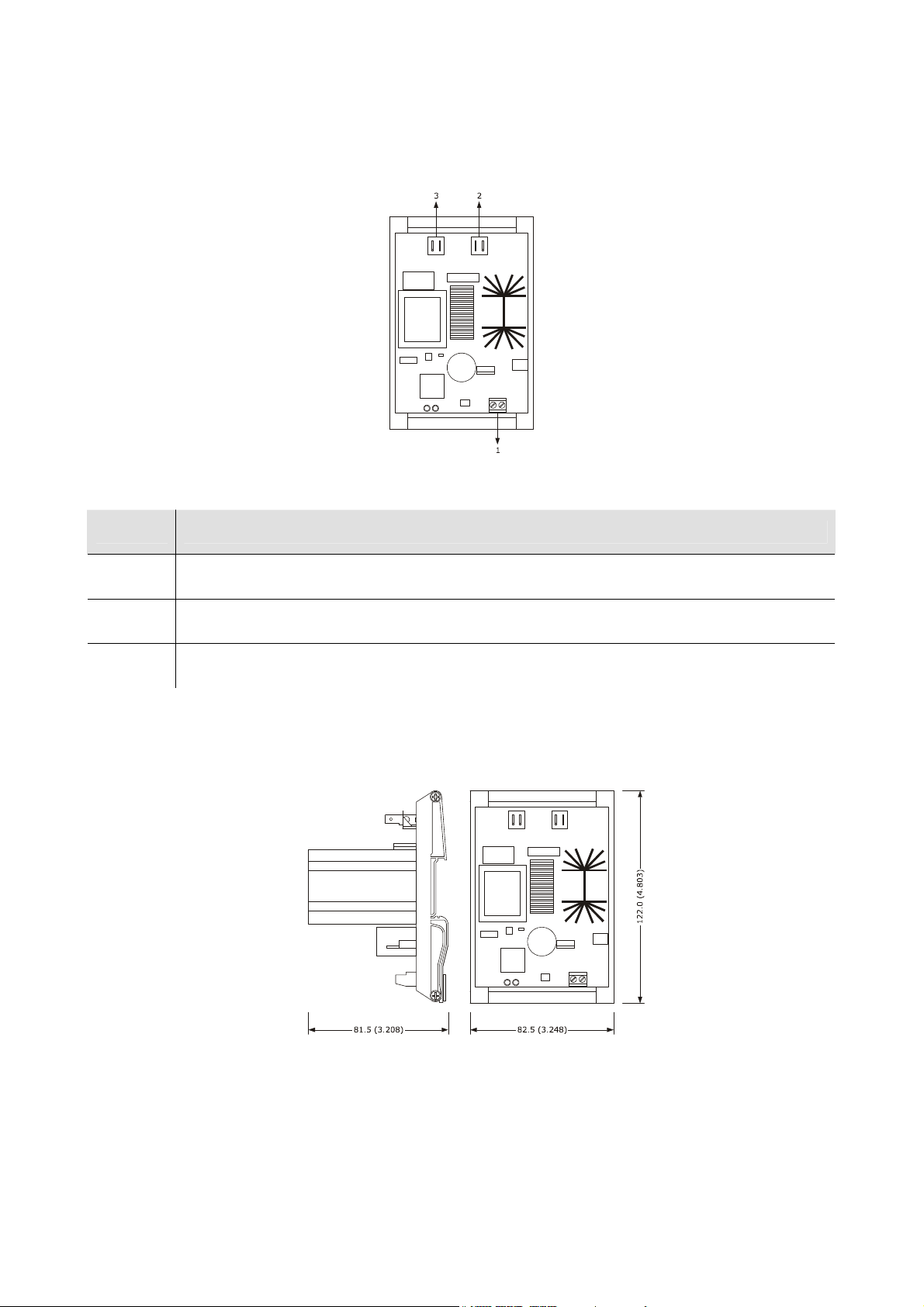

2.1 Description of the user interface

The following drawing illustrates the aspect of the EVF818 user interface.

The following table illustrates the meaning of EVF818 user interface parts.

Part Meaning

1

2 hard blast chilling or soft deep freezing key, hereon called HARD/SOFT" key

3 communication port with the control module (signal)

4 temperature-controlled cycle/time-controlled cycle key, hereon also called "TIME/TEMPERATURE key"

5 display

6 decrease key, hereon called "DOWN key"

7 increase key, hereon called "UP key"

8 cycle start/cycle cut-off key, hereon called "START/STOP key"

9 communication port with the control module (power supply)

on/off key, herein called also "ON/STAND-BY key"

10 programs memorisation/execution key, hereon also called “PROGRAMS key”

11 blast chilling/deep freezing intensity key, hereon also called "BLAST CHILLING INTENSITY key"

12 deep freezing key

13 blast chilling key

For further information, see the next chapters.

page 10 of 76

Page 11

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

2.2 Description of the control module

The following drawing illustrates the aspect of the EVF818 control module.

The following table illustrates the meaning of EVF818 control module parts.

Part Meaning

1 power supply

2 digital outputs K3 and K4

3 digital output K2

4 digital output K1

5 digital output K5

6 digital inputs

7 digital output K6

8 digital outputs K7 and K8

9 reserved

10 TTL type serial port

11 reserved

12 digital inputs (cabinet probe, evaporator probe and condenser probe)

13 digital inputs (needle probe 1, needle probe 2 and needle probe 3)

14 reserved

page 11 of 76

Page 12

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

15 PWM analogue output

16

RS-485 serial port with MODBUS communication protocol and communication port with user interface

(signal and power supply)

For further information, see the next chapters.

page 12 of 76

Page 13

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

3 DIMENSIONS AND INSTALLATION

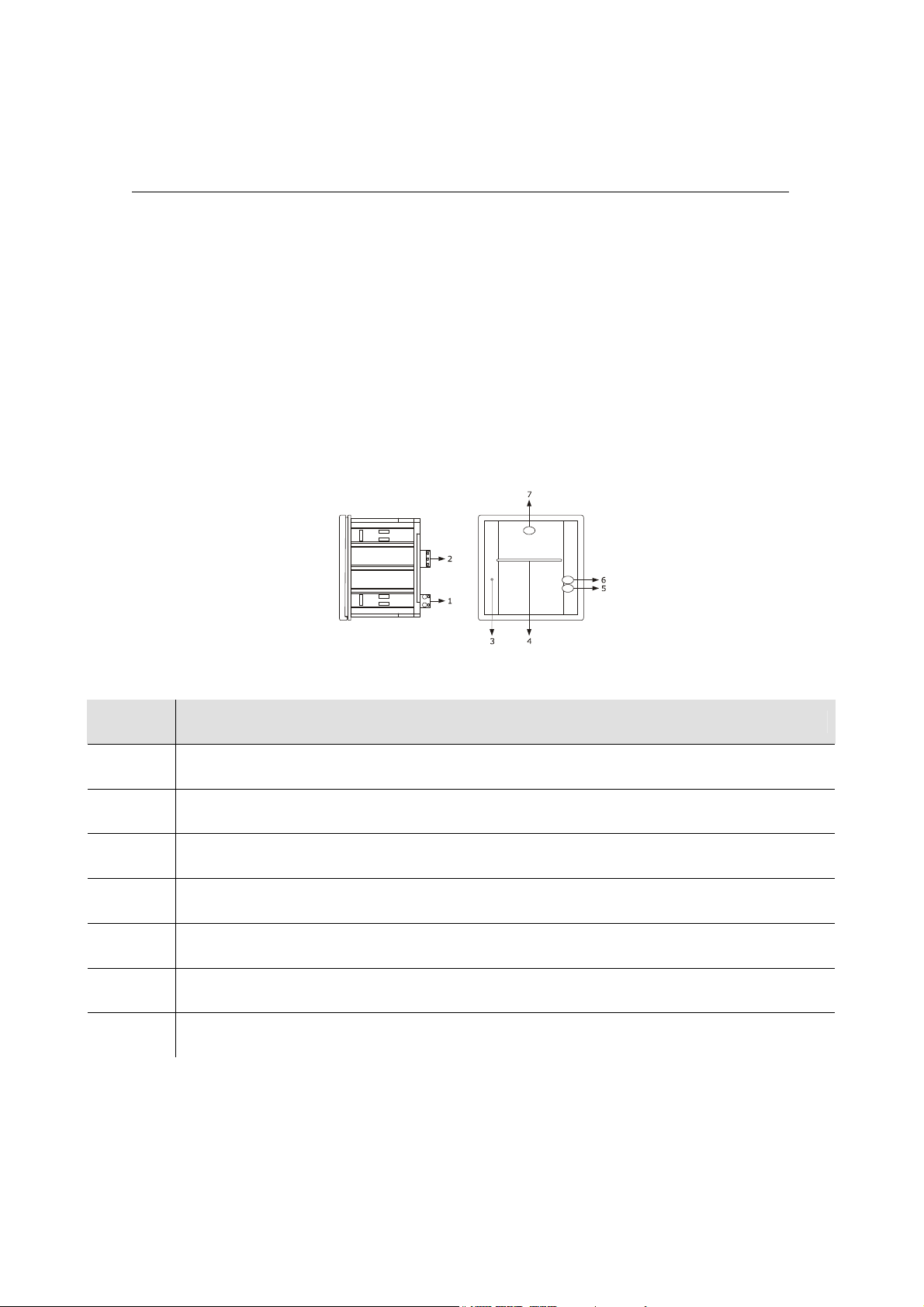

3.1 User interface dimensions

The following drawing illustrates the EVF818 user interface dimensions; these are expressed in mm (in).

3.2 Control module dimensions

The following drawing illustrates the EVF818 control module dimensions; these are expressed in mm (in).

page 13 of 76

Page 14

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

3.3 User interface installation

Back panel via studs

3.4 Control module installation

On flat surface, with spacers.

3.5 Installation warnings

- make sure that the device work conditions (temperature of use, humidity, etc.) lie within the limits indicated;

see chapter 15 "TECHNICAL DATA"

- do not install the device near to any heat sources (heating elements, hot air ducts etc.), equipment containing

powerful magnets (large diffusers, etc.), areas affected by direct sunlight, rain, humidity, excessive dust,

mechanical vibrations or shocks.

- any metal parts in proximity of the control module must be at a distance such that they do not compromise the

safety distances.

- in compliance with Safety Standards, the device must be installed correctly and in a way to protect against any

contact with electric parts; all parts that ensure protection must be fixed in a way that they cannot be removed

without the use of tools.

page 14 of 76

Page 15

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

4 ELECTRIC CONNECTION

4.1 Electric connection

The following drawing illustrates the EVF818 electric connection.

The utility managed by the K7 output, depends on parameter u11, as follows:

- cabinet light (u11 = 0, pre-defined setting)

- UV light (u11 = 1).

For the settings relative to the parameters, see chapter 10 “CONFIGURATION”.

The utility managed by the K8 output, depends on parameter u1, as follows:

- pump down valve (u1 = 0, per-defined setting)

- alarm (u1 = 1).

For the settings relative to the parameters, see chapter 10 “CONFIGURATION”.

The TTL port is the port used for connection of the controller to the EVKEY programming key.

page 15 of 76

Page 16

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

The RS-485 port is for the connection of the controller to the following additional products:

- Parameters Manager set-up software system

- RICS plants monitoring and surveillance systems

- device for recording data and to download recorded data (via USB) EVUSBREC01

- print module PM 100A X9S001.

The port must not be used simultaneously with more than one of these products.

4.1.1 Connection of the terminating resistors

The terminating resistor must be connected in order to reduce the reflections on the signal transmitted along the

cables that connect the user interface to the control model.

To connect the terminating resistors, position the jumper as illustrated in the following drawing.

To disconnect the terminating resistors, position the jumper as illustrated in the following drawing.

4.2 Warnings for the electric connection

- do not use electric or pneumatic screwdrivers on the device terminal board

- if the device has been taken from a cold to hot place, humidity could condense inside; wait about 1 hour before

powering it

- make sure that the power supply voltage, the frequency and the operational electric power of the device,

correspond with those of the local power supply; see chapter 15 "TECHNICAL DATA"

- disconnect the device power supply before proceeding with any type of maintenance

- do not use this device as a safety device

- for repairs and information regarding the device, contact the EVCO sales network.

page 16 of 76

Page 17

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

5 USER INTERFACE

5.1 Foreword

The following operating status exist:

- the “off” status (the device is not powered)

- the “stand-by” status (the device is powered and is off)

- the “on” status (the device is powered, is on and is in stand-by for the start-up of an operating cycle)

- the “run” status (the device is powered, is on and an operating cycle is in progress).

Hereon, the term "device switch-on" means the passage from the "stand-by" status to the "on" status. the term

"switch-off" means passage from the "on" status to the "stand-by" status.

If a power cut occurs during the "stand-by" status or during the "on" status, the device will re-propose the same

status when the power supply is restored.

If a power cut occurs during the "run" status, the device will operate as follows when this is restored:

- if a temperature-controlled blast chilling or deep freezing operation was in progress, these will be started again

from the beginning

- if a time-controlled blast chilling or deep freezing operation was in progress, these will be started again from

the moment the power supply was cut-off

- if storage was in progress, this will be re-proposed.

5.2 Switching the device on/off

Operate as follows:

1. Make sure that the keyboard is not locked and that no procedure is in progress.

2. Hold the ON/STAND-BY key down for 2 s: the LED will switch on/off.

5.3 The display

All displays are off during the "off" status and during the "stand-by" status.

During the "on" state:

- the 1 digit display is off.

- the 3 digit display:

- will display the blast chilling end temperature if a temperature-controlled blast chilling cycle has been

selected or the deep freezing end temperature if a temperature-controlled deep freezing cycle has been

selected.

- will display the blast chilling duration if a temperature-controlled blast chilling cycle has been selected or

the deep freezing duration if a temperature-controlled deep freezing cycle has been selected.

- the 4 digit display:

- will display the work set-point during blast chilling if temperature-controlled blast chilling has been

selected or the work set-point during deep freezing if temperature-controlled deep-freezing has been

selected.

- will be off if time-controlled blast chilling or time-controlled deep freezing has been selected.

During the "run" state:

- the 1 digit display shows the program number if there is one in progress.

- the 3 digit display:

- will show the temperature detected by the needle probe if a temperature-controlled blast chilling or deep

freezing cycle is in progress

- will display the residual blast chilling time if time-controlled blast chilling is in progress or the residual

deep freezing time if time-controlled deep freezing is in progress

page 17 of 76

Page 18

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

- the 4 digit display:

- will show the temperature of the cabinet.

5.4 Cabinet temperature display

Operate as follows:

1. Make sure that the keyboard is not locked and that no procedure is in progress.

2. Hold the DOWN key down for 2 s: the 3 digit display will show the first label available.

3. Press and release the UP or DOWN key to select “Pb1”.

4. Press and release the BLAST CHILLING key: the 4 digit display will show the cabinet temperature.

Operate as follows to exit the procedure:

5. Press and release the BLAST CHILLING key or do not operate for 60 s: the 4 digit display will switch off.

6. Press and release the UP or DOWN key until the display shows the magnitude indicated in paragraph 5.3 "The

display" or do not operate for 60 s.

5.5 Evaporator temperature display

Operate as follows:

1. Make sure that the keyboard is not locked and that no procedure is in progress.

2. Hold the DOWN key down for 2 s: the 3 digit display will show the first label available.

3. Press and release the UP or DOWN key to select “Pb2”.

4. Press and release the BLAST CHILLING key: the 4 digit display will show the evaporator temperature.

Operate as follows to exit the procedure:

5. Press and release the BLAST CHILLING key or do not operate for 60 s: the 4 digit display will switch off.

6. Press and release the UP or DOWN key until the display shows the magnitude indicated in paragraph 5.3 "The

display" or do not operate for 60 s.

If the evaporator probe is not enabled, i.e. if parameter P4 is set at 0, the “Pb2“ label will not be displayed.

5.6 Condenser temperature display

Operate as follows:

1. Make sure that the keyboard is not locked and that no procedure is in progress.

2. Hold the DOWN key down for 2 s: the 3 digit display will show the first label available.

3. Press and release the UP or DOWN key to select “Pb3”.

4. Press and release the BLAST CHILLING key: the 4 digit display will show the condenser temperature.

Operate as follows to exit the procedure:

5. Press and release the BLAST CHILLING key or do not operate for 60 s: the 4 digit display will switch off.

6. Press and release the UP or DOWN key until the display shows the magnitude indicated in paragraph 5.3 "The

display" or do not operate for 60 s.

If the condenser probe is not enabled, i.e. if parameter P5 is set at 0, the “Pb3“ label will not be displayed.

page 18 of 76

Page 19

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

5.7 Display of the temperature detected by needle probe

1, needle probe 2 and needle probe 3

Operate as follows:

1. Make sure that the keyboard is not locked and that no procedure is in progress.

2. Hold the DOWN key down for 2 s: the 3 digit display will show the first label available.

3. Press and release the UP or DOWN key to select “Pb4” (needle probe 1), “Pb5” (needle probe 2) or “Pb6”

(needle probe 3).

4. Press and release the BLAST CHILLING key: the 4 digit display will show the temperature detected by the

respective needle probe.

Operate as follows to exit the procedure:

5. Press and release the BLAST CHILLING key or do not operate for 60 s: the 4 digit display will switch off.

6. Press and release the UP or DOWN key until the display shows the magnitude indicated in paragraph 5.3 "The

display" or do not operate for 60 s.

If the needle probe 1 is not enabled, i.e. if parameter P3 is set at 0, the “Pb4“ label will not be displayed.

If the needle probe 2 is not enabled, i.e. if parameter P3 is set at 0 or 1, the “Pb5“ label will not be displayed.

If the needle probe 3 is not enabled, i.e. if parameter P3 is set at 0 1 or 2, the “Pb6“ label will not be displayed.

5.8 Defrosting activation in manual mode

Operate as follows:

1. Make sure the device is in the "on" status and that pre-cooling or storage cycle is in progress.

2. Make sure that the keyboard is not locked and that no procedure is in progress.

3. Hold the UP key down for 4 s: the 3 digit display will show “dEF”.

If the evaporator probe is enabled, i.e. the parameter P4 is set at 1 and on activation of defrosting the evaporator

temperature is above that established with parameter d2, defrosting will not be activated.

5.9 Switch-on/off of the cabinet light in manual mode

Operate as follows:

1. Make sure that parameter u11 is set at 0.

2. Make sure no procedures are in progress

3. Press and release the DEEP FREEZING key for 2 sec.: the AUX LED will switch on/off.

5.10 Locking/unlocking the keyboard

Operate as follows to lock the keyboard:

1. Make sure no procedures are in progress

2. Hold the DOWN key and the ON/STAND-BY key down for 2 s: the 3 digit display will show “Loc” for 2 seconds.

The following operations will not be allowed if the keyboard is locked:

- switching the device on/off

- cabinet temperature display (with the procedure given in paragraph 5.4)

- evaporator temperature display

- condenser temperature display

- display of the temperature detected by needle probe 1, needle probe 2 and needle probe 3

- defrosting activation in manual mode

- operating cycle start-up/cut-off

- switching on UV light for sterilisation cycle

- heating the needle probe

page 19 of 76

Page 20

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

- display of information relative to the HACCP alarms

- memorisation of a program

- execution of a program

- deleting the information relative to the HACCP alarms

- display of compressor operating hours

- deleting the compressor operating hours

- setting the real date and time.

Operate as follows to unlock the keyboard:

1. Make sure no procedures are in progress

2. Hold the DOWN key and the ON/STAND-BY key down for 2 s: the 3 digit display will show “UnL” for 2 seconds.

5.11 Silencing the buzzer

Operate as follows:

1. Make sure no procedures are in progress

2. Press and release the key.

page 20 of 76

Page 21

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

6 OPERATION

6.1 Foreword

The device can manage the following operating cycles:

- temperature-controlled blast chilling and storage

- temperature-controlled hard blast chilling and storage

- time-controlled blast chilling and storage

- time-controlled hard blast chilling and storage

- continuous blast chilling

- temperature-controlled deep freezing and storage

- temperature-controlled soft deep freezing and storage

- time-controlled deep freezing and storage

- time-controlled soft deep freezing and storage

- continuous deep freezing

For further information, see the next paragraphs

Every operating cycle can be preceded by pre-cooling; see paragraph 6.13 "Pre-cooling start-up".

The temperature-controlled cycles are preceded by a test to verify the correct insertion of the needle probe; see

paragraph 6.14 " Test for verification of the correct insertion of the needle probe".

If the needle probe is not enabled, i.e. if parameter P3 is set at 0, the temperature-controlled cycles will be started

with time-control.

The following functions can also be used:

- switching on sterilisation cycle UV light

- heating the needle probe.

For further information, see the next paragraphs

6.1.1 Foreword regarding needle probe

The device can manage "multipoint" needle probes (with up to three sensors).

Parameter P3 establishes the number of needle probe sensors as indicated:

- if parameter P3 is set at 0, the needle probe will not be enabled

- if parameter P3 is set at 1, there will be one sensor (needle probe 1)

- if parameter P3 is set at 2, there will be 2 sensors (needle probe 1 and needle probe 2)

- if parameter P3 is set at 3, there will be 3 sensors (needle probe 1 and needle probe 2 and needle probe 3).

If parameter P3 is set at values different to 0, the temperature-controlled cycles will be preceded by a test to verify

the correct insertion of the needle probe; see paragraph 6.14 " Test for verification of the correct insertion of the

needle probe".

On conclusion of the test, the device will operate as indicated:

- the sensor that has detected the lowest temperature is then used as the reference temperature for heating the

needle probe.

- the sensor that has detected the highest temperature is then used as the reference for the temperature-

controlled cycles

- the sensors for which the test is not completed successfully are not used successively.

6.2 Temperature-controlled blast chilling and storage

The temperature-controlled blast chilling and storage cycle is divided into the following two phases:

- blast chilling

- storage.

page 21 of 76

Page 22

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

On conclusion of a phase, the device passes automatically to the next.

Operate as indicated to start the cycle:

1. Make sure the device is in the "on" status.

2. Make sure that the keyboard is not locked and that no procedure is in progress.

3. Press and release the BLAST CHILLING key: the

4.1 If parameter r19 is set at 0, the 4 digit display will show the work set-point during blast chilling; this value can

also be set via parameter r7.

4.2 If parameter r19 is set at 1, the 3 digit display will show the blast chilling end temperature; this value can also

be set via parameter r3.

4.3 Press and release the UP or DOWN key within 60 s to modify the parameter value:

5. Press and release the START/STOP key: the LED and the LED will remain permanently on and the test to

verify the correct insertion of the needle probe will be started; see paragraph 6.14 " Test for verification of the

correct insertion of the needle probe".

5.1 If the test is completed successfully, the cycle will be started.

The maximum blast chilling duration count is started on condition that the temperature detected by the

needle probe is below that established with parameter r15.

5.2 If the test is not completed successfully, the cycle will be started with timed-control; see paragraph 6.4

"Time-controlled blast chilling and storage".

Operate as indicated to stop the cycle:

6. Hold the START/STOP key down for 2 s.

During blast chilling, the 3 digit display will show the temperature detected by the needle probe and the 4 digit display

shows the cabinet cell.

The successive parameters establish the following values:

- parameter r3 establishes the blast chilling end temperature

- parameter r5 establishes the maximum blast chilling duration

- parameter r7 establishes the work set-point during blast chilling.

To display the cabinet work set-point during blast chilling, press and release the BLAST CHILLING, DEEP FREEZING or

the HARD/SOFT key; to restore the normal display, press and release the same key again or do not operate for 60 s.

If the temperature detected by the needle probe reaches the blast chilling end temperature within the maximum blast

chilling duration, it means that blast chilling has been completed successfully, the device will automatically pass to

storage and the buzzer will be activated for the period of time established with parameter AA.

Press and release a key to silence the buzzer.

During storage, the 3 digit display shows the time taken to complete blast chilling successfully, the 4 digit display

shows the cabinet temperature and the LED is on.

Parameter r10 establishes the work set-point during storage.

If the temperature detected by the needle probe does not reach the blast chilling end temperature within the

maximum blast chilling duration, blast chilling will not be completed successfully but will continue, the LED will

flash and the buzzer will be activated.

Press and release a key to restore normal display and to silence the buzzer.

When the temperature detected by the needle probe reaches the blast chilling end temperature, the device

automatically passes to storage in the same way as illustrated previously.

LED and the LED will flash.

6.3 Temperature-controlled hard blast chilling and

storage

The temperature-controlled hard blast chilling and storage cycle is divided into the following three phases:

- blast chilling hard phase

- blast chilling

page 22 of 76

Page 23

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

- storage.

On conclusion of a phase, the device passes automatically to the next.

Operate as indicated to start the cycle:

1. Make sure the device is in the "on" status.

2. Make sure that the keyboard is not locked and that no procedure is in progress.

3. Press and release the BLAST CHILLING key: the

LED and the LED will flash.

4. Press and release the HARD/SOFT key: the HARD LED will flash.

5.1 If parameter r19 is set at 0, the 3 digit display will show the work set-point during blast chilling; this value can

also be set via parameter r7.

5.2 If parameter r19 is set at 1, the 4 digit display will show the blast chilling end temperature; this value can also

be set via parameter r3.

5.3 Press and release the UP or DOWN key within 60 s to modify the parameter value:

6. Press and release the START/STOP key: the LED, the LED and the HARD LED will remain permanently

on and the test to verify the correct insertion of the needle probe will be started; see paragraph 6.14 " Test for

verification of the correct insertion of the needle probe".

6.1 If the test is completed successfully, the cycle will be started.

The maximum blast chilling duration count is started on condition that the temperature detected by the

needle probe is below that established with parameter r15.

6.2 If the test is not completed successfully, the cycle will be started with timed-control; see paragraph 6.5

"Time-controlled hard blast chilling and storage".

Operate as indicated to stop the cycle:

7. Hold the START/STOP key down for 2 s.

During the hard blast chilling phase, the 3 digit display will show the temperature detected by the needle probe and

the 4 digit display shows the cabinet cell.

The successive parameters establish the following values:

- parameter r5 establishes the maximum blast chilling duration

- parameter r9 establishes the work set-point during the blast chilling hard phase

- parameter r13 establishes blast chilling hard phase end temperature.

When the temperature detected by the needle probe reaches the hard blast chilling phase end temperature, the device

automatically passes to blast chilling mode.

During blast chilling, the 3 digit display will show the temperature detected by the needle probe and the 4 digit display

shows the cabinet cell.

The successive parameters establish the following values:

- parameter r3 establishes the blast chilling end temperature

- parameter r5 establishes the maximum blast chilling duration

- parameter r7 establishes the work set-point during blast chilling.

To display the cabinet work set-point during blast chilling, press and release the BLAST CHILLING, DEEP FREEZING or

the HARD/SOFT key; to restore the normal display, press and release the same key again or do not operate for 60 s.

If the temperature detected by the needle probe reaches the blast chilling end temperature within the maximum blast

chilling duration, it means that blast chilling has been completed successfully, the device will automatically pass to

storage and the buzzer will be activated for the period of time established with parameter AA.

Press and release a key to silence the buzzer.

During storage, the 3 digit display shows the time taken to complete blast chilling successfully, the 4 digit display

shows the cabinet temperature and the LED is on.

Parameter r10 establishes the work set-point during storage.

If the temperature detected by the needle probe does not reach the blast chilling end temperature within the

maximum blast chilling duration, blast chilling will not be completed successfully but will continue, the

LED will

flash and the buzzer will be activated.

page 23 of 76

Page 24

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

Press and release a key to restore normal display and to silence the buzzer.

When the temperature detected by the needle probe reaches the blast chilling end temperature, the device

automatically passes to storage in the same way as illustrated previously.

6.4 Time-controlled blast chilling and storage

The time-controlled blast chilling and storage cycle is divided into the following two phases:

- blast chilling

- storage.

On conclusion of a phase, the device passes automatically to the next.

Operate as indicated to start the cycle:

1. Make sure the device is in the "on" status.

2. Make sure that the keyboard is not locked and that no procedure is in progress.

3. Press and release the BLAST CHILLING key: the LED and the LED will flash.

4. Press and release the TIME/TEMPERATURE key: the LED flashes and the LED will switch off.

5.1 If parameter r19 is set at 0, the 4 digit display will show the work set-point during blast chilling; this value can

also be set via parameter r7.

5.2 If parameter r19 is set at 1, the 3 digit display will show the blast chilling duration; this value can also be set

via parameter r1.

5.3 Press and release the UP or DOWN key within 60 s to modify the parameter value:

6. Press and release the START/STOP key: the LED and the LED will remain permanently on and the cycle

will be started.

Operate as indicated to stop the cycle:

7. Hold the START/STOP key down for 2 s.

During blast chilling, the 3 digit display shows the residual time of the blast chilling duration and the 4 digit display

shows the cabinet temperature.

To modify the residual time, operate as indicated:

8. Press and release the UP or DOWN key again to modify the time value: the display will flash.

9. Do not operate for 4 s: the display will stop flashing and remain on permanently.

The successive parameters establish the following values:

- parameter r1 establishes blast chilling duration

- parameter r7 establishes the work set-point during blast chilling.

To display the cabinet work set-point during blast chilling, press and release the BLAST CHILLING, DEEP FREEZING or

the HARD/SOFT key; to restore the normal display, press and release the same key again or do not operate for 60 s.

On expiry of the blast chilling duration, the device automatically passes to storage mode and the buzzer is activated

for the time period established with parameter AA.

Press and release a key to silence the buzzer.

During storage, the 3 digit display shows blast chilling duration, the 4 digit display shows the cabinet temperature and

the LED is on.

Parameter r10 establishes the work set-point during storage.

6.5 Time-controlled hard blast chilling and storage

The time-controlled hard blast chilling and storage cycle is divided into the following three phases:

- blast chilling hard phase

- blast chilling

- storage.

page 24 of 76

Page 25

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

On conclusion of a phase, the device passes automatically to the next.

Operate as indicated to start the cycle:

1. Make sure the device is in the "on" status.

2. Make sure that the keyboard is not locked and that no procedure is in progress.

3. Press and release the BLAST CHILLING key: the

4. Press and release the HARD/SOFT key: the HARD LED will flash.

5. Press and release the TIME/TEMPERATURE key: the LED flashes and the LED will switch off.

6.1 If parameter r19 is set at 0, the 4 digit display will show the work set-point during blast chilling; this value can

also be set via parameter r7.

6.2 If parameter r19 is set at 1, the 3 digit display will show the blast chilling duration; this value can also be set

via parameter r1.

6.3 Press and release the UP or DOWN key within 60 s to modify the parameter value:

7. Press and release the START/STOP key: the LED, the LED and the HARD LED will remain permanently on

and the cycle will be started.

Operate as indicated to stop the cycle:

8. Hold the START/STOP key down for 2 s.

During the hard blast chilling phase, the 3 digit display shows the residual time of the blast chilling duration and the 4

digit display shows the cabinet temperature.

To modify the residual time, operate as indicated:

9. Press and release the UP or DOWN key again to modify the time value: the display will flash.

10. Do not operate for 4 s: the display will stop flashing and remain on permanently.

The successive parameters establish the following values:

- parameter r9 establishes the work set-point during the blast chilling hard phase

- parameter r14 establishes blast chilling hard phase duration.

On expiry of the hard blast chilling phase duration, the device automatically passes to blast chilling.

During blast chilling, the 3 digit display shows the residual time of the blast chilling duration and the 4 digit display

shows the cabinet temperature.

The successive parameters establish the following values:

- parameter r1 establishes blast chilling duration

- parameter r7 establishes the work set-point during blast chilling.

To display the cabinet work set-point during blast chilling, press and release the BLAST CHILLING, DEEP FREEZING or

the HARD/SOFT key; to restore the normal display, press and release the same key again or do not operate for 60 s.

On expiry of the blast chilling duration, the device automatically passes to storage mode and the buzzer is activated

for the time period established with parameter AA.

Press and release a key to silence the buzzer.

During storage, the 3 digit display shows blast chilling duration, the 4 digit display shows the cabinet temperature and

the LED is on.

Parameter r10 establishes the work set-point during storage.

LED and the LED will flash.

6.6 Continuous blast chilling

Operate as indicated to start the cycle:

1. Make sure the device is in the "on" status.

2. Make sure that the keyboard is not locked and that no procedure is in progress.

3. Press and release the BLAST CHILLING key: the

4. Press and release the TIME/TEMPERATURE key: the LED flashes and the LED will switch off.

5. Press and release the TIME/TEMPERATURE key again: the 3 digit display will show “inF”.

LED and the LED will flash.

page 25 of 76

Page 26

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

6.1 The 4 digit display will show the work set-point during blast chilling; this value can also be set via parameter r7.

6.2 Press and release the UP or DOWN key within 60 s to modify the parameter value:

7. Press and release the START/STOP key: the

will be started.

Operate as indicated to stop the cycle:

8. Hold the START/STOP key down for 2 s.

During blast chilling, the 3 digit display shows “inF” and the 4 digit display shows the cabinet cell.

Parameter r7 establishes the work set-point during blast chilling.

To display the cabinet work set-point during blast chilling, press and release the BLAST CHILLING, DEEP FREEZING or

the HARD/SOFT key; to restore the normal display, press and release the same key again or do not operate for 60 s.

LED and the LED will remain permanently on and the cycle

6.7 Temperature-controlled deep freezing and storage

The temperature-controlled deep freezing and storage cycle is divided into the following two phases:

- deep freezing

- storage.

On conclusion of a phase, the device passes automatically to the next.

Operate as indicated to start the cycle:

1. Make sure the device is in the "on" status.

2. Make sure that the keyboard is not locked and that no procedure is in progress.

3. Press and release the DEEP FREEZING key: the LED, the LED, the LED and the HARD LED will flash.

4.1 If parameter r19 is set at 0, the 4 digit display will show the work set-point during deep freezing; this value can

also be set via parameter r8.

4.2 If parameter r19 is set at 1, the 3 digit display will show the deep freezing end temperature; this value can also

be set via parameter r4.

4.3 Press and release the UP or DOWN key within 60 s to modify the parameter value:

5. Press and release the START/STOP key: the LED, the LED, the LED and the HARD LED will remain

permanently on and the test to verify the correct insertion of the needle probe will be started; see paragraph

6.14 " Test for verification of the correct insertion of the needle probe".

5.1 If the test is completed successfully, the cycle will be started.

The maximum deep freezing duration count is started on condition that the temperature detected by the

needle probe is below that established with parameter r15.

5.2 If the test is not completed successfully, the cycle will be started with timed-control; see paragraph 6.9

"Time-controlled deep freezing and storage".

Operate as indicated to stop the cycle:

6. Hold the START/STOP key down for 2 s.

During deep freezing, the 3 digit display will show the temperature detected by the needle probe and the 4 digit

display shows the cabinet cell.

The successive parameters establish the following values:

- parameter r4 establishes the deep freezing end temperature

- parameter r6 establishes the maximum deep freezing duration

- parameter r8 establishes the work set-point during deep freezing.

To display the cabinet work set-point during deep freezing, press and release the BLAST CHILLING, DEEP FREEZING or

the HARD/SOFT key; to restore the normal display, press and release the same key again or do not operate for 60 s.

If the temperature detected by the needle probe reaches the deep freezing end temperature within the maximum deep

freezing duration, it means that deep freezing has been completed successfully, the device will automatically pass to

storage and the buzzer will be activated for the period of time established with parameter AA.

Press and release a key to silence the buzzer.

page 26 of 76

Page 27

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

During storage, the 3 digit display shows the time taken to complete deep freezing successfully, the 4 digit display

shows the cabinet temperature and the

Parameter r11 establishes the work set-point during storage.

If the temperature detected by the needle probe does not reach the deep freezing end temperature within the

maximum deep freezing duration, deep freezing will not be completed successfully but will continue, the LED will

flash and the buzzer will be activated.

Press and release a key to restore normal display and to silence the buzzer.

When the temperature detected by the needle probe reaches the deep freezing end temperature, the device

automatically passes to storage in the same way as illustrated previously.

LED is on.

6.8 Temperature-controlled soft deep freezing and

storage

The temperature-controlled soft deep freezing and storage cycle is divided into the following three phases:

- deep freezing soft phase

- deep freezing

- storage.

On conclusion of a phase, the device passes automatically to the next.

Operate as indicated to start the cycle:

1. Make sure the device is in the "on" status.

2. Make sure that the keyboard is not locked and that no procedure is in progress.

3. Press and release the DEEP FREEZING key: the LED, the LED, the LED and the HARD LED will flash.

4. Press and release the HARD/SOFT key: the HARD LED will switch off.

5.1 If parameter r19 is set at 0, the 4 digit display will show the work set-point during deep freezing; this value can

also be set via parameter r8.

5.2 If parameter r19 is set at 1, the 3 digit display will show the deep freezing end temperature; this value can also

be set via parameter r4.

5.3 Press and release the UP or DOWN key within 60 s to modify the parameter value:

6. Press and release the START/STOP key: the LED, the LED and the LED will remain permanently on

and the test to verify the correct insertion of the needle probe will be started; see paragraph 6.14 " Test for

verification of the correct insertion of the needle probe".

6.1 If the test is completed successfully, the cycle will be started.

The maximum deep freezing duration count is started on condition that the temperature detected by the

needle probe is below that established with parameter r15.

6.2 If the test is not completed successfully, the cycle will be started with timed-control; see paragraph 6.10

"Time-controlled soft deep freezing and storage".

Operate as indicated to stop the cycle:

7. Hold the START/STOP key down for 2 s.

During soft deep freezing phase, the 3 digit display will show the temperature detected by the needle probe and the 4

digit display shows the cabinet cell.

The successive parameters establish the following values:

- parameter r3 establishes deep freezing soft phase end temperature

- parameter r6 establishes the maximum deep freezing duration

- parameter r7 establishes the work set-point during the deep freezing soft phase

When the temperature detected by the needle probe reaches the end temperature of the soft phase, the device

automatically passes to deep freezing.

During deep freezing, the 3 digit display will show the temperature detected by the needle probe and the 4 digit

display shows the cabinet cell.

page 27 of 76

Page 28

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

The successive parameters establish the following values:

- parameter r4 establishes the deep freezing end temperature

- parameter r6 establishes the maximum deep freezing duration

- parameter r8 establishes the work set-point during deep freezing.

To display the cabinet work set-point during deep freezing, press and release the BLAST CHILLING, DEEP FREEZING or

the HARD/SOFT key; to restore the normal display, press and release the same key again or do not operate for 60 s.

If the temperature detected by the needle probe reaches the deep freezing end temperature within the maximum deep

freezing duration, it means that deep freezing has been completed successfully, the device will automatically pass to

storage and the buzzer will be activated for the period of time established with parameter AA.

Press and release a key to silence the buzzer.

During storage, the 3 digit display shows the time taken to complete deep freezing successfully, the 4 digit display

shows the cabinet temperature and the

Parameter r11 establishes the work set-point during storage.

If the temperature detected by the needle probe does not reach the deep freezing end temperature within the

maximum deep freezing duration, deep freezing will not be completed successfully but will continue, the LED will

flash and the buzzer will be activated.

Press and release a key to restore normal display and to silence the buzzer.

When the temperature detected by the needle probe reaches the deep freezing end temperature, the device

automatically passes to storage in the same way as illustrated previously.

LED is on.

6.9 Time-controlled deep freezing and storage

The time-controlled deep freezing and storage cycle is divided into the following two phases:

- deep freezing

- storage.

On conclusion of a phase, the device passes automatically to the next.

Operate as indicated to start the cycle:

1. Make sure the device is in the "on" status.

2. Make sure that the keyboard is not locked and that no procedure is in progress.

3. Press and release the DEEP FREEZING key: the LED, the LED, the LED and the HARD LED will flash.

4. Press and release the TIME/TEMPERATURE key: the LED flashes and the LED will switch off.

5.1 If parameter r19 is set at 0, the 4 digit display will show the work set-point during deep freezing; this value can

also be set via parameter r8.

5.2 If parameter r19 is set at 1, the 3 digit display will show the deep freezing duration; this value can also be set

via parameter r2.

5.3 Press and release the UP or DOWN key within 60 s to modify the parameter value:

6. Press and release the START/STOP key: the LED, the LED, the LED and the HARD LED will remain

permanently on and the cycle will be started.

Operate as indicated to stop the cycle:

7. Hold the START/STOP key down for 2 s.

During deep freezing, the 3 digit display shows the residual time of the deep freezing duration and the 4 digit display

shows the cabinet temperature.

To modify the residual time, operate as indicated:

8. Press and release the UP or DOWN key again to modify the time value: the display will flash.

9. Do not operate for 4 s: the display will stop flashing and remain on permanently.

The successive parameters establish the following values:

- parameter r2 establishes deep freezing duration

- parameter r8 establishes the work set-point during deep freezing.

page 28 of 76

Page 29

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

To display the cabinet work set-point during deep freezing, press and release the BLAST CHILLING, DEEP FREEZING or

the HARD/SOFT key; to restore the normal display, press and release the same key again or do not operate for 60 s.

On expiry of the deep freezing duration, the device automatically passes to storage mode and the buzzer is activated

for the time period established with parameter AA.

Press and release a key to silence the buzzer.

During storage, the 3 digit display shows deep freezing duration, the 4 digit display shows the cabinet temperature

and the

Parameter r11 establishes the work set-point during storage.

LED is on.

6.10 Time-controlled soft deep freezing and storage

The time-controlled soft deep freezing and storage cycle is divided into the following three phases:

- soft deep freezing phase

- deep freezing

- storage.

On conclusion of a phase, the device passes automatically to the next.

Operate as indicated to start the cycle:

1. Make sure the device is in the "on" status.

2. Make sure that the keyboard is not locked and that no procedure is in progress.

3. Press and release the DEEP FREEZING key: the LED, the LED, the LED and the HARD LED will flash.

4. Press and release the HARD/SOFT key: the HARD LED will switch off.

5. Press and release the TIME/TEMPERATURE key: the LED flashes and the LED will switch off.

6.1 If parameter r19 is set at 0, the 4 digit display will show the work set-point during deep freezing; this value can

also be set via parameter r8.

6.2 If parameter r19 is set at 1, the 3 digit display will show the deep freezing duration; this value can also be set

via parameter r2.

6.3 Press and release the UP or DOWN key within 60 s to modify the parameter value:

7. Press and release the START/STOP key: the LED, the LED and the LED will remain permanently on

and the cycle will be started.

Operate as indicated to stop the cycle:

8. Hold the START/STOP key down for 2 s.

During the soft deep freezing phase, the 3 digit display shows the residual time of the deep freezing duration and the

4 digit display shows the cabinet temperature.

To modify the residual time, operate as indicated:

9. Press and release the UP or DOWN key again to modify the time value: the display will flash.

10. Do not operate for 4 s: the display will stop flashing and remain on permanently.

The successive parameters establish the following values:

- parameter r7 establishes the work set-point during the deep freezing soft phase.

- parameter r14 establishes deep freezing soft phase duration.

On expiry of the soft deep freezing phase duration, the device automatically passes to deep freezing.

During deep freezing, the 3 digit display shows the residual time of the deep freezing duration and the 4 digit display

shows the cabinet temperature.

The successive parameters establish the following values:

- parameter r2 establishes deep freezing duration

- parameter r8 establishes the work set-point during deep freezing.

page 29 of 76

Page 30

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

To display the cabinet work set-point during deep freezing, press and release the BLAST CHILLING, DEEP FREEZING or

the HARD/SOFT key; to restore the normal display, press and release the same key again or do not operate for 60 s.

On expiry of the deep freezing duration, the device automatically passes to storage mode and the buzzer is activated

for the time period established with parameter AA.

Press and release a key to silence the buzzer.

During storage, the 3 digit display shows deep freezing duration, the 4 digit display shows the cabinet temperature

and the

Parameter r11 establishes the work set-point during storage.

LED is on.

6.11 Continuous deep freezing

Operate as indicated to start the cycle:

1. Make sure the device is in the "on" status.

2. Make sure that the keyboard is not locked and that no procedure is in progress.

3. Press and release the DEEP FREEZING key: the LED, the LED, the LED and the HARD LED will flash.

4. Press and release the TIME/TEMPERATURE key: the LED flashes and the LED will switch off.

5. Press and release the TIME/TEMPERATURE key again: the 3 digit display will show “inF”.

6.1 The 4 digit display will show the work set-point during deep freezing; this value can also be set via parameter

r8.

6.2 Press and release the UP or DOWN key within 60 s to modify the parameter value:

7. Press and release the START/STOP key: the LED, the LED, the LED and the HARD LED will remain

permanently on and the cycle will be started.

Operate as indicated to stop the cycle:

8. Hold the START/STOP key down for 2 s.

During deep freezing, the 3 digit display shows “inF” and the 4 digit display shows the cabinet cell.

Parameter r8 establishes the work set-point during deep freezing.

To display the cabinet work set-point during deep freezing, press and release the BLAST CHILLING, DEEP FREEZING or

the HARD/SOFT key; to restore the normal display, press and release the same key again or do not operate for 60 s.

6.12 Blast chilling/deep freezing intensity

The device can manage the phase cut speed regulator for EVDFAN1 single phase fans (to be ordered separately); see

paragraph 14.4 “phase cut speed regulator for EVDFAN1 single phase fans”.

The regulator can be used to manage evaporator fan activities with a single analogue control, i.e. via the PWM

analogue output of the device and the regulator phase cut output (the digital output K3 is however activated).

Parameter F0 must be set at 3.

Parameters F18... F22 establish speed 1... 5 of the evaporator speed (intended as a percentage of the maximum

speed), parameter F23 establishes the speed at which the evaporator fan is switched on during post blast chilling

storage and parameter F24 establishes the speed at which the evaporator fan is switched on during post deep freezing

storage (the latter intended as one of the speeds 1... 5).

page 30 of 76

Page 31

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

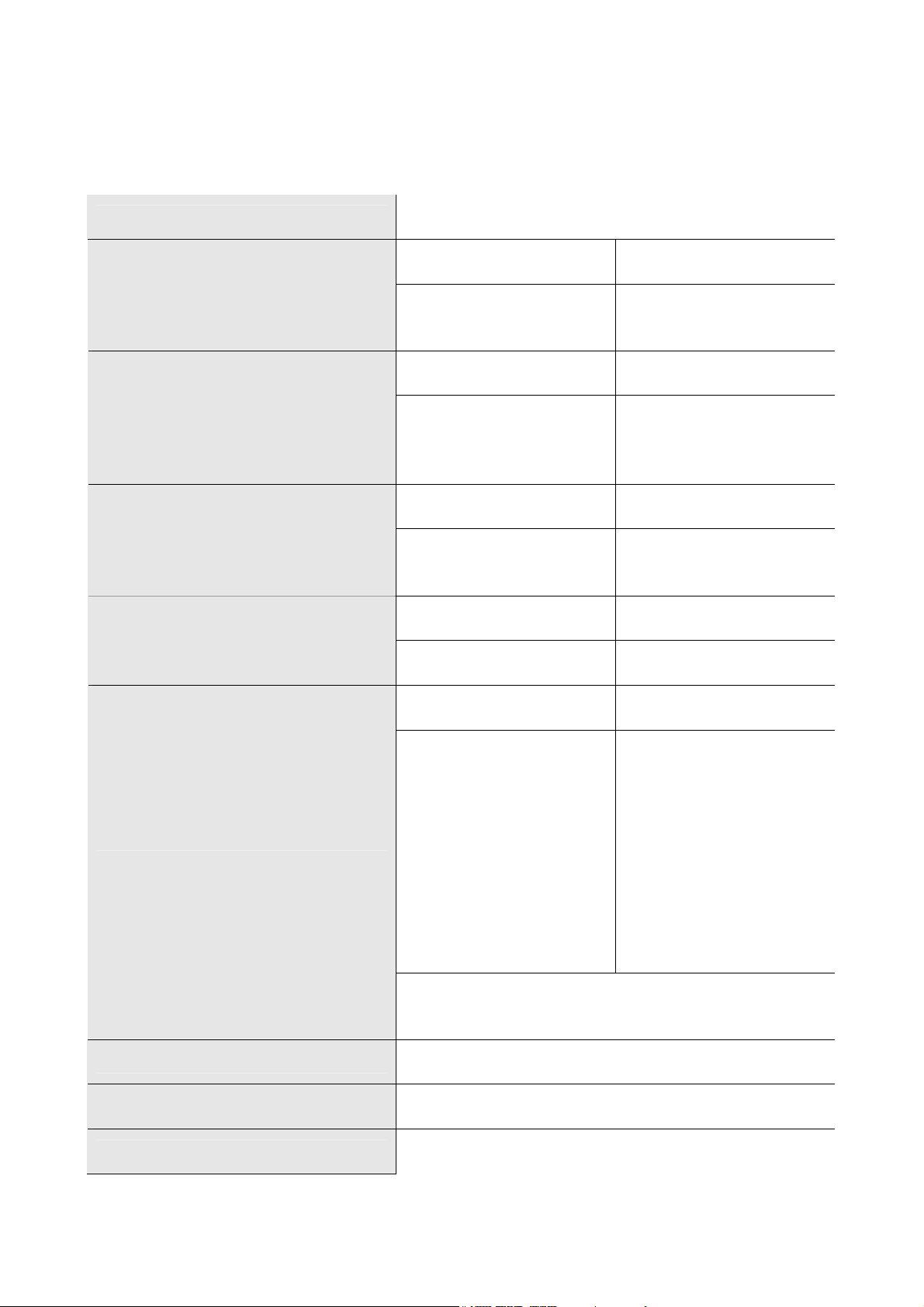

The following table illustrates the speeds at which the evaporator fan is switched on during the operating cycles.

A different speed can be selected using the procedure given in 6.12.1 (intended as one of the speeds 1.. 5) in

temporary mode (i.e. if a power cut occurs, on restore of the same the speeds illustrated in the following table will be

shown), except if the selection is made before starting a blast chilling and storage cycle or before starting a hard blast

chilling and storage cycle or before starting a soft deep freezing and storage cycle (in this case the speeds are

memorised instead).

Blast chilling

and storage

Hard blast

chilling and

storage

Deep freezing

and storage

Soft deep

freezing and

storage

Blast chilling hard phase - speed 5 - -

Blast chilling

speed 1... 5 (can

be memorised

with the

procedure given

in paragraph

6.12.1 if selected

before starting

the operating

cycle)

speed 1... 5 (can

be memorised

with the

procedure given

in paragraph

6.12.1 if selected

before starting

the operating

cycle)

- -

speed 1... 5 (can

be memorised

with the

procedure given

Deep freezing soft phase - - -

in paragraph

6.12.1 if selected

before starting

the operating

cycle)

Deep freezing - - speed 5 speed 5

Storage

speed established

with parameter

F23

speed established

with parameter

F23

speed established

with parameter

F24

speed established

with parameter

F24

6.12.1 Selecting the evaporator fan speed

Operate as follows:

1. Press and release the BLAST CHILLING INTENSITY key: the LED bars will supply information relative to fan

speed (for example, one bar corresponds to speed 1, two bars on correspond to speed 2, three bars on

correspond to speed 3, etc.).

Pressing and releasing the BLAST CHILLING INTENSITY key causes the speed to be selected in pre-defined mode, as

indicated:

- speed 5 - speed 4 - speed 3 - speed 2 - speed 1 - speed 2 - speed 3 - speed 4 - speed 5.

The fan is switched on at the selected speed after 5 s from release of the BLAST CHILLING INTENSITY key.

page 31 of 76

Page 32

EVCO S.p.A. EVF818 | Installer manual ver. 1.0 | Code 144F818E104

6.13 Pre-cooling start-up

Every operating cycle can be preceded by pre-cooling.

Operate as indicated to start pre-cooling:

1. Make sure the device is in the "on" status.

2. Make sure no procedures are in progress

3. Hold the BLAST CHILLING key down for 2 s: the LED will flash.

Operate as indicated to cut-off pre-cooling:

4. Hold the BLAST CHILLING key for 2 s or start an operating cycle.

Parameter r120 establishes the work set-point during pre-cooling.

When the cabinet temperature reaches that established with parameter r12, pre-cooling continues, the LED remains

on permanently and the buzzer is activated for 2 s.

6.14 Management of the test regarding correct insertion of

the needle probe

If the needle probe is enabled, i.e. the parameter P3 is set at values different to 0, the temperature-controlled cycles

are preceded by a test on two phases for the verification of the correct insertion of the needle probe.

The second phase is only performed if the first is not completed successfully.

The first phase is completed successfully if the "temperature detected by the needle probe - cabinet temperature"

difference is greater than the value established with parameter r17 in at least 3 controls out of 5 (the controls are

performed at 10 s intervals, consider the difference without sign).

The second phase is completed successfully if the "temperature detected by the needle probe - cabinet temperature"

difference is 1°C/1°F higher with respect to the previous control in at least 6 controls out of 8 (the controls are

performed at time intervals corresponding to 1/8 of the time established with parameter r18; consider the difference

without sign).

If the test is completed successfully, the cycle will be started; if the test is not completed successfully, the LED

will flash and the buzzer will be activated for 5 s every 60 s.

To start the temperature-controlled cycle, press the BLAST CHILLING key or the DEEP FREEZING key. After

1 min from the signal that the test has not been completed successfully without having operated, the cycle is started

with time control.

If parameter r17 is set at 0, the test will not be carried out (neither first nor second phase).

6.15 Switching on UV light for sterilisation cycle

Operate as follows:

1. Make sure that parameter u11 is set at 2.

2. Make sure the device is in the "on" status and that the door is closed, i.e. the door micro switch is not active.

3. Make sure that the keyboard is not locked and that no procedure is in progress.

4. Hold the DEEP FREEZING key down for 2 s: the AUX LED will switch on.

The UV light is switched on for the time period established by parameter u6; opening the door i.e. the activation of the

door micro switch cause the light to switch off.

If the UV light is on, it will not be allowed to select or start any operating cycle.

6.16 Needle probe heating

Operate as follows:

page 32 of 76

Page 33