Page 1

ETC® Installation Guide

Unison® Heritage Rack Mount Contact Interface

Overview

This guide includes instruction for installation of the Unison Heritage Rack Mount Contact Interface.

The Rack Mount Contact Interface (model# UHCI-RM) provides convenient interface and integration to

external devices by sending and receiving contact closures. Up to eight switch input and relay output

connections are provided. Closures are configurable for either maintained or momentary operation.

Product Specification

• Dry contact inputs with no voltage applied.

• Dry contact outputs consist of Normally-Open (NO) 2 pole contact closu

1 amp at 28 Vdc, .5A at 120 VAC.

• Relay outputs are capable of switching resistive or inductive loads.

• Inputs and outputs are configurable in the Paradigm configuration using LightDesigner software.

• Contact inputs support up to 1,000 feet (305m) of 16 AWG (1.5mm

common.

re outputs, rated up to

2

) wire between input and

Unison

Installation Requirements

• Installs in a 19” rack mount enclosure utilizing two (E.I.A.) rack units.

• Thermal requirements:

• Ambient room temperature of 0-40°C (32-104°F) with an ambient humidity of 30-90%, non-

condensing.

Corpora te Headquarters

London, UK

Rome, IT

Holzkir chen , DE

Hong Kon g

Service:

Web:

7181M211 2

®

Unit 26-28, Vi ctoria Industrial Estate, Victoria Road, London W3 6UU, UK Tel +44 (0)20 88 96 1000 Fax +44 (0)20 8896 20 00

Via Ennio Quirino Visconti, 11, 00193 Rome, Italy Tel +39 (06) 32 111 683 Fax +4 4 (0) 20 8752 8486

Rm 1801, 18/F, Tower 1 Ph ase 1, Enterpr ise Square, 9 Sheung Yuet Road, Kowloon Bay, Kowloon, Hong Kon g Tel +852 2799 122 0 Fax +852 2799 9325

(Amer icas) service@e tcconnect.com (UK) service@etceur ope.com (DE) techserv-ho ki@etcconnect.co m (Asia) service@etcasia.com

www.etcconnect.com

Rev A Releas ed 11/20 08

3031 P leasant View Road, P.O. Box 620979 , Middleton, Wisconsin 53562-0 979 USA Tel +608 831 411 6 Fax +608 836 1736

Ohms trasse 3, 83607 Holzkirc hen, Germa ny Tel +49 (80 24) 47 00-0 Fa x +49 (80 24 ) 47 00-3 00

Copyright © 2008 ETC. All Rights Reserve d. Product inf ormation and specifications subject to change.

ETC intends this d ocument to be provided in its entirety.

.cnI ,slortnoC ertaehT cinortcelE3 fo 1 egaPecafretnI tcatnoC tnuoM kcaR egatireH

Page 2

ETC Installation Guide

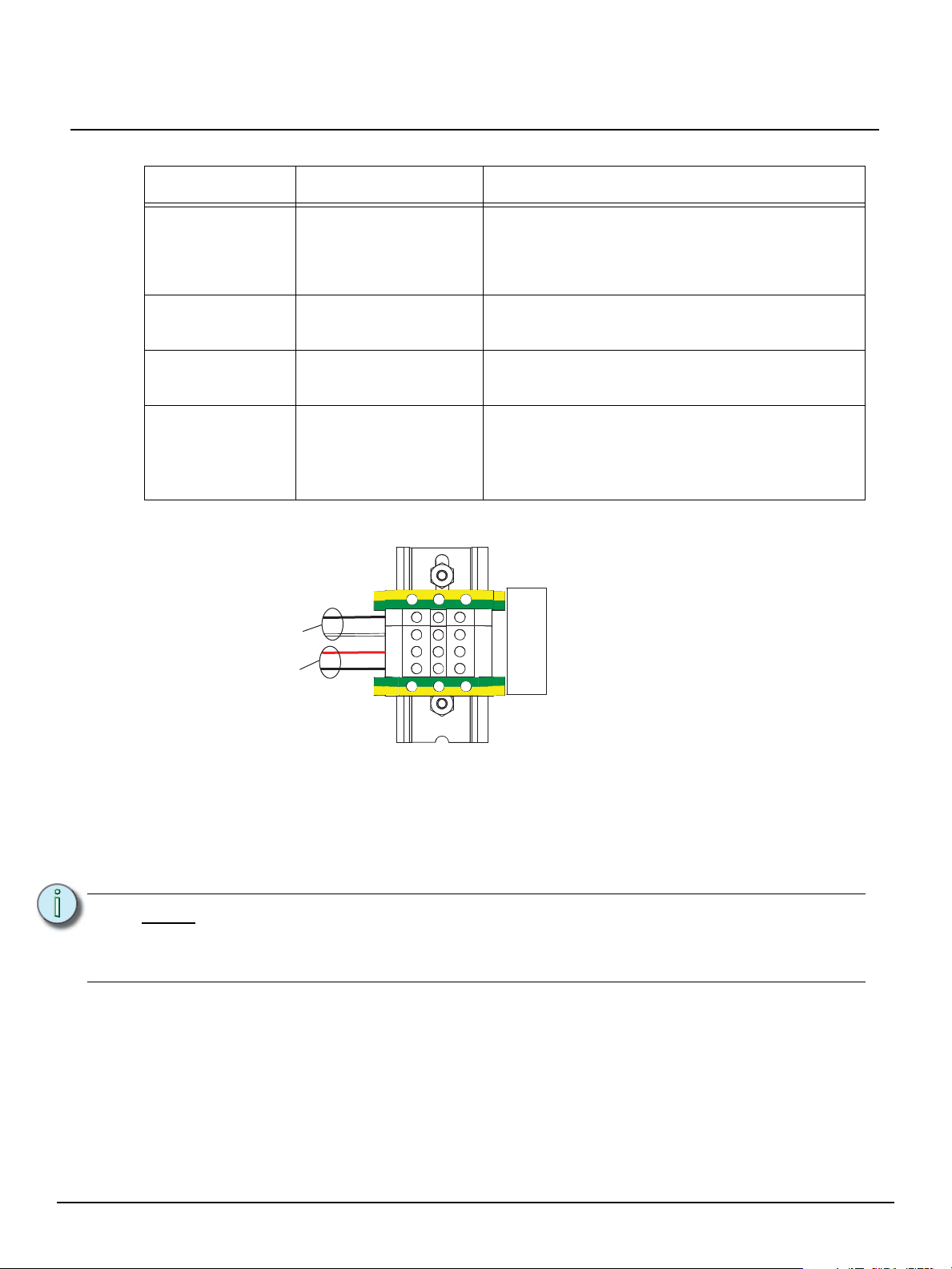

Wire Requirements and Specification

Purpose Wire Type Notes

Interface Series

Link Power

(LinkConnect)

control network

Auxiliary power

(24 Vdc)

Chassis Ground 18 - 10 AWG

Contact Input and

Contact Output

terminals

Terminate Wiring

on control PCB

factory wiring

to Aux power

on control PCB

factory wiring

to LinkPower

Belden 8471

(or approved equal)

(2) 18 -10 AWG

(0.75 - 6mm

(0.75-6mm

2

)

2

)

24 - 12 AWG

(0.2 - 2.5mm

2

)

Echelon

®

LinkPower® (LinkConnect) control network utilizes low voltage Class II wire.

Wiring is topology free, polarity independent with a

maximum total system length of 1,640 feet (500m).

Required when wiring is not installed in grounded

metal conduit.

Two wires are required per switch (switch in or

switch out and common). Supports up to 1,000 feet

(305m) of 16 AWG (1.5mm

2

) between input and

common.

Ground

ULPULP+

+24VDC

Common

Ground

Step 1: Terminate LinkPower.

a: Strip 7/16” (11mm) from the ends of each LinkPower wire (typically black and white

twisted pair).

b: Using a jewelers screwdriver, open the ULP+ and ULP- terminals.

c: Insert the (typically white) wire from the pair into the ULP+ terminal.

d: Insert the (typically black) wire from the pair into the ULP- terminal.

Note:

LinkPower is topology free and polarity independent. You can install your LinkPower

wiring in any combination of bus, star, loop, or home-run. If more than one pair of

LinkPower wires are to be terminated be sure to label each pair individually. Each ULP

terminal can accept up to two conductors per terminal.

e: Tighten each terminal screw firmly to secure the wires in place.

Step 2: Terminate Auxiliary power (24 Vdc) wiring.

a: Strip 7/16” (11mm) from the ends of each Auxiliary power wire (typically a 16 AWG

black and red twisted pair).

b: Using a jewelers screwdriver, open the +24 VDC and Common terminals.

c: Insert the (typically red) wire from the pair into the+ 24 VDC terminal.

d: Insert the (typically black) wire from the pair into the Common terminal.

e: Tighten the terminal screw to secure the wire(s) in place.

Unison® Heritage Rack Mount Contact Interface Page 2 of 3 Electronic Theatre Controls, Inc.

Page 3

ETC Installation Guide

NC. NO.COM

NC.

NO. COM

NC.

NO. COM NC. NO.

COM

1234

NC. NO.COM

NC.

NO. COM

NC.

NO. COM NC. NO.

COM

5678

12345678

Contact Inputs

COM

factory wiring

to input

terminals

Contact Outputs

1 - 4

Contact Outputs

5 - 8

Contact Inputs

1 - 8 plus

Commons

Step 3: Terminate chassis ground.

a: Strip 7/16” (11mm) from the end of each chassis ground wire.

b: Loosen the terminal screw on a green/yellow terminal block. The green/yellow

terminal blocks are located at both ends of the terminal strip.

c: Insert the ground wire and tighten the screw firmly onto the wire.

Step 4: Terminate contact wires. All contact input and output terminations are made to the

removable pluggable connectors on the control PCB. When terminating a switch to a

Contact Interface, each pair of terminations, either Switch In or Switch Out, requires one

switch and one common connection.

Interface Series

Note:

There are only two Common terminals available for Contact Inputs and each Common

terminal allows up to two conductors. Additional connections should be bussed

together to share the line using WAGO CAGE CLAMP

®

connectors as required.

Unison® Heritage Rack Mount Contact Interface Page 3 of 3 Electronic Theatre Controls, Inc.

a: Strip 1/4” (7mm) from the ends of each wire.

b: Remove the connector from the control PCB.

c: Loosen the terminal screw for each required termination.

d: Insert the wires into the corresponding terminal block number and tighten the screws

firmly onto the wires.

Loading...

Loading...